Page 1

122A

OSGlllOSCOPE

OPERATING AND SERVICING MANUAL

Page 2

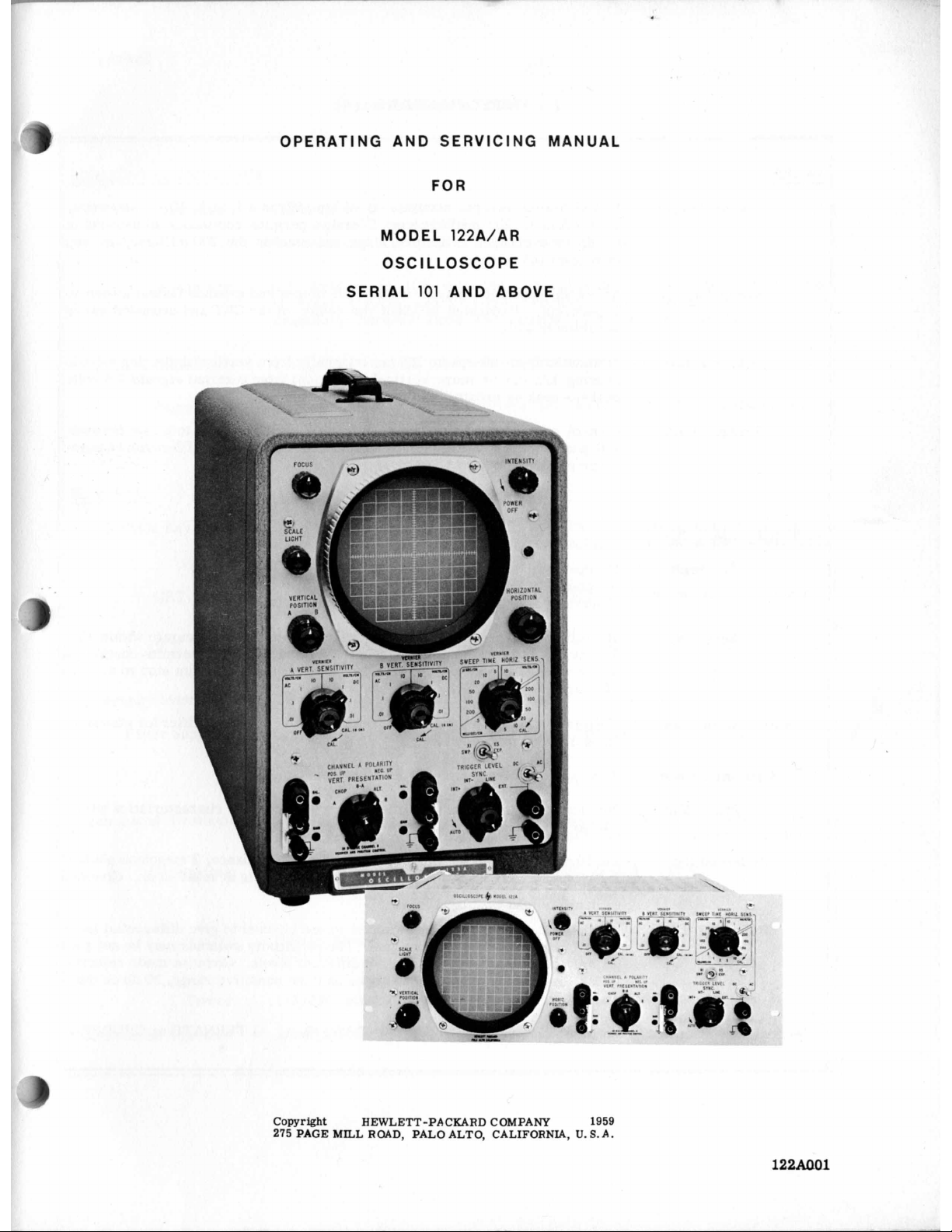

OPERATING AND SERVICING MANUAL

FOR

MODEL 122A/AR

OSCILLOSCOPE

101

SERIAL

AND ABOVE

Copyright HEWLETT-PACKARD COMPANY

275

PAGE MILL ROAD, PAL0 ALTO, CALIFORNIA,

U.

1959

S.

A.

122AQ01

Page 3

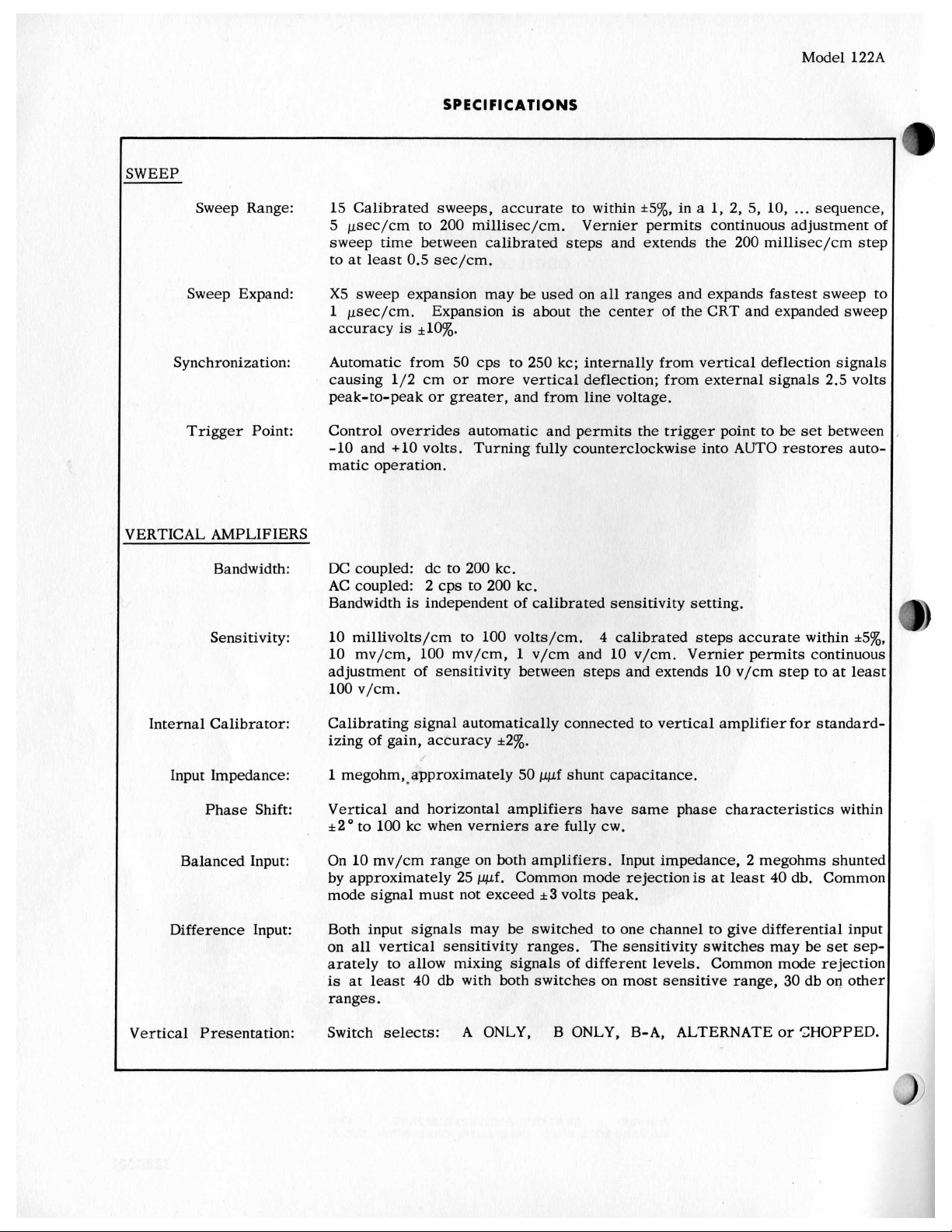

SWEEP

Model 122A

SPECIFICATIONS

Sweep Range: 15 Calibrated sweeps, accurate to within

Sweep Expand:

Synchronization:

Trigger Point: Control overrides automatic ailu

VERTICAL AMPLIFIERS

Bandwidth:

Sensitivity:

*5%,

in a 1, 2,

5

psec/cm to 200 millisec/cm.

Vernier

permits continuous adjustment

sweep time between calibrated steps and extends the 200 millisec/cm

to at least

X5

sweep expansioil

1

psec/cm.

accuracy

Automatic from

0.5

is

40%.

sec/c

lllay

Expansion

50

cps to

uc;

ust;u

is

about the

mu

ail

xaiigcs

center

KC;

internally rrom vertical deflection signals

and expands fastest sweep

of the CRT and expanded

causing 1/2 cm or more vertical deflection; from external signals

peak-to-peak or greater, and from

d

+10

-10 an

Dperation.

I

matic

DC

coupled: dc to

AC coupled: 2 cps to

Bandwidth

10

millivolts/cm to

volts. Turning fully counterclockwise into AU1

200

kc.

200

kc.

is

independent of calibrated sensitivity setting.

100

volts/cm.

line

voltage.

,,F;Illllcu

clIF;

LILRRF;l

--

4

calibrated steps accurate within

5,

10,

to be set between

-

r0

restores auto-

...

sequence,

2.5

01

steF

ta

sweep

volts

*5%,

10 mv/cm, 100 mv/cm, 1 v/cm and 10 v/cm. Vernier permits continuous

stem

adjustment of sensitivitv between

and extends 10 v/cm step to at least

100 v/cm.

Internal Calibrator:

Input Impedance:

Phase Shift:

Balanced Input:

Difference Input:

Vertical

Presentation:

Calibrating signal automatically connected to vertical amplifier for standardizing of gain, acc

1

megohm,-apprc

Vertical and hoi

*2"

to 100

10

mv/cm

On

by approximate

mode signal mi

Both input signals

all

on

vertical sensitivity ranges. The sensitivity switches may be set sep-

:uracy *2%.

50

)ximately

-:.--.-..-I

ilruiiLai

then verniers

kc

w

'ange on both amplifiers. Input impeda

r

ppf.

:ly 25

1st not exceed

may

ppf shunt capacitance.

---1:1:---

amuiiiiers

are

fully

L

----

nave

cw.

-----

same

Common mode rejectionis

*3

volts peak.

IJ~

swiccneu

to

one cnannei to give differential input

-L-

unase

I-

characteristics within

nce,

2 megohms shunted

40

at least

db. Common

arately to allow mixing signals of different levels. Common mode rejection

is

at

least

40

db with

on most sensitive range,

30

db on other

es

ranges.

A

Switch selects:

O~LY,

B

ONLY, B-A, ALTERNATE

or

CHOPPED.

Page 4

Model 122A

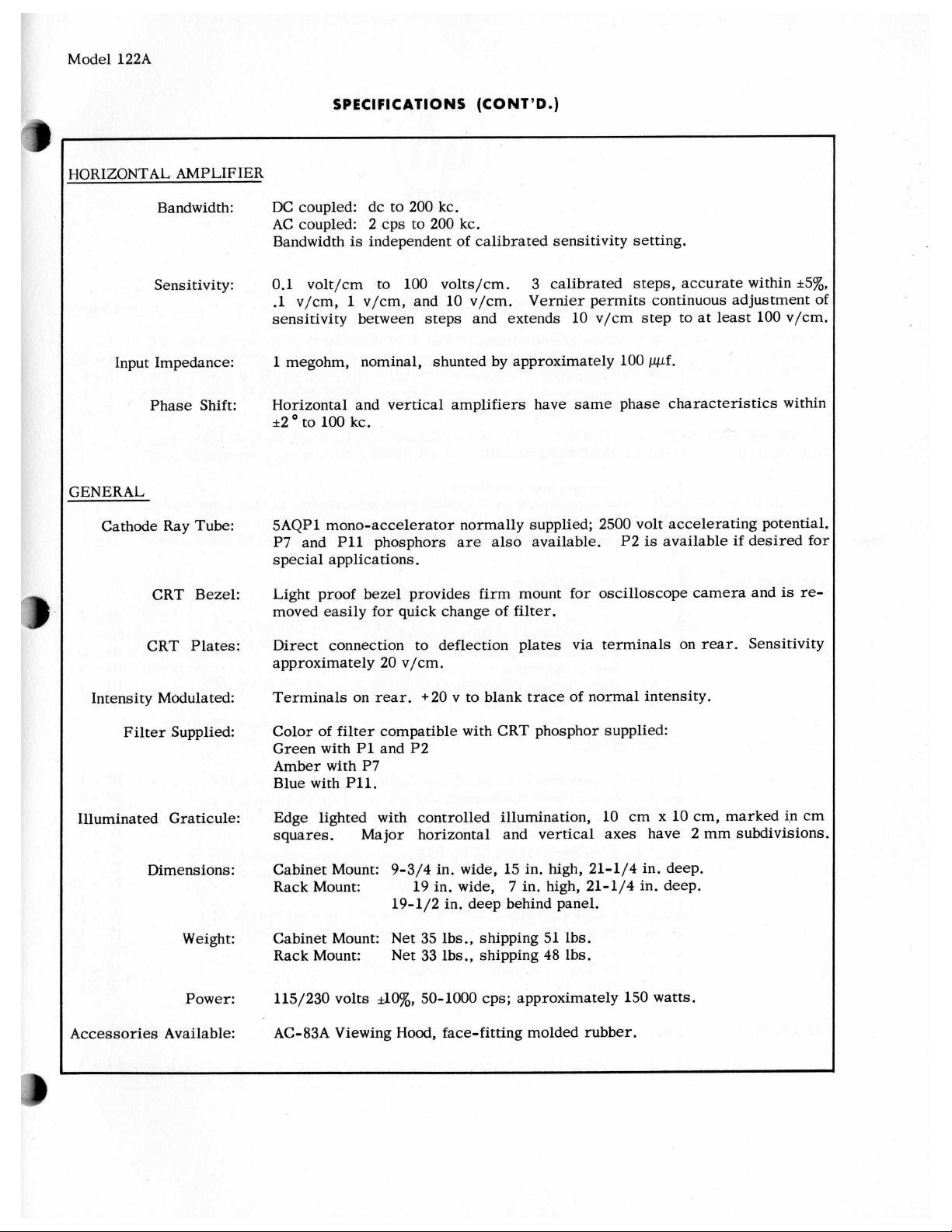

-IORIZONTAL AMPLIFIER

SPECIFICATIONS (CONT’D.)

Bandwidth:

Sensitivity:

Input Impedance:

Phase Shift:

SENERAL

Cathode Ray Tube:

CRT Bezel:

CRT Plates:

DC coupled: dc

AC coupled: 2 cps to 200 kc.

Bandwidth

0.1 volt/cm to 100 volts/cm.

v/cm, 1 v/cm, and 10 v/cm. Vernier permits continuous adjustment

.1

sensitivity between steps and extends 10 v/cm step to

1

megohm, nominal, shunted by approximately 100

Horizontal and vertical amplifiers have same phase characteristics within

*2 to 100 kc.

5AQPl mono-accelerator normally supplied; 2500 volt accelerating potential.

P7 and

special applications.

Light proof bezel provides firm mount for oscilloscope camera and

moved easily for quick change

Direct connection

approximately 20 v/cm.

P11

to

200 kc.

is

independent of calibrated sensitivity setting.

3

calibrated steps, accurate within

phosphors

are

also available. P2

of

filter.

to

deflection plates via terminals on

wf.

is

available

at

rear.

least

if

desired for

Sensitivity

.5%,

of

100 v/cm.

is

re-

Intensity Modulated:

Filter

Illuminated Graticule:

Supplied:

Dimensions:

Weight:

Power:

Accessories

Available:

Terminals on

Color of

Green with

Amber with P7

Blue with

Edge lighted with controlled illumination,

squares. Major horizontal and vertical axes have 2 mm subdivisions,

Cabinet Mount: 9-3/4 in. wide, 15 in. high, 21-1/4 in. deep.

Rack Mount:

Cabinet Mount: Net 35 lbs., shipping 51 Ibs.

Rack Mount:

115/230 volts

AC-83A Viewing

rear.

+20 v to blank

filter

compatible with CRT phosphor supplied:

P1

and P2

P11.

19 in. wide,

19-1/2 in. deep behind panel.

Net

33

lbs., shipping 48 lbs.

+lo%,

50-1000 cps; approximately 150 watts.

Hood,

face-fitting molded rubber.

trace

of normal intensity.

7

in. high, 21-1/4 in. deep.

10 cm x 10 cm, marked in cm

Page 5

CONTENTS

SECTION

SECTION I1 OPERATING INSTRUCTIONS

SECTION

SECTION IV MAINTENANCE

111

I

GENERAL INFORMATION Page

1

.

1

General Description

1

.

2

Damage in Transit

1

.

3

Power Line Voltages

1

.

4

Conversion for 230 Volt

1

.

5

Accessories Available

2

.

1

Controls and Terminals

2

.

2

.

2 . 4

CIRCUIT DESCRIPTION

3

.

3 . 2

3 . 3

3

.

3 . 5

.

3 6

Vertical Amplifier Input Considerations

2

Checking Horizontal Amplifier Gair Calibration

3

Operating Drawings

1

General Content

Vertical Amplification Channels

Horizontal Amplification Channels

4

Sweep Generator

High Voltage Power supply

Low Voltage Power Supply

..........................

........................

.........................

.

.

0

.

.............

.............

.............

.......................

..............

..........

........................

..................

.................

..........................

.....................

.....................

i

.

i

.

1-1

1-1

1-1

I1 . 1

11

.

I1 . 1

I1

.

111 . 1

111

.

I11

.

111

.

111

.

.

111

1

1

1

1

1

2

3

3

3

SECTION

V

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-a

4-9

4

.

4

.

4 . 12

.

4

TABLEOFREPLACEABLEPARTS

5

.

Introduction

Front Panel Operational Check

Removing the Cabinet

Tube Replacement.

Trouble-Shooting Procedure

Condensed Test and Adjustment Procedure

Complete Adjustment Procedure

Turn On Procedure

Power Supplies

Trigger Generator

10

Vertical Amplifier

11

Horizontal Amplifier Adjustments

Sweep Generator

13

Table

1

.............................

.........................

.........................

.........................

...........................

.........................

.........................

..........................

of

Replaceable

Parts

...................

....................

............

..................

.................

.....................

IV

.

1

IV

.

2

IV

.

5

IV

.

5

IV

.

7

IV

.

9

IV

.

11

IV . 11

IV

.

11

IV

.

12

IV

.

13

IV

.

15

IV

.

15

V . 1

Page 6

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

CATHODE RAY TUBE WARRANTY

The cathode ray

ray tubes purchased from

date

of

sale by the Hewlett-PackardCompany. Broken tubes or tubes with burned phosphor

not included in this guarantee.

Your local Hewlett-Packard representative maintains

glad to process your warranty claim for you. Please consult him.

Whenever

out in full and returned with the tube. Follow shipping instructions carefullyto insure safe

rival, since no credit can be allowed on broken tubes.

1)

2)

3)

4)

5)

6)

tube

supplied in your Hewlett-Packard Oscilloscope and replacement cathode

@

,

are guaranteed against electrical failure for one year from the

a

stock of replacement tubes and

a

tube

is

returned for a warranty claim, the reverse side of this sheet must

SHIPPING INSTRUCTIONS

Carefully wrap the

padding material.

Wrap the above in heavy kraft paper.

Pack in a rigid container which

the tube in each dimension.

Surround the tube withat

similar shockabsorbing material.

tight

all

around the

Tubes

Ship prepaid preferably by AIR FREIGHTor RAILWAY EXPRESS.

We do not recommend parcel post or

returned from outside the continental United States should

be

packed in a wooden

tube

in

tube.

box.

1/4"

thick cotton batting or other soft

is

at least 4 inches larger than

least

four inches ofpackedexcelsior or

Be

certain that

air

parcel post shipment.

the

packing

is

be

will

filled

are

be

ar-

HEWLETT-PACKARD

co.

275

PAGE

MILL

ROAD,

PALO ALTO,

CALIF.

U.S.A.

Page 7

FROM:

COMPANY:

ADDRESS:

Person to contact for further inform

NAME

TITLE

COMPANY:

ADDRESS:

To process your claim quickly pl

1)

2)

:

:

@INSTRUMENT MODEL

TUBE TYPE

ease

-

CRT WARRANTY CLAIM

~~~~~~~

enter the information indic

SERIA:

SERIA:

:ated

L

L

below:

I

DATE:

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

3)

ORIGINALTUBE

4)

YOUR PURCHASE ORDER NO

5)

DATE PURCHASED

6)

PURCHASED FROM

7)

COMPLAINT: (Please describe nature

~~~

8)

OPERATING CONDITIONS: (Please describe conditions prior to and

REPLACEMEN

of

trouble)

SIGNATURE

r

TUBE

at

time of failure

I

‘9

Page 8

Model 122A Sect. I Page

1

SECTION

GENERAL INFORMATION

1-1 GENERAL DESCRIPTION 1-3 POWER LINE VOLTAGES

The Model 122A

cathode-ray oscilloscope. It has accurately

brated input sensitivity and sweep-speed ranges.

This oscilloscope features dc-coupled differential

amplifiers and dual-trace operation.

Differential amplifiers

the common-mode (in-phase) part

amplifying the differential (out-of-phase) part. For

instance, they

plifying the desired signal. In addition, using differential amplifiers has other advantages. Normally dc amplifiers are difficult

Changes such as aging and changes of potentials

cause

the common-mode type and

ferential amplifiers. Thus differential amplifiers

are also used

this drift. However, these changes are of

is

a dc

to

200 kc dual-trace

are

useful since they reject

of

the input

will

reject hum pick-up while am-

to

are

rejected by dif-

to

stabilize dc amplifiers.

cali-

while

keep stable.

This instrument

inal 115 or

operate satisfactorily over a

the nominal value,

130/260 volts

normally high line voltage

line voltage

127 volts.

1-4 CONVERSION FOR

The instrument can be converted from 115 v

230

v operation by reconnecting the power transformer dual primary windings as follows: Remove

the instrument from the cabinet by removing the

two large

the instrument from the cabinet by pushing on the

rear

screws

of

the chassis.

is

designed to operate from a nom-

230

volt

source.

i.e.

103-127 volts. Operationat

will

damage the instrument. If ab-

to

be certain

from the rear

The instrument

*lo%

is

suspected monitor the

it

does not exceed

230

VOLT OPERATION

of

the cabinet. Push

1

will

variation from

to

Dual-trace operation

switch.

at the same time. The two signals may be viewed

either alternately during consecutive sweeps

chopped on each sweep. Chopped operation involves

switching rapidly between the

both appear to be traced simultaneously. The most

useful type

upon the frequencies involved. Generally, chopped

operation

signals may

difference

1-2 DAMAGE

Refer

damage

This

permits observation of

of

presentation in each

is

used with low frequency signals. These

also

(B-A)

to

the warranty page in this manual

is

apparent upon receipt.

is

obtained with an electronic

two

signals

or

two

signals

case

be viewed separately or with their

displayed on the screen.

IN

TRANSIT

will

so

that

depend

if

any

Locate the

next

to

minals on each side

ing the windings in parallel. Remove these jumpers.

Connect an insulated jumper between the second

and fourth terminals, connecting the windings in

series.

Schematic

blow fuse with a 1.0 amp slow-blow fuse.

1-5 ACCESSORIES AVAILABLE

An AC-83 Viewing

is

This

shade the

ambient light conditions. It

lower

power

the power transformer. The twoouter

Refer

for

a face-fitting moulded rubber hood used

face

beam intensity setting.

supply terminal strip situated

are

jumpered together connect-

to

the Low Voltage

details. Replace the 2.0 amp slow-

Hood

is

available

of

the cathode-ray tube under high

will

Power

at

extra cost.

permit the useof

ter-

Supply

to

Page 9

Sect.

11

Page

0

e

c

Y

VI

Model

122A

c

I

I

I

\\

\\

\\

\

I

\

I

I

I

I

I

E

c

C

2

Y

I

I

I II

I

Page 10

122A

Sect. I1 Page

1

P

ONTROLS AND TERMINALS

2-1

briefly shows how

nt. Additional detailed information

VERTICAL AMPLIFIER INPUT

:ONSIDERATIONS

exceed the common-signal voltage limit

my conditions. This limit

Note

rid.

-

c

plus peak ac).

he

attenuators are used the voltage to the

brminals may

the

attenuation as follows:

to

operate the in-

is

*3

that this

be

TABLE

is

the sum of

increased by the amount of

2-1

is

given

volts on the

all

volt-

SECTION

II

OPERATING INSTRUCTIONS

C. Other Types of Input

Other types of input

balanced input with either dual or single channel

operation

as

with most other types

that

ranges must be observed. Thus the commonsignal limit

since there

red input terminal and the input grid. The

red terminal does not have an attenuator between

it and its input grid.’ Therefore balanced input

with attenuation

channel without external attenuators. However, this

may be accomplished using both channels

paragraph B above and Figure

is

possible

it

may only be used on the

is

*3

is

an attenuator only between the upper

are

possible. For example,

(see

Figure

of

volts. This limitation

is

not possible using only a single

2-4).

However,

input, the limitation

.01

VOLTS/CM

is

necessary

2-3).

lower

(see

Attenuator Setting Common-Signal Limi

0.01

VOLTS/CM

0.1

1

.o

10

NOTE Maximum peak input voltage limit

volts (dc plus peak

ommended ways

fer

to

Figures

cerning connections.

A.

Unbalanced Input

Maximum voltage limit

B. Differential (B-A) Input (see Figure

Maximum voltage limit from each line

as

in table

least

40

VOLTS/CM.

ranges, functions of the controls

2-1.

db with both switches

Rejection

ac).

The following are

of

connecting the oscilloscope. Re-

2-1

to

2-4

for further details con-

(see

Figure

as

in table

Common-signal rejection

is

at least

2-2)

set

volts

*3

30

300

500

is

600

rec-

2-1.

2-3)

to

ground trations that follow.

is

at

on

10

MILLI- model. The location of the controls on the front

30

db on other panel

2-3

CHECKING HORIZONTAL AMPLIFIER

GAIN CALIBRATION

The horizontal amplifier may be calibrated by comparing it with the vertical amplifier. First, calibrate the vertical amplifier as shown in Figure

Set both VERT. and HORIZ. SENSITIVITY switches

to

0.1

VOLTS/CM with VERNIER’S in Cal. Feed

1

an external

zontal input terminals. Adjust the input amplitude

for

a

10

R114,

2-4

Basic operating procedures are shown in the

cabinet model but are the same for the rack mount

for exactly

OPERATING DRAWINGS

is

volt signal into the verticaland hori-

cm high pattern. Set Horiz. Gain Adj.,

10

cm of horizontal deflection.

Directions are given for the

different in the rack mount model but the

are

2-10.

illus-

the same.

Page 11

Sect.

I1

Page

2

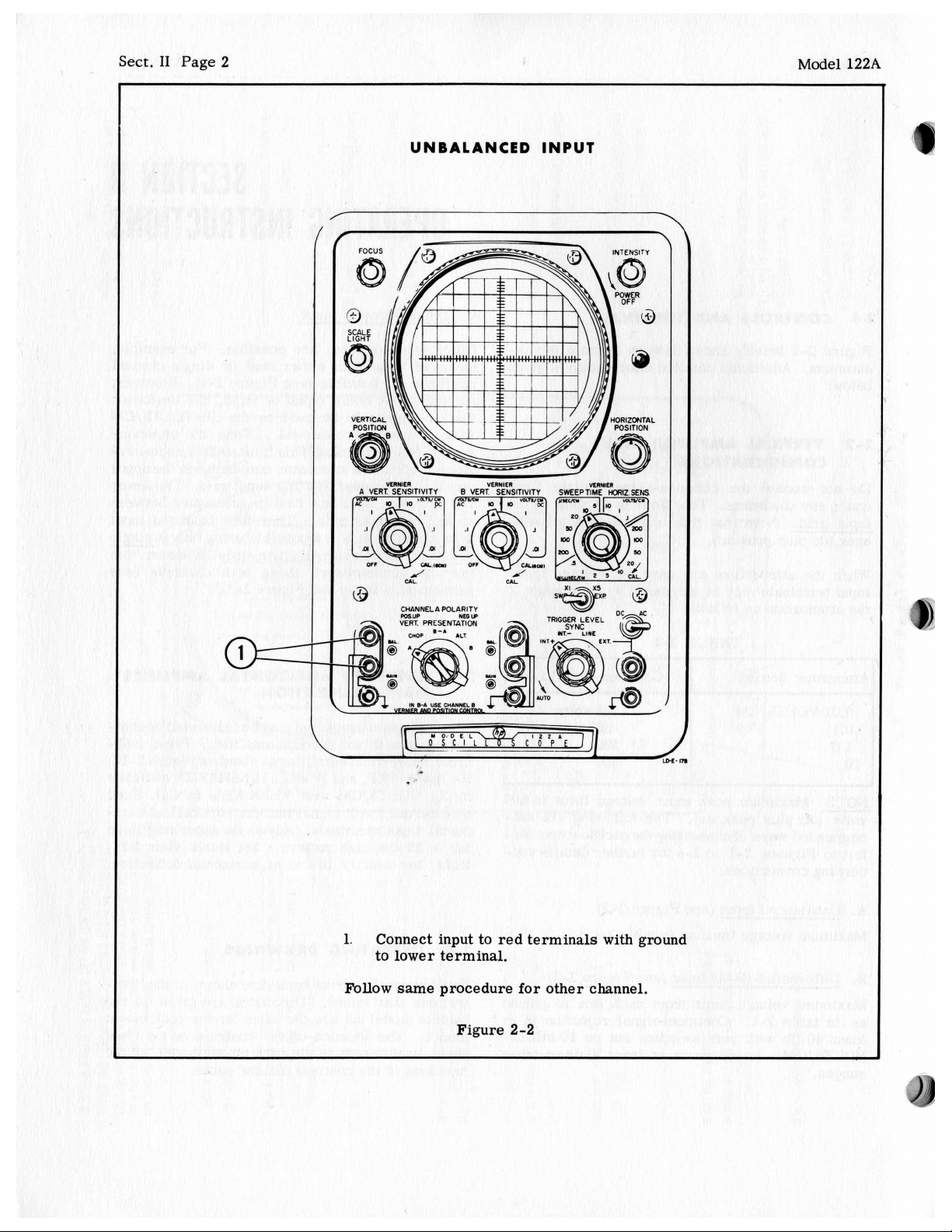

UNBALANCED INPUT

mim

A VERT SENSITIVITY

Model

I

122A

3

\

1.

CHANNELA POLARITY

pos

UP

NE6

up

YODEL

0

SCI

c'i

'P~E

L

J

Connect input to red terminals with ground

to lower terminal.

Follow same procedure for other channel.

Figure

2-2

Page 12

:1

122A

Sect.

I1

Page

3

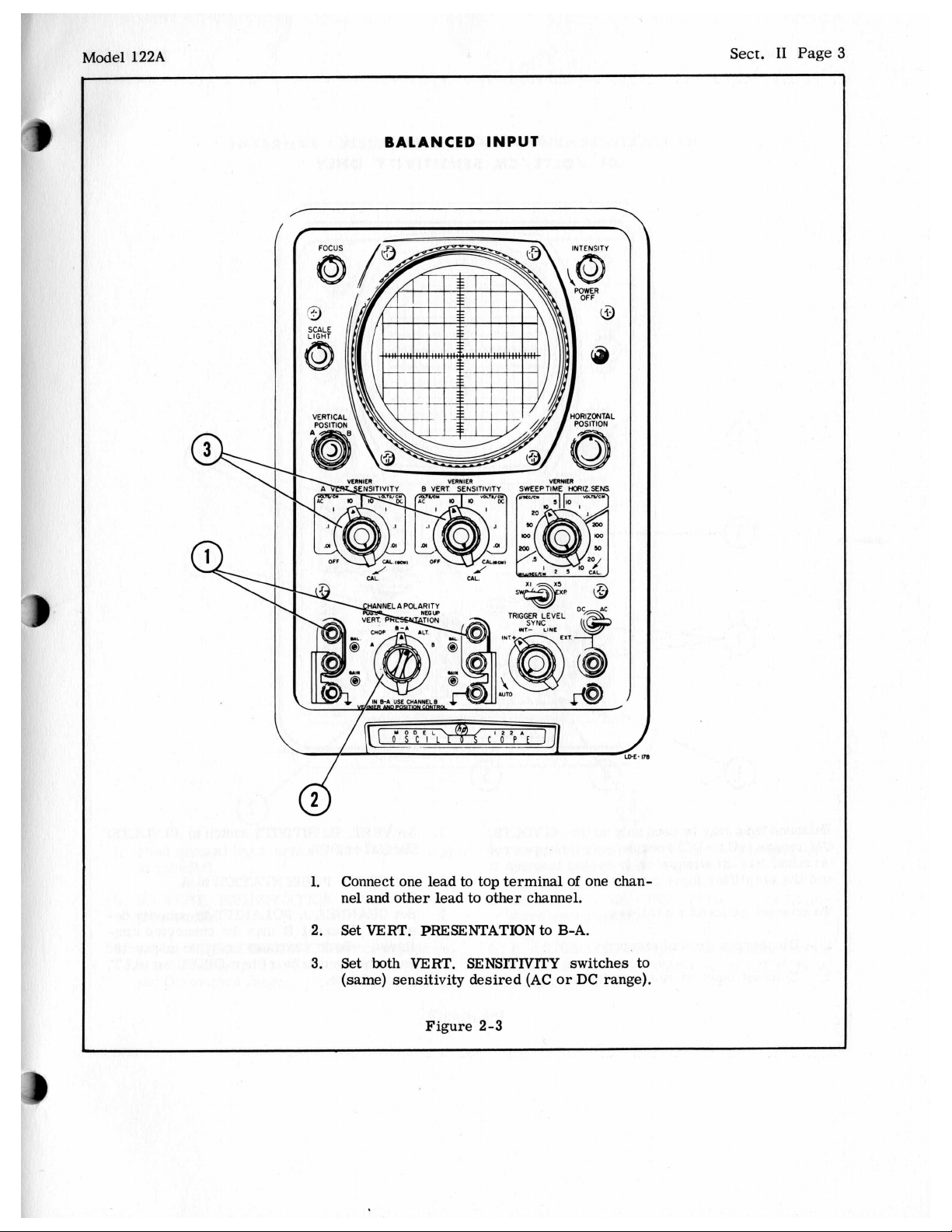

BALANCED

INPUT

/L

Connect one lead

1.

YODEL

-JI

0

SCI

L

112.

COP

to

top terminal

nel and other lead to other channel.

2.

Set VERT. PRESENTATION to B-A.

3.

Set

both

VERT.

SENSITIVlTY

(same) sensitivity desired

Figure

2-3

of

switches to

(AC

or DC range).

one chan-

Page 13

Sect.

I1

Page

4

Model

122A

BALANCED INPUT

.01

VOLTS/CM SENSITIVITY ONLY

VLI*ILR

A

VERT SENSITIVITY B VERT SENSITIVITY SWEEPTIME

"EIWlLl

vLI)yDI

,

WIZ

SEM

Balanced input may

CM

ranges (AC

be

used only on

or

DC) because only the upper red

the

.

OlVOLTS/

terminal has an attenuator in series between

and the amplifier input grid.

To

connect proceed

1.

Disconnect ground strap.

Connect input to red terminals.

2.

as

follows:

I

it

Figure

Set

3.

4.

5.

VERT. SENSITMTY

CM

(AC or DC).

Set

VERT. PRESENTATION

Set

CHANNEL

sired.

A POLARITY

Channel

B

may

ilarly. Both channels may

and observed with either CHOP.

presentation.

2-4

switch

to

to

to polarity de-

be

connected

be

.01

VOLTS/

A.

connected

or

sim-

ALT.

Page 14

Model

122A

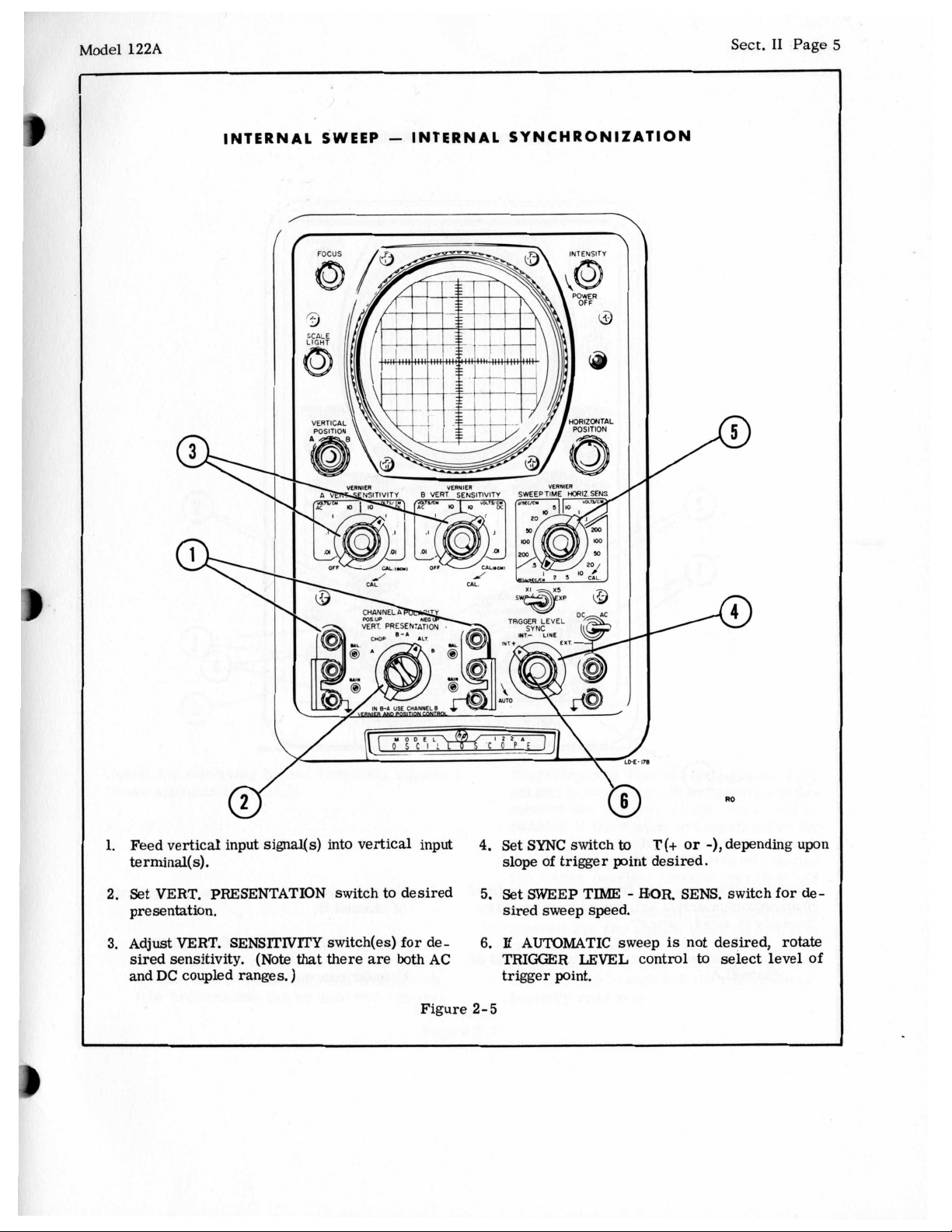

INTERNAL SWEEP - INTERNAL SYNCHRONIZATION

Sect.

I1

Page

5

1.

Feed vertical input signal(s) into vertical input

terminal(s).

2.

Set

VERT. PRESENTATION

presentation.

3.

Adjust VERT. SENSITIVlTY

sired sensitivity.

and

DC

coupled ranges.

(Note

switch to desired

switch(es) for de-

that

there are

)

both

AC

Figure

4.

Set

slope

5.

Set

sired

6.

E

AUTOMATIC

TRIGGER

trigger point.

2-5

SYNC

switch

of

trigger

SWEEP TIME

sweep speed.

LEVEL

T(+

€€OR

is

control

or

SENS.

not desired, rotate

to

to

point desired.

-

sweep

-),depending upon

switch for de-

select level of

Page 15

Sect.

I1

Page

6

CH

0

PP

ED

0

PER

AT1 0 N

Model

122A

.

.

’-

d

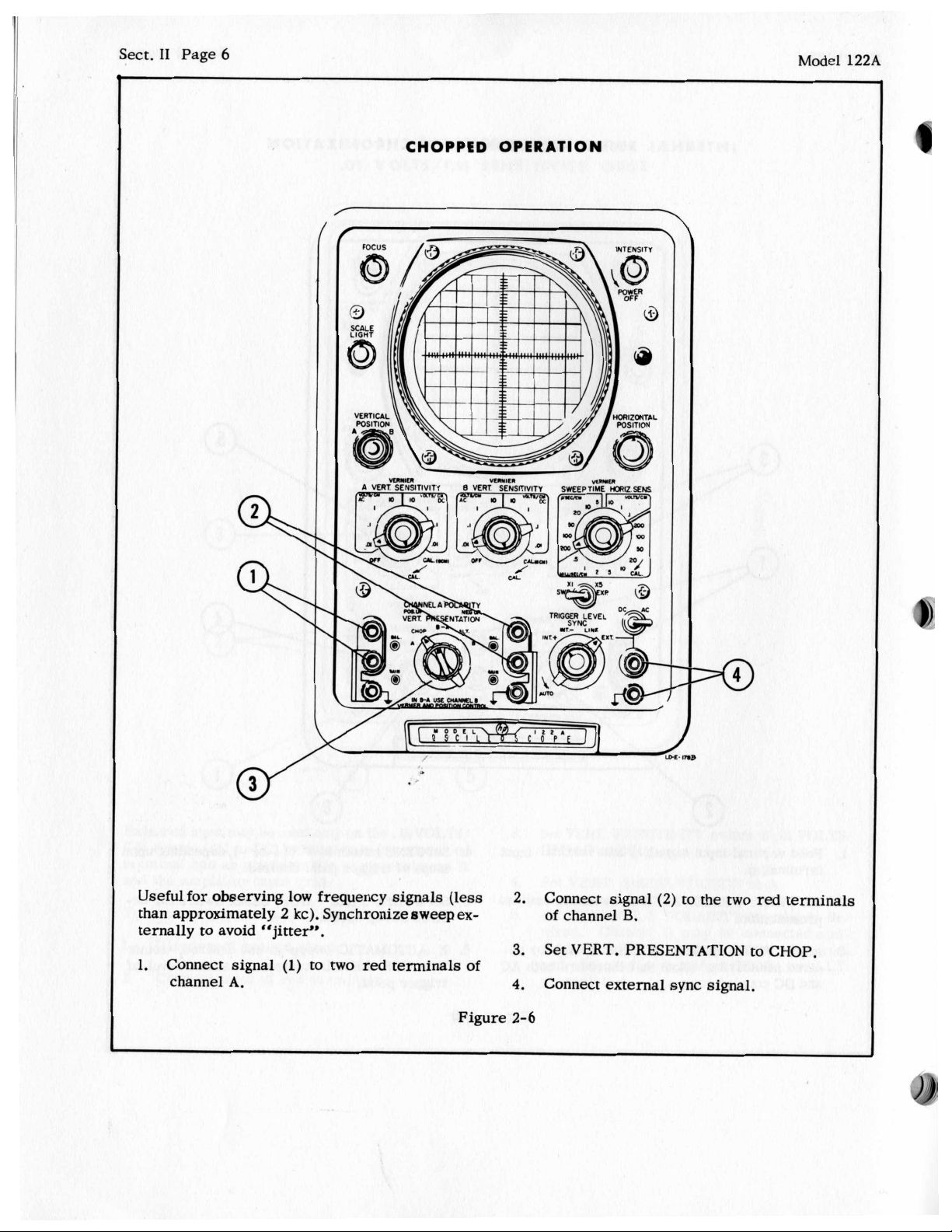

Usefulfor observing low frequency signals (less

than approximately

ternally

1.

to

avoid

Connect signal

channel

A.

2

kc). Synchronize sweep ex-

“Jitter”.

(1)

to

two

red terminals of

Figure

2.

Connect signal

of channel

3.

Set VERT. PRESENTATION

4.

Connect external sync signal.

2-6

B.

(2)

to

the

two

red terminals

to

CHOP.

Page 16

Model

122A

ALTERNATE SWEEP OPERATION

/

Sect.

I1

Page

7

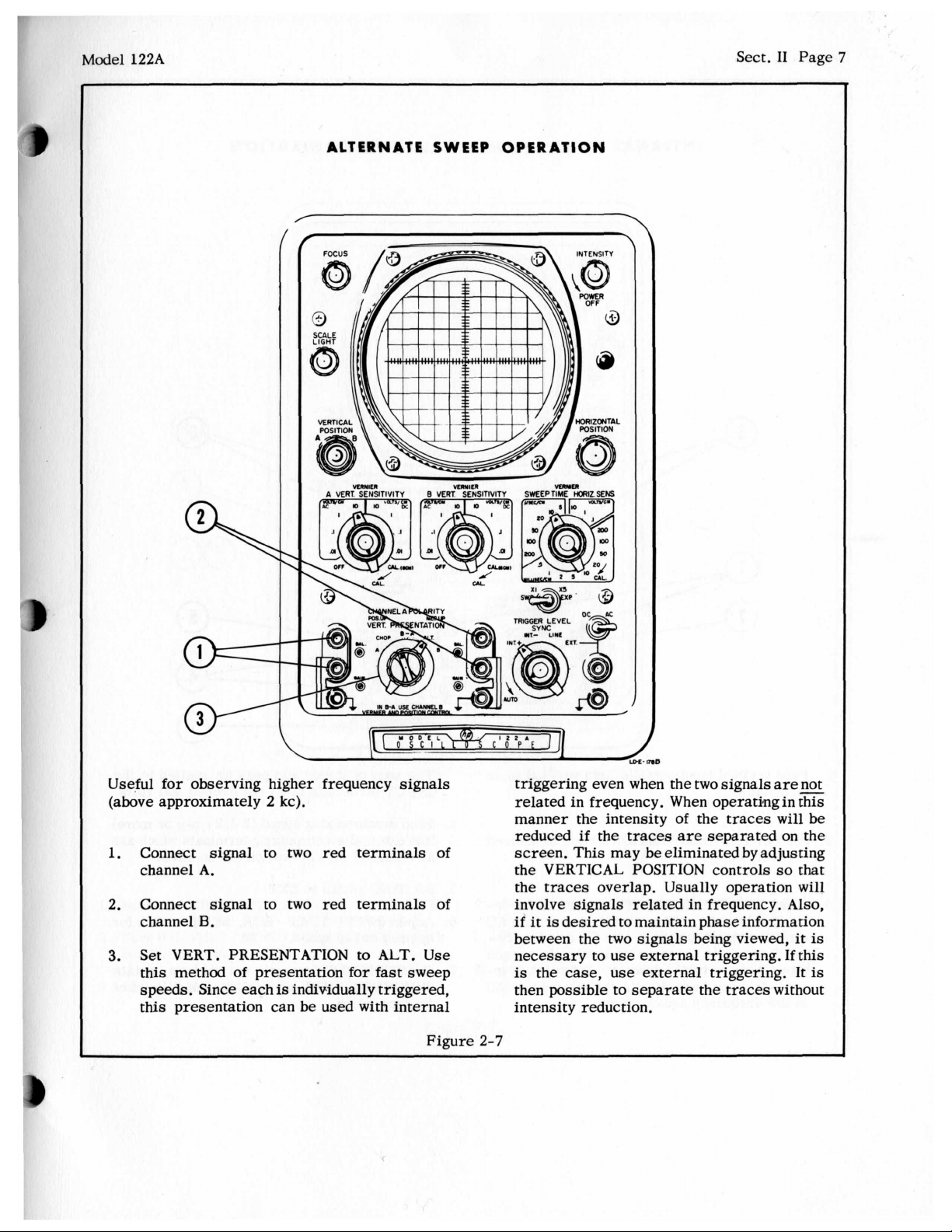

Useful

(above approximately

1.

2.

3.

for

observing higher frequency signals

2

kc).

Connect signal

channel

A.

Connect signal

channel

B.

to

two red terminals

to

two

red terminals

Set VERT. PRESENTATION

this method

speeds. Since each

of

presentation

is

individually triggered,

to

for

ALT.

fast

this presentation can be used with internal

of

of

Use

sweep

Figure

triggering even when the

two

signals

related in frequency. When operating in this

of

manner the intensity

reduced

if

the

traces

the traces

are

separated on the

screen. This may be eliminated by adjusting

the VERTICAL POSITION controls

the

traces

overlap. Usually operation

involve signals related in frequency.

if

it

is

desired to maintain phase information

between the

necessary

is

the

then possible

case,

two

signals being viewed,

to

use

external triggering. If this

use

external triggering. It

to

separate the traces without

intensity reduction.

2-7

ares

will

be

so

that

will

Also,

it

is

is

Page 17

Sect.

I1

Page

8

INTERNAL SWEEP - EXTERNAL SYNCHRONIZATION

B

VERT

SENSITIVIT

Model

122A

UL

RO

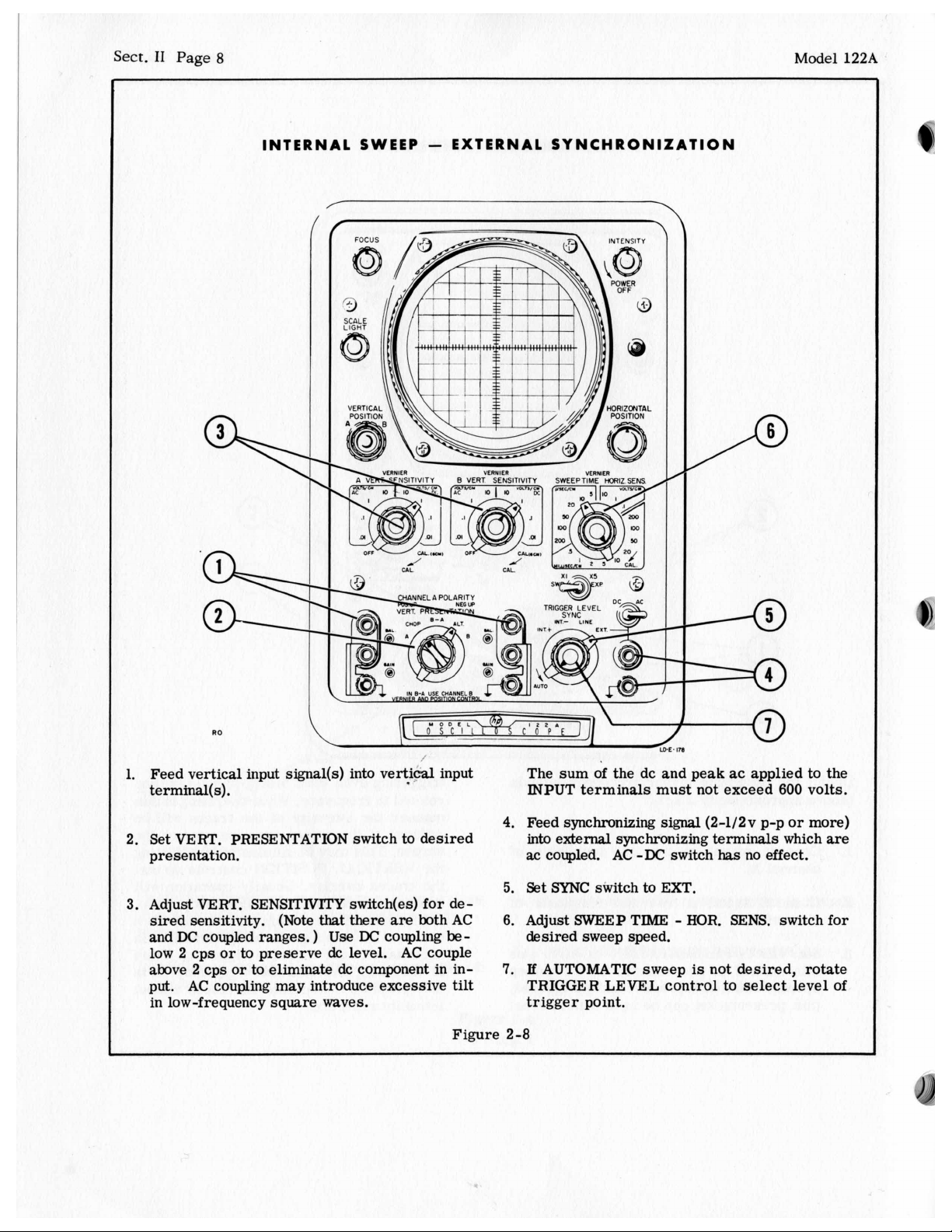

1.

Feed vertical input signal(s) into vertid input

terminal(

2.

Set

presentation.

3.

Adjust VERT. SENSITIVITY switch(es) for desired sensitivity. (Note

and

low 2 cps

above

put.

in low-frequency square waves.

s).

VERT.

DC

PRESENTATION switch to desired

coupled ranges.

or

to preserve

2

cps or to eliminate dc component in in-

AC

coupling may introduce excessive

I

that

there are both AC

)

Use DC

dc

level. AC couple

coupling

be-

tilt

The sum of the dc and peak ac applied to the

INPUT

4.

Feed synchronizing

into external synchronizing terminals which

ac

5.

Set SYNC switch to EXT.

6.

Adjust SWEEP TIME - HOR.

desired sweep speed.

7.

If

TRIGGER LEVEL control to select level of

trigger point.

terminals must not exceed

signal

coupled.

AUTOMATIC sweep

AC

-DC

switch

600

(2-1/2v p-p or more)

has

no effect.

SENS.

is

not desired, rotate

switch for

volts.

are

Figure 2-8

Page 18

Model

122A

VERTICAL BALANCE ADJUSTMENT

Sect.

I1

Page

9

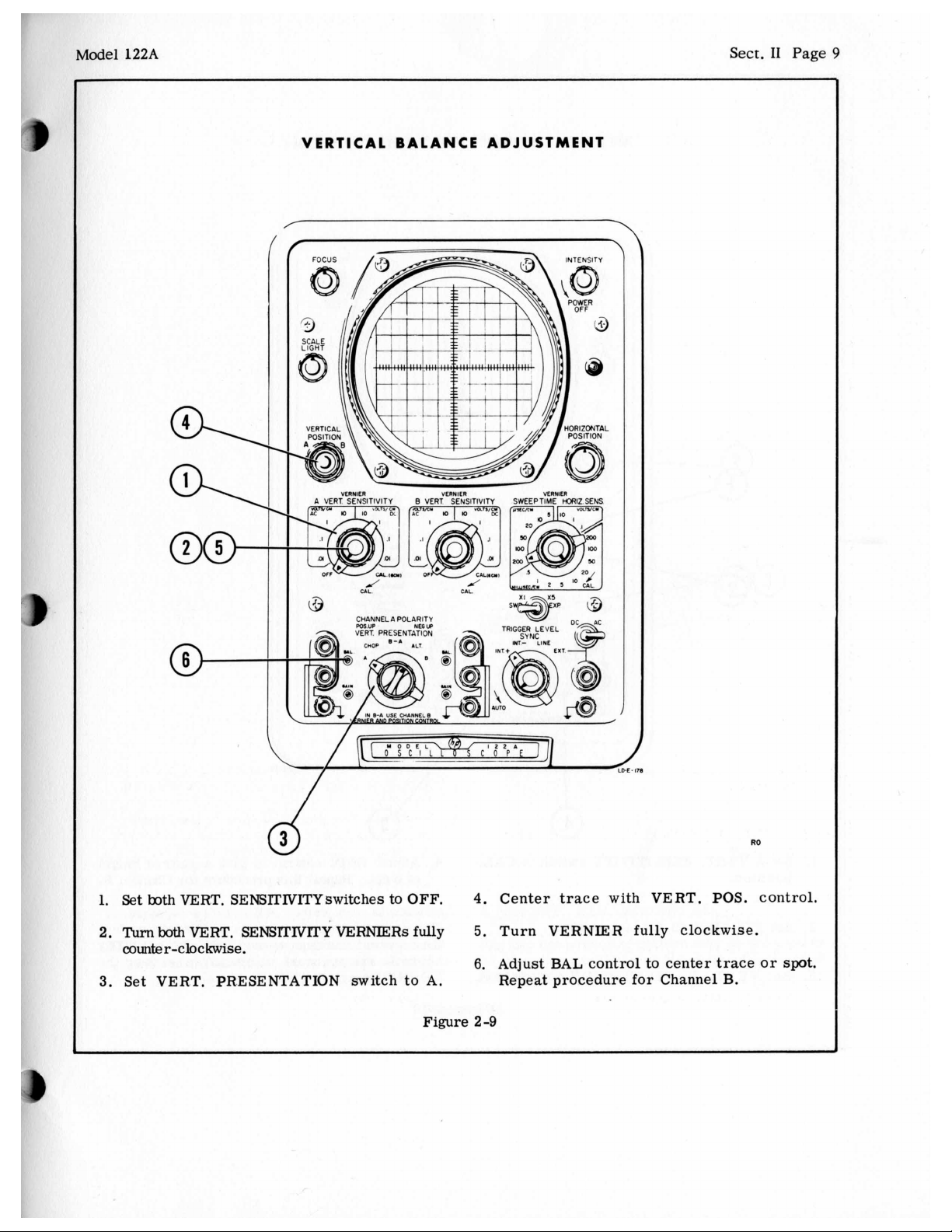

1.

Set

both

VERT. SENSTI'IVITYswitches to OFF. 4. Center trace with VERT.

2.

TurnbothVERT.

SENSFlWTYVERNIERsfully

5.

Turn VERNIER fully clockwise.

counter-clockwise.

6.

Adjust BAL control

3.

Set VERT. PRESENTATION switch to A. Repeat procedure for Channel B.

Figure

2-9

to

center

POS.

trace

no

control.

or spot.

Page 19

Sect.

I1

Page

10

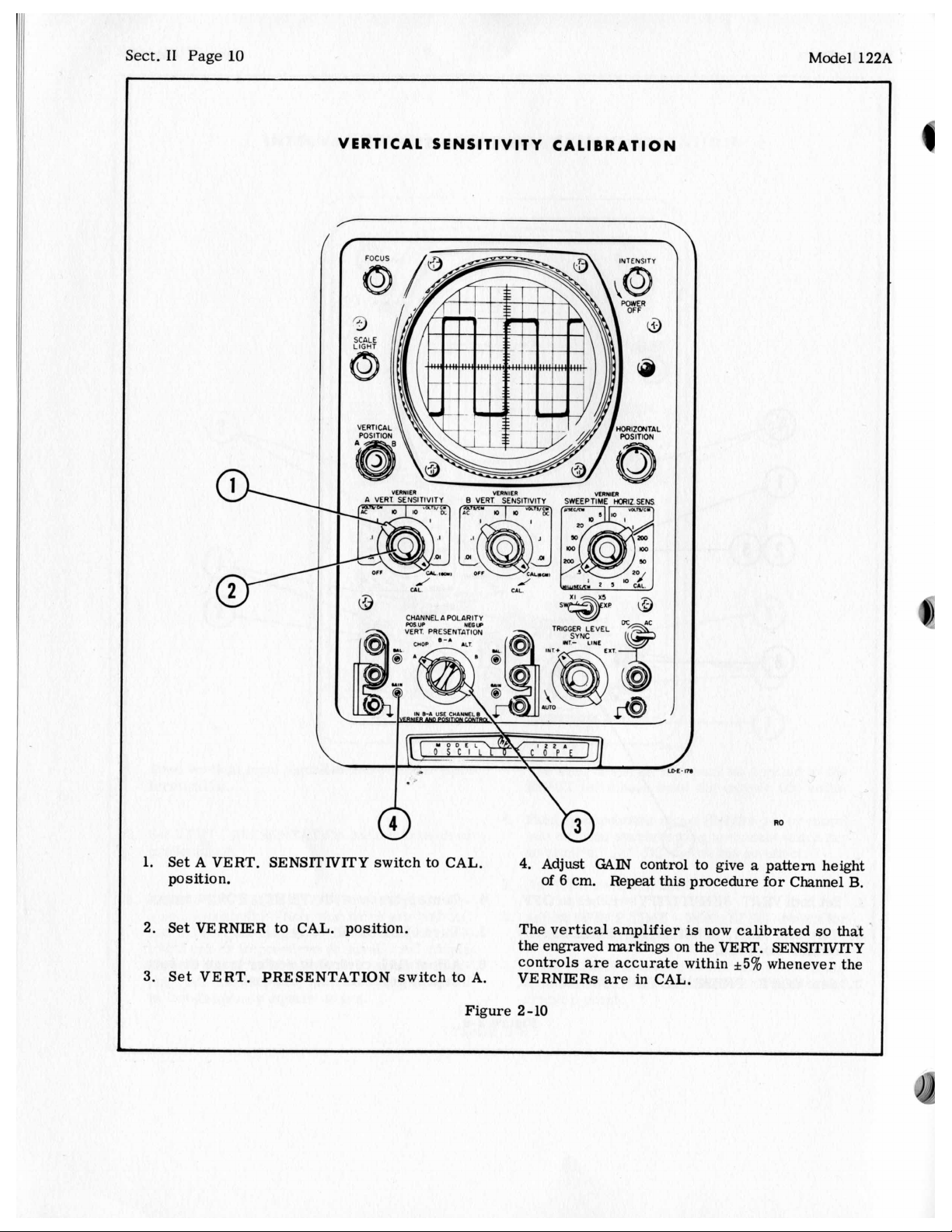

VERTICAL SENSITIVITY CALIBRATION

Model

122A

mien

A

MRT SENSITIVITY 0 VERT SENSITIVITY

1.

Set A VERT. SENSITIVITY switch

position. of

2.

Set

3.

VERNIER

Set

VERT. PRESENTATION switch

to

CAL. position.

to

vEnmn

CAL.

to

A. VERNIERS

b

4.

Adjust

The vertical amplifier

the engraved markings on

controls

GAIN

6

cm. Repeat

are

accurate within

are

control to give a pattern height

this

in CAL.

M)

procedure for Channel

is

now

the

calibrated

VERT.

+5%

whenever

so

SENSlTIVlTY

B.

that

the

Figure 2-10

Page 20

Mod€

:1

122A

Sect.

I1

Page

11

r

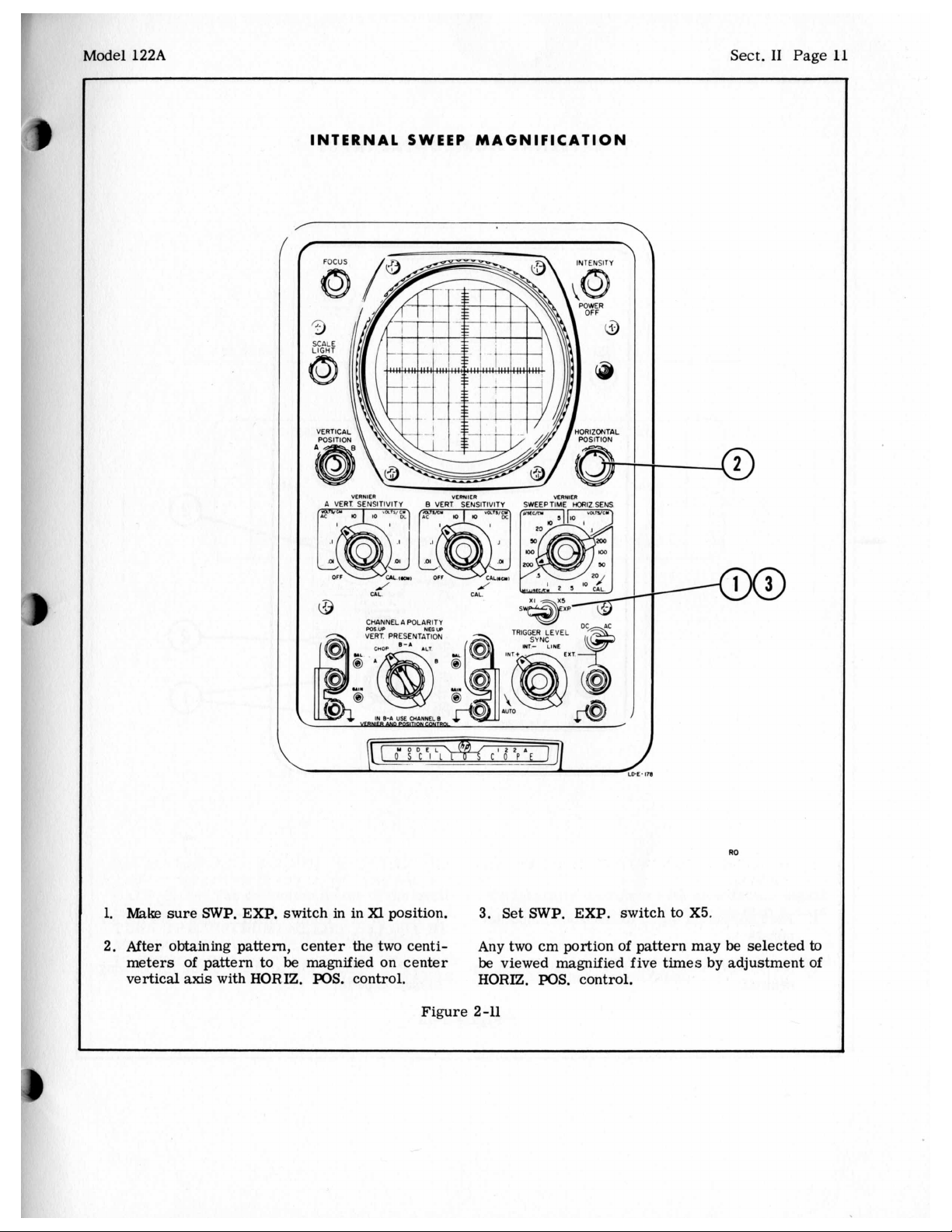

INTERNAL SWEEP MAGNIFICATION

/

A

VERT

WnlcR

SENSITIVITY

e

VERT

"ERllEl

SENSITIVITY

VEwm

SWEEPTIME

KRIZ SENS

1.

Make

sure

SWP.

EXP. switch in in

2.

After obtaining pattern, center the

meters of pattern to

axis

vertical

with

be

HORIZ.

magnified on center

POS.

Xl

position.

two

control.

centi-

Figure 2-11

3.

Set SWP. EXP. switch to X5.

Any two cm portion of pattern may

be

viewed magnified five times by adjustment

HORIZ.

POS.

control.

be

selected

to

of

Page 21

Sect.

I1

Page

12 Model 122A

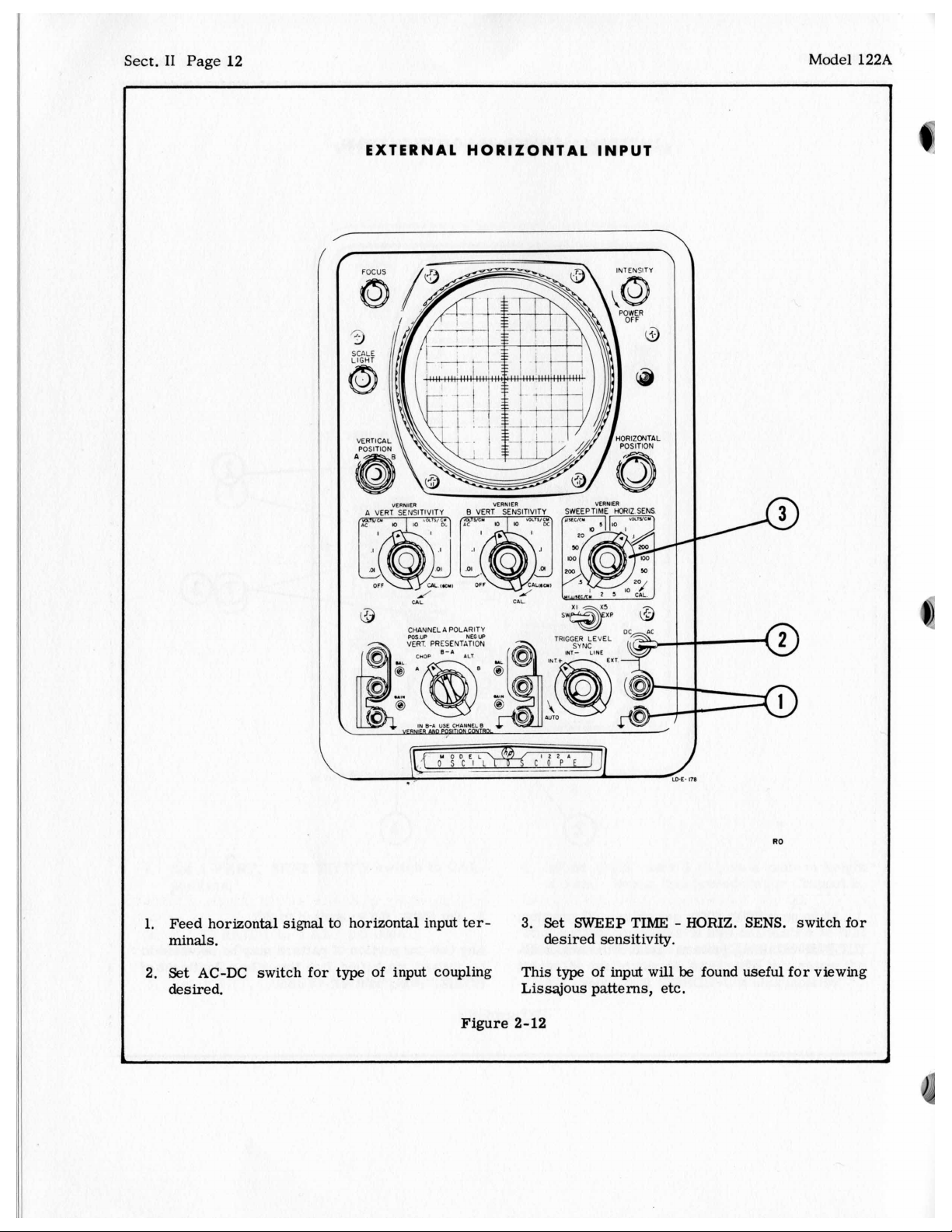

EXTERNAL HORIZONTAL INPUT

7'

1. Feed horizontal

signal

to horizontal input ter-

CHANNELA POLARITY

VERT PRESENTATION

3.

TRIGGER LEVEL

Set

SWEEP

minds. desired sensitivity.

2.

Set

AC-DC

switch for type of input coupling

This type of input will

desired. Lissajous patterns, etc.

Figure

2-12

TIME

RO

-

HOlUZ.

be

SENS.

switch for

found useful for viewing

Page 22

'1

122A

HORIZONTAL

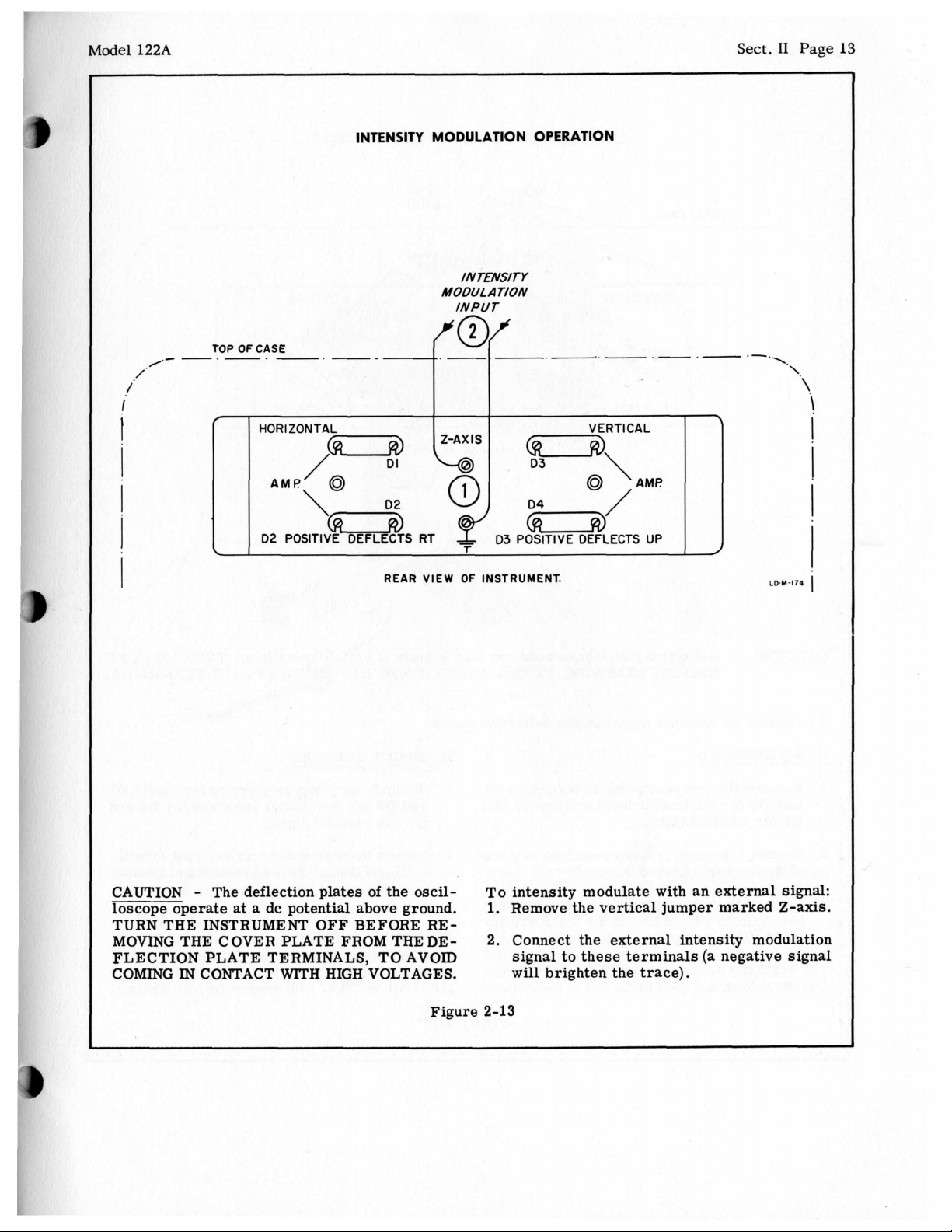

INTENSITY MODULATION OPERATION

dYICAL

D3

Sect.

I1

Page

13

03

L

REAR

T

VIEW

OF INSTRUMENT.

POSITIVE DEFLECTS UP

I

!

LDY-174

I

AUTION - The deflection plates of the oscil- To intensity modulate with an external signal:

Iscope operate

URN

THE INSTRUMENT OFF BEFORE RE-

at

a

dc potential above ground.

OVING THE COVER PLATE FROM THEDE-

Remove the vertical jumper marked

2.

Connect the external intensity modulation

Z-axis.

1.

LECTION PLATE TERMINALS, TO AVOID signal to these terminals (a negative signal

OMING

IN

CONTACT WITH

HIGH

VOLTAGES.

will

brighten the trace).

Figure

2-13

Page 23

Sect.

I1

Page

14

Model

122A

/

I

I

I

./.----

TOP

-.

OF

CASE

-.--

CONNECTION

HOR/Z.

/wur

-

REAR VIEW OF INSTRUMENT.

TO

DEFLECTION

VERT

iwur

PLATES

-.-.-.

LO-M-169

-.

'\.

\

i

i

i

i

RO

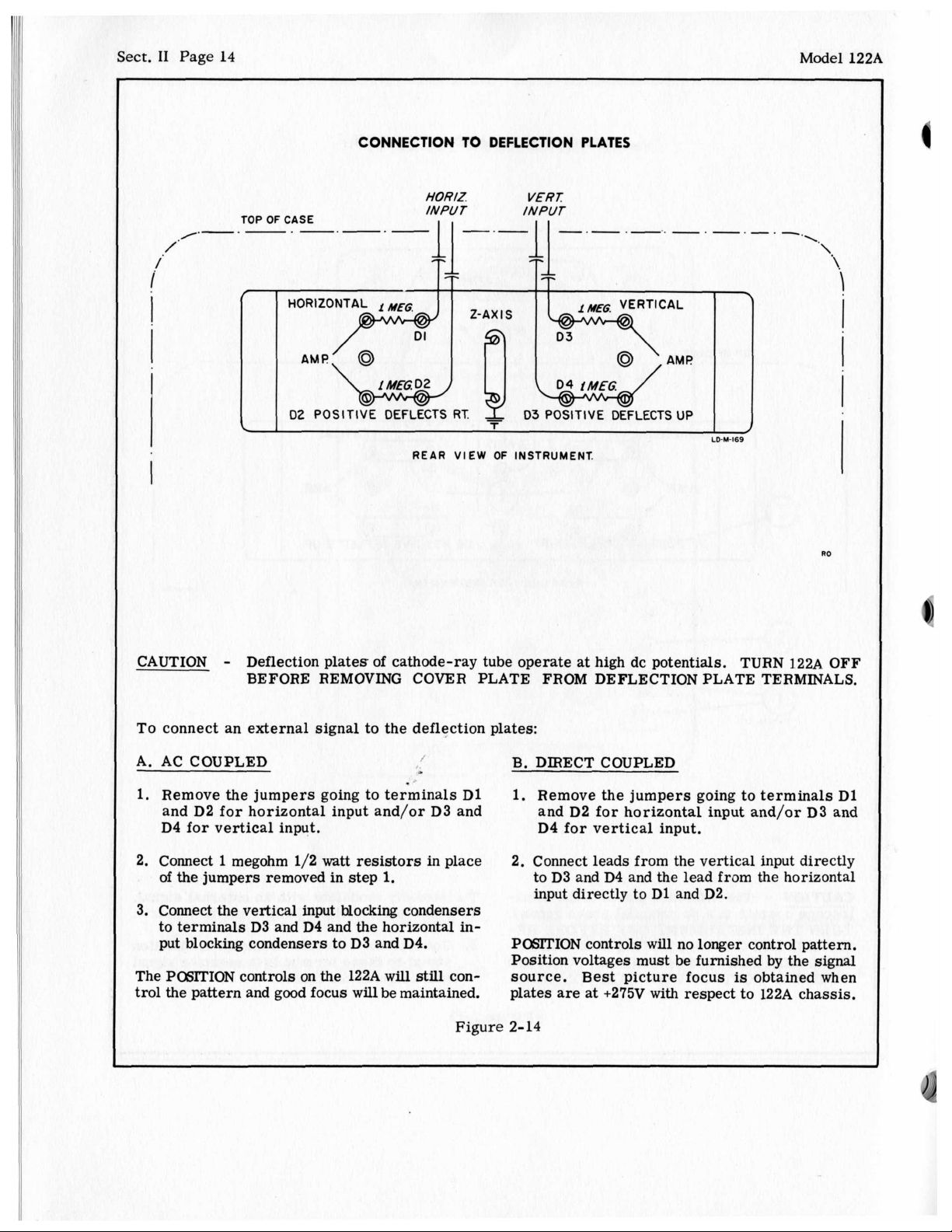

CAUTION

To connect an external signal to the deflection plates:

-

Deflection plates of cathode-ray tube operate

BEFORE REMOVING COVER PLATE FROM DEFLECTION PLATE TERMINALS.

I

I

A.

AC COUPLED

1.

Remove the jumpers going to terminals D1

and D2 for horizontal input and/or D3 and

D4 for

2. Connect

of

3. Connect the

to terminals D3 and

put blocking condensers to D3 and D4.

The POSlTION controls on the 122A

trol the pattern and good focus

vertical

1

megohm 1/2

the jumpers removed in step

input.

vertical

watt

input

D4

resistors in place

blocking

and

the

will

1.

condensers

horizontal in-

will

still

con-

be maintained.

Figure

at

high dc potentials. TURN 122~ OFF

B. DIRECT COUPLED

1.

Remove the jumpers going to terminals D1

and D2 for horizontal input and/or D3 and

D4 for vertical input.

2. Connect leads from the vertical input directly

to D3 and D4 and the lead from the horizontal

input directly to D1 and D2.

POSITION controls

Position voltages

source. Best picture focus

plates are at +275V with respect to

2-14

will

no longer control pattern.

must

be furnished

is

obtained when

122A

by

the signal

chassis.

Page 24

Model 122A Sect.

I1

Page 15

ALIGNING

SCOPE TRACE

WITH

GRATICULE

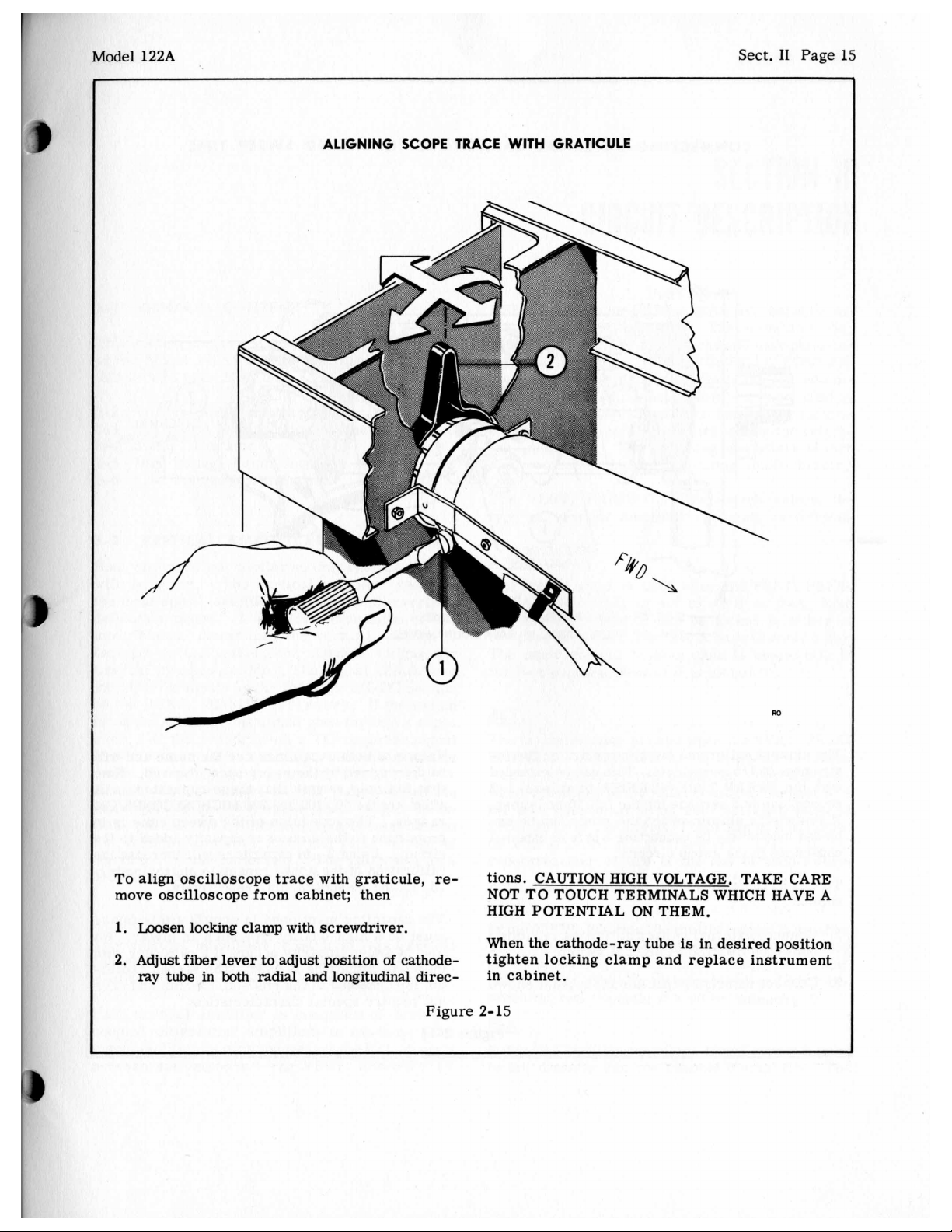

To align oscilloscope trace with graticule,

move oscilloscope from cabinet; then

1.

Loosen locking clamp with screwdriver.

2.

Adjust fiber lever to adjust position

ray

tube

in

both

radial

and longitudinal direc-

of

cathode-

re-

tions. CAUTION HIGH VOLTAGE. TAKE CARE

NOT TO TOUCH TERMINALS WHICH HAVE A

HIGH POTENTIAL ON THEM.

When the cathode-ray tube is

tighten locking clamp and replace instrument

in cabinet.

Figure 2-15

in

desired position

Page 25

Sect.

I1

Page

16

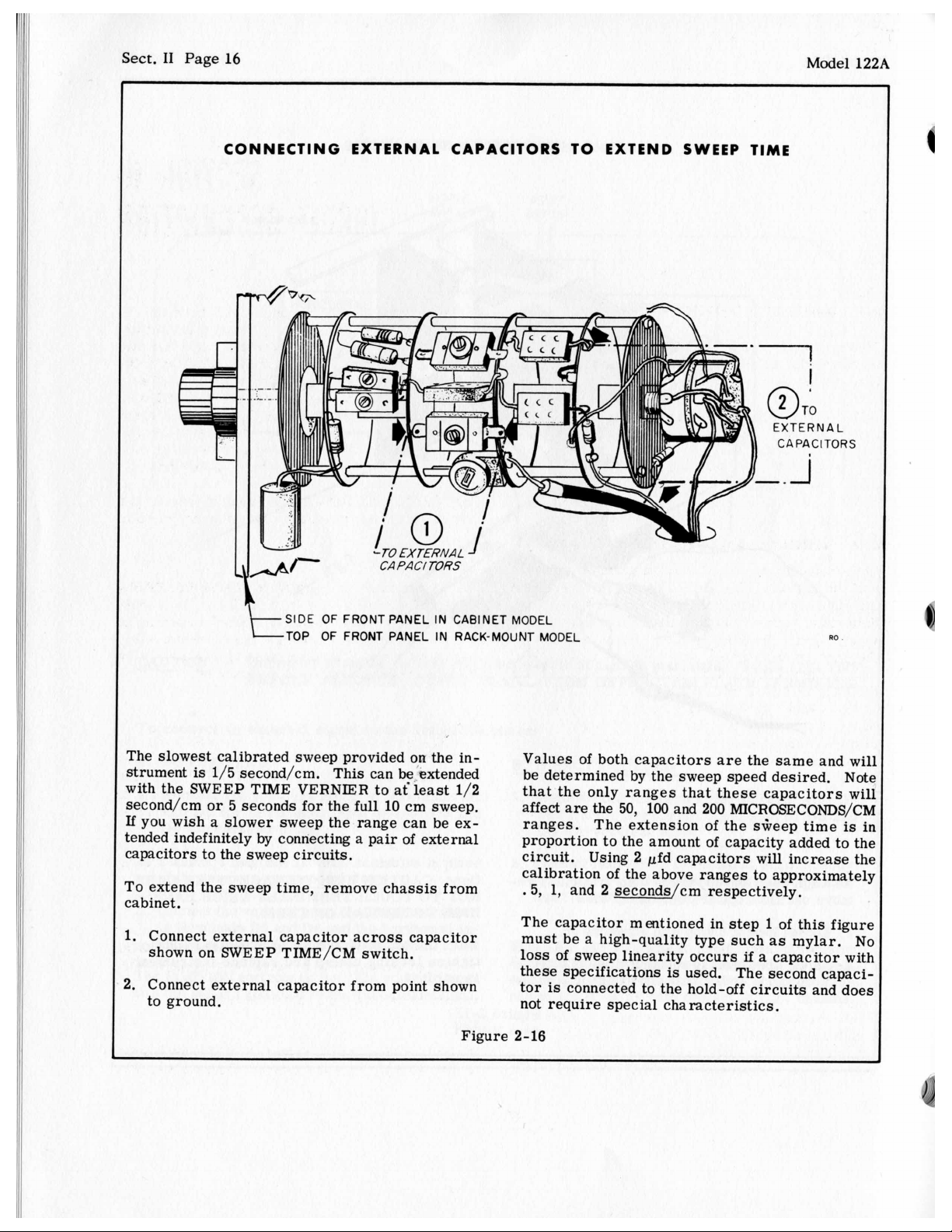

CONNECTING EXTERNAL CAPACITORS TO EXTEND SWEEP TIME

Model

122A

4

CAPACITORS

-SIDE OF FRONTPANEL

-

TOP OF

rhe slowest calibrated sweep provided

strument

vith the SWEEP TIME VERNIER to af least

;econd/cm or 5 seconds for the

f

you wish a slower sweep the range can be exended indefinitely

apacitors to the sweep circuits.

'0

'abinet.

.

.

Connect external capacitor from point shown

to ground.

is

1/5

second/cm. This can

by

connecting a pair of external

extend the sweep time, remove chassis from

Connect external capacitor across capacitor

shown on SWEEP TIME/CM switch.

FRONT

full

10

IN

PANEL IN RACK-MOUNT MODEL

on

the in-

be

extended

cm sweep.

CABINET

1/2

C A PAC1

MODEL

Values of both capacitors are the same and

be determined by the sweep speed desired.

that the only ranges that these capacitors

affect are the

ranges.

proportion to the amount of capacity added to the

circuit.

calibration

.5,

1,

and 2 seconds/cm respectively.

The capacitor mentioned

must be a high-quality type such

loss of sweep linearity occurs

these specifications

tor

is

connected to the hold-off circuits and does

not require special characteristics.

50,

100

and

200

MICROSECONDS/CM

The extension of the sieep time

Using

2

pfd capacitors

of

the above ranges to approximately

in

is

used. The second capaci-

will

step 1 of this figure

as

if

a

capacitor with

TORS

a0

Note

is

increase the

mylar.

wil:

will

in

No

Figure

2-16

Page 26

Ma

del

122A

Sect.

111

Page

1

D

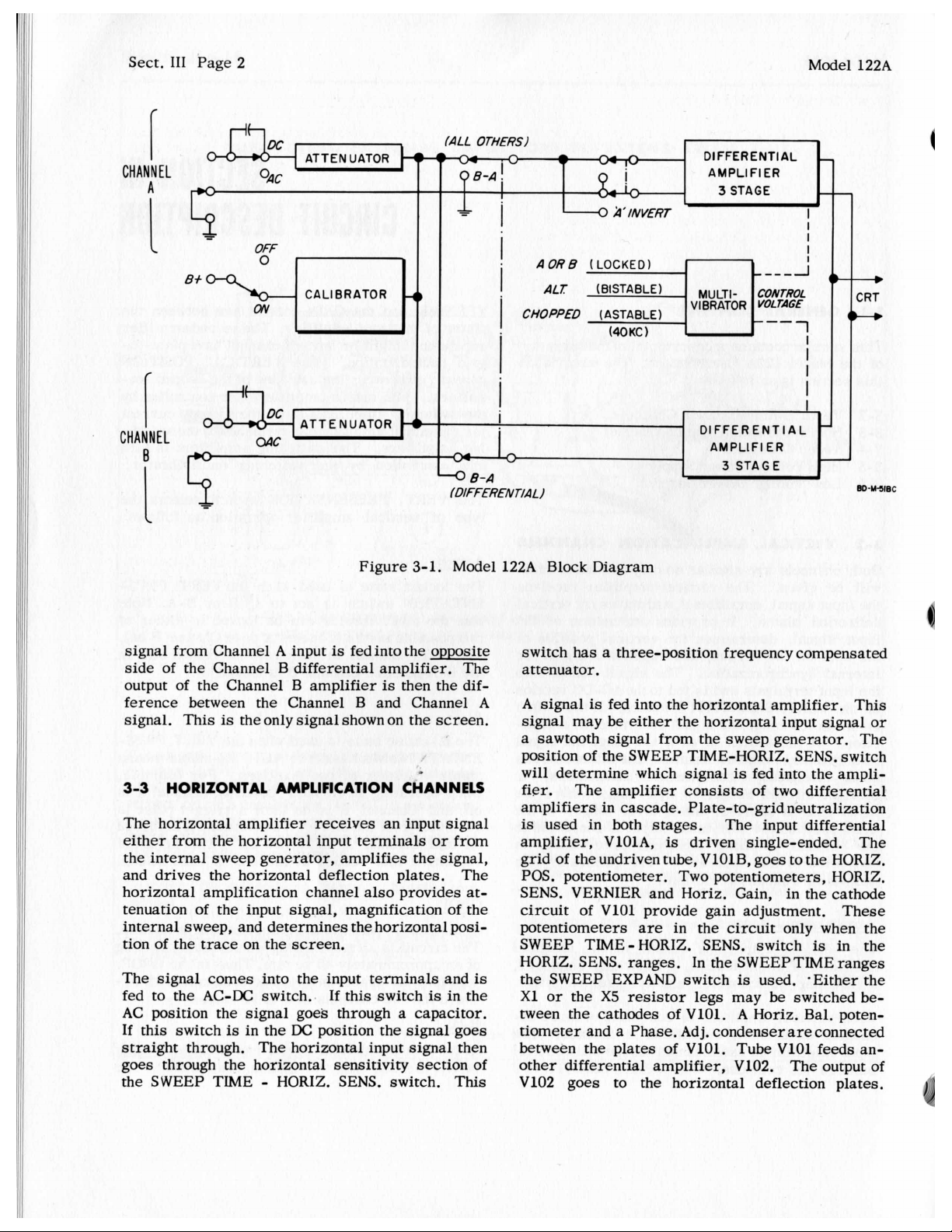

GENERAL CONTENT

3

-1

Thj

is

section contains a description

of

the Model 122A Oscilloscope. The material in

this

3

section

!

Vertical Amplification Channels

3-2

i

Horizontal Amplification Channel

3-3

.

Sweep Generator

3-4

I

High Voltage

3-5

I

Low Voltage Power Supply

3-0

I

3-1

Bot

.h channels

wil:

1

be given. The vertical amplifier receives

the

input signal, amplifies

def:

lection plates. It provides attenuation

inpi

ut signal, determines the vertical position

the

spot on the screen, and supplies a signal

intc

xnal synchronization. The signal comes into

the

input terminals and

the VERT. SENSITIVITY switch. If the switch

of

1

is

<

3n an AC range the signal goes through a capa-

citc

)r.

s

directly

goe

:e

thrc

str;

light-through range, an

inpi

it grid

CAI

L.

position the calibrator output

the

vertical

nected

con

neo

n-lamp relaxation oscillator.

Ver

.tical Amplifiers

-

!

vertical amplifiers consist

The

cha

nnels of amplification,

witching multivibrator, and

a

s\

:h vertical amplifier

Eac

pled differential amplifiers in cascade. The

cou:

inpi

it

amplifier in each channel has the BAL. control

ween

is

as

follows:

Power

VERTICAL AMPLIFICATION CHANNELS

are

similar

If the switch

to

the attenuator.

frequency - compensated attenuators,

is

shorted, and a CAL. range. In the

amplifier input and plate voltage

to

the calibrator. The calibrator

its

cathodes. The VERT. SENSITIVITY

Supply

so

it,

anddrives the vertical

is

fed tothe AC-DC section

is

on

a

OFF

a

is

composed of three dc-

of

the operation

only one description

Dc

range the signal

The attenuator has

range where the

is

connected to

of

two identical

switching amplifier,

a

trigger amplifier.

SECTION

C

I

R

C

U

IT

DES

VERNIER and the GAIN control

plates

and output amplifier in each channel have plate-to-

grid neutralization. The VERTICAL POSITION

control

plifiers.

the switching amplifiers since the cathode current

for

ing amplifiers. The switching amplifiers in turn

are

The VERT. PRESENTATION switch

type

A

The locked state

ENTATION switch

of

the

for

is

that the multivibrator can be locked in either of

of

two

The other channel in each

the B-A position Channel B

ALT.

The bi-stable

ENTATION switch

a

stable in either

when operating in the ALT. position, Channel

off

received from the sweep. Then Channel

is

on and Channel B

a

repetitive and occurs at the end of each sweep.

CHOP

In the CHOP. position the multivibrator

The circuit

at

position, the

tween the

B-A

-

In the B-A position the signal fromchannel B input

is

of

the input amplifier. The secondamplifier

is

between the cathodes of the second am-

The output amplifiers

the output amplifiers

controlled by the switching multivibrator.

of

vertical amplifier operation as

or

B

is

possible states (Channel A on or Channel B on).

state

of

and Channel

an approximately

two

fed directly into the channel B amplifier. The

B

is

a

free-running multivibrator running

trace

channels

is

furnished by the switch-

used

when theVERT. PRES-

is

set

to

case

is

is

used when the VERT. PRES-

is

set to ALT. Bi-stable means

two positions.

is

on until a trigger pulse

is

turned off. This action

40

kc

rate.

is

switched back and forth be-

at a 40

C

R

I

PTI

are

between the

are

controlled by

selects

A, B or B-A.

is

biasedoff. In

locked on.

For

A

is

Thus, in the CHOP.

kc

rate.

Ill

0

N

the

follows:

Note

example,

A

is

is

is

turned

is

astable.

Page 27

Sect.

III

Page 2

Model 122A

CHANNEL

A

e+

f

CHANNEL

B

OFF

0

ATTENUATOR

CALIBRATOR

ATT E N U ATOR

Figure

4)

I

(DIFFERENTIAL)

3-1.

(40KC)

8-A

Model 122A Block Diagram

DIFFERENTIAL

AMPLIFIER

3

STAGE

DIFFER ENTIA

AMPLlFl ER

I

I

I

I

I

L

-

--

I

I

I

I

A

input

is

signal from Channel

side of the Channel

output

of

the Channel B amplifier

B

differential amplifier. The

ference between the Channel B and Channel

signal. This

3-3

HORIZONTAL AMPLIFICATION CHANNELS

is

the only signal shown on the screen.

The horizontal amplifier receives an input

either from the horizontal input terminals

fedintothe opposite

is

then the dif-

A

signal

or

from

the internal sweep generator, amplifies the signal,

and drives the horizontal deflection plates.

horizontal amplification channel

tenuation

of

the input signal, magnification of the

also

provides

The

at-

internal sweep, and determines the horizontal position of the

The signal comes into the input terminals and

fed

to

AC position the signal goeb through

If this switch

trace

on the screen.

the AC-DC switch..

is

in the

DC

is

If

this switch

is

a

capacitor.

in the

position the signal goes

straight through. The horizontal input signal then

goes through the horizontal sensitivity section

the SWEEP TIME - HORIZ. SENS. switch.

of

This

switch has a three-position frequency compensated

attenuator.

A

signal

is

fed

into the horizontal amplifier. This

signal may be either the horizontal input signal or

a

sawtooth signal from the sweep generator. The

position of the SWEEP TIME-HORIZ. SENS. switch

will

determine which signal

fier.

The amplifier consists

is

fed into the ampli-

of

two

differential

amplifiers in cascade. Plate-to-grid neutralization

is

used in both stages. The input differential

amplifier,

grid

of

POS.

VlOlA,

is

driven single-ended. The

the undriven tube, VlOlB, goes to the HORIZ.

potentiometer.

Two

potentiometers, HORIZ.

SENS. VERNIER and Horiz. Gain, in the cathode

circuit of

potentiometers

SWEEP TIME-HORIZ. SENS. switch

HORIZ. SENS. ranges.

the SWEEP EXPAND switch

X1

or the X5 resistor legs may

tween the cathodes

tiometer and

between the plates

other differential amplifier, V102.

V102

goes

VlOl

provide gain adjustment. These

are

in the

circuit

only when the

is

in the

In the SWEEPTlME ranges

is

used. 'Either the

be

switched be-

of

V101. A

a

Phase. Adj. condenser

of

V101.

Horiz.

Tube

Bal. poten-

are

connected

VlOl

The

feeds

output of

to the horizontal deflection plates.

an-

Page 28

Model 122A Sect.

111

Page 3

3-4

SWEEP GENERATOR

The sweep generator consists of a trigger generator

and a sawtooth generator. The trigger generator

receives the synchronizing signal, selected by the

SYNC selector, and generates a pulse which

itiates the action of

the

sawtooth generator. The

in-

sawtooth generator then goes through one complete

cycle. It automatically

shuts

itself

off bymeans of

feedback upon completion of one cycle. The sweep

circuit

will

operate again

when

another pulse

is

received from the trigger generator, but only after

a hold-off time during which all of

had time to

delay

is

necessary

return

to

their

quiescent voltages. This

so

that successive waveforms

the

circuits have

will start from the same voltage each time.

Trigger Generator

The trigger generator consists of a synchronizing

circuit and a trigger generator, V201. The

syn-

chronizing circuit receives a signal either from

the

vertical amplifier for internal synchronization

(+

or

-),

from an internal 6.3 volt source for line

the

frequency synchronization, or from

horizontal

input terminals for external synchronization. The

trigger generator converts the signal into a fast,

constant-amplitude pulse for operation of the startstop trigger, V202.

The trigger generator, V201,

with narrow hysteresis limits.

is

a Schmitt Trigger

A

negative signal

starts the action by causing the trigger generator

to change state. This action generates a square

is

wave output. This square wave output

differentiated by L201 into a series of positive and negative pulses. These pulses are fed to the start-

s

top trigger.

Sawtooth Generator

The sawtooth generator consists of a start-stop

trigger, an integrator switch, an integrator, and a

hold-off cathode follower. The pulse from

the

trigger generator controls the start-stop trigger

in

which,

turn, controls the integrator switch.

The integrator switch controls the action of the

integrator. The integrator generates a linear,

rising, voltage. This action

plus

the switching

action of .the integrator switch generates a sawtooth

is

voltage. This sawtooth voltage

fed to the horizontal amplifier and to the hold-off cathode follower.

The output of the hold-off cathode follower

the grid of the start-stop trigger.

keeps the start-stop trigger from triggering

all

the circuits have had time to recover to their

is

fed to

This voltage

until

original quiescent voltage.

Gate Cathode-Follower

Another function of

a positive pulse to unblank

This pulse

is

Normally the voltage applied to the grid

cathode-ray tube cuts

the

sweep

obtained from

off

generator

the

the

start-stop trigger.

the

beam. During

is

cathode-ray tube.

to furnish

of

the

the

time of the sweep operation a positive pulse is applied which overrides

negative voltage and

un-

the

blanks the picture.

3-5

HIGH VOLTAGE POWER SUPPLY

The High Voltage Power Supply consists of a Hartley

Oscillator feeding two separate secondary windings

and rectifiers.

Hartley Oscillator

The Hartley Oscillator consists of a pentode, V302,

and a tapped winding on

the

high-voltage transformer. This circuit oscillates at approximately

100 kc. The high-voltage transformer has two

separate secondaries and feeds two separate recti-

fier tubes. Output of one rectifier, V304,

nected to the grid of

INTENSITY control

ply determines the voltage on

thus

and

ing pulse

the brilliance

is

also direct-coupled to

hence to the grid of

the

from

other rectifier

of the cathode-ray tube. Voltage

supply and fed

into

the

cathode-ray tube. The

in

the

output divider of this sup-

the

CRT control grid

of

the

pattern. The unblank-

this

the

cathode-ray tube. Output

is

connected to

is

taken from

the

input of a two stage dccoupled amplifier. The output of this amplifier

fed back to the screen of

the

proper phase to oppose any change

the

Hartley Oscillator

is

con-

supply and

the

cathode

this

is

in

in

the dc

output of the cathode supply.

The Intensity-Modulation terminals are ac coupled

to

the

voltage

cathode of

input

the

cathode-ray tube. A negative

will

brighten the trace while a positive

voltage of approximately twenty volts will blank the

tube from normal intensity.

3-6

LOW VOLTAGE POWER SUPPLY

The

Low Voltage Power Supply consists of three

regulated supplies, one positive and one negative

and a dc filament

supply.

Positive Voltage Supply

The Positive Voltage supply furnishes

+

380 volts

and +lo0 volts. It consists of a transformer, four

Page 29

Sect.

111

Page

4

silicon rectifiers, a pentode amplifier and a triode

in

regulator

figuration, and a triode cathode-follower. Full

output of the supply

ode-follower drops this down to furnish +lo0 volts.

Neon tube, V315, protects V307B from excessive

cathode-to-grid voltage during warm-up.

Negative Voltage Supply

The Negative Voltage Supply furnishes

and -30

silicon rectifiers, and a

erence tube combination

power supply configuration. The

the usual regulated

is

+380 volts. The output cath-

volts.

It consists

regulator-amplifier-ref-

power

supply con-

-150

of

a transformer, two

in

the usual regulated

-30

volt output

volts

is

Model

used

as

a filament reference voltage and fed to the

the

center tap of

Regulated Filament Supply

This supply furnishes regulated

heaters of the four input tubes

plifier. These tubes,

nected in series-parallel. By supplying this filament voltage from

drift

is

greatly reduced.

The

supply consists of a transformer, a silicon

rectifier, and two pnp transistors. Transistor

is

the

series

emitter follower controlling 4301. Reference voltage

is

obtained from the -150 volt supply.

Hum Balance potentiometer.

+24

volts to the

of

the vertical am-

V1,

2,

and

V4,

a

regulated source vertical trace

element. Transistor

122A

5 are con-

4301

4302

is

an

Page 30

Model

122A

Sect. IV Page

1

SECTION

IV

MAINTENANCE

I-1

INTRODUCTION

This section contains instructions

justing, and trouble-shooting the Model 122A

cilloscope.

The Front Panel Operational Check, paragraph 4-2,

is

a

fast method

instrument. The Trouble-Shooting Procedure,

paragraph 4-5,

section

The Condensed

paragraph 4-6,

basic

Test Procedure, paragraph 4-7,

the condensed

Paragraphs 4-3 and 4-4 contain information on

I

removing the cabinet and replacing tubes.

Schematic Diagrams and the Table

Parts

of

the instrument that

adjustments

are

of

checking the operation

is a rapid means of isolating

Test

and Adjustment Procedure,

is

a

fast

method

of

the instrument. The Complete

test

and adjustment procedure.

located at the end

for

testing, ad-

is

not functioning.

of

checking the

is

an expansion

of

Replaceable

of

this section.

of

Os-

the

a

of

YZE

4

AI

EXTRA DATA

SPECIFICATIONS.

In general, the Model 122A can be divided into

sections with the

located behind the front panel controls for that

section. The

on the top chassis brace. Thematerial that

is

divided into sections according

functions. Each section has

adjustment instructions.

The following

and adjusting the Model 122A Oscilloscope during

manufacture. Equivalent

used for testing purposes.

1) “Reference Oscillator” with frequency range

400 cps

5

millivolts

Wide Range Oscillator.

to

RTICULAR INSTRUMENT. THIS

P.

CANNOT BE CONSIDERED AS

parts

power

test

500 kilocycles, and adjustable output

to

20 volts, such

for

any particular section

supplies

equipment

test

are

in the

rear

and

follows

to

circuit

a

complete

is

used

equipment may be

as

@Model 200CD

for

set

testing

of

of

F

Standard, readily available components

for

manufacture

sible. Special components

from the

source

local

stock

please specify instrument model and serial number

plus the component description and stock number

appearing in the Table

Your

plete

assist

or

repair

ments

SPECIFICATIONS FOR THE @ 122A OSCILLO-

SCOPE ARE GIVEN IN THE FRONT OF THIS

MANUAL. THE SERVICE PROCEDURES THAT

FOLLOW CONTAINEXTRADATATOHELPYOU

@

for

@

representative who maintains a parts

for

your convenience. When ordering

local

facilities

you with any engineering, application,

problems you may have with @instru-

.

of

@

instruments whenever

are

available directly

factory. Perhaps the most convenient

spare

@

or

replacement parts

of

Replaceable

representative

and specially trained personnel

also

maintains com-

are

is

used

pos-

your

parts,

Parts.

to

test,

2) “Reference VTVM” with

to

500 kilocycles frequency range, and 50 milli-

volts

to

60

volts voltage range, suchas the @Model

400H Vacuum Tube

3) “Marker Generator” with frequency range

200 kilocycles

steps and an accuracy

Tektronix 180 Time Mark Generator.

4) “Calibration Generator” furnishing lOOv dc and

100

v

ac

at

400

curacy

erator”

the voltage to 20 millivolts in

uation with an accuracy

cation 23678

meet these specifications.

5)

steps from

Attenuator

of * 0.25%. In addition the “Calibration Gen-

must have an attenuator which

“Adjustable Attenuator” having adjustable db

or

Voltmeter.

to 1 cycle per second in decade

or

1000 cps,

Voltmeter

1

to

110

equivalent.

1%

accuracy, 400 cps

of

*0.3%,

all

voltages with an ac-

a

of

*0.25%. The @ Specifi-

Calibration Generator

db.

Use

such

as

will

reduce

1-2-5 times atten-

an @ Model 350A

of

the

will

Page 31

Sect.

IV

Page

2

6)

“Square Wave Generator” capable of furnishing

square waves or pulses, audio frequencies, such

as

the @Models

4-2

Perform the following procedure whenever there

is

the instrument. This

if

sociated equipment. Always perform

ation Check before attempting instrument adjustment or repair.

For a Proof-of-Performance Check complete the

steps as given and compare the

specifications.

strument

up for at least fifteen minutes.

A.

1)

Figure

2)

shown

function properly,

section of the maintenance procedure before proceeding further.

B.

FRONT PANEL OPERATIONAL CHECK

any question about the proper functioning of

the malfunction

in

ADJUST

CALIBRATION

Check the vertical dc balance as shown in

2-9.

Check the vertical sensitivity calibration as

in

VERTICAL AMPLIFIER SENSITIVITY

211A

and

212A.

will

enable you to determine

is

in

this instrument or as-

this

Oper-

results

All

tests are made with the

the cabinet and the instrument warmed

DC

Figure

BALANCE

2-10.

refer

If these controls donot

to VERTICAL AMPLIFIER

AND

with the

VERTICAL

in-

Model

2)

Connect

tion Generator” to input terminal

trace should

refer

tenance procedure.

3)

Check dc

voltage from the “calibration generator”

As

on.

spot should shift

VERTICAL POSITION

4)

Check the accuracy of the remaining VOLTS/CM

positions.

and gives peak-to-peak and

should produce the deflection listed.

5)

Repeat steps 3 and 4 using the A VERT. SEN-

SITIVITY AC ranges.

6)

Repeat above procedure for channel B.

C. VERTICAL AMPLIFIER BANDWIDTH

1)

Set VERTICAL PRESENTATION to

A

TRIGGER LEVEL to AUTO.

2)

Connect the

minal

“reference vtvm”.

3)

Set “reference oscillator” to 2 kilocycles and

adjust for

“reference vtvm”.

a

0.1

volt

ac

signal from the“Ca1ibra-

The vertical

A.

be

10

cm

*5%

(9.5 - 10.5

to

VERTICAL AMPLIFIER section of main-

response

the voltage

10

Table

by switching a

is

switched

cm

*5%

as

necessary.

4-1

lists the selector positions

off

(9.5 - 10.5

rms

cm).

0.1

and on the CRT

cm). Adjust

voltages which

-

A

VERT. SENSITIVITY to

“reference

A,

and monitor the input voltage with the

10

cm of deflection. Note reading on

oscillator” to input ter-

.01

VOLTS/CM

122A

If

not,

volt dc

off

and

I

d

1)

Set VERTICAL PRESENTATION to

A

VERT. SENSITIVITY to

A

VERT. SENSITIVITY VERNIER

TRIGGER LEVEL maximum counterdockwise

but not in AUTO.

Sensitivity

Volts/cm

.01

A

VOLTS/CM,(DC)

ro

Deflection Voltage Required

cm

.01

.1

1

10

CAL.

+

5%

5

5

5

5

4)

Set “reference oscillator” to

rmS

0.0

1767

0.1767

1.767

17.67

“reference

Set output to previous reading on

The deflection should be at least

down point).

section

If

not, refer toVERTICAL AMPLIFIER

of

maintenance procedure.

Peak/Peak

0.05

0.5

5.0

50.0

200

kilocycles.

7.07

vtvm”.

cm

(3db

4

Page 32

Model 122A

Sect.

IV

Page

3

Repeat above procedure for channel B.

5)

VERTICAL AMPLIFIER COMMON

REJECTION

Set

A

VERT. SENSITIVITY to .01 VOLTS/CM

A

VERT. SENSITIVITY VERNIER to CAL.

SWEEP TIME to

VERT. PRESENTATION to

TRIGGER LEVEL to AUTO.

SYNC to INT

Connect the “reference oscillator” to the chan-

2)

ne1

1

A

input terminal through an “adjustable atten-

tor”

Ual

3)

ma

of

4)

int

Stl

cil

5)

of

E.

terminated with

With “reference oscillator’’ set to 1 kc and

tximum output, switch in attenuation until

deflection

Change input

o

both red input terminals. Remove ground

.ap and connect ground side

lator” to black terminal.

Switch “adjustable attenuator” until

1

cm

inge

least

at

Repeat above procedure for channel B.

VERTICAL AMPLIFIER COMMON-SIGNAL

REJECTION (B-A)

is

displayed.

so

is

again obtained. The external attenuation

is

the common-signal rejection and should

40 db.

0.5

MILLISECONDS/CM

A

600

ohms.

that the same signal

of

\

-

“reference

a

deflection

SIGNAL

1

cm

is

fed

os-

6)

Switch A VERT. SENSITIVITY and B VERT.

SENSITIVITY to 0.1 VOLTS/CM. There should

less

than

10

cm of deflection.

7)

Switch VERT. PRESENTATION to B.

8)

Set the “reference oscillator” to 200 kc, and

5

adjust for

9)

Repeat steps 4, 5 and

as

before.

If the instrument

consult the appropriate part of the VERTICAL

AMPLIFIER section

F. WAL TRACE PRESENTATION

1) Set TRIGGER LEVEL to AUTO.

2) Adjust remaining oscilloscope controls to display the chopped

3)

The A VERT.

chopped trace and

move the other.

4) Set VERT. PRESENTATION to ALT. Thechan-

A

ne1

alternately.

cm of deflection.

Limits

6.

fails

to meet any

of

the maintenance procedure.

SYNC to INT

VERT. PRESENTATION

SWEEP TIME to

A

VERT. SENSITIVITY to OFF

B VERT. SENSITIVITY to OFF

50

of

to

CHOP

MILLISECONDS/CM

trace.

POS

control should move one

B

VERT. POS control should

and channel B

traces

should

are

the same

these limits

be

displayed

be

b

1

A

VERT. SENSITIVITY

B

VERT. SENSITIVITY to

B VERT. SENSITIVITY VERNIER to CAL.

SWEEP TIME to

VERT. PRESENTATION to B

Connect the “reference oscillator” to

2)

tnnel

A

cha

Set “reference

3)

out

put for

Switch VERT. PRESENTATION

4)

:tion should

flec

Set

5)

n

ti01

and channel B input terminals.

5

cm

A&

B VERT. SENSITIVITY to 1 V.

should

be

of

deflection.

be

less

less

0.5

oscillator”

than

to

10

VOLTS/CM

10

VOLTS/CM

MILLISECONDS/CM

to 2 kc and adjust

to

B-A.

than

0.1

cm.

1.0

cm.

both

the

De-

Deflec-

HORIZONTAL AMPLIFIER SENSITIVITY

G.

1) Set HORIZ SENS to

HORIZ SENS VERNIER to CAL

VERT PRESENTATION to

DC-AC (horizontal input coupling) to

2) Connect the “calibration generator”,

1.0

volts 4WPTP to the horizontal input terminals. Adjust the position controls to center the

horizontal

(9.5-

AMPLIFIER section

3)

Check the dc response by switching

dc voltage from the “calibration generator”

and on.

CRT “spot” should shift

VERT. POS.

trace.

10.5

cm). If not,

As

the voltage

as

necessary.

.1

VOLTS/CM

A

The trace should

refer

of

the maintenance procedure.

is

switched

10

be

10

to the HORIZONTAL

off

and on, the

cm

*5%.

set

*5%

a

0.1

Adjust

DC

for

long

volt

off

A

Page 33

Sect. IV Page

4)

Check the accuracy of the remaining VOLTS/CM

positions as given

Sensitivity

Volts/cm

.1

1

4

in

the

following table:

Voltage for 10 ( 5%) cm Deflection

Peak/Peak RMS

1.0 0.3535

10.0 3.535

Model 122A

vertical input.

~

with the

6)

7)

lator” until the pattern goes out of synchronization.

The reading on

0.885 volts or

“reference

Set SYNC switch to EXT.

Decrease the amplitude of the “reference oscil-

Monitor the

vtvm”.

the

“reference vtvm” should be

less.

sine

wave

amplitude

10

H.

HORIZONTAL AMPLIFIER BANDWIDTH

1) Set HORIZ SENS to

TRIGGER LEVEL to AUTO

Connect the “reference oscillator” to the

2)

cilloscope horizontal input terminals. Monitor

the

sine

3) Adjust the remaining oscilloscope controls

display the horizontal trace.

4)

Set the “reference oscillator” to 2 kilocycles

and adjust for 10 cm

on “reference vtvm”.

5) Set “reference oscillator” to

Set output to previous reading on “reference vtvm”.

The deflection should now be at least

down point).

AMPLIFIER section

I.

SWEEP GENERATOR TRIGGERING

1)

Set SYNC to INT

TRIGGER LEVEL to AUTO

A

A

VERT PRESENTATION to

2) Connect the

approximately 0.5

scope vertical input.

3)

Adjust remaining oscilloscope controls to dis-

play a

4)

lator” until the pattern

The pattern should

5)

synchronization terminals and the oscilloscope

few

Decrease the input from the

Connect

I

100.0 35.35

I

.1

VOLTS/CM

os-

wave amplitude with the “reference vtvm”

of

deflection. Note reading

200

kilocycles.

7.07

cm (3 db

If

not,

refer

to the HORIZONTAL

of

the maintenance procedure.

VERT SENSITIVITY to

VERT SENSITIVITY VERNIER to CAL

“reference

v

rms,

400

cycles of signal.

goes

be

0.5 cm high or

“reference

oscillator” to the external

0.1

VOLTS/CM

A

oscillator”, set for

cps, to the oscillo-

“reference

out of synchronization.

oscil-

less.

to

If the oscilloscope fails to meet either check,

to the TRIGGER GENERATOR section of the maintenance procedure.

J.

INTERNAL SWEEP TIME

1

1)

.

2) Connect

to the oscilloscope vertical input. Set “marker

generator” for 1/1,000 sec of a

period.

display the signal

to-peak deflection of

signal should produce 10 cycles

cm of horizontal deflection.

3)

checked using

step. Table 4-2 provides complete information on

selector position, frequency or period of the timing

signal and cycles of the signal produced in 9.5-10.5

cm of horizontal deflection.

does not meet these checks,

GENERATOR section of the maintenance procedure.

K.

1)

2)

to the oscilloscope vertical input. Set “marker

generator” for 1,00O/sec.

Ad just remaining oscilloscope controls to display

the

deflection of

produce 10 cycles

zontal deflection.

SWEEP TIME to

Set

SWEEP TIME VERNIER to CAL

SYNC to INT

TRIGGER LEVEL to AUTO

SWEEP EXPAND to

the

output of the “marker generator”

Adjust remaining oscilloscope controls to

with

a vertically centered peak-

4

Each step of the SWEEP TIME/CM selector

the

method outlined

EXPANDED SWEEP CALIBRATION

Set SWEEP TIME to 1 MILLISECONDS/CM

SWEEP TIME VERNIER to CAL.

SYNC. to INT.

TRIGGER LEVEL to AUTO.

SWEEP EXPAND to

Connect

signal with a vertically centered peak-to-peak

the

output of the “marker generator”

4

to 6 centimeter. This signal should

in

10 (55%) centimeters of hori-

MILLISECONDS/CM

X1

1

millisecond

to 6 centimeters. This

in

10 *5% (9.5 - 10.5)

in

the previous

If

your oscilloscope

refer

to the TRIGGER

X1

or

a 1 millisecond period.

refer

is

Page 34

Model

122A

Sect. IV Page

5

SWEEP TIME/CM

Position

*200

MILLISECONDS

100

MILLISECONDS

50

MILLISECONDS

20

MILLISECONDS

10

MILLISECONDS

5

MILLISECONDS

2

MILLISECONDS

1.

MILLISECONDS

.5

MILLISECONDS

200

MICROSECONDS

100

MICROSECONDS

50

MICROSECONDS

20

MICROSECONDS

TABLE

Frequency

1

10

10

10

100

100

100

1,OOO

1,000

1,OOO

10

10

10

4-2.

SWEEP TIME ACCURACY

Timing Signal

cycle

cycles

cycles

cycles

cycles

cycles

cycles

cycles

cycles

cycles

kilocycles

kilocycles

kilocycles

Period

1

second

100

milliseconds

100

milliseconds

100

milliseconds

10

milliseconds

10

milliseconds

10

milliseconds

1

millisecond

1

millisecond

1

millisecond

100

microseconds

100

microseconds

100

microseconds

Cycles Produced in

9.5

to

10.5

cm

2

10

5

2

10

5

2

10

5

2

10

5

2

10

MICROSECONDS

5

MICROSECONDS

*

Use

DC

input coupling

3)

Set SWEEP EXPAND switch

plete

cycles should now appear in

neters

4-3

Disconnect power cord and remove

screws on the

front panel

3ut

[f

moved, dangerous voltages

of

horizontal deflection.

REMOVING THE CABINET

rear

screws.

of

cabinet.

the instrument

is

to

avoid degrading input signal.

of

cabinet.

Slide oscilloscope forward

CAUTION

operated with the cabinet

are

100

100

to

X5.

10

Do

not remove any

exposed. Take

kilocycles

kilocycles

Two

com-

(fig)

centi-

two

large

re-

10

microseconds

10

microseconds

adequate safety precautions, especially when working around the cathode-ray tube terminals and the

power

4-4

In many

rected by replacing a weak

fore

ment, check the tubes. Adjustments that

in an attempt

will often complicate the

It

rather than by use

supplies.

TUBE REPLACEMENT

cases

instrument malfunction can

changing the setting

to

compensate

is

good practice

to

of

check

a

10

5

or

defective tube. Be-

of

any internal adjust-

for a defective tube

repair

problem.

tubes

“tube

by substitution

checker”. The

be

are

cor-

made

Page 35

Sect. IV Page 6

Model 122A

results obtained from the "tube

misleading. Before removing

that

if

the tube

same socket. Replace only tubes proved to be which should

weak or defective. replaced.

CIRCUIT

REFERENCE

I

4301

4302

is

good it can

TABLE 4-3.

v1

v2

v3

v4

v5

V6

v7

V8

v9

VlOl

v102

v201

v202

V203

V204

v205

V301

V302

V303

&

V304

V305

V306

V307

V308

V309

V310

checker"

a

tube, mark it

be

returned to the The following table lists the tests and adjustments

TUBE

TUBE OR TRANSISTOR

TYPE

CTPl113 Regulator

2N383 Amplifier

12AU7 Vert. Input Amp.

12AU7 Vert. Amp.

6DJS/ECC88 Output Amp.

12AU7 Vert. Input Amp.

12AU7 Vert. Amp.

6DJ8/ECC88 Output Amp.

6DJ8/ECC88 Switching Amp.

12AU7 Switching Multivibrator

6AU6 Switching Amplifier

6DJ8/ECC88 Horiz. Amp.

12AT7 Output Amplifier

6AN8 Trigger Generator

6U8 Start-Stop Trigger

12AU7 Gate and Hold-off

12AU7 Integrator Switch

6U8 Sawtooth Integrator

12AU7 Amplifier

6AQ5 Oscillator

5642

5AQP- Cathode-Ray

12B4A Regulator

6U8 Amp.- Output

12B4A Regulator

6AU6 Amplifier

5651

AND

Cathode-Follower.

H.

V.

Cathode-Follower

Reference

can be Any tube with corresponding standard EIA (JEDEC)

so

&

TRANSISTOR REPLACEMENT CHART

FUNCTION

characteristics can

Check+ 24 volt power supply output.

Same as 4301.

Check Vertical Balance and Gain.

Same as

Check Vertical Gain and Balance.

Same as

Same as

Same as

None.

None.

None.

Entire Horiz. Amp. test procedure ex-

cept Attenuator Compensation.

Same as V101.

Check Trigger Generator.

Check Sweep Stability Control Adj.

None.

Hum Balance.

None.

Check

Same as V301.

Rectifier

Tube

Same as V301.

See adjustments under

check Vert. and Horiz. Gain.

Check +380 volt

Check+380 and +lo0

Check -150 volt output voltage.

Same as V308.

Same as V308.

be

used as a replacement.

be

performed after the tubes are

TESTS

AND/OR

V1.

V1.

V1.

ADJUSTMENTS

V3.

H.

V.

Power Supply Output.

TURN

power

supply output.

v

output voltages.

ON

and

Page 36

Model

122A

Sect.

IV Page

7

)

4-5

Ci

time

that

w:

is

imp

any inti

only

a

A.

CH:

-

All

ac

ments

cor

and

ti

If the

1)

Che

of the

usually

Check

B. CHI

-

Check

4-9

PC

refer

tc

and

Ta

MENT

C. CHI

-

TROUBLE-SHOOTING PROCEDURE

1

del

122A Oscilloscope

isic

sections

an

be

minimized by following a procedure

ill

isolate

to

Irtant

ernal adjustments. In the majorityof

tube change

I

ECK AC POWER CIRCUIT

power

will

light with the instrument turned on

inected

ubes

will

ck the power line

Ehassis. The cause

be

found in the

silicon

ECK

DC

dc voltages

)WER SUPPLIES. If you replace any tubes

3

Table 4-3 TUBE REPLACEMENT CHART

ble 4-4 CONDENSED TEST AND ADJUST-

PROCEDURE.

ECK HIGH VOLTAGE CIRCUITS

or

the section needing

isolate the problem before changing

will

be

circuits

to

not light:

a

suitable

are

rectifiers,

LOW VOLTAGE CIRCUITS

as

described under paragraph

is

composed

circuits. Repair and

of

repair.

cases,

required.

normal if any tube