Page 1

Hoshizaki America, Inc.

Hoshizaki

Water Electrolyzer

Model

ROX-20TB2-U

“A Superior Degree

of Reliability”

www.hoshizaki.com

SERVICE MANUAL

Number: X002-858

Issued: 3-9-2012

Page 2

IMPORTANT

Only qualified service technicians should install, service, and maintain the

unit. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualified service technicians in the

maintenance and service of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

1

Page 3

IMPORTANT

This manual should be read carefully before the unit is serviced or maintenance

operations are performed. Only qualified service technicians should install,

service, and maintain the unit. Read the warnings contained in this booklet

carefully as they give important information regarding safety. Please retain this

booklet for any further reference that may be necessary.

I. GENERAL INFORMATION --------------------------------------------------------------------------5

1. SAFETY INSTRUCTIONS -------------------------------------------------------------------------5

2. PRODUCT INFORMATION -----------------------------------------------------------------------7

[a] FEATURES ----------------------------------------------------------------------------------------7

[b] MODEL NAME -----------------------------------------------------------------------------------8

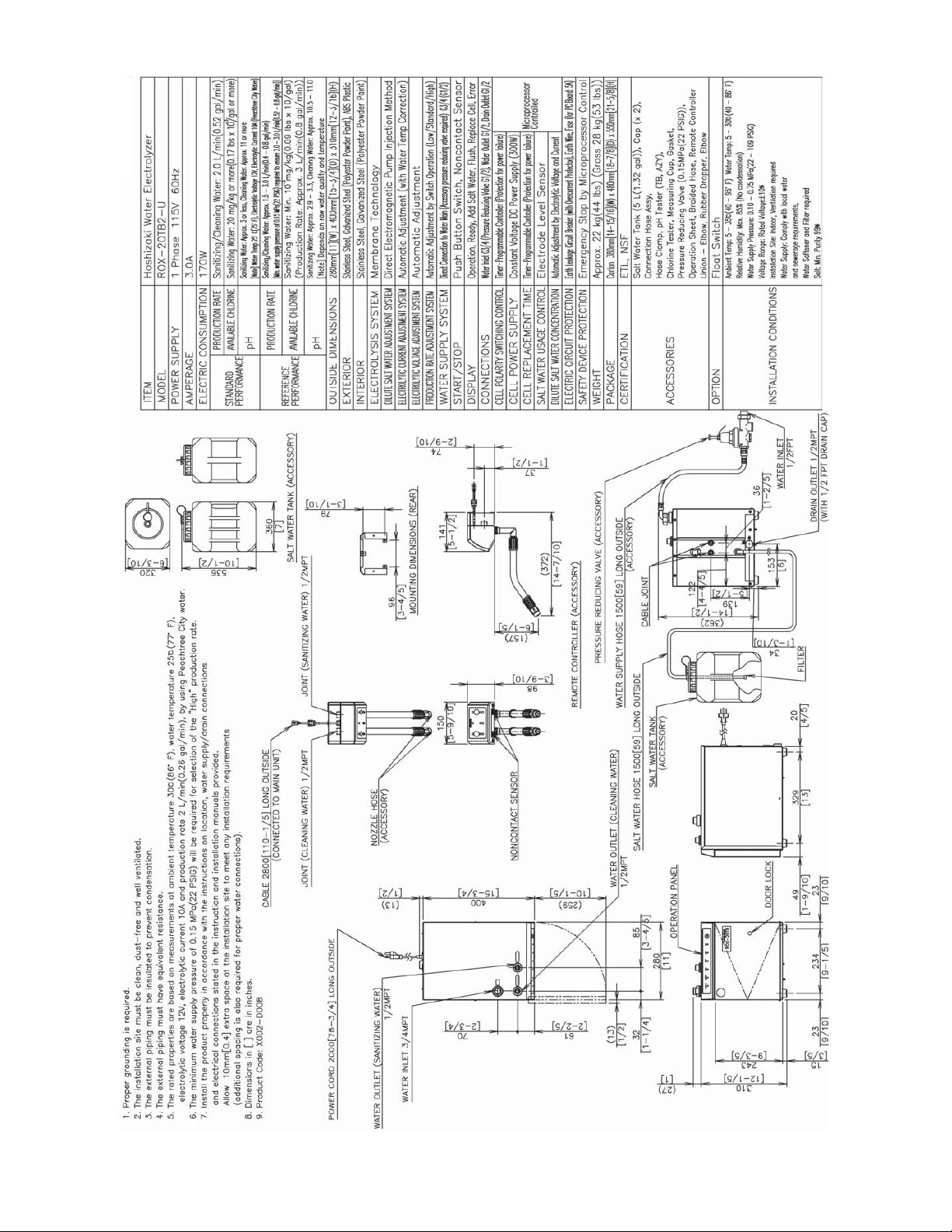

3. DIMENSIONS/SPECIFICATIONS ---------------------------------------------------------------9

4. PERFORMANCE DATA -------------------------------------------------------------------------- 10

II. TECHNICAL INFORMATION --------------------------------------------------------------------- 11

1. PRINCIPLE OF ELECTROLYSIS -------------------------------------------------------------- 11

2. CONSTRUCTION ---------------------------------------------------------------------------------- 14

[a] GENERAL --------------------------------------------------------------------------------------- 14

[b] MECHANISM ----------------------------------------------------------------------------------- 16

[c] CONTROL BOX -------------------------------------------------------------------------------- 17

3. WIRING DIAGRAM -------------------------------------------------------------------------------- 19

4. WATER CIRCUIT ---------------------------------------------------------------------------------- 20

5. FUNCTIONS AND OPERATION --------------------------------------------------------------- 21

[a] NORMAL MODE ------------------------------------------------------------------------------- 21

[b] SHORT MODE --------------------------------------------------------------------------------- 21

[c] ADJUSTMENT MODE ------------------------------------------------------------------------ 21

[d] CHECK MODE --------------------------------------------------------------------------------- 22

CONTENTS

PAGE

III. SERVICE INFORMATION ------------------------------------------------------------------------ 27

1. ERROR CODES ----------------------------------------------------------------------------------- 27

2. SERVICE DIAGNOSIS --------------------------------------------------------------------------- 27

3. FLOW RATE ADJUSTMENT -------------------------------------------------------------------- 29

4. REMOVAL AND REPLACEMENT OF COMPONENTS ---------------------------------- 30

[a] ELECTROLYTIC CELL ----------------------------------------------------------------------- 30

2

Page 4

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING

NOTICE

Indicates a situation which could result in damage to the unit or

IMPORTANT

In the context of this manual, the term "sanitizing water" refers to acidic water and

"cleaning water" refers to alkaline water.

Indicates a hazardous situation which could result in death or

serious injury.

property.

Indicates important information about the use and care of the

unit.

WARNING

This product should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for injury

or damage resulting from improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or fi re, follow

basic precautions including the following:

• Only qualifi ed service technicians should install and service the unit.

• This unit must be installed in accordance with applicable national, state, and

local codes and regulations.

• This unit requires an independent power supply. See the nameplate for

proper voltage and breaker/fuse size. Failure to use a proper breaker or fuse

can result in a tripped breaker, blown fuses, or damage to existing wiring.

This could lead to heat generation or fi re.

• THIS APPLIANCE MUST BE GROUNDED. This appliance is equipped

with a NEMA 5-15 three-prong grounding plug to reduce the risk of potential

shock hazards. It must be plugged into a properly grounded, independent

3-prong wall outlet. If the outlet is a 2-prong outlet, it is your personal

responsibility to have a qualified electrician replace it with a properly

grounded, independent 3-prong wall outlet. Do not remove the ground prong

from the power cord and do not use an adapter plug. Failure to follow these

instructions may result in death, electric shock, or fi re.

• Turn off the power supply before servicing. Lockout/Tagout to prevent the

power supply from being turned back on inadvertently.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, fi re, or damage to the unit.

• This unit is not intended for outdoor use (including under canopy). Exposure

to rain may cause electric leak or shock. Direct sunlight can damage the

plastic tank exterior, resulting in cracks and water leaks.

3

Page 5

• Ensure adequate ventilation. Hydrogen gas or chlorine gas may cause

health problems.

• Do not mix electrolyzed water with other chemicals. Mixture with acidic

or chlorine-based chemicals can cause chlorine gas, resulting in health

problems.

• Do not use a large volume of sanitizing water only. Generation of a

large amount of chlorine gas may cause health problems or corrosion of

surrounding equipment.

• Do not use a flame near a container or tank holding electrolyzed water.

Hydrogen gas from cleaning water may cause ignition.

4

Page 6

I. GENERAL INFORMATION

1. SAFETY INSTRUCTIONS

The following instructions contain important safety precautions and should be strictly

observed.

WARNING

1. When there is no need to energize the unit during disassembly or cleaning,

be sure to unplug the unit or disconnect the main power supply before

servicing the unit to prevent electric shocks.

2. If the unit must be energized for inspection of the electric circuit, use rubber

gloves to avoid contact with any live parts, which may result in electric

shocks.

3. Check for proper ground connections, and repair if necessary to prevent

electric shocks.

4. Always use service parts intended for the applicable model for replacement

of defective parts. Use proper tools to secure the wiring. Otherwise

abnormal operation or trouble may occur and cause electric leaks or fi re.

5. Check for proper part installations, wiring conditions and soldered or

solderless terminal connections to avoid smoke, fi re or electric shocks.

6. Be sure to replace damaged or deteriorated power cords and lead wires to

prevent electric shocks, fl ames or smoke.

7. Lead wires using solderless terminals or the like must be bound with their

closed ends up to avoid entrance of moisture that could lead to electric leaks

or fi re.

8. After servicing, always use a megohmmeter (500VDC) to check for

the insulation resistance of minimum 1 megohm between the live part

(attachment plug) and the dead metal part (ground terminal). Negligence in

checking may cause electric leaks or shocks.

9. Do not service the electrical parts with wet hands to prevent electric leaks or

shocks.

10. Always ask the user to keep children away from the work area. They may

be injured by tools or disassembled products.

5

Page 7

NOTICE

1. After servicing, be sure to check for water leaks from the water supply and

drain lines to prevent wetting the surrounding properties.

2. After servicing, always check for proper operation.

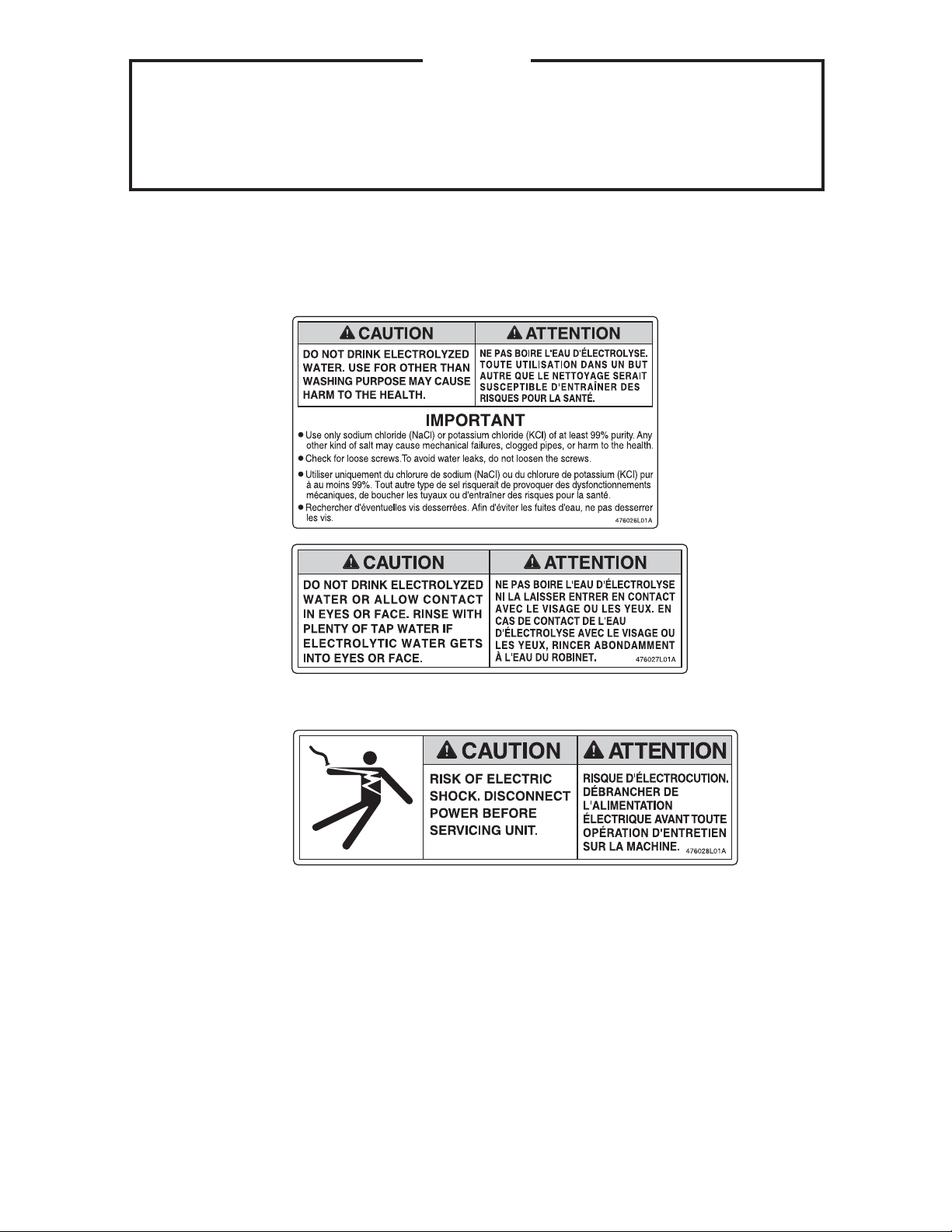

CAUTION LABEL LOCATIONS

The following caution labels are attached where special care should be taken.

On top panel

Inside door

6

Page 8

2. PRODUCT INFORMATION

[a] FEATURES

1) Space saving

The compact unit [W11" x D16" x H12" (W280 x D400 x H310 mm)] allows for

installation under sink.

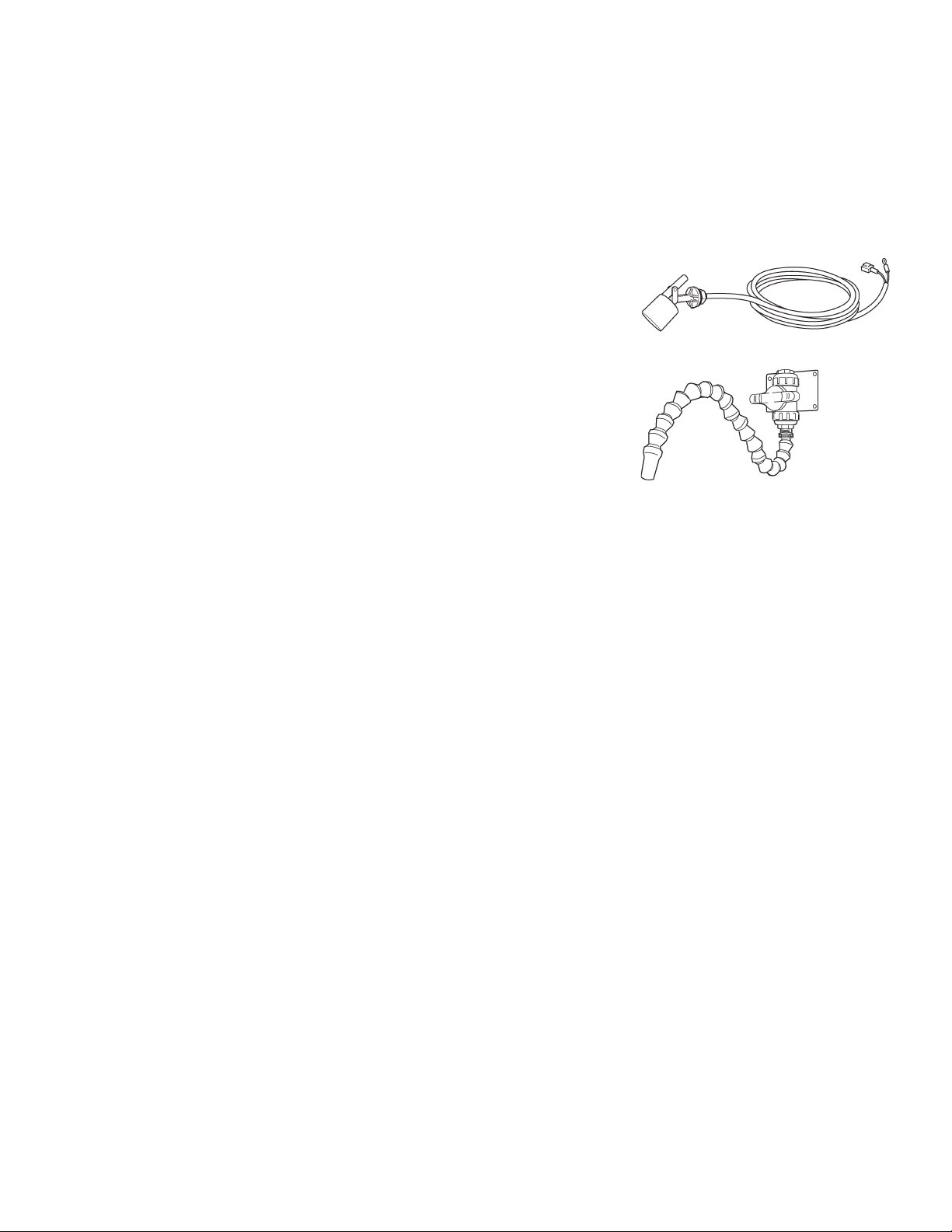

2) Various optional parts available

Float switch: Detects the tank water level to automatically

start/stop operation. Includes the upper

and lower sanitizing water tank level float

switches and upper and lower cleaning

water tank level fl oat switches.

Outlet valve: Allows use of electrolyzed water stored in

the tank, as required. Connected with the

electrolyzed water outlets [for sanitizing

and cleaning water outlets] on the water

tank. Use as needed [yellow for sanitizing

water, blue for cleaning water].

3) Concentrated salt water direct injection system

Direct addition of concentrated salt water held in the salt water tank (accessory) into

the water fl ow requires no tank for diluted salt water, resulting in reducing the space

required.

4) Built-in current sensor

No salt concentration sensor is required. The built-in current sensor provides highly

accurate control.

5) Constant-voltage DC power supply

Current control by a constant-voltage power supply uses the salt concentration to

correct reduction of the electrolyzation effi ciency, resulting in stable concentration of

available chlorine.

6) Available chlorine concentration 20 - 30 mg/L or more

Sanitizing water contains undissociated hypochlorous acid (HOCl) which sanitizes

faster than sodium hypochlorite (NaOCl) and does not leave residue.

7) Built-in fl ow rate adjusting valve

The built-in fl ow rate adjusting valve automatically controls the fl ow rate according to

the selection (low, medium, high).

7

Page 9

[b] MODEL NAME

ROX - 20 T B2 - U

For USA

Development order

Table-top or under-sink installation

Maximum fl ow rate (x 0.1 L/min)

Hoshizaki water electrolyzer

8

Page 10

3. DIMENSIONS/SPECIFICATIONS

9

Page 11

4. PERFORMANCE DATA

The following graph shows the electrode performance curve. The electrode life cycle

depends on the free chlorine concentration as well as the raw water quality. To optimize

the electrolyzed water, we recommend the electrolytic cell should be replaced every 3,000

hours of operation.

60

50

40

30

20

Available Chlorine <ppm>

10

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Time <h>

10

Page 12

II. TECHNICAL INFORMATION

1. PRINCIPLE OF ELECTROLYSIS

Water (H2O) we use in our daily life has a mysterious power. Adding a small amount of salt

(NaCl) to water (H2O) and electrolyzing it with special electrodes will generate "electrolytic

oxidizing water (acidic water)" with strong oxidizing effects and "electrolytic reducing water

(alkaline water)" with strong reducing effects. Here we explain this electrolysis process and

the meaning of such terms as "pH" and "oxidization/reduction" which may sound unfamiliar.

Electrolysis Process - See the diagram on the following page for the electrolysis

mechanism inside the electrolytic cell.

1) Electrolysis with a higher salt concentration around 5 - 20% is apt to generate chlorine

gas (Cl2) at the anode. The electrolyzer with a lower salt concentration around 0.07 -

0.15% is apt to generate hypochlorous acid (HOCl) at the anode.

2) At the anode, oxidization will generate hypochlorous acid (HOCl) and chlorine gas (Cl2).

3) At the cathode, reduction will generate hydrogen gas (H2) and sodium hydroxide (NaOH).

Oxidization/Reduction - Oxidization and reduction occur a the same time, while electrons

are transferred.

1) Oxidization - Reaction of a substance to emit electrons.

2) Reduction - Reaction of a substance to receive electrons.

Oxidization/Reduction Potential - Degree of liability to oxidization and reduction,

indicated in "mV".

1) Positive potential - An oxidizing agent (= a substance capable of oxidizing other

substances) is contained. The higher potential shows the higher tendency to oxidize

other substances.

2) Negative potential - An reducing agent (= a substance capable of reducing other

substances) is contained. The lower potential shows the higher tendency to reduce

other substances.

pH - Concentration index of hydrogen ions. pH7 means neutrality, the higher pH alkalinity,

and the lower pH acidity.

11

Page 13

(

)

(

)

Flow of electrons

12 V DC

DC Power Supply

Anode

(OX)

-

2e

Hypochlorous Acid

HOCl

+

Na

Diaphragm

HOCl

-

Cl

Negative ions

drawn to anode

Electrolytic Cell

H

2

H

Sodium Hydroxide

(NaOH)

Positive ions drawn

to cathode

+

Na

-

OH

-

OH

Na Na

O

2

H2O

-

Cl

Na

+

Cathode

RED

-

2e

Salt Water (NaCl)

Reactions at Anode

Chloride ions (Cl-) and hydroxide ions emit

electrons (e-) to the anode, which become

hypochlorous acid (HOCl).

Reactions at Cathode

Sodium ions (Na+) receive electrons (e-)

from the cathode and become sodium

metal (Na) which reacts with water (H2O)

and becomes sodium hydroxide (NaOH)

and hydrogen gas (H2).

12

Page 14

Salt water contains four kinds of ions; sodium ions (Na+), chlorine ions (Cl-), hydrogen ions

(H+) and hydroxide ions (OH-).

NaCl + H

O → Na+ + Cl- + H+ + OH

2

-

(Mix water and salt) Salt water (4 kinds of ions)

When two electrodes are inserted into salt water and voltage is applied:

Negative ions (Cl-) are drawn to the anode, and

Positive ions (Na+) are drawn to the cathode.

At the anode, hydrogen chloride (HCl) and hypochlorous acid (HOCl) are generated.

2Cl- + H

O → HCl + HOCl + 2e

2

-

Electrons (2e-) are emitted to the anode, which means the acidic water (HCl + HOCl)

causes

oxidization. [As electrons are emitted, the oxidization/reduction potential becomes positive

(+mV).]

Chlorine ions also emit electrons and become chlorine gas (Cl2).

2Cl- → Cl

2

+ 2e

-

(Cl2 = chlorine gas)

At the cathode, sodium hydroxide (NaOH) and hydrogen gas (H2) are generated.

Na+ + H2O + H+ + 2e- → NaOH + H

2

Electrons (2e-) are received from the cathode, which means the alkali water (NaOH)

causes reduction. [As electrons are received, the oxidization/reduction potential becomes

negative (-mV).]

13

Page 15

2. CONSTRUCTION

[a] GENERAL

(1) Operation Panel [Body]

Displays the present state of the electrolyzer.

(2) Door

Provided behind are the power switch (ground fault interrupter) and the buttons to

adjust the operating conditions and various set values.

14

Page 16

(3) Coin Lock

Locks the door.

(4) Cleaning Water Outlet

Dispenses cleaning water (sanitizing water in flushing process). Should be

connected with the cleaning water outlet [remote].

(5) Sanitizing Water Outlet

Dispenses sanitizing water (cleaning water in flushing process). Should be

connected with the sanitizing water outlet [remote].

(6) Water Supply Inlet

Should be connected with the water supply hose (G3/4) provided.

(7) Panel

Only a responsible maintainer or service personnel may open.

(8) Rear Panel

Only a responsible maintainer or service personnel may open for connection of the

remote controller cable.

(9) Panel (L)

Only a responsible maintainer or service personnel may open.

(10) Panel (R)

Only a responsible maintainer or service personnel may open for connection of the

remote controller cable.

(11) Leg

Do not remove. Not adjustable. Use spacers, if required, for stable installation.

(12) Drain Outlet

Can be connected with a drain pipe (G1/2), if the internal water circuit should be

drained.

(13) Power Cord

Single phase 115V. Be careful not to jerk or pinch.

(14) Salt Water Filter

Removes foreign matter from concentrated salt water in the salt water tank. Do not

clog. Clean at least once a month.

(15) Salt Water Hose

Supplies concentrated salt water from the salt water tank. Do not curve or bend by

force.

(16) Remote Controller Receptacle

Connects the remote controller cable with the electrolyzer body. Remove the

grommet, and attach the super lock of the remote controller.

(17) Operation Panel [Remote]

For the remote controller. Attachable at a point of use.

(18) Cleaning Water Outlet [Remote]

Should be connected with the cleaning water outlet to dispense cleaning water

(sanitizing water in fl ushing process).

(19) Sanitizing Water Outlet [Remote]

Should be connected with the sanitizing water outlet to dispense sanitizing water

(cleaning water in fl ushing process).

(20) Controller Bracket

Fixes the remote controller. Secure on a wall with anchor bolts.

15

Page 17

(21) Cable

Electrically connects the remote controller and the electrolyzer body. Be sure to

make the connection when using the remote controller.

(22) Salt Water Tank

Makes 1.32 gal (5 L) of electrolyte (concentrated salt water) and adds it to water

(diluted salt water).

(23) Motion Sensor

Non-contact sensor to start and stop dispensing electrolyzed water.

[b] MECHANISM

33 24

29 30

28 27 26

31

34

(24) Control Box

Functions as the brain of the electrolyzer to control its operation

(25) Dispense Button [Body]

Starts and stops dispensing sanitizing water and cleaning water.

(26) Water Valve

Supplies water from the water supply hose to the electrolytic cell.

(27) Flow Switching Valve

Operates every 12 hours to change the fl ow direction when the DC voltage to the

electrolytic cell reverses.

(28) Gear Motor

Rotates the impeller inside the fl ow switching valve.

32

25

16

Page 18

(29) Microswitch [Location]

Senses the location of the fl ow switching valve.

(30) Microswitch [Direction]

Senses the direction of the fl ow switching valve.

(31) Flow Control Valve

Located between the water supply inlet and the electrolytic cell. Adjusts the rate of

water supply.

(32) Electrolytic Cell

Electrolyzes diluted salt water to generate sanitizing water and cleaning water.

(33) Salt Water Pump (Electromagnetic Pump)

Feeds a fi xed amount of concentrated salt water (electrolyte) into the electrolytic

cell.

(34) Thermistor

Senses the water temperature and automatically reduces the electrolytic current to

prevent excessive available chlorine concentration in low temperature conditions.

[c] CONTROL BOX

35

37

44

45

42

43

46

47

40

41

36

39

38

17

Page 19

(35) Relay (X1)

Located on the supply line of the switching regulator [electrolytic cell]. Turns on/off

the switching regulator by using a make contact.

(36) CB Relay

Changes the polarity of the voltage on the electrolytic cell.

(37) Current Sensor

Measures the current of the electrolytic cell.

(38) Noise Absorber

Noise absorbing board provided with a surge absorber.

(39) Switching Regulator [Main Control Board]

DC power supply to drive the DC electrical components.

(40) Main Control Board

Functions as the brain of the controls to verify inputs and command outputs.

(41) Switching Regulator [Electrolytic Cell]

DC power supply for electrolysis in the electrolytic cell.

(42) Power Switch (Ground Fault Interrupter)

Shuts off the primary power supply in case of ground leakage or overcurrent.

(43) Display

Displays the cell run time (h) normally and the present conditions of the electrolyzer

by switch operation.

(44) Display Select Button

In the normal mode, selects the display indication between the cell run time, current,

and voltage.

(45) Flush Button

In the normal mode, operates the fl ow changing valve to fl ush the water circuit.

(46) Set/Reset Button

Adjusts various set values.

(47) Flow Rate Select Button

Adjusts the fl ow rate.

18

Page 20

3. WIRING DIAGRAM

19

Page 21

4. WATER CIRCUIT

Pressure

Gauge

Filter

Water

Supply

Pressure Reducing

Valve (Accessory)

Water Electrolyzer

(ROX-20TB2-U)

Control Box

Thermistor

Flow Switching

Valve

Pressure Reducing

Valve (35 psi)

Water

Softener

Water Valve

Flow Control

Valve

Salt Water

Pump

Electrolytic

Cell

Salt

Water

20

Remote Controller

or Tank

Page 22

5. FUNCTIONS AND OPERATION

[a] NORMAL MODE

The following menus are available in the normal mode. The display shows from 1 to 3

every time the display select button is pressed.

No. Menu Description

1 Cell run time (h) Total electrolytic cell run time at present.

2 Current (A)

3 Voltage (V)

[b] SHORT MODE

Use this mode to change the polarity every 2 minutes.

1) While the power switch (ground fault interrupter) is off, hold down the fl ush button and

set/reset button.

2) Turn on the power switch (ground fault interrupter).

3) After 5 seconds, release the fl ush button and set/reset button.

Current fl owing in electrolytic cell at present as measured by

current sensor.

Voltage provided on electrolytic cell at present as measured

by main control board.

Note: The operation lamp fl ashes while the short mode is selected.

[c] ADJUSTMENT MODE

The following menus are available in the adjustment mode.

No. Menu Factory default Adjustable range/increments

A1 Current (A) Lo: 10, Std: 10, Hi: 10

A2 Voltage (V) Lo: 12, Std: 12, Hi: 12 7.0 to 18.0/0.1

A3 Total fl ow rate (L/min) Lo: 3.0, Std: 4.0, Hi: 6.0 1.5 to 8.0/0.1

A4 Combination 1 Main: 1, Sub: 2

A5 Portion control time (min) 1 1 to 60/1

Cleaning water dispensing

A6

time for hand washing (s)

Sanitizing water dispensing

A7

time for hand washing (s)

Cell run time/reversal time

A8

reset

A9 Initial fl ash time (s) Std Std, 0 to 20/1

30 15 to 120/5

30 15 to 120/5

N/A

5.0 to 18.0/0.1

[wt=77°F(25°C)]

Display present run time, then

hold down set/reset button

(10s) to reset

21

Page 23

No. Menu Factory default Adjustable range/increments

A10 Cell replacement time (h) 3000 1500 to 9000/100

A11 Cell reversal time (h) 12 0.033 (check), 1 to 150/1

Continuous dispensing

A12

protection time (min)

A13 Single nozzle 2 Single: 1, Std: 2

Water temperature correction

A14

factor

Flow rate adjustment factor,

A15

operation time factor

A16 Skip N/A Skip

Flow rate correction value (L/

A17

min)

Water softener regeneration

A18

output cycle (h)

Salt water supply factor,

A19

feedback

Salt water supply factor, initial

A22

non-electrolysis time (s)

Salt water supply factor,

A23

feedback cycle

Salt water supply factor,

A25

stroke subtraction after

reaching set point (times/s)

A26 Reset N/A

Flow control valve open/

A27

closed

Cont Cont, 10 to 720/10

4 0 to 8/1

0.3 0.1 to 2.0/0.1

0 -0.5 to 0.5/0.1

0 0 to 100/1

1.0 1.0 to 5.0/0.1

5 1 to 10/1

1.0 1.0 to 5.0/0.1

N/A Skip

Display "rSEt", then hold down

set/reset button (10s) to reset

N/A Display current status

* Basically do NOT adjust the menus in gray.

[d] CHECK MODE

The following menus are available in the check mode.

No. Menu

C1 Inputs

C2 Inputs

C3 Outputs

C4 Salt water pump stroke (spm: strokes per minute)

C5 Total fl ow rate (L/min)

C6 Water temperature (°C)

C7 Set current at present water temperature (A)

C8 Corrected current (A)

C9 Elapsed cell reversal time (min)

22

Page 24

No. Menu

C10 Elapsed time after regeneration output (h)

C11 Last error number

C12 Cell run time at last error

C13 Cell reversal time at last error

C14 Current at last error

C15 Voltage at last error

C16 Total fl ow rate at last error

C17 Salt water pump stroke at last error (spm: strokes per minute)

C18 Water temperature at last error (°C)

C19 Set current at water temperature at last error (A)

C20 Corrected current at last error (A)

C21 Second from last error number

C22 Cell run time at second from last error

C23 Cell reversal time at second from last error

C24 Current at second from last error

C25 Voltage at second from last error

C26 Total fl ow rate at second from last error

C27 Salt water pump stroke at second from last error (spm: strokes per minute)

C28 Water temperature at second from last error (°C)

C29 Set current at water temperature at second from last error (A)

C30 Corrected current at second from last error (A)

C31 Third from last error number

C32 Cell run time at third from last error

C33 Cell reversal time at third from last error

C34 Current at third from last error

C35 Voltage at third from last error

C36 Total fl ow rate at third from last error

C37 Salt water pump stroke at third from last error (spm: strokes per minute)

C38 Water temperature at third from last error (°C)

C39 Set current at water temperature at third from last error (A)

C40 Corrected current at third from last error (A)

C41 Model confi guration (8: ROX-20TB2-U, 10: ROX-20TB2-U with tank)

C42 Control board version

* Fahrenheit and celusius conversion formulae:

°C = (°F - 32) x 5/9

°F = (9/5) x °C + 32

23

Page 25

p

ON: closed

p

g

OFF: open

valve

location

Flow sw

Flow sw

valve

direction

micro SW

micro SW

Float SW

left tank

lower

ON: closed

OFF: open

ON: closed

OFF: open

Float SW

right tank

ON: closed

OFF: open

Float SW

protection

right pump

Float SW

left tank

upper

upper

ON: closed

OFF: open

ON: closed

OFF: open

ON: closed

OFF: open

lower

right tank

Float SW

ON: closed

OFF: open

Float SW

left pump

protection

Element A

Element B

Motor rotation opens/closes valve

Spare

SW 1

ON: closed

OFF: open

SW

External

TP1

0° (close)

hall

element A

ON: closed

OFF: open

Model

input 1

Unused

ON: closed

OFF: open

ON: closed

OFF: open

ON:

detected

OFF: not

detected

Always

OFF

ON:

closed

Model

Always

Level

sensor

en

OFF:

o

input 3

TP2

315° (open)

element B

OFF

Unused

Unused

ON: salt water

tank full

OFF: salt water

tank not full

ON: closed

OFF: open

ON:

hall

detected

OFF: not

detected

Always

OFF

ON: not

full

Tank input

ON:

provided

Remote

OFF: full

(20TB+tank)

rovided

OFF: not

controller

ON: closed

OFF: open

Model

input 2

OFF

Always

Unused

eratin

Flow control

valve o

Close Open

OFF

Always

Always

Unused

OFF

Always

OFF

Always

Unused

OFF

Always

OFF

OFF

Always

Unused

Flow control valve mechanism

Unused

C1 Display

Unused

Always

OFF

Unused

Unused

Always

OFF

Unused

Model inputs

1: ON when ROX-10WB-U is used

2: ON when ROX-20TB2-U is used

3: ON when ROX-20TB2-U with tank is usedٕٕ

Element A detection (0°) ٟٟ

Element B detection (315°) ٨٨ٟ, ٨ = hall element detection

24

Page 26

Body

flow rate select

SW (SW64)

ON: on

OFF: off

Body

set/reset SW

(SW63)

ON: on

OFF: off

OFF

Always

ON: on

OFF: off

Body

dispense

SW (SW60)

Unused

Ext. right

beam

sensor input

ON: detected

OFF: not

detected

beam

Ext. left

Remote

sensor input

R button

(SW50)

Unused

Always

OFF

ON: detected

OFF: not

detected

ON: on

OFF: off

Always

OFF

OFF

Always

Unused

Body

display select

SW (SW61)

Hand or

pool

ON: detected

OFF: not

detected

sensitivity

Remote

sensor lower

Ext. left beam

M button

(SW51)

Unused

ON: on

OFF: off

ON: closed

OFF: open

ON: on

OFF: off

Always

OFF

ON: on

OFF: off

Body

(SW62)

flush SW

ON: on

OFF: off

(SW52)

Remote

L button

Unused

ON: detected

OFF: not

detected

sensitivity

sensor lower

Ext. right beam

OFF

Always

(0.5 second delay after detection)

OFF

Always

Unused

Unused

Unused

OFF

Always

Unused

C2 Display (ROX-20TB2-U)

Unused

Always

OFF

Always

OFF

Always

OFF

Always

Always

OFF

Unused

OFF

Unused

Unused

Unused

Unused

Always

OFF

Always

OFF

Always

OFF

25

OFF

Always

Unused

Unused

OFF

Always

R

OFF

Always

Unused

Unused

Hand or pool Beam sensor detection

M

L

ON when tank is used Beam sensor input: real-time display of sensor reaction

Remote panel

(with/without remote controller short circuit connector) Beam sensor lower sensitivity: display according to operation

Page 27

X2

sw valve

relay

ON: positive

OFF: negative

ON: excited

OFF: not

excited

ON during

electrolysis

ON: excited

OFF: not

excited

X3

ON: excited

OFF: not

excited

ON: excited

OFF: not

excited

ON: excited

OFF: not

X8

TDT right

excited

pump

X1

polarity sw

relay (10WB)

add salt

output

X10

regeneration

output signal

(12V)

ON: excited

OFF: not

excited

X9

pump

TDT left

X14

polarity sw

relay (20TB)

Flow

control

valve 1

ON: full

OFF: not

full

X6

ON: positive

OFF: negative

ON: excited

OFF: not

excited

ON: excited

OFF: not

excited

Combination

of 2 valves

X7

output

inspection

X5

WV

relay

X11

unused

ON: negative

OFF: positive

X15

polarity sw

relay (20TB)

X13

unused

Flow

control

valve 2

OFF

Always

ON: excited

OFF: not

excited

ON: excited

OFF: not

excited

ON: excited

OFF: not

excited

Combination

of 2 valves

X4

DC power

ON: excited

OFF: not

X12

Always

supply relay

excited

unused

OFF

ON: on

OFF: off

Fan motor

OFF

Always

Unused

Tank output

(20TB+tank)

OFF

Always

Unused

C3 Display

Unused

Unused

Unused

Always

OFF

Always

OFF

Always

OFF

Always

Unused

OFF

Unused

Unused

Unused

Unused

Always

OFF

Always

OFF

Always

OFF

26

Unused

OFF

Always

OFF

Always

Unused

Unused

Flow control valve 1 b2 ON ON OFF OFF

Brake Close Open Stop

Flow control valve outputs

Flow control valve 2 C2 ON OFF ON OFF

Brake: valve stopping, Close: decreasing flow rate, Open: increasing flow rate, Stop: valve OFF

Page 28

III. SERVICE INFORMATION

1. ERROR CODES

Lamp No. Error Problem Operation

Flow rate stayed below 0.13

Error E11 Low water

Error E14 Water shutoff

Error E53 Contactor supply

Error E61

— E74 Thermistor

— E82

Add salt

water

— EE1 Model setting

Error EF0 Control board EEPROM error Production stops Error no.

Flow switching

valve

Float switch (if

provided with

tank)

— Salt water level

gal/min (0.5 L/min) for 10 sec

with water valve on

Flow rate stayed above 0.13

gal/min (0.5 L/min) for 10 sec

with water valve off

Current stayed below 0.5A for 2

sec

Switching did not complete

within 30 sec

Open circuit [-22°F (-30°C)] or

short circuit [140°F (60°C)]

Upper switch on, lower switch

off

Salt water pump stayed at 700

spm (strokes per minute) for 90

sec

Model setting connector lost or

wrong

Production stops after

water valve turns off

two times

Production stops after

water valve turns on

two times

Production stops after

contactor switches

three times

Production stops Error no.

Production continues

as 41°F (5°C) (open

circuit) or 86°F (30°C)

(short circuit)

Production continues

(for at least 3 min)

Production stops (Add salt lamp on)

Production stops Error no.

Control panel

Error no.

Error no.

Error no.

Alternate between

normal display

and error no.

Alternate between

normal display

and error no.

display

2. SERVICE DIAGNOSIS

Lamp Error code Problem Check Possible cause Remedy

Add salt

water

— Salt water pump stayed

700 spm (strokes per

minute) for 90 sec

Salt water tank Low salt water

concentration

Salt water hose Loose connection to

salt water tank

Clogged Unclog

Vapor lock Prime

Filter Dirty Clean

Switching

regulator

(electrolytic cell)

Magnetic switch Defective Repair or replace

Relay Defective Repair or replace

Current sensor Defective Repair or replace

Defective Repair or replace

DC supply line open

circuit

Bad contacts Repair

Bad contacts Repair

Add salt in salt

water tank

Reconnect

Correct

27

Page 29

Lamp Error code Problem Check Possible cause Remedy

Add salt

water

Error E11 Flow control valve (fl ow

Error E14 Flow rate sensor

Error E53 Electrolytic current

Error E61 Flow switching did not

— E74 Thermistor open circuit

— E82 Upper fl oat switch turned

— EE1 Model setting connector

— EF0 EEPROM memory

— (Continued) Salt water pump Defective Repair or replace

rate sensor) detected

fl ow rate below 0.13 gal/

min (0.5 L/min) for 10

sec with water valve on

detected fl ow rate above

0.13 gal/min (0.5 L/min)

for 10 sec with water

valve off

stayed below 0.5A for 2

sec

complete within 30 sec

[-22°F (-30°C)] or short

circuit [140°F (60°C)]

was detected

on and lower fl oat switch

turned off

lost or wrong

element error

Improper stroke dial

setting

Supply line open circuit Correct

Signal line open circuit Correct

Water supply line Water failure Recover water

Electrolyzed

water outlet

Joint hose Crushed or bent Correct

Filter Clogged Unclog

Water valve Defective Repair or replace

Flow rate sensor Defective Repair or replace

Water valve Defective Repair or replace

Flow rate sensor Defective Repair or replace

Current sensor Defective Repair or replace

Switching

regulator

Main control

board

Gear motor Defective Repair or replace

Location

microswitch

Direction

microswitch

Thermistor Defective Repair or replace

Float switch Defective Repair or replace

Main control

board

Main control

board

Blocked Unblock

Scaled Replace

Clogged Unclog

Supply line open circuit Correct

Clogged Unclog

Signal line open circuit Correct

Clogged Unclog

12V DC line open

circuit

Signal line open circuit Correct

Defective Repair or replace

Defective Repair or replace

Loose chip insertion Correct

Overrun Lubricate motor

Defective Repair or replace

Defective Repair or replace

Incorrect wiring

connector

Defective Replace

Set to "E" (far to

left)

supply

Correct

shaft

Correct

28

Page 30

3. FLOW RATE ADJUSTMENT

Pressing fl ow rate select

button will not change fl ow

rate and display

Dispensing action is

stopped

Yes

Normal (Nor.) mode is

selected

Yes

Flow control valve connector

is disconnected

Yes

1. Flow control valve defective

2. Open circuit

No

No

No

Stop dispensing and press

fl ow rate select button

Select normal (Nor.) mode

and press fl ow rate select

button

Reconnect

Valves and pipes free from

Yes

foreign matter or clogging

Flow rate remains

unchanged or below

"HI" setting

Water supply pressure not less

than 0.15 MPa (21.76 psi)

Yes

Low water

supply pressure

Pressure ensured even

with a large amount of tap

water used elsewhere

Yes

Low water

supply pressure

No

No

No

Remove foreign matter,

unclog or replace

Note: The actual fl ow rate may differ from the setting depending on variation of the fl ow

rate sensor in the fl ow control valve.

e.g. Total fl ow rate setting [standard 1.06 gal/min (4.0 L/min)] --> actual fl ow rate [1.19

gal/min (4.5 L/min)]

If the difference is too large, use the adjustment mode (AdJ.) to adjust the total fl ow

rate (A3).

e.g. Total fl ow rate setting [0.92 gal/min (3.5 L/min)] --> actual fl ow rate [1.06 gal/min

(4.0 L/min)]

29

Page 31

4. REMOVAL AND REPLACEMENT OF COMPONENTS

[a] ELECTROLYTIC CELL

WARNING

To prevent electric shock, be careful not to crush or drag the pipes or wires

when removing the electrolytic cell.

NOTICE

To prevent water leaks resulting in wetting the surrounding properties, be sure to

drain water before removing the electrolytic cell.

1) Remove the front panel, turn off the power switch (ground fault interrupter), and unplug

the unit.

2) Close the water supply line shut-off valve, and disconnect the water supply, cleaning

water, and sanitizing water hoses.

3) Unscrew and remove the top and side panels.

4) Remove the drain cap on the back of the unit to drain the electrolytic cell.

5) Disconnect the power cord (red/black) on the electrolytic cell from the terminal block.

6) Remove the four union nuts from the electrolytic cell.

7) Unscrew the cell stopper and frame assembly, and remove the cell stopper from the unit

base.

8) Slide out the electrolytic cell towards you.

9) To replace, reverse the above pocedure.

30

Loading...

Loading...