Page 1

HPE 10000 G2 Series Rack Options

Abstract

This document is for the person who installs racks and rack products. This procedure is performed only by trained personnel. Hewlett

Part Number: 489899-006R

November 2015

Edition: 7

Installation Guide

Packard Enterprise assumes you are qualified in performing installations and trained in recognizing hazards in rack products.

Page 2

© Copyright 2008, 2015 Hewlett Packard Enterprise Development LP

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard Enterprise products and services

are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

About this guide ..................................................................................................................................... 7

Rack options installation guide ................................................................................................................................. 7

Important safety information ..................................................................................................................................... 7

Additional rack considerations .................................................................................................................................. 7

Rack options .......................................................................................................................................... 9

Ordering rack options ............................................................................................................................................... 9

100 Kilo Sliding Shelf kit ...................................................................................................................... 11

About this device .................................................................................................................................................... 11

Kit contents .................................................................................................................................................. 11

Required tools ............................................................................................................................................. 11

Preparing the sliding shelf rail assemblies for installation ...................................................................................... 11

Installing the sliding shelf rail assemblies ............................................................................................................... 12

Installing the sliding shelf ....................................................................................................................................... 14

Using the 100 Kilo Sliding Shelf ............................................................................................................................. 16

Airflow Optimization kit ......................................................................................................................... 17

About this device .................................................................................................................................................... 17

Kit contents .................................................................................................................................................. 17

Required tools ............................................................................................................................................. 17

Installing foam rail gaskets ..................................................................................................................................... 17

Installing foam rail gaskets between racks .................................................................................................. 18

Installing the floor gasket ........................................................................................................................................ 20

Ballast kit ............................................................................................................................................. 22

About this device .................................................................................................................................................... 22

Kit contents .................................................................................................................................................. 22

Required tools ............................................................................................................................................. 22

Installing the ballast kit ........................................................................................................................................... 22

Baying kit ............................................................................................................................................. 25

About this device .................................................................................................................................................... 25

Kit contents .................................................................................................................................................. 25

Required tool ............................................................................................................................................... 25

Installing the baying kit ........................................................................................................................................... 25

Cable Management Bracket kit ............................................................................................................ 28

About this device .................................................................................................................................................... 28

Kit contents .................................................................................................................................................. 28

Required tools ............................................................................................................................................. 28

Installing the 1U cable management bracket ......................................................................................................... 29

Installing the 2U cable management bracket ......................................................................................................... 30

Installing the cable management D-ring bracket .................................................................................................... 30

Front mount ................................................................................................................................................. 31

Side mount .................................................................................................................................................. 32

Installing the cross-over bracket ............................................................................................................................. 32

Installing the hook-and-loop cabling straps ............................................................................................................ 34

Cable Management Tray kit ................................................................................................................. 36

About this device .................................................................................................................................................... 36

Kit contents .................................................................................................................................................. 36

Required tool ............................................................................................................................................... 36

Installing the cable management tray ..................................................................................................................... 37

Installing the cable management inner and outer trays .......................................................................................... 39

Ground bonding stud location ................................................................................................................................ 41

Contents 3

Page 4

Fan (110V/220V) kit ............................................................................................................................. 42

About this device .................................................................................................................................................... 42

Kit contents .................................................................................................................................................. 42

Required tools ............................................................................................................................................. 42

Installing the fan ..................................................................................................................................................... 42

Filler Panel kit ...................................................................................................................................... 45

About this device .................................................................................................................................................... 45

Kit contents .................................................................................................................................................. 45

Required tools ............................................................................................................................................. 45

Installing the filler panel .......................................................................................................................................... 45

Front Door kit ....................................................................................................................................... 46

About this device .................................................................................................................................................... 46

Kit contents .................................................................................................................................................. 46

Required tools ............................................................................................................................................. 46

Installing the hinge brackets and lock catches ....................................................................................................... 46

Installing the front door ........................................................................................................................................... 47

Ground Bonding kit .............................................................................................................................. 49

About this device .................................................................................................................................................... 49

Kit contents .................................................................................................................................................. 49

Required tools ............................................................................................................................................. 49

Installing the ground bonding rack option kit on HPE 10000 G2 Series Racks ...................................................... 49

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack side panels ......................... 55

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack fan kits ................................ 57

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack 150-mm extension kits ....... 58

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack 200-mm extension kits ....... 59

Installing the ground bonding rack option kit on HPE 10000 Series Racks ........................................................... 61

Installing the ground bonding rack option kit on HPE 10000 Series Rack side panels ............................... 65

Installing the ground bonding rack option kit on HPE 10000 Series Rack fan kits ...................................... 66

Heavy Duty Stabilizer kit ...................................................................................................................... 68

About this device .................................................................................................................................................... 68

Kit contents .................................................................................................................................................. 68

Required tools ............................................................................................................................................. 68

Installing the rack stabilizer option kit ..................................................................................................................... 68

Hook-and-Loop Cabling Strap Clip kit .................................................................................................. 71

About this device .................................................................................................................................................... 71

Kit contents .................................................................................................................................................. 71

Required tools ............................................................................................................................................. 71

Installing the hook-and-loop cabling strap clips ...................................................................................................... 72

Light kit ................................................................................................................................................ 75

About this device .................................................................................................................................................... 75

Kit contents .................................................................................................................................................. 75

Required Tool .............................................................................................................................................. 75

Important safety information ................................................................................................................................... 75

Installing the 110V/220V Light ................................................................................................................................ 76

Operating the HPE 110V/220V Light ...................................................................................................................... 78

Connecting the power cord to the 110V/220V light ................................................................................................ 78

Connecting devices to the 110V/220V light ............................................................................................................ 78

0V/220V light kit specifications ............................................................................................................................... 79

F14W/133-T8 fluorescent lamp specifications ....................................................................................................... 80

Material disposal .................................................................................................................................................... 81

Mini Stabilizer kit .................................................................................................................................. 82

About this device .................................................................................................................................................... 82

Kit contents .................................................................................................................................................. 82

Required tools ............................................................................................................................................. 82

Installing the stabilizer ............................................................................................................................................ 82

Contents 4

Page 5

Rack Air Duct kit .................................................................................................................................. 85

About this kit ........................................................................................................................................................... 85

Kit contents .................................................................................................................................................. 85

Required tools ............................................................................................................................................. 86

Installation video ..................................................................................................................................................... 86

Installing the Top Exhaust Retrofit kit ..................................................................................................................... 87

Removing the rear doors ............................................................................................................................. 87

Installing the solid rack top plate ................................................................................................................. 88

Installing the solid rack base plate .............................................................................................................. 89

Installing the airflow gasket ......................................................................................................................... 90

Installing the floor gasket ............................................................................................................................. 92

Installing the Top Exhaust Extension kit ................................................................................................................. 92

Removing the rear doors ............................................................................................................................. 93

Installing the rear extension assembly ........................................................................................................ 94

Installing the solid rear doors....................................................................................................................... 96

Assembling the kits...................................................................................................................................... 97

Installing the kit assembly.......................................................................................................................... 100

Adjusting the kit ......................................................................................................................................... 101

Baying options ...................................................................................................................................................... 102

Rear Extension kit .............................................................................................................................. 103

About this device .................................................................................................................................................. 103

Kit contents ................................................................................................................................................ 103

Required tools ........................................................................................................................................... 103

Removing the rear doors ...................................................................................................................................... 103

Installing the rear extension assembly ................................................................................................................. 105

Installing the rear doors ........................................................................................................................................ 107

Installing the cable management brackets ........................................................................................................... 108

Server/Utility Shelf kit ......................................................................................................................... 110

About this device .................................................................................................................................................. 110

Kit contents ................................................................................................................................................ 110

Required tools ........................................................................................................................................... 110

Installing the server/utility shelf ............................................................................................................................ 110

Side Panel kit ..................................................................................................................................... 113

About this device .................................................................................................................................................. 113

Kit contents ................................................................................................................................................ 113

Required tools ........................................................................................................................................... 113

Installing the side panels ...................................................................................................................................... 114

Tie-Down kit ....................................................................................................................................... 116

About this device .................................................................................................................................................. 116

Kit contents ................................................................................................................................................ 116

Required tools ........................................................................................................................................... 116

Installing the tie-down kit ........................................................................................................................... 116

Securing the rack to the floor..................................................................................................................... 118

1200 mm Full Frame Rack Tie-down Kit .............................................................................................................. 118

Installing the 1200 mm full frame rack tie-down kit.................................................................................... 118

1200 mm full frame rack tie-down kit contents .......................................................................................... 119

Required tools ........................................................................................................................................... 119

Securing the 1200 mm full frame rack to the floor ..................................................................................... 120

Vertical PDU Mounting kit .................................................................................................................. 121

About this device .................................................................................................................................................. 121

Kit contents ................................................................................................................................................ 121

Required tools ........................................................................................................................................... 121

Installing the Vertical PDU Mounting kit ............................................................................................................... 121

Electrostatic discharge ....................................................................................................................... 123

Preventing electrostatic discharge ....................................................................................................................... 123

Grounding methods to prevent electrostatic discharge ........................................................................................ 123

Contents 5

Page 6

Support and other resources.............................................................................................................. 124

Accessing Hewlett Packard Enterprise Support ................................................................................................... 124

Information to collect ................................................................................................................................. 124

Accessing updates ............................................................................................................................................... 124

Websites ............................................................................................................................................................... 124

Customer Self Repair ........................................................................................................................................... 125

Remote support .................................................................................................................................................... 132

Acronyms and abbreviations .............................................................................................................. 133

Documentation feedback ................................................................................................................... 134

Contents 6

Page 7

About this guide

Rack options installation guide

This installation guide includes the instructions for installing rack option kits that are compatible with the

HPE 10000 G2 Series Rack.

For more information, see the 10000 G2 Series Rack User Guide on the Hewlett Packard Enterprise

website (http://www.hpe.com/info/rackandpower).

Important safety information

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The rear leveling feet are extended to the floor.

• The full weight of the rack rests on the rear leveling feet and front stabilizer feet.

WARNING: To reduce the risk of personal injury or damage to the rack and equipment, the

racks must be positioned and secured together according to these instructions. Failure to do so

could result in an unstable installation.

WARNING: Components can be very heavy. To reduce the risk of personal injury or damage

to the equipment:

• Remove all pluggable power supplies and modules to reduce the weight of the product

before lifting it.

• Observe local occupational health and safety requirements and guidelines for manual

material handling.

• Get help to lift and stabilize the product during installation or removal, especially when the

product is not fastened to the rails. When the component weighs more than 22.5 kg (50 lb),

at least two people must lift the component into the rack together. If the component is

loaded into the rack above chest level, a third person must assist in aligning the rails while

the other two support the component.

• Use caution when installing the component in or removing the component from the rack; it is

unstable when not fastened to the rails.

Additional rack considerations

Consider the following specifications and components, with regard to your specific rack configuration:

• Power—If a UPS is installed, do not exceed its output rating. Be sure to review the installation

instructions provided with each component for important cautions and warnings.

• PDUs—Install PDUs before installing other components.

• Height—The height of the rack and of rack-mountable components is measured in U increments,

where U = 4.5 cm (1.75 in). When you are configuring your rack installation, remember that the total

U measurement of the components you want to install cannot exceed the stated U height of the rack.

• Keyboard—The rack keyboard requires installation of a 1U keyboard drawer rack option kit.

• Monitor—The monitor requires installation of a monitor/utility shelf rack option kit unless you are

using a rack-mountable flat-panel monitor.

About this guide 7

Page 8

• Server console switch—If a console switch is configured, use the CPU-to-console switch cable

included with the server. The standard distance between the console switch and the keyboard,

monitor, and mouse can vary by 3-, 7-, 12-, 20-, and 40-ft lengths.

NOTE: National electrical regulations governing the installation of building wiring require that

an appropriate cable, meeting fire-safety standards, must be used any time cabling is routed:

• Through an overhead drop-ceiling

• Under raised flooring

• From room to room

• From floor to floor

Be sure that the cable jacket or sleeving is made of material that does not burn easily and does

not exude toxic fumes when exposed to heat. Be sure that the cable you have selected is

appropriate for your installation site. If you require a U.S. plenum-rated (CL2P) cable, contact

your local Hewlett Packard Enterprise authorized reseller to obtain any of the following options:

• 149363-B21-20-foot plenum cable

• 149364-B21-40-foot plenum cable

• Rack baying option kits—The number of baying kits needed to join a series of racks is one less than

the number of racks in the suite. Each baying kit supplies parts to bay two cabinets on 600 mm (24

in) center line spacing.

• Side panels—Only one set of side panels is required for each row of bayed racks.

• Stabilizer kit—A stabilizer kit is either required or recommended, depending on your rack

configuration. There are four stabilizer kit options.

o The standard 600-mm (23.6 in) or 800-mm (31.5 in) front foot is required with deployments of

stand-alone racks. Rack rows with four or more bayed racks, without a single rack-mountable

component exceeding 99.8 kg (220 lb), do not need a stabilizer kit installed.

o The heavy duty 600-mm (23.6 in) or 800-mm (31.5 in) front foot is required when a single

rack-mountable component weighing 99.8 kg (220 lb) or more is installed in a stand-alone rack or

in a rack belonging to a rack row of three or fewer bayed racks.

About this guide 8

Page 9

Rack options

number

page 11)

234672-B21

Enables easy access to various rack components

page 17)

AF090A

Enables you to improve airflow of your rack

120672-B21

Provides rack stability when you install, remove, or access

Baying kit (on page 25)

248929-B21

Joins multiple racks of the same series, height, and depth

(on page 28)

AF099A

Enables you to manage your cable configurations

383982-B21

383984-B21

Enables you to manage your cable configurations

42)

257414-B21

Enhances natural convection cooling by increasing the

AF072A

Enables you to control airflow by covering empty locations in

AF009A

Enables you to add a door to the front of your rack

49)

AF074A

Reduces the level of electromagnetic emissions outside the

page 68)

AF064A

Increases the stability of free-standing racks

Clip kit (on page 71)

379820-B21

Enables you to manage your cable configurations

Light kit (on page 75)

361589-B21

Provides additional light inside your rack

AF062A

AF066A

Increases the stability of free-standing racks

•

•

•

Removes warm air from the rack by channeling the warm air

•

•

Enables you to add 200-mm (7.87 in) of depth to the rear of

110)

253449-B21

Holds rack components inside the rack

Side Panel kit (on page 113)

AF054A

Provides enclosures for the sides of a rack

Ordering rack options

Hewlett Packard Enterprise provides several rack option kits to complement or complete your rack

solution. The following list is a sample of the many rack option kits available.

For information about ordering rack option kits, see the Hewlett Packard Enterprise website,

(http://www.hpe.com/info/rackandpower) or contact your nearest Hewlett Packard Enterprise authorized

reseller.

Rack option kit Part

100 Kilo Sliding Shelf kit (on

Airflow Optimization kit (on

Description

Ballast kit (on page 22)

Cable Management Bracket kit

Cable Management Tray kit (on

page 36)

Fan (110V/220V) kit (on page

Filler Panel kit (on page 45)

Front Door kit (on page 46)

Ground Bonding kit (on page

Heavy Duty Stabilizer kit (on

Hook-and-Loop Cabling Strap

Mini Stabilizer kit (on page 82)

Rack Air Duct kit (on page 85)

Top exhaust extension kit

Top exhaust field retrofit kit

Top exhaust rack

Rear Extension kit (on page

103)

42U rear extension kit

47U rear extension kit

Server/Utility Shelf kit (on page

383983-B21

AF028A

AF029A

AF030A

AF036A

AF043A

heavy equipment within the rack

airflow in the rack

your rack

rack

into the data center ceiling return air plenum

your rack

Rack options 9

Page 10

Tie-Down kit (on page 116)

AF076A

Increases the stability of free-standing racks

page 121)

H6L32A

Allows PDU vertical models to be mounted in the rack

Rack option kit Part

Description

number

Vertical PDU Mounting kit (on

Rack options 10

Page 11

100 Kilo Sliding Shelf kit

Shelf with handle

1

Right rail with fixed brackets

1

Left rail with fixed brackets

1

Sliding rail

2

hardware

1

Rack template

1

•

•

•

•

•

•

•

•

•

•

•

•

•

•

About this device

The HPE 100 Kilo Sliding Shelf kit enables you to install a sliding shelf in your rack mount system for

placement and easy access to various components. This option occupies 2Us of rack space.

Kit contents

Item Quantity

Cable management arm with

Hardware kit

M4 x 12 flat HD screw

M4 external washer

M4 x 10 pan HD screw

M6 x 12 pan HD screw

M4 plain washer

M4 nut

M6 external washer

Extra hardware might be included for your convenience.

Required tools

8

8

2

12

2

6

10

The following tools are required for installation:

• No. 2 Phillips screwdriver

• No. 3 Phillips screwdriver

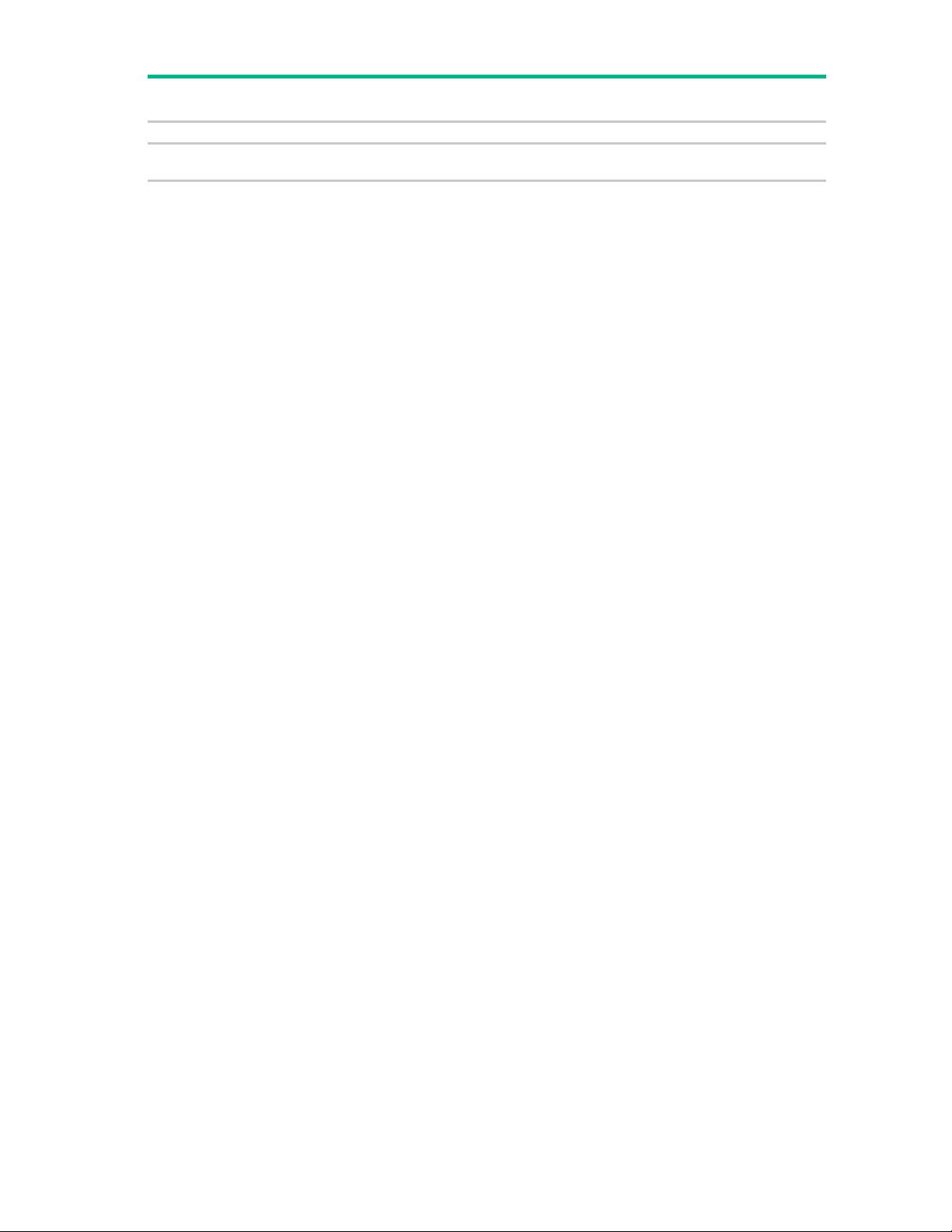

Preparing the sliding shelf rail assemblies for installation

Each sliding shelf rail assembly consists of a rail with fixed brackets attached to a sliding rail. To construct

the sliding shelf rail assemblies:

1. Hold the flat side of the left rail with fixed brackets facing toward you.

2. Place the sliding rail on top of the left rail with fixed brackets.

3. Extend the inner slides of the sliding rail until the screw holes on the sliding rail and the left rail with

fixed brackets are aligned. Gently push down on the sliding rail to lock it into place.

100 Kilo Sliding Shelf kit 11

Page 12

4.

Secure the rails together with two M4 x 12 flat HD screws and M4 external washers.

5. Repeat steps 1 through 4 for the right rail with fixed brackets.

Installing the sliding shelf rail assemblies

WARNING: The rack air duct weighs approximately 22.5 kg (50 lb). To reduce the risk of

personal injury or damage to the equipment:

• Observe local occupational health and safety requirements and guidelines for manual

material handling.

• Use at least two people to lift and stabilize the product during installation or removal.

• Use step stools to install the product to the top of the rack. Do not lift the air duct over your

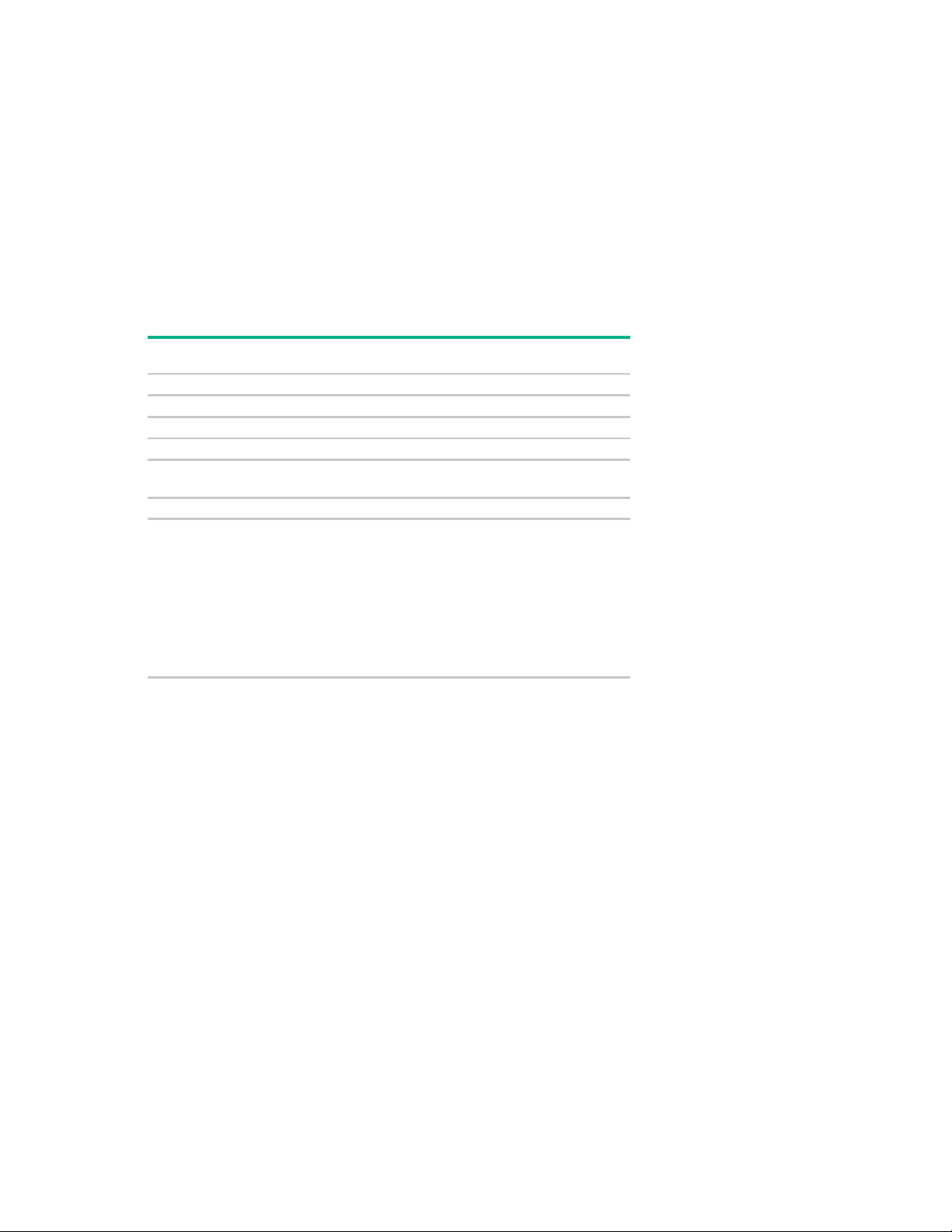

You must install the sliding shelf rail assemblies before installing the sliding shelf. Follow these steps

closely to install the sliding shelf rail assemblies into the rack:

head.

100 Kilo Sliding Shelf kit 12

Page 13

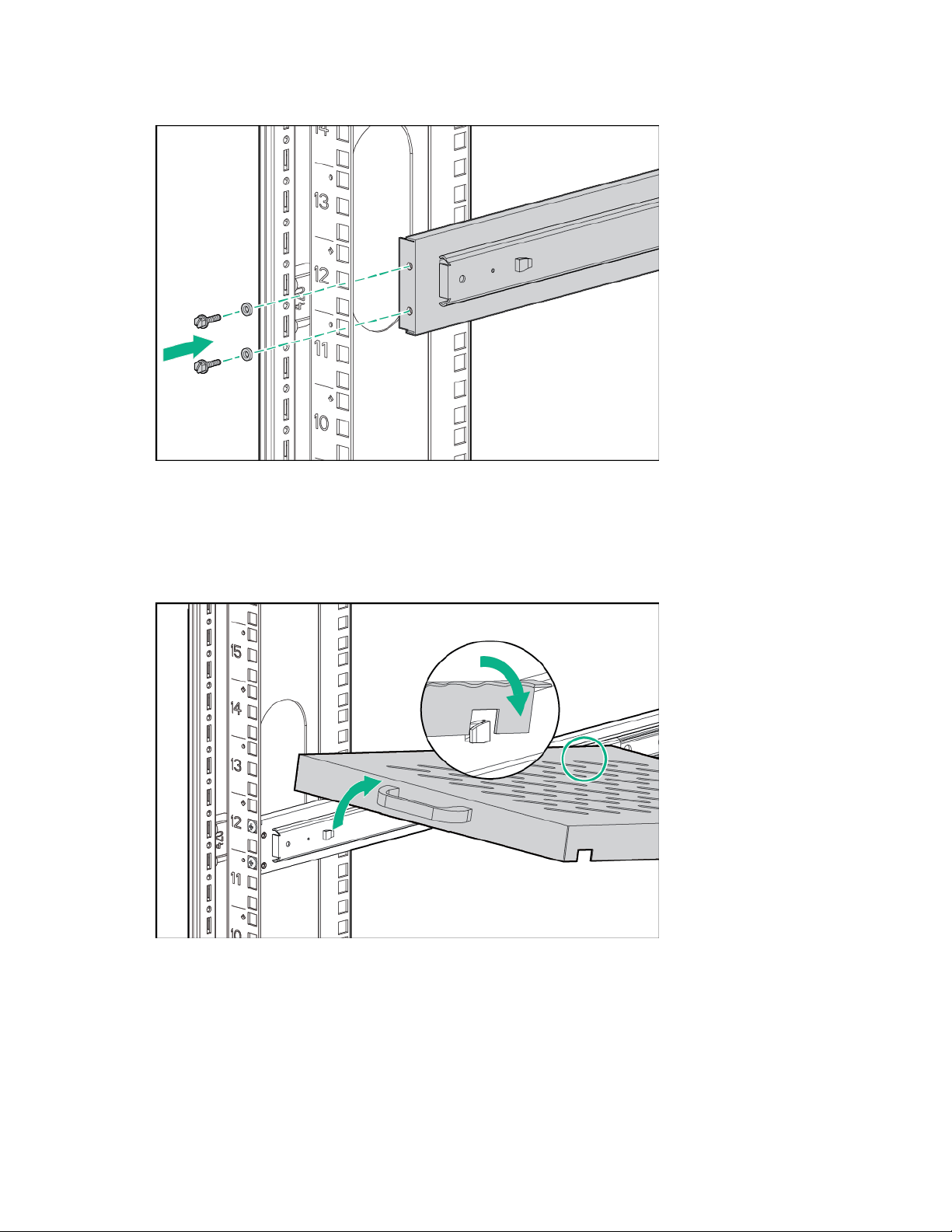

1.

Use the template on the front and rear of the rack frame to mark the attachment points for the sliding

shelf rail assemblies, by measuring from the top of the component installed below the desired

position for the sliding shelf.

IMPORTANT: When using the template on the rear of the rack frame, mark the rack at the

top of the template to help align the next rack component.

2. Align and secure the rear of the left sliding shelf rail assembly to the rear of the rack frame with two

M6 x 12 pan HD screws and M6 external washers.

100 Kilo Sliding Shelf kit 13

Page 14

3.

Secure the front of the left sliding shelf rail assembly to the front of the rack frame with two M6 x 12

pan HD screws and M6 external washers.

4. Repeat steps 2 and 3 to install the right sliding shelf rail assembly.

Installing the sliding shelf

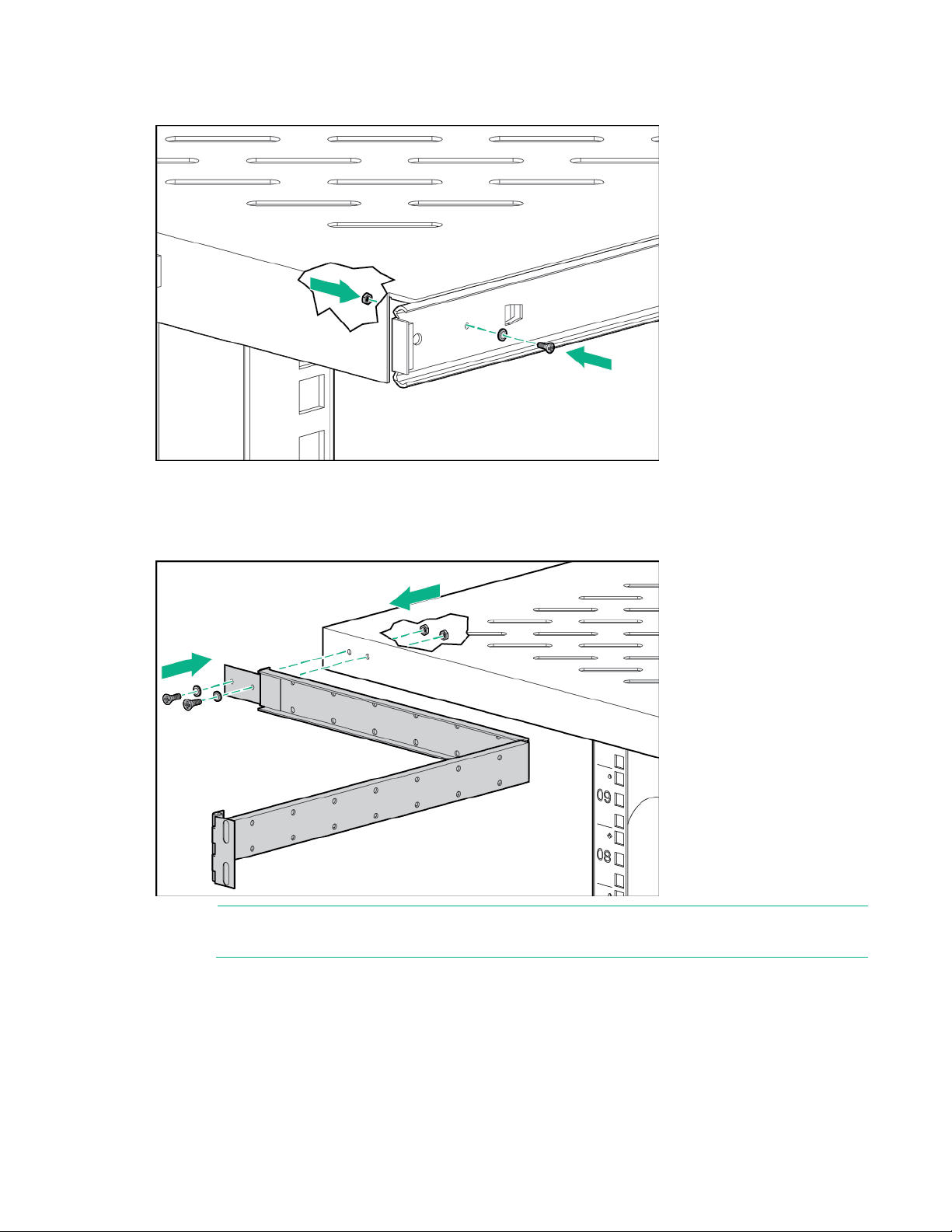

1. Move the sliding shelf into the rack while tilting the front of the shelf up. Align the rear notches on the

sliding shelf over the rear tabs on the sliding shelf rail assemblies.

2. Push the sliding shelf down onto the rear tabs to align the front notches on the sliding shelf with the

front tabs on the sliding shelf rail assemblies.

3. Lower the front of the sliding shelf over the tabs on the front of the sliding shelf rail assemblies and

push down gently to lock the shelf into place.

100 Kilo Sliding Shelf kit 14

Page 15

4.

Secure the sliding shelf to each sliding rail using one M4 x 12 flat HD screw and M4 external washer

with one M4 nut on the inside of the shelf.

5. Attach the cable management arm to the sliding shelf with the flat side of the cable management arm

mounting bracket flush with the sliding shelf.

6. Secure the cable management arm to the sliding shelf using two M4 x 12 flat HD screws and M4

external washers with two M4 nuts on the inside of the shelf.

NOTE: The cable management arm attaches to the rear of the sliding shelf on either the right

or left side.

100 Kilo Sliding Shelf kit 15

Page 16

7.

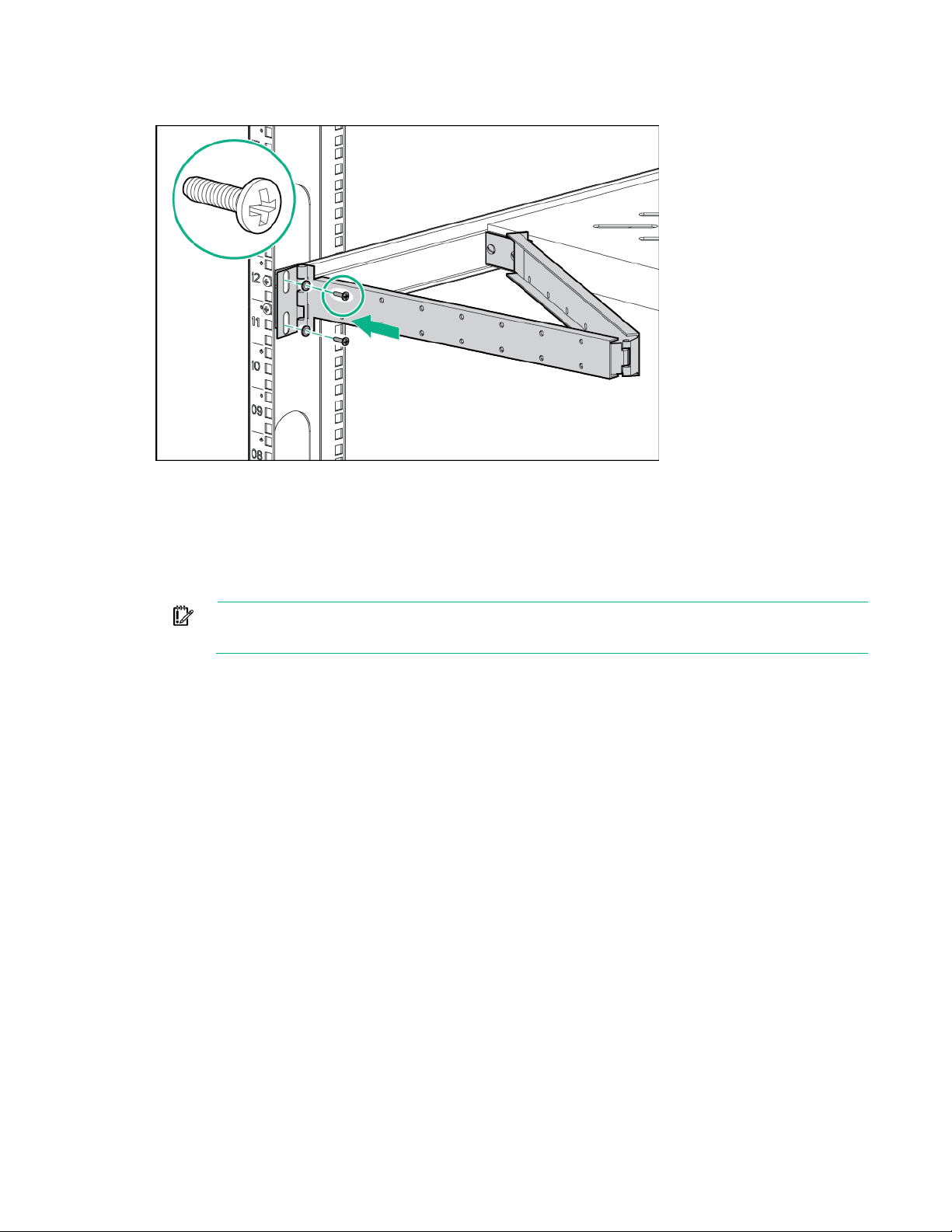

Secure the opposite end of the cable management arm to the rack using two M6 x 12 pan HD screws

and M6 external washers.

Installation is complete.

Using the 100 Kilo Sliding Shelf

Use the handle on the front of the sliding shelf to slide it in and out of the rack. When sliding the shelf back

into the rack, there may be resistance. Apply pressure as needed to fully move the shelf into the rack.

IMPORTANT: Be sure to secure all rack mount system components when moving the shelf

out of the rack.

100 Kilo Sliding Shelf kit 16

Page 17

Airflow Optimization kit

gasket

1

Foam rail gasket roll

4

About this device

The Airflow Optimization kit enables you to install foam rail gaskets in your HPE 10000 G2 Series 22U,

36U, 42U, and 47U 600-mm (24-in) wide racks and in to 42U 800-mm (31-in) wide racks to improve

separation between hot and cold aisles in the data center.

Kit contents

Item Quantity

600-mm (24-in) perforated floor

gasket

—or—

800-mm (31-in) perforated floor

Extra hardware might be included for your convenience.

1

Required tools

No tools are required for this procedure.

Installing foam rail gaskets

IMPORTANT: This option kit is only compatible with racks that are 600-mm (24 in) or

800-mm (31 in) wide.

1. Cut the foam rail gasket to fit the size of your rack.

2. Insert the foam rail gasket into the rack front door on both sides of the rack.

Airflow Optimization kit 17

Page 18

3.

Insert the foam rail gasket into the space between the 19-in mounting rails and the vertical frame on

both sides of the rack, with the closed cell side of the foam rail gasket facing the front of the rack.

4. Gently push the foam rail gasket into the space until it is flush with the vertical frame.

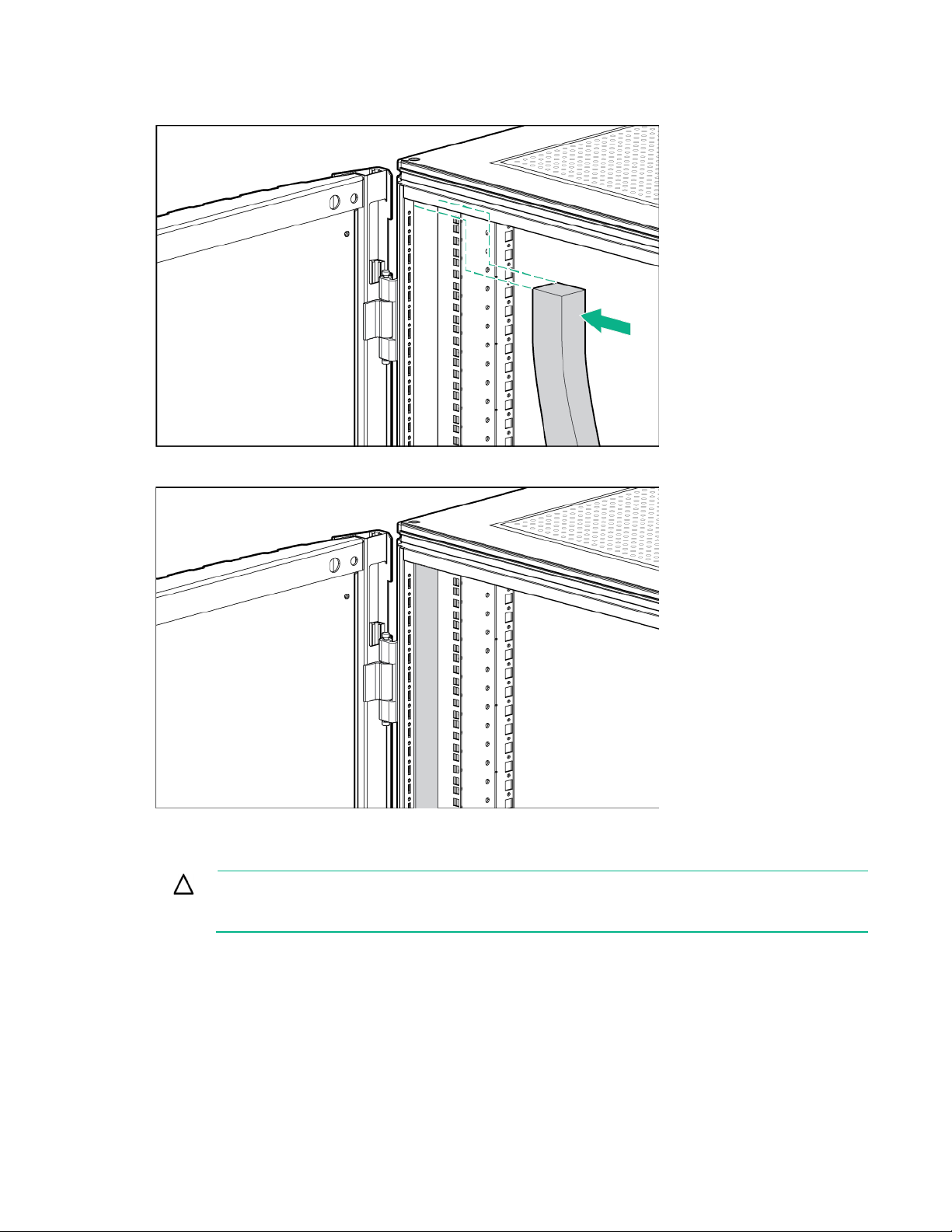

Installing foam rail gaskets between racks

CAUTION: The foam rail gasket must be installed into the rack before two or more racks can

be bayed together. For additional information on baying racks, see the HPE Baying Rack

Option Kit.

If installing the foam rail gasket between racks that have a baying kit installed, the baying bracket must be

removed before the foam rail gasket can be inserted between the racks.

1. Position the racks side by side.

2. Cut the foam rail gasket to fit the size of your rack.

Airflow Optimization kit 18

Page 19

3.

Insert the foam rail gasket into the space between the racks with the closed cell side of the foam rail

gasket facing the front of the rack.

NOTE: Follow steps 1 through 3 to install the foam rail gasket into a rack that will be bayed

using a 24-in. baying bracket.

If the rack will be bayed using a 600-mm baying bracket, rotate the foam rail gasket 90 degrees

4. Gently push the foam rail gasket into the space between the racks until it is flush with the vertical

before inserting it into the space between the racks.

frame.

Airflow Optimization kit 19

Page 20

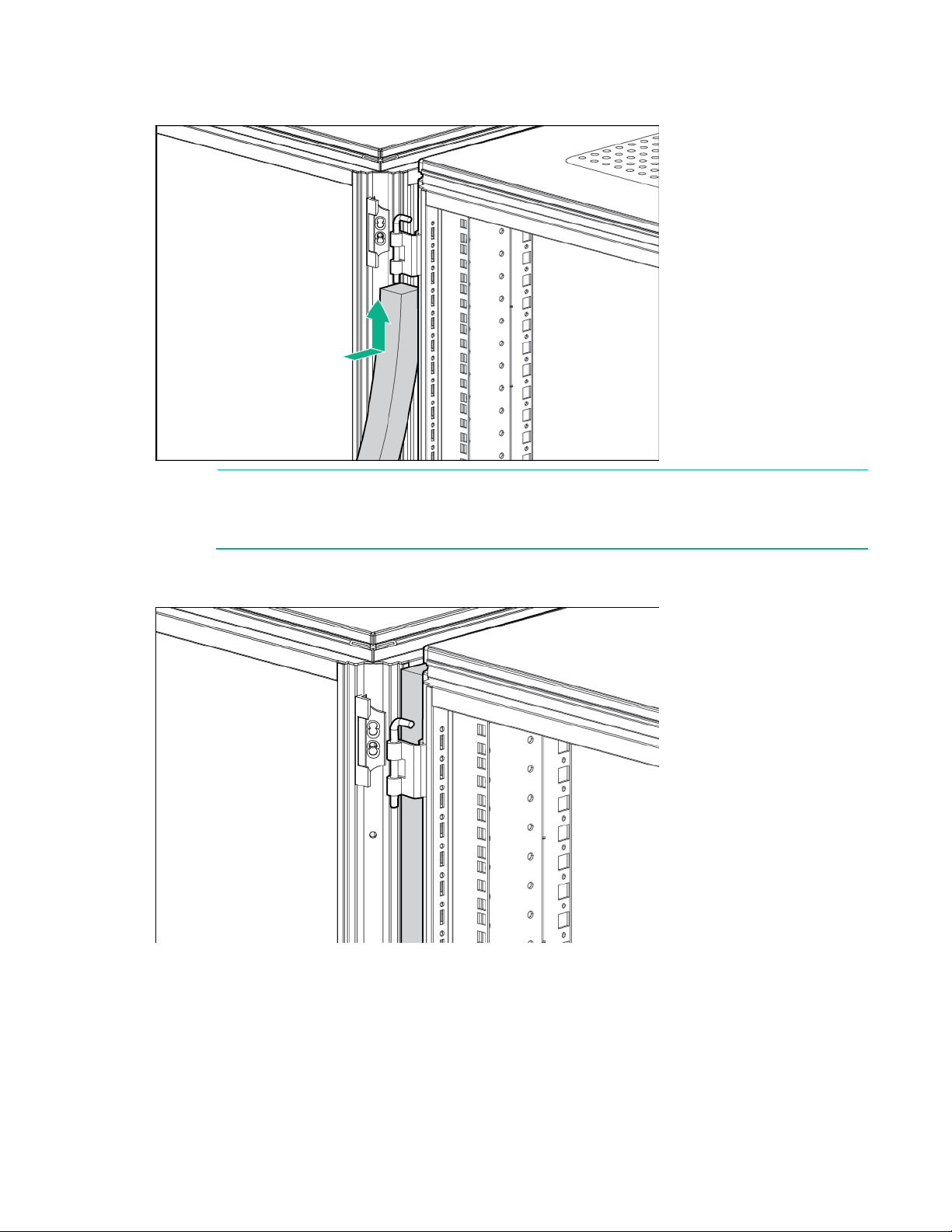

5. (Optional) See the HPE Baying Rack Option Kit for specific information on baying racks.

Installing the floor gasket

1. Depending on the size of your rack, cut the floor gasket at the perforation to reduce the length from

800-mm (31 in) to 600-mm (24 in).

Airflow Optimization kit 20

Page 21

2.

Remove the protective tape from the bottom edge of the floor gasket, and apply it to the bottom of the

rack with the adhesive strip facing the front of the rack.

Installation is complete.

Airflow Optimization kit 21

Page 22

Ballast kit

2

M6 screws

10

Cage nuts

10

About this device

Kit contents

The Ballast kit provides additional stability with single-rack installations.

Item Quantity

Ballast assembly

Extra hardware might be included for your convenience.

Required tools

The following tools are required for installation:

• Cage nut insertion tool (included in your original rack hardware kit)

• One of the following screwdrivers:

o Flathead screwdriver

o T-25 Torx driver

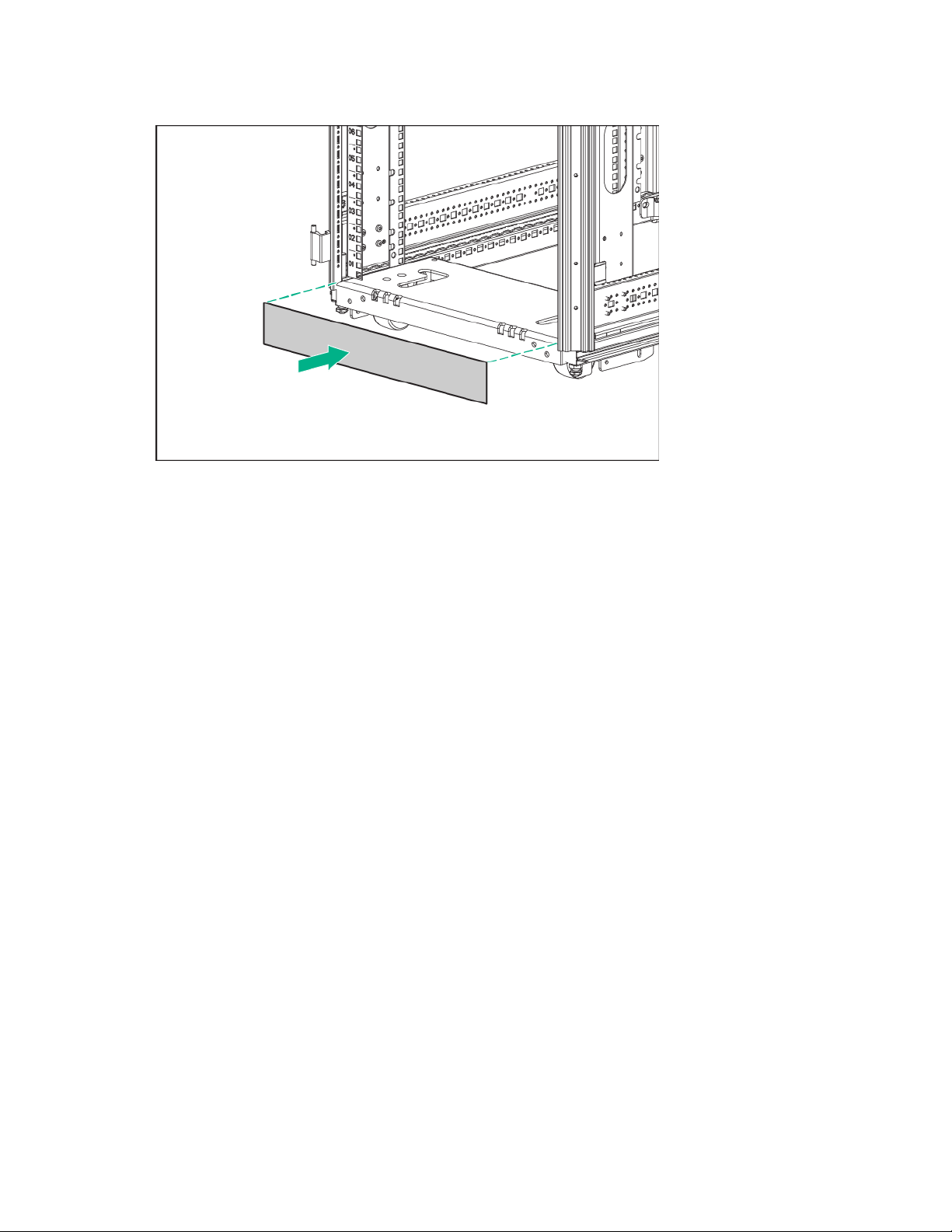

Installing the ballast kit

Hewlett Packard Enterprise recommends installing a single ballast assembly as close to the bottom

of the rack as possible. Occasionally, more than one ballast kit might be necessary. In these cases,

install the first ballast assembly as close to the bottom of the rack as possible and move up the rack

accordingly.

CAUTION: To reduce the risk of personal injury or damage to the equipment, Hewlett

Packard Enterprise recommends that you install the Ballast kit only in unconfigured racks.

Ballast kit 22

Page 23

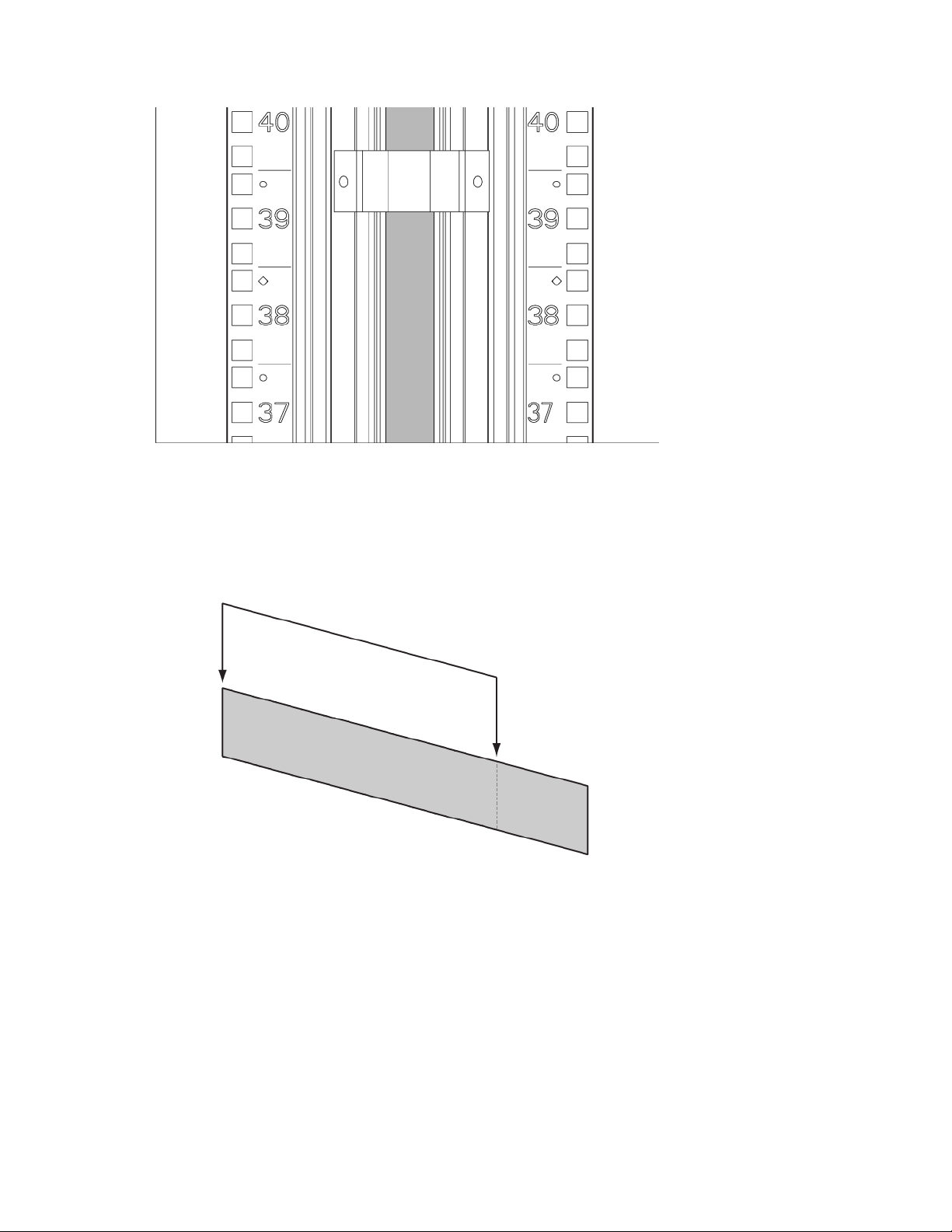

1.

Install the two bottom cage nuts using the cage nut insertion tool included in your original rack

hardware kit.

2. Count 16 holes up the rack, starting at the bottom cage nuts, and install the two top cage nuts using

the cage nut insertion tool.

3. Align the screw holes of the ballast assembly with the installed cage nuts.

Ballast kit 23

Page 24

4.

Insert the M6 screws into one side of the ballast assembly to secure it to the rack.

5. Repeat step 4 to secure the other side of the ballast assembly to the rack.

Installation is complete.

Ballast kit 24

Page 25

Baying kit

24-inch baying brackets

6

600-mm baying brackets

6

15

About this device

The Baying kit enables you to connect multiple racks of the same series (10000 and 10000 G2 Series

Racks), height, and depth. For example, two 10622 Racks can be bayed together, as well as two 10842

Racks.

Kit contents

Item Quantity

T-30 Torx screws

Extra hardware might be included for your convenience.

Required tool

You will need a T-30 Torx driver.

Installing the baying kit

WARNING: To reduce the risk of personal injury or damage to the rack and equipment, the

racks must be positioned and secured together according to these instructions. Failure to do so

could result in an unstable installation.

NOTE: The appearance of the rack might vary depending on the model of the rack

purchased.

Baying kit 25

Page 26

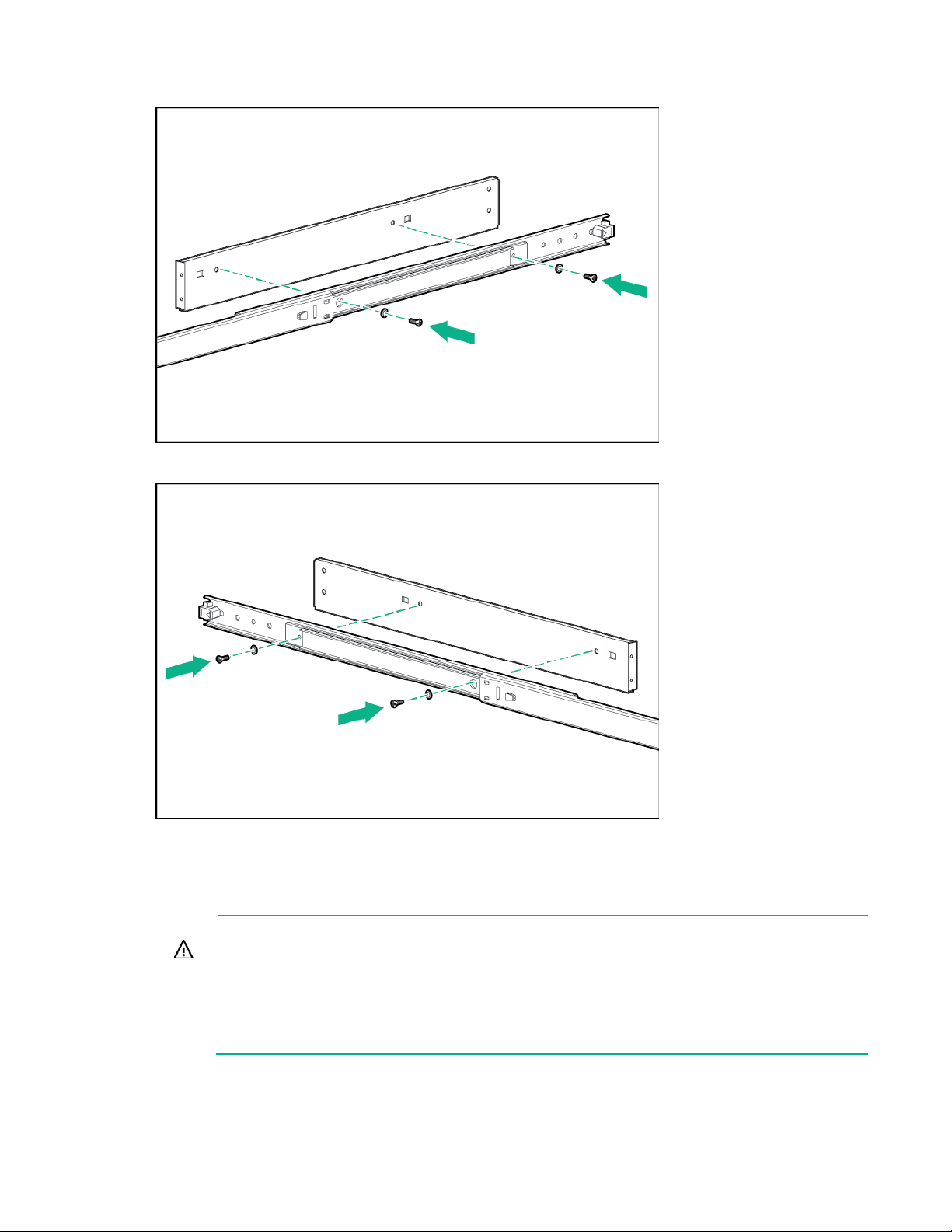

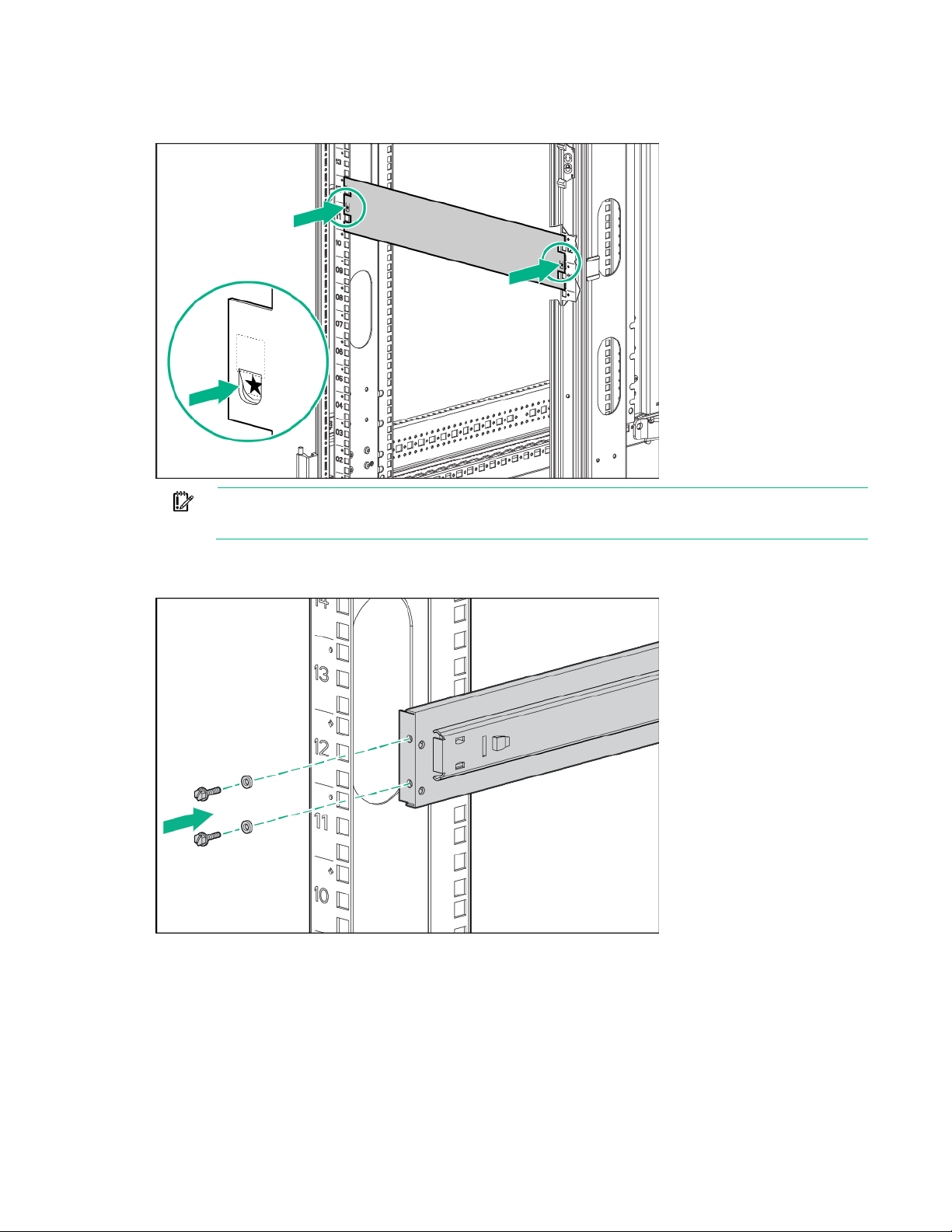

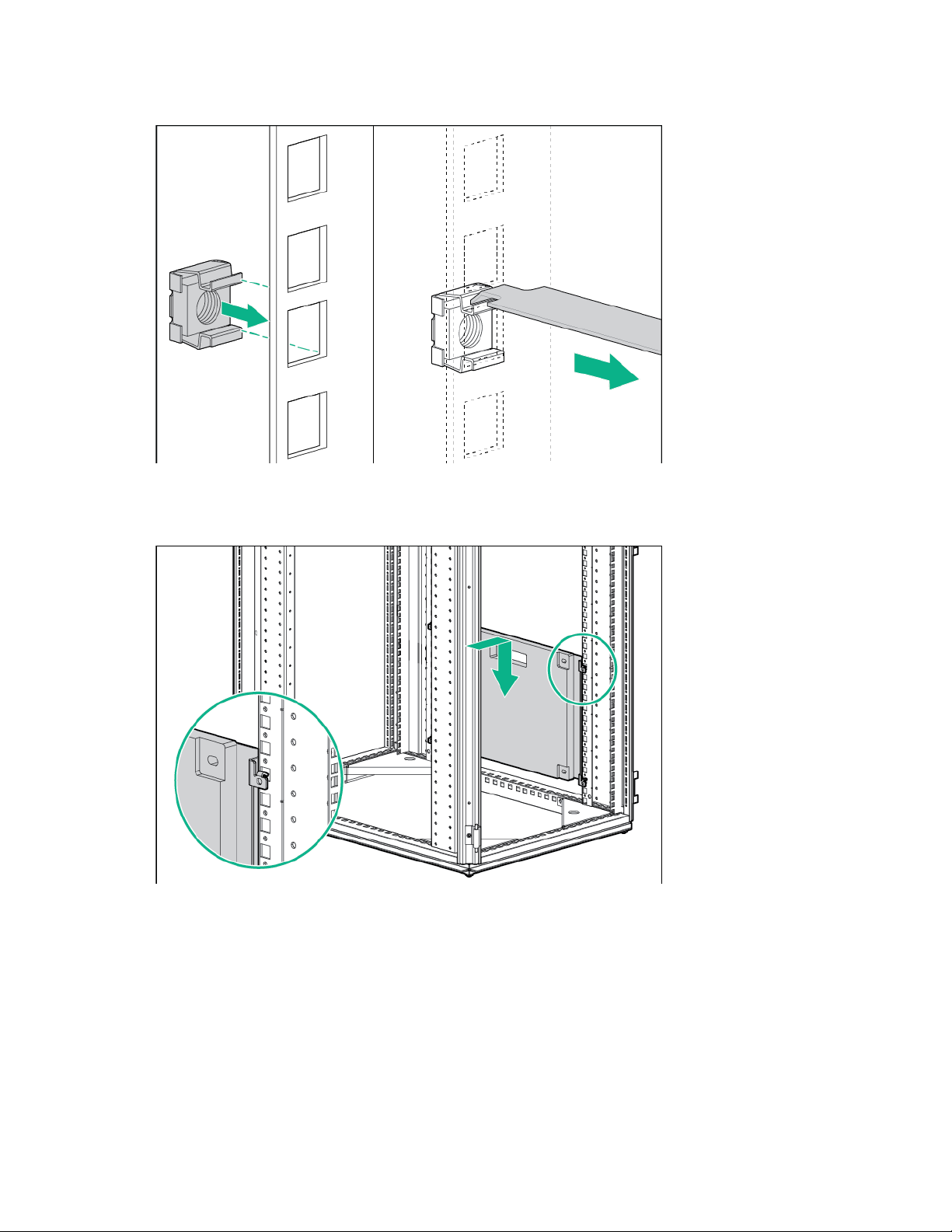

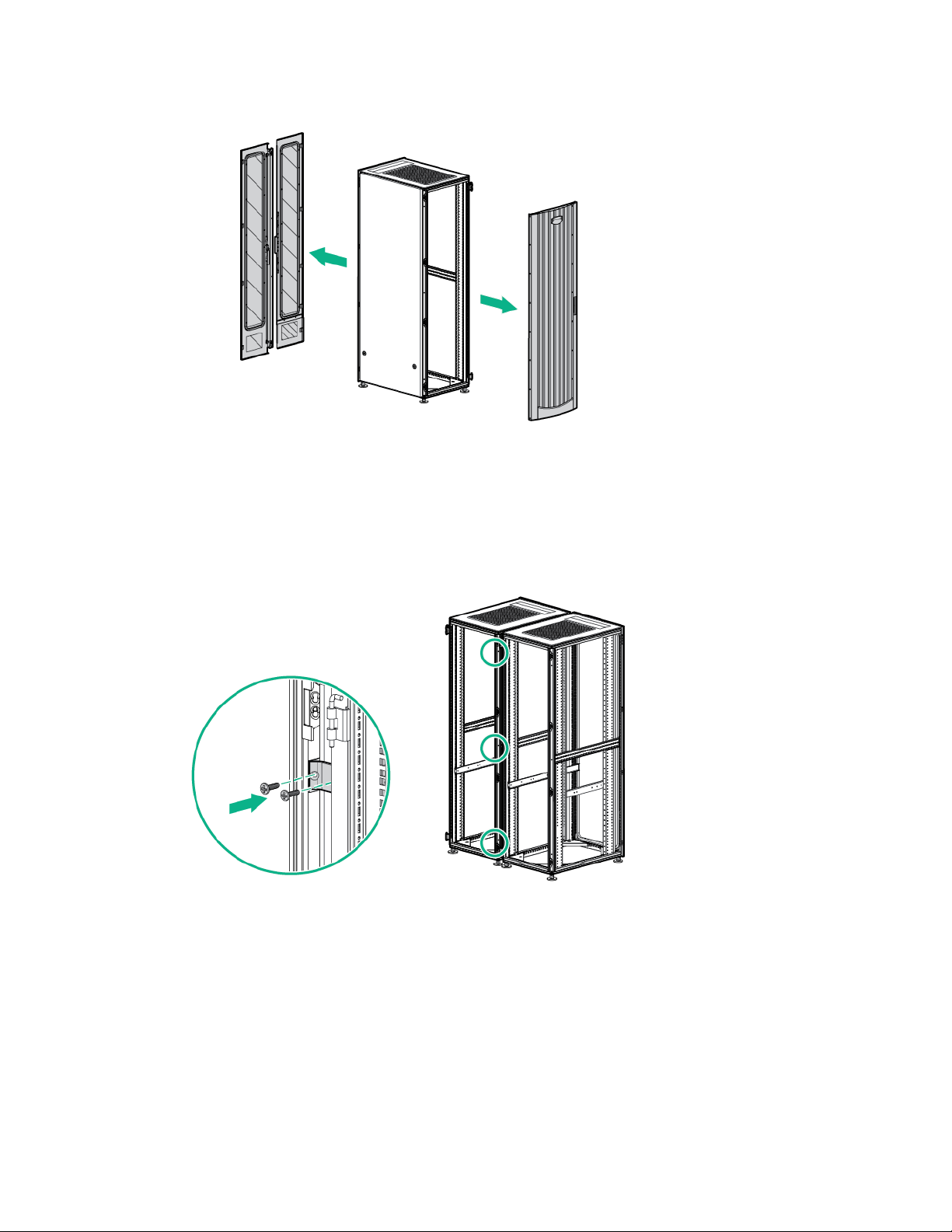

1.

Remove the front and rear doors.

2. Remove the side panels (if present between the racks).

3. Position the racks side by side, ensuring that the feet of the racks are on solid flooring (no cracks or

openings).

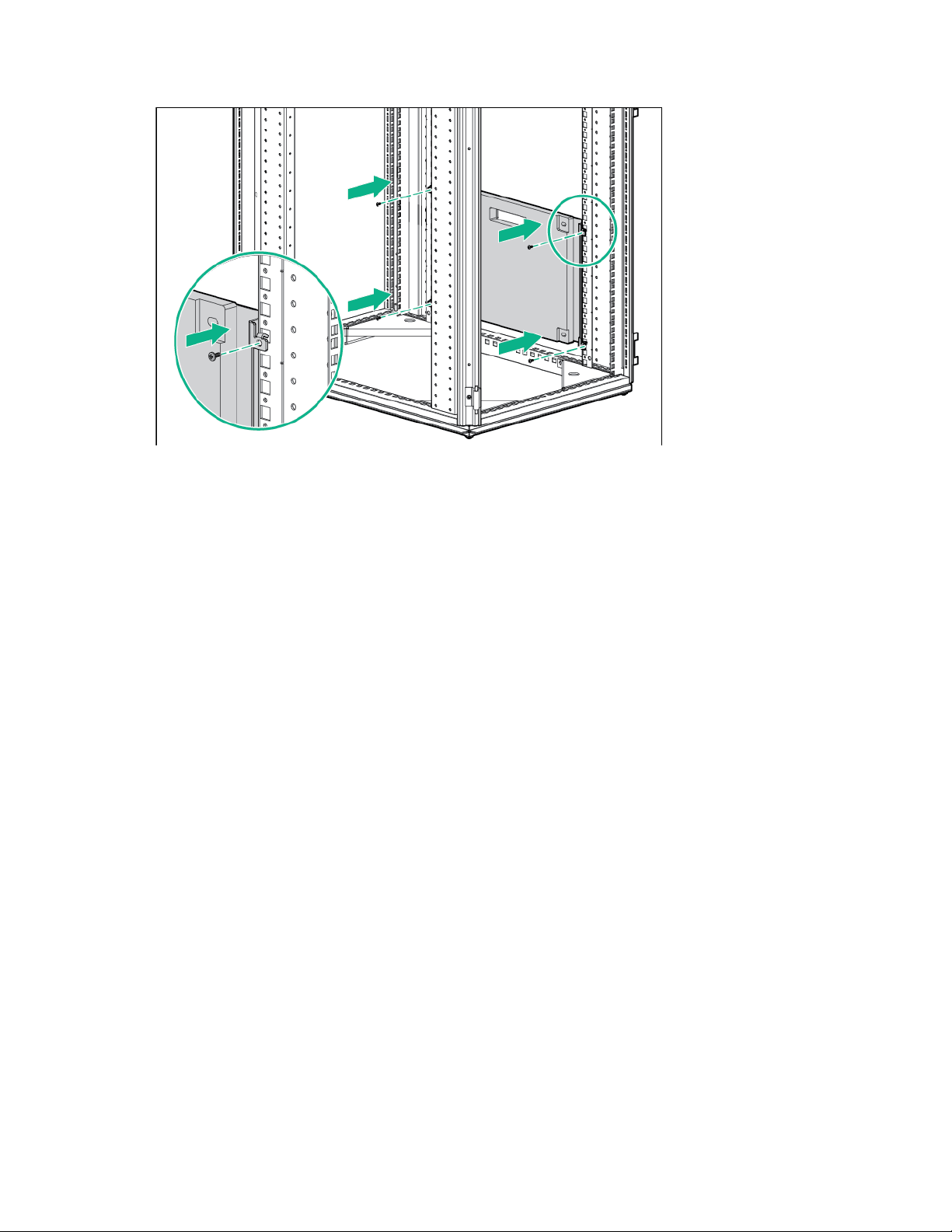

4. Attach three baying brackets (either 24-inch or 600-mm depending on the floor layout) to the front

and rear of each rack set using two T-30 Torx screws in each bracket.

-or-

Baying kit 26

Page 27

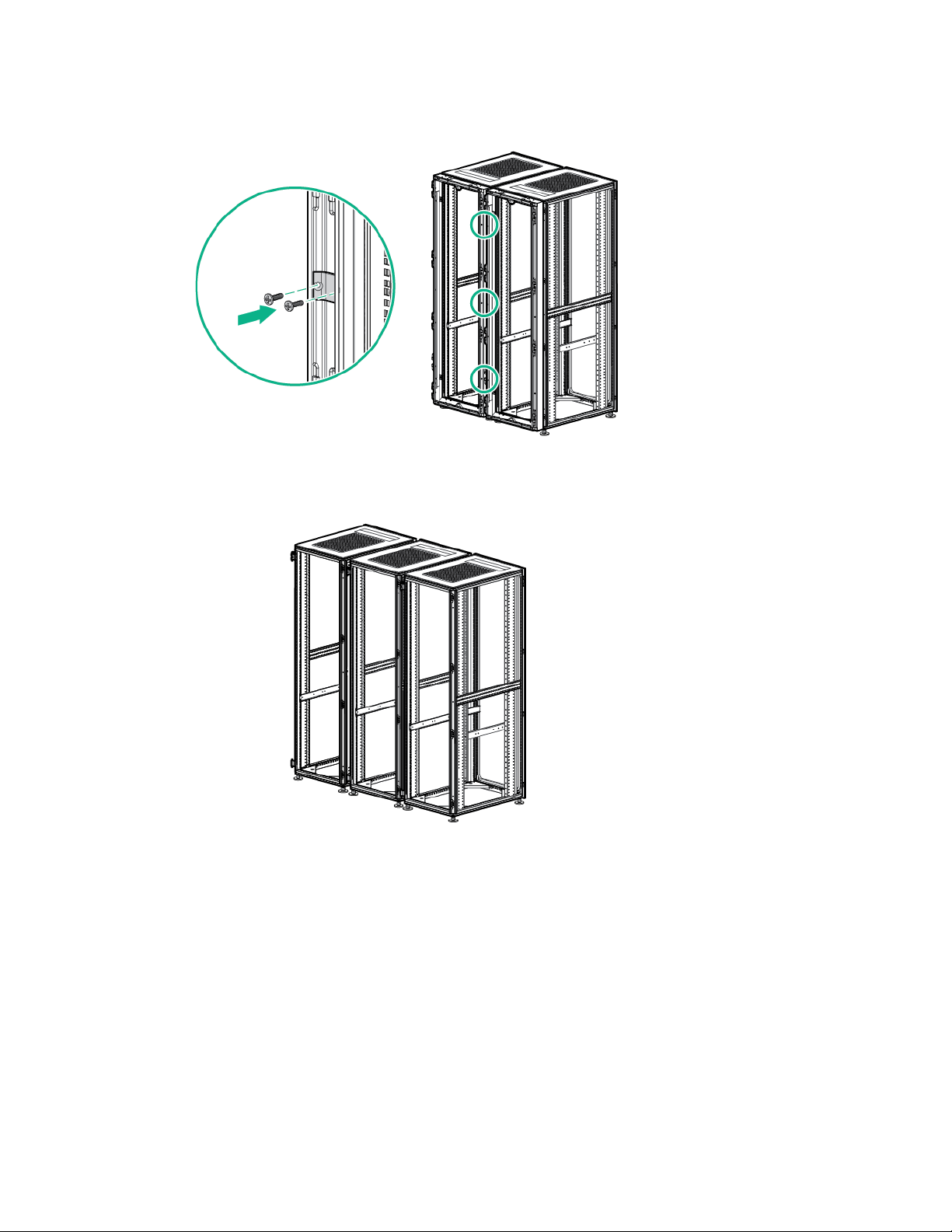

If you bay racks with a rear extension, you do not need to remove the rear extensions. Attach three

baying brackets to the rear extensions using two T-30 Torx screws in each bracket.

5. Bay any additional racks.

6. Attach side panels to each end of the bayed racks, and reattach the front and rear doors.

Installation is complete.

Baying kit 27

Page 28

Cable Management Bracket kit

1U cable management bracket

1

1

clips

10

clamps

10

Cross-over brackets

2

loop cabling

strap

10

loop cabling

strap clips

10

M6 cage nuts

11

M6 x 16-mm Torx screws

11

M5.5-mm x 10-mm Torx screws

9

1/4 turn plastic latches

6

About this device

Kit contents

The Cable Management Bracket kit assists with cable management and is designed for use with all racks.

Item Quantity

2U cable management bracket

Cable management D-ring bracket

Cable management D-ring bracket

12.7-cm (5-in) hook-and-

20.3-cm (8-in) hook-and-

Extra hardware might be included for your convenience.

Required tools

The following tools are required for installation:

• T-25 Torx driver

• Cage nut insertion tool (included with your original rack hardware kit)

Cable Management Bracket kit 28

Page 29

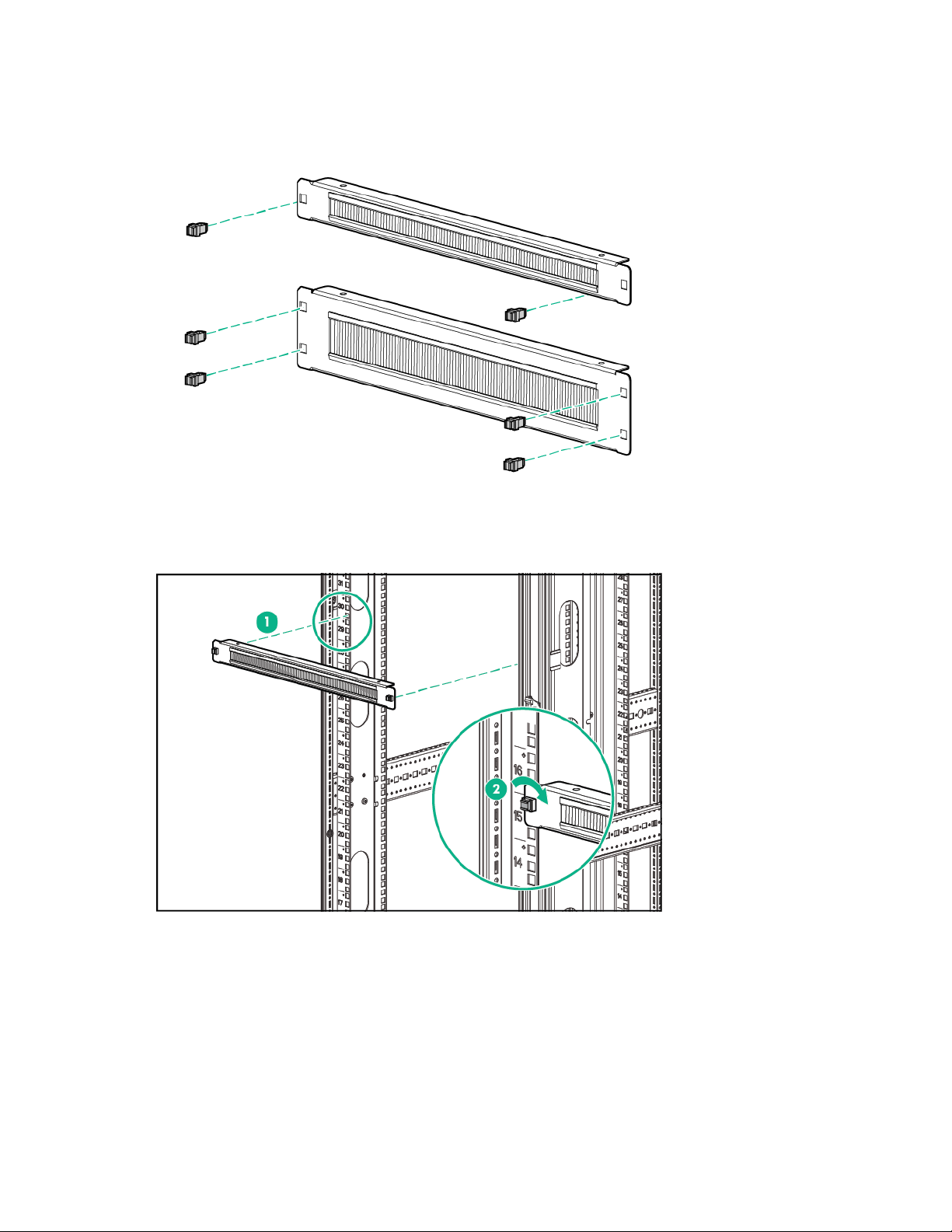

Installing the 1U cable management bracket

1. Insert one 1/4 turn plastic latch on either side of the 1U cable management bracket.

2. Align the 1U cable management bracket to the screw holes in the desired location of the rack (1).

3. Turn the 1/4 turn plastic latch on either side of the 1U cable management bracket clockwise until it

locks in place (2).

Cable Management Bracket kit 29

Page 30

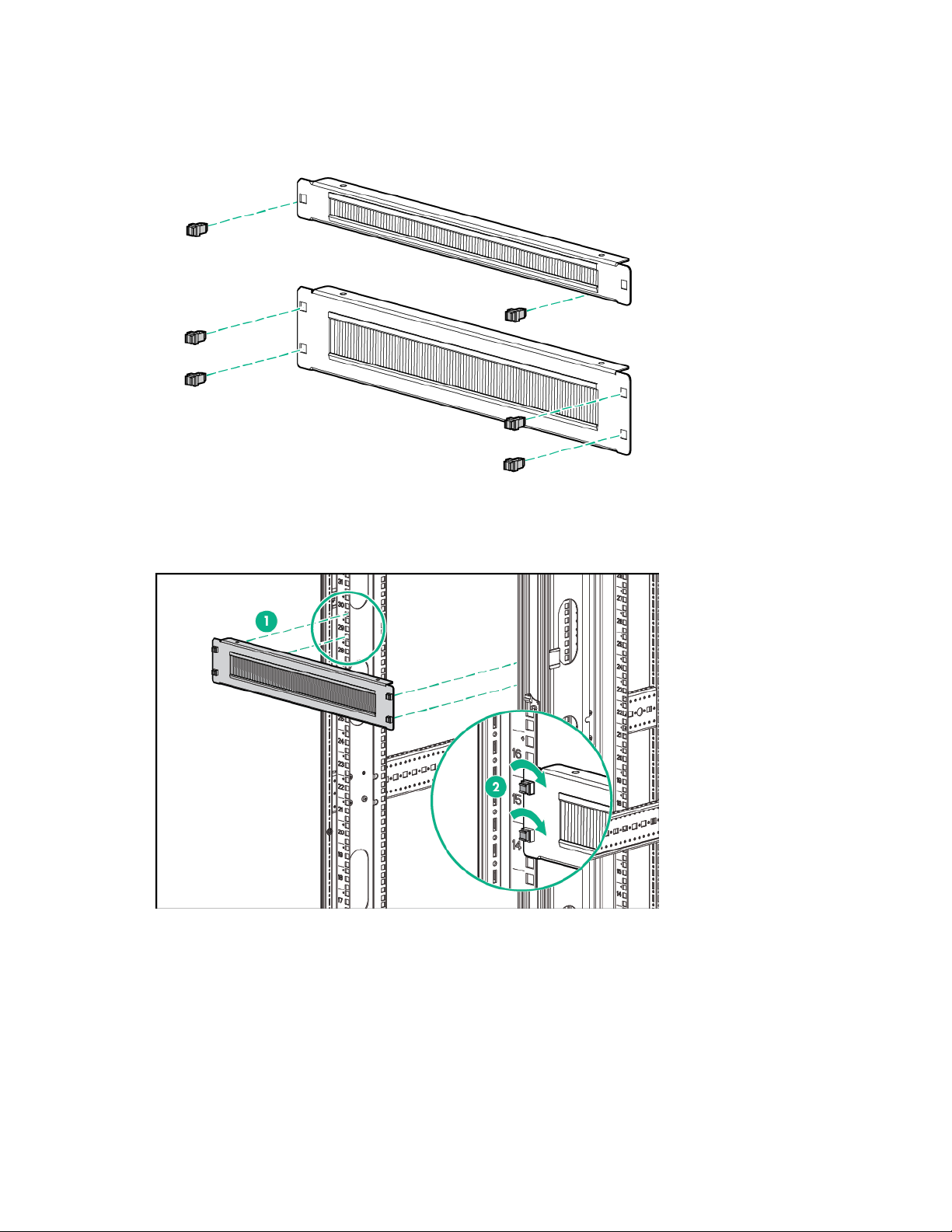

Installing the 2U cable management bracket

1. Insert two 1/4 turn plastic latches on either side of the 2U cable management bracket.

2. Align the 2U cable management bracket to the screw holes in the desired location of the rack (1).

3. Turn the two 1/4 turn plastic latches on either side of the 2U cable management bracket clockwise

until they lock in place (2).

Installing the cable management D-ring bracket

The cable management D-ring bracket can be installed in either a front mount or a side mount, depending

on your rack configuration.

Cable Management Bracket kit 30

Page 31

1.

Place a cable management D-ring bracket clip (1) on a cable management D-ring bracket clamp (2).

2. Install the cable management D-ring bracket in a front mount ("Installing the cable management

D-ring bracket" on page 30, "Front mount" on page 31).

3. Install the cable management D-ring bracket in a side mount ("Installing the cable management

D-ring bracket" on page 30, "Side mount" on page 32).

Front mount

1. Using a cage nut insertion tool, install an M6 cage nut into the desired location on the front of your

rack.

2. Align the cable management D-ring bracket with the previously installed M6 cage nut (1).

Cable Management Bracket kit 31

Page 32

3.

Using a T-25 Torx driver, insert one M6 x 16-mm Torx screw to secure the cable management D-ring

bracket to the rack (2).

Side mount

1. Align the cable management D-ring bracket with the screw hole in the desired location on the side of

your rack (1).

2. Using a T-25 Torx driver, insert one M5.5 x10-mm Torx screw to secure the cable management

D-ring bracket to the rack (2).

Installing the cross-over bracket

1. Align the cross-over bracket with the appropriate screw holes in the desired location across the back

of the rack (1).

NOTE: The screw holes for the cross-over bracket are located on the side of the rear rack

screw column, towards the inside of the rack.

Cable Management Bracket kit 32

Page 33

2.

Using a T-25 Torx driver, insert two M5.5 x 10-mm Torx screws on either side of the cross-over

bracket and secure to the rack frame (2).

Cable Management Bracket kit 33

Page 34

Installing the hook-and-loop cabling straps

Attach the clip to the rack in any of the following positions, then route and secure your cables with the

hook-and-loop cabling straps.

Cable Management Bracket kit 34

Page 35

Installation is complete.

Cable Management Bracket kit 35

Page 36

Cable Management Tray kit

600-mm cable management tray

1

600-mm cable trough

8

Wire for trough

16

Cover

8

800-mm cable management tray

1

1

2

Cover

1

Item

Quantity

Cable trough inner tray

1

Cable trough outer tray

1

About this device

The Cable Management Tray kit enables you to attach cable management trays to the top of racks to

Kit contents

improve cable management.

Depending on which kit you order, this kit includes the following items:

Item Quantity

—or—

Item Quantity

800-mm cable trough

Wire for trough

—or—

Extra hardware might be included for your convenience.

Required tool

You will need a T-30 Torx driver.

Cable Management Tray kit 36

Page 37

Installing the cable management tray

1. Attach the wire for the trough to the cable management tray.

2. Remove the two screws from the rack top.

Cable Management Tray kit 37

Page 38

3.

Install the cable management tray on top of the rack, using the same two screws you removed in

step 2.

4. Route the cables through the cable management tray.

Cable Management Tray kit 38

Page 39

5.

Hook and slide the cover into place.

Installing the cable management inner and outer trays

1. Attach the cable management outer tray to the cable management tray.

Cable Management Tray kit 39

Page 40

2.

Slide the inner tray into the outer tray, and adjust them to the desired length.

3. Attach the cable management inner tray to the cable management tray.

Cable Management Tray kit 40

Page 41

4.

Route the cables through the cable management tray.

Ground bonding stud location

Cable Management Tray kit 41

Page 42

Fan (110V/220V) kit

Fan assembly

1

Power cord

2

Cable fastener

4

About this device

Kit contents

The Fan (110V/220V) kit enhances the natural convection cooling by increasing rack airflow.

Item Quantity

This kit might contain extra hardware for your convenience.

Required tools

You will need a T-30 Torx driver.

Installing the fan

NOTE: The rack top covers might be different, but the installations are identical.

1. Using a T-30 Torx driver, remove the four T-30 Torx screws securing the rack top cover to the rack,

and remove the rack top cover. Retain the screws.

2. Align the fan assembly so that the power cord faces the rear of the rack.

Fan (110V/220V) kit 42

Page 43

3.

Insert the fan assembly into the top of the rack and secure using the four T-30 Torx screws from step

1.

4. Connect the power cord to the fan assembly.

Fan (110V/220V) kit 43

Page 44

5.

Insert the notched end of the tie wrap into a small hole in the rack rail and push the tie wrap in to lock

it in place. Encircle the power cord with the tie wrap by inserting the free end of the tie wrap into the

hole on the other end of the tie wrap, pulling the tie wrap tight, and cutting off excess length.

Installation is complete.

Fan (110V/220V) kit 44

Page 45

Filler Panel kit

1U Filler panels

10

About this device

Kit contents

The Filler Panel kit enables you to cover open areas of the rack to better control airflow.

Item Quantity

1U Filler panels

—or—

This kit might contain extra hardware for your convenience.

100

Required tools

No tools are required for this procedure.

Installing the filler panel

1. Position the filler panel in the desired rack location.

2. Snap the filler panel into place.

CAUTION: Always use filler panels to fill all remaining empty front panel U-spaces in the

rack. This arrangement ensures proper airflow. Using a rack without filler panels results in

improper cooling, which can lead to thermal damage.

Filler Panel kit 45

Page 46

Front Door kit

Item

Quantity

Front door

1

Keys

2

Hinge brackets

2

Lock catches

2

About this device

The Front Door kit enables you to add a front door to your HPE 10000 G2 Series rack. You can also install

this option kit on 10000 series racks of the same size.

Kit contents

This kit might contain extra hardware for your convenience.

Required tools

The following tools are required for installation:

• T-25 Torx driver

• Phillips screwdriver

Installing the hinge brackets and lock catches

The following tables indicate where the hinge brackets and lock catches are to be mounted in a 36U or

42U front door installation. The distance is measured from the bottom of the rack to an indicated hinge

bracket or lock catch fastening hole.

Front Door kit 46

Page 47

1598.5 mm (62.9 in)

1856 mm (73.1 in)

2

98.5 mm (3.9 in)

98.5 mm (3.9 in)

3

569.5 mm (22.4 in)

698.5 mm (27.5 in)

4

1127.5 mm (44.4 in)

1256.5 mm (49.5 in)

Hinge bracket mounting distance from the bottom of the rack

Position number 36U 42U

1

Lock catch mounting distance from the bottom of the rack

Position number 36U 42U

Installing the front door

1. Slide the bottom door hinge onto the hinge bracket on the rack frame.

2. Lift the top hinge pin up, and slide the upper door hinge into place.

Front Door kit 47

Page 48

3.

Release the top hinge pin to secure the front door to the rack.

4. Close the front door.

Installation is complete.

Front Door kit 48

Page 49

Ground Bonding kit

Item

Quantity

15.24-cm (6-in) grounding straps

6

(with a connector on one end)

6

36.83-cm (14.5-in) grounding straps

8

in) grounding straps

(with a connector on one end)

6

M8 internal serrated lock washer

20

M8 hex nut

20

M5.5 T-25 Torx screw

12

M6 x 10-mm Torx screw

1

M8 x 20-mm bolt

1

M8 Belleville toothed washer

1

M5 Belleville toothed washer

1

About this device

The Ground Bonding kit reduces the electromagnetic emissions outside the rack. These emissions are

produced during normal operation of the electronic components within the rack. Typically, rack-mounted

equipment must meet class A emissions levels, but you might want to reduce these levels even further.

Use this kit to tie all the conductive structural components together with conductive cables, and then

attach the kit to a ground bonding point on the AC power distribution device of the rack or the building

ground.

Kit contents

15.24-cm (6-in) grounding straps

36.83-cm (14.5-

This kit might contain extra hardware for your convenience.

Required tools

The following tools are required for installation:

• T-25 Torx driver

• M8 socket

Installing the ground bonding rack option kit on HPE 10000 G2 Series Racks

Attach the appropriate grounding straps to the following locations:

From the system chassis to the front door (without a grounding lug):

1. Remove the rack front door.

a. Unlock and open the front door.

Ground Bonding kit 49

Page 50

b.

Lift the top hinge pin up, and tilt the door away from the rack.

c. Lift the door up and out of the bottom hinge.

2. Insert an M6 T-25 Torx screw through one end of a 15.24-cm (6-in) grounding strap, and insert it in

the second hole below the upper front door hinge on the vertical frame member of the rack. Tighten

the screw.

3. Replace the rack front door.

Ground Bonding kit 50

Page 51

4.

Insert a T-25 Torx screw through the other end of the same grounding strap, and insert it in the hole

on the rack front door. Tighten the screw.

From the system chassis rail to the front door (with a grounding lug):

1. Insert a T-25 Torx screw through one end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the front door.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the front

door and tighten.

From the system chassis rail to the right rear door:

1. Insert a T-25 Torx screw through the end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the right rear door.

Ground Bonding kit 51

Page 52

3.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the right rear

door and tighten.

From the system chassis rail to the left rear door:

1. Insert a T-25 Torx screw through the end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Place the other end of the grounding strap over the grounding lug on the left rear door.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the left rear

door and tighten.

From the left rear door to the left rear door cable access panel:

1. Place one end of a 15.24-cm (6-in) grounding strap over the grounding lug on the left rear door.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the left rear

door and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the cable access panel.

Ground Bonding kit 52

Page 53

4.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the cable

access panel and tighten.

From the system chassis rail to the rack top:

1. Insert a T-25 Torx screw through one end of a 15.24-cm (6-in) grounding strap, and secure it to the

system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the rack top.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the rack top

and tighten.

From the grounding lug on the rack top to the grounding lug on the perforated panel:

1. Place one end of a 36.83-cm (14.5-in) grounding strap over the grounding lug on the rack top.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the rack top

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the perforated panel.

Ground Bonding kit 53

Page 54

4.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel and tighten.

From the grounding lug on the perforated panel or fan kit to the grounding lug on the egress slot:

1. Place one end of a 15.24-cm (6-in) grounding strap over the grounding lug on the perforated panel or

fan kit.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel or fan kit and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the egress slot.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the egress

slot and tighten.

Ground Bonding kit 54

Page 55

From the rack to a building facility, contact your building supervisor for more information. The following

48.26-cm (19-in) mounting rail (the mounting hole is

2

M8 hex nut

3

M8 Belleville toothed washer

4

Facility ground (not included with this kit)

5

M8 x 20 bolt

figure illustrates parts for this step.

Reference Item

1

located at the top or bottom of the rail)

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack side panels

From the middle system chassis rail to the bottom side panel:

1. Connect a 36.83-cm (14.5-in) and a 15.24-cm (6-in) grounding strap with connectors together.

2. Insert a T-25 Torx screw through the end of the 36.83-cm (14.5-in) grounding strap, and secure it to

the middle system chassis rail.

3. Place the end of the 15.24-cm (6-in) grounding strap over the grounding lug on the bottom side

panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the bottom

side panel and tighten.

Ground Bonding kit 55

Page 56

5.

Repeat steps 1 through 4 for the other bottom side panel.

From the middle system chassis rail to the middle side panel:

1. Connect a 36.83-cm (14.5-in) and a 15.24-cm (6-in) grounding strap with connectors together.

2. Insert a T-25 Torx screw through the end of the 36.83-cm (14.5-in) grounding strap, and secure it to

the middle system chassis rail.

3. Place the end of the 15.24 (6-in) grounding strap over the grounding lug on the middle side panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the middle

side panel and tighten.

5. Repeat steps 1 through 4 for the other middle side panel.

From the middle system chassis rail to the top side panel:

1. Connect a 36.83-cm (14.5-in) and a 15.24-cm (6-in) grounding strap with connectors together.

2. Insert a T-25 Torx screw through the end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the middle system chassis rail.

3. Place the end of the 15.24-cm (6-in) grounding strap over the grounding lug on the top side panel.

Ground Bonding kit 56

Page 57

4.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the top side

panel and tighten.

5. Repeat steps 1 through 4 for the other top side panel.

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack fan kits

From the grounding lug on the rack top to the grounding lug on the fan kit:

1. Place one end of a 15.24-cm (6-in) grounding strap over the grounding lug on the rack top.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the rack top

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the perforated panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel and tighten.

From the grounding lug on the fan kit to the grounding lug on the egress slot:

Ground Bonding kit 57

Page 58

1.

Place one end of a 36.83-cm (14.5-in) grounding strap over the grounding lug on the fan kit.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the fan kit

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the egress slot.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the egress

slot and tighten.

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack 150-mm extension kits

1. Insert a T-25 Torx screw through one end of a 15.24-cm (6-in) grounding strap, and secure it to the

rear rack chassis.

2. Place an M8 internal serrated lock washer and the other end of the same grounding strap over the

grounding lug on the extension kit.

3. Place an M8 hex nut over the grounding lug and tighten.

Ground Bonding kit 58

Page 59

Installing the ground bonding rack option kit on HPE 10000 G2 Series Rack 200-mm extension kits

From the extension kit to the bottom rack side panel:

1. Insert a T-25 Torx screw through the end of the 36.83-cm (14.5 in) grounding strap, and secure it to

the bottom side panel.

2. Place the other end of the same grounding strap over the grounding lug on the extension kit.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

extension kit and tighten.

4. Repeat the previous steps for the opposite side of the rack.

From the extension kit to the top rack side panel:

1. Insert a T-25 Torx screw through the end of the 36.83-cm (14.5 in) grounding strap, and secure it to

the top side panel.

2. Place the other end of the same grounding strap over the grounding lug on the extension kit.

Ground Bonding kit 59

Page 60

3.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

extension kit and tighten.

From the side panel grounding lug to the bottom panel grounding lug:

1. Place the 36.83-cm (14.5 in) grounding strap over the grounding lug on the side panel of the

extension kit.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the side

panel of the extension kit and tighten.

3. Repeat the previous steps to secure the other end of the same grounding strap to the grounding lug

on the bottom panel of the extension kit.

From the egress panel grounding lug to the bottom panel grounding lug:

1. Place the 36.83-cm (14.5 in) grounding strap over the grounding lug on the egress panel of the

extension kit.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the egress

panel of the extension kit and tighten.

Ground Bonding kit 60

Page 61

3.

Repeat the previous steps to secure the other end of the same grounding strap to the grounding lug

on the bottom panel of the extension kit.

Installing the ground bonding rack option kit on HPE 10000 Series Racks

Attach the appropriate grounding straps to the following locations:

From the system chassis rail to the front door:

1. Insert a T-25 Torx screw through one end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Remove the inside front door panel screw.

3. Place an M5 Belleville toothed washer and the other end of the grounding strap over the front door

panel screw.

4. Reinsert and tighten the front door panel screw.

Ground Bonding kit 61

Page 62

From the system chassis rail to the right rear door:

1. Insert a T-25 Torx screw through the end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the right rear door.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the right rear

door and tighten.

From the system chassis rail to the left rear door:

1. Insert a T-25 Torx screw through the end of a 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the left rear door.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the left rear

door and tighten.

From the left rear door to the left rear door cable access panel:

1. Place one end of a 15.24-cm (6-in) grounding strap over the same grounding lug on the left rear

door.

Ground Bonding kit 62

Page 63

2.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the left rear

door and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the cable access panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the cable

access panel and tighten.

From the system chassis rail to the rack top:

1. Insert a T-25 Torx screw through on end of a 15.24-cm (6-in) grounding strap and secure it to the

system chassis rail.

2. Place the other end of the same grounding strap over the grounding lug on the rack top.

3. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding strap on the rack

top and tighten.

From the grounding lug on the rack top to the grounding lug on the perforated panel:

1. Place one end of a 36.83-cm (14.5-in) grounding strap over the same grounding strap on the rack

top.

Ground Bonding kit 63

Page 64

2.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the rack top

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the perforated panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel and tighten.

From the grounding lug on the perforated panel or fan kit to the grounding lug on the egress slot:

1. Place one end of a 15.24-cm (6-in) grounding strap over the grounding lug on the perforated panel or

fan kit.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel or fan kit and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the egress slot.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the egress

slot and tighten.

Ground Bonding kit 64

Page 65

From the rack to a building facility, contact your building supervisor for more information. The following

48.26-cm (19-in) mounting rail (the mounting hole is

2

M8 hex nut

3

M8 Belleville toothed washer

4

Facility ground (not included with this kit)

5

M8 x 20 bolt

figure illustrates parts for this step.

Reference Item

1

located at the top or bottom of the rail)

Installing the ground bonding rack option kit on HPE 10000 Series Rack side panels

From the system chassis rail to the side panel:

1. Connect a 36.83-cm (14.5-in) and a 15.24-cm (6-in) grounding strap with connectors together.

2. Insert a T-25 Torx screw through the end of the 36.83-cm (14.5-in) grounding strap, and secure it to

the system chassis rail.

3. Place the end of the 15.24-cm (6-in) grounding strap over the grounding lug on the side panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the side

panel and tighten.

Ground Bonding kit 65

Page 66

5.

Repeat steps 1 through 4 for the other side panel.

Installing the ground bonding rack option kit on HPE 10000 Series Rack fan kits

From the grounding lug on the rack top to the grounding lug on the fan kit:

1. Place one end of a 15.24-cm (6-in) grounding strap over the grounding lug on the rack top.

2. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the rack top

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the perforated panel.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the

perforated panel and tighten.

From the grounding lug on the fan kit to the grounding lug on the egress slot:

1. Place one end of a 36.83-cm (14.5-in) grounding strap over the grounding lug on the fan kit.

Ground Bonding kit 66

Page 67

2.

Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the fan kit

and tighten.

3. Place the other end of the same grounding strap over the grounding lug on the egress slot.

4. Place an M8 internal serrated lock washer and an M8 hex nut over the grounding lug on the egress

slot and tighten.

Ground Bonding kit 67

Page 68

Heavy Duty Stabilizer kit

Heavy duty front stabilizer mount

1

2

M8 x 16-mm bolt

8

M8 x 30-mm bolt

2

M8 flat washer

10

About this device

The Heavy Duty Stabilizer kit provides stability and support and prevents possible tipping when you

install, remove, or access equipment within the rack.

If you have a stand-alone rack with a single rack-mountable component that exceeds 99.8 kg (220 lb) or if

you have three or fewer bayed racks with a single rack-mountable component that exceeds 99.8 kg (220

lb), you must use the heavy duty stabilizer.

Kit contents

Item Quantity

Heavy duty stabilizer feet

This kit might contain extra hardware for your convenience.

Required tools

The following tools are required for installation:

• Ratchet with sockets

• Adjustable wrench

Installing the rack stabilizer option kit

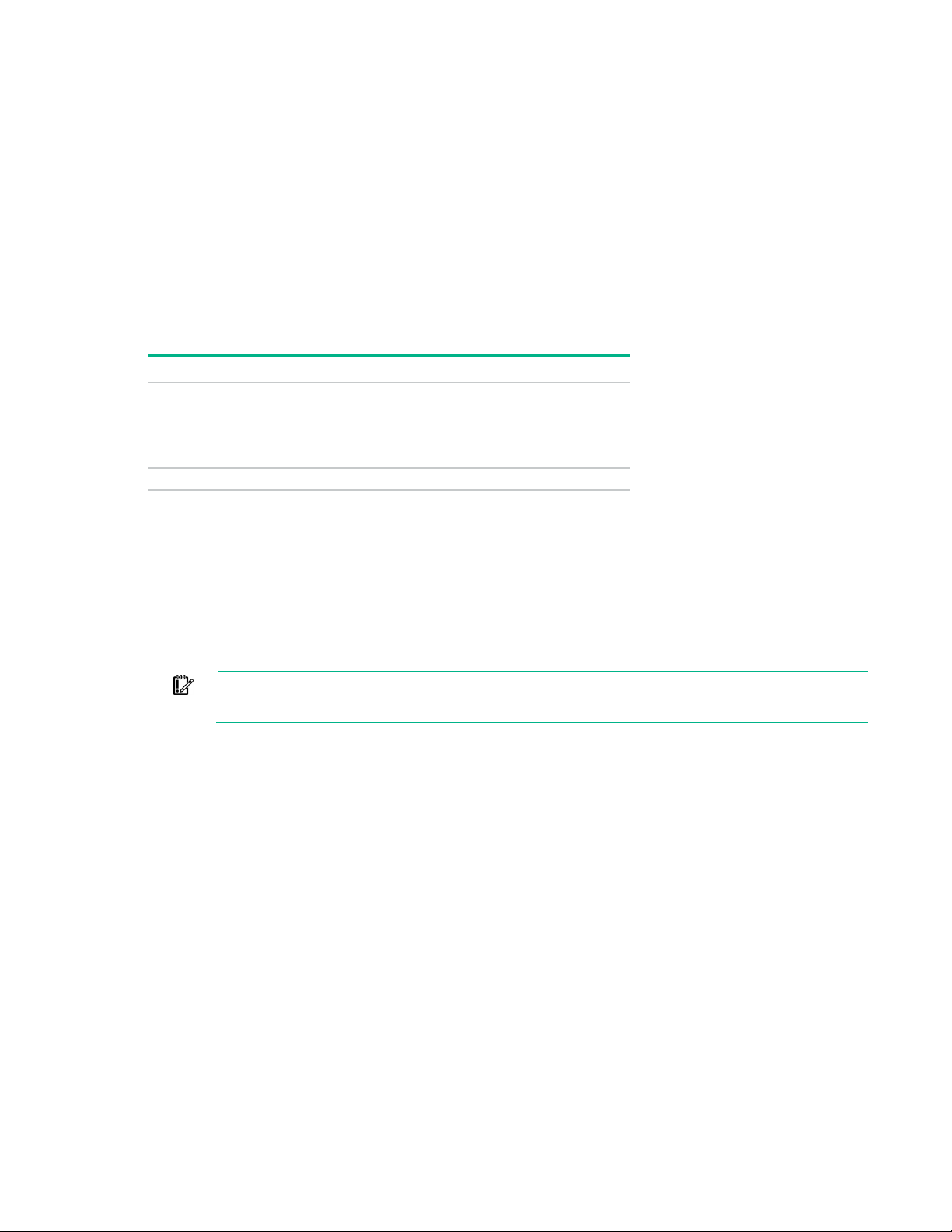

1. Install the front stabilizer mount.

a. Align the front stabilizer mount to the mounting holes on the rack front caster plate.

Heavy Duty Stabilizer kit 68

Page 69

b.

Insert and partially tighten four M8 x16-mm bolts with washers, securing the front stabilizer

mount to the front caster plate.

c. Insert and partially tighten two M8 x16-mm bolts with washers on each side of the caster plate

skirt, securing the front stabilizer mount to the front caster plate.

d. Tighten the bolts from step b.

e. Tighten the bolts from step c.

Heavy Duty Stabilizer kit 69

Page 70

2.

Slide the rack into its final location.

3. Raise the rack by lowering the leveling feet, raising the casters approximately 6.4 mm (0.25 in) off