Page 1

Cooker Hood

HE63

HE73

HE93

Instruction on mounting and use

Page 2

! It is important to conserve this booklet for

consultation at any moment. In the case of sale,

cession or move, make sure it is together with the

product.

! Read the instructions carefully: there is important

information about installation, use and safety.

! Do not carry out electrical or mechanical variations

on the product or on the discharge conduits.

Installation

Electric connection

! The power tension must correspond with the tension

shown on the characteristics label situated inside the

hood. If provided with a plug, attach the hood to a

socket conforming to the regulations in force and

placed in an accessible zone. If without a plug,

(

connected directly to the power supply

regulation bipolar switch with a distance of the

contacts on opening not less than 3mm (

! If necessary, the situating of the supply cable must

be carried out by the technical assistance service or a

qualified person.

! An authorized installer must carry out the electrical

connection of the hood.

! The company declines any responsibility whenever

these regulations are not respected.

), use a

accessible

).

2

Page 3

The minimum distance between the supporting surface

for the cooking vessels on the hob and the lowest part

of the range hood must be not less than 50cm from

electric cookers and 70cm from gas or mixed cookers.

If the instructions for installation for the gas hob specify

a greater distance, this must be adhered to.

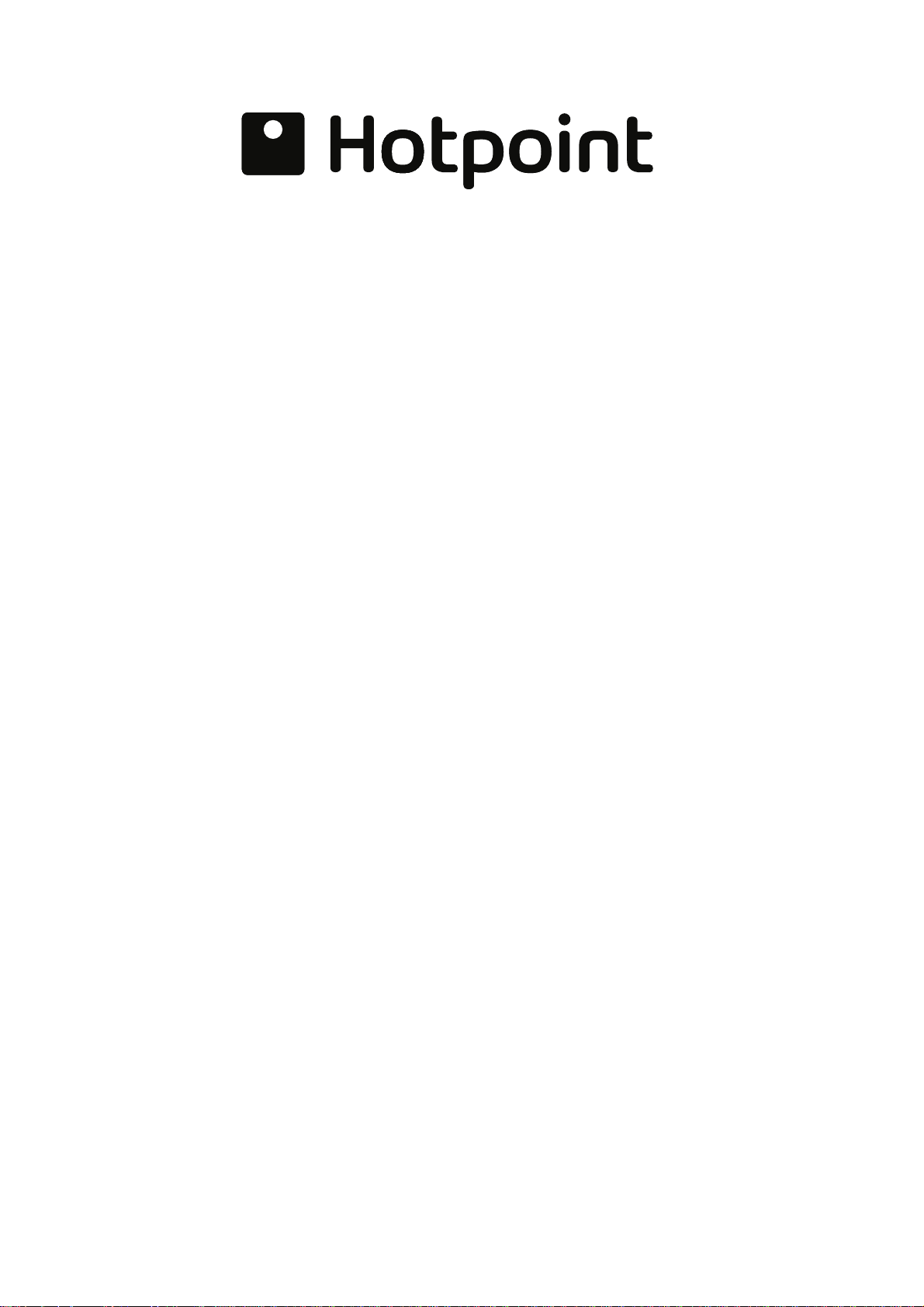

Fix the bracket behind the hood near the joining ring

(Fig. 4.1a).

Note: The bracket can be adjusted horizontally. This is

useful for successive small adjustments of the position

of the hood (Fig. 4.1b).

Draw a centerline on the wall from the cooking top to

the ceiling (Fig. 5.2).

Taking account of the distance from the cooking top,

mark the distance from the cooking top and position

the template (if supplied) to the wall on the mark (Fig.

5.3).

Mark the hole to be made, make it and insert the dowel

and partially screw 1 screw up (Fig. 5.4).

Fix the flue support to the wall as close as possible to

the ceiling (Fig. 6.1). In this phase, for the filter version,

also fix the baffle (Fig. 6.2).

Connect the hood to the partially screwed screw (Fig.

6.3a – if necessary the hood can be adjusted

horizontally, repositioning the bracket suitably – Fig-

6.3b)

Mark the 4 definitive fixing points of the hood:

2 below: removing the fat filters (Fig. 6.4), 2 above at

the sides of the bracket.

Remove the hood, make the holes, insert the dowels

(Fig. 6.5), replace the hood, insert and screw all the

screws up decisively (Fig.6.6 - Fig. 6.7).

Suction Version: the steam is sucked and sent outside

through a discharge tube that is fixed to the joining ring

positioned on the upper part of the hood.

Attention! If the hood is provided with a mounted

carbon filter, this must be removed.

The discharge air must not be discharged in a conduit

used for expelling fumes produced by gas or other fuel

apparatuses but must have an independent exit. All the

national regulations about the discharge of air must be

respected.

Filter Version: the filtered air passing through a carbon

filter is recycled into the surrounding environment.

Attention! If the hood is not provided with a carbon

filter it must be ordered and mounted before use.

Installing the telescopic flue.

Connect the hood to the power supply and fix the

telescopic flue to the support with two screws and let

the lower part slide until reaching the appropriate seat

on the upper side of the hood (Fig. 7).

2 x Ø 3,5x9,5

1a.

1b.

Fig. 4 Fig. 5

1.

2 x Ø 8mm

2 x 5x45

3a.

3b.

7.

6.

3.

4.-5.-6.

Fig. 6

4 x Ø 8mm

4 x 5x45

4.-5.-6.

÷ 5 mm

2.

1 x Ø 8mm

1 x 5x45

5.

2 x Ø 3x9

Fig. 7

4.

6.

4.

3.

2.

2 x Ø 3,5x6,5

4.

6.

5.

5.

3

Page 4

Control panel

Press

Press

To increase or diminish the suction speed, press keys

1,2 or 3.

Press O to interrupt the suction function.

to enable all the functions (ON/OFF key).

to turn the lights on and off.

4

Page 5

! We advise switching the hood on, at minimum power,

before beginning to cook to favour the optimal

expulsion of odours. In addition we advise turning it off

every time 10/15 minutes after finishing cooking.

! We advise frying under the hood only under constant

supervision.

! It is forbidden to cook flambé under the hood

because there is the risk of causing a fire.

The best performance of the apparatus is obtained

with external expulsion: we advise using the hood in

this version if possible.

External exhausting version

In this case the fumes are

conveyed outside by means of a

special pipe connected with the

connection ring located on top of

the hood Diameter of the

exhausting pipe must be equal to

that of the connection ring =

150mm.

In the horizontal runs the exhausting pipe must be

slightly slanted (about 10°) and directed upwards to

vent the air easily from the room to the outside.

Attention! If the hood is supplied with active charcoal

filter, then it must be removed.

Filtering version

One active charcoal filter is needed for this and can be

obtained from your usual retailer.

The filter removes the grease and smells from the

extracted air before sending it back into the room

through the upper outlet grid.

5

Page 6

! It is always necessary to isolate the hood from the

power supply during cleaning and maintenance.

Therefore remove the plug.

We recommend carrying our maintenance regularly

(about every 10 days) to ensure efficacious and

constant performance of the hood.

Cleaning the hood

The hood should be cleaned frequently, both internally

and externally. Use a cloth damped in neutral

detergent liquids.

Avoid the use of products containing abrasives.

Attention: failure to observe the cleaning regulations of

the hood and the substitution and cleaning of the filters

leads to the risk of fire. We therefore recommend

keeping to the suggested instructions.

Cleaning the grease filters

The fats filter serves to capture the particles of fat in

suspension that come from the cooking.

It must be cleaned once a month with non-aggressive

detergents manually or in a dishwasher at low

temperature and short cycle.

If washed in a dishwasher it can become opaque over

time but its filtering ability is not lessened in any way.

Dismantle it using the corresponding handles, pushing

them backward first and then pulling them down.

After having washed it, dry it carefully and assemble it

again in its seat, reversing the procedure.

Clean the perimeter suction panel (when envisaged)

with the same frequency as the anti-fat filter. Use a

cloth and a not too concentrated liquid detergent.

Never use abrasive substances.

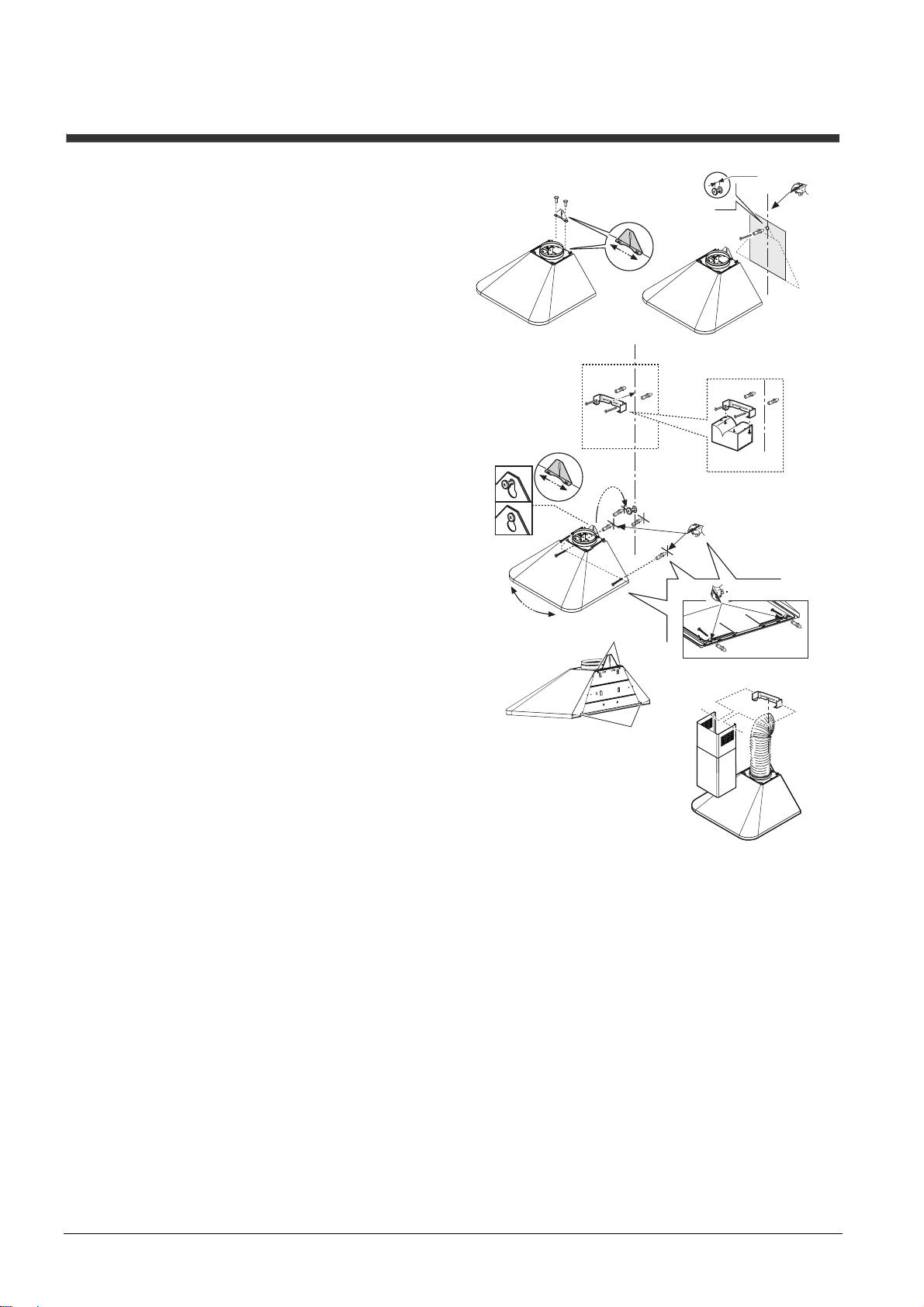

Mounting and changing the filter

The carbon filter must be changed every 6 months.

1-Remove the fats filter (a.b)

2-Mount the filters as illustrated in the figures below.

3-To dismantle, proceed inversely.

4-Put the anti-fat filters back.

Replacing lamps

Remove the plug!

Bulb/s:

Remove the overhead light and remove the bulb to

change. Only use 40W lamps.

Make sure the bulbs are cold before touching them.

Halogen bulbs:

Use a small screwdriver or other tool suitable for

prising.

Substitute the halogen bulb with another of equal

value. Close with the trigger fixing.

6

Page 7

General safety

! The hood has been designed and constructed in

conformity with international safety regulations. These

warnings are provided for safety reasons and must be

carefully read.

• This apparatus has been designed for use by adults.

• Children and invalids are not allowed to use this

apparatus without supervision. Check that children do

not play with the apparatus.

• The premises must have sufficient ventilation when

the hood is being used at the same time as other

apparatuses that use gas and other fuels. If the hood

must be installed in a kitchen where there is a waterheater or a gas heating system we recommend, for

safety reasons, not using the suction version. It is

therefore necessary to equip the apparatus with an

active carbon filter, in this way allowing recycling use.

• For safe performance, low pressure should not

exceed 0.04 mbar: in this way re-suction of the

expulsion gas will be avoided. This can be obtained

ensuring entry of air into the room through openings

that cannot be closed.

• The sucked air must not be conveyed in a conduit

used for the discharge of fumes from apparatuses

supplied with energy other than electricity.

• It is severely forbidden to cook food on the flame

under the hood.

• The use of naked flame damages the filters and can

cause fires. It must therefore be avoided in any case.

• Frying must be carried out under control to avoid the

overheated oil catching fire.

• As far as the technical and safety measures to adopt

for the discharge of fumes are concerned, keep strictly

to what is envisaged by the regulations of the

competent authorities.

• For any problem regarding the expulsion of fumes,

keep to the instructions of the competent authority.

The company declines any responsibility in the case of

damage or fire caused by apparatus resulting from

failure to observe the above-mentioned instructions.

• Disused domestic appliances can be delivered to

the public collecting service, taken to suitable local

authority areas or, if envisaged by national laws on the

matter, resold to dealers at the same time as

purchasing new, equivalent, types of product.

• All the main producers of domestic appliances are

active in the creation and management of collecting

systems of disused apparatuses.

! In case of anomalies apply to the authorized technical

assistance service and require original spare parts.

! The information and technical data are subject to

change and the producer, in line with technical

progress, maintains the right to make modifications

that he considers necessary without prior notice.

This appliance is marked according to the European

directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE). By ensuring this product

is disposed of correctly, you will help prevent potential

negative consequences for the environment and

human health, which could otherwise be caused by

inappropriate waste handling of this product.

The symbol

accompanying the product, indicates that this

appliance may not be treated as household waste.

Instead it shall be handed over to the applicable

collection point for the recycling of electrical and

electronic equipment. Disposal must be carried out in

accordance with local environmental regulations for

waste disposal.

For more detailed information about treatment,

recovery and recycling of this product, please contact

your local city office, your household waste disposal

service or the shop where you purchased the product.

on the product, or on the documents

Disposal

• Disposing of the packaging material: keep to the

local regulations so that the packaging can be re-used.

• European directive 2002/96/CE on electric and

electronic apparatus waste provides that domestic

appliance should not be disposed of in the normal flow

of solid urban waste. The disused apparatuses must

be collected separately to make the rate of recovering

and recycling of the materials they consist of and

prevent potential damage to health and the

environment. The symbol of the barred basket is shown

on all the products to remind users of the need for

separate collection.

7

Page 8

LI2S7A

Loading...

Loading...