Page 1

Glass Door Merchandiser

Model

RM-10

RM-10

Number: RM-10

Issued: 02-22-2017

Revised: 02-22-2017

Page 2

2

RM-10

Page 3

TABLE OF CONTENTS

Page

UNIT FEATURES 4

CROSS SECTION VIEWS 5

EXPLODED VIEW 6, 7

REFRIGERATION SYSTEM 8, 9

CONDENSING UNIT ASSEMBLY AND ITS COMPONENTS 10, 11

SWING DOOR ASSEMBLY AND ITS COMPONENTS 12, 13

INTERIOR LIGHTING SYSTEM 14, 15

FRONT GRILL ASSEMBLY 16, 17

115V./60Hz./1 PHASE ELECTRICAL WIRING DIAGRAM 18

TROUBLESHOOTING 19, 20, 21

REFRIGERATION SYSTEM 22, 23

- Component description

THE REFRIGERATION CYCLE 24

RM-10

3

Page 4

UNIT FEATURES

Energy saving electronic thermostat

with digital temperature reading

Forced-air evaporator for quick

temperature pull down

Durable PVC frame

Strong body with 1 3/4” thick

walls, injected with

polyurethane foam using

cyclopentane as the blowing

agent earth friendly

Exterior cabinet made of

galvanized, pre-painted steel,

with baked polyester paint

Heavy duty hinges

Double-pane Low-E glass

door for high ambient

condition

Interior lighting LED lamp strip

NSF compliant interior

cabinet

Reinforced heavy

duty shelves

Heavy duty R-134a

condensing unit with

easy access for

maintenance

4

Lint free

condenser

Reinforced, 16 gauge,

galvanized, steel base

RM-10

Page 5

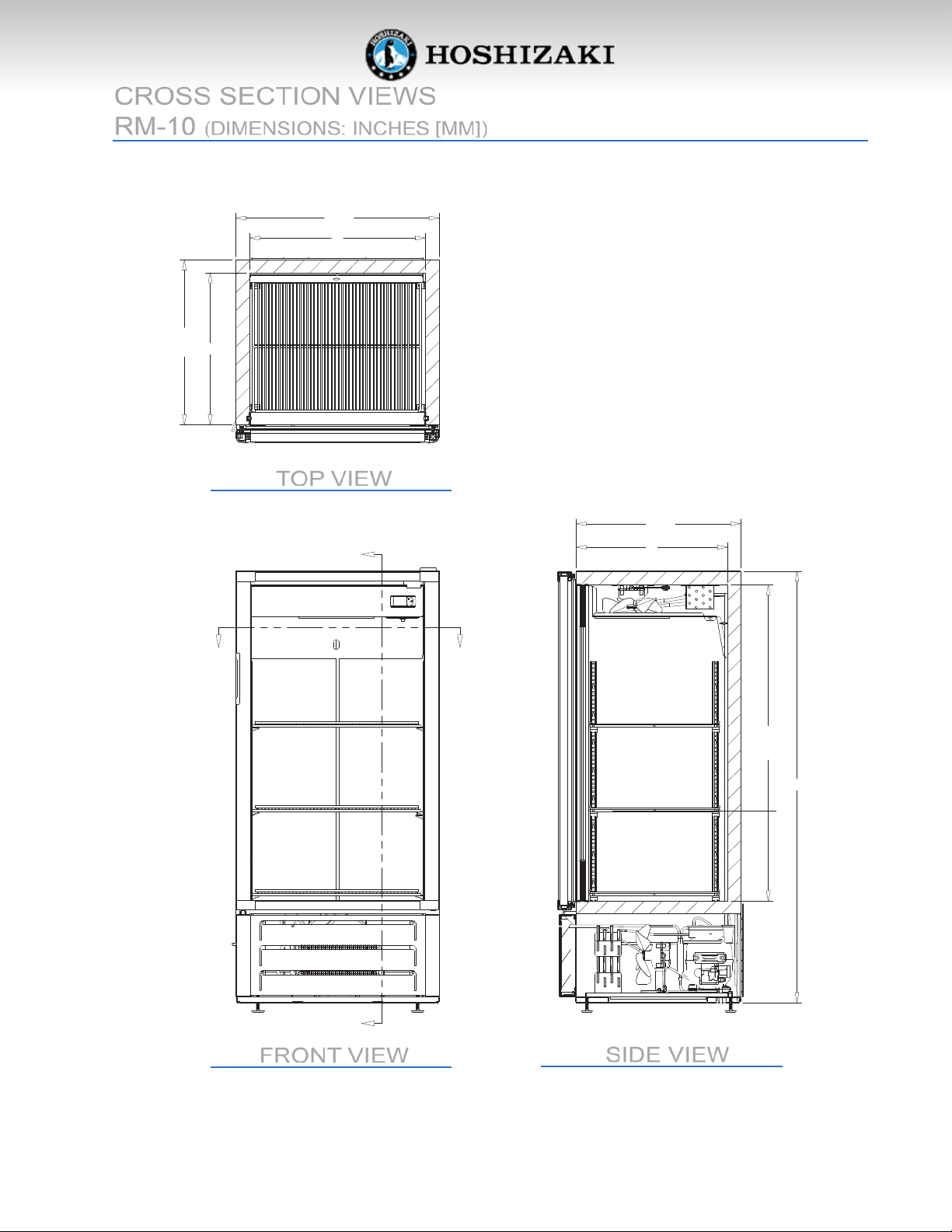

CROSS SECTION VIEWS

RM-10 (DIMENSIONS: INCHES [MM])

25 1/2

22

8

/

5

9

0

1

2

TOP VIEW

B

20 5/8

19

A

FRONT VIEW

A

6

1

/

9

9

3

4

5

B

SIDE VIEW

RM-10

5

Page 6

6

8

1

3

1

0

1

3

2

5

1

1

1

2

9

7

4

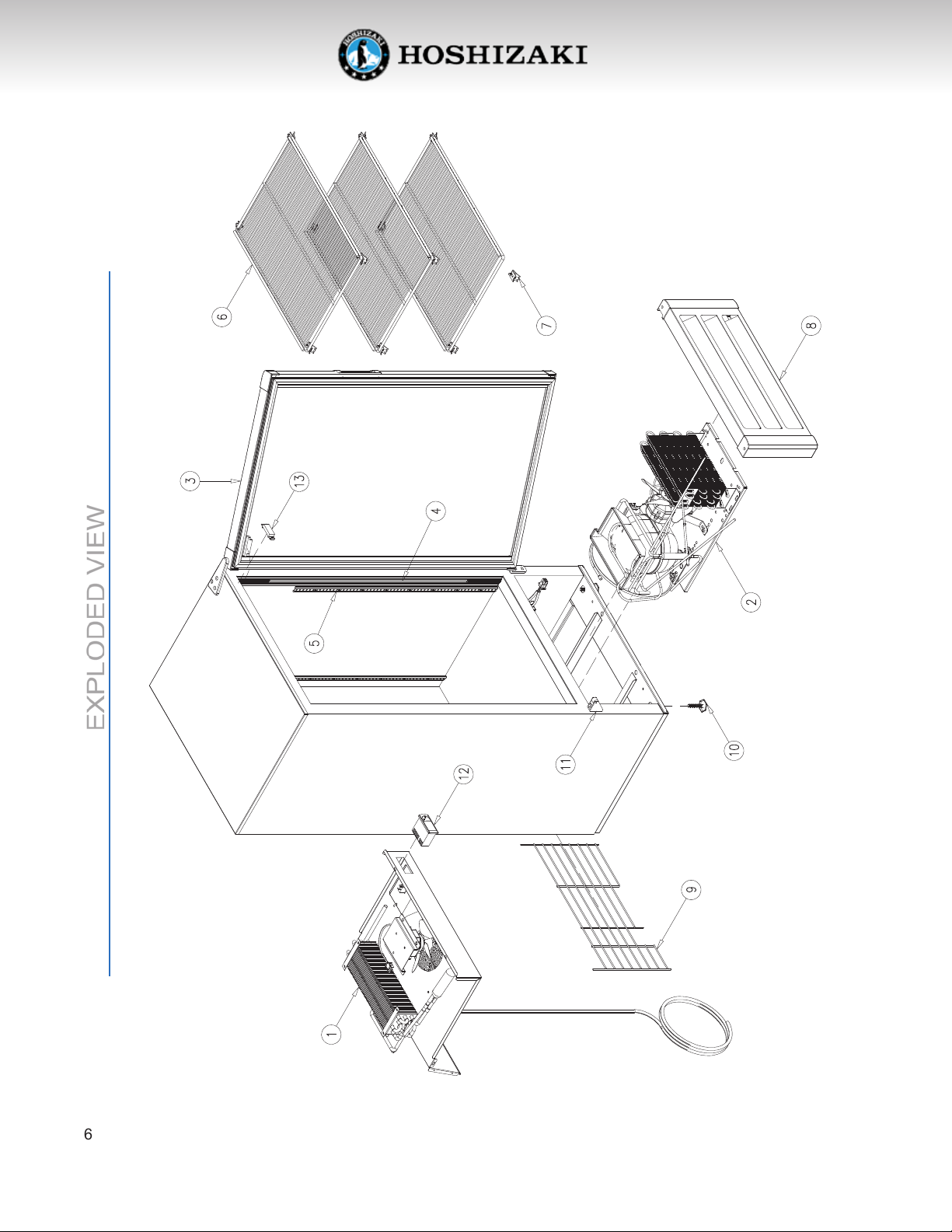

EXPLODED VIEW

6

RM-10

Page 7

EXPLODED VIEW

Quantity

Item No. Description Part No. per cooler

1 REFRIGERATION SYSTEM See pages 8 &9 1

2 COMPLETE 1/5HP 115V/60HZ CONDENSING UNIT EMY70HER-R 1

3 COMPLETE DOOR OT-PTA-RM10 1

4 INTERIOR LIGHTING SYSTEM See pages 14 & 15

5 PILASTER 30” PI-73 4

6 FLAT SHELF SH-0078-4-HD-FE 3

7 SHELF CLIPS CL-51-SS-E 12

8 FRONT GRILL EN-2334 1

9 BACK GRILL SH-0173-G-B 1

10 LEVELING LEGS LG-27 4

11 DOOR SUPPORT HA-200 1

12 ENERGY SAVING ELECTRONIC THERMOSTAT CT-185-CA 1

13 MAGNETIC SWITCH EL-360-C 1

RM-10

7

Page 8

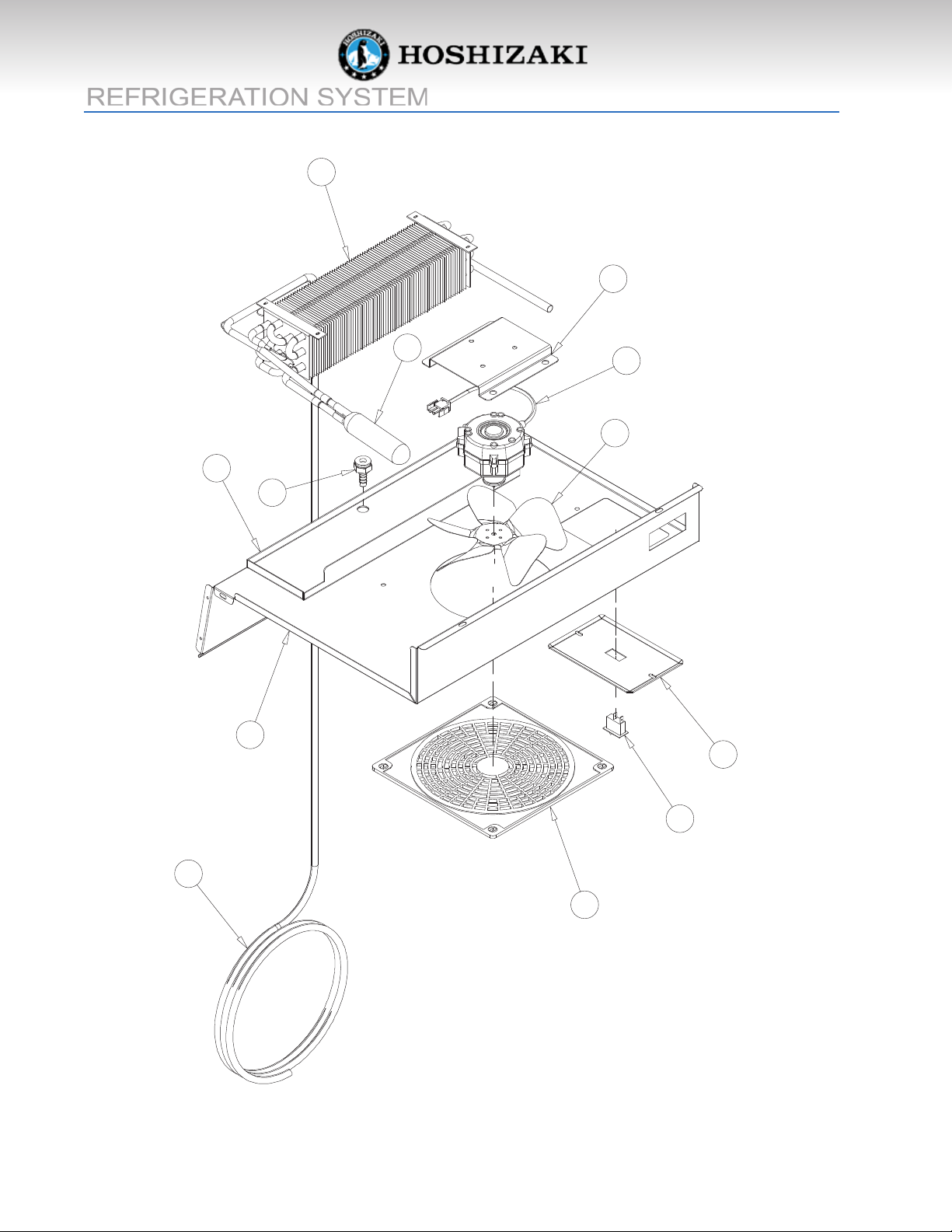

REFRIGERATION SYSTEM

1

6

5

2

7

8

10

4

12

11

3

9

8

RM-10

Page 9

REFRIGERATION SYSTEM

Quantity

Item No. Description Part No. per cooler

1 EVAPORATOR CO-325 1

2 ACCUMULATOR DR-19-C 1

3 HEAT EXCHANGER TUB-0138 1

4 BAFFLE OT-19439 1

5 EVAPORATOR PAN OT-8776 1

6 EVAPORATOR FAN MOTOR BRACKET OT-8916 1

7 EVAPORATOR FAN MOTOR FA-41 1

8 EVAPORATOR FAN BLADE FA-2-EBM 1

9 FAN GUARD FA-62 1

10 PLASTIC DRAIN DR-1-P 1

11 LIGHT SWITCH EL-303-E 1

12 SWITCH BRACKET OT-9981 1

RM-10

9

Page 10

CONDENSING UNIT ASSEMBLY AND ITS COMPONENTS

3

8

5

2

1

7

10

1

2

11

6

9

4

10

RM-10

Page 11

CONDENSING UNIT ASSEMBLY AND ITS COMPONENTS

Quantity

Item No. Description Part No. per cooler

1 1/5HP 115V/60HZ COMPRESSOR EMY70HER 1

2 4TM762MFBZZ-53 OVERLOAD PROTECTOR EL-1989-R 1

3 21351500-7 RELAY EL-1990-R 1

4 ELECTRICAL BOX EL-1991-R 1

5 270-324 µF START CAPACITOR CAP-270-324-K 1

6 CONDENSER CO-452 1

7 CONDENSER FAN MOTOR FA-41 1

8 CONDENSER FAN BLADE FA-2-EBM 1

9 CONDENSER FAN MOTOR BRACKET FA-39 1

10 DRIER DR-31-C 1

11 COMPRESSOR EVAPORATION TRAY DP-4 1

12 POWER CORD EL-1265-9 1

RM-10

11

Page 12

SWING DOOR ASSEMBLY AND ITS COMPONENTS

3

6

2

5

7

12

1

RM-10

4

Page 13

SWING DOOR ASSEMBLY AND ITS COMPONENTS

Quantity

Item No. Description Part No. per cooler

1 GLASS PANE GL-675-AD-E 1

2 MAGNETIC GASKET TPE GA-313-B 1

3 UPPER HINGE ASSEMBLY HA-496-R 1

4 LOWER HINGE ASSEMBLY HA-535-R 1

5 TORSION MECHANISM HA-479 1

6 MAGNETIC SWITCH EL-360-D 1

7 DOOR HANDLE OT-HA-627 1

RM-10

13

Page 14

INTERIOR LIGHTING SYSTEM

1

2

3

14

RM-10

Page 15

INTERIOR LIGHTING SYSTEM

Quantity

Item No. Description Part No. per cooler

1 29 1/2” LED LAMP STRIP EL-147 2

2 4 7/8” LED PROFILE COVER OT-BR-253-57-4.875 4

3 1.25 Amp. LED POWER SUPPLY OT-EL-151-T 1

RM-10

15

Page 16

FRONT GRILL ASSEMBLY

3

9

2

1

5

9

7

4

8

6

3

16

RM-10

Page 17

FRONT GRILL ASSEMBLY

Quantity

Item No. Description Part No. per cooler

1 FRONT GRILL LEFT PROFILE PL-634-GREY-10.125 1

2 FRONT GRILL OT-19438 1

3 FRONT GRILL CORNER B PL-633-A 2

4 FRONT GRILL CORNER A PL-632-A 1

5 FRONT GRILL CORNER C PL-632-B 1

6 FRONT GRILL RIGHT PROFILE PL-634-GREY-10.125 1

7 FRONT GRILL REINFORCEMENT OT-18183 1

8 FRONT GRILL REINFORCEMENT OT-18002 3

9 FRONT GRILL REINFORCEMENT OT-19437 2

RM-10

17

Page 18

115 V./60 Hz./1 PHASE ELECTRICAL WIRING DIAGRAM

18

RM-10

Page 19

TROUBLESHOOTING

Possible causes and solutions

PROBLEM POSSIBLE CAUSE SOLUTION

COMPRESSOR NO VOLTAGE IN THE ELECTRICAL USE A VOLTMETER TO

WILL NOT START SOCKET CHECK THE VOLTAGE

THE ELECTRICAL CONDUCTOR USE AN OHMMETER,

OR WIRES MAY BE CUT TO CHECK FOR CONTINUITY

DEFECTIVE ELECTRICAL REPLACE DEFECTIVE

COMPONENTS SUCH AS: COMPONENTS

THERMOSTAT, RELAY, THERMAL

PROTECTOR, ETC.

COMPRESSOR MOTOR HAS A MEASURE THE OHMIC

WINDING OPEN OR SHORTED RESISTANCE OF THE MAIN AND

AUXILIARY WINDINGS USING AN

OHMMETER. COMPARE THEM WITH

THE CORRECT VALUES

DIRTY CONDENSER, LACK OF AIR CLEAN CONDENSER AND

FLOW ALLOW FOR AIR CIRCULATION

LOW VOLTAGE USE A VOLTAGE REGULATOR IF

THE VOLTAGE IS LOWER THAN

100 VOLTS

COMPRESSOR IS STUCK CHANGE THE COMPRESSOR

THE TEMPERATURE THERMOSTAT DOES NOT DISCONNECT CHECK THE INSTALLATION OF THE

IS TOO COLD THE CONDENSING UNIT THERMOSTAT. IF THE PROBLEM

PERSISTS, CHANGE THE THERMOSTAT

THERMOSTAT’S AMBIENT SENSOR IS CORRECTLY FASTEN THE

LOOSE OR INSTALLED IMPROPERLY THERMOSTAT’S AMBIENT SENSOR

THE TEMPERATURE CONDENSER IS DIRTY; LACK OF AIR CLEAN THE CONDENSER AND

IS NOT COLD ENOUGH FLOW ALLOW FOR AIR CIRCULATION

RM-10

19

Page 20

PROBLEM POSSIBLE CAUSE SOLUTION

THE TEMPERATURE THE REFRIGERATOR HAS BEEN THE UNIT MUST NOT BE NEAR

IS NOT COLD ENOUGH PLACED AT AN INADEQUATE STOVES, WALLS THAT ARE

LOCATION EXPOSED TO THE SUN, OR PLACES

THAT LACK SUFFICIENT AIR FLOW

THE REFRIGERATOR HAS BEEN USED THE SHELVES MUST NEVER BE

IMPROPERLY COVERED WITH ANY TYPE OF PLASTIC OR

OTHER MATERIAL THAT WILL BLOCK THE

CIRCULATION OF COLD AIR WITHIN THE

REFRIGERATOR

THE REFRIGERATOR HAS BEEN CHECK TO SEE IF CONDENSATION

OVERCHARGED WITH THE OR ICE CRYSTALS HAVE FORMED

REFRIGERANT GAS ON THE SUCTION LINE. IF SO, CHARGE

WITH THE CORRECT AMOUNT OF GAS

THE REFRIGERANT GAS IS LEAKING FIND THE LOCATION WHERE THE GAS IS

LEAKING IN ORDER TO SEAL IT OR

REPLACE THE DEFECTIVE COMPONENT.

CHANGE THE DRIER. PERFORM A GOOD

VACUUM AND RECHARGE THE UNIT

THE EVAPORATOR AND/OR CHECK THE ELECTRICAL CONNECTIONS

CONDENSER FANS AREN’T WORKING AND MAKE SURE THAT THE FAN BLADE

ISN’T STUCK. REPLACE THE FAN MOTOR

IF IT DOESN’T WORK

LOW VOLTAGE USE A VOLTAGE REGULATOR IF THE

VOLTAGE IS LOWER THAN 100 VOLTS

ELECTRICAL SHOCKS WIRES OR ELECTRICAL COMPONENTS CHECK FOR APPROPRIATE INSULATION ON

ARE IN DIRECT CONTACT WITH THE CONNECTIONS OF EACH ELECTRICAL

METALLIC PARTS COMPONENT

NOISE THE REFRIGERATOR IS NOT CHECK IF THE NOISE GOES

PROPERLY LEVELED AWAY AFTER YOU LEVEL THE

REFRIGERATOR

THE CONDENSER IS NOT FASTENED WHILE THE COMPRESSOR IS WORKING,

CORRECTLY. COPPER TUBINGS CHECK TO SEE IF METAL PARTS ARE IN

ARE IN CONTACT WITH METAL CONTACT WITH ONE ANOTHER AND/OR

IF THE SCREWS THAT FASTEN THE

CONDENSER ARE TIGHTENED

THE EVAPORATOR AND/OR CHECK IF THE FANS ARE SECURELY

CONDENSER FANS ARE LOOSE FASTENED. ALSO, CHECK IF THE

FAN BLADES ARE LOOSE, BROKEN

OR CROOKED. IF SO, CHANGE THE

FAULTY BLADE

COMPRESSOR HAS AN INTERNAL IF THE NOISE PERSISTS AFTER

NOISE ALL OTHER MEASURES HAVE BEEN

TAKEN, IT MAY BE ORIGINATING FROM

THE COMPRESSOR

20

RM-10

Page 21

PROBLEM POSSIBLE CAUSE SOLUTION

EXTREME CONDENSATION THERMOSTAT’S AMBIENT SENSOR IS CORRECTLY FASTEN THE

INSIDE THE REFRIGERATOR LOOSE OR INSTALLED IMPROPERLY THERMOSTAT’S AMBIENT SENSOR

THE OUTSIDE ENVIRONMENT’S THIS TYPE OF OCCURRENCE IS

RELATIVE HUMIDITY IS VERY HIGH CAUSED BY LOCAL CLIMATIC

(OVER 75%) CONDITIONS AND NOT BY THE

REFRIGERATED UNIT

THE REFRIGERATOR DOOR WON’T CHECK THE DOOR AND/OR THE

SHUT COMPLETELY MAGNETIC GASKET. ADJUST THE

DOOR HINGES IF NEEDED; REPLACE

THE GASKET IF BROKEN

THE REFRIGERATOR HAS BEEN THE UNIT MUST NOT BE NEAR

PLACED AT AN INADEQUATE SOURCES THAT PRODUCE

LOCATION TOO MUCH HEAT

NO ILLUMINATION THE LIGHT SWITCH IS IN “OFF” PRESS THE LIGHT SWITCH

POSITION TO THE “ON” POSITION

FALSE CONTACT ON THE LIGHT INSPECT ALL CONNECTIONS

SWITCH OR LED

LIGHT SWITCH OR LED ARE DAMAGED REPLACE THE DAMAGED COMPONENT

THE THERMOSTAT IS SET TO OPERATE SET THE THERMOSTAT IN NORMAL

IN ENERGY SAVING MODE OPERATION MODE

RM-10

21

Page 22

REFRIGERATION SYSTEM

Component Description

COMPRESSOR:

The compressor is a factory sealed unit located

underneath (outside) the cooling cabinet. This

pump is activated by a motor which draws low

pressure vapor (refrigerant) from the evaporator.

It then compresses the gas and forces it into the

condenser at a high pressure.

situation, if the compressor overheats or if the

voltage source varies drastically, the thermal

protector opens, turning o the compressor. After

the compressor cools down to a normal and safe

working temperature, the thermal protector turns

on the compressor.

STARTER RELAY:

The starter relay is attached on one side of the

compressor box. The compressor motor has two

windings: one for starting and another for running.

In order to provide for the necessary additional

torque when the motor is rst ignited, the starter

relay connects the additional start-up windings. After the motor reaches its correct operating speed,

the relay opens the ignition windings and the motor

carries on with the operation windings.

THERMAL PROTECTOR:

This protector is a thermo-sensible device attached

to one side of the compressor’s box. In any given

EVAPORATOR CONDENSER

CAPILLARY

CONDENSER:

The condenser is located underneath (outside)

the cooling cabinet in front of the compressor. Its

receives hot, high pressure refrigerant gas from

the compressor, and cools it down until it returns

to liquid state.

CONDENSER FAN MOTOR:

The condenser fan motor is located underneath

the cooling cabinet. It is a ventilation device which

forces the ambient air to ow over the condenser in

order to cool down the refrigerant owing inside it.

The fan motor works only if the compressor is on.

DRIER

22

EVAPORATOR

FAN MOTOR

ACCUMULATOR

SUCTION

COMPRESSOR

RM-10

DISCHARGE

LEGEND

CONDENSER

FAN MOTOR

GAS

FLOW

Page 23

REFRIGERATION SYSTEM

Component Description

EVAPORATOR:

The evaporator is located inside the cooling

cabinet. As the gas ows at a low pressure through

the evaporator, it absorbs serpentine and removes

the heat from inside the cabinet.

EVAPORATOR FAN MOTOR:

This device produces the required circulation of

air through the cooling cabinet as well as over the

surface of the evaporator’s serpentine thermal

exchange area. This fan motor runs continuously.

The evaporator and condenser serpentines have

aluminum ns that help increase the surfaces for

the thermal exchange in an ecient way.

CAPILLARY TUBE:

It consist of several feet of tubing having a small

inside diameter. It is a device used to control

the amount od refrigerant that flows into the

evaporator.

DRIER:

The drier is located in between the condenser and

the evaporator. It traps and removes moisture

in the refrigeration system while allowing oil and

refrigerant to ow freely.

ENERGY SAVING ELECTRONIC

THERMOSTAT:

The electronic thermostat is responsable for

detecting temperature changes inside the cabinet.

It starts the compressor whenever the cabinet

temperature rises above the desired temperature.

The compressor recirculates the refrigerant

throughout the system, lowering the temperature

inside the cooling compartment. When the

temperature drops to the set point programmed

in the thermostat, it turns o the compressor and

a new cycle starts again.

This electronic thermostat contains a dispositive

to save energy when the sales of the day are

over. This dispositive is activated by pressing the

“Energy Saving” button of the thermostat. When

this button is pressed, the lights are turned o

and the refrigerator starts operating in a warmer

temperature setting, consuming less energy.

COOLING CABINET:

This is the area where the goods are stored. It

has been designed to allow for constant cold air

circulation to ow through the goods.

ACCUMULATOR:

The accumulator is located in between the

evaporator and the compressor. It is a storage

tank which receives refrigerant liquid from the

evaporator and prevents it from owing into the

compressor.

RM-10

23

Page 24

THE REFRIGERATION CYCLE

1. As the temperature inside the cooling compartment increases, it is detected by the thermostats’

sensor. The thermostat then turns the compressor and the condenser motor on once the

programmed temperature is reached.

2. The compressor recirculates the refrigerant throughout the system by drawing the refrigerant gas

at a low vapor pressure from the evaporator. Then it compresses the refrigerant and forces it

into the condenser.

3. The condenser, with the help of its fan motor, removes the refrigerants’ heat as its ows through

the condenser. The heat is then released to the outside environment. Consequently, the decrease

in temperature will change the refrigerant from a gaseous to a liquid state.

4. The capillary tube regulates the amount of refrigerant that is discharged into the evaporator and

expands it. This expansion causes the refrigerant temperature to decrease.

5. The evaporators' serpentine allows the refrigerant to absorb and remove heat from the cooling

compartment.

6. The drop in temperature inside the cooling compartment is caused by the refrigerant’s continuous

circulation through the system. This gas continuously absorbs the heat that exists inside the

cooling compartment and expels it to the outside environment. When the temperature drops to

its programmed set point, it is detected by the thermostat and it turns o the compressor and

condenser motor.

24

RM-10

Page 25

1Axxxx-010

Loading...

Loading...