Page 1

HP

This vintage Hewlett Packard document was

preserved and distributed by

Archive

vvwvv.

Please visit us on the web

Scanned by on-line curator: Tony Gerbic

h parc hive.com

!

**

For

FREE

Distribution Only

***

Page 2

Page 3

OPERATING AND SERVICE MANU'AL

MODEL

SERIALS

PREFIXED:

175A

235

OSCILLOSCOPE

4

-

01526-1

Copyrieh)

1501

PAOt

HtWLtIT-PACKARO COMPANY

MILL

ROAD,

PAL0

ALlO,

0

CALIFORNIA,

1963

U.S.A.

Printed:

FEB

1963

Page 4

Table of Contents Model 175A

Section

I

GENERALINFORMATION

1.1

.

Description

1.3 . Auxiliary EquipmeQt

1.5

.

Instrument Identification

1.7

.

Warranty

1.9

.

Special Features

1.11

.

Cathode-Ray Tube

1.13

.

Special Controls

I1

INSTALLATION

2.1

.

Incoming Inspection

2.2

.

MechanicalInspection

2.4

.

Performance Check

2.6

.

Installation

2.8

.

Rack Mounting

.

2.10

2.13

2.15

2.17

m

OPERATION

3.1

3.3

3.5

3.7

3.9

3.11

3.13

3.15

3.17

3.18

3.20

3.23

3.25

3.27

IV

PRINCIPLES

4.1

4.9

4.11

4.13

4.15

4.17

4.19

4.21

4.23

4.25 . Sweep Generator

4.27

4.30

cooling

.

Power Requirement

.

Safety Power Cable

.

Repackaging for Shipment

.............

.

General

.

.

.

Triggering

.

.

.

.

.

Sweep Controls

.

.

.

Horizontal Functions

.

Intensity Modulation

.

.

Overall FunctionDescription

.

Vertical Amplifier

.

.

.

.

.

.

.

.

.

.............

Beam Finder

Calibration

Trigger

Trigger Level

Trigger Slope

Sweep Mode

Sweep Time

Sweep Magnifier

Step-by-StepProcedures

OF

Cross-Coupled Cathode Follower. 4-2

Differential Amplifier

Peaking

Sync Amplifier

Delay Line

Circuit Protection

Scan Output

Trigger Generator

SweepGeneratingcircuits

TABLE

*

...

...

Page

1-1

1-1

1-1

1-1

1-1

1-4

1-4

1-4

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

4-1

4-1

4-1

4-2

4-2

4-2

4-2

4-1

4-2

4-2

4-2

4-3

*

*

* . * *

...........

.......

....

...........

........

.......

........

............

.......

.....

......

..........

.........

............

......

.......

.....

.........

..........

...........

Source

........

.........

.........

..........

.........

..........

........

.......

.......

....

OPERATION

.

* . *

........

.....

............

........

..........

.......

..........

.........

......

OF

CONTENTS

Section

IV PRINCIPLES OF OPERATION (Cont'd)

4.38

.

Single-Sweep Operation

4.40

.

4.43

4.47

4.51

4.53

4.55

V MAINTENANCE

5.1

5.3

5.5

5.7

5.9

5.11

5.14

5.20

5.21

5.22

5.23

5.24

5.25

5.27

5.29

5.31

5.33

5.35

5.40

5.47

5.53

5.58

5.59

5.61

5.64

5.67

5.68

5.70

5.77

5.81

5.87

5.93

VI

REPLACEABLE PARTS

6

.

1

6.4

Schmitt Trigger Circuit

.

Horizontal Amplifier

.

High-Voltage Power Supply

.

Intensity Control

.

Scale Control

.

Low-Voltage Power Supplies

.

Introduction

.

Servicing the

.

Performance Check

.

Test Equipment

.

Preliminary Settings

.

Horizontal Amplifier

.

Sweep Generator

.

Vertical Amplifier Bandwidth

.

Calibrator

.

Intensity Modulation

.

Sweep and Gate Output

(Option Feature)

.

Accessory Probes

.

Adjustments

.

Equipment Neededfor Adjustments 5-4

.

Locationof Adjustments

.

Preliminary Settings

.

Low-Voltage Power Supplies

.

High-Voltage Power Supply

.

Horizontal Amplifier

.

Sweep Generator

.

Vertical Amplifier

.

Calibrator

.

Repairs

.

Equipment Required

.

Procedure

.

Troubleshooting

.

Isolating Troubles to

Major Section

.

Low-Voltage Power Supplies

.

High-Voltage

.

Vertical Amplifier

.

Sweep Generator

.

Horizontal Amplifier

.

Introduction

.

Ordering Information

.........

............

...........

Air

Filter

.........

...........

..........

.............

..........

.........

........

Power

........

........

...........

.....

.....

.......

....

........

......

.......

........

......

......

........

......

.......

.......

....

......

......

.......

.......

......

a

Supplies

.......

......

......

Page

...

. .

.

.

...

. .

.

.

4-4

4-4

4-5

4-6

4-6

4-6

4-6

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-2

5-3

5-4

5-4

5-4

5-4

5-4

5-4

5-4

5-5

5-5

5-8

5-10

5-11

5-12

5-12

5-13

5-13

5-13

5-13

5-13

5-16

5-16

5-17

5-18

6-1

6

.

1

6-1

ii

01526-1

Page 5

Model 175A

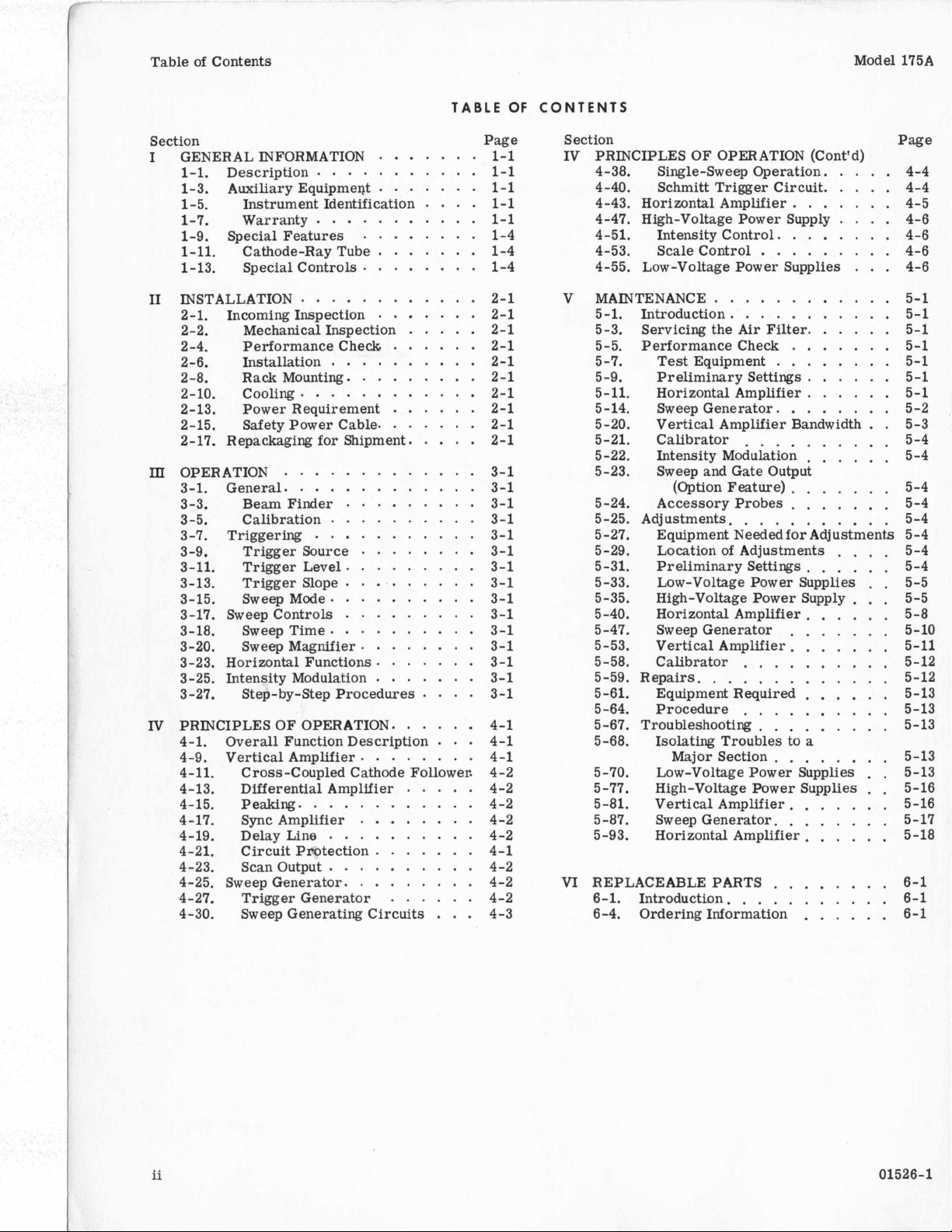

LIST

OF

ILLUSTRATIONS

List of Illustrations

List of Tables

Number Title

1-1.

1-2.

3-1.

3-2.

3-3.

3-4.

3-5.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

5-10.

5-11.

5-12.

5-13. ModLl 175A Component Locations,

5-14. Model 175A Component Locations,

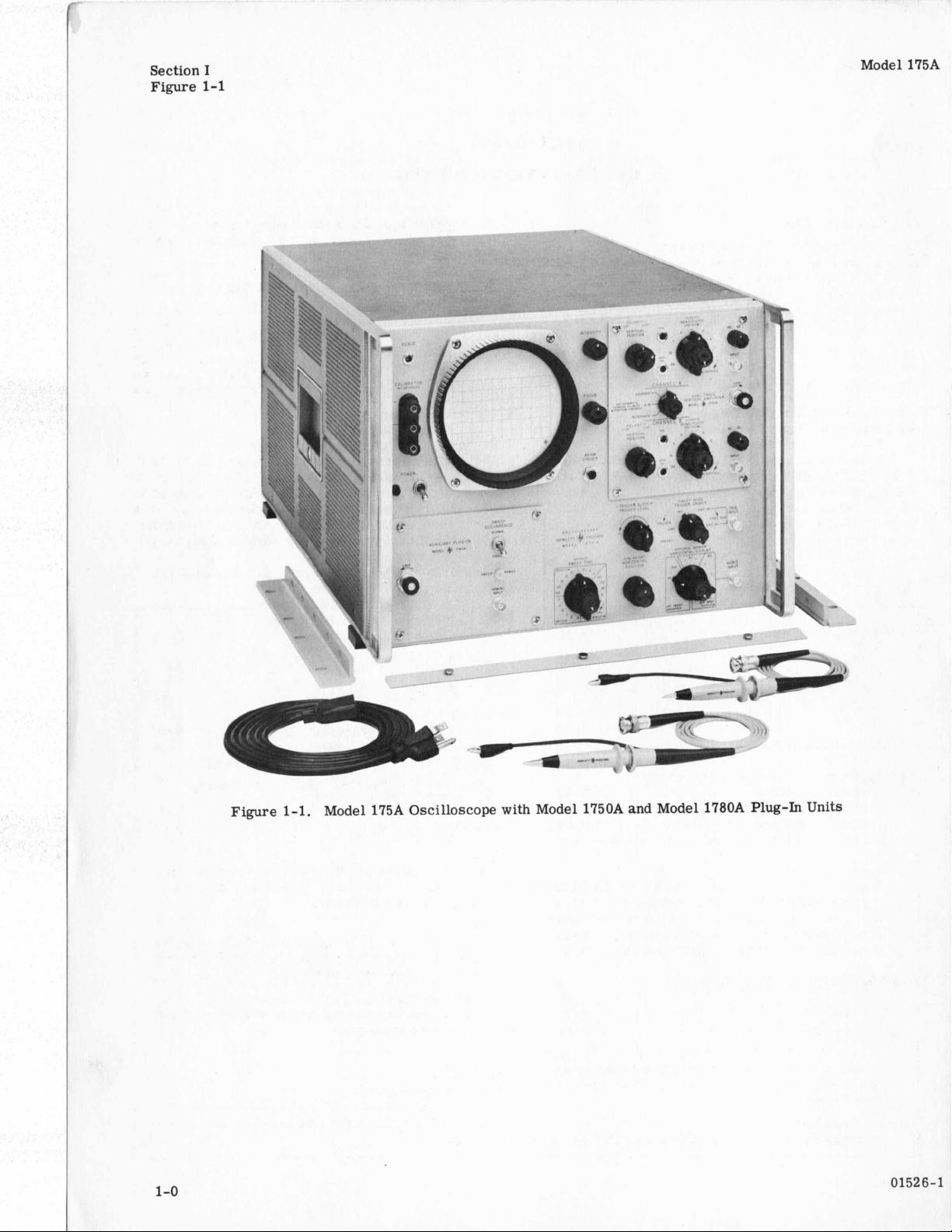

Model 175A Oscilloscope with MOI !11750A

and Model 1780A Plug-In

Cathode-Ray TubeWarranty.

Model 175A Controls and Terminals

Internal Sweep

Magnified Sweep

Probe Compensation

Intensity Modulation

Overall Block Diagram of Model 175A

with Model 1750A Plug-In

Vertical Amplifier Block Diagram

Cross-Coupled Cathode Follower

Simplified Schematic Diagram

Sweep Generator Block Diagram.

Trigger Generator Simplified Circuit

and Composite Characteristic

Simplified Schmitt Trigger Circuit.

Horizontal Amplifier Block Diagram

High-Voltage Power -Supply

Block Diagram.

Low-Voltage Power-Supply

Block Diagram.

Test Plug

Adjustments and Component Locations,

Top View

Adjustments and Component Locations,

Bottom View.

Pattern Adjustment.

Frequency Compensation

Attenuator Compensation

Trigger Sensitivity

Scan Balance

Mid

-

Frequency Response

Preliminary Adjustment

Mid-Frequency Response

Final Adjustment.

High-FrequencyResponse

Model 175A Component Locations,

T~D View

Bottom View.

Right Side View

. . .

.

. . . .

.

. .

.

. .

. . . . . . . .

.

. . . . . . . . . .

.

. .

. .

.

.

. . . .

.

Units

. . . .

.

. . . .

.

. .

. .

. . . . .

Unit

. . . . . . . .

.

.

.

. . . . . .

. . . . . . .

. . . . . . . . .

. . . . . . .

. . .

. . . . . .

. . .

. . . . . . . . .

. . .

. . .

.

. . .

.

.

. . . . .

. . . .

. .

.

. . . . . .

. . . . . . .

.

.

.

. .

. .

. . .

.

.

.

.

. .

. .

.

. .

.

.

. . .

. .

.

. . .

.

. .

. .

.

.

.

.

.

. .

.

.

.

. . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

1-0

1-2

3-0

3-2

3-3

3-4

3 -5

4-0

4-1

4-2

4-3

4-4

4-5

4-5

4-6

4-7

5-5

5-6

5-7

5-8

5 -9

5-10

5-10

5-11

5-12

5-12

5-12

5-19

5-20

5-21

Number Title Page

5-15. Model 175A Component Locations,

Left Side View

5-16.

A1

Vertical-Input Assembly

Component Locations

5-17. A2 Vertical-Output Assembly

5-18. Beam-Finder Switch S1,

5-19. Vertical Amplifier (schematic diagram) 5-25

5-20. A101 Sweep-Generator Assembly

5-21. A102 Trigger-Source Switch Assembly,

5-22. A103 Trigger-Level and -Slope Switch

5-23. Sweep Generator (schematic diagram) 5-27

5-24.

5-25. A1002 Sweep-Time Switch Assembly,

5-26. Sweep-Time Switch

5-27. A201 Horizontal Amplifier Assembly

5-28. A202 Horizontal Display Switch Assembly,

5-29. Horizontal Amplifier (schematic diagram)5 -31

5-30. A301 High-Voltage and Calibrator

5-31. A302 High-Voltage Deck Assembly

5-32. High-Voltage Power Supply and

5-33. A401 Low-Voltage Power Supply

5-34. Low-Voltage Power Supply.

5-35. Heater Circuit (schematic diagram

5-36. A701 Gate- and Sweep-Output Assembly

5-37.

5-38. Connectors

Component Locations

Mounted Components

Component Locations

Mounted Components

Assembly, Mounted Components

AlOOl

Sweep-Switch Circuit Board

Component Locations

Mounted Components

(schematic diagram).

Component Locations

Mounted Components

Assembly Component Locations

Component Locations

Calibrator (schematic diagram).

Component Locations

(schematic diagram)

Component Locations

Gate

and Sweep Output

(schematicdiagram)

.

.

. . . . .

. . . . . .

. .

. . . . .

. . . . . . .

.

.

.

. .

. . . . .

. , . . . . .

.

. . .

. . .

. . . . . .

. .

. . . .

. . . . .

. . .

.

. .

. . .

.

. . . .

.

. . .

. . .

. .

. . . . . .

.

. . . .

. . . .

.

. .

.

. .

.

.

. .

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

5-21

5-23

5-24

5

-2

5-26

5 -26

5-26

5-28

5-28

5-29

5-30

5-30

5-32

5-32

5-33

5-34

5-35

5-36

5-36

5-36

5-37

5

LIST

Number Title Page

1-1.

Specifications

1-2. Associated Equipment and Accessories. 1-3

Test Equipment for Checks and

5-1.

5-2. Sweep Calibration

5-3. Power Supply Tolerances

01526-1

Adjustments

.

. .

. . . . . . . . .

.

. . . . . . . .

.

.

.

. .

.

. .

.

. .

. . . . .

. . .

.

1-1

5-0

5-3

5-5

OF

TABLES

Number Title Page

5-4. Sweep Time

5-5. Troubleshooting the Low -Voltage Supply 5-14

5-6. Vertical Amplifier Troubleshooting.

5-7. SweepGenerator Troubleshooting Guide 5-17

5-8. Horizontal Amplifier Troubleshooting

6-1. Index by ReferenceDesignator

6-2. Replaceable Parts

. . . . . .

.

.

. . .

.

. . . . .

. . . .

. . . .

.

.

5-11

5-17

5-18

6-2

6-13

iii

Page 6

Section

Figure

I

1-1

Model

175A

1-0

Figure

1-1.

Model

175A

Oscilloscope with Model

1750A

and Model

1780A

Plug-In

Units

01526-1

Page 7

Model 175A

Paragraphs

Section

1-1

to 1-8

I

SECTION

GENERAL INFORMATION

1-1.

DES

C

R

I

PTI

0

N.

1-2.

The @ Model 175A Oscilloscope

general-purpose

width

of 50 megacycles and a 6 x 10 cm display. Optional plug-in units and accessories are available to

increase the versatility of this instrument. Specifications are listed in table

1-3.

AUXILIARY EQUIPMENT.

Available associated equipment and accessories

1-4.

are

listed

in table

a. Plug-Ins.

clude dual-trace and single-trace vertical amplifiers

which collectively cover 5 mv/cm to 20 v/cm sensitivities and dc to 50-mc bandwidth. Horizontal units

include single sweep, sweep delay, a time-mark

generator, and a display scanner.

test

instrument with a vertical band-

1-1.

1-2.

Plug-in units for the Model 175A in-

is

a calibrated

Table

1-1.

I

b.

Accessories. Each oscilloscope

two Model 10003A (AC-21M) high-impedance probes

and a detachable power cable.

1-5. INSTRUMENT IDENTIFICATION.

1-6. Hewlett-Packard uses

serial number

of the serial number on your instrument

with those

sheets supplied with the manual will define differences

between your instrument andthe Model 175A described

in this manual.

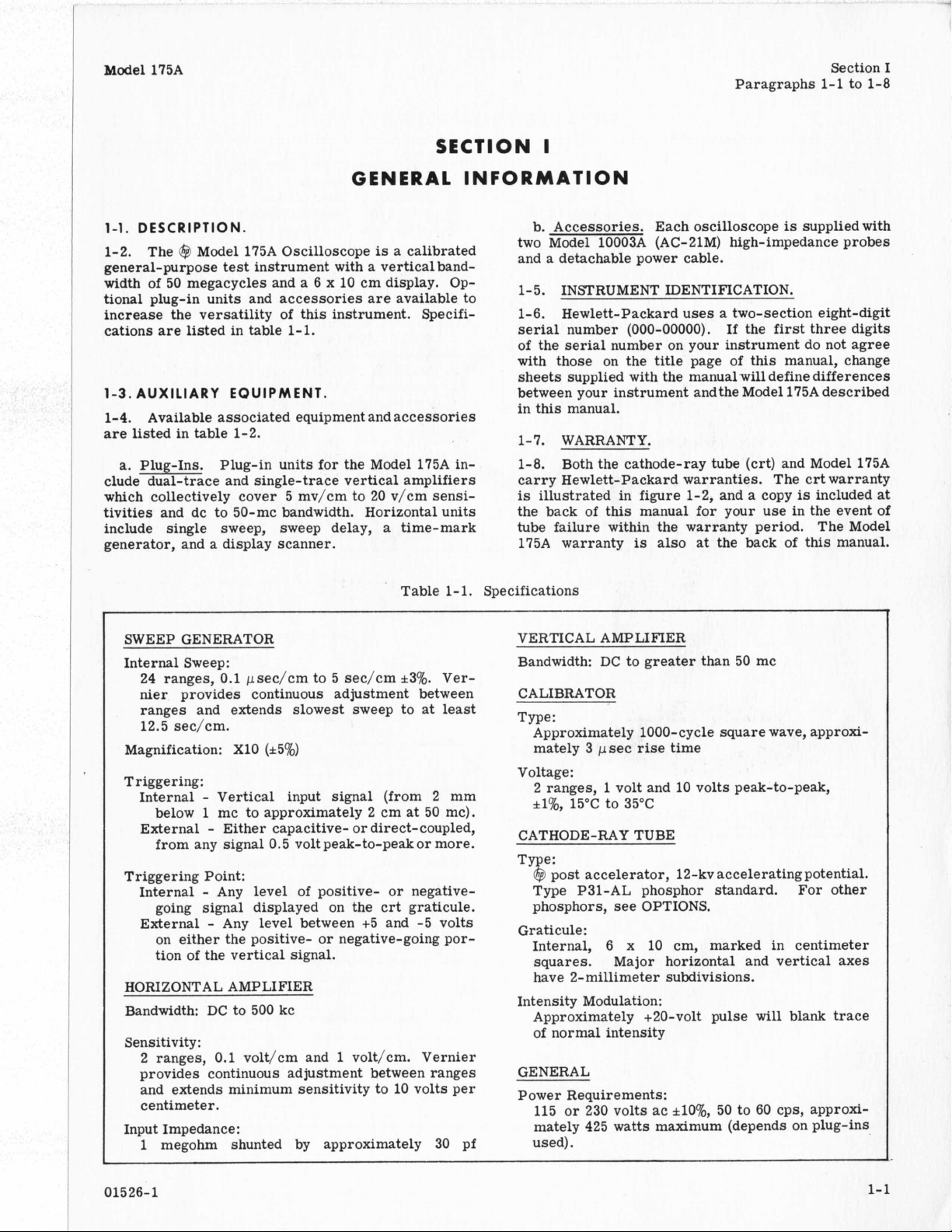

1-7. WARRANTY.

1-8. Both the cathode-ray tube

carry Hewlett-Packard warranties. The

is

illustrated in figure 1-2, and a copy

the back of this manual for your use in

tube failure within the warranty period. The Model

175A warranty

Specifications

(000-00000).

on the

title

is

also at the back of this manual.

a

two-section eight-digit

If

page of this manual, change

is

supplied with

the

first

do

(crt)

and Model 175A

crt

is

three digits

the

not agree

warranty

included at

event of

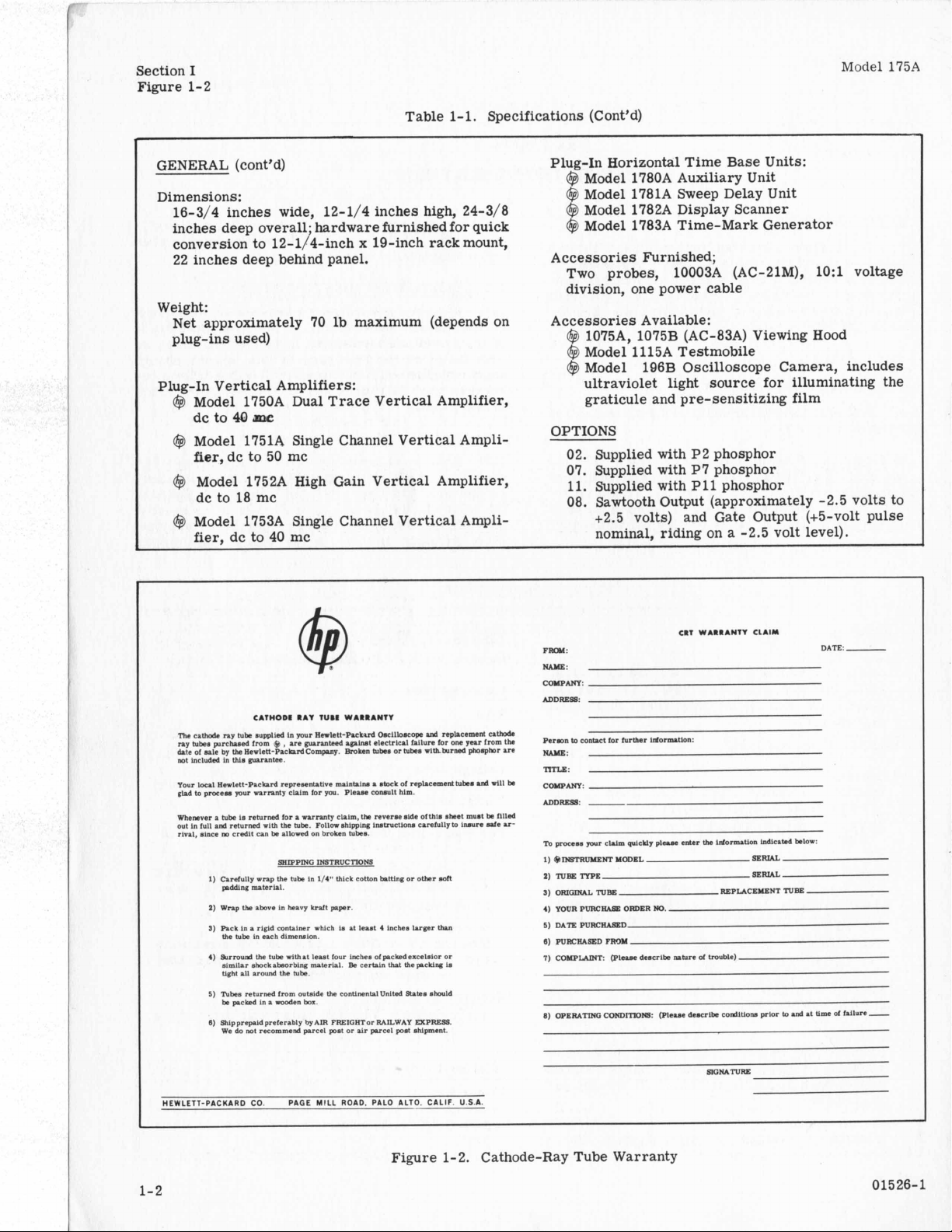

SWEEP GENERATOR

Internal Sweep:

24 ranges, 0.1 psec/cm to 5 sec/cm

nier

provides continuous adjustment between

ranges and extends slowest sweep to at least

12.5 sec/cm.

Magnification: X10 (*5%)

Triggering:

Internal

below

External

from any signal 0.5 volt peak-to-peakor more.

Triggering Point:

Internal

going signal displayed on the crt graticule.

External

on either the positive- or negative-going portion of the vertical signal.

HORIZONTAL

Bandwidth DC to 500 kc

Sensitivity:

2

ranges, 0.1 volt/cm and 1 volt/cm. Vernier

provides continuous adjustment between ranges

and extends minimum sensitivity to 10 volts per

centimeter.

Input Impedance:

1

-

Vertical input signal (from 2 mm

1

mc to approximately 2 cm

-

Either capacitive-

-

Any level of positive- or negative-

-

Any level between +5 and -5 volts

AMP

LIFTER

megohm shunted by approximately 30 pf

or

*3%.

at

50 mc).

direct-coupled,

Ver-

VERTICAL AMPLIFTER

Bandwidth: DC to greater than 50 mc

CALIBRATOR

Type:

Approximately 1000-cycle square wave, approximately 3 psec rise time

Voltage:

2

ranges, 1 volt and 10 volts peak-to-peak,

*l%,

15°C to 35°C

CATHODE-RAY TUBE

Type:

@

post accelerator, 12-kv accelerating potential.

Type P31-AL phosphor standard. For other

phosphors,

Graticule:

Internal, 6 x 10 cm, marked in centimeter

squares. Major horizontal and vertical axes

have 2-millimeter subdivisions.

Intensity Modulation:

Approximately +20-volt pulse

of normal intensity

GENERAL

Power Requirements:

115 or 230 volts ac

mately 425 watts maximum (depends on plug-ins

used).

see

OPTIONS.

will

*lo%,

50 to 60 cps, approxi-

blank trace

01526-1

1-1

Page 8

Section

Figure

I

1-2

Model 175A

Table

1-1.

GENERAL (cont'd)

Dimensions:

16-3/4 inches wide, 12-1/4 inches high, 24-3/8

inches deep overall; hardware furnished for quick

conversion to 12-1/4-inch

x

19-inch rack mount,

22 inches deep behind panel.

Weight:

Net

approximately

70

lb

maximum (depends on

plug-ins used)

Plug-In Vertical Amplifiers:

($3

Model 1750A Dual Trace Vertical Amplifier,

40

dc to

@

Model 1751A Single Channel Vertical Ampli-

arx

fier,dc to 50 mc

@

Model 1752A High Gain Vertical Amplifier,

dc to 18 mc

@

Model 1753A Single Channel Vertical Amplifier, dc to 40 mc

Specifications (Cont'd)

Plug-In Horizontal Time Base Units:

($3

Model 1780A Auxiliary Unit

@

Model 1781A Sweep Delay Unit

@

Model 1782A Display Scanner

@

Model 1783A Time-Mark Generator

Accessories Furnished;

Two probes, 10003A (AC-21M),

division, one power cable

Accessories Available:

($3

1075A, 1075B (AC-83A) Viewing Hood

($3

Model 1115A Testmobile

($4

Model

ultraviolet light source for illuminating the

graticule and pre-sensitizing film

OPTIONS

02. Supplied with

07.

Supplied with

11.

Supplied with

08. Sawtooth Output (approximately -2.5 volts to

+2.5 volts) and Gate Output (+5-volt pulse

nominal, riding on a

1O:l

voltage

196B Oscilloscope Camera, includes

P2

phosphor

P7

phosphor

P11

phosphor

-

2.5 volt level).

HEWLETT-PACKARD CO. PAGE MILL

1-2

ROAD.

PAL0 ALTO. CALIF.

U.S.A.

Figure 1-2. Cathode-Ray Tube Warranty

01526-1

Page 9

Model 175A Section I

Table

1-2

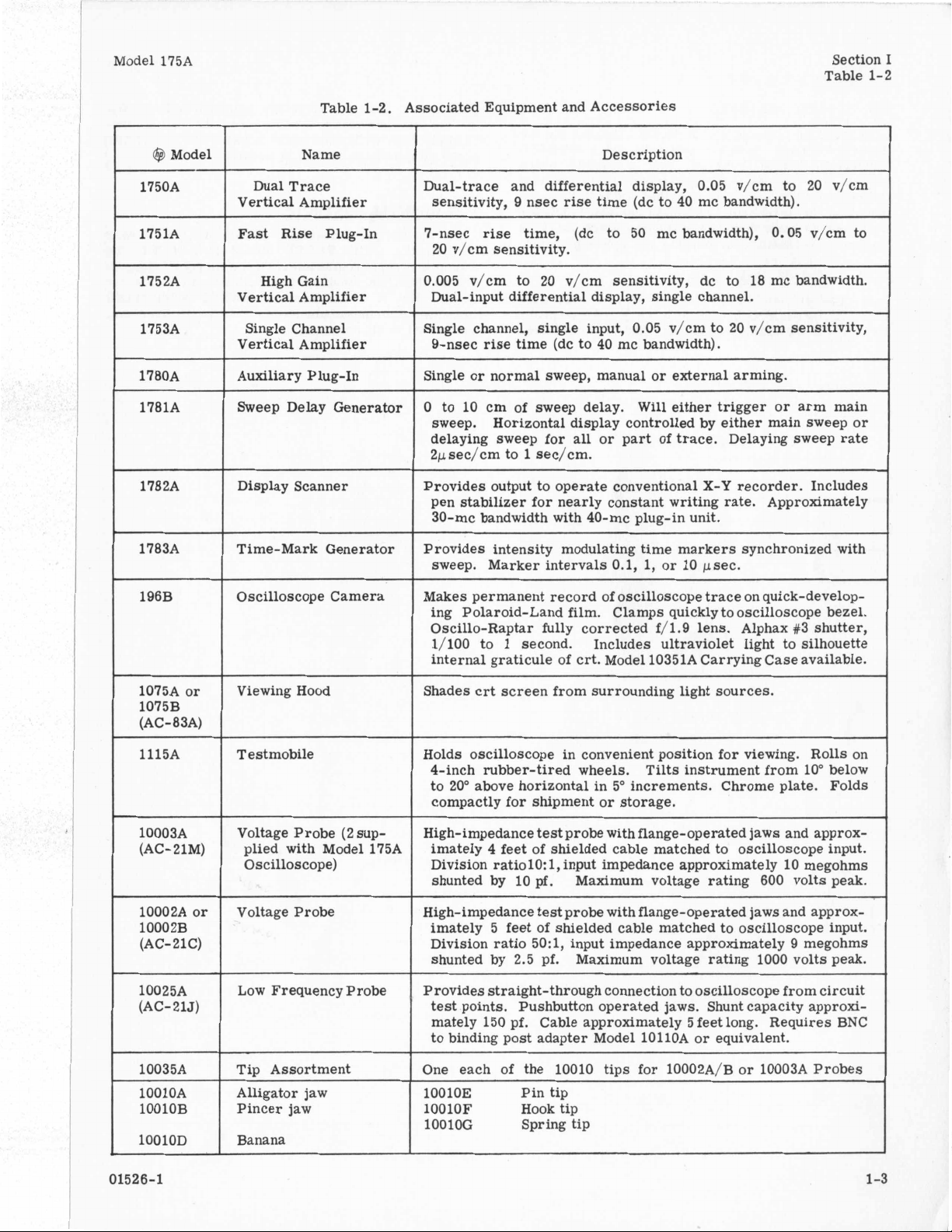

Table 1-2. Associated Equipment and Accessories

@

Model Name

Description

1750A

Dual Trace

Vertical Amplifier

1751A

1752A

Fast

High Gain

Rise Plug-In

Vertical Amplifier

1753A

Single Channel

Vertical Amplifier

1780A

1781A

Auxiliary Plug-In

Sweep Delay Generator

1782A Display Scanner

1783A

Time-Mark Generator Provides intensity modulating time markers synchronized with

Oscilloscope Camera Makes permanent record of oscilloscope trace on quick-develop-

~~ ~

1075A or

Viewing Hood

1075B

(AC-83A)

Dual-trace and differential display, 0.05 v/cm to 20 V/Cm

sensitivity, 9 nsec rise time (dc to

40

mc bandwidth).

7-nsec rise time, (dc to 50 mc bandwidth), 0.05 v/cm to

20 v/cm sensitivity.

0.005 v/cm to 20 v/cm sensitivity, dc to 18 mc bandwidth.

Dual-input differential display, single channel.

Single channel, single input, 0.05 v/cm to 20 v/cm sensitivity,

rise

9-nsec

time (dc to 40 mc bandwidth).

Single or normal sweep, manual or external arming.

to 10 cm of sweep delay.

0

Will

either trigger or arm main

sweep. Horizontal display controlled by either main sweep or

delaying sweep for all or part of trace. Delaying sweep rate

2psec/cm to

Provides output to operate conventional

1

sec/cm.

X-Y

recorder. Includes

pen stabilizer for nearly constant writing rate. Approximately

30-mc bandwidth with 40-mc plug-in unit.

1,

sweep. Marker intervals 0.1,

or 10 psec.

ing Polaroid-Land film. Clamps quickly to oscilloscope bezel.

Oscillo-Raptar fully corrected f/1.9 lens. Alphax #3 shutter,

1/100 to

internal graticule of

1

second. Includes ultraviolet light to silhouette

crt.

Model 10351A Carrying Case available.

Shades crt screen from surrounding light sources.

1115A

Testmobile Holds oscilloscope in convenient position for viewing. Rolls on

4-inch rubber-tired wheels. Tilts instrument from 10" below

to 20" above horizontal in 5" increments. Chrome plate. Folds

compactly for shipment or storage.

10003A

(AC- 21M)

10002B

(AC- 21C)

Voltage Probe (2 sup-

plied with Model 175A

Oscilloscope)

Voltage Probe 10002A or

High-impedance

imately

4

Division ratiolO:l, input impedance approximately 10 megohms

shunted

High-impedance

imately 5

Division ratio 50:

test

probe with flange-operated jaws and approx-

feet of shielded cable matched to oscilloscope input.

by

10

pf.

Maximum voltage rating 600 volts peak.

test

probe with flange-operated jaws and approx-

feet

of shielded cable matched to oscilloscope input.

1,

input impedance approximately 9 megohms

~~ ~

shunted by 2.5 pf. Maximum voltage rating 1000 volts peak.

10025A

(AC-21J)

10035A

lOOlOA

lOOlOB

lOOlOD

Low Frequency Probe

~~~~

Tip Assortment

Alligator jaw

Pincer jaw

Banana

Provides straight-through connection to oscilloscope from circuit

test

points. Pushbutton operated jaws. Shunt capacity approxi-

mately 150 pf. Cable approximately

to binding post adapter Model

5

lOllOA

feet long. Requires BNC

or equivalent.

One each of the 10010 tips for 10002A/B or 10003A Probes

lOOlOE Pin tip

lOOlOF

lOOlOG

Hook tip

Spring tip

01526-1 1-3

Page 10

Section I

Paragraphs 1-9 to 1-14

Model 175A

1-9.

SPECIAL FEATURES.

1-10. Special features of the Model 175A include the

Hewlett-Packard internal-graticule crt, PRESET

triggering, BEAM FINDER, and a cabinet which

serves both bench- and rack-mount requirements.

Optional plug-in units are provided for both the vertical and the time axis. The main vertical amplifier

rise

time

is

less

than 7 nanoseconds which provides

maximum versatility for present and future plug-ins.

1-11.

CATHODE-RAY TUBE.

1-12. The

12-kv post-accelerator type with the

cule which eliminates parallax, and an aluminized

crt

used in the Model 175A

is

a multi-grid

@

internal grati-

phosphor. The gun structure provides a large

10 cm distortionless viewing area as well as extremely high deflection-plate sensitivity. No frontpanel astigmatism control

1-13. SPECIAL CONTROLS.

1-14. Special panel controls make the Model 175A easy

to operate. With SWEEP MODE in PRESET, the

sweep will synchronize internally on nearly all signals.

BEAM FINDER enables the operator to locate the

beam when

increases the maximum sweep rate to 10 nsec/cm,

calibrated in

it

is

off screen. SWEEP MAGNIFIER

all

positions.

is

required.

6

x

1-4

01526-1

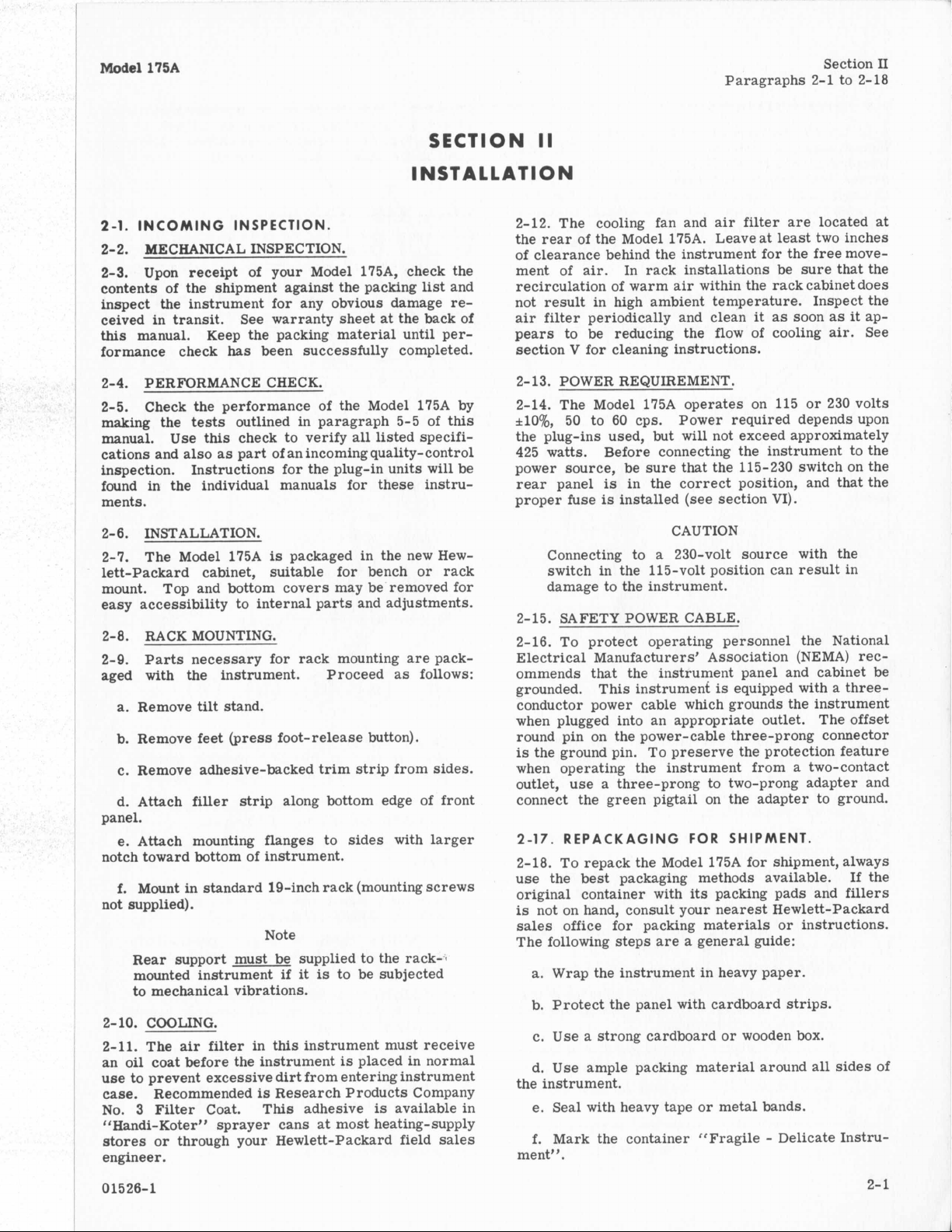

Page 11

Model

175A

Paragraphs

Section

2-1

to 2-18

11

SECTION

INSTALLATION

2-1.

INCOMING

2-2. MECHANICAL INSPECTION.

2-3. Upon receipt of your Model 175A, check the

contents of the shipment against the packing

inspect the instrument for any obvious damage received in transit. See warranty sheet at the back of

this

manual. Keep the packing material until per-

formance check

2-4. PERFORMANCE CHECK.

2-5. Check the performance of the Model 175A by

making the

manual. Use this check to verify

cations and also

inspection. Instructions for the plug-in units will be

found in the individual manuals for these instruments.

2-6. INSTALLATION.

2-7. The Model 175A

lett-Packard cabinet, suitable for bench or rack

mount. Top and bottom covers may

easy accessibility to internal parts and adjustments.

2-8. RACK MOUNTING.

2-9. Parts necessary for rack mounting are pack-

aged with

a. Remove

b. Remove

c.

Remove adhesive-backed trim strip from sides.

d. Attach filler strip along bottom edge of front

panel.

e.

Attach mounting flanges to sides with larger

notch toward bottom of instrument.

f.

Mount in standard 19-inch rack (mounting screws

not supplied).

Rear support must be supplied to the rack-.<

mounted instrument

to mechanical vibrations.

2-10.

2-11. The air filter in this instrument must receive

an oil coat before the instrument

use

to prevent excessive dirt from entering instrument

case. Recommended

No.

3

“Handi-Koter” sprayer cans at most heating-supply

stores or through your Hewlett-Packard field sales

engineer.

the

COOLING.

Filter Coat. This adhesive

INSPECTION.

has

been successfully completed.

tests

outlined in paragraph 5-5 of this

all

listed specifi-

as

part of an incoming quality-control

is

packaged in the new Hew-

be

removed for

instrument. Proceed as follows:

tilt

stand.

feet

(press foot-release button).

Note

if

it

is

to be subjected

is

placed in normal

is

Research Products Company

is

available in

list

and

II

2-12. The cooling fan and air filter are located at

the rear of the Model 175A. Leaveat least two inches

of clearance behind the instrument for the free move-

ment of air. In rack installations be sure that the

recirculation of warm

not result in high ambient temperature. Inspect the

air

filter periodically and clean

pears to be reducing the flow of cooling

section V for cleaning instructions.

2-13. POWER REQUIREMENT.

2-14. The Model 175A operates on 115 or 230 volts

*lo%,

the plug-ins used, but will not exceed approximately

425 watts. Before connecting the instrument to the

power source, be sure

rear

proper fuse

2-15. SAFETY POWER CABLE.

2-16. To protect operating personnel the National

Electrical Manufacturers’ Association (NEMA) recommends that the instrument panel and cabinet be

grounded. This instrument

conductor power cable which grounds the instrument

when plugged into an appropriate outlet. The offset

round pin on the power-cable three-prong connector

is

when operating the instrument from a two-contact

outlet, use a three-prong to two-prong adapter and

connect the green pigtail on the adapter to ground.

2-17.

2-18. To repack the Model 175A for shipment, always

use the best packaging methods available. If the

original container with

is

sales office for packing materials or instructions.

The following steps are a general guide:

the instrument.

ment”.

50

to

60

panel

Connecting to a 230-volt source with the

switch in the 115-volt position can result in

damage to the instrument.

the ground pin. To preserve the protection feature

not on hand, consult your nearest Hewlett-Packard

a. Wrap the instrument in heavy paper.

b.

Protect the panel with cardboard strips.

c.

Use a strong cardboard or wooden

d. Use ample packing material around all sides of

e.

Seal with heavy tape or metal bands.

f.

Mark the container “Fragile - Delicate Instru-

is

in the correct position, and that the

is

installed (see section VI).

REPACKAGING FOR SHIPMENT.

air

within the rack cabinet does

it

as soon as

cps. Power required dependsupon

that

the 115-230 switch on the

CAUTION

is

equipped with a three-

its

packing pads and fillers

air.

it

apSee

box.

01526-1

2-

1

Page 12

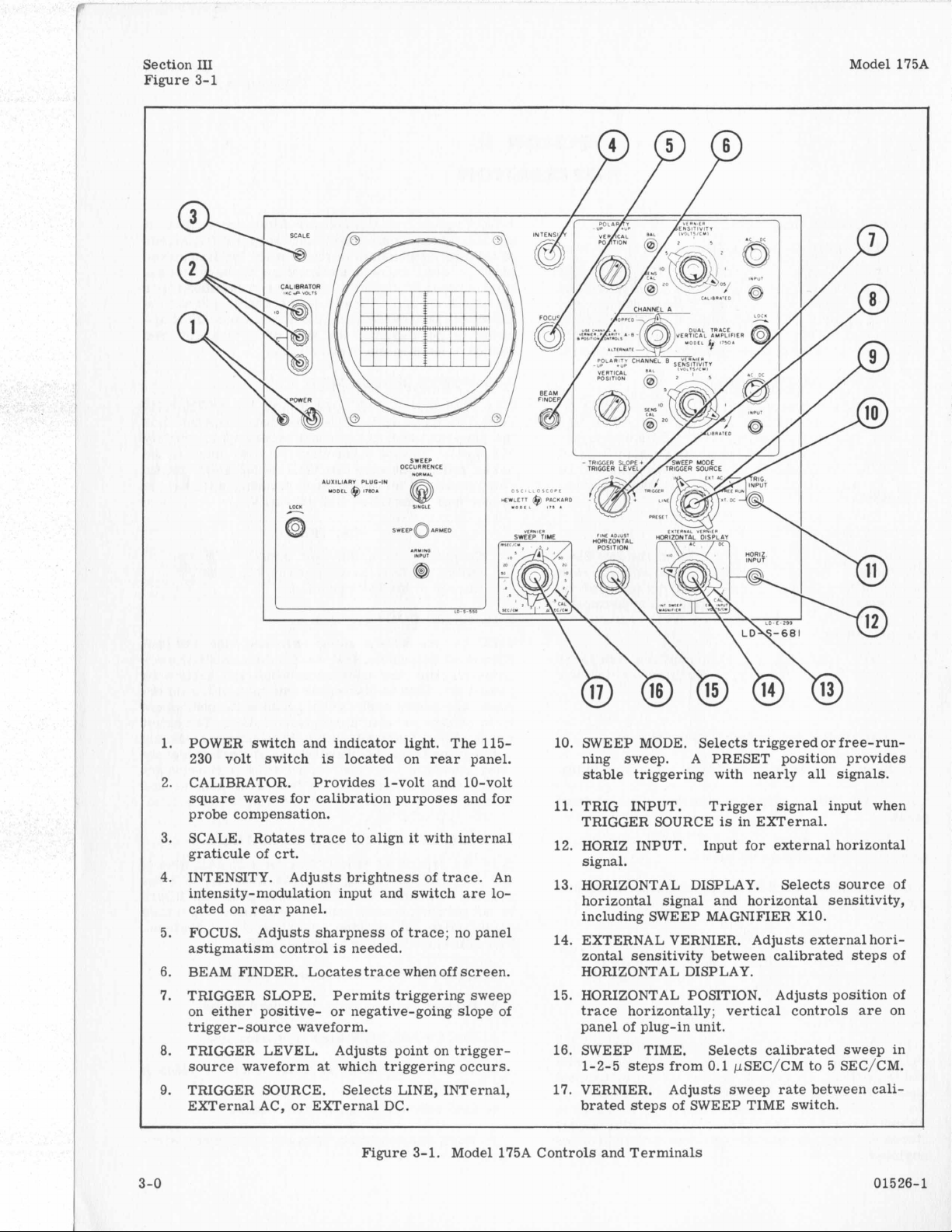

Section

Figure

111

3-1

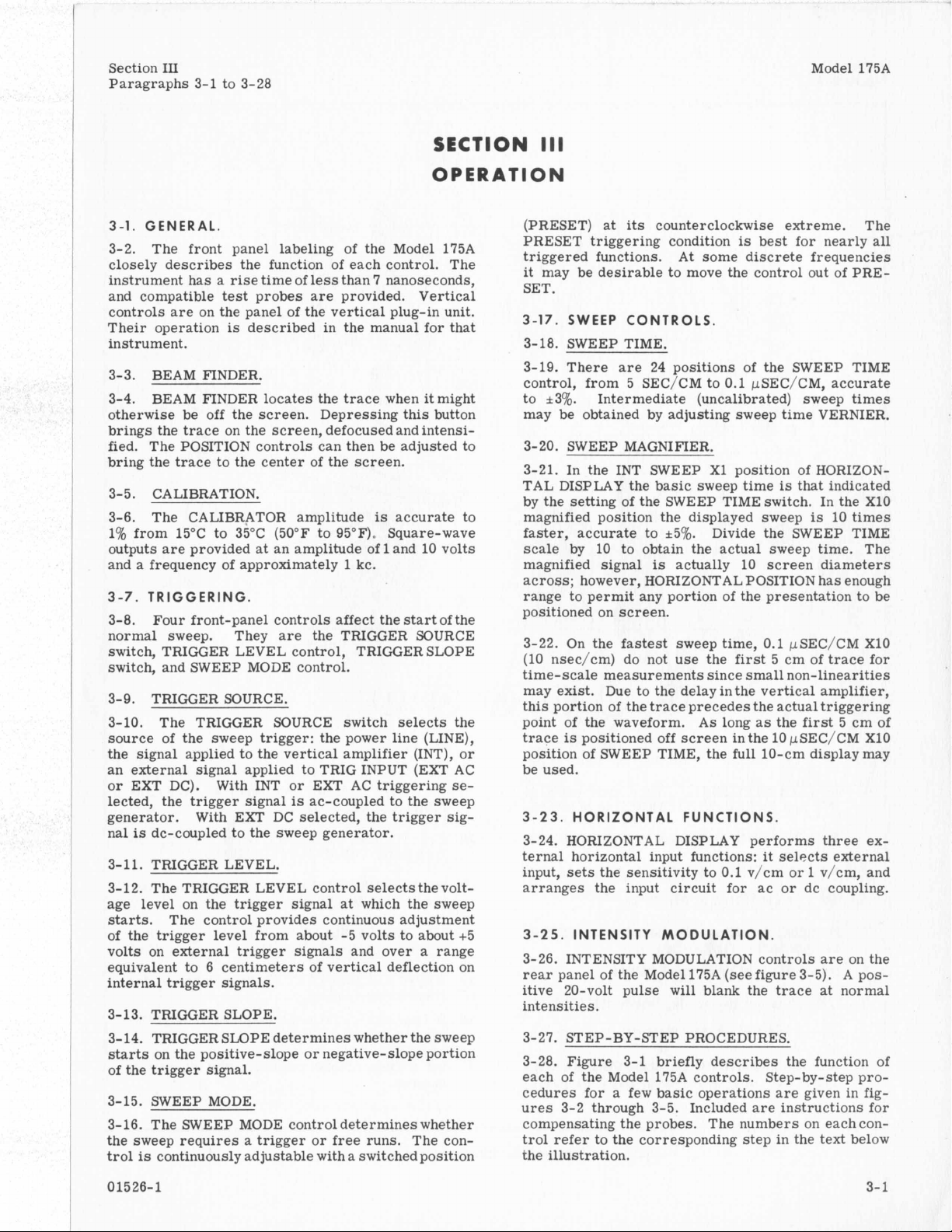

SWEEP

OCCURRENCE

Model 175A

POWER switch and indicator light. The 115-

1.

230 volt switch

CALIBRATOR. Provides 1-volt and 10-volt

2.

is

located on

rear

square waves for calibration purposes and for

probe compensation.

SCALE. Rotates

3.

graticule of

4.

INTENSITY. Adjusts brightness of

crt.

trace

to align

it

with internal

trace.

intensity-modulation input and switch

cated on

5.

FOCUS. Adjusts sharpness of trace; no panel

astigmatism control

BEAM FINDER. Locates

6.

TRIGGER SLOPE. Permits triggering sweep

7.

rear

panel.

is

needed.

trace

when off screen.

on either positive- or negative-going slope of

trigger-source waveform.

TRIGGER LEVEL. Adjusts point on trigger-

8.

source waveform

TRIGGER SOURCE. Selects LINE, INTernal,

9.

at

which triggering occurs.

EXTernal AC, or EXTernal DC.

Figure

3-1.

panel.

An

are

lo-

Model 175A Controls and Terminals

10. SWEEP MODE. Selects triggered or free-running sweep.

stable

11.

TRIG INPUT. Trigger signal input when

triggering with nearly

TRIGGER SOURCE

A

PRESET position provides

all

signals.

is

in EXTernal.

12. HORIZ INPUT. Input for external horizontal

signal.

13.

HORIZONTAL DISPLAY. Selects source of

horizontal signal and horizontal sensitivity,

including SWEEP MAGNIFIER X10.

14. EXTERNAL VERNIER. Adjusts external hori-

zontal sensitivity between calibrated steps of

HORIZONTAL DISPLAY.

15. HORIZONTAL POSITION. Adjusts position of

trace

horizontally; vertical controls

are

on

panel of plug-in unit.

16. SWEEP TIME. Selects calibrated sweep in

1-2-5 steps from 0.1 pSEC/CM to 5 SEC/CM.

17. VERNIER. Adjusts sweep

rate

between

cali-

brated steps of SWEEP TIME switch.

3-0 01526-1

Page 13

Section

Paragraphs 3-1 to 3-28

111

Model 175A

SECTION

OPERATION

3-1. GENERAL.

3-2. The front panel labeling of the Model 175A

closely describes the function of each control. The

instrument

and compatible test probes are provided. Vertical

controls are on the panel of the vertical plug-in unit.

Their operation

instrument.

3-3. BEAM FINDER.

3-4. BEAM FINDER locates the trace when

otherwise be off the screen. Depressing this button

brings the trace on the screen, defocused and intensified. The POSITION controls can then be adjusted to

bring the trace to the center of the screen.

3-5. CALIBRATION.

3-6. The CALIBRATOR amplitude

1%

from 15°C to 35°C (50°F to 95°F). Square-wave

outputs are provided at an amplitude of

and a frequency of approximately

3-7. TRIGGERING.

3-8. Four front-panel controls affect the start of the

normal sweep. They are the TRIGGER SOURCE

switch, TRIGGER LEVEL control, TRIGGER SLOPE

switch, and SWEEP MODE control.

3-9. TRIGGER SOURCE.

3-10. The TRIGGER SOURCE switch selects the

source of the sweep trigger: the power line (LINE),

the signal applied to the vertical amplifier (INT), or

an external signal applied to TRIG INPUT (EXT AC

or EXT DC). With INT

lected, the trigger signal

generator. With EX” DC selected, the trigger signal

is

3-

11.

3-12. The TRIGGER LEVEL control selects the voltage level on the trigger signal at which the sweep

starts. The control provides continuous adjustment

of the trigger level from about -5 volts to about +5

volts on external trigger signals and over a range

equivalent to

internal trigger signals.

3-13. TRIGGER SLOPE.

3-14. TRIGGER SLOPE determines whether the sweep

starts

of the trigger signal.

3-15. SWEEP MODE.

3-16. The SWEEP MODE control determines whether

the sweep requires a trigger or free runs. The control

is

has

a rise time of less than 7 nanoseconds,

is

described in the manual for that

it

might

is

accurate to

1

and 10 volts

1

kc.

or EXT AC triggering se-

is

ac-coupled to the sweep

dc-coupled to the sweep generator.

TRIGGER LEVEL.

6

centimeters of vertical deflection on

on the positive-slope or negative-slope portion

continuously adjustable with a switched position

111

(PRESET) at

PRESET triggering condition

triggered functions.

it

may be desirable to move the control out of PRE-

SET.

3-17. SWEEP CONTROLS,

3-18. SWEEP TIME.

3-19. There are 24 positions of the SWEEP TIME

control, from

to *3%. Intermediate (uncalibrated) sweep times

may be obtained by adjusting sweep time VERNIER.

3-20. SWEEP MAGNIFIER.

3-21. In the INT SWEEP

TAL DISPLAY the basic sweep time

by the setting of the SWEEP TIME switch. In the X10

magnified position the displayed sweep

faster, accurate to

scale

by

magnified signal

across; however, HORIZONTAL POSITION has enough

range to permit any portion of the presentation to be

positioned on screen.

3-22. On the fastest sweep time, 0.1 pSEC/CM X10

(10 nsec/cm) do not use the

time-scale measurements since small non-linearities

may exist. Due to the delayinthe vertical amplifier,

this portion of the trace precedes the actual triggering

point of the waveform.

trace

is

position of SWEEP TIME, the

be used.

3-23. HORIZONTAL FUNCTIONS.

3-24. HORIZONTAL DISPLAY performs three external horizontal input functions: it selects external

input, sets the sensitivity to 0.1 v/cm or

arranges the input circuit for ac or dc coupling.

3-25. INTENSITY MODULATION.

3-26. INTENSITY MODULATION controls are on the

rear panel of the Model 175A (see figure 3-5).

itive 20-volt pulse

intensities.

3-27. STEP-BY-STEP PROCEDURES.

3-28. Figure 3-1 briefly describes the function of

each of the Model 175A controls.

cedures for a few basic operations are given in figures 3-2 through 3-5. Included are instructions for

compensating the probes. The numbers on each control refer

the illustration.

its

counterclockwise extreme. The

is

best for nearly all

At

some discrete frequencies

5

SEC/CM

10 to obtain the actual sweep time. The

is

positioned off screen in the 10 pSEC/CM X10

to

the corresponding step in the text below

to

0.1

~SEC/CM,

X1

position of HORIZON-

is

*5%.

Divide the SWEEP TIME

actually 10 screen diameters

first

5 cm of trace for

As

long as the

full

10-cm display may

will

blank the trace at normal

Step-by-step pro-

accurate

that

indicated

is

10 times

first 5 cm of

1

v/cm, and

A

pos-

01526-1

3-

1

Page 14

Section

Figure 3-2

111

SWEEP

OCCURRENCE

1

1

Model

175A

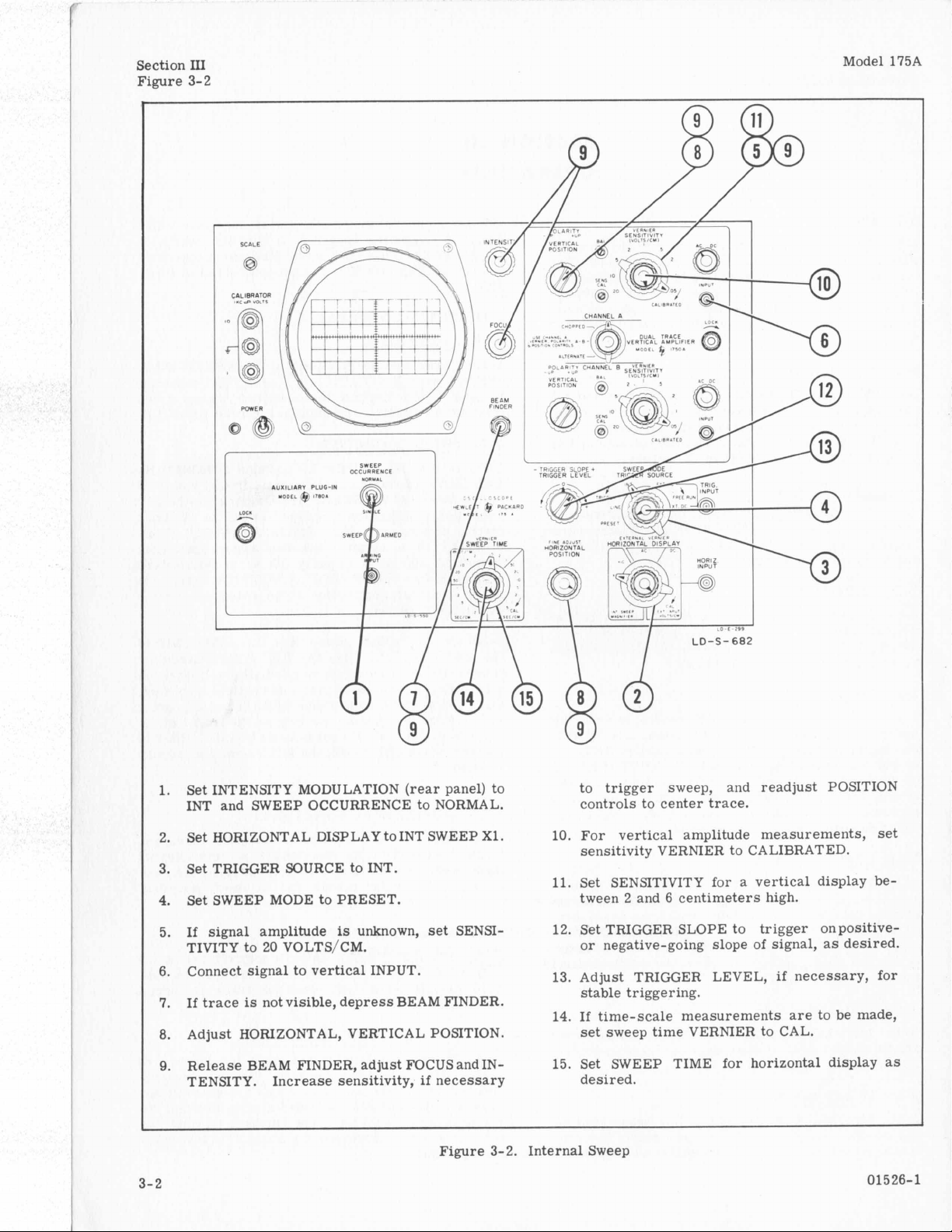

Set INTENSITY MODULATION (rear panel) to

1.

INT and SWEEP OCCURRENCE to NORMAL.

Set HORIZONTAL DISPLAY to INT SWEEP X1.

2.

Set TRIGGER SOURCE to INT.

3.

Set SWEEP MODE to PRESET.

4.

If

5.

6.

7.

8.

9.

3-2 01526-1

signal amplitude

TIVITY to 20 VOLTS/CM.

Connect signal to vertical INPUT.

If trace

Adjust HORIZONTAL, VERTICAL POSITION.

Release BEAM FINDER, adjust FOCUS and IN-

TENSITY. Increase sensitivity,

is

not visible, depress BEAM FINDER.

is

unknown,

set

SENSI-

if

necessary

Figure 3-2. Internal Sweep

to trigger sweep, and readjust POSITION

controls to center trace.

10. For vertical amplitude measurements,

sensitivity VERNIER to CALIBRATED.

11.

Set SENSITIVITY for a vertical display

tween 2 and 6 centimeters high.

12. Set TRIGGER SLOPE to trigger onpositive-

or negative-going slope of signal,

13. Adjust TRIGGER LEVEL,

stable triggering.

14. If time-scale measurements

set

sweep time VERNIER to CAL.

15. Set SWEEP TIME for horizontal display as

desired.

as

if

necessary, for

are

to be made,

set

be-

desired.

Page 15

Model

175A

INTENSITY

@

@

BEAM FlNDfR

-

TRIGGEff

TRIGGER

SLOPE

LEVEL

Section

III

Figure 3-3

__

. . . .

t

SWEEP

WE

TRIGGER

SOURCE

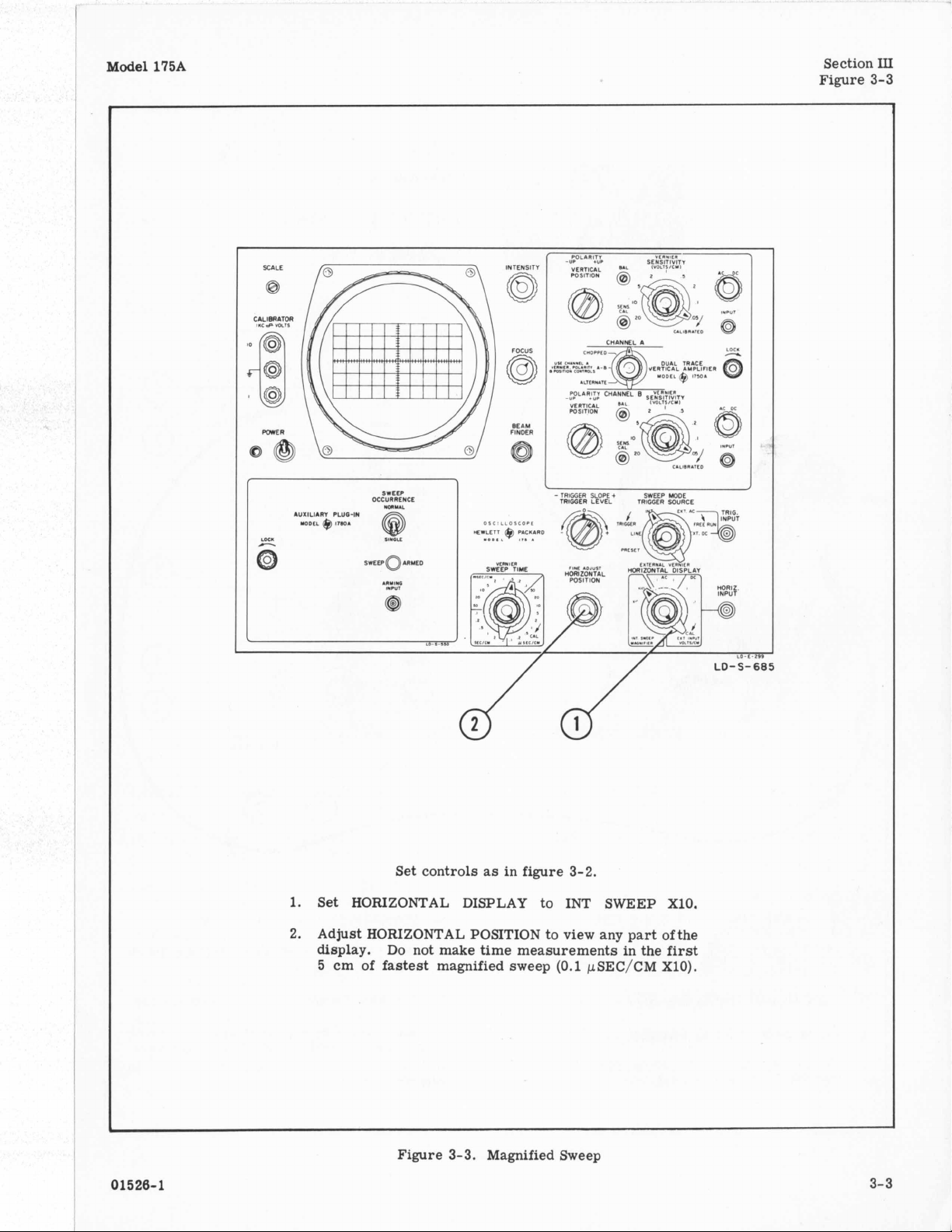

Set controls as in figure 3-2.

1. Set HORIZONTAL DISPLAY to INT

SWEEP

X10.

2. Adjust HORIZONTAL POSITION to view any part of the

display. Do

5

cm of fastest magnified sweep (0.1

not make time measurements in the first

pSEC/CM

X10).

Figure 3-3. Magnified Sweep

01526-1 3- 3

Page 16

Section

Figure

111

3-4

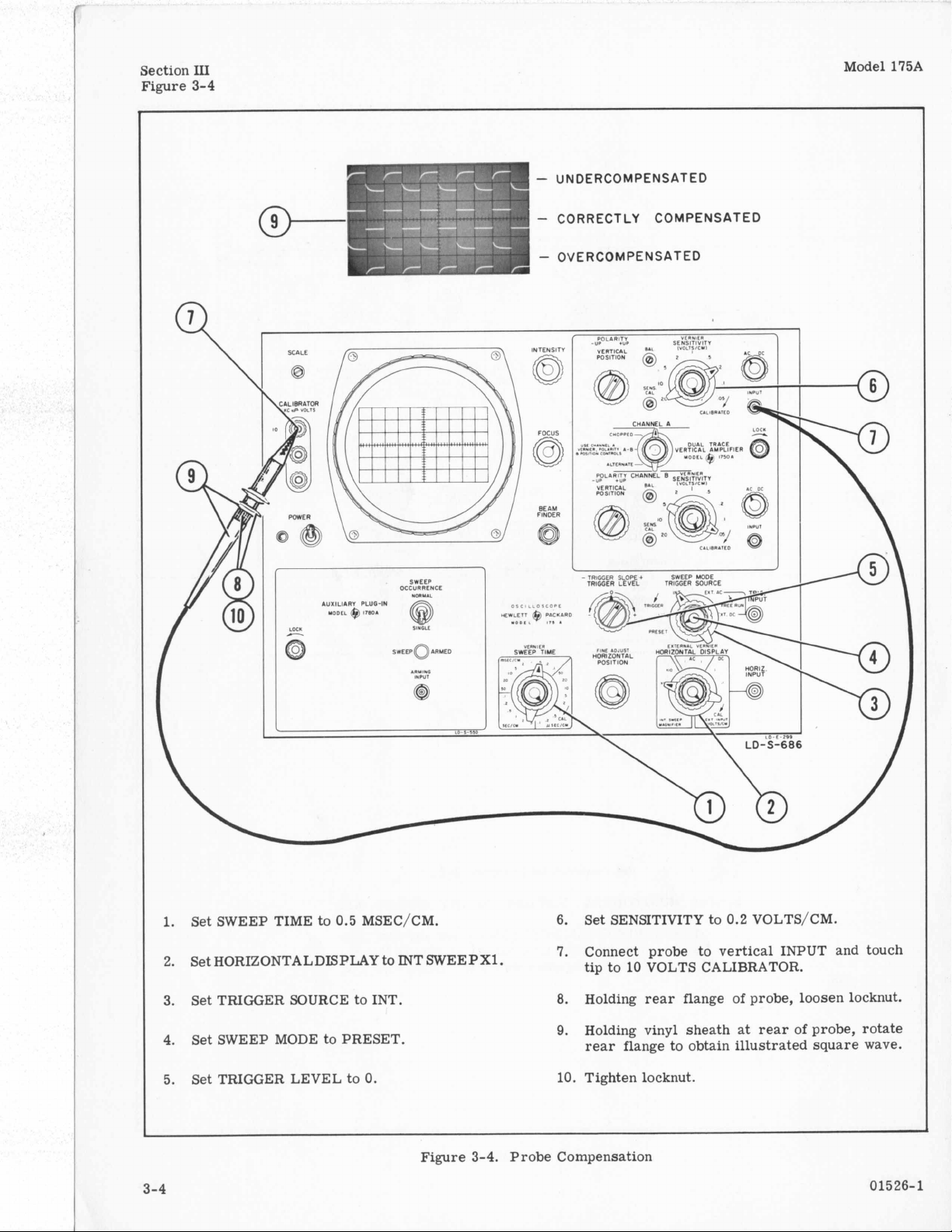

-

UNDERCOMPENSATED

-

CORRECTLY COMPENSATED

-

OVERCOMPENSATED

Model 175A

SWEEP

PLUG-IN

OCCURRENCE

69

IlMCLL

Connect probe to vertical INPUT and touch

7.

tip to 10 VOLTS CALIBRATOR.

8.

Holding rear flange of probe, loosen locknut.

Holding vinyl sheath

9.

at

rear of probe, rotate

rear flange to obtain illustrated square wave.

AUXILIARY

LO<.

1.

Set SWEEP TIME to 0.5 MSEC/CM. 6. Set SENSITIVITY to 0.2 VOLTS/CM.

2.

Set HORIZONTALDISPLAY to INTSWEEPXl.

3.

Set TRIGGER SOURCE to INT.

Set SWEEP MODE to PRESET.

4.

3-4

5.

Set TRIGGER LEVEL to

0.

Figure

10. Tighten locknut.

3-4.

Probe Compensation

01526-

1

Page 17

Model

175A

Section

III

Figure 3-5

INTENSITY

Connect modulating voltage to INPUT (+20 volts will

1.

blank trace

2.

Switch to EXTERNAL.

MODULATION

at

normal intensity).

Figure 3-5. Intensity Modulation

LD-

5-

687

LD-S-688

01526-1

3-

5

Page 18

Section

Figure

IV

4-1

VERTICAL

PRESENTATION

9

\

CHANNELA

CHANNEL

B

Model

175A

I

Q

[SENSITIVITY1

I

I I

9

1-1

I

I

!Qm]

\

\

‘.C

;;I

I

,I

I

I.,

’

I

TRACE

AMPLIFIER

I

I

9

[VERTICAL

4

POSITION/

VERTICAL

AMPLIFIER

\

7--

I

ro

CRT

vmn

CA

D

Ef

PL A TES

L

L

€C

nON

-1

I

I

I

I

I

I

I

I

4-0

Figure

4-1.

Overall

Model

Block

1750A

Diagram

Plug-In

of

Unit

Model

175A

with

01526-1

Page 19

Model

175A

Section

Paragraphs 4- 1 to

4-

IV

10

SECTION

PRINCIPLES

4-1.

OVERALL FUNCTIONAL DESCRIPTION.

4-2. The Model 175A consists of a high- and a lowvoltage supply, a vertical and

a

sweep generator and a calibrator. Bothpower sup-

plies are regulated,

tions include a gate- and sweep-output circuit not

included in the standard instrument. Figure 4-1

shows

the main functional units and controls.

a dual-trace plug-in amplifier has been shown as part

of the diagram. The circuits of the plug-in units are

described in the manuals for those instruments. Circuit diagrams

5-19 to 5-38.

4-3. VERTICAL AMPLIFIER. The vertical amplifier delays the signal received from the dual-trace

amplifier and applies the amplified signal to the vertical deflection plates of the crt. Before the signal

is

signal to the sweep generator for internal triggering

of the sweep.

4-4. SWEEP GENERATOR. The sweep generator

accepts a trigger signal from an internal or external

source and generates a fast-rising trigger which

synchronized with the trigger signal. The trigger

starts

the beam horizontally across the crt screen. The

sweep generator thus provides a linear time base on

which to measure the vertical signal. The sweep

generator also provides an unblanking pulse to turn

on the crt beam during the sweep.

4-5. HORIZONTAL AMPLIFIER. The horizontal

amplifier converts the internal sweep or external

a

block diagram of the instrument illustrating

delayed, the vertical amplifier applies part of the

the linearly rising sweep voltage which drives

of

the

as

Model

a

horizontal amplifier,

is

the dc heater supply. Op-

For clarity,

175A are shown in

figures

is

IV

OF

OPERATION

signal

the signal to the level required

deflection plates of the crt.

4-6. CALIBRATOR. The calibrator multivibrator

generates a square wave of about

and 10-volt outputs.

4-7. HIGH-VOLTAGE POWER SUPPLY. The highvoltage power supply

cuit which generates the three regulated dc voltages

required for operation of the crt.

4-8. LOW-VOLTAGE POWER SUPPLIES. Operating voltages for all the oscilloscope circuits, including the high-voltage supply, are provided

low-voltage power supplies.

regulated.

4-9.

4-10. The vertical amplifier

anced differential amplifier. The block diagram

shown in figure 4-2. The amplifier receives the

balanced signal from the plug-in vertical amplifier,

amplifies the signal, and drives the vertical deflection plates of the

line which delays the vertical signal 0.2 psec before

applying

the delay line, the signal from one side of the amplifier

generator for internal triggering of the sweep. This

starts

signal at the crt deflection plates. The delayed signal

5105 for use in the Model 1782A Display Scanner.

from unbalanced to balanced, and amplifies

to

drive the horizontal

1

kc with 1-volt

is

an

rf

oscillator-rectifier cir-

All

dc voltages are

VERTICAL AMPLIFIER.

is

a conventional bal-

crt.

The circuit includes a delay

it

to the vertical plates of the crt. Prior to

is

sampled, amplified and applied to the sweep

the sweep in advance of arrival of the vertical

is

also applied to horizontal plug-in connector

by

the

is

CATHODE

DELAY

LINE

VERTICAL INPUT

SIGNAL

FROM

PLUG-IN

01526-1 4-1

CATHODE

FOLLOWER

INPUT

AMPLIFIER

Figure 4-2. Vertical Amplifier Block Diagram

CATHODE AMPLIF I ER

-

FOLLOWER

v3

TRIGGER SIGNAL

TO SWEEP GENERATOR

THROUGH TRIGGER-SOURCE

+

A

SWITCH

SI02

v4

FOLLOWER

--*

DRIVER

v7

OUTPUT

AMPLIFIER CATHODE-RAY TO

CATHODE

FOLLOWER

-

I

CAL

VERT

OUTPUT

TUBE

DISPLAY

SCAN NE

R

Page 20

Section

IV

Paragraphs 4-11 to 4-29

Model 175A

INPUT+

---

I

V6A

U

INPUT+

t

+V

Figure 4-3. Cross-Coupled Cathode Follower

Simplified Schematic Diagram

4-11. CROSS-COUPLED CATHODE FOLLOWER.

4-12. Input stage

cross-coupled cathode followers. The simplified

schematic

is

cathode follower circuit provides

driving source for the following stage.

quencies, the stage acts as

High frequency signals appearing

readily pass through coupling capacitors to the opposite cathode. Since these high-frequency signals are

in phase with the signals

add to the current available to the load. The decrease

in load impedance at high frequencies

pensated by the increase in high-frequency current

offered by the cross-coupled cathode follower.

plate and cathode resistors are the same value, there-

fore voltages

in amplitude and the signals are effectively added in

parallel. Since the plate and cathode signals are

added at high frequencies, the effective output imped-

ance

is

reduced.

4- 13. DIFFERENTIAL AMPLIFIER.

4-14. Input amplifier

differential amplifiers. An unbalanced signal applied

to one grid will appear at both plates balanced

amplified. Common-mode signals, such as hum, at

V1,

as

well

as

V3 and V7, are

shown in figure 4-3. The cross-coupled

a

low impedance

At

a

simple cathode follower.

at

the plate circuits

at

the opposite cathode, they

low fre-

is

partly com-

The

at

the plates and cathodes are equal

V2

as well

as

V4 and V7 are

and

the grids

the circuit of amplifier V4, cathode degeneration

are

reduced in magnitude at the plates.

In

is

introduced by Gain control R45, reducing the gain of

the stage.

4-15. PEAKING.

4- 16. Series and shunt peaking are provided through-

out the amplifier to extend the bandwidth while maintaining optimum transient response. Coils L7 and L8

adjust high-frequency response. Capacitors C22 and

C35, which remove cathode degeneration in the circuits of V4 and V7

provide a means of adjusting mid-frequency

as

signal frequency increases,

and

low-frequency response.

4-17. SYNC AMPLIFIER.

4-18. The sync amplifier

is

composed of two cathode

followers (input and output) and two amplifiers. The

sync amplifier samples the signal prior to the vertical

amplifier delay line and delivers this amplified signal to the trigger generator to start the sweep. Since

the signal in the vertical amplifier

is

delayed 0.2 p sec

after the sync amplifier pick-off point, the sweep is

able to

start

before the vertical signal reaches the

crt deflection plates.

4-19. DELAY LINE.

4-20. The delay line

is

constructed to provide

0.2 psec delay. The internal impedance of input amplifier

and R24

V2

in parallel with plate load resistors R23

is

designed to match the impedance of the

delay line in order to minimize reflections. The delay line

is

peaked with L13 and L14 for optimum tran-

sient response.

4-21. CIRCUIT PROTECTION.

4-22. Diodes CR1,

2,

3, and 4 prevent the gridcathode voltage of V3 and V7 from becoming excessive

during turn-on time.

4-23. SCAN OUTPUT.

4-24. Cathode follower V10 provides low-impedance

output to the horizontal plug-in connector for use with

the Model 1782A Display Scanner.

R71-R73 and R74-R72, reduces the dc level

A

balanced divider,

at

the

plates of V7 to approximately zero volts; C36

and C37 compensate the divider

at

high frequencies.

C33 balances the high-frequency scan output.

4-25.

SWEEP

GENERATOR.

4-26. The sweep generator consists of sweep-generating circuits plus an amplifier and trigger generator

which actuate the sweep-generating circuits.

diagram of the sweep generator

is

shown in figure 4-4.

A

block

4-27. TRIGGER GENERATOR.

4-28. The trigger signal is applied through differential driver

YlOl

to trigger-generator tunnel diode

CR102 and amplifier Q103. TRIGGER SLOPE and

TRIGGER LEVEL controls are in the driver circuit.

4-29. The trigger generator

as

a

bistable device to convert

wave shape to

a

rectangular wave with very

is

a

tunnel diode acting

an

input signal of any

fast

a

4- 2

01526-1

Page 21

Model 175A

-IOOV

'

Section IV

Paragraphs 4-30 to 4-33

TIMING

SWITCH

SWEEP

HOLD-OFF

TIME RELATION

BETWEEN SWEEP

AND HOLD-OFF

A

4

nx

GATE OUTPUT

BIAS-CONTROL

CATHODE

FOLLOWER

VI09

I

/

I

SWEEP MODE

1

FOLLOW CATHODE ER

V105A

TIMING

CAPACITOR

HOLDOFF

CAPACITOR

-IOOV

I

-i?Nf

f4

I

CATHODE

I

FOLLOWER

I

I

-1

-

I

-&/I

f

VI07

4b-b

CATHODE

FOLLOWER

VI058

A

t

SWEEP OUTPUT

BO-

L-331

Figure 4-4. Sweep Generator Block Diagram

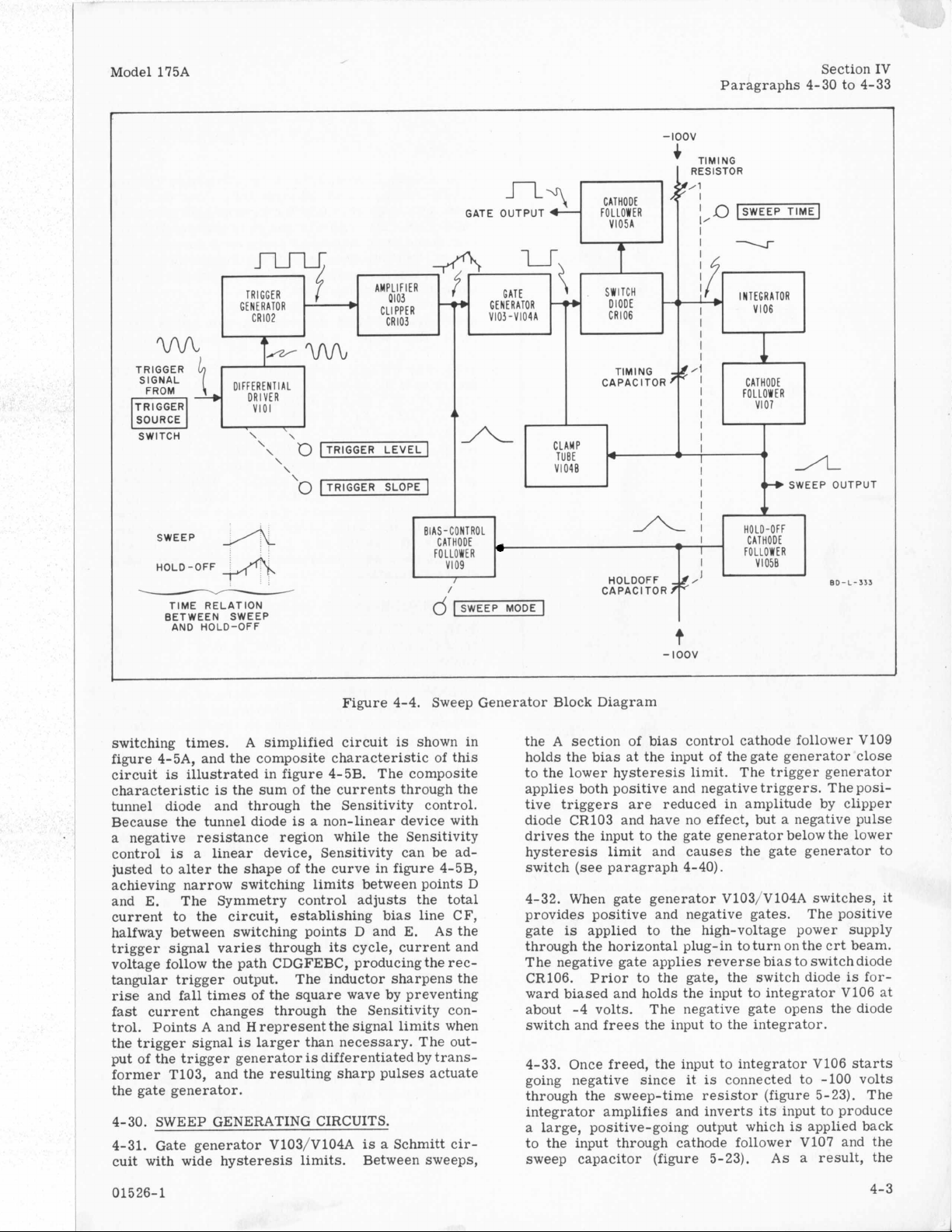

switching times. A simplified circuit

is

shown in

figure 4-5A, and the composite characteristic of this

circuit

characteristic

is

illustrated in figure 4-5B. The composite

is

the sum of the currents through the

tunnel diode and through the Sensitivity control.

Because the tunnel diode

a

negative resistance region while the Sensitivity

control

justed to

is

a linear device, Sensitivity can be ad-

alter

the shape of the curve in figure 4-5B,

is a non-linear device with

achieving narrow switching limits between points D

and E. The Symmetry control adjusts the total

current

halfway between switching points D and E.

trigger signal varies through

voltage follow the path CDGFEBC, producing the

to

the circuit, establishing bias line CF,

its

cycle, current and

As

rec-

the

tangular trigger output. The inductor sharpens the

rise and fall times of the square wave by preventing

fast

current changes through the Sensitivity con-

trol. Points A and

the trigger signal

put

of

the trigger generator

H

represent the signal limits when

is

larger than necessary. The out-

is

differentiated by transformer T103, and the resulting sharp pulses actuate

the gate generator.

4-30. SWEEP GENERATING CIRCUITS.

4-31. Gate generator V103/V104A

is

a

Schmitt

cir-

cuit with wide hysteresis limits. Between sweeps,

the A section of bias control cathode follower VI09

holds the bias at the input of thegate generator close

to the lower hysteresis limit.

The trigger generator

applies both positive and negative triggers. The positive triggers

are

reduced in amplitude by clipper

diode CR103 and have no effect, but a negative pulse

drives the input to the gate generator below the lower

hysteresis limit and causes the gate generator to

switch

4-32. When gate generator V103/V104A switches,

(see

paragraph 4-40).

it

provides positive and negative gates. The positive

gate

is

applied to the high-voltage power supply

through the horizontal plug-in to turn on the crt beam.

The negative gate applies reverse bias to switchdiode

CR106. Prior to the gate, the switch diode

is

forward biased and holds the input to integrator V106 at

about -4 volts. The negative gate opens the diode

switch and frees the input to the integrator.

4-33. Once freed, the input to integrator V106 starts

going negative since it

is

connected to

-100

volts

through the sweep-time resistor (figure 5-23). The

integrator amplifies and inverts its input to produce

a

large, positive-going output which

is

applied back

to the input through cathode follower V107 and the

sweep capacitor (figure 5-23).

As

a result, the

01526-1

4-3

Page 22

Section IV

Paragraphs

A.

CIRCUIT

I

5.5

uc?

4-34

to

0

4-41

+V

4

I

W-LI

OUTPUT

TRIGGER

SYMMETRY

Model

175A

diode

CR106.

integrator

The switch diode returns the input of

V106

to its pre-sweep level, discharging

the sweep capacitor.

4-35.

During a sweep time, hold-off cathode follower

V105B

ends, this capacitor

V103/V104A

charges a hold-off capacitor. After the sweep

lets

the input to gate generator

down slowly enough to prevent that circuit from being triggered again until the remaining

sweep circuits have recovered completely. The

SWEEP TIME switch changes the size of the hold-off

capacitor with sweep time.

4-36.

Clamp

from the same voltage level, about

4-37.

The SWEEP MODE control

determines the no-signal bias

erator

tion of bias control cathode follower

V104B

V103jV104A

ensures that each sweep starts

-50

volts.

R172

at

the input to gate gen-

by setting the

(figure

bias

on the A sec-

V109.

5-23)

With the

control set to PRESET or in the TRIGGER portion of

its adjustable range, the gate generator bias cannot

drop below its lower hysteresis limit unless the trigger generator provides a trigger. With the control

set in the FREE RUN portion of its adjustable range,

the gate bias

teresis limit. Thus

is

allowed to drop below its lower hys-

as

the hold-off capacitor

dis-

charges, it lets the gate generator bias all the way

down to the lower hysteresis limit, and another sweep

starts automatically.

-

V

LD-

Y

-

643

8.

Figure

I

COMPOSITE CURVE

4-5.

Trigger Generator Simplified Circuit

and Composite Characteristic

V106

change in voltage at the input to integrator

ing the sweep time

is

only about one volt. Voltage

dur-

across the sweep resistor, then, changes by about

1%,

and the current through the resistor changes by

the same amount. The current through the sweep

resistor

is

the charging current for the sweep capacitor; therefore, the voltage across the sweep capacitor

changes quite linearly with time, and the sweep signal

is

a nearly linear voltage ramp. The SWEEP

TIME switch changes the value of sweep resistor or

capacitor to change the sweep time. The sweep output

is

applied to the horizontal amplifier through the

horizontal plug-in.

4-34.

An

attenuated sweep signal is applied to the

input of gate generator

cathode follower

cathode follower

V105B

V109.

V103, V104A

through hold-off

and section B of bias control

This signal drives the input

of the gate generator up to the upper hysteresis limit

and causes the gate generator to switch back to its

pre-sweep state. The gate generator then ends the

the gates, blanking the crt and forward biasing switch

4-38.

SINGLE-SWEEP OPERATION,

4-39.

The SWEEP OCCURRENCE switch (on the panel

of the horizontal plug-in unit) selects normal or

single-sweep operation. Normal operation

is

discussed above. For single-sweep operation, the

SWEEP OCCURRENCE switch converts

Schmitt circuit.

cathode follower

As

the sweep signal from hold-off

V105B

rises

to end the gate from

V109

into a

the gate generator, the sweep signal also switches

the Schmitt circuit of

and

V109A

is

cut off. The B section of

holds the input to gate generator

enough

so

that triggers from the trigger generator

V109

so

that

V103/V104A

V109B

conducts

V109

then

high

cannot actuate the gate generator, and the sweep

generating circuits are effectively disabled.

itive signal applied to

circuit of

V109

so

cut off. The A section of

that

V109A

V109A

V109

switches the Schmitt

conducts and

then sets the input to

A

pos-

V109B

is

the gate generator according to the setting of the

SWEEP MODE control, and the sweep generating circuits are effectively armed. The switching signal

for

V109.4

can be an external signal applied to the

ARMING INPUT connector or an internal signal obtained by switching SWEEP MODE control out of its

PRESET position.

4-40.

SCHMITT TRIGGER CIRCUIT.

4-41.

The Schmitt trigger circuit

is

a form of bistable multivibrator used where fast-rising signals

are required. Figure

4-6

shows a simplified Schmitt

trigger circuit and input and output waveforms. If

initially the input voltage is such that

V2

conducts.

itive, it

As

the input voltage becomes more

will

eventually reach a predetermined level

(a) at which the circuit changes state;

V1

V1

is

cut off,

pos-

conducts

4- 4

01526-

1

Page 23

Mxlel

175A

Section

Paragraphs 4-42 to 4-46

IV

E+

c

VI

I

INPUT

-9

P--

OUTPUT

Figure

4-6.

Simplified Schmitt Trigger Circuit

Et

+

SD-u-79

4-43.

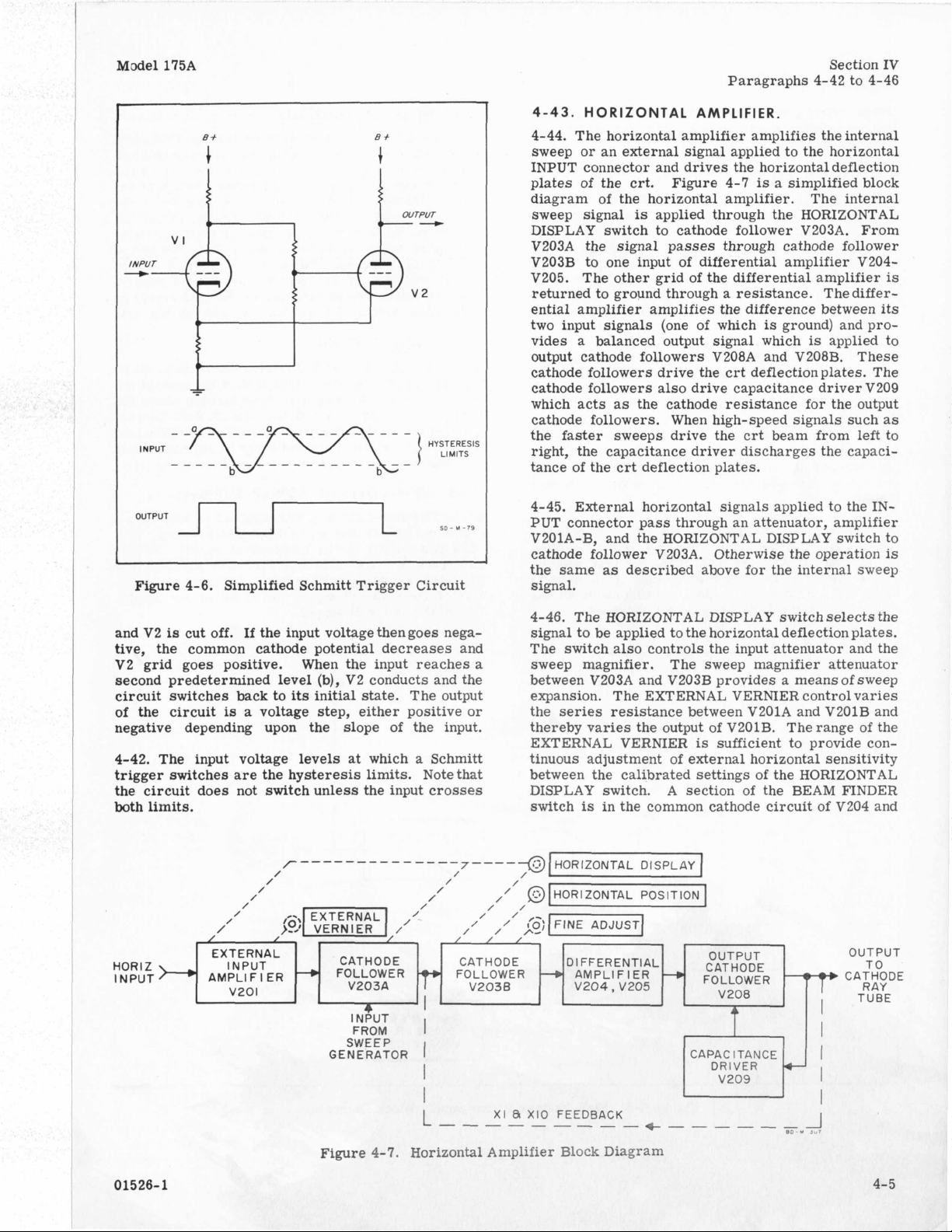

4-44. The horizontal amplifier amplifies the internal

sweep or an external signal applied to the horizontal

INPUT connector and drives the horizontal deflection

plates of the crt. Figure

diagram of the horizontal amplifier. The internal

sweep signal

DISPLAY switch to cathode follower V203A. From

V203A the signal passes through cathode follower

V203B to one input of differential amplifier V204V205. The other grid of the differential amplifier

returned to ground through a resistance. The differential amplifier amplifies the difference between its

two input signals (one of which

vides

output cathode followers V208A and V208B. These

cathode followers drive the crt deflection plates. The

cathode followers also drive capacitance driver V209

which acts

cathode followers. When high-speed signals such

the faster sweeps drive the crt beam from

right, the capacitance driver discharges the capacitance of the crt deflection plates.

4-45.

PUT connector pass through an attenuator, amplifier

V201A-B, and the HORIZONTAL DISPLAY switch to

cathode follower V203A. Otherwise the operation

the same

signal.

HORIZONTAL

is

a

balanced output signal which

as

the cathode resistance for the output

External horizontal signals applied to the

as

described above for the internal sweep

AMPLIFIER.

4-7

is

a

simplified block

applied through the HORIZONTAL

is

ground) and pro-

is

applied to

left

is

as

to

IN-

is

and V2

tive, the common cathode potential decreases and

V2 grid goes positive. When the input reaches

second predetermined level

circuit

of the circuit

negative depending upon the slope of the input.

4-42.

trigger switches are the hysteresis limits. Note that

the circuit does not switch unless the input crosses

both limits.

HORIZ

INPUT

is

cut off.

switches back to

The input voltage levels

*

If

the input voltagethengoes nega-

(b),

its

initial state.

is a voltage step, either positive or

EXTERNAL

INPUT

AMPLl

v201

F I ER

-+

GENERATOR

V2

conducts and the

at

which a Schmitt

C

ATH 0 DE

FOLLOWER

V203A

4

INPUT

FROM

SWEEP

The output

CATHODE DIFFERENTIAL

FOLLOWER

V203B

1

1

I

4-46. The HORIZONTAL DISPLAY switch selects the

signal to be applied to the horizontal deflection plates.

The switch also controls the input attenuator and the

a

sweep magnifier. The sweep magnifier attenuator

between V203A and V203B provides

expansion. The EXTERNAL VERNIER control varies

the series resistance between V201A and V201B and

thereby varies the output of V201B. The range of the

EXTERNAL VERNIER

tinuous adjustment of external horizontal sensitivity

between the calibrated settings of the HORIZONTAL

DISPLAY switch.

switch

-+

AMPLIFIER

V204,

is

in the common cathode circuit of V204 and

V205

is

sufficient to provide con-

A

section of the BEAM FINDER

OUTPUT OUTPUT

CATHODE

-+

FOLLOWER RAY

V208 TUBE

T

CAPACITANCE

DRIVER

V209

a

means of sweep

CATHODE

I

I

t

I

TO

01526-1

Figure 4-7. Horizontal Amplifier Block Diagram

4-5

Page 24

Section

W

Paragraphs 4-47 to 4-56

Model 175A

V205. When pressed, the switch reduces the gain

so

that an unbalance prior to V204 and V205 cannot de-

flect the crt beam off the screen.

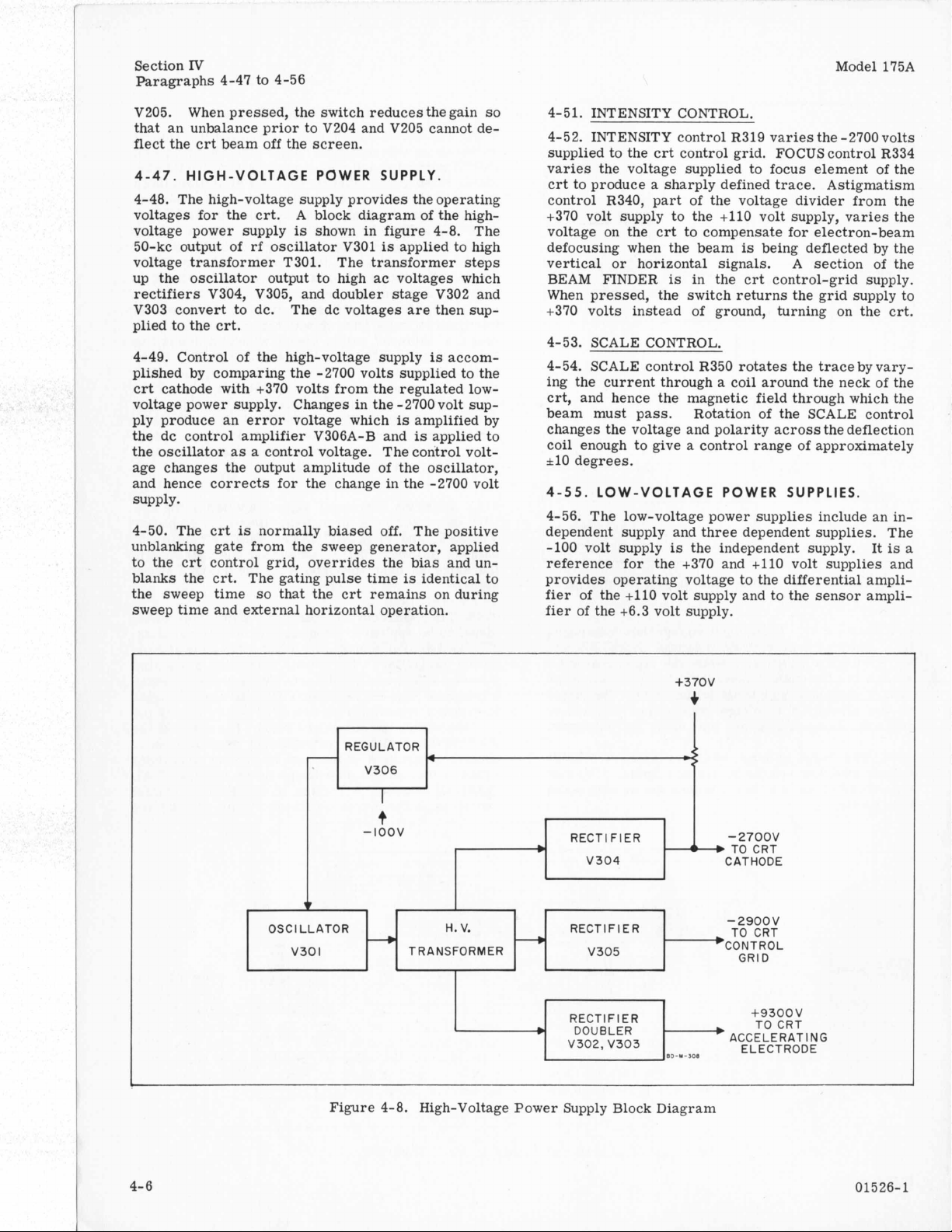

4-47.

HIGH-VOLTAGE POWER SUPPLY.

4-48. The high-voltage supply provides the operating

voltages for the crt.

voltage power supply

50-kc output

of

voltage transformer T301.

up the oscillator output to high

A

block diagram of the high-

is

shown in figure 4-8. The

rf

oscillator V301

is

applied to high

The transformer steps

ac

voltages which

rectifiers V304, V305, and doubler stage V302 and

V303 convert to dc.

The dc voltages

are

then sup-

plied to the crt.

4-49. Control of the high-voltage supply

is

accom-

plished by comparing the -2700 volts supplied to the

crt cathode with +370 volts from the regulated lowvoltage power supply.

ply produce an error voltage which

the dc control amplifier V306A-B and

the oscillator

as

Changes in the -2700 volt sup-

is

amplified by

is

applied to

a

control voltage. The control voltage changes the output amplitude of the oscillator,

and hence corrects for the change in the -2700 volt

supply.

4-50. The crt

unblanking

is

normally biased off. The positive

gate from the sweep generator, applied

to the crt control grid, overrides the bias andun-

blanks the crt.

the sweep time

The gating pulse time

so

that the crt remains onduring

is

identical to

sweep time and external horizontal operation.

4-51. INTENSITY CONTROL.

INTENSITY control R319 varies the -2700 volts

4-52.

supplied to the crt control grid.

FOCUS

control R334

varies the voltage supplied to focus element of the

crt to produce

control

a

sharply defined trace. Astigmatism

R340, part of the voltage divider from the

+370 volt supply to the +I10 volt supply, varies the

voltage on the crt to compensate for electron-beam

defocusing when the beam

is

being deflected by the

vertical or horizontal signals. A section of the

BEAM F'INDER

is

in the crt control-grid supply.

When pressed, the switch returns the grid supply to

+370 volts instead of ground, turning on the crt.

4-53. SCALE CONTROL.

4-54. SCALE control R350 rotates the trace by vary-

ing the current through

a

coil around the neck of the

crt, and hence the magnetic field through which the

beam must pass. Rotation of the SCALE control

changes the voltage and polarity across the deflection

coil enough to give

*lo

degrees.

4-55.

LOW-VOLTAGE POWER SUPPLIES.

a

control range of approximately

4-56. The low-voltage power supplies include an independent supply and three dependent supplies. The

-100 volt supply

reference for the +370 and

is

the independent supply.

+llO

volt supplies and

It

is

provides operating voltage to the differential amplifier of the +110 volt supply and to the sensor ampli-

fier of the +6.3 volt supply.

a

4- 6

REGULATOR

-

OSCl LLATOR

I

V30

Figure 4-8. High-Voltage Power Supply Block Diagram

V306

I

t

-IOOV

4

4

H.

V.

T R A NSFO RM ER

RECTI

b

RECTIFIER

V302, V303

FI

ER

V304

DOUBLER

c:

-2700V

-

W

CATHODE

ACCELERATING

TO CRT

+9300V

TO

CRT

ELECTRODE

01526-1

Page 25

Model

175A

Section

Paragraph

IV

4-57

RECTIFIER

F

I

LTER

F

I

RECTI

ER

FILTER

-i

DRIVER

a424

Q42

I

,Q422,Q423

DRIVER

Q443 Q444

REGULATOR

Q46

I

4

4

t

SENSOR

AMPLIFIER

Q425

at

A

SENSOR

AMPLIFIER

it

-

-

I

-

4

+370V

+llOV

-IOOV

RECTI FlER

FILTER

RECTIFIER

FILTER

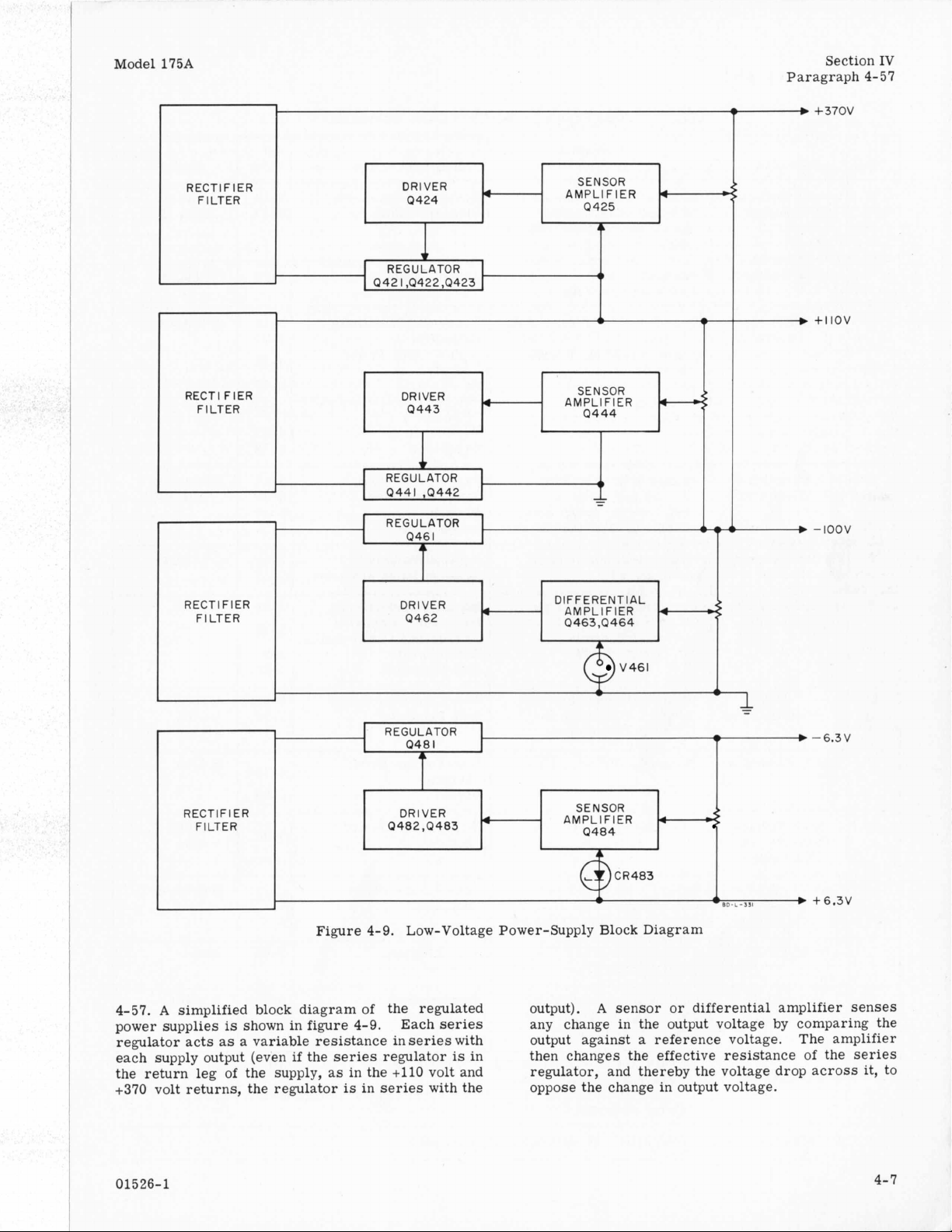

4-57.

A

simplified block diagram of the regulated output).

is

power supplies

regulator acts

each supply output (even

the return leg of the supply,

+370

volt returns, the regulator

shown in figure

as

a

variable resistance in series with output against a reference voltage. The amplifier

if

the series regulator

Figure

as

in the

is

DRIVER

DIFFERENTIAL

AMPL

I

FlER

V461

8

T

DRIVER

0402,4483

4-9.

Low-Voltage Power-Supply Block Diagram

4-9.

Each series

is

in then changes the effective resistance

+110

volt and regulator, and thereby the voltage drop across

in

series with the oppose the change in output voltage.

SENSOR

AMPLIFIER

0484

A

any change in the output voltage by comparing the

4

sensor or differential amplifier senses

w:

v

*’

A

-

BD-L-lll

b

-6.3V

b

+6.3V

of

the series

it,

to

01526-1

4-7

Page 26

Section

V

Table 5-1

Model 175A

~

Item

1

Instrument

~

'ertical Response

Table 5-1. Test Equipment for Checks and Adjustments

Instrument

Required to Test Mode 1

Horizontal Bandwidth

Trigger Sensitivity

Signal

Generator

~~~ ~

Characteristics

50 kc, 500 kc, 1 mc, 50mc,

1.5 volt output; output

amplitude constant with

frequency

Oscillator Trigger Point

Frequency:

1

kc

Amplitude: 10 volts

Calibration

Generator

Output: 0.3 to 50 volts peak-

0.2

0

to 300

volts

to peak, 0.03 to

rms (*0.350/0),

volts dc

Horizontal Sensitivity

Calibrator

High-Voltage Power

Supply

Sweep Gain

Trigger Sensitivity and

Symmetry

Vertical Gain

Calibrator

~~ ~

Time -Mark

Generator

Marker intervals from

0.1 psec to 5 sec in

1-2-5 steps; output am-

plitude greater than 50 mv

Sweep Calibration

Sweep Magnifier

Pattern

Sweep Time

Vertical Bandwidth

Tester

plug-in unit

Vertical Pulse Response

Ref

Para

5-13

5-17

5-16

5-12

5-21

5-37

5

-42

5-50

5-55

5-58

5-18

5-19

5-39

5-52

5-20

5-57

Tektronix

Type 19OA

@

200CD

@738 AR

Tektronix

Type 180A

9

10405A Mercury-pulser vertical

6

Square-Wave

Generator

Test

Oscilloscope

DC Voltmeter

9

High-Voltage

Vacuum -Tube

Voltmeter

10

11

AC Voltmeter

Test Plug

12 Vertical Test

Adapter

Frequency: 4 kc to

1

mc

Output (open circuit):

600 ohm: 50 volts

75 ohm:

7

volts

10-mc passband, external

sync, 0.1 psec/cm to

5 sec/cm sweep time

Range:

Range:

0

-

4CO

0 - 3000

vdc,

1%

vdc, 8%

full scale

Input Impedance:

To

be constructed

1

megohm

(see figure 5-1)

Test plug to allow signals

to be applied directly to

vertical amplifier

Intensity Modulation

Horizontal-Amplifier

Frequency Compensation

Sweep Length

Scan Response

Sweep and Gate Output

Scan Response

Low -Voltage Power

Supplies

Preset

High-Voltage Power

Supply

Low

-Voltage Power

Supplies

scan Response none

Vertical Gain

5-22

5-46

5-51

5-56

5-23

5-56

5-33

5-49

5-35

5-33

5-56

'@211A

$3

160B

$3

170A

@

175A w/08*

@

412A

'@

410B

\@

459A

$3

400D/H/L Range: 1 mv to 0.1 volt

@

10404A

13 Variable

Transformer

To vary line voltage from 102 to

measurement (para 5-33)

To

hold line voltage at 115 volts for waveform and voltage measurements

during adjustment

*

Model 175A Oscilloscope with option 08, Sweep and Gate Output

-0

5

128

(204 to 256) volts for power-supply

01526-1

Page 27

Model 175A

Paragraphs 5-1 to 5-12

Section

V

SECTION

MAINTENANCE

5

-1.

INTR

0

DU

CTION.

5-

2.

This section covers routine maintenance,

troubleshooting, and adjustment of the Model 175A

Oscilloscope.

may be used to verify proper operation of the instrument at incoming inspection or after adjustments

have been made.

5-3.

SERVICING THE AIR FILTER.

5-4. Inspect the

ment and clean

to restrict the flow of cooling

the

filter

in warm water and detergent. Dry thoroughly and

coat with a

from Research Products Company, Inc. This adhesive

your Hewlett-Packard sales representative.

5-5.

5-6. The performance check

mine whether or not the instrument

in

refer

horizontal plug-in units, refer to the individual manuals covering these instruments.

5-7. TEST EQUIPMENT.

5-8. Test equipment recommended for the per-

formance check

7.

istics may

5-9. PRELIMINARY SETTINGS.

5-10. Vertical and horizontal plug-in units must be

in place to make the performance check. Set the 115230 volt switch to the line voltage being used.

channel, select CHANNEL

trols. Make the following settings on the panel of

the vertical plug-in unit:

settings on the panel of the horizontal plug-in unit:

is

PERFORMANCE CHECK.

its

specifications. Should adjustment be required,

to paragraph 5-25.

Similar instruments having the listed character-

a.

If

the vertical plug-in unit

AC-DC..

SENSITIVITY

VERNIER

b.

Depending on model number, make the following

Model 1780A:

Model 1781A/B:

Model 1782A:

Model 1783A:

A

performance check

air

filter at the rear of the instru-

it

before

from the instrument and wash

filter

adhesive such

available from heating supply stores or from

is

listed in table 5-1, items 1 through

be

substituted.

it

becomes clogged enough

To check the vertical and

A

and use channel A con-

..................

..........

.................

SWEEP OCCURRENCE.

SWEEP SELECTOR

FUNCTION

TIME MARKER

.............

..........

is

included which

air.

To clean, remove

it

as

Filter Coat No. 3

is

intended to deter-

is

operating with-

has

more than one

2

VOLTS/CM

...

...

MAINSWEEP

thoroughly

AC

CAL

NORMAL

OFF

OFF

V

c. Make the following settings on the Model 175A:

POWER

INTENSITY MODULATION

SWEEP TIME

Sweep VERNIER

HORIZONTAL DISPLAY

EXTERNAL VERNIER

TRIGGER SOURCE

SWEEP MODE

TRIGGER LEVEL

TRIGGER SLOPE

d. Depress BEAM FINDER to locate trace. With

BEAM FINDER depressed, center display with horizontal and vertical position controls.