Page 1

Instructions for Installation and Use

50cm Free Standing Gas Cooker

GW38G

GW38K

GW38P

GW38X

To the Installer

Before installation fill in the product details on the back cover this book.

The information can be found on the rating plate.

To the User

You must read the instructions prior to installing and using the appliance and

then retain them for future reference.

Page 2

Contents

Introduction 3

Installation 4

Burner and Nozzle Specifications 9

Safety Information 10

Features 12

Control Panel 13

Use of hotplates 14

Grilling 15

Oven 16

Oven cooking charts 17

Using the Main Oven for Other Functions 18

Care and Cleaning 19

Cooking Results Not Satisfactory? 21

Something Wrong With Your Cooker? 22

Technical Characteristics 23

Electronic timer 24

After Sales Service 26

Hotpoint Guarantee 27

Key Contacts Back Cover

You must read these instructions prior to using your appliance and retain them for

future use.

2

Page 3

Introduction

Your new appliance is guaranteed* and will give lasting service. This guarantee is only applicable if the appliance

has been installed in accordance with the installation instructions detailed in this booklet.

To help make best use of your cooking equipment, please read this booklet carefully.

The cooker is designed specifically for domestic use and responsibility will not be accepted for use in any other

installation.

When the cooker is first used an odour may be emitted,

this will cease after a period of use.

When first using the cooker ensure that the room is well ventilated (e.g. open a window or use an extractor fan) and

that persons who may be sensitive to the odour avoid any fumes. It is suggested that any pets be removed from the

room until the smell has ceased. This odour is due to temporary finish on oven liners and elements and also any

moisture absorbed by the insulation.

* The guarantee is subject to the provisions that the appliance:

(a) Has been used solely in accordance with the Users Instruction Book.

(b) Has been properly connected to a suitable supply voltage as stated on the

rating plate attached to this equipment.

(c) Has not been subjected to misuse or accident or been modified or repaired by

any person other than the authorised employee or agent.

(d) Has been correctly installed.

1

This appliance is intended for nonprofessional use within the home.

2 These instructions are only for those countries whose symbols appear in the booklet and on the serial no. plate

of the appliance.

3 This owner’s manual is for a class 1 appliance (insulated) or class 2, subclass 1 appliances (installed

between two cabinets.

3

Page 4

Installation

The appliance must only be installed by a competent person. In the UK, CORGI registered installers undertake

to work to safe and satisfactory standards.

Before moving your cooker check that it is cool, and switch off at the cooker control unit. Movement of your cooker is

most easily achieved by lifting the front as follows:

Open the grill door sufficiently to allow a comfortable grip on the underside front edge of the oven roof, avoiding any

grill elements.

Note: Take care in moving the cooker as it is heavy. Take care to ensure that any floor covering is not damaged.

(FIG. C)

Splashplate optional, apply to Parts Department (see Back Cover for contact number.)

The following instructions should be read by a qualified technician to ensure that the appliance is installed,

regulated and technically serviced correctly in compliance with current regulations.

Important: remember to unplug the appliance from the mains before regulating the appliance or

carrying out any maintenance work.

Positioning

Important: this unit may be installed and used only in permanently ventilated rooms according to the British

Standards Codes Of Practice: B.S. 6172/B.S. 5440, Par. 2 and B.S. 6891 Current Editions. The following requirements

must be observed:

3

a) The cooker should not be installed in a bed sitting room with a volume of less than 20m

3

room of volume less than 5m

volume between 5m

3

and 10m3 a supplementary airvent area of 50cm2 is required, if the volume exceeds 11m

an air vent of effective area of 110cm2 is required, if it is installed in a room of

no airvent is required. However, if the room has a door or a window which opens directly to the outside no air

vent is required even when the volume is between 5m

3

and 11m3.

b) During prolonged use of the appliance you may consider it necessary to open a window to the outside to

improve ventilation.

c) If there are other fuel burning appliances in the same room, B.S.5440 Part 2 Current Edition, should, be

consulted to determine the requisite air vent requirements.

. If it is installed in a

3

Installation of the cooker

For a correct installation of the cooker the following precautions must be followed:

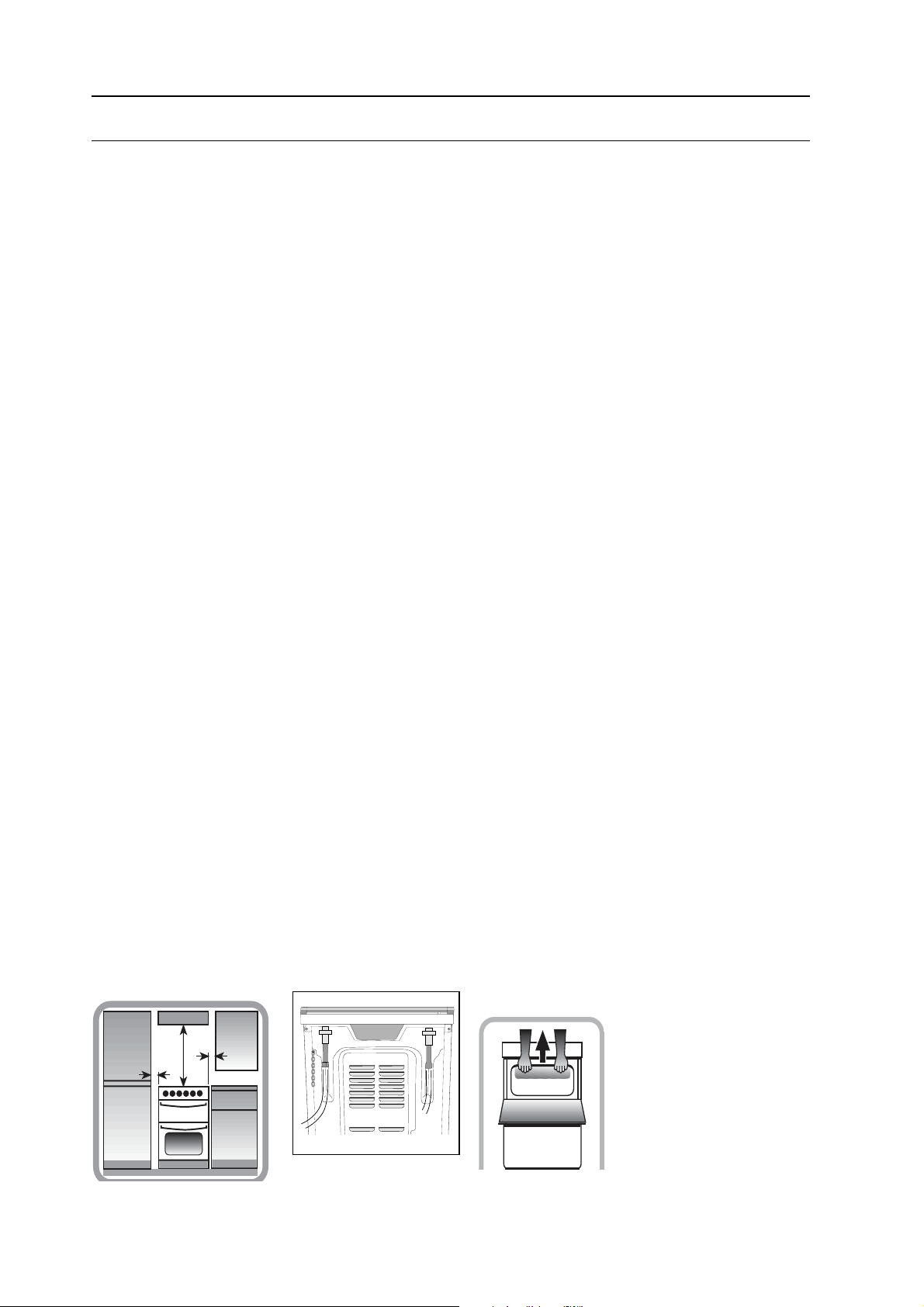

The height of the cooker can be adjusted by means of adjustable feet in the plinth (900mm - 930mm). Adjust the feet by

tilting the cooker from the side. Then install the product into position.

NOTE: This appliance must not be fitted on a platform.

The cooker is designed to fit between kitchen cabinets spaced 500mm apart. The space either side need only be sufficient

to allow withdrawal of the cooker for servicing. It can be used with cabinets one side or both as well as in a corner setting.

It can also be used free-standing.

Adjacent side walls which project above hob level, must not be nearer to the cooker than 150mm and should be protected

by heat resistant material. Any overhanging surface or cooker hood should not be nearer than 650mm. (Fig.A)

a) The cooker may be located in a kitchen, a kitonen/diner or bed sitting room, but not in a bathroom or

shower room.

b) The hoods must be installed according to the requirements in the hood handbook.

c) The wall in contact with the back of the cooker must be of flameproof material.

d) The cooker is fitted with a safety chain that must be attached to a hook, secured to the wall behind the

appliance.

Note: some models can have their gas connection inverted. It is important to make sure the safety chain

is always situated on the side which corresponds to the hose holder (Fig. B).

Moving the Cooker

150 mm

150 mm

650 mm

Fig. A Fig. B Fig. C

4

Page 5

Gas connection

The cooker should be connected to the gas-supply by a corgi registered installer. During installation of this

product it is essential to fit an approved gas tap to isolate the supply from the appliance for the convenience

of any subsequent removal or servicing. Connection of the appliance to the gas mains or liquid gas must be

carried out according to the prescribed regulation in force, and only after it is ascertained that it is adaptable

to the type of gas to be used. If not, follow the instructions indicated in the paragraph headed “Adaptation to

different gas types”. On some models the gas supply can be connected on the left or on the right, as

necessary; to change the connection, reverse the position of the hose holder with that of the cap and

replace the gasket (supplied with the appliance). In the case of connection to liquid gas, by tank, use

pressure regulators that conform to the regulation in force. The gas supply must be connected to the left of

the appliance. Be sure that the hose does not pass through the rear of the cooker touching hot parts.

HOT PARTS

600 mm

Important: make sure the supply pressure conforms with the values shown in the table entitled “Caracteristics of

the burners and nozzles”. When the cooker is installed between cabinets (recessed), the gas connection

must be effected by an approved flexible hose with bayonet fitting (BS 669 Current Edition). The gas inlet

for the cookers is a threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a flexible hose should be used corresponding to the current gas regulations which are:

• the hose must never be at any point in its lenght in contact with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or torsional stress and it must not have any excessively narrow

curves or bottlenecks;

• the hose must be easy to inspect along its entire length to check its condition;

• the hose must always be in good condition, never attempt to repair.

Important: the installation must comply with gas safety (installation and use) regulations 1984. In all cases for the

above, by low, a qualified, corgi approved engineer must be called for installation.

Important: Before using the oven, position the oven burner deflector "A" (provided with the appliance) in the

correct place by inserting the lower tab into the support slot (see figure).

A

5

Page 6

Disposing of the appliance

When disposing of the appliance please remove the plug by cutting the mains cable as close as possible to the

plug body and dispose of it as described above.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with respect to the gas for which it was produced

(indicated on the label attached to the lid), follow these steps:

a) replace the hose holder mounted on the appliance with that supplied in the bag of “cooker accessories”.

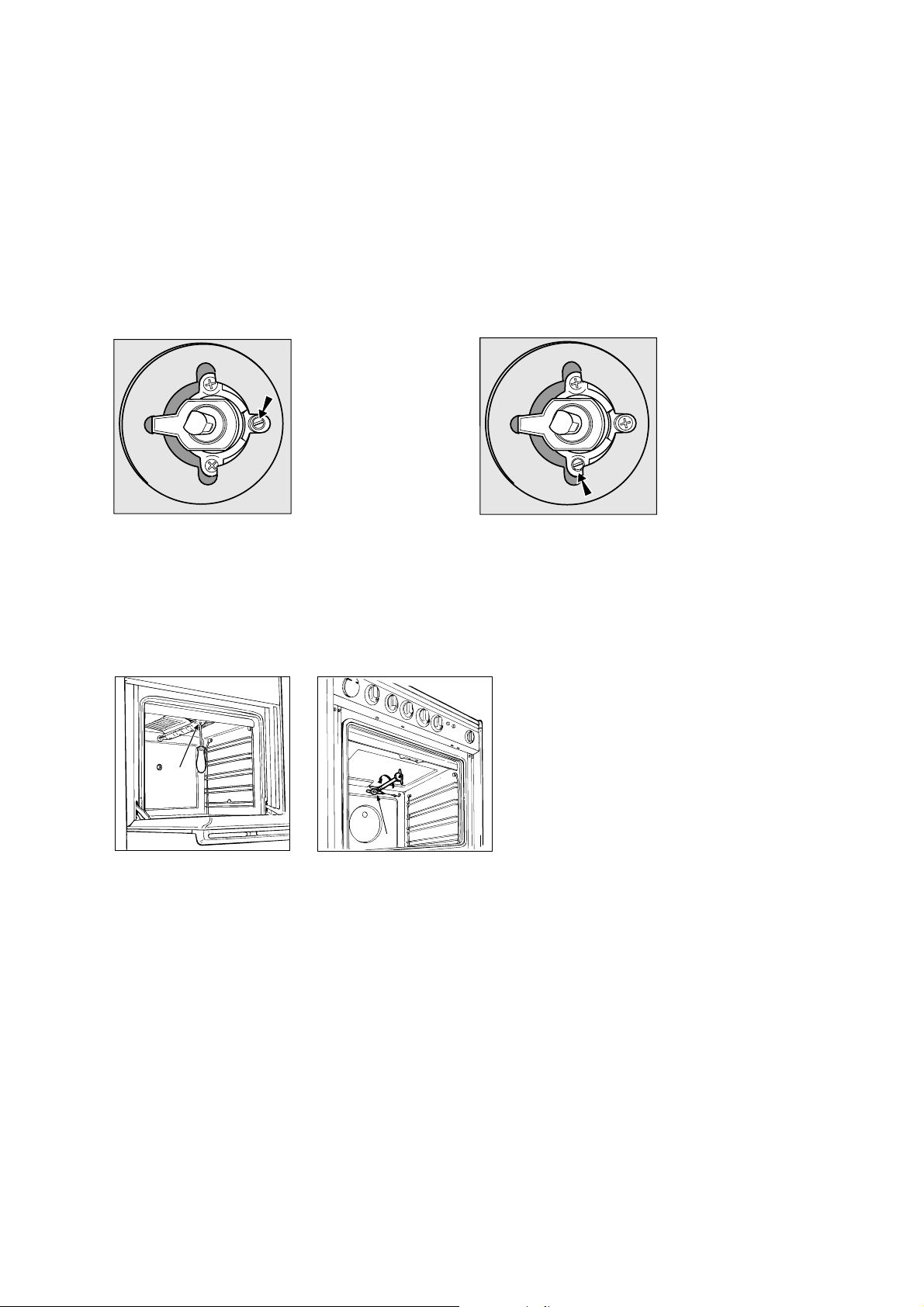

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their housings;

• unscrew the nozzles using a 7 mm socket spanner, and replace them with nozzles for the new type of

gas (see table 1 “Burner and nozzle characteristics”).

• replace all the components by repeating the steps in reverse order.

c) Minimum regulation of the hob burners:

•

turn the tap to minimum;

• remove the knob and adjust the regulation screw, which is positioned in or next to the tap pin, until the

flame is small but steady.

N.B.: in the case of liquid gas, the regulation screw must be screwed in to the bottom.

• check that the flame does not turn off when you turn the tap quickly from high to low.

d) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

Adapting to different types of gas

In order to adapt the oven to a different type of gas with respect to the gas for which it was manufactured

(indicated on the label), follow these simple steps:

a) Replacing the oven burner nozzle

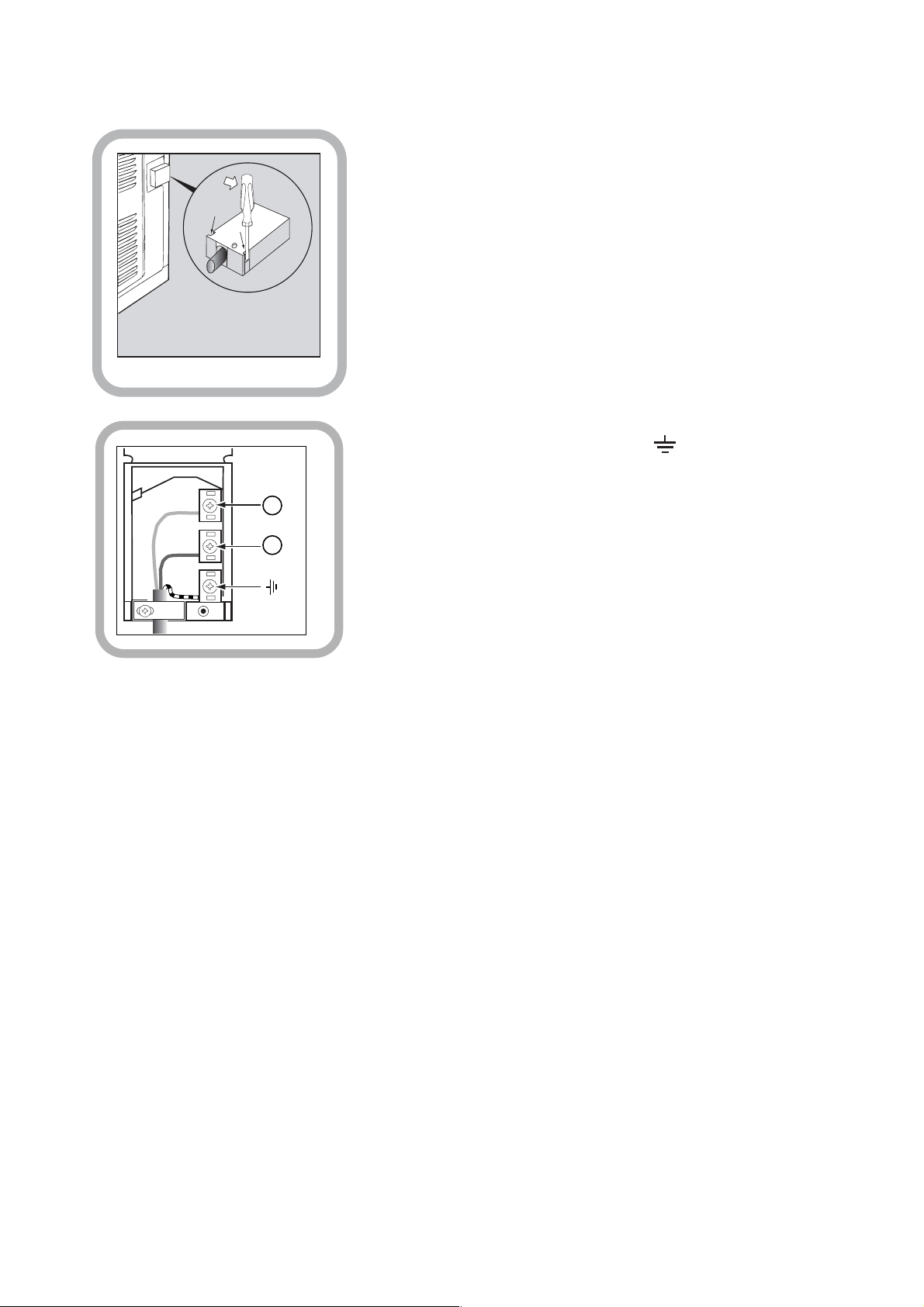

• open the oven door fully

• pull out the sliding oven bottom

• unscrew the burner fastening screws

V

V

Z

6

Page 7

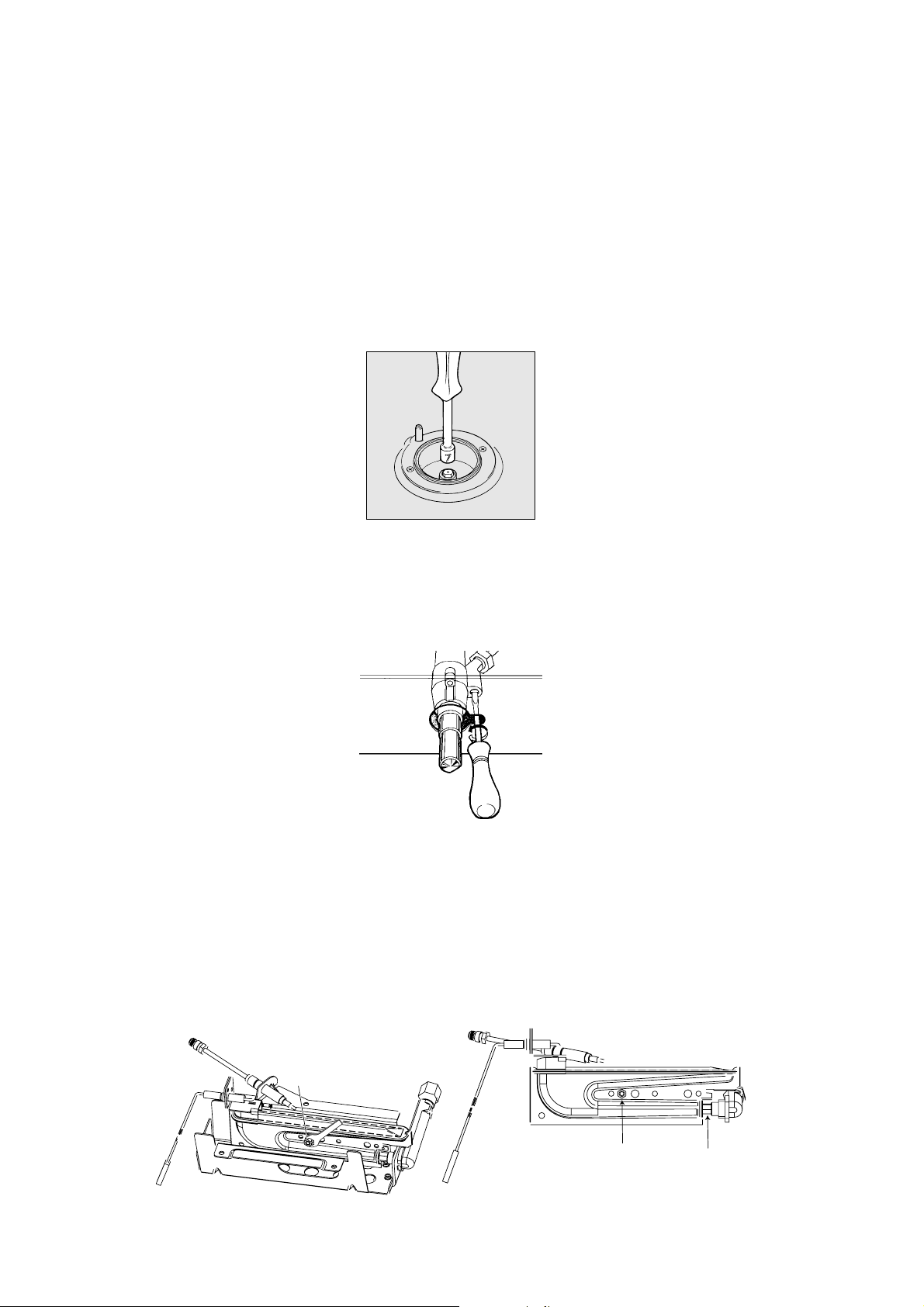

• remove screw “V” and then the oven burner;

• Unscrew the oven burner nozzle using the socket spanner for the nozzles “Z”, or a 7 mm socket spanner,

and replace it with a nozzle suited to the new type of gas (see Table 1).

Take particular care handling the spark plug wires and the thermocouple pipes.

• Replace all the parts, following the steps described above in the reverse order.

b) Minimum regulation of the gas oven burner with thermostat:

• light the burner as described in the paragraph “the oven knob” of the instruction booklet.

• turn the knob to Max for about 10 minutes and then turn the knob to the Min setting;

• remove the knob;

• regulate the screw positioned outside the thermostat pin until the flame is small but steady.

N.B.: in the case of liquid gas, the regulation screw must be screwed in to the bottom.

• check that the burner does not turn off when you turn the knob from Max to Min and and when you open

and close the oven door quickly.

Adapting the gas grill to different types of gas

Replacing the nozzle of the grill burner:

• remove the screw and then slide out the grill burner “V” (see Fig. E);

• unscrew the grill burner nozzle using the special socket spanner for the nozzles (see Fig. F) or better still

a 7 mm socket spanner; replace the nozzle with a nozzle for the new type of gas (see table 1).

V

I

Fig. E Fig. F

Important

On completion of the operation, replace the old rating sticker with one indicating the new type of gas used.

This sticker is available from our Service Centres.

Note

Should the pressure of the gas used be different (or vary) from the recommended pressure, it is necessary to

fit a suitable pressure regulator onto the inlet pipe in compliance with current National Regulations relative to

“regulators for channelled gas”.

7

Page 8

WARNING – THIS APPLIANCE MUST BE EARTHED.

Electrical connection

Electric cookers come without a power supply cable. The cooker is designed

to operate on an electricity supply which conforms to the electrical data

shown on the Rating Plate. The cooker can be connected to the mains only

after removing the back panel of the cooker itself with a screwdriver.

N.B.: the following installation procedure must be carried out by a qualified

electrician. The electrical installation must comply with the IEE Regulations,

Building & local By-Lays.

For the installation of the feeding cable carry out the following operations:

l Using a screwdriver, prise on the side tabs of the terminal board

cover (see fig. A);

l Pull and open the junction blok lid

Important: the wires in the mains lead are coloured in accordance with the

following code:

Fig. A

L

2

Green & Yellow Earth

Blue Neutral

Brown Live

As the colours of the wires in the mains lead may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

Green & Yellow wire to terminal marked “E” or

Green & Yellow.

Brown wire to terminal marked “L” or coloured Red.

Blue wire to terminal marked “N” or coloured Black (see fig. B).

l fix the feeding cable in the special cable stop and close the cover.

N

4

N.B.: the power supply cable must have these minimum requirements:

Type: H05RR-F

Section: 3x4 mm

or coloured Green or

2

Fig. B

Ensure that the mains cable is routed away from any brackets affixed to the

rear panel and is not trapped to the rear wall when pushing the cooker into

position between cabinets.

8

Page 9

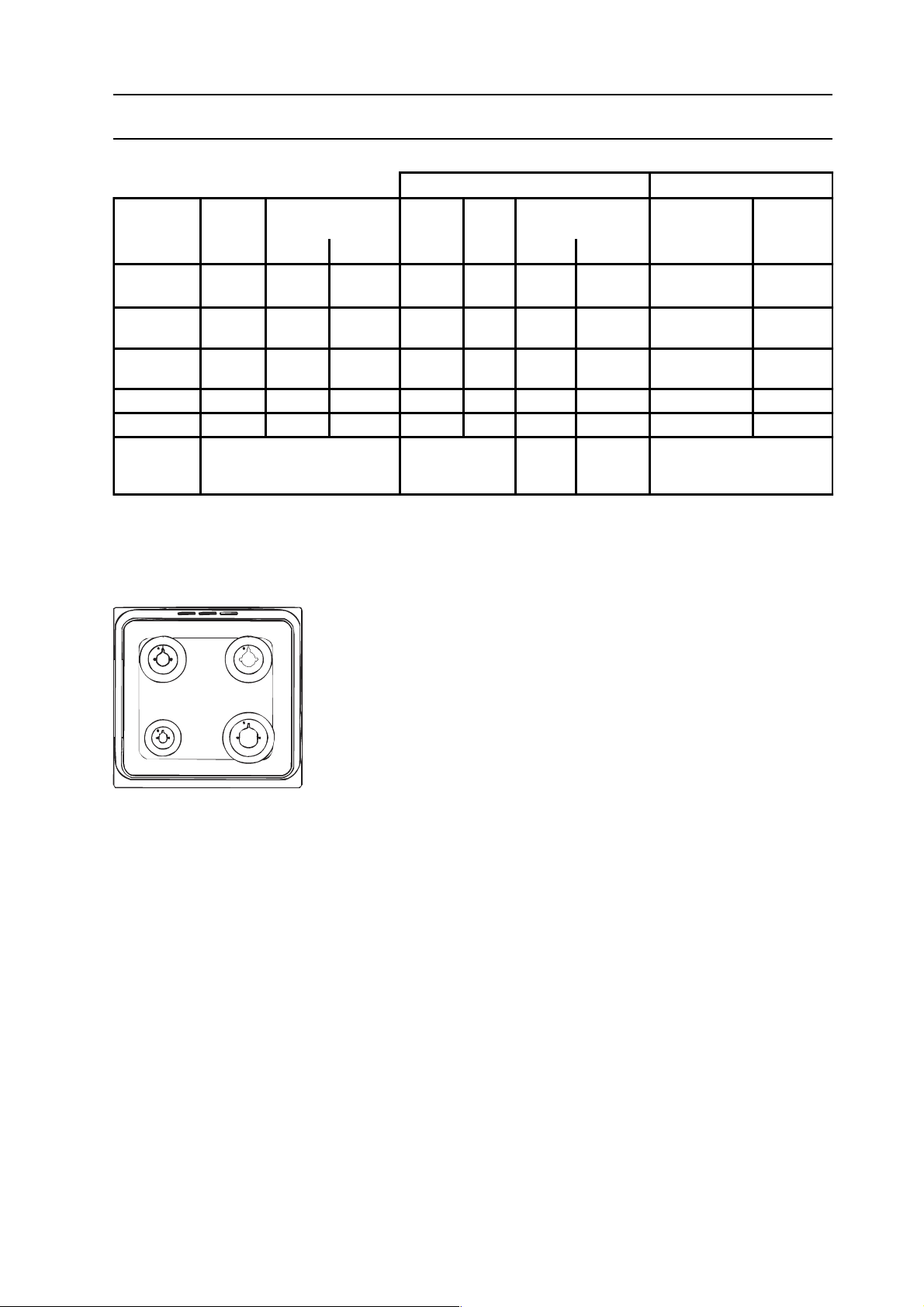

Burner and Nozzle Specifications

Table 1 Liquid Gas Natural Gas

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nominal Reduced (mm) (mm) *** ** (mm)

By-Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

Oven - 2,60 0,6 36 75 189 186 123 248

Grill - 2,50 1,3 63 80 182 179 122 238

Supply

Pressures

100 3,00 0,7 41 87 218 214 128 286

75 1,90 0,4 30 70 138 136 104 181

51 1,00 0,4 30 52 73 71 76 95

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

* At 15°C and 1013 mbar- dry gas

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m

S

S

R

A

3

GW38G

GW38K

GW38P

GW38X

9

Page 10

Safety Information

When used properly your appliance is completely safe but as with any electrical product there are certain

precautions that must be observed.

PLEASE READ THE PRECAUTIONS BELOW BEFORE USING YOUR APPLIANCE.

Always

l Remove all packing from inside the oven and grill compartments before switching on for the first time.

l Understand the controls prior to using the appliance.

l Keep children away from the appliance when grilling as the surfaces will get extremely hot during and after

use.

l Turn controls off when you have finished cooking and when not in use.

l Stand back when opening an oven door to allow any build up of steam or heat to disperse.

l Use dry good quality oven gloves when removing items from the oven/grill.

l Place pans centrally over the hotplate making sure handles are kept away from the edge of the hob and cannot

become heated by other hotplate/pans.

l Take care to avoid heat/steam burns when operating the controls.

l Turn off the electricity supply at the wall switch before cleaning and allow the appliance to cool.

l Make sure the shelves are in the correct position before switching on the oven.

l Keep the oven and grill doors closed when the appliance is not in use.

l Take care when removing items from the grill when the lower oven is on as the contents will be hot.

l Keep the appliance clean, as a build up of grease or fat from cooking can cause a fire.

l Follow the basic principles of food handling and hygiene to prevent the possibility of bacterial growth.

l Keep ventilation slots clear of obstructions.

l Refer servicing to a qualified appliance service engineer.

l Take care to avoid touching heating elements inside the oven, as during use the oven becomes hot.

l Before operating the product, remove all plastic film from the sides of the appliance.

10

Page 11

Safety Information

Never

l Never line the interior of the oven with foil as this may cause the appliance to overheat.

l Never leave children unsupervised where a cooking appliance is installed as all surfaces will be hot during and

after its use.

l Never allow anyone to sit or stand on any part of the appliance.

l Never store items above the appliance that children may attempt to reach.

l Never leave anything on the hob surface when unattended and not in use.

l Never remove the oven shelves whilst the oven is hot.

l Never heat up unopened food containers as pressure can build up causing the container to burst.

l Never store chemicals/food stuffs, pressurised container in or on the appliance, or in cabinets immediately

above or next to the appliance.

l Never place flammable or plastic items on or near the hob.

l Never fill a deep fat frying pan more than 1/3 full of oil, or use a lid.

DO NOT LEAVE UNATTENDED WHILE COOKING.

l Never operate the grill with the grill door closed as this will cause the appliance to overheat.

l Never use the appliance as a room heater.

l Never use the grill to warm plates.

l Never dry any items on either the hob or oven doors.

l Never install the appliance next to curtains or other soft furnishings.

l Never use steam cleaners.

SAFETY ADVICE IN CASE OF A CHIP-PAN FIRE

In the event of a chip pan fire or any other pan fire.

1. TURN OFF THE COOKER APPLIANCE AT THE WALL SWITCH.

2. COVER THE PAN WITH A FIRE BLANKET OR DAMP CLOTH, this will smother the flames and extinguish the

fire.

3. LEAVE THE PAN TO COOL FOR AT LEAST 60 MINUTES BEFORE MOVING IT. Injuries are often caused by

picking up a hot pan and rushing outside with it.

NEVER USE A FIRE EXTINGUISHER TO PUT OUT A PAN FIRE as the force

of the extinguisher is likely to tip the pan over.

Never use water to extinguish oil or fat fires.

11

Page 12

Features

HOB VENTILATION SLOTS

GRILL/MEAT PAN

WITH REMOVABLE

HANDLE AND WIRE

FOOD SUPPORT

GRILL DOOR

REMOVABLE

INNER GLASS

DOOR

1900W

GRILL

1000W

1900W

3000W

CONTROL

PANEL

MAIN OVEN

WIREWORK

SHELF

SUPPORTS

MODEL & SERIAL

NUMBER

OVEN ROD

SHELVES

12

Page 13

Control Panel

ELECTRONIC

TIMER

Control Knobs

for the gas

burners

Electronic

Ignition

for the Gas Hob*

Slow cooking ‘S’

Electronic

timer

MAIN

GRILL

OVEN

The position of the gas burner controlled by each one of the knobs is shown by a solid ring •. To

light one of the burners, hold a lighted match or lighter near the burner and, at the same time,

press down and turn the corresponding knob counter clockwise to the maximum

burner can be operated at its maximum, minimum or intermediate power. Shown on the knob are

the different symbols for off • (the knob is on this setting when the symbol corresponds with the

reference mark on the control panel), for maximum

the knob counter clockwise with respect to the off position. To turn off the burner, turn the knob

clockwise until it stops (corresponding again with the • symbol).

To light a specific burner push the corresponding knob all the way in and turn it counter-clockwise to

maximum

Important: Should the burner flames accidentally go out, turn off the control knob and wait

at least 1 minute before trying to relight.

The main oven has a ‘S’ setting specially designed to reduce energy usage. Full details of this can be

found in the Slow cooking section of this book.

The electronic timer displays the time and the timer function with countdown.

keeping it pressed down until the burner lights.

LEFT

FRONT

BURNER

LEFT

REAR

BURNER

and minimum . To obtain these settings, turn

RIGHT

REAR

BURNER

RIGHT

FRONT

BURNER

setting. Each

* (only available on certain models)

13

Page 14

Use of Hotplates

Practical Advice on Using the Burners

To use the burners as efficiently as possible, some basic guidelines should be followed:

• Use cookware that is the right size for each burner (see table) in order to prevent the flame from spreading

beyond the bottom of the cookware.

• Only use cookware with flat bottoms.

• As soon as the boiling point is reached, turn the knob to the lowest setting.

• Always use lids with pots and pans.

Burner ø Cookware diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

N.B.: On models equipped with a reduction grid, the grid should only be used with the auxiliary burner when

cookware with a diameter of less than 12 cm is used.

1. Press the ignition button and then push in and turn the control knob of the chosen burner anti-clockwise

to the large flame symbol. Continue to press the ignition button until the sparks light the gas.

2. Turn the control knob anti-clockwise to the desired setting. Only turn the control knob between the large

flame symbol and the small flame symbol for adjusting the setting.

3. To turn off, turn the control knob fully clockwise to the symbol O.

DO NOT use the hotplate unless all pan supports are in position.

DO NOT use mis-shapen pans which may be unstable.

DO NOT use round base woks directly on the pan supports.

DO NOT use the glass lid (if fitted) as a working surface.

Each burner is fitted with a spark ignitor for lighting the gas. To ensure rapid lighting of the burners every time they

are used, the ignitors must be kept clean and dry. Remove any food spillage or cleaning materials from the

electrode using a small nylon brush such as a tooth brush. Access to the electrode can be achieved by lifting off the

loose burner parts carefully when the burners are cool.

When the hotplate burner bodies and caps are removed for cleaning, be careful not to drop any food particles or

cleaning materials into the burner bases, to avoid the possibility of blocking the gas jets.

If aluminium based pans are used, a silvery deposit may appear on the top edge of the pan support fingers. See

'Care and Cleaning' section for cleaning information.

SAFETY REQUIREMENTS FOR DEEP FAT FRYING

1. Never fill chip pans more than one third full with oil or fat.

2. Never leave oil or fat unattended during the heating or cooling period.

3. Never heat fat or fry with a lid on the pan.

4. Always dry food thoroughly before frying, and lower it slowly into the hot oil or fat. Frozen foods in

particular will cause frothing and spitting if added too quickly.

5. Always keep the outside of the pan clean and free from streaks of oil or fat.

HOW TO DEAL WITH A FAT FIRE

1. Do not move the pan.

2. Turn off the hotplate burners.

3. Smother the flames with a fire blanket or damp cloth to extinguish the fire. Do not use water or a fire

extinguisher as the force of it may spread the burning fat or oil over the edge of the pan.

4. Leave the pan for at least 60 minutes before moving it.

14

Page 15

Grilling

CAUTION: ACCESSIBLE PARTS WILL BECOME HOT WHEN THE GRILL

To operate the grill proceed as follows:

l Open the grill door and remove the grill pan.

l Push and turn the grill control knob anti-clockwise to the large flame symbol. Continue to press the

control knob until the spark lights the gas.

Grill Pan Handle

l Turn the control knob anti-clockwise to the desired setting. There is a delay of about six seconds

whilst the safety device operates before the burner comes on full. Only turn the control knob between

the large flame symbol and the small flame symbol when adjusting the setting.

l To turn off, turn the control knob fully clockwise to the symbol O

Important (only on a few models): when using the grill, the oven door must be left open by

positioning the deflector “B” between control panel and deflector “A” to prevent the cooker knobs from

overheating.

GRILLING MUST BE DONE WITH THE GRILL DOOR OPEN.

CONTROL KNOBS MAY BECOME HOT DURING GRILLING.

IS USED - CHILDREN SHOULD BE KEPT AWAY.

A

B

Slide the grill pan along the runner towards the rear of the grill compartment until it stops. An

odour may be noticed when first using the grill - this schould cease after a short period of use.

Grill can be started from cold but for the best result preheat for approximately five

minutes. Most cooking is done with the heat on full, but it may be necessary after sealing the

food to reduce the heat as required.

For au gratin dishes eg. Macaroni Cheese and meringue toppings eg. Baked Alaska place the

dish on the floor of the grill compartment. The base of the grill pan can be used for warming

fruit garnishes on the reduced setting.

DO NOT cover the grill pan or grid with aluminium foil as this can hold fat, intensify the heat and create a fire hazard.

Relighting‘

the burner

Fixing the Grill Pan

Handle

In the event of the burner flames being accidentally extinguished, turn off the burner control and do not

attempt to re-ignite the burner for at least one minute.

The grill pan handle is detachable from the pan, to facilitate cleaning and storage. Fix the grill pan

handle securely in position before use.

The handle fits onto the grill pan edge with the small recess, Fig.1.

Tilt the handle over the recess and slide it towards the centre, Fig.2.

Ensure the handle is fully located. Insert the washer and fixing screw and tighten fully to ensure handle

is secured, Fig.3.

Always hold the dripping pan handle in the highlighted zone marked "OK" in figure 4.

Recess

Fig. 1

Fig. 2

Always fit the screw prior to use.

Fig. 3

Fig. 4

NO

OK

The food to be cooked should be placed on the grill pan/grill pan food support.

Place the grill pan on the runners and push back to the stop position when the grill pan is

correctly positioned beneath the grill element.

Plates and dishes placed on the floor of the grill compartment will be heated when the oven is

in use.

15

Page 16

Oven

The oven has different heat zones - the thermostat settings refer to the temperature on the

middle shelf; above this shelf it is hotter and below it is cooler. Two shelves enable full use of

the temperatures inside the oven.

Each shelf has a safety stop to prevent if from being pulled out too far when attending to

food. Shelves are removed from the oven by pulling them out to the stop and then lifting

them at the front to withdraw.

The grill pan without the handle can be used in the oven. The maximum size of baking tray

that should be used is 300mm x 330mm (12" x 13").

TO USE THE OVEN 1. Place oven shelves in the chosen positions (refer to cooking charts).

2. Push and turn the oven control knob fully anti-clockwise. Continue to press the oven control

knob until the spark lights the gas.

3. Turn the control knob clockwise to the required setting (refer to cooking chart). There is a

delay of about six seconds whilst the safety device operates before the burner comes on full.

4. To turn off, turn the control knob fully clockwise the the symbol 0.

Never place dishes on the oven base over the burner.

An odour may be noticed when first using the oven - this should cease after a short period of

use.

5. The oven temperature control marking are gas marked 0 to 9.

The equivalent degrees Celsius (sometimes called Centigrade) and degrees Fahrenheit

are shown below as a guide.

MAIN OVEN

Gas Mark

1120250

2150300

3175350

•

(Centre Oven Temperature)

Celisus

195 385

°C

Fahrenheit °F

Gas Mark

5210410

•

7230445

•

9245475

MAIN OVEN

(Centre Oven Temperature)

Celisus

Fahrenheit °F

°C

220 430

240 465

RELIGHTING

THE BURNER

COLD START

COOKING

ROASTING OF

LARGE POULTRY

STORAGE AND

RE-HEATING

OF FOOD

‘COOK CHILL’

DISHES

In the event of the burner flames being accidentally extinguished, turn off the burner control

and do not attempt to re-ignite the burner for at least one minute

Anything requiring long slow cooking such as casseroles and rich fruit cakes can be put into

a cold oven. Satisfactory results can also be obtained with creamed mixture, rich pastries or

yeast mixtures, but for perfection we recommend preheating the oven for about 15 minutes.

The maximum weight of poultry that can be accommodated is 8kg (18 Ibs) of suitable shape.

It is important to check that the bird DOES NOT overhang the burner at the back of the oven.

It is vitally important to strictly adhere to the basic principles of food handling and hygiene to

prevent the possibility of bacterial growth.

1. If food is to be frozen or not served immediately, cool it in a clean container as quickly as

possible.

2. Completely thaw frozen food in the refrigerator before reheating.

3. Re-heat food thoroughly and quickly either on the hotplate or in a hot oven, Mk. 6, and

then serve immediately.

4. Only re-heat food once.

These should always be placed in a pre-heated oven ideally on the first or second shelf

position. Follow the packet instructions for cooking time.

ALUMINIUM FOIL If using Aluminium Foil:

1. Remember that it is important to increase the cooking time by one third.

2. Never allow the foil to touch the sides of the oven.

3. Never cover the oven interior with foil.

4. Never cover the oven shelves with foil.

16

Page 17

Oven Cooking Chart

The following times and setting are for guidance only. You may wish to alter the setting to give a result more to your

satisfaction. When a different setting to that shown below is given in a recipe, the recipe instructions should be

followed. Allow 15 minutes preheat for best results. Always turn the thermostat knob to Mark 9 before selecting the

appropriate gas Mark. Shelf position 1 is the highest.

Food Gas

Fish

Oily and white fish 3 or 4 4 25-60 mins. depending on recipe

Meat and Poultry

Beef 4 or 5 4 25-30 mins per 450g (1 Ib) + 25 mins. extra

Ham 5 4

Lamb 5 4 30 mins per 450g (1 Ib) + 30 mins extra

Pork 5 4 40 mins per 450g (1 Ib) + 40 mins extra

Chicken 5 4 25 mins per 450g (1 Ib) + 25 mins extra

Duckling & Goose 5 4 25 mins per 450g (1 Ib) + 25 mins extra

Turkey 4 or 5 4 or 5 15-20 mins per 450g (1 Ib) + 20 mins

Casseroles 3 3or4 2-6 hrs. depending on cut of meat

Vegetables

Baked jacket potatoes 4 or 5 3 1½ - 3 hrs. until soft, depending on size

Puddings

Milk Puddings (500ml/1 pt) 3 4

Baked Custard (500ml/1 pt) 3 4 45-60 mins. bain-marie

Baked Sponge Puddings 4 3 40-50 mins

Baked Apples 3 3 30-45 mins depending on type and size of apples

Meringue Topped Puddings 1 3or4 15 mins or until "tinged" with brown

Apple Tart (1 x205mm/8//) 6 2 45-60 mins

Fruit Crumble 5 2 35 -45 mins

Cakes, Pastries & Biscuits

Small Cakes 2 trays 5 2 and 4 15-25 mins.

1 tray 5 2 15-22mins.

Victoria sandwich (2 x 7") 4 2 and 4 20-30 mins

Swiss Roll (3 egg quantity) 5 2 15-20 mins.

Meringues 1 3 2-3 hrs

Christmas cake (1 x 205mm / 8") 2 3 Time depending on recipe

Madeira cake (1 x 180mm /

Rich Fruit cake (1 x 180mm /

Scones 7 1 and 3 10-20 mins.

Shortbread (1 x 180mm /

Biscuits 4 1 and 3 10-20 mins.

Shortcrust Pastry 6 2 15 - 60 mins depending on use.

Rich Short Crust 5 1 and 3 20-30 mins.

Flaky/Puff Pastry 7 2 10-30 mins.

Choux Pastry 6 2 20-30mins.

Yeast Mixtures

Bread - rolls 7 2 and 4 20-30 mins.

Miscellaneous

Yorkshire Pudding:- large 7 1 30-40 mins

individual 7 2 20-30mins

7")

7")

7")

Mark

4 4 1¼-1½ hrs.

2 4 Time depending on recipe

2 3 55 -65 mins.

Shelf

Position

Approx. Cooking Time and Comments

40 mins per 450g (1 Ib) covered in foil plus 40 mins.

extra

1¾-2½ stand dish on baking tray and started with

warm milk

When baking with two trays or tins on two levels, the top tray is removed first and the lower tray moved up to the top

position for a few minutes longer.

Soft Margarine -

Use the oven settings recommended by the margarine manufacturer and not those indicated on the cooking chart.

17

Page 18

Using the Main Oven for Other Functions

‘S’

SLOW Setting

This is used for slow cooking, keeping food warm and warming plates for short periods. Extra care

should be taken when warming bone china, as it may be damaged in a hot oven.

DO NOT place food or plates directly on the oven floor as this could damage both the oven

lining and the plates which are being warmed.

Advantages of “SLOW” cooking are:

The oven stays cleaner because there is less splashing.

Timing of food is not as critical, so there is less fear of overcooking.

Inexpensive joints of meat are tenderised.

Fully loading the oven can be economical.

Cooking times can be extended in some cases by up to 2 hours.

Operation:

1. Place the prepared food in the main oven and ensure the door is fully closed.

2. Select ‘S’ (Slow Cooking Temperature) by turning the Main Oven Control clockwise ensuring the

oven door is fully closed.

Storage and re-heating of food:

1. If food is to be frozen or not used immediately, place it in a clean container and cool as soon as

possible.

2. Always thaw frozen food completely in the refrigerator before re-heating.

3. Always reheat food thoroughly and ensure it is piping hot before serving.

4. Only re-heat food once.

Points to consider when preparing food for “SLOW” cooking:

1. Make sure that the dishes to be used will fit into the oven ensuring enough room for air to circulate.

2. All dishes cooked on the slow setting will require a minimum of 6 hours, however, if they are cooked

for 1 -2 hours longer then deterioration in their appearance may be noticed.

3. Never cook joints of meat over 2.7kg (6 Ib) or poultry over 2.0kg (4lb 8oz).

We do not recommend that joints of meat or poultry are stuffed before cooking on the slow setting.

4. To seal in the meat juices, always cook meat or poultry at 170°C for 30 minutes before wrapping in

foil and placing on a rack over a tin (to allow good air circulation) before turning the control to the slow

setting and cooking immediately.

5. Always ensure that joints of pork and poultry are thoroughly cooked by checking with a meat

thermometer before serving.

6. Always thaw frozen foods completely before cooking. We do not recommend placing frozen food in

the oven to cook.

7. Always bring soups, liquids and casseroles to the boil before placing in the oven.

8. Ensure that casserole dishes have a good seal (not airtight) and cover to the top with foil to prevent

loss of moisture.

9. Ensure that fruit and vegetables are cut into even sized small pieces to cook properly.

10. Always adjust seasoning before serving.

11. If using dried red kidney beans it is important that the beans are soaked and then boiled fora

minimum of 10 minutes before using in any dish to destroy any toxins.

12. When cooking fish or egg dishes it may be necessary to check during cooking to avoid

overcooking.

18

Page 19

Care and Cleaning

Grill

Control Panel

Decorative Trims

Ovens

Oven Shelf

Supports

Oven Lamp

Replacement

Remove the grill pan and the wire grid food support, it is best to wash these items immediately after

use to prevent stains from being burnt on when used again. Wipe out the Grill compartment, use a fine

steel wool soap pad to remove stubborn stains from the grill runners and the floor of the compartment.

Wipe over the control panel with a damp cloth and polish with a dry cloth.

Do not use cream cleaners, oven cleaners or aerosols, scouring pads or abrasive powder for

cleaning the plastic knobs as damage will occur.

It is advisable to clean the decorative trims regularly to prevent any build up of soiling. The

recommended method of cleaning is to wipe over the trims with a soft cloth wrung out in warm water or

mild non-abrasive cleaner. (If in doubt try the cleaner on a small area of trim which is not noticeable in

normal use). Then, after wiping with a cloth wrung out in clear water, dry with a soft clean cloth.

Remove the rod shelves and grill pan. Use a fine steel wool soap pad to remove stubborn stains from

the rod shelves, grill pan and the floor of the oven.

sponge and a non-abrasive cleaning product, then dry thoroughly with a soft cloth. Do not use rough

abrasive material or sharp metal scrapers as these could scratch the surface and cause the glass to

crack.

The shelf supports are removable and dishwasher safe.

To remove hold the support at the front and pull away from the oven side, this can then be cleaned in

a sink or a dishwasher. When removed it allows access to the oven side, which can be cleaned with

warm soapy water.

To refit the support, insert the longer leg into the rear fixing hole and push in the front leg.

Open the oven door and remove the rod shelves. Using a suitable cloth to protect the fingers grip the

light glass dome, unscrew anti-clockwise and lift. Reach into the aperture with fingers, and unscrew the

lamp anticlockwise. Fit replacement lamp (25W 300°C rated SES), refit dome.

Clean the glass part of the oven door using a

WARNING: To avoid electric shocks - please ensure that the electricity supply to the appliance

is switched off and the appliance is fully cold, before removing the lamp lens.

19

Page 20

Care and Cleaning

CLEANING

THE DOORS

SIDE OPENING

DOORS

DROP DOWN

DOORS

Take particular care not to damage the inner surface of the door inner glass that iscoated with

a heat reflective layer. Do not use scouring pads, or abrasive powder,which will scratch the

glass. Ensure that the glass panel is not subjected to any sharpmechanical blows.

Stubborn stains can be removed by using a fine steel wool soap pad. For slight soiling theinner glass

panel may be cleaned, while still warm, without removing it from the door. Aftercleaning, rinse and dry

with a soft cloth.

Cleaning the door glass is the same as the drop down doors, except take care tosupport the

weight of the inner glass when removing and refitting.

Remove the door inner glass as follows.

1. Open the door fully and remove the extrusion end caps (This should be done by hand but if it proves

too difficult, simply lift the inner glass to ease the end caps out of position).

NOTE: If you need to use a tool - be careful not to damage the extrusion or end cap.

2. Carefully slide the inner glass towards you andwithdraw it from its locating slots. Ensure that the

door is not allowed to slam shut, due to the reduction in door weight. Clean the glass as described

above.

3. The inside of the outer door glass can now be cleaned while still fitted to the cooker.

NEVER OPERATE THE COOKER WITHOUT THE INNER DOOR GLASS IN POSITION.

Refit the door inner glass as follows.

1. Open the door fully.

2. Locate the inner door glass into its slots, so that the printing is readable from the face nearest the

oven in the closed position and the widest black band is towards the bottom of the door. The inner door

glass has a special reflective coating on one side, in order to minimise surface temperatures and

energy consumption during use, it is important it is fitted correctly.

3.Carefully slide the glass into its slots as far as it will go and replace the end caps.

20

Page 21

Cooking Results Not Satisfactory?

Problem Check

Grilling

Uneven cooking front to

back

Fat splattering Ensure that the grill is not set to too high a

Ensure that the grill pan is positioned centrally below

the grill element.

temperature.

Oven Baking

Uneven rising of cake

Sinking of cakes The following may cause cakes to sink:

Over/Under cooking

Fast/Slow cooking

Uneven cooking of

cakes

Uneven rising of cake Ensure that the shelf is level (see above) and that the

Food is taking too long

to cook

Ensure that the oven shelves are level by using a

spirit level on the rod shelf and adjusting, using

suitable packing e.g. wood, under the feet of the

appliance. This should be checked both left to right

and front to back. Ensure that the food is positioned

centrally in the oven.

1. Cooking at too high a temperature.

2. Using normal creaming method with soft margarine.

Refer to the cooking times and temperatures given in

the oven temperature charts, however, it may be

necessary to increase or decrease temperatures by

10°C to suit personal taste.

Do not use utensils greater than 2¼ ins in height.

1. Too large baking sheet used. (See 'Cookery Notes')

2. Over loading of oven and always ensure even air

gaps around baking tins.

food is positioned centrally in the oven.

Only cook one item at a time to avoid overloading the

oven.

21

Page 22

Something Wrong with your Cooker?

Before contacting your nearest Service Centre/Installer, check the problem guide below; there may be nothing wrong

with your cooker.

Problem Check

Ignition does not work

Hotplate Burner

Hob Top

Burner Ports Ignitor

If all burners fail to ignite:

Check that spark s ap pear at the burner s;

A clicki ng noise should be heard.

If not

Check that the plug is pl ugged i n to a

13amp El ectric so ck et and the supply

is switched on.

If all burners still fail to ignite

Check and r epl ac e if necess ary the 13amp fuse

If only one burner fails to ignite

Check that the burner i s dr y and that spi l l age of food or

cleaning fluid remains are not affecti ng the Ignitor or burner

ports.

Oven Temperat ure seems too

high or too low

Oven does not cook evenly.

Hotplates are slow to boil or will

not simmer

Odour or smoke when using your new cooker

Condensation / St eam in the Oven After Use

Condensation on the Wall at the Rear of the Cooker

Clean away any debris with a dry nylon brush such as an

old dry toothbrush.

If a wir e wool pad has been used for c leani ng around the

burner ensur e the Igni tor is free fr om any s tray s tr ands .

Any water on t he burner s houl d be dri ed wi th a c loth or

kitchen towel.

On the hotplate make s ure that all burner

parts are correctly seated

Check that the temperature has been set in accordance with

the t emperature charts. It may be necessary to incr eas e or

decr ease the recomm ended t emperature by 10 C to sui t your

taste

Check the temperature and shelf positi on are as recommended

in the temper ature charts

Check that the Utens il being used in the oven allow suffici ent

air f l ow ar ound them.

Check that the cook er is level .

Check that your pans c onfor m to the r ecomm endations i n

these instructions.

This is normal and should cease after a short period.

Condensati on and steam i s a by pr oduc t of c ooking food

with a water content.

To help mini mi se always:

A) Tr y to avoi d leav ing food i n the oven to cool af ter bei ng cooked

B) Use a cov ed Utensi l wher ever pos sibl e

Steam and/or condensat i on may appear fr om the vent at the rear of

the appli ance when us ing an oven, partic ul arly when cooking foods

with a high water content (Such as Oven Chips or Chicken).

Thi s is normal and any ex ces s should be wiped off

22

Page 23

Technical Characteristics

Main Oven

Dimensions (HxWxD): 34x39x31 cm

Volume: 41 Litres

Voltage and Frequency

220-240V~ 50/60Hz

Burners:

Adaptable for use with all the types of gas indicated on the data plate.

This appliance conforms with the following European Economic Community directives:

- 73/23/EEC of 19/02/73 (Low Voltage) and subsequent modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic Compatibility) and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent modifications (only for models which use gas);

- 93/68/EEC of 22/07/93 and subsequent modifications.

- 2002/96/EC

The European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE), requires that old

household electrical appliances must not be disposed of in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise the recovery and recycling of the materials they

contain and reduce the impact on human health and the environment. The crossed out “wheeled bin” symbol

on the product reminds you of your obligation, that when you dispose of the appliance it must be separately

collected.

Consumers should contact their local authority or retailer for information concerning the correct disposal of

their old appliance.

Mains frequency and voltage of the electric section and

characteristics of the gas section

Model Gas section

Class

GW38G

GW38K

GW38P

GW38X

(1) The values in g/h refer to the capacities with liquid gas (Butane,

Propane).

II2H3+

Rated power

kW (1)

12,90 (938 g/h - G30)

(921 g/h - G31)

23

Page 24

Electronic timer

The electronic timer displays the time and the timer function with countdown.

To set

the clock

To set

the timer

Note: This may be set while the oven is switched off or while it is switched on.

1. Press the

start to flash.

2. Use the “+” and “-” buttons to adjust the hour value.

3. Press the

4. Use the “+” and “-” buttons to adjust the minute value.

5. Press the

Note: If none of the buttons are pressed, the settings will be confirmed automatically after 10 seconds

have passed.

Note: This function does not interrupt cooking and does not affect the oven; it is simply used to

activate the buzzer when the set amount of time has elapsed.

1. Press the

start to flash.

2. Use the “+” and “-” buttons to adjust the hour value.

3. Press the

4. Use the “+” and “-” buttons to adjust the minute value.

5. Press the

The countdown will then be displayed; at the end of this period of time the buzzer will sound (this may

be stopped by pressing any of the buttons, or it will stop of its own accord after one minute).

button several times until the icon and the first two numerical digits on the display

button again so that the other two numerical digits on the DISPLAY begin to flash.

button again to confirm.

button several times until the icon and the first two numerical digits on the display

button again so that the other two numerical digits on the DISPLAY begin to flash.

button again to confirm.

To cancel a

previous setting

Press button “-” up until 0 • 00.

24

Page 25

25

Page 26

After Sales Service

"No company is better positioned to offer an after sales service on a

Hotpoint appliance than us - the manufacturer"

As part of our commitment to you, all Hotpoint appliances have the added benefit of a fully inclusive parts

and labour guarantee for the first 12 months. In addition to this you also have the advantage of free

replacement parts for the first 5 years when fitted by a Hotpoint

engineer. When the 12 months parts and labour guarantee expires we offer the following after sales

service options:

Repair Service and Information Help Desk

UK: 08709 066066

www.theservicecentre.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the Model number and the Serial number of your appliance

Available 364 days a year with a fast, effective and value for money service. We have the largest white

goods repair service in the UK with over 1200 of our own fully trained engineers. All repairs include a

parts and labour guarantee for 12 months from the date of the repair.

If you require any information or have any questions about your appliance, our operators are on hand with

help and advice.

All this ensures that you will receive the best available after sales service possible.

Extended Warranties

UK: 08709 088 088

www.theservicecentre.co.uk

Republic of Ireland: 1850 502 200

Whether you have just one or a number of Hotpoint appliances in your kitchen, we offer two service cover

plans to give you total peace of mind.

Repair Protection Plan - FREE service repairs for a single Hotpoint appliance during the period

l

of cover.

l

Kitchen Cover - FREE service repairs for all your Hotpoint appliances less than 8

years old.

Genuine Parts and AccessoriesUK: 08709 077 077

www.theservicecentre.co.uk

Republic of Ireland: (01) 842 6836

A wide range of genuine parts and accessories are available from our hotline or through our web site.

Genuine parts and accessories, extended warranties and service repairs are all

available on our web-site at:

26

www.theservicecentre.co.uk

Page 27

Guarantee

"Satisfaction guaranteed or your money back"

We give you a unique 'satisfaction guaranteed' promise - valid for 90 days - after you have

purchased your Hotpoint appliance. If there is a technical problem simply call Hotpoint Repair service

or visit our web-site at

engineer to call. If the technical problem is not resolved under this guarantee, we will replace your

All Hotpoint appliances carry a fully inclusive 12 month parts and labour guarantee as well as free

replacement parts for the first 5 years (except microwaves, selected integrated appliances and cooker

hoods, which have a one year guarantee) provided that they are fitted by a Hotpoint engineer.

Guarantee terms and conditions

Your guarantee is only applicable in the United Kingdom or Republic of Ireland and is subject to the

following provisions that your appliance:

l Has been installed and used correctly in accordance with this instruction booklet.

l Has been used solely for domestic purposes and is located on domestic premises (ie. not for

commercial or trade use).

l Has been properly connected to a suitable electrical supply voltage as stated on the appliance

rating plate.

l Has not been subject to misuse, accident, modified or repaired by anyone other than one of our

own service engineers.

www.theservicecentre.co.uk and where necessary, we will arrange for an

machine or, if you prefer, give you your money back.

For pre purchase information on any other Hotpoint product call: 08701 50 60 70

or visit: www.hotpoint.co.uk

Recycling & Disposal Information

As part of Hotpoint's continued commitment to helping the environment, Hotpoint reserves the right to

use quality recycled components to keep down customer costs and minimise material wastage.

Please dispose of packaging and old appliances carefully.

To minimise risk of injury to children, remove the plug and cut mains cable off flush with the appliance.

Dispose of these parts separately to ensure that the appliance can no longer be plugged into a mains

socket.

27

Page 28

Key Contacts

After Sales Service

Over 1200 trained specialists, directly employed by us, ensure that you can have complete confidence in

both the appliances and services we offer.

Repair Service and Information Desk

UK: 08709 066 066

(Open 8 to 8 Mon - Fri, 8 to 6 Sat, 10 to 4 Sun & Bank Holidays)

www.theservicecentre.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Model number:

Serial number:

Extended Warranties

UK: 08709 088 088

(Open 8 to 8 Mon - Sun)

www.theservicecentre.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

(Open 8-30 to 5-30 Mon - Fri & 9 to 12 Sat)

www.theservicecentre.co.uk

Republic of Ireland: (01) 842 6836

Indesit Company UK LTD, Morley Way, Peterborough, PE2 9JB.

03/2007 - 19506051100

Loading...

Loading...