Page 1

Instructions for use

WASHING MACHINE

GB

English,1

BHWMD 732

Contents

Installation, 2-3-4-5-6-7

Unpacking and levelling

Connecting the electricity and water supplies

The first wash cycle

Technical data

Instructions for the fitter

Description of the washing machine, 8-9

Control panel

Display

Running a wash cycle, 10

Wash cycles and functions, 11

Table of wash cycles

Wash functions

Detergents and laundry, 12

Detergent dispenser drawer

Preparing the laundry

Special wash cycles

Load balancing system

GB

Precautions and tips, 13

General safety

Disposal

Opening the porthole door manually

Care and maintenance, 14

Cutting off the water or electricity supply

Cleaning the washing machine

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

Troubleshooting, 15-16

Assistance, 17

1

Page 2

Installation

GB

! Keep this instruction manual in a safe place for future referen-

ce. Should the appliance be sold, transferred or moved, make

sure the instruction manual accompanies the washing machine

to inform the new owner as to its operation and features.

! Read these instructions carefully: they contain vital infor-

mation on installation, use and safety.

Unpacking and levelling

Unpacking

! This is a separate part of

the polystyrene base and

should be removed with the

base.

! IMPORTANT check

when unpacking your

machine.

1. Unpack the washing machine.

2. Check whether the washing machine has been damaged during transport. If this is the case, do not install it and

contact your retailer.

3. Remove the 4 protective

screws and the rubber bush

with the respective spacer,

situated on the rear of the

appliance (see also the

installation leaflet).

2. If the floor is not perfectly level, compensate for any

unevenness by tightening or loosening the adjustable front

feet (see figure); the angle of inclination, measured according to the worktop, must not exceed 2°.

Levelling your appliance correctly will provide it with stability and avoid any vibrations, noise and shifting during

operation. If it is placed on a fitted or loose carpet, adjust

the feet in such a way as to allow enough room for ventilation beneath the washing machine.

Electric and water connections

Connecting the water inlet hose

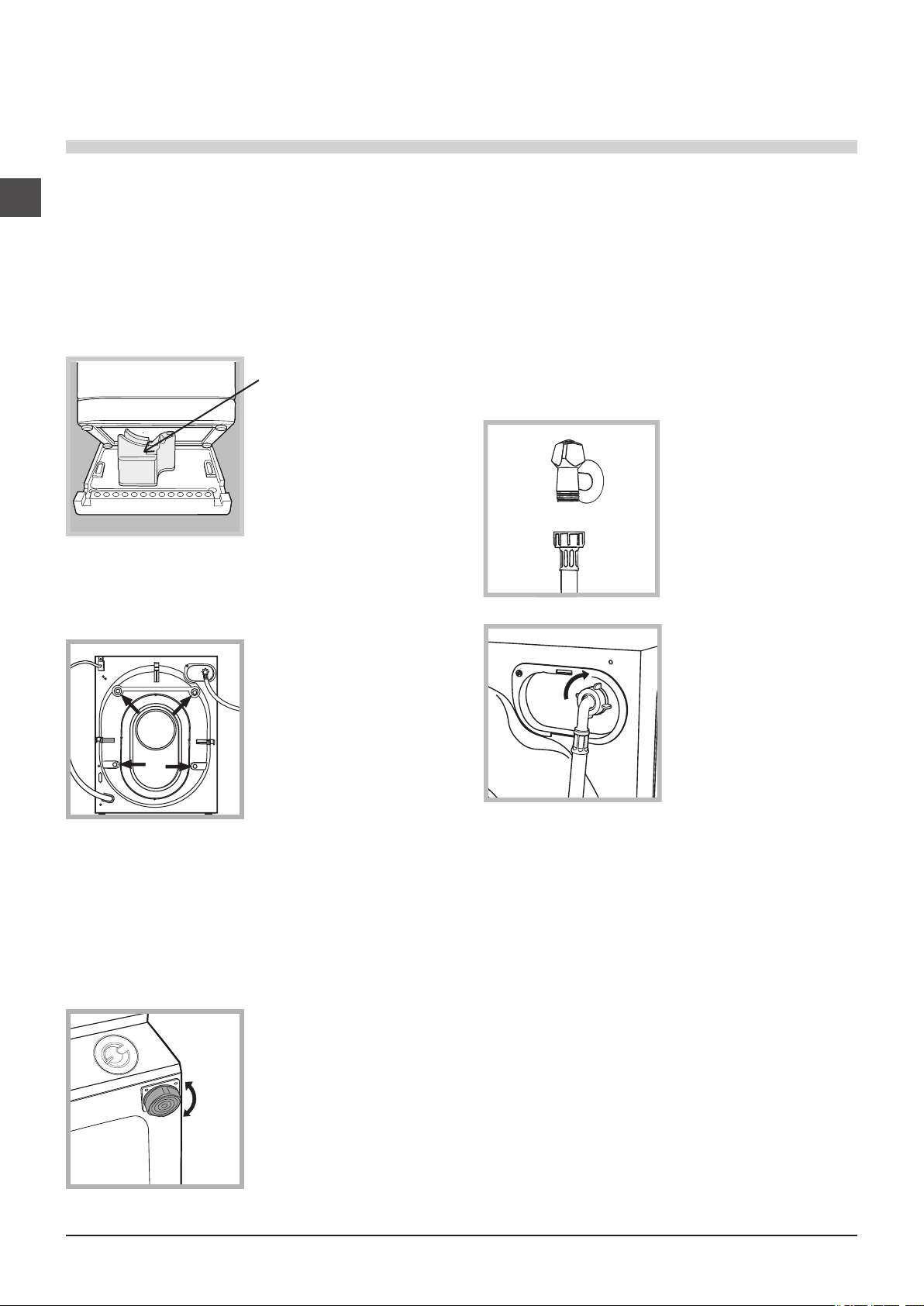

1. Connect the supply pipe

by screwing it to a cold

water tap using a

3/4 gas threaded connection (see figure).

Before performing the connection, allow the water to

run freely until it is perfectly

clear.

2. Connect the other end of

the water inlet hose to the

washing machine,

screwing it onto the appliance’s cold water inlet, situated

on the top right-hand side

on the rear of the appliance

(see figure).

4. Seal the gaps using the plastic plugs provided.

5. Keep all the parts: you will need them again if the washing machine needs to be moved to another location.

! Packaging materials are not children’s toys.

Levelling

Your machine may make a considerable amount of noise if the

two front feet have not been adjusted correctly.

1. Install the washing machine

on a flat sturdy floor, without

resting it up against walls,

furniture cabinets or other.

2

3. Make sure there are no kinks or bends in the hose.

! The water pressure at the tap must be within the values

indicated in the Technical details table

(on the page 5).

! If the water inlet hose is not long enough, contact a spe-

cialist store or an authorised serviceman.

! Ensure that the supply taps are allowing water through.

Old taps may seize in the closed position and thus prevent water reaching the machine.

Page 3

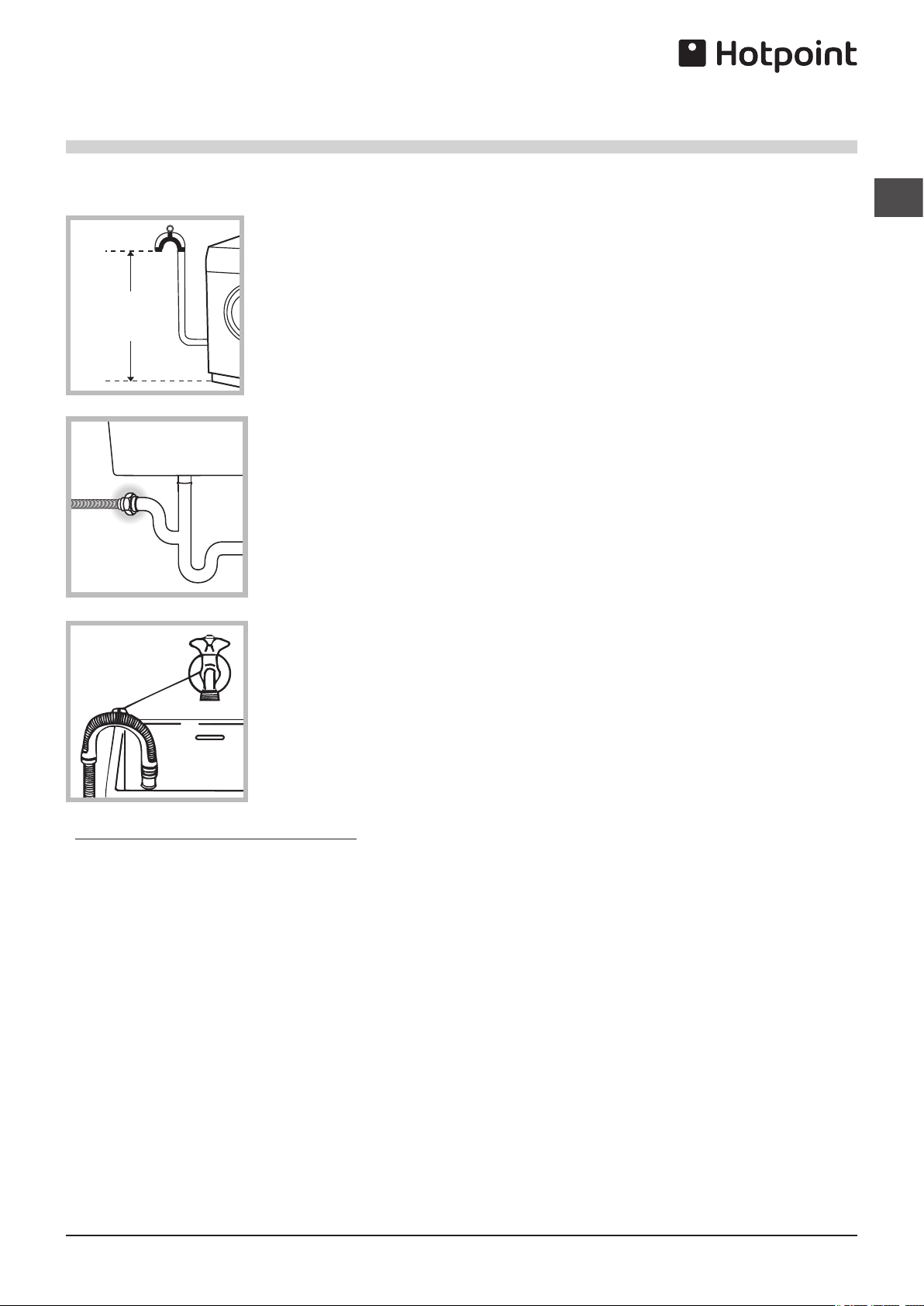

Connecting the drain hose

65 - 100 cm

Where it connects to

the waste water pipe

cut end off spigot or

remove the blanking cap

Connect the drain hose,

without bending it, to a

draining duct or a wall drain

situated between 65 and

100 cm from the floor;

The drain hose may be

connected to an under-sink

trap. Before connecting the

drain hose from the machine

ensure that any blanks or

removable ends have been

taken off the spigot.

If it is placed over the edge

of a basin or sink be sure

the free end of the hose

should not be underwater.

! We advise against the use of hose extensions; in case of

absolute need, the extension must have the same diameter

as the original hose and must not exceed 150 cm in length.

Ensure that if the drain hose is pushed into a standpipe, that

the end does not go down more than 15cms (6 inches). If

the hose is pushed down too far, this may cause the machine to self -syphon ie. continuously empty as it is filling.

Electric connection

Before plugging the appliance into the mains socket, make

sure that:

• the socket is earthed and in compliance with the applicable law;

• the supply voltage is included within the values indica ted on the Technical Data Plate fixed on the machine.

• the socket is compatible with the washing machine’s

plug. If this is not the case, replace the socket or the

plug.

Your appliance is now supplied with a 13 amp fused plug

it can be plugged into a 13 amp socket for immediate use.

Before using the appliance please read the instructions below.

WARNING - THIS APPLIANCE MUST BE EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE CARRIED

OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA approved

fuse to BS 1362 should always be used, and the fuse

cover re-fitted. If the fuse cover is lost, the plug must not

be used until a replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of the

correct colour as indicated by the coloured marking or the

colour that is embossed in words on the base of the plug.

Replacements can be obtained directly from your nearest

Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded plug and

you should wish to re-route the mains cable through partitions, units etc., please ensure that either:

the plug is replaced by a fused 13 ampere rewireable plug

bearing the BSI mark of approval.

or:

the mains cable is wired directly into a 13 amp cable outlet, controlled by a switch, (in compliance with BS 5733)

which is accessible without moving the appliance.

Disposing of the plug:

Ensure that before disposing of the plug itself, you make

the pins unusable so that it cannot be accidentally inserted

into a socket.

Instructions for connecting cable to an alternative plug:

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow Earth

Blue Neutral

Brown Live

GB

• the socket is able to sustain the appliance’s maximum

power load indicated in the Technical details table (see

page 5);

3

Page 4

GB

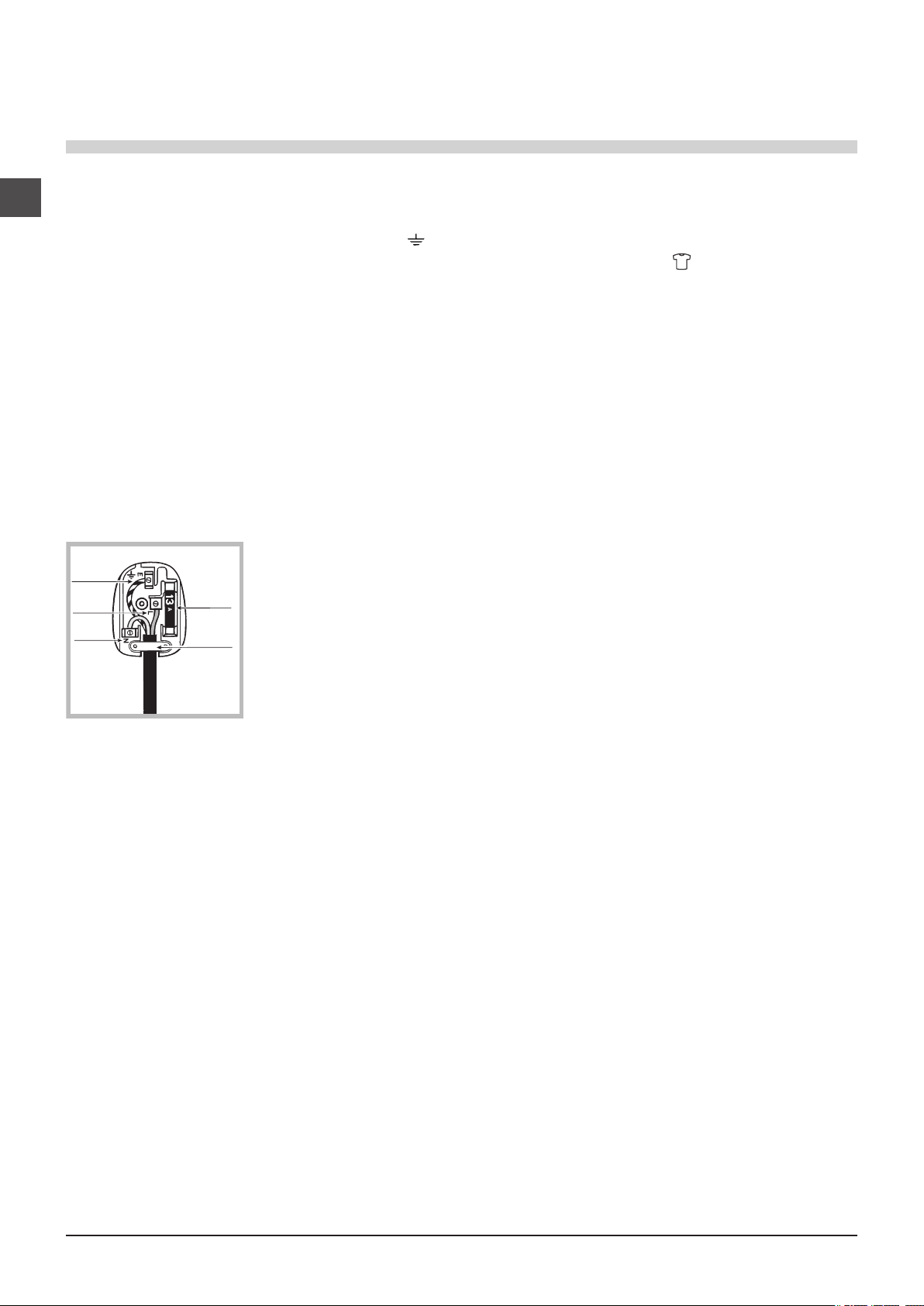

GREEN &

YELLOW

BROWN

BLUE

13 ampere fuse

CROSS-BAR

CORD GRIP

As the colours of the wires in the lead may not correspond

with the coloured markings identifying the terminals in your

plug, proceed as follows:

Connect Green & Yellow wire to terminal marked E or

or coloured Green or Green & Yellow.

Connect Brown wire to terminal marked L or coloured

Red.

Connect Blue wire to terminal marked N or coloured Black.

If a 13 amp plug (BS 1363) is used it must be fitted with a

13 amp fuse, either in the plug or adaptor or at the distribution board.

If you are in any doubt regarding the electrical supply to

your machine, consult a qualified electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in accordance

with the following code:

BLUE NEUTRAL (N)

BROWN LIVE (L)

GREEN & YELLOW EARTH (E)

The first wash cycle

Once the appliance has been installed, and before you use

it for the first time, run a wash cycle with detergent and no

laundry, using the wash cycle (60°C).

Disposing of the appliance:

When disposing of the appliance please remove the plug by

cutting the mains cable as close as possible to the plug body

and dispose of it as described above.

! The washing machine should not be installed in an ou-

tdoor environment, not even where the area is sheltered,

because it may be very dangerous to leave it exposed to

damp, rain and thunderstorms.

! When the washing machine is installed, the mains socket

must be within easy reach.

! Do not use extensions or multiple sockets.

! The power supply cable must never be bent or dange-

rously compressed.

! The power supply cable must only be replaced by an

authorised serviceman.

Warning! The company denies all liability if and when these

norms are not respected.

4

Page 5

Technical data

- 2004/108/EC (Electromagnetic Compatibility)

GB

Model

Dimensions

Capacity

Electrical

connections

Water connections

Spin speed

Test wash cycles

in accordance

with directives

1061/2010 and

1015/2010

BHWMD 732

width 59.5 cm

height 81.5 cm

depth 54.5 cm

from 1 to 7 kg

please refer to the technical data plate

fixed to the machine

maximum pressure 1 MPa (10 bar)

minimum pressure 0.05 MPa (0.5 bar)

drum capacity 52 litres

up to 1300 rotations per minute

programme

temperature 60°C (2nd press of the button);

temperature 40°C (3rd press of the button).

This appliance conforms to the following

EC Directives:

;

- 2006/95/EC (Low Voltage)

- 2002/96/EC

5

Page 6

GB

Tur seite

Instructions for the fitter

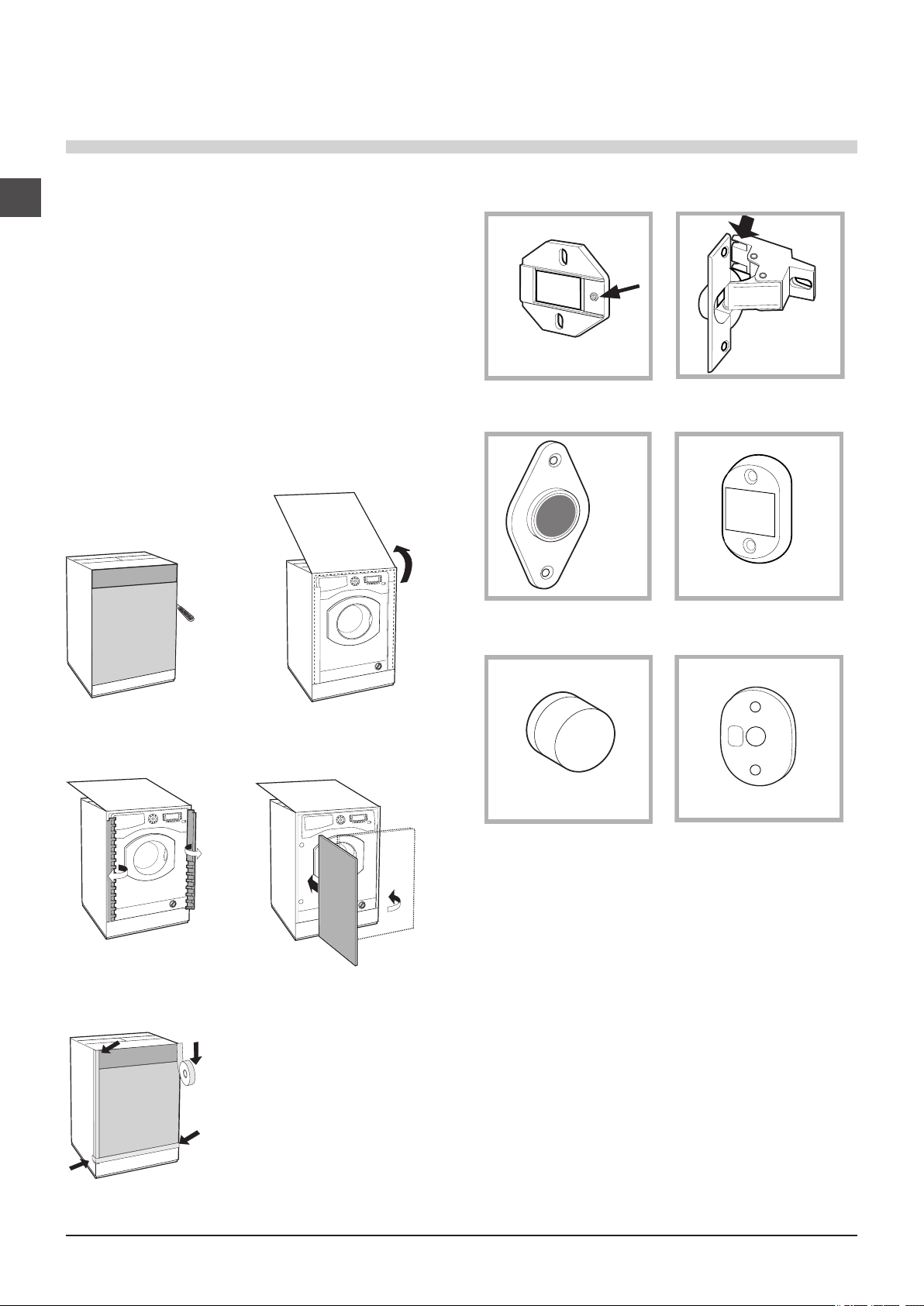

Mounting the wooden panel onto the door and inserting the machine into cabinets:

In the case where the machine must be shipped for final

installation after the wooden panel has been mounted, we

suggest leaving it in its original packaging. The packaging

was designed to make it possible to mount the wooden

panel onto the machine without removing it completely (see

figures below).

The wooden panel that covers the face of the machine must

not be less than 18 mm in thickness and can be hinged on

either the right or left. For the sake of practicality when using

the machine, we recommend that the panel be hinged on

the same side as the door for the machine itself - the left.

Door Mounting Accessories (Fig. 1-2-3-4-5).

N° 2 Hinge Supports

Fig. 1

N° 1 Magnet N° 1 Magnet plate

Fig. 3 Fig. 4

Fig. 2

N° 2 Hinges

A

C

E

B

D

N° 1 Rubber plug

Fig. 5

- No. 6 type A self-threading screws, l =13 mm.

- No. 2 type B metric, countersunk screws, l =25; for faste-

ning the magnet plate to the cabinet.

- No. 4 type C metric screws, l =15 mm; for mounting the

hinge supports to the cabinet.

- No. 4 type D metric screws, l =7 mm; for mounting the

hinges on the supports.

Mounting the Parts onto the Face of the Machine.

- Fit the hinge supports to the appliance front panel, positio-

ning the hole marked with an arrow in fig. 1 so that it is on the

inner side of the front panel. Fit a spacer (fig. 4/B) between

the surfaces using type C screws.

- Fit the magnet plate at the top of the opposite side, using

type B screws to fix two spacers (fig. 4/B) between the plate

and the surface.

Fig. 4/B

N° 4 Spacers

6

Page 7

Using the Drilling Template.

570

min

815

540

595

820 ÷ 900

600 min

L

I

H

G

- To trace the positions of the holes on the left-hand side of

the panel, align the drilling template to the top left side of the

panel using the lines traced on the extremities as a reference.

- To trace the positions of the holes on the right-hand side of

the panel, align the drilling template to the top right side of

the panel.

- Use an appropriately sized router to mill the holes for the

two hinges, the rubber plug and the magnet.

Mounding the Parts onto the Wooden Panel (Door).

- Insert the hinges into the holes (the movable part of the

hinge must be positioned facing away from the panel) and

fasten them with the 4 type A screws.

- Insert the magnet into the top hole on the opposite side of

the hinges and fasten it with the two type B screws.

- Insert the rubber plug into the bottom hole.

The panel is now ready to be mounted onto the machine.

Mounting the Panel into the machine.

Insert the nib of the hinge (indicated by the arrow in fig. 2)

into the hole for the hinge and push the panel towards the

front of the machine. Fasten the two hinges with the type D

screws.

Fastening the plinth guide.

If the machine is installed at the end of a set of modular cabinets, mount either one or both of the guides for the base

molding (as shown in fig. 8). Adjust them for depth based on

the position of the base molding, and, if necessary, fasten

the base to the guides (fig. 9).

This is how to assemble the plinth guide (fig. 8):

Fasten angle P using screw R, insert plinth guide Q into the

special slot and once it is in the desired position, lock it in

place using angle P and screw R.

Inserting the machine into the Cabinet.

- Push the machine into the opening, aligning it with the

cabinets (fig. 6).

- Regulate the adjustable feet to raise the machine to the

appropriate height.

- To adjust the position of the wooden panel in both the

vertical and horizontal directions, use the C and D screws,

as shown in fig. 7.

Important: close the lower part of the appliance front by

ensuring that the plinth rests against the floor.

GB

Fig. 8 Fig. 9

Accessories provided for the height adjustment.

The following can be found inside the polystyrene lid (fig. 10): 2

crossbars (G), 1 strip (M)

the following can be found inside

the appliance drum:

4 additional feet (H),

4 screws (I),

4 screws (R),

4 nuts (L),

2 plinth guides (Q)

Fig. 10

Adjusting the appliance height.

The height of the appliance can be adjusted (from 815 mm to

835 mm), by turning the 4 feet.

Should you require the appliance to be placed higher than the

above height, you need to use the following accessories to

raise it to up to 870 mm:

the two crossbars (G); the 4 feet (H); the 4 screws (I); the 4

nuts (L) then perform the following operations (fig. 11):

remove the 4 original feet, place a crossbar G at the front of the

appliance, fastening it in place using screws I (screwing them in

where the original feet were) then insert the new feet H.

Repeat the same operation at the back of the appliance.

Now adjust feet H to raise or lower the appliance from 835 mm

to 870 mm.

Once you have reached the desired height, lock nuts L onto

crossbar G.

To adjust the appliance to a height between 870 mm and

900 mm, you need to mount strip M, adjusting feet H to the

required height.

Insert the strip as follows:

loosen the three screws N situated at the front of the Top cover

of the appliance, insert strip M as shown in fig. 12, then fasten

screws N.

C

M

D

Fig. 6 Fig. 7

C

Fig. 11 Fig. 12

7

Page 8

Description of the washing machine

GB

Control panel

Detergent dispenser drawer

ON/OFF

button

WASH

CYCLE

SELECTOR

buttons

MY CYCLE

button

DELAY

TIMER

button

CHILD LOCK

button

DISPLAY

FUNCTION

buttons

TEMPERATURE

button

SPIN SPEED

button

START/PAUSE

button with

indicator light

Detergent dispenser drawer: used to dispense detergents and washing additives (see “Detergents and laundry”).

ON/OFF button : press this briefly to switch the machine on or off. The START/PAUSE indicator light, which

flashes slowly in a green colour shows that the machine is

switched on. To switch off the washing machine during the

wash cycle, press and hold the button for approximately 2

seconds; if the button is pressed briefly or accidentally the

machine will not switch off. If the machine is switched off

during a wash cycle, this wash cycle will be cancelled.

WASH CYCLE SELECTOR buttons: used to set the

desired wash cycle (see “Table of wash cycles”).

MY CYCLE button: press and hold the button to store a

cycle with your own set of preferences in the memory of

the machine. To recall a previously stored cycle, press the

MY CYCLE button.

FUNCTION buttons: press the button to select the

desired function. The corresponding indicator light on the

display will switch on.

SPIN button : press to reduce or completely exclude

the spin cycle - the value is indicated on the display.

TEMPERATURE button : press to decrease the tem-

perature: the value will be shown on the display.

CHILD LOCK button: to activate the control panel lock,

press and hold the button for approximately 2 seconds.

When the symbol is illuminated, the control panel is locked.

This means it is possible to prevent wash cycles from

being modified accidentally, especially where there are

children in the home. To deactivate the control panel lock,

press and hold the button for approximately 2 seconds.

DELAY TIMER button : press to set a delayed start

time for the selected wash cycle. The delay time will be

shown on the display.

START/PAUSE button with indicator light: when the green indicator light flashes slowly, press the button to start a

wash cycle. Once the cycle has started the indicator light

will remain lit in a fixed manner. To pause the wash cycle,

press the button again; the indicator light will flash in an

orange colour. If the symbol is not illuminated, the door

may be opened. To start the wash cycle from the point at

which it was interrupted, press the button again.

Standby mode

This washing machine, in compliance with new energy saving regulations, is fitted with an automatic standby system

which is enabled after about 30 minutes if no activity is

detected. Press the ON-OFF button briefly and wait for the

machine to start up again.

Consumption in off-mode: 0,5 W

Consumption in Left-on: 0,5 W

8

Page 9

Display

GB

B

A

D

C

E

F

The display is useful when programming the machine and provides a great deal of information.

The two upper strings A and B provide details of the wash cycle selected, the wash cycle phase in progress and all information relating to the progress status of the wash cycle.

String C shows the time remaining until the end of the wash cycle in progress and, if a DELAYED START has been set, the

time remaining until the start of the selected wash cycle.

String D shows the maximum spin speed value (this depends on the selected wash cycle); if the wash cycle does not include

a spin cycle, the string remains unused.

String E shows the maximum temperature value which may be selected (this depends on the wash cycle used); if the temperature of the wash cycle cannot be modified, the string remains unused.

Indicator lights F correspond to the functions and light up when the selected function is compatible with the set wash cycle.

Door locked symbol

If the symbol is lit, this indicates that the washing machine door is locked to prevent it from being opened accidentally. To

prevent any damage from occurring, wait for the symbol to switch itself off before opening the appliance door.

N.B.: if the DELAYED START function has been activated, the door cannot be opened; pause the machine by pressing the

START/PAUSE button if you wish to open it.

9

Page 10

Running a wash cycle

GB

1. SWITCH THE MACHINE ON. Press the On/Off

button ; the text HELLO will appear on the display

and the START/PAUSE indicator light will flash slowly in

a green colour.

2. LOAD THE LAUNDRY. Open the porthole door.

Load the laundry, making sure you do not exceed

the maximum load value indicated in the table of

programmes on the following page.

3. MEASURE OUT THE DETERGENT. Open the

detergent dispenser drawer and pour the detergent into

the relevant compartments as described in “Detergents

and laundry”.

4. CLOSE THE DOOR.

5. SELECT THE WASH CYCLE. Press one of the WASH

CYCLE SELECTOR buttons to select the required wash

cycle; the name of the wash cycle will appear on the

display. A temperature and spin speed is set for each

wash cycle; these may be adjusted. The duration of the

cycle will appear on the display.

6. CUSTOMISE THE WASH CYCLE. Use the relevant

buttons:

Modifying the temperature and/or spin

speed. The machine automatically selects the

maximum temperature and spin speed set for the

selected wash cycle; these values cannot therefore

be increased. The temperature can be decreased by

pressing the button, until the cold wash “OFF”

setting is reached. The spin speed may be progressively

reduced by pressing the button, until it is completely

excluded (the “OFF” setting). If these buttons are

pressed again, the maximum values are restored.

7. START THE PROGRAMME. Press the START/

PAUSE button. The corresponding indicator light will

become green, remaining lit in a fixed manner, and the

door will be locked (the DOOR LOCKED symbol will be

on). During the wash cycle, the name of the phase in

progress will appear on the display. To change a wash

cycle while it is in progress, pause the washing machine

using the START/PAUSE button (the START/PAUSE

indicator light will flash slowly in an orange colour); then

select the desired cycle and press the START/PAUSE

button again.

To open the door while a cycle is in progress, press

the START/PAUSE button; if the DOOR LOCKED

symbol is switched off the door may be opened. Press

the START/PAUSE button again to restart the wash

cycle from the point at which it was interrupted.

8. THE END OF THE WASH CYCLE. This will be

indicated by the text “END OF CYCLE” on the display;

when the DOOR LOCKED symbol switches off

the door may be opened. Open the door, unload the

laundry and switch off the machine.

! If you wish to cancel a cycle which has already begun,

press and hold the button. The cycle will be stopped

and the machine will switch off.

Setting a delayed start.

To set a delayed start for the selected programme,

press the corresponding button repeatedly until the

required delay period has been reached. When this

option is enabled, the symbol lights up on the

display. To remove the delayed start function press the

button until the text “OFF” appears on the display.

Modifying the cycle settings.

• Press the button to enable the function; the indicator

light corresponding to the button will switch on.

• Press the button again to disable the function; the

indicator light will switch off.

! If the selected function is not compatible with the

programmed wash cycle, the indicator light will flash

and the function will not be activated.

! If the selected function is not compatible with

another function which has been selected previously,

the indicator light corresponding to the first function

selected will flash and only the second function will

be activated; the indicator light corresponding to the

enabled function will remain lit.

! The functions may affect the recommended load value

and/or the duration of the cycle.

10

Page 11

Wash cycles and functions

Table of wash cycles

Detergents

Max.

Description of the wash cycle

Wash cycles

CLEAN Plus

Anti Stain

White Cottons (1st press of the button): extremely soiled whites and resistant colours. 90° 1300

Standard Cotton (1) (2nd press of the button): heavily soiled whites and delicate colours. 60° 1300

Standard Cotton (1-2) (3rd press of the button): lightly soiled whites and delicate colours. 40° 1300

Synthetics Resistant (1st press of the button): heavily soiled resistant colours. 60° 800

Synthetics Resistant (3) (1st press of the button): lightly soiled resistant colours. 40° 800

Synthetics Delicate (2nd press of the button): lightly soiled resistant colours. 40° 800

SPECIALS

Fast Wash (1st press of the button): to refresh normal soiled garments quickly

(not suitable for wool, silk and clothes which require washing by hand).

Fast Wash 30’ (2nd press of the button): to refresh lightly soiled garments quickly

(not suitable for wool, silk and clothes which require washing by hand).

M

My Cycle (Memory): allows for any wash cycle to be stored.

Anti Allergy

EXTRAS

Wool (Woolmark Platinum): for wool, cashmere, etc. 40° 800

Delicates

Fast Spin Cottons (1st press of the button) - 1300 - - 7 - - - 16’

Rinse Cottons (2nd press of the button) - 1300 -

Pump out (3rd press of the button) - 0 - - 7 - - - 2’

The length of cycle shown on the display or in this booklet is an estimation only and is calculated assuming standard working conditions. The actual duration can

vary according to factors such as water temperature and pressure, the amount of detergent used, the amount and type of load inserted, load balancing and any

wash options selected.

Max.

temp.

speed

(°C)

(rpm)

40° 1300

60° 1300

30° 800

60° 1300

30° 0

Wash

Fabric

softener

(kg)

pness %

Max. load

4 - 7 53 2,16 72 160’

7 53 1,10 58 190’

7 53 0,99 82 185’

3 44 0,93 47 115’

3 44 0,57 46 100’

3 - - - 75’

3,5 53 0,81 40 60’

3 71 0,15 35 30’

4 - - - 195’

1,5 - - - 70’

1 - - - 80’

7 - - - 36’

Energy con-

Residual dam-

Total water lt

sumption kWh

180’

-

GB

Cycle duration

For all Test Institutes:

1) Test wash cycle in compliance with directive 1061/2010: set wash cycle 60°C (2nd press of the button); set wash cycle 40°C (3rd press of the button).

This cycle is designed for cotton loads with a normal soil level and is the most efficient in terms of both electricity and water consumption; it should be used for garments which can be

washed at 60°C and 40°C. The actual washing temperature may differ from the indicated value.

2) Long wash cycle for cottons: set wash cycle 40°C (3rd press of the button).

3) Long wash cycle for synthetics: set wash cycle 60°C (1st press of the button); temperature of 40°C (press TEMPERATURE button).

Wash functions

Super Wash

Because a greater quantity of water is used in the initial

phase of the cycle, and because of the increased cycle

duration, this function offers a high-performance wash.

! It cannot be used with the , , , , “Spin” and

“Pump out”.

Extra rinse

By selecting this option, the efficiency of the rinse is increased and optimal residual detergent removal is guaranteed.

It is particularly useful for skin which is sensitive to detergents. We recommend this option is used with a full load of

washing, or when a large amount of detergent is required.

! It cannot be used with the “Fast Wash 30’”, , , “Spin”

and “Pump out”.

Reduced Creases

By selecting this function, the wash and spin cycles will be

modified in order to reduce the formation of creases.

At the end of the cycle the washing machine will perform

slow rotations of the drum; the “Reduced Creases” and

START/PAUSE indicator lights will flash (orange) and the

text “END OF CYCLE” will appear on the display.

To end the cycle, press the START/PAUSE button or the

“Reduced Creases” button.

! It cannot be used with the , “Fast Wash 30’”, , ,

, .

Time Saver

If you select this option, the wash cycle duration will be

reduced by up to 50%, depending on the selected cycle,

thereby guaranteeing simultaneous water and energy

saving. Use this cycle for lightly soiled garments.

! It cannot be used with the , “Fast Wash 60’”, , ,

, .

Eco Wash

The Eco Wash function saves energy by not heating the

water used to wash your laundry – an advantage both to

the environment and to your energy bill. Instead, intensified

wash action and water optimisation ensure great wash

results in the same average time of a standard cycle.

For the best washing results we recommend the usage of

a liquid detergent.

! It cannot be used with the , , , , .

11

Page 12

1

2

*

Detergents and laundry

GB

Detergent dispenser drawer

Good washing results also depend on the correct dose of

detergent: adding too much detergent will not necessarily

result in a more efficient wash, and may in fact cause a

build up on the inside of your appliance and contribute to

environmental pollution.

! Use powder detergent for white cotton garments, for

pre-washing, and for washing at temperatures over 60°C.

! Follow the instructions given on the detergent packaging.

! Do not use hand washing detergents because these

create too much foam.

Open the detergent dispenser drawer and pour

in the detergent or washing

additive, as follows.

! Do not pour detergent into the middle compartment (*).

Detergent should only be poured into the compartment 1.

compartment 1: Detergent for the wash cycle

(powder or liquid)

For best results liquid detergent should be poured in the

dispenser immediately before the start of the programme.

compartment 2: Additives (fabric softeners, etc.)

The fabric softener should not overflow the grid.

Preparing the laundry

• Divide the laundry according to:

- the type of fabric/the symbol on the label

- the colours: separate coloured garments from whites.

• Empty all garment pockets and check the buttons.

• Do not exceed the listed values, which refer to the weight

of the laundry when dry:

Durable fabrics: max. 7 kg

Synthetic fabrics: max. 3 kg

Delicate fabrics: max. 2 kg

Wool: max. 1,5 kg

How much does your laundry weigh?

Special wash cycles

Anti Stain : this programme is suitable to heavily-soiled

garments with resistant colours. It ensures a washing

class that is higher than the standard class (A class). When

running the programme, do not mix garments of different

colours. We recommend the use of powder detergent.

Pre-treatment with special additives is recommended if

there are obstinate stains.

Anti Allergy: use programme to remove major allergens

such as pollen, mites, cat’s and dog’s hair.

Wool: the wool wash cycle on this Hotpoint machine has

been tested and approved by The Woolmark Company

for washing wool garments labelled as hand washable

provided that the garments are washed according to the

instructions on the garment label and those issued by the

manufacturer of this washing machine. Hotpoint is the first

washing machine brand to be approved by The Woolmark

Company for Apparel Care- Platinum for its washing performance and consumption of energy and water. (M1126)

Delicates: use programme to wash very delicate

garments with decorative features, such as diamantes and

sequins.

We recommend turning the garments inside out before

washing and placing small items into the special bag

for washing delicates. Use liquid detergent on delicate

garments for best results.

Load balancing system

Before every spin cycle, to avoid excessive vibrations and

to distribute the load in a uniform manner, the drum rotates

continuously at a speed which is slightly greater than the

washing rotation speed. If, after several attempts, the load

is not balanced correctly, the machine spins at a reduced

spin speed. If the load is excessively unbalanced, the

washing machine performs the distribution process instead

of spinning. To encourage improved load distribution and

balance, we recommend small and large garments are

mixed in the load.

1 sheet 400-500 g

1 pillow case 150-200 g

1 tablecloth 400-500 g

1 bathrobe 900-1200 g

1 towel 150-250 g

12

Page 13

Precautions and tips

! This washing machine was designed and constructed in

accordance with international safety regulations. The following information is provided for safety reasons and must

therefore be read carefully.

General safety

• This appliance was designed for domestic use only.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that

they do not play with the appliance.

• Do not touch the machine when barefoot or with wet or

damp hands or feet.

• Do not pull on the power supply cable when unplugging

the appliance from the electricity socket. Hold the plug

and pull.

• Do not open the detergent dispenser drawer while the

machine is in operation.

• Do not touch the drained water as it may reach extremely high temperatures.

• Never force the porthole door. This could damage the safety

lock mechanism designed to prevent accidental opening.

• If the appliance breaks down, do not under any circumstances access the internal mechanisms in an attempt

to repair it yourself.

• Always keep children well away from the appliance while

it is operating.

• The door can become quite hot during the wash cycle.

• If the appliance has to be moved, work in a group of two

or three people and handle it with the utmost care. Never

try to do this alone, because the appliance is very heavy.

• Before loading laundry into the washing machine, make

sure the drum is empty.

Opening the porthole door manually

In the event that it is not possible to open the porthole

door due to a powercut, and if you wish to remove the

laundry, proceed as follows:

1. remove the plug from the electrical socket.

2. make sure the water level inside the machine is lower

than the door opening; if it is not, remove excess water

using the drain hose, collecting it in a bucket as indicated

in the figure.

3. pull outwards using the tab as indicated in the figure,

until the plastic tie-rod is freed from its stop position; pull

downwards and open the door at the same time.

GB

Disposal

• Disposing of the packaging materials: observe local regu-

lations so that the packaging may be re-used.

• The European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment, requires that old household

electrical appliances must not be disposed of in the normal

unsorted municipal waste stream. Old appliances must be

collected separately in order to optimise the recovery and

recycling of the materials they contain and reduce the impact on human health and the environment. The crossed

out “wheeled bin” symbol on the product reminds you of

your obligation, that when you dispose of the appliance it

must be separately collected. Consumers should contact

their local authority or retailer for information concerning the

correct disposal of their old appliance.

13

Page 14

Care and maintenance

1

2

GB

Cutting off the water and electricity

supplies

• Turn off the water tap after every wash cycle. This will limit

wear on the hydraulic system inside the washing machine

and help to prevent leaks.

• Unplug the washing machine when cleaning it and during all maintenance work.

Cleaning the washing machine

The outer parts and rubber components of the appliance

can be cleaned using a soft cloth soaked in lukewarm

soapy water. Do not use solvents or abrasives.

Cleaning the detergent dispenser drawer

Remove the dispenser by

raising it and pulling it out

(see figure).

Wash it under running water; this operation should be

repeated frequently.

To access the pre-chamber:

1. unscrew the lid by rotating it anti-clockwise (see

figure): a little water may

trickle out. This is perfectly

normal;

2. clean the inside thoroughly;

3. screw the lid back on;

Checking the water inlet hose

Check the inlet hose at least once a year. If there are any

cracks, it should be replaced immediately: during the wash

cycles, water pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

Caring for the door and drum of your

appliance

• Always leave the porthole door ajar in order to prevent

unpleasant odours from forming.

Cleaning the pump

The washing machine is fitted with a self-cleaning pump

which does not require any maintenance. Sometimes,

small items (such as coins or buttons) may fall into the prechamber which protects the pump, situated in its bottom

part.

! Make sure the wash cycle has finished and unplug the

appliance.

14

Page 15

Troubleshooting

Your washing machine could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure

that the problem cannot be solved easily using the following list.

Problem:

The machine does not switch on.

The wash cycle does not start.

The machine does not fill with water or “NO WATER CHECK SUPPLY”

appears on the display.

The machine continuously fills with

water and continually drains away

or Water left in the drum

or Stuck on wash.

Possible causes / Solutions:

• The appliance is not plugged into the socket fully, or not enough to make contact.

• There is no power to the socket, or the fuse has blown in the mains plug.

• The door is not closed properly.

• The ON/OFF button has not been pressed.

• The START/PAUSE button has not been pressed.

• The water tap has not been turned on to allow water to flow into the machine.

• A delayed start has been set (see “Running a wash cycle”).

• The water inlet hose is kinked.

• The water inlet hose is not connected to the water supply.

• The water pressure is too low.

• The water tap has not been turned on to allow water to flow into the machine.

• There is no water supply to the house.

• The inlet valve filter is blocked.

• The START/PAUSE button has not been pressed.

• The top of the drain hose is too low - It must be fitted at a height between 65

and 100 cm from the floor (see “Installation”).

• The drain hose is connected incorrectly to the sink trap allowing water to run

into the machine, the drain hose must be positioned higher than the bottom of

the sink to prevent water flowing down the drain hose.

• The end of the drain hose has been pushed too far down the standpipe, the

‘U’ bracket should be fitted 100 mm from the end of the drain hose.

GB

The machine does not drain or spin

or F05 error code in the display.

The machine does not heat or poor

wash results.

The programme takes too long

or The Display changes the estimated ‘Time to End’ during the programme.

The machine vibrates a lot during

the spin cycle.

• The Pump filter is blocked.

• The drain hose is kinked (see “Installation”).

• New Installation - The blanking cap or spigot has not been removed if connected under a sink.

• The drain hose or sink trap is blocked.

• The wash cycle does not include draining, some wash cycles require the drain

phase to be started manually.

• The REDUCED CREASES function button has been activated. To complete the

wash cycle, press the START/PAUSE button (see “Wash cycles and functions”).

• The ‘Spin Speed’ selector knob is in the “OFF” position.

• The ‘Temperature’ selector knob is in the “OFF” position.

• Programme times will vary due to water pressure, the incoming water temperature and if the wash load goes out of balance. This will increase the programme

times accordingly (see ‘ The machine wont spin properly’ below).

• The feet have not been adjusted, enabling the machine to rock.

• New Installation - Either the Transit Bolts including the plastic spacers, or the

Polystyrene Packaging have not been removed when installing the machine.

• The machine is trapped between cabinets and/or walls.

• The load is in a slight out of balance condition and machine is spinning, but at

a lower speed.

15

Page 16

GB

The machine is noisy.

The machine wont spin properly.

• There will always be some motor, pump and drum noise during spin.

• Out of Balance detected when attempting to go into a spin cycle - If this

happens the machine will continue to try to repeat the distribution of the load

required before the machine will go into higher spin speeds - This will increase

the programme time accordingly. This is a safety feature to prevent damage.

Out of Balance can be caused by washing a single heavy item (eg duvet, quilt,

etc). - Try the programme again using a different load.

The machine leaks from the dispenser.

The machine leaks (other than

dispenser).

The indicator lights on the console

are flashing rapidly.

The machine smells.

The machine door cannot be

opened.

Door Seal damaged at the bottom.

The water level is too low when

the machine is washing.

• The dispenser drawer is blocked with detergent and requires cleaning.

• The water pressure is too high and requires turning down - turn down the tap

on the water supply pipe slightly and try again.

• The machine is tilting forwards - It must be level when in its final position.

• The fill hose is loose, check both the cabinet and tap ends.

• The fill hose is tight but still leaks, if so replace the rubber washers, or the fill

hose is missing the rubber washer.

• The drain hose is not fixed in properly.

• Switch off the machine and unplug it, wait for approximately 1 minute and then

switch it back on again If the problem persists contact the Technical Assistance

Service.

• The machine requires a service wash. Run a 90 degree wash cycle with detergent and no laundry.

• The door will not open until the door lock indicator light goes out shortly after

the program has finished.

• The door seal has drainage holes at the bottom - This is normal.

• The water level is correct if it can be seen at the bottom of the door.

There is too much foam.

After completing the programme,

or before starting a programme,

the machine has turned itself off

(no lights).

General.

Remember, you will be charged for a service call for problems caused by incorrect installation, as listed

above.

Not emptying contents from pockets may cause pump or drain blockages, or may damage the machine.

Do not wash items which do not have a wash label, or wash items that are not intended as machine

washable.

16

• The detergent is not suitable for machine washing (it should display the text

‘for washing machines’ or ‘hand and machine wash’ or the like).

• Too much detergent was used - less detergent is required in soft water.

• To comply with new energy saving regulations the machine is fitted with an

automatic standby system. Press ‘ON/OFF’ button for 3 seconds to activate

the machine, it can then either be switched off or a new programme selected.

• Your washing machine contains sensors that monitor progress during the wash

cycle (eg: Water Levels, Temperatures, Out of Balance loads, Wash time/progress).

Normally, if your machine successfully completes the cycle, there is unlikely to

be anything wrong!

Page 17

Assistance

Before calling for Assistance:

• Check whether you can solve the problem alone (see “Troubleshooting”);

• Restart the programme to check whether the problem has been solved;

• If this is not the case, contact an authorised Technical Assistance Centre using the telephone number provided on the

guarantee certificate.

! Always request the assistance of authorised technicians.

Have the following information to hand:

• the type of problem;

• the appliance model (Mod.);

• the serial number (S/N).

This information can be found on the data plate applied to the rear of the washing machine, and can also be found on the

front of the appliance by opening the door.

GB

17

Page 18

GB

18

Page 19

GB

19

Page 20

GB

195102743.01

05/2012 - Xerox Fabriano

20

Loading...

Loading...