Hoshizaki ROX-20TA-U User Manual

NO. U8AA-554

ISSUED: DEC. 29, 2000

REVISED:

HOSHIZAKIHOSHIZAKI

HOSHIZAKI

HOSHIZAKIHOSHIZAKI

WATER ELECTROLYZERWATER ELECTROLYZER

WATER ELECTROLYZER

WATER ELECTROLYZERWATER ELECTROLYZER

MODEL

ROX-20TA-UROX-20TA-U

ROX-20TA-U

ROX-20TA-UROX-20TA-U

SERVICE MANUAL

CONTENTS PAGE

I. GENERAL INFORMA TION -------------------------------------------------------------------------- 1

1. SAFETY INSTRUCTIONS------------------------------------------------------------------------ 1

2. PRODUCT INFORMA TION ---------------------------------------------------------------------- 3

[a] FEATURES ------------------------------------------------------------------------------------- 3

[b] MODEL NAME--------------------------------------------------------------------------------- 3

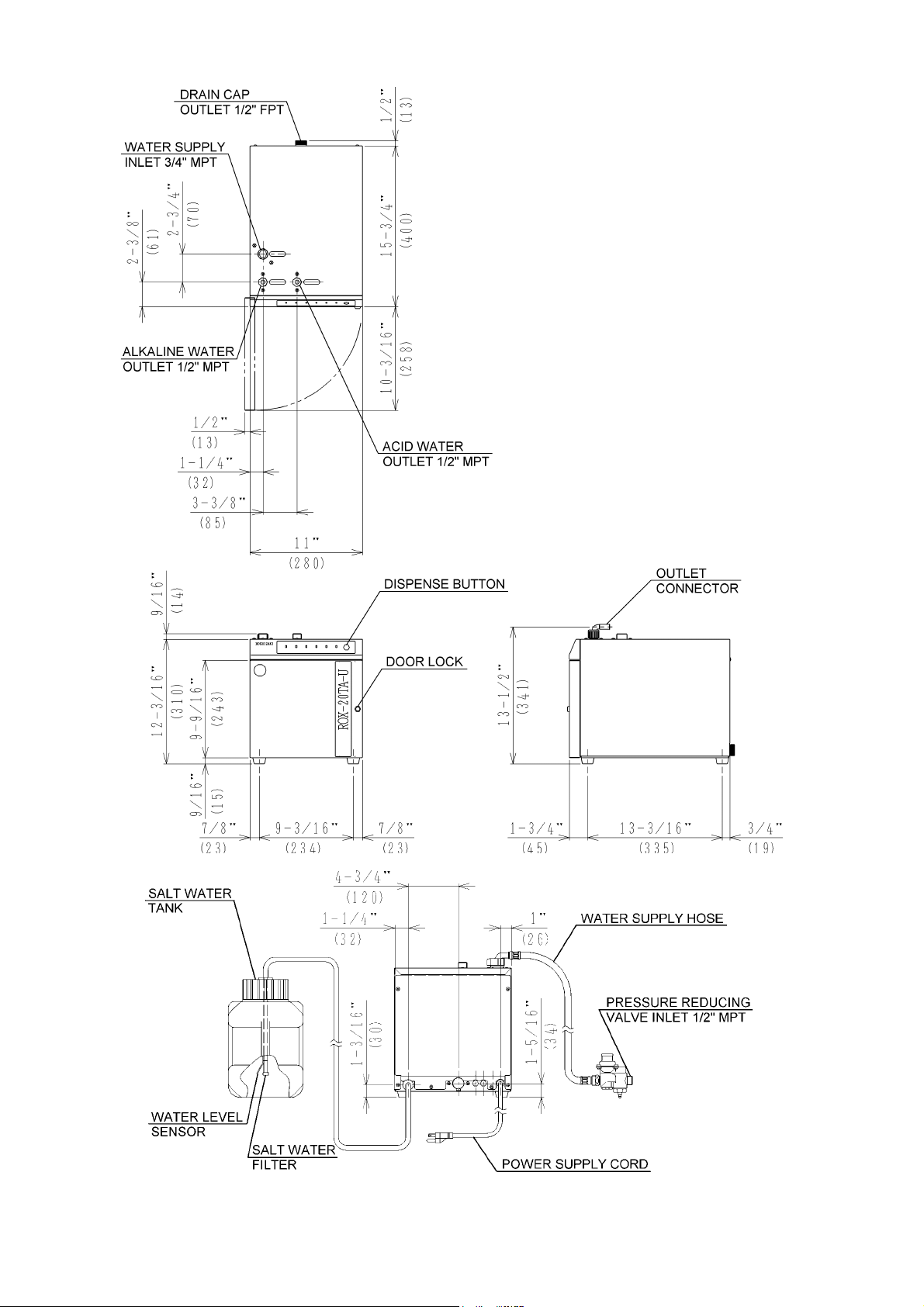

3. DIMENSIONS/CONNECTIONS----------------------------------------------------------------- 4

4. FEATURES OF STRONG ACID W ATER----------------------------------------------------- 5

5. PRINCIPLE OF STRONG ACID WA TER GENERATION --------------------------------- 6

II. CONSTRUCTION ------------------------------------------------------------------------------------- 7

1. GENERAL ------------------------------------------------------------------------------------------- 7

2. CONTROL P ANEL -------------------------------------------------------------------------------- 9

3. DISPLAY PANEL----------------------------------------------------------------------------------10

4. CONTROL BOX----------------------------------------------------------------------------------- 11

5. REMOTE CONTROLLER (OPTION) ---------------------------------------------------------12

6. WATER TANK FLOAT SWITCHES (OPTION)----------------------------------------------12

7. OUTLET V ALVES (OPTION) -------------------------------------------------------------------12

III. OPERATING INSTRUCTIONS --------------------------------------------------------------------13

1. FUNCTIONS AND ADJUSTMENT OF SET ITEMS---------------------------------------13

2. FUNCTIONS AND ADJUSTMENT OF CHECK ITEMS----------------------------------21

3. OPERA TION FLOW CHAR T -------------------------------------------------------------------24

IV . TECHNICAL INFORMA TION ---------------------------------------------------------------------25

1. WA TER CIRCUIT----------------------------------------------------------------------------------25

2. WIRING DIAGRAM -------------------------------------------------------------------------------26

3. PERFORMANCE DATA-------------------------------------------------------------------------27

V . SERVICE INFORMA TION -------------------------------------------------------------------------29

1. MAINTENANCE/INSPECTION ----------------------------------------------------------------29

2. SERVICE DIAGNOSIS --------------------------------------------------------------------------31

U8AA5540012

I. GENERAL INFORMATION

1. SAFETY INSTRUCTIONS

The following instructions contain important safety precautions and should be strictly observed.

The terms used here are defined as follows:

WARNING: There is a possibility of death or serious injury for the service person and a third

party or the user due to improper service operations or defects in serviced

products.

CAUTION: There is possibility of injury of the service person and a third party or the user or

damage to their property* due to improper service operations or defects in

serviced products.

* The term “damage to their property” here refers to extensive damage to houses, household

effects, livestock and pets.

W ARNING

1. When there is no need to energize the unit during disassembly or cleaning, be sure to

unplug the unit or disconnect the main power supply before servicing the unit to prevent

electric shocks.

2. If the unit must be energized for inspection of the electric circuit, use rubber gloves to avoid

contact with any live parts, which may result in electric shocks.

3. Check for proper earth connections, and repair if necessary to prevent electric shocks.

4. Always use service parts intended for the applicable model for replacement of defective

parts. Use proper tools to secure the wiring. Otherwise abnormal operation or trouble

may occur and cause electric leaks or fire.

5. Check for proper part installations, wiring conditions and soldered or solderless terminal

connections to avoid smoke, fire or electric shocks.

6. Be sure to replace damaged or deteriorated power cords and lead wires to prevent electric

shocks, flames or smoke.

7. Lead wires using solderless terminals or the like must be bound with their closed ends up

to avoid entrance of moisture that could lead to electric leaks or fire.

8. After servicing, always use a megohmmeter (DC500V) to check for the insulation resistance

of minimum 1 megohm between the live part (attachment plug) and the dead metal part

(earth terminal). Negligence in checking may cause electric leaks or shocks.

U8AA5540012

9. Do not service the electrical parts with wet hands to prevent electric leaks or shocks.

1

10. Always ask the user to keep children away from the work area. They may be injured by

tools or disassembled products.

CAUTION

1. After servicing, be sure to check for water leaks from the water supply and drain lines to

prevent wetting the surrounding properties.

2. After servicing, always check for proper operation.

CAUTION LABEL LOCATION

The following caution labels are attached where special care should be taken.

On top panel

Inside door

On remote controller (option)

On bottom front of control box

2

U8AA5540012

2. PRODUCT INFORMATION

[a] FEATURES

1) Space saving

The compact unit (W280 x D400 x H310 mm) allows for installation under sink.

2) Various optional parts available

Remote Controller: Makes the dispensing section remotely operable at hand.

Float Switch: Detects the tank water level to automatically start/stop operation.

Outlet Valve: Allows use of electrolyzed water stored in the tank, as required.

3) Concentrated salt water direct injection system

Direct addition of concentrated salt water held in the Salt Water Tank (accessory) into

the water flow requires no tank for diluted salt water, resulting in reducing the space

required.

4) Built-in current sensor

No salt concentration sensor is required. The built-in current sensor provides highly

accurate control.

5) Constant-voltage DC power supply

Current control by a constant-voltage power supply uses the salt concentration to correct

reduction of the electrolyzation efficiency , resulting in stable concentration of available

chlorine.

6) Available chlorine concentration 20 - 30 mg/L or more

Acid water contains undissociated hypochlorous acid (HOCl) which sanitizes faster

than sodium hypochlorite (NaOCl) and does not remain.

[b] MODEL NAME

ROX - 20 T A - U

For USA

Development Order

T able-top or under-sink installation

Maximum flow rate (x0.1L/min)

Hoshizaki Water Electrolyzer

U8AA5540012

3

3. DIMENSIONS/CONNECTIONS

Unit: inch (mm)

4

U8AA5540012

4. FEATURES OF STRONG ACID WATER

Electrolyzed water (electrolyzed functional water) is a solution with useful functions caused by

electrolyzation of thin salt water or tap water. Dif ferent conditions of electrolyzation produce

various kinds of electrolyzed water whose applications are categorized into: [1] sanitation

(strong acid water, strong alkaline water, weak acid water, hypochlorous acid water) and [2]

consumption (alkaline ionized water). The Water Electrolyzer ROX-20T A-U produces strong

acid water and strong alkaline water in the category [1].

Strong acid water has the following features:

(1) Main Ingredient: Hypochlorous acid*

1)

(2) pH: 2.2 - 2.7

(3) Oxidation-Reduction Potential*2): Max. +1 100mV

(4) Available Chlorine Concentration*3): 20 - 60mg/L

(5) Color: None

(6) Others: Stimulative smell of chlorine

(contains un-electrolyzed salt)

*1) Hypochlorous acid (HOCl)

Dissolution of chlorine gas in water generates hypochlorous acid (HOCl) whose ratio to

hypochlorous acid ion (ClO-) varies with the pH of water. In the pH range for strong acid

water, much more HOCl than ClO- exists. Both HOCl and ClO- have a bactericidal

effect, but HOCl is much stronger than ClO-.

*2) Oxidation-Reduction Potential (ORP)

Oxidizing (or reducing) effect of the solution. The larger positive number indicates the

higher oxidizing effect.

*3) Available Chlorine Concentration

Chlorine concentration contributing to the bactericidal activity . It indicates the amount

of chlorine corresponding to iodine isolated in the following reaction:

NaOCl + 2Kl + 2CH3•COOH I2 + 2CH3•COOK + NaCl + H2O

U8AA5540012

Note: The terms related to chlorine are defined as below:

Residual Chlorine: Remaining chlorine as the result of excessive chlorine addition into

tap water to optimize the bactericidal effect of chlorination.

Free Chlorine: Chlorine (Cl2), hypochlorous acid (HOCl) and hypochlorous acid ion

(OCl-) generated by dissolution of chlorine in water.

Combined Chlorine: Chloramine (NH2Cl, NHCl2, NCl3) generated by dissolution of chlorine

in water containing ammoniate or organic nitride. Combined chlorine

is stable and durable, but not so effective in a quick bactericidal activity .

Available Chlorine: Combination of free chlorine and combined chlorine.

5

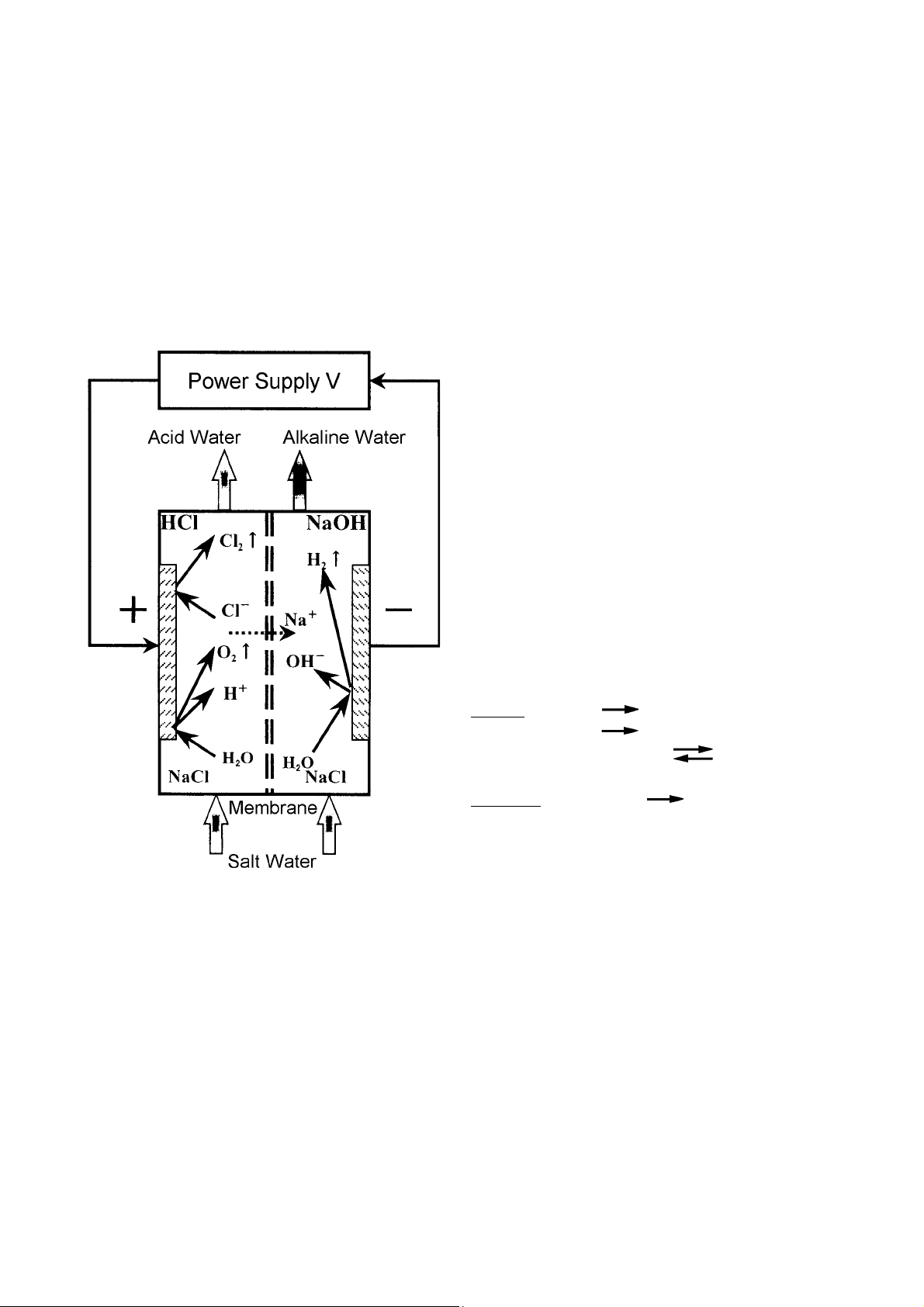

5. PRINCIPLE OF STRONG ACID WATER GENERATION

Strong acid water is generated at the anode inside the Electrolytic Cell where the membrane

divides the anode and cathode, by electrolyzation of 0.1% or less salt water . See the figure

below .

At the anode, chlorine ion (Cl-) generates chlorine gas which reacts with H2O to generate

chloride and hypochlorous acid (HOCl). H2O is also electrolyzed at the anode to become

oxygen (O2) and hydrogen ion (H+). Eventually , the anolyte pH falls below 2.7, the oxidationreduction potential (ORP) rises significantly , and the available chlorine concentration reaches

20 - 60 mg/L.

[Reaction Formula]

Anode H2O 1/2O2 + H+ + 2e

2Cl

-

Cl2 + 2e

-

Cl2(aq) + H2O HCl + HOCl

Cathode H2O + 2e

-

1/2H2 + OH

-

-

6

U8AA5540012

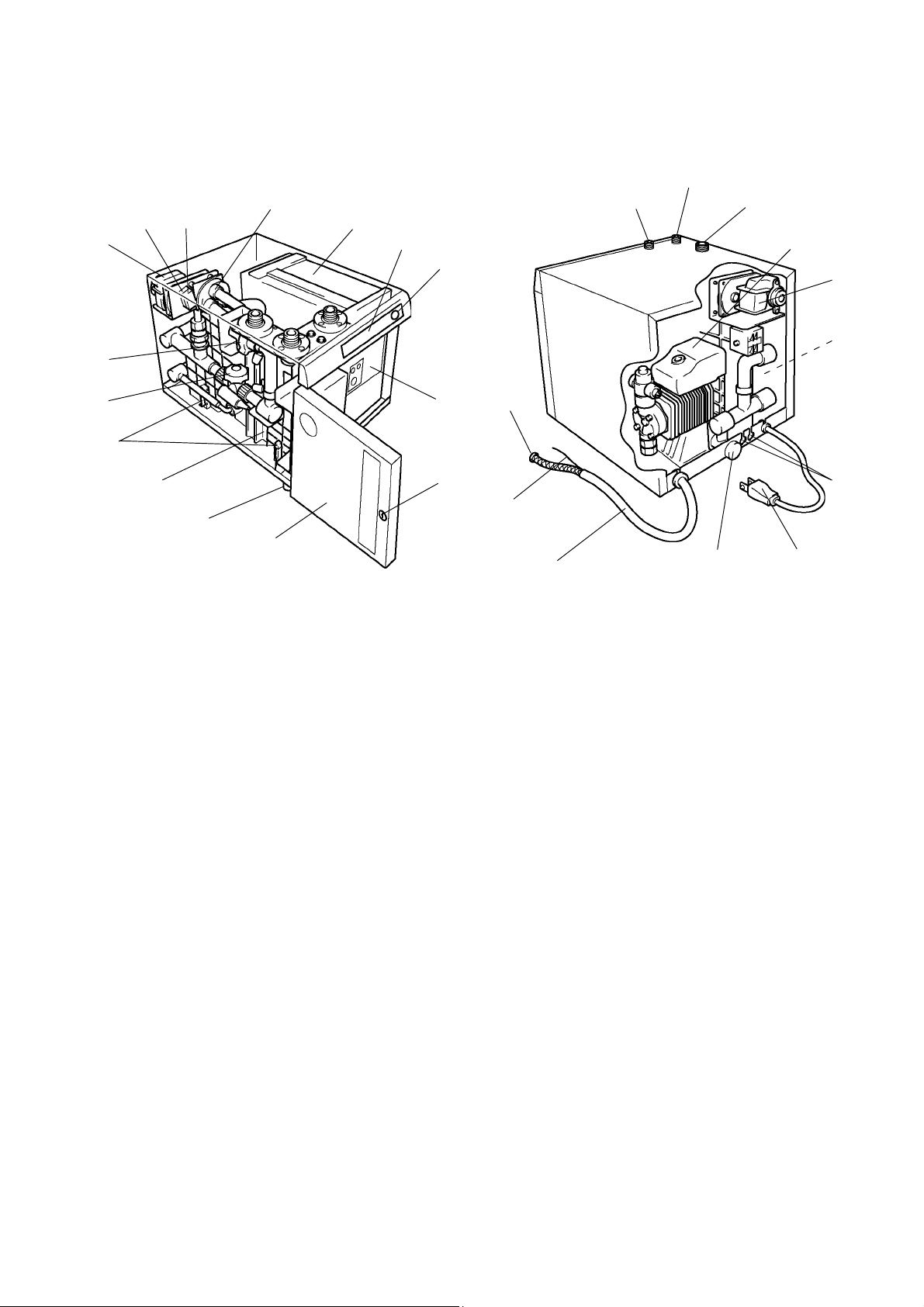

II. CONSTRUCTION

1. GENERAL

[4]

[6] [5] [3]

[7] [2]

[8]

[17]

[16] [18]

[19]

[1]

[20]

[21]

[9] [15]

[10]

[11] [14]

[12]

[13]

[1] Display Panel

See “3. DISPLAY PANEL“.

[2] Lamp Board

Board with lamps indicating unit status.

[3] Control Box

See “4. CONTROL BOX”.

[4] Flow Switching V alve

Changes the flow direction of electrolyzed water.

[5] Microswitch [Direction]

Senses the direction of the Flow Switching V alve.

[6] Microswitch [Location]

Senses the location of the Flow Switching V alve.

[7] Gear Motor

Rotates the Impeller inside the Flow Switching V alve.

[8] Water Valve

Supplies potable water to the Electrolytic Cell.

[9] Flow Rate Sensor

Senses potable water flow .

[10] Surge Absorber

Interrupts a temporary voltage surge.

[1 1] Electrolytic Cell

Electrolyzes diluted salt water and generates acid and alkaline water .

[12] Leg

Not adjustable.

[27]

[22]

[26]

[25] [24] [23]

U8AA5540012

7

[13] Door

Provided with Door Lock.

[14] Door Lock

Locks the Door.

[15] Control Panel

See “2. CONTROL P ANEL”.

[16] Acid Water Outlet

Dispenses acid water during the normal operation and alkaline water during the flushing

process.

[17] Alkaline Water Outlet

Dispenses alkaline water during the normal operation and acid water during the flushing

process.

[18] Water Supply Inlet

Inlet for potable water supplied to the unit.

[19] Electromagnetic Metering Pump

Supplies salt water to the unit.

[20] Terminal Block

Used when the Water Tank (sold separately) is installed.

[21] Rear Panel (not shown)

Removed when the Water Tank Float Switches are connected to the Terminal Block or

the Remote Controller is connected to the Control Box.

[22] Blind Bushing

Removed when the Water Tank Float Switches are connected to the Terminal Block or

the Remote Controller is connected to the Control Box.

[23] Power Supply Cord

Flexible cord with a grounding conductor and grounding type attachment plug.

[24] Drain Cap

Used for draining the pipes.

[25] Salt Water Hose

Includes the PVC hose and the Water Level Sensor .

[26] Water Level Sensor

Senses the level of salt water inside the Salt Water Tank.

[27] Salt Water Filter

Removes foreign substances in salt water.

8

U8AA5540012

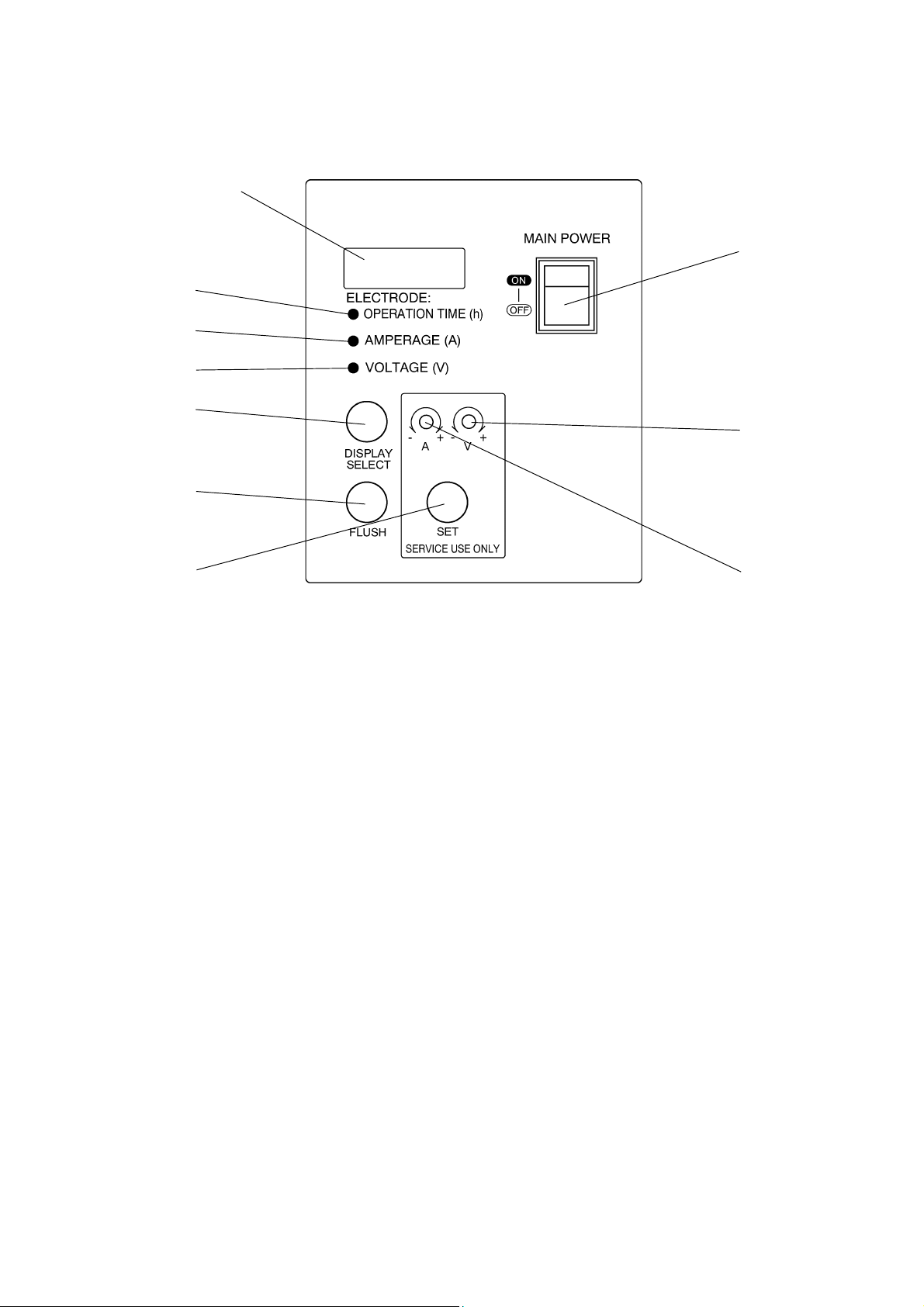

2. CONTROL PANEL

[1]

[2]

[3]

[4]

[5]

[6]

[10]

[9]

[7] [8]

[1] Display Window

Displays the operation time, amperage or voltage during the normal operation and

error codes in case of trouble.

[2] Operation Time Lamp

Display Window displays operation time (h) when this lamp is on.

[3] Amperage Lamp

Display Window displays amperage (A) when this lamp is on.

[4] Voltage Lamp

Display Window displays voltage (V) when this lamp is on.

[5] Display Select Button

Switches the display of the Display Window .

[6] Flush Button

Functions as a switch to flush the pipes beyond the acid and alkaline water outlets.

[7] Set Button

Only qualified service personnel or installer may press this button to adjust various set

values.

[8] Amperage Control Volume

Only qualified service personnel may turn this control to change the set amperage.

[9] Voltage Control Volume

Only qualified service personnel may turn this control to change the set voltage.

[10] Power Switch

Turns the unit on and off.

U8AA5540012

9

Loading...

Loading...