Page 1

SERVICE MANUAL

FOR MODEL RM-10

Page 2

REQUIRED TOOLS

CORDLESS DRILL

SCREWDRIVER SET WITH

9/32” SOCKET

COPPER CUTTING TUBE

VISE GRIP

1/2” OPEN WRENCH

PIERCING VALVE

SOLDERING IRON

PRECISION FLAT BLADE SLOTTED

SCREWDRIVER

Page 3

REQUIRED EQUIPMENT

OXY-ACETYLENE

EQUIPMENT

MANIFOLD HIGH & LOW

GAUGE PRESSURE KIT

DRY NITROGEN TANK

LEAK DETECTOR

VACUUM PUMP WITH GAUGE

METER WITH AN ACCURACY

IN MICRONS

REFRIGERANT RECOVERY

MACHINE

Page 4

CONTENTS

• Instructions to replace LED Power Supply.

• Instructions to replace LED strips lights.

• Instructions to replace condenser fan motor.

• Instructions to replace evaporator fan motor.

• Instructions to replace electronic thermostat.

• Instructions to replace thermostat ambient sensor.

• Instructions to replace starting relay, overload protector and starting capacitor.

• Instructions to replace compressor.

• Instructions to replace door.

Page 5

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace LED Power Supply.

1. Unscrew the four

screws that hold

in place the front

grill , using a

Phillips

screwdriver # 2

2. Pull out the front

grill .

3. In order to

remove the

Power Supply,

unscrew the two

screws that hold

it in place using

a Phillips

screwdriver # 2.

4. Disconnect the

Power Supply’s

electrical

connector.

5. To install the new

Power Supply

reverse the

previous steps.

Page 6

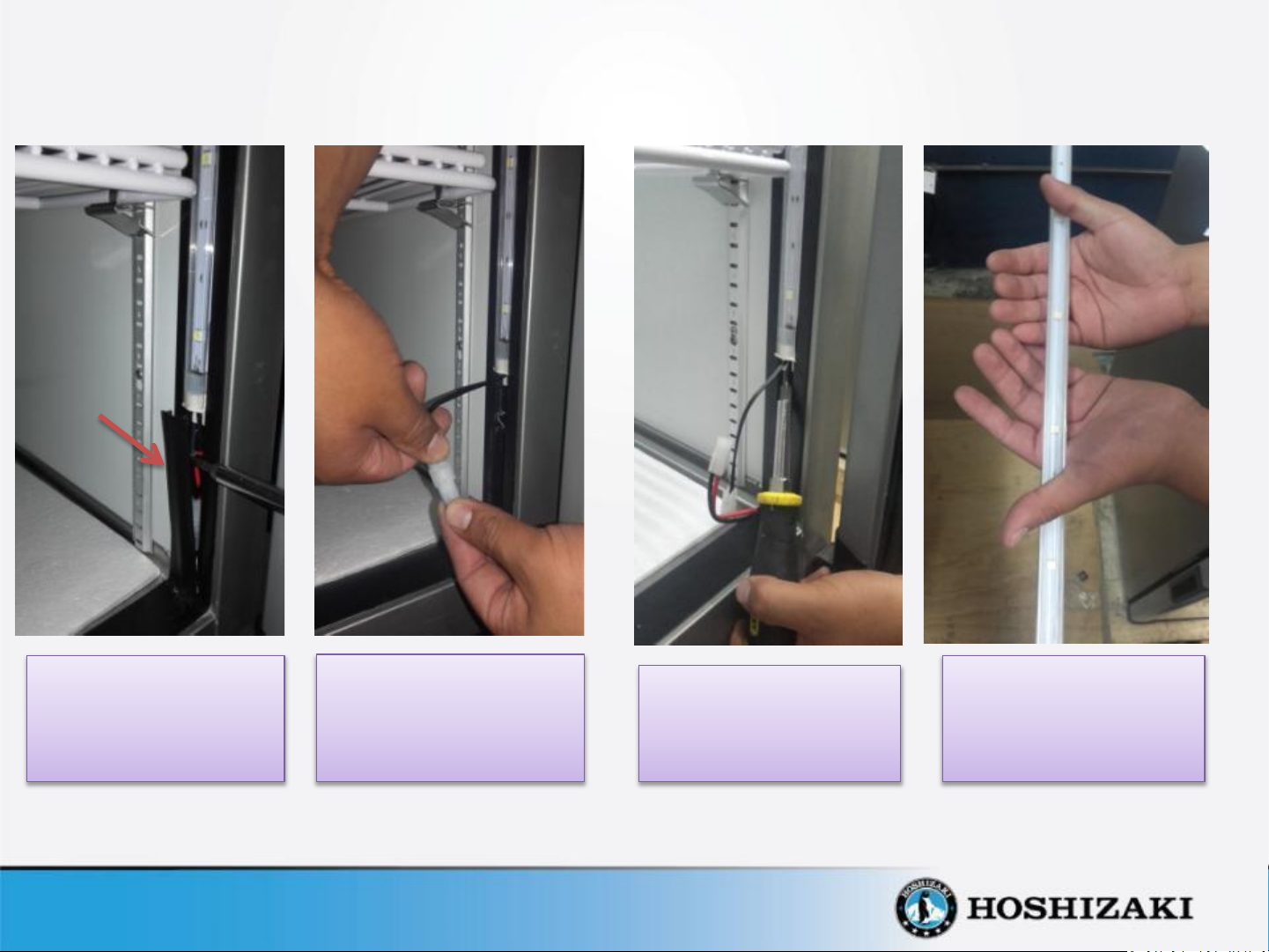

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

LED cover

profile

Instructions to Replace LED Strips.

1. Use a slotted

screwdriver to pull out

the LED cover profile.

2. Disconnect the LED

electrical connector.

3. Use a slotted

screwdriver to pull out

the LED strip.

4. To install the new LED

strip reverse the

previous steps.

Page 7

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Condenser Fan Motor

1. Unscrew the four

screws that hold

in place the front

grill , using a

Phillips

screwdriver # 2

2. Pull out the front

grill .

3. Disconnect the

Tyco electrical

connector of

condensing unit.

4. Remove the two bolts

that hold in place the

rails using a 1/2”

open wrench. These

rails support the

condensing unit.

5. Pull out the

condensing unit

from the base of

the cabinet.

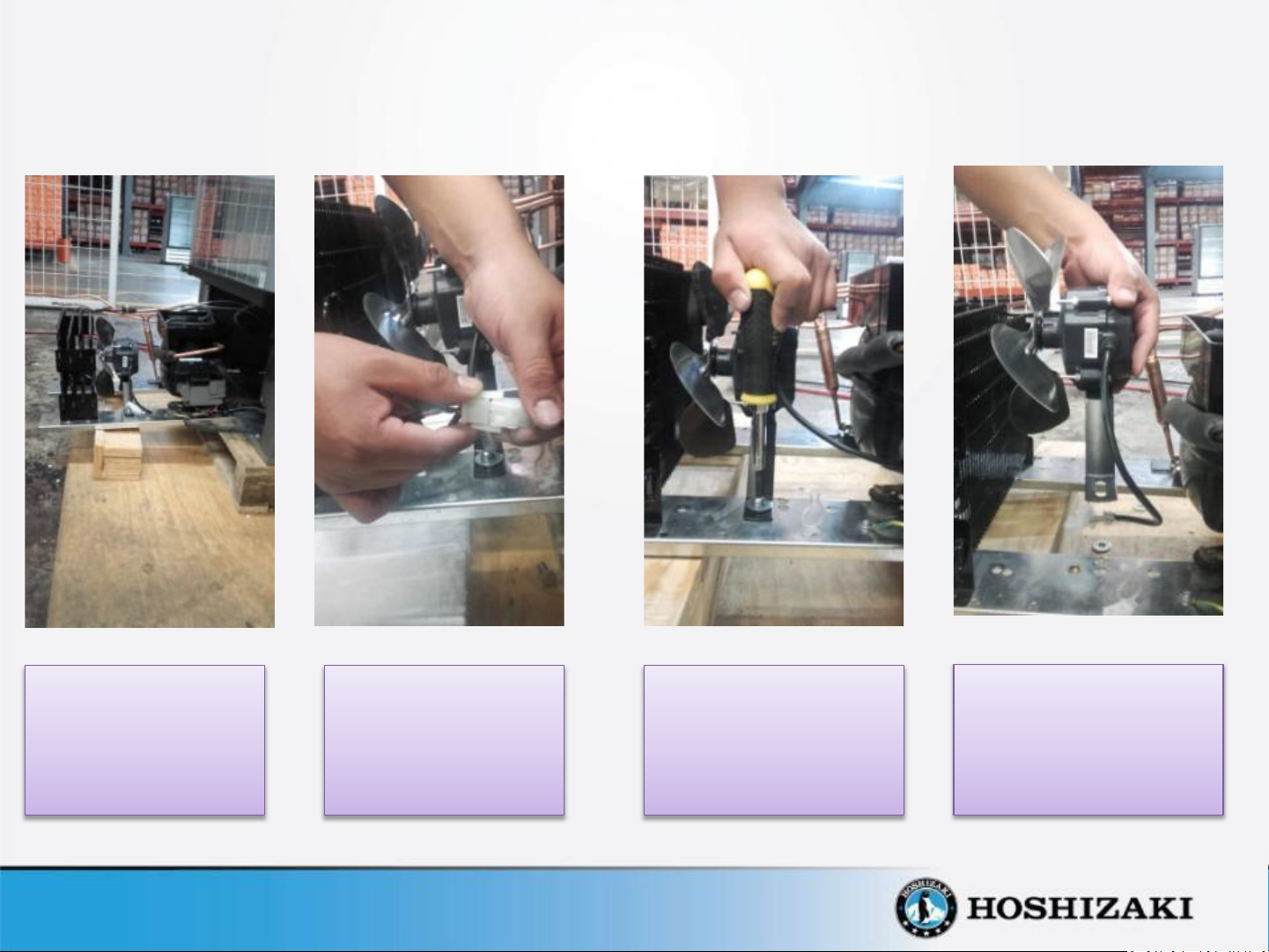

Page 8

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Condenser Fan Motor

6. The condensing unit

can be removed all

the way out for

easier service.

7. Disconnect the Tyco

electrical connector

of the condenser

fan motor.

8. Unscrew the two

screws that hold in

place the base motor

to the rails using a

Phillips screwdriver # 2

9. Remove the condenser

fan motor by pulling it

out

Page 9

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Condenser Fan Motor

10. Remove the bolt that hold in

place the fan blade to the fan

motor using a 9/32” socket

screwdriver.

11. Unscrew the two screws

that hold in place the base

motor to the fan motor

using a 9/32” socket

screwdriver.

12. To install the new

condenser fan motor

reverse the previous steps.

Page 10

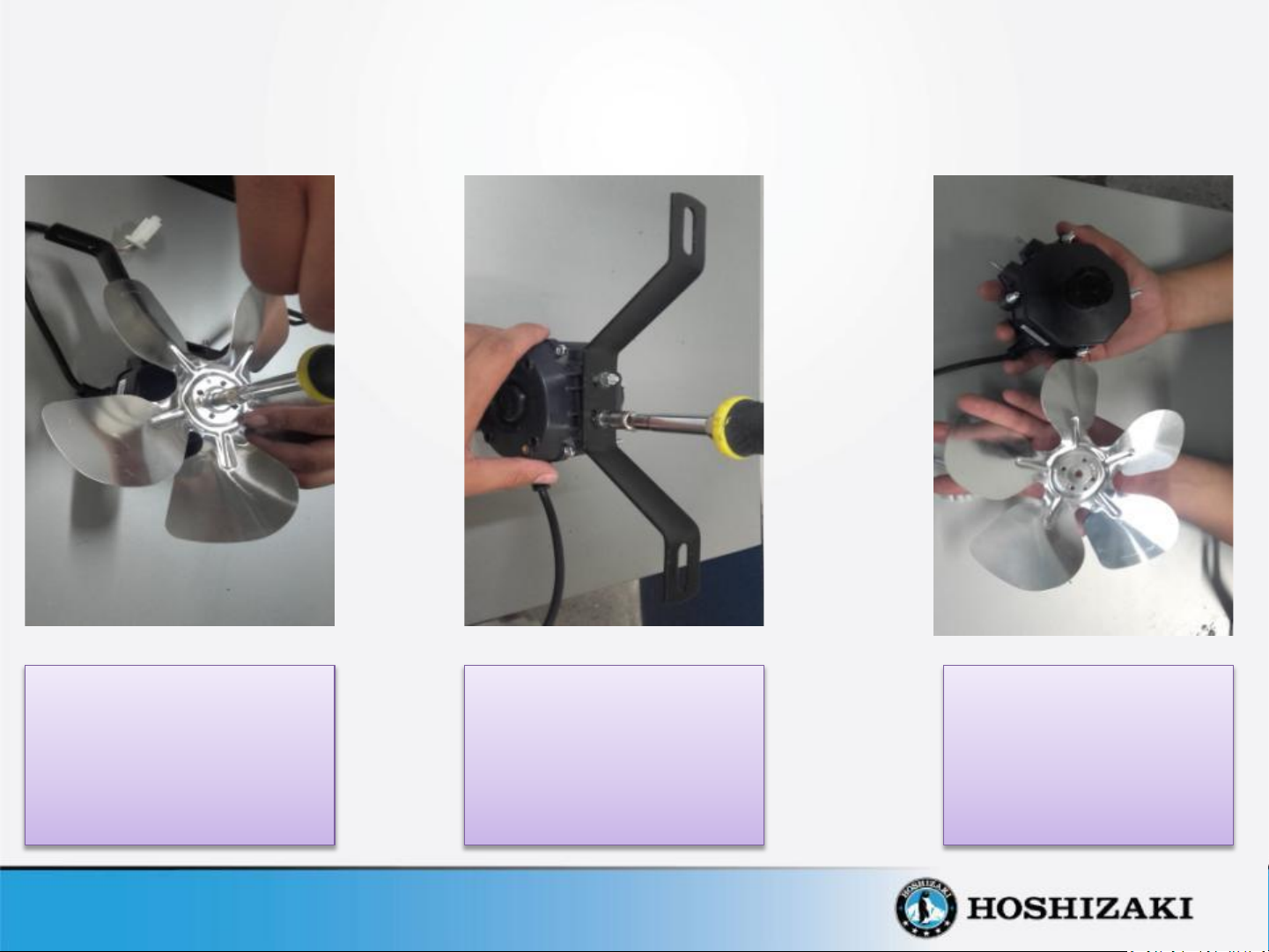

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Fan Guard

Instructions to Replace the Evaporator Fan Motor.

1. Unscrew the four screws that hold in

place the fan guard on the air baffle

using a Phillips screwdriver # 2.

2. Remove the bolt that holds in place

the fan blade to the fan motor

using a 9/32” socket screwdriver.

3. Unscrew the four screws that hold in

place the support base motor to the

top of cabinet using a Phillips

screwdriver # 2.

Page 11

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace the Evaporator Fan Motor.

4. Disconnect the Tyco electrical

connector of the evaporator fan

motor located in the top of cabinet.

5. Unscrew the three screws that hold

in place the support base motor to

the fan motor chassis using a 9/32”

socket screwdriver .

6. To install the new evaporator fan

motor reverse the previous steps.

Page 12

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace The Electronic Thermostat.

1. Remove the front

frame of the

thermostat using

your fingers.

2. Turn 90° both screws to loosen

their cams and the front panel will

detach . Then, proceed to remove

the thermostat from the panel, by

keeping it horizontally.

3. Disconnect the

connectors located

in the back of

thermostat. .

4. To install the new

electronic

thermostat reverse

the previous steps.

Page 13

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to replace Ambient Sensor.

1. Remove the front

frame of the

thermostat using

your fingers.

2. Turn 90° both screws to loosen

their cams and the front panel will

detach . Then, proceed to remove

the thermostat from the panel, by

keeping it horizontally.

3. Disconnect the

connector of the

ambient sensor

located on the back of

the thermostat, shown

in the picture.

4. Unscrew the two screws

that hold the wires in

place of the ambient

sensor using a precision

flat blade slotted

screwdriver.

Page 14

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to replace Ambient Sensor.

5. Unscrew the two screws that hold in

place the light switch support plate on

the baffle using a Phillips screwdriver # 2 .

6. Pull out the ambient sensor from its

plastic clip support.

7. To install the new ambient sensor

reverse the previous steps.

Page 15

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Starting Relay, Overload Protector and Starting Capacitor.

1. Unscrew the four

screws that hold

in place the front

grill using a

Phillips

screwdriver # 2

2. Pull out the front

grill.

3. Disconnect the

Tyco electrical

connector of the

condensing unit.

4. . Remove the two

bolts that hold in

place the rails using a

1/2” open wrench.

These rails support

the condensing unit.

5 Pull out the

condensing unit

from the base of

the cabinet.

Page 16

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Relay, Overload Protector and Starting Capacitor.

.

6. The condensing unit can be

removed all the way out for

easier service.

7. Insert a flat screwdriver in the slot of

the plastic electrical box to remove it

from the compressor. Use the flat

screwdriver as a pry bar to push the

box downward.

8. At the same time that the plastic

electric box is being pushed

downward with the slotted

screwdriver, hold the box with the

other hand and pull it out

downward.

Page 17

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Relay, Overload Protector and Starting Capacitor.

Overload protector

Overload protector

wires connection

Start Relay

LOCATION OF ELECTRICAL CONNECTIONS

Starting Capacitor

Ground wire .

Start Relay wire

connections

Starting capacitor wires

connections

Page 18

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Start Relay, Overload Protector

9. First disconnect the two black wires connecting the

starting capacitor and the blue color wire of the start

relay. Then use a slotted screwdriver as a pry bar to pull

out the relay / overload protector assembly from the

compressor shell.

10. To install the new relay / overload protector assembly

reverse the previous steps.

Page 19

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Starting Capacitor.

11. Use a slotted screwdriver as a pry bar to remove the

starting capacitor from its base: The base of the

capacitor is attached to the top of the electrical plastic

box.

12. Unsolder the terminals of the starting capacitor using a

soldering iron. To install the new starting capacitor

reverse the previous steps.

Page 20

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor

1. Unscrew the four

screws that hold

in place the front

grill using a

Phillips

screwdriver # 2

2. Pull out the front

grill.

3. Disconnect the

Tyco electrical

connector of the

condensing unit.

4. Remove the two bolts

that hold in place the

rails using a 1/2”

open wrench. These

rails support the

condensing unit.

5. Pull out the

condensing unit

from the base of

the cabinet.

Page 21

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

6. The condensing unit can be

removed all the way out for

easier service

7. Use a flat head screwdriver to

unscrew the terminals of the power

cord and electrical harness from the

plastic electrical box.

8. Please review the slides 15 through

19 to remove the relay, overload

protector and starting capacitor.

Page 22

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

9. The first step is to recover all

refrigerant from the system by

installing a piercing valve in the

compressor service tube.

10. Attach the hose of the recovery

machine to the service tubing. Use

an Allen Key Wrench to close the

piercing valve for piercing the

tube and open it to release the

refrigerant.

11. Open Manifold Gauge Pressure

valves and turn on the recovery

machine to recover all the

refrigerant.

Page 23

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

12. Separate the

discharge tubing

from the

compressor

evaporation tray.

13. Use a knife to cut

the double sided

tape that holds in

place the evaporator

tray pan on the

compressor.

14. Warm the brazing of

the discharge and

suction tubes in

order to unsolder

them from the

compressor.

15. To remove the filter

dryer, slowly warm

up the joint of the

capillary tubing with

the filter dryer and

pull them apart by

using pliers.

16. Remove the four

clips, pins and

washers that secure

the compressor to

the base rails.

Page 24

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

17. Remove the

compressor from the

base rails.

18. Not all compressor removal

requires cleaning the low and

high sides of the system.

However, if you suspect that

there are high levels of

contamination, sweep the

system using dry nitrogen at

250 psig.

19. Place the new

compressor on the

base rails

20. Insert the four clips,

pins and washers in

the base of the

compressor to hold it

in place to the base

rails.

Page 25

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

21. Proceed to braze the

service, discharge and

suction tubing.

22. Place double sided tape

in the compressor

evaporation tray pan and

fix it over the compressor

applying slight pressure.

Accommodate the

discharge tubing into the

evaporation tray pan.

23. Follow slides # 15

through #19 to

install the relay,

overload protector

and starting

capacitor.

24. Braze the filter to the

condenser discharge line and to

the capillary tubing.

Do not over heat the body of the

filter and take great care not to

block the capillary tubes with

solder material. The filter dryer

must be installed in a vertical

position with the capillary tube

inlet at the bottom of the filter.

Page 26

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor – Vacuum & Charging the System.

25. Use the Piercing Valve

already installed in the

service tube of the

compressor.

Proceed with the

evacuation and charging

process of the system.

.

26. Attach the hoses of

the manifold gauge to

the vacuum pumps

27. Turn on the vacuum pump to start evacuating the system.

This should take up to 20 minutes for the micron gauge to

reach 200 microns or less. Once this level has been

reached, continue to vacuum for an additional 10 minutes

to assure that non-condensable gases have been removed.

Then, close the manifold gauge valves.

Page 27

DISCONNECT UNIT FROM POWER SUPPLY BEFORE ANY SERVICE

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Compressor.

Instructions to Replace Compressor – Vacuum & Charging the System.

28. After the vacuum process has been finished,

close the valves of the manifold gauges and

proceed to connect the hose from the refrigerant

tank to the service line of the manifold. Open the

low pressure valve as well as the tank valve to

charge the refrigerant. Inject the amount specified

in the serial name plate of R-134a refrigerant into

the refrigeration system.

Wait until the pressure readings of the system have

equalized and then turn on the cooler.

29. Unplug the cooler. Pinch the service tubes using a vise pinch and

proceed to remove the manifold gauges and piercing valve. Check for

refrigerant leaks using a leak detector.

NOTE: To avoid leaks that may originate from Schrader Valves when

installed for service in the future, proceed to pinch off the tubing

using a vise grip and braze it with oxyacetylene welding. Check for

refrigerant leaks using a leak detector in all the soldered joints.

Page 28

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instructions to Replace Door.

1. Use a cordless drill drive with a

Phillips bit # 3 to remove the three

bolts that hold in place the upper

hinge .

2. To remove the door, pull it

upward form the bottom

hinge.

3. To install the new door

reverse the previous steps..

Page 29

Loading...

Loading...