Page 1

HP A-U200-A/A-U200-S

Unified Threat Management Product

Installation Guide

Part number: 5998-1414

Document version: 6PW100-20110909

Page 2

Legal and notice information

© Copyright 2011 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Product overview·························································································································································· 1

A-U200-A architecture description ··································································································································1

A-U200-S architecture description ··································································································································2

Preparing for installation ············································································································································· 3

Safety recommendations ··················································································································································3

Safety symbols ··························································································································································3

General safety recommendations ···························································································································3

Safety with electricity ···············································································································································3

Safety with laser ·······················································································································································4

Examining the installation site ·········································································································································4

Temperature and humidity·······································································································································4

Altitude ······································································································································································5

Cleanness··································································································································································5

Cooling system ·························································································································································5

ESD prevention ·························································································································································6

EMI·············································································································································································7

Lightning protection··················································································································································7

Rack-mounting···························································································································································8

Installation tools·································································································································································8

Accessories supplied by the UTM device ·······················································································································8

Checklist before installation ·············································································································································9

Installing the UTM device ··········································································································································11

Installation flow ······························································································································································11

Installing the UTM device in a 19-inch rack················································································································ 11

Grounding the UTM device··········································································································································· 13

Installing interface modules··········································································································································· 13

Installing a 2GE interface module ······················································································································· 13

Installing an NSQ1GT2UA0 or NSQ1GP4U0 interface module···································································· 14

Installing a CF card························································································································································ 15

Connecting Ethernet cables··········································································································································· 15

Connecting a copper Ethernet cable··················································································································· 15

Connecting an optical fiber ································································································································· 16

Connecting a power cord ············································································································································· 17

Logging in to the UTM device and configuring basic settings················································································19

Logging in to the UTM device through the console port···························································································· 19

Connecting the UTM device to a configuration terminal through a console cable········································ 19

Setting terminal parameters·································································································································· 20

Powering on the UTM device········································································································································ 23

Checking before power-on··································································································································· 23

Checking after power-on ······································································································································ 23

Logging in to the UTM device through Telnet ············································································································· 24

Logging in to the UTM device through a web browser ····························································································· 24

Performing basic settings for the UTM device············································································································· 25

Launching the basic configuration wizard·········································································································· 25

Configuring the system name and user password····························································································· 26

Configuring service management························································································································ 27

Configuring the IP address for an interface········································································································ 29

i

Page 4

Configuring NAT··················································································································································· 30

Completing the configuration wizard ·················································································································31

Hardware management and maintenance ··············································································································33

Displaying detailed information about the UTM device ····························································································33

Displaying software and hardware version information of the UTM device··························································· 34

Displaying the electrical label information of the UTM device ················································································· 34

Displaying the CPU usage of the UTM device ············································································································ 35

Displaying the memory usage of the UTM device······································································································ 35

Displaying the CF card information ····························································································································· 35

Displaying the operational status of the fans ·············································································································· 36

Displaying the operational status of a power module ······························································································· 36

Displaying the temperature information of the UTM device ······················································································ 36

Displaying operational statistics of the UTM device··································································································· 37

Saving the running configuration of the UTM device································································································· 37

Rebooting the UTM device············································································································································ 38

Replacement procedures ···········································································································································40

Safety recommendations ··············································································································································· 40

Replacing an interface module····································································································································· 40

Replacing a CF card······················································································································································ 41

Replacing a transceiver module ··································································································································· 42

Troubleshooting··························································································································································44

Power supply system failure·········································································································································· 44

Fan failure······································································································································································· 44

Configuration terminal problems·································································································································· 45

No terminal display ·············································································································································· 45

Garbled terminal display······································································································································ 45

Password loss ································································································································································· 45

User password loss ··············································································································································· 45

Super password loss ············································································································································· 46

Cooling system failure ··················································································································································· 47

Interface module failure················································································································································· 47

Appendix A Technical specifications ······················································································································48

Dimensions and weight ················································································································································· 48

Storages ·········································································································································································· 48

Power consumption range············································································································································· 48

Power consumption range············································································································································· 48

Fixed Ethernet ports specifications ······························································································································· 49

Console port··························································································································································· 49

Appendix B LEDs·······················································································································································50

LEDs ················································································································································································· 50

Appendix C Interface modules ································································································································52

2GE interface module···················································································································································· 52

NSQ1GT2UA0 interface module································································································································· 53

NSQ1GP4U0 interface module ··································································································································· 54

Appendix D AC power cables used in different countries or regions··································································56

10A AC power cables used in different countries or regions··················································································· 56

16A AC power cables used in different countries or regions··················································································· 59

Support and other resources ·····································································································································62

Contacting HP ································································································································································ 62

Subscription service ·············································································································································· 62

ii

Page 5

Related information························································································································································ 62

Documents······························································································································································ 62

Websites································································································································································· 62

Conventions ···································································································································································· 63

Index ···········································································································································································65

iii

Page 6

Product overview

This chapter includes these sections:

• A-U200-A architecture description

• A-U200-S architecture description

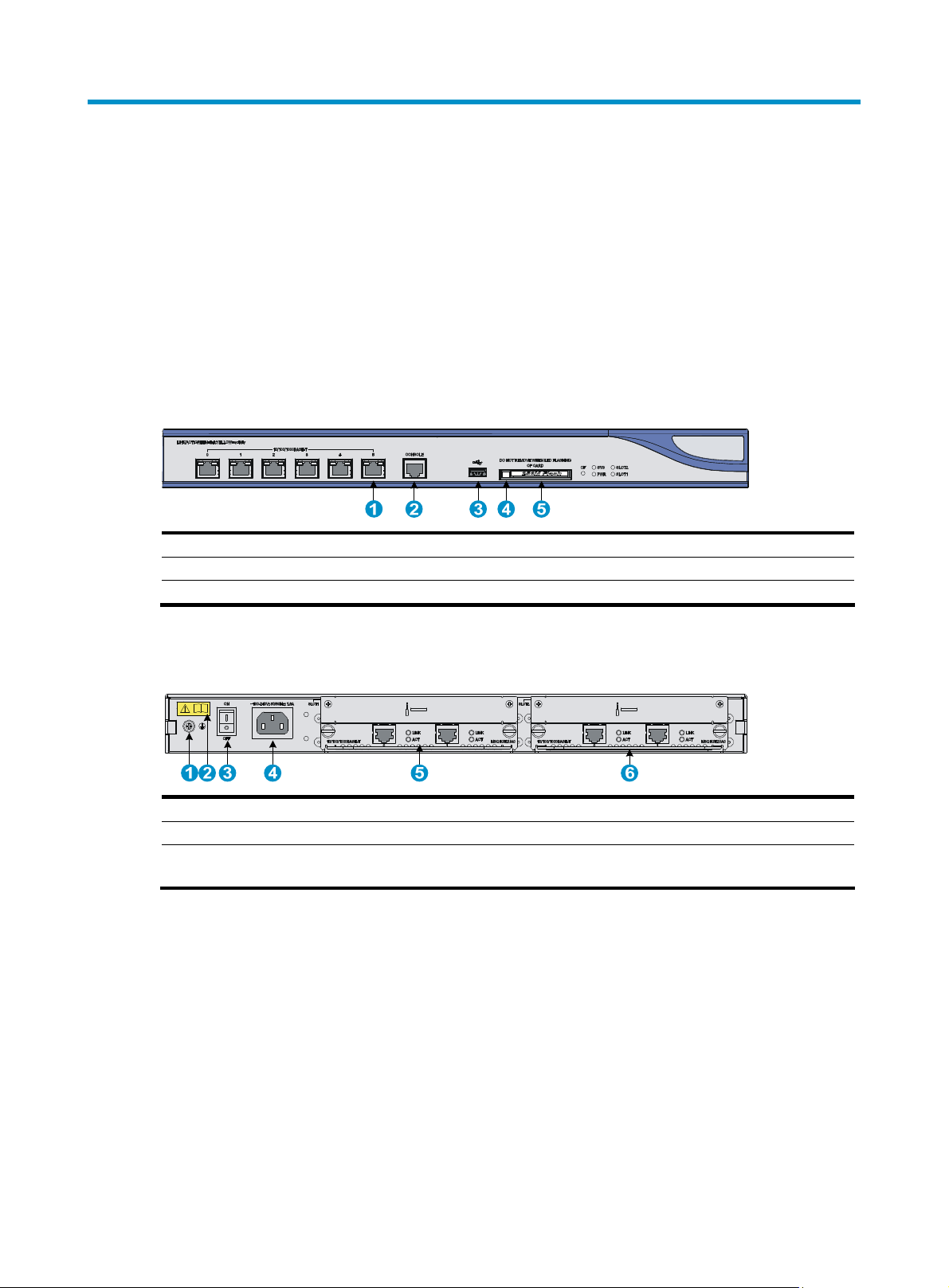

A-U200-A architecture description

Front panel

Figure 1 A-U200-A front panel

(1) Copper Ethernet ports (GE0 through GE5) (2) Console port

(3) USB interface (4) CF card eject button

(5) CF card slot

Rear panel

Figure 2 A-U200-A rear panel

(1) Grounding terminal and mark (2) “OPEN BOOK” mark

(3) AC power switch (ON/OFF) (4) AC power receptacle

(5) Slot1 (with an NSQ1GT2UA0 interface module

installed in this diagram)

(6) Slot2 (with an NSQ1GT2UA0 interface module

installed in this diagram)

1

Page 7

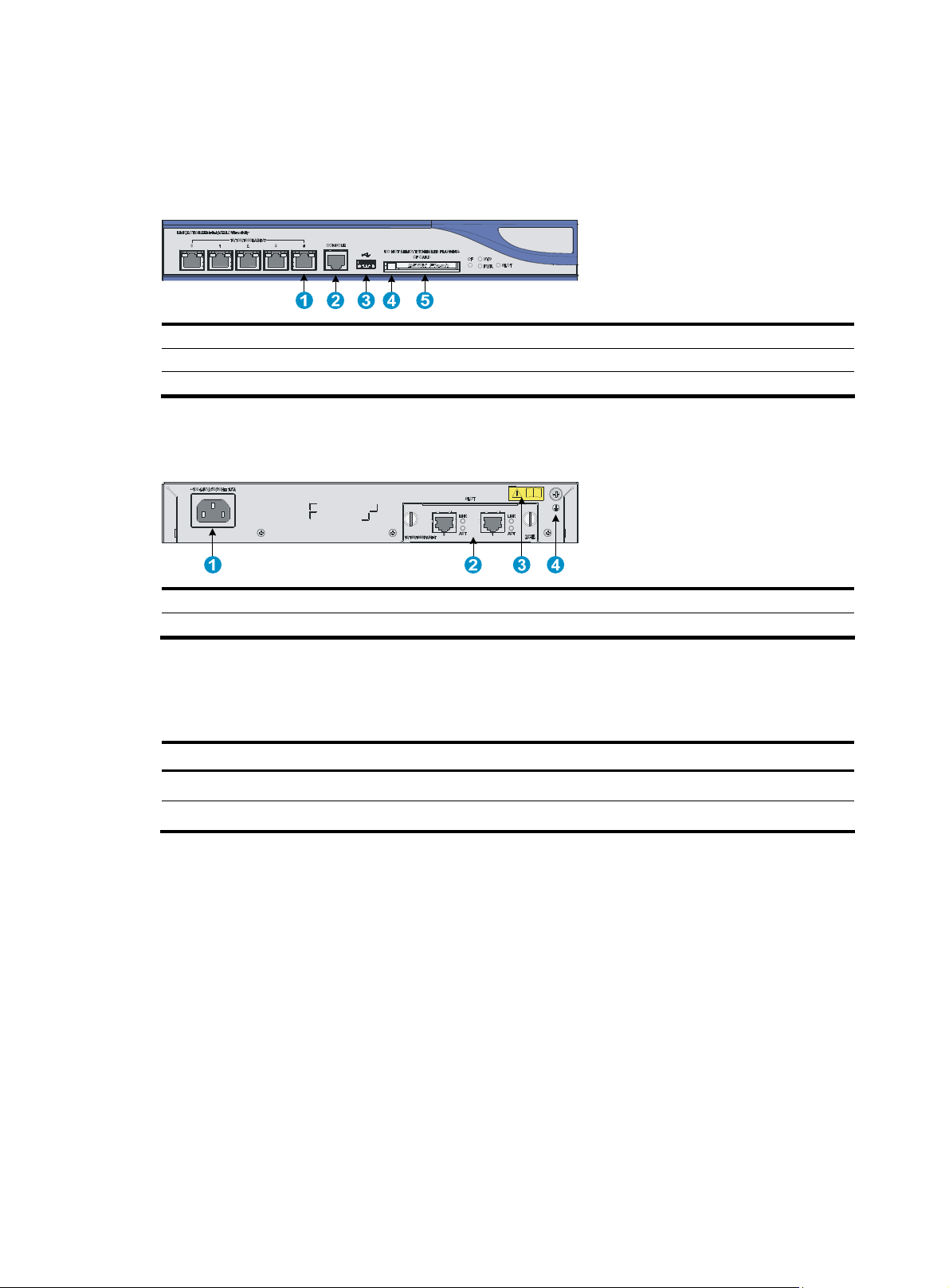

A-U200-S architecture description

Front panel

Figure 3 A-U200-S front panel

(1) Copper Ethernet ports (GE0 through GE4) (2) Console port

(3) USB interface (4) CF card eject button

(5) CF card reader

Rear panel

Figure 4 A-U200-S rear panel

(1) AC power receptacle (2) Slot (with a 2GE interface module installed in this diagram)

(3) Grounding terminal and mark (4) “OPEN BOOK” mark

The OPEN BOOK mark indicates that the operator must read the following chapters before working with

the UTM device:

Table 1 References for the operations

Operation Reference

Ground the UTM device See “Grounding the UTM device.”

Connect the power supply See “Connecting a power cord.”

2

Page 8

Preparing for installation

This chapter includes these sections:

• Safety recommendations

• Examining the installation site

• Installation tools

• Accessories supplied by the UTM device

• Checklist before installation

Safety recommendations

To avoid possible bodily injury and equipment damage, read the safety recommendations in this chapter

carefully before installing a UTM device. The recommendations do not cover every possible hazardous

condition.

This section includes these topics:

• Safety symbols

• General safety recommendations

• Safety with electricity

• Safety with laser

Safety symbols

When reading this document, note the following symbols:

WARNING means an alert that calls attention to important information that if not understood or

followed can result in personal injury.

CAUTION means an alert that calls attention to important information that if not understood or

followed can result in data loss, data corruption, or damage to hardware or software.

General safety recommendations

• Keep the chassis and installation tools away from walk areas.

• Make sure that the ground is dry and flat and anti-slip measures are in place.

• Unplug all the external cables (including power cables) before moving the chassis.

Safety with electricity

• Locate the emergency power-off switch in the room before installation. Shut the power off at once in

case accident occurs.

• Make sure that the UTM device has been correctly grounded.

• Connect the interface cables for the UTM device correctly.

• Use an uninterruptible power supply (UPS).

3

Page 9

• Do not work alone when the UTM device has power.

• Always check that the power has been disconnected.

Safety with laser

• Do not stare into the optical port or fiber connector because the laser light emitted from the optical

fiber may hurt your eyes.

• Install a dust plug on the transceiver module to avoid damage to the transceiver module.

Examining the installation site

The UTM device can only be used indoors. To ensure that the UTM device works properly and to prolong

its service lifetime, the installation site must meet the following requirements:

• Temperature and humidity

• Altitude

• Cleanness

• Cooling system

• ESD prevention

• EMI

• Lightning protection

• Rack-mounting

Temperature and humidity

You must maintain a proper temperature and humidity in the equipment room. Long-term high humidity

may lead to bad insulation, electricity leakage, mechanical property changes, and metal corrosion.

However, if the humidity is too low, captive screws may become loose as the result of contraction of

insulation washers and static electricity may be produced in a dry environment to jeopardize the circuits

on the device. A high temperature is the most undesirable condition, because it accelerates the aging of

insulation materials and significantly lowers reliability and service life of the UTM device.

Table 2 Temperature requirements

Item Temperature

Operating temperature 0°C to 45°C (32°F to 113°F)

Storage temperature –40°C to 70°C(–40°F to 158°F)

Table 3 Humidity requirements

Item Humidity

Operating humidity 10% to 95%

Storage humidity 5% to 95%

4

Page 10

Altitude

Table 4 Altitude requirements

Item Altitude

Operating altitude –60 m (–196.85 ft) to 3 km (1.86 miles)

Storage altitude –60 m (–196.85 ft) to 4.5km(2.8 miles)

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor humidity is low. In the worst case, electrostatic

adsorption can cause communication failure.

Table 5 Dust concentration limit in the equipment room

Substance Concentration limit (particles/cu m)

Dust particles

NOTE:

Dust particle diameter 5 m

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 6.

Table 6 Harmful gas li

Gas Max. (mg/m

SO2 0.2

H2S 0.006

NH

3

Cl

2

Cooling system

The UTM device adopts left to right airflow for heat dissipation. The following diagram takes an

A-U200-S for example.

3 x 104

(No visible dust on desk in three days)

mits in an equipment room

0.05

0.01

3

)

5

Page 11

Figure 5 UTM device airflow

• Make sure there is enough space (greater than 10 cm (3.94 in)) around the air intake and outlet

vents on the UTM device for good ventilation.

• Make sure the installation site has a good cooling system.

ESD prevention

To prevent electrostatic discharge (ESD), note the following guidelines:

• Make sure that the UTM device and the floor are well grounded.

• Take dust-proof measures for the equipment room.

• Maintain the humidity and temperature at a proper level.

• Always wear an ESD-preventive wrist strap when touching a circuit board or transceiver module.

• Place the removed CF card or interface module on an antistatic workbench, with the face upward,

or put it into an antistatic bag.

• Touch only the edges, instead of electronic components when observing or moving a removed CF

card or interface module.

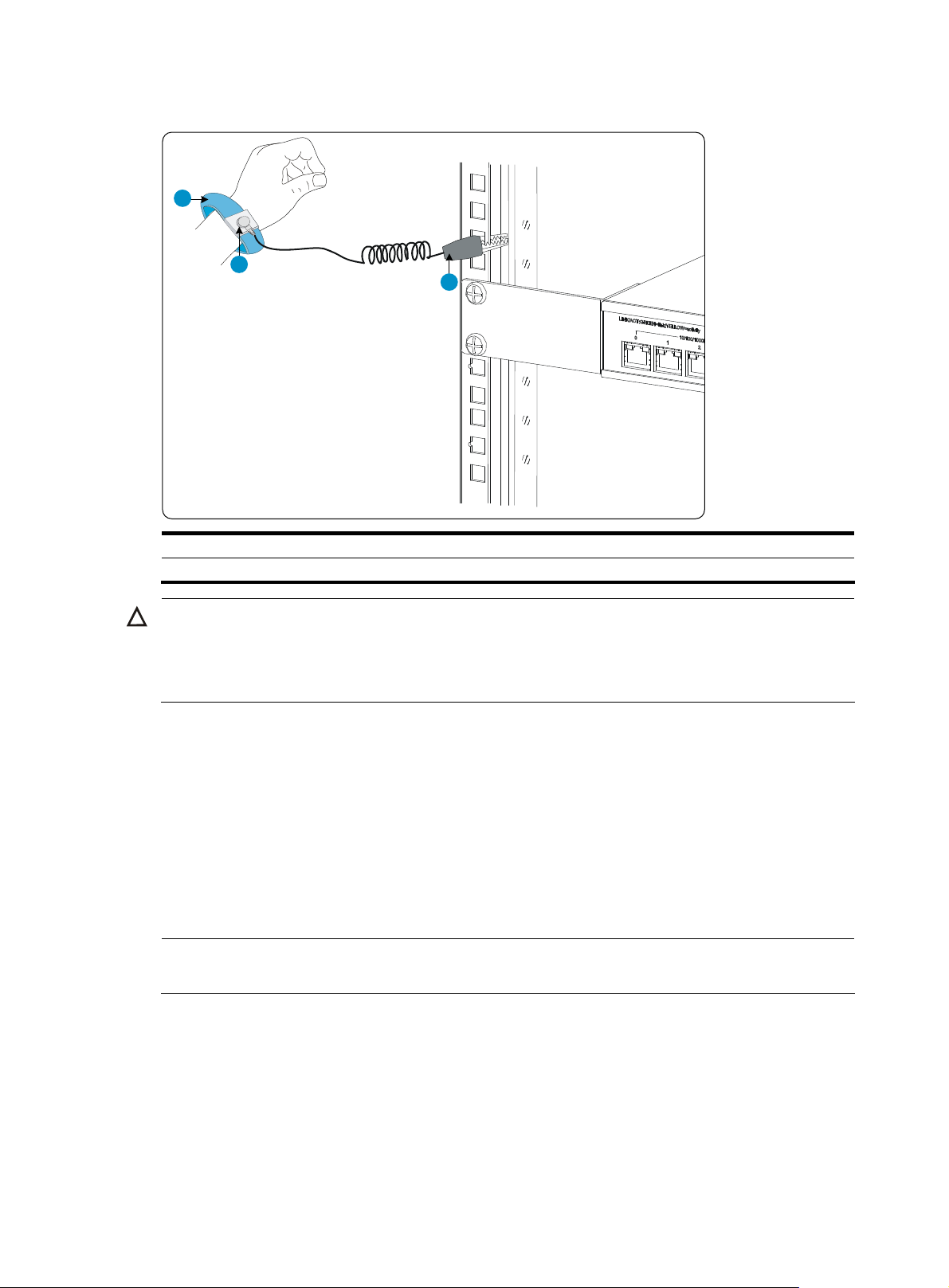

To use the ESD-preventive wrist strap, perform the following steps:

Step1 Wear the wrist strap on your wrist.

Step2 Lock the wrist strap tight around your wrist to keep good contact with the skin.

Step3 Attach the ESD-preventive wrist strap to the rack with the alligator clips.

Step4 Make sure that the rack is well grounded.

6

Page 12

g

Figure 6 Use an ESD-preventive wrist strap

1

2

3

EMI

NOTE:

(1) ESD-preventive wrist strap (2) Lock

(3) Alligator clip

CAUTION:

• Check the resistance of the ESD-preventive wrist strap for safety. The resistance readin

should be in the

range of 1 to 10 megohm (Mohm) between human body and the ground.

• No ESD-preventive wrist strap is provided with the HP UTM device. Prepare it yourself.

To prevent electromagnetic interference (EMI) when using the UTM device, note the following guidelines:

• Take measures against interference from the power grid.

• Do not use the UTM device together with the grounding equipment or light-prevention equipment of

power equipment, and keep the UTM device far away from them.

• Keep the UTM device far away from high-power radio launchers, radars, and equipment with high

frequency or high current.

Use electromagnetic shielding when necessary.

Lightning protection

To protect the UTM device from lightning better, do as follows:

• Make sure the grounding cable of the chassis is well grounded.

• Make sure the grounding terminal of the AC power receptacle is well grounded.

7

Page 13

• Install a lightning arrester at the input end of the power supply to enhance the lightning protection

capability of the power supply.

Rack-mounting

Before mounting the UTM device in a standard 19-inch rack, adhere to the following requirements:

• The rack is sturdy enough to support the UTM device and installation accessories.

• Make sure that the size of the rack is appropriate for the UTM device, and that there is enough

clearance around the left and right sides of the UTM device for heat dissipation.

• For heat dissipation and device maintenance, make sure the front and rear of the rack should be at

least 0.8 m (2.62 ft) away from walls or other devices, and that the headroom in the equipment

room should be no less than 3 m (9.84 ft).

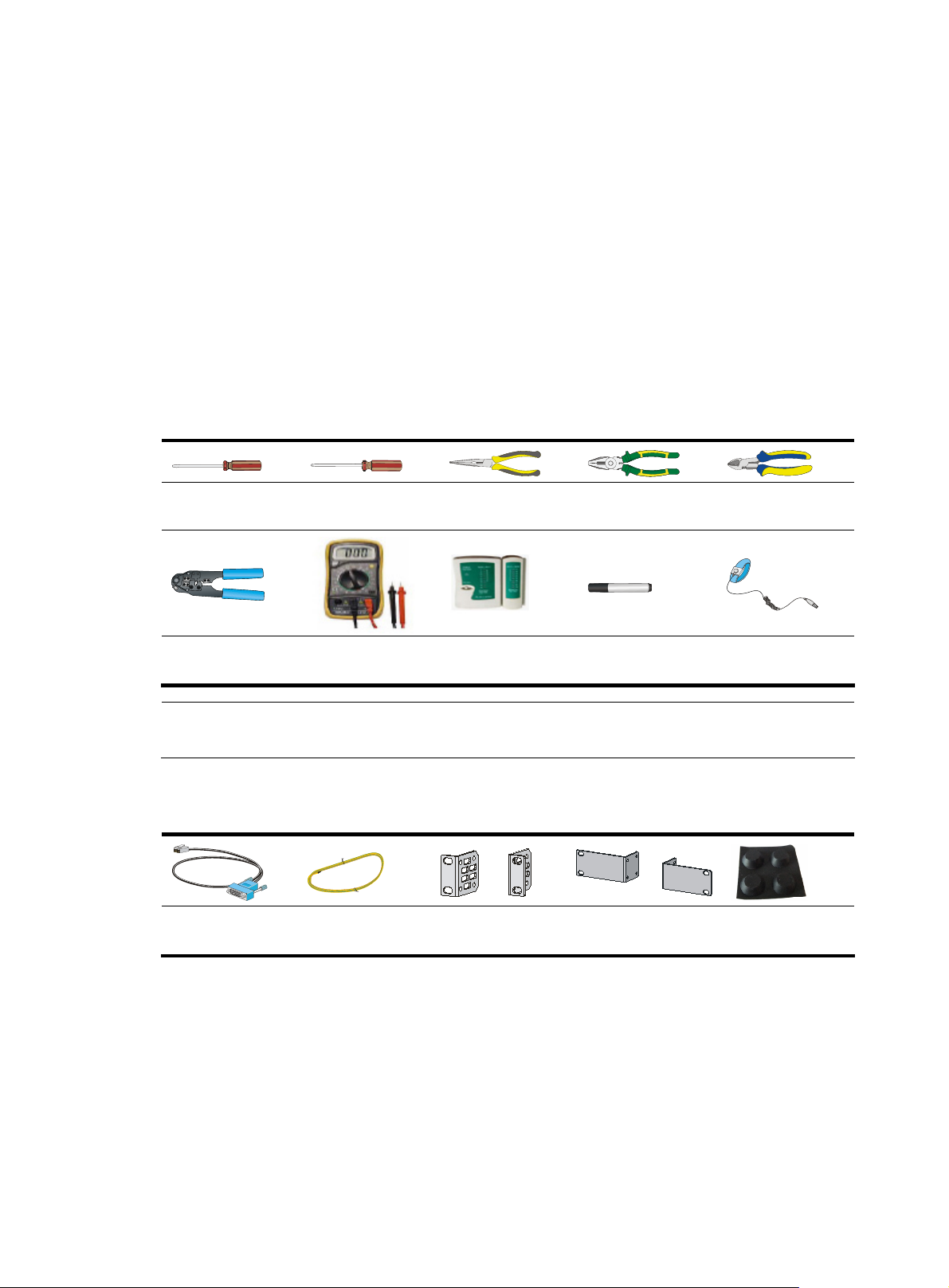

Installation tools

Flat-blade

screwdriver

RJ45 crimping

pliers

Phillips screwdriver

Multimeter

Needle-nose pliers

Network cable

tester

Wire-stripping

pliers

Mark pen

NOTE:

No installation tool or ESD-preventive wrist strap is provided with the UTM device. Prepare them yourself.

Accessories supplied by the UTM device

Console cable Grounding cable

Mounting bracket

for A-200-A

Mounting bracket for

A-200-S

Diagonal pliers

ESD-preventive

wrist strap

Feet

8

Page 14

Checklist before installation

Table 7 Checklist before installation

Item Requirements Result

• There is a minimum clearance of 10 cm (3.9 in) around

Ventilation

the inlet and exhaust vents for heat dissipation of the

UTM device chassis.

• A ventilation system is available at the installation site.

Installation site

Operating

temperature

Operating

humidity

Cleanness Dust concentration 3 × 104 particles/m3

0°C to 45°C (32°F to 113°F)

10% to 95%

• The equipment and floor are well grounded.

• The equipment room is dust-proof.

• The humidity and temperature are at a proper level,

respectively.

• Wear an ESD-preventive wrist strap and uniform when

ESD prevention

touching a circuit board.

• Place the removed CF card or interface module on an

antistatic workbench, with the face upward, or put it

into an antistatic bag.

• Touch only the edges, instead of electronic components

when observing or moving a removed CF card or

interface module.

• Take effective measures to protect the power system

from the power grid system.

• Separate the protection ground of the UTM device from

the grounding device or lightning protection grounding

EMI prevention

device as far as possible.

• Keep the UTM device far away from radio stations,

radar and high-frequency devices working in high

current.

• Use electromagnetic shielding when necessary.

Lightning

protection

• The grounding cable of the chassis is well grounded.

• The grounding terminal of the AC power receptacle is

well grounded.

• Equip an uninterruptible power supply (UPS).

Electricity safety

• In case of emergency during operation, switch off the

external power switch.

Rack-mounting

requirements

• The rack is sturdy enough to support the weight of the

UTM device and installation accessories.

• The size of the cabinet is appropriate for the UTM

device.

• The front and rear of the cabinet are at least 0.8 m

(31.50 in) away from walls or other devices.

9

Page 15

Item Requirements Result

Safety

precautions

Tools

Reference

• The UTM device is far away from any moist area and heat source.

• The emergency power switch in the equipment room is located.

• Installation accessories supplied with the UTM device

• User supplied tools

• Documents shipped with the UTM device

• Online documents

10

Page 16

Installing the UTM device

This chapter includes these sections:

• Installation flow

• Installing the UTM device in a 19-inch rack

• Grounding the UTM device

• Installing interface modules

• Installing a CF card

• Connecting Ethernet cables

• Connecting a power cord

Installation flow

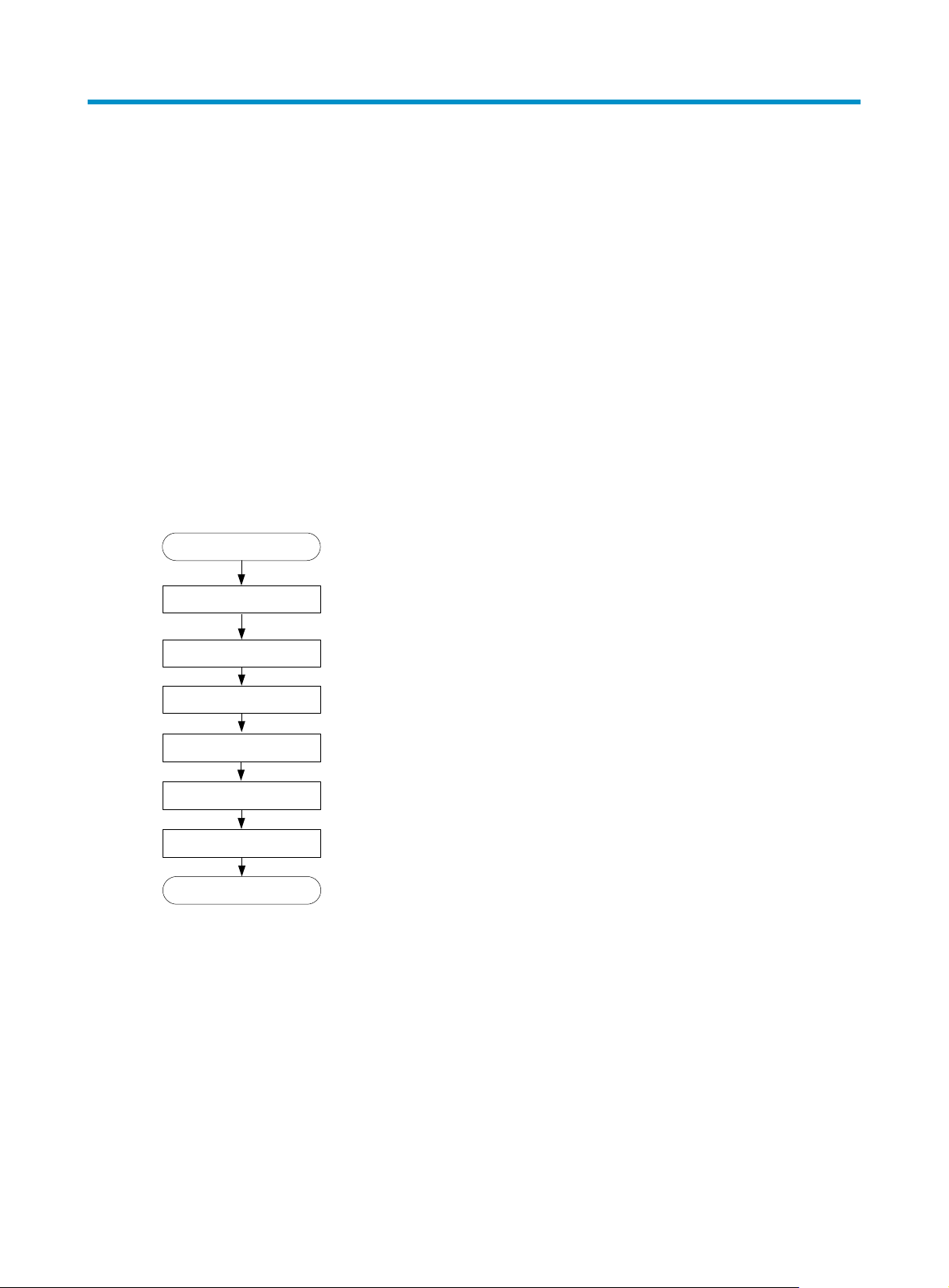

Figure 7 HP A-U200-A/A-U200-S UTM device installation flow

Start

Install the UTM to a 19' rack

Ground the UTM

Install an interface module

Install a CF card

Connect Ethernet cables

Connect the power cord

End

Installing the UTM device in a 19-inch rack

The installation procedure of an A-U200-A is similar to an A-U200-S. This section takes an A-U200-S as

an example.

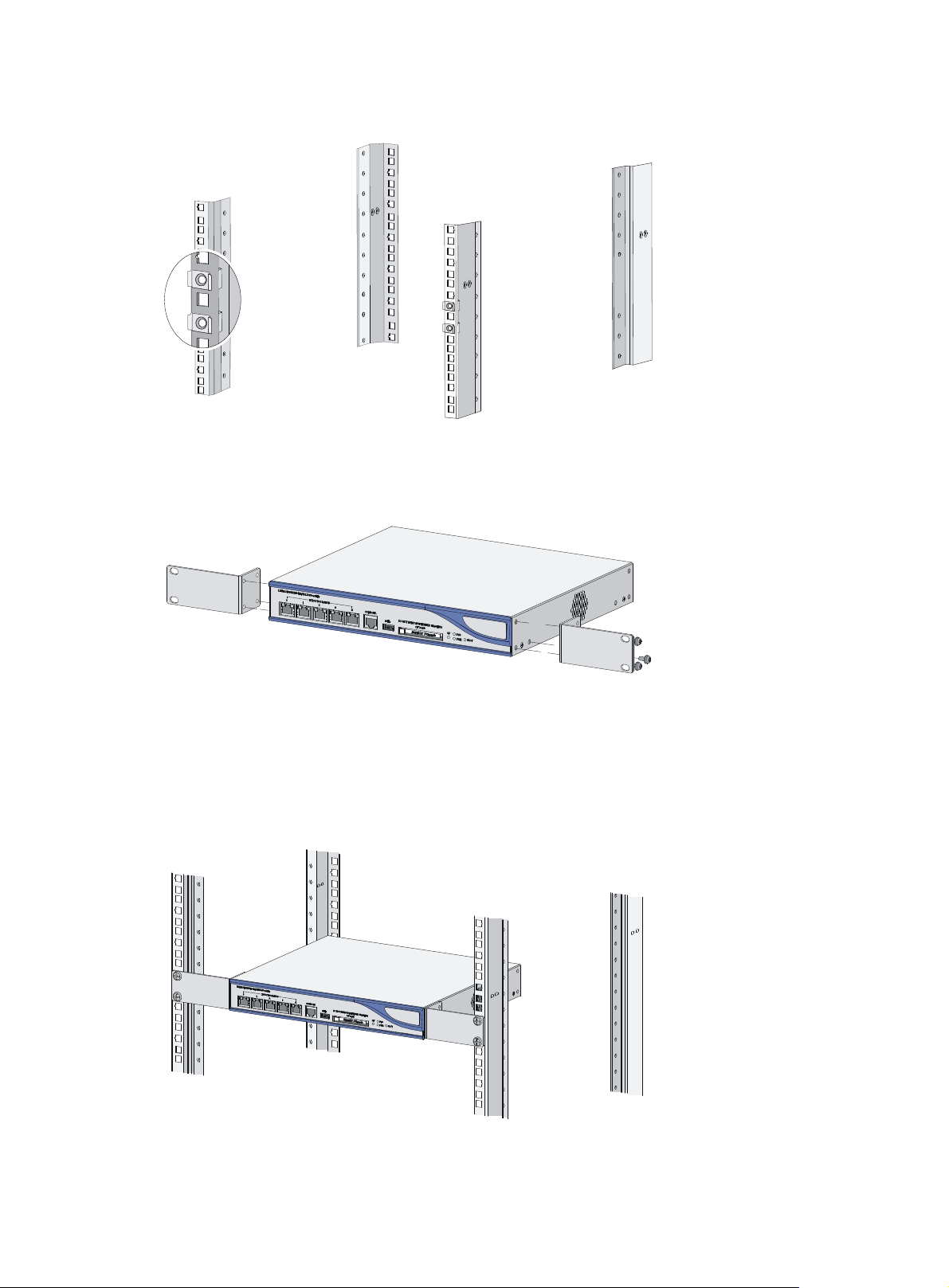

Step1 As shown in Figure 8, install the cage nuts to proper positions on the rack posts.

11

Page 17

Figure 8 Install cage nuts

Step2 Install the mounting brackets to both sides of the front panel.

Figure 9 Install the mounting brackets to both sides of the front panel

Step3 Supporting the UTM device bottom with one hand, push the UTM device into the rack horizontally.

Step4 Fix the UTM device horizontally by fastening the front mounting brackets at both sides to the rack with

appropriate pan head screws. The specifications of pan head screws must satisfy the installation

requirements, and rustproof treatment has been made to their surfaces.

Figure 10 Fix the UTM device to the rack

12

Page 18

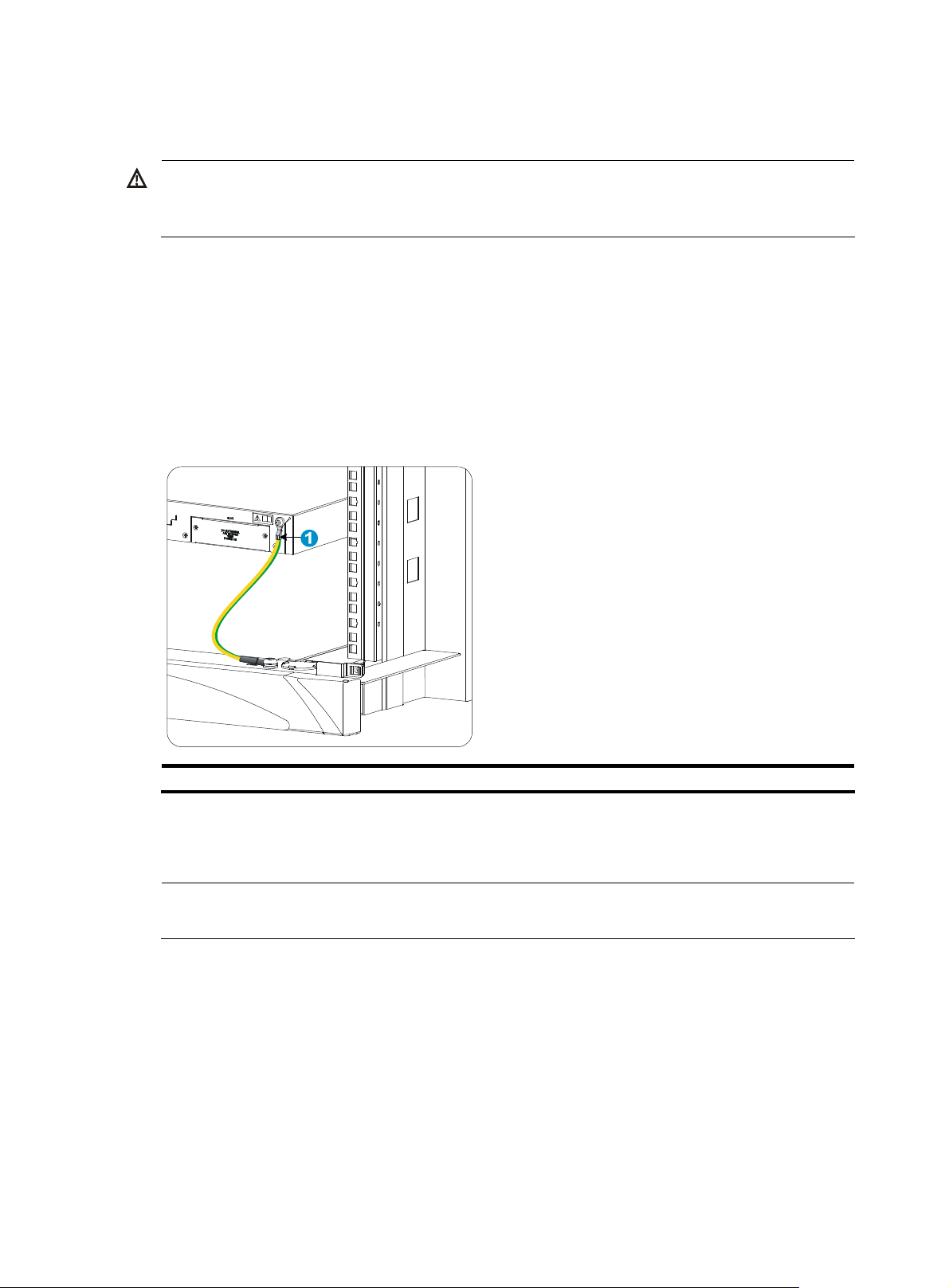

Grounding the UTM device

WARNING!

Correctly connecting the UTM device grounding cable is crucial to lightning protection and EMI

protection.

Follow these steps to connect the grounding cable:

Step1 Remove the grounding screw from the rear panel of the UTM device chassis.

Step2 Attach the grounding screw to the OT terminal of the grounding cable.

Step3 Use a screwdriver to fasten the grounding screw into the grounding screw hole.

Step4 Ground the other end of the grounding cable, as shown in Figure 11, by connecting the other end of the

grounding cable to the grounding terminal of the rack.

Figure 11 Connect the grounding cable

(1) OT terminal

Installing interface modules

NOTE:

Keep the removed filler panel and screws for future use.

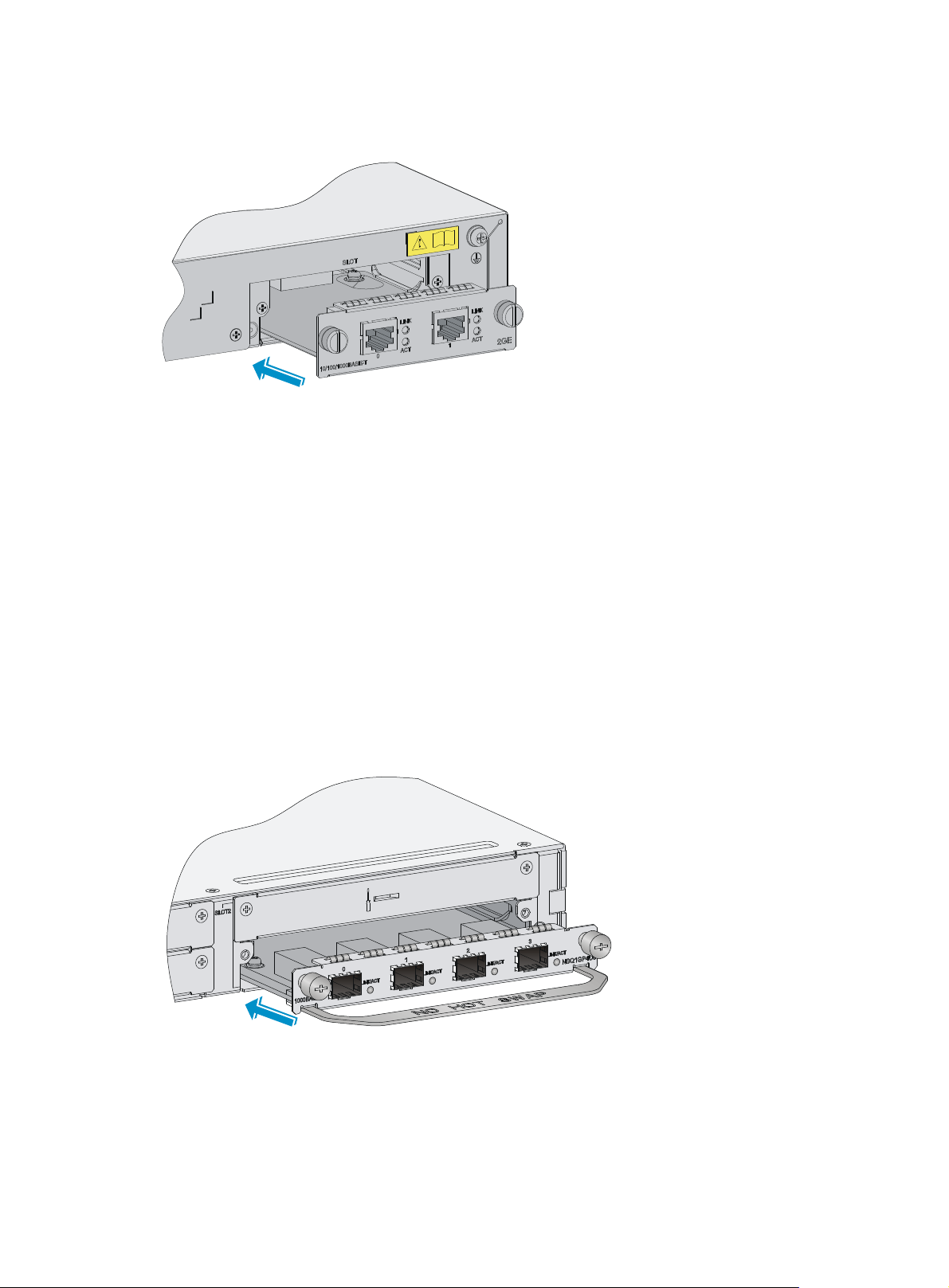

Installing a 2GE interface module

The A-U200-S supports only 2GE interface modules. Follow these steps to install a 2GE interface

module:

Step1 Use a Phillips screwdriver to loosen the fastening screws on the filler panel, and then remove the filler

panel.

Step2 Push the 2GE interface module slowly along the guide rails into the slot until it touches the slot bottom,

as shown in Figure 12.

13

Page 19

Step3 Use a screwdriver to fasten the captive screws on the 2GE interface module.

Figure 12 Install a 2GE interface module

Installing an NSQ1GT2UA0 or NSQ1GP4U0 interface module

The A-U200-A supports NSQ1GT2UA0 and NSQ1GP4U0 interface modules. The installation

procedure of the two interface modules are the same. This section takes an NSQ1GP4U0 interface

module for example. Follow these steps to install an NSQ1GP4U0 interface module:

Step1 Select the slot where you want to install the NSQ1GP4U0 interface module. Use a Philips screwdriver to

loosen the fastening screws on the filler panel, and remove the filler panel. The interface module can be

installed only in the lower slot.

Step2 Push the interface module slowly along the guide rails into the slot until it touches the slot bottom, as

shown in Figure 13.

Step3 Use a screwdriver to fasten the captive screws on the NSQ1GP4U0 interface module.

Figure 13 Install an NSQ1GP4U0 interface module

14

Page 20

t

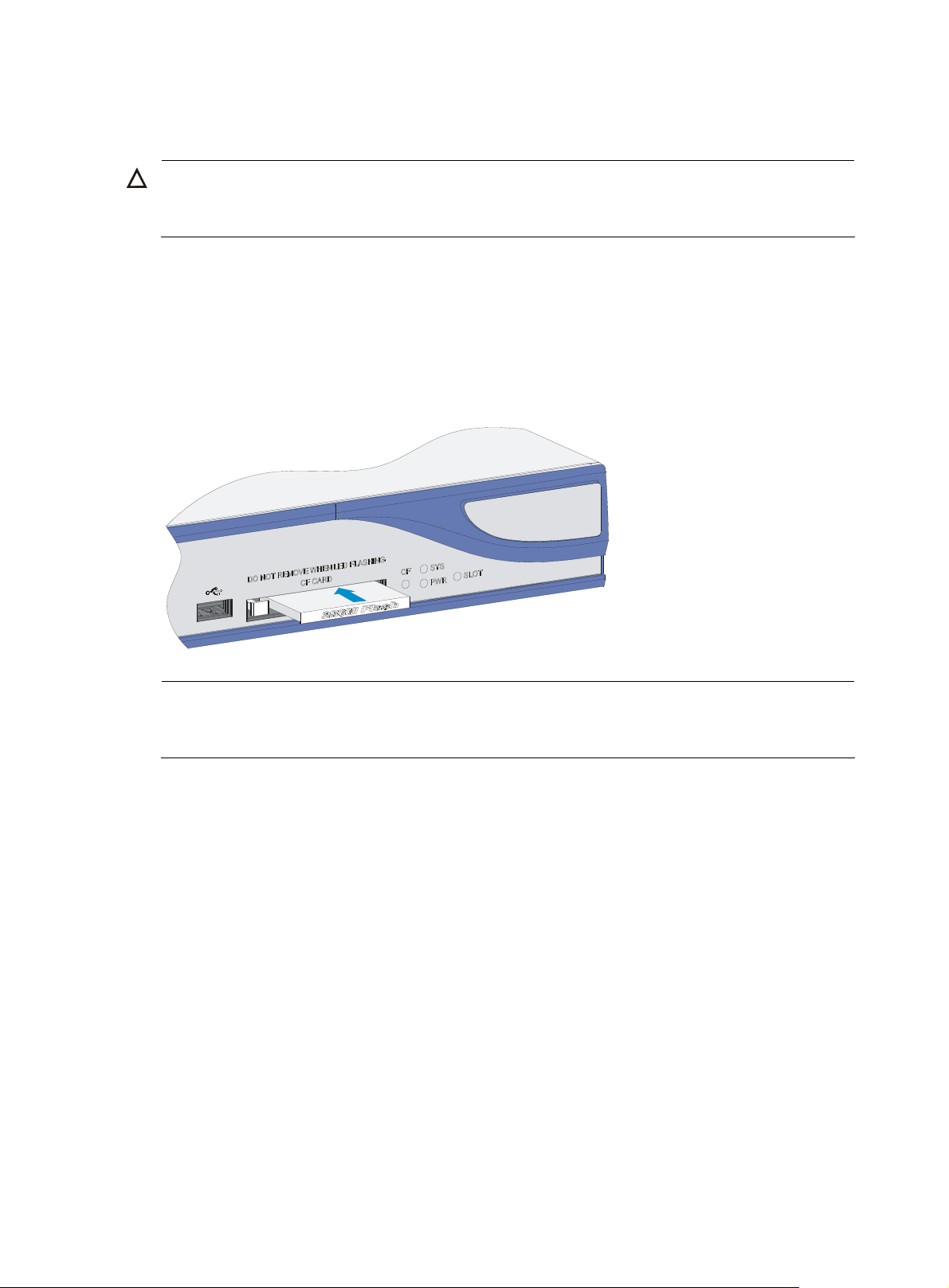

Installing a CF card

CAUTION:

The UTM device supports only HP-provided CF cards, and does not guarantee compatibility with any

other CF cards.

Follow these steps to install a CF card:

Step1 Push the CF card eject button all the way into the slot, and make sure that the button does not project from

the panel.

Step2 Insert the CF card into the slot following the direction shown in Figure 14, and make sure it does not

project from the slot.

Figure 14 Install the CF card

NOTE:

If the boot file of the UTM device is stored in the CF card, before booting the UTM device, make sure tha

the CF card has been correctly installed. Otherwise, the UTM device cannot be booted.

Connecting Ethernet cables

Connecting a copper Ethernet cable

The copper Ethernet ports of the HP A-U200-A/A-U200-S UTM device support MDI/MDI-X auto-sensing.

You can use either standard network cables or crossover Ethernet cables.

Follow these steps to connect a copper Ethernet cable:

Step1 Connect one end of an Ethernet twisted pair cable to the copper Ethernet port on the UTM device.

Step2 Connect the other end of the cable to the peer device.

Step3 Check the LINK LED of the port when you power on the UTM device. If the LINK LED is steady on, you

can be sure that the link is connected. For more information about the LED status, see the chapters

“Appendix B LEDs.

” and “Appendix C Interface modules.”

15

Page 21

g

Connecting an optical fiber

Before connecting an optical fiber to the SFP port of an NSQ1GP4U0 interface module, you must install

a transceiver module to the SFP port, and then insert a LC fiber connector to the transceiver module.

WARNING!

When connecting an optical fiber, note the following guidelines:

• Never bend or curve a fiber when connectin

not less than 10 cm (3.94 in).

• Keep the fiber end clean.

• Make sure that the fiber connector matches the transceiver module.

• Before connecting a fiber, make sure that the optical power at the receiving end does not exceed the

upper threshold of the optical receive power of the transceiver module. Otherwise, the transceiver

module may be damaged. For the optical power of a transceiver module, see the chapter “Appendix C

face modules.”

Inter

Follow these steps to connect optical fibers:

Step1 Remove the dust plug of the SFP port.

Figure 15 Remove the dust plug

it. After a fiber is installed well, the bend radius must be

Step2 Plug the transceiver module into the SFP port of the UTM device, as shown in Figure 16.

16

Page 22

Figure 16 Install the transceiver module

Step3 Remove the dust cap from the transceiver module and the protective caps from the fibers.

Step4 Plug the LC connectors on one end of the fiber cable into the Rx and Tx ports, and plug the LC connectors

on the other end to the Tx and Rx ports on the peer device, as shown in Figure 17.

Figure 17 Connect the fi

ber connectors

Step5 Check the LED of the fiber port when you power on the UTM device. If the LINK LED is steady on, it means

that the link is connected. For more information about the LED status, see the chapter “Appendix C

Inter

face modules.”

Connecting a power cord

To connect an AC power cord, follow these steps:

Step1 Make sure the UTM device is well grounded.

Step2 Make sure that the power switch on the UTM device is in the OFF position. An A-U200-S UTM device

does not provide a power switch, so you should turn off the switch of the power source.

Step3 Connect one end of the AC power cord to the AC receptacle on the UTM device, and the other end to

the AC power source.

Step4 (Optional) Use cable ties to secure the power cord to the rack to avoid drop of the power cord.

17

Page 23

Figure 18 Connect an AC power cord to the UTM device (A-U200-A for example)

18

Page 24

Logging in to the UTM device and configuring basic settings

This chapter includes these sections:

• Logging in to the UTM device thr

• Powering on the UTM device

• Logging in to the UTM device through Telnet

• Logging in to the UTM device through a web browser

• Performing basic settings for the UTM device

his chapter describes only the commonly used methods for logging in to the UTM device. For more UTM

T

device login methods, such as login through SSH and NMS, see the configuration guides for the UTM

device.

ough the console port

Logging in to the UTM device through the console port

Connecting the UTM device to a configuration terminal through a console cable

Follow these steps to connect a configuration terminal to the UTM device by using the console cable:

Step1 Select a configuration terminal, which can be a character terminal with an RS232 serial port, or a PC.

This section takes connecting an A-U200-S UTM device to a PC for example.

Step2 Plug the DB-9 female connector to the serial port of the PC.

Step3 Connect the RJ-45 connector to the console port of the UTM device.

19

Page 25

Figure 19 Connect the console cable

CAUTION:

• When you connect a PC to a powered-on UTM device, connect the DB-9 connector of the console cable

to the PC before connecting the RJ-45 connector to the UTM device.

• When you disconnect a PC from a powered-on UTM device, disconnect the DB-9 connector of the

console cable from the PC after disconnecting the RJ-45 connector from the UTM device.

Setting terminal parameters

Follow these steps to set terminal parameters on a terminal, for example, Windows XP HyperTerminal:

Step1 Select Start > All Programs > Accessories > Communications > HyperTerminal to enter the

HyperTerminal window. The Connection Description dialog box appears, as shown in Figure 20.

20

Page 26

Figure 20 Connection description of the HyperTerminal

Step2 Type the name of the new connection in the Name text box and click OK. The following dialog box

appears. Select the serial port to be used from the Connect using drop-down list.

Figure 21 Set the serial port used by the HyperTerminal connection

Step3 Click OK after selecting a serial port and the following dialog box appears. Set Bits per second to 9600,

Data bits to 8, Parity to None, Stop bits to 1, and Flow control to None.

21

Page 27

Figure 22 Set the serial port parameters

NOTE:

To use the default settings, click Restore Defaults.

Step4 Click OK after setting the serial port parameters and the system enters the following interface.

22

Page 28

Figure 23 HyperTerminal window

Step5 Click Properties in the HyperTerminal window to enter the aaa Properties dialog box. Click the Settings

tab, set the Emulation to VT100, and then click OK.

Powering on the UTM device

Checking before power-on

Before powering on the UTM device, verify the following items:

• The power cord and grounding cable are properly connected.

• The power source matches that required by the UTM device.

• The console cable is properly connected; the terminal or PC used for configuration has started; and

the configuration parameters have been set.

• If a CF card is used, check whether the CF card is in position.

Checking after power-on

After powering on the UTM device, check the following items:

• The LEDs on the front panel are normal. For information about the LED status, see the chapter

“Appendix B LEDs.”

• The fans work properly, and you can hear fan rotating.

• The configuration terminal displays information normally. You can see the startup window on the

local configuration terminal.

• After the POST, the system prompts you to press Enter. When the command line prompt appears,

the UTM device is ready to configure.

23

Page 29

Logging in to the UTM device through Telnet

NOTE:

For more information about the Telnet login, see the configuration guides for the UTM device.

You can use the default information to log in to the A-U200-A/A-U200-S UTM device. The default login

information includes:

• Username: admin

• Password: admin

• IP address of port GigabitEthernet 0/0: 192.168.0.1/24

Follow these steps to log in to the UTM device through Telnet:

Step1 Log in to the UTM device through the console port and then use the telnet server enable command in

system view to enable the Telnet function of the UTM device.

By default, Telnet is disabled on the UTM device.

Step2 Connect the UTM device to a PC.

Connect port GigabitEthernet 0/0 of the UTM device to a PC by using an Ethernet cable.

Step3 Configure an IP address for the PC, ensuring the PC and the UTM device can ping each other.

Set the IP address to any one but 192.168.0.1 within the range of 192.168.0.0/24. For example, set the

address to 192.168.0.2.

Step4 Use the Telnet command to log in to the UTM device.

Logging in to the UTM device through a web browser

The UTM device supports web-based network management, which allows you to manage and maintain

the UTM device in a more user-friendly way.

Your UTM device was delivered with the default web logging information. You can use this default

information to log in to the web page of your UTM device. The default web logging information includes:

• User name: admin

• Password: admin

• IP address of port GigabitEthernet 0/0: 192.168.0.1/24

Follow these steps to log in to your UTM device through a web browser:

Step1 Connect a cable to the UTM device.

Connect the Ethernet interface GigabitEthernet 0/0 of the UTM device to a PC by using a network cable.

Step2 Configure an IP address for the PC, making sure that the PC and the UTM device can ping each other.

Set the IP address to any one but 192.168.0.1 within the range of 192.168.0.0/24. For example, set the

address to 192.168.0.2.

Step3 Launch the web browser and input the login information.

24

Page 30

Launch the web browser on the PC. Type 192.168.0.1 in the address bar and press Enter. The login dialog

box appears, as shown in Figure 24. In this di

verify code and click Login.

Figure 24 Web login dialog box

Then, the web interface of the UTM device appears.

alog box, enter your user name (admin), password (admin),

Performing basic settings for the UTM device

This section describes the fast configuration by using the basic configuration wizard. For more

information about how to configure the protocols and features for the A-U200-A/A-U200-S UTM device,

see the configuration guides for the UTM device.

NOTE:

The web interfaces may vary by the software version.

Launching the basic configuration wizard

Select Wizard from the navigation tree to enter the Configuration Wizard page, and then click the Basic

Device Information hyperlink to enter the first page of the basic configuration page, as shown in Figure

25.

25

Page 31

Figure 25 Basic configuration wizard: 1/6

Configuring the system name and user password

Click Next on the first page of the basic configuration wizard to enter the basic information configuration

page, as shown in Figure 26.

26

Page 32

Figure 26 Basic configuration wizard: 2/6 (basic information)

Table 8 Basic information configuration items

Item Description

Sysname Set the system name. By default, the system name of the UTM device is HP.

Modify Current User

Password

New Password

Confirm Password

Specify whether to modify the login password of the current user.

To modify the password of the current user, set the new password and the confirm

password, and the two passwords must be identical.

By default, the UTM device login username and password are both admin.

Configuring service management

Click Next on the basic information configuration page to enter the service management page, as shown

in Figure 27.

27

Page 33

Figure 27 Basic configuration wizard: 3/6 (service management)

Table 9 Service management configuration items

Item Description

FTP

Telnet

HTTP

Specify whether to enable FTP on the device.

Disabled by default.

Specify whether to enable telnet on the device.

Disabled by default.

Specify whether to enable HTTP on the device, and set the HTTP port number.

Enabled by default.

IMPORTANT:

• If the current user has logged in to the web interface through HTTP, disabling HTTP

or modifying the HTTP port number will result in disconnection with the device;

therefore, perform the operation with caution.

• When you modify a port number, ensure that the port number is not used by

another service.

28

Page 34

Item Description

Specify whether to enable HTTPS on the device, and set the HTTPS port number.

HTTPS is the HTTP protocol that supports the Secure Sockets Layer (SSL) protocol. It

can improve device security.

Disabled by default.

IMPORTANT:

HTTPS

• If the current user logged in to the web interface through HTTPS, disabling HTTPS

or modifying the HTTPS port number will result in disconnection with the device;

therefore, perform the operation with caution.

• When you modify a port number, ensure that the port number is not used by

another service.

• By default, HTTPS uses the PKI domain default. If this PKI domain does not exist, the

system will prompt you for it when the configuration wizard is completed; however,

this will not affect the execution of other configurations.

Configuring the IP address for an interface

Click Next on the service management configuration page to enter the interface IP address configuration

page, as shown in Figure 28. T

Ethernet interfaces and VLAN interfaces. You can click a value in the table and then modify it. Only when

the IP configuration is Static Address, can you configure the IP address and mask.

he table lists the IP address configuration information for all Layer 3

Figure 28 Basic configuration wizard: 4/6 (interface IP configuration)

29

Page 35

Table 10 Interface IP address configuration items

Item Description

Set the approach for obtaining the IP address, including:

• None: The IP address of the interface is not specified,

that is, the interface has no IP address.

• Static Address: Specify the IP address for the interface

IP Configuration

manually; if you select this item, you need to specify

both the IP address and the mask.

• DHCP: The interface obtains an IP address

automatically through the DHCP protocol.

• Do not change: The IP address of the interface does not

change.

IMPORTANT:

Modification to the

interface IP address will

result in disconnection

with the device, so make

changes with caution.

IP Address

Mask

Configuring NAT

Click Next on the interface IP address configuration page to enter the NAT configuration page, as shown

in Figure 29.

Figure 29 Basic c

onfiguration wizard: 5/6 (NAT configuration)

If you select Stack Address as the approach for obtaining

the IP address, you need to set the interface IP address and

network mask.

30

Page 36

Table 11 NAT configuration items

Item Description

Interface

Dynamic NAT

Source IP/Wildcard If dynamic NAT is enabled, set the source IP address and wildcard for packets.

Destination

IP/Wildcard

Protocol Type

Internal Server

External IP: Port

Select an interface on which the NAT configuration will be applied. Generally, it is

the outgoing interface of the device.

Specify whether to enable dynamic NAT on the interface.

If dynamic NAT is enabled, the IP address of the interface will be used as the IP

address of a matched packet after the translation.

By default, dynamic NAT is disabled.

If dynamic NAT is enabled, set the destination IP address and wildcard for packets.

If dynamic NAT is enabled, select the protocol type carried over the IP protocol,

including TCP, UDP, and IP (indicating all protocols carried by the IP protocol).

Specify whether to enable the internal server.

You can configure an internal server on the NAT device by mapping a public IP

address and port number to the private IP address and port number of the internal

server.

By default, the internal server is disabled.

IMPORTANT:

Configuration of the internal server may result in disconnection with the device (for

example, specify an external IP address as the IP address of the local host or as the IP

address of the current access interface). Perform the operation with caution.

When the internal server is enabled, set the valid IP address and service port number

for the external access.

Internal IP: Port

If the internal server is enabled, set the IP address and service port number for the

server on the internal LAN.

Completing the configuration wizard

Click Next on the NAT configuration page to enter the page shown in Figure 30.

31

Page 37

Figure 30 Basic configuration wizard: 6/6

This page lists all configurations you have made in the basic configuration wizard. Confirm the

configurations. To modify your configuration, click Prev to go back to the previous page; if no

modification is needed, click Finish to execute all configurations.

32

Page 38

Hardware management and maintenance

This chapter includes these sections:

• Displaying detailed information about the UTM device

• Displaying software and hardware version information of the UTM device

• Displaying the electrical label information of the UTM device

• Displaying the CPU usage of the UTM device

• Displaying the memory usage of the UTM device

• Displaying the CF card information

• Displaying the operational status of the fans

• Displaying the operational status of a power module

• Displaying the temperature information of the UTM device

• Displaying operational statistics of the UTM device

• Saving the running configuration of the UTM device

• Rebooting the UTM device

NOTE:

• The CLI and outputs may vary by the software version. For more information about the commands used

in this chapter, see the command references for the UTM device.

• This chapter uses an A-U200-S for example.

Displaying detailed information about the UTM device

Use the display device verbose command to display detailed information of the device and interface

module, including the operational status and hardware version information.

<Sysname>display device verbose

Status :OK

Type :RPU

Hardware :B

Driver :1.0

CPLD :2.0

SubCard Num :2

CFCard Num :1

Usb Num :1

The Fixed SubCard0 on Board0

Status :Normal

Type :Fixed Subcard

Hardware :B

33

Page 39

Driver :1.0

CPLD :2.0

The SubCard1 on Board0:

Status :Normal

Type :ETH82571-2GE CARD

Hardware :B

Driver :1.0

CPLD :1.0

Displaying software and hardware version information of the UTM device

Use the display version command to display software and hardware version information of the UTM

device.

<Sysname> display version

HP Comware Platform Software

Comware Software, Version 5.20, Release 5116P18

Copyright (c) 2010-2011 Hewlett-Packard Development Company, L.P.

HP A-U200-S uptime is 0 week, 0 day, 0 hour, 15 minutes

512M bytes DDR2 SDRAM Memory

32M bytes Flash Memory

247M bytes CF0 Card

PCB Version:Ver.B

Logic Version: 2.0

Basic BootWare Version: 1.01

Extend BootWare Version: 29.29

[FIXED PORT] CON (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[FIXED PORT] GE0/0 (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[FIXED PORT] GE0/1 (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[FIXED PORT] GE0/2 (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[FIXED PORT] GE0/3 (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[FIXED PORT] GE0/4 (Hardware)Ver.B, (Driver)1.0, (Cpld)2.0

[SUBCARD 1] 2GE (Hardware)Ver.B, (Driver)1.0, (Cpld)1.0

Displaying the electrical label information of the UTM device

Use the display device manuinfo command to display your UTM device’s electrical label information.

<Sysname> display device manuinfo

slot 0

DEVICE_NAME :aaaa

DEVICE_SERIAL_NUMBER:xxxx

MAC_ADDRESS :000F-E287-3DC4

MANUFACTURING_DATE :2011-7-29

34

Page 40

VENDOR_NAME :HP

slot 1

DEVICE_NAME :NONE

DEVICE_SERIAL_NUMBER:NONE

MAC_ADDRESS :NONE

MANUFACTURING_DATE :NONE

VENDOR_NAME :HP

Displaying the CPU usage of the UTM device

Use the display cpu-usage command to display the CPU usage of a UTM device.

<Sysname> display cpu-usage

Unit CPU usage:

1% in last 5 seconds

1% in last 1 minute

1% in last 5 minutes

Displaying the memory usage of the UTM device

Use the display memory command to display the memory usage of a UTM device.

<Sysname> display memory

System Total Memory(bytes): 472887200

Total Used Memory(bytes): 151376488

Used Rate: 32%

Displaying the CF card information

Use the display device cf-card command to display the CF card information.

<Sysname> display device cf-card

Compacted Flash Card Information:

CF ID 1

Status: Normal

Size : 247M bytes

Table 12 Output description

Field Description

CF ID Slot number of the CF card

Operational status of the CF card:

Status

• Absent—No CF card is present in the slot.

• Fault—The CF card fails.

• Normal—The CF card is operating properly.

Size Storage capacity of the CF card

35

Page 41

Displaying the operational status of the fans

Use the display fan command to display the operational status of the fans.

<Sysname> display fan

Fan 1 State: Normal

Table 13 Output description

Field Description

Fan 1 Number of the fan

The fan state:

State

• Normal—The fan is operating properly.

• Absent—The fan is not in position.

• Fault—The fan fails.

Displaying the operational status of a power module

Use the display power command to display the operational status of a power module.

<Sysname> display power

Power Information:

Power 1 Status: Normal

Table 14 Output description

Field Description

Power 1 Number of the power module

The power module state:

Status

• Normal—The power module is operating properly.

• Absent—The power module is not in position.

• Fault—The power module fails.

Displaying the temperature information of the UTM device

Use the display environment command to display the temperature information of the UTM device.

<Sysname> display environment

System Temperature information (degree centigrade):

--------------------------------------------------- SlotNo Temperature Lower limit Upper limit

0 36 0 50

Field Description

System Temperature information (degree centigrade) System temperature (°C)

36

Page 42

Field Description

SlotNO Number of the slot holding the interface module

Temperature Current temperature

Lower limit Lower threshold

Upper limit Upper threshold

Displaying operational statistics of the UTM device

When you perform routine maintenance or the system fails, you may need to display the operational

information of each functional module for locating failures. Generally, you need to run the display

commands one by one. To collect more information one time, you can execute the display

diagnostic-information command in any view to display or save the operational statistics of multiple

functional modules of the UTM device. This command displays the output of the display clock, display

version, display device, display current-configuration commands,and so on.

• Save the operational statistics of each functional module of the UTM device.

<Sysname> display diagnostic-information

Save or display diagnostic information (Y=save, N=display)? [Y/N]:y

Please input the file name(*.diag)[cfa0:/default.diag]:aa.diag

Diagnostic information is outputting to cfa0:/aa.diag.

Please wait...

Save succeeded.

Execute the more aa.diag command in user view, and then press the Page Up and Page Down keys to

view the contents of the file aa.diag.

• Display the operational statistics of each functional module of the UTM device.

<Sysname> display diagnostic-information

Save or display diagnostic information (Y=save, N=display)? [Y/N]:n

=================================================

===============display clock===============

=================================================

08:54:16 UTC Fri 11/12/2010

===================================================

===============display version===============

===================================================

Omitted

Saving the running configuration of the UTM device

You can save the running configuration of the UTM device in one of the following modes:

• Fast saving: Executing the save command without the safely keyword. This mode saves th e file more

quickly but is likely to lose the existing configuration file if the device reboots or the power fails

during the process. The fast saving mode is suitable for environments where the power supply is

stable.

• Safe saving: Executing the save command with the safely keyword. The mode saves the file more

slowly but can retain the configuration file in the device even if the device reboots or the power fails

37

Page 43

g

r

NOTE:

during the process. The safe saving mode is preferred in environments where a stable power supply

is unavailable or remote maintenance is involved.

Follow these steps to save the current configuration of the UTM device:

To do… Use the command… Remarks

Save the current configuration to the specified

file, but the configuration file will not be set as

the file for the next startup

Save the current configuration to the root

directory of the storage medium and specify

the file as the startup configuration file that will

be used at the next system startup

save file-url

Use either command

Available in any view

save [ safely ]

• The configuration file must be with extension .cfg.

• During the execution of the save

command, the startup configuration file to be used at the next system

startup may be lost if the device reboots or the power supply fails. In this case, the device will boot with

the factory defaults, and after the device reboots, you need to re-specify a startup confi

the next system startup.

Rebooting the UTM device

To reboot a UTM device, use one of the following methods:

• Use the reboot command to reboot a UTM device.

• Enable the scheduled reboot function at the CLI. You can set a time at which the UTM device can

automatically reboot, or set a delay so that the UTM device can automatically reboot within the

delay.

• Power on the UTM device after powering it off, which is also called hard reboot or cold start.

Powering off a running UTM device causes data loss and hardware damages, and therefore is not

recommended.

Perform the following operation to reboot the UTM device immediately:

To do… Use the command… Remarks

Reboot the UTM device immediately reboot

uration file fo

Required

Available in user view

Perform the following operation to enable the scheduled reboot function:

To do… Use the command… Remarks

Enable the scheduled reboot function

and specify a specific reboot time

and date

Enable the scheduled reboot function

and specify a reboot waiting time

schedule reboot at hh:mm

[ date ]

schedule reboot delay

{ hh:mm | mm }

38

Use either command

The scheduled reboot function is

disabled by default.

Available in user view

Page 44

CAUTION:

• If the main host software file is not specified, do not use the reboot command to reboot the UTM device.

In this case, you should specify the main host software file first, and then reboot the UTM device.

• The precision of the rebooting timer is 1 minute. One minute before the rebooting time, the device

prompts “REBOOT IN ONE MINUTE” and reboots in one minute.

• If you are performing file operations when the device is to be rebooted, the system does not execute the

reboot command for security.

39

Page 45

Replacement procedures

This chapter includes these sections:

• Safety recommendations

• Replacing an interface module

• Replacing a CF card

• Replacing a transceiver module

Safety recommendations

1. Always wear an ESD-preventive wrist strap or ESD-preventive gloves when maintaining the UTM

device hardware.

2. When operating a pluggable module, such as a CF card or interface module, note the following

guidelines:

• Ensure good alignment with the slot to avoid damage to the module during installation or removal.

• Before removing a module, make sure that the captive screws are completely loosened. Otherwise,

the panel of the module may be deformed.

• Avoid touching any components on the PCB of a module when observing or moving the module.

• Put a removed module on an antistatic workbench with the PCB side up or place it in an antistatic

bag.

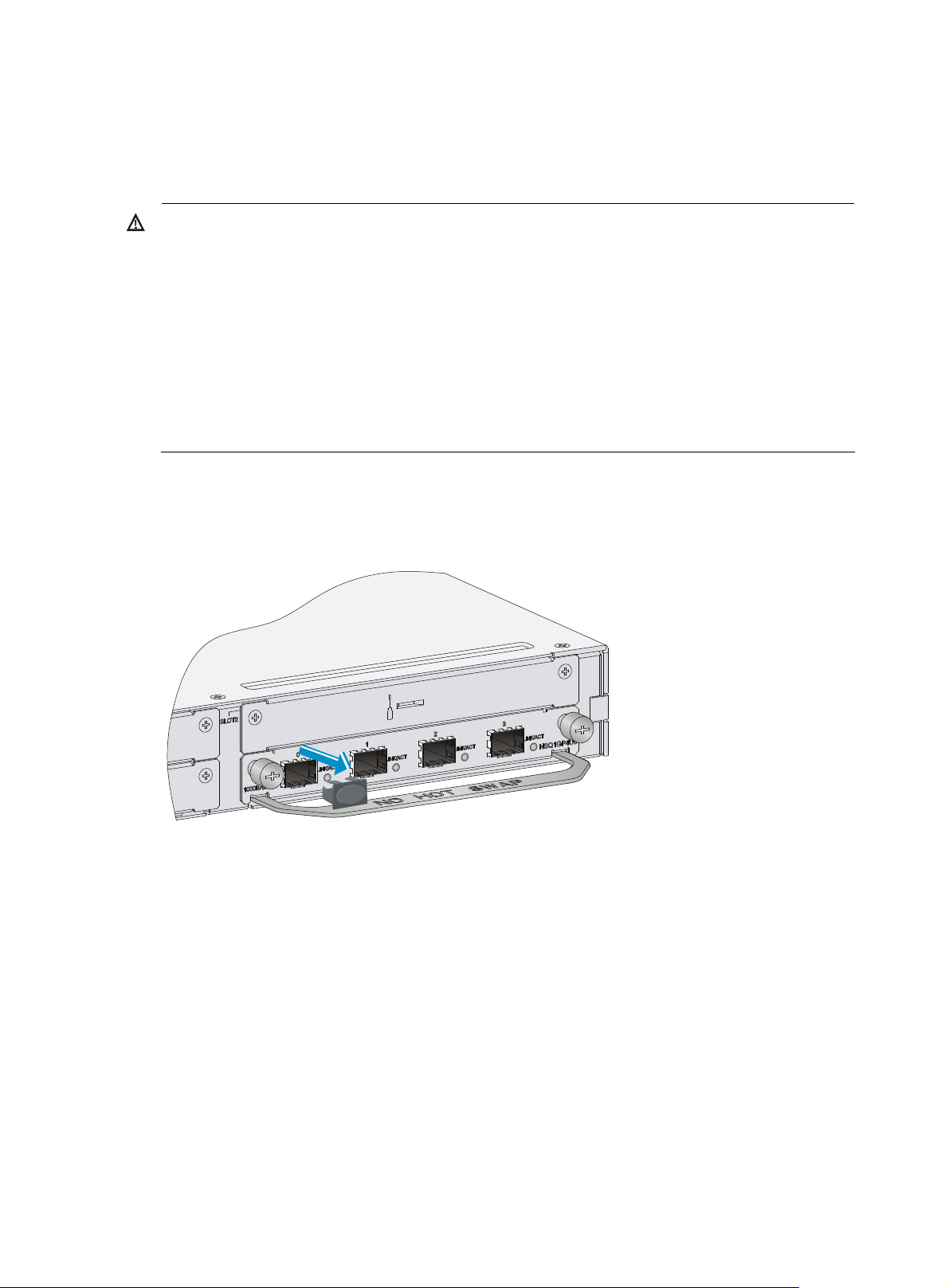

Replacing an interface module

The replacement procedures of 2GE, NSQ1GT2UA0, and NSQ1GP4U0 interface modules are the

same. This section takes an NSQ1GP4U0 interafce module for example. Follow these steps to replace an

interface module:

Step1 Use a screwdriver to loosen the captive screws of the interface module to be removed.

Step2 Holding the interface module handle, slowly pull the interface module out of the slot along the guide

rails.

40

Page 46

g

Figure 31 Remove an interface module

Step3 If you do not install a new interface module in the slot, install the filler panel. To install an interface

module, see the chapter “Installing the UTM device.”

Replacing a CF card

CAUTION:

• To avoid hardware damage, do not remove the CF card when the UTM device is bootin

LED is blinking.

• To protect the CF card, place it into an antistatic bag.

Follow these steps to replace a CF card:

Step1 Make sure that the CF card LED is not blinking.

Step2 Press the CF card eject button so that the eject button projects from the panel.

Figure 32 Press the eject button

or the CF card

Step3 Press the eject button again to eject the CF card part way out of the slot, and then pull the CF card out

of the slot.

41

Page 47

g

Figure 33 Press the eject button to eject the CF card

Step4 Install a new CF card. For more information, see the chapter “Installing the UTM device.”

Replacing a transceiver module

NOTE:

When replacin

a transceiver module, make sure that the two transceiver modules connected by the same

optical fiber have the same wavelength.

WARNING!

• Do not stare into the optical fibers.

• When removing a transceiver module, do not touch the golden finger of the transceiver module.

Follow these steps to replace a transceiver module:

Step1 Remove the optical fibers from the transceiver module.

Step2 Pivot the clasp downward to the horizontal position.

Step3 As shown in Figure 34, holding the handle of the transceiver module, gently pull the transceiver module

out.

Figure 34 Remove a transceiver module

42

Page 48

Step4 Insert the dust cap to the removed transceiver module, and put the module into its original shipping

materials.

Step5 Install a new transceiver module. For more information, see the chapter “Installing the UTM device.”

43

Page 49

Troubleshooting

This chapter includes these sections:

• Power supply system failure

• Fan failure

• Configuration terminal problems

• Password loss

• Cooling system failure

• Interface module failure

NOTE:

• The barcode stuck on the UTM device chassis contains production and servicing information. Before you

return a faulty UTM device for serving, provide the barcode information of the UTM device to your local

sales agent.

• Keep the tamper-proof seal on a mounting screw on the chassis cover intact, and if you want to open the

chassis, contact the local agent of HP for permission. Otherwise, HP shall not be liable for any

consequence caused thereby.

Power supply system failure

The UTM device cannot be powered on. The power LED on the front panel is off.

Follow these steps to troubleshoot the power supply system:

Step1 Turn off the power switch.

Step2 Check whether the power cord is properly, firmly connected.

Step3 Check whether the power cord is damaged.

If the cause cannot be located in the steps above and the problem persists, contact your local sales

agent.

Fan failure

After the UTM device is booted, the following information appears:

%Jun 22 16:11:37:485 2010 HP DEV/4/FAN FAILED:

Fan 1 failed.

If such information appears, you need to open the chassis to check the fan. Contact your local sales

agent.

44

Page 50

Configuration terminal problems

If the configuration environment setup is correct, the configuration terminal displays boot information

when the UTM device is powered on. If the setup is incorrect, the configuration terminal displays nothing

or garbled text.

No terminal display

If the configuration terminal displays nothing when the UTM device is powered on, check the following

items:

• The power supply system works properly.

• The console cable is properly connected.

If no problem is found, the following reasons may apply:

• The console cable is connected to an incorrect serial interface (the serial interface in use is not the

one set on the terminal).

• The properties of the terminal are incorrect. You must configure the configuration terminal as follows:

set Bits per second to 9600, Data bits to 8, Parity to None, Stop bits to 1, Flow control to None, and

Terminal Emulation to VT100.

• The console cable is not in good condition.

Garbled terminal display

If terminal display is garbled, check that the Data bits field is set to 8 for the configuration terminal.

Password loss

User password loss

If you lose your password, you cannot enter the system. In this case, you can boot the system by ignoring

the system configuration. Follow these steps to solve the user password loss:

Step1 Enter the BootWare main menu, and select 6 to boot the system by ignoring the system configuration.

The system prompts the following:

Flag Set Success.

The output indicates that the setting succeeded.

Step2 When the BootWare main menu appears again, select 0 to reboot the system.

System is starting...

Booting Normal Extend BootWare.

Step3 Set a new password in system view after the system reboots.

<Sysname> system-view

[Sysname] user-interface console 0

[Sysname-ui-console0] authentication-mode password

[Sysname-ui-console0] set authentication password simple 123456

The output shows that the console port uses password authentication, and the password is set to 123456

and stored in plain text.

45

Page 51

When you set the password by using the set authentication password { cipher | simple } password

command, follow these guidelines.

• If the cipher keyword is specified, the password is stored in cipher text. You cannot view the

password by using the display current-configuration command.

• If the simple keyword is specified, the password is stored in plain text. You can use the display

current-configuration command to view the password in the current configuration.

NOTE:

After the UTM device reboots, the system runs with the initial default configuration, but the previous

configuration file is still stored in the storage medium. To restore the previous configuration, use the

display saved-configuration command to display the configuration, and then copy and execute the

configuration.

Step4 Save the new password.

[Sysname] save

NOTE:

• To save the new password, execute the save command after modifying the user password.

• HP recommends saving the modification as the default configuration file.

Super password loss

You can clear the super password by selecting 8 on the BootWare main menu.

========================<EXTEND-BOOTWARE MENU>========================

|<1> Boot System |

|<2> Enter Serial SubMenu |

|<3> Enter Ethernet SubMenu |

|<4> File Control |

|<5> Modify BootWare Password |

|<6> Skip Current System Configuration |

|<7> BootWare Operation Menu |

|<8> Clear Super Password |

|<9> Storage Device Operation |

|<0> Reboot |

======================================================================

Enter your choice(0-9):8

The following output indicates that you have successfully cleared the super password.

Clear Application Password Success!

NOTE:

• Select option 8, quit the menu, reboot the UTM device, and then you can enter system view directly.

• This setting (password clearing) is valid only for the first reboot of the UTM device. The super password

will be restored after a second reboot.

46

Page 52

Cooling system failure

When the temperature inside the UTM device exceeds 45°C (113°F), the cooling system may have failed.

Follow these steps to troubleshoot the cooling system:

Step1 Check whether the fans are running properly.

Step2 Check whether the working environment of the UTM device is well ventilated.

Step3 If the temperature inside the UTM device exceeds 60°C (140°F), the following information appears on

the configuration terminal:

%Jun 28 10:27:27:653 2010 HP DRVMSG/3/Temp2High: Temperature Point 0/0 Too High.

#Jun 28 10:27:28:432 2010 HP DEV/1/BOARD TEMPERATURE UPPER:

Trap 1.3.6.1.4.1.2011.2.23.1.12.1.16:frameIndex is 0, slotIndex 0.0

%Jun 28 10:27:28:433 2010 HP DEV/4/BOARD TEMP TOOHIGH:

Board temperature is too high on Chassis 0 Slot 0, type is RPU.

Step4 Use the display environment command to check whether the temperature in the UTM device keeps rising.

If the temperature inside the UTM device exceeds 90°C (194°F), power off the UTM device immediately

and contact your local sales agent.

Interface module failure

After an interface module is installed and the UTM device is powered on, the LEDs on the interface

module panel indicate abnormal operation.

Follow these steps to solve this problem:

Step1 Check whether the interface module cable is correctly selected.

Step2 Check whether the interface module cable is correctly connected.

Step3 Use the display interface command to check whether the interface has been correctly configured and is

working properly.

47

Page 53

Appendix A Technical specifications

Dimensions and weight

Table 15 Dimensions and weight

Item Specification

Dimensions (H × W × D),

excluding feet and

mounting brackets

Weight (fully configured)

Storages

Table 16 Storages

Item Specification

Flash 32 MB

Memory type and capacity

Compact flash (CF) card

USB interface Host mode, reserved without software support

A-U200-A: 44.2 × 442 × 400 mm (1.74 × 17.40 × 15.75 in.)

A-U200-S: 43.6 × 300 × 260 mm (1.72 × 11.81 × 10.24 in.)

A-U200-A: 5.9 kg (13.01 lb)

A-U200-S: 2.22 kg (4.89 lb)

A-U200-A: DDR2 SDRAM, 1GB (default)

A-U200-S: DDR2 SDRAM, 512 MB (default)

256 MB by default for the built-in CF card; 256 MB, 512 MB, or 1 GB for an

optional external CF card

Power consumption range

Table 17 Power consumption range of the entire system

Item Specification

Power consumption range

Power consumption range

Table 18 Power consumption range of the entire system

Item Specification

Rated voltage range 100 VAC to 240 VAC; 50 Hz or 60 Hz

48

A-U200-A: 30 W to 46 W

A-U200-S: 20 W to 27 W

Page 54

Item Specification

Maximum input current

Maximum power

A-U200-A: 1.6A

A-U200-S: 1.5A

A-U200-A: 100W

A-U200-S: 54W

Fixed Ethernet ports specifications

Table 19 Fixed Ethernet ports specifications

Item Specifications

Quantity

Connector type RJ-45

Interface type

Frame format

A-U200-A: 6 (GE0 through GE5)

A-U200-S: 5 (GE0 through GE4)

Autosensing (Ethernet does not support MDI/MDIX autosensing when

working in the forced mode)

Ethernet_II

Ethernet_SNAP

10 Mbps (autosensing) Half-/full-duplex auto-negotiation

Rate and negotiation mode

NOTE:

The media dependent interface (MDI) standard is typically used for the Ethernet interfaces of network

adaptors. The media dependent interface crossover (MDI-X) standard is typically used on hubs or LAN

switches.

Console port

Table 20 Technical specifications for the console port

Item Specification

Connector RJ-45

Compliant standard RS-232

Baud rate

Transmission distance 15 m (49.21 ft)

Services

100 Mbps (autosensing) Half-/full-duplex auto-negotiation

1000 Mbps (autosensing) Full-duplex auto-negotiation

9600 bps to 115200 bps

9600 bps (default)

• Provides connection to an ASCII terminal

• Provides connection to the serial port of a local PC to run the terminal emulation

program

• Command line interface (CLI)

49

Page 55

Appendix B LEDs

LEDs

Figure 35 A-U200-A LEDs

56