Page 1

Instructions for Installation and Operation

3 PHASE AC MOTOR SPEED CONTROL

3 PHASE AC MOTOR SPEED CONTROL

3 PHASE AC MOTOR SPEED CONTROL3 PHASE AC MOTOR SPEED CONTROL

Model 2995, for 115/230 VAC power supply, with NEMA 4

enclosure and line filter for CE Mark

P/N 074 01040 B (DX)

Page 2

QUICK REFERENCE

This manual contains the basic information needed to install and operate Bodine

PACESETTER

does not profess to cover all details or variations in equipment, nor to provide for

every possible contingency associated with installation, operation, or

maintenance. No warranty of fitness for purpose is expressed or implied.

Should further information be desired or should particular problems arise which

are not covered sufficiently for the user’s purpose, the matter should be referred

to the Bodine Electric Company.

Read this manual completely and carefully. Pay special attention

to all warnings, cautions, and safety rules. Failure to follow the

instructions could produce safety hazards that could injure

personnel or damage the control, motor, or other equipment. If

you have any doubts about how to connect the control or motor,

refer to the detailed sections of this manual.

TM

115/230V “NEMA 4” series inverter model 2995. This manual

IMPORTANT

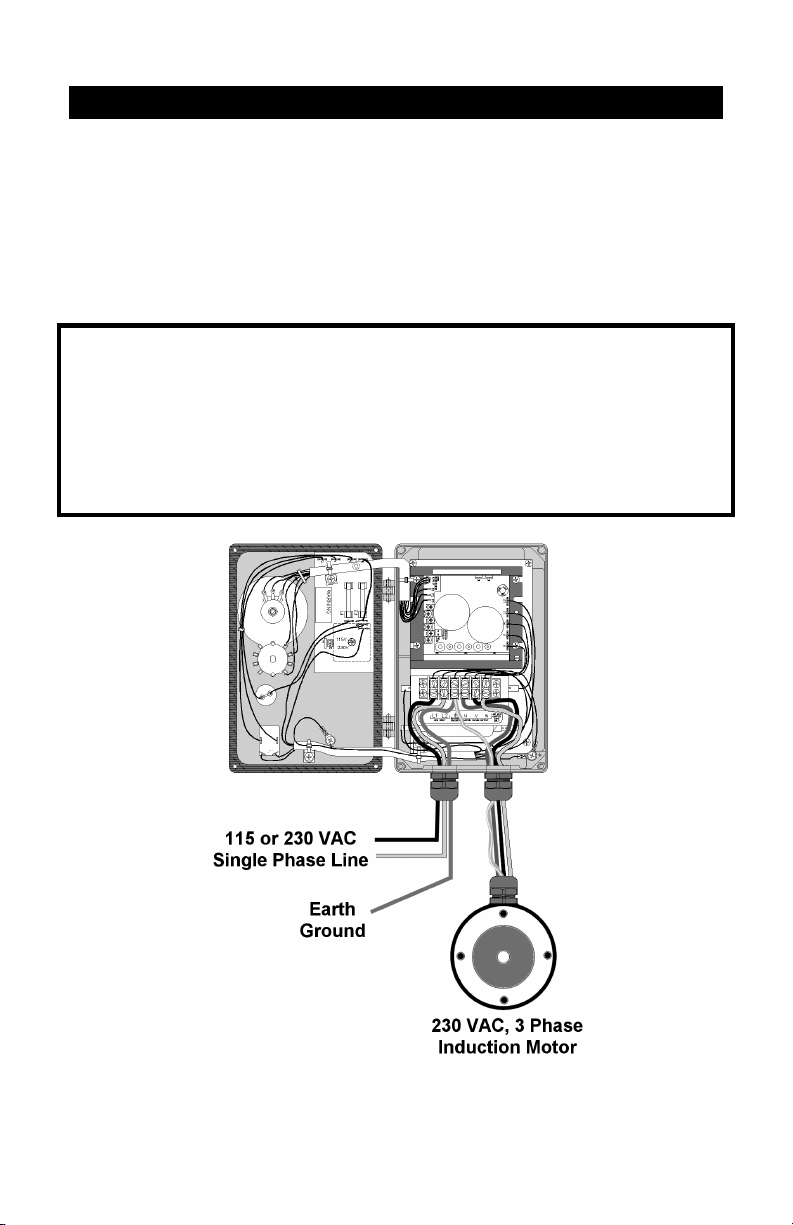

FIGURE 1 – Overview of installation for reference only and not be used as a replacement for the

detailed instructions within this manual.

2

Page 3

TABLE OF CONTENTS

PAGE

QUICK REFERENCE 2

PRODUCT SPECIFICATIONS 4

IMPORTANT SAFETY PRECAUTIONS 5

INSTALLATION 6

Step 1 – Examine Before Installation 6

Step 2 – Choose a Suitable Location 7

Step 3 – Mount the Control 7

CONNECTION 8

Step 4 – Preliminary Setup 8

Step 5 – Connect Motor 10

Step 6 – Install Fuse 11

Step 7 – Connect AC Line Cord 11

Step 8 – Close and Seal the Enclosure 12

Step 9 – Connect to AC Power 12

OPERATION 12

Step 10 – Check System Before Operating 12

Step 11 – Operate Inverter 13

Step 12 – Adjust Trim Pots (optional) 13

TROUBLESHOOTING 17

DECLARATION OF CONFORMITY 19

WARRANTY 20

copyright 2002 Bodine Electric Company. All Rights Reserved. Printed in U.S.A.

3

Page 4

PRODUCT SPECIFICATIONS

ABOUT THIS PRODUCT - Bodine’s PACESETTER

inverter is designed to provide variable speed control of standard threephase AC induction motors. Adjustable linear acceleration and

deceleration are provided, making the drive suitable for soft start

applications. The output voltage is sinewave coded PWM operating at 16

kHz, which provides high motor torque, high efficiency, and low noise.

The full featured drive is easy to install and operate. Simple trimpot

adjustments eliminate the computer-like programming required on other

drives. However, for most applications, no adjustments are necessary.

Table 1 – Electrical Ratings

Input Volts 115 or 230 VAC +/- 10%, Single Phase, 50/60Hz

Input Current 11.0 (115V) or 7.0 (230V) Amps AC

Output Volts 0 – 230 VAC, Three Phase

Output Current, per Phase 2.4 Amps RMS

Maximum Motor HP (kW) ½ HP (0.37 kW)

Table 2 - General Performance Specifications

Parameter

Maximum Load 150% Current Overload for 2 Minutes Switching Frequency at Motor 16 kHz Signal Following Input Voltage 0 – 5 VDC Signal Following Input Resolution 8 bits Minimum Speed Trimpot Range 0 – 40% of frequency setting 0

Output Frequency Setting 50 Hz, 60 Hz, or 120 Hz 60

Maximum Speed Trimpot Range 70 – 110% of frequency setting 100

Speed Range 50:1 Acceleration Trimpot Range .3 – 20 seconds 1.0

Deceleration Trimpot Range .3 – 20 seconds 1.0

Boost Trimpot Range (50Hz only) 6 – 30% Slip Compensation Trimpot

Range

Current Limit Trimpot Range 1.5 – 4.5 Amps AC 3.8

Speed Regulation (0 to Full Load,

30:1 Speed Range)

Operating Temperature Range 0 to +40OC Overload Protector Trip Time

(Stalled Motor)

Bus Overvoltage Trip Point 400 VDC (283 VAC Line Volts)

Bus Undervoltage Trip Point 260 VDC (184 VAC Line Volts)

Specification

0 – 3 Volts/Hz/Amp 1.5

2.5% of Base Speed -

6 seconds -

TM

“NEMA 4” series

Factory

Setting

4

Page 5

IMPORTANT SAFETY PRECAUTIONS

Model 2995 has been evaluated by Underwriters Laboratories for conformance

to UL standards 508 and 50 and CSA standard C22.2 No. 14 and bears the UL

Recognized Component mark.

The AC Drive is a power electronic device. For safety reasons, please read

through this operations manual in detail and observe those paragraphs with the

safety alert symbol.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a potentially hazardous

WARNING

CAUTION

CAUTION

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

WARNING

Do not touch printed circuit board (PCB) right after

turning off power. Wait until power light turns off.

Do not attempt to wire circuitry while power is on.

Do not attempt to examine components and signals on

the PCB while the inverter is operating.

Do not attempt to disassemble or modify internal

circuitry, wiring, or components of the inverter.

Inverter must be properly grounded.

5

Page 6

INSTALLATION

This control should only be installed by a qualified person familiar

with its operation and associated hazards. The National Electrical

Code (NEC), local electrical and safety codes, and when

applicable, the Occupational Safety and Health Act (OSHA) should

be observed to reduce hazards to personnel and property.

Step 1. Examine before installation

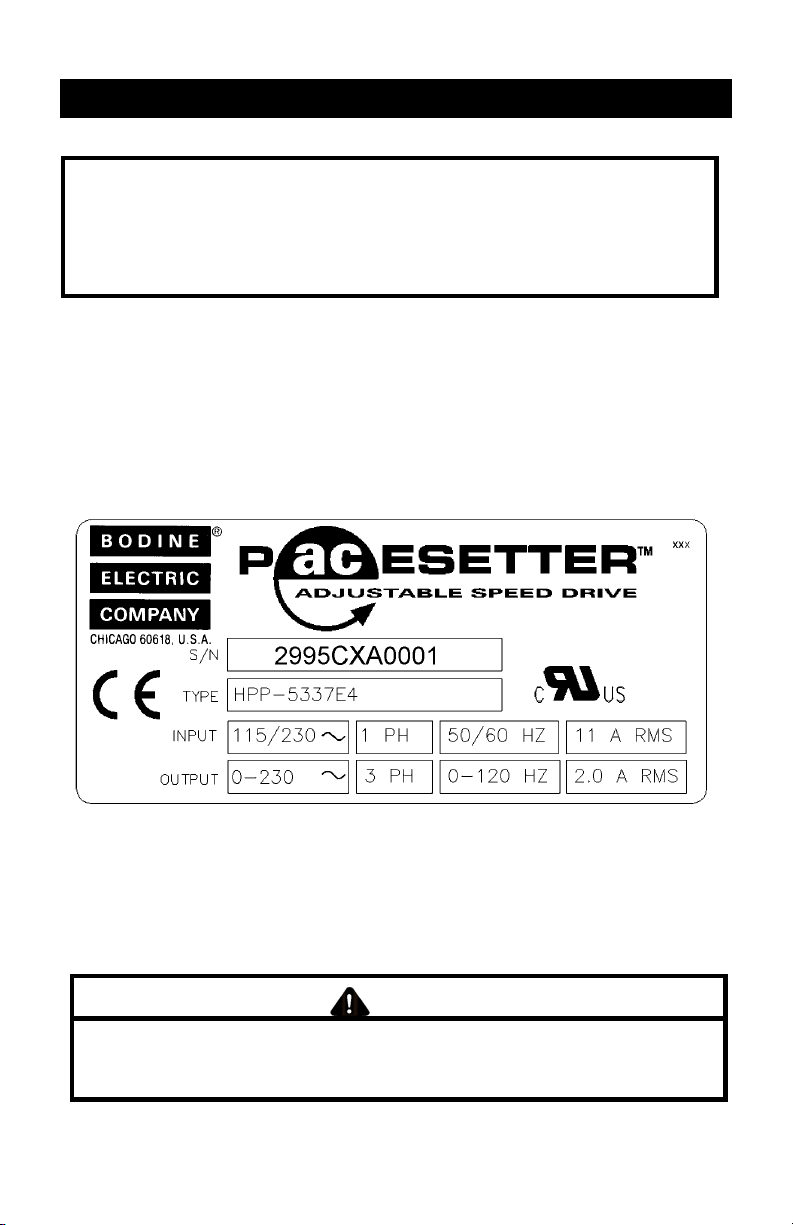

Check that the model number on the control matches the model number

ordered. The control model number is printed as part of the serial number on an

adhesive label on the outside bottom surface of the control enclosure. Carefully

examine the control for shipping damage. Parts errors should be reported to

Bodine. Shipping damage claims should be made to the freight carrier.

Figure 2 – The model number is the first four digits of the serial number

(S/N) on the control’s nameplate.

CAUTION

Do not connect the control to the power supply if there is

any sign of damage. Notify the carrier and your distributor

immediately.

6

Page 7

Step 2. Choose a Suitable Location

The installation site directly impacts the functionality and lifespan of the control.

Avoid areas where surrounding air temperature exceeds 40OC (direct

sunlight or near heating equipment or inside a panel without a cooling fan.

Avoid locations where the front panel dial and switch may be bumped and

accidentally turned on/off or damaged.

Avoid environments with corrosive gas.

Avoid locations near radioactive matter or flammable material.

Avoid locations near equipment that generate electromagnetic interference

(soldering or power machinery).

Avoid mounting the control to a surface that vibrates.

Step 3 – Mount the

Control

Prepare the mounting surface by

drilling four holes with their

centers located as shown in

Figure 3. If #10 screws are to be

used for mounting, then use a #6

(.204) clearance drill. If #10-32

machine screws are to be used

for mounting, then use a #20

(.161) tap drill. After the

mounting surface has been

prepared, mount the control with

screws through the four

mounting brackets (already

attached to back of control

enclosure).

Figure 3 - Mounting

Dimensions

7

Page 8

f

CONNECTION

CAUTION

The PCB inside the inverter enclosure is vulnerable to

static electrical charges. Avoid contact with the PCB.

Choose an appropriate power source with correct

voltage settings for the specification of the AC inverter.

Do not use a separate device between control and

motor to switch motor ON or OFF during operation.

Step 4 – Preliminary Setup

Figure 4 - Inside of control, showing location of jumpers and fuses.

BASE FREQUENCY JUMPER - Model

2995 is factory set to operate 60 Hz and

50/60 Hz motors. For 50 Hz motors,

remove jumper J1 on the lower printed

circuit board. When the control is set for

50 Hz operation, the DECEL/B trimpot

will automatically change to adjustable

boost. The control can also operate 60

Hz and 50/60 Hz motors (not 50 Hz

motors) in an over speed mode by

moving the jumper to the 120 Hz

position.

8

Figure 5 - The different ways o

setting the base frequency jumper.

Page 9

In this mode, the motor will produce full rated torque up to 60 Hz. Above 60 Hz,

torque will linearly reduce to 50% at 120 Hz.

Figure 6 - Graph showing reduction in motor torque at frequencies above 60 Hz.

AC LINE VOLTAGE SELECTOR JUMPERS – There are three voltage selector

jumpers that must be repositioned if the input line voltage is 230 VAC instead of

115 VAC. If the control is to be operated from a 230 VAC power supply, pull out

the voltage selector jumpers J1, J2, and J10 from their “115V” positions and

reinsert them into their “230V” positions. See Figure 4 for the locations of the

jumpers.

CAUTION

Connecting 230 VAC to a control configured for 115 VAC will

permanently damage the control.

AC LINE FUSE JUMPER WIRE – If the control is to be operated from a twophase 230 VAC power supply, where both lines are hot (typically in the USA),

then remove the jumper wire between the spades labeled “J5” and “J8.”

AC LINE FUSES – Model 2995 has a 12A fuse already installed in both the “F1”

and “F2” fuse holders. A fuse is only really necessary in “F2” if a two-phase 230

VAC power supply (with two hot sides) is used.

9

Page 10

Step 5 – Connect the Motor

A cord should be used for the motor connection in order to properly seal the

liquid tight fitting. The fitting will accept cord diameters between 0.17” and 0.47”

diameter. The length of the cord should be kept short for minimum voltage drop

and only copper wire with 60

from the liquid tight fitting and insert the cord through the fitting and into the

enclosure. Connect the three motor power leads to “U”, “V”, and “W” on the

terminal block inside the control. Since the controls are capable of changing

motor direction electronically, it doesn’t really matter which motor wires go to

which terminal. However, if it is desired for the motor to rotate a specific

direction when wired a certain way, then refer to the connection diagrams for

Bodine inverter-duty motors in Figures 8 and 9 on the next page. If the motor

doesn’t rotate in the desired direction as connected, with reference to the

“forward” and “reverse” settings of the direction switch on Model 2995, then

swap any two of the three motor wires. Note that these connection diagrams

apply to Bodine motors only. The terminal block will accept wire sizes from 18 to

14 gauge. The terminal block screws should be tightened to 6 lb-in (0.678 Nm).

Connect the motor frame ground to “CHASSIS GROUND” on the terminal block.

When the connections are done, tighten the nut on the liquid tight fitting.

O

C rated insulation should be used. Loosen the nut

Figure 7 - Electrical connections for Model 2995.

10

Page 11

Table 3 - Direction of Bodine motor

driveshaft rotation, viewing end of

driveshaft, when connected per the

diagrams at the left and with control

set for “forward” direction

Bodine Motor Type Direction

Figure 8 - Connection diagram for

Bodine 230V inverter-duty motors.

Figure 9 - Connection diagram for

Bodine 230/460V inverter-duty

motors wired for 230V operation.

30R2BEPP CCW

30R4BEPP CCW

30R2BEPP-D3 CW

30R4BEPP-D3 CW

30R2BEPP-D4 CCW

30R4BEPP-3N CCW

34R6BEPP-Z2 CCW

34R6BEPP-Z3 CCW

34R6BEPP-Z4 CW

34R4BFPP-E1 CCW

34R4BFPP-E2 CW

34R4BFPP-E3 CCW

34R4BFPP-E4 CW

34R6BFPP CW

34R6BFYP CW

42R6BFPP CCW

42R6BFPP-GB CW

42R6BFPP-F1 CW

42R6BFPP-F2 CCW

42R6BFPP-F3 CW

42R6BFPP-5N CCW

42R6BFPP-5H CCW

48R5BFYP CCW

Step 6 – Connect AC Line Cord

A cord should be used for the AC power connection in order to properly seal

against water through the liquid tight fitting. Connect the hot side of the line to

“L1” and the neutral side to “L2.” Connect earth ground to the terminal labeled

“CHASSIS GROUND.” Tighten the barrier terminal block screws to 6 lb-in.

Step 7 – Close and Seal the Enclosure

Close the hinged cover and tighten the four screws, one at each corner.

Step 8 - Connect to AC Power

After all other connections are made and the control is closed, connect the AC

line cord to the AC power supply.

11

Page 12

OPERATION

Step 9 – Check System Before Starting

WARNING

Recheck all connections.

Do not open the cover of the inverter when the power is

ON to avoid injury caused by electrical shock.

Do not attempt to wire circuitry while power is on.

CAUTION

Do not attempt to make or break connections between

motor and inverter when the power supply is turned on,

or the inverter may be damaged due to a surge peak.

Check that motor is securely mounted.

Test motor unloaded first to verify proper setup.

Check all rotating members. Be sure keys, pulleys, etc.

are securely fastened and safety guards are in place.

Check for proper mounting and alignment of products,

and verify safe loading on shafts and gears.

The inverter can be easily operated from a low speed to

a high speed. Reconfirm the operating speed range of

the motor and the machinery you are controlling.

FIGURE 10 – Control panel layout

12

Page 13

Step 10 – Operate the Inverter

The PACESETTERTM “NEMA 4” series inverter is operated using the switches

and speed dial on the front panel of the control. See Figure 10 for panel layout.

1) Turn the AC power ON using the toggle switch. The power lamp will

illuminate.

2) Turn the direction switch to either the “forward” or “reverse” position.

3) Adjust speed by turning the knob of the speed potentiometer. Turning the

pot fully CCW will produce the minimum output frequency, as set by the MIN

trim pot inside the control (factory setting is 0 Hz). Turning the pot fully CW

will produce the maximum output frequency, as set by the max speed

jumper and the MAX trim pot inside the control (factory setting is 60 Hz).

4) To stop the motor momentarily, turn the direction switch to the “stop”

position.

5) To change direction of the motor, turn the direction switch to the “stop”

position, wait until the motor comes to a complete stop, and then turn the

direction switch to either “forward” or “reverse” position.

6) To stop the motor for long periods of time, turn the AC power off using the

toggle switch.

7) If the motor does not start promptly and run smoothly, refer to the

“TROUBLESHOOTING” section.

Step 11 – Adjust Trim Pots (Optional)

These controls contain trim pots that have been factory adjusted for most

applications. Some applications may require readjustment of the trim pots in

order to tailor the control to exact requirements.

WARNING

Do not adjust trim pots with main power on if possible. If

adjustments are made with power on, insulated adjustment

tools must be used and safety glasses must be worn. High

voltage exists in this control. Electrocution and/or fire

hazard can result if caution is not exercised.

Figure 12 - Location of trim pots inside enclosure.

13

Page 14

4

0

MIN: Minimum Speed

The MIN trim pot is used to set the minimum

output frequency of the drive, which sets the

minimum motor speed. The minimum speed is

factory set to 10 Hz. Readjust the trim pot as

follows:

1. Rotate main speed potentiometer to the

minimum speed position (full

counterclockwise).

2. Increase setting of MIN trim pot so that motor

runs at desired minimum speed.

HERTZ

17

0

MIN

MAX: Maximum Speed

The MAX trim pot is used to set the maximum

output frequency of the drive, which sets the

maximum motor speed. The maximum speed is

factory set to full rated motor speed. Readjust

the trim pot as follows:

1. Rotate main speed potentiometer to the

maximum speed position (full clockwise).

2. Adjust setting of MAX trim pot so that motor

runs at desired maximum speed.

HERTZ

40

MAX

ACC: Acceleration

The ACC trim pot sets the time it takes the motor

to reach full speed from an initial zero start. The

trim pot is factory set to approximately 1.5

seconds. Adjust the ACC trim pot as required for

the application.

Note: When the control is set for 50 Hz

operation, the ACC trim pot will automatically

change to adjustable acceleration and

deceleration.

Note: Rapid acceleration may cause the current limit circuit to activate.

This will automatically extend the acceleration time.

3.0 17.0

0.3 20.

SECONDS

10.0

ACC

2

6030

18.51.5

14

Page 15

DEC/B: Deceleration (with 60 Hz or 120 Hz configuration)

The DEC/B trim pot sets the time it will take the

motor to reach zero speed from an initial full speed

setting. The trim pot is factory set to approximately

1.5 seconds. Adjust the trim pot as required for the

application.

Application Note: On applications with high inertial

loads, the deceleration may automatically increase

in time. This will slow down the rate of speed

decrease to prevent the DC bus voltage from rising

to the overvoltage trip point. This function is called regeneration protection.

It is recommended that for very high inertial loads that both the ACC and

DEC/B trim pots be set to a minimum of 10 seconds.

SECOND S

(60Hz ONLY)

10.0

DEC

DEC/B: Boost (with 50 Hz configuration)

When the control is set for 50 Hz motors, the DEC/B

trim pot becomes Adjustable Boost. Most 60 Hz

motors conforming to NEMA standards can operate

from a preset volts/Hz curve. 50 Hz motors generally

differ widely in their characteristics. Therefore, it is

necessary to have Adjustable Boost to obtain

maximum motor performance. Since the boost trim

pot was the deceleration trim pot in the 60 Hz mode, it

will take on the prior setting of the DEC/B trim pot.

In order for the 50 Hz motor to run properly, the boost

must be adjusted. If the application does not require full torque below 10

Hz, the boost trim pot can be conservatively set at 8% (9 o’clock position).

If more precise speed regulation is required due to varying load, the boost

can be set as follows.

1. Place an AC analog RMS ammeter in series with one motor lead

(Generally, digital or clamp-on meters do not yield accurate readings).

2. Run the motor unloaded* at approximately 4 Hz (or 120 RPM). (*Note:

An unloaded motor with excessive boost will draw more current than a

partially loaded motor.)

3. Turn up boost until the ammeter reaches the nameplate rating.

4. Using the main speed potentiometer, slowly adjust motor speed over a

0 – 15 Hz (0 – 450 RPM) range. If motor current exceeds nameplate

rating, lower boost setting.

50 Hz

% BOOST

10

DEC/B

17.03.0

18.51.5

20.00.3

18

26

306

CAUTION

To avoid motor winding overheating and failure, do not over

boost motor.

15

Page 16

CL: Current Limit with I2t Shutdown

The CL trim pot is used to set the maximum motor

current that occurs in a stalled condition. The CL

trim pot is factory set to approximately 160% of full

control rating (3.8 amps). The CL trim pot can be

readjusted as required.

The current limit also contains an I

2

t trip function.

The control will trip according to a predetermined

current versus time function. The trip curve is

directly related to the CL set point and can be changed with the CL trim

pot. The current limit with I

2

t shutdown is designed to provide motor

overload protection. Readjust the CL trim pot so that it is set to 160% of

full rated motor current as follows.

1. Connect an AC ammeter in series with one motor phase.

2. Lock motor shaft and quickly adjust desired locked rotor motor current

using CL trim pot. Note: This adjustment must be made within 60

seconds or I

2

t trip will occur.

Example: A ½ HP motor has a full load current of 1.8 amps. Set the CL

trim pot to 1.8 X 160% = 2.9 amps.

Percent of CL

Setpoint

Trip Time

(Minutes)

Control Rating

(%)

Motor Current

(Amps/Phase)

100 .1 (6 sec) 160 3.8

88 .8 140 3.4

75 30 120 2.9

63

4

100 2.4

COMP: Slip Compensation

The COMP trim pot is used to maintain set motor speed under varying

loads. The factory setting of 1.5 volts/Hz/amp provides excellent speed

regulation for most motors. The COMP trim pot can be adjusted for

specific applications as required.

1. Wire an AC ammeter in series with one motor

phase.

2. Run motor and set unloaded speed to

approximately 50% speed. Using a tachometer,

record unloaded speed.

3. Load motor to rated motor current (AC amps)

4. Adjust COMP trim pot so that loaded RPM is

equal to unloaded RPM.

5. Motor is now compensated.

16

Page 17

TROUBLESHOOTING

WARNING

Do not remove the cover of the inverter when the power

is ON to avoid injury caused by electrical shock.

This control does not require maintenance under normal conditions. If you

encounter a problem, read all instructions provided with this control and doublecheck the wiring. If problems persist, contact your source of purchase or a

Bodine Authorized Service Center and describe the problem in detail.

Performing unauthorized repairs will void the Warranty.

GENERAL EVALUATION – Knowing the circumstances under which the problem

occurred can help to identify the root cause of the problem.

Has the system ever operated properly?

doesn’t work right, then it is likely that something wasn’t done correctly in the

installation. However, if the system has been working for an extended period of

time and just recently stopped working, then this would indicate that the control

was initially installed properly but something has somehow changed.

Is the problem continuous or intermittent? If the problem always occurs and

never goes away, then it would indicate something inherently wrong in the

connections or a defective component. On the other hand, if the system

operates properly most of the time and only occasionally does something wrong,

then this might indicate loose connections or electrical noise interference.

Table 4 - General problem evaluation method

ABNORMALITY CHECK POINT COUNTERMEASURE

Motor does not run

Is the main speed pot damaged? Examine the speed pot and correct it.

Motor runs, but in

wrong direction

can’t be adjusted

Motor runs, but

speed is too high

or too low

Motor runs, but with

abnormal speed

variations

Is main power lamp illuminated? Check that power source is switched on.

Is a problem indicated by the LED

status indicator?

Is there a direction command?

Is wiring to the motor correct? Swap any two of the three motor wires.

Is the main speed pot damaged? Examine the speed pot and correct it. Motor runs, but speed

Is the loading too heavy?

Is motor specification correct? Reconfirm motor specification.

Is the gear ratio correct? Reconfirm gear ratio

Is the MAX trim pot setting correct?

Is the loading too heavy? Increase inverter and motor capacity

Is the loading variation too large? Reduce loading variation

Is input power steady and stable?

If the control was just installed and

Reconfirm the power voltage level.

See Table 5 for interpretation.

Check that the direction switch is set at

either Forward or Reverse.

Change direction jumper (Model 2997)

Change direction switch (Model 2996)

Reduce loading

Check MAX trim pot setting.

Install AC reactor on power supply input.

17

Page 18

Figure 13 – Location of LED Status Indicators inside the enclosure

LED STATUS INDICATORS – Models 2995 contains two LED status indicators on

the printed circuit board inside the enclosure. One LED is a green Power On

indicator (PWR) that indicates the presence of the bus voltage and the operation

of the main control logic power supply.

The other LED is a tricolor lamp (ST) that indicates a fault or abnormal condition.

The information provided can be used to diagnose an installation problem, such

as incorrect input voltage, overload condition and control circuit miswiring. It

also provides a “normal” signal that informs the user that all control and

microprocessor operating parameters are proper. The meaning of the different

colors and flash frequencies are explained in Table 5.

TABLE 5 – Interpretation of ST indicator LED

OPERATING

CONDITION

Motor Running Normally GREEN SLOW FLASH* N/A

Motor Running, but in

Current Limit

Motor Stopped due to

Current Limit Trip

Motor Stopped due to

Short Circuit

Motor Stopped due to

Control Under Voltage

Motor Stopped due to

Control Over Voltage

Normal Stop Condition YELLOW STEADY, NO FLASH N/A

LED

COLOR

RED STEADY, NO FLASH LED will return to slow flashing green

RED QUICK FLASH*

RED SLOW FLASH* Motor will restart automatically if

RED/YELLOW QUICK FLASH* Motor will restart automatically if

RED/YELLOW SLOW FLASH* Motor will restart automatically if

LED FLASH

FREQUENCY

CORRECTIVE

ACTION

if overload is removed before trip

supply voltage is corrected

supply voltage is corrected

supply voltage is corrected

*FLASH DEFINITIONS:

• Slow Flash = 1 second on, 1 second off

•

Quick Flash = .25 second on, .25 second off

18

Page 19

DECLARATION OF CONFORMITY

We, the Bodine Electric Company, 2500 W. Bradley Place, Chicago, Illinois,

U.S.A., phone (773) 478-3515, fax (773) 478-3232, declare under our sole

responsibility that the following products:

Type HPP-5337E4 AC Motor Speed Control, Model number 2995

Are in conformity with the following standards when installed in accordance with

the supplied installation instructions:

EN61010-1 Safety Requirements for Electrical Equipment

EN61800-3 Adjustable Speed Electrical Power Drive Systems EMC

Product Standard

EN50081 Electromagnetic Compatibility - General Emissions Standard

EN50082 Elecromagnetic Compatibility - Generic Immunity Standard

EN55011 Radiated and Conducted Emissions

EN61000 Electromagnetic Compatibility – Low Voltage Supply

Fluctuations and Harmonics

And therefore satisfies the conditions for the following EC directives:

Low Voltage Directive

EMC Directive 89/336/EEC

making the products eligible for the CE Mark.

The undersigned hereby declares that the products specified above conform to

the above standards:

Signature:

Full Name: Terrence J. Auchstetter

Position: Product Manager

Date: August 2, 2002

19

Page 20

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free of

defects in workmanship and materials when used under Normal Operating

Conditions and when applied in accordance with nameplate specifications.

When Bodine motors and gearmotors have been purchased with and used only

with appropriately applied Bodine controls, this warranty shall be in effect for a

period of twenty-four months from date of purchase or thirty months from date of

manufacture, whichever comes first. Bodine motors and gearmotors used with

non-Bodine controls and Bodine controls used with non-Bodine motors and

gearmotors are covered by the standard twelve-month warranty period.

The Bodine Electric Company will repair or replace at its option, any of its

products which has been found to be defective and is within the warranty period,

provided that the product is shipped freight prepaid, with previous authorization,

to Bodine’s plant in Chicago, Illinois 60618 U.S.A., or to the nearest Bodine

Authorized Service Center. At its option, all return shipments are F.O.B.

Bodine’s plant or Authorized Service Center. Bodine is not responsible for

removal, installation, or any other incidental expenses incurred in shipping the

products to or from Bodine.

This warranty is in lieu of any other expressed or implied warranty - including

(but not limited to) any implied warranties of merchantability and/or fitness for a

particular use or purpose.

Bodine’s liability under this warranty shall be solely limited to repair or

replacement of the Bodine product within the warranty period and Bodine shall

not be liable, under any circumstances, for any consequential, incidental or

indirect damages or expenses associated with the warranted products.

Commutator and/or brush wear and its associated effects are normal

occurrences and are not covered by this warranty.

Any Bodine product that is damaged due to misuse, abuse, negligence or has

been modified or dismantled without the knowledge or written consent of Bodine,

is not covered by this warranty.

Proof of purchase of motor or gearmotor and matching control as a system must

be provided with any claim.

Bodine Electric Company

2500 W. Bradley Place

Chicago, Illinois 60618 U.S.A.

TEL: (773) 478-3515

FAX: (773) 478-3232

www.bodine-electric.com

P/N 074 01040 B (DX)

20

Loading...

Loading...