Page 1

Instructions - Parts

Automatic Airless

Spray Guns

Part No. 288048

For airless spraying of paints and coatings.

Part No. 288554

For sealant streaming applications.

4000 psi (28 MPa, 280 bar) Maximum Working Fluid Pressure

Mounting manifolds must be ordered separately. Refer to Parts section.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

311053C

Model 288048 Shown

TI8089a

II 2 G c T6

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ventilate Spray Booth . . . . . . . . . . . . . . . . . . . . . 5

Configure Gun and Manifold . . . . . . . . . . . . . . . . 5

Install Air Fittings . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ground System . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mount Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Line and Accessory Recommendations . . . . 8

Fluid Line and Accessory Recommendations . . . 8

Flush Spray Gun . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust Spray Pattern . . . . . . . . . . . . . . . . . . . . . 10

Adjust a Streaming Tip . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Procedure . . . . . . . . . . . . . . . . 11

Apply the Fluid . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daily Gun Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General System Maintenance . . . . . . . . . . . . . . 13

Daily Cleaning Procedure . . . . . . . . . . . . . . . . . 13

Daily Flushing Procedure . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General Troubleshooting . . . . . . . . . . . . . . . . . . 14

Spray Pattern Troubleshooting . . . . . . . . . . . . . 16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GG0 Series Tip Selection Charts . . . . . . . . . . . . . 24

Sealer Application Tip and Air Cap Selection Charts

25

Shower Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Streaming Tips . . . . . . . . . . . . . . . . . . . . . . . . . 25

Single Orifice Fan Pattern Spray Tips . . . . . . . . 25

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting Hole Layout . . . . . . . . . . . . . . . . . . . . . . 28

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

Related Manuals

The Automatic Airless Spray Guns manual is available in the following languages. See the following chart for specific

language and part number.

Manual Language

Manual Language

311053

311665

311666

311667

311668

311669

311670

311671

English

Chinese

Danish

Dutch

Finnish

French

German

Italian

311672

311673

311674

311675

311676

311677

311678

Japanese

Korean

Norwegian

Polish

Russian

Spanish

Swedish

2 311053C

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

311053C 3

Page 4

Warnings

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 311053C

Page 5

Installation

Installation

Ventilate Spray Booth

Check and follow all National, State, and Local

codes regarding air exhaust velocity requirements.

Check and follow all local safety and fire codes.

Configure Gun and Manifold

(Order manifold separately. See Accessories, page

26.)

Manifolds 241161 and 241162

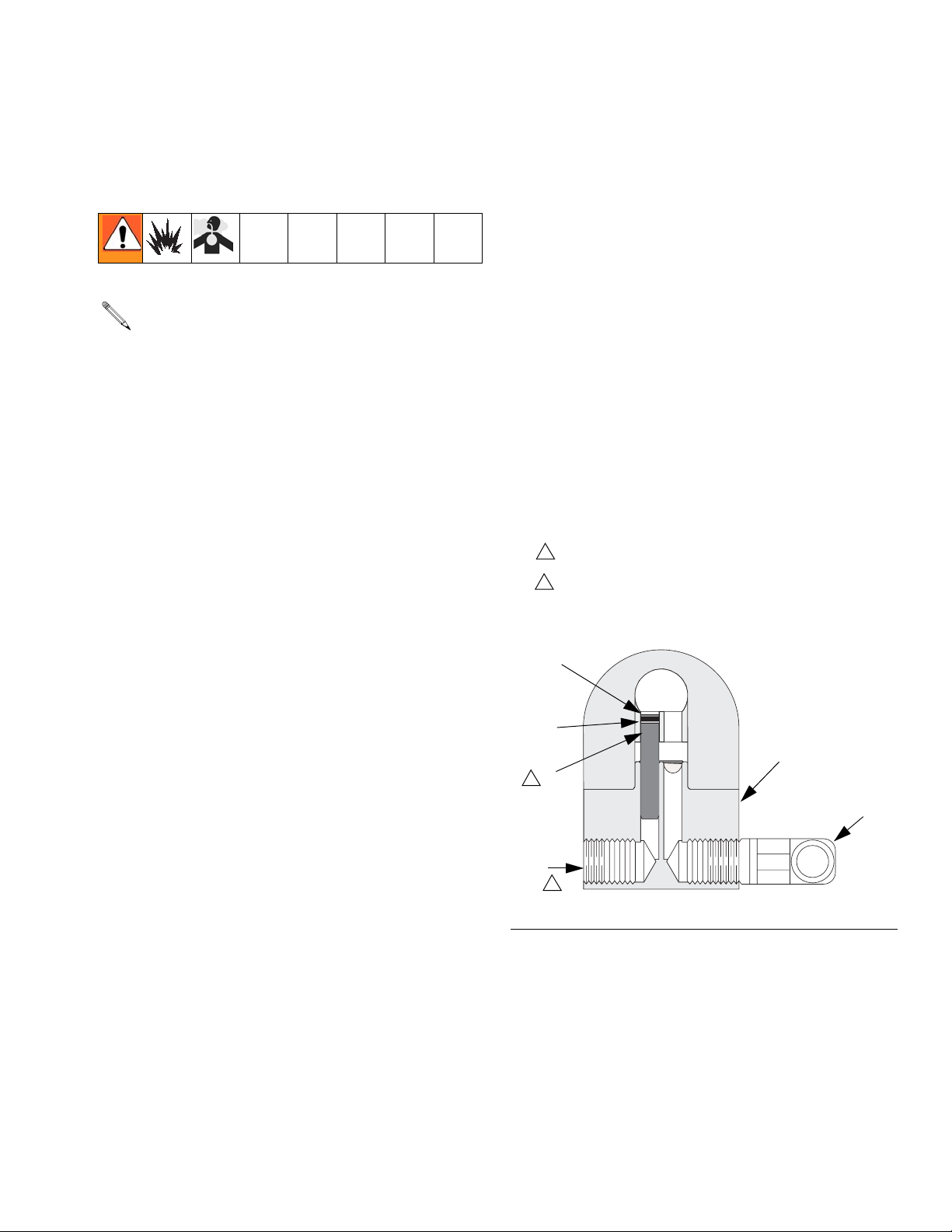

The gun is supplied with an internal fluid plug (4). See

F

IG. 1. To use the gun in a circulating system, remove

the internal plug. In a non-circulating system, leave the

plug in place to minimize flush time.

Non-circulating System:

1. Apply anti-seize lubricant 222955 to the threads and

mating faces of manifold (101), plug (109), and

elbow (107), supplied unassembled.

2. Install an elbow (107) in one fluid port of the manifold (101), and a plug (109) in the other port.

3. Install the internal plug (4) in the gun fluid port on

the same side as the manifold plug.

4. Connect the fluid supply line to the manifold elbow

(107). See F

5. Install the gun on the manifold, using the four

screws (14). Start the threads of all four screws, and

tighten the front two screws first, and then tighten

the back two screws to 65 in-lb (7.3 N•m).

1

Remove when used in circulating systems.

2

Replace with an elbow (107) when used in circulating

systems.

IG. 1.

Circulating System

1. Apply anti-seize lubricant 222955 to the threads and

mating faces of the manifold (101) and the elbows

(107), supplied unassembled.

2. Install the elbows (107) in both fluid ports of the

manifold (101).

3. Connect the fluid supply line to one elbow and the

fluid return line to the other. The manifold fluid ports

are reversible.

5

6

101

4

1

109

2

FIG. 1: Non-Circulating Setup (Cutaway View)

107

TI8587b

311053C 5

Page 6

Installation

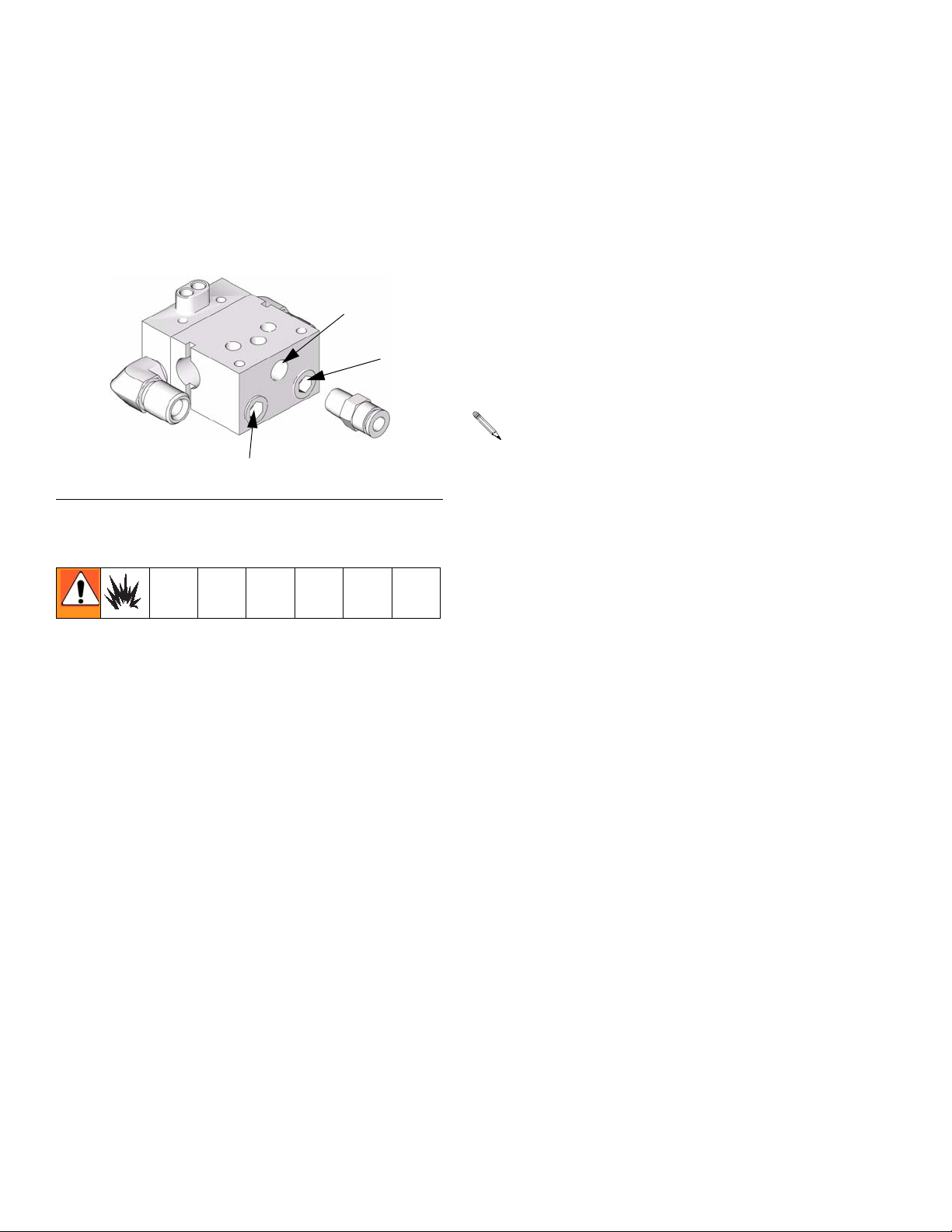

Install Air Fittings

1. Install 1/4 in. tube fitting into the cylinder (CYL) air

port.

2. Install plugs into the atomization (ATOM) air port

and the fan (FAN) air port.

CYL

ATOM

TI8225a

F

IG. 2: Air Fittings

FAN

Ground System

Ground Air Compressors and Hydraulic

Power Supplies

Ground them according to the manufacturer recommendations.

Ground Air, Fluid, and Hydraulic Hoses

Connected to Pump

Use only electrically conductive hoses with a maximum

of 100 ft (30.5 m) combined hose length to ensure

grounding continuity. Check the electrical resistance of

your air and fluid hoses at least once a week. If the total

resistance to ground exceeds 25 megohms, replace the

hose immediately.

Use a meter that is capable of measuring resistance at this level.

Ground Spray Gun

Ground the spray gun by connecting it to a properly

grounded fluid hose and pump.

The following grounding instructions are minimum

requirements for a system. Your system may include

other equipment or objects that must be grounded.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment. Your

system must be connected to a true earth ground.

Ground Pump

Ground the pump by connecting a ground wire and

clamp between the fluid supply and a true earth ground

as instructed in your separate pump instruction manual.

Ground Fluid Supply Container

Ground the fluid supply container according to local

code.

Ground Object Being Sprayed

Ground the object being sprayed according to local

code.

Ground Solvent Pails

Ground all solvent pails that are used with flushing

according to local code. Use only metal pails, which are

conductive. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which interrupts

the grounding continuity.

6 311053C

Page 7

Installation

Mount Gun

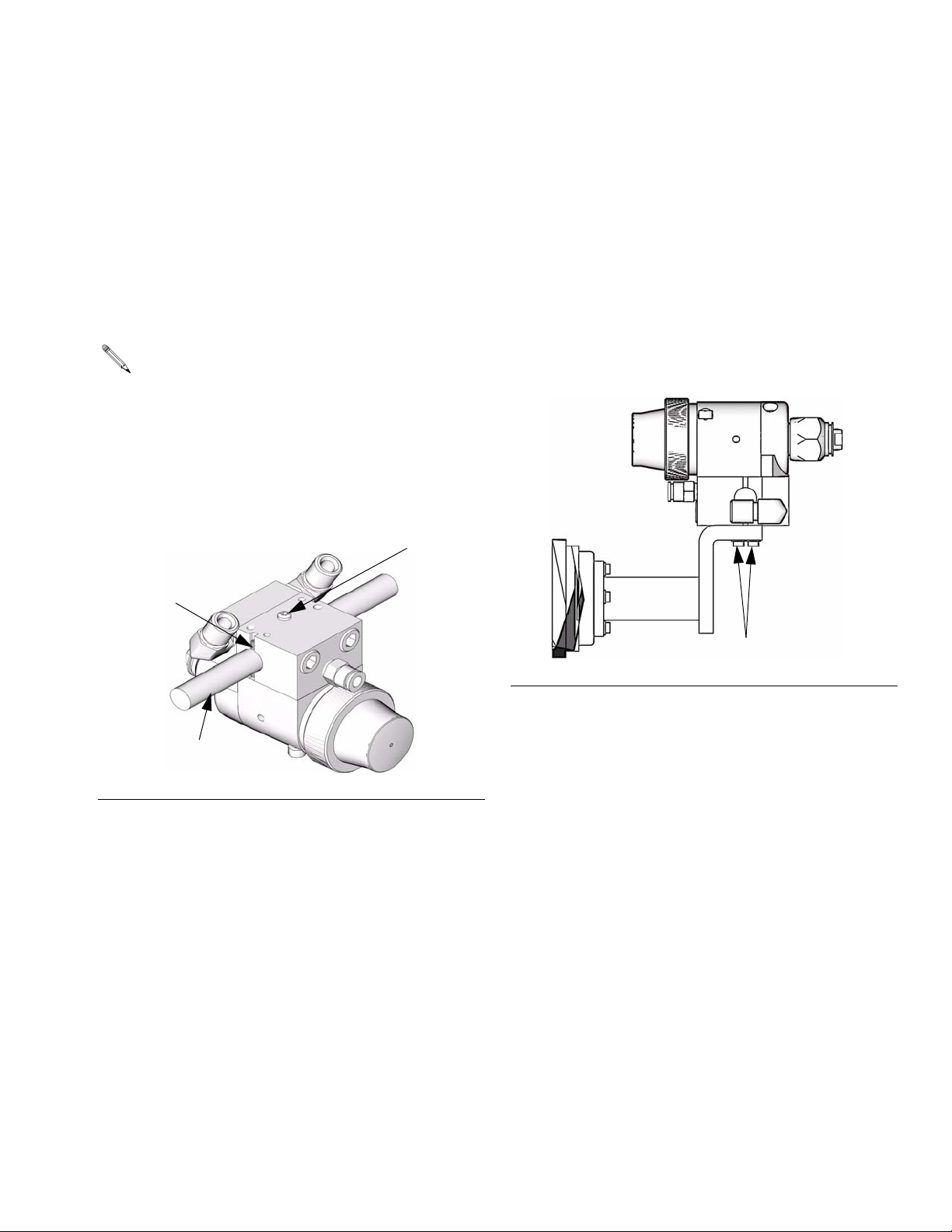

Reciprocating Arm Rod Mount

Manifolds 241161 and 241162

To mount the gun on a reciprocating arm rod [0.5 in. (13

mm) diameter maximum]:

1. Insert the mounting bar (A) through the hole in the

manifold as shown in F

Use the 1/8 in. alignment pin (P) to assist in

orienting the gun.

2. Secure the gun to the bar by tightening the mounting screw (B).

3. Ensure the tip of the gun is 8 to 10 in. (150 to 200

mm) from the surface of the object being sprayed.

IG. 3.

B

Stationary Support Mount

All Manifolds

To mount the gun on a stationary support (refer to F

4. and Mounting Hole Layout, page 28):

1. Attach the gun to the support with two M5 x 0.8 capscrews (C). The screws must be long enough to

engage the threaded holes in the gun manifold to a

depth of 1/4 in. (6 mm).

2. Ensure the tip of the gun is 8 to 10 in. (150 to 200

mm) from the surface of the object being sprayed.

IG.

P

A

F

IG. 3: Reciprocating Arm Mount

TI8111a

IG. 4: Stationary Support Mount

F

C

TI8112a

311053C 7

Page 8

Setup

Setup

Air Line and Accessory Recommendations

1. Install an air pressure regulator on the gun cylinder

air supply line.

A minimum of 70 psi (0.49 MPa, 4.9 bar) air pressure must be supplied to the cylinder for proper

operation. Air pressure opens the valve, a spring

closes the valve. A three-way air valve, which

exhausts cylinder air, is required.

2. Install a bleed-type air shutoff valve on the main air

line. Install an additional bleed-type valve on each

pump air supply line, downstream of the pump air

regulator, to relieve air trapped between this valve

and the pump after the air regulator is shut off.

The bleed-type air shutoff valve is required in your system to relieve air trapped between this valve and the

pump after the air regulator is closed. Trapped air can

cause the pump to cycle unexpectedly, which could

result in serious injury.

Fluid Line and Accessory Recommendations

• A fluid drain valve(s) is required in your system to

assist in relieving fluid pressure in the displacement

pump, hose and gun; triggering the gun to relieve

pressure may not be sufficient.

• A fluid pressure regulator must be installed in the

system if the pump's maximum working pressure

exceeds the gun's maximum fluid working pressure

(see the front cover).

1. Install a fluid filter and drain valve(s) close to the

pump's fluid outlet.

2. Install a fluid pressure regulator to control fluid pressure to the gun.

Some applications require fine-tuned control of fluid

pressure. You can control fluid pressure more accurately with a fluid pressure regulator than by regulating the air pressure to the pump.

3. Install a bleed-type air shutoff valve on the gun air

cylinder supply line, downstream of the air regulator,

to shut off air to the gun cylinder. Connect the air

supply line to the gun cylinder air inlet (C). See Fig.

4.

The cylinder air inlet accepts 1/4 in. (6.3 mm) O.D.

tubing.

3. Install a fluid shutoff valve to shut off the fluid supply

to the gun.

4. For paint spray applications, install an in-line fluid filter, part no. 210500, on the gun fluid inlet (F) to

avoid clogging the spray tip with particles from the

fluid. See Fig. 4.

5. Connect the electrically conductive fluid hose to the

gun fluid inlet (F) or optional in-line filter.

8 311053C

Page 9

Setup

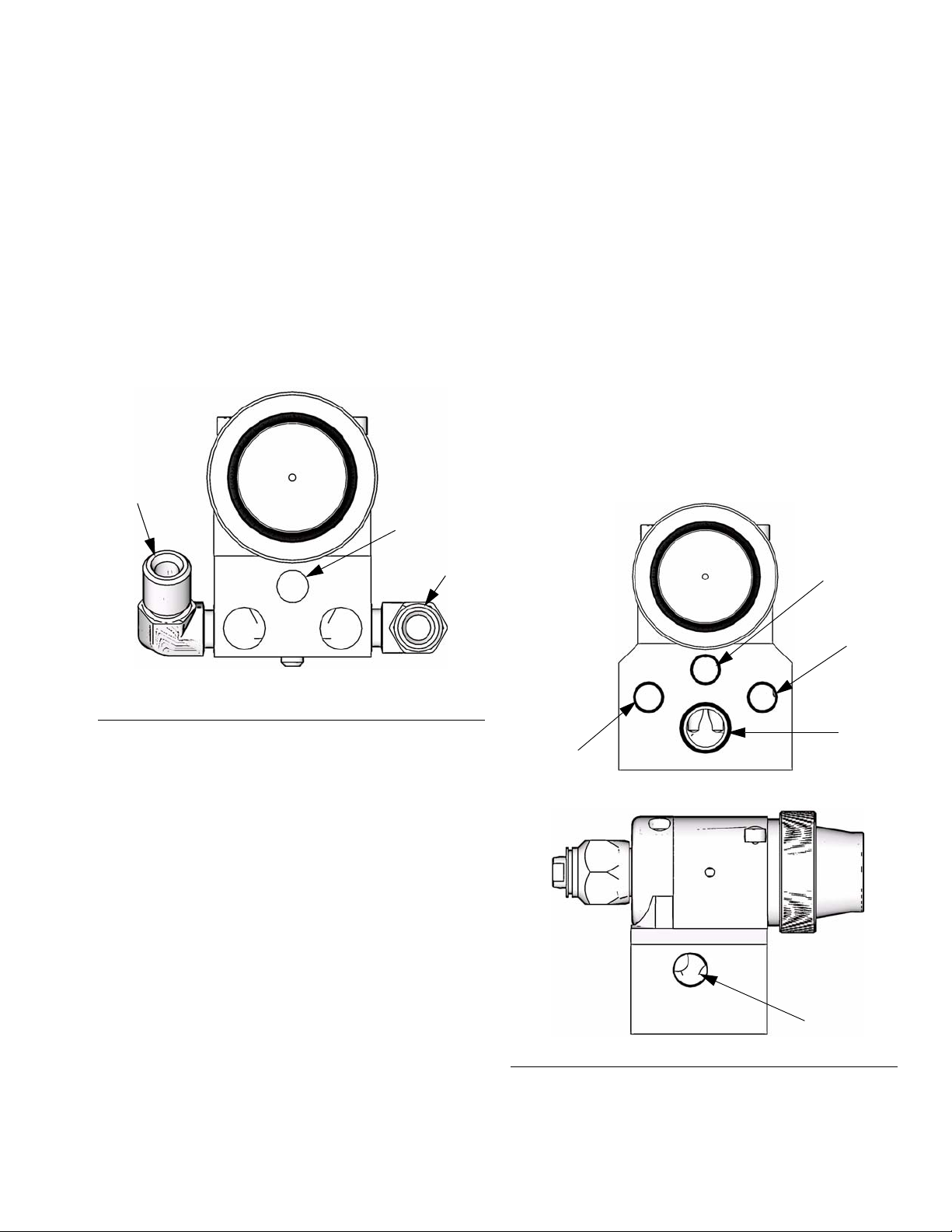

Manifolds 288219 and 288220

6. In a circulating system, connect an electrically conductive fluid hose to the gun fluid outlet (G).

In a non-circulating system, remove the gun fluid

outlet fitting (G) and plug the outlet port with the

pipe plug (109) supplied.

KEY

C Cylinder Air Inlet: accepts 1/4 in. (6.3 mm) O.D. tubing

F Fluid Inlet: 1/4-18 nptf or #5 JIC (1/2-20 unf)

G Fluid Outlet (circulating gun only): 1/4-18 nptf or #5 JIC (1/2-20 unf)

G (or F)

C

F (or G)

FAN

ATOM

Manifold 244930

7. This manifold is equipped with passages for circulating water to maintain the temperature of the gun.

Ports provided are:

• Side water inlet, 1/4 npt(f)

• Top water outlets, 1/8 npt(f)

• Side RTD sensor, 1/8 npt(f)

See Accessories, page 26, for available fittings and

sensors.

KEY

L Water Outlet: 1/8 npt(f)

M Air Inlet (to open valve): 1/8 npt(f)

N Fluid Inlet: 3/8(f)

P Water Inlet: 1/4 npt(f)

M

F

IG. 5

CYL

TI8113a

FIG. 6

L

N

L

TI8115a

P

TI8116a

311053C 9

Page 10

Setup

Flush Spray Gun

Before running any paint through the spray gun:

1. Flush the gun with a solvent that is compatible with

the fluid to be sprayed, using the lowest possible

fluid pressure and grounded metal container.

2. Perform Pressure Relief Procedure; see page 11.

Install Spray Tip

1. Perform Pressure Relief Procedure; see page 11.

2. Install the spray tip (H) and the gasket (J) in the tip

retainer nut (K). Screw the assembly firmly onto the

gun. Tighten the assembly with a wrench. See F

7.

IG.

Adjust Spray Pattern

1. To adjust the spray pattern direction with fan tips,

orient the slot in the tip horizontally for a horizontal

pattern and vertically for a vertical pattern. See Fig.

7.

2. Start the pump. Adjust the fluid pressure until the

spray is completely atomized. Use the lowest pressure necessary to get the desired results. Higher

pressure may not improve the spray pattern and will

cause premature tip wear and pump wear.

3. The spray tip orifice and spray pattern angle determines the coverage and size of pattern. When more

coverage is needed, follow the Pressure Relief

Procedure, page 11, and install a larger spray tip

rather than increasing fluid pressure.

K

H

FIG. 7: Install Spray Tip

Gaskets are included with Streaming Tips 270XXX

or Fan Tips 182XXX.

J

TI8577a

Vertical Pattern

TI8170a

TI8196a

FIG. 8: Spray Pattern

Horizontal Pattern

Adjust a Streaming Tip

Select a tip that will supply a stream at the required flow

rate at the lowest pressure.

10 311053C

Page 11

Operation

Operation

Pressure Relief Procedure

1. Shut off the power to the pump.

2. Turn off the air and fluid supply to the gun.

3. Close the bleed-type master air valve (required in

the system).

4. Trigger the gun into a grounded metal waste container to relieve the fluid pressure.

TI8174a

FIG. 9: Pressure Relief

Apply the Fluid

Adjust the system control device, if it is automatic, so the

gun starts spraying just before meeting the workpiece

and stops as soon as the workpiece has passed. Keep

the gun a consistent distance, 8 to 10 in. (200 to 250

mm), from the surface of the object being sprayed.

To achieve best results when applying fluid:

• Keep gun perpendicular and 8 to 10 inches (200 to

250 mm) from object being sprayed.

• Use smooth, parallel strokes across surface to be

sprayed with 50% overlap. See F

Incorrect

IG. 10.

5. Open the pump drain valve (required in the system)

to help relieve fluid pressure in the displacement

pump. In addition, open the drain valve connected to

the fluid pressure gauge (in a system with fluid regulation) to help relieve fluid pressure in the hose and

gun. Triggering the gun to relieve pressure may not

be sufficient. Have a container ready to catch the

drainage.

6. Leave the drain valve(s) open until you are ready to

spray again.

7. If you suspect that the spray tip or hose is completely clogged or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the hose end coupling and relieve pressure

gradually, then loosen the coupling completely. Now

clear the tip or hose obstruction.

TI8098a

Correct

TI8099a

FIG. 10: Correct Spray Method

311053C 11

Page 12

Daily Gun Care

Daily Gun Care

CAUTION

Methylene chloride with formic or propionic acid is not

recommended as a flushing or cleaning solvent with

this gun as it will damage aluminum and nylon components.

CAUTION

Solvent left in gun air passages could result in a poor quality paint finish. Do not use any cleaning method which

may allow solvent into the gun air passages.

Do not point the gun up while cleaning it.

Do not wipe the gun with a cloth soaked in solvent;

ring out the excess.

TI8100a

Do not immerse the gun in solvent.

TI8101a

TI4827a

12 311053C

Page 13

Daily Gun Care

General System Maintenance

•Perform Pressure Relief Procedure, page 11.

• Clean the fluid and air line filters daily.

• Check for any fluid leakage from the gun and fluid

hoses. Tighten fittings or replace equipment as

needed.

• Flush the gun before changing colors and whenever

you are done operating the gun.

Daily Cleaning Procedure

CAUTION

This gun is not adjustable. To ensure proper shutoff,

screw the piston cap (18) onto the housing (1) until it

bottoms out.

Clean the front of the tip frequently during the day

to help reduce buildup.

Daily Flushing Procedure

To reduce the risk of serious injury, including splashing fluid in the eyes or on the skin, or static electric

discharge when flushing:

• Ensure that the entire system, including flushing

pails, are properly grounded.

• Remove the spray tip.

• Maintain metal to metal contact between the gun

and the flushing pail.

• Use the lowest possible pressure.

Flush the pump and gun before the fluid can dry in

it.

If it is available, the flushing procedure provided in

the pump or sprayer manual should be used

instead of this procedure.

1. Follow Pressure Relief Procedure, page 11.

1. Follow Pressure Relief Procedure, page 11.

2. Clean the outside of the gun with a soft cloth dampened with compatible solvent.

3. To avoid damaging the spray tip, clean it with a compatible solvent and soft brush.

4. If using an in-line filter, remove and clean it thoroughly in a compatible solvent.

5. Clean the system's fluid filter and air line filter.

2. Remove the spray tip. Clean the parts.

3. Supply a compatible solvent to the gun fluid inlet.

4. Start the pump and operate it at its lowest pressure.

5. Trigger the gun into a grounded metal waste container until all the material is removed from the gun

passages.

TI8174a

F

IG. 11

6. Follow Pressure Relief Procedure, page 11.

7. Disconnect the solvent supply.

311053C 13

Page 14

Troubleshooting

Troubleshooting

Check all possible remedies in the troubleshooting

charts before disassembling the gun.

Some improper patterns are caused by the

improper balance between air and fluid. Refer to

Spray Pattern Troubleshooting, page 16.

General Troubleshooting

Problem Cause Solution

Fluid leakage through venting holes. Worn o-rings or packings on needle

assembly (12).

Air leakage through venting hole. Worn o-ring (23). Check and replace as needed.

Air leakage from back of gun. Worn o-rings (22, 23). Replace o-rings.

Fluid leakage from front of gun. Fluid needle (12) is dirty, worn, or

damaged

Replace o-rings or needle assembly.

Clean or replace fluid needle.

Dirty or worn seat (10, 41).

Spray tip seal is leaking.

Seat (10, 41) is insufficiently tight-

ened or gasket (11) is missing or

worn from multiple uses.

Clean or replace the seat (10, 41)

and gasket (11). The gasket must be

replaced whenever you remove the

seat from the gun.

Tighten nut (7) or replace spray tip

gasket (8).

Tighten seat (10, 41) and replace

gasket (11). The gasket must be

replaced whenever you remove the

seat from the gun.

14 311053C

Page 15

Problem Cause Solution

Fluid needle will not trigger Loose or missing fluid needle stop

(17) or setscrew (16).

Troubleshooting

Replace stop (17) or tighten setscrew

(16).

Broken fluid needle (12).

Air leaking around piston (21).

Swollen piston o-ring (22).

Insufficient air pressure on the trigger.

Spray tip (9) is plugged.

Plug (4) is in the incorrect fluid port.

Fluid does not shut off. Piston cap (18) not fully tightened.

Spring (19) not in place.

Swollen piston o-ring (22).

Replace fluid needle (12).

Replace o-ring (22) or piston assembly (21).

Replace o-ring (22). Do not immerse

piston in solvent.

Increase the air pressure or clean the

air line.

Clean the spray tip (9).

Move the plug to the fluid port consistent with manifold plumbing, unless

you are using the gun in a circulating

system. If you are, all fluid ports

should be open, both inside the gun

and on the manifold.

Tighten piston cap until it bottoms

out.

Check spring position.

Replace o-ring. Do not immerse piston in solvent

311053C 15

Page 16

Troubleshooting

Spray Pattern Troubleshooting

Problem Cause Solution

Fluttering spray. Insufficient fluid supply.

Adjust fluid regulator or fill fluid supply tank.

Air in paint supply line.

Spitting spray. Worn seat (10, 41) or needle (12)

ball.

Dirty spray tip (9).

Swollen piston o-ring (22).

Irregular pattern. Fluid build-up or spray tip partially

plugged.

Air cap loosening. (Sealant gun only) Air cap (18) not properly tightened.

Gasket (38) worn.

Check, tighten siphon hose connections, bleed air from paint line.

Inspect seat and needle for wear.

Replace if necessary. The gasket

(11) must be replaced whenever you

remove the seat from the gun.

Clean.

Replace o-ring. Do not immerse piston in solvent.

Clean spray tip; see Daily Gun Care,

page 12.

Tighten. See Reassembly, page 19,

step 13.

Replace gasket.

16 311053C

Page 17

Service

Service

Follow the Service Notes in Figs. 8 and 9 when

reassembling the gun.

Gun repair kits are available. See page 18. Reference numbers marked with an asterisk (*) in the

service procedures are included with the 288171

Air Seal Repair Kit. Reference numbers marked

with a symbol (†) in the service procedures are

included with the 288137 Fluid Repair Kit.

Disassembly

1. Follow Pressure Relief Procedure, page 11.

2. Unscrew the four screws (14) and remove the gun

from the manifold.

3. Unscrew the tip retainer nut (7). Remove the spray

tip (9) and gasket (8). See Figs. 8 and 9.

4. Remove the cap (18) from the piston housing (1).

Remove the springs (20 and 19).

9. Remove the piston. Using a pliers, pull the piston

(21) out of the piston housing (1).

10. If necessary, unscrew the two screws (15) holding

the fluid housing (2) to the piston housing (1). If

worn, remove the gasket (13) from the bottom of the

piston housing.

15

2

38

(model 288554 only)

15

1

FIG. 12

11. Remove the large o-ring (22) from the piston and

the smaller o-ring (23) from the piston shaft.

Remove the two o-rings (25, 26) from each of the

piston stems. Check that the stems are solidly in

place. If they are loose, replace the entire piston

assembly (21).

TI8197a

5. Using the supplied wrench (34), loosen the fluid

needle setscrew (16). Remove the needle stop (17).

6. Remove the seat (10, 41).

CAUTION

Be sure to keep the needle straight when removing it

from the gun. If the needle is bent it must be replaced.

7. Pull the needle assembly (12) straight out the front

of the gun. Remove the o-rings (31) from the fluid

needle (12).

8. Remove the gasket (11).

CAUTION

Install a new gasket (11) whenever you remove the

seat (10, 41) from the gun. Failure to install a new

gasket may result in fluid leaking into the air chamber.

12. Perform the following applicable step:

• Non-circulating Paint Guns: Remove the fluid

outlet port plug (4) and gasket (3) from the fluid

housing (2). Remove the o-ring (5) and backup

(6) from the plug.

• Circulating Paint Guns: Remove the gasket (3)

from the fluid housing (2).

• Sealant Gun: Remove the gasket (3).

13. Clean all parts and replace any worn parts. When

assembling, lubricate the threads with anti-seize

lubricant.

311053C 17

Page 18

Service

8

22*

3

25*

3

1

2

18

20

2

2

11†

10

2

7

5

1

26*

3

9

17

6

16

7

19

21

38

23*

3

3

8

4

12

13*

9

TI8117a

3†

SERVICE NOTES:

Seat gasket (11) must be replaced if seat (10) is

1

removed or replaced to avoid fluid leakage

Lubricate threads with anti-seize lubricant

2

3

Lubricate with light-weight oil

4

Do not lubricate

Torque to 20-25 ft-lb (27-34 N•m)

5

6

Apply semi-permanent anaerobic sealant

Torque to 4-5 in-lb (0.45-0.56 N•m)

7

Tighten cap (18) until it bottoms out

8

9

Model 288554 only

FIG. 13

18 311053C

Page 19

Reassembly

Service

1. Perform the following applicable step:

• Non-circulating Paint Guns: Lubricate the

backup (6) and o-ring (5) and install them on the

fluid outlet port plug (4). Install the plug in the

fluid outlet port of the fluid housing (2). See F

13. Reinstall the gasket (3).

• Circulating Paint Guns: Reinstall the gasket (3)

in the fluid housing (2).

• Sealant Gun: Reinstall gasket (3).

2. Install the o-rings (22*, 23*) on the piston (21).

Install two o-rings (25*, 26*) on each of the piston

stems. Lubricate all the o-rings, the piston, and the

piston stems.

3. Install the fluid housing (2) on the piston housing (1)

with the gasket in place.

4. Reinstall the two screws (15) to secure the piston

housing to the fluid housing (2). Torque to 30 in-lb

(3.4 N•m).

IG.

7. Install the o-rings (31) on the fluid needle assembly

(12). Lubricate with light weight oil.

CAUTION

Be sure to keep the needle straight when installing it

in the piston housing. If the needle is bent it must be

replaced.

8. Insert the needle assembly (12) into the front of the

fluid housing (2). Push it straight back through the

piston.

9. Install a new gasket (11) in the fluid housing (2).

10. Lubricate the threads of the seat (10, 41). Screw it

into the fluid housing (2) and torque to 20-25 ft-lb

(27-34 N•m).

11. Install the needle stop (17) on the needle. Coat the

setscrew (16) with semi-permanent anaerobic sealant and install the screw into the needle stop.

Torque to 4-5 in-lb (0.45-0.56 N•m). Pull on the needle to make sure it seats fully.

5. Insert the piston (21) into the piston housing (1).

6. Remove the protective paper from the sticky side of

the gasket (13*) and adhere the gasket to the bottom of the piston housing (1), making sure the three

holes in the gasket are properly aligned with the

matching holes in the housing.

CAUTION

Install a new gasket (11) whenever you remove the

seat (10, 41) from the gun. Failure to install a new

gasket may result in fluid leaking into the air chamber.

12. Install the springs (19, 20).

13. Lubricate the threads of the piston housing (1).

Screw the cap (18) onto the housing until it bottoms

out.

14. Model 288554 only: Hand tighten cap (18) until it

engages gasket (38). Then tighten cap a half turn

more to ensure cap will not loosen during operation.

15. Do not lubricate the gasket (8). Install the spray tip

(9) and gasket (8) in the tip retainer nut (7). Screw

the assembly firmly onto the gun. Tighten the

assembly with a wrench, but do not exceed 5 ft-lb

(6.8 N•m) for model 233670 gun.

16. Reinstall the gun on the manifold with the four

screws (14). Torque to 65 in-lb (7.3 N•m).

311053C 19

Page 20

Parts

Parts

Model 288048

2

2

12

14

11†

1

8

9

7

4

6†

3

9

5†

9

3

4

9

18

8

20

2

14

10

3

5

23*

3†

22*

19

6

16

3

7

17

FIG. 14

13*

12 (ref)

21

25*

26*

15

1

2

3

3

TI8090a

SERVICE NOTES:

Seat gasket (11) must be replaced if seat (10) is

1

removed or replaced to avoid fluid leakage

Lubricate threads with anti-seize lubricant

2

3

Lubricate with light-weight oil

4

Do not lubricate

Torque to 20-25 ft-lb (27-34 N•m)

5

6

Apply semi-permanent anaerobic sealant

Torque to 4-5 in-lb (0.45-0.56 N•m)

7

Tighten cap (18) until it bottoms out

8

9

Used on non-circulating guns only

20 311053C

Page 21

Model 288554

Parts

2

2

12

11†

1

14

16

3†

19

6

7

18

8

17

7

Ref. only

Ref. only

2

41

5

22*

3

3

23*

14

13*

12 (ref)

21

25*

15

26*

3

3

40

1

2

20

TI9523a

SERVICE NOTES:

Seat gasket (11) must be replaced if seat (10) is

1

removed or replaced to avoid fluid leakage

Lubricate threads with anti-seize lubricant

2

3

Lubricate with light-weight oil

4

Do not lubricate

Torque to 20-25 ft-lb (27-34 N•m)

5

6

Apply semi-permanent anaerobic sealant

Torque to 4-5 in-lb (0.45-0.56 N•m)

7

Tighten cap (18) until it bottoms out

8

9

Used on non-circulating guns only

FIG. 15

311053C 21

Page 22

Parts

Parts

Ref.

No. Part No. Description Qty.

1BODY 1

2 HOUSING, fluid 1

3†★ 288200 GASKET, fluid, acetal

homopolymer, pack of 10

4❖ 192687 PLUG, fluid, internal, SST 1

5†❖ 114244 PACKING, o-ring, fluoroelastomer 1

6†❖ 114340 RING, back-up, PTFE 1

7 NUT, retainer 1

❖171602

◆198391

8 166969 GASKET, non-metallic 1

9✓❖ GG0xxx TIP (see GG0 Series Tip Selec-

tion Charts, page 24)

10✓❖ 288196 DIFFUSER, seat, 3/16 in. ball 1

11† 189970 GASKET, diffuser/valve 1

12✓ NEEDLE, cartridge, assy. 1

❖288195

◆253886

13* 114134 GASKET, polyethylene, bottom 1

14 15H317 SCREW, mounting manifold (M5) 4

15 15H318 SCREW, SHCS 2

16 114137 SCREW, set, 6-32, 1/8 in. long 1

17 192452 STOP, needle, SST 1

18 192453 CAP, piston 1

Ref.

No. Part No. Description Qty.

19✓ SPRING, compression 1

❖114138

◆120696

20✓ 114139 SPRING, compression 1

21 240895 PISTON, assy 1

2

22* 115066 PACKING, o-ring, fluoroelastomer 1

23* 111450 PACKING, o-ring, fluoroelastomer 1

25* 112319 PACKING, o-ring, fluoroelastomer 2

26* 111504 PACKING, o-ring, fluoroelastomer 2

34 114141 WRENCH, hex (not shown) 1

37 15H702 INSERT, plastic (not shown) 1

40◆ 15K097 GASKET, piston cap 1

41◆ 233671 SEAT, airless 1

1

* Parts included in Air Seal Repair Kit 288171 (pur-

chase separately). The kit includes some parts that

are not used on this gun.

† Parts included in Fluid Seal Repair Kit 239896 (pur-

chase separately).

★ An extra gasket (3) is included as a spare.

✓ Keep these spare parts on hand to reduce down

time.

❖ Model 288048 only.

◆ Model 288554 only.

22 311053C

Page 23

Part No. 241161

North America Manifold

Part No. 241162

International Manifold

Ref.

No. Part No. Description Qty.

101 192441 MANIFOLD, side fluid ports 1

103 120388 FITTING, tube, air inlet;

1/4 in. OD tube x 1/8 npt(m)

105 114246 SCREW, set; 5/16;0.437 in. long 1

107 2

114342❖ ELBOW, fluid, male;

1/4 nptf(mbe); SST

114247◆ ELBOW, fluid, male;

#5 JIC x 1/4 - 18 npt

109❄ 101970 PLUG, pipe, SST; 1/4-18 ptf, sup-

plied to plug fluid outlet port in

non-circulating applications

❖ Part No. 241161 only.

◆ Part No. 241162 only.

Parts

2

Apply anti-seize lubricant (222955) to threads and mating faces

of manifold (101) and any fittings and/or plugs used in fluid

ports.

101

1

2

107

3

103

107

105

109

TI8148b

F

IG. 16: North America and International Manifold

Part No. 244930

High Flow Ambient or Temperature Conditioned Manifold for streaming or spraying.

Ref.

No. Part No. Description Qty.

101 198325 MANIFOLD, aluminum 1

102 110208 PLUG, 1/8 npt, SST 3

101

102

TI1396b

F

IG. 17: Part No. 244930

311053C 23

Page 24

GG0 Series Tip Selection Charts

GG0 Series Tip Selection Charts

GG0 Series Spray Tips

* Fluid Output

oz/min (lpm)

Orifice Size in.

(mm)

0.007 (0.178) .053 (0.20) 107 307

0.009 (0.229) .087 (0.33) 109 209 309

0.011 (0.279) 0.13 (0.49) 111 211 311 411 511 611

0.013 (0.330) 0.18 (0.69) 213 313 413 513 613 713

0.015 (0.381) 0.24 (0.91) 115 215 315 415 515 615 715 815

0.017 (0.432) 0.31 (1.17) 117 217 317 417 517 617 717 817 917

0.019 (0.483) 0.39 (1.47) 219 319 419 519 619 719 819

0.021 (0.533) 0.47 (1.79) 221 321 421 521 621 721 821 921

0.023 (0.584) 0.57 (2.15) 323 423 523 623 723 823 923

0.025 (0.635) 0.67 (2.54) 325 425 525 625 725 825 925

0.027 (0.686) 0.78 (2.96) 327 427 527 627 727 827 927

0.029 (0.737) 0.90 (3.42) 429 529 629 729

0.031 (0.787) 1.03 (3.90) 331 431 531 631 731 931

0.033 (0.838) 1.17 (4.42) 433 533 633 733

0.035 (0.889) 1.31 (4.98) 335 435 535 635 735

0.037 (0.940) 1.47 (5.56) 737

0.039 (0.991) 1.63 (6.18) 539 639

0.041 (1.041) 1.80 (6.83) 541 841

0.043 (1.092) 1.99 (7.51) 543 643

0.045 (1.143) 2.17 (8.23) 545

0.047 (1.197) 2.37 (8.98) 547 749

0.049 (1.245) 2.58 (9.76) 553

0.053 (1.35) 3.02 (11.4) 655

0.055 (1.40) 3.25 (12.3)

at 600 psi

(4.1 MPa, 41 bar)

2 to 2.5

(50)

4 to 4.5

(100)

Maximum Pattern Width at 12 in. (300 mm)

10 to

6 to 6.5

(150)

8 to 8.5

(200)

10.5

(250)

12 to 13

(300)

14 to 15

(350)

16 to 17

(400)

18 to 19

(450)

24 311053C

Page 25

Sealer Application Tip and Air Cap Selection Charts

Sealer Application Tip and Air Cap Selection Charts

Shower Tip

Orifice Size

No. of Orifices

6 0.021 (0.533) C08224

in. (mm)

Streaming Tips

Part. No.

Orifice Size

in. (mm)

0.025 (0.635) 270025 0.039 (0.991) 270037

0.027 (0.686) 270027 0.041 (1.041) 270039

0.029 (0.736) 270029 0.043 (1.092) 270041

0.031 (0.787) 270031 0.045 (1.143) 270043

0.035 (0.889) 270035 0.057 (1.448) 270059

Part. No.

Orifice Size

in. (mm)

Part. No.

Single Orifice Fan Pattern Spray Tips

Orifice Size

in. (mm)

0.021

(0.533)

0.023

(0.527)

0.025

(0.635)

0.027

(0.686)

Fan Width at 12 in. (300

mm)

in. (mm)

8-10 (200-250) 182421

10-12 (250-300) 182521

12-14 (300-350) 182621

14-16 (350-400) 182721

16-18 (400-460) 182821

8-10 (200-250) 182423

10-12 (250-300) 182523

12-14 (300-350) 182623

14-16 (350-400) 182723

16-18 (400-460) 182823

8-10 (200-250) 182425

10-12 (250-300) 182525

12-14 (300-350) 182625

14-16 (350-400) 182725

16-18 (400-460) 182825

8-10(200-250) 182427

12-14 (300-350) 182627

Part No.

0.029

(0.736)

0.031

(0.787)

0.035

(0.889)

0.039

(0.991)

0.043

(1.041)

0.047

(1.194)

Orifice Size

in. (mm)

Fan Width at 12 in. (300

mm)

in. (mm)

8-10 (200-250) 182429

12-14 (300-350) 182629

16-18 (400-460) 182726

8-10 (200-250) 182431

12-14 (300-350) 182631

16-18 (400-460) 182831

8-10 (200-250) 182435

10-12(250-300) 182535

12-14 (300-350) 182635

8-10 (200-250) 182439

10-12(250-300) 182539

12-14 (300-350) 182639

8-10 (200-250) 182443

10-12(250-300) 182543

12-14 (300-350) 182643

18-20 (450-500) 182643

18-20 (450-500) 182947

Part No.

311053C 25

Page 26

Accessories

Accessories

Gun Manifolds

Order separately; not included with gun.

(See Parts, page 22.)

Part No. 241161

North America Manifold

Part No. 241162

International Manifold

Part No. 244930

High Flow Ambient or Temperature Conditioned Manifold for streaming or spraying.

Grounding Clamp and Wire 222011

High Pressure Ball Valves, Fluoroelastomer

Seals

5000 psi (34 MPa, 345 bar) Maximum Working Pressure

Can be used as fluid drain valve.

Part No. Description

210657 1/2 npt(m)

210658 3/8 npt(m)

210659 3/8 x1/4 npt(m)

Brush 101892

For cleaning the gun.

In-line Fluid Filter 210500

5000 psi (35 MPa, 350 bar) Maximum Working Pressure

100 mesh. Fits onto the gun's fluid connector. 1/4-18

npsm. Includes the parts shown below.

210501

168517

Filter

164075

}

205264

F

IG. 18: In-line Fluid Filter

Needle/Diffuser Options

Needles must be used only with the specified seat to

guarantee proper seating and life.

• Standard viscosity/standard flow

Bleed-type Master Air Valve

300 psi (2.1 MPa, 21 bar) Maximum Working Pressure

Relieves air trapped in the air line between the pump air

inlet and this valve when closed.

Part No. Description

107141 3/4 npt(m x f) inlet and outlet

107142 1/2 npt(m x f) inlet and outlet

Gasket Filter

Gasket filter 288201, package of 10. Small filter can be

installed in the inlet gasket (3) for added filtration.

Tube Fittings for Air or Water

250 psi (1.7 MPa, 17 bar) Maximum Working Pressure

160° F (71° C) temperature rating

Part No. Length

104172 1/8 npt(m) x 1/4 OD tube

597151 1/8 npt(m) x 1/4 OD tube, 90° elbow (swivel)

• Fluid Needle 288195, 3/16 in. carbide ball

• Seat 288196

• Acid catalyzed materials/very low viscosity

materials

• Fluid Needle 241468, 3/16 in. plastic ball

• Seat 288196

Temperature Sensor and Cable

For temperature conditioned manifold

Part No. Length

198457 RTD Sensor, 100 ohm, 1/8 npt(m) with 3 pin

Picofast connector

198458 RTD cable, 6 ft. (1.83 m) Flex cable to St.

Clair connector

26 311053C

Page 27

Dimensions

Dimensions

2.0 in. (50.8 mm)

3.0 in.

(76.2 mm)

TI8113a

3.86 in. (98.0 mm)

5.23 in. (139.7 mm)

1.375 in.

(34.9 mm)

2.0 in.

(50.8 mm)

0.5 in.

(12.7 mm)

FIG. 19

311053C 27

2.245 in.

(57.02 mm)

TI8114a

Page 28

Mounting Hole Layout

Mounting Hole Layout

0.5 in.

(12.7 mm)

0.805 in. (20.5 mm)

Remove set screws

when using bottom

mounting pattern.

0.187 in. (4.8 mm)

2.125 in.

(54 mm)

0.4 in.

Two M5 x 0.8 x 0.25 in.

(6.3 mm) holes

1.750 in.

1.375 in.

(35 mm)

Two 0.128 diameter x

0.31 in. (7.8 mm) deep

holes (for alignment pin)

(44.5 mm)

TI8116a

TI8107a

FIG. 20: Manifold Mounting Hole Layout

28 311053C

Page 29

Technical Data

Technical Data

Maximum Working Fluid Pressure . . . . . . . . . . . . . . . . . . 4000 psi (28 MPa, 280 bar)

Maximum Working Air Pressure . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum Working Fluid Temperature . . . . . . . . . . . . . . . 120° F (49° C): paint applications

140° F (60° C): non-flammable sealant applications

Minimum Air Cylinder Actuation Pressure . . . . . . . . . . . . 70 psi (0.49 MPa, 4.9 bar)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 lbs (895 g)

Wetted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel, Carbide, Ultra High Molecular Weight

Polyethylene, Acetal, PEEK, Chemically Resistant Fluo-

roelastomer, PTFE

Triggering Speed

These values apply to a new gun with a 6 ft (1.8 m), 1/4 in. (6.3 mm) OD cylinder air line and a 0.019 in. tip. These

values will vary slightly with use and with variations in equipment.

Cylinder Air Pressure

psi (kPa, bar)

70 (0.49, 4.9) 600 (4.2, 42) 51 72

70 (0.49, 4.9) 1800 (12.4, 124) 56 73

70 (0.49, 4.9) 4000 (28, 280) 69 73

Fluid Pressure

psi (kPa, bar) msec to fully open msec to fully close

Sound Pressure Levels (dBa)

Sound pressure measured 3.28 ft (1 m) from equipment.

Input Fluid Pressures

1500 psi (10.5 MPa, 105 bar) 4000 psi (28 MPa, 276 bar)

79.0 dB(A) 86.6 dB(A)

Sound Power Levels (dBa)

Sound power measured per ISO-9641-2.

Input Fluid Pressures

1500 psi (10.5 MPa, 105 bar) 4000 psi (28 MPa, 276 bar)

75.7 dB(A) 86.3 dB(A)

311053C 29

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311053

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised 2/2008

Loading...

Loading...