Page 1

Operating Instructions

HOB

GB

English,1

ES

Español, 14

PK 741 RQO GH AG

PK 750 RL GH AG

PK 640 RL GH AG

PK 760 RF GH AG

PT

Português, 29

Contents

GB

Installation, 2-6

Positioning

Electrical connection

Gas connection

Data plate

Burner and nozzle specifications

Description of the appliance, 7

Overall view

Start-up and use, 8-10

Practical advice on using the burners

Practical advice on using the the Ceramic Glass

Module

Precautions and tips, 11

General safety

Disposal

Maintenance and care, 12

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Troubleshooting, 13

1

Page 2

Installation

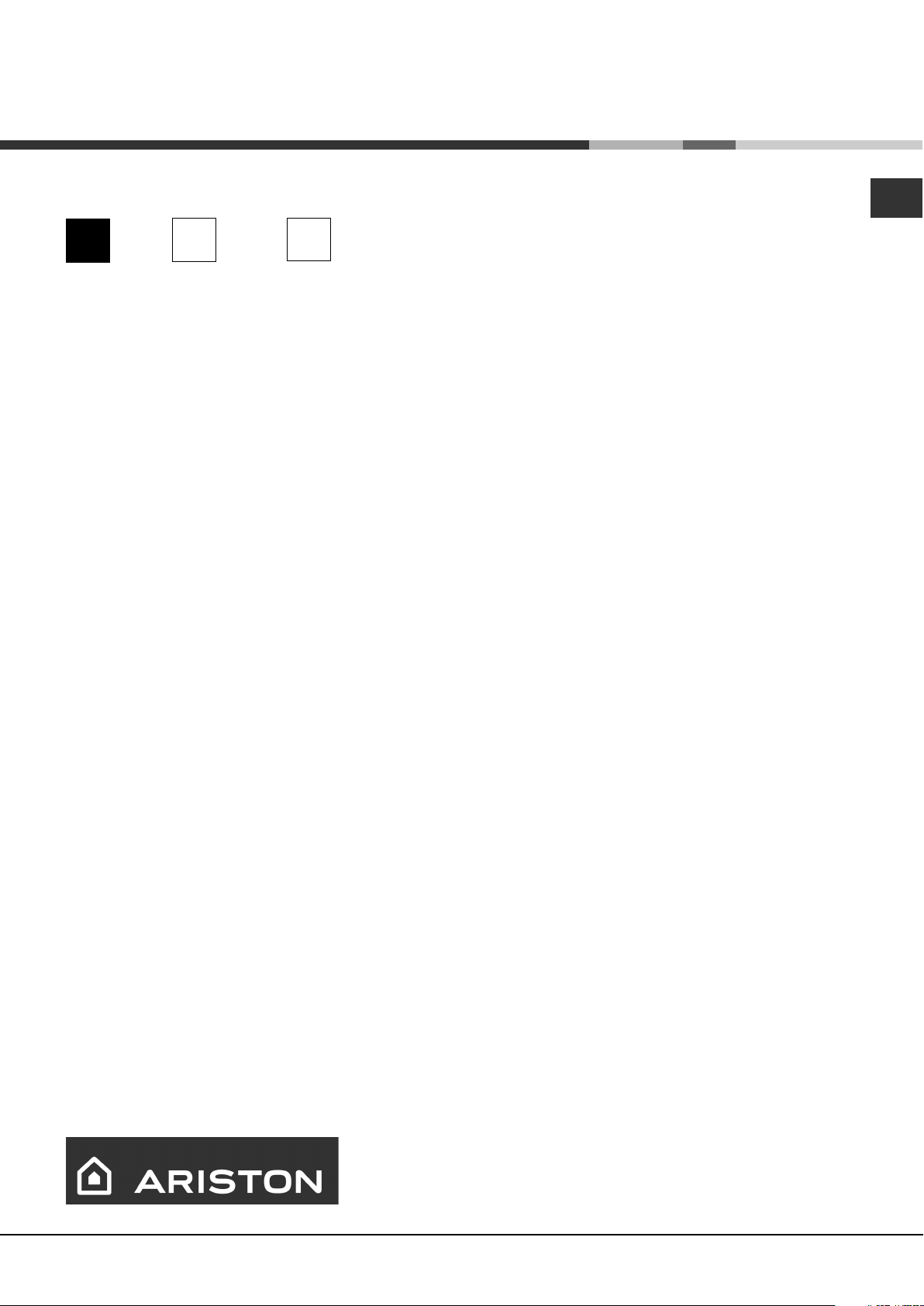

Enlarging the ventilation slot

between window and floor.

Adjacent

Room

Room to be

Vented

A

Examples of ventilation holes

for comburant air.

In a chimney stack or branched flue.

(exclusively for cooking appliances)

Directly to

the Outside

600mm min.

600mm min.

700mm min.

GB

! Before operating your new appliance please read this

instruction booklet carefully. It contains important

information for safe use, installation and care of the

appliance.

! Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

Positioning

! Keep packaging material out of the reach of children. It

can become a choking or suffocation hazard (see

Precautions and tips).

! The appliance must be installed by a qualified

professional according to the instructions provided.

Incorrect installation may cause harm to people and

animals or may damage property.

! This unit may be installed and used only in permanently

ventilated rooms in accordance with British Standard

Codes Of Practice: B.S. 6172 / B.S. 5440, Par. 2 and B.S.

6891 Current Editions. The following requirements must be

observed:

• The room must be equipped with an air extraction

system that expels any combustion fumes. This may

consist of a hood or an electric fan that automatically

• Liquid petroleum gas sinks to the floor as it is heavier

than air. Therefore, rooms containing LPG cylinders

must also be equipped with vents to allow gas to

escape in the event of a leak. As a result LPG

cylinders, whether partially or completely full, must not

be installed or stored in rooms or storage areas that are

below ground level (cellars, etc.). It is advisable to

keep only the cylinder being used in the room,

positioned so that it is not subject to heat produced by

external sources (ovens, fireplaces, stoves, etc. ) which

could raise the temperature of the cylinder above 50°C.

Fitting the appliance

Gas and mixed hobs are manufactured with type X

degree protection against overheating. The following

precautions must be taken when installing the hob:

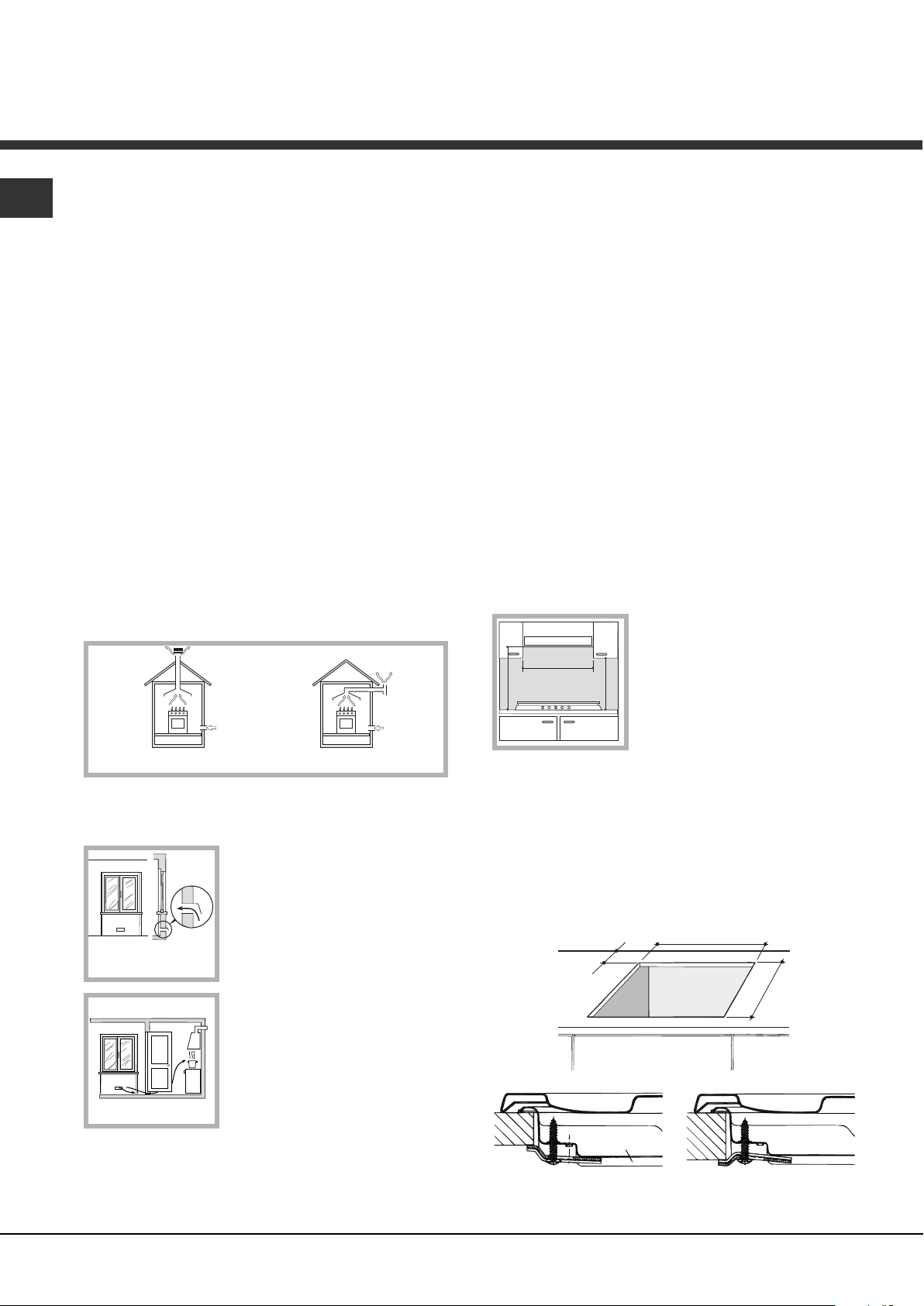

• Kitchen cabinets adjacent to the appliance and taller

than the top of the hob must be at least 600 mm from

the edge of the hob.

• Hoods must be installed according to their relative

installation instruction manuals and at a minimum

distance of 650 mm from the hob.

• Place the wall cabinets adjacent to the hood at a

minimum height of 420 mm from

the hob (see figure).

starts each time the appliance is switched on.

• The room must also allow proper air circulation, as air is

needed for combustion to occur normally. The flow of

air must not be less than 2 m

per kW of installed power.

The air circulation system may

take air directly from the outside

by means of a pipe with an inner

cross section of at least 100

2

; the opening must not be

cm

vulnerable to any type of

blockages.

The system can also provide the

air needed for combustion

indirectly, i.e. from adjacent

rooms fitted with air circulation

tubes as described above.

However, these rooms must not

be communal rooms, bedrooms

or rooms that may present a fire hazard.

If the hob is installed beneath a

wall cabinet, the latter must be

situated at a minimum of 700 mm

above the hob (see figure).

• The installation cavity should have the dimensions

3

/h

indicated in the figure.

Fastening hooks are provided, allowing you to fasten

the hob to tops that are between 20 and 40 mm thick.

To ensure the hob is securely fastened to the top, we

recommend you use all the hooks provided.

555 mm

55 mm

475 mm

Hook fastening diagram

Hooking position Hooking position

for top H=20 mm for top H=30 mm

2

Page 3

Front

560 mm

.

4

5

m

m

.

Hooking position Back

for top H=40 mm

! Use the hooks contained in the “accessory pack”

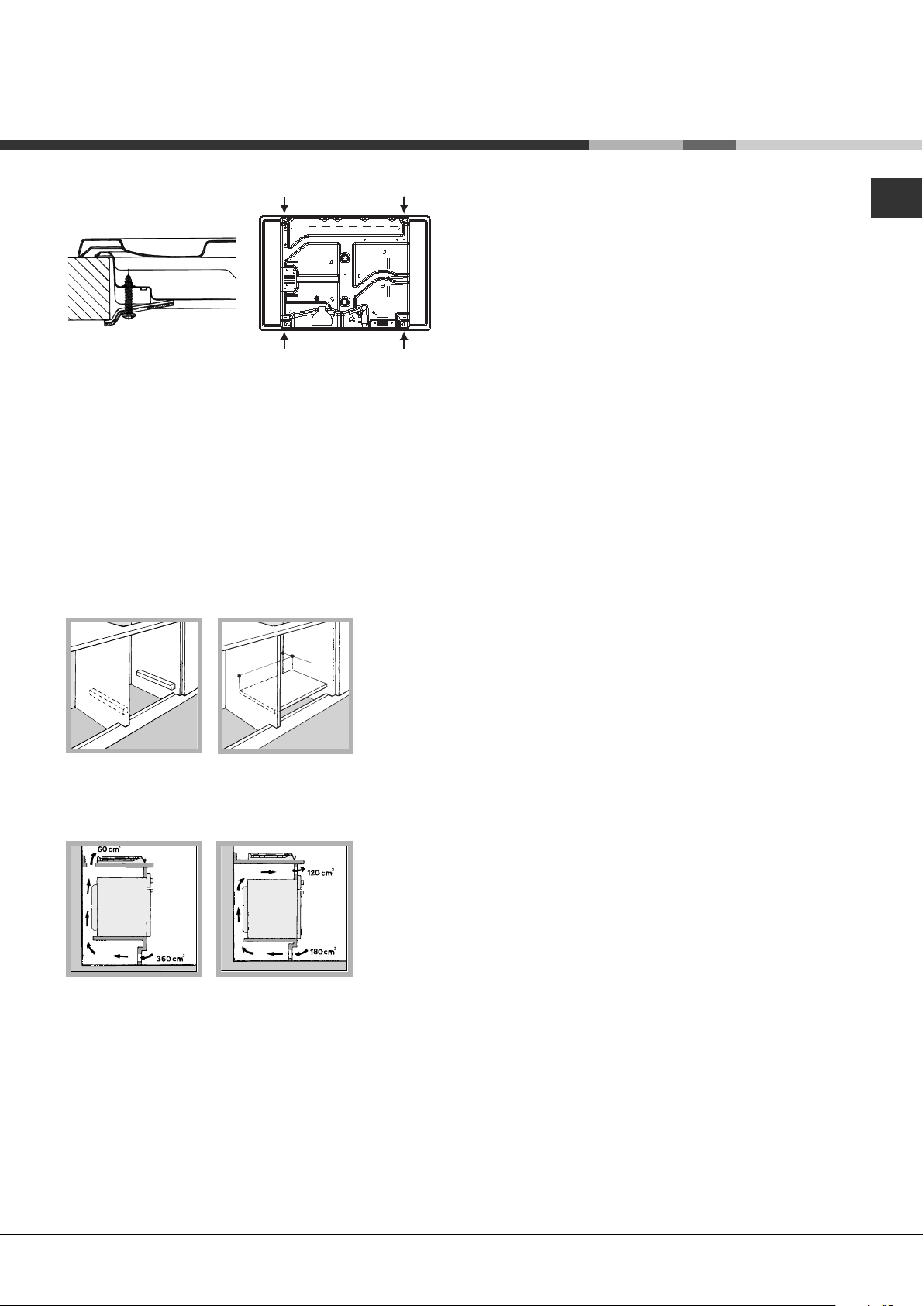

• Where the hob is not installed over a built-in oven, a

wooden panel must be installed as insulation. This

must be placed at a minimum distance of 20 mm from

the lower part of the hob.

Ventilation

To ensure adequate ventilation, the back panel of the

cabinet must be removed. It is advisable to install the

oven so that it rests on two strips of wood, or on a

completely flat surface with an opening of at least 45 x

560 mm (see diagrams).

When installing the cooktop above a built-in oven

without forced ventilation, ensure that there are air

inlets and outlets for ventilating the interior of the

cabinet adequately.

Electrical connection

Hobs equipped with a three-pole power supply cable are

designed to operate with alternating current at the voltage

and frequency indicated on the data plate (this is located

on the lower part of the appliance). The earth wire in the

cable has a green and yellow cover. If the appliance is to

be installed above a built-in electric oven, the electrical

connection of the hob and the oven must be carried out

separately, both for electrical safety purposes and to

make extracting the oven easier.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load

indicated on the data plate.

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum contact

opening of 3 mm installed between the appliance and the

mains. The circuit-breaker must be suitable for the charge

indicated and must comply with current electrical

regulations (the earthing wire must not be interrupted by the

circuit-breaker). The supply cable must not come into

contact with surfaces with temperatures higher than 50°C.

! The installer must ensure that the correct electrical

connection has been made and that it is compliant with

safety regulations.

Before connecting to the power supply, make sure that:

• The appliance is earthed and the plug is compliant with

the law.

• The socket can withstand the maximum power of the

appliance, which is indicated on the data plate.

• The voltage is in the range between the values

indicated on the data plate.

• The socket is compatible with the plug of the

appliance. If the socket is incompatible with the plug,

ask an authorised technician to replace it. Do not use

extension cords or multiple sockets.

! Once the appliance has been installed, the power supply

cable and the electrical socket must be easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced by

authorised technicians only (see Assistance).

! The manufacturer declines any liability should these

safety measures not be observed.

Gas connection

The appliance should be connected to the main gas

supply or to a gas cylinder in compliance with current

national regulations. Before carrying out the connection,

make sure the cooker is compatible with the gas supply

you wish to use. If this is not the case, follow the

instructions indicated in the paragraph “Adapting to

different types of gas.”

When using liquid gas from a cylinder, install a pressure

regulator which complies with current national regulations.

! Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (“Burner and nozzle

specifications”). This will ensure the safe operation and

longevity of your appliance while maintaining efficient

energy consumption.

Connection with a rigid pipe (copper or steel)

! Connection to the gas system must be carried out in

such a way as not to place any strain of any kind on the

appliance.

GB

3

Page 4

GB

There is an adjustable L-shaped pipe fitting on the

appliance supply ramp and this is fitted with a seal in

order to prevent leaks. The seal must always be replaced

after rotating the pipe fitting (seal provided with

appliance). The gas supply pipe fitting is a threaded 1/2

gas cylindrical male attachment.

Connecting a flexible jointless stainless steel pipe to a

threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas

cylindrical male attachment.

These pipes must be installed so that they are never

longer than 2000 mm when fully extended. Once

connection has been carried out, make sure that the

flexible metal pipe does not touch any moving parts and

is not compressed.

! Only use pipes and seals that comply with current

national regulations.

Checking the tightness of the connection

! When the installation process is complete, check the

pipe fittings for leaks using a soapy solution. Never use a

flame.

Adapting to different types of gas

To adapt the hob to a different type of gas other than

default type (indicated on the rating plate at the base of

the hob or on the packaging), the burner nozzles should

be replaced as follows:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

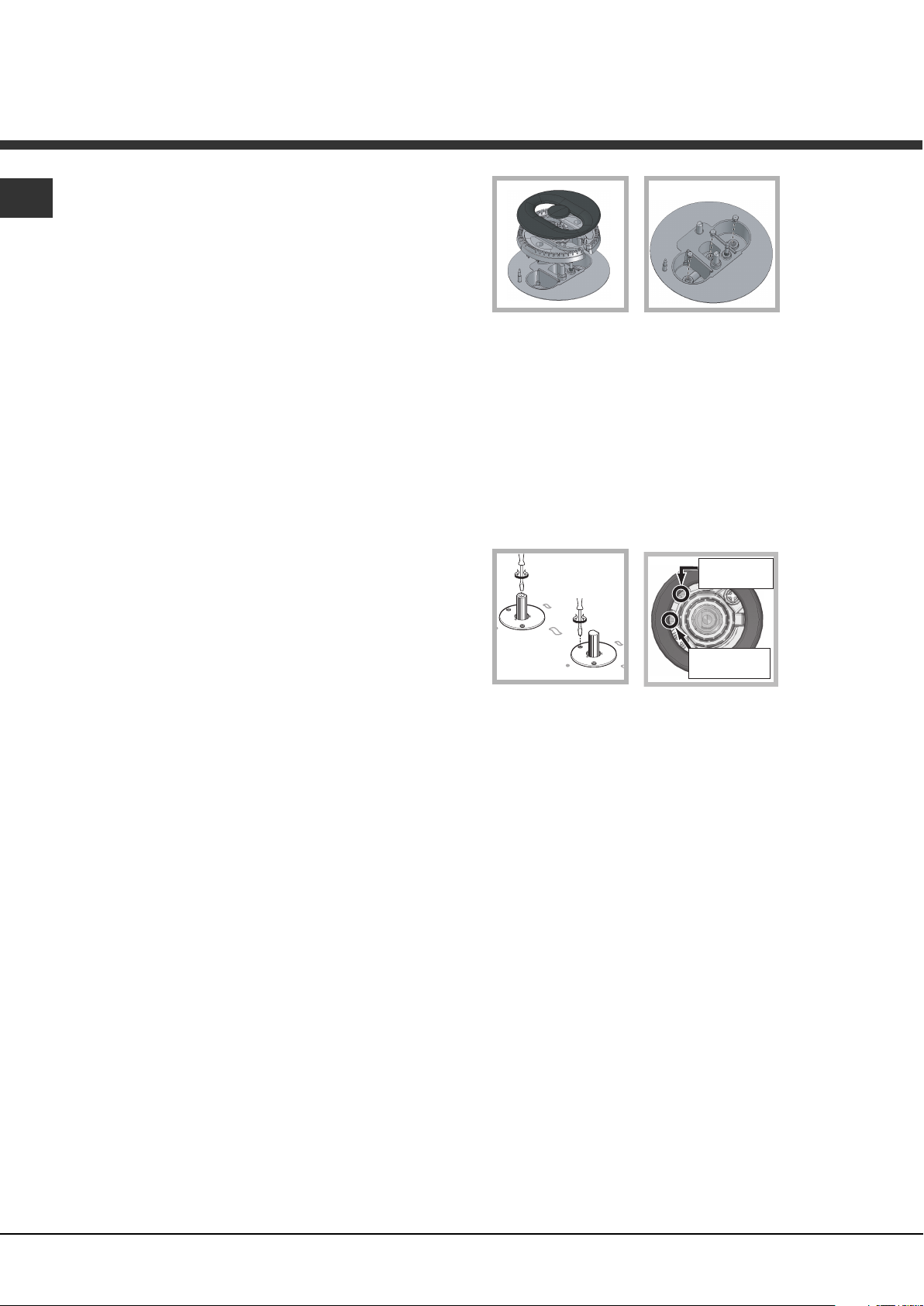

Replacing the nozzles on separate “double flame “

burners:

1. remove the grids and slide the burners from their

housings. The burner consists of 2 separate parts (see

figure);

2. unscrew the burers with a 7 mm wrench spanner. The

internal burner has a nozzle, the external burner has

two (of the same size). Replace the nozzle with models

suited to the new type of gas (see table 1).

3. replace all the components by repeating the steps in

reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw,

which is positioned in or next to the tap pin, until the

flame is small but steady.

! In the event of single-control DRDA (DCDR) burners,

adjustment can be performed by intervening on the 2

screws located near the tap pin (see picture).

Total DRDA

(DCDR) burner

adjustment

Inner DRDA (DCDR)

burner adjustment

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

6. In the event of discrete-adjustment knobs with

LED visualisation, turn the knob to the minimum

power setting them remove it and intervene on the

adjustment screw located near the tap pin.

7. Minimum setting adjustment of the DRDA (DCDR)

burner with discrete adjustment and LED

visualisation:

• To adjust the outer ring, turn the knob anticlockwise to the minimum power position.

• To adjust the minimum power setting of the

inner ring, turn the knob clockwise to the minimum

power position.

• Remove the knob and intervene on the

adjustment screw located near the tap pin.

4

Page 5

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).

Burner and nozzle specifications (for 60 cm versions only)

Table 1 Liquid Gas Natural Gas

Burner Diameter Thermal Thermal By-pass Nozzle Flow* Thermal Nozzle Flow*

power power 1/100 1/100 (g/h) power 1/100 (l/h)

kW kW kW

(p.c.s.*) (p.c.s.*) (p.c.s.*)

(mm) Reduced Nominal (mm) (mm) *** ** Nominal (mm)

Reduced Fast (RR)

100

0.70

2.60

39

80

189

186

2.60

122 (H)

248

GB

Semi Fast (S)

Auxiliary (A)

Double flame

(DCDR internal) (1)

Double

flame (1)

Supply pressures

(1) For single-control DRDA (DCDR) burner only

* At 15°C and 1013 mbar - dry gas

** Propane P.C.S. = 50.37 MJ/Kg

*** Butane P.C.S. = 49.47 MJ/Kg

Natural P.C.S. = 37.78 MJ/m³

(DCDR

internal)

(DCDR

external

2 nozzle)

75

55

30 0,30 0,90 27 44 65 64 0,90 74 86

130 1,50 3,60

0.40

0.40

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

A

RR

DC

S

PK 640 RL GH AG

1.65

1.00

28

28

27 44

55 60x2 100x 2

64

50

DATA PLAT E

Electrical

connections

120

73

262 257 3,60

28-30

20

35

118

71

37

25

45

see data plate

This appliance conforms to the following

European Economic Community directives:

- 2006/95/EEC dated 12/12/06 (Low

Voltage) and subsequent amendments

- 2004/108/EEC dated 15/12/04

(Electromagnetic Compatibility) and

subsequent amendments

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 2009/142/EEC dated 30/11/09 (Gas) and

subsequent amendments.

- 2002/96/EC and subsequent

amendments.

1.65

1.00

96 (Y)

79 (6)

74

157

95

343

20

17

25

5

Page 6

GB

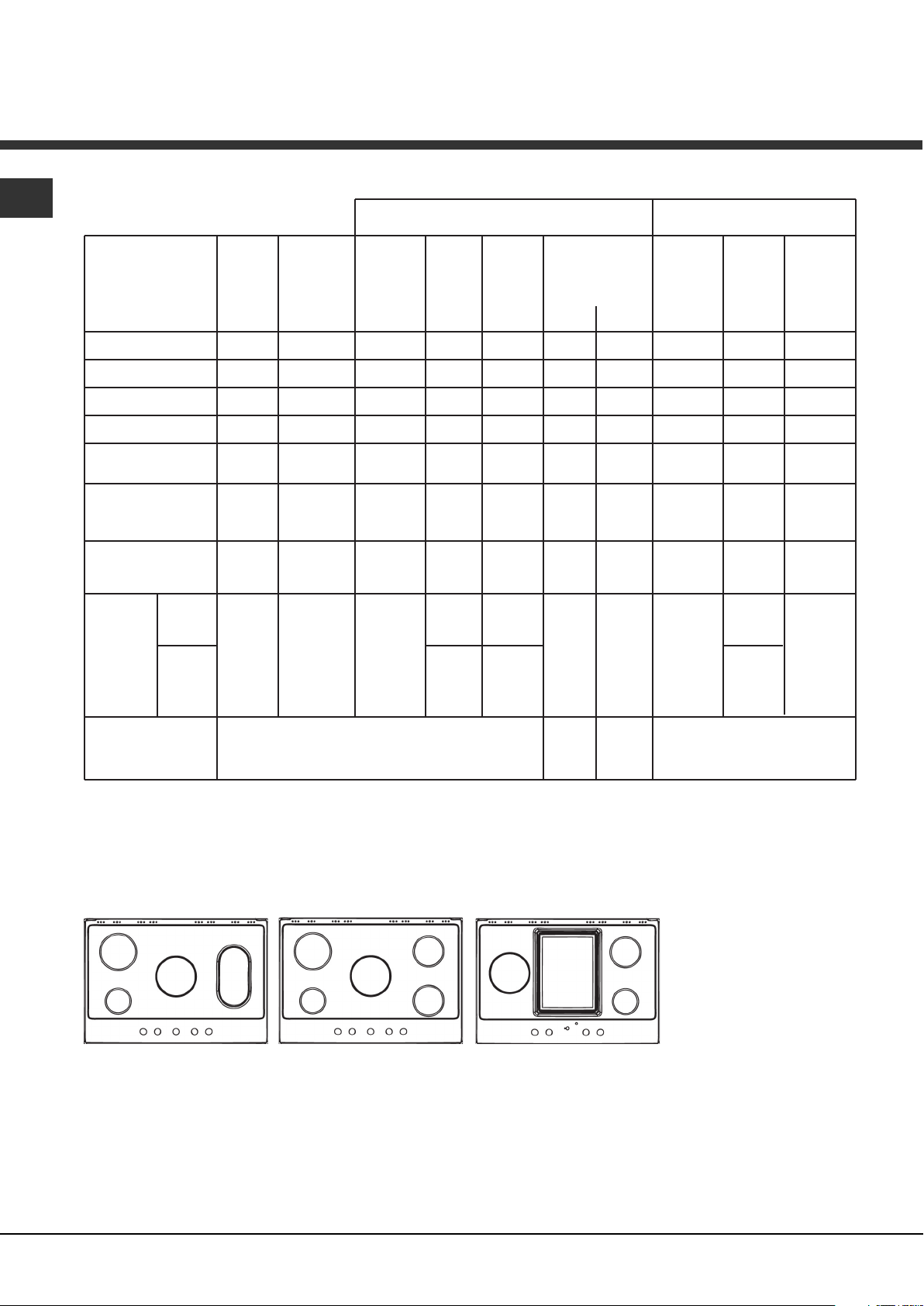

Burner and nozzle specifications (for 75 cm versions only)

Table 1 Liquid Gas Natural Gas

Burner Diameter Thermal Thermal By-pass Nozzle Flow* Thermal Nozzle Flow*

power power 1/100 1/100 (g/h) power 1/100 (l/h)

kW kW kW

(p.c.s.*) (p.c.s.*) (p.c.s.*)

(mm) Reduced Nominal (mm) (mm) *** ** Nominal (mm)

Reduced Fast (RR)

Semi Fast (S)

Auxiliary (A)

Semi-Fishburner (SP)

Double Flame

(DCDR Internal) (2)

Double Flame

(DCDR External)

2 nozzle (2)

Double flame

(DCDR internal) (1)

Double

flame (1)

Supply pressures

(DCDR

internal)

(DCDR

external

2 nozzle)

100

75

55

—

30

130

30 0,30 0,90 27 44 65 64 0,90 69 86

130 1,50 4,60

0.70

0.40

0.40

0.70

0.40

1.50

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

2.60

1.65

1.00

1.50

0.90

4.10

39

28

28

39

28

61

27 44

55 70 x 2 113 x 2

80

64

50

60

44

70x2

189

120

73

109

65

298

334 329 5,00

28-30

20

35

186

118

71

107

64

293

37

25

45

2.60

1.65

1.00

1.50

0.90

4.10

122 (H)

96 (Y)

79 (6)

88

70

114x2

69

476

20

17

25

248

157

95

143

86

390

(1) For single-control DRDA (DCDR) burner only

(2) For dual-control DRDA (DCDR) burner only

* At 15°C and 1013 mbar - dry gas

** Propane P.C.S. = 50.37 MJ/Kg

*** Butane P.C.S. = 49.47 MJ/Kg

Natural P.C.S. = 37.78 MJ/m³

RR

DC SP

A

PK760RF GH AG

RR

DC

A

PK750RL GH AG

S

S

DC

S

A

PK741RQO GH AG

6

Page 7

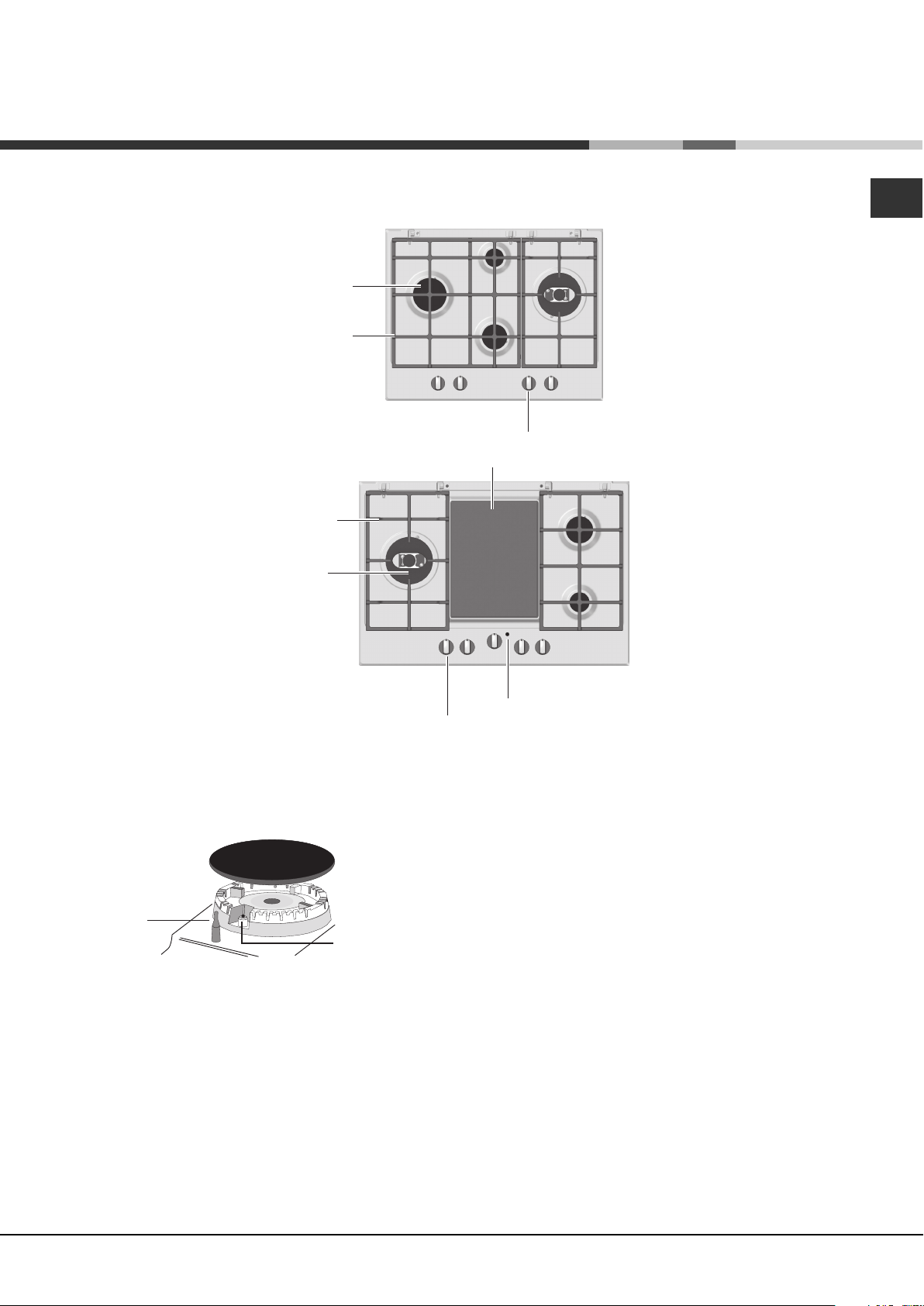

Description of the

appliance

Overall view

GB

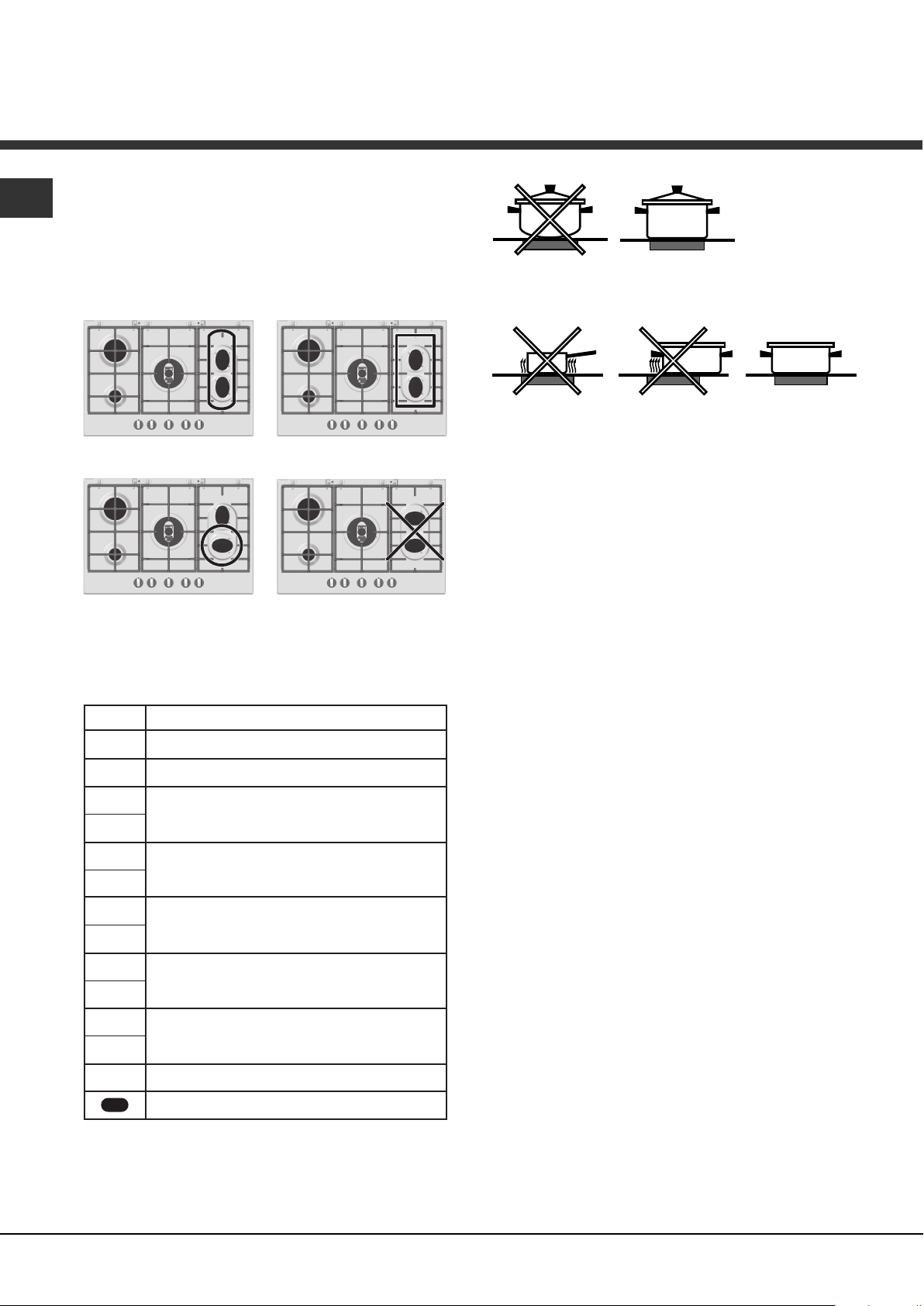

GAS BURNERS

Support Grid for

COOKWARE

Control Knobs for

GAS BURNERS

CERAMIC GLASS MODULE *

Support Grid for

COOKWARE

GAS BURNERS

Control Knobs for

GAS BURNERS and

CERAMIC GLASS MODULE*

SAFETY

DEVICES *

• The INDICATOR LIGHT FOR CERAMIC GLASS

MODULE switches on whenever the selector knob

is moved from the ‘off’ position.

• GAS BURNERS differ in size and power. Use the

diameter of the cookware to choose the most

appropriate burner to cook with.

Ignition for

GAS BURNERS *

Indicator Light for

CERAMIC GLASS MODULE *

• GAS BURNER ignition* enables a specific burner

to be lit automatically.

• SAFETY DEVICE* stops the gas flow if the flame is

accidentally extinguished.

• Control Knobs for GAS BURNERS and CERAMIC

GLASS MODULE* adjust the power or the size of

the flame.

Only available on certain models.

*

7

Page 8

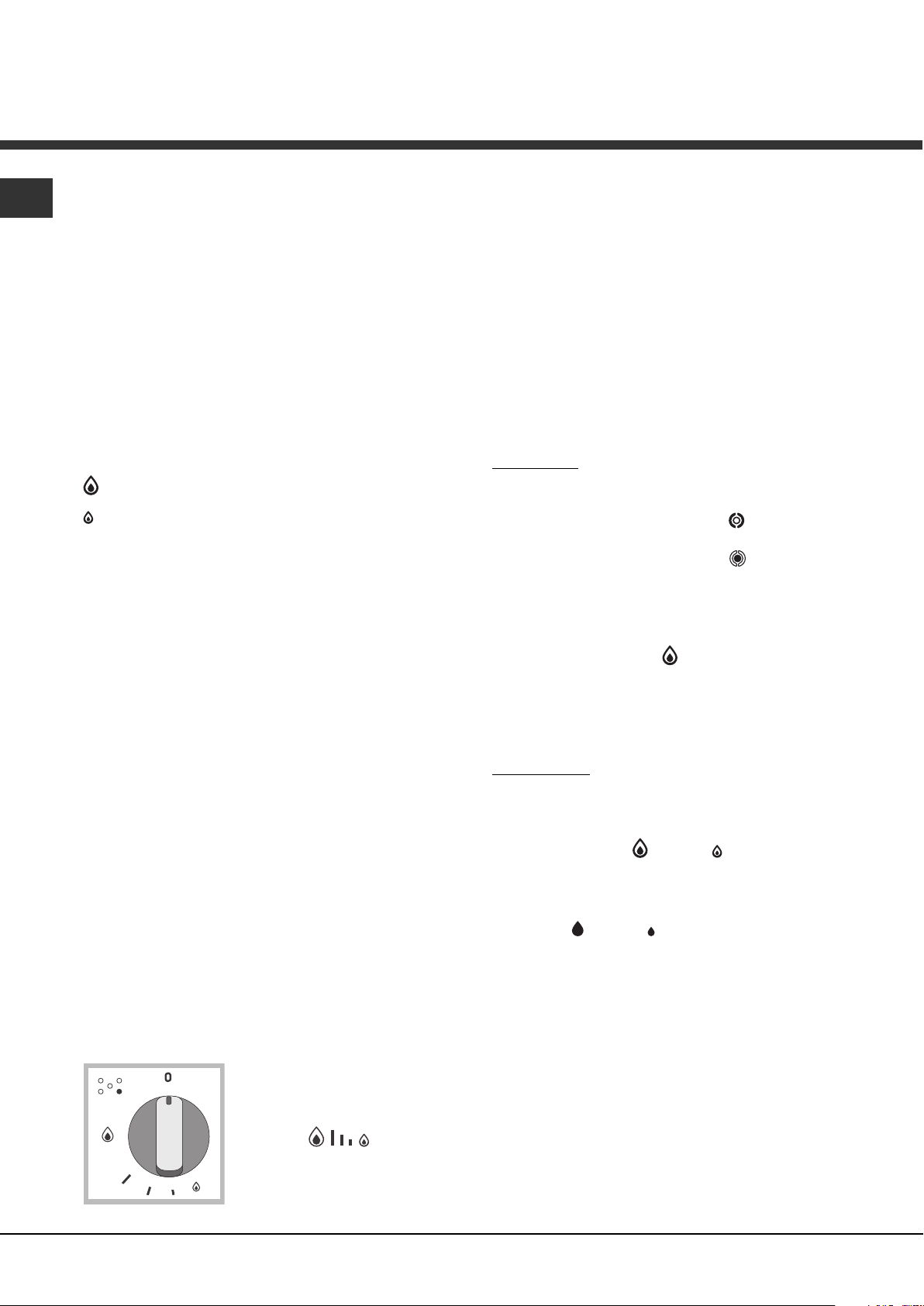

Start-up and use

GB

! The position of the corresponding gas burner or

electric hotplate* is shown on every knob.

Gas cooker hobs are equipped with discrete power

adjustment that allows for accurately adjusting the

flame to 5 different power levels. Thanks to this

system, gas hobs are also capable of guaranteeing

the same cooking results for each recipe, as the

optimal power level for the desired type of cooking

can be identified in an easier, more accurate way.

Gas burners

Each burner can be adjusted to one of the following

settings using the corresponding control knob:

• Off

Maximum

Minimum

To light one of the burners, hold a lit match or lighter

near the burner and, at the same time, press down

and turn the corresponding knob anti-clockwise to the

maximum setting.

Since the burner is fitted with a safety device, the

knob should be pressed for approximately 2-3

seconds to allow the automatic device keeping the

flame alight to heat up.

When using models with an ignition button, light the

desired burner pressing down the corresponding

knob as far as possible and turning it anticlockwise

towards the maximum setting.

! If a flame is accidentally extinguished, turn off the

control knob and wait for at least 1 minute before

trying to relight it.

To switch off the burner, turn the knob in a clockwise

direction until it stops (when reaches the “•” position).

Discrete flame adjustment

The selected burner can be adjusted - by means of

the knob - to 5 different power levels.

To shift between levels, simply turn the knob

towards the desired power level.

A click signals the passage from one power level to

the other.

The selected power level is

indicated by the

corresponding symbol

(symbols

hobs equipped with a

display, by the LEDs that turn

) and, on

on (5 = max. power; 1 = min. power). The system

guarantees accurate flame adjustment and uniform

cooking results by facilitating selection of the

desired power level.

The "double-flame" burner

This gas burner consists of two concentric flame

rings that can operate jointly or independently (in

case of dual-control only).

As the burner is fitted with a safety device, the

knob should be pressed down for approximately 2-3

seconds until the device keeping the flame

automatically alight heats up.

Dual control:

Each ring comprising the burner has its own control

knob:

The knob marked with the symbol

outer ring.

The knob marked with the symbol

inner ring.

To activate any one of the two rings, press the

corresponding knob and turn it anti-clockwise to the

maximum power setting

In order to use the double-flame burner to its full

potential, avoid simultaneously setting the inner

ring to minimum power and the outer ring to

maximum power.

Single control:

The rings comprising the burner are activated

through a single control knob.

To simultaneously turn on both rings, position the

knob on the symbol

and turn the knob anti-clockwise.

To turn on the inner ring only, position the knob on

the symbol

the knob clockwise.

(to switch modes, it is necessary to switch off the

burner).

To switch off the burner, press and turn the knob

clockwise until it stops (when it reaches the "•"

position).

Ceramic Glass Module*

This cooktop is fitted with dual-ring radiant heating

elements located beneath the glass. It is possible to

turn on only the circular part of the elemement

(identified by the letter "A") or the cooking surface

Only available on certain models.

*

(max.) - (min.) then press and turn

.

(max.) - (min.) then press

controls the

controls the

8

Page 9

can be enlarged by turning on both "A" and "B". To

turn only the circular "A" element, simply turn the

knob in the clockwise direction to any one of the 12

available settings. To add the "B" section, turn the

knob to setting 12 and then click it into the

setting. Then proceed by turning the knob in the

counter-clockwise direction to one of the 12

settings.

The figure shows the heating zones, which become

red when the element is turned on.

A. Circular heating zone;

B.Extended heating zone;

C.Indicator light to show when the cooking zone is

above 60°C, even after the heating element has

been turned off.

B

A

O

val R

C

ing

When the knob is on any of the settings other than

"Off", the Indicator Light for Ceramic Glass Module

comes on.

Burner

Rapid (R)

Semi-Rapid (S)

Auxiliary (A)

Double Flame (DCDR internal)

Double Flame (DCDR external)

Ø Cookware Diameter (cm)

24 - 26

16 - 20

10 - 14

10 - 14

24 - 26

Pans to be used on 60 cm hobs

Burner

Reduced Rapid (RR)

Semi-Rapid (S)

Auxiliary (A)

Semi-Fishburner (SP)

Double Flame (DCDR internal)

Double Flame (DCDR external)

Ø Cookware Diameter (cm)

24 - 26

16 - 20

10 - 14

16 - 20

10 - 14

26 - 28

Pans to be used on 75 cm hobs

! On the models supplied with a reducer shelf,

remember that this should be used only for the Double

flame internal (DCDR internal) burner when you use

casserole dishes with a diameter under 12 cm.

To identify the type of burner, refer to the designs in

the section entitled, "Burner and Nozzle

Specifications".

GB

Practical advice on using the burners

To ensure the burners operate efficiently:

• Use appropriate cookware for each burner (see

table) so that the flames do not extend beyond the

bottom of the cookware.

• Always use cookware with a flat base and a cover.

• When the contents of the pan reach boiling point,

turn the knob to minimum.

Only available on certain models.

*

Practical Advice on Using the Half Fish-Kettle

Burner *

The two "Half Fish-Kettle" burners, are eliptic in form

and can be turned up to 90°. This makes the cooktop

more flexible in terms of how it can be used.

To turn the two burners 90°, proceed as follows:

• Make sure that the burners are cool;

• Lift the burner completely out of its housing;

• Replace it in its housing in the position desired;

• Make sure that the burners are positioned

correctly before use.

In addition, the two burners can be used in tandem

or speartely with cookware of different shapes and

sizes:

• Double burner for a fish-kettle or oval cookware

(Fig.A).

9

Page 10

GB

• Double burner for a griddle or rectangular/square

cookware with minimum dimensions of 28x28 cm

(Fig.B)

• Single burner for medium size cookware (diameter

of 16-20 cm) (Fig.C).

• NEVER use the double burner in the configuration

represented in figure D.

Fig. A Fig. B

Fig. C Fig. D

Practical Advise on Using the Ceramic

Glass Module*

Set.

Radiant Burner

0

Off.

1

To melt butter and chocolate.

2

To heat liquids.

3

• Always use pans with a diameter that is large

enough to cover the hotplate fully, in order to use

all the available heat.

• Make sure that the bottom of the cookware is

always dry and clean to guarantee correct

adherence and long life, not only for the cooking

zones but also for the cookware itself.

• Avoid using the same cookware that is used on

gas burners: the heat concentration on gas

burners may deform the base of the pan, causing

it not to adhere correctly.

• Never leave a cooking zone on without cookware

on it because as it heats up and rapidly reaches

the maximum level, which could damage the

heating elements.

! The glue used for sealing the glass may leave

greasy residues. We recommend removing them

with a non-abrasive cleaning product prior to

operating the appliance. During the first few hours of

operation, there may be a smell of rubber that will

soon disappear.

4

For creams and sauces.

5

6

For cooking at the boiling point.

7

8

For Roasts.

9

10

11

12

For boiling large pieces of meat.

For frying.

For utilising both cooking areas.

To obtain the best results from your hob:

• Use flat-bottomed pans to ensure that they adhere

to the cooking zone perfectly.

10

Page 11

Precautions and tips

! This appliance has been designed and manufactured

in compliance with international safety standards. The

following warnings are provided for safety reasons and

must be read carefully.

General safety

• This is a class 3 built-in appliance.

• Gas appliances require regular air exchange to

maintain efficient operation. When installing the

hob, follow the instructions provided in the

paragraph on “Positioning” the appliance.

• These instructions are only valid for the countries

whose symbols appear in the manual and on the

serial number plate.

• The appliance was designed for domestic use inside

the home and is not intended for commercial or

industrial use.

• The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the

appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with wet

or damp hands and feet.

• The appliance must be used by adults only for the

preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous. The

manufacturer may not be held liable for any

damage resulting from improper, incorrect and

unreasonable use of the appliance.

• Ensure that the power supply cables of other

electrical appliances do not come into contact with

the hot parts of the oven.

• The openings used for ventilation and dispersion of

heat must never be covered.

• Always make sure the knobs are in the “”/“

position when the appliance is not in use.

• When unplugging the appliance always pull the plug

from the mains socket, do not pull on the cable.

• Never carry out any cleaning or maintenance work

without having detached the plug from the mains.

• In case of malfunction, under no circumstances

should you attempt to repair the appliance yourself.

Repairs carried out by inexperienced persons may

cause injury or further malfunctioning of the

appliance. Contact a Service Centre (see

Assistance).

• Always make sure that pan handles are turned

towards the centre of the hob in order to avoid

accidental burns.

• Do not close the glass cover (if present) when the gas

burners or electric hotplates are still hot.

”

• Do not leave the electric hotplate switched on without

a pan placed on it.

• Do not use unstable or deformed pans.

• Remove any liquid from the lid before

opening it.

• Prevent children and the disabled from coming into

contact or having access at the ceramic glass

cooking surface (if present) immediately before and

after use, as the cooking surface will remain hot for at

least a half hour after being turned off;

• Contact service centers authorized by the

manufacturer in the event the ceramic glass cooking

surface breaks.

• It is recommended that you follow the guidelines

below:

• Disconnect the appliance from the electrical supply in

the event the ceramic glass cooking surface

breakds.

• The appliance should not be operated by people

(including children) with reduced physical, sensory or

mental capacities, by inexperienced individuals or by

anyone who is not familiar with the product. These

individuals should, at the very least, be supervised

by someone who assumes responsibility for their

safety or receive preliminary instructions relating to

the operation of the appliance.

• Do not let children play with the appliance.

• The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

Disposal

• When disposing of packaging material: observe local

legislation so that the packaging may be reused.

• The European Directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE), requires

that old household electrical appliances must not be

disposed of in the normal unsorted municipal waste

stream. Old appliances must be collected separately

in order to optimise the recovery and recycling of the

materials they contain and reduce the impact on

human health and the environment. The crossed out

“wheeled bin” symbol on the product reminds you of

your obligation, that when you dispose of the

appliance it must be separately collected.

Consumers may take their old appliance to public

waste collection areas, other communal collection

areas, or if national legislation allows return it to a

retailer when purchasing a similar new product.

All major household appliance manufacturers are

active in the creation of systems to manage the

collection and disposal of old appliances.

GB

11

Page 12

Maintenance and care

GB

Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Do not use abrasive or corrosive detergents such as

stain removers, anti-rust products, powder detergents

or sponges with abrasive surfaces: these may scratch

the surface beyond repair.

! Never use steam cleaners or pressure cleaners on

the appliance.

• It is usually enough to wash the hob with a damp

sponge and dry it with absorbent kitchen roll.

• The removable parts of the burners should be

washed frequently with warm water and soap and

any burnt-on substances removed.

• For hobs which ligth automatically, the terminal part

of the electronic instant lighting devices should be

cleaned frequently and the gas outlet holes should

be checked for blockages.

• Stainless steel can be marked by hard water that

has been left on the surface for a long time, or by

aggressive detergents containing phosphorus.

After cleaning, rinse and dry any remaining drops

of water.

items, objects made of synthetic material, sugar

or foods with a high sugar content that have

melted onto the surface must be removed

immediatley with a scraper while the cooking

surface is still hot. Special cleaning products for

ceramic glass surfaces form a transparent

protective layer which fights diry buildup. This

also protects the surface from damage caused by

food with a high

sugar content. Do

not use abrasive

sponges or cleaning

products under any

circumstances. This

holds true for

chemically

aggressive cleaners,

like oven sprays and

stain removers.

! It is not necessary to remove the pan supports in

order to clean the hob surface. Thanks to the

support system, simply lift and hold the pan

supports or rotate them until they rest against a rear

support.

Do not place the hot grids on top of the glass

cover (if applicable), otherwise the rubber plugs

on the glass may be damaged.

• Before using the ceramic glass module, the surface

must be cleaned, using a damp cloth to remove

dust or food residues. The ceramic glass surface

should be cleaned regularly with a soultion of warm

water and a nonabrasive detergent.

Periodically, special

products will need to

be used to clean the

surface. First,

remove all food

buildup or grease

with a cleaning

scraper, e.g.

(not

supplied.

Clean the cooking surface when it is still warm with

a suitable cleaning product (such as the one in the

Solutions product line available from any AfterSales Service Centre) and paper towels. Then rub

with a damp cloth and dry. Aluminum foil, plastic

12

Gas tap maintenance

Over time, the taps may become jammed or difficult

to turn. If this happens, the tap must be replaced.

! This procedure must be performed by a qualified

technician authorised by the manufacturer.

Page 13

Troubleshooting

It may happen that the appliance does not function properly or at all. Before calling the service centre for

assistance, check if anything can be done. First, check to see that there are no interruptions in the gas and

electrical supplies, and, in particular, that the gas valves for the mains are open.

GB

Problem

The burner does not light or the flame is not

even around the burner.

The flame dies in models with a safety device.

The burner does not remain lit when set to

minimum.

The cookware is unstable.

If, despite all these checks, the hob does not function properly and the problem persists, call the nearest

Customer Service Centre. Please have the following information handy:

• The appliance model (Mod.).

• The serial number (S/N).

This information can be found on the data plate located on the appliance and/or on the packaging.

Possible causes/Solution

• The gas holes on the burner are clogged.

• All the movable parts that make up the burner are

mounted correctly.

• There are draughts near the appliance.

• You pressed the knob all the way in.

• You keep the knob pressed in long enough to activate the

safety device.

• The gas holes are not blocked in the area corresponding

to the safety device.

• The gas holes are not blocked.

• There are no draughts near the appliance.

• The minimum setting has been adjusted properly.

• The bottom of the cookware is perfectly flat.

• The cookware is positioned correctly at the centre of the

burner.

• The pan support grids have been positioned correctly.

! Never use unauthorised technicians and never accept replacement parts which are not original.

13

Page 14

Manual de

ES

instrucciones

GB

English,1

ES

Español, 14

PK 741 RQO GH AG

PK 750 RL GH AG

PK 640 RL GH AG

PK 760 RF GH AG

PT

Português, 29

ENCIMERA

Sumario

Instalación, 15-21

Colocación

Conexión eléctrica

Conexión gas

Características de los quemadores e inyectores

Placa de características

Descripción del aparato, 22

Vista de conjunto

Puesta en funcionamiento y uso, 23-25

Consejos prácticos para el uso de los quemadores

Consejos prácticos para el uso de la placa

Vitrocerámica

Precauciones y consejos, 26

Seguridad general

Eliminación

Mantenimiento y cuidados, 27

Cortar la corriente eléctrica

Limpiar el aparato

Mantenimiento de las llaves de gas

Placa de características

Anomalías y soluciones, 28

14

Page 15

Instalación

Aumento de la ranura entre

puerta y suelo

Habitación

adyacente

Habitación

por ventilar

A

Ejemplos de aperture

de ventilación

para aire comburente

En chimenea o tubo de chimenea ramificado

(reservado a los aparatos de cocción)

Directamente

al externo

600mm min.

600mm min.

700mm min.

! Es importante conservar este manual para poder

consultarlo en todo momento. En caso de venta, de cesión

o de mudanza, verifique que permanezca junto al aparato

para informar al nuevo propietario sobre su funcionamiento

y sobre las advertencias correspondientes.

! Lea atentamente las instrucciones: contienen importante

información sobre la instalación, el uso y la seguridad.

Colocación

! Los embalajes no son juguetes para niños y se deben

eliminar respetando las normas para la recolección de

residuos (ver Precauciones y consejos).

! La instalación se debe realizar siguiendo estas

instrucciones y por personal profesionalmente calificado.

Una instalación incorrecta puede producir daños a

personas, animales o cosas.

! Este aparato puede ser instalado y funcionar sólo en

lugares ventilados permanentemente, de acuerdo a las

prescripciones de l’Orden de 29.03.1974. Deben ser

observados los siguentes requisitos:

• El ambiente debe poseer un sistema de descarga de los

humos de la combustión al exterior, utilizando una

campana o un electroventilador que entre

automáticamente en funcionamiento cada vez que se

enciende el aparato.

• El ambiente debe poseer un sistema que permita la

entrada del aire necesario para una combustión normal.

El caudal de aire necesario para la combustión no debe

ser inferior a 2 m

instalada.

3

/h por cada kilovatio (kW) de potencia

El sistema puede tomar aire del

exterior del edificio a través de un

2

conducto de 100 cm

, como

mínimo, de sección útil de modo

que no pueda ser obstruido

accidentalmente.

• Los gases de petróleo licuados, más pesados que el aire,

se depositan en las partes más bajas. Por lo tanto, los

ambientes que contienen botellas de GPL deben tener

aberturas hacia el exterior para permitir la evacuación

desde abajo de eventuales escapes de gas. Además, las

botellas de GPL, vacías o parcialmente llenas, no deben

ser instaladas o depositadas en ambientes o espacios a un

nivel más bajo del suelo (sótanos, etc.) Es conveniente

conservar en el ambiente sólo la botella que se está

utilizando, colocada de modo que no quede expuesta a la

acción directa de fuentes de calor (hornos, chimeneas,

estufas, etc.) capaces de llevarla a temperaturas superiores

a 50°C.

Empotramiento

Las encimeras a gas y mixtas están fabricadas con un grado de

protección contra calentamientos excesivos de tipo X, y por lo

tanto, es posible su instalación al lado de muebles cuya altura no

supere la de la superficie de trabajo. Para una correcta instalación

de la encimera se deben observar las siguientes precauciones:

• Los muebles situados a un costado, cuya altura supere la

de la superficie de trabajo, deben estar situados a 600

mm., como mínimo, del borde de la misma.

• Las campanas deben ser instaladas de acuerdo con los

requisitos establecidos en los manuales de instrucción

de las mismas, siempre manteniendo una distancia

mínima de 650 mm.

• Coloque los armarios de pared adyacentes a la campana

a una altura mínima desde la superficie de trabajo, de

420 mm. (ver la figura).

Siempre que la encimera se

instale debajo de un armario de

pared, éste último deberá

mantener una distancia mínima de

la superficie de trabajo de 700

mm. (ver la figura).

• El espacio para el mueble deberá tener las dimensiones

indicadas en la figura. Se han previsto ganchos de fijación

que permiten fijar la encimera a superficies de 20 a 40 mm.

de espesor. Para un buena fijación de la encimera, es

aconsejable usar todos los ganchos que se suministran.

555 mm

ES

También puede hacerlo de

manera indirecta, desde

ambientes adyacentes que

posean un conducto de

ventilación hacia el exterior, como

se describe más arriba, y que no

sean partes en común del

inmueble, ambientes con peligro

de incendio o dormitorios.

55 mm

475 mm

15

Page 16

ES

560 mm.

4

5

m

m

.

Esquema de fijación de los ganchos

Posición del gancho para Posición del gancho para

superficies

Posición del gancho para Atrás

superficies

H=20mm superficies H=30mm

Adelante

H=40mm

! Use los ganchos contenidos en el “paquete de

accesorios”

• Cuando la encimera no se instale sobre un horno

empotrado, es necesario introducir un panel de madera

como aislamiento. El mismo deberá colocarse a una

distancia mínima de 20 mm. de la pared inferior de la

encimera.

Aireación

Para garantizar una buena aireación es necesario eliminar

la pared posterior del hueco para el horno. Es preferible

instalar el horno apoyado sobre dos listeles de madera o

sobre una superficie continua que tenga una abertura de

45 x 560 mm. como mínimo (ver las figuras).

Cuando se trate de instalación sobre un horno

empotrable sin ventilación forzada de refrigeración,

para permitir una adecuada ventilación en el interior

del mueble, se garantizan tomas de aire de entrada

y de salida.

Conexión eléctrica

Las encimeras que poseen cable de alimentación tripolar,

se fabrican para funcionar con corriente alterna, a la

tensión y frecuencia de alimentación indicadas en la placa

de características (ubicada en la parte inferior de la

encimera). El conductor de puesta a tierra del cable se

distingue por los colores amarillo-verde. Cuando se

realiza la instalación sobre un horno empotrado, la

conexión eléctrica de la encimera y la del horno se deben

realizar por separado, ya sea por razones de seguridad

eléctrica, como para facilitar la eventual extracción del

horno.

Conexión del cable de alimentación eléctrica a la red

Instale en el cable un enchufe normalizado para la carga

indicada en la placa de características.

En el caso de conexión directa a la red, es necesario

interponer entre el aparato y la red, un interruptor omnipolar

con una distancia mínima entre los contactos de 3 mm.,

dimensionado para esa carga y que responda a las normas

vigentes (el conductor de tierra no debe ser interrumpido

por el interruptor). El cable de alimentación eléctrica se

debe colocar de modo tal que no alcance en ningún punto

una temperatura que supere en 50°C la temperatura

ambiente.

! El instalador es responsable de la correcta conexión

eléctrica y del cumplimiento de las normas de seguridad.

Antes de efectuar la conexión verifique que:

• la toma tenga conexión a tierra y que sea conforme con

la ley;

• la toma sea capaz de soportar la carga máxima de

potencia de la máquina indicada en la placa de

características;

• la tensión de alimentación eléctrica esté comprendida

dentro de los valores indicados en la placa de

características;

• la toma sea compatible con el enchufe del aparato. Si no

es así, sustituya la toma o el enchufe; no utilice

prolongaciones ni conexiones múltiples.

! Una vez instalado el aparato, el cable eléctrico y la toma

de corriente deben ser fácilmente accesibles.

! El cable no debe sufrir pliegues ni compresiones.

! El cable debe ser revisado periódicamente y sustituido

sólo por técnicos autorizados (ver Asistencia).

! La empresa declina toda responsabilidad cuando estas

normas no sean respetadas.

Conexión de gas

La conexión del aparato a la tubería o a la botella de gas se

deberá efectuar de acuerdo a lo prescripto por las Normas

Nacionales vigentes, sólo después de haber verificado que

el mismo está regulado para el tipo de gas con el cual será

alimentado. Si no es así, realice las operaciones indicadas

16

Page 17

en el párrafo “Adaptación a los distintos tipos de gas”.

En el caso de alimentación con gas líquido, desde

botella, utilice reguladores de presión conformes con las

Normas Nacionales vigentes.

! Para un funcionamiento seguro, un adecuado uso de la

energía y una mayor duración del aparato, verifique que la

presión de alimentación cumpla con los valores indicados

en la tabla 1 “Características de los quemadores e

inyectores”.

Conexión con tubo rígido (cobre o acero)

! La conexión a la red de gas se debe efectuar de modo

que no provoque esfuerzos de ningún tipo al aparato.

En el tubo de alimentación del aparato se encuentra una

unión en “L” orientable, cuya estanqueidad está asegurada

por una junta. Si resultara necesario girar la unión, sustituya

siempre la junta estanca (suministrada con el aparato). La

unión de entrada de gas al aparato es roscada 1/2 gas

macho cilíndrico.

Conexión con tubo flexible de acero inoxidable de pared

continua con uniones roscadas

La unión de entrada de gas al aparato es roscada 1/2 gas

macho cilíndrico.

La colocación de dichos tubos se debe efectuar de modo

tal que su longitud, en condiciones de máxima extensión,

no sea mayor que 2000 mm. Una vez realizada la conexión,

verifique que el tubo metálico flexible no permanezca en

contacto con partes móviles o no quede aplastado.

! Utilice exclusivamente tubos y juntas estancas conformes

a la Normas Nacionales en vigencia.

Control de la estanqueidad

! Finalizada la instalación, controle la perfecta estanqueidad

de todas las uniones utilizando una solución jabonosa pero

nunca una llama.

Adaptación a los distintos tipos de gas

Para adaptar la encimera a un tipo de gas diferente de

aquel para el que fue fabricada (indicado en la etiqueta

fijada en la parte inferior de la encimera o en el embalaje),

es necesario sustituir los inyectores de los quemadores

efectuando las siguientes operaciones:

1. quite las parrillas de la encimera y extraiga los

quemadores.

2. desenrosque los inyectores utilizando una llave tubular

de 7mm. y sustitúyalos por los que se adapten al nuevo

tipo de gas (ver tabla 1 “Características de los

quemadores e inyectores”).

3. vuelva a colocar las piezas realizando las operaciones

en sentido contrario.

4. al finalizar la operación, sustituya la anterior etiqueta de

calibrado con la correspondiente al nuevo gas que se va

a utilizar, disponible en nuestros Centros de Asistencia

Técnica.

Sustitución de los picossen el quemador “doble

llama” independente:

• sacar las rejillas y quitar los quemadores de sus

sedes. El quemador está compuesto de 2 partes

separados (ver Fig. E y Fig. F)

• destornillar los picos, sirviéndose de una llave de tubo

de 7 mm. El quemador interno tiene un pico, el

quemador externo tiene dos (del mismo tamaño).

Reemplazar los picos por los que se adapten al nuevo

tipo de gas (ver tabla 1).

• Volver a colocar todos los componentes en sus

respectivas posiciones, efectuando las operaciones

inversas, respecto a la secuencia arriba indicada.

• Regulación de aire principal de los quemadores

Los quemadores no necesitan de ninguna regulación de

aire principal.

• Regulación de los mínimos

1. Lleve la llave hasta la posición de mínimo;

2. Quite el mando y accione el tornillo de regulación situado

en el interior o al costado de la varilla de la llave hasta

conseguir una pequeña llama regular.

! En el caso del quemador DCDR monomando, la

regulación se debe realizar con los 2 tornillos

ubicados al costado de la varilla del grifo (ver la

figura).

Regulación

DCDR total

Regulación

DCDR interno

3. Verifique que girando rápidamente el mando desde la

posición de máximo hasta la de mínimo, no se

apaguen los quemadores.

4. En los aparatos provistos del dispositivo de seguridad

(termopar), si dicho dispositivo no funcionara con los

quemadores al mínimo, aumente la capacidad de los

mínimos utilizando para ello el tornillo de regulación.

5. Una vez efectuada la regulación, vuelva a colocar los

precintos ubicados en los by-pass con lacre o un

material equivalente.

6. En el caso de mandos con regulación discreta y

visualización con led, coloque el mando en la

ES

17

Page 18

ES

posición de mínimo, luego extraiga el mando y

trabaje con el tornillo de regulación ubicado al

costado de la varilla del grifo.

7. Regulación de los mínimos del quemador DCDR

con regulación discreta y visualización con led:

• para regular la corona externa, gire el mando

en sentido antihorario hasta la posición de

mínimo;

• para regular el mínimo de la corona interna,

gire el mando en sentido horario hasta la posición

de mínimo;

• extraiga el mando y trabaje con el tornillo de

regulación ubicado al costado de la varilla del

grifo.

! En el caso de ga

s líquido, el tornillo de regulación

deberá enroscarse a fondo.

! Al finalizar la operación, sustituya la anterior etiqueta de

calibrado con la correspondiente al nuevo gas que se va

a utilizar, disponible en nuestros Centros de Asistencia

Técnica.

! Cuando la presión del gas utilizado sea distinta de la

prevista (o variable), es necesario instalar, en la tubería de

entrada, un regulador de presión conforme con las

Normas Nacionales en vigencia.

18

PLACA DE CARACTERÍSTICAS

Conexiones

eléctricas

ver placa de características

Este aparato es conforme con las

siguientes Normas Comunitarias:

- 2006/95/CEE del 12/12/06 (Baja

Tensión) y posteriores modificaciones

- 2004/108/CEE del 15/12/04

(Compatibilidad Electromagnética) y

posteriores modificaciones

- 93/68/CEE del 22/07/93 y posteriores

modificaciones.

- 2009/142/CEE del 30/11/09 (Gas) y

posteriores modificaciones.

- 2002/96/CEE y posteriores

modificaciones successives.

Page 19

Presión de trabajo para Gas Licuado 280 mm c.a

Características de los quemadores e inyectores (sólo modelo PK 640 R L GH AG)

Presión de trabajo para Gas Natural 180 mm c.a - Preparado para GN convertible a GPL

ES

HORNALLA

AUXILAR 1 1,00 860 50 860 79

SEMIRÁPIDO

RÁPIDO 1 2,60 2236 86 2236 116

Doble

llama

(1)

TOTAL 6 8,85 7610 - 7610 Tension de alimentacion 220-240 V~ 50-60Hz

Potencia: 0,6 W

INDUSTRIA ITALIANA

Importador: Indesit Argentina S.A.

(1) Sólo para DCDR monomando

IMPORTANTE: NO INSTALAR EN LUGARES SIN VENTILACION PERMANENTE

ESTE ARTEFACTO DEBE SER INSTALADO, DE ACUERDO CON LAS NORMASY REGLAMENTACIONES EN

VIGENCIA, FOR UN INSTALADOR MATRICULADO

CONSULTAR LAS INSTRUCCIONES ANTES DE INSTALAR Y UTILIZAR ESTE ARTEFACTO

AV.EDUARDO MANDERO 900 PISO 18 BUENOS AIRES; TEL. 011-4131-1513

Este artefacto esta preparado para trabajar con gas natural 18mb para gas natural. Se provee el juego de inyectores

para realizar el cambio de tipo de gas.

Sr. Instalador: en el caso de cambio de tipo de gas, sirvase aclararlo.

Tipo de gas: NATURAL/LICUADO (tache lo que no corrisponde)

(DCDR

Interno)

(DCDR

Externo

2 pico.)

N°

IN Y

1 1,65 1419 64 1419 106

3 3,60 3095

KW KCAL/H Inyector

GAS LICUADO GAS NATURAL

KW KCAL/H Inyector 1/100 (mm)

1/100 (mm)

1,00

1,65

2,60

44

3,60

60 x2 94 x2

8,85

Clase del artefacto: 3

Categoria de gas: II2H3B/P

Aprobado bajo norma:

NAG 312

3095

74

A

RR

DC

S

PK 640 RL GH AG

19

Page 20

ES

Características de los quemadores e inyectores (sólo modelo PK 741 RQO GH AG)

Presión de trabajo para Gas Natural 180 mm c.a - Preparado para GN convertible a GPL

Presión de trabajo para Gas Licuado 280 mm c.a

HORNALLA

N°

IN Y

KW KCAL/H Inyector

AUXILAR 1 1,00 860 50 860 79

SEMIRÁPIDO

Doble llama

(DCDR Interno) (2)

Doble llama

(DCDR Externo)

2 Pico (2)

1

1,65 1419 64 1419 106

144 70

4,60 3956

2

TOTAL 5 7,25 6235 - 6579 Tension de alimentacion 220-240 V~ 50-60Hz

Potencia: 2000 W

INDUSTRIA ITALIANA

Importador: Indesit Argentina S.A.

(2) Sólo para DCDR doble comando

IMPORTANTE: NO INSTALAR EN LUGARES SIN VENTILACION PERMANENTE

ESTE ARTEFACTO DEBE SER INSTALADO, DE ACUERDO CON LAS NORMASY REGLAMENTACIONES EN

VIGENCIA, FOR UN INSTALADOR MATRICULADO

CONSULTAR LAS INSTRUCCIONES ANTES DE INSTALAR Y UTILIZAR ESTE ARTEFACTO

AV.EDUARDO MANDERO 900 PISO 18 BUENOS AIRES; TEL. 011-4131-1513

Este artefacto esta preparado para trabajar con gas natural 18mb para gas natural. Se provee el juego de inyectores

para realizar el cambio de tipo de gas.

Sr. Instalador: en el caso de cambio de tipo de gas, sirvase aclararlo.

Tipo de gas: NATURAL/LICUADO (tache lo que no corrisponde)

GAS LICUADO GAS NATURAL

KW KCAL/H Inyector 1/100 (mm)

1/100 (mm)

1,00

1,65

5,00

4300

70 x2

7,65

Clase del artefacto: 3

Categoria de gas: II2H3B/P

Aprobado bajo norma:

NAG 312

114 x2

Características de los quemadores e inyectores (sólo modelo PK 750 RL GH AG)

Presión de trabajo para Gas Natural 180 mm c.a - Preparado para GN convertible a GPL

Presión de trabajo para Gas Licuado 280 mm c.a

HORNALLA

N°

IN Y

KW KCAL/H Inyector

AUXILAR 1 1,00 860 50 860 79

SEMIRÁPIDO

RÁPIDO 1 2,60 2236 86 2236 116

(DCDR

Doble

llama

(1)

Interno)

(DCDR

Externo

2 pico.)

2

1,65 1419 64 1419 106

1

4,60 3956

2

TOTAL 7 11,50 9890 - 10234 Tension de alimentacion 220-240 V~ 50-60Hz

Potencia: 0,6 W

INDUSTRIA ITALIANA

Importador: Indesit Argentina S.A.

(1) Sólo para DCDR monomando

IMPORTANTE: NO INSTALAR EN LUGARES SIN VENTILACION PERMANENTE

ESTE ARTEFACTO DEBE SER INSTALADO, DE ACUERDO CON LAS NORMASY REGLAMENTACIONES EN

VIGENCIA, FOR UN INSTALADOR MATRICULADO

CONSULTAR LAS INSTRUCCIONES ANTES DE INSTALAR Y UTILIZAR ESTE ARTEFACTO

AV.EDUARDO MANDERO 900 PISO 18 BUENOS AIRES; TEL. 011-4131-1513

Este artefacto esta preparado para trabajar con gas natural 18mb para gas natural. Se provee el juego de inyectores

para realizar el cambio de tipo de gas.

Sr. Instalador: en el caso de cambio de tipo de gas, sirvase aclararlo.

Tipo de gas: NATURAL/LICUADO (tache lo que no corrisponde)

GAS LICUADO GAS NATURAL

KW KCAL/H Inyector 1/100 (mm)

1/100 (mm)

1,00

1,65

2,60

44

5,00

4300

60 x2 94 x2

11,90

Clase del artefacto: 3

Categoria de gas: II2H3B/P

Aprobado bajo norma:

NAG 312

74

20

Page 21

Características de los quemadores e inyectores (sólo modelo PK 760 RF GH AG)

Presión de trabajo para Gas Natural 180 mm c.a - Preparado para GN convertible a GPL

Presión de trabajo para Gas Licuado 280 mm c.a

HORNALLA

AUXILAR 1 1,00 860 50 860 79

SEMIPESCADERA

RÁPIDO 1 2,60 2236 86 2236 116

N°

IN Y

2

KW KCAL/H Inyector

1,50 1290 64 1290 106

GAS LICUADO GAS NATURAL

KW KCAL/H Inyector 1/100 (mm)

1/100 (mm)

1,00

1,50

2,60

ES

(DCDR

Doble

llama

(1)

TOTAL 7 11,20 9632 - 9976 Tension de alimentacion 220-240 V~ 50-60Hz

Potencia: 0,6 W

INDUSTRIA ITALIANA

Importador: Indesit Argentina S.A.

(1) Sólo para DCDR monomando

IMPORTANTE: NO INSTALAR EN LUGARES SIN VENTILACION PERMANENTE

ESTE ARTEFACTO DEBE SER INSTALADO, DE ACUERDO CON LAS NORMASY REGLAMENTACIONES EN

VIGENCIA, FOR UN INSTALADOR MATRICULADO

CONSULTAR LAS INSTRUCCIONES ANTES DE INSTALAR Y UTILIZAR ESTE ARTEFACTO

AV.EDUARDO MANDERO 900 PISO 18 BUENOS AIRES; TEL. 011-4131-1513

Este artefacto esta preparado para trabajar con gas natural 18mb para gas natural. Se provee el juego de inyectores

para realizar el cambio de tipo de gas.

Sr. Instalador: en el caso de cambio de tipo de gas, sirvase aclararlo.

Tipo de gas: NATURAL/LICUADO (tache lo que no corrisponde)

Interno)

(DCDR

Externo

2 pico.)

RR

DC SP

A

1

4,60 3956

2

RR

S

DC

A

S

44

5,00

60 x2 94 x2

11,60

Clase del artefacto: 3

Categoria de gas: II2H3B/P

Aprobado bajo norma:

NAG 312

4300

S

DC

A

74

PK760RF GH AG

PK750RL GH AG

PK741RQO GH AG

21

Page 22

Descripción

del aparato

ES

Vista de conjunto

QUEMADORES

Parrillas de apoyo de

RECIPIENTES DE COCCIÓN

Mandos de selección de los

QUEMADORES

PLACA VITROCERÁMICA *

Parrillas de apoyo de

RECIPIENTES DE COCCIÓN

QUEMADORES

Mandos de selección de los

QUEMADORES o de las

PLACA VITROCERÁMICA *

DISPOSITIVO DE

SEGURIDAD *

• Piloto de FUNCIONAMIENTO DE LA PLACA

VITROCERÁMICA*: se enciende cuando el mando

está en cualquier otra posición que no sea la de

apagado.

• QUEMADORES A GAS: son de distintas

dimensiones y potencias. Elija siempre el más

adecuado para el diámetro del recipiente que va a

utilizar.

Bujía de encendido de los

QUEMADORES A GAS *

Luz indicadora de

funcionamiento de las

PLACA VITROCERÁMICA *

• Bujía de encendido de los QUEMADORES A

GAS:* permite el encendido automático del

quemador.

• DISPOSITIVO DE SEGURIDAD:* si se apaga

accidentalmente la llama, interrumpe la salida de

gas.

• Mandos de los QUEMADORES A GAS y de la

PLACA VITROCERÁMICA* para la regulación de

la llama o de la potencia.

22

Presente sólo en algunos modelos.

*

Page 23

Puesta en

funcionamiento y uso

! En cada mando está indicada la posición del

quemador a gas o de la placa eléctrica*

correspondiente.

Las encimeras a gas poseen regulación discreta de

la potencia lo que permitirá regular con precisión la

llama en 5 niveles diferentes. Gracias a este

sistema será posible obtener siempre los mismos

resultados para cada receta, ya que será más

simple y precisa la individualización del nivel de

potencia óptimo para el tipo de cocción elegido,

incluso para las encimeras a gas.

Quemadores a gas

El quemador elegido se puede regular con el mando

correspondiente de la siguiente manera:

• Apagado

Máximo

Mínimo

Para encender uno de los quemadores, acerque al

mismo una llama o un encendedor, pulse a fondo y

gire el mando correspondiente en sentido antihorario

hasta la posición de máxima potencia.

En los modelos que poseen dispositivo de seguridad

es necesario mantener presionado el mando durante

2-3 segundos aproximadamente hasta que se caliente

el dispositivo que mantiene automáticamente

encendida la llama.

En los modelos que poseen bujía de encendido, para

encender el quemador elegido, pulse a fondo y gire el

mando correspondiente en sentido antihorario hasta

la posición de máxima potencia.

! Si se apagara accidentalmente la llama del

quemador, cierre el mando y vuelva a intentar

encenderlo después de 1 minuto, como mínimo.

Para apagar el quemador es necesario girar el mando

en sentido horario hasta el apagado (correspondiente

al símbolo “•”).

través del símbolo correspondiente (símbolos

a través del encendido de los LED (5 = máx.

potencia, 1 = mín. potencia). El sistema garantiza

una perfecta regulación de la llama y permite

obtener el mismo resultado de cocción,

individualizando más fácilmente el nivel de potencia

deseado.

El quemador de "dos llamas"

Este quemador a gas está formado por dos fuegos

concéntricos que pueden funcionar juntos o de

manera independiente (sólo en el caso del doble

mando).

Debido a que el quemador está dotado de un

dispositivo de seguridad, es necesario mantener

presionada la perilla durante 2 o 3 segundos hasta

que se caliente el dispositivo que mantiene la llama

encendida automáticamente.

Doble mando:

Cada corona que compone el quemador tiene su

mando:

el mando identificado con el símbolo

corona externa;

el mando identificado con el símbolo

corona interna.

Para encender la corona deseada, presione y gire el

mando correspondiente en sentido antihorario hasta

llegar a la posición de máxima potencia

Para utilizar en forma óptima el quemador de

llama doble, no regule nunca simultáneamente la

corona interna al mínimo y la externa al máximo.

Mono Mando:

Las coronas que componen el quemador poseen un

mando.

Para encender ambas coronas simultáneamente

presione y gire el mando en sentido antihorario

hasta el símbolo

) y, en las encimeras que poseen pantalla,

controla la

controla la

.

(máx) - (mín).

ES

Regulación discreta de la llama

El quemador elegido se puede regular en 5 niveles

distintos de potencia, utilizando el mando

correspondiente.

Para pasar de un nivel a otro

basta girar el mando hacia el

nivel elegido.

Un disparo/clic advierte el

paso de un nivel a otro.

La visualización del nivel

seleccionado se produce a

Para pasar a la corona interna solamente presione y

gire el mando en sentido horario hasta el símbolo

(máx) - (mín).

(para pasar de una modalidad a otra, se debe

apagar el quemador).

Para apagar el quemador es necesario presionar y

girar el mando “•” en sentido horario hasta el tope.

Presente sólo en algunos modelos.

*

23

Page 24

ES

Vitrocerámica*

Esta zona de cocción dispone de calentadores

radiantes de doble diámetro, situados debajo del

cristal. Se puede encender la zona circular "A"

únicamente o, si se desea mayor espacio, ambas

zonas "A" y "B". Para activar la zona circular "A"

bastará mover el mando en sentido horario,

coincidiendo con una de las 12 posiciones de

regulación disponibles. Para activar la zona "B" llegar

hasta la posición 12 y efectuar un clic hasta la

posición

, seguidamente se procederá a su

regulación moviendo el mando en sentido

antihorario, hasta alcanzar uno de los 12 niveles

posible.

La ilustración del Manual indica la zona de calor que

se pone roja al momento de activarla.

A. Zona de cocción circular

B. Zona de cocción extensible

C. Piloto indicador de calor residual: indica que

la zona tiene temperatura superior a 60°C, que

permanece después de apagado el elemento.

B

A

O

val R

C

ing

Para cualquier posición del mando, diferente de la

de apagado, se produce el encendido de la luz

indicadora de funcionamiento de la placa

Vitrocerámica.

Quemador

Rápido (R)

Semi Rápido (S)

Auxiliar (A)

Doble llama (DCDR Interno)

Doble llama (DCDR Externo)

Ø Diámetro Recipientes (cm)

24 - 26

16 - 20

10 - 14

10 - 14

24 - 26

Ollas que deben utilizarse en placas de 60 cm

Quemador

Rápido Reducido (RR)

Semi Rápido (S)

Auxiliar (A)

Semi-Pescadera (SP)

Doble llama (DCDR Interno)

Doble llama (DCDR Externo)

Ø Diámetro Recipientes (cm)

24 - 26

16 - 20

10 - 14

16 - 20

10 - 14

26 - 28

Ollas que deben utilizarse en placas de 75 cm

! En los modelos dotados de rejilla de reducción,

esta última deberá ser usada únicamente para el

quemador Doble llama interno (DCDR Interno),

cuando se usan recipientes de diámetro inferior a 12

cm.

Para identificar el tipo de quemador ver los diseños

presentes en el párrafo "Características de los

quemadores y boquillas".

Consejos prácticos para uso de los quemadores

centrales “Semi-Elíptica”*

El uso de los dos quemadores “Semi-Elíptica” de

forma elíptica, con rotación de 90°C ofrece mayor

flexibilidad de empleo de la encimera.

Consejos prácticos para el uso de los

quemadores

Si desea obtener el máximo rendimiento, es útil

recordar lo siguiente:

• utilice recipientes adecuados para cada

quemador (ver la tabla) con el fin de evitar que

las llamas sobresalgan por el fondo de los

recipientes.

• utilice siempre recipientes con el fondo plano y

con tapa.

• cuando se produce la ebullición, gire el mando

hasta la posición de mínimo.

Presente sólo en algunos modelos.

*

24

Para efectuar la rotación de los quemadores

elípticos, conviene proceder de esta manera:

• Esperar que los quemadores estén fríos

• Levantar totalmente el quemador

• Colocarlo de nuevo en su lugar, pero en la

posición deseada

• Comprobar el ajuste de todas las piezas

Los dos quemadores se pueden usar juntos o

separadamente con ollas de distinta forma y

Page 25

dimensiones, a saber:

• quemador doble, elíptico (Pecera) para

recipientes ovalados (A).

• quemador doble para asaderas o recipientes

rectangulares o cuadrados de medidas mínimas

28x28 cm (Fig. B)

• Quemador individual para recipientes medianos

(16-20 cm diam). (Fig. C).

• NO utilice NUNCA el quemador doble en la

configuración representada en la figura D.

Fig. A Fig. B

Fig. C Fig. D

Consejos prácticos para uso de

vitrocerámica*

Pos.

Placa automática

0

Apagado.

1

Para derretir manteca, chocolate.

2

Para calentar líquidos.

3

Para obtener el rendimiento máximo conviene tener

en cuenta lo siguiente:

• Sobre la placa de vitrocerámica se pueden usar

todo tipo de ollas. Lo importante es que tengan

fondo perfectamente plano: las cacerolas de

fondo espeso son las mejores porque aseguran

mejor distribución del calor.

• Usar ollas con diámetro suficiente para ocupar

toda la zona recalentada, para garantizar el uso

de todo el calor disponible.

• Comprobar que la base de las ollas esté siempre

limpia y bien seca; se consigue mejor contacto y

larga duración de placa y cacerolas.

• No usar la misma vajilla para quemadores de gas.

La concentración del calor sobre los quemadores

de gas es tal que puede deformar el fondo de la

cacerola, con lo que nunca se podrá obtener el

resultado deseado al usarla con placa de

vitrocerámica.

! El pegamento usado para sellar el cristal a veces

deja huellas de grasa. Es aconsejable eliminarlas

antes del primer uso del aparato, con un producto

suave para este tipo de limpieza. Durante las

primeras horas de uso, se advierte a veces olor a

caucho, que desaparece en breve.

ES

10

11

12

4

Para cremas y salsas.

5

6

Para cucinar a temperatura de hervor.

7

8

Para asados.

9

Per hervir grandes cantidades de alimentos.

Para freir.

Encendido de las zonas de cocina.

Presente sólo en algunos modelos.

*

25

Page 26

Precauciones y consejos

ES

! El aparato ha sido proyectado y fabricado en

conformidad con las normas internacionales de

seguridad. Estas advertencias se suministran por

razones de seguridad y deben ser leídas atentamente.

Seguridad general

• Este aparato se refiere a un aparato empotrable de

clase 3.

• Para su correcto funcionamiento, los aparatos a

gas necesitan un regular cambio de aire. Verifique

que en su instalación se respeten los requisitos

contenidos en el párrafo correspondiente a la

“Colocación”.

• Las instrucciones son válidas sólo para los países

de destino, cuyos símbolos figuran en el manual y

en la placa de características.

• El aparato ha sido fabricado para un uso de tipo no

profesional en el interior de una vivienda.

• El aparato no se debe instalar al aire libre, tampoco si

el espacio está protegido porque es muy peligroso

dejarlo expuesto a la lluvia y a las tormentas.

• No toque la máquina descalzo o con las manos y pies

mojados o húmedos.

• El aparato debe ser utilizado para cocinar

alimentos, sólo por personas adultas y siguiendo

las instrucciones contenidas en este manual.

Cualquier otro uso (como por ejemplo: calefacción

de ambientes) se debe considerar impropio y, por

lo tanto, peligroso. El fabricante no puede ser

considerado responsable por los daños derivados

de usos impropios, erróneos e irracionales.

• Evite que el cable de alimentación eléctrica de otros

electrodomésticos entre en contacto con partes

calientes del horno.

• No obstruya las aberturas de ventilación y de

eliminación del calor.

• Controle siempre que los mandos estén en la posición

“”/“” cuando no se utiliza el aparato.

• No desconecte el aparato de la toma de corriente

tirando del cable sino sujetando el enchufe.

• No realice la limpieza o el mantenimiento sin haber

desconectado primero el aparato de la red eléctrica.

• En caso de avería, no acceda nunca a los

mecanismos internos para intentar una reparación.

Llame al Servicio de Asistencia Técnica (ver

Asistencia).

• Verifique que los mangos de las ollas estén siempre

dirigidos hacia dentro de la encimera para evitar que

sean chocados accidentalmente.

• No cierre la tapa de vidrio (si existe) cuando los

quemadores o la placa eléctrica todavía están

calientes.

• No deje encendida la placa eléctrica sin ollas.

• No utilice ollas inestables o deformadas.

• Elimine el líquido que se podría encontrar sobre la tapa

antes de abrirla.

• Tratándose de fuentes de peligro, evitar que los niños

se pongan en contacto con la vitrocerámica (cuando

existe), mientras funciona e inmediatamente después,

debido a que la misma permanece recalentada hasta

media hora después de apagada.

• Es necesario llamar a los centros de asistencia

autorizados por el fabricante en caso de rotura de la

superficie vitrocerámica.

• Es conveniente desconectar el aparato de la red de

energía eléctrica, en caso de rotura en la zona

vitrocerámica;

• No está previsto que el aparato sea utilizado por

personas (niños incluidos) con reducidas capacidades

físicas, sensoriales o mentales, por personas

inexpertas o que no tengan familiaridad con el

producto, a menos que no sean vigiladas por una

persona responsable de su seguridad o que no hayan

recibido instrucciones preliminares sobre el uso del

aparato.

• Evitar que los niños jueguen con el aparato.

• El aparato no se debe poner en funcionamiento a

través de un temporizador externo o de un sistema

de mando a distancia.

Eliminación

• Eliminación del material de embalaje: respete las

normas locales, de esta manera los embalajes podrán

ser reutilizados.

• En base a la Norma europea 2002/96/CE de Residuos

de aparatos Eléctricos y Electrónicos (RAEE), los

electrodomésticos viejos no pueden ser arrojados en

los contenedores municipales habituales; tienen que

ser recogidos selectivamente para optimizar la

recuperación y reciclado de los componentes y

materiales que los constituyen, y reducir el impacto en

la salud humana y el medioambiente. El símbolo del

cubo de basura tachado se marca sobre todos los

productos para recordar al consumidor la obligación

de separarlos para la recogida selectiva.

El consumidor podrá llevar los electrodomésticos

viejos a las áreas especiales preparadas por las

administraciones municipales, entregarlos al servicio

público de recogida o, si la legislación nacional lo

contempla, entregarlos en la tienda al hacer la compra

de los electrodomésticos nuevos de tipología análoga.

Todos los principales productores están involucrados

en la creación y gestión de sistemas optimizados para

la recogida y eliminación de los residuos de los

electrodomésticos.

26

Page 27

Mantenimiento y cuidados

Cortar la corriente eléctrica

Antes de realizar cualquier operación, desconecte el

aparato de la red de alimentación eléctrica.

Limpiar el aparato

! Evite el uso de detergentes abrasivos o corrosivos

como los quitamanchas y productos anticorrosivos,

jabones en polvo y esponjas con superficie abrasiva:

pueden rayar irremediablemente la superficie.

! No utilice nunca limpiadores a vapor o de alta

presión para la limpieza del aparato.

• Para un mantenimiento ordinario, es suficiente lavar

la encimera con una esponja húmeda, secándola

luego con un papel absorbente para cocina.