Page 1

Operating Instructions

COOKER

GB FR

Français, 13English,1

GB

English,37

AR

CG64SG1 EX

ES

Espanol, 25

Contents

GB

Installation, 2-6

Positioning and levelling

Electrical connection

Gas connection

Adapting to different types of gas

Technical data

Table of burner and nozzle specifications

Description of the appliance, 7

Overall view

Control panel

Start-up and use, 8-10

Using the hob

Using the oven

Oven cooking advice table

Precautions and tips, 11

General safety

Disposal

Respecting and conserving the environment

Care and maintenance, 12

Switching the appliance off

Cleaning the appliance

Replacing the oven light bulb

Gas tap maintenance

Assistance

Page 2

Installation

GB

Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

The appliance must be installed by a qualified

professional according to the instructions provided.

Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

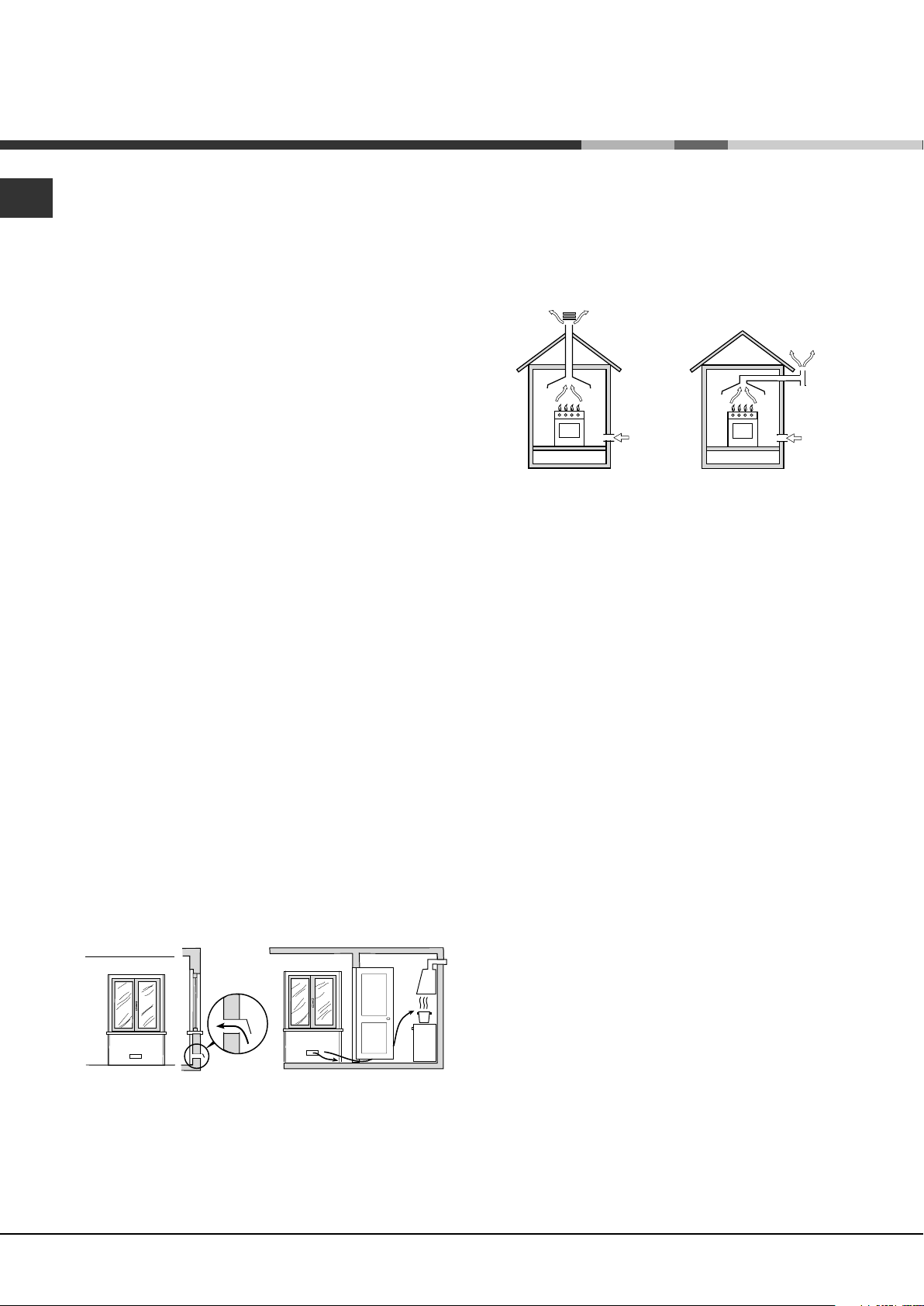

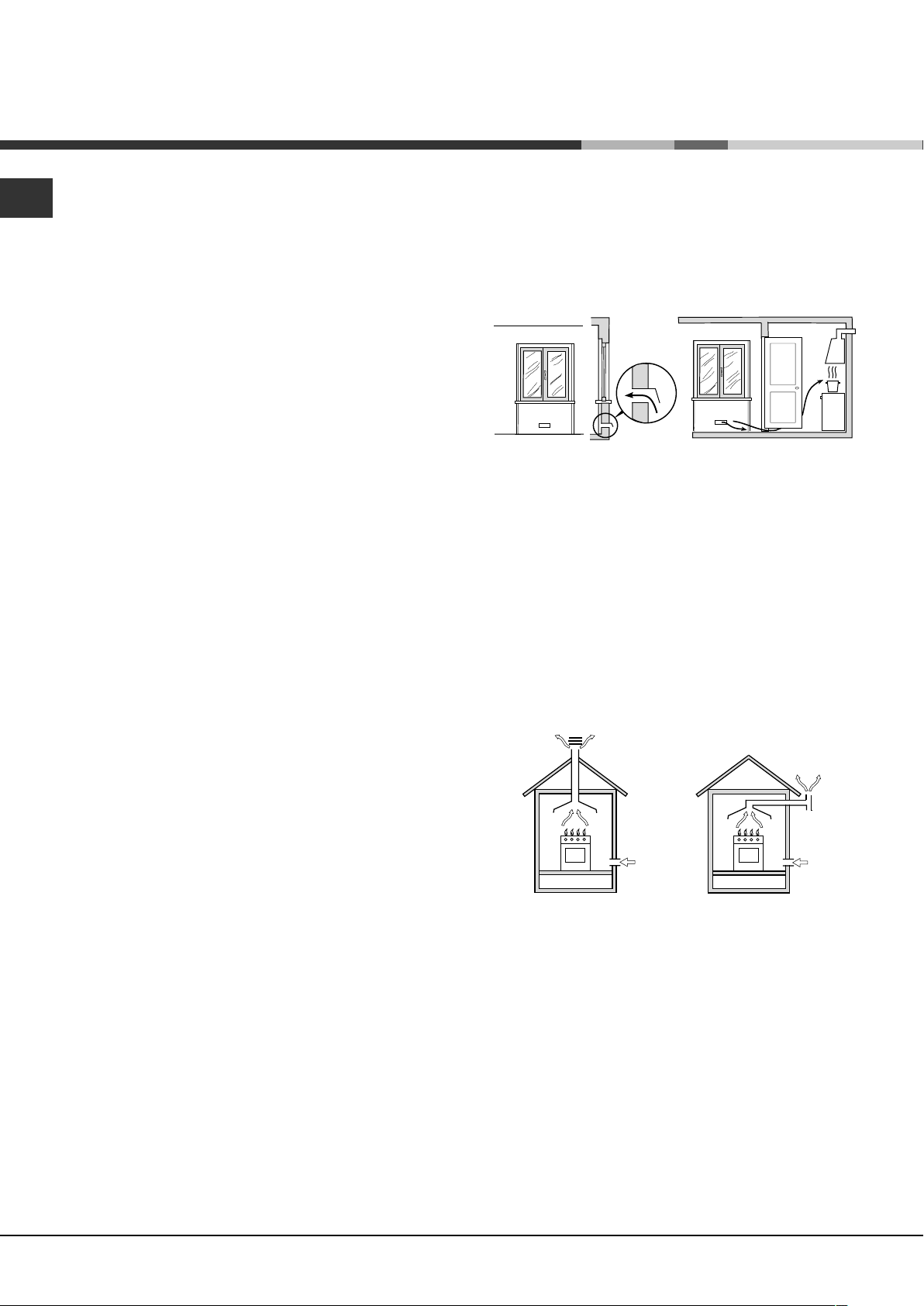

Room ventilation

The appliance may only be installed in permanentlyventilated rooms, according to current national

legislation. The room in which the appliance is

installed must be ventilated adequately so as to

provide as much air as is needed by the normal gas

combustion process (the flow of air must not be

3

lower than 2 m

/h per kW of installed power).

The air inlets, protected by grilles, should have a

duct with an inner cross section of at least 100 cm

2

and should be positioned so that they are not liable

to even partial obstruction (see figure A).

These inlets should be enlarged by 100% - with a

2

minimum of 200 cm

- whenever the surface of the

hob is not equipped with a flame failure safety

device. When the flow of air is provided in an

indirect manner from adjacent rooms (see figure B),

provided that these are not communal parts of a

building, areas with increased fire hazards or

bedrooms, the inlets should be fitted with a

ventilation duct leading outside as described above.

Adjacent room Room requiring

ventilation

A B

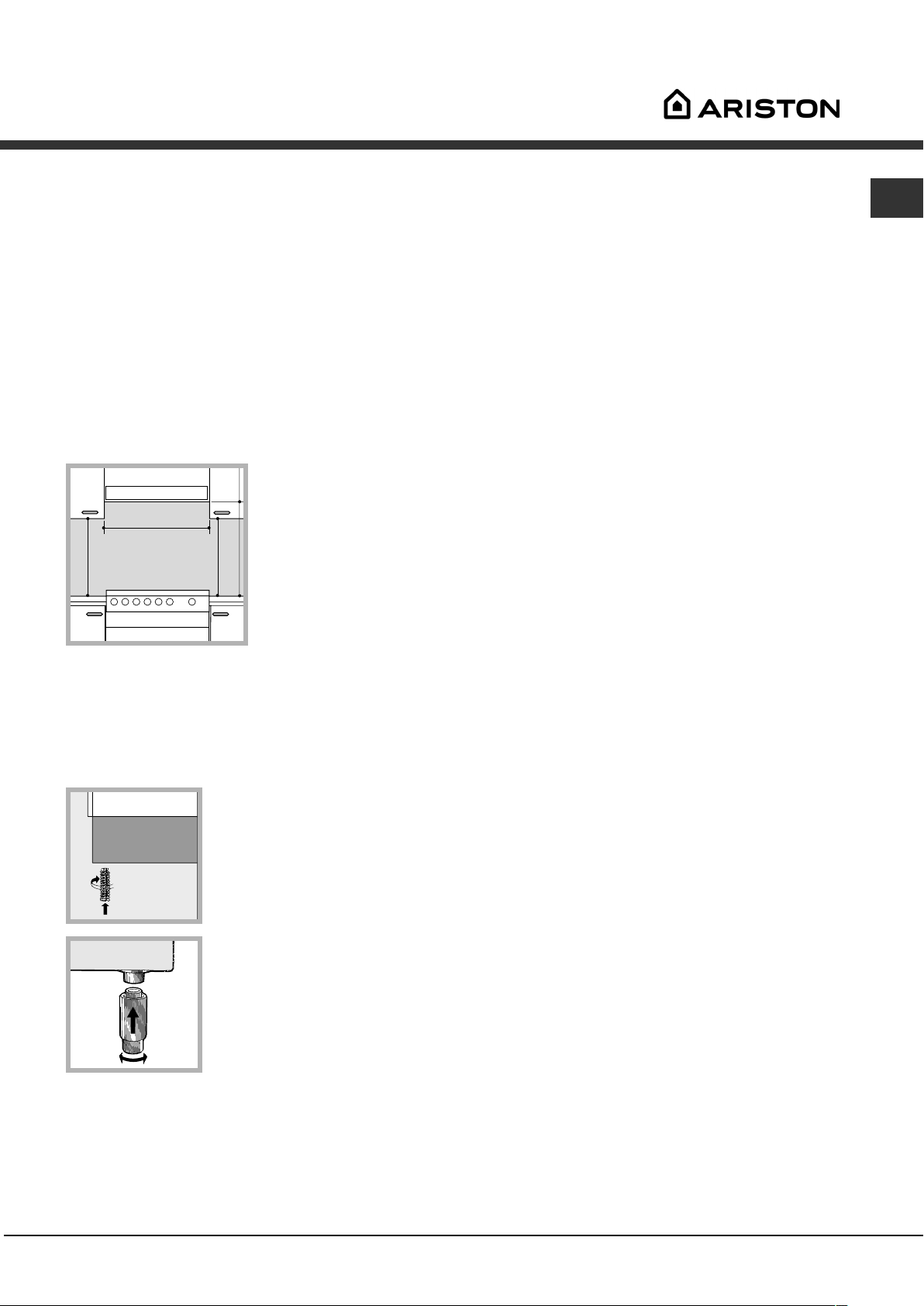

Disposing of combustion fumes

The disposal of combustion fumes should be

guaranteed using a hood connected to a safe and

efficient natural suction chimney, or using an electric

fan that begins to operate automatically every time

the appliance is switched on (see figure).

Fumes channelled

straight outside

Fumes channelled through

a chimney or a branched

flue system (reserved for

cooking appliances)

The liquefied petroleum gases are heavier than air

and collect by the floor, therefore all rooms

containing LPG cylinders must have openings

leading outside so that any leaked gas can escape

easily.

LPG cylinders, therefore, whether partially or

completely full, must not be installed or stored in

rooms or storage areas that are below ground level

(cellars, etc.). Only the cylinder being used should

be stored in the room; this should also be kept well

away from sources of heat (ovens, chimneys,

stoves) that may cause the temperature of the

cylinder to rise above 50°C.

Positioning and levelling

It is possible to install the appliance alongside

cupboards whose height does not exceed that of the

hob surface.

Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heatresistant material (T 90°C).

A

Ventilation opening

for comburent air

Increase in the gap

between the door and

the flooring

After prolonged use of the appliance, it is

advisable to open a window or increase the speed of

any fans used.

2

To install the appliance correctly:

Place it in the kitchen, dining room or the bed-sit

(not in the bathroom).

If the top of the hob is higher than the cupboards,

the appliance must be installed at least 600 mm

away from them.

If the cooker is installed underneath a wall

cabinet, there must be a minimum distance of 420

mm between this cabinet and the top of the hob.

This distance should be increased to 700 mm if the

wall cabinets are flammable (see figure).

Page 3

mm.

420

Min.

HOOD

Min. mm.

600

mm. with hood

420

650

Min. mm.

min.

mm. without hood

700

min.

The voltage is in the range between the values

indicated on the data plate.

The socket is compatible with the plug of the

appliance. If the socket is incompatible with the

plug, ask an authorised technician to replace it.

Do not use extension cords or multiple sockets.

Once the appliance has been installed, the power

supply cable and the electrical socket must be

easily accessible.

GB

Do not position blinds behind the cooker or less

than 200 mm away from its sides.

Any hoods must be installed according to the

instructions listed in the relevant operating manual.

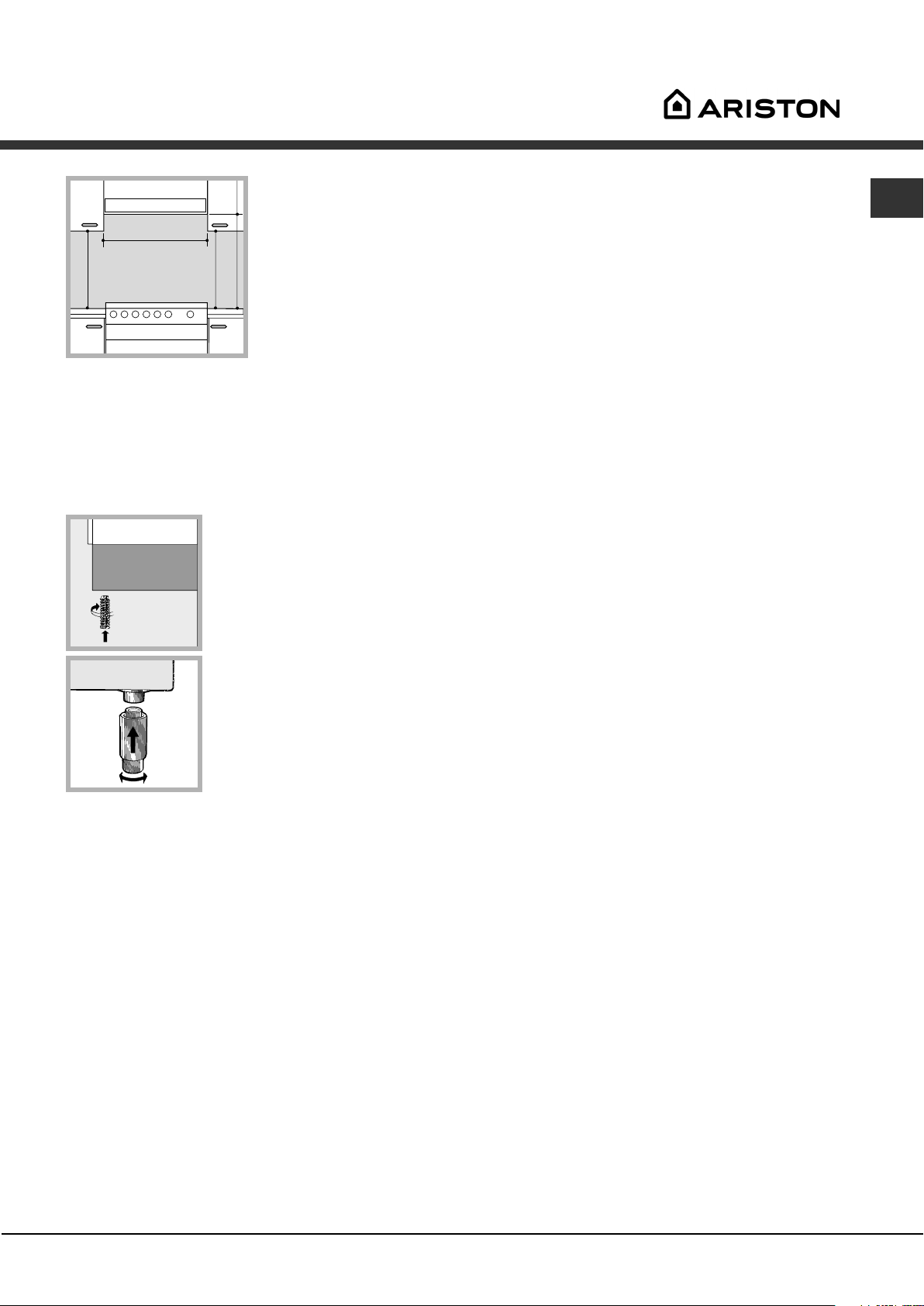

Levelling

If it is necessary to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (see figure).

The legs* fit into the slots on

the underside of the base of

the cooker.

Electrical connection

Install a standardised plug corresponding to the

load indicated on the appliance data plate (see

Technical data table).

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum

contact opening of 3 mm installed between the

appliance and the mains. The circuit-breaker must be

suitable for the charge indicated and must comply with

current national legislation (the earthing wire must not

be interrupted by the circuit-breaker). The supply cable

must be positioned so that it does not come into

contact with temperatures higher than 50°C at any point.

Before connecting the appliance to the power

supply, make sure that:

The appliance is earthed and the plug is compliant

with the law.

The socket can withstand the maximum power of

the appliance, which is indicated by the data plate.

* Only available in certain models

The cable must not be bent or compressed.

The cable must be checked regularly and replaced

by authorised technicians only.

The manufacturer declines any liability should

these safety measures not be observed.

Gas connection

Connection to the gas network or to the gas cylinder

may be carried out using a flexible rubber or steel

hose, in accordance with current national legislation

and after making sure that the appliance is suited to

the type of gas with which it will be supplied (see the

rating sticker on the cover: if this is not the case see

below). When using liquid gas from a cylinder, install a

pressure regulator which complies with current national

regulations. To make connection easier, the gas

supply may be turned sideways*: reverse the position

of the hose holder with that of the cap and replace the

gasket that is supplied with the appliance.

Check that the pressure of the gas supply is

consistent with the values indicated in the Table of

burner and nozzle specifications (see below). This

will ensure the safe operation and durability of your

appliance while maintaining efficient energy

consumption.

Gas connection using a flexible rubber hose

Make sure that the hose complies with current

national legislation. The internal diameter of the hose

must measure: 8 mm for liquid gas supply; 13 mm

for methane gas supply.

Once the connection has been performed, make

sure that the hose:

Does not come into contact with any parts that

reach temperatures of over 50°C.

Is not subject to any pulling or twisting forces and

that it is not kinked or bent.

Does not come into contact with blades, sharp

corners or moving parts and that it is not

compressed.

3

Page 4

GB

Is easy to inspect along its whole length so that

its condition may be checked.

Is shorter than 1500 mm.

Fits firmly into place at both ends, where it will be

fixed using clamps that comply with current

regulations.

If one or more of these conditions is not fulfilled or if

the cooker must be installed according to the conditions

listed for class 2 - subclass 1 appliances (installed

between two cupboards), the flexible steel hose must

be used instead (see below).

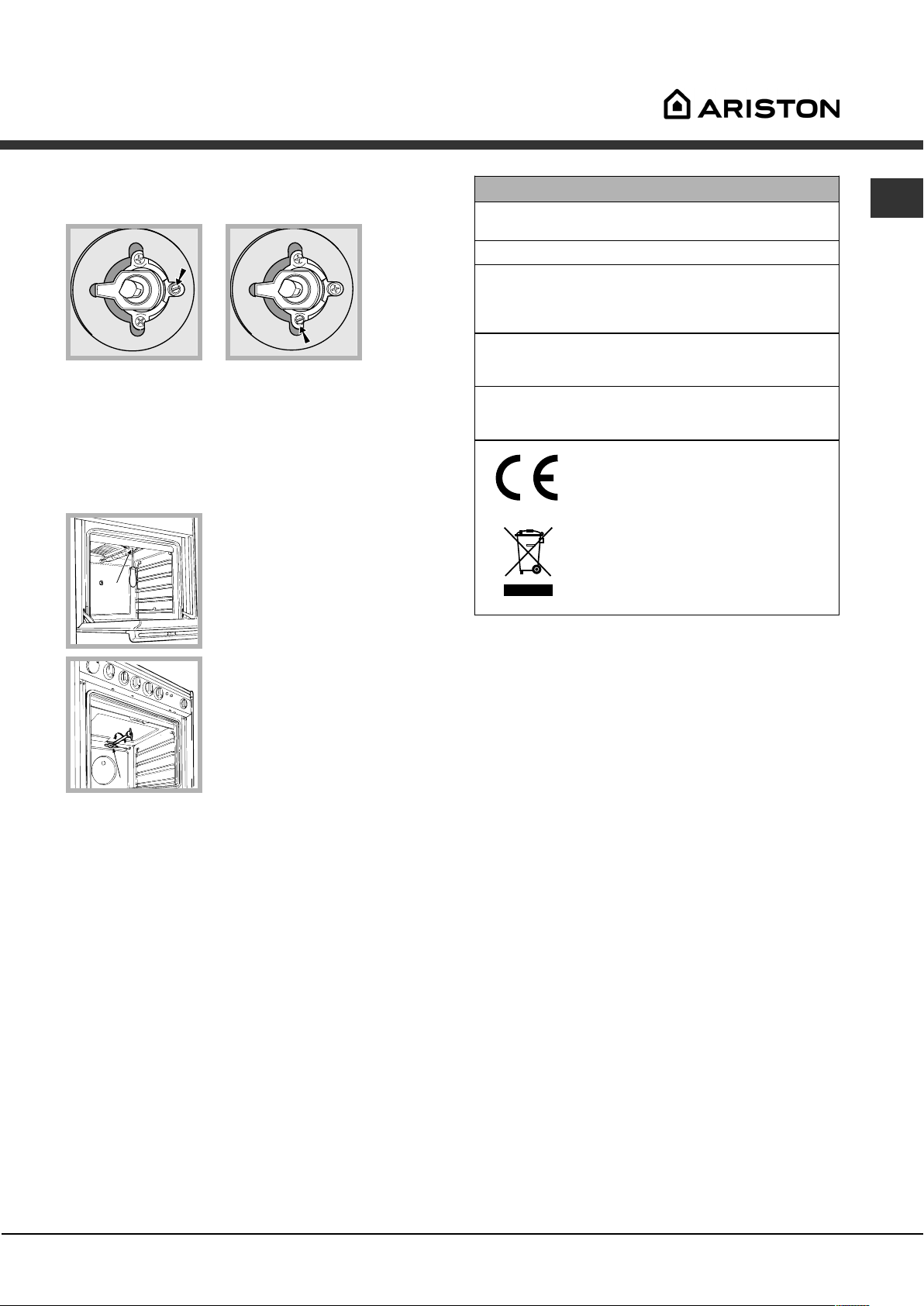

Adjusting the hob burners minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible.

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

Connecting a flexible jointless stainless steel

pipe to a threaded attachment

Make sure that the hose and gaskets comply with

current national legislation.

To begin using the hose, remove the hose holder on

the appliance (the gas supply inlet on the appliance

is a cylindrical threaded 1/2 gas male attachment).

Perform the connection in such a way that the hose

length does not exceed a maximum of 2 metres,

making sure that the hose is not compressed and

does not come into contact with moving parts.

Checking the tightness of the connection

When the installation process is complete, check the

hose fittings for leaks using a soapy solution. Never

use a flame.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

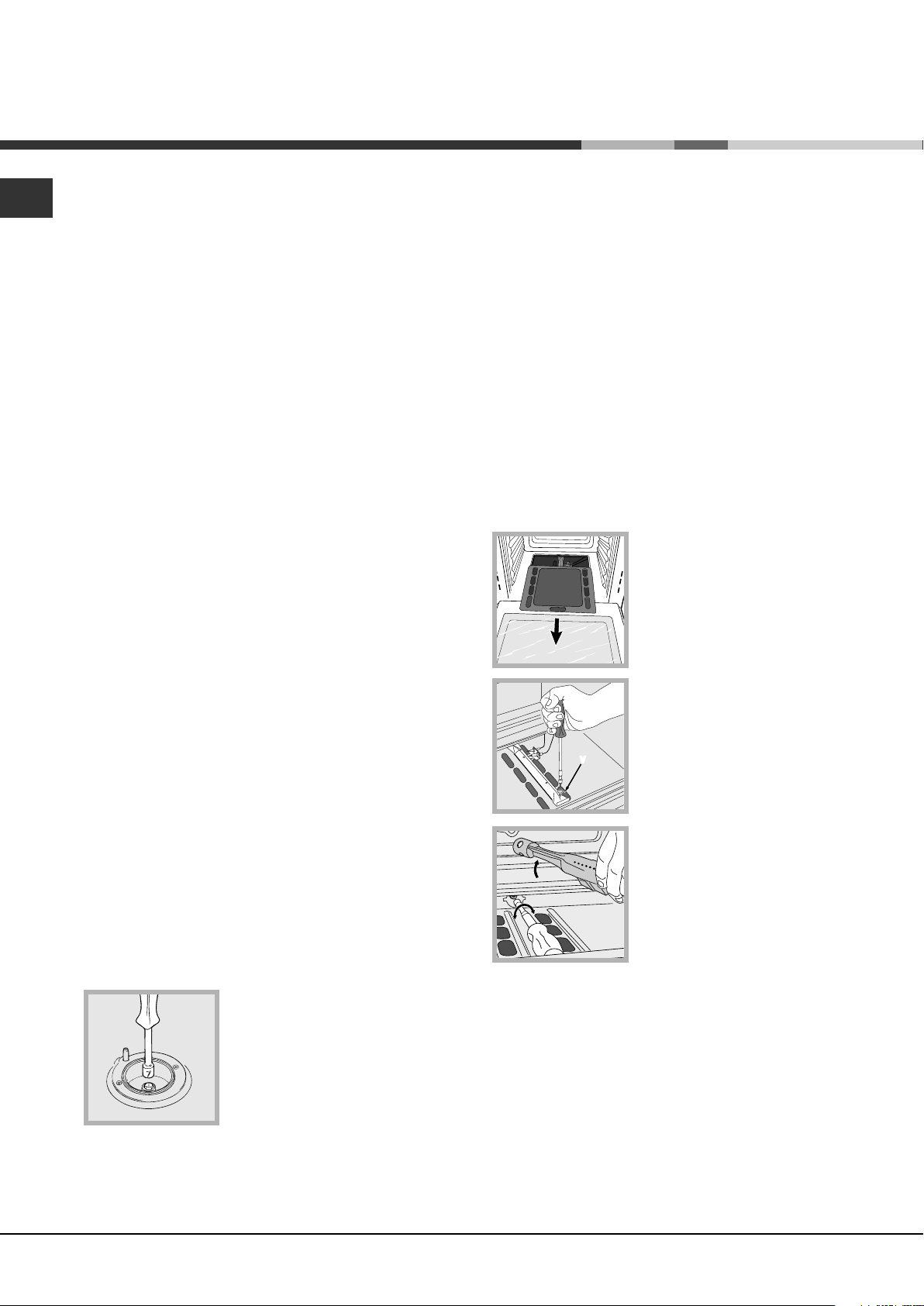

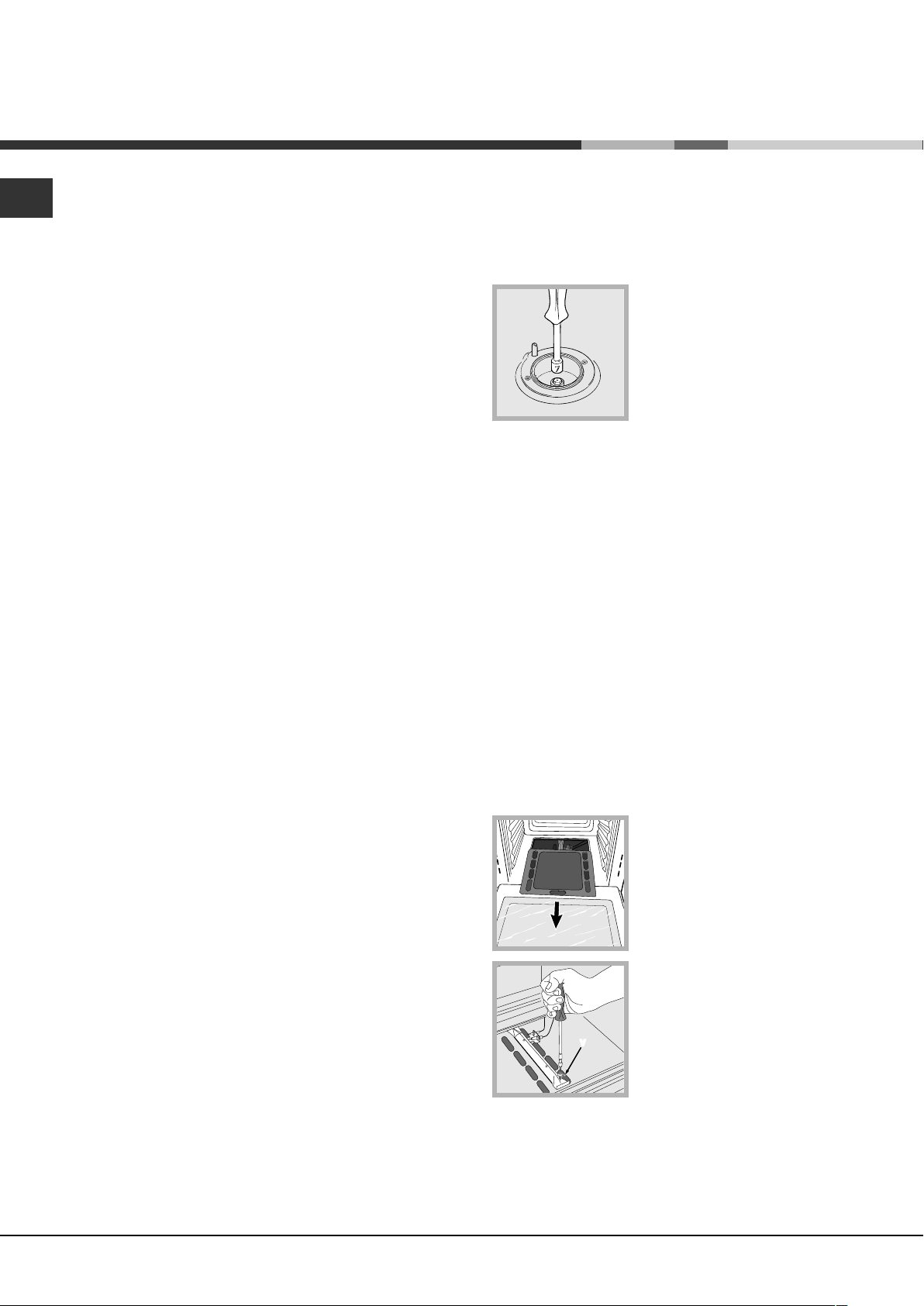

Adapting the hob

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off

their seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (see

figure), and replace them with

nozzles suited to the new type

of gas (see Burner and nozzle

specifications table).

3. Replace all the components

by following the above

instructions in reverse.

The hob burners do not require primary air adjustment.

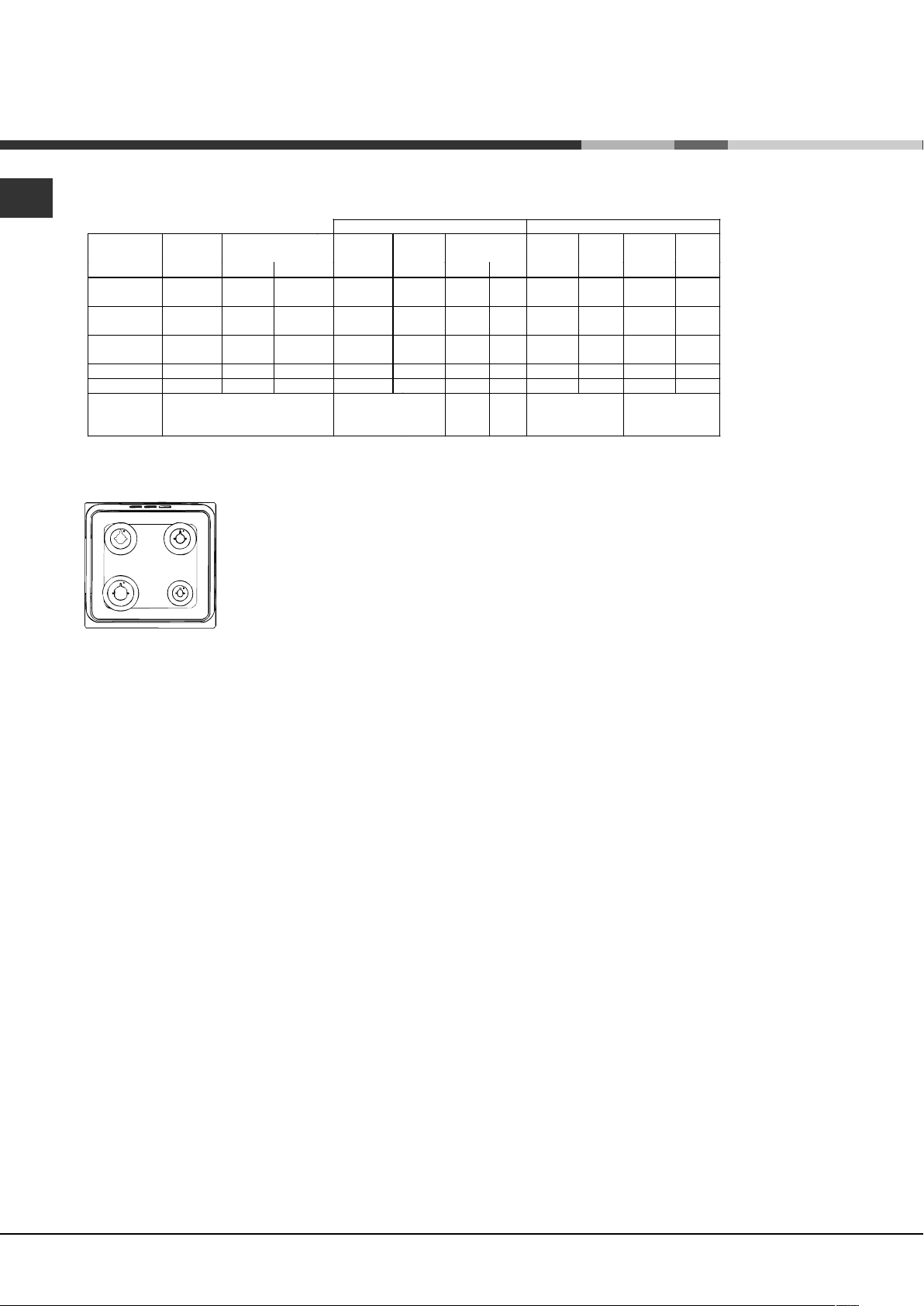

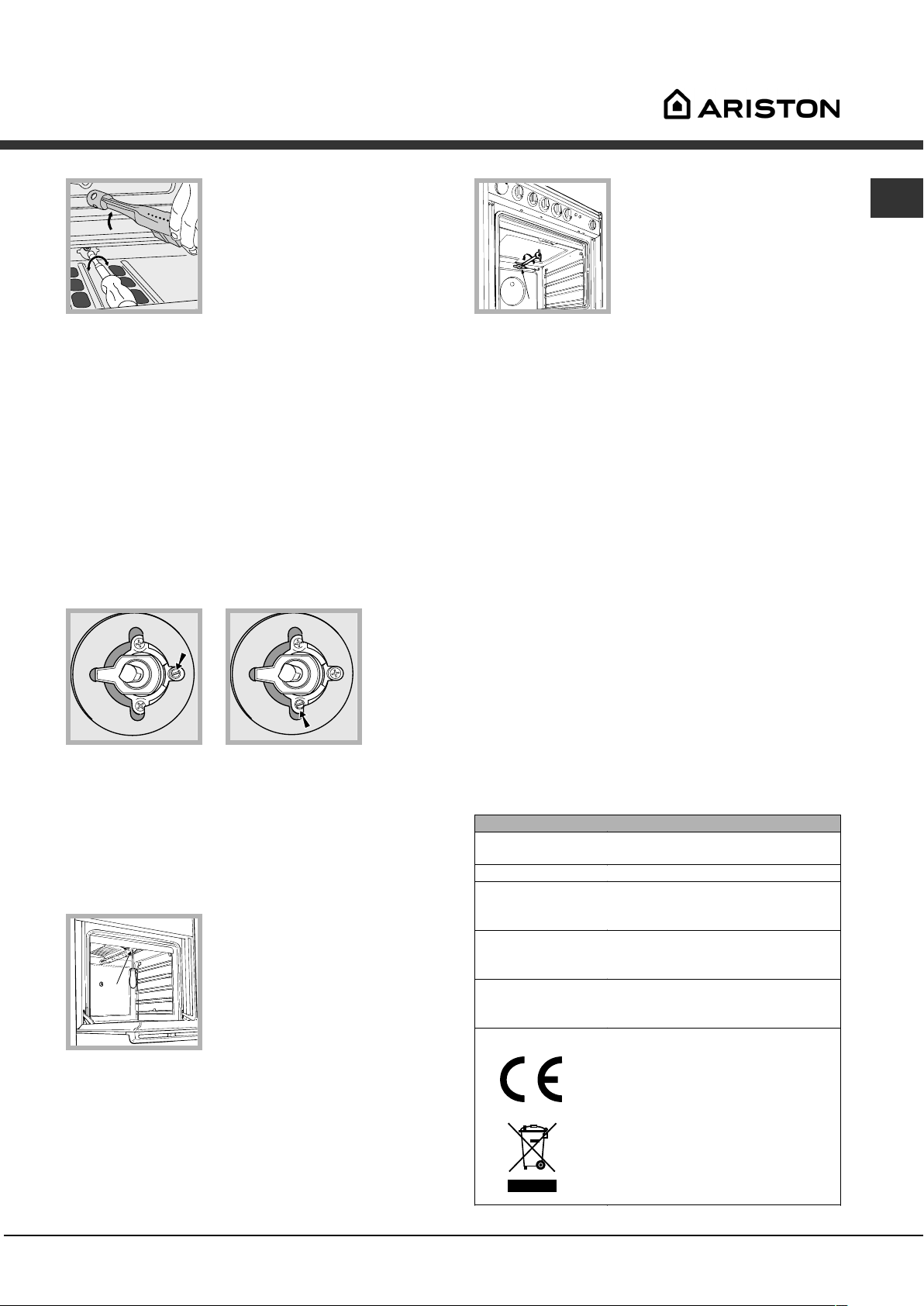

Adapting the oven

Replacing the oven burner nozzle:

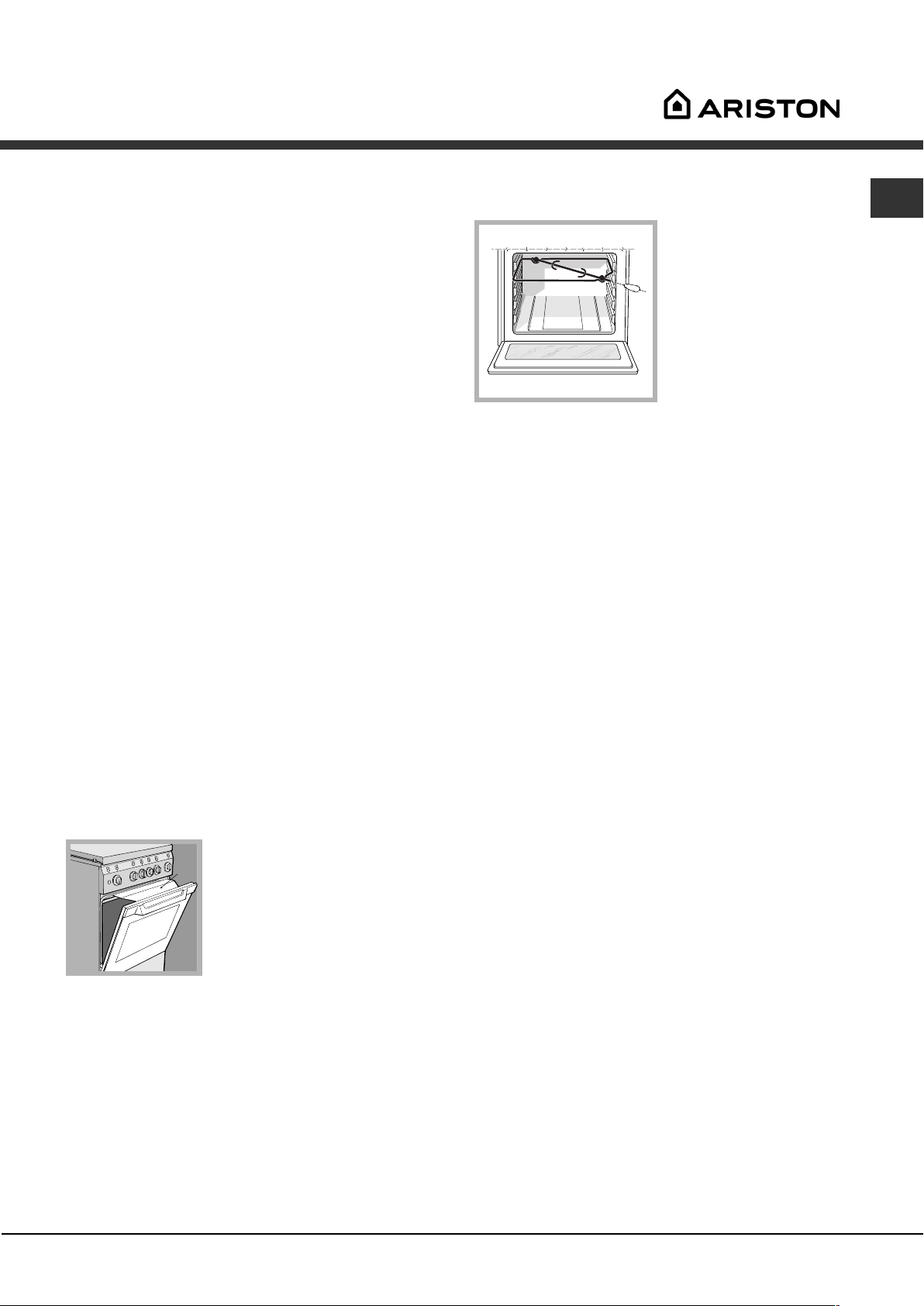

1. Open the oven door fully

2. Pull out the sliding oven

bottom (see diagram).

3. Remove the oven burner

after unscrewing the screws V

(see figure).

V

4. Unscrew the nozzle using a

special nozzle socket spanner

(see figure) or with a 7 mm

socket spanner, and replace it

with a new nozzle that is

suited to the new type of gas

(see Burner and nozzle

specifications table).

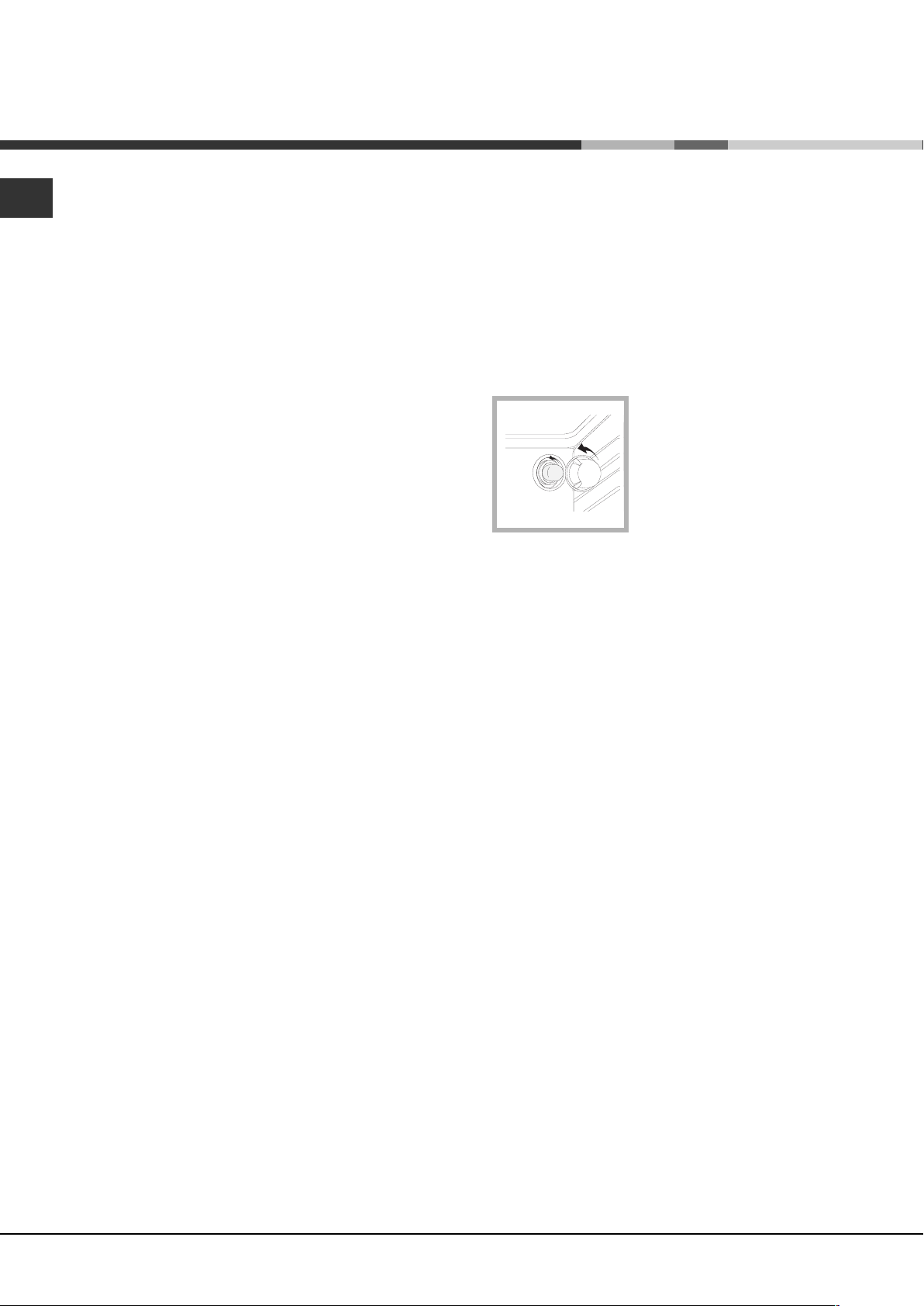

Adjusting the gas oven burners minimum

setting:

1. Light the burner (see Start-up and Use).

2. Turn the knob to the minimum position (MIN) after

it has been in the maximum position (MAX) for

approximately 10 minutes.

3. Remove the knob.

4. Tighten or loosen the adjustment screws on the

outside of the thermostat pin (see figure) until the

flame is small but steady.

4

Page 5

In the case of natural gas, the adjustment screw must

I

be unscrewed by turning it anti-clockwise.

TECHNICAL DATA

Oven Dimensions

HxWxD

Volume

Useful

measurements

relating to the

oven compartment

GB

31x43,5x43,5 cm

58 l

width 46 cm

depth 42 cm

height 8,5 cm

5. Turn the knob from the MAX position to the MIN

position quickly or open and shut the oven door,

making sure that the burner is not extinguished.

Adapting the grill

Replacing the grill burner nozzle:

1. Remove the oven burner

after loosening screw V (see

figure).

V

2. Unscrew the grill burner

nozzle using a special nozzle

socket spanner (see figure) or

preferably with a 7 mm socket

spanner, and replace it with a

new nozzle that is suited to the

new type of gas (see Burner

and nozzle specifications table).

Voltage and

frequency

Burners

see data plate

may be adapted for use with any

type of gas shown on the data

plate.

EC Directives 73/23/EEC dated

19/02/73 (Low Voltage) and

subsequent amendments 89/336/EEC dated 03/05/89

(Electromagnetic Compatibility)

and subsequent amendments -

90/369/EEC dated 29/06/90 (Gas)

and subsequent amendments -

90/68/EEC dated 22/07/93 and

subsequent amendments. 2002/96/EEC.

Be careful of the spark plug wires and the

thermocouple tubes.

The oven and grill burners do not require primary

air adjustment.

After adjusting the appliance so it may be used

with a different type of gas, replace the old rating

label with a new one that corresponds to the new

type of gas (these labels are available from

Authorised Technical Assistance Centres).

Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to regulators for channelled gas.

5

Page 6

GB

g

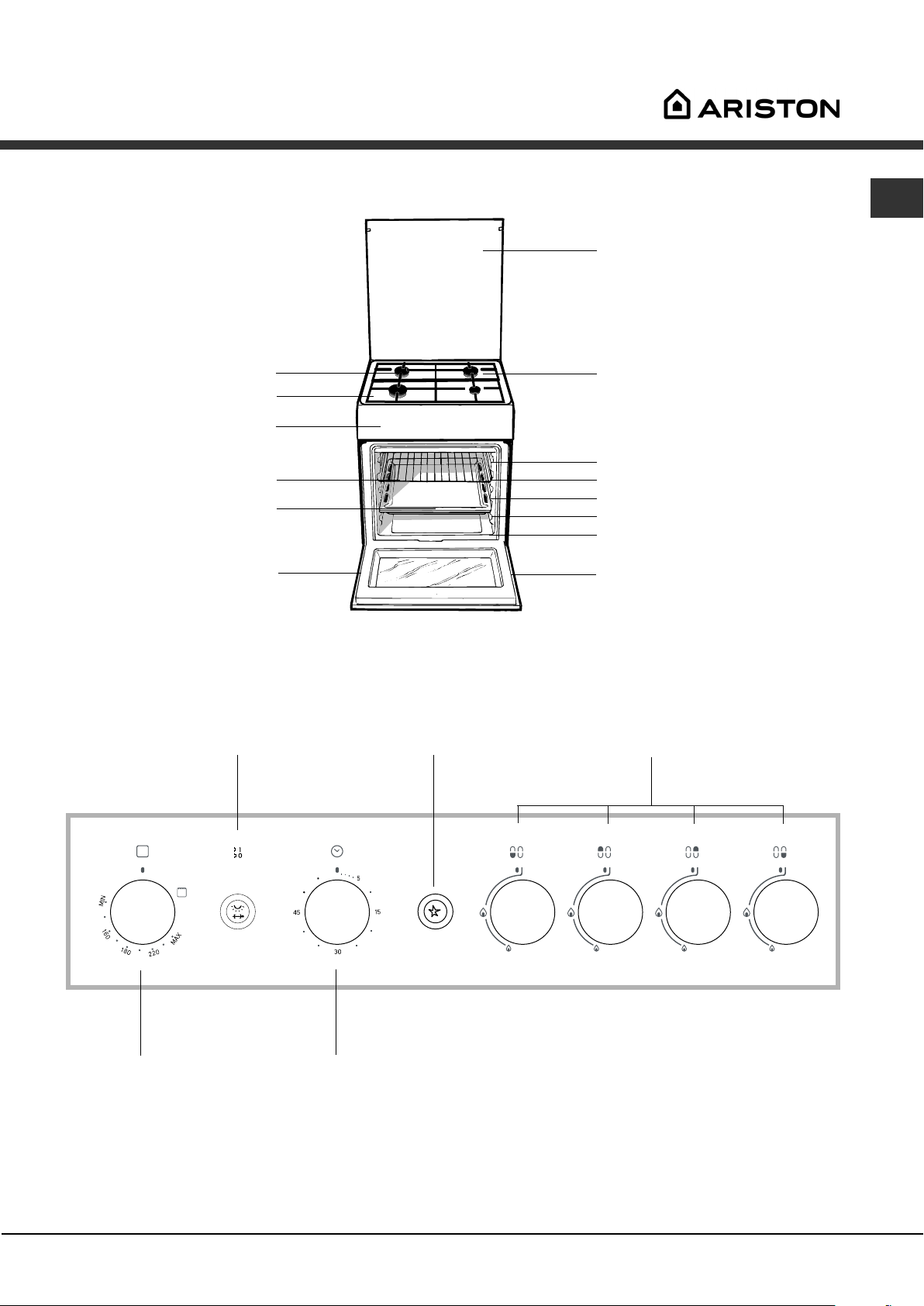

Table of burner and nozzle specifications

Table 1 Liquid Gas Natural Gas

Burner

Diameter

(mm)

Thermal Power

kW (p.c.s.*)

By Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Nozzle

1/100

Nominal Reduced (mm) (mm) *** ** (mm) (mm)

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

100 3.00 0.7 41 86 218 214 116 286 143 286

75 1.90 0.4 30 70 138 136 106 181 118 181

55 1.00 0.4 30 50 73 71 79 95 80 95

Oven - 2.60 1.0 52 78 189 186 119 189 132 238

Grill - 2.50 - - 80 182 179 122 238 139 227

Supply

Pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

13

6,5

18

* At 15°C 1013 mbar-dry gas *** Butane P.C.S. = 49,47 MJ/Kg

** Propane P.C.S. = 50,37 MJ/K

S

S

R

A

Natural P.C.S. = 37,78 MJ/m³

CG64SG1 EX

Flow*

l/h

6

Page 7

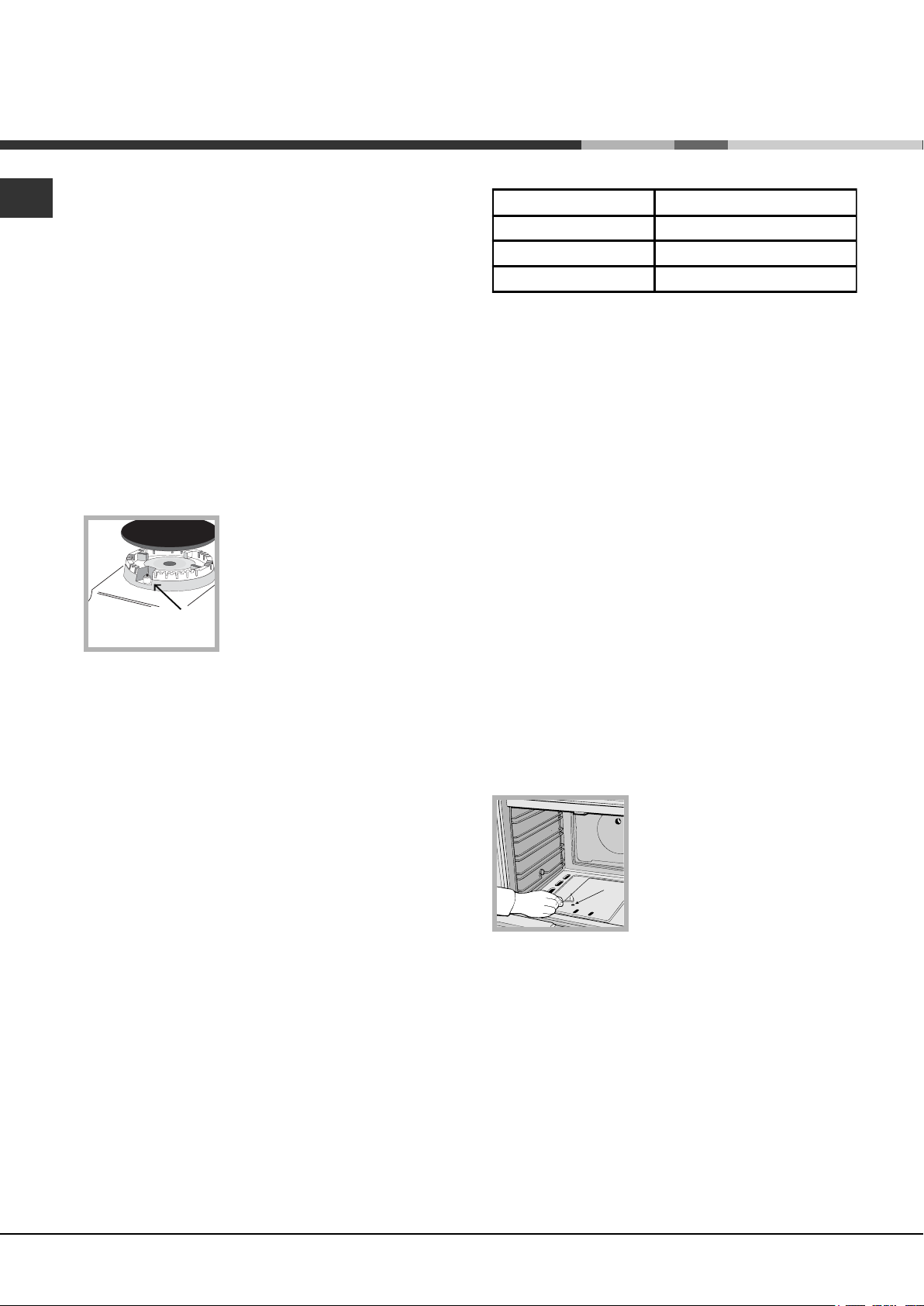

Description of the

appliance

Overall view

Gas burner

Hob grid

Control panel

GRILL rack

DRIPPING PAN

Adjustable foot

Glass cover

Containment

surface for spills

GUIDE RAILS

for the sliding racks

position 5

position 4

position 3

position 2

position 1

Adjustable foot

*

GB

Control panel

OVEN LIGHT and

ROTISSERIE button

OVEN

control knob

GAS BURNER

ignition button*

TIMER

knob*

Hob BURNER

control knobs

Only available in certain models.

*

7

Page 8

Start-up and use

)

GB

Using the hob

Lighting the burners

For each BURNER knob there is a complete ring

showing the strength of the flame for the relevant

burner.

To light one of the burners on the hob:

1. Bring a flame or gas lighter close to the burner.

2. Press the BURNER knob and turn it in an

anticlockwise direction so that it is pointing to the

maximum flame setting -.

3. Adjust the intensity of the flame to the desired

level by turning the BURNER knob in an

anticlockwise direction. This may be the minimum

setting +, the maximum setting - or any position in

between the two.

If the appliance is fitted with

an electronic lighting device*

(see figure), press the ignition

button, marked with the

symbol

BURNER knob down and turn

it in an anticlockwise direction,

towards the maximum flame setting, until the burner

is lit.The burner may be extinguished when the knob

is released. If this occurs, repeat the operation,

holding the knob down for a longer period of time.

, then hold the

Burner ø Cookware diameter (cm

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

To identify the type of burner, please refer to the

diagrams contained in the Burner and nozzle

specifications.

On the models supplied with a reducer shelf,

remember that this should be used only for the

auxiliary burner when you use casserole dishes with

a diameter under 12 cm.

Using the oven

The first time you use your appliance, heat the

empty oven with its door closed at its maximum

temperature for at least half an hour. Ensure that the

room is well ventilated before switching the oven off

and opening the oven door. The appliance may emit

a slightly unpleasant odour caused by protective

substances used during the manufacturing process

burning away.

Never put objects directly on the bottom of the

oven; this will avoid the enamel coating being

damaged. Only use position 1 in the oven when

cooking with the rotisserie spit.

If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight it.

If the appliance is equipped with a flame failure

safety device*, press and hold the BURNER knob

for approximately 2-3 seconds to keep the flame

alight and to activate the device.

To switch the burner off, turn the knob until it

reaches the stop position

Practical advice on using the burners

For the burners to work in the most efficient way

possible and to save on the amount of gas

consumed, it is recommended that only pans that

have a lid and a flat base are used. They should also

be suited to the size of the burner.

Only available in certain models.

*

.

Lighting the oven

To light the oven burner, bring

a flame or gas lighter close to

opening F (see figure) and

press the OVEN control knob

while turning it in an

F

anticlockwise direction until it

reaches the MAX position.

If the appliance is fitted with an electronic lighting

device* (see figure), press the ignition button,

marked with the symbol

control knob and turn it in an anticlockwise direction,

towards the MAX position, until the burner is lit. If,

after 15 seconds, the burner is still not alight,

release the knob, open the oven door and wait for at

least 1 minute before trying to light it again. If there

is no electricity the burner may be lit using a flame

or a lighter, as described above.

The oven is fitted with a safety device and it is

therefore necessary to hold the OVEN control knob

, then hold the OVEN

8

Page 9

down for approximately 6 seconds.

If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight the oven.

Adjusting the temperature

To set the desired cooking temperature, turn the

OVEN control knob in an anticlockwise direction.

Temperatures are displayed on the control panel and

may vary between MIN (150°C) and MAX (250°C).

Once the set temperature has been reached, the

oven will keep it constant by using its thermostat.

Grill

To light the grill, bring a flame or gas lighter close to

the burner and press the OVEN control knob while

turning it in a clockwise direction until it reaches the

@ position. The grill enables the surface of food to

be browned evenly and is particularly suitable for

roast dishes, schnitzel and sausages. Place the

rack in position 4 or 5 and the dripping pan in

position 1 to collect fat and prevent the formation of

smoke.

The grill is fitted with a safety device and it is

therefore necessary to hold the OVEN control knob

down for approximately 6 seconds.

Turnspit

GB

To operate the

rotisserie (see diagram)

proceed as follows:

1. Place the dripping

pan in position 1.

2. Place the rotisserie

support in position 4

and insert the spit in the

hole provided on the

back panel of the oven.

3. Acitvate the function by pressing the TURNSPIT

button.

Oven light

The light may be switched on at any moment by

pressing the OVEN LIGHT button.

Timer*

To activate the Timer proceed as follows:

1. Turn the TIMER knob in a clockwise direction "

for almost one complete revolution to set the buzzer.

2. Turn the TIMER knob in an anticlockwise direction

# to set the desired length of time.

If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight the grill.

When using the grill, leave

the oven door ajar, positioning

D

the deflector D between the

door and the control panel

(see figure) in order to prevent

the knobs from overheating.

Only available in certain models.

*

9

Page 10

GB

Oven cooking advice table

Foods Weight (in

Pasta

Lasagne

Cannelloni

Gratin dishes

Meat

Veal

Chicken

Duck

Rabbit

Pork

Lamb

Fish

Mackerel

Dentex

Trout baked in foil

Pizza

Neapolitan-style 1 3 15 220 15-20

Pies

Biscuits

Tart

Savoury pies

Leavened cakes

Grilled foods

Veal steak

Cutlets

Hamburgers

Mackerel

Toast

Grillling using the rotisserie

Spit-roast veal

Spit-roast chicken

Grillling using the multi-spit rotisserie*

Meat kebabs

Vegetable kebabs

kg)

2.5

2.5

2.5

1.7

1.5

1.8

2

2.1

1.8

1.1

1.5

1

0.5

1.1

1

1

1

1.5

1

1

4 pcs

1

2

1

0.8

Rack

position

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

3

4

4

-

-

-

-

Preheating time (min) Recommended

10

10

10

10

10

10

10

10

10

10

10

10

15

15

15

15

5

5

5

5

5

5

5

5

5

Temperature (°C)

210

200

200

200

220

200

200

200

200

180-200

180-200

180-200

180

180

180

180

Cooking time

(minutes)

60-75

40-50

40-50

85-90

90-100

100-110

70-80

70-80

90-95

35-40

40-50

40-45

30-35

30-35

45-50

35-40

15-20

15-20

70-80

70-80

40-45

25-30

20

7

5

10

Page 11

Precautions and tips

This appliance has been designed and manufactured

in compliance with international safety standards.

The following warnings are provided for safety

reasons and must be read carefully.

General safety

The appliance was designed for domestic use

inside the home and is not intended for

commercial or industrial use.

The appliance must not be installed outdoors, even

in covered areas. It is extremely dangerous to

leave the appliance exposed to rain and storms.

Do not touch the appliance with bare feet or with

wet or damp hands and feet.

The appliance must be used by adults only for the

preparation of food, in accordance with the

instructions provided in this booklet (the

instructions apply to all countries listed at the

beginning of the booklet).

The instruction booklet accompanies a class 1

(insulated) or class 2 - subclass 1 (recessed

between 2 cupboards) appliance.

When the appliance is in use, the heating

elements and some parts of the oven door

become extremely hot. Make sure you don't

touch them and keep children well away.

Make sure that the power supply cables of other

electrical appliances do not come into contact

with the hot parts of the oven.

The openings used for the ventilation and

dispersion of heat must never be covered.

Do not close the glass hob cover (selected

models only) when the burners are alight or when

they are still hot.

Always use oven gloves when placing cookware

in the oven or when removing it.

Do not use flammable liquids (alcohol, petrol,

etc...) near the appliance while it is in use.

Do not place flammable material in the lower

storage compartment or in the oven itself. If the

appliance is switched on accidentally, it could

catch fire.

The internal surfaces of the compartment (where

present) may become hot.

Always make sure the knobs are in the

and that the gas tap is closed when the appliance

is not in use.

When unplugging the appliance, always pull the plug

from the mains socket; do not pull on the cable.

Never perform any cleaning or maintenance work

without having disconnected the appliance from

the electricity mains.

If the appliance breaks down, under no

circumstances should you attempt to repair the

appliance yourself. Repairs carried out by

inexperienced persons may cause injury or further

malfunctioning of the appliance. Contact Assistance.

Do not rest heavy objects on the open oven door.

position

Disposal

When disposing of packaging material: observe local

legislation so that the packaging may be reused.

The European Directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE),

requires that old household electrical appliances

must not be disposed of in the normal unsorted

municipal waste stream. Old appliances must be

collected separately in order to optimise the

recovery and recycling of the materials they contain

and reduce the impact on human health and the

environment. The crossed out wheeled bin

symbol on the product reminds you of your

obligation, that when you dispose of the appliance

it must be separately collected.

Consumers should contact their local authority or

retailer for information concerning the correct

disposal of their old appliance.

Respecting and conserving the

environment

You can help to reduce the peak load of the

electricity supply network companies by using the

oven in the hours between late afternoon and the

early hours of the morning.

Always keep the oven door closed when using the

GRILL mode This will achieve better results while

saving energy (approximately 10%).

Check the door seals regularly and wipe them clean

to ensure they are free of debris so that they adhere

properly to the door, thus avoiding heat dispersion.

GB

11

Page 12

Care and maintenance

GB

Switching the appliance off

Disconnect your appliance from the electricity

supply before carrying out any work on it.

Cleaning the appliance

Never use steam cleaners or pressure cleaners on

the appliance.

The stainless steel or enamel-coated external

parts and the rubber seals may be cleaned using

a sponge that has been soaked in lukewarm water

and neutral soap. Use specialised products for

the removal of stubborn stains. After cleaning,

rinse well and dry thoroughly. Do not use abrasive

powders or corrosive substances.

The hob grids, burner caps, flame spreader rings

and burners may be removed to make cleaning

easier; wash them in hot water and non-abrasive

detergent, making sure all burnt-on residue is

removed before drying them thoroughly.

Clean the terminal part of the flame failure safety

devices* frequently.

The inside of the oven should ideally be cleaned

after each use, while it is still lukewarm. Use hot

water and detergent, then rinse well and dry with

a soft cloth. Do not use abrasive products.

Inspecting the oven seals

Check the door seals around the oven regularly. If

the seals are damaged, please contact your nearest

Authorised After-sales Service Centre. We

recommend that the oven is not used until the seals

have been replaced.

Replacing the oven light bulb

1. After disconnecting the

oven from the electricity mains,

remove the glass lid covering

the lamp socket (see figure).

2. Remove the light bulb and

replace it with a similar one:

voltage 230 V, wattage 25 W,

cap E 14.

3. Replace the lid and reconnect the oven to the

electricity supply.

Gas tap maintenance

Over time, the taps may become jammed or difficult

to turn. If this happens, the tap must be replaced.

This procedure must be performed by a

qualified technician authorised by the

manufacturer.

Clean the glass part of the oven door using a

sponge and a non-abrasive cleaning product,

then dry thoroughly with a soft cloth. Do not use

rough abrasive material or sharp metal scrapers

as these could scratch the surface and cause the

glass to crack.

The accessories can be washed like everyday

crockery, and are even dishwasher safe.

Do not close the cover when the burners are alight

or when they are still hot.

Assistance

Never use the services of an unauthorised

technician.

Please have the following information to hand:

The type of problem encountered.

The appliance model (Mod.).

The serial number (S/N).

The latter two pieces of information can be found on

the data plate located on the appliance.

Only available in certain models.

*

12

Page 13

Mode demploi

CUISINIERE

GB

English, 1

GB

English, 37

CG64SG1 EX

FR

Français, 13

AR

ES

Espanol, 25

Sommaire

FR

Installation, 14-18

Positionnement et nivellement

Raccordement électrique

Raccordement gaz

Adaptation aux différents types de gaz

Caractéristiques techniques

Tableau Caractéristiques des brûleurs et des

injecteurs

Description de lappareil, 19

Vue densemble

Tableau de bord

Mise en marche et utilisation, 20-22

Utilisation du plan de cuisson

Utilisation du four

Tableau de cuisson

Précautions et conseils, 23

Sécurité générale

Mise au rebut

Economies et respect de lenvironnement

Nettoyage et entretien, 24

Mise hors tension

Nettoyage de lappareil

Entretien robinets gaz

Remplacement de lampoule déclairage du four

Assistance

Page 14

A

Installation

FR

Conservez ce mode demploi pour pouvoir le

consulter à tout moment. En cas de vente, de cession

ou de déménagement, veillez à ce quil suive

lappareil.

Lisez attentivement les instructions : elles

contiennent des conseils importants sur linstallation,

lutilisation et la sécurité de votre appareil.

Linstallation de lappareil doit être effectuée par un

professionnel du secteur conformément aux

instructions du fabricant.

Nimporte quelle opération de réglage, dentretien,

etc., doit être effectuée après avoir débranché la prise

de la cuisinière.

Conditions réglementaires dinstallation

Le raccordement gaz devra être fait par un

professionnel qualifié qui assurera la bonne

alimentation en gaz et le meilleur réglage de la

combustion des brûleurs. Ces opérations

dinstallation, quoique simples, sont délicates et

primordiales pour que votre cuisinière vous rende le

meilleur service. Linstallation doit être effectuée

conformément aux textes réglementaires et règles de

lart en vigueur, notamment:

Arrêté du 2 août 1977. Règles techniques et de

sécurité applicables aux installations de gaz

combustibles et dhydro-carbures liquéfiés situées

à lintérieur des bâtiments dhabitation et de leur

dépendances.

Norme DTU P45-204. Installations de gaz

(anciennement DTU n° 61-1-installations de gaz Avril 1982 + additif n°1 Juillet 1984).

Règlement sanitaire départemental.

pièces voisines (voir figure B) à condition quil ne

sagisse pas de parties communes du bâtiment, de

chambres à coucher ou de locaux à risque dincendie

équipées dun conduit daération avec lextérieur

comme décrit plus haut.

Local adjacent Local à ventiler

A B

Ouverture de ventilation

pour lair comburant

Après une utilisation prolongée de lappareil, il est

conseillé douvrir une fenêtre ou daugmenter la

vitesse de ventilateurs éventuels.

Evacuation des fumées de combustion

La pièce doit prévoir un système dévacuation vers

lextérieur des fumées de combustion réalisé au

moyen dune hotte reliée à une cheminée à tirage

naturel ou par ventilateur électrique qui entre

automatiquement en fonction dès quon allume

lappareil (voir figures).

Agrandissement de la

fissure entre la porte et

le sol

Aération des locaux

Lappareil doit être installé dans des locaux qui sont

aérés en permanence, selon les prescriptions des

Normes en vigueur dans le pays dinstallation. Il est

indispensable que la pièce où lappareil est installé

dispose dune quantité dair égale à la quantité dair

comburant nécessaire à une bonne combustion du

gaz (le flux dair doit être dau moins 3 m

puissance installée).

Les prises dair, protégées par des grilles, doivent

disposer dun conduit dau moins 2 cm2 de section

utile et dans une position qui leur évite tout risque

dêtre bouchées accidentellement, même

partiellement (voir figure A).

Ces ouvertures doivent être agrandies de 100%

(surface minimale 2 cm2) en cas dappareils

dépourvus du dispositif de sécurité de flamme et

quand lafflux de lair provient de manière indirecte de

"

3

/h par kW de

Evacuation

directement à

lextérieur

Les gaz de pétrole liquéfiés, plus lourds que lair, se

déposent et stagnent dans le bas. Les locaux qui

contiennent des bouteilles de G.P.L doivent donc

prévoir des ouvertures vers lextérieur afin de permettre

lévacuation du gaz par le bas en cas de fuites

accidentelles. Ne pas installer ou entreposer de

bouteilles de GPL, vides ou partiellement pleines, dans

des locaux qui se trouvent en sous-sol (caves etc.). Ne

gardez dans la pièce que la bouteille que vous êtes en

train dutiliser, loin de sources de chaleur (fours, feux

de bois, poêles etc.) qui pourraient amener sa

température à plus de 50°C.

Evacuation par cheminée ou

conduit de fumée ramifié (réservé

aux appareils de cuisson)

Page 15

Positionnement et nivellement

Lappareil peut être installé à côté de meubles dont

la hauteur ne dépasse pas celle du plan de cuisson.

Assurez-vous que le mur en contact avec la paroi

arrière de lappareil est réalisée en matériel ignifuge

résistant à la chaleur (T 90°C).

Pour une installation correcte :

installez cet appareil dans une cuisine, une salle à

manger ou un studio (jamais dans une salle de

bains);

si le plan de cuisson de la cuisinière dépasse le

plan de travail des meubles, ces derniers doivent

être placés à au moins 200 mm de lappareil;

si la cuisinière est

HOOD

Min. mm.

600

mm.

420

Min.

420

Min. mm.

ne placez pas de rideaux derrière la cuisinière ou

sur ses côtés à moins de 200 mm de distance;

pour linstallation de hottes, conformez-vous aux

instructions de leur notice demploi.

installée sous un

élément suspendu, il

faut que ce dernier soit

placé à au moins 420mm

de distance du plan. Il

mm. with hood

mm. without hood

650

700

faut prévoir une distance

min.

min.

de 700mm si les

éléments suspendus sont

inflammables (voir

figure);

intercaler entre lappareil et le réseau un interrupteur à

coupure omnipolaire ayant au moins 3 mm

décartement entre les contacts, dimensionné à la

charge et conforme aux normes en vigueur (le fil de

terre ne doit pas être interrompu par linterrupteur). Le

câble dalimentation ne doit atteindre, en aucun point,

des températures dépassant de 50°C la température

ambiante.

Avant de procéder au branchement, assurez-vous que :

la prise est bien munie dune terre conforme à la loi;

la prise est bien apte à supporter la puissance

maximale de lappareil, indiquée sur la plaquette

signalétique;

la tension dalimentation est bien comprise entre les

valeurs indiquées sur la plaquette signalétique;

la prise est bien compatible avec la fiche de

lappareil. Si ce nest pas le cas, remplacez la prise

ou la fiche, nutilisez ni rallonges ni prises multiples.

Après installation de lappareil, le câble électrique et

la prise de courant doivent être facilement

accessibles

Le câble ne doit être ni plié ni excessivement écrasé.

Le câble doit être contrôlé périodiquement et ne

peut être remplacé que par un technicien agréé.

Nous déclinons toute responsabilité en cas de

non respect des normes énumérées ci-dessus.

Raccordement gaz

FR

Nivellement

Pour mettre lappareil bien à

plat, vissez les pieds de

réglage fournis aux

emplacements prévus aux

coins à la base de la cuisinière

(voir figure).

Montage des pieds* par

encastrement sous la base.

Raccordement électrique

Montez sur le câble une prise normalisée pour la

charge indiquée sur létiquette des caractéristiques

(voir tableau des caractéristiques techniques).

En cas de raccordement direct au réseau, il faut

Pour raccorder lappareil au réseau de distribution du

gaz ou à la bouteille de gaz utilisez un tuyau flexible

en caoutchouc ou en acier, conformément à la

réglementation en vigueur. Assurez-vous auparavant

que lappareil est bien réglé pour le type de gaz

dalimentation utilisé (voir étiquette sur le couvercle :

autrement voir ci-dessous). Si lalimentation seffectue

avec du gaz liquide en bouteille, utilisez des

régulateurs de pression conformes à la

réglementation en vigueur dans le pays. Pour

simplifier le raccordement, lalimentation du gaz est

orientable latéralement* : inversez labout annelé avec

le bouchon de fermeture et remplacez le joint

détanchéité (fourni avec lappareil).

Pour un fonctionnement en toute sécurité, pour un

meilleur emploi de lénergie et une plus longue durée

de vie de lappareil, vérifiez que la pression

dalimentation respecte bien les valeurs indiquées

dans le tableau Caractéristiques des brûleurs et des

injecteurs (voir ci-dessous).

*Nexiste que sur certains modèles

#

Page 16

FR

Raccordement gaz par tuyau flexible en caoutchouc

Assurez-vous que le tuyau est bien conforme aux

normes applicables dans le pays dinstallation. Le

tuyau doit avoir un diamètre intérieur de : 8 mm en cas

dalimentation au gaz liquide; 15 mm en cas

dalimentation au gaz naturel.

Après avoir effectué le raccordement, assurez-vous

que le tuyau :

ne touche en aucun point à des parties pouvant

atteindre plus de 50°C;

ne soit pas soumis à traction ou torsion et ne

présente pas de pliures ou étranglements;

ne risque pas dentrer en contact avec des corps

tranchants, des arêtes vives, des parties mobiles et

ne soit pas écrasé;

puisse être facilement contrôlable sur toute sa

longueur pour vérifier son état de conservation;

ait moins de 1500mm de long;

soit bien fixé à ses deux extrémités à laide de

bagues de serrage conformes à la réglementation

en vigueur dans le pays.

Si une ou plusieurs de ces conditions ne peuvent

être remplies ou que la cuisinière est installée dans

des conditions de classe 2 sous-classe 1 (appareil

encastré entre deux meubles), il faut utiliser un tuyau

flexible en acier (voir ci-dessous).

Raccordement gaz par tuyau flexible en acier inox,

à paroi continue avec raccords filetés

Assurez-vous que le tuyau et les joints sont bien

conformes aux normes applicables dans le pays

dinstallation.

Pour installer le tuyau, enlevez labout annelé équipant

lappareil (le raccord dentrée du gaz à lappareil est

fileté 1/2 gaz mâle cylindrique).

Adaptation du plan de cuisson

Remplacement des injecteurs des brûleurs du plan de

cuisson:

1.enlevez les grilles du plan de cuisson et sortez les

brûleurs de leur logement;

2. dévissez les injecteurs à

laide dune clé à tube de 7mm

(voir figure), et remplacez-les

par les injecteurs adaptés au

nouveau type de gaz (voir

tableau Caractéristiques des

brûleurs et des injecteurs) ;

3.remontez les différentes parties en effectuant les

opérations dans le sens inverse.

Réglage des minima des brûleurs du plan de

cuisson :

1.placez le robinet sur la position minimum;

2.enlevez le bouton et tournez la vis de réglage

positionnée à lintérieur ou sur le côté de la tige du

robinet jusquà obtenir une petite flamme régulière;

En cas de gaz naturel, il faut dévisser la vis de

réglage en tournant dans le sens inverse des aiguilles

dune montre;

3.vérifiez si, en tournant rapidement le robinet du

maximum au minimum, le brûleur ne séteint pas.

Les brûleurs du plan de cuisson ne nécessitent pas

de réglage de lair primaire.

Adaptation du four

Remplacement du brûleur du four:

1. ouvrez complètement la porte du four;

2. enlever la protection

coulissante

(voir figure);

Procédez au raccordement de manière à ce que la

longueur du tuyau ne dépasse pas 2 mètres

dextension maximale. Veillez à ce que le tuyau ne

soit pas écrasé et ne touche en aucun point à des

parties mobiles.

Vérification de létanchéité

Une fois linstallation terminée, vérifiez létanchéité de

tous les raccords en utilisant une solution

savonneuse, nutilisez jamais de flamme.

Adaptation aux différents types de gaz

Lappareil peut être adapté à un type de gaz autre

que celui pour le quel il a été conçu (indiqué sur

létiquette de réglage sur le couvercle).

$

3. déposer le brûleur du four

après avoir enlevé la vis V (voir

figure);

V

Page 17

4. dévisser linjecteur du brûleur

à laide de la clé à tube spéciale

pour injecteurs (voir figure) ou

dune clé à tube de 7 mm et le

remplacer par linjecteur adapté

au nouveau type de gaz (voir

tableau Caractéristiques des

brûleurs et des injecteurs).

Réglage du minimum du brûleur du four à gaz :

1. allumer le brûleur (voir Mise en marche et

Utilisation);

2. amener la manette sur la position minimum (MIN)

après lavoir laissée pendant environ 10 minutes sur la

position maximum (MAX);

3. enlever le bouton;

4. agir sur la vis de réglage positionnée à lextérieur

de la tige du thermostat (voir figure) jusquà obtenir

une petite flamme régulière.

En cas de gaz naturel, il faut dévisser la vis de

réglage en tournant dans le sens inverse des aiguilles

dune montre;

2. dévisser l'injecteur du

brûleur du gril à l'aide de la clé

à tube adaptée pour les

injecteurs (voir Figure), ou

mieux encore avec une clé à

tube de 7 mm. et le remplacer

I

par celui adapté au nouveau

type de gaz (voir tableau

Caractéristiques brûleurs et injecteurs).

Les brûleurs du four et du gril ne nécessitent pas de

réglage de l'air primaire.

Faire très attention aux câbles des bougies et aux

tuyaux des thermocouples.

Après avoir procédé au réglage pour le nouveau

type de gaz, remplacer la vieille étiquette par celle

correspondant au nouveau gaz, disponible dans les

centres dassistance technique agréés.

Si la pression du gaz diffère (ou varie) par rapport à

la pression prévue, il faut installer, sur la tuyauterie

dentrée un régulateur de pression approprié

conforme à la réglementation sur les régulateurs pour

gaz canalisés en vigueur dans le pays.

FR

5. vérifier si, en tournant rapidement le bouton de la

position MAX à la position MIN, ou en ouvrant et

fermant rapidement la porte du four, le brûleur ne

séteint pas.

Adaptation du gril

Remplacement de l'injecteur du brûleur du gril :

1. déposer le brûleur du gril

après avoir enlevé la vis V (voir

figure);

V

CARACTERISTIQUES TECHNIQUES

Dimensions ıdu

Four HxLxP

Volume

Dimensions utiles

du tiroir chauffeplats

Tension et

fréquence

d’alimentation :

Brûleurs

31x43,5x43,5 cm

58 l

largeur 46 cm

profondeur 42 cm

hauteur 8,5 cm

voir plaquette signalétique

adaptables à n'importe quel type de

gaz parmi ceux indiqués sur le

plaquette signalétique

Directives Communautaires

73/23CEE du 19/02/73 (Basse

Tension) et modifications suivantes

- 89/336/CEE du 03/05/89

(Compatibilité Electromagnétique)

et modifications suivantes 90/369/CEE du 29/06/90 (Gaz) et

modifications suivantes 93/68/CEE du 22/07/93 et

modifications suivantes 2002/96/CE

%

Page 18

FR

Tableau Caractéristiques des brûleurs et des injecteurs

Tableau 1 Gaz liquide Gaz naturel

Brûleur Diamètre

(mm)

Puissance

thermique

Bipasse

1/100

injecteur

1/100

débit*

g/h

injecteur

1/100

débit*

l/h

kW (p.c.s.*)

Nomin. Réduit. (mm) (mm) *** ** (mm) G20 G25

Rapide

(Grand)(R)

Semi Rapide

(Moyen)(S)

Auxiliaire

(Petit)(A)

100 3.00 0.70 41 86 218 214 116 286 332

75 1.90 0.40 30 70 138 136 106 181 210

55 1.00 0.40 30 50 73 71 79 95 111

Four — 2.60 1.00 52 78 182 179 119 238 277

Gril — 2.50 — — 80 182 179 122 238 277

Pressions

d'alimentation

* A 15°C et 1013 mbar-gaz sec

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Naturel G20 P.C.S = 37,78 MJ/m

Naturel G25 P.C.S = 32,49 MJ/m

Nominale (mbar)

Minimum (mbar)

Maximum (mbar)

3

3

28-30

20

35

37

25

45

20

17

25

25

20

30

S

S

R

A

CG64SG1 EX

Tension et fréquence d'alimentation de la partie électrique et

caractéristiques de la partie gaz

Modèle Partie gaz Partie électrique

Classe Puissance nominale

kW (1)

CG64SG1 EX

(1) Les valeurs exprimées en g/h se réfèrent aux capacités pour

les gaz liquides (butane, propane).

II2E+3+

10,40 (756 g/h-G30)

(743 g/h - G31)

Tension

220-240V~

50-60Hz

&

Page 19

Description de lappareil

Vue densemble

Grille du plan de cuisson

Tableau de bord

Support GRILLE

Support LECHEFRITE

Pied de réglage

Brûleur à gaz

FR

Couvercle en verre*

Plateau du

plan de cuisson

GLISSIERES

de coulissement

niveau 5

niveau 4

niveau 3

niveau 2

niveau 1

Pied de réglage

Tableau de bord

TOURNEBROCHE et ECLAIRAGE FOUR

Manette

FOUR

Bouton

Manette

MINUTEUR*

Bougie d’allumage des

BRÛLEURS GAZ*

Manettes BRÛLEURS

du plan de cuisson

Nexiste que sur certains modèles

*

'

Page 20

)

Mise en marche et utilisation

FR

Utilisation du plan de cuisson

Allumage des brûleurs

Un petit cercle plein près de chaque manette

BRULEUR indique le brûleur associé à ce dernier.

Pour allumer un brûleur du plan de cuisson :

1. approchez une flamme ou un allume-gaz ;

2. poussez sur le manette du BRULEUR tout en le

tournant dans le sens inverse des aiguilles dune

montre jusquau symbole grande flamme -.

3. pour régler la puissance de la flamme souhaitée,

tournez le manette BRULEUR dans le sens inverse

des aiguilles dune montre : sur la position minimum +,

sur la position maximum - ou sur une position

intermédiaire.

Si l'appareil est équipé d'un

allumage électronique* (voir

figure) il faut d'abord appuyer

sur la touche d'allumage,

repérée par le symbole

correspondant

pousser à fond et tourner en

même temps dans le sens

inverse des aiguilles d'une montre le bouton

BRULEUR pour l'amener en face du symbole grande

flamme, jusqu'à l'allumage.

En cas dextinction accidentelle des flammes,

éteignez le brûleur et attendez au moins 1 minute

avant de tenter de rallumer.

Pour éteindre le brûleur, tournez le bouton jusquà la

position darrêt

Conseils pratiques pour lutilisation des brûleurs

.

, puis

Utilisation du four

Lors de son premier allumage, faites fonctionner le

four à vide, porte fermée, pendant au moins une heure

en réglant la température à son maximum. Puis

éteignez-le, ouvrez la porte et aérez la pièce. Lodeur

qui se dégage est due à lévaporation des produits

utilisés pour protéger le four.

Ne posez jamais dobjets à même la sole du four,

vous pourriez abîmer lémail. Nutilisez la position 1 du

four quen cas de cuissons au tournebroche.

Allumage du four

Pour allumer le brûleur du four,

approchez une flamme ou un

allume-gaz de lorifice F (voir

figure), poussez sur le bouton

FOUR et tournez-le en même

F

temps dans le sens inverse

des aiguilles dune montre

jusquà la position MAX.

Si l'appareil est équipé d'un allumage électronique* il

faut d'abord appuyer sur la touche d'allumage,

repérée par le symbole correspondant

sur le bouton FOUR et tournez-le en même temps

dans le sens inverse des aiguilles dune montre

jusquà la position MAX., jusqu'à l'allumage. Si au

bout de 15 secondes le brûleur ne sest toujours pas

allumé, lâchez le bouton, ouvrez la porte du four et

attendez au moins 1 minute avant de tenter un nouvel

allumage. En cas de panne de courant, vous pouvez

allumer le brûleur avec une flamme ou avec un

allume-gaz comme décrit plus haut.

, poussez

Pour un meilleur rendement des brûleurs et une

moindre consommation de gaz, utilisez des

casseroles à fond plat, munies de couvercle et dun

diamètre adapté au brûleur :

Brûleur ø Diamètre récipients (cm

Rapide (R) 24 – 26

Semi-Rapide (S) 16 – 20

Auxiliaire (A) 10 – 14

Pour distinguer le type de brûleur reportez-vous aux

dessins figurant dans le paragraphe "Caractéristiques

des brûleurs et des injecteurs"

Pour les modèles équipés d'une grille de réduction,

n'utilisez cette dernière que pour le brûleur auxiliaire

quand vous utilisez des casseroles ayant moins de 12

cm de diamètre.

Le four étant équipé dun dispositif de sécurité de

flamme, il faut pousser sur le bouton du FOUR

pendant environ 6 secondes.

En cas dextinction accidentelle de flamme, éteignez

le brûleur et attendez au moins 1 minute avant de

tenter de rallumer.

Pour éteindre le brûleur, tourner le bouton jusquà la

position darrêt

Nexiste que sur certains modèles

*

.

Page 21

Réglage de la température

Pour sélectionner la température de cuisson

souhaitée, tournez le bouton FOUR dans le sens

inverse des aiguilles dune montre. Les températures

sont indiquées sur le tableau de bord et vont dun MIN

(140°C) à un MAX (250°C). Une fois que la

température est atteinte dans le four, un thermostat la

maintient constante au degré prêt.

Gril

Tournez le bouton FOUR dans le sens inverse des

aiguilles dune montre jusquà la position @ pour

brancher le gril à rayons infrarouges. Le gril vous

permet de dorer vos préparations en surface, il est

tout particulièrement recommandé pour la cuisson de

roast-beef, rôtis, côtelettes, saucisses. Placez la grille

au niveau 4 ou 5 et la lèchefrite au niveau 1 pour

recueillir les jus de cuisson et éviter la formation de

fumée.

Le gril étant équipé dun dispositif de sécurité de

flamme, il faut pousser sur le bouton du FOUR

pendant environ 6 secondes.

Pour la cuisson au gril, la porte du four doit être

fermée, vous obtiendrez de meilleurs résultats et ferez

des économies dénergie (10% environ).

Lors de l'utilisation du gril,

garder la porte du four

D

entrebâillée en plaçant le

déflecteur "D" (voir figure) entre

la porte du four et le tableau de

bord pour éviter toute

surchauffe des boutons.

Tournebroche

FR

Pour actionner le tournebroche (voir figure) procédez

comme suit :

1. placez la lèchefrite

au gradin 1;

2. placez le berceau au

gradin 4 et encastrez le

bout arrière de la

broche dans le trou

situé au fond de

lenceinte;

3. actionnez-le en

appuyant sur la touche

TOURNEBROCHE.

Eclairage du four

La lampe du four peut être allumée à tout moment, il

suffit pour cela dappuyer sur la touche ECLAIRAGE

FOUR.

Minuteur*

Pour actionner le Minuteur procédez comme suit :

1.faites faire au bouton MINUTEUR un tour presque

complet dans le sens des aiguilles dune montre "

pour remonter la sonnerie;

2.tournez le bouton MINUTEUR dans les sens inverse

des aiguilles dune montre # pour sélectionner la

durée désirée.

*Nexiste que sur certains modèles

Page 22

FR

Tableau de cuisson

Aliments

Pâtes

Lasagnes

Cannelloni

Gratin de pâtes

Viande

Veau

Poulet

Canard

Lapin

Porc

Agneau

Poisson

Maquereaux

Denté

Truite en papillote

Pizza

Napolitaine 1 3 15 220 15-20

Gâteaux

Biscuits

Tarte

Tartes salées

Gâteaux levés

Cuisson au gril

Côtes de veau

Côtelettes

Hamburgers

Maquereaux

Croque-monsieur

Cuisson au gril avec

tournebroche

Veau à la broche

Poulet à la broche

Cuisson au gril avec

tournebrochettes *

Brochettes de viande

Brochettes de légumes

Poids

(Kg)

2,5

2,5

2,5

1,7

1,5

1,8

2

2,1

1,8

1,1

1,5

1

0.5

1,1

1

1

1

1,5

1

1

n.4

1

2

1

0,8

Niveau

enfournement

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

3

4

4

-

-

-

-

Préchauffage

(minutes)

10

10

10

10

10

10

10

10

10

10

10

10

15

15

15

15

5

5

5

5

5

5

5

5

5

Température

préconisée

(°C)

210

200

200

200

220

200

200

200

200

180-200

180-200

180-200

180

180

180

180

Durée

cuisson

(minutes)

60-75

40-50

40-50

85-90

90-100

100-110

70-80

70-80

90-95

35-40

40-50

40-50

30-35

30-35

45-50

35-40

15-20

20

7

15-20

5

70-80

70-80

40-45

25-30

*Nexiste que sur certains modèles

Page 23

Précautions et conseils

Cet appareil a été conçu et fabriqué conformément

aux normes internationales de sécurité.

Ces conseils sont fournis pour des raisons de sécurité

et doivent être lus attentivement.

Sécurité générale

Cet appareil a été conçu pour un usage familial, de

type non professionnel.

Cet appareil ne doit pas être installé en extérieur,

même dans un endroit abrité, il est en effet très

dangereux de le laisser exposé à la pluie et aux

orages.

Ne touchez pas à lappareil si vous êtes pieds nus

ou si vous avez les mains ou les pieds mouillés ou

humides.

Cet appareil a été conçu pour cuire des aliments et

pour être utilisé par des adultes conformément aux

instructions fournies par cette notice, applicables à

tous les pays dont les symboles figurent au début

de la notice. .

Cette notice concerne un appareil classe 1 (libre

pose) ou classe 2 - sous-classe 1 (encastré entre

deux meubles).

En cours de fonctionnement, les éléments

chauffants et certaines parties du four

deviennent très chaudes. Attention à ne pas les

toucher et à garder les enfants à distance.

Evitez que le cordon dalimentation dautres petits

électroménagers touche à des parties chaudes de

lappareil.

Les orifices ou les fentes daération ou dévacuation

de la chaleur ne doivent pas être bouchés

Utilisez toujours des gants de protection pour

enfourner ou sortir des plats du four.

Ne tirez surtout pas sur le câble pour débrancher la

fiche de la prise de courant.

Neffectuez aucune opération de nettoyage ou

dentretien sans avoir auparavant débranché la

fiche de la prise de courant.

En cas de panne, nessayez en aucun cas

daccéder aux mécanismes internes pour tenter de

réparer lappareil. Faites appel au service

dassistance.

Ne posez pas dobjets lourds sur la porte du four

ouverte.

Mise au rebut

Mise au rebut du matériel demballage : conformez-

vous aux réglementations locales, les emballages

pourront ainsi être recyclés.

La directive européenne 2002/96/CE relative aux

déchets déquipements électriques et électroniques

(DEEE), prévoit que les électroménagers ne

peuvent pas être traités comme des déchets

solides urbains normaux. Les appareils usagés

doivent faire lobjet dune collecte séparée pour

optimiser le taux de récupération et de recyclage

des matériaux qui les composent et empêcher tout

danger pour la santé et pour lenvironnement. Le

symbole de la poubelle barrée sur roues est

appliqué sur tous les produits pour rappeler quils

font lobjet dune collecte sélective.

Les électroménagers usagés pourront être remis au

service de collecte public, déposés dans les

déchetteries communales prévues à cet effet ou, si

la loi du pays le prévoit, repris par les revendeurs

lors de lachat dun nouvel appareil de même type.

Tous les principaux fabricants délectroménagers

sappliquent à créer et gérer des systèmes de

collecte et délimination des appareils usagés.

FR

Nutilisez pas de solutions inflammables (alcool,

essence..) à proximité de lappareil lorsquil est en

marche.

Ne stockez pas de matériel inflammable dans la

niche de rangement du bas ou dans le four : si

lappareil était par inadvertance mis en marche, il

pourrait prendre feu.

Les surfaces intérieures du tiroir (s'il y en a un)

peuvent devenir chaudes.

Lorsque lappareil nest pas utilisé, assurez-vous

que les boutons sont bien sur la position

le robinet du gaz est fermé.

et que

Economies et respect de

lenvironnement

Pour faire des économies délectricité, utilisez

autant que possible votre four pendant les heures

creuses.

Pour vos cuissons au GRILL, nous vous conseillons

de garder la porte du four fermée: Vous obtiendrez

de meilleurs résultats tout en faisant de sensibles

économies dénergie (10% environ).

Gardez toujours les joints propres et en bon état

pour quils adhèrent bien à la porte et ne causent

pas de déperditions de chaleur.

!

Page 24

Nettoyage et entretien

FR

Mise hors tension

Avant toute opération de nettoyage ou dentretien

coupez lalimentation électrique de lappareil.

Nettoyage de lappareil

Ne nettojez jamais lappareil avec des nettoyeurs

vapeur ou haute pression.

Nettoyez lextérieur émaillé ou inox et les joints en

caoutchouc à laide dune éponge imbibée deau

tiède additionnée de savon neutre Si les taches

sont difficiles à enlever, utilisez des produits

spéciaux. Rincez abondamment et essuyez

soigneusement. Nutilisez ni poudres abrasives ni

produits corrosifs.

Les grilles, les chapeaux, les couronnes et les

brûleurs du plan de cuisson sont amovibles et

peuvent ainsi être nettoyés plus facilement. Lavezles à leau chaude additionnée dun détergent non

abrasif, éliminez toute incrustation et attendez quils

soient parfaitement secs avant de les remonter.

Dans le cas de tables équipées d'allumage

automatique, nettoyer fréquemment et

soigneusement l'extrémité des dispositifs

d'allumage électronique instantané et vérifier que

les orifices de sortie du gaz ne sont pas bouchés.

Nettoyez lenceinte du four après toute utilisation,

quand il est encore tiède. Utilisez de leau chaude

et du détergent, rincez et séchez avec un chiffon

doux. Evitez tout produit abrasif.

Entretien robinets gaz

Il peut arriver quau bout dun certain temps, un

robinet se bloque ou tourne difficilement. Il faut alors

le remplacer.

Cette opération doit être effectuée par un

technicien agréé par le fabricant.

Remplacement de lampoule déclairage

du four

1. Débranchez le four, enlevez

le couvercle en verre du

logement de la lampe (voir

figure).

2. Dévissez lampoule et

remplacez-la par une autre de

même type : tension 230 V,

puissance 25 W, culot E 14.

3.Remontez le couvercle et rebranchez le four au

réseau électrique.

Assistance

Indiquez-lui :

le modèle de votre appareil (Mod.)

son numéro de série (S/N)

Ces informations figurent sur la plaquette signalétique

apposée sur votre appareil et/ou sur son emballage.

Nettoyer la vitre de la porte avec des produits non

abrasifs et des éponges non grattantes, essuyer

ensuite avec un chiffon doux. Ne pas utiliser de

matériaux abrasifs ou de racloirs métalliques

aiguisés qui risquent de rayer la surface et de

briser le verre.

Les accessoires peuvent être lavés comme de la

vaisselle courante y compris en lave-vaisselle.

Evitez de refermer le couvercle si les brûleurs sont

allumés ou encore chauds.

Contrôler les joints du four

Contrôlez périodiquement létat du joint autour de la

porte du four. Sil est abîmé, adressez-vous au service

après-vente le plus proche de votre domicile. Mieux

vaut ne pas utiliser le four tant quil nest pas réparé.

"

Page 25

Manual de instrucciones

COCINA

GB

English, 1

GB

English, 37

CG64SG1 EX

FR

Français, 13

AR

ES

Espanol, 25

Sumario

ES

Instalación, 26-30

Colocación y nivelación

Conexión eléctrica

Conexión de gas

Adaptación a los distintos tipos de gas

Datos técnicos

Tabla de características de quemadores e

inyectores

Descripción del aparato, 31

Vista de conjunto

Panel de control

Puesta en funcionamiento y uso, 32-34

Uso de la encimera

Uso del horno

Tabla de cocción en horno

Precauciones y consejos, 35

Seguridad general

Eliminación

Ahorrar y respetar el medio ambiente

Mantenimiento y cuidados, 36

Cortar la corriente eléctrica

Limpiar el aparato

Para sustituir la bombilla de iluminación del horno

Mantenimiento de las llaves de gas

Asistencia

Page 26

Instalación

ES

Es importante conservar este manual para poder

consultarlo en todo momento. En caso de venta, cesión

o traslado, controle que permanezca junto al aparato.

Lea atentamente las instrucciones: contienen

información importante sobre la instalación, el uso y

la seguridad.

La instalación del aparato se debe realizar siguiendo

estas instrucciones y por personal calificado.

Cualquier intervención de regulación o

mantenimiento se debe efectuar con la cocina

desconectada de la red eléctrica.

Ventilación de los ambientes

El aparato se puede instalar sólo en ambientes

permanentemente ventilados, según las normas

nacionales vigentes. En el ambiente en el que se

instala el aparato debe poder afluir la cantidad de

aire necesaria para la normal combustión (el caudal

3

de aire no debe ser inferior a 2 m

/h por kW de

potencia instalada).

Las tomas de aire, protegidas por rejillas, deben

2

poseer un conducto de 100 cm

de sección útil,

como mínimo, y estar colocadas de modo que no

puedan ser obstruidas, ni siquiera parcialmente (ver

la figura A).

Dichas tomas deben ser aumentadas en un 100% -

2

con un mínimo de 200 cm

cuando la superficie de

trabajo del aparato no posea un dispositivo de

seguridad por ausencia de llama y cuando el flujo

de aire se produce de modo indirecto desde

ambientes adyacentes (ver la figura B) siempre

que no sean partes comunes del inmueble,

ambientes con peligro de incendio o habitaciones

dotados de un conducto de ventilación con la parte

externa como se describe precedentemente.

Ambiente adyacente Ambiente que se debe

ventilar

A B

Descarga de los humos de la combustión

La descarga de los humos de la combustión debe

estar asegurada mediante una campana conectada

a una chimenea de tiro natural de óptimo

funcionamiento, o mediante un electroventilador que

comience a funcionar automáticamente cada vez

que se enciende el aparato (ver las figuras).

Descarga directamente Descarga mediante al

exterior chimenea o conducto de

humos ramificado

(reservado a los aparatos

de cocción)

Los gases de petróleo licuados, más pesados que

el aire, se depositan en las zonas más bajas, por lo

tanto, los ambientes que contienen botellas de GPL

deben poseer aberturas hacia el exterior para la

evacuación, desde dichas zonas bajas, de las

posibles fugas de gas.

Las botellas de GPL, vacías o parcialmente llenas, no

deben ser instaladas o depositadas en ambientes o

espacios a un nivel más bajo que el suelo (sótanos,

etc.) En el ambiente debe permanecer sólo la botella

en uso, lejos de fuentes de calor (hornos, chimeneas

o estufas) capaces de llevarla a temperaturas

superiores a los 50ºC.

Colocación y nivelación

Es posible instalar el aparato al lado de muebles

que no sean más altos que la superficie de trabajo.

Verifique que la pared que está en contacto con la

parte posterior del aparato sea de material no

inflamable y resistente al calor (T 90°C).

A

Abertura de ventilación Aumento de la rendija para

el aire comburente. entre la puerta y el piso

Después de un uso prolongado del aparato, es

aconsejable abrir una ventana o aumentar la

velocidad de los ventiladores (si existen).

26

Para una correcta instalación:

coloque el aparato en la cocina, en el comedor o

en un monolocal (no en el cuarto de baño);

si la parte superior de la cocina es más alta que

la de los muebles, los mismos se deben ubicar,

como mínimo, a 600 mm. del aparato;

si la cocina se instala debajo de un armario de

pared, este último deberá mantener una distancia

mínima del plano de cocción de 420 mm.

Dicha distancia debe ser de 700 mm. si los armarios

son de material inflamable (ver la figura);

Page 27

mm.

420

Min.

HOOD

Min. mm.

600

mm. with hood

420

650

Min. mm.

min.

mm. without hood

700

min.

características;

la tensión de alimentación eléctrica esté

comprendida dentro de los valores indicados en

la placa de características;

la toma sea compatible con el enchufe del aparato.

Si no es así, sustituya la toma o el enchufe; no

utilice prolongaciones ni conexiones múltiples.

Una vez instalado el aparato, el cable eléctrico y la

toma de corriente deben ser fácilmente accesibles.

ES

no coloque cortinas detrás de la cocina o a menos

de 200 mm. de sus costados;

las campanas se deben instalar siguiendo las

indicaciones contenidas en el correspondiente

manual de instrucciones.

Nivelación

Si es necesario nivelar el

aparato, enrosque las patas de

regulación suministradas con

el aparato, en los ángulos de

la base de la cocina (ver la

figura).

Las patas* se encastran en la

base de la cocina.

Conexión eléctrica

Instale en el cable, un enchufe normalizado para la

carga indicada en la placa de características colocada

en el aparato (ver la tabla de Datos técnicos).

En el caso de conexión directa a la red, es necesario

interponer entre el aparato y la red, un interruptor omnipolar

con una distancia mínima entre los contactos de 3 mm.,

dimensionado para esa carga y que responda a las

normas nacionales vigentes (el conductor de tierra no

debe ser interrumpido por el interruptor). El cable de

alimentación eléctrica se debe colocar de modo tal que

no alcance en ningún punto una temperatura que supere

en 50°C la temperatura ambiente.

Antes de efectuar la conexión verifique que:

la toma tenga conexión a tierra y que sea conforme

con la ley;

la toma sea capaz de soportar la carga máxima de

potencia de la máquina indicada en la placa de

* Presente sólo en algunos modelos.

El cable no debe sufrir pliegues ni compresiones.

El cable debe ser revisado periódicamente y

sustituido sólo por técnicos autorizados.

La empresa declina toda responsabilidad en los

casos en que no hayan sido respetadas estas

normas.

Conexión de gas

La conexión a la red de gas o a la botella de gas se

puede realizar con un tubo flexible de goma o de acero

según las normas nacionales vigentes y después de

haber verificado que el aparato esté regulado para el

tipo de gas con el que será alimentado (ver la etiqueta

de calibrado en la tapa: si no es así, ver más adelante).

En el caso de alimentación con gas líquido, desde

botella, utilice reguladores de presión conformes con

las normas nacionales vigentes. Para facilitar la

conexión, la alimentación de gas se puede orientar

lateralmente*: invierta la boquilla para la conexión con el

tapón de cierre y sustituya la junta estanca

suministrada con el aparato.

Para un funcionamiento seguro, un adecuado uso

de la energía y una mayor duración del aparato,

verifique que la presión de alimentación cumpla con

los valores indicados en la tabla Características de

los quemadores e inyectores (ver más adelante).

Conexión de gas con tubo flexible de goma

Verifique que el tubo responda a las normas

nacionales vigentes. El diámetro interno del tubo

debe ser: 8 mm. para alimentación con gas líquido;

13 mm. para alimentación con gas metano.

Una vez realizada la conexión, controle que el tubo:

no esté en contacto, en ningún punto, con partes

que alcancen temperaturas superiores a 50ºC;

no esté sometido a esfuerzos de tracción o de

torsión y no presente pliegues o estrechamientos;

no esté en contacto con objetos cortantes, con

bordes o con partes móviles y que no quede

27

Page 28

ES

aplastado;

se pueda inspeccionar fácilmente en todo su

recorrido, para poder controlar su estado de

conservación;

tenga una longitud inferior a 1500 mm;

esté bien calzado en sus dos extremos, donde

va fijado con abrazaderas de manguera

conformes con las normas nacionales vigentes.

Si alguna de estas condiciones no puede se

respetada o si la cocina se instala según las

condiciones de la clase 2 subclase 1 (aparato

empotrado entre dos muebles), es necesario

recurrir al tubo flexible de acero (ver más adelante).

Conexión de gas con tubo flexible de acero

inoxidable de pared continua con uniones

roscadas

Verifique que el tubo y las juntas respondan a las

normas nacionales vigentes.

Para poner en funcionamiento el tubo, elimine la

boquilla presente en el aparato (la unión de

entrada de gas al aparato es roscada 1/2 gas

macho cilíndrica).

Realice la conexión de modo tal, que la longitud

de la tubería no supere los 2 metros de extensión

máxima y verifique que el tubo no esté en contacto

con partes móviles y que no quede aplastado.

tabla Características de los quemadores e

inyectores);

3. vuelva a colocar en su posición todos los

componentes siguiendo las operaciones en sentido

contrario al de la secuencia descripta arriba.

Regulación del mínimo de los quemadores de la

encimera:

1. lleve la llave a la posición de mínimo;

2. extraiga el mando y accione el tornillo de

regulación situado en el interior o al costado de la

varilla de la llave hasta conseguir una pequeña

llama regular.

En el caso de gas líquido, el tornillo de regulación

deberá enroscarse a fondo;

3. compruebe que, al girar rápidamente la llave de

la posición de máximo a la de mínimo, no se

apague la llama.

Los quemadores de la encimera no necesitan

regulación de aire principal.

Adaptación del horno

Sustitución del inyector del quemador del horno:

1. abra la puerta del horno completamente;

2. extraiga el fondo del horno

deslizable (ver la figura);

Control de la estanqueidad

Finalizada la instalación, controle la perfecta

estanqueidad de todas las uniones utilizando una

solución jabonosa pero nunca una llama.

Adaptación a los distintos tipos de gas

Es posible adaptar el aparato a un tipo de gas