Page 1

m

r-

0

b

F

P

OPERATING AND

SERVICE

MANUAL

OSCILLOSCOPE

1707B

HEWLETT

~-

-

_-

-

PACKARD

Page 2

.

OPERATING AND SERVICE MANUAL

MODEL

1707B

OSCILLOSCOPE

4

SERIALS

Refer to Section

standard options:

and

631.

PREFIXED:

VI1

for instruments with the following

002,007,011,012,015,602,607,611

1410A

H

1900

Manual

Microfiche Number 01 707-908 16

Part

Number 01707-90916

EWLETT-PAC KA R D

GARDEN

OF

THE GODS ROAD, COLORADO SPRINGS, COLORADO, U.S.A.

COMPANY/COLO RA DO SPRINGS DIV

IS1

ON

PRINTED: APRIL

1974

Page 3

SAFETY

SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair

of this instrument. Failure to comply with these precautions

or

with specific warnings elsewhere

in

this

manual violates safety standards of design, manufacture, and intended use of the instrument. HewlettPackard Company assumes no liability for the customer's failure to comply with these requirements.

GROUND THE INSTRUMENT.

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. The instrument is equipped with a three-conductor ac power cable. The power cable

must either be plugged into an approved three-contact electrical outlet

or

used with a three-

contact to two-contact adapter with the grounding wire (green) firmly connected to an elmtrical

ground (safety ground) at the power outlet. The power jack and mating plug of the-power cable

meet International Electrotechnical Commission

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do

not operate the instrument

in

the presence of flammable gases

(IEC)

safety standards.

or

fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

KEEP

AWAY

FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel.

Do

not replace components with

power ca ble connected. Under certain conditions, dangerous voltages may exist even with the

power cable removed.

To

avoid injuries, always disconnect power and discharge circuits before touching them.

DO NOT SERVICE

Do

not attempt internal service

OR

ADJUST ALONE.

or

adjustment unless another person, capable of rendering first

aid and resuscitation, is present.

USE CAUTION WHEN EXPOSING

Breakage of

the

cathode-ray tube (CRT) causes a high-velocity scattering of glass fragments

(implosion). To prevent

Handling of the

CRT

shall be done only by qualified maintenance personnel using approved

OR

HANDLING THE CRT.

CRT

implosion, avoid rough handling or jarring of the instrument.

safety mask and gloves.

DO NOT SUBSTITUTE PARTS

Because of

the

danger of introducing additional hazards,

OR

MODIFY INSTRUMENT.

do

not install substitute parts

or

perform any

un-

authorized modification to the instrument. Return the instrument to a Hewlett-Packard Sales and Service

Office for service and repair to ensure that safety features are maintained.

DANGEROUS PROCEDURE WARNINGS.

Warnings, such as the example below, precede potentially dangerous procedures throughout this

manual. Instructions contained in the warnings must be followed.

I

Dangerous voltages, capable of causing death, are present in this instrumezt.

Use

extreme

caution when handling, testing, and adjusting.

Page 4

Model

1707H

TABLE

Section Page

I

GENERAL INFORMATION

1.1

1.4

1.5

1.7

1-1

1.17

1.20 .

1.22 .

1.24 .

1.26 .

1.30 .

I1 INSTALLATION .........................

2.1

2.3 .

2.6 .

2.7

2-1

2.13

2- 15 .

2.17 .

2.19 .

I11 OPERATION

3.1

3.3

3.5

3.7

3.9

3.11

3.13

3.15

3.17

3.24

3.26

3.28

3.30

3.32

3.34

3.36

3.38

3.40

J

I

I

3.42 .

3.44

3.46 .

Introduction

.

.

Description

.

.

1

.

.

.

.

1

.

.

.

.

.

.

.

.

.

.

.

.

. B

.

.

.

.

.

.

.

.

Introduction

Vertical Circuits

Horizontal Circuits

Cathode-ray Tube

Warranty

Accessories Furnished

Accessories Available

Instrument and Manual

Identification

Inquiries

Introduction

Initial Inspection

Preparation for Use

Power Requirements

Three-conductor AC Power

Cable

DC

Battery Installation

Claims

Repacking for Shipment

Introduction

Controls and Connectors

Beam Finder

Scale Illumination

Trace Align

Calibrator

Focus and Astigmatism

Coupling

Display

Trig

Polarity

Sweep Display

Ext

Main Sweep

Mixed Sweep

Delayed Sweep

Time/Div

Vernier

Trigger Level

Trigger Holdoff

Slope

......................

.......................

......................... 1-5

..........................

...................... 2-1

.......................

Plug

......................

............................

.............................

......................

...................... 3-1

........................

.........................

............................

...................... 3-4

Horiz Input

....................... 3-4

.........................

............................ 3.4

..............

..................

..............

............

.................

............ 1-5

.............

................... 1-5

.................

............... 2-1

..........

...........

.......... 2-2

..........

....................

.............. 3-1

.....................

.........

..................

................. 3-4

.................... 3-4

...................

.................. 3-4

...................

.................

1-1

1-1

1 . 1

1-1

1-1

1-1

1-5

1-5

1-5

2-1

2-1

2-1

2-1

2-2

2-2

2-2

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-4

3-4

3-4

3-4

3-4

3-4

3-4

OF

CONTENTS

Section Page

IV PRINC11’1,ES OF OPERATION

3.48 .

3.51 .

3.54 .

3.56 .

3.58

.

3.59

.

3.61

.

3.63

.

3.65 .

3.67

.

3.69 .

3.71 .

3.73

.

3.75 .

3.77 .

3.80 .

4.1

.

4.3

.

4.6 .

4.8

.

4-

10

.

4-12

4.14

.

4-

16

.

4.21 .

4.24 .

4.27

.

4..31

.

‘1

-;

35

.

4.41

.

4.44

.

4.46

.

4.48

.

4.53 .

4.79

.

4.81

.

4.86

.

4.104 .

4-1 19 .

4.124

4- 130

4.148 .

4.156 .

4.158 .

4.162

4.165 .

4.174 .

Sweep Mode

Trigger Selection

Magnetic Interference

Battery Recharge Operation

Preoperational Adjustments

Initial Turn.on

Focus and Astigmatism Adjust

Operating Procedures

Operators Performance Check

Operating Information

Auto Versus

Auto Versus

AC Versus DC

Mixed Sweep

Delayed Sweep

Line Sync

Introduction ......................

Block Diagram Discussion

Input Attenuator

Vertical I’rcamplifier

1)cllay

Vertical Output Amplifier

Trigger Circuits

M

ai n In t egr a t o r

Holdoff and Comparator

I

)el ay ed Integra tor

‘l’iming Sequence

Horizontal Mode Assembly

I.

ow

Voltage Power

High Voltage Power Supply

Gate Amplifitr

Detailed Circuit Theory

Input Attenuators

Vertical Preamplifier

Delay Line

Vertical Output Amplifier

Trigger Circuits

Main Integrator

Holdoff and Comparator

.

Delayed Integrator

.

Horizontal Mode

Gate Assembly

Calibrator

Horizontal Preamplifier and

Output Assemblies

Indicator Drivers

.

Low Voltage Power

Supply

High Voltage Power

Supply

....................

................

............. 3-5

..................

.............

............

Norm

..............

Trig

...............

.................. 3-7

....................

..................

....................... 3-7

...........

..............

I.ine

....................

...............

...............

............

..............

Supply

................

..........

.............. 4-4

...........

.....................

................

................

............ 4-10

..............

.................

.....................

...........

..............

.......................

.......................

....... 3-5

.......

.. 3-6

..... 3-6

.......

..........

.....

......

....

....

...

...... 4-6

......

3-5

3-5

3-5

3-5

3-6

3-7

3-7

3-7

3-7

3-7

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4

.

4-2

4-2

4-;3

4-:3

4-;j

4-3

4-4

4-4

4-4

4-6

4-6

4-8

4-10

4-11

4-13

4-14

4-14

4-14

4-14

4-16

1

111

Page 5

Table of Contents

Model 1707B

TABLE

Section Page

V

PERFORMANCE: CHECK AND

A1)JUS’I’ME:NTS

5.1

5.3

5.5

5.8

5.10

5-

5.13

5.18

5.23

5.28

5.33

5.38

5.43

5.48

5.53

5.58

5.63

5.68

5.73

5-78

5.83

5.88

5.93

5.98

5.103

5.108

5-113

5.118

5.123

5.128

5-133

5.138

5.142

5.143

5.148

5.153

5.157

5.162

5.167

5.172

5.177

5.181

5-

Introduction

.

Test Equipment

.

Performance Check

.

Front-panel Adjustments

.

Front-panel Settings

.

Performance Tests

12

.

Deflection Factor

Rise time

Handwidth

A+B Mode

Alt Mode

Chop Mode

Single Sweep

Auto

Z

Axis

Beam Finder

Coupling Switch

Input Resistance

Common Rejection Ratio

(CMRR)

Main

Delayed Sweep Time

Delay Time Accuracy

Delay Time Linearity

Delay Jitter

Main Triggering

Delayed Triggering

Main Trigger Level Range and

Polarity

Delayed Trigger Level Range

and Polarity

Ext Horizontal Bandwidth

Ext Horizontal Deflection

Factor

Calibrator

Adjustments

Adjust Procedures

Low

Adjustment

High

Adjustment

Intensity Limit Adjustment

Y-Axis

Gate Amplifier Response

Adjustment

Trigger Amplifier Balance and

DC

Trigger Sensitivity

Position Centering Adjustment . 5-22

Sweep Length Adjustment

Main Sweep Timing

Adjustment

185

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.......................

......................

...................

...............

..........

..............

................

.............

.....................

....................

......................

.......................

.....................

...................

Trig

Recovery Time

Sensitivity

...............

....................

................

................

......................

Sweep Time

...............

............

..........

..........

....................

...............

............

......................

.................

......................

.....................

.....................

................

Voltage Power Supply

..................

Voltage Power Supply

..................

Alignment

..............

..................

Adjustment

.............

.............

..................

OF

........

....

....

.....

CONTENTS

5-1

5-1

5-1

5-1

5-

5-1

5-1

5-1

5-2

5-3

5-3

5-4

5-4

55

5-5

56

5-6

5-6

5-7

5-8

5-8

5-9

5-10

511

5-12

5-13

5-14

5-15

5-16

5-16

5-17

5-17

5-19

5-19

5-19

5-19

5-20

520

5-20

5-21

5-21

5-22

523

(Cont’d)

Section Page

5.190

5.195

5.200

5.205

5.210

5-2

1

VI REPI.ACEAH1. E PARTS

VI1

VI11 SCHEMATICS ANI) TROUH1.E:

15

5.220

5.225

5.230

6.1

.

6.3

.

MAZNUAI. CHANGES AN!)

7.1

.

7.3

.

7.5

.

7.9

.

SHOOTING

8.1

.

8.3

.

8.8

.

8-

12

8-

1.5

8-

17

8.22

8.27

8.29

8-:3

1

8..n

8..35 .

8437

8.42

8.44

.

8.46

.

8.48

.

Delayed Sweep Time

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Adjustment

X10 Gain Adjustment

Mag Centering Adjustment

Calibrator Adjustment

Ext Horiz Input Compensation . 5-25

Ext

Horiz

Low-frequency Pulse Response

Adj

............................

Input Capacitance and Attenuator

Compensation Adjustment

High-frequency Pulse

Response Adj

Introduction

Ordering Information

Introduction

Manual Changes

Special Options

Standard Options

............................

Introduction

Schematics

Reference Designations

Component

Preventive Maintenance

Mechanical Inspection

Switch Maintenance

Repair and Replacement

CRT Removal and Replace-

ment

Vertical Amplifier Module

Removal and Replacement

Delay line Removal and

Replacement

Attenuator Removal

Replacement

Removal and Replacement

Assemblies in Horizontal

Amplifier Module

Power

Removal and Replacement

Power

assembly and Reassembly

Semiconductor Removal and

Replacement

At

t

e

n

u

..................

Gain Adjust

...............

.................

......................

.............

OP‘I’IONS

......................

..................

...................

.................

......................

.......................

...........

I.

ocations

........................

S

u

p p

1

Supply

a

t o r Ser vi c i n

.............

................ 8-3

................

...........

y

Mod

u

1

e

Module

................

g

..........

....

.........

.........

. .

....

.

..........

........

..........

..........

. . 8-3

and

of

IXs-

. .

..........

5-23

524

524

5-25

5-26

5.26

5-26

5-27

6-1

6-1

6-1

7-1

7-1

7-1

7-1

7-1

8-1

8-1

8-1

8-1

8-1

8-1

8-1

8-2

8-2

8-2

8-3

8-5

8-5

8-5

8-6

8-6

iv

Page 6

Model 1707B

Table of Contents

List of Illustrations

TABLE

)

Section Page Section Page

8.50 . Circuit Hoards

8.52

.

8.54

.

8.56

.

8.60

.

Figure Title Page Figure Title Page

.

1.1 Model 1707R Oscilloscope 1-0 5.12

1.2

.

Instrument Serial Number

1.3

2.1

2.2 Battery Pack Installation 2-2 5-16 . EXT Horizontal Bandwidth

3.1

3.2

1

3.3

3.4

3.5

3.6

3.7

4.1

4.2

4.3

4.4

5.1

5-2

5.3

5-4

55

5-6

5-7

58

59

5-10

5-11

Service Kit for HP 1700-series

.

Oscilloscopes

.

Rear Panel Power Module

.

.

Controls and Connectors 3-2

Sweep Combinations

.

.

DC BAL Adjust

.

CALAdjust

Algebraic Addition and Differential

.

Operation

Delayed Sweep

.

Mixed Sweep

.

Timing Sequence

.

Step-by-step operation of the

.

.

.

.

.

.

.

.

.

.

.

.

Gate Schmitt Trigger

Step-by-step operation of the Set-

reset Multivibrator 4-9

Blanking Sequence

Deflection Factor Test Setup

Rise time Test Setup

Bandwidth Test Setup

A+B

Input Resistance Test Setup

CMRR Test Setup

Main Sweep Time Test Setup

Delayed Sweep Time Test Setup

Delay Time Accuracy Test Setup

.

Delay Time Linearity Test Setup

Delay Jitter Test Setup

.

Hoard Connect ions

Servicing Etched Circuit

Hoards

Integrated Circuit Replace- 8-7 1

ment 8.6 8.73

Service Kit

.............................

............................

...........................

Mode Test Setup

.....................

.............

.......................

.........................

.....................

...............

............

.......................

...............

...............

................

....................

.........................

.........................

........................

...............

..................

...................

............

....................

.................

..................

.............

.......................

............

.................

OF

LIST

OF

........

.......

.......

CONTENTS (Cont'd)

8-6

8-6

8.6

8.7

8.62

.

8.64

.

8.66 . Troubleshooting

8.69

.

.

.

8.75

.

Soldering

Aids

.........................

Heat Sink Removal

DC Voltages

Waveforms

Test Points

Circuit Checking

ILLUSTRATIONS

.

Main Triggering

5.13

.

1-5

1-6

2-1 Polarity Test Setup

3-5

3-8 Test Setup

3-9

3-10

3-11

3-12

4-2

4-7

4-12

5-2

5-3

33

5-4

5-7

5-8

5-8

5.10

5.10

5.11

5.12

5.14

5.15

517

518

5-19

6-1

6-2

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8-8

8-9

8-10

8.11

8.12

8.13

8-14

8-15

Delayed Triggering Test Setup

Main Trigger Level Range and Polarity

.

Test Setup

.

Delayed Trigger Level Range and

Test Setup

EXT

.

Horizontal Deflection Factor

...........................

...........................

...........................

.

Calibrator Test Setup

Adjustment

.

Knob Locator

.

Mechanical

.

Vertical Module Mechanical Parts

.

.

.

.

.

.

.

.

.

Removal

Attenuator Removal

Semiconductor Terminal Identification

Component Identification. Interior Front

and rear Panel

Component and Assembly Locations . 8-23

Vertical Module A5 Component

Identification

Horizontal Module A6 Component

Identification

Main Block Diagram

Power Supply Block Diagram

Attenuator Component Identification . 8-28

.

Attenuator Schematic

.

Vertical Preamplifier Assembly A5A4

.

Component Identification

Vertical Preamplifier Assembly

.

A5A4

Vertical Preamplifier Assembly

.

A5A4

.

Vertical Preamplifier Assembly A5A4

Component Identification

..........................

...........................

Parts

..............................

......................

......................

..............................

................................

Tool.

Solder. and

............

...................

...................

....................

....................

...............

Test

Setup

............

.........

................

..................

Locator

.....................

...............

....................

.................

........

................

..........

............

8-7

8.8

8.8

8.8

8.8

8.8

8.9

5.13

5.14

5.15

5-16

5.17

5.17

5.18

529

6-2

6-3

8-4

8-4

. .

8-7

8-23

8-24

8-24

8-25

8-27

8-29

830

8-31

8.33

8.34

V

Page 7

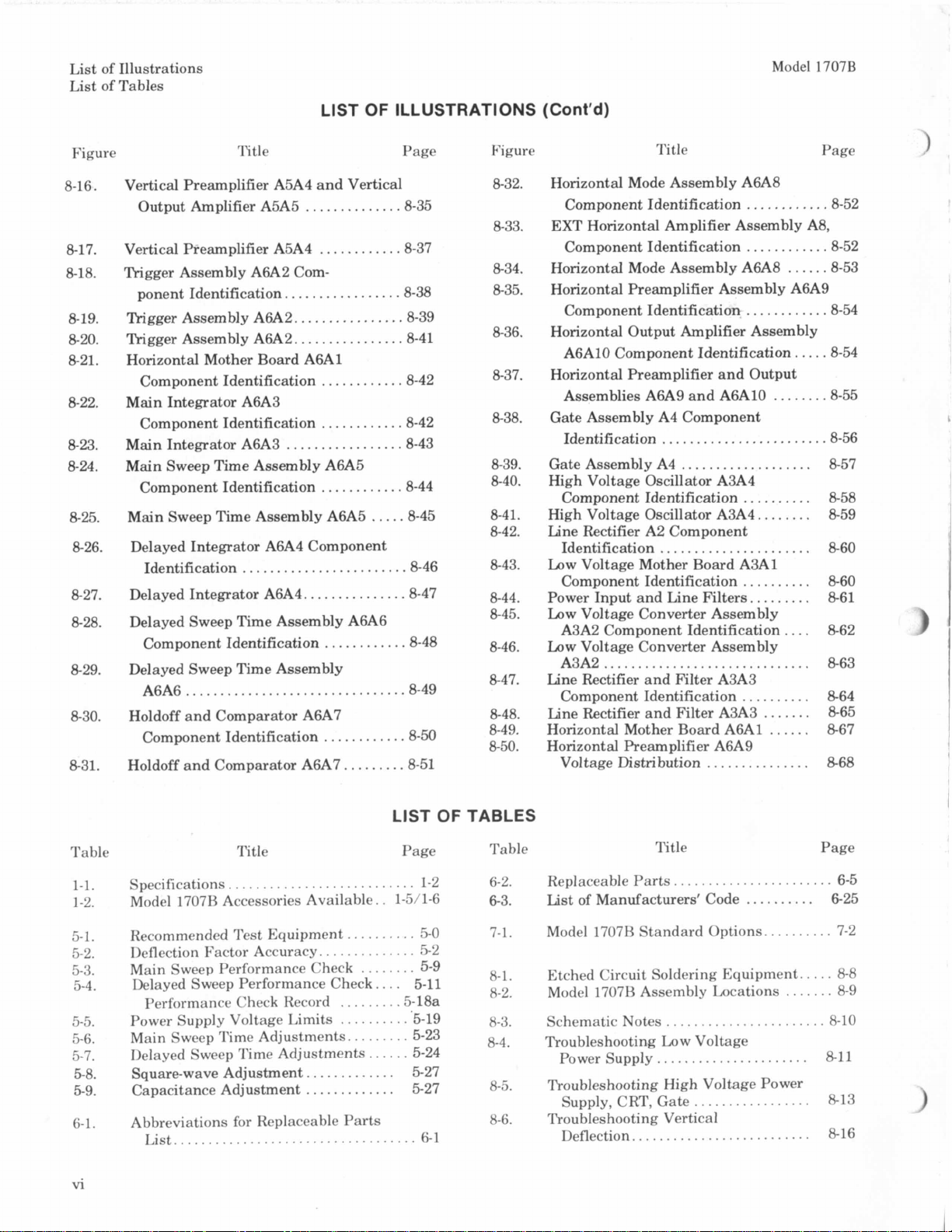

List of Illustrations

List

of

Tables

LIST

OF

ILLUSTRATIONS

(Cont‘d)

Model

1707B

Figure Title Page

8.16

8.17

8.18

8.19

8.20

8-21

8.22

8.23

8.24

8.25

8.26

8.27

8-28

8.29

8.30

8.31

Vertical Preamplifier A5A4 and Vertical

.

Output Amplifier A5A5

Vertical Preamplifier A5A4

.

Trigger Assembly A6A2 Com-

.

ponent Identification

Trigger Assembly A6A2

.

Trigger Assembly A6A2

.

.

Horizontal Mother Board A6A1

Component Identification

.

Main Integrator A6A3

Component Identification

Main Integrator A6A3

.

.

Main Sweep Time Assembly A6A5

Component Identification

Main Sweep Time Assembly A6A5

.

Delayed Integrator A6A4 Component

.

Identification

Delayed Integrator A6A4

.

Delayed Sweep Time Assembly A6A6

.

Component Identification

Delayed Sweep Time Assembly

.

A6A6

................................

Holdoff and Comparator A6A7

.

Component Identification

.

Holdoff and Comparator A6A7

........................

..............

............

.................

................

................

............

............

.................

............

...............

............

............

.....

.........

8.35

8.37

8.38

8.39

8.41

8-42

8.42

8.43

8.44

8.45

8.46

8.47

8.48

8-49

8.50

8-51

Figure Title Page

8.32

8.33

8-34

8.35

8-36

8.37

8.38

8.39

8.40

8.41

8.42

8.43

8.44

8.45

8.46

8.47

8.48

8.49

8.50

Horizontal Mode Assembly A6A8

.

Component Identification

EXT Horizontal Amplifier Assembly A8.

.

Component Identification

Horizontal Mode Assembly A6A8

.

Horizontal Preamplifier Assembly A6A9

.

Component Identification

Horizontal Output Amplifier Assembly

.

A6A10 Component Identification

Horizontal Preamplifier and Output

.

Assemblies A6A9 and A6A10

Gate Assembly A4 Component

.

Identification

Gate Assembly A4

.

High Voltage Oscillator A3A4

.

Component Identification

High Voltage Oscillator A3A4

.

.

Line Rectifier A2 Component

Identification

Low Voltage Mother Board A3A1

.

Component Identification

.

Power Input and Line Filters

.

Low Voltage Converter Assembly

A3A2 Component Identification

.

Low Voltage Converter Assembly

A3A2

..............................

.

Line Rectifier and Filter A3A3

Component Identification

Line Rectifier and Filter A3A3

.

.

Horizontal Mother Board A6A1

Horizontal Preamplifier A6A9

.

Voltage Distribution

........................

...................

......................

............

............

............

..........

..........

.........

..........

...............

......

.....

........

........

....

.......

......

8.52

8.52

8.53

8.54

8.54

8.55

8.56

a57

8-58

8-59

a60

8-60

8-61

a62

8-63

864

a65

8-67

868

Table

1.1

.

1.2

.

5.1

.

5.2

.

5.3

.

5.4

.

5.5

.

5.6

.

5.7

.

5.8

.

5.9

.

6.1

.

vi

LIST

OF

TABLES

Title Page Table

Specifications

Model 1707H Accessories Available

Recommended Test Equipment

Ileflection Factor Accuracy

Main Sweep Performance Check

Delayed Sweep Performance Check

Performance Check Record

Power Supply Voltage Limits

Main Sweep Time Adjustments 5-23 8.4

Ilelayed Sweep Time Adjustments

Square-wave Adjustment

Capacitance Adjustment

Abbreviations for Replaceable Parts

List

...................................

...........................

. .

1-5/14? 6.3

..........

..............

........

....

.........

..........

.........

......

.............

.............

1-2

5-0

5-2

5-9

5-11

5.18a

‘5-19

5-24

5-27

5-27

6-1

6.2

8.1

8.3

8.5

7.1

8.2

8.6

Title Page

Replaceable Parts

.

List of Manufacturers’ Code

.

Model 1707H Standard Options

.

Etched Circuit Soldering Equipment

.

Model 1707H Assembly Locations

.

Schematic Notes

.

.

Troubleshooting Low Voltage

Power Supply

.

Troubleshooting High Voltage Power

Supply.

Troubleshooting Vertical

.

Deflection

CRT.

.......................

.......................

......................

Gate

.................

..........................

..........

..........

.....

.......

6-5

6-25

7-2

8-8

8-9

8-10

8-11

8-13

8-16

Page 8

Model

1707B

LIST

OF

TABLES

List of Tables

(Cont’d)

Table

8-7.

8-8.

8-9.

8-

10.

8-1 1.

8-

12.

8-13.

8-14.

8-15.

8-16.

8-17.

Title Page Table Title Page

Troubles hooting Horizontal

Troubleshooting Time Base

Block Diagram Measurement

Conditions

Schematic 4 Measurement Con-

ditions and Waveforms..

Schematic 5 Measurement Con-

ditions and Waveforms..

Schematic 6 Measurement Con-

ditions and Waveforms..

Schematic 7 Measurement Con-

ditions and Waveforms.. 8-36

Schematic 8 Measurement Con-

ditions and Waveforms..

Schematic 9 Measurement Con-

ditions and Waveforms..

Schematic 10 Measurement Con- 8-25. Schematic 19 Measurement Con-

ditions and Waveforms..

Schematic

ditions..

..........................

11

Measurement Con- 8-26. Schematic 20 Measurement Con-

...........................

..........

..........

...........

...........

...........

...........

...........

...........

...........

8-

19

8-20

.8-24

8-31

8-32

83-34

8-38

8-40

843 ditions..

8-44 ditions and Waveforms..

8-18.

8-19. Schematic

8-20. Schematic

8-21. Schematic

8-22. Schematic 16 Measurement Con-

8-23. Schematic 17 Measurement Con-

8-24. Schematic

Schematic 12 Measurement Con-

ditions and Waveforms..

13

Measurement Con-

ditions..

ditions and Waveforms..

ditions and Waveforms.

ditions and Waveforms..

ditions and Waveforms.

ditions and Waveforms.

...........................

14

Measurement Con-

15

Measurement Con-

18

Measurement Con-

...........

...........

............

...........

............

............

...........................

...........

8-46

8-48

8-50

8-52

8-54

8-56

8-58

8-60

8-62

vii

i

Page 9

Gcncral Information

Model 1707B

1-0

<.*

-"

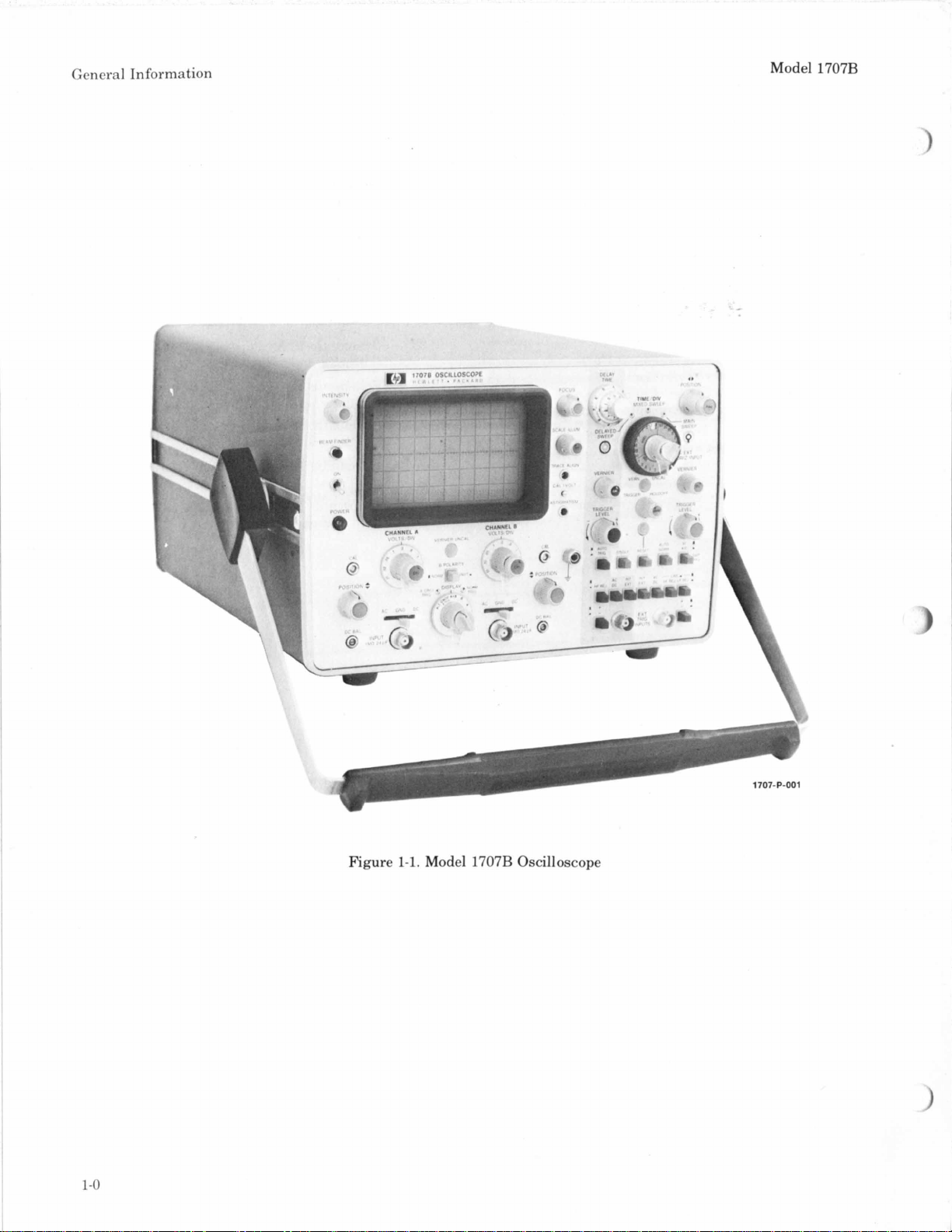

Figure

1-1.

Model 1707B Oscilloscope

1707-PO01

Page 10

Model 1707B

1

I

h

General Information

SECTION

I

GENERAL INFORMATION

1-1.

INTRODUCTION.

1-2.

This

manual provides operating and service

information for the Hewlett-Packard Model 1707B

i

Oscilloscope (figure

1-1).

This manual

is

divided into

eight sections, each covering a specific topic or

aspect of the instrument. All schematics are located

at

the rear of the manual.

the manual are instruction cards located

Also

located

at

the rear of

in

an

envelope attached to the inside back cover. These

cards explain the function of each instrument control.

The card

is

designed to fit the inside lid of the front

panel storage cover.

1-3. This section contains a description of Model

1707B. Instrument specifications are listed in table

1-1.

Table 7-2 lists the options available for Model

1707B.

1-4.

DESCRl PTION.

1-10. With the dual-trace feature, displays can be

obtained on either channel A or B, channels A

and B together, channels A + B, and channels A

-

B. Simultaneous display of two signals

is

possible

in either chop or alternate mode of operation. During

chop operation, channels are switched

at

an approximate rate of 400-kHz during each sweep. In the

alternate mode of operation, the signal applied to

each channel

Triggering

is

displayed on alternate sweeps.

is

selectable from either A ONLY TRIG

or NORM TRIG position. In the NORM TRIG position,

the instrument triggers on the displayed signal.

In the A ONLY TRIG position, the instrument

triggers on the signal applied to channel A.

1-11.

HORIZONTAL CIRCUITS.

1-12. The horizontal circuits provide four types of

sweep displays. The displays are main sweep, mixed

sweep, delayed sweep and external horizontal input.

1-5.

INTRODUCTION.

1-13.

Operation of the delayed sweep while in the

main sweep mode provides trace intensification.

1-6. The Model 1707B

is

a

general-purpose, wideband oscilloscope designed for bench or field service.

The Model 1707B operates from an ac line, dc line

or optional battery pack. The optional ,rechargable

nickel cadmium batteries provide up

to

4% hours of

operation and require a recharge time of approximately

of transportation and

14

hours. A carrying handle provides ease

is

adjustable, allowing the

Model 1707B to be placed at an angle for viewing

the CRT.

i

1-7.

VERTICAL CIRCUITS.

The amount of intensification width depends on the

delayed front panel settings. In the delayed mode,

the intensified portion is displayed across the entire

CRT.

1-14.

Sweep speed settings from 0.1 usec/div to

2 sec/div (main sweep) and 0.1 usec/div to

0.2 sec/div (delayed sweep) are available in

a

1,

2,

sequence. Vernier controls allow continuous adjustment between steps and extend the slowest sweep

to 5 sec/div (main sweep) and

0.5

sec/div (delaved

>I

sweep). Using the magnifier function, the fastest

sweep speed can be expanded to 10 ns/div. The

5

mixed sweep function provides for simultaneous

1-8.

Vertical bandwidth

is

75

MHz with a rise time

less than 4.7 ns. Maximum vertical deflection factor

is

10 mV/div. The Model 1707B contains two identical

vertical amplifiers for single or dual channel

display of an input waveform and an expanded

portion of the waveform.

The delayed circuits are

calibrated, permitting accurate time difference meas-

urements to be made.

operation. Each channel offers a choice of ac or

1-15.

dc coupling. Common mode rejection

dB

at 10 mV/div, and

20

dB

for the rest of the

deflection ranges.

is

at

least .40

The main and delayed trigger circuits have

provisions for either internal or external operation.

Choice of trigger coupling

is

provided; ac/dc,

high

frequency reject, and low frequency reject. The

1-9. Nine calibrated switch settings provide

a

deflection factor range from 10 mV/div to 5 V/div in

a

1, 2, 5 sequence. The vertical verniers permit

continuous adjustment between calibrated steps and

extend the least sensitive deflection factor

div) to

at

least 12.5 V/div.

(5

V/

delayed trigger circuit does not have low frequency

reject trigger coupling.

1-16.

An external horizontal input allows the use of

an external signal to drive the horizontal deflection

plates of the CRT.

1-1

Page 11

General Information Model 1707B

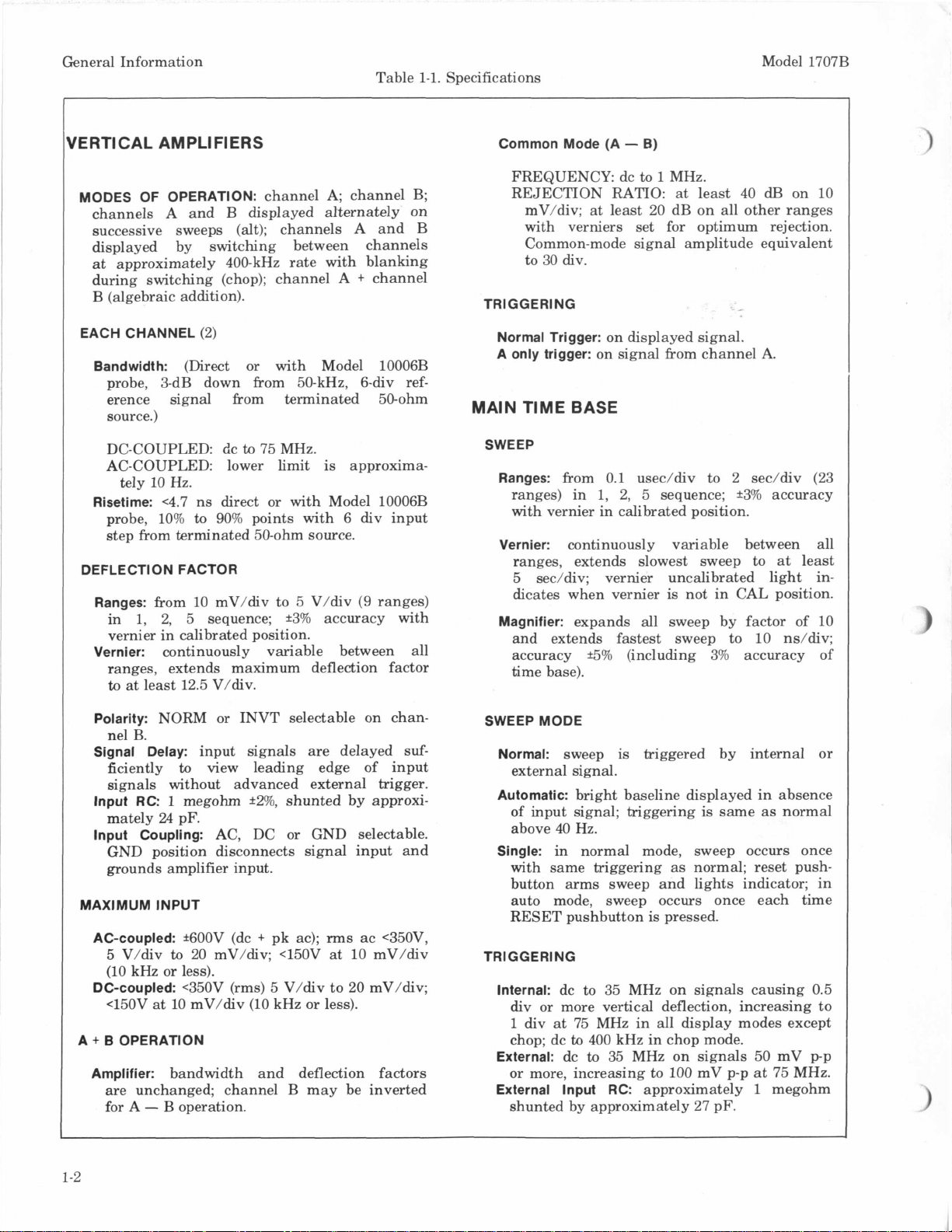

Table

1-1.

Specifications

IERTICAL AMPLIFIERS

MODES OF OPERATION:

channels A and B displayed alternately on

successive sweeps (alt); channels

displayed by switching between channels

at approximately 400-kHz rate with blanking

during switching (chop); channel A + channel

B

(algebraic addition).

EACH CHANNEL

Bandwidth:

(2)

(Direct or with Model 10006B

probe, 3-dB down from 50-kHz, 6-div reference signal from terminated 5@ohm

source.)

DC-COUPLED: dc

AC-COUPLED: lower limit

tely

10

Hz.

Risetime:

probe, 10%

<4.7

ns

to

90%

step from terminated 50-ohm source.

DEFLECTION FACTOR

Ranges:

from 10 mV/div to 5 V/div

in 1,

2,

5

sequence;

vernier in calibrated position.

Vernier:

continuously variable between all

ranges, extends maximum deflection factor

to

at

least 12.5 V/div.

channel A; channel B;

A

to

75 MHz.

is

approxima-

direct or

with

Model 10006B

points with 6 div input

*3%

accuracy with

(9

and B

ranges)

Common Mode (A

-

B)

FREQUENCY: dc to 1 MHz.

REJECTION RATIO:

mV/div;

at

least

at

least

40

20

dB on all other ranges

with verniers set for optimum rejection.

Common-mode signal amplitude equivalent

to 30 div.

TR

I

G GE

RI

N

G

Normal Trigger:

A only trigger:

on displayed signal.

on signal from channel A.

MAIN TIME BASE

SWEEP

Ranges:

ranges) in 1,

with vernier

Vernier:

ranges, extends slowest sweep to

5

dicates when vernier

Magnifier:

and extends fastest sweep to 10 ns/div;

accuracy *5% (including

time base).

from 0.1 usec/div to 2 sec/div (23

2,

5

sequence; *3% accuracy

in

calibrated position.

continuously variable between all

sec/div; vernier uncalibrated light

is

not in

CAL

expands all sweep by factor of 10

3%

accuracy of

dB

on 10

at

least

position.

in-

Polarity:

NORM or INVT selectable on chan-

nel B.

Signal Delay:

ficiently

input signals are delayed

to

view leading edge of input

signals without advanced external trigger.

Input

RC

1

megohm

mately

Input Coupling:

24

pF.

*2%,

shunted by approxi-

AC, DC or GND selectable.

GND position disconnects signal input and

grounds amplifier input.

MAXIMUM INPUT

AC-coupled:

5

V/div

*600V (dc + pk ac);

to

20 mV/div; <150V

rms

ac <350V,

at

10 mV/div

(10 kHz or less).

DC-coupled:

<150V

A + B OPERATION

Amplifier:

<350V (rms) 5 V/div to

at

10 mV/div (10 kHz or less).

20

bandwidth and deflection factors

are unchanged; channel B may be inverted

for A - B operation.

suf-

mV/div;

SWEEP MODE

Normal:

sweep

is

triggered by internal or

external signal.

Automatic:

of input signal; triggering

bright baseline displayed in absence

is

same

as

above 40 Hz.

Single:

in

normal mode, sweep occurs once

with same triggering

button

arms sweep and lights indicator; in

as

normal; reset push-

auto mode, sweep occurs once each time

RESET pushbutton

TRIGGER1 NG

Internal:

dc to

is

pressed.

35

MHz on signals causing 0.5

div or more vertical deflection, increasing to

1

div

at

75 MHz in all display modes except

chop; dc

External:

to

400 kHz in chop mode.

dc

to

35

MHz on signals 50 mV p-p

or more, increasing to 100 mV p-p at 75 MHz.

External Input RC:

approximately 1 megohm

shunted by approximately 27 pF.

normal

1-2

Page 12

Model

1707B

Table

1-1.

Specifications (Cont’d)

General Information

Level and Slope

INTERNAL

at

any point on vertical wave-

form displayed.

EXTERNAL continuously variable from

+12V

to

-1.2V on either slope of trigger

signal. Maximum input, *lOOV.

Coupling:

AC, DC, LF REJ, or HF REJ.

AC: attenuates signals below approximately

20 Hz.

LF REJ: attenuates signals below approxi-

mately 15 kHz.

HF REJ: attenuates signals above approxi-

mately 30 kHz.

TRIGGER HOLDOFF:

time between sweeps

continuously variable.

DELAYED TIME BASE

TRACE INTENSIFICATION:

of main time base to be expanded to full

screen in delayed time base mode. Rotating

time base switch from OFF position activates

intensified mode.

SWEEP

Ranges:

in 1,

0.1 usec/div to

2,

5

sequence;

brated position.

Vernier:

continuously variable between all

ranges, extends slowest sweep to 0.5 sec/div.

Magnifier:

expands all sweeps by a factor of

10 and extends fastest sweep to 10 ns/div;

accuracy *5% (including

time base).

SWEEP MODE

Trigger:

delayed sweep

delay period.

Auto:

delayed sweep

at end of delay period.

TRIGGERING

same

as

Internal:

External:

is

same

approximately

approximately

Level and Slope

INTERNAL

main time base.

as

main time base. Input RC

27

pF.

at

any point on vertical wave

form displayed.

EXTERNAL continuously variable from

+1.2V

to

-1.2V on either slope of trigger

signal.

intensifies

0.2

sec/div

*3%

with vernier

3%

is

armed

is

automatically triggered

1

megohm shunted by

that

(20

accuracy of

at

part

ranges)

in

cali-

end of

Coupling:

selectable, AC, DC, or HF REJ. AC

attenuates signals below approximately

Hz. HF REJ attenuates signals above approxi-

mately 30 kHz.

DELAY (Before start of delayed sweep.)

Time:

continuously variable from

2

sec.

Time Jitter:

maximum delay

Calibrated delay Accuracy:

MIXED SWEEP

<0.005%

in

each sweep.

(1

part

fl%;

0.1

in

20,000)

linearity,

usec to

Combines main and delayed sweeps into

one display. Sweep

base and

is

is

started by main time

completed by faster delayed

time base.

EXTERNAL HORIZONTAL INPUT

BANDWIDTH:

COUPLl NG:

DEFLECTION FACTOR:

X10;

0.1

VERNIER:

adjustment between ranges.

DYNAMIC RANGE:

left edge of CRT with 0 to -5V input.

MAXIMUM INPUT

INPUT RC:

30

pF.

dc

to

1

MHz.

dc.

X1; 1 V/div.

V/div.

1O:l

vernier provides continuous

beam may be positioned to

*lOOV.

1

megohm shunted by approximately

CATHODE-RAY TUBE AND CONTROLS

TYPE:

potential; aluminized

phosphors available, refer to options).

GRATICULE:

major division consists of 5 subdivisions on

major axes; 1 div

TRACE ALIGN:

cule line.

BEAM FINDER:

of settings of vertical, horizontal, or intensity

controls.

INTENSITY MODULATION:

blanks trace of any intensity. Input R equals

1000 ohms

Maximum Input: lOV (dc plus pk ac).

post-accelerator, 22.2-kV accelerating

P31

phosphor (other

6

X 10 div internal graticule; each

=

1

cm.

aligns

trace with horizontal

returns trace to CRT regardless

+4V, dc to 1 MHz,

*lo%.

GENERAL

CALI B RAT0

Type:

Voltage:

1

kHz

1V

R

*lo%

pp

square wave.

*l%.

20

of

*O.Wo.

grati-

1-3

Page 13

General Information

Table

1-1.

Specifications (Cont'd)

Model 1707B

c

3

1/8

(79.4)

1

7

TOP

1-

14 3/8(365.1)

MAX PROJECTION (1701A)

15 5/16(388.9)

MAX PROJECTION (1701A)

15 9/16(395.31

20 7/8 (530.2)

15

3/4 (400.1)

-1

-

NOTE:

DIMENSIONS IN INCHES

c

c

7 21/64

(1 86.1)

7

53/64

(198.0)

a-

b--11 15/64(286.1)

I

13 3/8(339.7)

AND

(MILLIMETERS)

-4

POWER REQUIREMENTS

AC Line:

DC Line:

Battery (optional)

OPERATING TIME: up

RECHARGE TIME: 14

LOW BATTERY INDICATOR: power light

RECHARGING: batteries are recharging

115V or 230V *20%, 48 to 440 Hz.

11.5V

to

36V.

to

4.5 hours.

hr

minimum charging

time for a fully discharged battery.

flashes

charged and further operation may damage battery.

whenever POWER MODE switch

switch

POWER switch ON, trickle charge

applied.

to

indicate that batteries are dis-

off,

full charge

is

applied; with

is

set to

is

ID

WEIGHT

Without Panel Cover:

ping, 35 lb (15.9 kg).

With Panel Cover and Accessories:

(12.3 kg); shipping,

With Panel Cover, Accessories, and Battery

net, 35 lb (16 kg); shipping, 46 lb

Pack:

(20.9 kg).

DI MENS1 ONS:

ENVIRONMENT (Oscilloscope operates within

specifications over following ranges):

temperature 0°C to +55"C; humidity, to 95%

relative humidity

ft;

vibration, in three planes for 15 min each

with 0.010-inch excursion,

ACCESSORIES FURNISHED:

Model 10115A; front panel storage cover,

Model 10101B; two Model 10006B probes;

and one ac power cord with right angle plug.

refer to outline drawing.

net, 24 lb

38

lb (17.2 kg).

to

40°C; altitude, to 15,000

(11

kg); ship-

net, 27 lb

10

to 55 Hz.

blue contrast filter,

1-4

Page 14

Model 1707B

1-17. CATHODE-RAY TUBE.

1-18. The Model 1707B uses a post-accelerator CRT

with a nonglare, rectangular faceplate. An internal

graticule

to eliminate parallax errors. The CRT

mately 22 -kV accelerating potential, and 6 vertical

by 10 horizontal divisions. Each division

centimeter.

1-19. A type

CRT. Other types of phosphors are available by

special order. Refer to Section VI1 for further information about optional and special-order modifications.

is

located on the same plane

P31

phosphor

is

used in the standard

as

the display

has

approxi-

is

a

square

General Information

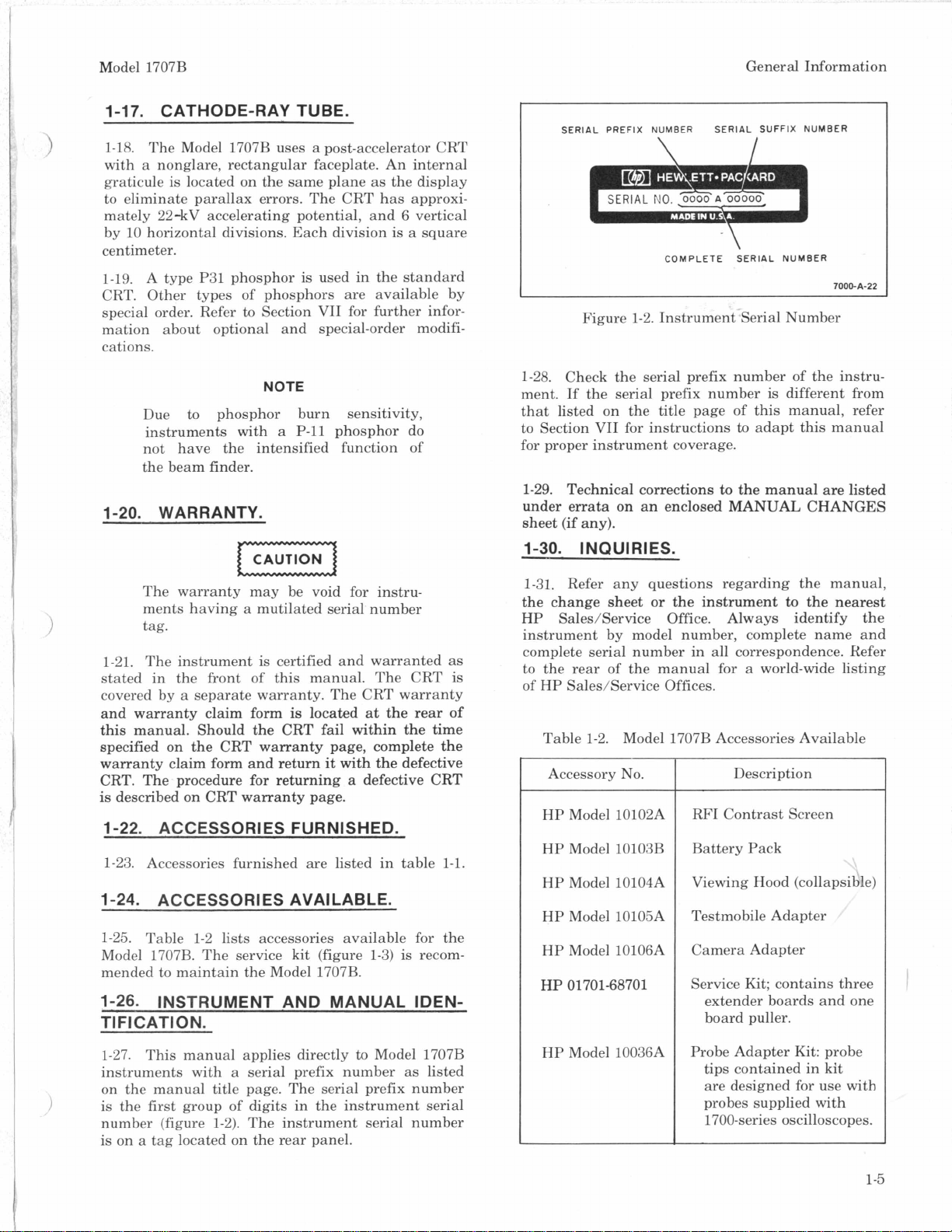

SERIAL PREFIX NUMBER SERIAL SUFFIX NUMBER

rZBirn*h

SERIAL

rJG

0000

A

00000

-\

COMPLETE SERIAL NUMBER

7000-A-22

Figure 1-2. Instrument Serial Number

I

NOTE

Due to phosphor burn sensitivity,

instruments with

not have the intensified function of

the beam finder.

a

P-11

phosphor do

1-20. WARRANTY.

1

CAUTION

The warranty may be void for instruments having a mutilated serial number

tag.

1-21. The instrument is certified and warranted

stated in the front of this manual. The CRT

covered by a separate warranty. The CRT warranty

and warranty claim form

this manual. Should the CRT fail

specified on the CRT warranty page, complete the

warranty claim form and return

CRT. The procedure for returning a defective CRT

is

described on CRT warranty page.

is

3

located

at

the rear of

within

it

with the defective

as

is

the time

1-28. Check the serial prefix number of the instrument. If the serial prefix number

that listed on the title page of this manual, refer

to Section VI1 for instructions

for proper instrument coverage.

1-29. Technical corrections to the manual are listed

under errata on an enclosed MANUAL CHANGES

sheet (if any).

is

different from

to

adapt this manual

1-30. INQUIRIES.

1-31.

Refer any questions regarding the manual,

the change sheet or the instrument to the nearest

HP Sales/Service Office. Always identify the

instrument by model number, complete name and

complete serial number in all correspondence. Refer

to the rear of the manual for a world-wide listing

of HP SaledService Offices.

Table 1-2. Model 1707B Accessories Available

1

Accessory No.

HP Model 10102A

I

Description

RFI Contrast Screen

I

1-22. ACCESSORIES FURNISHED.

I

1-23. Accessories furnished are listed in table

1-1.

HP Model 10103B

HP Model 10104A

Battery Pack

Viewing Hood (collapsible)

1-24. ACCESSORIES AVAILABLE.

Testmobile Adapter

Camera Adapter

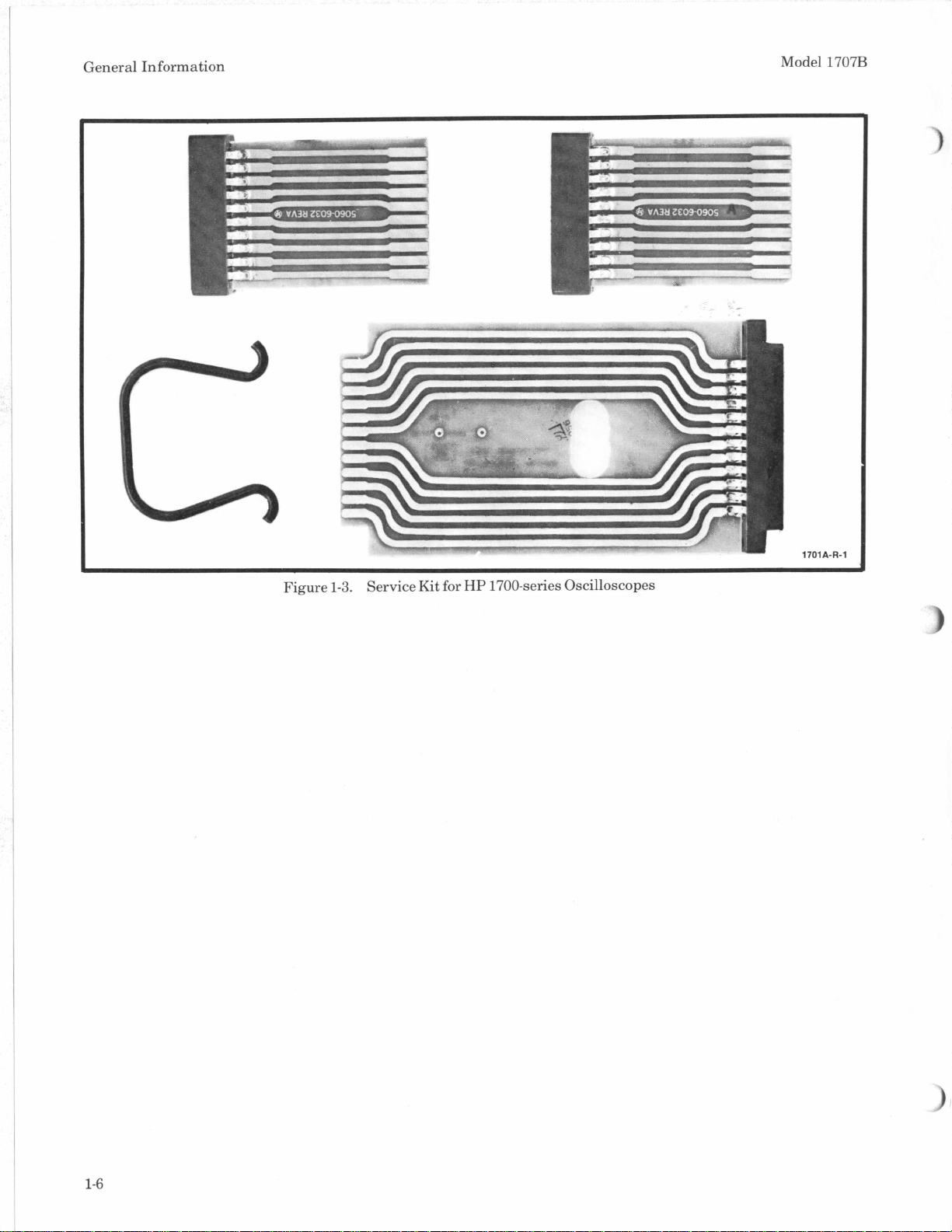

Service Kit; contains three

extender boards and one

board puller.

1-25. Table 1-2 lists accessories available for the

Model 1707B. The service kit (figure

mended to maintain the Model 1707B.

1-3)

is

recom-

1-26. INSTRUMENT AND MANUAL IDEN-

FI

CAT1 ON.

TI

HP Model 10105A

HP Model 10106A

HP

01701-68701

1-27. This manual applies directly to Model 1707B

instruments with a serial prefix number

on the manual title page. The serial prefix number

is

the first group of digits in the instrument serial

number (figure 1-2). The instrument serial number

is

on a tag located on the rear panel.

as

listed

HP Model 10036A

Probe Adapter Kit: probe

tips contained in kit

are designed for use with

probes supplied with

1700-series oscilloscopes.

1-5

Page 15

Gen era1

In

form ation

Model

1707B

Figure

1-3.

Service

Kit

for

HP

1700-series Oscilloscopes

1701A-R-1

I

1-6

Page 16

Model 1707B

Installation

SECTION

I

NSTALLATI 0 N

2-1. INTRODUCTION.

2-2. This section contains instructions for performing an initial inspection of the Model 1707B. Installation procedures and precautions are presented

in step-by-step order. The procedures for making

a

claim for warranty repairs and for repacking the

instrument for shipment are also described

section.

2-3.

INITIAL INSPECTION.

2-4. The instrument was inspected mechanically and

electrically before shipment. Upon receipt, inspect

it

for damage that may have occurred in transit.

Check for broken knobs, bent or broken connectors,

and dents or scratches. If damage

is

to the claims paragraph in this section. Retain the

packing material for possible future use.

in

this

found, refer

II

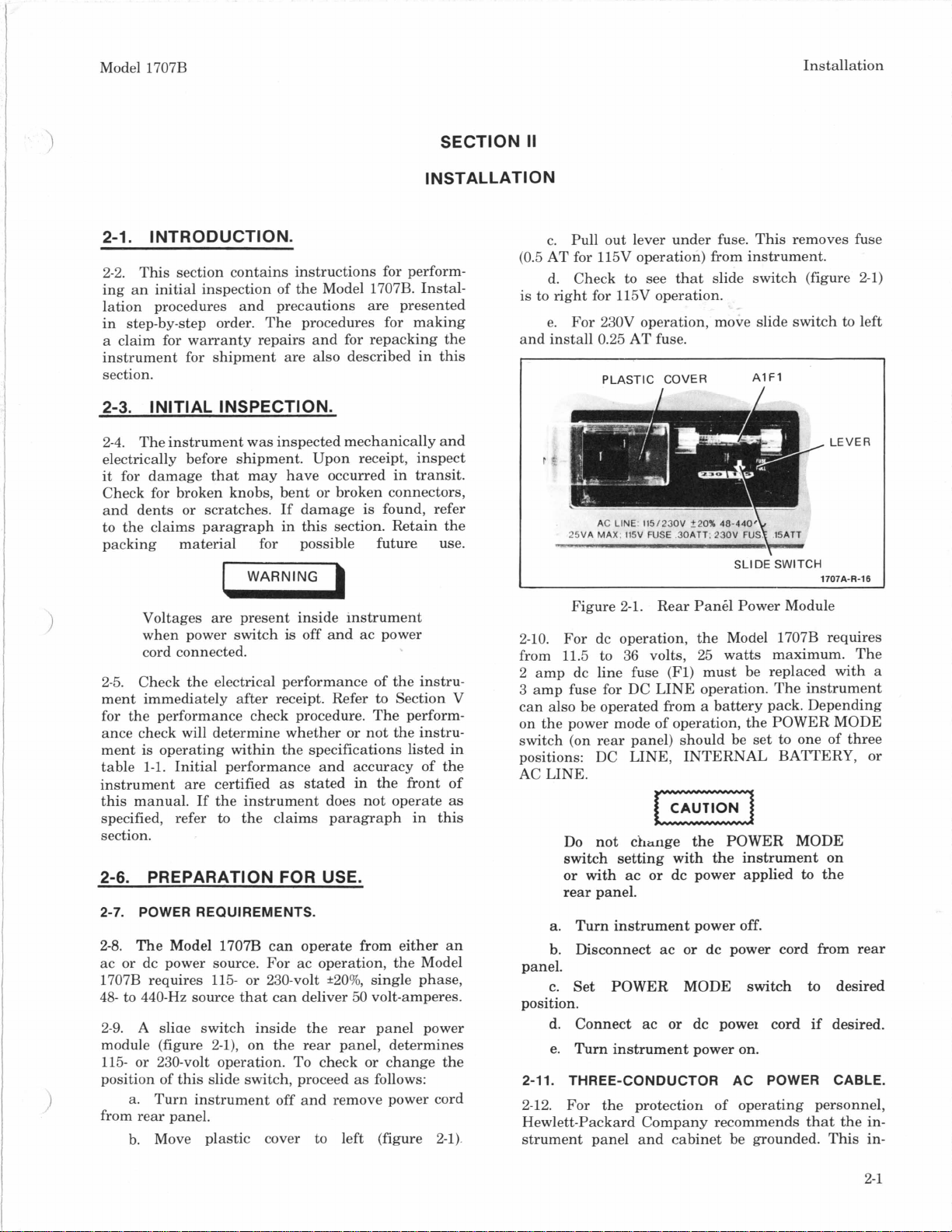

c. Pull out lever under fuse. This removes fuse

(0.5 AT for 115V operation) from instrument.

d. Check to see

is

to right for 115V operation.

e.

For 230V operation, move slide switch to left

and install 0.25 AT fuse.

PLASTIC COVER A1

that

slide switch (figure 2-1)

F1

~

SLIDE

SWITCH

LEVER

1707A-R-16

)

1

Voltages are present inside instrument

when power switch

is

off and ac power

cord connected.

2-5. Check the electrical performance of the instrument immediately after receipt. Refer to Section V

for the performance check procedure. The performance check will determine whether or not the instrument

is

operating within the specifications listed in

table

1-1.

Initial performance and accuracy of the

instrument are certified

this manual. If the instrument does not operate

specified, refer to the claims paragraph

as

stated

in

the front of

in

as

this

section.

2-6.

PREPARATION FOR USE.

2-7.

POWER REQUIREMENTS.

2-8.

The Model

1707B

can operate from either

an

ac or dc power source. For ac operation, the Model

1707B requires

48- to 440-Hz source that can deliver

115-

or 230-volt *20%, single phase,

50

volt-amperes.

2-9. A sliae switch inside the rear panel power

module (figure 2-1), on the rear panel, determines

115- or 230-volt operation. To check or change the

position of this slide switch, proceed

a.

Turn instrument off and remove power cord

as

follows:

from rear panel.

b. Move plastic cover to left (figure 2-1).

Figure 2-1. Rear Pan61 Power Module

2-10. For dc operation, the Model 1707B requires

from

11.5

to 36 volts, 25 watts maximum. The

2 amp dc line fuse

3

amp fuse for DC LINE operation. The instrument

(Fl)

must be replaced with

a

can also be operated from a battery pack. Depending

on the power mode of operation, the POWER MODE

switch (on rear panel) should be set to one of three

positions: DC LINE, INTERNAL BATTERY, or

AC LINE.

Do not change the POWER MODE

switch setting with the instrument on

or

with

ac or dc power applied

to

the

rear panel.

a.

Turn instrument power

b.

Disconnect ac or dc power cord from rear

off.

panel.

c. Set POWER

MODE

switch to desired

position.

d.

Connect ac or dc powei cord if desired.

e. Turn instrument power on.

2-11.

THREE-CONDUCTOR AC POWER CABLE.

2-12. For the protection of operating personnel,

Hewlett-Packard Company recommends that the

strument panel and cabinet be grounded. This

in-

in-

2-1

Page 17

Installation

Model 1707B

strument

is

equipped with a three-conductor ac power

cable that, when connected to an appropriate receptacle, grounds the instrument through the

offset pin. The power jack and mating plug of the

power cord meet International Electro-technical

Commission (IEC) safety standards. To preserve

this

protection feature when operating from a twocontact outlet, use a three-conductor to two-conductor

adapter, and connect the adapter wire to ground

at

the power outlet.

2-13.

2-14. A dc jack

DC

PLUG.

is

provided for operating from a dc

line. The cable used for the dc power cord should

be 2 wire (grounded) and must be able to carry

2.5A of current with a voltage loss of less than

1

volt.

2-15.

BATTERY INSl’ALLATION.

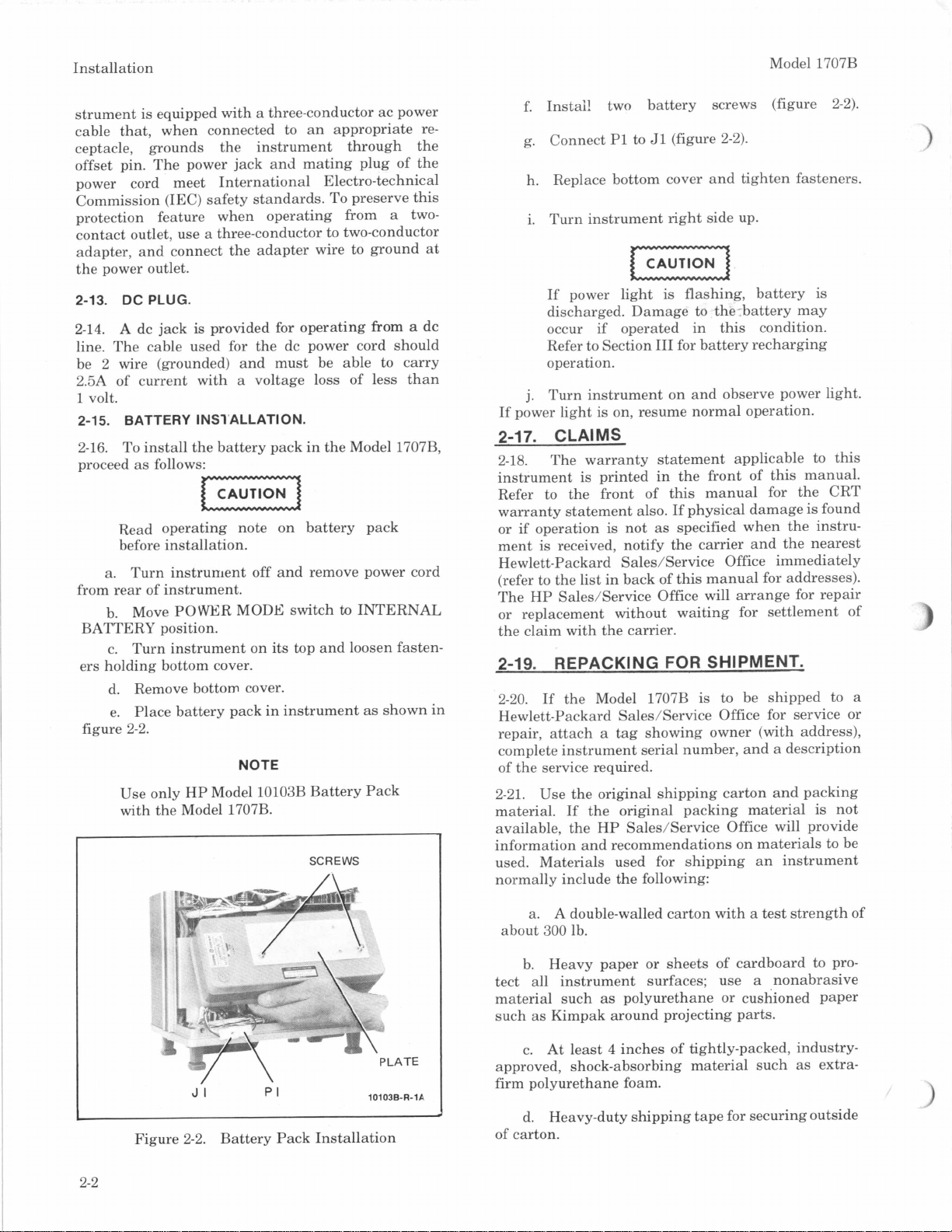

2-16. To install the battery pack in the Model 1707B,

proceed

as

follows:

Read operating note on battery pack

before inst all ation.

a.

Turn instrument off and remove power cord

from rear of instrument.

Move POWER MODE switch

b.

to

INTERNAL

BATTERY position.

Turn instrument on

c.

its

top and loosen fasten-

ers holding bottom cover.

d. Remove bottom cover.

Place battery pack in instrument

e.

as

shown

in

figure 2-2.

NOTE

Use only HP Model 10103B Battery Pack

with the Model 1707B.

SCREWS

f. Instal! two battery screws (figure 2-2).

g.

Connect

P1

to

Jl

(figure 2-2).

h. Replace bottom cover and tighten fasteners.

i.

Turn instrument right side up.

If power light

is

flashing, battery

is

discharged. Damage to the:battery may

occur if operated in this condition.

Refer to Section

I11

for battery recharging

operation.

Turn instrument on and observe power light.

j.

If power light

2-17.

2-18. The warranty statement applicable to

instrument

Refer to the front of

warranty statement also. If physical damage

or if operation

ment

is

is

on, resume normal operation.

CLAIMS

this

is

printed

is

received, notify the carrier and the nearest

not

in

the front

this

as

specified when the instru-

of

this

manual.

manual for the CRT

is

found

Hewlett-Packard Sales/Service Office immediately

(refer to the list in back of this manual for addresses).

The

HP

Sales/Service Office will arrange for repair

or replacement without waiting for settlement of

the claim with the carrier.

2-19.

2-20. If the Model 1707B

REPACKING

FOR

SHIPMENT,

is

to be shipped to

Hewlett-Packard Sales/Service Office for service or

repair, attach a tag showing owner

(with

address),

complete instrument serial number, and a description

of the service required.

2-21. Use the original shipping carton and packing

material. If the original packing material

is

not

available, the HP Sales/Service Office will provide

information and recommendations on materials to be

used. Materials used for shipping

an

instrument

normally include the following:

a

2-2

JI

PI

10103B-R-IA

Figure 2-2. Battery Pack Installation

a.

A double-walled carton with a test strength of

about

300

lb.

Heavy paper or sheets of cardboard to pro-

b.

tect all instrument surfaces; use a nonabrasive

material such

such

as

Kimpak around projecting parts.

as

polyurethane or cushioned paper

c. At least 4 inches of tightly-packed, industry-

approved, shock-absorbing material such

as

extra-

firm polyurethane foam.

d.

Heavy-duty shipping tape for securing outside

of carton.

Page 18

Model 1707B

Operation

SECTION

OPERATION

3-1. I NTR 0 D U CTI ON.

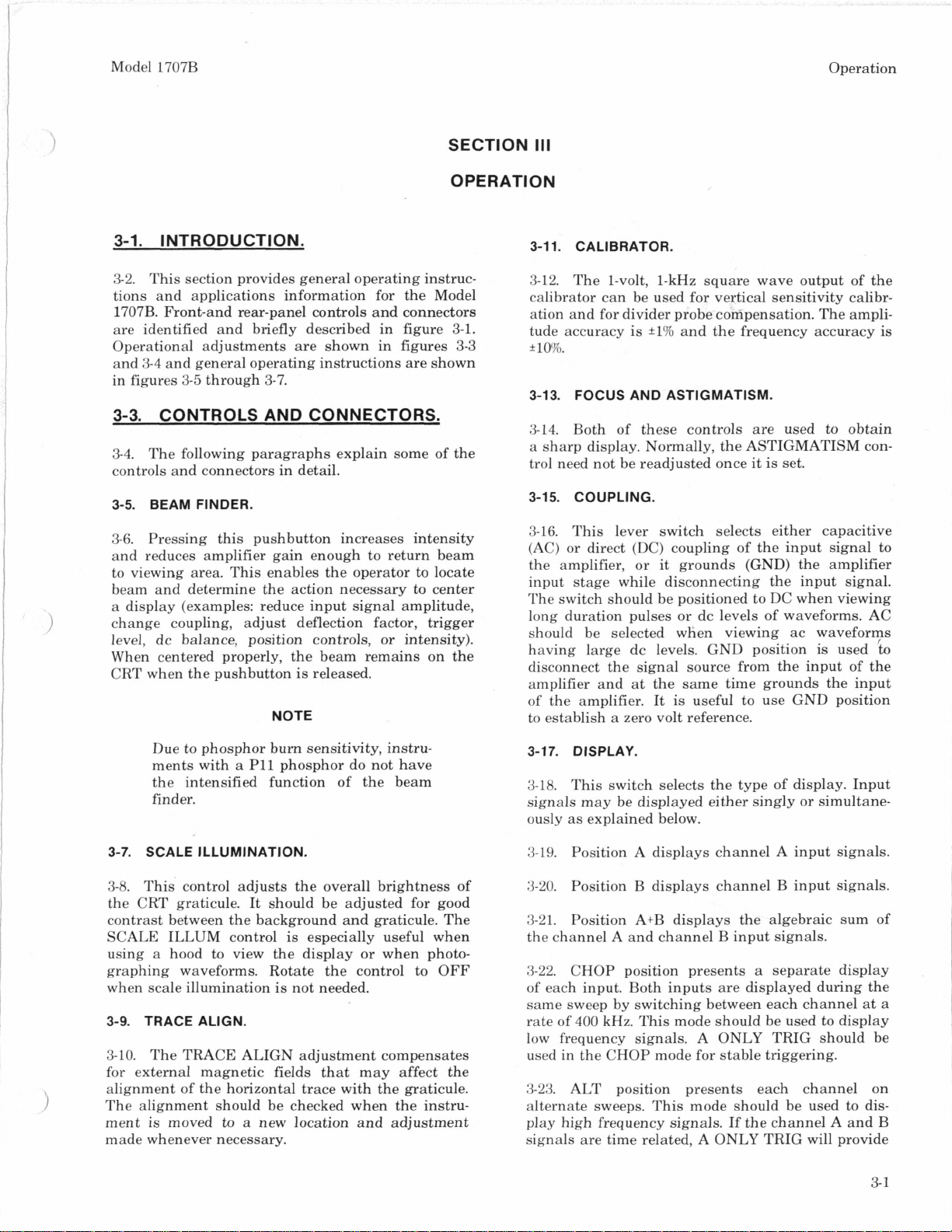

3-2. This section provides general operating instructions and applications information for the Model

1707B. Front-and rear-panel controls and connectors

are identified and briefly described in

figure

Operational adjustments are shown in figures

and 3-4 and general operating instructions are shown

in figures

3-3.

3-5

through 3-7.

CONTROLS AND CONNECTORS.

3-4. The following paragraphs explain some of the

controls and connectors in detail.

3-5. BEAM FINDER.

3-6. Pressing this pushbutton increases intensity

and reduces amplifier gain enough to return beam

to viewing area. This enables the operator to locate

beam and determine the action necessary to center

a

display (examples: reduce input signal amplitude,

change coupling, adjust deflection factor, trigger

level, dc balance, position controls, or intensity).

When centered properly, the beam remains on the

CRT when the pushbutton

is

NOTE

released.

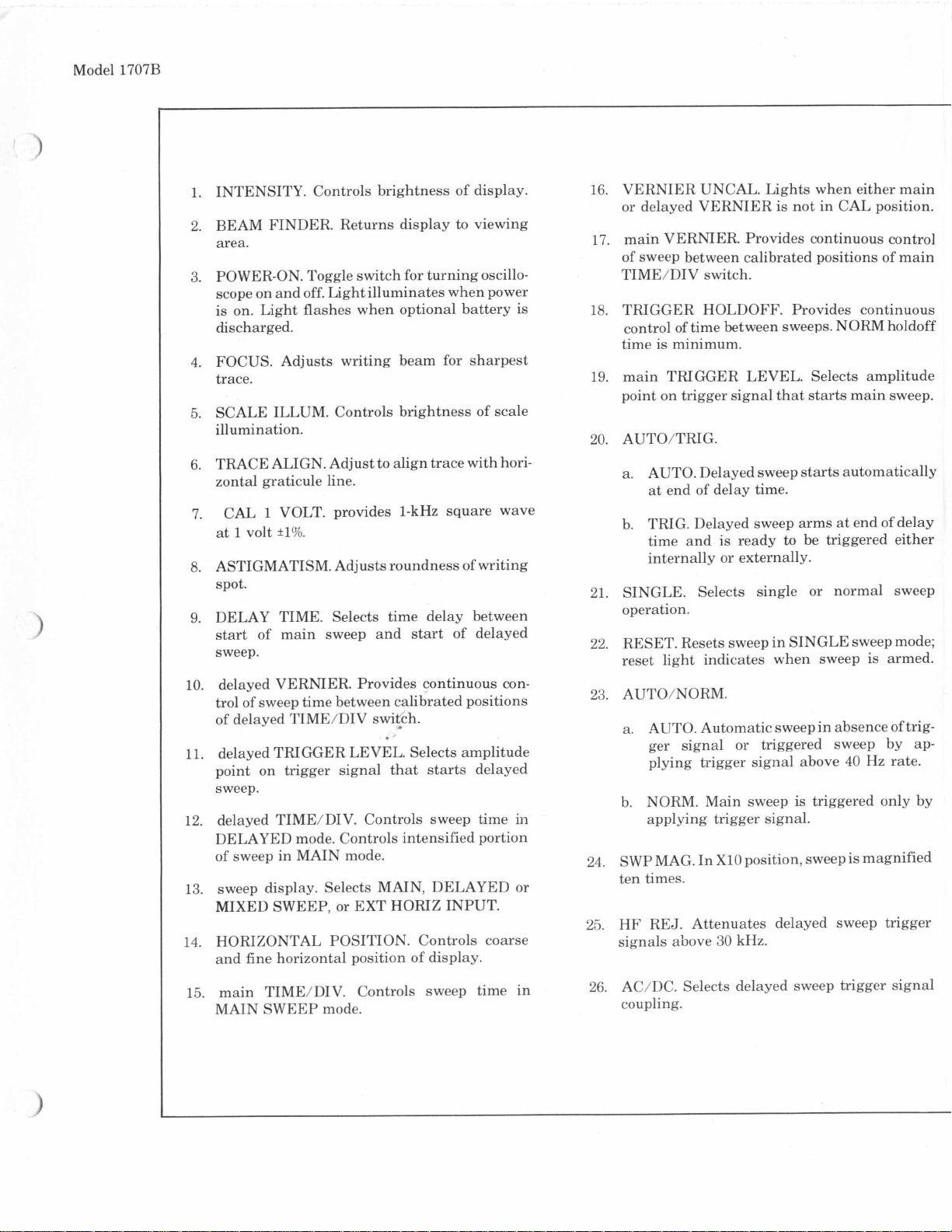

3-1.

3-3

111

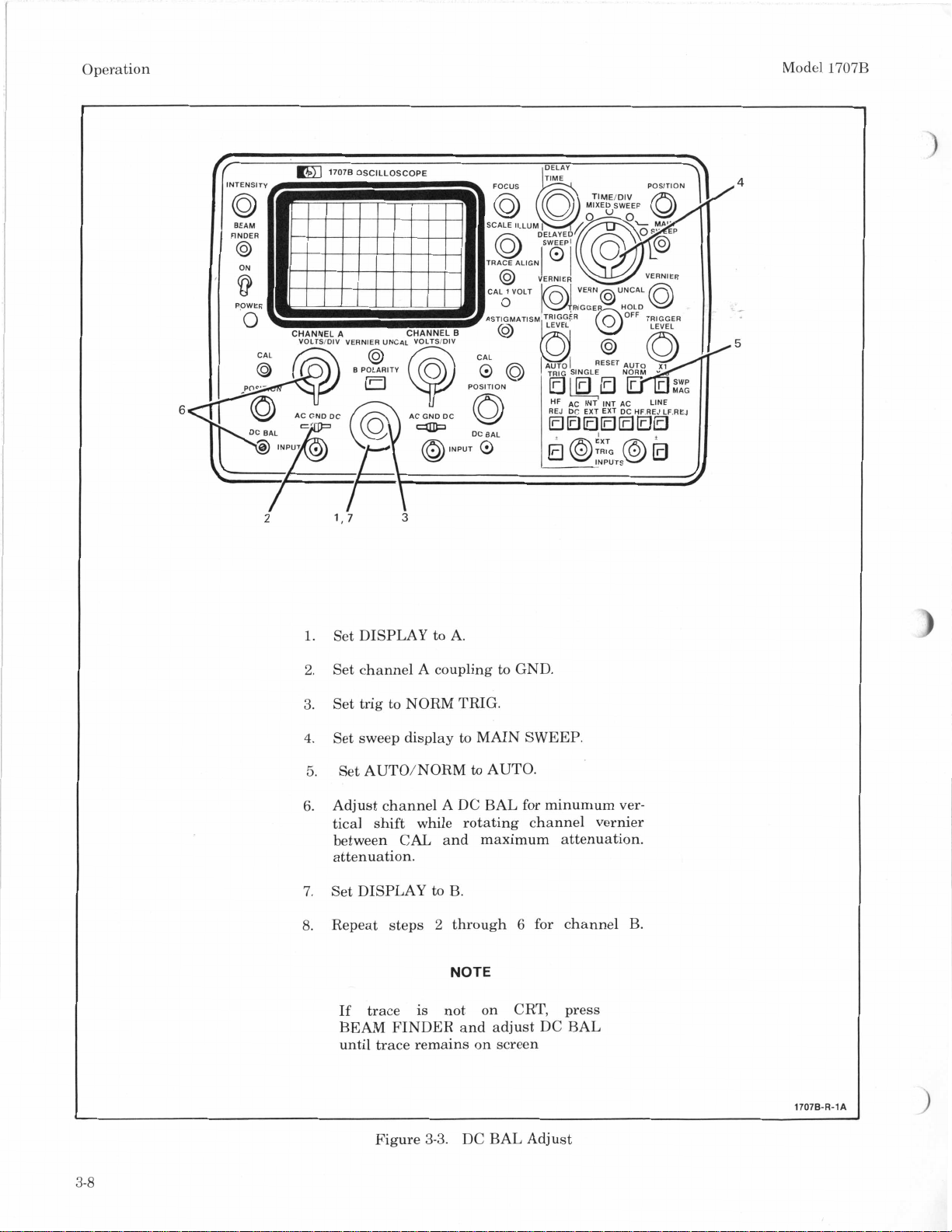

3-1 1. CALIBRATOR.

3-12. The 1-volt, l-kHz square wave output of the

calibrator can be used for vertical sensitivity calibration and for divider probe compensation. The amplitude accuracy

*

10'70.

3-13. FOCUS AND ASTIGMATISM.

3-14. Both of these controls are used to obtain

a

sharp display. Normally, the ASTIGMATISM con-

trol need not be readjusted once

3-15. COUPLING.

3-16. This lever switch selects either capacitive

(AC) or direct (DC) coupling of the input signal to

the amplifier, or it grounds (GND) the amplifier

input stage while disconnecting the input signal.

The switch should be positioned to

long duration pulses

should be selected when viewing ac waveforms

having large dc levels. GND position

disconnect the signal source from the input of the

amplifier and at the same time grounds the input

of

the amplifier.

to establish a zero volt reference.

is

*l%

and the frequency accuracy

it

is

set.

DC

when viewing

or

dc levels of waveforms. AC

It

is

useful to use GND position

is

used

is

to

Due to phosphor burn sensitivity, instruments with

a P11

phosphor do not have

the intensified function of the beam

finder.

3-7. SCALE ILLUMINATION.

3-8.

This control adjusts the overall brightness of

the CRT graticule.

It

should be adjusted for good

contrast between the background and graticule. The

SCALE ILLUM control

is

especially useful when

using a hood to view the display or when photographing waveforms. Rotate the control to OFF

when scale illumination

3-9. TRACE ALIGN.

is

not needed.

3-10. The TRACE ALIGN adjustment compensates

for external magnetic fields that may affect the

alignment of the horizontal trace with the graticule.

The alignment should be checked when the instrument is moved to a new location and adjustment

made whenever necessary.

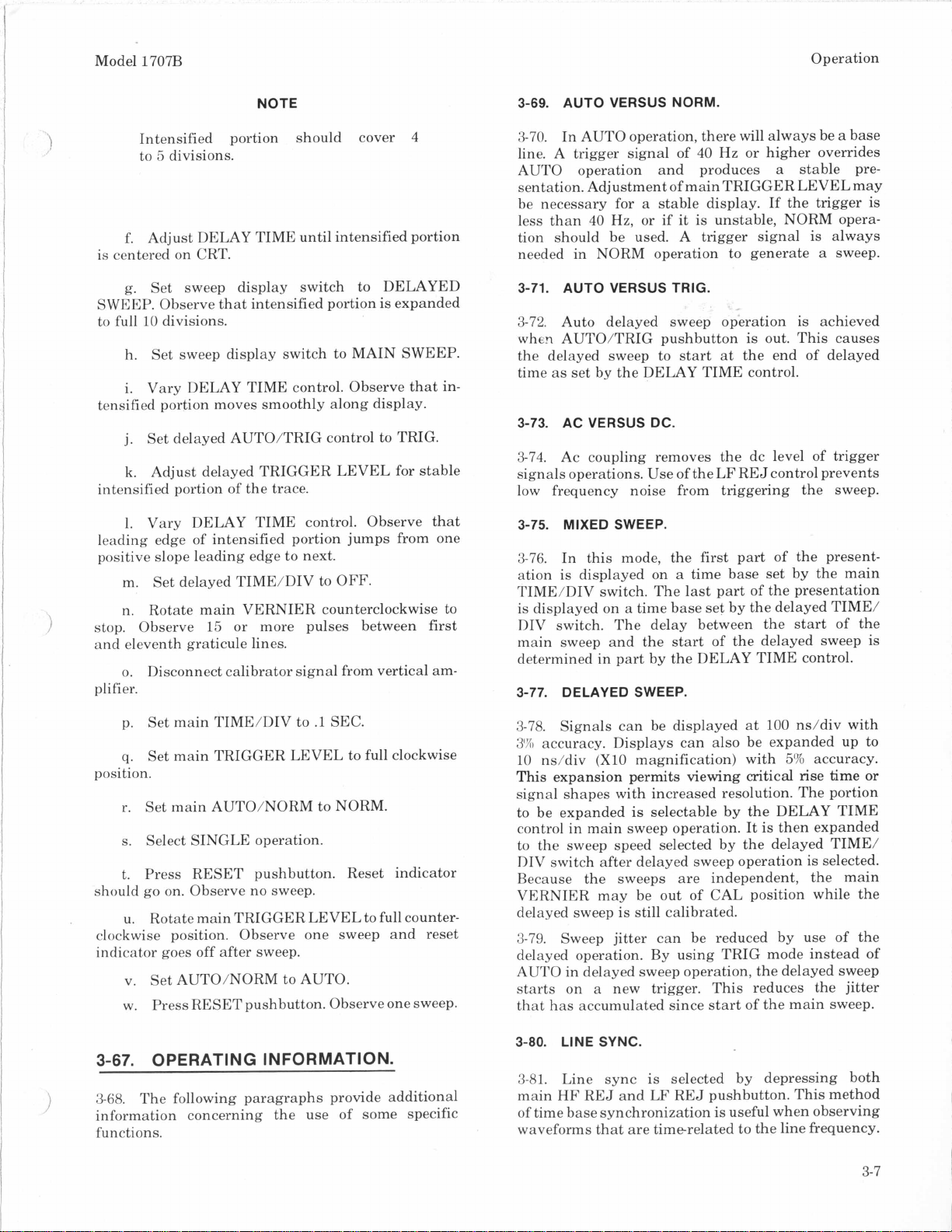

3-17. DISPLAY.

3-18. This switch selects the type of display. Input

signals may be displayed either singly or simultaneously

as

explained below.

Position A displays channel A input signals.

3-19.

3-20. Position B displays channel B input signals.

3-21.

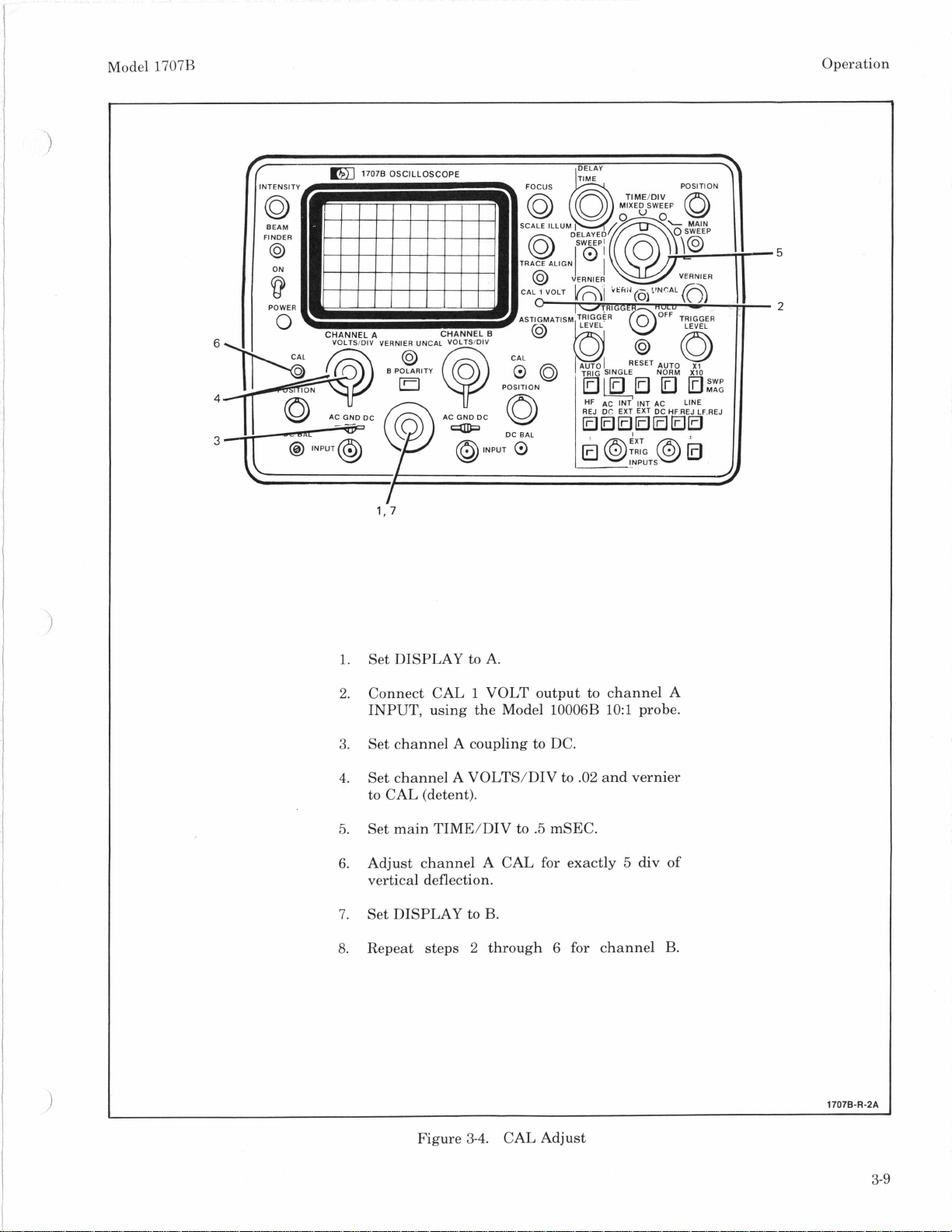

Position A+B displays the algebraic sum of

the channel A and channel B input signals.

3-22. CHOP position presents a separate display

of

each input. Both inputs are displayed during the

same sweep by switching between each channel

rate of

400

kHz, This mode should be used to display

at

a

low frequency signals. A ONLY TRIG should be

used in the CHOP mode for stable triggering.

3-23. ALT position presents each channel on

alternate sweeps. This mode should be used to display high frequency signals. If the channel A and B

signals are time related, A ONLY TRIG will provide

3-

1

Page 19

Operation Model

4-8 9-1 1 12 13 14

15

16

1707B

1-3

46

45

44

43

42 41 40 39 38 37 36 35 34 33 32

\\

El

\\.

'ORIZ INPUT

/

17

18

19

2025-

49

-24

-31

3-2

1.

SET FRONT PANEL POWER SWITCH TO OFF.

2.

SET

3. APPLY AC POWER

POWER

MODE

INTERNALBATTERY

@

c

53 52 51 50

Figure

31.

Controls and Connectors

FRONT

PANEL

POWER

MODE

SWITCH

TO

TO

INSTRUMENT.

c-3

[~y,lnrj

AC LINE

5/230

0'0

AC.

~

48-440

Page 20

e'

a

I

Page 21

Model

1707B

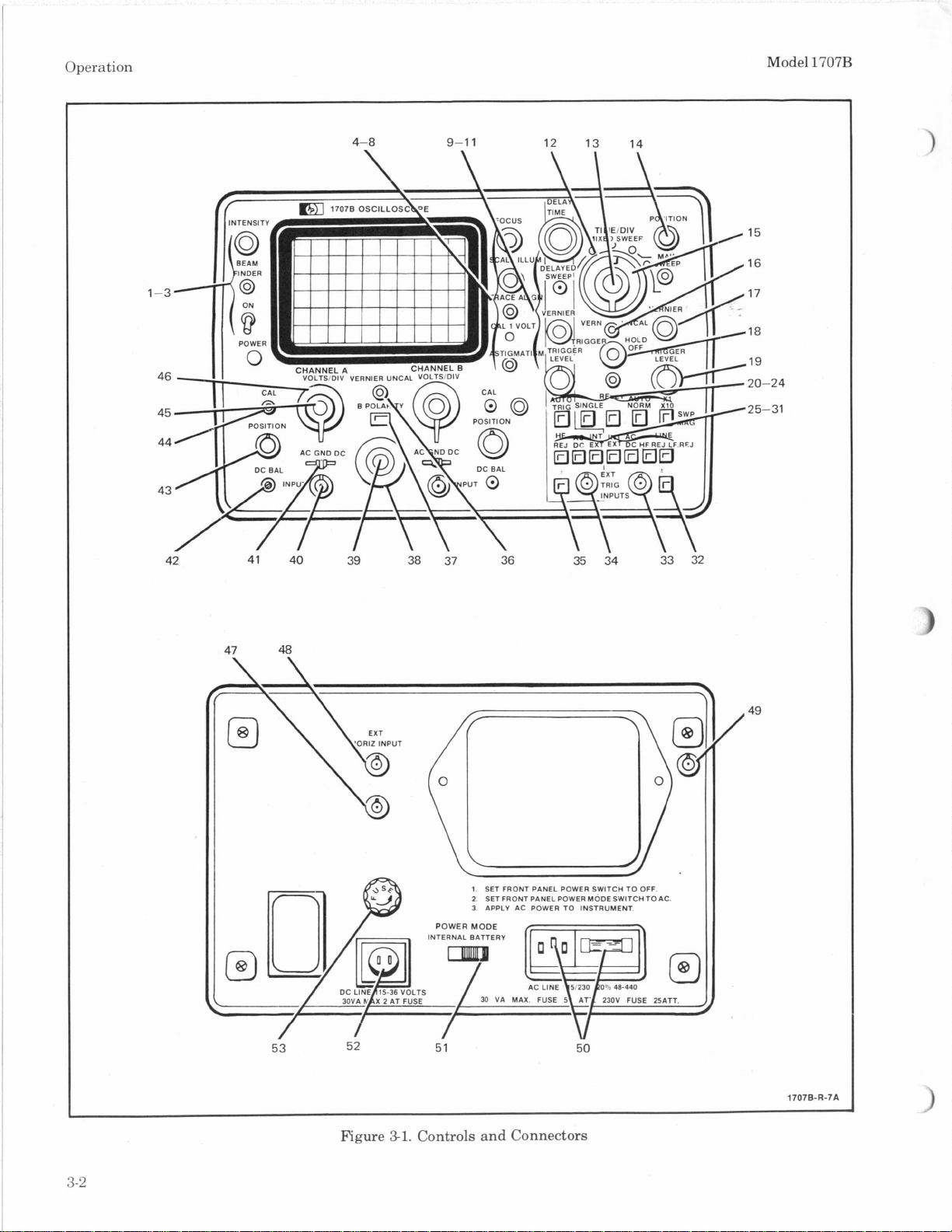

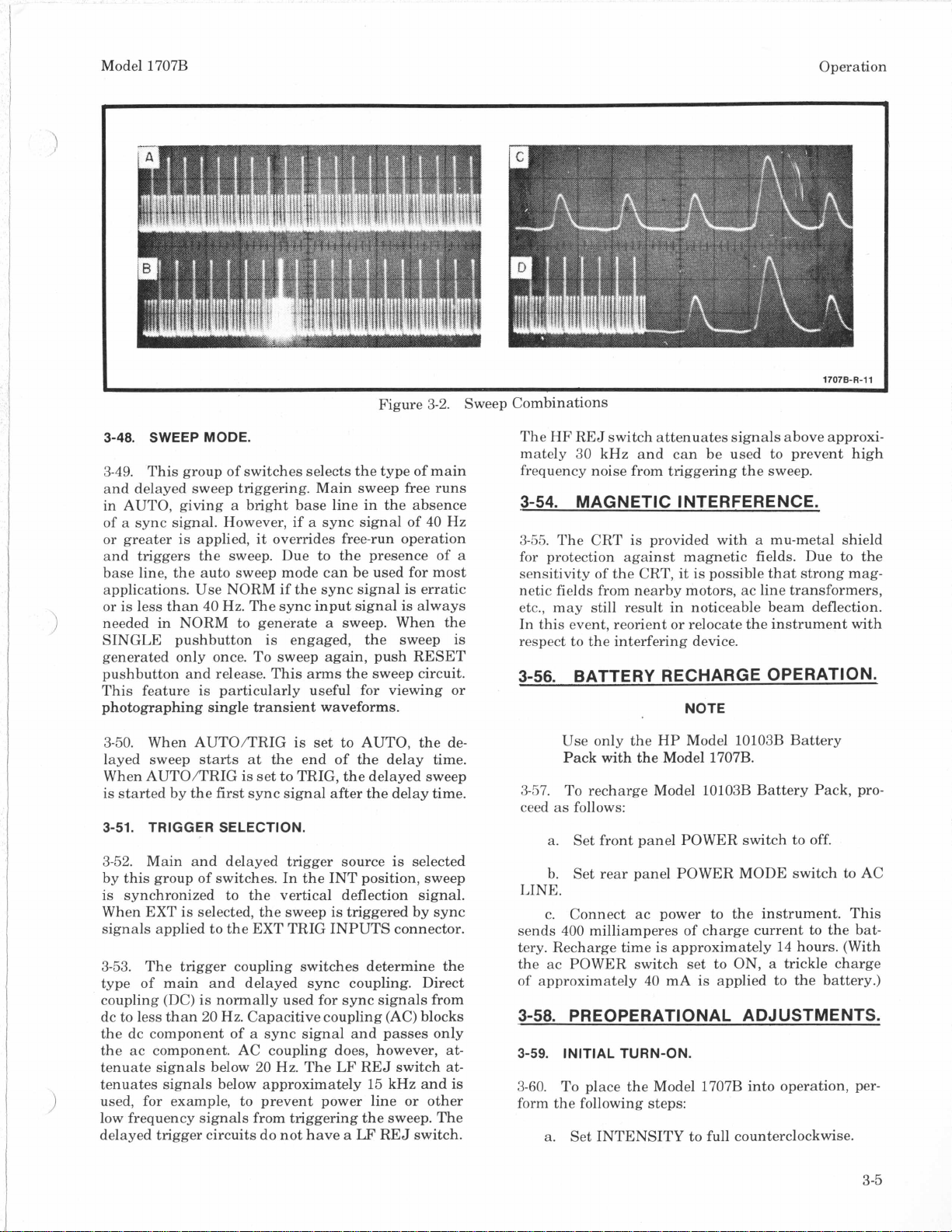

INTENSITY. Controls brightness of display.

1.

BEAM FINDER. Returns display to viewing

2.

area.

POWER-ON. Toggle switch for turning oscillo-

3.

scope on and off. Light illuminates when power

is

on. Light flashes when optional battery

discharged.

FOCUS. Adjusts writing beam for sharpest

4.

trace.

SCALE ILLUM. Controls brightness of scale

5.

illumination.

TRACE ALIGN. Adjust to align trace with hori-

6.

zontal graticule line.

CAL

1

7.

at 1 volt

ASTIGMATISM. Adjusts roundness of writing

8.

VOLT. provides

*I%.

1-kHz

square wave

spot.

DELAY TIME.

9.

start

of main sweep and

Selects time delay between

start

of delayed

sweep.

delayed VERNIER. Provides continuous con-

10.

trol of sweep time between calibrated positions

of delayed TIME/DIV switch.

delayed TRIGGER LEVEL. Selects amplitude

11.

point on trigger signal that

starts

sweep.

delayed TIME/DIV. Controls sweep time

12.

DELAYED mode. Controls intensified portion

of sweep in MAIN mode.

sweep display. Selects MAIN, DELAYED or

13.

MIXED SWEEP, or EXT HORIZ INPUT.

HORIZONTAL POSITION. Controls coarse

14.

and fine horizontal position of display.

is

delayed

in

VERNIER UNCAL. Lights when either main

16.

or delayed VERNIER

main VERNIER. Provides continuous control

17.

is

not in CAL position.

of sweep between calibrated positions of main

TIME/DIV switch.

18.

TRIGGER HOLDOFF. Provides continuous

control of time between sweeps. NORM holdoff

time

is

minimum.

main TRIGGER LEVEL. Selects amplitude

19.

point on trigger signal that

AUTO/TRIG.

20.

a.

AUTO. Delayed sweep

at

end of delay time.

b. TRIG. Delayed sweep arms

time and

is

ready to be triggered either

starts

starts

automatically

at

main sweep.

end of delay

internally or externally.

SINGLE. Selects single or normal sweep

21.

operation.

RESET. Resets sweep

22.

in

SINGLE sweep mode;

reset light indicates when sweep

AUTO/NORM.

23.

AUTO. Automatic sweep in absence of trig-

a.

ger signal or triggered sweep by

plying trigger signal above

b. NORM. Main sweep

is

40

triggered only by

applying trigger signal.

SWP

24.

MAG. In XI0 position, sweep

is

ten times.

HF REJ. Attenuates delayed sweep trigger

25.

signals above 30 kHz.

is

armed.

ap-

Hz rate.

magnified

main TIME/DIV. Controls sweep time in

15.

MAIN SWEEP mode.

26. AC/DC. Selects delayed sweep trigger signal

coupling.

Page 22

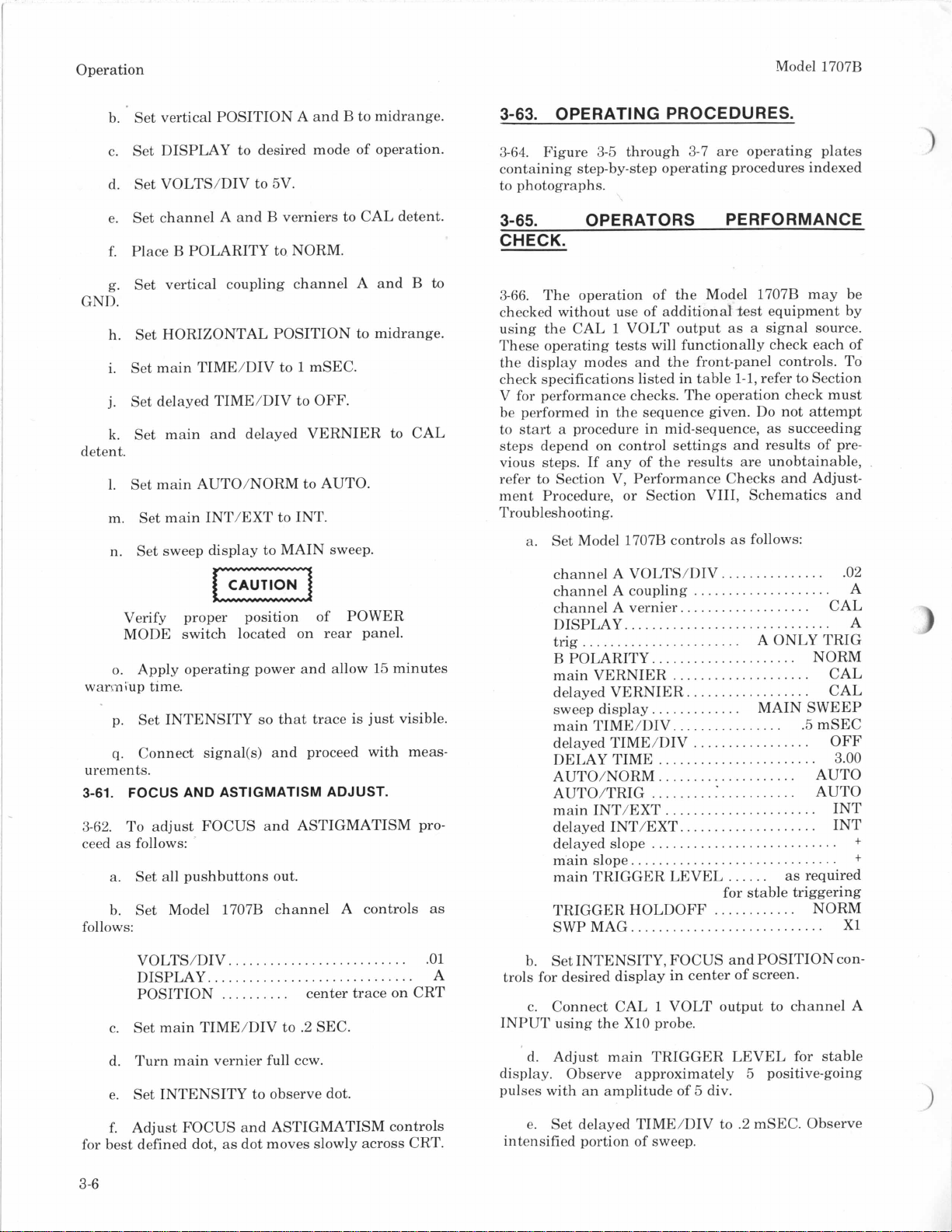

INT/EXT. Selects internal or external sweep

27.

triggering for delayed sweeps.

INT/EXT. Selects internal or external sweep

28.

triggering for main sweep.

AC/DC. Selects main sweep trigger signal

29.

coupling.

30.

HF RE

J.

Attenuates main sweep trigger

signals above 30 kHz.

LF REJ. Attenuates main sweep trigger signals

31.

below

15

kHz.

NOTE

Depressing both HF REJ and LF REJ

selects a LINE SYNC mode of triggering.

main slope. Selects slope of main trigger

32.

signal that

EXT TRIG INPUTS. Main sweep external trig

33.

starts

sweep.

ger input.

EXT TRIG INPUTS. Delayed sweep external

34.

trigger input.

delayed slope. Selects slope of delayed sweep

35.

trigger signal.

VERNIER UNCAL. Lights when either ver-

36.

nier control

is

out of full clockwise CAL

detent position.

i

Operation

b. NORM TRIG. Instrument triggers on dis-

played signal except in ALT mode.

ALT mode

is

triggered on composite sync (LF REJ must be used to

maintain pro per triggering)

40.

INPUT. Input signal connects to BNC con-

.

nector.

41.

coupling. Selects capacitive (AC) or direct

(DC) coupling of input signal, or grounds

(GND) amplifier stage.

DC BAL. Adjust to minimize vertical shift of

42.

trace when vernier

43.

POSITION. Varies vertical position of display.

44.

CAL. Adjust to calibrate amplifier with setting

is

rotated.

of VOLTS/DIV switch.

45.

vernier. Provides continuous adjustments

of

volts/div between calibrated positions of

VOLTS/DIV switch.

46.

VOLTS/DIV. Selects vertical deflection

factor necessary for calibrated measurements

47.

ext horiz VERNIER. Permits

zont

a1

amplifier gain.

48.

EXT HORIZ INPUT. Input to external

1O:l

hori-

amplifier.

49.

Z AXIS INPUT. Z-axis input connector.

B

37.

38.

POLARITY. Controls channel B polarity.

DISPLAY. Selects display mode of channel A,

B,

A+B, CHOP or ALT.

trig.

39.

A ONLY TRIG. Internal trigger signal

a.

derived from channel A.

is

50.

AC LINE. Power input from ac line. Power

module contains ac line fuse (0.50 amp slowblow for 125V, 0.25 amp slow-blow for 230V)

and line selector switch.

51.

POWER MODE. Selects dc line, ac line or intern

a1

battery operati on.

52.

DC LINE. Power input for dc line operation.

53.

FUSE. 2 amp slow-blow fuse for all modes of

operation except DC LINE

(3

amp used in DC

LINE).

Controls and Connectors (Cont’d)

Figure

3-1.

3-3

Page 23

Operation

Model

1707B

the most stable triggering. If the two signals are

not time related, then NORM TRIG should be used.

3-24. TRIG.

3-25. This switch selects the signal to be used

as

the internal trigger signal. In A ONLY TRIG position,

the signal on channel A is used

as

the internal

trig-

ger signal. In NORM TRIG position, the instrument

triggers on the signal being displayed, except in ALT

mode. In ALT mode, the instrument triggers on the

composite sync signal and LF REJ trigger coupling

should be used to maintain stable triggering.

3-26. B POLARITY.

3-27. This switch inverts the channel B display

180 degrees. This switch can also be used to present

an A-B display. Set DISPLAY to A+B mode. Put

R

POLARITY switch in INVT position. Display

observed is A-B.

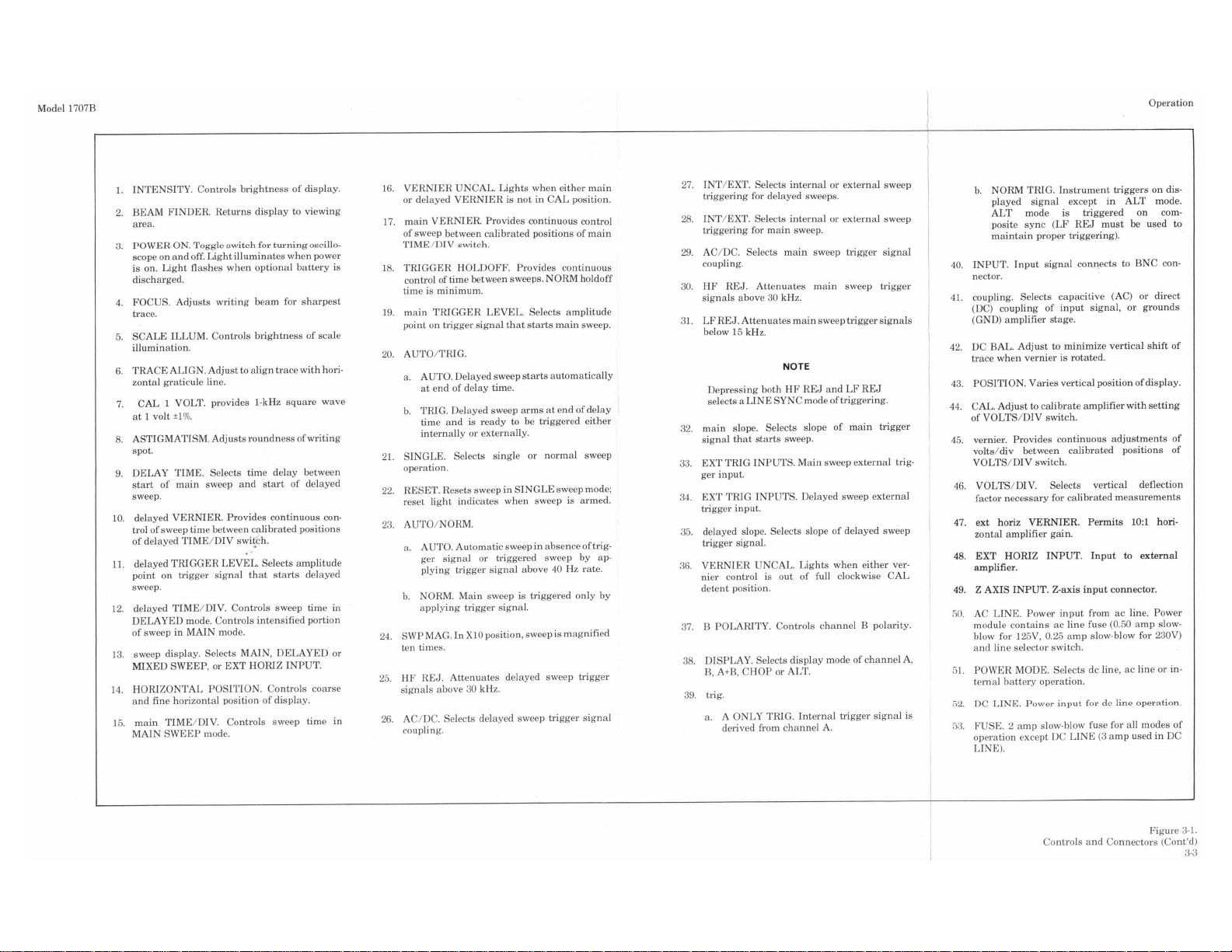

3-28. SWEEP DISPLAY.

3-29. This switch, mounted concentric to the main

and delayed TIME/DIV controls, determines the hori-

zontal sweep display modes. Modes are EXT HORIZ

INPUT, MAIN SWEEP, MIXED SWEEP and DE-

LAYED SWEEP. The function of each mode is

as

fol-

lows:

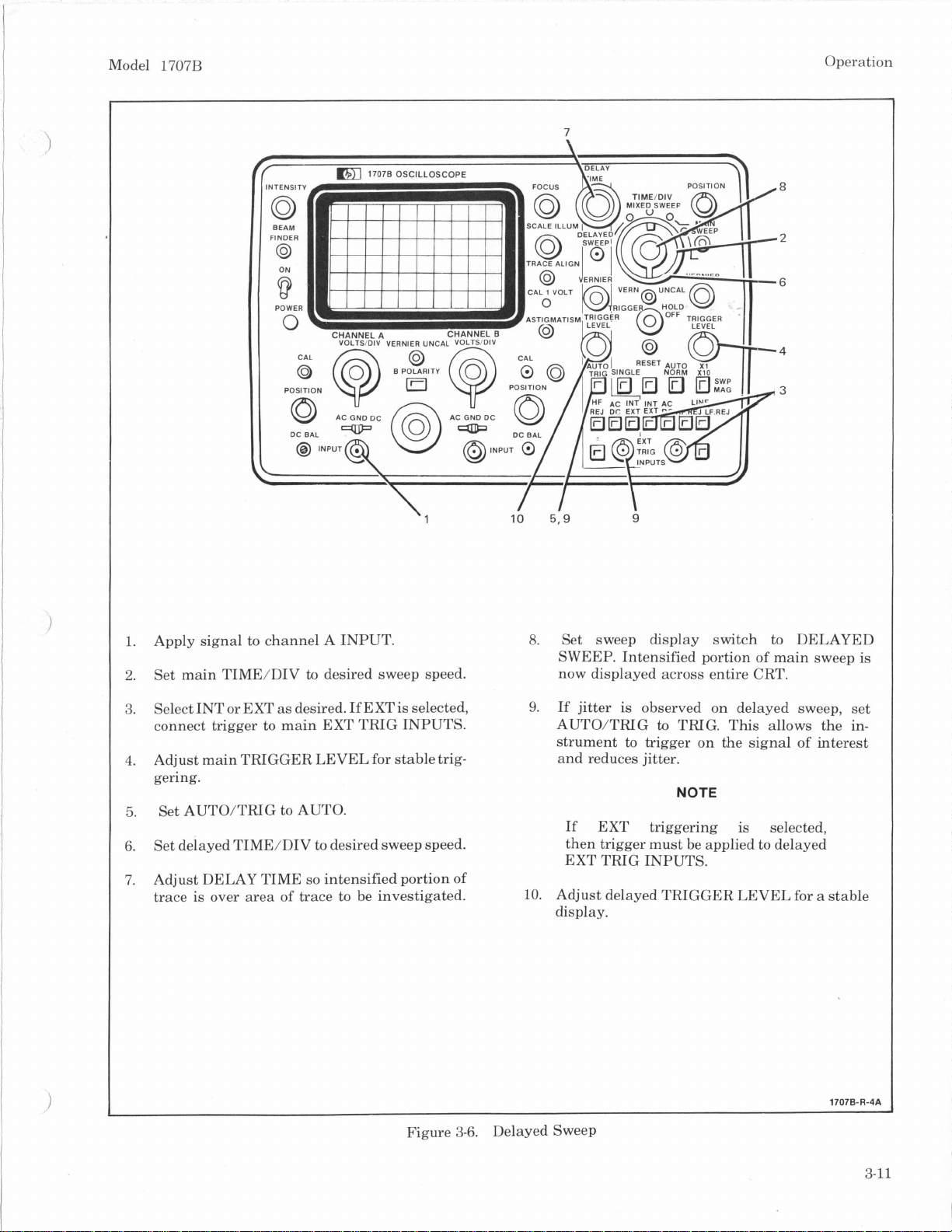

3-36. DELAYED SWEEP.

3-37. Main sweep is not displayed in this mode.

The sweep speed

is

controlled by delayed TIME/

DIV.

3-38. TIME/DIV.

3-39. Main and delayed TIMEIDIV switches

determine the amount of time to sweep horizontally

one graticule division. Both switches are concentric

and interlocked

so

the delayed sweep

is

always

faster than the main sweep, Mairi sweep speeds are

selectable by main TIME/DIV in 23 ranges from 0.1

usecldiv to 2 sec/div. Twenty ranges of delayed

sweep speeds from 0.1 usec/div to 0.2 sec/div are

provided by delayed TIME/DIV. By using the

SWP

MAG switch, a display can be expanded 10

times, increasing the fastest sweep to 10 ns/div.

3-40. VERNIER.

3-41.

Sweep speeds are calibrated to the TIME/DIV

switch when both the main and delayed VERNIER

controls are set fully clockwise to the CAL detent

position. As the VERNIER controls are turned

counterclockwise, the VERNIER UNCAL indicator

lights and sweep speeds decrease. The main VER-

NIER control extends the slowest sweep to

5

sec/div. The vernier controls are useful for making

at

least

continuous adjustments of sweep speed, however,

TIME/DIV readings are uncalibrated.

3-42. TRIGGER LEVEL.

3-30. EXT

3-31.

HORIZ

INPUT.

In this mode, the CRT horizontal plates are

driven by an external source.

3-32. MAIN SWEEP.

3-33. In this mode, the main sweep sets a time

base reference €or the vertical signal. Main sweep

controls are mounted on the right side of the front

panel, and sweep speed

is

selected by main TIME/

DIV. If delayed TIME/DIV is set to OFF, sweep

intensity is uniform. However, any other setting

of delayed ’I’IME/DIV causes the sweep to intensify

during the time that the delayed sweep is generated.

This

feature makes it possible to select a point of

interest on the main sweep time base before viewing

in the delayed sweep mode.

3-34. MIXED SWEEP.

3-35. In this mode, the first portion of signal

referenced to the main time base and the expanded

portion is referenced to the delayed time base.

Turning the

DELAY

TIME control varies the amount

of display controlled by the delayed time base.

is

3-43. These controls select the point on the sync

signal that starts the sweep. Triggering point is

adjustable

INT position.

at

any level on the displayed signal in

In the EXT position, the triggering

point is adjustable from +1.2V to -1.2V along the

sync signal. Delayed TRIGGER LEVEL has no

function when AUTO/TRIG

3-44. TRIGGER HOLDOFF.

3-45. This adjustment

is

set to AUTO.

is

a

dual purpose control.

When the control is rotated out of detent position,

the first portion of the control acts

frequency stability control.

gering on

is

rotated further out of detent position,

as

a

high

frequency waveforms.

trigger holdoff and allows the instrument

This

prevents double

as

As

the control

it

functions

a

high

trig-

to

synchronize on complex waveforms.

3-46. SLOPE.

3-47. These switches determine whether the sweep

triggers on the positivegoing

(-1

portion of the sync signal. When the AUTO/

(+)

or negative-going

TRIG is set to AUTO, the delayed slope control

has no function.

3

-4

Page 24

Model 1707B Operation

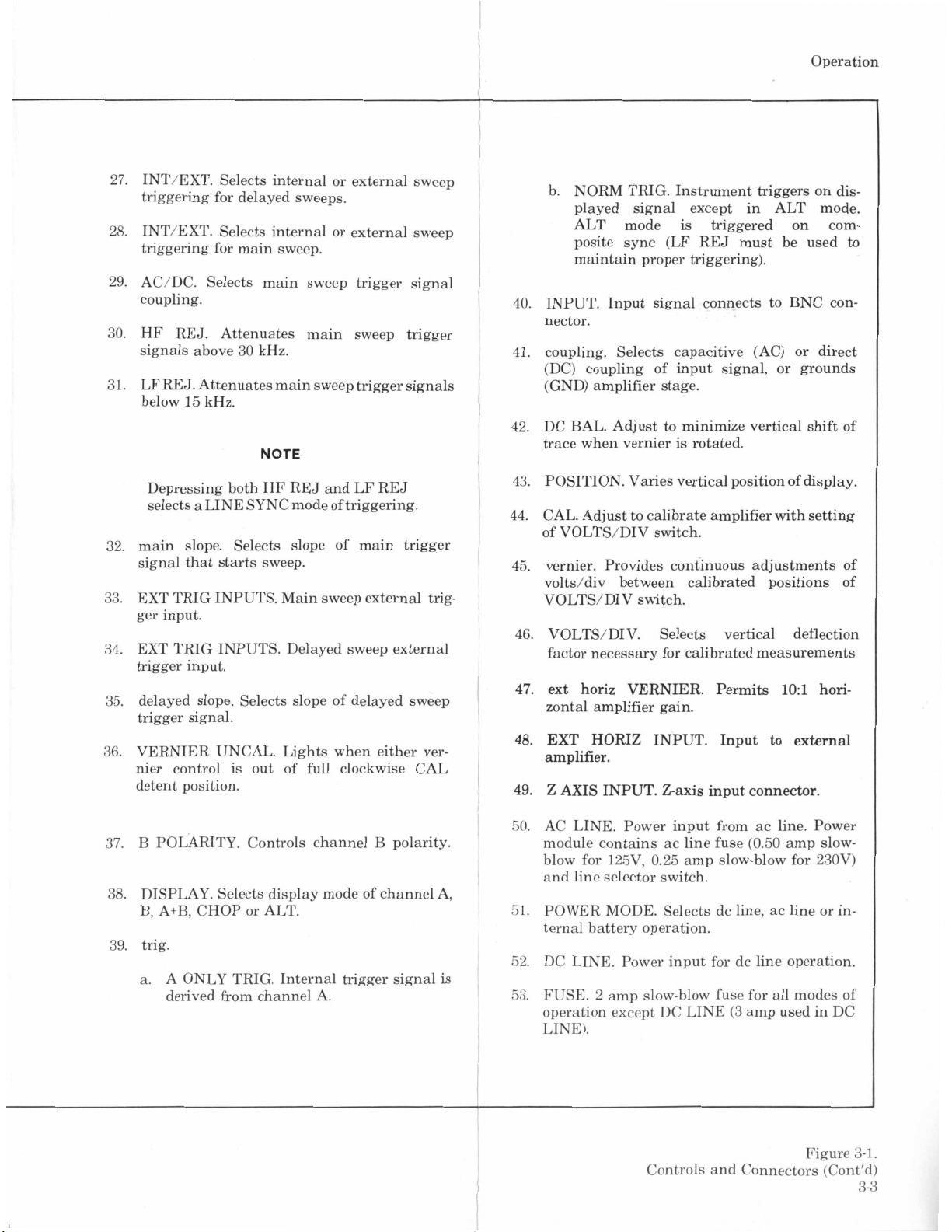

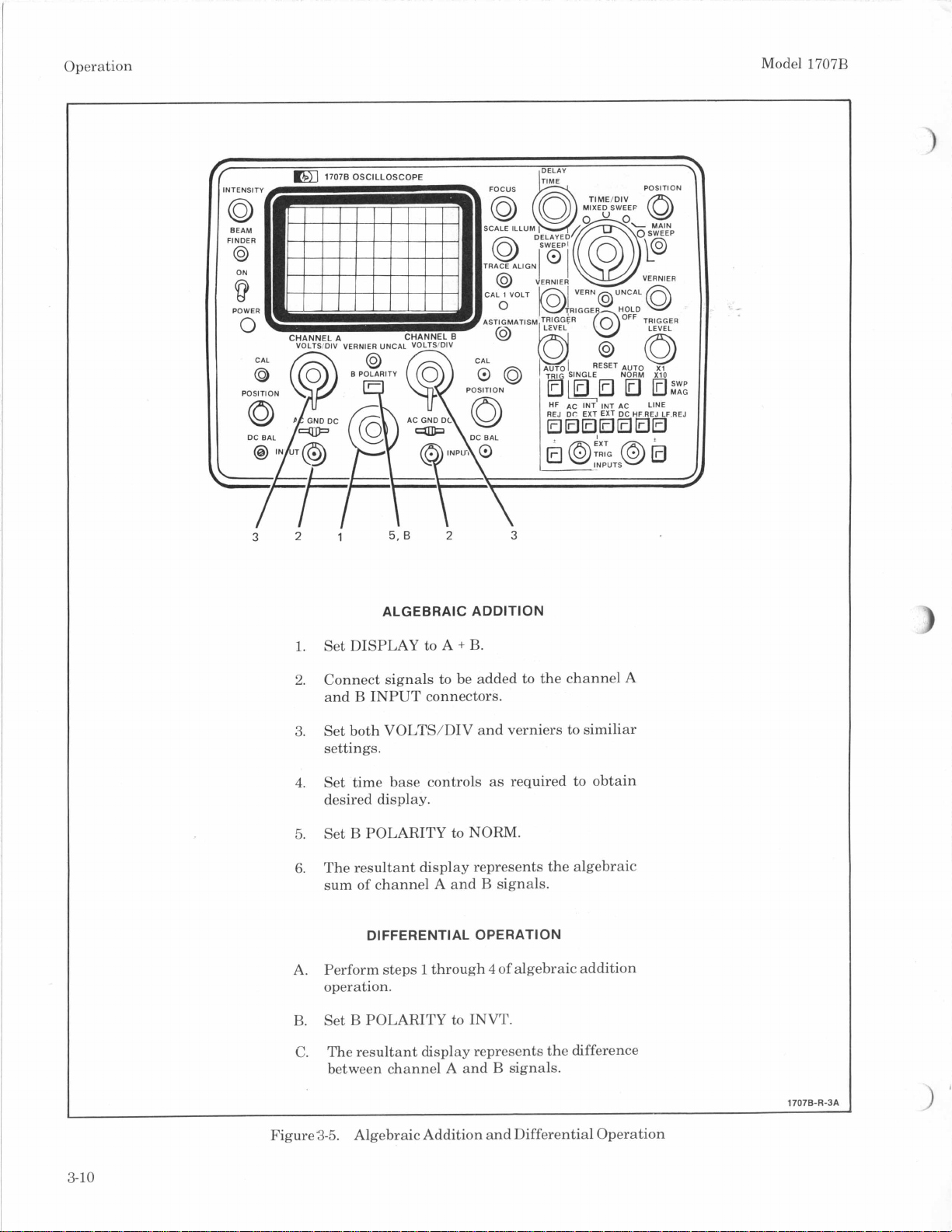

17070-R-11

Figure 3-2. Sweep Combinations

3-48.

SWEEP MODE.

The HF REJ switch attenuates signals above approximately 30 kHz and can be used to prevent high

3-49. This group of switches selects the type of main

frequency noise from triggering the sweep.

and delayed sweep triggering. Main sweep free runs

in AUTO, giving a bright base line in the absence

of

a

sync signal. However, if a sync signal of 40 Hz

or greater

and triggers the sweep. Due to the presence of

is

applied, it overrides free-run operation

a