Page 1

Operating Instructions

HOB

AUS

FR ES

Français, 15 Español, 29English,1

PK 750 RT GH AUS

PK 640 R GH AUS

Contents

AUS

Installation, 2-8

Positioning

Electrical connection

Gas connection

Data plate

Burner and nozzle specifications

Description of the appliance, 9

Overall view

Start-up and use, 10-11

Practical advice on using the burners

Precautions and tips, 12

General safety

Disposal

Maintenance and care, 13

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Troubleshooting, 14

1

Page 2

Installation

AUS

! Before operating your new appliance please read this

instruction booklet carefully. It contains important

information for safe use, installation and care of the

appliance.

! Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

Compliance with standards

This cooktop must be installed by an authorised

person in accordance with the requirements of local

gas and electrical authorities, as well as the latest

published versions of the following standards:

• AS/NZS 5601 Gas Installations and pipe sizing

• SAA Wiring Rules.

Positioning

! Keep packaging material out of the reach of children. It

can become a choking or suffocation hazard (

Precautions and tips

! The appliance must be installed by a qualified and

authorised professional according to the instructions

provided. Incorrect installation may cause harm to people

and animals or may damage property.

Kitchen Ventilation

Where the total input of all appliances exceeds 3

MJ/h for each cubic metre of the room or enclosure

volume, the space shall be ventilated by one of the

methods detailed below. For the purpose of

assessing the adequacy of ventilation, the space

that cannot be isolated by doors is the ‘volume of a

room’.

Natural ventilation direct from outside

Two permanent openings shall be provided directly

to outside. The openings shall be located to ensure

the distance between the top of the upper opening

and the ceiling of the room or enclosure, and the

distance between the bottom of the lower opening

and the floor of the room or enclosure does not

exceed 5% of the height of the room or enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

A = 3 × T

where

A = the minimum free ventilation area (cm

T = the total gas consumption of all appliances

(MJ/h)

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

).

see

2

)

NOTE 1

to outside’ means any one of the following options,

provided that the ventilation path is unobstructed by

building material or insulation:

NOTE 2

provided that the top and bottom of the opening

reach the limits set by this Clause.

Natural ventilation via adjacent room

Two permanent openings shall be provided in the

room or enclosure. The openings shall be located to

ensure the distance between the top of the upper

opening and the ceiling of the room or enclosure,

and the distance between the bottom of the lower

opening and the floor of the room or enclosure does

not exceed 5% of the height of the room or

enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

where

These requirements shall apply to all subsequent

rooms until a room is ventilated to outside, in

accordance with the previous section, or the total

input of the appliances does not exceed 3 MJ/h for

each cubic metre of the total volume of the

enclosure and rooms.

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

NOTE

provided that the top and bottom of the opening

reach the limits set by this Clause.

• Liquid petroleum gas sinks to the floor as it is heavier

When used in this Clause, the term ‘directly

(a) Directly through an outside wall (preferred

option).

(b) Through to an outside wall but offset.

(c) Into a cavity ventilated to outside.

(d) Into an under floor space ventilated to outside.

(e) Into a roof space ventilated to outside.

The two openings may be combined

A = 6 × T

2

A = the minimum free ventilation area (cm

T = the total gas consumption of all appliances

(MJ/h)

: :

: The two openings may be combined

: :

than air. Therefore, rooms containing LPG cylinders

must also be equipped with vents to allow gas to

escape in the event of a leak. As a result LPG

cylinders, whether partially or completely full, must not

be installed or stored in rooms or storage areas that are

below ground level (cellars, etc.). It is advisable to

keep only the cylinder being used in the room,

positioned so that it is not subject to heat produced by

external sources (ovens, fireplaces, stoves, etc. ) which

could raise the temperature of the cylinder above 50°C.

)

2

Page 3

Adjacent cabinetry

600mm min.

420mm min.

700mm min.

The location of connection points is given in the

table on page 5 . For trouble-free operation of

appliances installed in housing units, the minimum

distances shown in fig.4 should be observed. It is

recommended that the adjacent kitchen surfaces

should be capable of withstanding temperatures of

65°C. Also, the following must be observed:

• The appliance should be installed next to

cabinetry which is no taller than the top of the

cooker hob.

• The wall in direct contact with the back panel of

the cooker must be made of non-flammable

material. During operation of the cooker, the back

panel of the cooker could reach a temperature of

50°C above room temperature.

• Kitchen cabinets installed next to the cooker that

are higher than the top of the hob, must be at

least 600 mm from the edge of the hob itself.

• If the hood is installed below a wall cabinet, the

latter must be at least 700 mm (millimetres) above

the surface of the hob.

• Cabinets installed adjacent to the hood must be

at least 420 mm above the hob,

The following minimum

clearances to combustible

materials must be observed:

• Minimum clearance from

edge of burner to side wall

must be 200 mm.

• Minimum clearance from

edge of burner to rear wall

must be 55 mm.

Range hoods

Range hoods and overhead exhaust fans must be

installed according to manufacturers’ instructions

but in no case shall clearance from hob burners be

less than 600 mm for range hoods and 750 mm for

overhead exhaust fans.

• If the hood is installed below a wall cabinet, the

latter must be at least 700 mm (millimetres) above

the surface of the hob.

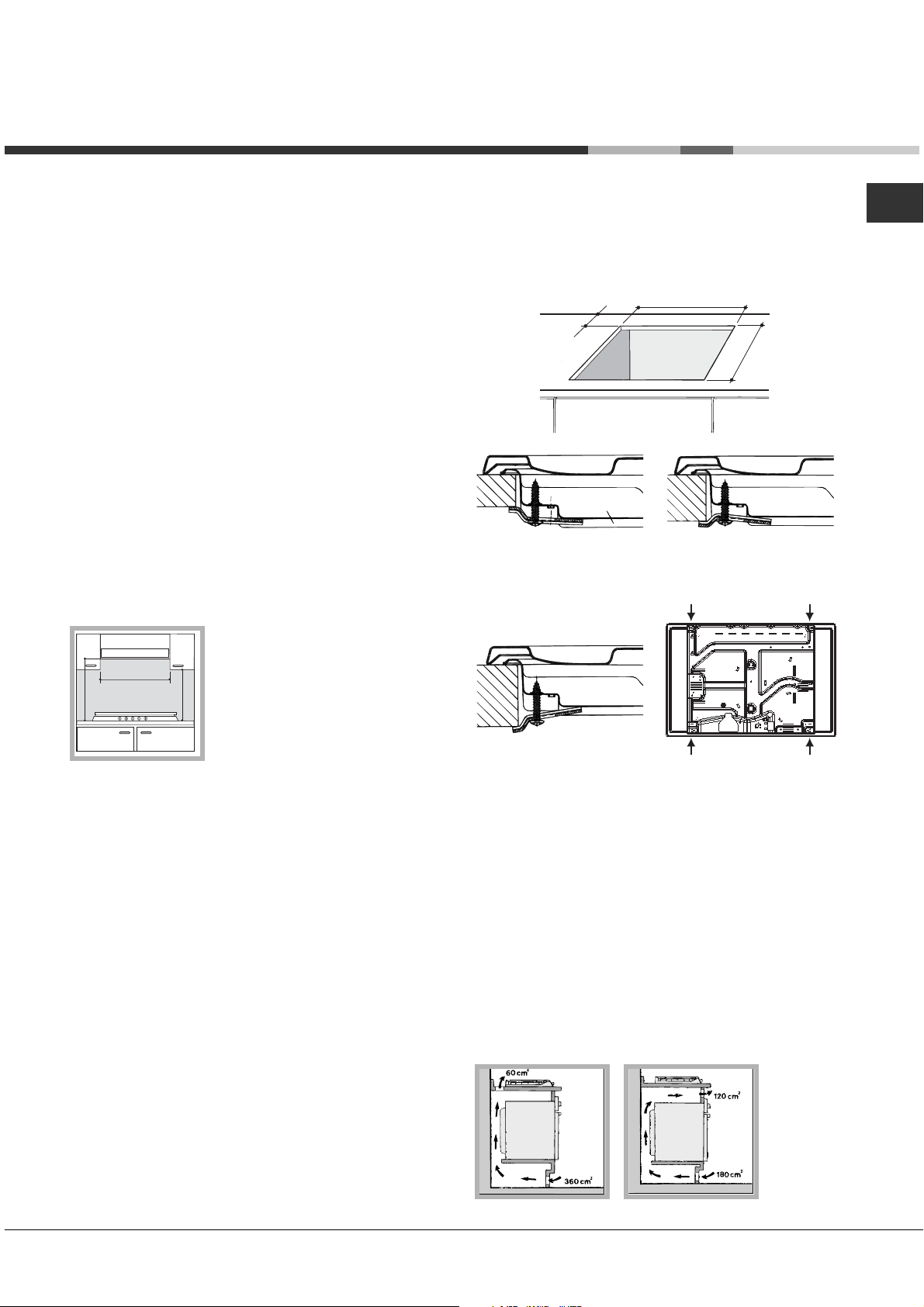

Fitting the cooktop above an oven

When installing the cooktop above an oven, both the

electricity supply cable and the gas pipe or flexible

hose must not touch hot parts of the oven housing.

When installing above a built-under oven without

forced cooling ventilation, suitable air vents should

be provided for (inlet at least 200 cm² from the

bottom, outlet at least 120 cm² from the top part) to

allow adequate ventilation inside the housing unit.

Also a wooden panel should be installed beneath

the hob as insulation, positioning it at a minimum

distance of 15 mm from the hob housing

• The installation cavity should have the dimensions

indicated in the figure. Fastening hooks are provided,

allowing you to fasten the hob to tops that are between

20 and 40 mm thick. To ensure the hob is securely

fastened to the top, we recommend you use all the

hooks provided.

555 mm

55 mm

475 mm

Hook fastening diagram

Hooking position Hooking position

for top H=20 mm for top H=30 mm

Front

Hooking position Back

for top H=40 mm

! Use the hooks contained in the “accessory pack”

• Where the hob is not installed over a built-in oven, a

wooden panel must be installed as insulation. This

must be placed at a minimum distance of 20 mm from

the lower part of the hob.

Ventilation

To ensure adequate ventilation, the back panel of the

cabinet must be removed. It is advisable to install the

oven so that it rests on two strips of wood, or on a

completely flat surface with an opening of at least 45 x

560 mm (

see diagrams

).

AUS

3

Page 4

AUS

Electrical connection

Hobs equipped with a three-pole power supply cable are

designed to operate with alternating current at the voltage

and frequency indicated on the data plate (this is located

on the lower part of the appliance). The earth wire in the

cable has a green and yellow cover. If the appliance is to

be installed above a built-in electric oven, the electrical

connection of the hob and the oven must be carried out

separately, both for electrical safety purposes and to

make extracting the oven easier.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load

indicated on the data plate.

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum contact

opening of 3 mm installed between the appliance and the

mains. The circuit-breaker must be suitable for the charge

indicated and must comply with current electrical

regulations (the earthing wire must not be interrupted by the

circuit-breaker). The supply cable must not come into

contact with surfaces with temperatures higher than 50°C.

! The installer must ensure that the correct electrical

connection has been made and that it is compliant with

safety regulations.

Before connecting to the power supply, make sure that:

• The appliance is earthed and the plug is compliant with

the law.

• The socket can withstand the maximum power of the

appliance, which is indicated on the data plate.

• The voltage is in the range between the values

indicated on the data plate.

• The socket is compatible with the plug of the

appliance. If the socket is incompatible with the plug,

ask an authorised technician to replace it. Do not use

extension cords or multiple sockets.

! Once the appliance has been installed, the power supply

cable and the electrical socket must be easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced by

authorised technicians only (

! The manufacturer declines any liability should these

safety measures not be observed.

see Assistance

).

Gas connection

Check The Gas Type

! Before installation, check that the gas type (natural

gas or Universal LPG) of the cooker is suitable for

the gas type available to the installation. It is

extremely dangerous to use the wrong gas type with

any appliance, as fire or serious injury can result.

This cooker is supplied from the factory already set

for Natural Gas. To convert the cooker to LPG (or

back to Natural Gas from LPG), follow the directions

later in this section.

Fit regulator supplied for Natural Gas (if applicable)

at rear of appliance, and as close as practicable to

the appliance.

It is recommended that an isolating valve and union

be fitted, to enable simple disconnection for

servicing. These are to be in an accessible location.

! Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (“Burner and nozzle

specifications”). This will ensure the safe operation and

longevity of your appliance while maintaining efficient

energy consumption.

Pipe or Hose Connection

This appliance is suitable for use with either a

flexible connection or rigid copper connection.

Either a rigid metal pipe with fittings in compliance

with the standards in force must be used for

connecting to the nipple union (threaded ½”G male

fitting) situated at the rear of the appliance to the

right (fig.8), or an approved flexible hose of class B

or D.

Should it be necessary to turn the fitting, the gasket

(supplied with the appliance) must be replaced.

If a flexible hose is used, it should be as short as

possible with a maximum length of 1.2 metres;

• The flexible connection must be approved to

class B or D of AS/NZS1869 as a minimum.

• it should not be bent, kinked or compressed;

• it should not be in contact with the rear wall of the

appliance or in any case with parts which may

reach a temperature of 50°C;

• it should not come into contact with pointed parts

or sharp corners;

• it should not be subject to any pulling or twisting

forces;

• it should be easy to inspect along its entire length

in order to be able to check its condition.

• The supply connection point must be accessible

with the appliance installed.

• The inner diameters of the pipe are as follows:

8 mm for LPG;

13 mm for Natural Gas.

Checking the tightness of the connection

Upon completion of installation, check the gas

circuit, the internal connections and the taps for

leaks using a soapy solution (never a flame). Also

check that the connecting pipe cannot come into

contact with moving parts which could damage or

crush it. Make sure that the natural gas pipe is

4

Page 5

adequate for a sufficient supply to the appliance

when all the burners are lit

Duplicate Data Plate

Where the data plate is obscured by cabinetry when

the cooker is in the installed position, place a

duplicate data plate on a surface of the cabinetry

adjacent to the cooker.

AUS

Adapting to different types of gas

To adapt the hob to a different type of gas other than

default type (indicated on the rating plate at the base of

the hob or on the packaging), the burner nozzles should

be replaced as follows:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

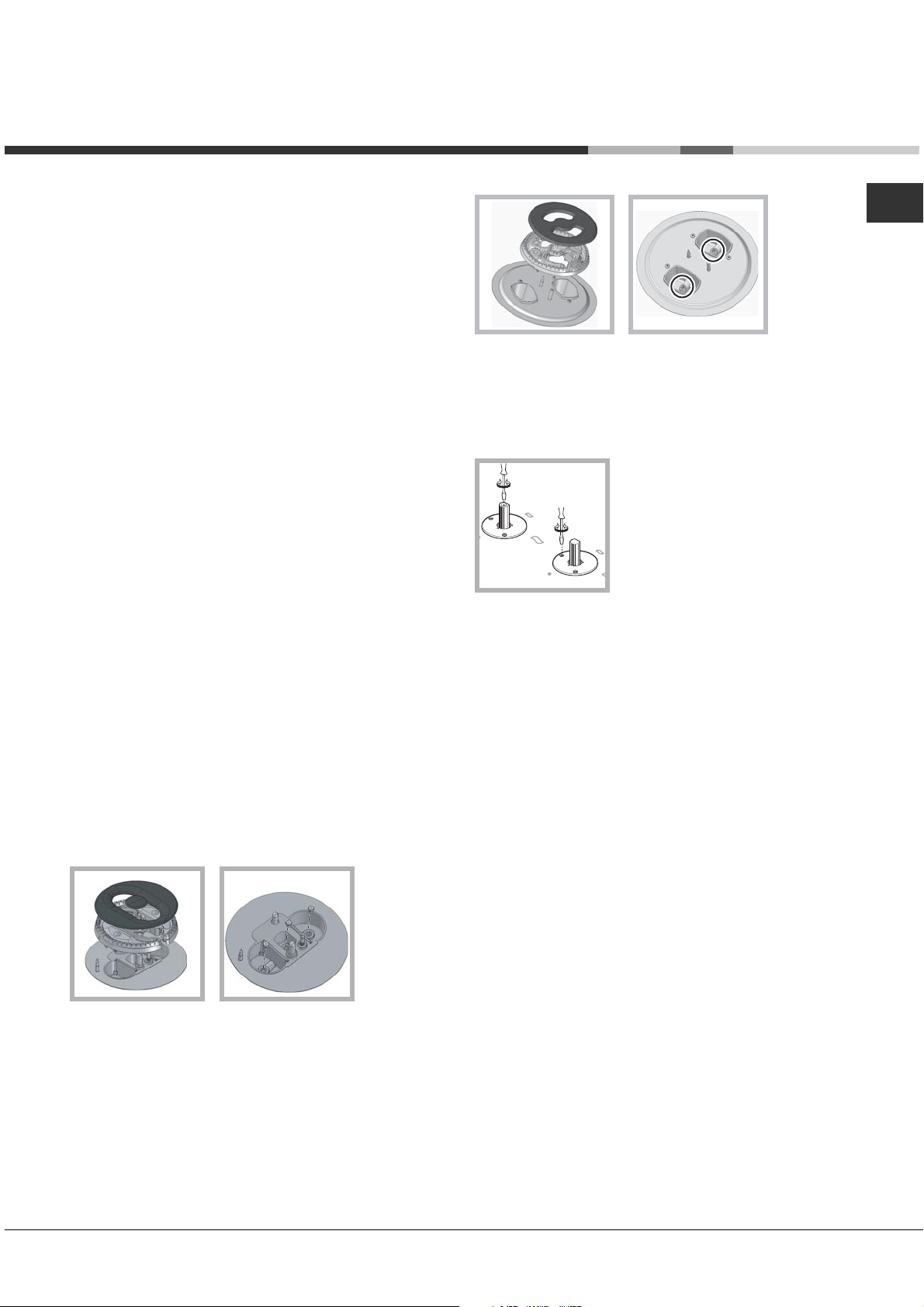

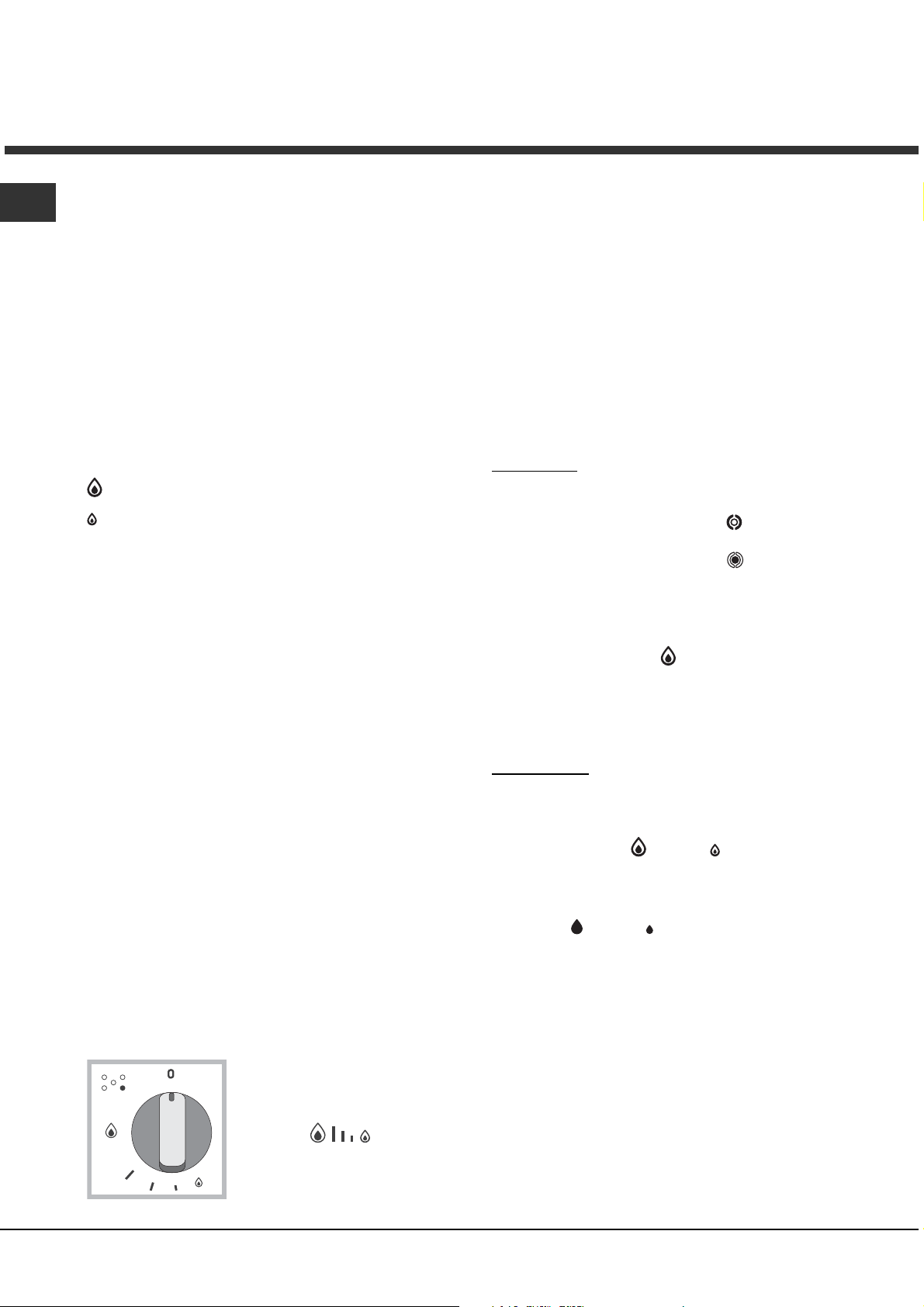

Replacing the nozzles on separate “double flame “

burners:

1. remove the grids and slide the burners from their

housings. The burner consists of 2 separate parts (

);

figure

2. unscrew the burers with a 7 mm wrench spanner. The

internal burner has a nozzle, the external burner has

two (of the same size). Replace the nozzle with models

suited to the new type of gas (see table 1).

3. replace all the components by repeating the steps in

reverse order.

see

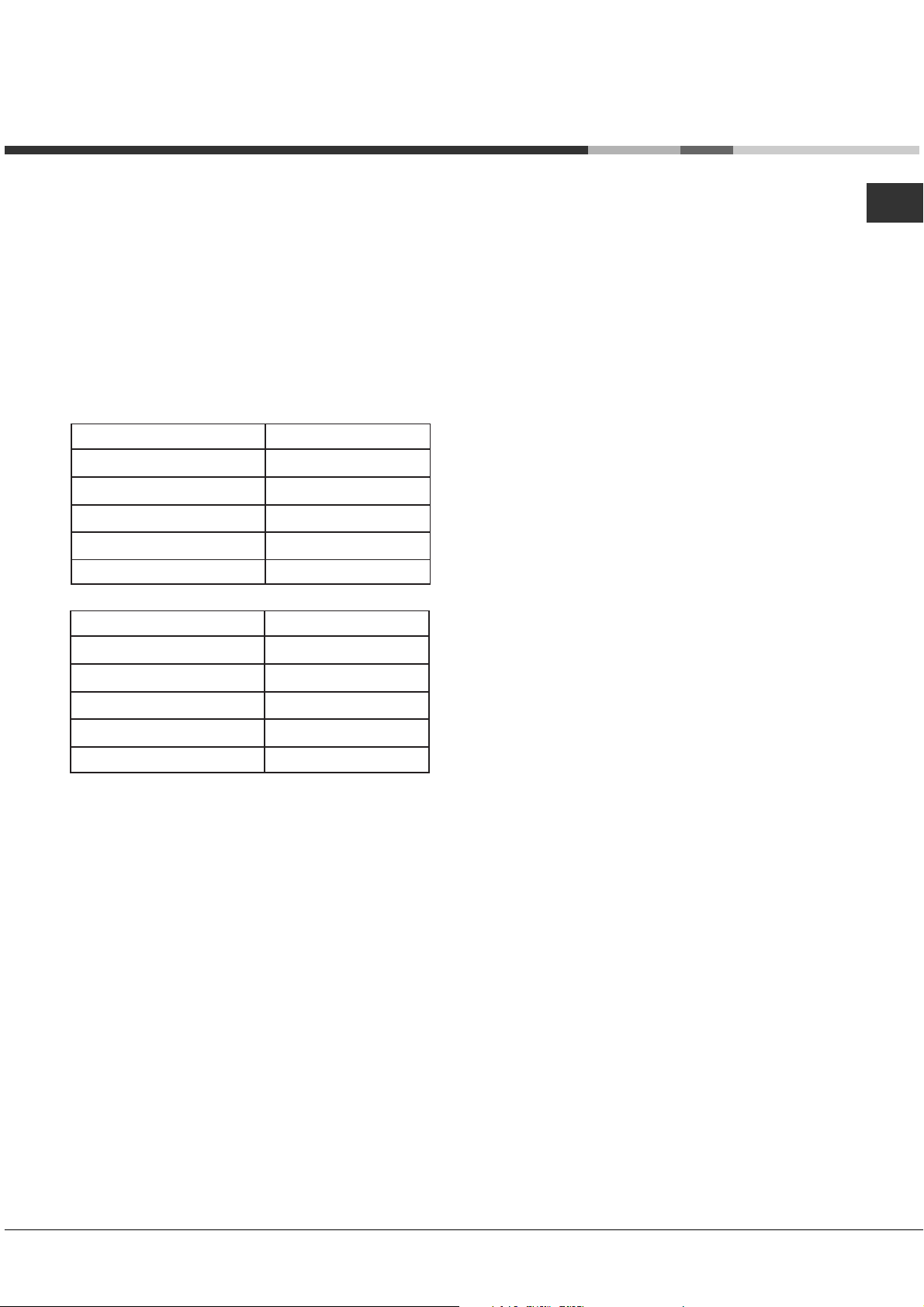

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust

the adjustment screw, which is

positioned in or next to the tap

pin, until the flame is small but

steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate parts

(see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

Post Installation Checks

Perform post installation checks and ensure proper

and safe operation before leaving. Test all burners

individually and in combination.

Leak Check

• Ensure all gas control knobs are in the Off

position.

• Ensure the gas supply is switched on.

5

Page 6

AUS

• Spray a solution of soapy water onto all gas joints

as well as the full length of any flexible hoses.

UNDER NO CIRCUMSTANCES USE A NAKED

FLAME IN CHECKING FOR LEAKS.

If bubbles appear anywhere, turn the gas supply off,

check all connections and retest. If satisfactory

operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Flame check

Turn each burner on, and ensure that the flame is

blue with minimal yellow tipping. If there is

significant yellow tipping, flame lift off or excessive

noise, check pressure and adjust at the regulator if

necessary.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Igniter operation

Check that the igniter for each burner successfully

ignites the gas.

If an igniter fails to work, first remove the plug from

the electrical power outlet, and then check that all

the electrical connections are in place.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Low flame setting

Check the low flame setting for each hob burner to

ensure that the minimum flame will not be

extinguished by air draughts.

• Light the burner.

• Turn the control until it engages in the minimum

position.

• Ensure the flame is stable and will not be

extinguished by air draughts.

To adjust the minimum flame:

Follow the procedure described in the gas

conversion instruction.

DO NOT MODIFY THIS APPLIANCE IN ANY WAY,

OTHER THAN AS DESCRIBED IN THESE

INSTRUCTIONS.

6

Page 7

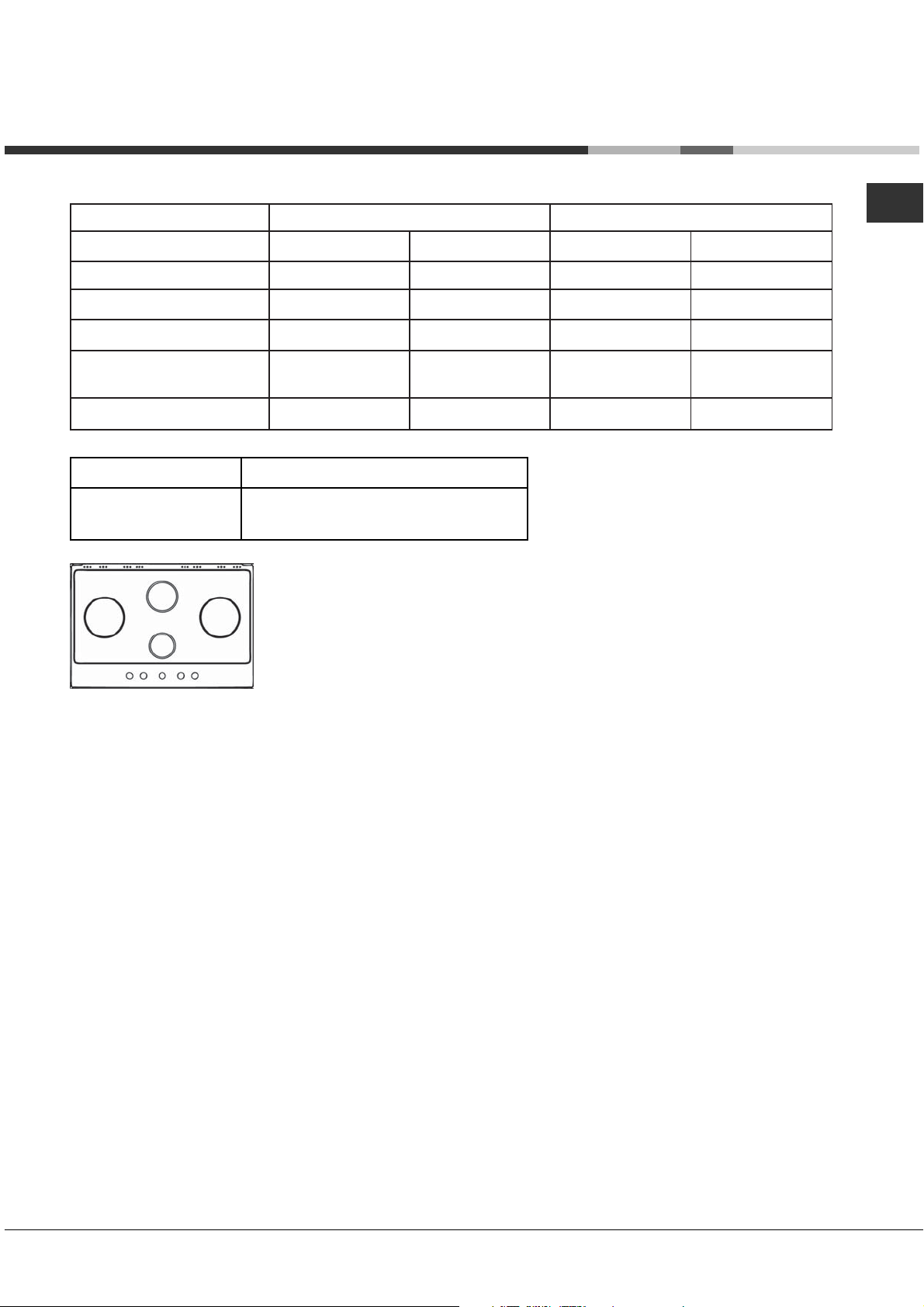

Gas Consumption

Natural Gas (1.0 kPa)

ULPG (2.75 kPa)

AUS

Ø Injector (mm)

Auxiliary Burner

Semi Rapid Burners

Wok Burner

Dual Control Wok Burner

Total

Gas Connection

Gas Inlet fitting 1/2” BSP (male) thread

Location of gas inlet 40 mm from rear edge

40 mm fro

0.85

1.10

1.19 (x2)

0.80 + 1.19 + 1.19

S

DC TC

A

GC (MJ/hr)

3.6

6.0

13.5

17.0

40.1

Ø Injector (mm)

0.50

0.64

0.70 (x2)

0.50 + 0.70 + 0.70

GC (MJ/hr)

3.3

5.5

13.0

16.5

38.3

PK 750 RT GH AUS

! The product was tested in accordance with AS4551 standard

7

Page 8

AUS

Gas Consumption

Natural Gas (1.0 kPa)

ULPG (2.75 kPa)

Ø Injector (mm)

Auxiliary Burner

Semi Rapid Burners

Rapid

Dual Control Wok Burner

Total

Gas Connection

Gas Inlet fitting 1/2” BSP (male) thread

Location of gas inlet 40 mm from rear edge

40 mm fro

0.85

1.10

1.24

0.85 + 1.07 + 1.07

A

R

DC

S

GC (MJ/hr)

3.6

6.0

7.8

13.0

30.4

Ø Injector (mm)

0.50

0.64

0.80

0.50 + 0.64 + 0.64

GC (MJ/hr)

3.3

5.5

9.0

13.0

30.8

PK 640 R GH AUS

! The product was tested in accordance with AS4551 standard

8

Page 9

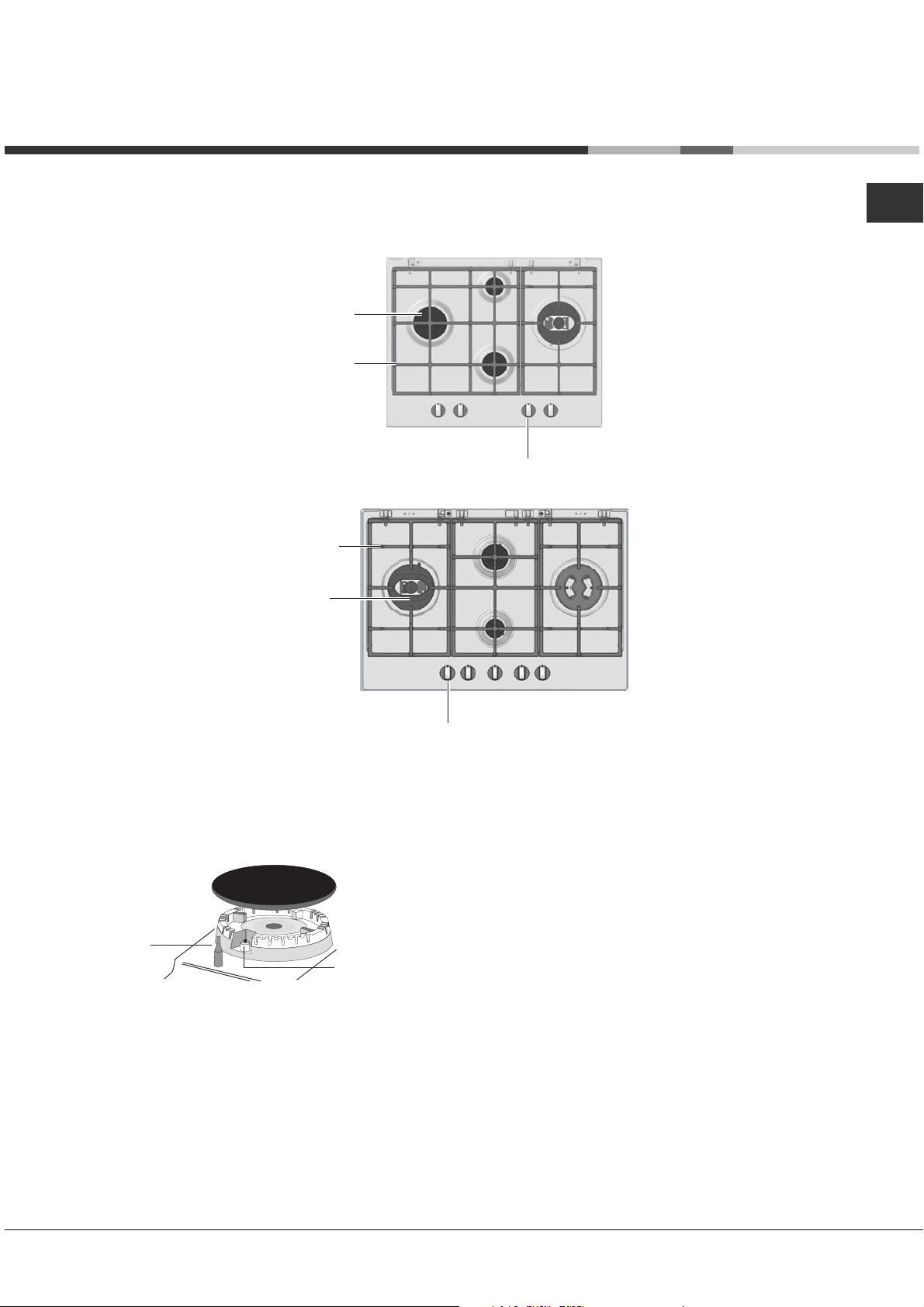

Description of the

appliance

Overall view

AUS

GAS BURNERS

Support Grid for

COOKWARE

Control Knobs for

GAS BURNERS

Support Grid for

COOKWARE

GAS BURNERS

Control Knobs for

GAS BURNERS

SAFETY

DEVICES *

• GAS BURNERS differ in size and power. Use the

diameter of the cookware to choose the most

appropriate burner to cook with.

• Control Knobs for GAS BURNERS adjust the size

of the flame.

Ignition for

GAS BURNERS *

• GAS BURNER ignition* enables a specific burner

to be lit automatically.

• SAFETY DEVICE* stops the gas flow if the flame

is accidentally extinguished.

9

Page 10

Start-up and use

AUS

! The position of the corresponding gas burner or

electric hotplate* is shown on every knob.

Gas cooker hobs are equipped with discrete power

adjustment that allows for accurately adjusting the

flame to 5 different power levels. Thanks to this

system, gas hobs are also capable of guaranteeing

the same cooking results for each recipe, as the

optimal power level for the desired type of cooking

can be identified in an easier, more accurate way.

Gas burners

Each burner can be adjusted to one of the following

settings using the corresponding control knob:

• Off

Maximum

Minimum

To light one of the burners, hold a lit match or lighter

near the burner and, at the same time, press down

and turn the corresponding knob anti-clockwise to the

maximum setting.

Since the burner is fitted with a safety device, the

knob should be pressed for approximately 2-3

seconds to allow the automatic device keeping the

flame alight to heat up.

When using models with an ignition button, light the

desired burner pressing down the corresponding

knob as far as possible and turning it anticlockwise

towards the maximum setting.

! If a flame is accidentally extinguished, turn off the

control knob and wait for at least 1 minute before

trying to relight it.

To switch off the burner, turn the knob in a clockwise

direction until it stops (when reaches the “•” position).

Discrete flame adjustment

The selected burner can be adjusted - by means of

the knob - to 5 different power levels.

To shift between levels, simply turn the knob

towards the desired power level.

A click signals the passage from one power level to

the other.

The selected power level is

indicated by the

corresponding symbol

on (5 = max. power; 1 = min. power). The system

guarantees accurate flame adjustment and uniform

cooking results by facilitating selection of the

desired power level.

The "double-flame" burner

This gas burner consists of two concentric flame

rings that can operate jointly or independently (in

case of dual-control only).

As the burner is fitted with a safety device, the

knob should be pressed down for approximately 2-3

seconds until the device keeping the flame

automatically alight heats up.

Dual control:

Each ring comprising the burner has its own control

knob:

The knob marked with the symbol

outer ring.

The knob marked with the symbol

inner ring.

To activate any one of the two rings, press the

corresponding knob and turn it anti-clockwise to the

maximum power setting

In order to use the double-flame burner to its full

potential, avoid simultaneously setting the inner

ring to minimum power and the outer ring to

maximum power.

Single control:

The rings comprising the burner are activated

through a single control knob.

To simultaneously turn on both rings, position the

knob on the symbol

and turn the knob anti-clockwise.

To turn on the inner ring only, position the knob on

the symbol

the knob clockwise.

(to switch modes, it is necessary to switch off the

burner).

To switch off the burner, press and turn the knob

clockwise until it stops (when it reaches the "•"

position).

(max.) - (min.) then press and turn

.

(max.) - (min.) then press

controls the

controls the

10

(symbols

hobs equipped with a

display, by the LEDs that turn

) and, on

Page 11

Practical advice on using the burners

To ensure the burners operate efficiently:

• Use appropriate cookware for each burner (see

table) so that the flames do not extend beyond

the bottom of the cookware.

• Always use cookware with a flat base and a cover.

• When the contents of the pan reach boiling point,

turn the knob to minimum.

AUS

Burner

Rapid (R)

Semi-Rapid (S)

Auxiliary (A)

Double Flame (DCDR internal)

Double Flame (DCDR external)

Ø Cookware Diameter (cm)

24 - 26

16 - 20

10 - 14

10 - 14

24 - 26

Pans to be used on 60 cm hobs

Burner

Semi-Rapid (S)

Auxiliary (A)

Triple Crown (TC)

Double Flame (DCDR internal)

Double Flame (DCDR external)

Ø Cookware Diameter (cm)

16 - 20

10 - 14

24 - 26

10 - 14

26 - 28

Pans to be used on 75 cm hobs

! On the models supplied with a reducer shelf,

remember that this should be used only for the

Double flame internal (DCDR internal) burner when

you use casserole dishes with a diameter under 12

cm.

To identify the type of burner, refer to the designs in

the section entitled, "Burner and Nozzle

Specifications".

11

Page 12

Precautions and tips

AUS

! This appliance has been designed and manufactured

in compliance with international safety standards. The

following warnings are provided for safety reasons and

must be read carefully.

General safety

• This is a class 3 built-in appliance.

• Gas appliances require regular air exchange to

maintain efficient operation. When installing the

hob, follow the instructions provided in the

paragraph on “Positioning” the appliance.

• These instructions are only valid for the countries

whose symbols appear in the manual and on the

serial number plate.

• The appliance was designed for domestic use inside

the home and is not intended for commercial or

industrial use.

• The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the

appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with wet

or damp hands and feet.

• The appliance must be used by adults only for the

preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous. The

manufacturer may not be held liable for any

damage resulting from improper, incorrect and

unreasonable use of the appliance.

• Ensure that the power supply cables of other

electrical appliances do not come into contact with

the hot parts of the oven.

• The openings used for ventilation and dispersion of

heat must never be covered.

• Always make sure the knobs are in the “”/“

position when the appliance is not in use.

• When unplugging the appliance always pull the plug

from the mains socket, do not pull on the cable.

• Never carry out any cleaning or maintenance work

without having detached the plug from the mains.

• In case of malfunction, under no circumstances

should you attempt to repair the appliance yourself.

Repairs carried out by inexperienced persons may

cause injury or further malfunctioning of the

appliance. Contact a Service Centre (

Assistance

• Always make sure that pan handles are turned

towards the centre of the hob in order to avoid

accidental burns.

• Do not close the glass cover (if present) when the gas

burners are still hot.

).

see

”

• Do not use unstable or deformed pans.

Remove any liquid from the lid beforeRemove any liquid from the lid before

•

Remove any liquid from the lid before

Remove any liquid from the lid beforeRemove any liquid from the lid before

opening it.opening it.

opening it.

opening it.opening it.

• The appliance should not be operated by people

(including children) with reduced physical, sensory or

mental capacities, by inexperienced individuals or by

anyone who is not familiar with the product. These

individuals should, at the very least, be supervised

by someone who assumes responsibility for their

safety or receive preliminary instructions relating to

the operation of the appliance.

• Do not let children play with the appliance.

• The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

Safety WarningsSafety Warnings

Safety Warnings

Safety WarningsSafety Warnings

• Do not use or store flammable materials near this

appliance.

• Do not spray aerosols in the vicinity of this appliance

while it is in operation.

• Do not modify this appliance.

• Not suitable for operation with aftermarket lids or

covers fitted.

• Where this appliance is installed in marine craft or in

caravans,it shall not be used as a space heater.

Disposal

• When disposing of packaging material: observe local

legislation so that the packaging may be reused.

• The European Directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE), requires

that old household electrical appliances must not be

disposed of in the normal unsorted municipal waste

stream. Old appliances must be collected separately

in order to optimise the recovery and recycling of the

materials they contain and reduce the impact on

human health and the environment. The crossed out

“wheeled bin” symbol on the product reminds you of

your obligation, that when you dispose of the

appliance it must be separately collected.

Consumers may take their old appliance to public

waste collection areas, other communal collection

areas, or if national legislation allows return it to a

retailer when purchasing a similar new product.

All major household appliance manufacturers are

active in the creation of systems to manage the

collection and disposal of old appliances.

12

Page 13

Maintenance and care

Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Do not use abrasive or corrosive detergents such as

stain removers, anti-rust products, powder detergents

or sponges with abrasive surfaces: these may scratch

the surface beyond repair.

! Never use steam cleaners or pressure cleaners on

the appliance.

• It is usually enough to wash the hob with a damp

sponge and dry it with absorbent kitchen roll.

• The removable parts of the burners should be

washed frequently with warm water and soap and

any burnt-on substances removed.

• For hobs which ligth automatically, the terminal part

of the electronic instant lighting devices should be

cleaned frequently and the gas outlet holes should

be checked for blockages.

Gas tap maintenance

AUS

Over time, the taps may become jammed or difficult

to turn. If this happens, the tap must be replaced.

! This procedure must be performed by a qualified

technician authorised by the manufacturer.

• Stainless steel can be marked by hard water that

has been left on the surface for a long time, or by

aggressive detergents containing phosphorus.

After cleaning, rinse and dry any remaining drops

of water.

!!

!

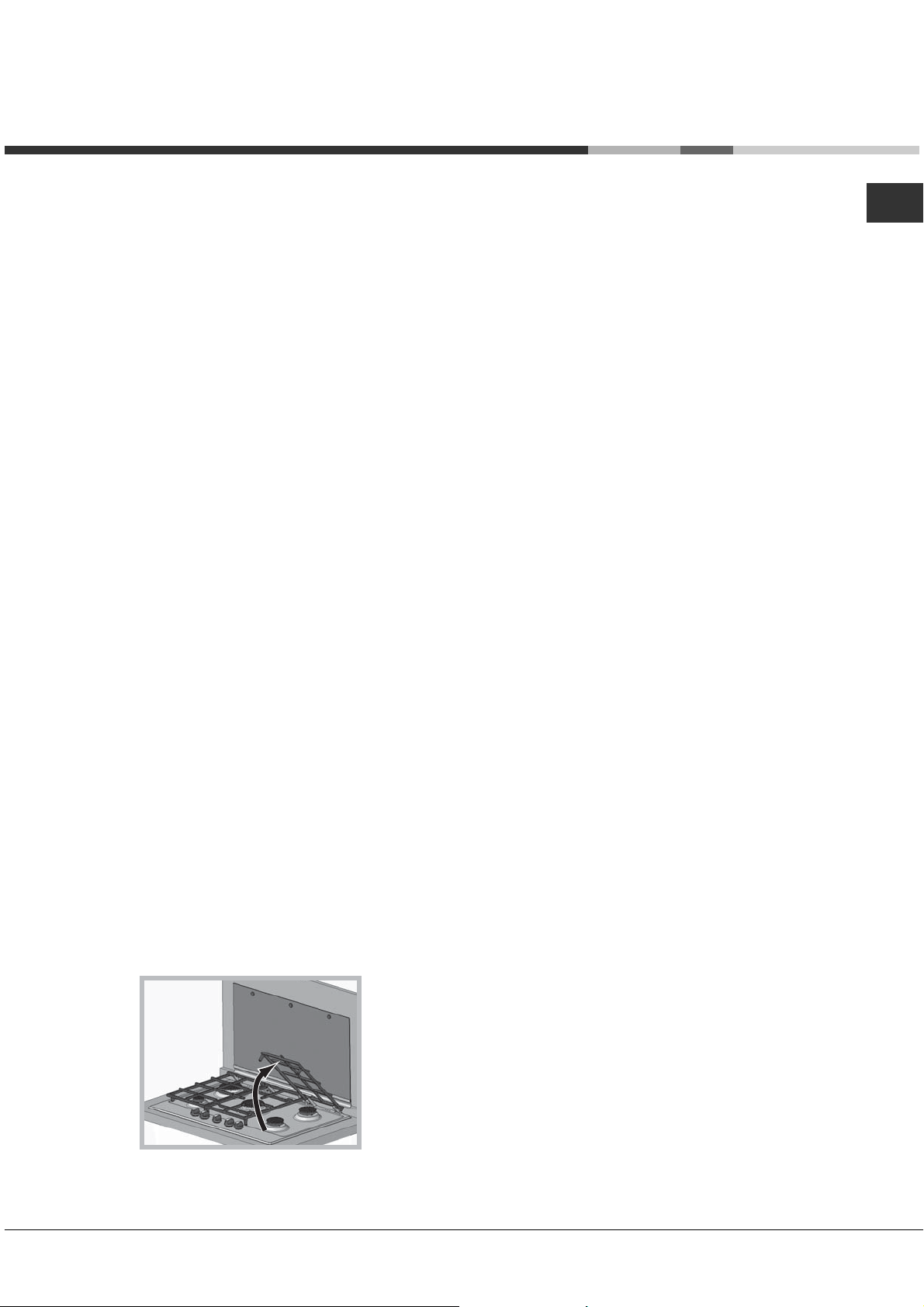

It is not necessary to remove the pan supports in

!!

order to clean the hob surface. Thanks to the

support system, simply lift and hold the pan

supports or rotate them until they rest against a rear

support.

Do not place the hot grids on top of the glass

cover (if applicable), otherwise the rubber plugs

on the glass may be damaged.

13

Page 14

Troubleshooting

AUS

It may happen that the appliance does not function properly or at all. Before calling the service centre for

assistance, check if anything can be done. First, check to see that there are no interruptions in the gas and

electrical supplies, and, in particular, that the gas valves for the mains are open.

Problem

The burner does not light or the flame is not

even around the burner.

The flame dies in models with a safety device.

The burner does not remain lit when set to

minimum.

The cookware is unstable.

Possible causes/Solution

• The gas holes on the burner are clogged.

• All the movable parts that make up the burner are

mounted correctly.

• There are draughts near the appliance.

• You pressed the knob all the way in.

• You keep the knob pressed in long enough to activate the

safety device.

• The gas holes are not blocked in the area corresponding

to the safety device.

• The gas holes are not blocked.

• There are no draughts near the appliance.

• The minimum setting has been adjusted properly.

• The bottom of the cookware is perfectly flat.

• The cookware is positioned correctly at the centre of the

burner.

• The pan support grids have been positioned correctly.

If, despite all these checks, the hob does not function properly and the problem persists, call the nearest

Customer Service Centre. Please have the following information handy:

• The appliance model (Mod.).

• The serial number (S/N).

This information can be found on the data plate located on the appliance and/or on the packaging.

! Never use unauthorised technicians and never accept replacement parts which are not original.

Service

Annual servicing by an authorised person is recommended. If the appliance produses unusal odour,

yellow tipping flame, flame lifting off the burner or is not performing as per original installation, or for

service please contact:

ARISTON

PRIORITY SERVICE

If you are not completely satisfied with your appliance

or require service call:

Australia

Phone: 1300 815 589

New Zealand

Phone: (09) 306 1020

AUSTRALIA

ARISIT PTY LIMITED

40-44 Mark Anthony Drive, Dandenong South,

VIC 3175, Australia

Fax: Service & Sales (03) 9768 0838

accessories are available for your appliance call:

NEW ZEALAND

ARISIT PTY LIMITED

PO Box 68-140 Newton, Auckland

1145, New Zealand

Fax: (09) 302 0077

GENUINE ACCESSORIES

& SPARE PARTS

A wide range of genuine

Australia

Phone: 03 9768 0888

New Zealand

Phone: (09) 306 1020

Email: consumer.care@arisit.com

14

Email: sales@aristonappliances.co.nz

Page 15

Mode d’emploi

TABLE DE CUISSON

AUS ES

FR

Français, 15English,1

Español, 29

PK 750 RT GH AUS

PK 640 R GH AUS

Sommaire

FR

Installation, 16-22

Positionnement

Raccordement électrique

Raccordement gaz

Plaquette signalétique

Caractéristiques des brûleurs et des injecteurs

Description de l’appareil, 23

Vue d’ensemble

Mise en marche et utilisation, 24-25

Conseils pratiques pour l’utilisation des brûleurs

Précautions et conseils, 26

Sécurité générale

Mise au rebut

Nettoyage et entretien, 27

Mise hors tension

Nettoyage de l’appareil

Entretien robinets gaz

Anomalies et remèdes, 28

15

Page 16

Installation

FR

! Avant d'utiliser votre nouvel appareil, veuillez lire cette

notice avec la plus grande attention. Elle contient des

informations importantes destinées à assurer votre

sécurité lors de l'utilisation, l'installation et l'entretien de

l'appareil.

! Veuillez conserver cette notice afin de pouvoir la

consulter ultérieurement. En cas de cession de l'appareil à

un tiers, veuillez également lui transmettre cette notice.

Conformité aux normes en vigueur

Cette table de cuisson doit être installée

conformément aux règles définies par les autorités

locales de gaz et d'électricité et aux dernières

versions publiées des normes suivantes :

• AS/NZS 5601 Code relatif à l'installation

d'appareils à gaz

• Règles de câblage de la SAA

Positionnement

! Conservez les matériaux d'emballage hors de portée

des enfants. Ils peuvent représenter un danger

d'étouffement

! L'appareil doit être installé par un professionnel qualifié

conformément aux instructions fournies. Une installation

incorrecte peut être à l'origine de blessures pour les

personnes et les animaux ou de dommages matériels.

Ventilation de la cuisine

Si la consommation totale de tous les appareils

dépasse les 3 MJ/h par mètre cube de la pièce ou

du volume de l'enceinte, l'espace doit être ventilé

par l'une des méthodes décrites en détails cidessous. Le critère " volume de la pièce " pris en

compte pour déterminer si la ventilation est

adéquate ou non correspond à l'espace ne pouvant

pas être isolé par des portes.

Ventilation naturelle directe venant de l'extérieur

Deux ouvertures permanentes vers l'extérieur

doivent être ménagées. Les ouvertures doivent être

placées de manière à assurer que la distance entre

le haut de l'ouverture supérieur et le plafond de la

pièce ou de l'enceinte, et la distance entre le bas de

l'ouverture inférieure et le sol de la pièce ou de

l'enceinte ne dépassent pas 5 % de la hauteur de la

pièce ou de l'enceinte. La surface de ventilation libre

minimale fournie par chaque ouverture sera calculée

en utilisant la formule suivante :

A = 3 × T

où

A = la surface de ventilation libre minimale (cm2)

T = la consommation totale de gaz de tous les

appareils (MJ/h)

La dimension verticale minimale de toute ouverture

de ventilation libre doit être de 6 mm.

NOTE 1

directement vers l'extérieur " signifie l'une des

options ci-dessous, à condition que le chemin de

ventilation ne soit pas obstrué par des matériaux de

construction ou d'isolation :

(a) Directement à travers un mur extérieur (option

préférée).

(voir Précautions et conseils)

Lorsqu'elle est utilisée ici, l'expression "

.

(b) À travers un mur extérieur mais avec un

décalage.

(c) Dans une cavité ventilée vers l'extérieur.

(d) Dans un espace situé sous le sol et ventilé

vers l'extérieur.

(e) Dans un espace en toiture ventilé vers

l'extérieur.

NOTE 2

combinées à condition que le haut et le bas de

l'ouverture atteignent les limites fixées dans cette

notice.

Ventilation naturelle par le biais d'une pièce

adjacente

Deux ouvertures permanentes doivent être

ménagées dans la pièce ou l'enceinte. Les

ouvertures doivent être placées de manière à

assurer que la distance entre le haut de l'ouverture

supérieur et le plafond de la pièce ou de l'enceinte,

et la distance entre le bas de l'ouverture inférieure et

le sol de la pièce ou de l'enceinte ne dépassent pas

5 % de la hauteur de la pièce ou de l'enceinte.

La surface de ventilation libre minimale fournie par

chaque ouverture sera calculée en utilisant la

formule suivante :

où

Ces exigences s'appliquent à toutes les pièces

suivantes, jusqu'à ce qu'une pièce soit ventilée vers

l'extérieur, conformément à la section précédente,

ou si la consommation totale de tous les appareils

ne dépasse pas les 3 MJ/h par mètre cube du

volume total de l'enceinte ou des pièces.

La dimension verticale minimale de toute ouverture

de ventilation libre doit être de 6 mm.

REMARQUE

combinées à condition que le haut et le bas de

l'ouverture atteignent les limites fixées dans cette

notice.

• Les gaz de pétrole liquéfiés, plus lourds que l'air, se

Les deux ouvertures peuvent être

A = 6 × T

A = la surface de ventilation libre minimale (cm2)

T = la consommation totale de gaz de tous les

appareils (MJ/h)

: :

: Les deux ouvertures peuvent être

: :

déposent et stagnent au niveau du sol. Par

conséquent, les pièces contenant des bouteilles de

gaz liquéfié doivent aussi disposer d'ouvertures vers

l'extérieur afin de permettre l'évacuation des

éventuelles fuites de gaz. C'est pourquoi les bouteilles

de gaz liquéfié, qu'elles soient partiellement ou

complètement pleines, ne doivent pas être installées

dans des pièces ou des espaces de stockage se

situant en-dessous du niveau du sol (par exemple,

dans des caves, etc.). Il est conseillée de ne conserver

dans la pièce que la bouteille en cours d'utilisation et

de la placer de telle sorte qu'elle ne puisse pas être

exposée à la chaleur produite par des sources

extérieures (fours, cheminées, poêles, etc.) qui

pourraient faire grimper la température de la bouteille

au-dessus de 50 °C.

16

Page 17

Mobilier adjacent

600mm min.

420mm min.

700mm min.

L'emplacement des points de raccordement est

indiqué au tableau situé à la page 5. Pour éviter les

problèmes de fonctionnement des appareils

encastrés dans des meubles, il convient de

respecter les distances minimales représentées sur

la figure 4. Il est recommandé que les surfaces

adjacentes de la cuisine soient capables de résister

à des températures de 65°C. Les conditions

suivantes doivent également être respectées :

• L'appareil doit être installé à proximité de mobilier

dont la hauteur ne dépasse pas le dessus de la

plaque de cuisson.

• Le mur en contact direct avec le panneau arrière

de la cuisinière doit être composé d'un matériau

non inflammable. Pendant le fonctionnement de

la cuisinière, le panneau arrière de cette dernière

peut atteindre une température de 50 °C

supérieure à la température de la pièce.

• Les meubles de cuisine installés à côté de la

cuisinière et qui sont plus hauts que le dessus de

la plaque de cuisson doivent être situés à au

moins 600 mm du bord de la plaque elle-même.

• Si la hotte est installée en-dessous d'un élément

mural, ce dernier doit être situé au moins 700 mm

(millimètres) au-dessus de la surface de la

plaque.

• Les meubles installés à côté de la hotte doit être

situé au moins 420 mm au-dessus de la plaque

de cuisson.

Il faut respecter les espacements minimum suivants

par rapport aux matériaux combustibles :

• L'espacement minimum

entre le bord du brûleur et le

mur latéral doit être de 200

mm.

• L'espacement minimum

entre le bord du brûleur et le

mur arrière doit être de 55

mm.

En cas d'installation au-dessus four encastré ne

disposant pas de ventilation forcée pour assurer son

refroidissement, il faut créer des ouvertures

d'aération afin de permettre une ventilation adéquate

à l'intérieur du meuble (au moins 200 cm² en bas

pour l'arrivée d'air et au moins 120 cm² en haut pour

la sortie).

Il faut en outre installer une planche de bois sous la

plaque de cuisson en guise d'isolation, à une

distance minimale de 15 mm du meuble

• Le trou réalisé pour y installer la plaque de cuisson doit

avoir les dimensions représentées sur la figure. Des

crochets de fixation sont fournis, destinés à fixer la

plaque de cuisson sur des plans de travail de 20 à 40

mm d'épaisseur. Pour assurer la bonne fixation de la

plaque sur le plan de travail, nous vous

recommandons d'utiliser tous les crochets fournis.

555 mm

55 mm

475 mm

Schéma de fixation des crochets

Position des crochets pour

un plan de travail de

20 mm20 mm

20 mm

20 mm20 mm

d'épaisseur

Position des crochets pour

un plan de travail de 30 mm

d'épaisseur

Avant

FR

Hottes

Les hottes et les systèmes de ventilation de plafond

doivent être installés selon les instructions du

fabricant mais l'espacement par rapport aux

brûleurs de la plaque de cuisson ne doit en aucun

cas être inférieur à 650 mm pour les hottes et 750

mm pour les systèmes de ventilation.

• Si la hotte est installée en-dessous d'un élément

mural, ce dernier doit être situé au moins 700 mm

(millimètres) au-dessus de la surface de la

plaque.

Installation de la table de cuisson au-dessus d'un

four

En cas d'installation de la table de cuisson audessus d'un four, il est impératif que ni le câble

d'alimentation électrique ni le tuyau de gaz (flexible

ou non) ne soient en contact avec les parties

chaudes du four.

Position des crochets pour

un plan de travail de 40 mm

d'épaisseur

Arrière

! Utilisez les crochets se trouvant dans le " kit

d'accessoires "

• Si la plaque de cuisson n'est pas installée au-dessus

d'un four encastré, il faut installer une planche de bois

en guise d'isolation. Celle-ci doit être placée à une

distance minimale de 20 mm de la partie inférieure de

la plaque de cuisson.

17

Page 18

FR

Ventilation

Pour assurer une ventilation adéquate, le panneau arrière

du meuble doit être retiré. Il est conseillé d'installer le four

de telle sorte qu'il repose sur deux tasseaux de bois ou

sur une surface complètement plante avec une ouverture

d'au moins 45 x 560 mm

(voir schémas)

.

Branchement électrique

Les plaques de cuisson équipées d'un câble

d'alimentation électrique à trois pôles sont conçues pour

fonctionner sur le courant alternatif à la tension et à la

fréquence indiquées sur la plaque signalétique (située

dans la partie inférieure de l'appareil). Le fil de terre dans

le câble possède une gaine de couleur verte et jaune. Si

l'appareil doit être installé au-dessus d'un four électrique

encastré, le raccordement électrique de la plaque de

cuisson et du four doit être réalisé séparément, à la fois

pour des raisons de sécurité électrique et pour faciliter

l'extraction du four.

Branchement du câble d'alimentation électrique au

réseau

Installez une fiche standard correspondant à la charge

indiquée sur la plaque signalétique.

L'appareil doit être raccordé directement au réseau

électrique en utilisant un disjoncteur omnipolaire ayant une

ouverture de contact minimum de 3 mm et installé entre

l'appareil et le réseau. Le disjoncteur doit être adapté à la

charge indiquée et doit être conforme aux réglementations

en vigueur en matière d'électricité (le fil de terre ne doit

pas être interrompu par le disjoncteur). Le câble

d'alimentation ne pas entrer en contact avec des surfaces

dont la température dépasse les 50°C.

! L'installateur doit s'assurer que le raccordement

électrique qui a été réalisé est correct et conforme aux

règles de sécurité en vigueur.

Avant le raccordement à l'alimentation électrique, assurezvous que :

• L'appareil est mis à la terre et la fiche est conforme aux

exigences légales.

• La prise de courant peut supporter la puissance

maximale de l'appareil qui est indiquée sur la plaque

signalétique.

• La tension est située dans la plage de valeurs indiquée

sur la plaque signalétique.

• La prise de courant est compatible avec la fiche de

l'appareil. Si la prise de courant n'est pas compatible

avec la fiche, demandez à un technicien agréé de la

remplacer. N'utilisez pas de rallonges ni de prises

multiples.

! Une fois l'appareil installé, le câble d'alimentation et la

prise de courant doivent être faciles d'accès.

! Le câble ne doit pas être plié ni comprimé.

! Le câble doit être inspecté régulièrement et remplacé

uniquement par des techniciens agréés (voir Assistance).

! Le fabricant décline toute responsabilité si ces mesures

de sécurité ne sont pas respectées.

Raccordement gaz

Vérifiez le type de gaz

! Avant l'installation, vérifiez que le type de gaz (gaz

naturel ou gaz liquéfié/propane) de la cuisinière est

adapté au gaz disponible dans le lieu d'installation.

Il est extrêmement dangereux d'utiliser le mauvais

type de gaz avec quelque appareil que ce soit. Cela

peut entraîner un incendie ou de blessures graves.

À sa sortie d'usine, cette cuisinière est configurée

pour fonctionner au gaz naturel. Pour utiliser la

cuisinière avec du gaz liquéfié (ou au gaz naturel

après l'avoir utilisée précédemment au gaz liquéfié),

veuillez suivre les indications reportées plus loin

dans cette section.

Installez le régulateur fourni pour le gaz naturel (le

cas échéant) à l'arrière de l'appareil et le plus près

possible de l'appareil.

Il est recommandé d'installer un robinet et un

raccord d'isolement afin de faciliter la déconnexion

pour les interventions d'entretien. Ces derniers

doivent être situés à un endroit accessible.

! Vérifiez que la pression de l'alimentation en gaz

correspond aux valeurs indiquées dans le Tableau 1 ("

Caractéristiques des brûleurs et des injecteurs "). Cela

garantira le fonctionnement en toute sécurité et la

longévité de votre appareil tout en conservant une bonne

efficacité énergétique.

Raccordement du tuyau ou flexible

Cet appareil est adapté pour être utilisé soit avec un

raccord flexible soit avec un raccord rigide en

cuivre.

Pour effectuer la connexion au raccord à mamelon

(raccord mâle G fileté de ½") situé à l'arrière de

l'appareil sur la droite (figure 8), il faut utiliser soit un

tuyau rigide en métal doté de raccords conformes

aux normes en vigueur soit un tuyau flexible de

classe B ou D.

Au cas où il serait nécessaire de tourner le raccord,

il faudra remplacer le joint d'étanchéité (fourni avec

l'appareil).

Si un tuyau flexible est utilisé, il devra être le plus

court possible, avec une longueur maximale de 1,5

mètres ;

• le raccord du flexible doit être conforme au

minimum à la classe B ou D de la réglementation

AS/NZS1869.

• il ne doit être ni plié, ni entortillé ni comprimé ;

• il ne doit pas être en contact avec la paroi arrière de

l'appareil ou, dans tous les cas, avec des pièces

pouvant atteindre une température de 50 °C ;

• il ne doit pas entrer en contact avec des éléments

18

Page 19

pointus ou des angles tranchants ;

• il ne doit pas être soumis à des forces de traction

ou de torsion ;

• il doit être facile à inspecter sur toute sa longueur

afin de pouvoir contrôler son état.

• Le point de connexion à l'alimentation doit être

accessible une fois l'appareil installé.

• Le diamètre intérieur du tuyau doit respecter les

conditions suivantes :

8 mm pour le gaz liquéfié ;

13 mm pour le gaz naturel.

Vérification de l'étanchéité du raccord

Une fois l'installation terminée, vérifiez le circuit de

gaz, les connexions internes et les robinets en

utilisant une solution savonneuse (jamais une

flamme). Vérifiez également que le tuyau de

raccordement ne peut pas entrer en contact avec

des parties mobiles qui pourraient l'endommager ou

l'écraser. Assurez-vous que le tuyau de gaz naturel

est adapté pour une alimentation en gaz suffisante

lorsque tous les brûleurs sont allumés.

Copie de la plaque signalétique

Si la plaque signalétique se trouve cachée par le

mobilier lorsque la cuisinière est en place, placez

une copie de la plaque signalétique sur une surface

du mobilier situé à côté de la cuisinière.

Adaptation aux différents types de gaz

Pour adapter l'appareil à un type de gaz autre que le gaz

par défaut (indiqué sur la plaque signalétique située à la

base de la plaque de cuisson ou sur l'emballage),

remplacez les injecteurs de tous les brûleurs en

procédant comme suit :

1. Enlevez les grilles du plan de cuisson et sortez les

brûleurs de leur logement.

2. Dévissez les injecteurs à l'aide d'une clé à douille de 7

mm et remplacez-les par les injecteurs adaptés au

nouveau type de gaz (voir tableau 1 " Caractéristiques

des brûleurs et des injecteurs ").

3. Remontez les différentes parties en effectuant la

procédure ci-dessus en sens inverse.

4. Une fois cette procédure terminée, remplacez

l'ancienne étiquette par une étiquette indiquant le

nouveau gaz utilisé. Vous pouvez vous procurer cette

étiquette auprès de n'importe lequel de nos Services

d'assistance.

Remplacement des injecteurs sur les brûleurs à "

deux flammes " indépendantes :

1. Retirez les grilles et faites glisser les brûleurs hors de

leurs logements. Le brûleur est composé de deux

parties distinctes

2. Dévissez les brûleurs à l'aide d'une clé plate de 7 mm.

Le brûleur interne possède un injecteur et le brûleur

externe en possède deux (de la même taille).

Remplacez l'injecteur par un modèle d'injecteur adapté

au nouveau type de gaz (voir tableau 1).

3. Remettez tous les composants en place en répétant

les étapes dans le sens inverse.

(voir figure)

;

FR

Remplacement des injecteurs du brûleur à triple

couronne

1. Retirez les supports pour casseroles et soulevez les

brûleurs hors de leur logement. Le brûleur est composé

de deux parties distinctes (voir figures).

2. Dévissez les injecteurs à l'aide d'une clé à douille de 7

mm. Remplacez les injecteurs par des modèles

d'injecteurs adaptés pour le nouveau type de gaz (voir

Tableau 1). Les deux injecteurs ont le même diamètre

d'orifice.

3. Remettez tous les composants en place en répétant

les opérations ci-dessus dans le sens inverse.

• Réglage de l'air primaire des brûleurs :

Ne nécessite pas de réglage.

• Réglage des brûleurs au minimum :

1. Tournez le robinet dans la position de minimum.

2. Retirez le bouton et ajustez la

vis de réglage qui se situe dans

ou à côté de la tige du robinet,

jusqu'à ce que la flamme soit

petite mais régulière.

3. Une fois obtenu le débit minimal souhaité, allumez le

brûleur et tournez brusquement le bouton de la position

de minimum à la position de maximum et vice versa à

plusieurs reprises, en vérifiant que la flamme ne s'éteint

pas.

4. Certains appareils sont équipés d'un système de

sécurité (thermocouple). Si l'appareil ne fonctionne pas

lorsque les brûleurs sont réglés sur la position de

minimum, augmentez le réglage du minimum à l'aide

de la vis de réglage.

5. Après avoir procédé à ce réglage, reposez les scellés

sur les by-pass en utilisant de la cire ou une substance

équivalente.

! Si l'appareil est raccordé à une bouteille de gaz liquide,

la vis de réglage doit être serrée au maximum.

19

Page 20

FR

! Une fois cette procédure terminée, remplacez l'ancienne

étiquette par une étiquette indiquant le nouveau gaz

utilisé. Vous pouvez vous procurer cette étiquette auprès

de n'importe lequel de nos Services d'assistance.

! Au cas où la pression de gaz utilisée serait différente (ou

seulement légèrement différente) de la pression

recommandée, il faut installer un régulateur de pression

adapté sur le tuyau d'arrivée de gaz (afin d'être en

conformité avec les réglementations nationales en

vigueur).

Vérifications après installation

Effectuez des vérifications après installation et

assurez-vous que l'appareil fonctionne correctement

et en toute sécurité avant de vous en éloigner.

Testez tous les brûleurs individuellement et l'un

après l'autre.

Vérification de la présente de fuite

• Veillez à ce que tous les boutons de commande

de gaz soient dans la position éteinte.

• Veillez à ce que l'alimentation en gaz soit ouverte.

• Vaporisez une solution d'eau savonneuse sur tous

les raccords de l'alimentation en gaz ainsi que sur

toute la longueur des tuyaux flexibles.

VOUS NE DEVEZ EN AUCUN CAS UTILISER UNE

FLAMME NUE AFIN DE DÉTECTER

L'ÉVENTUELLE PRÉSENCE DE FUITES DE GAZ.

Si des bulles apparaissent à un endroit ou un autre,

coupez l'alimentation en gaz, vérifiez tous les

raccords et refaites un test. Si vous ne parvenez

pas à un fonctionnement satisfaisant, contactez

votre lieu d'achat ou leur technicien d'entretien

agréé.

Réglage du minimum

Vérifiez le réglage du minimum pour chaque brûleur

de la plaque de cuisson afin de vous assurer que la

flamme minimale ne risque pas d'être éteinte par les

courants d'air.

• Allumez le brûleur.

• Tournez le bouton jusqu'à la position de minimum.

• Assurez-vous que la flamme est stable et ne

s'éteindra pas au moindre courant d'air.

Pour ajuster la flamme minimale :

Suivez la procédure décrite dans les instructions

relatives au changement de gaz utilisé.

NE MODIFIEZ EN AUCUN CAS CET APPAREIL SI

CE N'EST TEL QUE DÉCRIT DANS CETTE

NOTICE.

Vérification de la flamme

Allumez chaque brûleur et vérifiez que la flamme est

bleue avec le moins de jaune possible. S'il y a

beaucoup de jaune, si la flamme s'éteint ou bien si

la combustion est excessivement bruyante, vérifiez

la pression et ajustez-la au niveau du régulateur si

cela s'avère nécessaire.

Si vous ne parvenez pas à un fonctionnement

satisfaisant, contactez votre lieu d'achat ou leur

technicien d'entretien agréé.

Fonctionnement de l'allumeur

Vérifiez que l'allumeur de chaque brûleur parvient à

enflammer correctement le gaz.

Si un allumeur ne fonctionne pas, débranchez

d'abord la fiche de la prise de courant puis vérifiez

que toutes les connexions électriques sont

correctes.

Si vous ne parvenez pas à un fonctionnement

satisfaisant, contactez votre lieu d'achat ou leur

technicien d'entretien agréé.

20

Page 21

Consommation de gaz

Gaz naturel (1,0 kPa)

Gaz liquéfié (2,75 kPa)

FR

Diamètre des injecteurs

Brûleur auxiliaire

Brûleurs semi-rapides

Brûleur wok à

triple couronne

Double flamme

Total

Raccordement gaz

Raccord d'arrivée de gaz Filetage (mâle) BSP de 1/2”

Emplacement de

l'arrivée de gaz

0.85 mm

1,10 mm

2 x 1.19 mm

0.80 mm + 1.19 mm

+ 1.19 mm

40 mm du bord arrière

40 mm du bord latéral

Consommation de gaz

3.6 MJ/hr

6.0 MJ/h

13.5 MJ/hr

17.0 MJ/hr

40.1 MJ/hr

S

DC TC

A

Diamètre des injecteurs

0.50 mm

0,64 mm

2 x 0.70 mm

0.50 mm + 0.70 mm

+ 0.70 mm

Consommation de gaz

3.3 MJ/hr

5,5 MJ/h

13.0 MJ/hr

16.5 MJ/hr

38.3 MJ/hr

PK 750 RT GH AUS

! Le produit a été testé conforme à la norme AS4551

21

Page 22

FR

Consommation de gaz

Gaz naturel (1,0 kPa)

Gaz liquéfié (2,75 kPa)

Diamètre des injecteurs

Brûleur auxiliaire

Brûleurs semi-rapides

Rapide

Double flamme

Total

Raccordement gaz

Raccord d'arrivée de gaz Filetage (mâle) BSP de 1/2”

Emplacement de

l'arrivée de gaz

0.85 mm

1,10 mm

1.24 mm

0.85 mm + 1.07 mm

+ 1.07 mm

40 mm du bord arrière

40 mm du bord latéral

Consommation de gaz

3.6 MJ/hr

6.0 MJ/h

7.8 MJ/hr

13.0 MJ/hr

30.4 MJ/hr

A

R

DC

S

PK 640 R GH AUS

Diamètre des injecteurs

0.50 mm

0,64 mm

0.80 mm

0.50 mm + 0.64 mm

+ 0.64 mm

Consommation de gaz

3.3 MJ/hr

5,5 MJ/h

9.0 MJ/hr

13.0 MJ/hr

30.8 MJ/hr

! Le produit a été testé conforme à la norme AS4551

22

Page 23

Description

de l’appareil

Vue d’ensemble

Grilles support de

BRÛLEURS GAZ

FR

BRÛLEURS GAZ

Grilles support de

CASSEROLES

Manettes de commande des

BRÛLEURS GAZ

CASSEROLES

Manettes de commande des

BRÛLEURS GAZ

DISPOSITIF DE

SÉCURITÉ *

• BRÛLEURS GAZ ils ont plusieurs dimensions et

puissances. Choisissez celui qui correspond le

mieux au diamètre de votre casserole.

• Manettes de commande des BRÛLEURS GAZ

pour le réglage de la flamme.

Bougie d’allumage des

BRÛLEURS GAZ *

• La bougie d’allumage des BRÛLEURS GAZ*

permet l’allumage automatique du brûleur

sélectionné.

• DISPOSITIF DE SÉCURITÉ* en cas d’extinction

accidentelle de la flamme, coupez

immédiatement l’arrivée du gaz.

23

Page 24

Mise en marche et

utilisation

FR

! La position du brûleur gaz ou de la plaque électrique*

correspondante est indiquée sur chaque manette.

Les tables de cuisson sont équipées de réglage de

puissance " discret " permettant de régler avec

précision la flamme jusqu'à 5 niveaux différents.

Grâce à ce système, les tables à gaz permettent de

toujours obtenir les mêmes résultats pour chaque

recette car il est plus simple de repérer avec

précision le niveau de puissance optimal pour le

type de cuisson choisi.

Brûleurs à gaz

Chaque manette permet de régler le brûleur

sélectionné comme suit:

• Eteint

Maximum

Minimum

Pour allumer un brûleur, approchez une flamme ou

un allume-gaz, appuyez à fond et tournez la manette

correspondante dans le sens inverse des aiguilles

d’une montre pour sélectionner la position de

puissance maximale.

Sur les modèles équipés d’un dispositif de sécurité

gaz, appuyez pendant au moins 2-3 secondes de

suite sur la manette pour permettre au dispositif de

se réchauffer.

Pour allumer un brûleur sur les modèles équipés de

bougie d’allumage, appuyez ensuite à fond sur la

manette correspondante et tournez-la dans le sens

inverse des aiguilles d’une montre jusqu’à sa

position de puissance maximale.

! En cas d’extinction accidentelle des flammes du

brûleur, tournez la manette jusqu’à l’arrêt et attendez

au moins 1 minute avant de tenter de rallumer.

Pour éteindre le brûleur tournez la manette dans le

sens des aiguilles d’une montre pour la ramener en

face du symbole “•”.

Réglage " discret " de la flamme

Il est possible de régler à l'aide de la manette 5

niveaux de puissance pour le brûleur choisi.

Pour passer d'un niveau à

l'autre, il suffit de tourner la

manette vers le niveau choisi.

Un déclic /clic signale le

passage d'un niveau à

l'autre.

Le niveau sélectionné est

signalé par le symbole

correspondant (symboles ) et, sur les

tables équipées d'afficheur, par allumage des LED

(5 = puissance max. ; 1= puissance min.). Ce

système assure un réglage parfait de la flamme et

permet de toujours obtenir le même résultat de

cuisson car il est plus facile de régler le niveau de

puissance désiré.

Le brûleur à " deux flammes "

Ce brûleur à gaz est formé de deux anneaux de

flamme concentriques pouvant fonctionner ensemble

ou séparément (uniquement dans le cas de double

commande).

Le brûleur étant équipé d'un dispositif de sécurité

de flamme, appuyer pendant au moins 2-3

secondes de suite sur la manette pour permettre au

dispositif de se réchauffer.

Double commande :

Chaque couronne composant le brûleur a sa propre

manette de commande :

la manette caractérisée par le symbole

l'anneau extérieur ;

la manette caractérisée par le symbole

l'anneau intérieur ;

Pour allumer la couronne souhaitée, appuyer sur la

manette correspondante en tournant dans le sens

inverse des aiguilles d'une montre jusqu'à la

position de puissance maximale

Pour une utilisation optimale du foyer double

flamme, ne jamais régler, simultanément,

l'anneau du centre sur sa position minimale et

l'anneau extérieur sur sa position maximale.

Mono Commande :

Les couronnes qui composent le brûleur ont une

manette de commande.

Pour allumer les deux anneaux en même temps,

appuyer sur la manette en tournant dans le sens

inverse des aiguilles d'une montre jusqu'au symbole

(max) - (min).

Pour passer à l'allumage de l'anneau du centre

uniquement, appuyer sur la manette en tournant

dans le sens des aiguilles d'une montre jusqu'au

symbole

(pour passer d'un mode à l'autre, il faut éteindre le

brûleur).

Pour éteindre le brûleur, appuyer sur la manette en

tournant dans le sens des aiguilles d'une montre

pour la ramener en face du symbole “•”).

(max) - (min).

contrôle

contrôle

.

24

Page 25

Conseils pratiques pour l’utilisation des

brûleurs

Pour obtenir un meilleur rendement, n’oubliez pas :

• d’utiliser des récipients appropriés à chaque

brûleur (voir tableau) pour éviter que les flammes

ne dépassent de sous les casseroles.

• de toujours utiliser des casseroles à fond plat et

avec couvercle.

• de tourner la manette dans la position minimum

au moment de l’ébullition.

FR

Brûleurs

Rapide (R)

Semi Rapide (S)

Auxiliaire (A)

Deux Flammes (DCDR intérieur)

Deux Flammes (DCDR extérieur)

Casseroles à utiliser sur les tables de cuisson de 60 cm

Brûleurs

Semi Rapide (S)

Auxiliaire (A)

Triple Couronne (TC)

Deux Flammes (DCDR intérieur)

Deux Flammes (DCDR extérieur)

Casseroles à utiliser sur les tables de cuisson de 75 cm

Ø Récipients (cm)

24 - 26

16 - 20

10 - 14

10 - 14

24 - 26

Ø Récipients (cm)

16 - 20

10 - 14

24 - 26

10 - 14

26 - 28

! Sur les modèles munis de grille de réduction, cette

dernière ne doit être utilisée que sur le brûleur Deux

flammes intérieur (DCDR intérieur), lorsque l’on utilise

des récipients de diamètre inférieur à 12 cm.

Pour distinguer le type de brûleur reportez-vous aux

dessins figurant dans le paragraphe "Caractéristiques

des brûleurs et des injecteurs"

25

Page 26

Précautions et conseils

FR

! Cet appareil a été conçu et fabriqué conformément aux

normes internationales de sécurité. Ces conseils sont

fournis pour des raisons de sécurité et doivent être lus

attentivement.

Sécurité générale

• Ce mode d’emploi concerne un appareil à

encastrer classe 3.

• Pour bien fonctionner, les appareils à gaz ont

besoin d’un apport d’air régulier. Il est important

de vérifier lors de leur installation, que tous les

points indiqués dans le paragraphe relatif à leur

“Positionnement” soient respectés.

• Les instructions fournies ne sont applicables

qu’aux pays dont les symboles sont reportés dans

la notice et sur la plaquette d’immatriculation.

• Cet appareil a été conçu pour un usage familial, de

type non professionnel.

• Cet appareil ne doit pas être installé en extérieur, même

dans un endroit abrité, il est en effet très dangereux de

le laisser exposé à la pluie et aux orages.

• Ne touchez pas à l’appareil si vous êtes pieds nus ou si

vous avez les mains ou les pieds mouillés ou humides.

• Cet appareil qui sert à cuire des aliments ne doit

être utilisé que par des adultes conformément aux

instructions du mode d’emploi. Toute autre

utilisation (comme par exemple le chauffage d’une

pièce) est impropre et donc dangereux. Le fabricant

décline toute responsabilité en cas de dommages

provoqués par un usage impropre ou erroné.

• Evitez que le cordon d’alimentation d’autres petits

électroménagers touche à des parties chaudes du four.

• Les orifices ou les fentes d’aération ou d’évacuation de

la chaleur ne doivent pas être bouchés

• Contrôlez toujours que les manettes sont bien dans la

position “”/“

• Ne tirez surtout pas sur le câble pour débrancher la

fiche de la prise de courant.

• N’effectuez aucune opération de nettoyage ou

d’entretien sans avoir auparavant débranché la fiche

de la prise de courant.

• En cas de panne, n’essayez en aucun cas d’accéder

aux mécanismes internes pour tenter de réparer

l’appareil. Contactez le service d’Assistance (

Assistance

• Faites attention à ce que les manches des casseroles

soient toujours tournés vers l’intérieur de la table de

cuisson pour éviter tout risque d’accident.

• N’abaissez pas le couvercle en verre (s’il y en a un)

tant que les brûleurs gaz ou la plaque électrique sont

chauds.

• Ne laissez pas la plaque électrique allumée sans

casserole dessus.

” quand l’appareil n’est pas utilisé.

voir

).

• N’utilisez pas de casseroles instables ou déformées.

• Essuyez tout liquide pouvant se trouver sur le

couvercle avant de l'ouvrir.

• Cet appareil n’est pas prévu pour être utilisé par des

personnes (y compris les enfants) dont les capacités

physiques, sensorielles ou mentales sont réduites, ou

des personnes dénuées d’expérience ou de

connaissance, sauf si elles ont pu bénéficier, par

l’intermédiaire d’une personne responsable de leur

sécurité, d’une surveillance ou d’instructions

préalables concernant d’utilisation de l’appareil.

• S'assurer que les enfants ne jouent pas avec

l'appareil.

• Le dispositif n'est pas destiné à être mis en œuvre

par une minuterie externe ou un système de

télécommande séparée.

Mise au rebut

• Mise au rebut du matériel d’emballage : conformezvous aux réglementations locales, les emballages

pourront ainsi être recyclés.

• La Directive Européenne 2002/96/CEE sur les Déchets

des Equipements Electriques et Electroniques (DEEE),

exige que les appareils ménagers usagés ne soient

pas jetés dans le flux normal des déchets municipaux.

Les appareils usagés doivent être collectés

séparément afin d’optimiser le taux de récupération et

le recyclage des matériaux qui les composent et

réduire l’impact sur la santé humaine et

l’environnement. Le symbole de la ‘‘poubelle barrée’’

est apposée sur tous les produits pour rappeler les

obligations de collecte séparée.

Les consommateurs pourront confier leur appareil

usagé au service de collecte des collectivités locales

ou de leurs groupements, ou si la législation nationale

le permet, le rendre au revendeur lors de l’achat d’un

nouvel appareil similaire.

Tous les principaux fabricants d’appareils ménagers

travaillent activement dans la création et la gestion de

systèmes de collecte et d’enlèvement des appareils

usagés.

26

Page 27

Nettoyage et entretien

!!

!

Mise hors tension

Avant toute opération de nettoyage ou d’entretien

coupez l’alimentation électrique de l’appareil.

Nettoyage de l’appareil

! N’utilisez pas de détergents abrasifs ou corrosifs,

tels que détacheurs et dérouilleurs, poudres à récurer

et éponges à surface abrasive : ils risquent de rayer

irrémédiablement la surface.

! Ne nettoyez jamais l’appareil avec des nettoyeurs

vapeur ou haute pression.

• Pour un entretien courant, passez une éponge

humide sur la surface et séchez avec du papier

essuie-tout.

• Les parties démontables des brûleurs doivent être

lavées fréquemment à l’eau chaude avec du

détergent en éliminant soigneusement toute

incrustation.

• Dans le cas de tables équipées d’allumage

automatique, nettoyez fréquemment et

soigneusement l’extrémité des dispositifs

d’allumage électronique instantané et vérifiez que

les orifices de sortie du gaz ne sont pas bouchés.

Pas besoin de retirer les grilles pour nettoyer la

!!

surface du plan de cuisson. Grâce à leur système

de support, il suffit de soulever les grilles et de les

garder dans cette position ou des les faire pivoter

pour les poser sur un support arrière.

Attention à ne pas poser les grilles chaudes sur

l'éventuel couvercle en verre pour éviter que les

caoutchoucs sur le verre s'abîment.

Entretien robinets gaz

Il peut arriver qu’au bout d’un certain temps, un

robinet se bloque ou tourne difficilement. Il faut alors

le remplacer.

! Cette opération doit être effectuée par un

technicien agréé par le fabricant.

FR

• Des taches peuvent se former sur l’acier inox si

ce dernier reste trop longtemps au contact d’une

eau très calcaire ou de détergents agressifs

(contenant du phosphore). Il est conseillé de

rincer abondamment et d’essuyer après le

nettoyage. Mieux vaut essuyer aussitôt tout

débordement d’eau.

27

Page 28

FR

Anomalies et remèdes

Il peut arriver que l’appareil ne fonctionne pas ou ne fonctionne pas très bien. Avant d’appeler le service aprèsvente, voyons ensemble que faire. Vérifiez avant tout s’il n’y a pas de coupure de gaz ou de courant, et si les

robinets du gaz en amont de l’appareil sont bien ouverts.

Anomalies

Le brûleur ne s’allume pas ou la flamme n’est

pas uniforme.

La flamme s’éteint dans les versions

équipées de sécurité de flamme.

Le brûleur s’éteint quand il est réglé sur la

position de minimum.

Les casseroles sont instables.

Causes / Solutions possibles

• les orifices de sortie du gaz ne sont pas par hasard

bouchés.

• les pièces amovibles composant le brûleur sont bien

montées correctement.

• il y a des courants d’air dans les environs du plan de

cuisson

• vous avez bien appuyé à fond sur la manette.

• vous avez bien appuyé à fond sur la manette pendant un

laps de temps suffisant pour permettre l’activation du

dispositif de sécurité.

• les orifices de sortie du gaz situés en face du dispositif de

sécurité ne sont pas par hasard bouchés.

• les orifices de sortie du gaz ne sont pas par hasard

bouchés