Hoyt NA5 User Manual

ONE-CHANNEL

DIGITAL-TO-ANALOGUE METER

WITH A MULTICOLOURED

BARGRAPH AND A SERIAL

INTERFACE

NA5 TYPE

USER’S GUIDE

2

3

CONTENTS Page

1. APPLICATION .............................................................................................5

2. SET OF THE METER ..................................................................................6

3. BASIC REQUIREMENTS, OPERATIONAL SAFETY .................................. 7

4. INSTALLATION ............................................................................................ 9

5. SERVICING ...............................................................................................13

6. RS-485 INTERFACE .................................................................................31

7. TECHNICAL DATA .....................................................................................49

8. BEFORE A FAILURE HAS BEEN DECLARED .........................................53

9. EXAMPLES OF NA5 METER PROGRAMMING ....................................... 55

10. ORDERING PROCEDURE .......................................................................58

11. MAINTENANCE AND GUARANTEE ......................................................... 60

One-channel digital-to-analogue meter

with multicoloured bargraph and a interface

NA5 TYPE

USER’S GUIDE

4

5

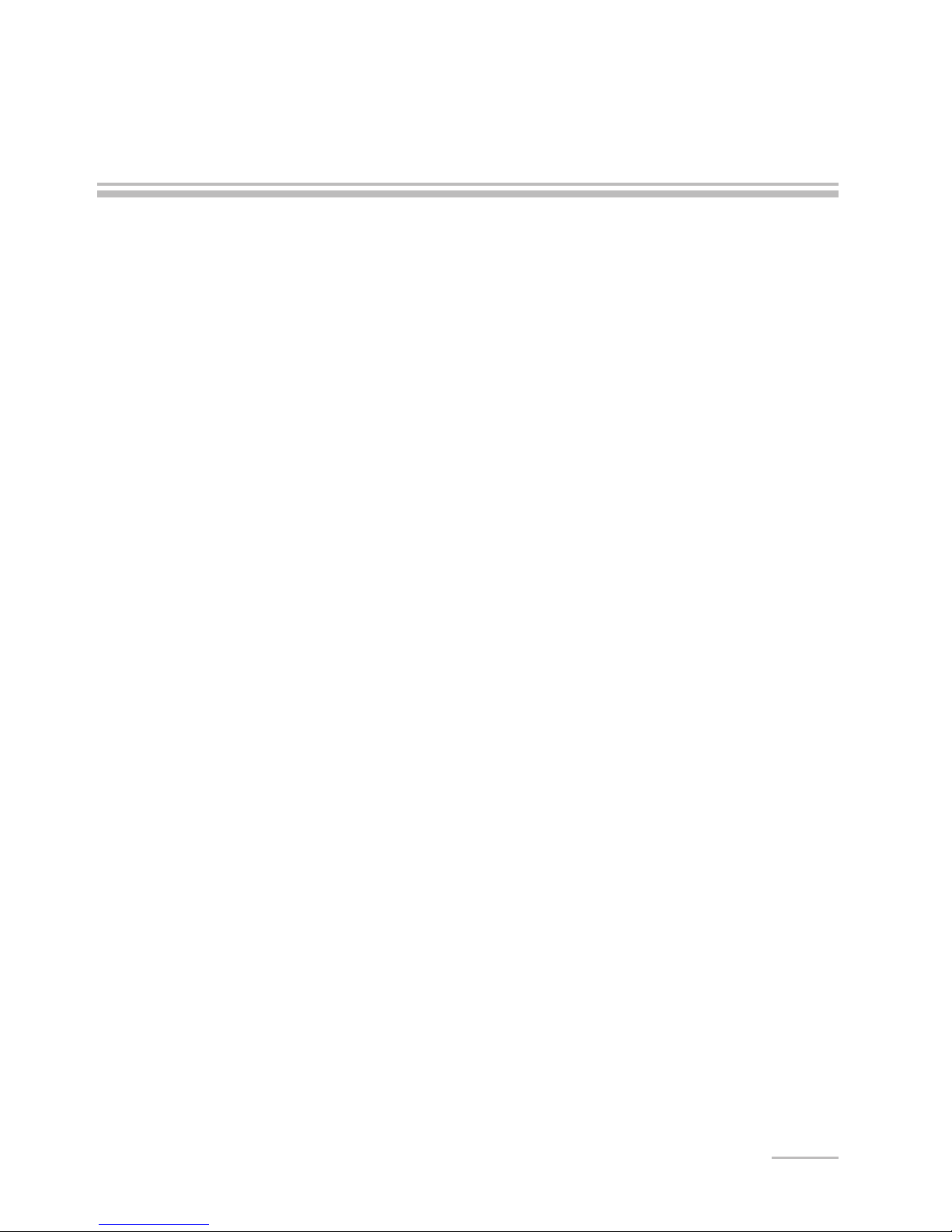

1. APPLICATION

NA5 series meters with multicoloured bargraphs have an universal input destined to measure temperature, resistance, voltage from shunts, standard signals,

d.c. voltage and d.c. current.

They can find application in various industrial fields, e.g. food industry, intermediate

pumping stations, sewage treatment plants, chemical industry, weather stations,

breweries.

They are destined for the visualisation of the measured value and evaluation of

change trends of checked technological processes. They can also find application

in automation systems where programmed controllers are applied.

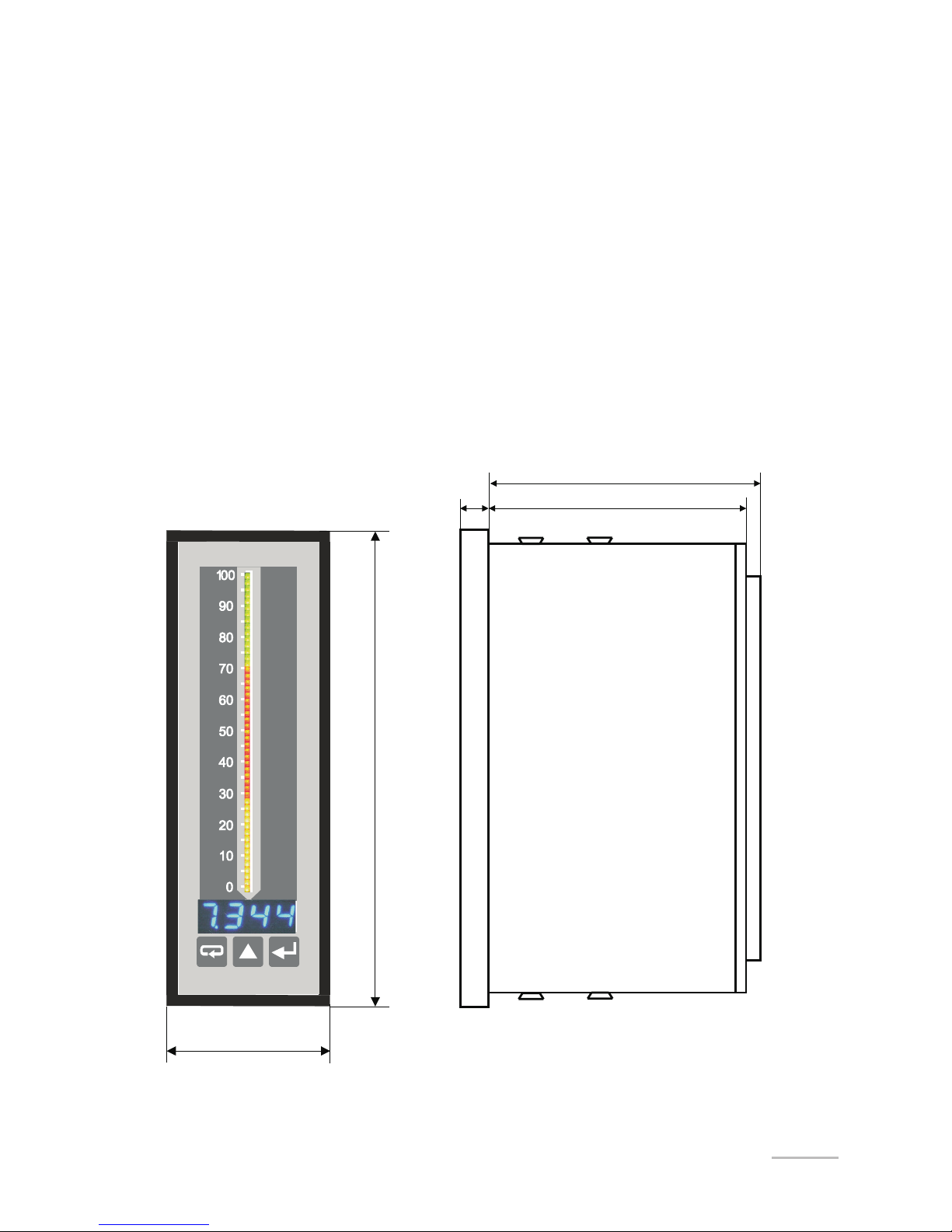

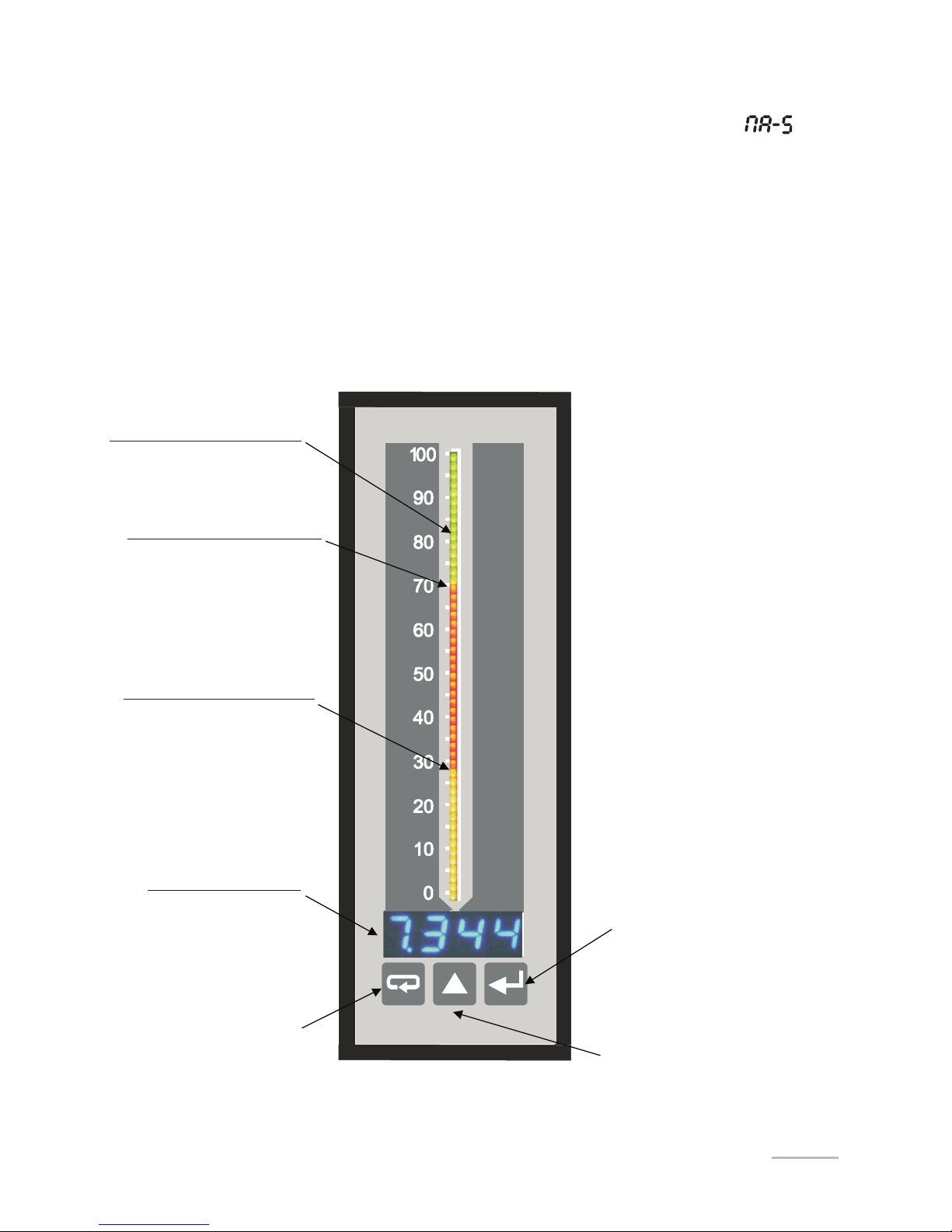

Fig.1. View of the NA5 meter.

6

NA5 meters can have in option: a continuous analogue output, a relay output, open

collector (OC) type outputs and an RS-485 digital output.

They are programmed by means of the keyboard and through RS-485.

NA5 meters realise following functions:

– measurement of the input quantity and displaying it on the display and the

bargraphs,

– recounting of the input signal into indication on the base of the individual

linear characteristic,

– arithmetical functions: raising to a power, extraction of roots,

– programming of colours and bargraph resolutions,

– signalling of alarm value setting exceedings,

– recording of the measured signal in programmed time segments,

– storage of maximal and minimal values,

– programming of the measurement averaging time,

– programming of the indication resolution,

– deadlock of the parameter introduction by means of a password,

– conversion of the measured quantity into a voltage or current output signal,

– service of the RS-485 interface in MODBUS protocol, both in ASCII

and RTU mode.

2. SET OF THE NA5 METER

We deliver in the set:

- NA5 meter 1 pc.

- user’s guide 1 pc.

- guarantee card 1 pc.

- plug with screw terminals 1 or 2 pcs (depending on execution)

- holders to fix the meter in the panel 2 pcs

- set of stickers with units 1 pc.

When unpacking the meter, please check whether the type and execution code

on the data plate correspond to the order.

7

3. BASIC REQUIREMENTS, SAFETY INFORMATION

Symbols located in this service manual mean:

WARNING!

Warning of potential, hazardous situations. Especially important. One must

acquaint with this before connecting the NA5 meter. The non-observance

of notices marked by these symbols can occasion severe injuries of the

personnel and the damage of the instrument.

CAUTION!

Designates a general useful note. If you observe it, handling of the meter is made easier. One must take note of this when the instrument is

working inconsistently to the expectations.

Possible consequences if disregarded !

In the security scope the meter meets the requirements of the EEC

Low-Voltage directive (EN 61010 -1 issued by CENELEC).

Remarks concerning the operator safety:

1. General

The NA5 meter is destined to be mounted on a panel.

Non-authorized removal of the required housing, inappropriate use, incorrect

installation or operation creates the risk of injury to personnel or damage to

equipment. For more detailed information please see the user’s guide.

All operations concerning transport, installation, and commissioning as well as

maintenance must be carried out by qualified, skilled personnel and national

regulations for the prevention of accidents must be observed.

According to this basic safety information, qualified, skilled personnel are

persons who are familiar with the installation, assembly, commissioning, and

operation of the product and who have qualifications necessary for their

occupation.

2. Transport, storage

Please observe the notes on transport, storage and appropriate handling. Observe

the climatic conditions given in Technical Data.

3. Installation

The NA5 meter must be installed according to the regulation and instructions

given in this user’s guide.

8

Ensure proper handling and avoid mechanical stress.

Do not bend any components and do not change any insulation distances.

Do not touch any electronic components and contacts.

Instruments may contain electrostatically sensitive components, which can easily

be damaged by inappropriate handling.

Do not damage or destroy any electrical components since this might

endanger your health!

4. Electrical connection

Before switching the meter on, one must check the correctness of connection

to the network.

In case of the protection terminal connection with a separate lead one must

remember to connect it before the connection of the instrument to the mains.

When working on live instruments, the applicable national regulations for the

prevention of accidents must be observed.

The electrical installation must be carried out according to the appropriate

regulations (cable cross-sections, fuses, PE connection). Additional

information can be obtained from the user’s guide.

The documentation contains information about installation in compliance with

EMC (shielding, grounding, filters and cables). These notes must be observed

for all CE-marked products.

The manufacturer of the measuring system or installed devices is responsible

for the compliance with the required limit values demanded by the EMC

legislation.

5. Operation

Measuring systems including NA5 meters must be equipped with protection

devices according to the corresponding standard and regulations for

prevention of accidents.

After the instrument has been disconnected from the supply voltage, live

components and power connections must not be touched immediately because

capacitors can be charged.

The housing and the door must be closed during operation.

6. Maintenance and servicing

Please observe the manufacturer’s documentation.

Read all product-specific safety and application notes in this user’s guide manual

9

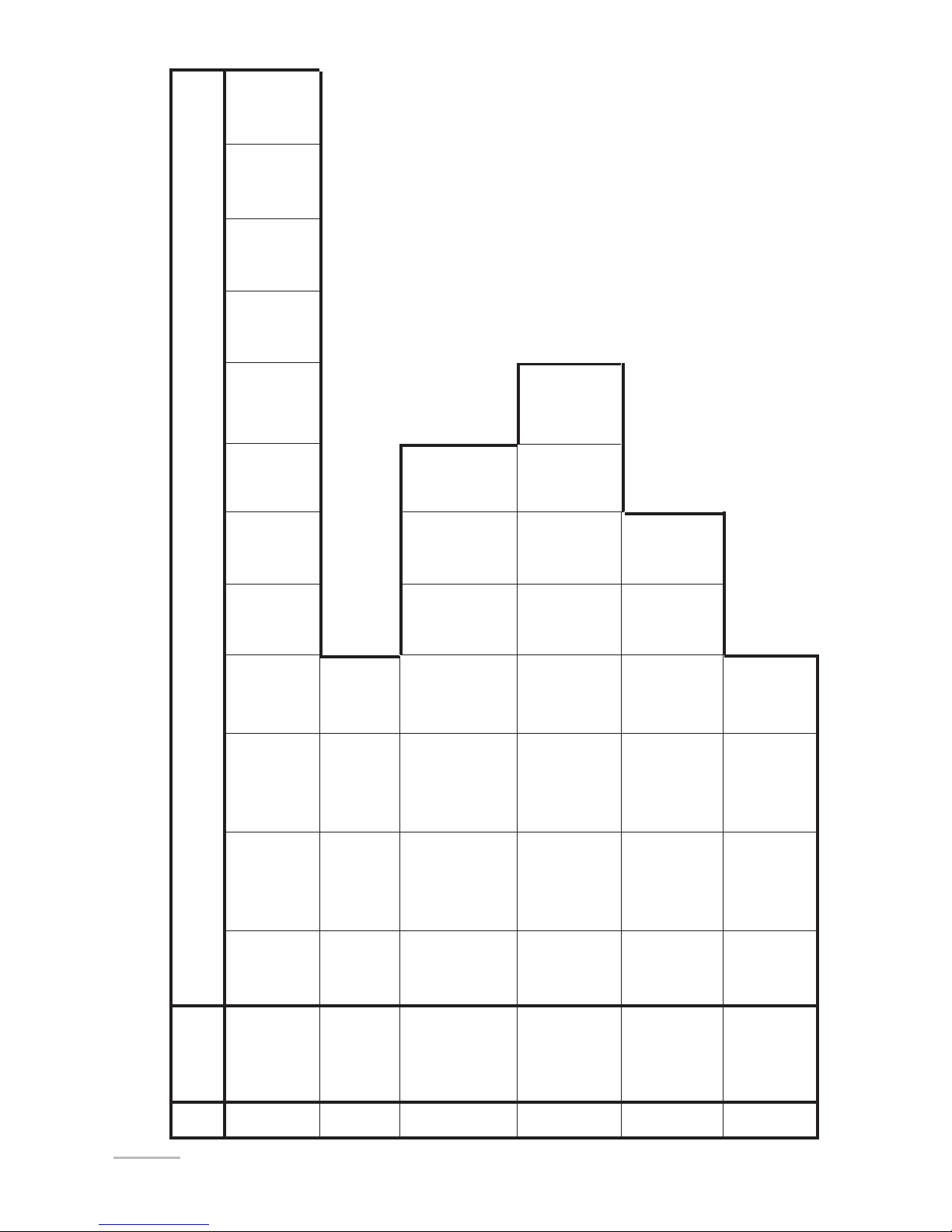

Fig. 2. Meter overall dimension

Before taking the meter housing out, one must turn the supply off.

The removal of the instrument housing during the guarantee contract period

may cause its cancellation.

4. INSTALLATION

4.1. Fitting

Prepare a (44

+0.5

x 137.5

+0.5

) mm hole in the panel. The thickness of the material

from which the panel is made should be in the range 1...45 mm.

The meter has screw terminal strips which enable the connection of 2.5 mm

2

cross-

section external conductors.

Meter dimensions are shown on the fig. 2.

48

144

77

max92

8

10

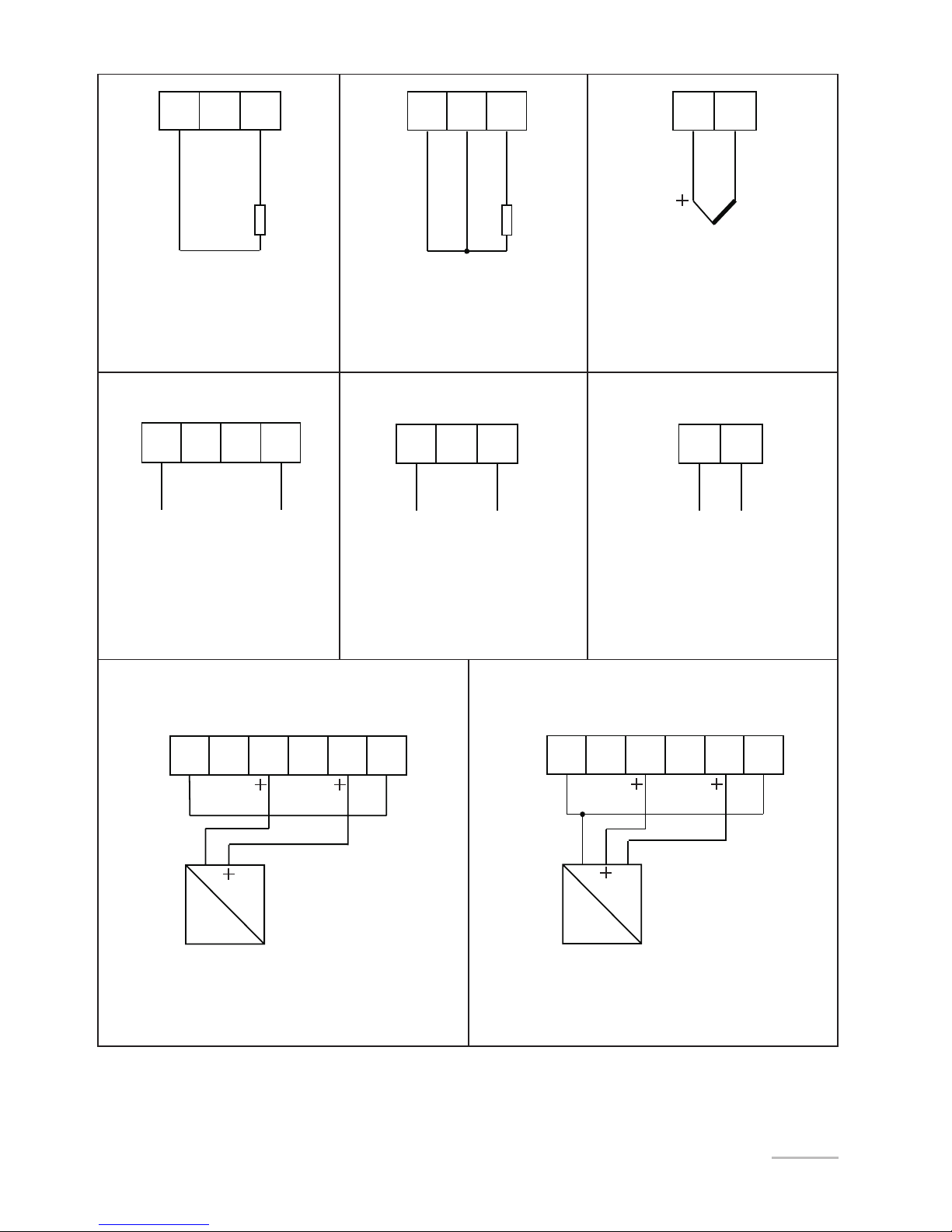

4.2. External connection diagrams

The description of terminal strips are shown on the fig. 3a.

Connections of input signals are shown on the fig 3b and output signals on fig.

3c and 3d.

The meter has programmable inputs. Maximal measuring ranges are given on

figures.

a/ Description of the terminal strip

6

1

2

5

3

4

12

7

8

11

9

10

15

14

13

21

17

20

18

19

27

22

23

26

24

25

30

29

28

1632

31

A1

A3

A5

A7

RS-485

A

B

GND

A2

A4

A6

A8

A1

A3

A5

A7

GND

E

Resistance thermometer

Power supply

Analogue

output

8 OC outputs

4 rela outputs

Supply of object

transducers

24Vd.c.

GND

5A

40 mA

600 V

Thermocouple or 300 mV

voltage from shunt

11

5 A current input

b/ Connection way of input signals

Resistance thermometer

in two-wire system or

resistance measurement

Resistance thermometer

in three-wire system

Thermocouple

or

300 mV voltage

600 V voltage input 40 mA current input

Two-wire object transducer

Three-wire object transducer

321

321

32

-

543 6

543

43

-

-

-

-

145 133

-

-

-

-

145 133

S

40 mA 40 mA

24 V d.c. 24 V d.c.

GND

600 V

GND GND

40 mA 5 A

12

Taking into consideration electromagnetic interference it is recommended to use

shielded conductors for the connection of input and output signals.

The power supply must be connected by means of a two-wire conductor with

a suitable cross-section ensuring its protection by means of an installation fusible

cut-out, in case of a short-circuit. Requirements concerning the supply cable are

regulate by EN 61010-1 p.6.10 standard.

Fig.3 External connections of the NA5 meter

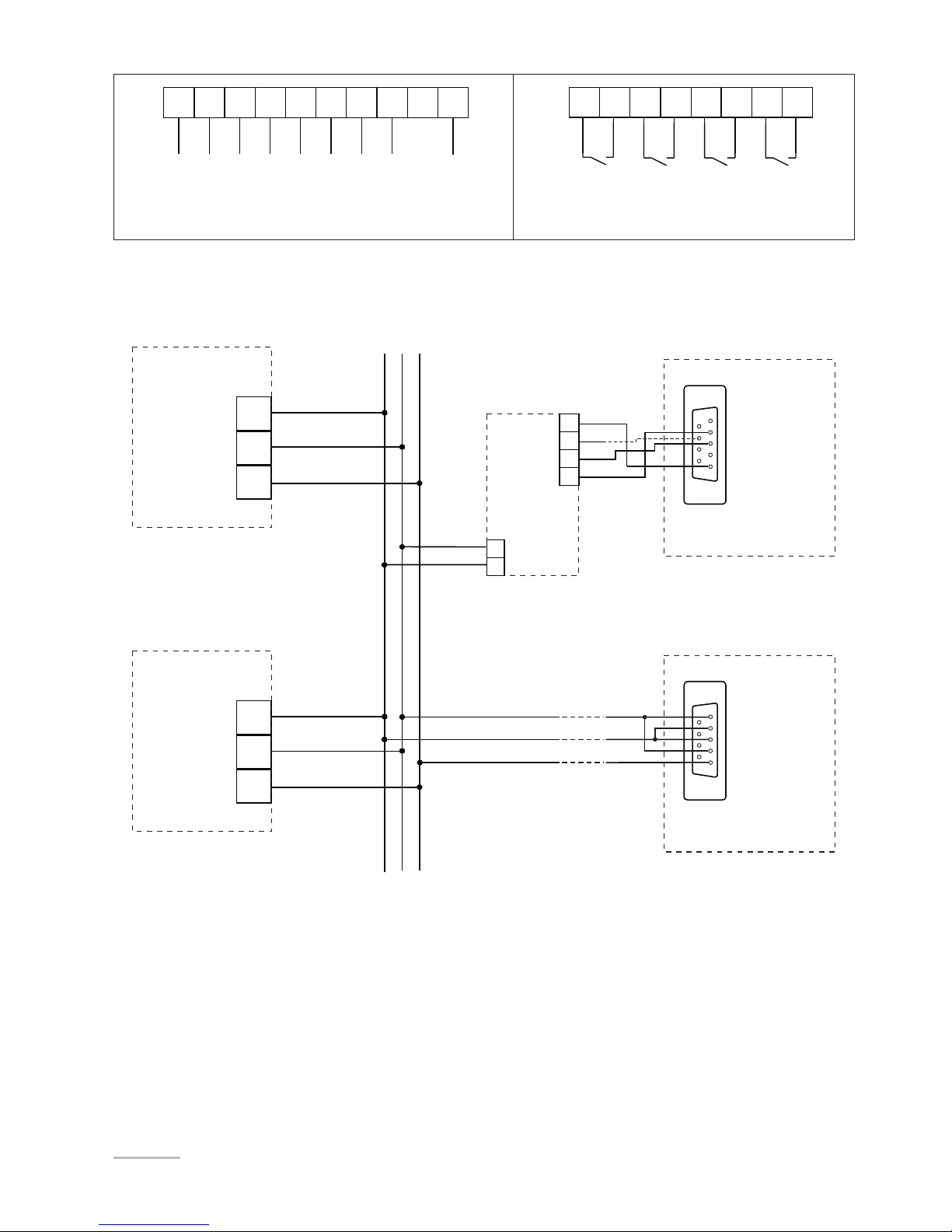

8 outputs of OC type

4 relay outputs

c/ Connection way of digital and analogue output signals depending on the

execution code

27 2326 242530 29 2832 31

A1 A2

A3 A4 A5 A6 A7 A8 GND

27 26 2530 29 2832 31

A1

A3 A5 A7

...

A

GND

B

B

A

GND

GND

A

B

RTS

RxD

TxD

DB9

6

1

9

5

DB9

6

1

9

5

19

17

18

NA5 Meter

19

17

18

NA5 Meter

IBM PC computer

IBM PC computer

with an RS-485 card

10

11

12

13

8

9

PD5

d/ Connection way of the RS-485 interface

13

5. SERVICING

After connecting external signals and switching the meter on, its name and

also the current version of the program, e.g.

n100. are displayed.

After ca 3 seconds, the meter transits automatically into the working mode in which

it carries out the measurement and the display of the measured value on the display

and the bargraph.

Depending on alarm parameter settings, the resolution and bargraph type, alarm

thresholds are also displayed on the bargraph.

The meter blanks automatically insignificant zeros.

Key functions:

Fig. 4 Description of the NA5 frontal plate.

55-element bargraph (in

three-colour execution)

Upper alarm threshold

Lower alarm threshold

Display

Escape key

Acceptation key

Value increasing key

29-element bargraph (in

seven-colour execution)

14

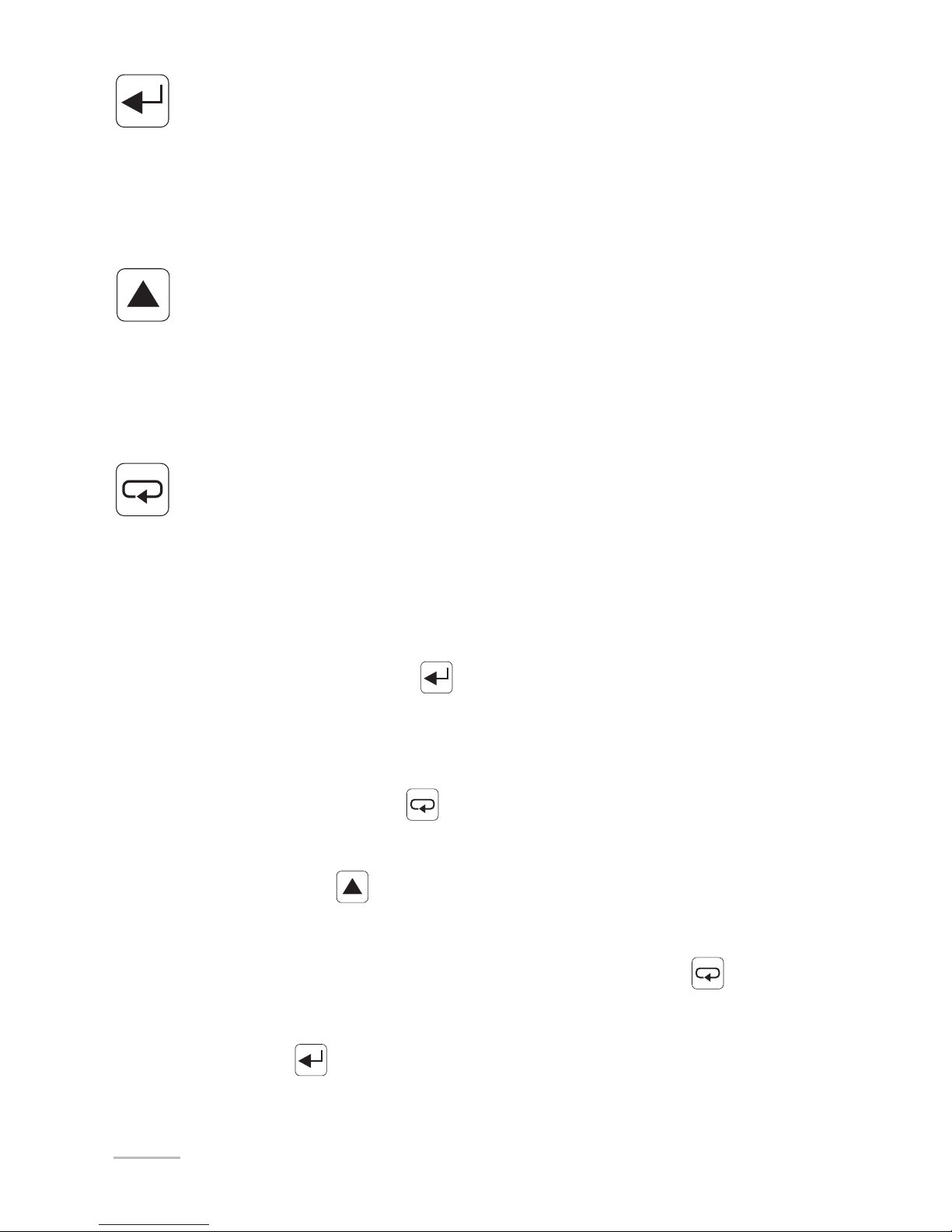

- acceptation key

- entry into the programming mode (hold down during ca 3 seconds),

- entry into the chosen parameter level,

- entry into the changing mode of the parameter value,

- acceptation of the changed parameter value.

- Key to increase the value

- display of the minimal value (first pressure), maximal (second pressure),

return to measurement (third pressure),

- mowing on the preview menu or programming matrix,

- change of the chosen parameter value - increasing of the value.

- Escape key

- entry into the menu of recording results,

- entry into the preview menu or programming matrix,

- exit from the preview menu or programming matrix,

- escape from the parameter change.

The pressure and hold down the

key during 3 seconds causes the entry into

the programming mode. The programming mode is protected by the seC safety

code.

The pressure and hold down the

key during 3 seconds causes the entry into the

preview menu and the menu of recorded values. One must move on the preview

menu by means of the key. In this menu, only all programmed parameters

except servicing parameters, are accessible to readout.

The exit from the preview menu is operated by means of the key. It is also

possible in the preview menu to review recorded resl values.

The pressure of the key on the resl parameter causes the entry into the pre-

15

view menu of recorder values. The recorded result number is displayed alternately

with the value e.g. n320/2174.

The moving on recorded values follows by means of the key. The pressure of

this key longer than ca 2 seconds will cause the acceleration of the review. The

pressure of the key in any moment will cause the lighting of the number of

recorded results. The exit from the review of recorded values is operated by means

of the key.

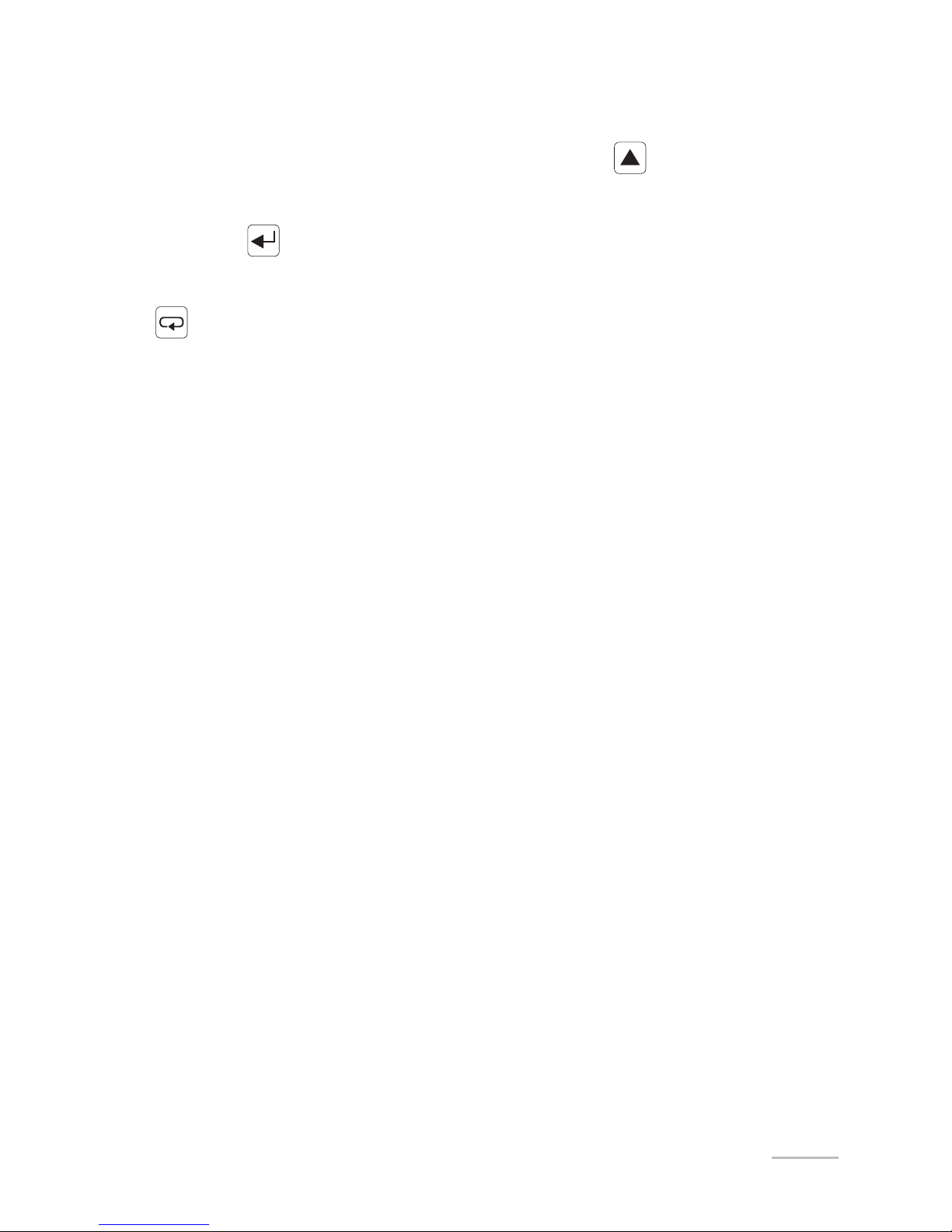

The algorithm of the meter servicing is presented on the fig. 5.

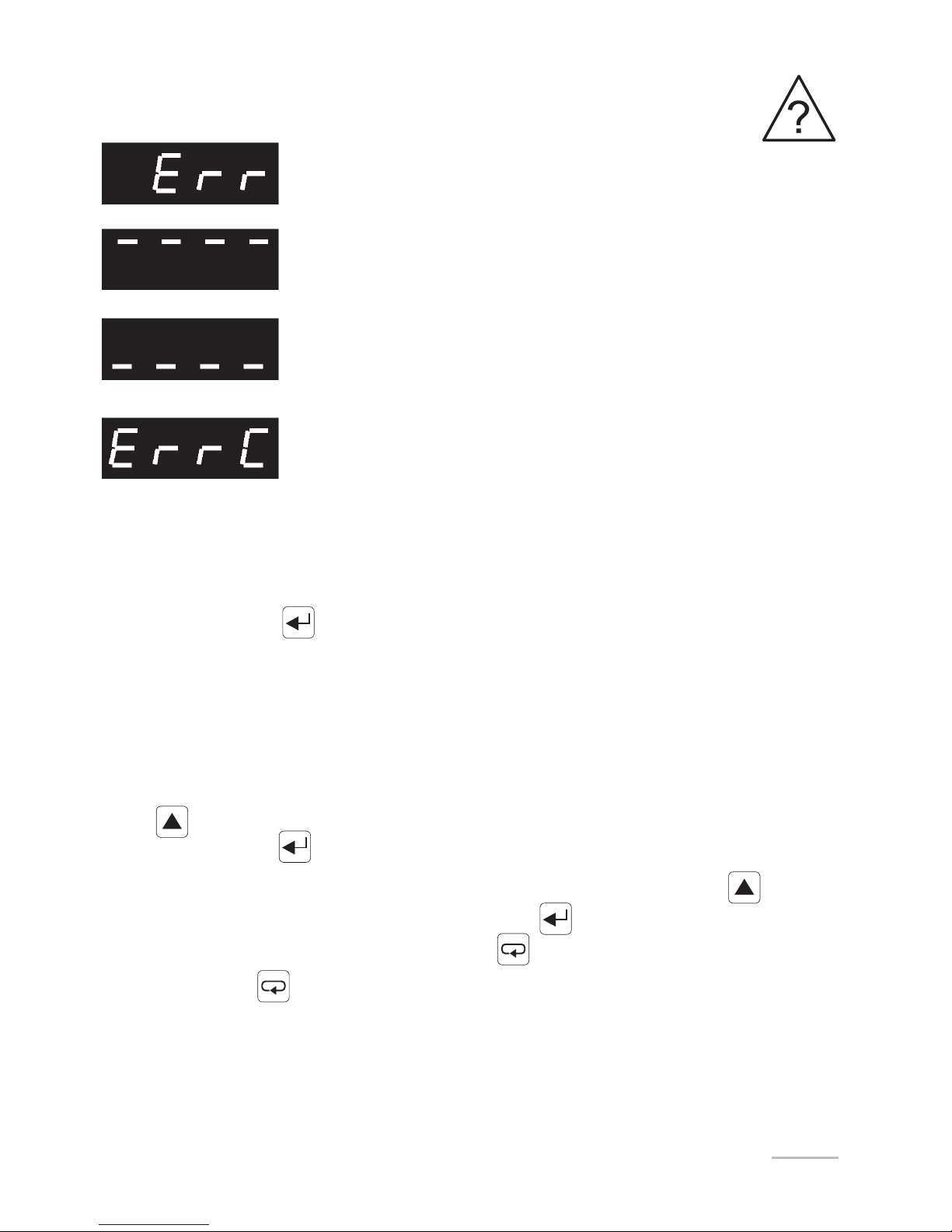

The appearance of the following symbols and inscriptions on the

display means:

16

Fig 5. Servicing algorithm of the NA5 meter.

3 sec

3 sec

-

Display of

the minimal

value

Measurement

Display of

the maximal

value

Password

introduction

mode

Programming

matrix

Check

the

password

Erasing

of alarm

outputs

Preview

menu

Moving on the

preview menu

Moving on the

matrix

Exit from the matrix

- Entry into the selected level

- Entry into parameter changes

Incorrect

Correct

Display of the

inscription

Monitoring of programmable

meter parameters

Monitoring of recorded

measured values

17

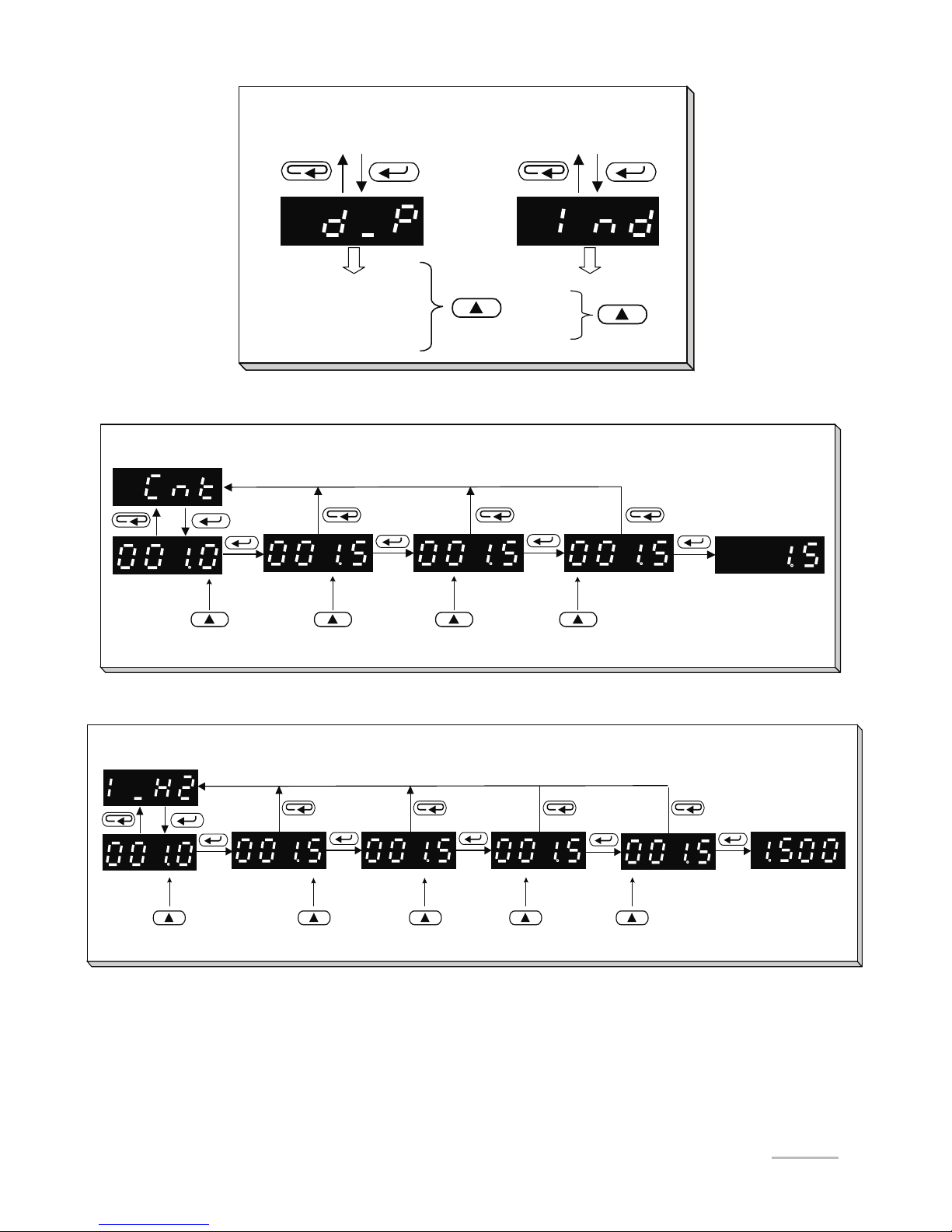

It is possible to change meter parameters:

- from the meter keyboard ( p 5.1)

- through RS-485 (p.6.)

5.1. Change of the NA5 meter parameters from the keyboard

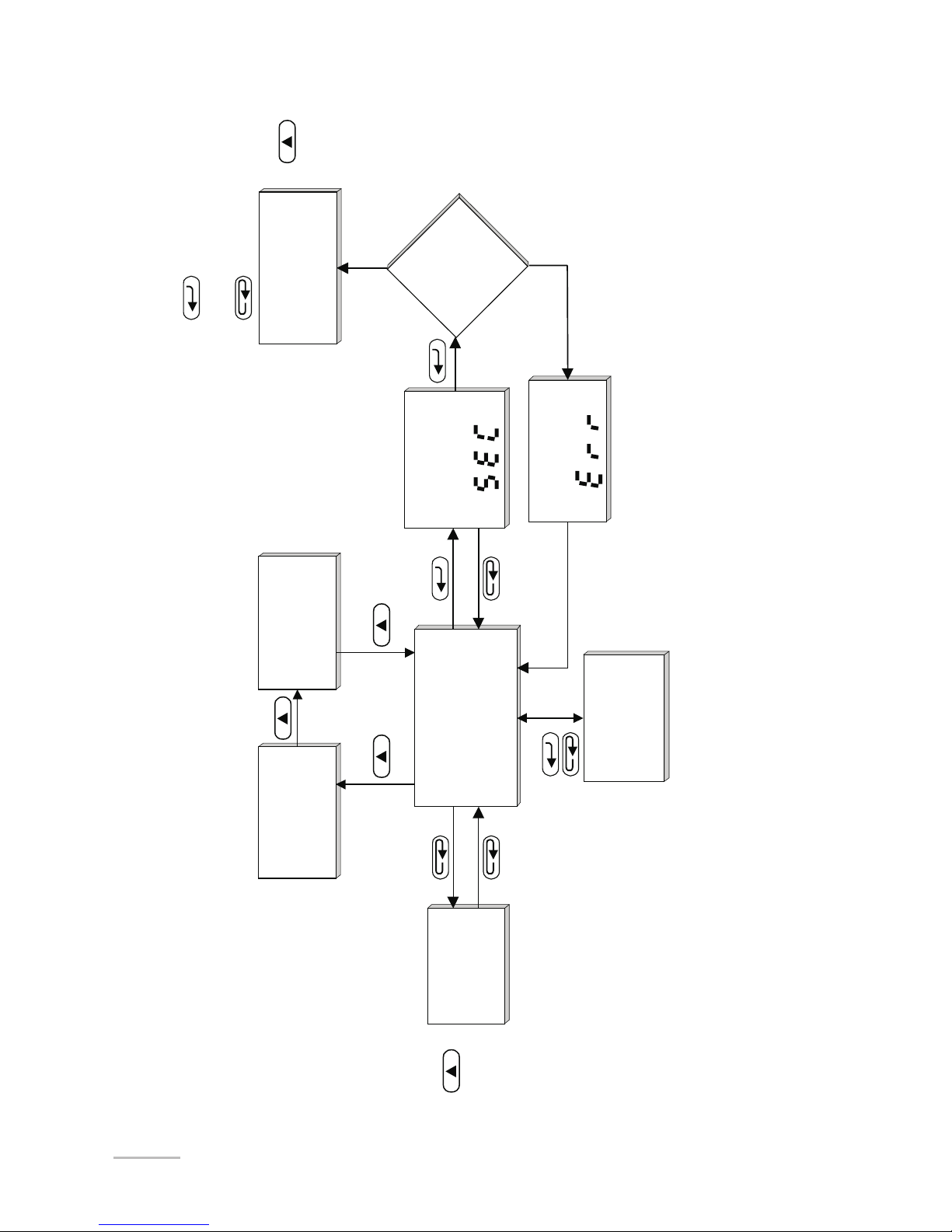

The pressure of the key during circa three seconds causes the display

of the seC.

Inscription alternately with the set zero value by the manufacturer. The intro-

duction of the correct code causes the entry into the programming mode. The fig.6

represents the transition matrix into the programming mode. One can move on

groups of main parameters eg: Ch1, Ch2, bAr1, bAr2, Al1, Al2, etc, by means

of the key.

The pressure of the key on the given level, causes the entry into parameters of

this level. The moving on the given level is operated by means of the key.

In order to change the value, one must use the key. In order to escape from

the parameter change, one must press the key.

By means of the key, one can exit from the selected level and programming

matrix to the measurement.

Incorrectly introduced safety code

Exceeding of the upper measuring range or

lack of sensor

Exceeding of the lower measuring range or

short-circuited sensor

Error of the conductor resistance compensation. No

connected conductor or damaged conductor.

18

Fig. 6. Transition matrix into the programming

mode

Parameters of the selected level

Lev.

Nr

Main

menu

Bargr.

type

Bargr.

colour

Lower

bargr.

Upper

bargr.

Input

indiv.

charac.

Baud

rate

Kind of

transm.

Device

adress

Param.

inscript.

Passw.

change

Test of

display +

bargr.

Time

change

Erasing

of min.

value

Erasing

of max.

value

Record. Chan.1

record.

start

Upper

threshold

Alarm

delay

Alarm

support

Lower

marker

colour

Upper

marker

colour

Param.

indiv.

charac.

Param.

indiv.

charac.

Param.

of indiv.

charac.

1

2

3

11

12

13

barg

l0gr

Chn

al8

al1

10

ser

0ut

typb

typ

reC

set

Input

type

÷

÷

lo:n

Lower value

of input range

Hi:n

Upper value

of input range

func

Mathem.

func.

Con

Kind of

comp.

d_p

Decim.

point

Cnt

Meas.

time

colr brl brH

prl

Lower

threshold

prH typa

Alarm

type

dly H0ld Curl CurH

:nd0 d_H1 d_H20_y1 0_y2

Param.

of indiv.

charac.

baud tryb adr

seC tst Hour Clrl ClrH

gor1 dat1 :nt1

Chan.1

record.

date

Chan.1

record.

interv.

:nd:

Input ind.

charact.

:_H:

Param.

of ind.

charact.

Param.

of ind.

charact.

d_y: :_H2 d_y2

Param.

of ind.

charact.

Param.

of ind.

charact.

19

0000

000.0

00.00

0.000

Auto

On

Off

Examples of value changing of the

chosen parameter (parameter-symbol)

Change of the

flickering position

Change of the

flickering position

Change of the

flickering position

Blanking of

insignificant

zeros

Change of the

flickering position 0-9, -, -1

Example of value changing of the chosen parameter

without changing of the decimal point (number parameter)

Adjustment

of the decimal

point

Change of the

flickering position

Change of the

flickering position

Change of the

flickering position

Change of the

flickering coma

Change of the

flickering position 0-9, -, -1

Example of value changing of the chosen parameter

with changing of the decimal point (number parameter)

Fig. 7.

Meter programmable parameters are presented in the table 1. The programming of

parameters is possible after the previous introduction of the password.

Loading...

Loading...