Hoshizaki KM-500MAH, KM-500MWH, KM-500MRH Manuel de service

Reliability is a

beautiful thing

TM

MODULAR CRESCENT CUBER

KM-500MAH

KM-500MWH

SERVICE MANUAL

KM-500MRH

™

NUMBER:

ISSUED:

REVISED:

73104

NOV. 7, 2002

DEC. 16, 2003

IMPORTANT

Only qualified service technicians should attempt to service or maintain this icemaker.

No service or maintenance should be undertaken until the technician has thoroughly

read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City , GA 30269

Attn: HOSHIZAKI T echnical Support Department

Phone: 1-800-233-1940 T echnical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: T o expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

• Please review this manual. It should be read carefully before the icemaker is serviced

or maintenance operations performed. Only qualified service technicians should service

and maintain the icemaker. This manual should be made available to the technician

prior to service or maintenance.

CONTENTS

PAGE

I. SPECIFICATIONS...................................................................................................... 5

1. KM-500MAH (Air-cooled)..................................................................................... 5

2a. KM-500MWH (Water-cooled) Serial #L00001D - M20960C .............................. 6

2b. KM-500MWH Serial #M30961D ........................................................................ 7

3. KM-500MRH (Remote air-cooled)........................................................................ 8

4. CONDENSER UNIT, URC-6F.............................................................................. 9

II. GENERAL INFORMATION ...................................................................................... 11

1. CONSTRUCTION............................................................................................... 11

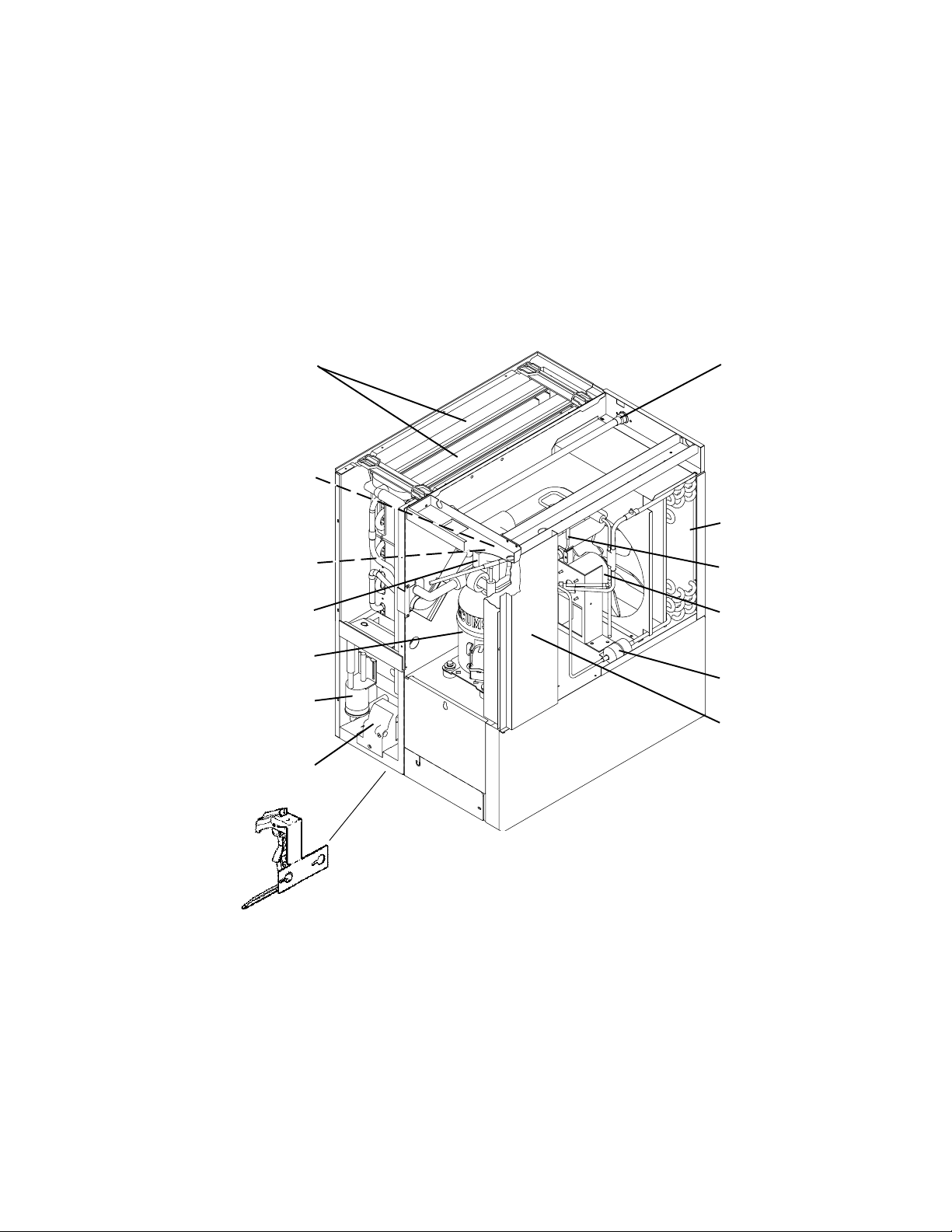

[a] KM-500MAH (Air-cooled)............................................................................. 11

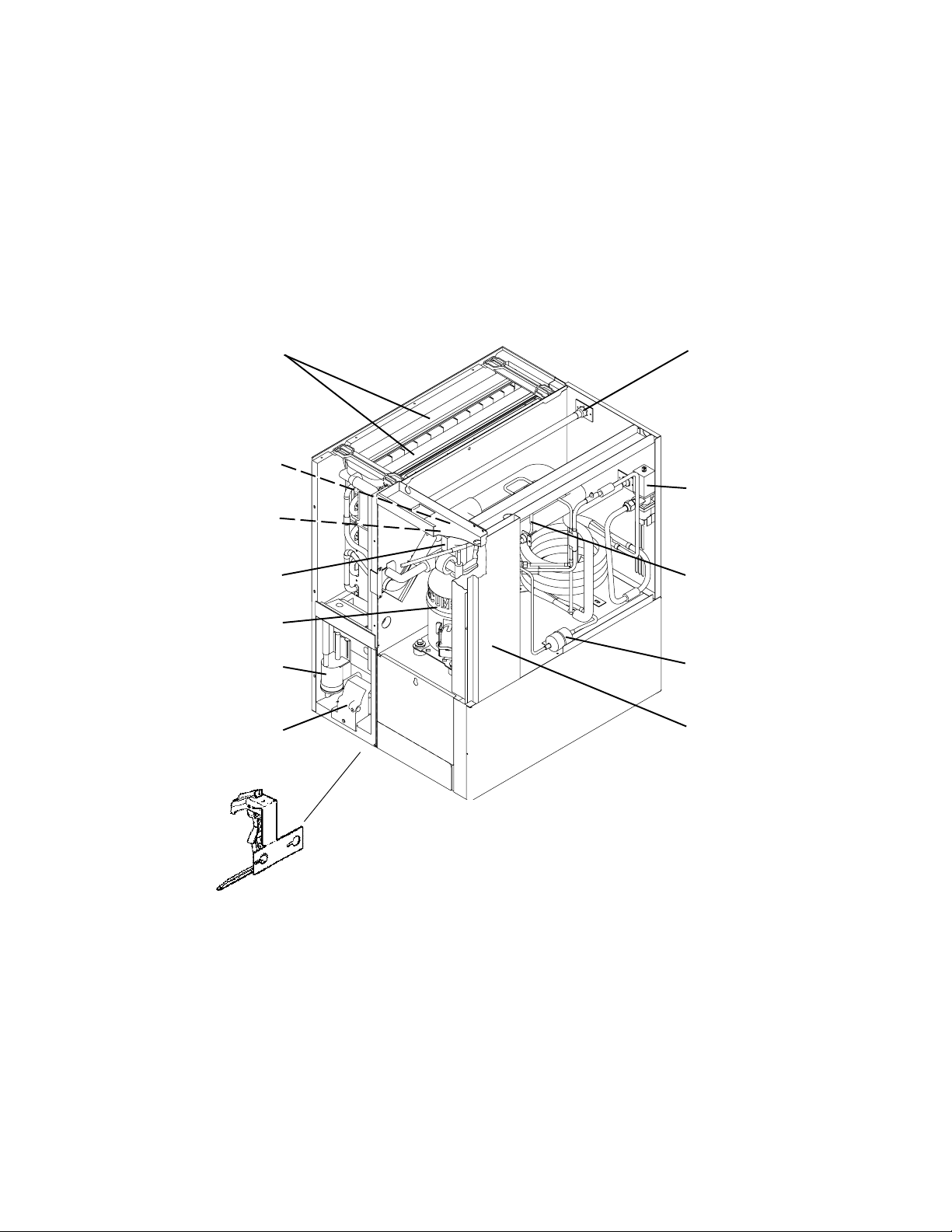

[b] KM-500MWH (Water-cooled)....................................................................... 12

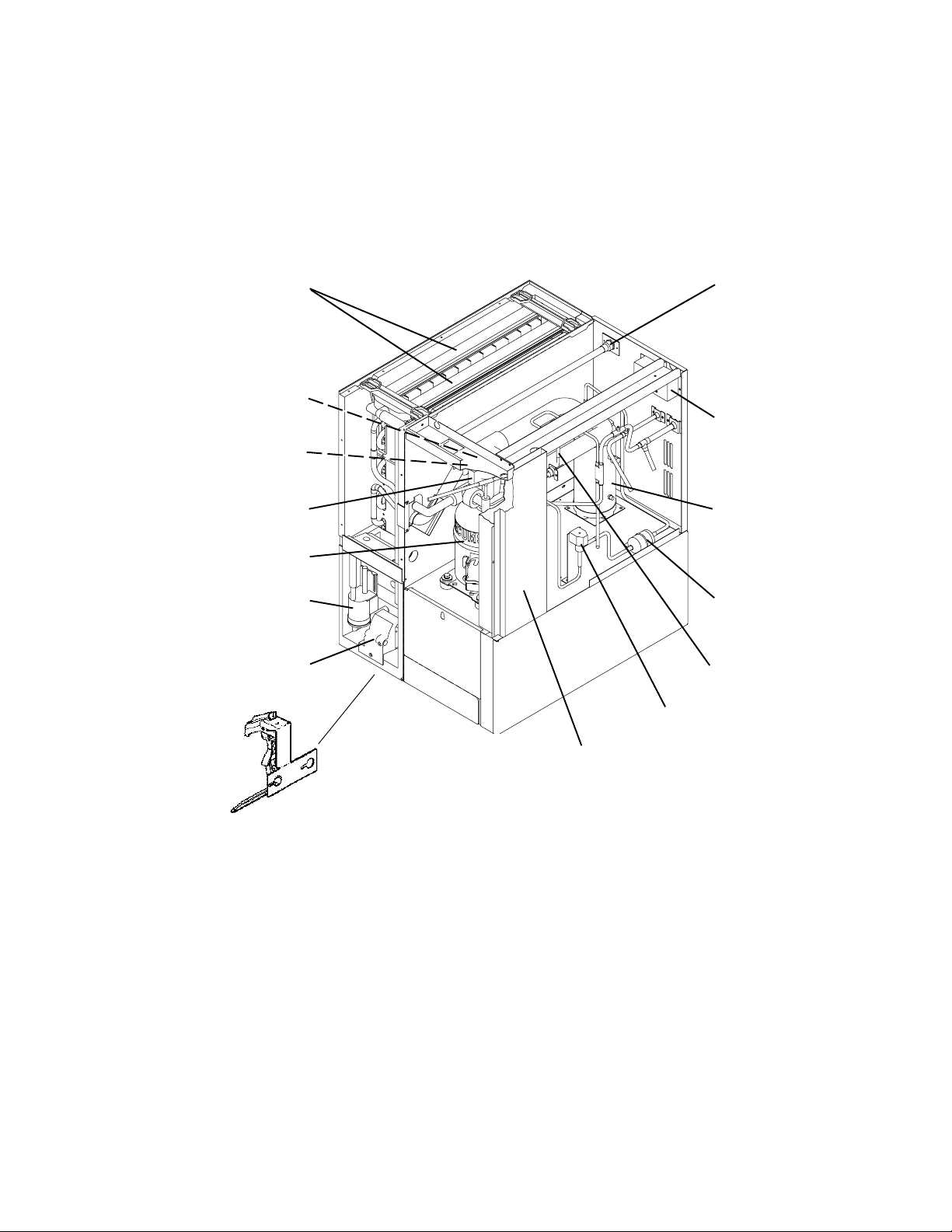

[c] KM-500MRH (Remote air-cooled) ................................................................ 13

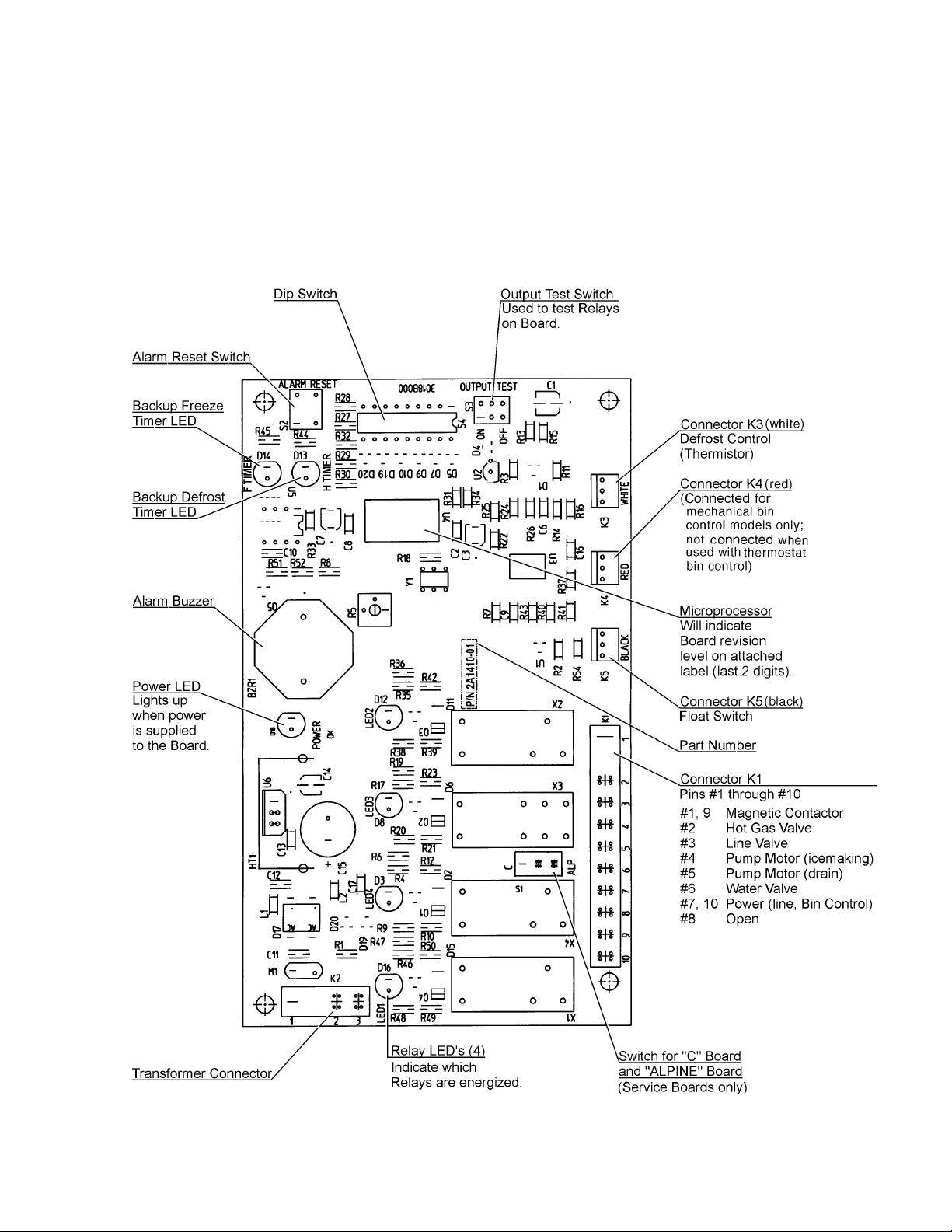

2. CONTROLLER BOARD..................................................................................... 14

[a] SOLID-STATE CONTROL ........................................................................... 14

[b] CONTROLLER BOARD............................................................................... 14

[c] SEQUENCE ................................................................................................ 18

[d] CONTROLS AND ADJUSTMENTS ............................................................. 20

[e] CHECKING CONTROLLER BOARD ........................................................... 24

3. MECHANICAL BIN CONTROL........................................................................... 26

[a] PROXIMITY SWITCH ................................................................................... 26

[b] EXPLANATION OF OPERATION................................................................ 26

[c]

TROUBLESHOOTING ................................................................................. 27

III. TECHNICAL INFORMATION .................................................................................. 28

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT .............................................. 28

[a] KM-500MAH ................................................................................................ 28

[b] KM-500MWH ............................................................................................... 29

[c] KM-500MRH ................................................................................................ 30

2. WIRING DIAGRAMS .......................................................................................... 31

[a] KM-500MAH and KM-500MWH ................................................................... 31

[b] KM-500MRH ................................................................................................ 33

3. TIMING CHART.................................................................................................. 35

4. PERFORMANCE DATA .................................................................................... 37

[a] KM-500MAH ................................................................................................ 37

[b] KM-500MWHSerial #L00001D - M20960C.................................................. 38

[c]

KM-500MWH Serial #M30961D .................................................................. 39

[d] KM-500MRH ................................................................................................ 40

3

IV. SERVICE DIAGNOSIS ...........................................................................................41

1. NO ICE PRODUCTION.........................................................................................41

2. EVAPORATOR IS FROZEN UP ..........................................................................42

3. LOW ICE PRODUCTION......................................................................................42

4. ABNORMAL ICE ..................................................................................................45

5. OTHERS .............................................................................................................. 45

V. REMOVAL AND REPLACEMENT OF COMPONENTS............................................46

1. SERVICE FOR REFRIGERANT LINES ..............................................................46

[a] REFRIGERANT RECOVERY........................................................................46

[b] EVACUATION AND RECHARGE.................................................................. 46

2. BRAZING.............................................................................................................47

3. REMOVAL AND REPLACEMENT OF COMPRESSOR .......................................48

4. REMOVAL AND REPLACEMENT OF DRIER .....................................................50

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE ............................... 50

6. REMOVAL AND REPLACEMENT OF HOT GAS VALVE AND ...............................

LINE VALVE........................................................................................................51

7. REMOVAL AND REPLACEMENT OF EVAPORATOR ........................................52

8. REMOVAL AND REPLACEMENT OF WATER-REGULATING VALVE ..................

- WATER COOLED MODEL ONLY.....................................................................54

9. ADJUSTMENT OF WATER-REGULATING VALVE ................................................

- WATER COOLED MODEL ONLY.....................................................................55

10. REMOVAL AND REPLACEMENT OF CONDENSING PRESSURE ........................

REGULATOR (C.P.R.) - REMOTE AIR-COOLED MODEL ONLY .......................56

11. REMOVAL AND REPLACEMENT OF THERMISTOR.......................................... 57

12. REMOVAL AND REPLACEMENT OF FAN MOTOR ............................................58

13. REMOVAL AND REPLACEMENT OF WATER VALVE........................................59

14. REMOVAL AND REPLACEMENT OF PUMP MOTOR .........................................59

15. REMOVAL AND REPLACEMENT OF SPRAY TUBES ........................................60

VI. CLEANING AND MAINTENANCE INSTRUCTIONS...............................................61

1. PREPARING THE ICEMAKER FOR LONG STORAGE ......................................61

2. CLEANING AND SANITIZING PROCEDURES...................................................63

[a] CLEANING PROCEDURE .............................................................................64

[b] SANITIZING PROCEDURE ...........................................................................66

3. MAINTENANCE....................................................................................................67

4

I. SPECIFICATIONS

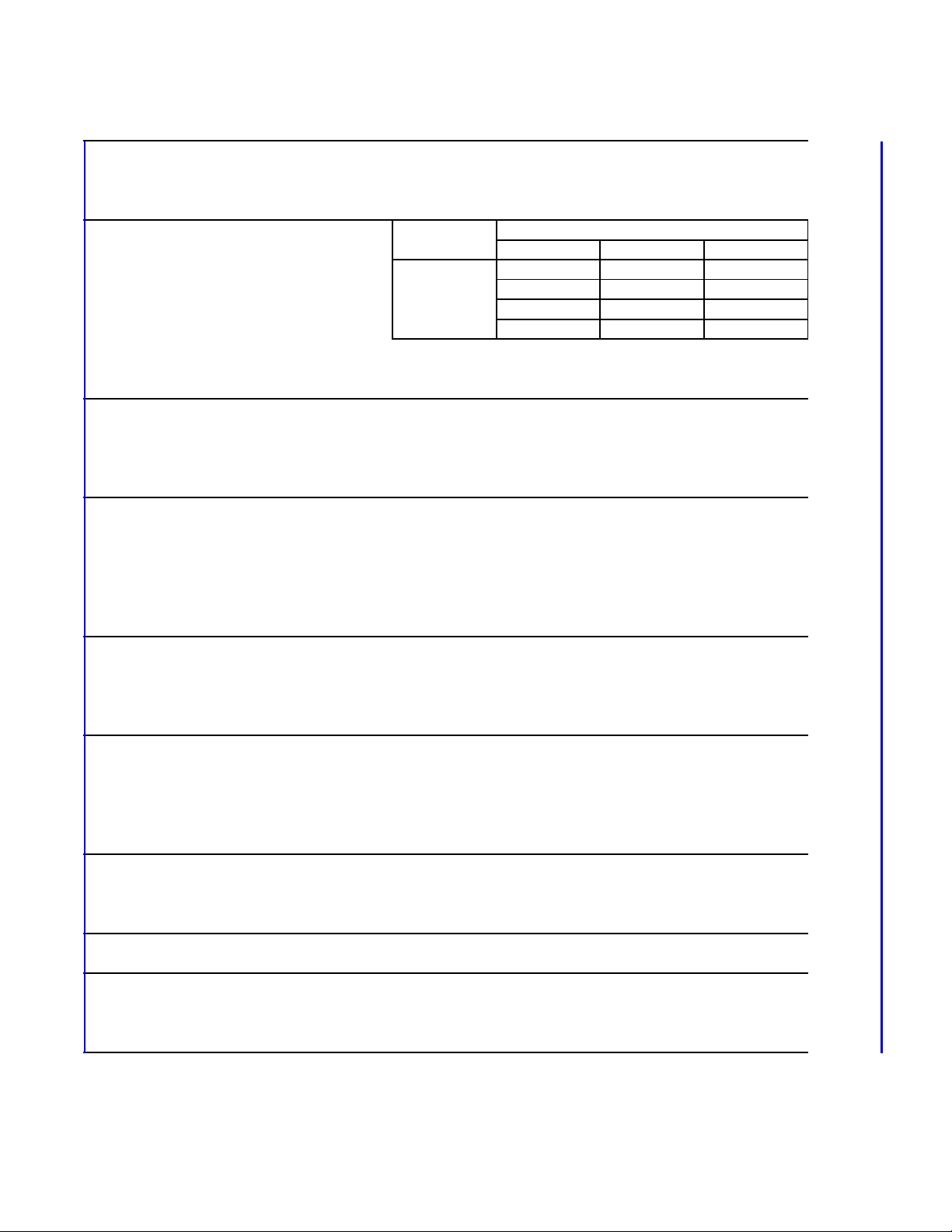

1. KM-500MAH

AC SUPPLY VOLTAGE 115/60/1

AMPERAGE 13 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIMUM CIRCUIT AM PA CITY 20 A

MAXIMUM FUSE SIZE 20 A

APP RO XIMATE ICE PRO DUCTION Ambi en t WATE R TE MP. (°F)

PE R 24 HR. Temp.(°F) 50 70 90

lbs ./day ( kg/day ) 70 *499 (226) 468 (212) 428 (194)

Reference wit h out * m arks 80 475 (216) 427 (194) 389 (176)

90 468 (212) *393 (178) 353 (160)

100 461 (209) 384 (174) 317 (144)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION P ER CY C LE 9. 5 l b s. ( 4 .3 kg ) 4 80 p cs.

APPROXIMATE STORAGE CAPACITY N/A

EL ECTRIC & WATER CONSUM PTION 90/ 7 0° F 70/50° F

ELECTRIC W (kWH/100 lbs.) 1212 (7.4) 1164 (5.6)

W ATER gal./ 24HR (gal./ 100 lbs.) 113 (28.8) 250 (50.1)

EXTERIOR DIMENSIONS (W xDxH) 22" x 27-3/8" x 30-5/ 6" (560 x 695 x 770 mm )

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

W E IGHT Net 151 lbs. ( 69 kg ), Shipping 175 lbs. (80 k g)

CONNE C TIONS - ELECTRIC Pe rmanent - Con n ection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

3/8" OD Pi pe

CUB E CONTROL SY STEM Fl oa t Switc h

HARVESTING CONTROL SYS TEM Hot Gas and Water, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Con trol led. Overflow Pipe

COOLING WATER CO NTROL N/ A

BIN CO NTROL SY STEM Pr oxi m it y Switch wi th Delay

COMPRESSOR Hermetic, Model AKA9455ZXA

CONDENSER Air-c ooled, F i n and t ube t ype

EV A P ORATOR Verti c al type, S t ainl es s S t eel and Copper

REFRIGE RANT CONTROL Therm ostatic E xpa n si on Val ve

REFRIGERANT CHARGE R-404A, 1 lb. 10 oz . ( 735 g )

DESIGN PRE SS URE High 46 7 PS IG, Lo w 2 30 PS IG

P.C. BOARD CIRCUIT PROTECTION High V ol tage Cu t-out ( Int ern al )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW W ATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OP ERA TING CONDITIONS VO LTA G E RA N GE 104 - 12 7 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 9 0° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

Note: We reserve the right to make changes in specifications and design without prior notice.

5

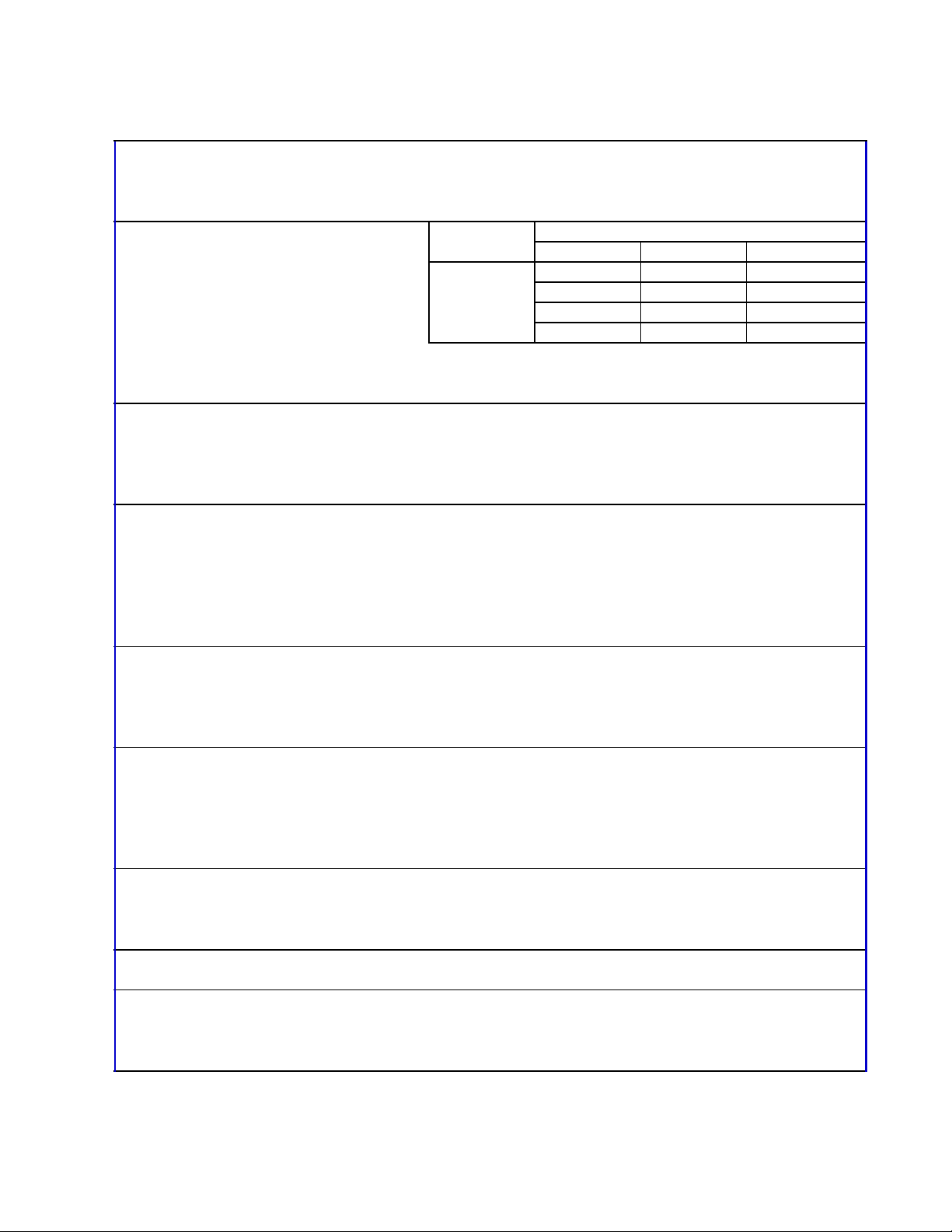

2a. KM-500MWH Serial #L00001D - M20960C

AC SUPPLY VOLTAGE 115/60/1

AM P E RA GE 10 A ( 5 Mi n. F reez e A T 104°F / WT 80°F)

MINIMUM CIRCUIT AM PA CITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PE R 24 HR. Temp.(°F) 50 70 90

lbs . /day ( kg/day ) 70 *463 (210) 448 (203) 423 (192)

Referenc e wit hout * m ark s 80 451 (205) 428 (194) 401 (180)

90 448 (203) *411 (186) 385 (175)

100 442 (200) 405 (184) 361 (164)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 9.5 lbs. ( 4.3 kg ) 480 pcs.

APPROXIMATE STORAGE CAPA CITY N/A

ELE CTRIC & WATER CONSUM P TION 90/70°F 70/50°F

ELE CTRIC W (k WH/100 l bs .) 1130 (6.6) 1100 (5.7)

WATER gal./24HR (gal./100 lbs.) 135 (32) 245 (52.8)

WATER COOLED CONDENSER 723 (176) 380 (82)

gal./24HR (gal./100 l bs.)

EXTERIOR DIMENSIONS (Wx Dx H) 22" x 27-3/ 8" x 30-5/ 16" (560 x 695 x 770 m m )

EXTERIOR FINISH St ai nless S teel, Gal vanized St eel (Rear)

WEIGHT Net 146 lbs . ( 66 kg ), S hi ppi ng 170 lbs. (77 k g.)

CONNECTIONS - ELE CTRIC Permanent - Connec t i on

- WATER SUPPLY Inlet 1/2" FPT Condenser Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT Condenser Outlet 3/8" FPT

3/8" OD P i pe

CUBE CONTROL SY STEM Fl o at S wit ch

HARVESTING CONTROL SYSTEM Hot Gas and W at er, Thermis tor and Timer

ICE MAK ING W ATER CONTROL Timer Controlled. Overflow Pi pe

COOLING WATER CONTROL Pre ssure Re gu l a tor

BIN CO NTROL SY STEM Pro xi m it y S wit ch wi th De l ay

COMPRE S SOR Hermeti c , Model A KA9455ZXA

CONDENSER Water-cool ed, Tube in tube t ype

EV A PORATOR V ert i cal t ype, S tainless S t eel and Copper

REFRIGERA NT CONTROL Thermost atic E xpans ion Valve

REFRIGERA NT CHARGE R-404A, 13.2 oz. ( 375 g )

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

P.C. BOARD CIRCUIT PROTE CTION High Vol tage Cu t-out ( Interna l )

COMPRE S SOR PROTECTIO N Aut o-reset Overload Protector ( Internal )

REF R IGERA NT CIRCUIT PROTECTION Aut o -r eset Hig h Press u re Co n trol Switch

LOW W ATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPE RA TING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

Note: We reserve the right to make changes in specifications and design without prior notice.

6

2b. KM-500MWH Serial #M30961D -

AC SUPPLY VOLTAGE 115/60/1

AM P ERAGE 10 A ( 5 Min. Freeze AT 104°F / WT 80°F)

MINIM UM CIRCUIT AMP ACITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

P E R 24 HR. Temp. ( °F) 5 0 70 90

lbs./day ( kg/day ) 70 * 480 (218) 471 (213) 439 (199)

Reference without *m arks 80 473 (214) 458 (208) 417 (189)

90 471 (213) *448 (203) 410 (186)

100 458 (208) 439 (199) 375 (170)

SHAPE OF ICE Cres cent Cube

ICE PRODUCTION PER CYCLE 9.5 lbs. (4.3 kg) 480 pcs.

APPROXIMATE STORAGE CAPACITY N/A

ELE CTRIC & WATER CONSUMP TION 90/70°F 70/ 50°F

ELECTRIC W (kWH/100 lbs.) 1157 (6.2) 1140 (5.7)

WATER gal. /24HR (gal./100 l bs.) 133 (29.7) 268 (55.8)

WATER COOLED CONDENSE R 699 (156) 394 (82)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (Wx Dx H) 22" x 27-3/8" x 30-5/16" (560 x 695 x 770 mm )

EXTERIOR FINISH St ainl es s St eel , Galvanized Steel (Rear)

W E IGHT Net 146 lbs . ( 66 k g ), Shipping 170 lbs . ( 77 k g )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT Condenser Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT Condenser Outlet 3/ 8" FPT

3/8" OD P i pe

CUBE CONTROL SYS TEM Fl oat S wi tc h

HA RV ES TING CONTROL S YS TEM Hot G as an d Wa ter, Thermistor an d Timer

ICE MAKING WA TER CONTROL Timer Cont rolled. Overflow P i p e

COOL ING WATER CO NTROL P re ss u re Re gu l a t o r

B IN CONTROL SY STEM P ro ximity S wi tch wi th Del a y

COMPRESSOR Hermetic, Model AKA9455ZXA

CONDENSER W at er-cooled, Tube in tube type

EV APORA TOR V ertic al type, Stainless Steel and Copper

REFRIGERANT CONTROL Thermost at ic Expansi on Val ve

REF RIGE RA NT CHARGE R-404A, 1 5 oz. ( 425 g )

DESIGN PRES SURE High 427 PSIG, Low 206 PSIG

P .C. BO ARD CIRCUIT PRO TE CTION High Vol tage Cu t-ou t ( Intern a l )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PRO TEC TI ON F lo at Sw itch

ACCESSORIES -SUP PLIED N/A

-REQUIRED Ice Storage Bin

OP ERATING CONDITIONS V O LTA G E RANGE 104 - 1 2 7 V

AMBIENT TE MP . 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PS IG

7

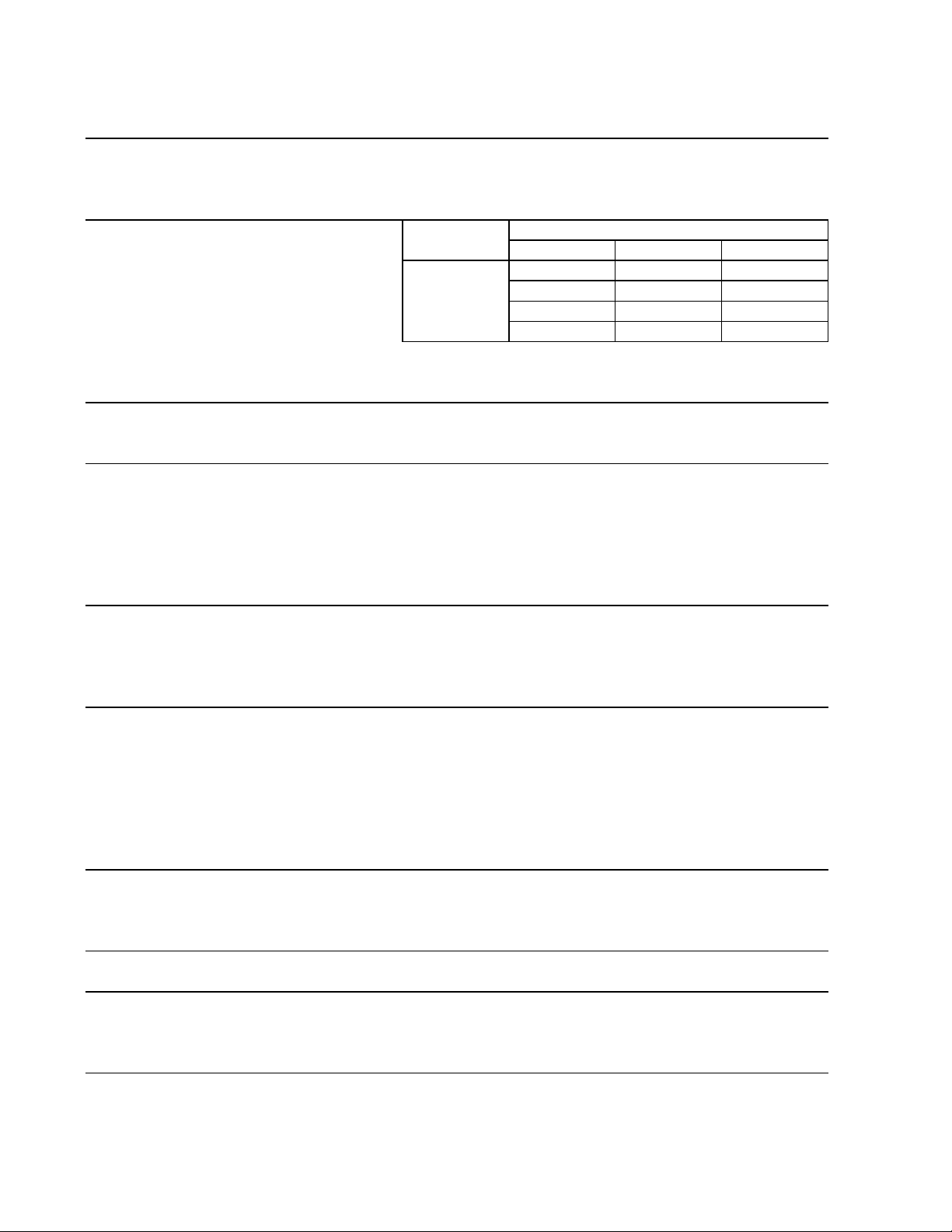

3. KM-500MRH

AC SUPPLY VOLTAGE 115/60/1

AM P E RA GE 15 A ( 5 Min. F reez e A T 104°F / WT 80°F)

MINIMUM CIRCUIT AMP ACITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PE R 24 HR. Temp.(°F) 50 70 90

lbs . / day ( kg/ day ) 70 *517 235) 493 (224) 449 (204)

Reference without *m ark s 80 499(226) 462 (210) 411 (187)

90 493 (224) * 436 (198) 387 (176)

100 480 (218) 425 (193) 342 (155)

SHA P E OF ICE Cresc ent Cube 480

ICE PRODUCTION PE R CYCLE 9. 5 lbs. (4.3 kg ) 480 pcs.

APPROXIMATE STORAGE CAPACITY N/A

E LECTRIC & WA TE R C ONSUM PTION 90/7 0° F 70/50 °F

ELE CTRIC W (kWH/ 100 lbs.) 1272 (7. 0) 1206 (5.6)

WATER gal./ 24HR (gal. / 100 lbs. ) 137 (31.3) 233 (45.1)

EXTERIOR DIMENS IONS (W xDxH) 22" x 27-3/ 8" x 30-5/16" (560 x 695 x 770 m m )

EXTE RIOR FINISH St ai n l ess Steel , Galvanized S teel (Rear)

W EIGHT Net 151 l bs. ( 69 kg ), Shipping 175 l bs. ( 80 kg )

CONNECTIONS - ELE CTRIC P erm anent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

3/8" OD Pipe

CUBE CO NTROL SYS TEM F l oa t Switc h

HARVESTING CONTROL S YS TEM Hot Gas and Wat er, Thermis tor and Timer

ICE MAK ING WA TER CONTROL Timer Controll e d. O verflow P ipe

COOLING W A TER CONTROL N/A

BIN CONTROL SYS TEM Prox i m i ty Switc h wi t h Del ay

COMP RESSO R Hermet ic, M odel A KA9455ZXA

CONDENSE R A i r-cooled Remot e, Condens er Unit URC 6F

EV A PORATOR Vertical t ype, S tainless S t eel and Copper

REFRIGERA NT CONTROL Therm ostatic E xpans i on V alve

Condensing P res sure Regulator on URC-6F

REFRIGERA NT CHARGE R-404A, 4 lbs . 0 oz . ( 1800 g )

( Icemak er 2 lbs . 1.5 oz. Cond. Unit 1 lb. 14 oz . )

DES IGN PRES SURE High 467 PS IG, Low 230 PSIG

P . C . B O ARD CIRCUIT PRO TE CTION Hi gh V o lt age Cut -out ( Internal )

COMP RESSO R PROTECTION Aut o -res et Overload P rot ec t or ( Internal )

REFRIGERA NT CIRCUIT P ROTECTION Aut o-res et High Press ure Control S wit ch

LOW WA TER PROTECTIO N Float S witc h

ACCE SSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bi n, Remot e Condenser Unit

OPE RA TING CONDITIONS V OLTAGE RA NGE 104 - 127 V

AMBIENT TEMP. 45 -100° F

W ATER SUPPLY TEM P. 45 - 90° F

W ATER SUPPLY PRES SURE 10 - 113 PSIG

Note: We reserve the right to make changes in specifications and design without prior notice.

8

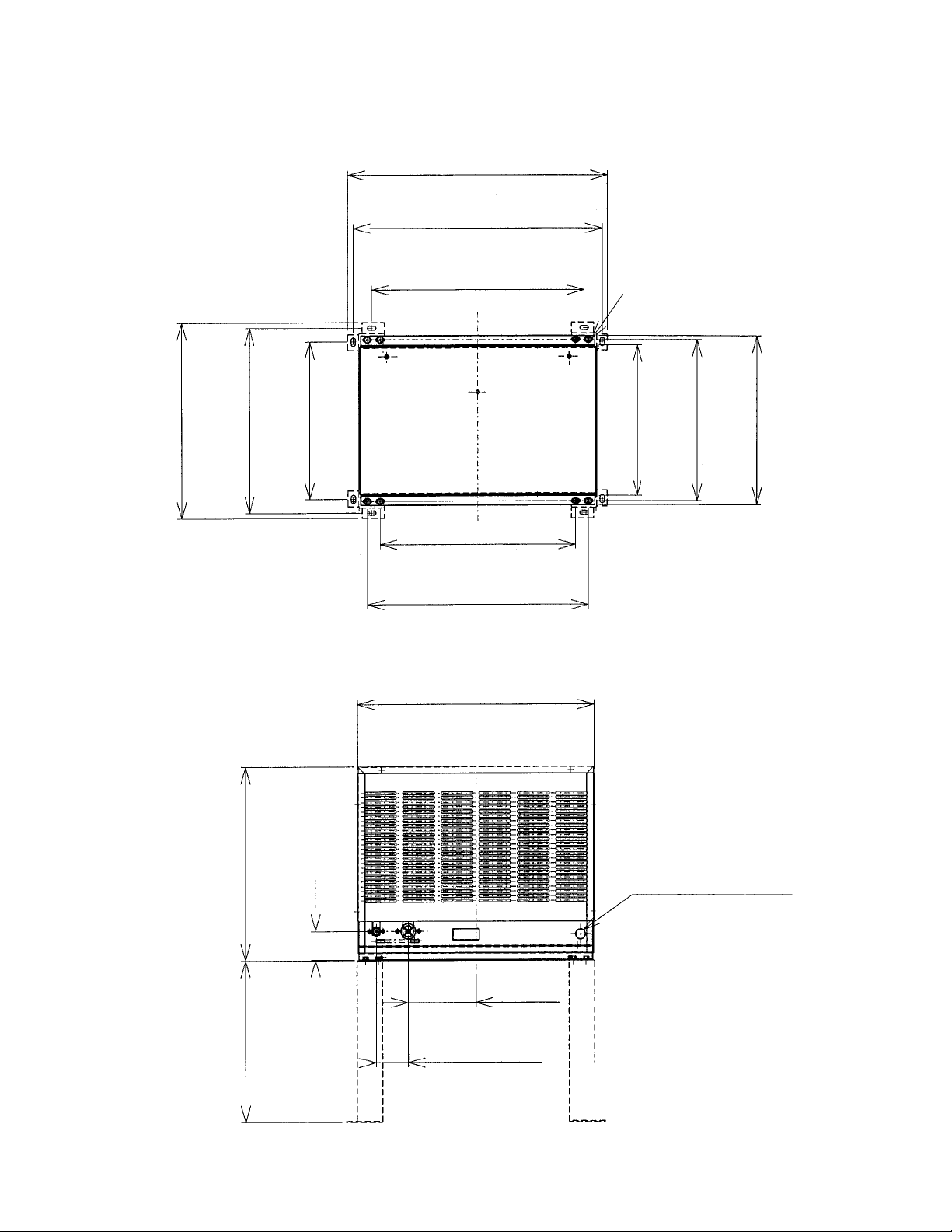

4. CONDENSER UNIT

URC-6F

24"

(610 mm.)

23-1/32"

(585 mm.)

18-1/8"

(460 mm.)

17-1/8"

(435 mm.)

14-9/16"

(370 mm.)

19-11/16"

(500 mm.)

18-1/8"

(460 mm.)

20-15/32"

(520 mm.)

21-15/16"

(557 mm.)

6/16" x 3/4" (10 mm. x 20 mm.)

4 x 2 (SLOTTED HOLES)

14-1/8"

(358 mm.)

14-15/16"

15-11/16"

(380 mm.)

(398 mm.)

17-7/8"

(454 mm.)

14-15/16"

(380 mm.)

2-1/2"

(63 mm.)

7/8" DIA. HOLE

(23 mm. DIA.)

6-5/16"

(160 mm.)

2-15/16"

(75 mm.)

9

MODEL: URC-6F

SPECIFICATIONS

EXTERIOR

DIMENSIONS (W x D x H)

REFRIGERANT CHARGE

WEIGHT

CONNECTIONS

REFRIGERANT

ELECTRICAL

CONDENSER

HEAD PRESSURE CONTROL

AMBIENT CONDITION

Galvanized Steel

21-15/16" x 15-11/16" x 17-7/8"

(557 x 398 x 453.8 mm.)

R404A 1 lb. 2 oz. (505 g)

Net 61 lbs. (28 kg)

Shipping 68 lbs. (31 kg)

One Shot Couplings (Aeroquip)

Permanent Connection

Air-cooled

Condensing Pressure Regulator

Min. -20°F - Max. +122°F

(-29°C to +50°C)

Outdoor use

10

II. GENERAL INFORMATION

1. CONSTRUCTION

[a] KM-500MAH

Spray Tubes Water Supply Inlet

Control Switch

Bin Control Thermostat

(except models with

Mechanical Bin Control)

Expansion Valve Fan Motor

Compressor

Float Switch

Water Pump

Mechanical

Bin Control

(except models

with Thermostat)

Condenser

Hot Gas Valve

Condenser

Drier

Control Box

11

[b] KM-500MWH

Spray Tubes Water Supply Inlet

Control Switch

Bin Control Thermostat

(except models with

Mechanical Bin Control)

Water Regulator

Expansion Valve Hot Gas Valve

Compressor

Float Switch Drier

Water Pump Control Box

Mechanical

Bin Control

(except models

with Thermostat)

12

[c] KM-500MRH

Spray Tubes Water Supply Inlet

Control Switch

Bin Control Thermostat

(except models with

Mechanical Bin Control)

Expansion Valve Receiver Tank

Compressor

Junction Box

Float Switch Drier

Water Pump Hot Gas Valve

Line Valve

Control Box

Mechanical

Bin Control

(except models

with Thermostat)

13

2. CONTROLLER BOARD

[a] SOLID-STATE CONTROL

1) A HOSHIZAKI exclusive solid-state control is employed in Modular Crescent Cubers.

2) A Printed Circuit Board (hereafter called “Controller Board”) includes a stable and high

quality control system.

3) All models are pretested and factory-adjusted.

[b] CONTROLLER BOARD

CAUTION

1. Fragile, handle very carefully.

2. A controller board contains integrated circuits, which are susceptible to

failure due to static discharge. It is especially important to touch the metal

part of the unit when handling or replacing the board.

3. Do not touch the electronic devices on the board or the back of the board to

prevent damage to the board.

4. Do not change wiring and connections. Do not misconnect K3, K4 and K5,

because the same connector is used for the Thermistor (white), Float Switch

(black), and Mechanical Bin Control (red).

(For machines with thermostat, there is no connection on K4.)

5. Always replace the whole board assembly when it goes bad.

6. Do not short out power supply to test for voltage.

PART NUMBER TYPE

2A1410-01 HOS-001A (Control Products)

Features of Control Products “E” Controller Board

1) Maximum Water Supply Period - 6 minutes

Water Solenoid Valve opening, in the Defrost (Harvest) Cycle, is limited by the defrost

timer. The Water Valve cannot remain open longer than the

maximum period. The Water Valve can close in less than six minutes if the defrost cycle is

completed.

14

2) Defrost Timer

The defrost cycle starts when the Float Switch opens and completes the freeze cycle.

But the Defrost Timer does not start counting until the Thermistor senses 48°F at the

Evaporator outlet. The period from the end of the freeze cycle up to the point of the

Thermistor's sensing varies depending on the ambient and water temperatures.

3) High Temperature Safety - 127 ± 7°F

The temperature of the suction line in the refrigerant circuit is limited by the High

Temperature Safety.

During the defrost cycle the Evaporator temperature rises. The Thermistor senses

48°F and starts the Defrost Timer. After the Defrost Timer counts down to zero,

the normal freeze cycle begins. If the Evaporator temperature continues to rise,

the Thermistor will sense the rise in temperature and at 127 ± 7°F the Thermistor

operates the High Temperature Safety.

This High Temperature Safety shuts down the circuit and the icemaker automatically

stops.

This High Temperature Safety protects the unit from excessive temperature. The Control

Board will Beep every 3 seconds. The white Reset Button on the Control Board must be

pressed with power on to reset the Safety.

4) Low Water Safety

If the Pump Motor is operated without water, the mechanical seal can fail. To prevent this

type of failure, the Controller Board checks the position of the Float Switch at the end of

the initial one minute water fill cycle and at the end of each defrost cycle.

If the Float Switch is in the up position (electrical circuit closed), the Controller Board

changes to the ice making cycle. If the Float Switch is in the down position (electrical

circuit open), the Controller Board changes to a one minute water fill cycle before starting

the ice making cycle. This method allows for a Low Water Safety shut down to protect the

Water Pump from mechanical seal failure.

For water-cooled model, if the water is shut off, the unit is protected by the High Pressure

Switch.

5) High Voltage Cutout

The maximum allowable supply voltage of this icemaker is limited by the High Voltage Cutout.

If miswiring (especially on single phase 3 wire models) causes excessive voltage on the

Controller Board, the High Voltage Cutout shuts down the circuit in 3 seconds and the

icemaker automatically stops. When the proper supply voltage is resumed, the icemaker

automatically starts running again. The Control Board will signal this problem using 7 Beeps

every 3 seconds.

6) LED Lights and Audible Alarm Safeties

The red LED indicates proper control voltage and will remain on unless a control voltage

problem occurs. At startup a 5 second delay occurs while the board conducts an internal

timer check. A short beep occurs when the power switch is turned ON or OFF.

15

The green LED’s 1-4 represent the corresponding relays and energize and sequence 5

seconds from initial start-up as follows:

Sequence Step LED’s on Length: Min. Max. Avg.

1 Minute Fill Cycle LED4 60 sec.

Harvest Cycle LED1, 4, & 2 2 min. 20 min. 3-5 min.

Freeze Cycle LED1 5 min. 60 min. 30-35 min.

Reverse Pump Out LED1, 3, & 2 10 sec. 20 sec. Factory set.

{LED 1 – Comp; LED 2 - HGV/CFM; LED 3 – PM; LED 4 - WV}

The built in safeties shut down the unit and have alarms as follows:

1 beep every 3 sec. = High Evaporator Temperature >127 ° F.

Check for defrost problem (stuck HGV or relay), hot water entering unit, stuck

headmaster, or shorted thermistor.

2 beeps every 3 sec. = Defrost Back Up Timer. Defrost >20 minutes.

Orange LED marked 20 MIN energizes.

Check for open thermistor, HGV not opening, TXV leaking by, low charge, or inefficient

compressor.

3 beeps every 3 sec. = Freeze Back Up Timer. Freeze > 60 minutes.

Yellow LED marked 60 MIN energizes.

Check for F/S stuck closed (up), WV leaking by, HGV leaking by, TXV not feeding

properly, low charge, or inefficient compressor.

4 beeps every 3 sec. = Short Circuit between the K4 connection on

Machines

with

mechanical

bin control

ONLY

the control board and the bin control relay. Check connections and

replace wire harness if necessary.

5 beeps every 3 sec. = Open Circuit between the K4 connection

on the control board and the bin control relay. Check connections and

replace wire harness if necessary.

To manually reset the above safeties, depress white alarm reset button with the power

supply ON.

6 beeps every 3 sec. = Low Voltage. Voltage is 92 Vac or less.

7 beeps every 3 sec. = High Voltage. Control voltage > 147 Vac ±5%.

The red LED will de-energize if voltage protection operates.

The voltage safety automatically resets when voltage is corrected.

The Output Test switch “S3” provides a relay sequence test. With power OFF, place S3

ON and switch power to ICE. The correct lighting sequence should be none, 2, 3, 4, 1, & 4,

normal sequence every 5 seconds. S3 should remain in the “OFF” position for normal

operation.

16

The application switch located between relay X3 & X4 must be set to match the original

board application. Place this switch in the ALP position if there is no white wire supplied

to the K1 connector. If there is a white wire, place the switch in the C position. If this

switch is placed in the wrong position, either the compressor contactor will remain energized with the control switch OFF, or the unit will not start.

The dip switches should be adjusted per the adjustment chart published in the Tech

Specs book. Number 8 must remain in the OFF position.

(Control Products HOS-001A Board)

17

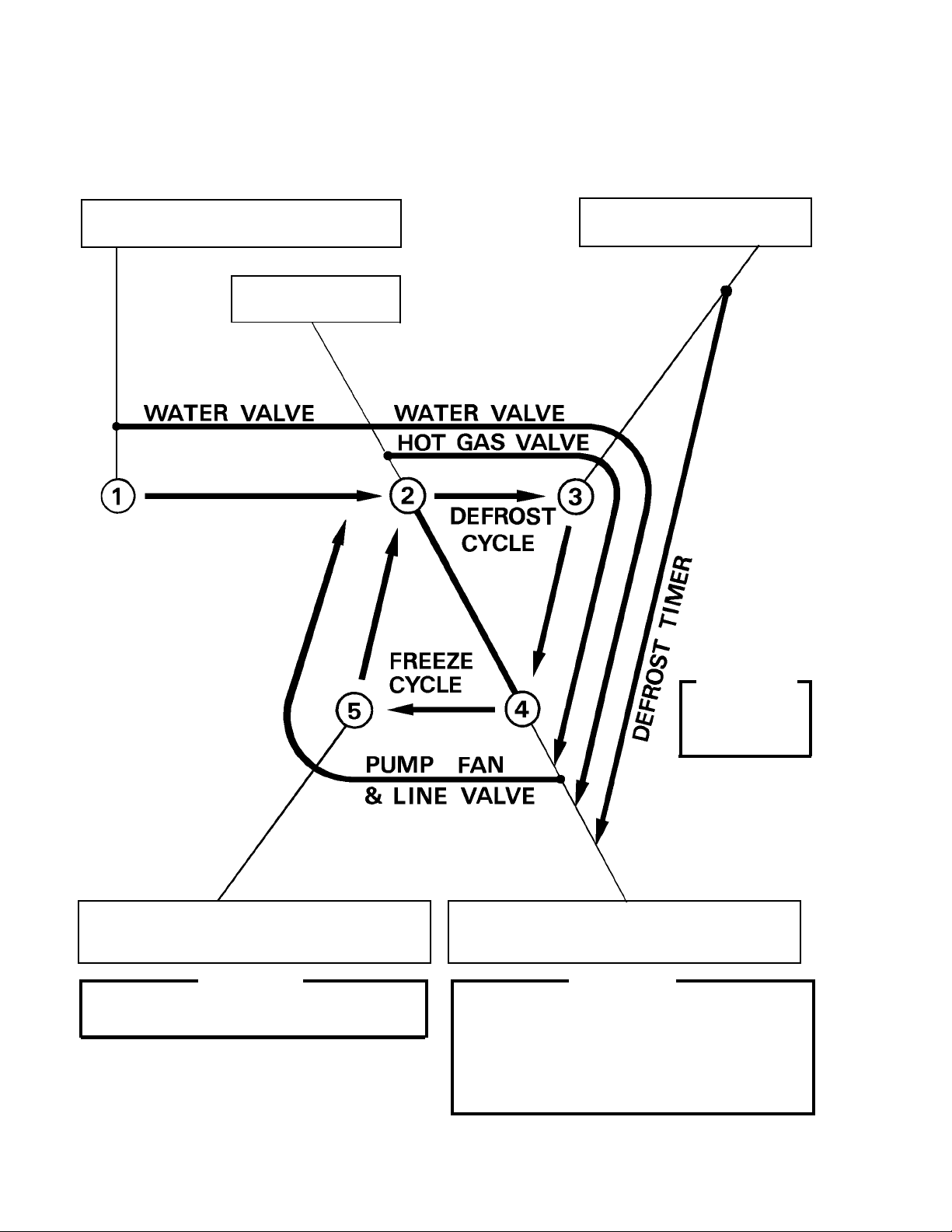

[c] SEQUENCE

1st Cycle

1. Unit energized and Control Switch to “ICE”

position. Water supply cycle starts.

2. After 1 minute,

Defrost cycle starts.

3. Thermistor reads 48° F.

Defrost Timer starts counting.

5. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

IMPORTANT

Water Valve

opening is limited

to 6 minutes.

&

4. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion

signal within the first 2 minutes in defrost

cycle.

2. Defrost cycle time is limited to 20 minutes

even if Defrost Timer does not stop counting.

18

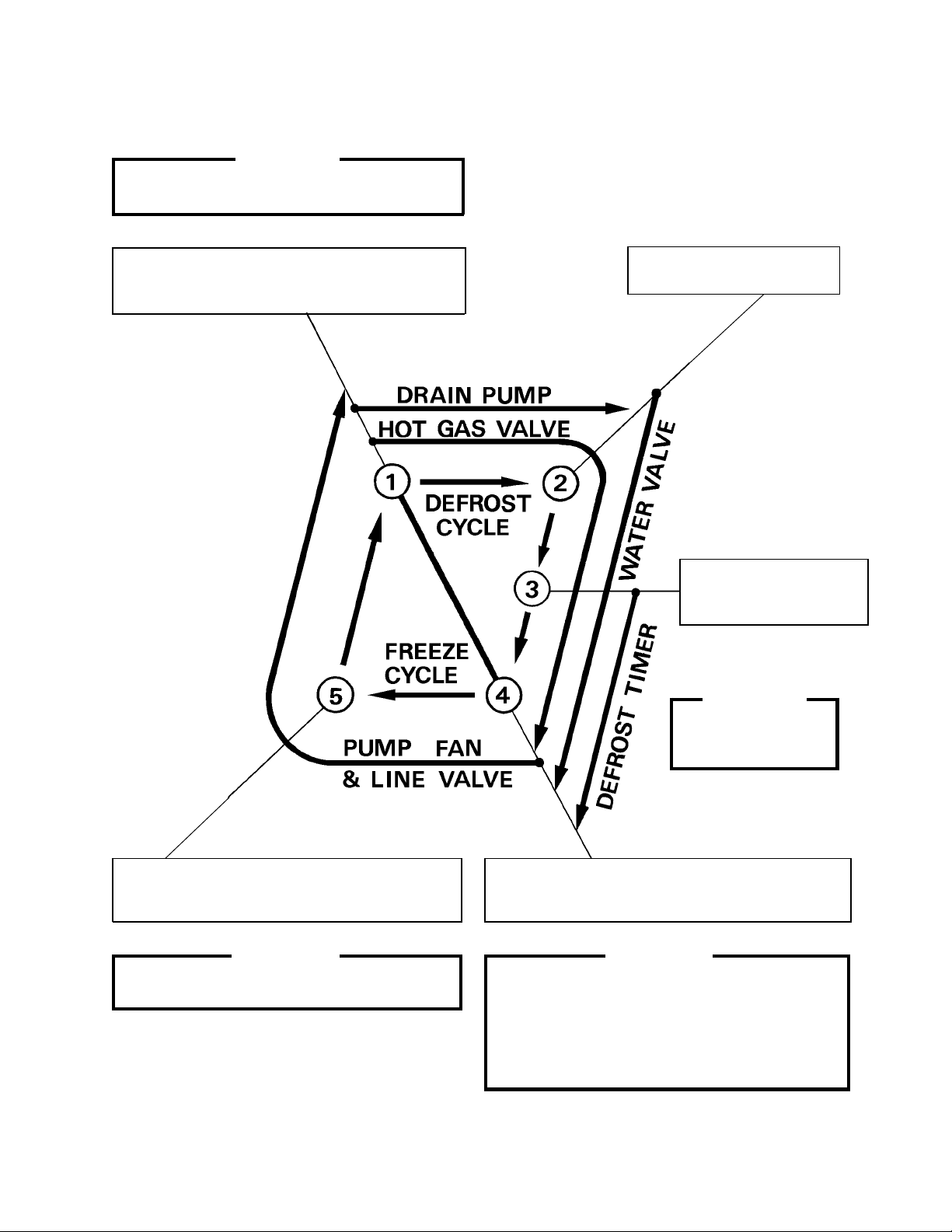

2nd Cycle and after with pump drain

IMPORTANT

Freeze cycle time is limited to 60 minutes even

if Float Switch does not open.

1. Float Switch opens and signals to complete

freeze cycle.

Drain timer starts counting.

&

2. Drain timer stops counting.

Pump drain is completed

3. Thermistor reads 48° F.

Defrost Timer starts

counting.

IMPORTANT

Water Valve

opening is limited to 6

minutes.

5. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

4. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion

signal within the first 2 minutes in defrost

cycle.

2. Defrost cycle time is limited to 20 minutes

even if Defrost Timer does not stop counting.

19

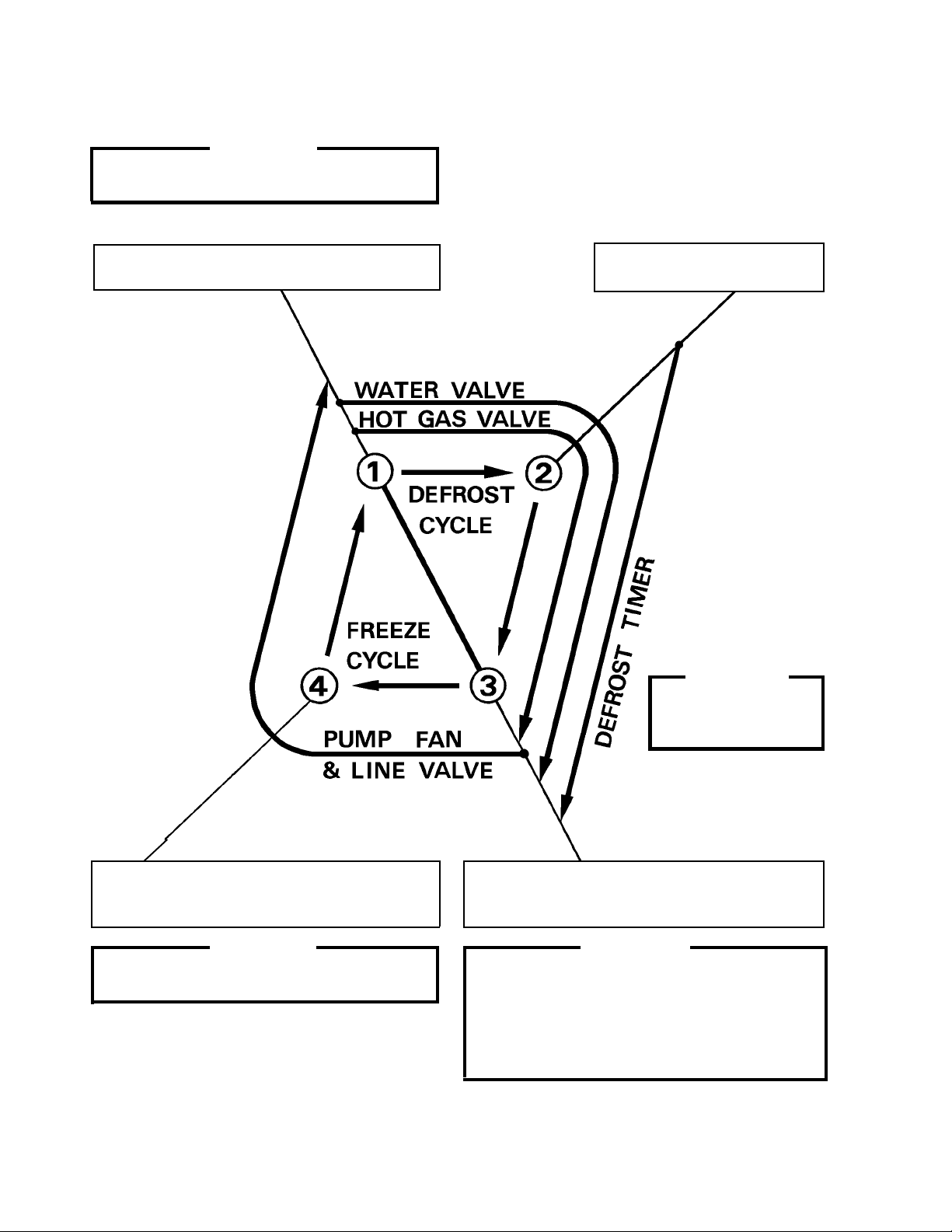

2nd Cycle and after with no pump drain

IMPORTANT

Freeze cycle time is limited to 60 minutes even

if Float Switch does not open.

1. Float Switch opens and signals to complete

freeze cycle.

&

2. Thermistor reads 48° F.

Defrost Timer starts counting.

IMPORTANT

Water Valve

opening is limited to 6

minutes.

4. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

3. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion

signal within the first 2 minutes in defrost

cycle.

2. Defrost cycle time is limited to 20 minutes

even if Defrost Timer does not stop counting.

20

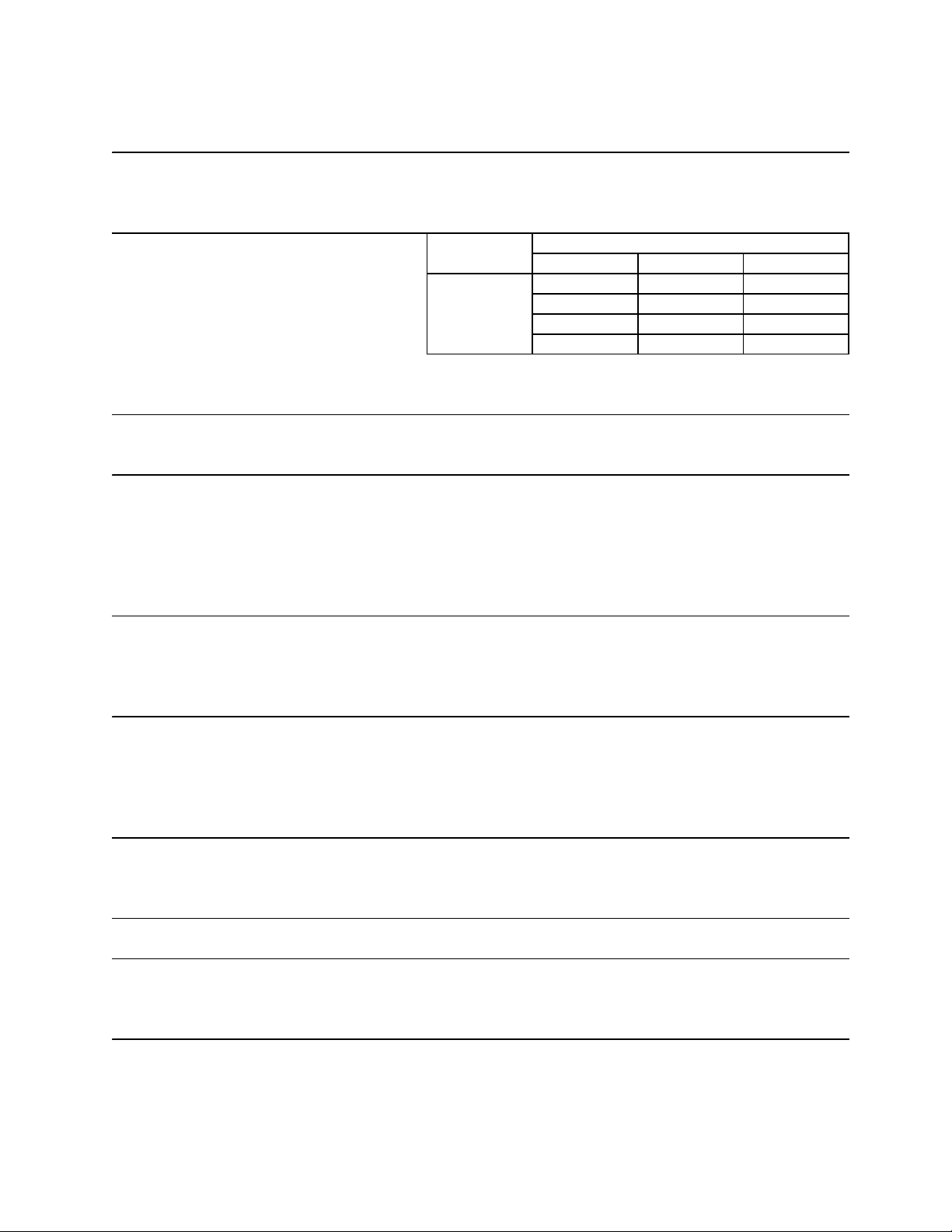

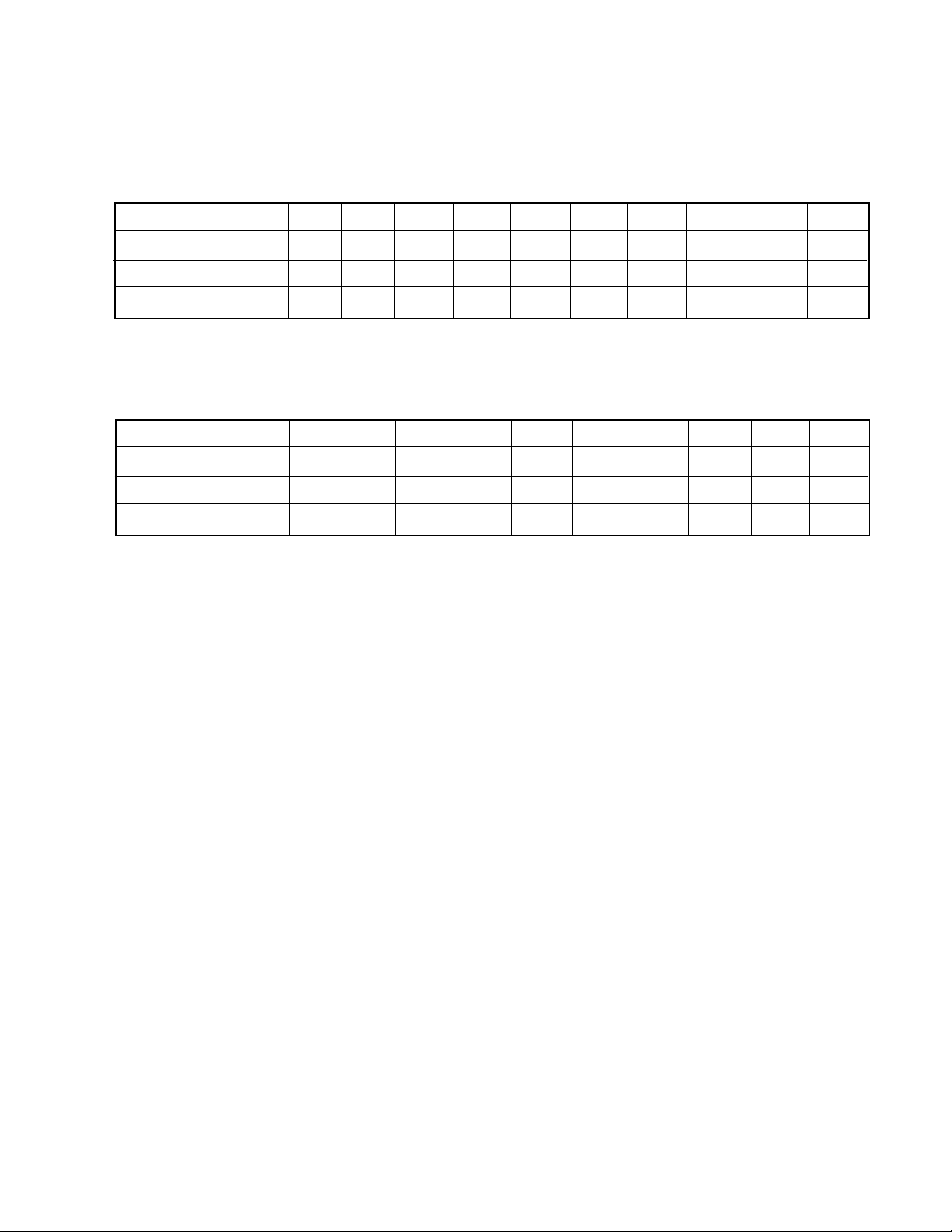

[d] CONTROLS AND ADJUSTMENTS

The Dip Switch is factory-adjusted to the following positions:

FOR MODELS WITH MECHANICAL BIN CONTROL:

DIP SWITCH NO. 1 2 3 4 5 6 7 8 9 10

KML-500MAH OFF OFF OFF OFF ON ON ON OFF ON OFF

KML-500MWH OFF OFF OFF OFF ON ON ON OFF OFF OFF

KML-500MRH OFF OFF OFF OFF ON ON ON OFF OFF OFF

FOR MODELS WITH THERMOSTAT :

DIP SWITCH NO. 1 2 3 4 5 6 7 8 9 10

KML-500MAH OFF OFF OFF OFF ON ON OFF OFF ON OFF

KML-500MWH OFF OFF OFF OFF ON ON OFF OFF OFF OFF

KML-500MRH OFF OFF OFF OFF ON ON OFF OFF OFF OFF

Switch Nos. 1 and 2:

Used for adjustment of the Defrost Timer.

The Defrost Timer starts counting when the Thermistor reads a certain temperature

at the Evaporator outlet.

Switch Nos. 3 and 4:

Used for adjustment of the Drain Timer.

When a freeze cycle is completed, the Pump Motor stops, and the icemaker

resumes operation in 2 seconds. Then the Pump Motor drains the Water Tank

for the time determined by the Drain Timer. The Drain Timer also determines the

time to restrain completion of a defrost cycle, i.e. the minimum defrost time.

Switch Nos. 5 and 6:

Used for adjustment of the Drain Counter.

The Pump Motor drains the Water Tank at the frequency determined by the Drain

Counter.

Switch No. 7:

Used only on models with mechanical bin control. Dip Switch should be set “ON”.

(Models with bin thermostat, Switch No. 7 should be set in the “OFF” position.)

Switch No. 8:

Used only for checking the Controller Board. Usually set in OFF position.

21

Loading...

Loading...