Page 1

HP 2000i G2 Modular Smart Array

User Guide

Part number: 481598-005

First edition: January 2013

Page 2

Legal and notice information

© Copyright 2009, 2013 Hewlett-Packard Development Company, L.P.

The information combined herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, Windows NT, and Windows XP are U.S. registered trademarks of Microsoft Corporation.

UNIX® is a registered trademark of The Open Group.

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty.

Page 3

Contents

About this guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document conventions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rack stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HP technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Customer self repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Subscription service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HP web sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Documentation feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Features and benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2312i G2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2324i G2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Disk drive bay numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Rear panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2312i G2 and 2324i G2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MSA2000 3.5" 12-drive enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MSA70 2.5” 25-drive enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transportable CompactFlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Super-capacitor pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Installing the enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting controller and drive enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting controller and MSA2000 3.5" 12-drive enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting controller and MSA70 2.5” 25-drive enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting controller and mixed-connect 3.5” and 2.5” drive enclosures. . . . . . . . . . . . . . . . . . . . . . 22

Additional cable requirements for drive enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2312i G2 and 2324i G2 cable requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Testing enclosure connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Obtaining IP values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting management port IP addresses using DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting management port IP addresses using the CLI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Connecting hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Host system requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting the enclosure to data hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

iSCSI host ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting direct attach configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Single controller configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

One server/one HBA/single path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dual controller configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

One server/one HBA/dual path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Two servers/one HBA per server/dual path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting remote management hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

HP 2000i G2 Modular Smart Array User Guide 3

Page 4

5 Basic operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Powering on/powering off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Updating firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Selecting an appropriate time to perform the online upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 LED descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Front panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Disk drive LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rear panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2312i G2 and 2324i G2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MSA2000 3.5" 12-drive enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MSA70 2.5” 25-drive enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7 Configuring a system for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configuring your web browser for SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Signing in to SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tips for using the main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tips for using the help window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Changing the system date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

To use manual date and time settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

To obtain the date and time from an NTP server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Using the Configuration Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Using the Provisioning Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Testing the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Signing out of SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fault isolation methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Gather fault information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Determine where the fault is occurring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Review the event logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Isolate the fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

If the enclosure does not initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Correcting enclosure IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Diagnostic steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Is the front panel Fault LED amber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Is the controller back panel OK LED off? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Is the controller back panel Fault/Service Required LED amber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Are both drive module LEDs off (Online/Activity and Fault/UID)? . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Is the drive module Fault/UID LED blinking amber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Is a connected host port’s Host Link Status LED off? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Is a connected port’s Expansion Port Status LED off?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Is a connected port’s Network port link status LED off? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Is the power supply’s AC Power Good LED off? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Is the drive enclosure back panel OK LED off?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Is the drive enclosure Fault/Service Required LED amber?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Controller failure in a single-controller configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

If the controller has failed or does not start, is the Cache Status LED on/blinking? . . . . . . . . . . . . . . . . 52

Transporting Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Isolating a host-side connection fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Isolating a controller module expansion port connection fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Resolving voltage and temperature warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Sensor locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Power supply sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cooling fan sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Power supply module voltage sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4

Page 5

A Environmental requirements and specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Safety requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Site requirements and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Site wiring and AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Site wiring and DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Weight and placement guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electrical guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Ventilation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cabling requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Management host requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Physical requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Electrical requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Site wiring and power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Power cord requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

B Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Preventing electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Grounding methods to prevent electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C Regulatory compliance and safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Regulatory compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Federal Communications Commission notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Class A equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Class B equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Declaration of conformity for products marked with the FCC logo, United States only. . . . . . . . . . . . . . 63

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Regulatory compliance identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Regulatory compliance label location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Laser device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Laser safety warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Certification and classification information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Laser product label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

International notices and statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Canadian notice (avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Class A equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Class B equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

European Union notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

BSMI notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Japanese notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Korean notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Battery replacement notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Taiwan battery recycling notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Japanese power cord notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Preventing electrostatic damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Grounding methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

HP 2000i G2 Modular Smart Array User Guide 5

Page 6

6

Page 7

Figures

1 Cabling connections between a single-controller enclosure and one MSA2000 3.5" 12-drive enclosure 23

2 Cabling connections between a dual-controller enclosure and one MSA2000 3.5" 12-drive enclosure. 23

3

Cabling connections between a dual-controller enclosure and three MSA2000 3.5" 12-drive enclosures

4 Cabling connections between a dual-controller enclosure and one MSA70 drive enclosure. . . . . . . . . 24

5 Cabling connections between a dual-controller enclosure and three MSA70 drive enclosures . . . . . . . 25

6 Cabling connections between a dual-controller enclosure and mixed drive enclosures. . . . . . . . . . . . . 26

. 24

HP 2000i G2 Modular Smart Array User Guide 7

Page 8

8

Page 9

Tables

1 Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 SAS cable requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Terminal emulator display settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Terminal emulator connection settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Disk drive LED combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Power supply sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Cooling fan sensor descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9 Controller module temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Power supply temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11 Voltage sensor descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

12 Rackmount enclosure dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

13 Rackmount enclosure weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

14 Operating environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

HP 2000i G2 Modular Smart Array User Guide 9

Page 10

10

Page 11

About this guide

This guide provides information about the HP StorageWorks 2312i G2 Modular Smart Array and 2324i

G2 Modular Smart Array.

Product branding initially included the term StorageWorks, which is no longer used. Although the term is

removed from the title and footers in this version of the document, references to related documents, media,

and user interfaces use the term.

Intended audience

This guide is intended for use by system administrators and technicians who are experienced with the

following:

• Storage area network (SAN) management and direct attach storage (DAS)

• Network administration

• Network installation

• Storage system installation and configuration

Prerequisites

Prerequisites for installing and configuring this product include familiarity with:

• Servers and computer networks

• Internet SCSI (iSCSI) and Ethernet protocols

Related documentation

In addition to this guide, please refer to other documents for this product:

• HP StorageWorks MSA2000 G2 Installation Instructions

• HP StorageWorks 2000 G2 Modular Smart Array Cable Configuration Guide

• HP StorageWorks 2000 G2 Modular Smart Array Reference Guide

• HP StorageWorks 2000 G2 Modular Smart Array CLI Reference Guide

• Online help for HP StorageWorks Storage Management Utility (SMU) and Command Line Interface

(CLI)

These and other HP documents can be found on the HP documents web site:

http://www.hp.com/support/

HP 2000i G2 Modular Smart Array User Guide 11

Page 12

Document conventions and symbols

Table 1 Document conventions

Convention Element

Medium blue text: Figure 1 Cross-reference links and e-mail addresses

Medium blue, underlined text

(http://www.hp.com)

Bold font • Key names

Italics font Text emphasis

Monospace font • File and directory names

Monospace, italic font

Monospace, bold font Emphasis of file and directory names, system output, code, and text

Web site addresses

• Text typed into a GUI element, such as into a box

• GUI elements that are clicked or selected, such as menu and list

items, buttons, and check boxes

• System output

• Code

• Text typed at the command-line

• Code variables

• Command-line variables

typed at the command line

WARNING! Indicates that failure to follow directions could result in bodily harm or death.

CAUTION: Indicates that failure to follow directions could result in damage to equipment or data.

IMPORTANT: Provides clarifying information or specific instructions.

NOTE: Provides additional information.

TIP: Provides helpful hints and shortcuts.

12

Page 13

Rack stability

WARNING! To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, secure racks together.

• Extend only one rack component at a time. Racks may become unstable if more than one component is

extended.

HP technical support

Telephone numbers for worldwide technical support are listed on the HP support web site:

http://www.hp.com/support/

Collect the following information before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

• Detailed, specific questions

.

For continuous quality improvement, calls may be recorded or monitored.

Customer self repair

HP customer self repair (CSR) programs allow you to repair your StorageWorks product. If a CSR part

needs replacing, HP ships the part directly to you so that you can install it at your convenience. Some parts

do not qualify for CSR. Your HP-authorized service provider will determine whether a repair can be

accomplished by CSR.

For more information about CSR, contact your local service provider. For North America, see the CSR

website:

http://www.hp.com/go/selfrepair

Product warranties

For information about HP StorageWorks product warranties, see the warranty information website:

http://www.hp.com/go/storagewarranty

Subscription service

HP strongly recommends that customers sign up online using the Subscriber's choice web site:

http://www.hp.com/go/e-updates

• Subscribing to this service provides you with e-mail updates on the latest product enhancements, newest

versions of drivers, and firmware documentation updates as well as instant access to numerous other

product resources.

• After signing up, you can quickly locate your products by selecting Business support and then Storage

under Product Category.

.

HP web sites

For other product information, see the following HP web sites:

• http://www.hp.com

HP 2000i G2 Modular Smart Array User Guide 13

Page 14

• http://www.hp.com/go/msa

• http://www.hp.com/service_locator

• http://www.hp.com/go/storage

• http://www.hp.com/support/

• http://www.docs.hp.com

Documentation feedback

HP welcomes your feedback.

To make comments and suggestions about product documentation, please send a message to

storagedocs.feedback@hp.com. All submissions become the property of HP.

14

Page 15

1Overview

The 2312i G2 Modular Smart Array and 2324i G2 Modular Smart Array are high-performance storage

solutions that combine outstanding performance with high reliability, availability, flexibility, and

manageability.

Features and benefits

Product features and supported options are subject to change. Therefore, web site postings document

product and product family characteristics, including currently supported features, options, technical

specifications, configuration data, related optional software, and product warranty information.

IMPORTANT: This product contains one or more features which allow remote connection to HP or HP’s

authorized representatives for the benefit of the customer (such as troubleshooting). This feature is enabled

by default. Your use of this product indicates your acceptance of this feature. This feature cannot be

disabled.

NOTE: Check the QuickSpecs for a complete list of supported servers, operating systems, disk drives, and

options. QuickSpecs can be found from your HP MSA products page at http://www.hp.com/go/msa

Select MSA SAN Arrays, and then select your product. The link for QuickSpecs will be on the right.

.

HP 2000i G2 Modular Smart Array User Guide 15

Page 16

16 Overview

Page 17

2Components

MSA2000

132

4

5

6

MSA2000

132

4

5

6

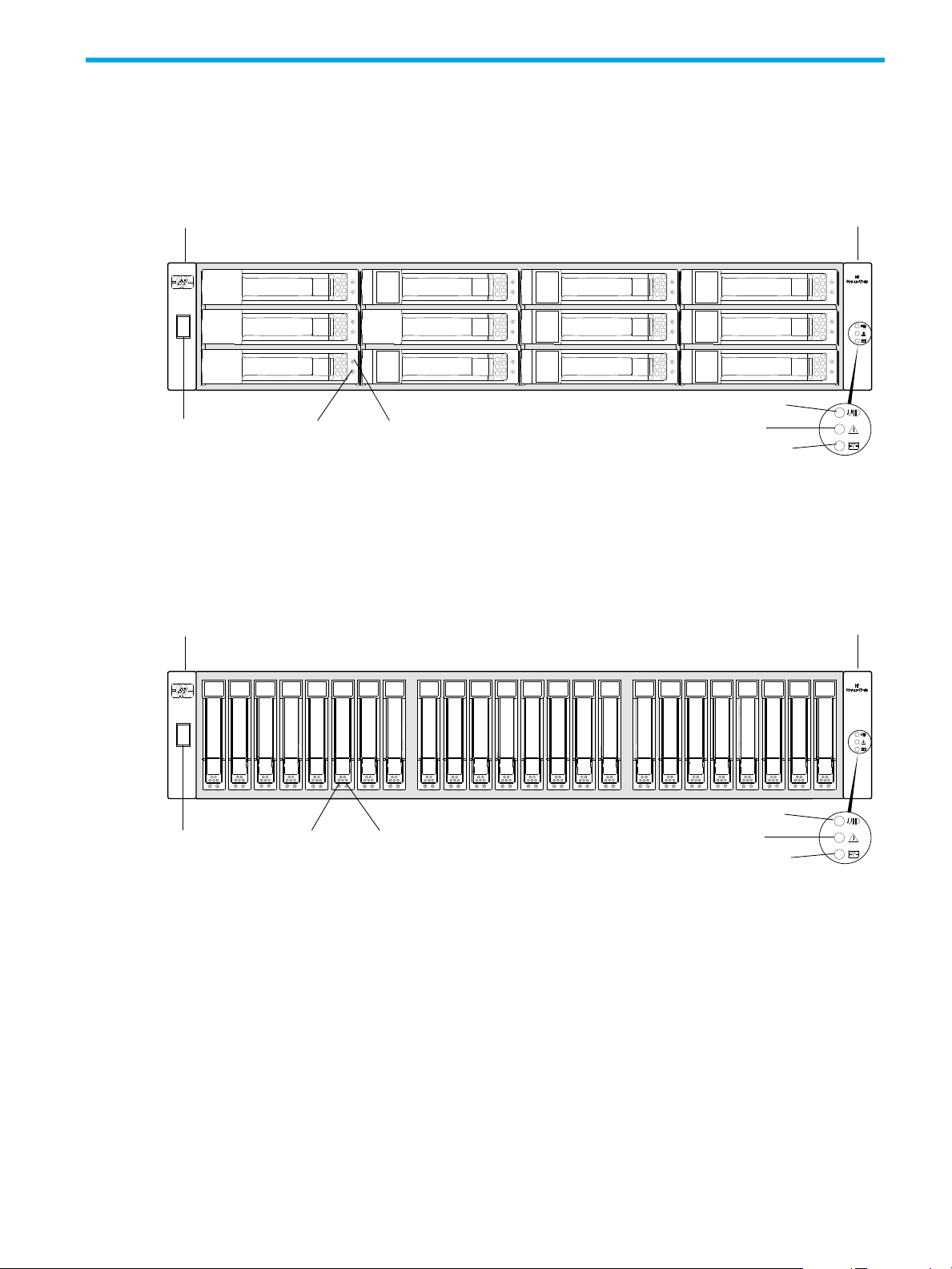

Front panel components

2312i G2

Left ear

1 Enclosure ID LED

2 Disk drive Online/Activity LED

3 Disk drive Fault/UID LED

2324i G2

Left ear

Right ear

4 Unit Identification (UID) LED

5 Fault ID LED

6 Heartbeat LED

Right ear

1 Enclosure ID LED

2 Disk drive Online/Activity LED

3 Disk drive Fault/UID LED

4 Unit Identification (UID) LED

5 Fault ID LED

6 Heartbeat LED

HP 2000i G2 Modular Smart Array User Guide 17

Page 18

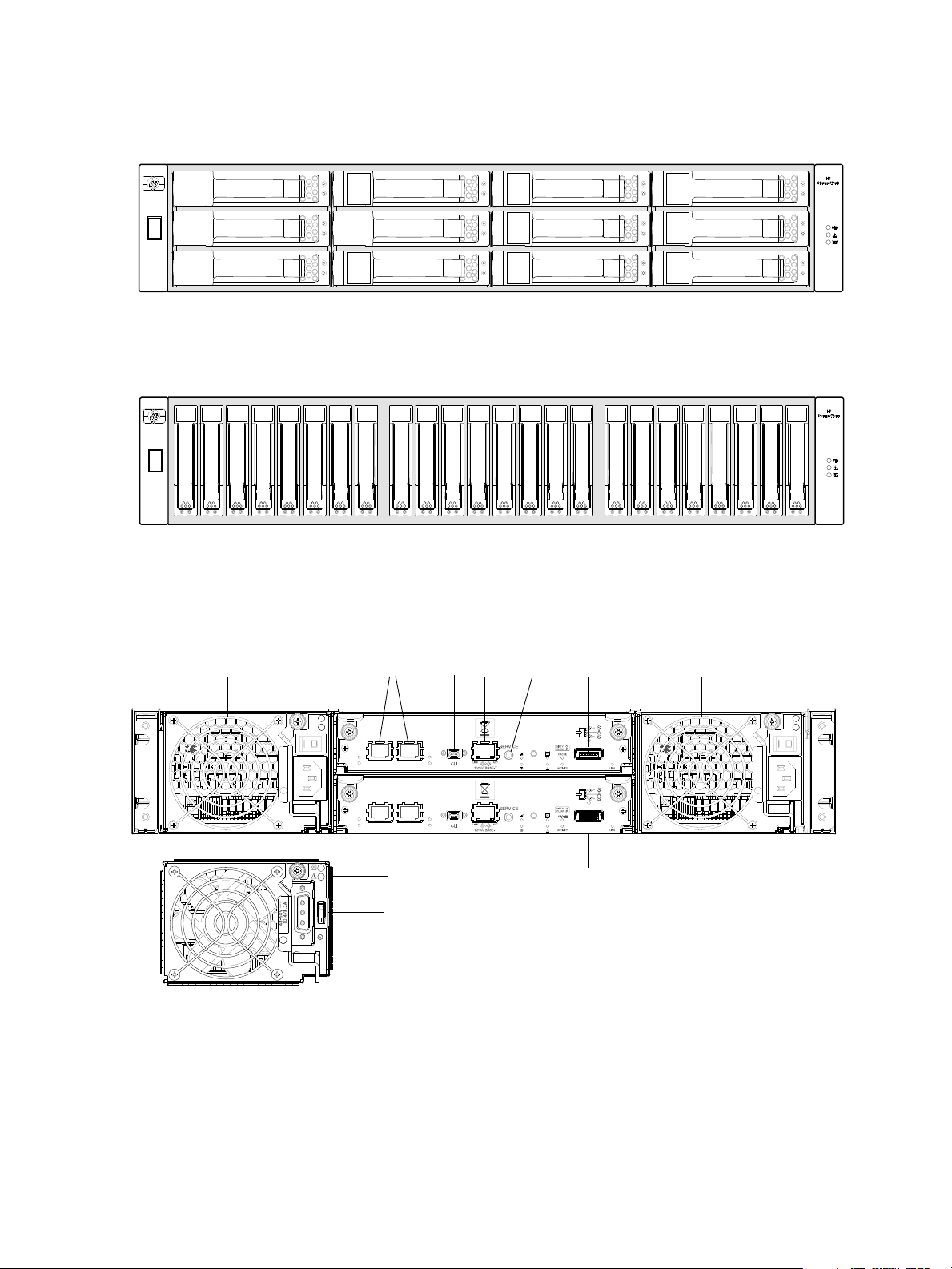

Disk drive bay numbers

MSA2000

1

2

3

4

5

6

7

8

9

10

11

12

MSA2000

1 2 3 4 5 6 7 8 9 10111213141516 1718192021222324

iSCSI 1

LINK

ACT

LINK

ACT

iSCSI 2

iSCSI 1

LINK

ACT

iSCSI 2

LINK

ACT

1234567

9

8

-

12

2312i G2

2324i G2

Rear panel components

2312i G2 and 2324i G2

1 AC Power supplies

2 AC Power switches

3 Host ports

4 CLI port

5 Network port

18 Components

6 Service port (used by service personnel only)

7 Expansion port

8 Optional iSCSI controller

9 DC Power supply (2) — (DC model only)

10 DC Power switch

Page 19

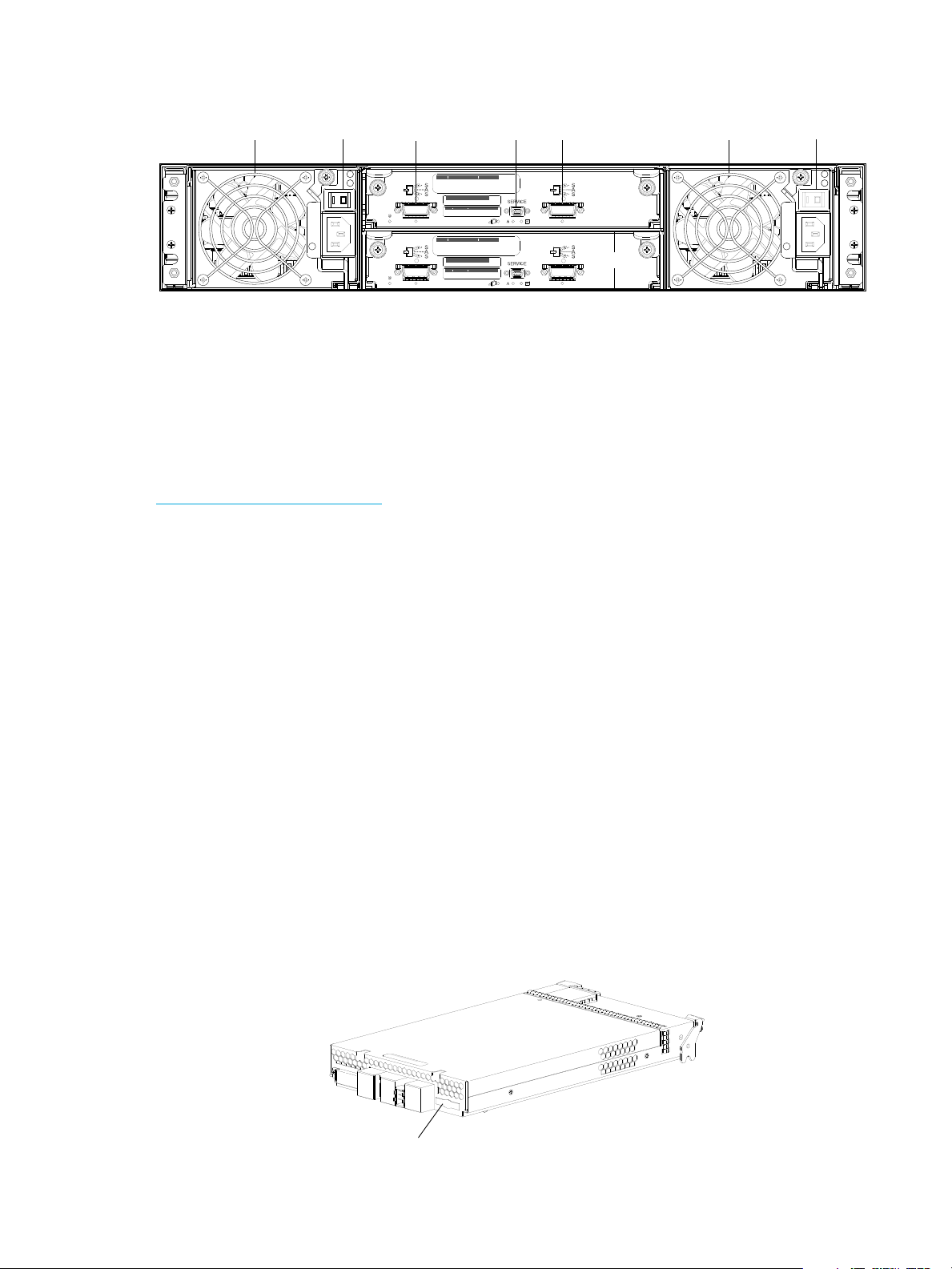

MSA2000 3.5" 12-drive enclosure

00

13452

6

12

CompactFlash

Controller Module

1 Power supplies

2 Power switches

3 SAS In port (connects to a controller enclosure)

MSA70 2.5” 25-drive enclosure

The 2324i G2 can also be attached to an MSA70 that is running firmware version 2.18 or later. For

information about the MSA70, see the HP StorageWorks 70 Modular Smart Array Enclosure user guide

located on the MSA2000 Software Support/Documentation CD shipped with your product or at

http://hp.com/support/manuals

.

Cache

To enable faster data access from disk storage, the following two types of caching are performed:

• Posted-write caching. The controller writes user data in the cache memory on the module rather than

directly to the drives. Later, when the storage system is either idle or aging — and continuing to receive

new I/O data — the controller writes the data to the drive array.

• Read-ahead caching. The controller detects sequential array access, reads ahead into the next

sequence of data, and stores the data in the read-ahead cache. Then, if the next read access is for

cached data, the controller immediately loads the data into the system memory, avoiding the latency of

a disk access.

Transportable CompactFlash

During a power loss or array controller failure, data stored in cache are saved off to non-volatile memory

(CompactFlash). These data are then written to disk after the issue is corrected. To protect against writing

incomplete data to disk, the image stored on the CompactFlash is verified before committing to disk.

4 Service port (used by service personnel only)

5 SAS Out port (connects to another drive enclosure)

6 Optional I/O module

In single-controller configurations, if the controller has failed or does not start, and the Cache Status LED is

on or blinking, the CompactFlash will need to be transported to a replacement controller to recover data

not flushed to disk. (See Controller failure in a single-controller configuration on page 52 for more

information.)

HP 2000i G2 Modular Smart Array User Guide 19

Page 20

CAUTION: To preserve the existing data stored in the CompactFlash, you must transport the

CompactfFlash from the failed controller to the replacement controller using a procedure outlined in the HP

StorageWorks 2312i/2324i G2 controller replacement instructions, shipped with the replacement

controller. Failure to use this procedure will result in the loss of data stored in the cache module. The

CompactFlash must stay with the same enclosure. If the CompactFlash is used/installed in a different

enclosure, data loss/data corruption will occur.

IMPORTANT: In dual controller configurations, there is no need to transport a failed controller’s cache to

a replacement controller because the cache is duplicated between the controllers.

Super-capacitor pack

To protect RAID controller cache in case of power failure, the 2312i G2 and 2324i G2 are equipped with

super-capacitor technology, in conjunction with CompactFlash memory, built into each controller module to

provide unlimited cache memory backup time. The super-capacitor pack and CompactFlash memory in

each controller module provide unlimited cache memory backup time. The super-capacitor pack provides

energy for backing up unwritten data in the write cache to the CompactFlash in the event of a power

failure. Unwritten data in CompactFlash memory is automatically committed to disk media when power is

restored. While the cache is being maintained by the super-capacitor, the Cache Status LED flashes at a

rate of 1/10 second on and 9/10 second off.

20 Components

Page 21

3Installing the enclosures

Installation checklist

The following table outlines the steps required to install the enclosures and initially configure the system. To

ensure a successful installation, perform the tasks in the order they are presented.

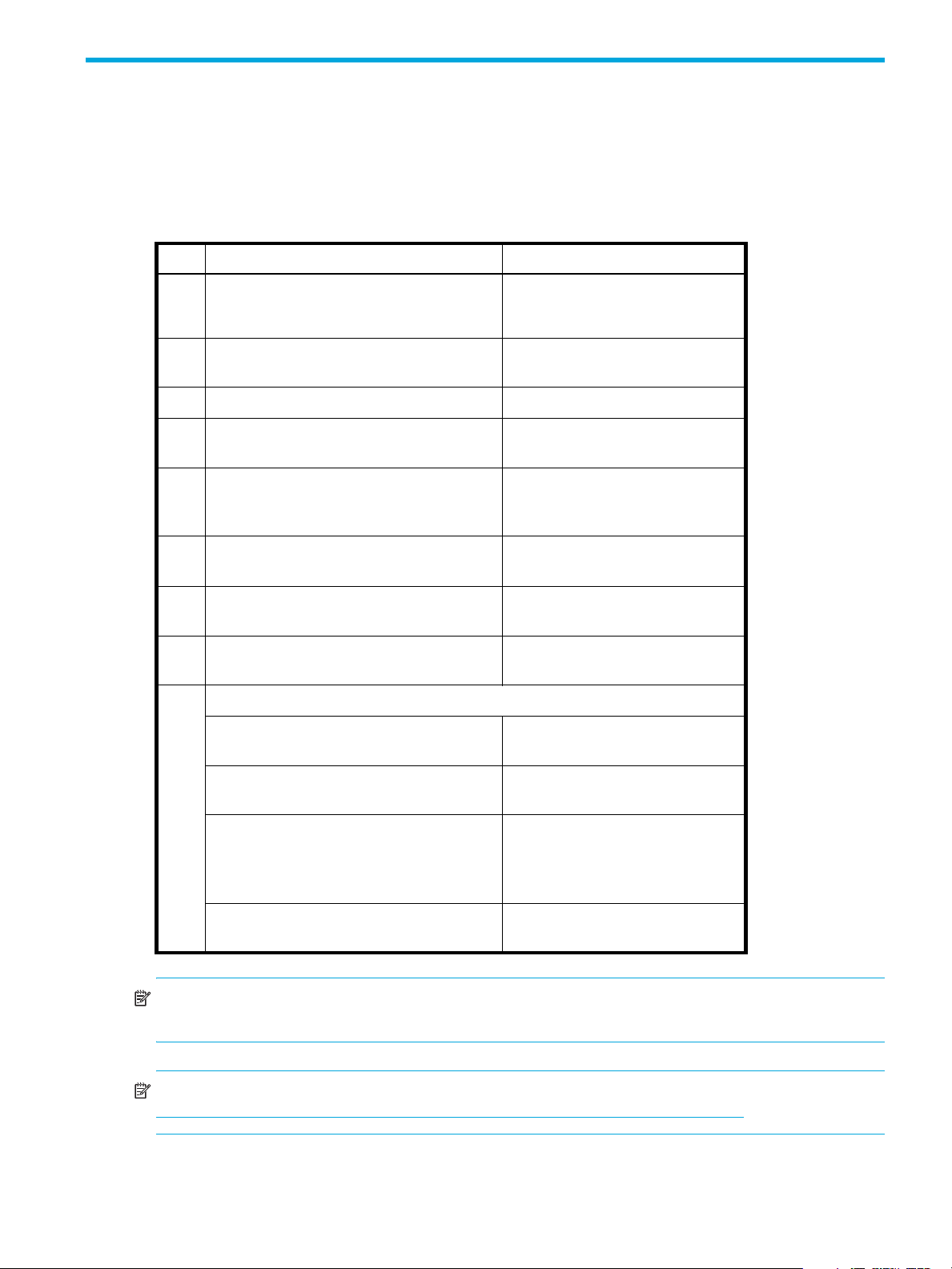

Table 2 Installation checklist

Step

1.

2. Connect controller enclosure and LFF/SFF

3. Connect power cords. See the installation poster.

4. Test enclosure connections. See Testing enclosure

5. Obtain IP values and set management

6. Install required host software. See Host system requirements on

7. Connect data hosts. See Connecting the enclosure to

8. Connect remote management hosts. See Connecting remote

9. Perform initial configuration tasks:

Task Where to find procedure

Install the controller enclosure and optional

drive enclosures in the rack, and attach ear

caps.

drive enclosures.

port IP properties on the controller

enclosure.

See the racking instructions

poster.

See Connecting controller and

drive enclosures on page 22.

connections on page 26.

See Obtaining IP values on

page 27.

page 31.

data hosts on page 31.

management hosts on page 32.

• Verify that controllers and enclosures

have the latest firmware.

• Set the date and time on the controller

enclosure.

• Initially configure and provision the

system.

• Test the configuration. See Testing the configuration on

NOTE: For help with installing your MSA2000 G2 product, see the HP StorageWorks 2000 Modular

Smart Array Software Support/Documentation CD shipped with your product.

NOTE: For information on NEBS Level-3 compliant carrier-grade enclosures, see

http://www.hp.com/products1/servers/carrier_grade/products/cgblades/enclosure

See Updating firmware on

page 33.

See Changing the system date

and time on page 42.

See Using the Configuration

Wizard on page 44 and Using

the Provisioning Wizard on

page 45.

page 45.

.

HP 2000i G2 Modular Smart Array User Guide 21

Page 22

Connecting controller and drive enclosures

Connecting controller and MSA2000 3.5" 12-drive enclosures

You can connect up to four MSA2000 3.5" 12-drive enclosures to a 2312i G2 and up to three MSA2000

3.5" 12-drive enclosures to a 2324i G2. The cabling diagrams shown in this section show the

recommended fault-tolerant cabling patterns. Connecting an MSA2000 3.5" 12-drive enclosure to a

2312i G2 or 2324i G2 requires mini-SAS to SAS cables.

IMPORTANT: Adding a fourth drive enclosure to a 2312i G2 may require a separate, longer cable. For a

current list of supported cables, check the MSA2000 G2 QuickSpecs located on the HP MSA products

page at http://www.hp.com/go/msa

QuickSpecs link is located on the right.

When connecting multiple drive enclosures, use reverse cabling to ensure the highest level of fault

tolerance. Controllers and I/O (expansion) modules are identified by

<enclosure-ID><controller-ID>. For example, Figure 3 on page 24 shows controller 1A

connected to I/O module 2A, and the chain of connections continuing down. Controller 1B is connected

to the lower module (B) of the last drive enclosure in the chain, with connections moving in the opposite

direction.

Connecting controller and MSA70 2.5” 25-drive enclosures

The 2324i G2 can also be attached to an MSA70 running firmware version 2.18 or later. For information

about the MSA70, including detailed steps to upgrade the firmware, see the HP StorageWorks 70 Modular

Smart Array Enclosure User Guide located on the MSA2000 Software Support/Documentation CD

shipped with your product, or at http://hp.com/support/manuals

. Select MSA SAN Arrays, and then select your product. The

.

Connecting controller and mixed-connect 3.5” and 2.5” drive enclosures

You can connect LFF MSA2000 3.5" 12-drive enclosures and SFF MSA70 2.5” 25-drive enclosures to a

2324i G2 controller enclosure in mixed-connect fashion, as shown in Figure 6 on page 26, and as further

described in the following documents:

• HP StorageWorks MSA2000 G2 Installation Instructions

• HP StorageWorks 2000 G2 Modular Smart Array Cable Configuration Guide

These documents also address connection of the controller enclosure to either LFF or SFF drive enclosures.

A few sample connection diagrams are provided in Figures 1-5 on the following pages.

Additional cable requirements for drive enclosures

IMPORTANT:

• When installing SAS cables, only use supported SAS 4x cables with 3Gb connectors.

• SAS to SAS 0.6m cables are provided for the MSA2000 3.5" 12-drive enclosure (one per controller).

• Mini-SAS to mini-SAS 0.5m cables are provided with the MSA70 drive enclosure (one per controller).

• The maximum cable length allowed in any configuration is 2m.

• If additional or longer cables are required, they must be ordered separately (see MSA2000 G2 Quick

Specs).

• When expanding storage capacity, a maximum of five enclosures

ninety-nine (99) disk drives are allowed in the array.

—including the array enclosure— or

2312i G2 and 2324i G2 cable requirements

The table below provides SAS cable requirements for connection combinations between MSA controllers

and drive enclosures.

22 Installing the enclosures

Page 23

Table 3 SAS cable requirements

In Out

1B

1A

2A

2B

Controller A

In Out

1B

1A

2A

2B

Controller A

Controller B

In Out

Item MSA2000 G2 controller MSA70 I/O module MSA2000 3.5” 12-drive

I/O module

MSA2000 G2 controller

MSA70 I/O module

MSA2000 3.5” 12-drive

N/A mini-SAS to mini-SAS mini-SAS to SAS

mini-SAS to mini-SAS mini-SAS to mini-SAS mini-SAS to SAS

mini-SAS to SAS mini-SAS to SAS SAS to SAS

I/O module

Mini-SAS to SAS cables must be purchased separately.

0.5m cables are recommended for mini-SAS to SAS connections and mini-SAS to mini-SAS connections, respectively.

IMPORTANT: For a complete list of supported cables, cable part numbers, available options, and cabling

illustrations, see the MSA2000 G2 QuickSpecs at http://www.hp.com/go/msa

.

NOTE: For clarity, the schematic illustrations of the controllers shown in this section provide only relevant

details such as generic expansion ports. For detailed illustrations showing all components, see Rear panel

components on page 18.

Figure 1 Cabling connections between a single-controller enclosure and one MSA2000 3.5" 12-drive

enclosure

Figure 2 Cabling connections between a dual-controller enclosure and one MSA2000 3.5" 12-drive

enclosure

HP 2000i G2 Modular Smart Array User Guide 23

Page 24

Figure 3 Cabling connections between a dual-controller enclosure and three MSA2000 3.5" 12-drive

Out

In

Controller A

Controller B

Out

In

Out

In

Out

In

Out

In

Out

In

1A

1B

2A

2B

3A

3B

4A

4B

Controller A

Controller B

0A

0B

1A 1B

In Out In Out

1A

enclosures

Figure 4 Cabling connections between a dual-controller enclosure and one MSA70 drive enclosure

24 Installing the enclosures

Page 25

Figure 5 Cabling connections between a dual-controller enclosure and three MSA70 drive enclosures

0B

0A

Controller B

Controller A

In Out

1A

In Out

1B

In Out

2A

In Out

2B

In Out

3A

In Out

3B

HP 2000i G2 Modular Smart Array User Guide 25

Page 26

0B

0A

Controller B

Controller A

In

1A

In Out

1B

Out

In OutIn

OutIn

2B

2A

In

3A

In Out

3B

Out

OutIn

OutIn

4B

4A

Figure 6 Cabling connections between a dual-controller enclosure and mixed drive enclosures.

TIP: For comprehensive configuration options and associated illustrations, see the HP StorageWorks

2000 G2 Modular Smart Array Cable Configuration Guide.

Testing enclosure connections

1. Press the power switches at the back of each drive enclosure to On.

IMPORTANT: This ensures that the disks in the enclosures have enough time to completely spin up before

being scanned by the RAID modules in the controller enclosure.

While enclosures power up, their LEDs blink. After the LEDs stop blinking, if no LEDs on the front and

back of the enclosure are amber, the power-on sequence is complete and no faults have been detected.

For a description of LED behavior and status, see LED descriptions on page 35.

2. Press the power switches at the back of the controller enclosure to On.

Depending on the number and type of drives in the system, it can take several minutes for the system to

power up.

If the enclosure’s power-on sequence succeeds as described in Step 1, the system is ready to be

connected to hosts.

26 Installing the enclosures

Page 27

Obtaining IP values

NOTE: For help with configuring your MSA2000 G2 product, also see the MSA2000 Software

Support/Documentation CD shipped with your product.

Setting management port IP addresses using DHCP

1. Look in the DHCP server’s pool of leased addresses for two IP addresses assigned to “HP

StorageWorks MSA Storage.”

2. Use the MSA Device Discovery Tool to discover “HP StorageWorks MSA2300i” storage devices on the

local LAN through SNMP.

If the MSA Device Discovery tool is not installed on your system, then install the program:

a. Insert the MSA2000 Software Support/Documentation CD into the computer’s CD drive.

b. When the dialog appears onscreen, double-click AUTORUN.exe.

c. From the dialog’s Tools tab, select MSA Device Discovery Tool.

d. Complete the installation.

3. Use a ping broadcast to try to identify the device through the host’s ARP table.

If you do not have a DHCP server, you will need to ask your system administrator to allocate two IP

addresses and set them using the CLI during initial configuration (see Setting management port IP

addresses using the CLI).

Setting management port IP addresses using the CLI

If you did not use the DHCP to set network port IP values, set them manually (default method) as described

below.

Network ports on controller module A and controller module B are configured with the following default

values:

• Management Port IP Address: 10.0.0.2 (controller A), 10.0.0.3 (controller B)

• IP Subnet Mask: 255.255.255.0

• Gateway IP Address: 10.0.0.1

If the default IP addresses are not compatible with your network, you must set an IP address for each

management port using the command-line interface (CLI) embedded in each controller module. The CLI

enables you to access the system using RS-232 communication and terminal emulation software.

Use the CLI commands described in the steps below to set the IP address for the Network port on each

controller module.

Once new IP addresses are set, you can change them as needed using SMU. Be sure to change the IP

address via SMU before changing the network configuration.

NOTE: Changing IP settings can cause management hosts to lose access to the storage system.

1. From your network administrator, obtain an IP address, subnet mask, and gateway address for

controller A and controller B.

HP 2000i G2 Modular Smart Array User Guide 27

Page 28

2. Use the provided micro-DB9 serial cable to connect controller A to a serial port on a host computer.

Service

CACHE

CLI

ACTIVITY

LINK

SAS 1

CLI

DIRTY

iSCSI 1

iSCSI 2

Connect serial cable to CLI

port on controller faceplate

Your package contents include a micro-DB9-to-DB9 serial cable. If necessary, use a DB9-to-DB25 adapter

(not included) for connecting the serial cable to a DB25 serial port on the host computer.

3. Start and configure a terminal emulator, such as HyperTerminal or VT-100, using the display settings in

Table 4 and the connection settings in Table 5.

.

Table 4 Terminal emulator display settings

Parameter Value

Terminal emulation mode VT-100 or ANSI (for color support)

Font Terminal

Translations None

Columns 80

Table 5 Terminal emulator connection settings

Parameter Value

Connector COM1 (typically)

Baud rate 115,200

Data bits 8

Parity None

Stop bits 1

Flow control None

4. In the terminal emulator, connect to controller A.

5. Press Enter to display the CLI prompt (#).

6. At the prompt, type the following command to set the values you obtained in Step 1 for each Network

port, first for controller A and then for controller B:

set network-parameters ip

address

netmask

netmask

gateway

gateway

controller a|b

where:

•

address

•

netmask

•

gateway

is the IP address of the controller

is the subnet mask

is the IP address of the subnet router

• a|b specifies the controller whose network parameters you are setting

For example:

# set network-parameters ip 192.168.0.10 netmask 255.255.255.0 gateway

192.168.0.10 controller a

28 Installing the enclosures

Page 29

# set network-parameters ip 192.168.0.11 netmask 255.255.255.0 gateway

193.168.0.10 controller b

7. Type the following command to verify the new IP addresses:

show network-parameters

Network parameters, including the IP address, subnet mask, and gateway address are displayed for

each controller.

8. Use the ping command to verify network connectivity.

For example:

# ping 192.168.0.10 (gateway)

Info: Pinging 192.168.0.10 with 4 packets.

Success: Command completed successfully. The remote computer responded

with 4 packets.

9. In the host computer's command window, type the following command to verify connectivity, first for

controller A and then for controller B:

ping controller-

IP-address

If you cannot your access your system for at least three minutes after changing the

IP address, your network might require you to restart the Management Controller(s) using the serial

CLI. When you restart a Management Controller, communication with it is temporarily lost until it

successfully restarts.

Type the following command to restart the management controller on both controllers:

restart mc both

10. When you are done using the CLI, exit the emulator.

HP 2000i G2 Modular Smart Array User Guide 29

Page 30

30 Installing the enclosures

Page 31

4 Connecting hosts

Host system requirements

Data hosts connected to 2312i G2 and 2324i G2 arrays must meet the following requirements:

• Depending on your system configuration, data host operating systems may require that multi-pathing is

supported.

TIP: See the HP StorageWorks MSA2000 Family VDS and VSS Hardware Providers Installation

Guide and HP StorageWorks MSA2000 Family MPIO DSM Installation Guide to aid in planning

and implementing your MPIO DSM installation.

If fault tolerance is required, then multi-pathing software may be required. Host-based multi-path

software should be used in any configuration where two logical paths between the host and any

storage volume may exist at the same time. This would include most configurations where there are

multiple connections to the host or multiple connections between a switch and the storage.

• Use 2000sa G2 Modular Smart Array MPIO DSM with Windows Server 2003. To obtain the

2000sa G2 Modular Smart Array MPIO DSM, go to the HP MSA products page at

http://www.hp.com/go/msa

products.

• Use native Microsoft MPIO DSM support with Windows Server 2008. Use either the Server

Manager or the command line interface (mpclaim CLI tool) to perform the installation. Refer to the

following web sites for information about using the Windows 2008 native MPIO DSM:

http://support.microsoft.com/gp/assistsupport

http://technet.microsoft.com (search the site for “multipath I/O overview”)

• Use the HP Multi-path Device Mapper for Linux Software with Linux servers. To download the

appropriate device mapper multi-path enablement kit for your specific enterprise Linux operating

system, go to http://www.hp.com/go/devicemapper

• To prevent Microsoft Windows 2003 data hosts from displaying the Found New Hardware Wizard

when the storage system is discovered, install the 2000sa G2 Modular Smart Array SCSI Enclosure

Services driver. Download 2000sa G2 Modular Smart Array SCSI Enclosure Services (SES) driver

package from h

Related products.

ttp://www.hp.com/go/msa. Select MSA SAN Arrays, select your product, and go to

. Select MSA SAN Arrays, select your product, and go to Related

.

NOTE: MSA2000 Family SCSI Enclosure Services driver is required for Microsoft Windows 2003.

Connecting the enclosure to data hosts

Cable connections vary depending on configuration. Common cable configurations are shown in this

section. A complete list of supported configurations resides on the MSA2000 G2 product site at

http://hp.com/support/manuals

Guide, which is updated to describe newly-supported direct connect, switch-connect, and expansion

configuration options for the MSA2000 G2.

Any number or combination of LUNs can be shared among connected servers, provided the total does not

exceed 512 LUNs per MSA2000 G2. Moreover, a volume cannot be mapped to LUN zero.

iSCSI host ports

2312i Modular Smart Array and 2324i Modular Smart Array use Internet SCSI (Small Computer System

Interface) interface protocol for host port connection, featuring either one or two controller modules. Each

controller provides two iSCSI host ports — supporting data rates up to 1Gb/second, featuring a 1.8 GHz

processor with128 MB memory, and 1 GB cache — using either one-way or mutual CHAP

(Challenge-Handshake Authentication Protocol).

. Locate the HP StorageWorks MSA2000 G2 Cable Configuration

HP 2000i G2 Modular Smart Array User Guide 31

Page 32

The 2312i Modular Smart Array and 2324i Modular Smart Array use Unified LUN Presentation (ULP) — a

Server 1

Server 1

Server 1 Server 2

controller firmware feature enabling hosts to access mapped volumes via host ports — without the need for

internal or external switches.

Connecting direct attach configurations

The 2312i G2 and 2324i G2 support up to four direct-connect server connections, two per controller.

Connect appropriate cables from the servers’ HBAs to the controller host ports as shown in the following

illustrations.

Single controller configuration

One server/one HBA/single path

Dual controller configurations

One server/one HBA/dual path

Two servers/one HBA per server/dual path

Connecting remote management hosts

The management host directly manages systems out-of-band over an Ethernet network.

1. Connect an Ethernet cable to the network port on each controller.

2. Connect the other end of each Ethernet cable to a network that your management host can access

(preferably on the same subnet).

NOTE: Connections to this device must be made with shielded cables with metallic RFI/EMI connector

hoods in order to maintain compliance with FCC Rules and Regulations.

32 Connecting hosts

Page 33

5 Basic operation

Powering on/powering off

Before powering on the enclosure for the first time:

• Install all disk drives in the enclosure so the controller can identify and configure them at power-up.

• Connect the cables and power cords to the enclosure as explained in the installation poster.

• Generally when powering up, make sure to power up the enclosures and associated data host in the

following order:

•Drive enclosures first

• Controller enclosure next

• Data hosts last (if they are powered down for maintenance purposes)

TIP: Generally, when powering off, you will reverse the order of steps used for powering on.

To power on the system:

1. Press the power switches at the back of each drive enclosure to the On position.

2. Press the power switches at the back of the controller enclosure to the On position.

To power off the system:

1. Stop all I/O from hosts to the system.

Ensure that the host has flushed all I/O from cache to disk before the controller is shut down.

2. Use SMU to shut down both controllers. See the SMU online help for information on shutting down a

controller.

Wait until SMU indicates that processing is complete.

3. Press the power switches at the back of each drive enclosure to the Off position.

4. Press the power switches at the back of the controller enclosure to the Off position.

Updating firmware

After installing the hardware and powering up the enclosure for the first time, verify that the controller and

all enclosures have the latest firmware. SMU enables you to view the firmware and hardware version

information for each enclosure.

TIP: See Signing in to SMU on page 41 for SMU usage.

To view controller module firmware versions, in the Configuration View panel, right-click the system, select

View > Overview, and select the Versions component in the System Overview Table.

To view expansion module firmware versions, in the Configuration View panel, right-click a drive enclosure

and select View > Overview. Expansion module A’s firmware version is shown as EMP A Revision;

expansion module B’s firmware version is shown as EMP B Revision.

For software and firmware updates, including update instructions, go to http://www.hp.com/go/msa

Select MSA SAN Arrays, select your product, and go to Support.

Selecting an appropriate time to perform the online upgrade

To ensure the success of an online upgrade, selecting the appropriate time is essential. Selecting a period

of low I/O activity will ensure the upgrade completes as quickly as possible, and will avoid disruptions to

host and applications due to timeouts. Attempting to upgrade a storage system that is in the middle of

processing a large I/O intensive batch job will likely cause hosts to lose connectivity with the storage

system. Consequently, finding an appropriate time for the upgrade is very important.

.

HP 2000i G2 Modular Smart Array User Guide 33

Page 34

For software and firmware updates, go to http://www.hp.com/go/msa. Select MSA SAN Arrays, select

your product, and go to Support.

For detailed steps on updating the firmware, see the reference guide or the CLI reference guide.

For information on logging into SMU, see Configuring a system for the first time on page 41.

34 Basic operation

Page 35

6 LED descriptions

MSA2000

1 2

4

5

6

3

Left ear

Right ear

MSA2000

Front panel LEDs

Left ear Right ear

4

1 2

3

5

6

LED Description Definition

1 Enclosure ID Green — On

Enables you to correlate the enclosure with logical views presented

by management software. Sequential enclosure ID numbering of

controller enclosures begins with the integer 1. The enclosure ID for

an attached drive enclosure is nonzero.

2 Disk drive Online/Activity See Table 6 on page 36, Disk drive LED combinations.

3 Disk drive Fault/UID See Table 6 on page 36, Disk drive LED combinations.

4 Unit Identification (UID) Blue — Identified

Off — Identity LED off

5 Fault ID Amber — Fault condition exists. The event has been identified, but

the problem needs attention.

Off — No fault condition exists.

6 Heartbeat Green — The enclosure is powered on with at least one power

supply operating normally.

Off — Both power supplies are off; the system is powered off.

HP 2000i G2 Modular Smart Array User Guide 35

Page 36

Disk drive LEDs

12

12

3.5” LFF disk drive

2.5” SFF disk drive

LED Description

1 Fault/UID (amber/blue)

2Online/Activity (green)

Table 6 Disk drive LED combinations

Online/Activity

Fault/UID (amber/blue) Description

(green)

On Off Normal operation. The drive is online, but it is not

currently active.

Blinking irregularly Off The drive is active and operating normally.

Off Amber; blinking regularly (1 Hz) Offline; the drive is not being accessed. A predictive

failure alert may have been received for this device.

Further investigation is required.

On Amber; blinking regularly (1 Hz) Online; possible I/O activity. A predictive failure alert

may have been received for this device. Further

investigation is required.

Blinking irregularly Amber; blinking regularly (1 Hz) The drive is active, but a predictive failure alert may

have been received for this drive. Further investigation

is required.

Off Amber; solid

Off Blue; solid Offline. The drive has been selected by a

1

Offline; no activity. A failure or critical fault condition

has been identified for this drive.

management application (SMU).

On or blinking Blue; solid The controller is driving I/O to the drive, and it has

36 LED descriptions

been selected by a management application (SMU).

Page 37

Table 6 Disk drive LED combinations (continued)

iSCSI 1

LINK

ACT

LINK

ACT

iSCSI 2

iSCSI 1

LINK

ACT

iSCSI 2

LINK

ACT

1

2

4567

83 9 :;1w

Online/Activity

(green)

Blinking regularly (1 Hz) Off

Off Off Either there is no power, the drive is offline, or the

1. This Fault/UID state can indicate that the disk is a leftover. The fault may involve metadata on the disk, rather than the disk itself.

See the Clearing disk metadata topic in the reference guide or SMU online help.

Rear panel LEDs

2312i G2 and 2324i G2

Fault/UID (amber/blue) Description

CAUTION: Do not remove the drive.

Removing a drive may terminate the current

operation and cause data loss. The drive is

rebuilding.

drive is not configured.

LED Description Definition

1 Power supply LEDs See Power supply LEDs on page 40.

2 Host 1Gb iSCSI Link Status (port 1) Off — The port is empty or the link is down.

Green — The port is connected and the link is up.

3 Host 1Gb iSCSI Link Activity (port 2) Off — The link is idle.

Blinking green— The link has I/O activity.

4 OK to Remove Off — The controller module is not prepared for removal.

Blue — The controller module is prepared for removal.

5 Unit Locator Off — Normal operation.

Blinking white— Physically identifies the controller module.

6 OK Off — Controller module is not OK.

Blinking green — System is booting.

Green — Controller module is operating normally.

7 Fault/Service Required Amber — A fault has been detected or a service action is required.

8 Network Port Link Status Off — The Ethernet port is not connected or the link is down.

9 Network Port Activity Off — The Ethernet link has no I/O activity.

Blinking amber — Hardware-controlled powerup or a cache flush

or restore error.

Green — The Ethernet link is up.

Blinking green— The Ethernet link has I/O activity.

HP 2000i G2 Modular Smart Array User Guide 37

Page 38

LED Description Definition

10 Cache Status Green — Cache is dirty (contains unwritten data) and operation is

normal. The unwritten information can be log or debug data that

remains in the cache, so a Green cache status LED does not, by

itself, indicate that any user data is at risk or that any action is

necessary.

Off — In a working controller, cache is clean (contains no

unwritten data).

Blinking green — A CompactFlash flush or cache self-refresh is in

progress. Indicates cache activity (See also If the controller has

failed or does not start, is the Cache Status LED on/blinking? on

page 52).

If the LED is blinking evenly, a cache flush is in progress. When a

controller module loses power and write cache is dirty (contains

data that has not been written to disk), the super-capacitor pack

provides backup power to flush (copy) data from write cache to

CompactFlash memory. When cache flush is complete, the cache

transitions into self-refresh mode.

If the LED is blinking momentarily slowly, the cache is in a

self-refresh mode. In self-refresh mode, if primary power is restored

before the backup power is depleted (3–30 minutes, depending on

various factors), the system boots, finds data preserved in cache,

and writes it to disk. This means the system can be operational

within 30 seconds, and before the typical host I/O time-out of 60

seconds, at which point system failure would cause host-application

failure. If primary power is restored after the backup power is

depleted, the system boots and restores data to cache from

CompactFlash, which can take about 90 seconds.

The cache flush and self-refresh mechanism is an important data

protection feature; essentially four copies of user data are

preserved: one in each controller’s cache and one in each

controller’s CompactFlash.

11 Host Activity Off — Host ports have no I/O activity.

Blinking green — At least one host port has I/O activity.

12 Expansion Port Status Off — The port is empty or the link is down.

Green — The port is connected and the link is up.

NOTE: Once a Link Status LED is lit, it remains so, even if the controller is shutdown via SMU or CLI.

When a controller is shutdown or otherwise rendered inactive —its Link Status LED remains

illuminated—falsely indicating that the controller can communicate with the host. Though a link exists

between the host and the chip on the controller, the controller is not communicating with the chip. To reset

the LED, the controller must be properly power-cycled (see Powering on/powering off on page 33).

38 LED descriptions

Page 39

MSA2000 3.5" 12-drive enclosure

00

1 2

4356 7

1

LED Description Definition

1 Power supply LEDs See Power supply LEDs on page 40.

2 Unit Locator Off — Normal operation.

3 SAS In Port Status Green — Port link is up and connected.

4 OK to Remove Not implemented.

Blinking white — Physically identifies the expansion module.

Off — Port is empty or link is down.

5 Fault/Service Required Amber — A fault has been detected or a service action is required.

6 OK Green — Expansion module is operating normally.

7 SAS Out Port Status Green — Port link is up and connected.

MSA70 2.5” 25-drive enclosure

The 2324i G2 can also be attached to an MSA70 running firmware version 2.18 or later. For information

about the MSA70, including detailed steps to upgrade the firmware, see the HP StorageWorks 70 Modular

Smart Array Enclosure User Guide located on the MSA2000 G2 Software Support/Documentation CD

shipped with your product, or at http://hp.com/support/manuals

Blinking amber — Hardware-controlled powerup or a cache flush

or restore error.

Blinking green — System is booting.

Off — Expansion module is not OK.

Off — Port is empty or link is down.

.

HP 2000i G2 Modular Smart Array User Guide 39

Page 40

Power supply LEDs

1

2

1

2

Power redundancy is achieved through two independent load-sharing power supplies. In the event of a

power supply failure, or the failure of the power source, the storage system can operate continuously on a

single power supply. Greater redundancy can be achieved by connecting the power supplies to separate

circuits.

AC model DC model

LED Description Definition

1 Input Source Power good Green — Power is on and input voltage is normal.

Off — Power is off or input voltage is below the minimum

threshold.

2 DC Voltage/Fan Fault/Service Required Amber — DC output voltage is out of range or a fan is

operating below the minimum required RPM.

Off— DC output voltage is normal.

40 LED descriptions

Page 41

7 Configuring a system for the first time

Configuring your web browser for SMU

Before using SMU to perform remaining steps, ensure that your web browser is properly configured

according to the following guidelines:

• Your browser must be Mozilla Firefox 1.5 or Microsoft Internet Explorer 6, or later. For better

performance, use Firefox or Internet Explorer 7 or later.

NOTE: Check the QuickSpecs for currently supported browsers. QuickSpecs can be found from

your HP MSA products page at http://www.hp.com/go/msa

select your product. The link for QuickSpecs will be on the right.

• To see the help window, you must enable pop-up windows.

• To optimize the display, use a color monitor and set its color quality to the highest setting.

• To navigate beyond the Sign In page (with a valid user account):

• Set the browser’s local-intranet security option to medium or medium-low.

• Verify that the browser is set to allow cookies at least for the IP addresses of the storage-system

network ports.

Signing in to SMU

. Select MSA SAN Arrays, and then

To sign in:

1. In the web browser’s address field, type the IP address of a controller network port and press Enter.

The SMU Sign In page is displayed. If the Sign-in page does not display, verify that you have entered

the correct IP address.

Do not include a leading zero in the IP address. For example, enter 10.1.4.6; not 10.1.4.06.

2. On the Sign In page, enter the name and password of a default or configured user, and select your

preferred display language.

If you are logging in to the SMU for the first time and no language packages have been installed, the

Language field displays user setting or English, either of which when selected results in English. See the

reference guide for information on configuring languages.

Each user has a Monitor or Manage access level, as described in the user accounts topic in SMU‘s

reference guide and help. Multiple monitor and manage users can be signed-in to a controller

simultaneously.

3. Click Sign In.

If the system is available, the System Overview page is displayed; otherwise, a message indicates that

the system is unavailable.

For each active SMU session, an identifier is stored in the browser. Depending on how your browser treats

this session identifier, you might be able to run multiple independent sessions simultaneously. Each instance

of Internet Explorer can run a separate SMU session; however, all instances of Firefox share the same

session.

To sign out, see ”Signing out of SMU” on page 45

Tips for using the main window

• The Configuration View panel displays logical and physical components of the storage system. To

perform a task, select the component to act on and then either:

• Right-click to display a context menu and select the task to perform. This is the method that help

topics describe.

• Click a task category in the main panel and select the task to perform.

HP 2000i G2 Modular Smart Array User Guide 41

Page 42

• The System Status panel shows how many events of each severity have occurred in the system. To view

event details, click a severity icon.

• Do not use the browser's Back, Forward, Reload, or Refresh buttons. SMU is essentially a single page

that is automatically updated to show current data. You do not need to refresh it, and if you click Back,

you may exit the application.

• An asterisk (*) identifies a required setting.

• Many tables can be sorted by a specific column. To do so, click the column heading to sort low to high;

click again to sort high to low.

• Below the communication status icon, a timer shows how long your session can be idle until you are

automatically signed out. This timer resets after each action you perform. One minute before

auto-signout, you are prompted to continue using SMU. The timer does not appear if the current user’s

Auto Sign Out preference is set to Never.

• Select the help icon to access help for the last selected item, whether it is a component in the

Configuration View panel, or a subpanel in the main panel. Select the icon to access the SMU

online help table of contents.

• For more tips about using SMU, see the Getting Started topic in SMU’s reference guide and help.

Tips for using the help window

• In the main panel, clicking the help icon displays help for the last-selected item, whether it is a

component in the Configuration View panel or a subpanel in the main panel.

• In the help window, clicking the arrowed border on the left displays or hides the help contents pane.

A topic remains displayed until you browse to another topic in the help window, display help for a different

item in the main window, or close the help window.

Changing the system date and time

You can change the storage system's date and time, which are displayed in the System Status panel. It is

important to set the date and time so that entries in system logs and event-notification email messages have

correct time stamps.

You can set the date and time manually or configure the system to use Network Time Protocol (NTP) to

obtain them from a network-attached server. When NTP is enabled, and if an NTP server is available, the

system time and date can be obtained from the NTP server. This allows multiple storage devices, hosts, log

files, and so forth to be synchronized. If NTP is enabled, but no NTP server is present, the date and time

are maintained as if NTP was not enabled.

NTP server time is provided in Universal Time (UT), which provides several options:

• If you want to synchronize the times and logs between storage devices installed in multiple time zones,

set all the storage devices to use UT.

• If you want to use the local time for a storage device, set its time zone offset.

• If a time server can provide local time rather than UT, configure the storage devices to use that time

server, with no further time adjustment.

Whether NTP is enabled or disabled, the storage system does not automatically make time adjustments,

such as for U.S. daylight savings time. You must make such adjustments manually.

To use manual date and time settings

1. In the Configuration View panel, right-click the system and select Configuration > System Settings >

Date, Time. The date and time options appear.

2. Set the options:

• Time. Enter the time in the format hh:mm:ss.

•Month.

•Day.

• Year. Enter the year using four digits.

•NTP. Select Disabled.

3. Click Apply.

42 Configuring a system for the first time

Page 43

To obtain the date and time from an NTP server

1. In the Configuration View panel, right-click the system and select Configuration > System Settings >

Date, Time. The date and time options appear.

2. Set the options:

•NTP. Select Enabled.

• NTP Time Zone Offset. Optional. If the system timestamps should use the NTP server's time zone

instead of the local time zone, enter the time zone offset.

• NTP Server Address. Optional. If the system should retrieve time values from a specific NTP server,