Page 1

Ser vice Manual

Self-Contained Crescent Cuber

Models

KM-230BAJ

KM-300BAJ, BWJ

hoshizakiamerica.com

Number: F111-1006

Issued: 03-15-2018

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No service should be undertaken until

the technician has thoroughly read this Service Manual. Failure to service and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage. Proper installation is the responsibility of the installer. Product failure or

property damage due to improper installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

maintenance and service of the product.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

1

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read the

warnings and guidelines contained in this manual carefully as they provide essential

information for the continued safe use, service, and maintenance of the appliance.

Retain this manual for any further reference that may be necessary.

Important Safety Information ..........................................................................................4

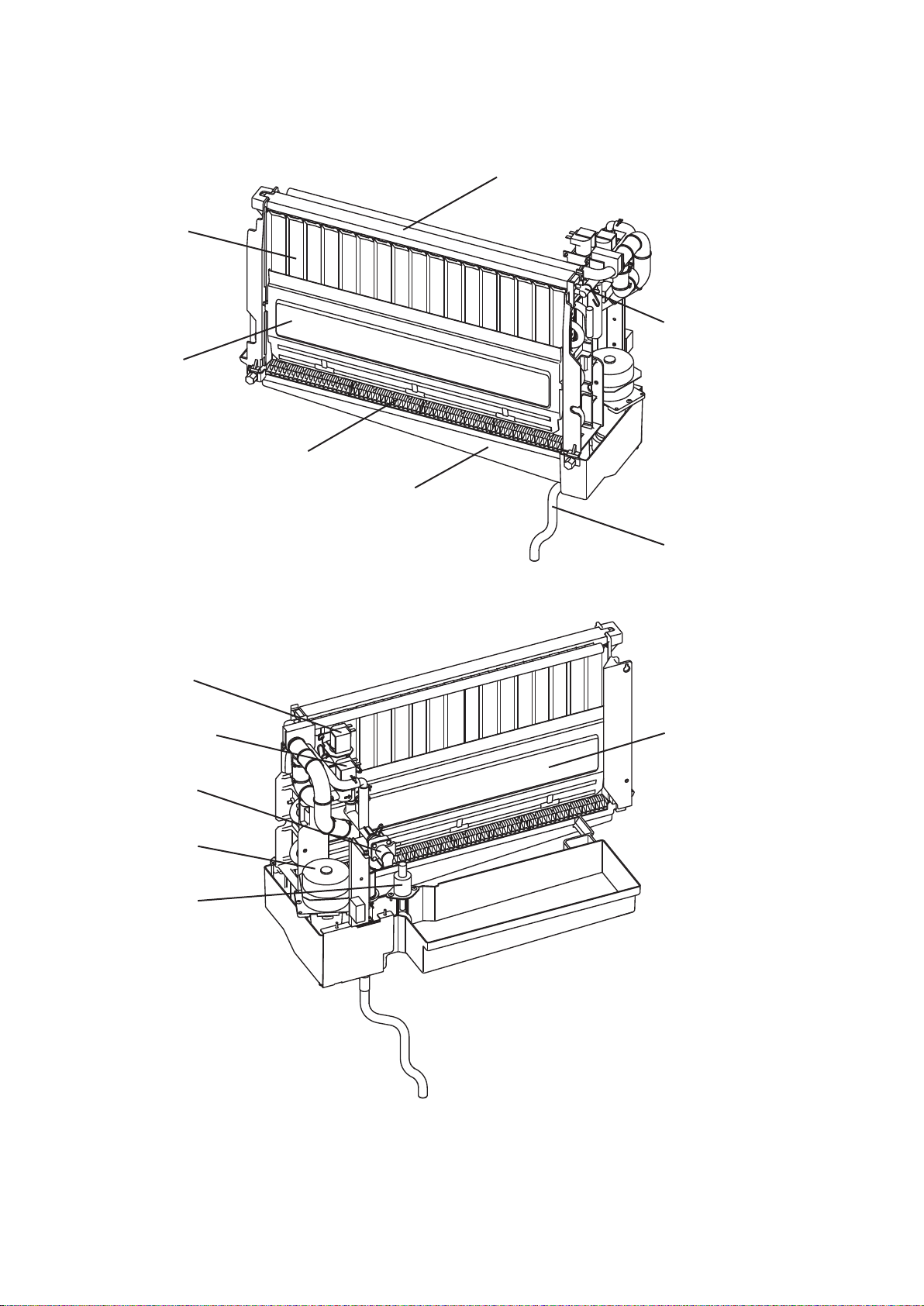

I. Construction and Water/Refrigeration Circuit Diagram ...............................................6

A. Construction ...........................................................................................................6

1. KM-230BAJ, KM-300BAJ .................................................................................6

2. KM-300BWJ .....................................................................................................7

3. Icemaking Compartment ..................................................................................8

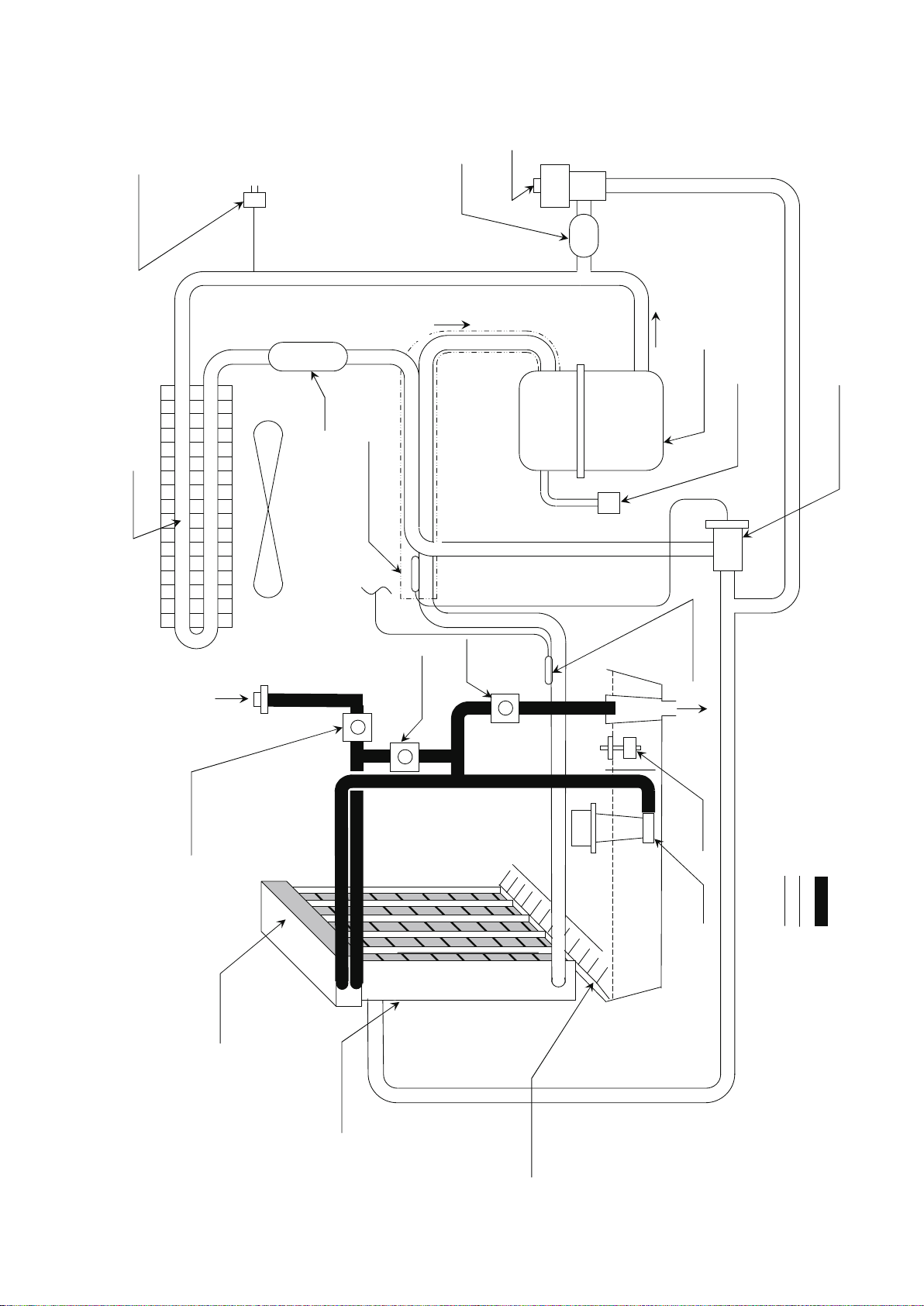

B. Water/Refrigeration Circuit Diagram ......................................................................9

1. KM-230BAJ ......................................................................................................9

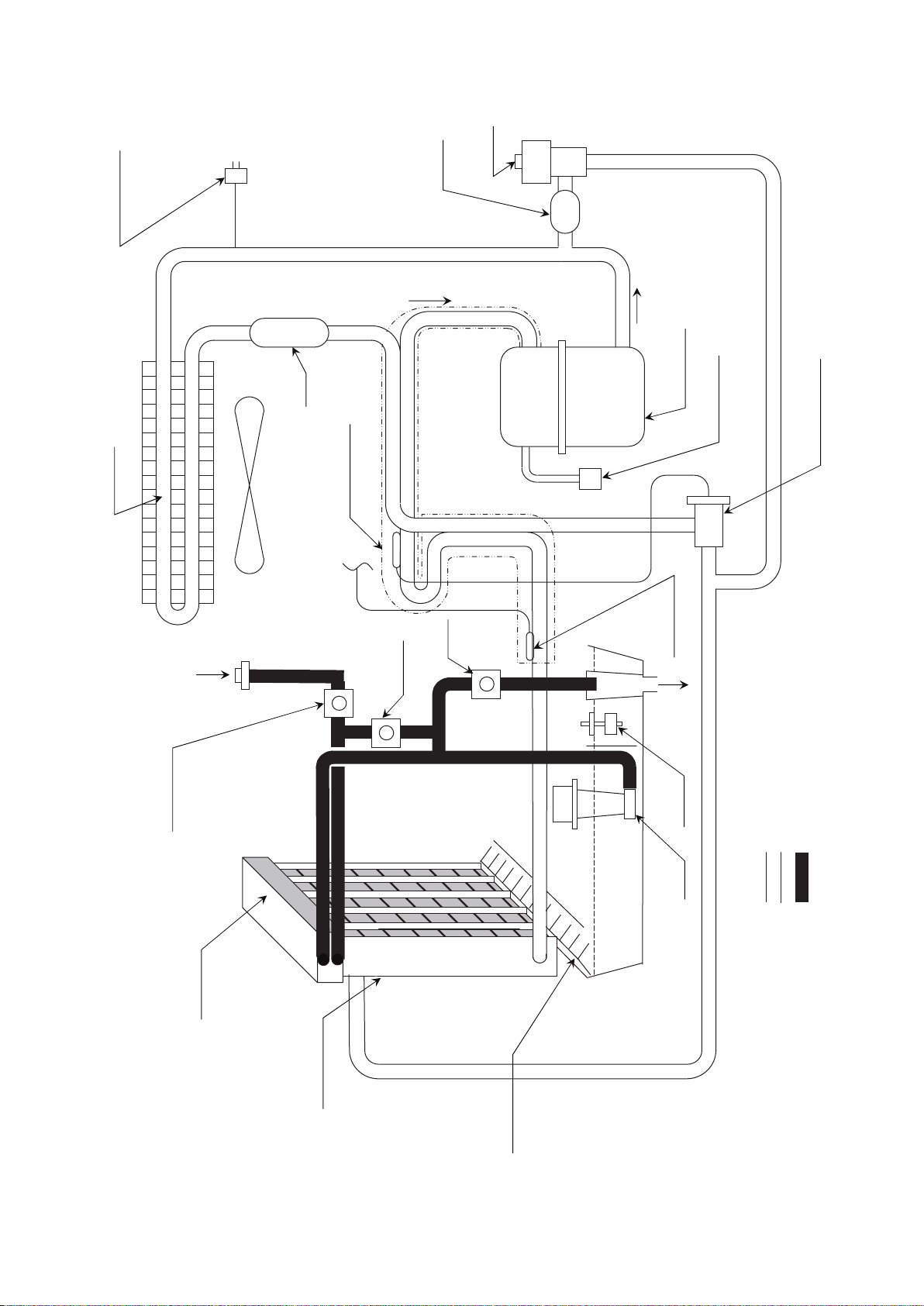

2. KM-300BAJ ....................................................................................................10

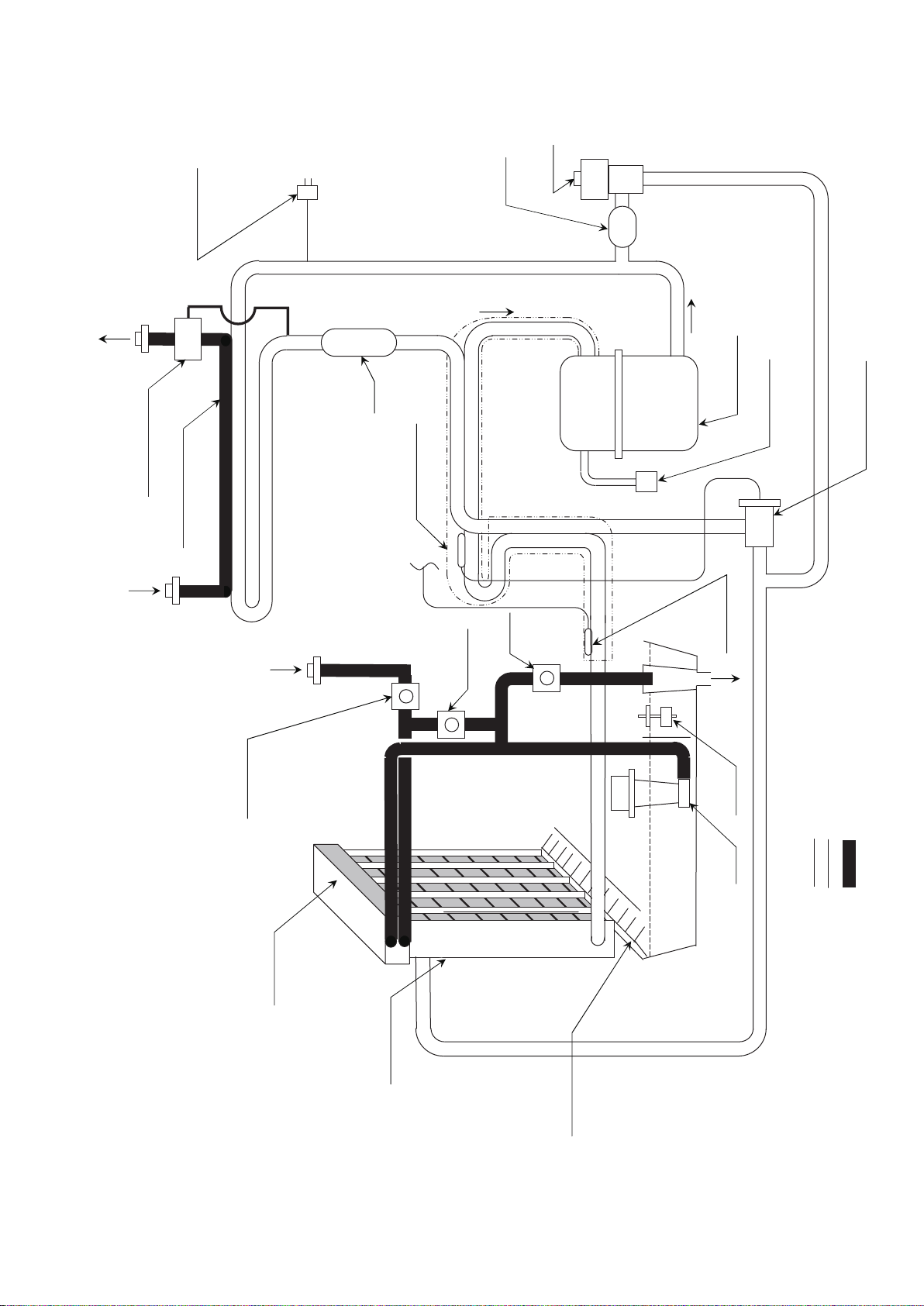

3. KM-300BWJ ................................................................................................... 11

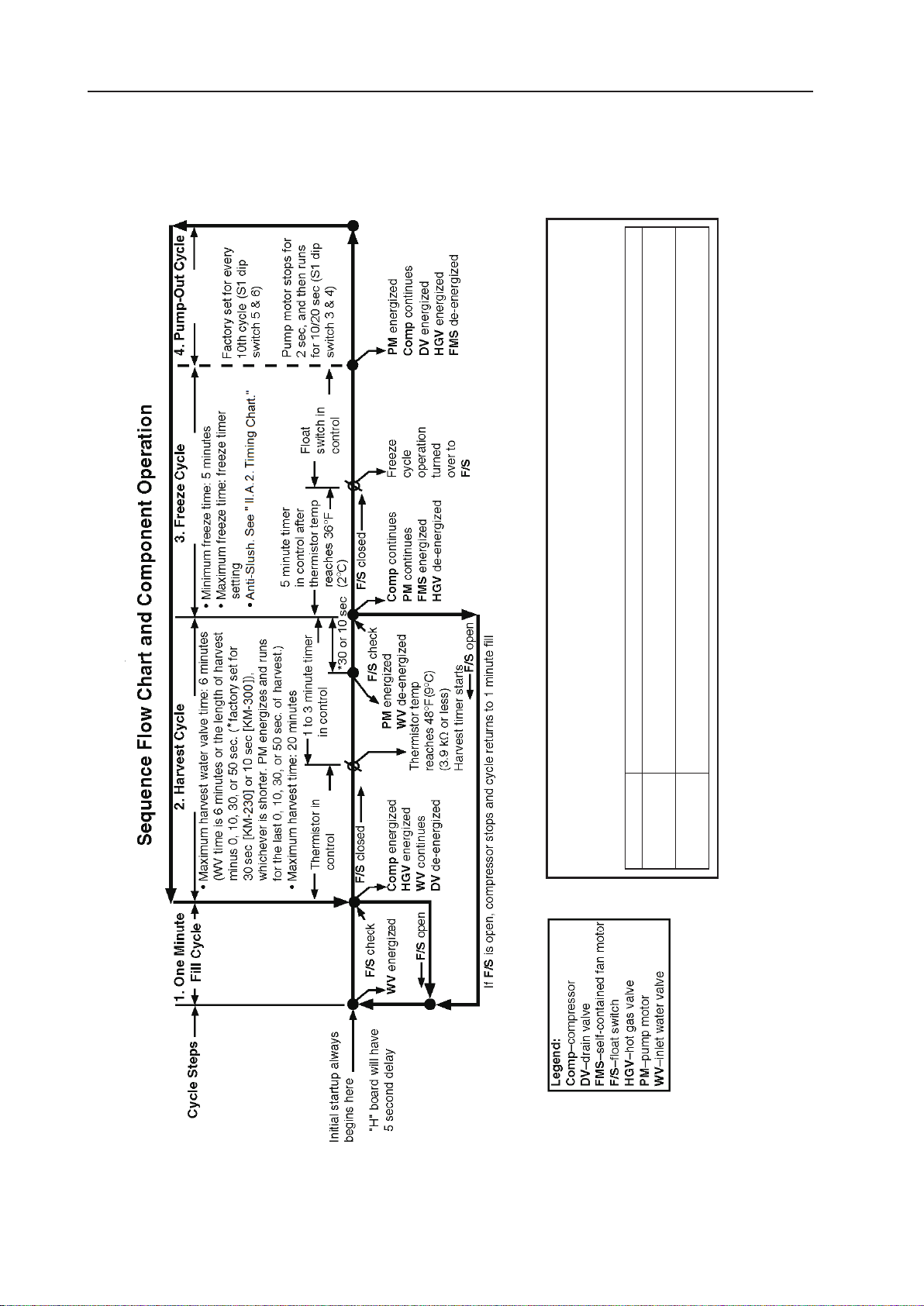

II. Sequence of Operation and Service Diagnosis ........................................................12

A. Sequence of Operation ........................................................................................12

1. Flow Chart ......................................................................................................12

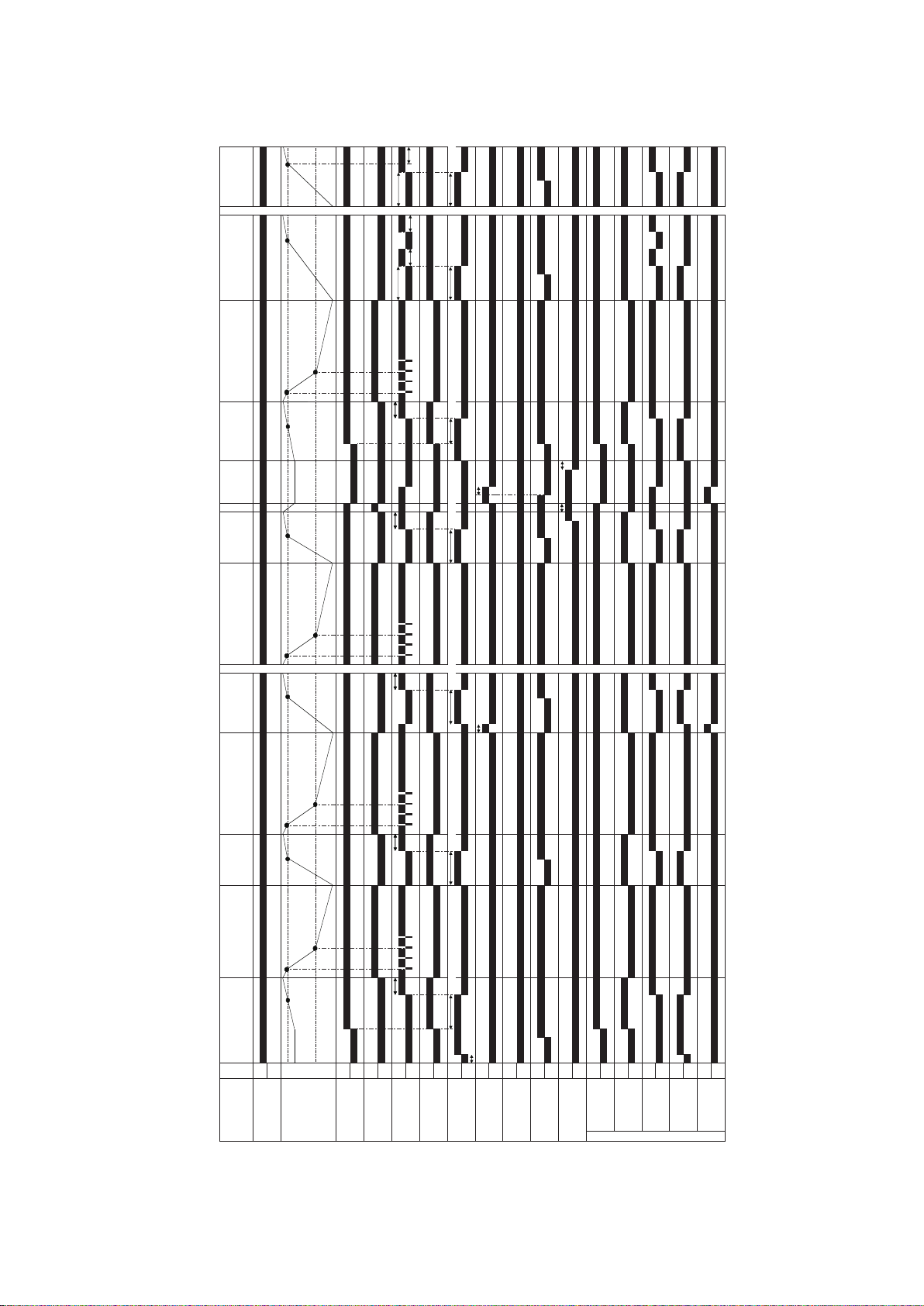

2. Timing Chart ...................................................................................................13

3. Details ............................................................................................................14

B. Service Diagnosis ................................................................................................16

C. Control Board Check ...........................................................................................18

D. Bin Control Check and Cleaning .........................................................................18

1. Bin Control Check ..........................................................................................19

2. Bin Control Cleaning ......................................................................................19

E. Float Switch Check and Cleaning ........................................................................21

1. Float Switch Check.........................................................................................21

2. Float Switch Cleaning ....................................................................................22

F. Thermistor Check .................................................................................................23

G. Diagnostic Tables ................................................................................................24

1. No Ice Production ...........................................................................................24

2. Freeze-Up ......................................................................................................27

3. Low Ice Production .........................................................................................28

4. Abnormal Ice ..................................................................................................28

5. Other ..............................................................................................................29

III. Controls and Adjustments........................................................................................30

A. Control Board Layout ...........................................................................................31

B. LED Lights and Audible Alarm Safeties ...............................................................32

C. Settings and Adjustments ....................................................................................33

1. Default Dip Switch Settings ............................................................................33

2. Harvest Timer .................................................................................................33

3. Pump-Out Timer .............................................................................................34

4. Pump-Out Frequency Control ........................................................................34

CONTENTS

2

Page 4

5. Harvest Pump Timer.......................................................................................35

6. Freeze Timer ..................................................................................................35

7. Pump-Out/Drain Selector ...............................................................................36

8. Harvest Promotion Control .............................................................................36

9. Rell Counter .................................................................................................36

10. Harvest Completion Detection Control ...........................................................36

11. Overfreeze Detection Control .........................................................................37

12. Anti-Slush Control ...........................................................................................37

13. Control Board Replacement ...........................................................................38

D. Switches ..............................................................................................................38

1. Control Switch ................................................................................................38

2. Service Switch ................................................................................................38

IV. Refrigeration Circuit and Component Service Information ......................................40

A. Refrigeration Circuit Service Information ............................................................. 40

1. Refrigerant Recovery .....................................................................................41

2. Brazing ...........................................................................................................41

3. Evacuation and Recharge (R-404A) ..............................................................41

B. Component Service Information ..........................................................................42

C. Water Tank ...........................................................................................................43

D. Separator .............................................................................................................44

E. Door .....................................................................................................................45

F. Adjustment of Water Regulating Valve (Water-Cooled Model) .............................46

V. Maintenance .............................................................................................................47

A. Maintenance Schedule ........................................................................................47

VI. Preparing the Appliance for Periods of Non-Use ....................................................48

VII. Disposal .................................................................................................................49

VIII. Technical Information ............................................................................................50

A. Specication Data ................................................................................................50

1. KM-230BAJ ....................................................................................................50

2. KM-300BAJ ....................................................................................................51

3. KM-300BWJ ...................................................................................................52

B. Performance Data ................................................................................................53

1. KM-230BAJ ....................................................................................................53

2. KM-300BAJ ....................................................................................................54

3. KM-300BWJ ...................................................................................................55

C. Wiring Diagram ....................................................................................................56

3

Page 5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the installation, use,

and care of the appliance.

WARNING

The appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting from

improper, incorrect, and unreasonable use. Failure to service and maintain the

appliance in accordance with this manual will adversely affect safety, performance,

component life, and warranty coverage and may result in costly water damage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service the appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations.

• The appliance requires an independent power supply of proper capacity. See

the nameplate for electrical specications. Failure to use an independent power

supply of proper capacity can result in a tripped breaker, blown fuse, damage to

existing wiring, or component failure. This could lead to heat generation or re.

• THE APPLIANCE MUST BE GROUNDED: The appliance is equipped with a

NEMA 5-15 three-prong grounding plug to reduce the risk of potential shock

hazards. It must be plugged into a properly grounded, independent 3-prong wall

outlet. If the outlet is a 2-prong outlet, it is your personal responsibility to have a

qualied electrician replace it with a properly grounded, independent 3-prong wall

outlet. Do not remove the ground prong from the plug and do not use an adapter

plug. Failure to properly ground the appliance could result in death or serious

injury.

• Do not use an extension cord.

• To reduce the risk of electric shock, do not touch the control switch, service switch,

or plug with damp hands. Make sure the control switch is in the "OFF" position

before plugging in or unplugging the appliance.

• Do not use an appliance with a damaged power cord. The power cord should not

be altered, jerked, bundled, weighed down, pinched, or tangled. Such actions

could result in electric shock or re. To unplug the appliance, be sure to pull the

plug, not the cord, and do not jerk the cord.

• Do not make any alterations to the appliance. Alterations could result in electric

shock, injury, re, or damage to the appliance.

4

Page 6

WARNING, continued

• The appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Young children should be properly supervised around the appliance.

• Do not climb, stand, or hang on the appliance or appliance door or allow children

or animals to do so. Serious injury could occur or the appliance could be

damaged.

• Be careful not to pinch ngers when opening and closing the door. Be careful

when opening and closing the door when children are in the area.

• Do not use combustible spray or place volatile or ammable substances near the

appliance. They might catch re.

• Keep the area around the appliance clean. Dirt, dust, or insects in the appliance

could cause harm to individuals or damage to the appliance.

NOTICE

• Protect the oor when moving the appliance to prevent damage to the oor.

• Follow the water supply, drain connection, and maintenance instructions carefully

to reduce the risk of costly water damage.

• In areas where water damage is a concern, install in a contained area with a oor

drain.

• Install the appliance in a location that stays above freezing. Normal operating

ambient temperature must be within 45°F to 100°F (7°C to 38°C).

• If water collects in the bin and will not drain, turn off the appliance and close the

water supply line shut-off valve. Locate and resolve the issue.

• Do not leave the appliance on during extended periods of non-use, extended

absences, or in sub-freezing temperatures. To properly prepare the appliance for

these occasions, follow the instructions in "VI. Preparing the Appliance for Periods

of Non-Use."

• Keep ventilation openings, in the appliance enclosure or in the built-in structure,

clear of obstruction.

• Do not place more than 33 lb. (15 kg) on the top panel.

• The storage bin is for ice use only. Do not store anything else in the storage bin.

5

Page 7

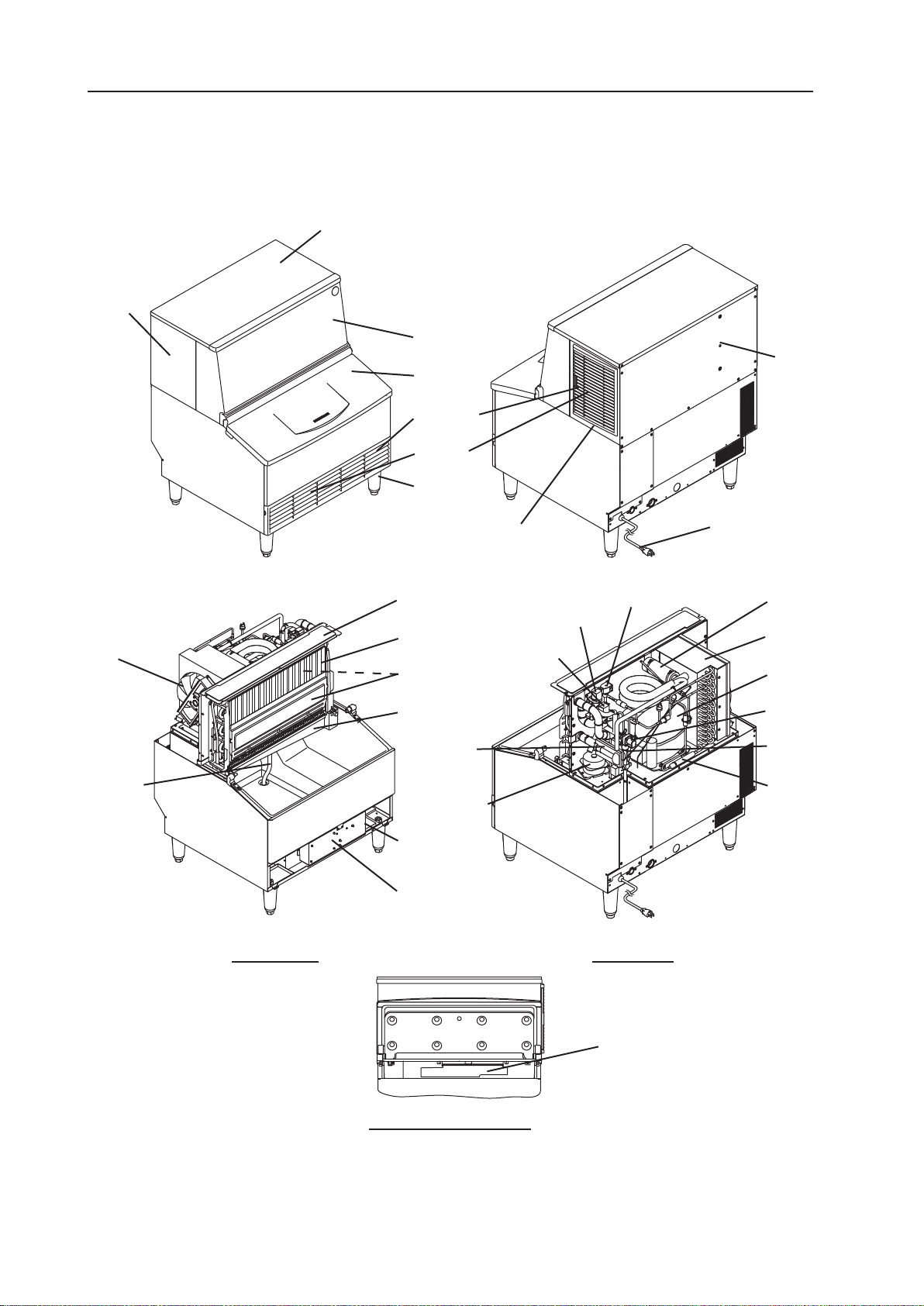

I. Construction and Water/Refrigeration Circuit Diagram

A. Construction

1. KM-230BAJ, KM-300BAJ

Top Panel

Side Panel (L)

Front Cover

Rear Panel

Door

Air Filter

Louver

Leg

Side Panel (R) Power Supply Cord

Top Cover Hot Gas Valve Thermistor

Drain Valve

Evaporator Condenser

Fan Motor Cleaning Valve

Separator Compressor

Water Tank Water Valve

Expansion Float Switch

Valve

Overow Pipe Drier

Pump Motor

Control Switch

Service Switch

Control Box

Front View Rear View

Bin Control Switch

With Tank Removed

6

Page 8

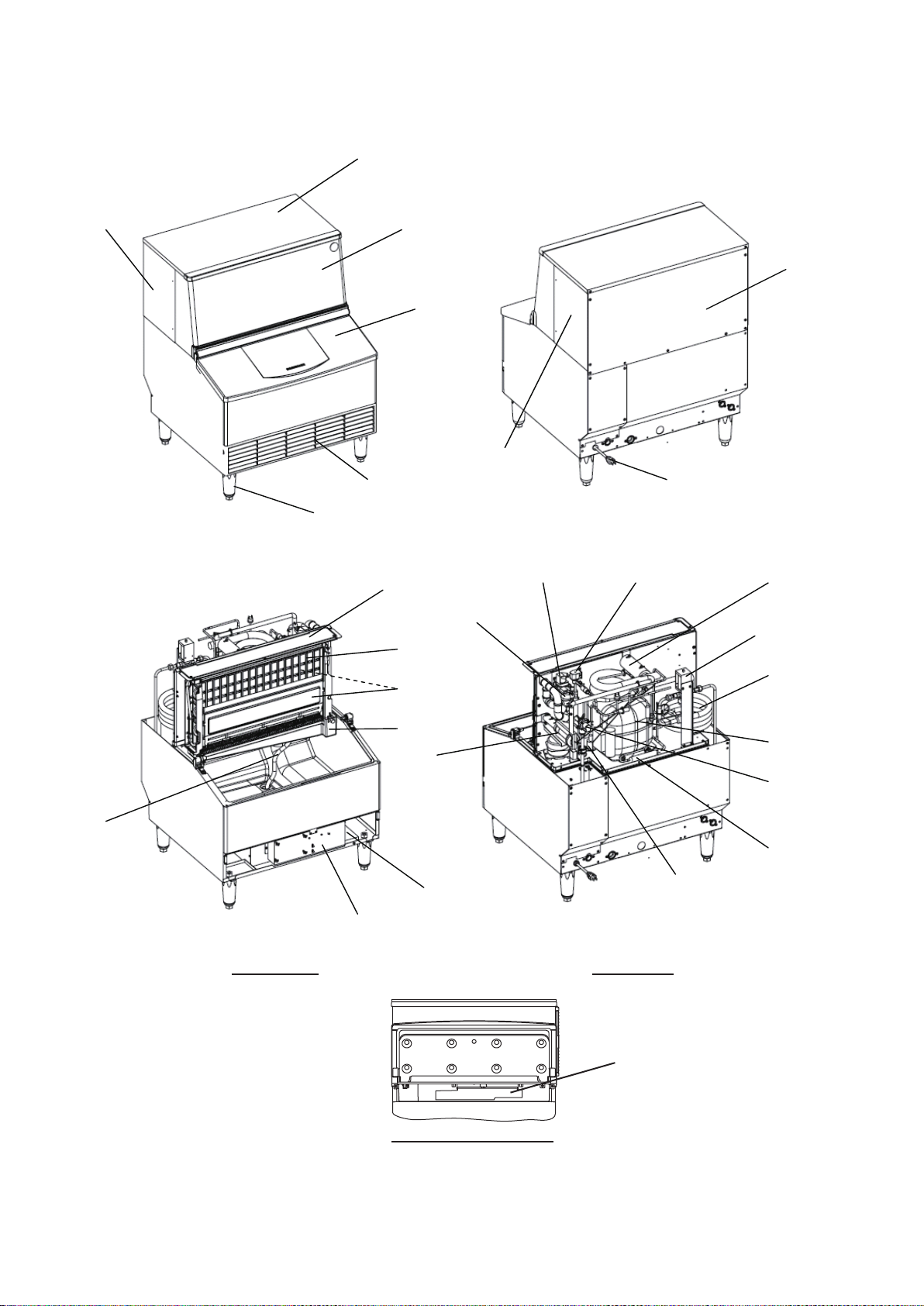

2. KM-300BWJ

Top Panel

Side Panel (L) Front Cover

Rear Panel

Door

Side Panel (R)

Louver Power Supply Cord

Leg

Top Cover Drain Valve Hot Gas Valve Thermistor

Cleaning Valve

Water Regulating

Evaporator Valve

Condenser

Separator

Water Tank

Compressor

Expansion

Valve Water Valve

Overow Pipe

Drier

Control Switch Float Switch

Service Switch

Control Box

Front View Rear View

Bin Control Switch

With Tank Removed

7

Page 9

3. Icemaking Compartment

Spray Tube

Evaporator

Water Supply Pipe

Separator

Cube Guide

Water Tank

Overow Pipe

Drain Valve

Cleaning Valve Separator

Water Valve

Pump Motor

Float Switch

8

Page 10

High Pressure

B. Water/Refrigeration Circuit Diagram

1. KM-230BAJ

Hot Gas

Strainer

Switch

Suction

Line

Valve

Discharge Line

Condenser

Water

Supply

Water Valve

Fan

Drier

Insulation Tube

Cleaning

Valve

Drain

Valve

Compressor

Thermistor

Drain

Float

Switch

Pump

Motor

Water Tank

ccess Valve

Refrigerant Circuit

Expansion Valve

Water Circuit

Spray Tube

Evaporator

9

Cube Guide

Page 11

2. KM-300BAJ

High Pressure

Switch

Suction

Line

Hot Gas

Strainer

Valve

Discharge Line

Condenser

Water

Supply

Water Valve

Fan

Drier

Insulation Tube

Cleaning

Valve

Drain

Valve

Compressor

Thermistor

Drain

Float

Switch

Pump

Motor

Water Tank

Access Valve

Refrigerant Circuit

Expansion Valve

Water Circuit

Spray Tube

Evaporator

Cube Guide

10

Page 12

3. KM-300BWJ

High Pressure

Switch

Drain

Suction

Line

Hot Gas

Strainer

Valve

Discharge Line

Water Regulating

Valve

Water Condenser

Water

Supply

Water

Supply

Water Valve

Drier

Compressor

Access Valve

Expansion Valve

Insulation Tube

Drain

Cleaning

Valve

Valve

Thermistor

Drain

Float

Switch

Refrigerant Circuit

Water Circuit

Pump

Water Tank

Motor

Spray Tube

Evaporator

Cube Guide

11

Page 13

II. Sequence of Operation and Service Diagnosis

A. Sequence of Operation

1. Flow Chart

12

extended periods of time over the outside surface of the evaporator.

DRAIN Power is supplied to the pump and drain valve. This drains the water tank.

Components Energized when the Control Switch is in the “SERVICE” Position

When in the “SERVICE” position, the control switch supplies power to the service switch and the machine

is in service mode. The service switch has three positions: “DRAIN”, “CIRCULATE”, and “WASH”. See the

CIRCULATE Power is supplied to the pump only. This operation can be used to circulate cleaner for

information below for details of each function.

and sanitizer over both the insde and outside surfaces of the evaporator.

WASH Power is supplied to the pump and cleaning valve. This operation is used to circulate cleaner

Page 14

n

2. Timing Chart

60sec

HARVEST CYCLE

Thermistor senses 9°C

after 6 min to 8 min 30 sec

in harvest cycle

HARVEST CYCLE

Thermistor senses 9°C after more

than 8 min 30 sec in harvest cycle

FREEZE CYCLE

HARVEST CYCLE

(AFTER BIN FULL)

BIN FULLPART NAME

FREEZE CYCLE HARVEST CYCLE

6min

10 or 30sec

3min

Max 6 min Max 6 mi

6min

10℃

10℃

10 sec OFF, 50 sec ON

Max 6 min

90 sec

10 sec

Max 6 min

15 sec

HARVEST CYCLE

(INCLUDING DRAIN)

FREEZE CYCLE HARVEST CYCLE FREEZE CYCLE

(INITIAL)

HARVEST CYCLE

10 sec

Max 6 min Max 6 min

10℃ 10℃

ON

9°C

OFF

POWER SWITCH

ON

1°C

THERMISTOR

10 sec OFF, 50 sec ON 10 sec OFF, 50 sec ON 10 sec OFF, 50 sec ON

Max 6 min

10 or 30sec 10 or 30sec 10 or 30sec 30 or 50sec 10 or 30sec

5 sec

ON

ON

ON

ON

ON

FAN MOTOR

OFF

*KM-230BAJ, 300BAJ

OFF

KM-230BAJ] 30sec

PUMP MOTOR

[

OFF

COMPRESSOR

ON

ON

ON

ON

OFF

OFF

OFF

OFF

DRAIN VALVE

WATER VALVE

HOT GAS VALVE

[KM-300BAJ/BWJ] 10sec

CLEANING VALVE

ON

OFF

OFF

SWITCH

BIN CONTROL

FLOAT SWITCH

ON

OFF

OFF

(COMP)

(HV/FM)

RELAY: X2

RELAY: X1

ON

ON

OFF

(PM)

RELAY: X3

OFF

OFF

(DV)

(WV)

RELAY: X6

RELAY: X4

CONTROLLER BOARD

13

Page 15

3. Details

The steps in the sequence are as outlined below. When power is supplied, a 5 second

delay occurs at startup. Note that the order of the LEDs from the outer edge of the board

is 5, 6, 8, 4, 7.

a) One Minute Fill Cycle

LED 8 is on. WV opens and the ll period begins. After 1 minute, the board checks for

a closed F/S. If F/S is closed, the harvest cycle begins. If not, WV will remain energized

through additional 1 minute cycles until water enters the sump and F/S closes. This

serves as a low water safety to protect the pump motor.

b) Initial Harvest Cycle

LEDs 5, 6, and 8 are on. WV remains open, Comp energizes, HGV opens, and harvest

begins. As the evaporator warms, the thermistor located on the suction line checks for a

48°F (9°C) temperature. When 48°F (9°C) is reached, a 3.9 kΩ signal turns the harvest

over to the adjustable harvest timer which is factory set for normal conditions. The timer

has settings of 60, 90, 120, and 180 seconds (S1 dip switch 1 & 2). When the harvest

timer completes its count down, the harvest cycle is complete and the freeze cycle

starts. The minimum total time allowed by the board for a complete harvest cycle is 2

minutes. WV is open during harvest for a maximum of 6 minutes or the length of harvest

minus 0, 10, 30, or 50 seconds (adjustable by S1 dip switch 7 & 8), whichever is shorter.

LED 8 goes off when WV closes. PM energizes and runs for the last 0, 10, 30, or 50

seconds of harvest depending on S1 dip switch 7 & 8 setting. LED 7 comes on when

PM energizes. At the end of harvest, the control board checks the position of F/S and

proceeds to the freeze cycle if it is closed or calls for a 1-minute ll if it is open.

c) Freeze Cycle

LEDs 5 & 7 are on. Comp continues to run, PM and FMS energize, HGV closes and the

freeze cycle starts. For the rst 5 minutes after the thermistor temperature reaches 36°F

(2°C), the control board will not accept a signal from F/S. This minimum freeze period

acts as a short cycle protection. At the end of this period, F/S assumes control. As the

evaporator cools, the thermistor located on the suction line checks the temperature and

PM stops (see “II. A. 2. Timing Chart” for details). This is to prevent slushing. As ice

builds on the evaporator the water level in the sump lowers. The freeze continues until

F/S opens and terminates ice production.

d) Pump-Out Cycle

LEDs 4, 5, 6, and 7 are on. Comp continues to run, HGV opens, FMS de-energizes. PM

stops for 2 seconds, DV energizes, then PM restarts to take water from the sump and

force it through DV and down the drain. When the drain timer stops counting, the drain

is complete. The drain timer has settings of 10 and 20 seconds (S1 dip switch 3 & 4).

Pump-out cycle always occurs on the 2nd harvest after startup. Then, depending on

14

Page 16

the control board setting, pump-out cycle occurs every cycle, or every 2nd, 5th, or 10th

cycle (S1 dip switch 5 & 6).

e) Normal Harvest Cycle

LEDs 5, 6, and 8 are on. Comp continues to run, HGV remains open and WV opens.

As the evaporator warms, the thermistor reaches 48°F (9°C). The control board then

receives the thermistor's 3.9 kΩ signal and starts the harvest timer. WV is open during

harvest for a maximum of 6 minutes or the length of harvest minus 0, 10, 30, or 50

seconds (adjustable by S1 dip switch 7 & 8), whichever is shorter. LED 8 goes off when

WV closes. PM energizes and runs for the last 0, 10, 30, or 50 seconds of harvest

depending on S1 dip switch 7 & 8 setting. LED 7 comes on when PM energizes. At the

end of harvest, the control board checks the position of F/S and proceeds to the freeze

cycle if it is closed or calls for a 1-minute ll if it is open.

The unit continues to cycle through c, d, and e sequence until the bin control is activated

and shuts the unit down. When the bin control is activated, the “POWER OK” LED

ashes.

f) Shutdown

When BC is activated (BC open), the “POWER OK” LED flashes. There is a delay

before the shutdown sequence begins. The delay varies depending on the cycle the

icemaker is in at the time of activation. For details, see the table below.

Cycle at Bin Control Activation Delay Before Shutdown Sequence Begins

Fill Cycle 15 seconds

Harvest Cycle 15 seconds after the next freeze cycle starts

Freeze Cycle 15 seconds if BC is activated between the beginning of

freeze and termination of the 5-minute short cycle protection

timer (timer starts when the thermistor temperature drops to

36°F (2°C) (5.5 kΩ or more)). After this time, the unit will not

shut down until the next harvest cycle is complete.

After the delay, all components de-energize. DV energizes after 2 seconds. PM

energizes after 2 seconds. PM takes water from the tank and forces it through DV and

down the drain. The water tank drains for a maximum of 5 minutes or until F/S opens.

DV and PM then de-energize. When BC closes again calling for ice, the unit starts at

the 1-minute ll cycle. There is a 90-second minimum off time before the icemaker can

restart.

Legend: BC–bin control; Comp–compressor; DV–drain valve; FMS–self-contained fan

motor; F/S–oat switch; HGV–hot gas valve; PM–pump motor; WV–inlet water

valve

15

Page 17

B. Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Control switch in "OFF" position does not de-energize all

loads. Use extereme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

• Before servicing the appliance, move the control switch to the “OFF“ position and

unplug the appliance.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the appliance is serviced. Make sure that none have fallen

into the ice storage bin.

• Make sure all food zones in the appliance and ice storage bin are clean after

service.

The diagnostic procedure is basically a sequence check which can be used at unit startup or for system diagnosis. Using this check out procedure will allow you to diagnose

electrical system and component failures in approximately 10 minutes under normal

operating conditions of 70°F (21°C) or warmer air and 50°F (10°C) or warmer water

temperatures. Before conducting a 10 minute checkout, check for correct installation,

proper voltage per unit nameplate and adequate water supply. As you go through the

procedure, check to assure the components energize and de-energize correctly. If not,

those components and controls are suspect.

1) Remove the louver. Move the control switch to the “OFF“ position, then unplug the

appliance. Access the control box. Clear any ice from the bin control actuator located

in the bin.

2) Plug in the appliance, then place the control switch in the “ICE” position. A 5 second

delay occurs. The “POWER OK” LED on the control board comes on. If the “POWER

OK” LED is ashing (indicating a full bin), check the bin control. See “II. D. 1 Bin

Control Check”.

3) One Minute Fill Cycle – The inlet water valve is energized. After 1 minute, the control

board checks the oat switch. If the oat switch is closed, the unit cycles to harvest.

If closed, continue to step 4. If the oat switch is open, the unit repeats the 1 minute

ll cycle until water enters and the oat switch closes (low water safety protection

during initial start up and at the end of each harvest). Diagnosis: If the water valve

does not open, check for no supply voltage at water valve terminals, bad coil, or

plugged screen or external lter (no water ow). If unit fails to start harvest, check for

open oat switch or bad 1 minute timer in board.

16

Page 18

4) Initial Harvest Cycle – The inlet water valve remains energized, contactor coil

energizes to start the compressor (and fan motor on a remote condenser unit),

and the hot gas valve energizes. The evaporator warms and the thermistor senses

48°F (9°C). The control board then receives the thermistor’s 3.9 kΩ signal and

turns operation of harvest over to the harvest timer. The timer completes counting

(1 to 3 minutes). The unit then cycles to freeze. Diagnosis: Check if compressor

is running, hot gas valve is open, water valve still open. Average harvest cycle at

factory setting is 2 to 3 minutes. How long does initial harvest last? 1.5 minutes after

initial harvest begins, touch the compressor discharge line. Is it hot? If not check

refrigerant pressures and compressor operation. If it is hot, touch the inlet line to the

evaporator. Is it hot? If it is hot and the freeze cycle is not starting, check the harvest

timer adjustment, the thermistor for open circuit, the discharge line temperature,

compressor efciency, and if the hot gas valve is fully open.

5) Freeze Cycle – The compressor remains energized, pump motor, (line valve if

applicable), and fan motor energize. The inlet water valve and hot gas valve deenergize. The unit is held in freeze by a 5 minute short cycle protection timer which

starts after the thermistor temperature reaches 36°F (2°C). After this period, the

freeze cycle operation is transferred to the oat switch for freeze termination. During

the rst 5 minutes of freeze, conrm that the evaporator temperature drops. After the

minimum freeze period, disconnect the oat switch at the 2-pin connector attached to

the red wires. The unit should immediately switch to the pump-out cycle. Diagnosis:

If the evaporator is not cold, check to see if the hot gas valve is still open or if the

expansion valve is not opening properly, if the water valve is continuing to ll the

reservoir, if there are improper unit pressures or an inoperative compressor. If the

unit remains in freeze with the oat switch removed, replace the board.

Note: Normal freeze cycle will last 20 to 40 minutes depending on model and

conditions. Cycle times and pressures should follow performance data provided

in this manual.

6) Pump-Out Cycle – The compressor remains energized, the hot gas valve energizes,

the fan motor de-energizes. The drain valve and pump motor energize, allowing

water to drain from the tank for 10 seconds. This removes contaminants from the

water tank. Diagnosis: If the drain valve does not open, check the circuit. Check for

proper voltage. If water does not drain out, check and clean the tubing at the drain

valve and then check and clean the valve assembly.

7) Normal Harvest Cycle – same as the initial harvest cycle – Return to step 4.

8) Shutdown – See “II. D. 1 Bin Control Check”. Note that after a bin-control initiated

shutdown, there is a 90 second minimum off time.

Note: Unit continues to cycle until bin control is satised or power is turned off. (The

pump-out cycle can be adjusted to occur every cycle, or every 2, 5, or 10 cycles.

The factory default is every 10 cycles.) The unit always restarts at the 1 minute

ll cycle.

17

Page 19

C. Control Board Check

Before replacing a control board that does not show a visible defect and that you

suspect is bad, always conduct the following check procedure. This procedure will help

you verify your diagnosis.

Alarm Reset: If CB is in alarm (beeping), press the “ALARM RESET” button on CB while

CB is beeping. WARNING! Risk of electric shock. Care should be

taken not to touch live terminals. Once reset, the icemaker starts at the

1-minute ll cycle. For audible alarm information, see “III.B. LED Lights

and Audible Alarm Safeties.”

1) Remove the louver. Move the control switch to the “OFF” position, then unplug the

appliance. Access the control box.

2) Check the dip switch settings to assure that S1 dip switch 3, 4, 7, 8, 9, & 10 and S2

dip switch 1 through 6 are in the factory default position. S1 dip switch 1, 2, 5, & 6

are cleaning adjustments and the settings are exible.

3) Plug in the appliance. Move the control switch to the “ICE” position and check for

proper control voltage. If the “POWER OK” LED is on, the control voltage is good.

If the “POWER OK” LED is off, check the control transformer circuit. If no voltage is

present, check the power supply circuit.

4) To perform a relay sequence test, move the control switch to the “ICE“ position while

pressing the “OUTPUT TEST” button. WARNING! Risk of electric shock. Care

should be taken not to touch live terminals. The correct lighting sequence should

be 5, 6, 7, 8, 9, 4. Some components (e.g., the compressor) will cycle during test.

Each LED comes on for 5 seconds. LED 5 is on while LED 6 is on. Following the

output test sequence, the icemaker will resume normal operation beginning with the

1 minute ll cycle.

D. Bin Control Check and Cleaning

This machine uses a lever-actuated proximity switch (mechanical bin control) to control

the ice level in the storage bin. No adjustment is required.

The bin control is connected to the K1 connector (pins 4 & 5) on the control board. When

the bin control is calling for ice (proximity switch closed; “POWER OK” LED on), the

control board continues icemaking operations. When the bin control is activated in the

bin full position (proximity switch open; “POWER OK” LED ashing), the control board

drains and shuts down the unit. However, to prevent incomplete batches of ice from

forming on the evaporator, the control board will only shut down the machine during the

freeze cycle before the ve minute timer expires. The ve minute timer starts counting

down when the thermistor temperature reaches 36°F (2°C). If, during the freeze cycle,

ice pushes in the lever after the ve minute timer expires, the control board will allow the

18

Page 20

machine to complete the freeze cycle and the following harvest cycle before shutting

down the machine.

When the bin control is activated, the “POWER OK” LED flashes. There is a delay

before the shutdown sequence begins. The delay varies depending on the cycle the

icemaker is in at the time of activation. For details, see the table below.

Cycle at Bin Control Activation Delay Before Shutdown Sequence Begins

Fill Cycle 15 seconds

Harvest Cycle 15 seconds after the next freeze cycle starts

Freeze Cycle 15 seconds if the bin control is activated between the

beginning of freeze and termination of the 5-minute short

cycle protection timer (timer starts when the thermistor

temperature drops to 36°F (2°C) (5.5 kΩ or more)). After this

time, the unit will not shut down until the next harvest cycle is

complete.

1. Bin Control Check

1) Remove the louver. Move the control switch to the “OFF” position, then unplug the

appliance. Access the control box.

2) Clear any ice away from the bin control.

3) Disconnect the bin control at the 2-pin connector attached to the black wires coming

from the K1 connector (pins 4 & 5) on the control board.

4) Check for continuity across the bin control leads. When calling for ice, the bin control

proximity switch should be closed. If open, replace the bin control. Activate the bin

control actuator (press the actuator in), check for continuity across the bin control

leads. The bin control proximity switch should be open. If closed, replace the bin

control.

5) Reconnect the 2-pin connector. Plug in the appliance, then move the control switch

to the “ICE“ position. Allow the machine to cycle into the freeze cycle. In the rst 5

minutes of the freeze cycle, activate the bin control actuator (press the actuator in).

The “POWER OK” LED should ash and the machine should turn off. If not, replace

the control board.

2. Bin Control Cleaning

Scale may build up on MBC. Scale can cause the actuator paddle and magnet to stick.

In this case, MBC should be cleaned.

19

Page 21

WARNING

CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the icemaker is serviced. Make sure that none have fallen into

the ice storage bin.

1) Remove the louver. Move the control switch to the “OFF” position, then unplug the

appliance.

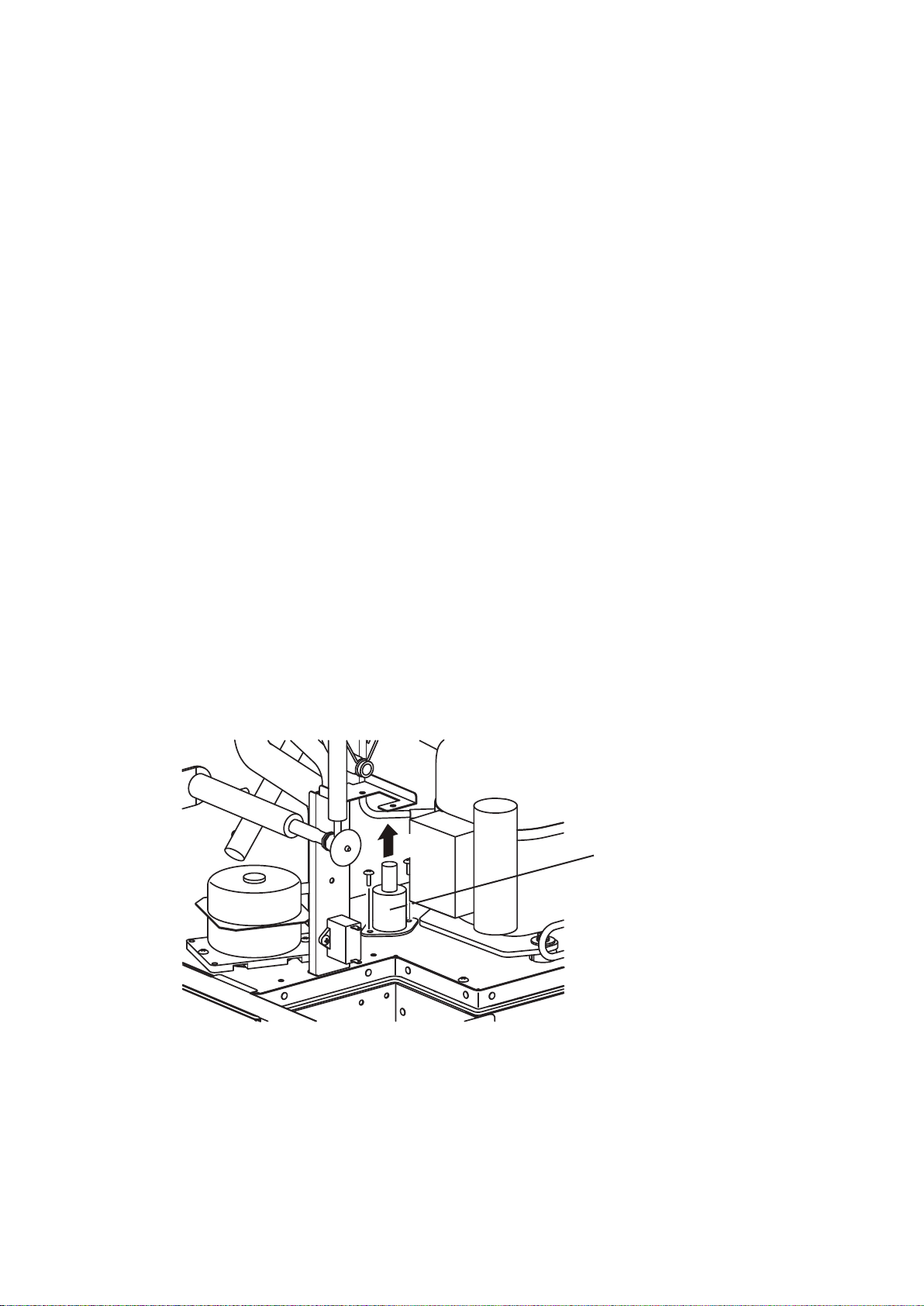

2) Remove the water tank (see “IV. C. WATER TANK“). The bin control switch is

located as shown below when viewed from the front.

Bin Control Switch

Fig. 1

3) Remove the top panel and the rear panel.

4) Disconnect the connector of the bin control switch lead (black) covered with a

silicone hose and remove the lead wire from the grommet.

5) Loosen the thumbscrew on the right side.

6) Remove the thumbscrew on the left side. Shift the bin control switch to the left to

remove.

Shift to the left

and remove

Remove Loosen

20

Fig. 2

Page 22

7) Wipe down MBC with a mixture of 1 part of Hoshizaki “Scale Away” and 25 parts of

warm water. Rinse the parts thoroughly with clean water.

8) Ret the removed parts in the reverse order of the removal procedure.

9) Plug in the appliance.

Legend: MBC–mechanical bin control

E. Float Switch Check and Cleaning

FS is used to determine that there is sufcient water in the water tank after the 1-min.

ll cycle and after each harvest cycle. FS is also used to determine that the appropriate

volume of water has been converted into ice before switching out of the freeze cycle. No

adjustment is required.

1. Float Switch Check

To check FS, follow the steps below.

1) Remove the louver.

2) Drain out the water tank by leaving the control switch in the “SERVICE“ position and

the service switch in the “DRAIN“ position until the tank is empty.

3) Move the control switch to the “OFF“ position, then unplug the appliance.

4) Remove the top panel, rear panel and right side panel.

5) Disconnect the connector of the FS lead.

6) Check for continuity across FS leads. With the water tank empty, FS should be

open. If open, continue to step 7. If closed, follow the steps in “II. E. 2. Float Switch

Cleaning.“ After cleaning FS, check it again. Replace if necessary.

7) Reconnect FS connector.

8) Move the control switch to the “ICE” position. Replace the top panel, rear panel and

right side panel in their correct positions, then plug in the appliance. After 1 min.,

the 1-min. ll cycle should end and the initial harvest cycle should begin. If the initial

harvest cycle begins, FS is good and the check is complete. If the initial harvest

cycle does not begin, continue to step 9.

9)Move the control switch to the “OFF” position, then unplug the appliance.

10) Remove the top panel, rear panel and right side panel.

21

Page 23

11) Disconnect the connector of the FS lead.

12) Check for continuity across FS leads. With the water tank full, FS should be closed.

If FS is closed and the icemaker will not switch from the 1-min. ll cycle to the initial

harvest cycle, replace CB.

If FS is open, conrm that the water tank is full. If the water tank is not full, check the

water supply, water lters, and inlet water valve. If the water tank is full, follow the

steps in “II.E.2. Float Switch Cleaning.” After cleaning FS, check it again. Replace if

necessary.

Legend: CB–control board; FS-oat switch

2. Float Switch Cleaning

Depending on local water conditions, scale may build up on FS. Scale on the switch can

cause the oat to stick. In this case, FS should be cleaned.

1) Remove the louver.

2) Drain out the water tank by leaving the control switch in the “SERVICE“ position and

the service switch in the “DRAIN“ position until the tank is empty.

3) Move the control switch to the “OFF“ position, then unplug the appliance.

4) Remove the top panel, rear panel and right side panel.

5) Disconnect the connector of the FS lead. Remove the two mounting screws and FS.

Lift off

Float Switch

Fig. 3

6) Wipe down shaft and oat with a mixture of 1 part Hoshizaki “Scale Away” and 25

parts warm water. Rinse the parts thoroughly with clean water.

22

Page 24

7) Replace FS in its correct position and secure it with the two screws. Then connect FS

connector.

8) Replace the right side panel, rear panel and top panel in their correct positions.

9) Plug in the appliance, then move the control switch to the “ICE” position.

Legend: CB–control board; FS-oat switch

F. Thermistor Check

A thermistor (semiconductor) is used as a harvest control sensor and anti-slush sensor.

The resistance varies depending on the suction line temperatures. The thermistor

detects the temperature of the evaporator outlet to start the harvest timer or momentarily

stop the pump motor during the freeze cycle. No adjustment is required. If necessary,

check for resistance between thermistor leads, and visually check the thermistor

mounting, located on the suction line next to the evaporator outlet.

Temperature (°F) Temperature (°C) Resistance (kΩ)

0 -18 14.401

10 -12 10.613

32 0 6.000

50 10 3.871

70 21 2.474

90 32 1.633

Check a thermistor for resistance by using the following procedure:

1) Remove the louver. Move the control switch to the “OFF” position, then unplug the

appliance.

2) Disconnect the connector K1 on the board.

3) Remove the thermistor.

4) Immerse the thermistor sensor portion in a glass containing ice and water for 2 or 3

minutes.

5) Check for resistance between the thermistor leads. Normal reading is within 4.7 to 6.2

kΩ. Replace the thermistor if it exceeds the normal reading.

23

Page 25

G. Diagnostic Tables

1. No Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] The icemaker

will not start.

a) Power Supply 1. OFF position. 1. Move to ON position.

2. Loose connections. 2. Tighten.

3. Bad contacts. 3. Check for continuity and

replace.

4. Voltage too high. 4. Check and get

recommended voltage.

5. Unplugged. 5. Plug in.

b) Fuse (inside fused

disconnect, if any)

c) Control Switch 1. OFF or SERVICE position. 1. Move to ICE position.

d) Bin Control Switch 1. Tripped with bin filled with

e) High Pressure

Control

f) Transformer 1. Thermal fuse blown or coil

g) Wiring to Control

Board

h) Thermistor 1. Leads shorted or open and

i) Hot Gas Solenoid

Valve

j) Water Supply Line 1. Water supply off and water

k) Inlet Water Valve 1. Mesh filter or orifice gets

l) Control Board 1. Defective. 1. See “II.C. Control Board

1. Blown. 1. Check for short circuit

and replace.

2. Bad contacts. 2. Check for continuity and

replace.

1. Remove ice.

ice.

2. Defective reed switch. 2. Check for continuity and

replace.

1. Bad contacts. 1. Check for continuity and

replace.

1. Replace.

winding open.

1. Loose connections or open. 1. Check for continuity and

replace.

1. See “II.F. Thermistor

high temperature safety

operates. If open, unit will

start but have long harvest

cycle.

1. Continues to open in freeze

cycle and high temperature

safety operates.

supply cycle does not finish.

2. Condenser water pressure

too low or off and high

pressure control opens and

closes frequently

(water-cooled model).

clogged and water supply

cycle does not finish.

2. Coil winding open. 2. Replace.

3. Wiring to water valve. 3. Check for loose

Check”.

1. Check for power off in

freeze cycle and replace.

1. Check and get

recommended pressure.

Check for water supply.

2. Check and get

recommended pressure.

1. Clean. Replace if

necessary.

connection or open, and

replace.

Check”.

24

Page 26

PROBLEM POSSIBLE CAUSE REMEDY

[2] Water

continues to be

supplied, and

the icemaker

will not start.

[3] Compressor

will not start or

operates

intermittently.

a) Float Switch 1. Connector disconnected. 1. Reconnect.

2. Leads open or defective

2. Check and replace.

switch.

3. Float does not move freely. 3. Clean or replace.

b) Control Board 1. Defective. 1. Replace.

a) Control Switch 1. SERVICE position. 1. Move to ICE position.

2. Bad contacts. 2. Check and replace.

b) High Pressure

Control

1. Dirty air filter or condenser. 1. Clean.

2. Ambient temperature too

warm.

2. Reduce ambient

temperature.

3. Refrigerant overcharged. 3. Recharge.

4. Fan not operating. 4. See chart 1 - [6].

5. Condenser water pressure

too low or off (water-cooled

5. Check and get

recommended pressure.

model).

6. Condenser water

temperature too warm

(water-cooled model).

7. Refrigerant line or

6. Check and get

recommended

temperature.

7. Clean and replace drier.

components plugged.

c) Overload

Protector

1. Bad contacts. 1. Check for continuity and

replace.

2. Voltage too low. 2. Increase voltage.

3. Refrigerant overcharged or

3. Recharge.

undercharged.

d) Starter 1. Bad contacts. 1. Check and replace.

2. Coil winding open. 2. Replace.

e) Start Capacitor 1. Defective. 1. Replace.

f) Power Relay 1. Bad contacts. 1. Check for continuity and

replace.

2. Coil winding open. 2. Replace.

g) Compressor 1. Wiring to compressor. 1. Check for loose

connection or open, and

replace.

2. Defective. 2. Replace.

3. Protector tripped. 3. Reduce temperature and

verify cause.

h) Control Board 1. Defective. 1. See “II.C. Control Board

Check”.

i) Condenser, Air

1. Clogged with dirt and dust. 1. Clean and unclog.

Filter

j) Water Regulating

Valve

1. Set too high. 1. Adjust lower.

2. Clogged or defective. 2. Clean or replace.

(water-cooled

model)

25

Page 27

PROBLEM POSSIBLE CAUSE REMEDY

[4] Water

continues to

be supplied in

freeze cycle.

a) Inlet Water Valve 1. Diaphragm does not close. 1. Check for water leaks

with icemaker off.

Replace if necessary.

b) Control Board 1. Defective. 1. See “II.C. Control Board

Check”.

[5] No water

comes from

Spray Tubes.

Water Pump

will not start,

or freeze

cycle time is

too short.

a) Water Supply Line 1. Water pressure too low and

water level in water tank too

1. Check and get

recommended pressure.

low.

b) Inlet Water Valve 1. Dirty mesh filter or orifice

1. Clean.

and water level in water tank

too low.

c) Water System 1. Water leaks. 1. Check connections for

water leaks, and replace.

2. Clogged. 2. Clean.

d) Pump Motor 1. Motor winding open. 1. Replace.

2. Bearing worn out. 2. Replace.

3. Wiring to pump motor. 3. Check for loose

connection or open, and

replace.

4. Defective capacitor. 4. Replace.

5. Defective or bound impeller. 5. Replace and clean.

e) Control Board 1. Defective. 1. See “II.C. Control Board

Check”.

[6] Fan Motor will

not start, or is

not operating.

a) Fan Motor 1. Motor winding open. 1. Replace.

2. Bearing worn out. 2. Replace.

3. Wiring to fan motor. 3. Check for loose

connection or open, and

replace.

4. Fan blade bound (locked fan

4. Check and replace.

motor).

b) Control Board 1. Defective. 1. See “II.C. Control Board

Check”.

[7] All

components

run but no ice

is produced.

a) Refrigerant 1. Undercharged. 1. Check for leaks and

recharge.

2. Air or moisture trapped. 2. Replace drier, and

recharge.

b) Compressor 1. Defective. 1. Replace.

c) Hot Gas Solenoid

Valve

1. Continues to open in freeze

cycle.

1. Check and replace.

26

Page 28

2. Freeze-Up

Defrost and clean the icemaker prior to diagnosing freeze-up. Fill out a freeze-up check

list.

See the Hoshizaki America Technician’s Pocket Guide or contact your local distributor

for a copy of the freeze-up checklist.

PROBLEM POSSIBLE CAUSE REMEDY

[1] Freeze cycle

time is too

long.

[2] All ice formed

on Evaporator

does not fall

into bin in

harvest cycle.

[3] Others a) Spray Tubes 1. Clogged. 1. Clean.

a) Float Switch 1. Leads shorted or defective

switch.

2. Float does not move freely. 2. Clean or replace.

b) Inlet Water Valve 1. Diaphragm does not close. 1. Check for water leaks

c) Control Board 1. Defective. 1. See “II.C. Control Board

a) Evaporator 1. Scaled up. 1. Clean.

b) Water Supply Line 1. Water pressure too low. 1. Check and get

c) Inlet Water Valve 1. Dirty mesh filter or orifice. 1. Clean.

2. Diaphragm does not close. 2. Check for water leaks

d) Ambient and/or

water temperature

e) Thermistor 1. Out of position or loose

f) Control Board 1. Harvest timer is set too

b) Water System 1. Dirty. 1. Clean.

c) Refrigerant 1. Undercharged. 1. Check for leaks and

d) Expansion Valve 1. Bulb out of position or loose

e) Hot Gas Solenoid

Valve

f) Water Supply Line 1. Too small; requires minimum

g) Water Filter 1. Flow rate too small. 1. Replace with filter that

1. Too cool. 1. Increase temperature.

attachment.

short.

2. Defective. 2. See “II.C. Control Board

2. Out of position. 2. Place in position.

attachment.

2. Defective. 2. Replace.

1. Coil winding open. 1. Replace.

2. Plunger does not move. 2. Replace.

3. Wiring to hot gas valve. 3. Check for loose

1/4" nominal ID copper water

tubing or equivalent line

dedicated per machine.

1. Check and replace.

with icemaker off.

Replace if necessary.

Check”.

recommended pressure.

with icemaker off.

Replace if necessary.

1. See “II.F. Thermistor

Check”.

1. Adjust longer, referring to

“III.C.2 Harvest Timer”.

Check”.

recharge.

1. Place in position.

connection or open, and

replace.

1. Increase water supply

line size.

has larger flow rate.

27

Page 29

3. Low Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] Freeze cycle

time is long.

[2] Harvest cycle

time is long.

a) See chart 1 - [3] and check dirty air filter or condenser, ambient or water

temperature, water pressure, water regulating valve (water-cooled model), and

refrigerant charge.

b) See chart 2 - [1] and check float switch, inlet water valve, and control board.

a) See chart 2 - [2] and check control board, thermistor, evaporator, ambient and/or

water temperature, water supply line, and inlet water valve.

4. Abnormal Ice

PROBLEM POSSIBLE CAUSE REMEDY

[1] Small cubes a) Cube Guide,

Water Tank

b) See chart 1 - [5] and check water supply line, inlet water valve, water system,

pump motor, and control board.

[2] Cloudy or

irregular cubes

a) See chart 2 - [1] and - [3] and check float switch, inlet water valve, control board,

spray tubes, water system, refrigerant charge and expansion valve.

b) Spray Guide 1. Dirty. 1. Clean.

c) Water Quality 1. High hardness or contains

1. Out of position. Circulated

water falls into bin.

impurities.

1. Check that cube guide is

properly installed on

water tank and tank is

fixed securely with snaps.

1. Install a water filter or

softener.

28

Page 30

5.

Other

PROBLEM POSSIBLE CAUSE REMEDY

[1] Icemaker will

not stop when

bin is filled with

ice.

[2] Abnormal

noise

[3] Ice in Storage

Bin often

melts.

a) Bin Control Switch 1. Completely disconnected

and dropped inside bin.

2. Detector broken. 2. Replace.

3. Detector out of position. 3. Place in position.

4. Defective reed switch. 4. Check for continuity and

5. Reed switch out of position. 5. Place in position.

6. Magnet disconnected from

detector.

b) Control Board 1. Defective. 1. See “II.C. Control Board

a) Pump Motor 1. Bearings worn out. 1. Replace.

b) Fan Motor 1. Bearings worn out. 1. Replace.

2. Fan blade deformed. 2. Replace fan blade.

3. Fan blade does not move

freely.

c) Compressor 1. Bearings worn out, or

cylinder valve broken.

2. Mounting pad out of position

or loose hold-down bolt.

d) Refrigerant Lines 1. Rub or touch lines or other

surfaces.

a) Bin Drain 1. Plugged. 1. Clean.

1. Place in position.

replace.

6. Place in position.

Check”.

3. Replace.

1. Replace.

2. Reinstall.

1. Reposition.

29

Page 31

III. Controls and Adjustments

* A HOSHIZAKI exclusive solid-state control is employed in crescent cubers.

* All models are pretested and factory-adjusted.

NOTICE

• Fragile, handle very carefully.

• The control board contains integrated circuits, which are susceptible to failure due

to static discharge. It is especially important to touch the metal part of the icemaker

when handling or replacing the control board.

• Do not touch the electronic devices on the control board or the back of the control

board.

• Do not change wiring and connections.

• Do not short out power supply to test for voltage.

• Always replace the whole control board assembly if it goes bad.

30

Page 32

A. Control Board Layout

1. Control Board Layout

• Relay LEDs (6)

(indicate which

relays are energized

as listed below)

• LED 5 (X1 Relay)

Compressor (Comp)

Fan Motor-Remote

(FMR)

• LED 6 (X2 Relay)

Hot Gas Valve (HGV)

Fan Motor (FM)

(FM off when LED on)

Liquid Line Valve (LLV)

(FM and LLV off when

LED on)

• LED 8 (X4 Relay)

Inlet Water Valve (WV)

(WV1) on units with

inlet water valves

• LED 9 (X5 Relay)

Inlet Water Valve

(WV) on units with

inlet water valves

• LED 4 (X6 Relay)

Drain Valve (DV)

• LED 7 (X3 Relay)

Pump Motor (PM)

"H" Control Board

• K7 Connector

Transformer

• K3 Connector

Power Relay

Magnetic Contactor

• "POWER OK" LED

(Lights when power is

supplied to the board.

Flashes when bin

control is activated.)

• K5 Connector

Pins

#1 Fan Motor (FM)

Liquid Line Valve (LLV)

# Hot Gas Valve

#3 Pump Motor

#4 Inlet Water Valve

#5 Open

#6 Drain Valve

• K6 Connector

Open

• K1 Connector

Pins

#1, 3 Float Switch

# Open

#4, 5 Bin Control

#6, 7 Thermistor

#8, 9 Open

• S1 Dip Switch

• S2 Dip Switch

Control Board

Part Number P01771-02

Type HKM2006V003

31

• Alarm Buzzer

• "OUTPUT TEST" Button

(used to test relays on

control board)

• "ALARM RESET" Button

Page 33

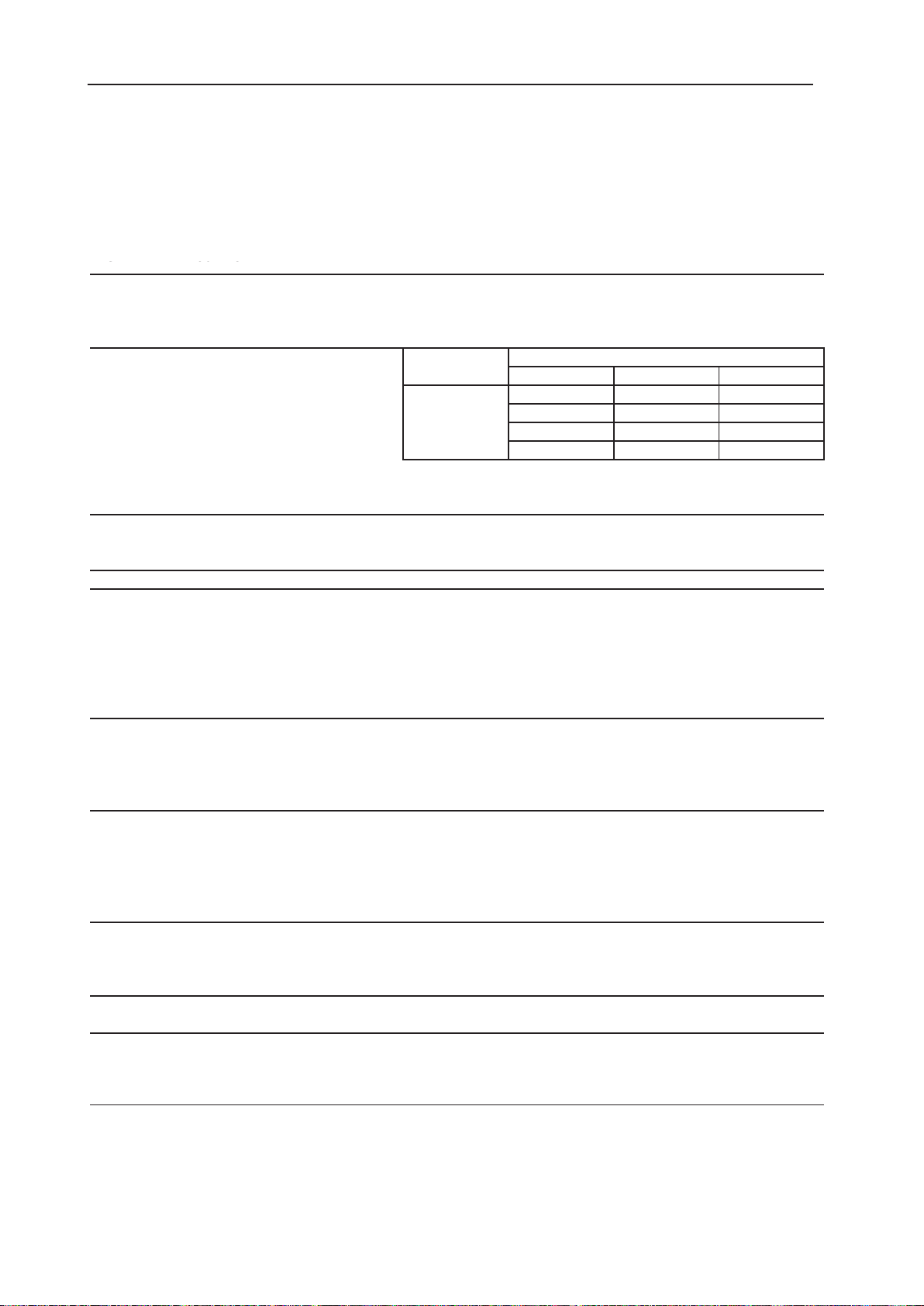

B. LED Lights and Audible Alarm Safeties

The control board includes LED indicator lights, audible alarm safeties, and an output

test feature. The “POWER OK” LED indicates control voltage and will remain on unless

a control voltage problem occurs. The “POWER OK” LED ashes continuously when the

bin is full and DV energizes for a maximum of 5 minutes to drain the water tank.

At startup, a 5 second delay occurs to stabilize the circuit. LEDs 4 through 8 energize

and sequence from initial startup as listed in the table below. Note that the order of the

LEDs from the outer edge of the board is 5, 6, 8, 9, 4, 7. For more information, see “II. A.

Sequence of Operation”.

Sequence Step LED

1 Minute Fill Cycle 8 WV 60 seconds

Harvest Cycle 5, 6, 8

Last 0, 10, 30, or 50 seconds (adjustable by dip switch) of harvest, WV de-energizes

and PM energizes (LEDs 5, 6, and 7 are on)

Freeze Cycle 5, 7

Pump-Out Cycle 5, 6, 4, 7

The built in safeties shut down the unit and have alarms as listed below.

No. of Beeps

(every 3 sec.)

High Evaporator Temp.

1

2

3

To reset the above safeties, press the “ALARM RESET” button with the power supply

on.

6

7

Legend:

(temperature > 127°F (53°C))

Harvest Backup Timer

(harvest > 20 min. for two

cycles in a row)

Freeze Timer

(freeze > specied setting for

two cycles in a row)

Timer is factory set using S1

dip switch 9 & 10

Low Voltage

(92Vac ± 5% or less)

High Voltage

(147Vac ± 5% or more)

Comp–compressor; DV–drain valve; FMS–self-contained fan motor; HGV–hot

gas valve; PM–pump motor; TXV–thermostatic expansion valve; WRV–water

regulating valve; WV–inlet water valve

Type of Alarm Notes

Energized

Components

WV, HGV,

Comp

Comp, PM,

FMS

Comp, HGV,

DV, PM

Min. Max. Avg.

2 minutes 20 minutes 3 to 5 minutes

5 minutes

10 seconds 20 seconds

Check for harvest problem (stuck HGV or

relay), hot water entering unit, stuck HM, or

shorted thermistor.

Check for open thermistor, HGV not

opening, TXV leaking by, low charge,

inefcient Comp, or WRV leaking by.

Check for a oat switch stuck closed (up),

WV leaking by, HGV leaking by, PM not

pumping, TXV not feeding properly, low

charge, or inefcient Comp.

“POWER OK” LED will turn off if voltage

protection operates.

The control voltage safeties automatically

reset when voltage is corrected.

Time LEDs are On

freeze timer

setting

25 to 30 minutes

factory default

setting

32

Page 34

C. Settings and Adjustments

NOTICE

Dip switches are factory set. Failure to maintain factory settings may adversely

affect performance and warranty coverage.

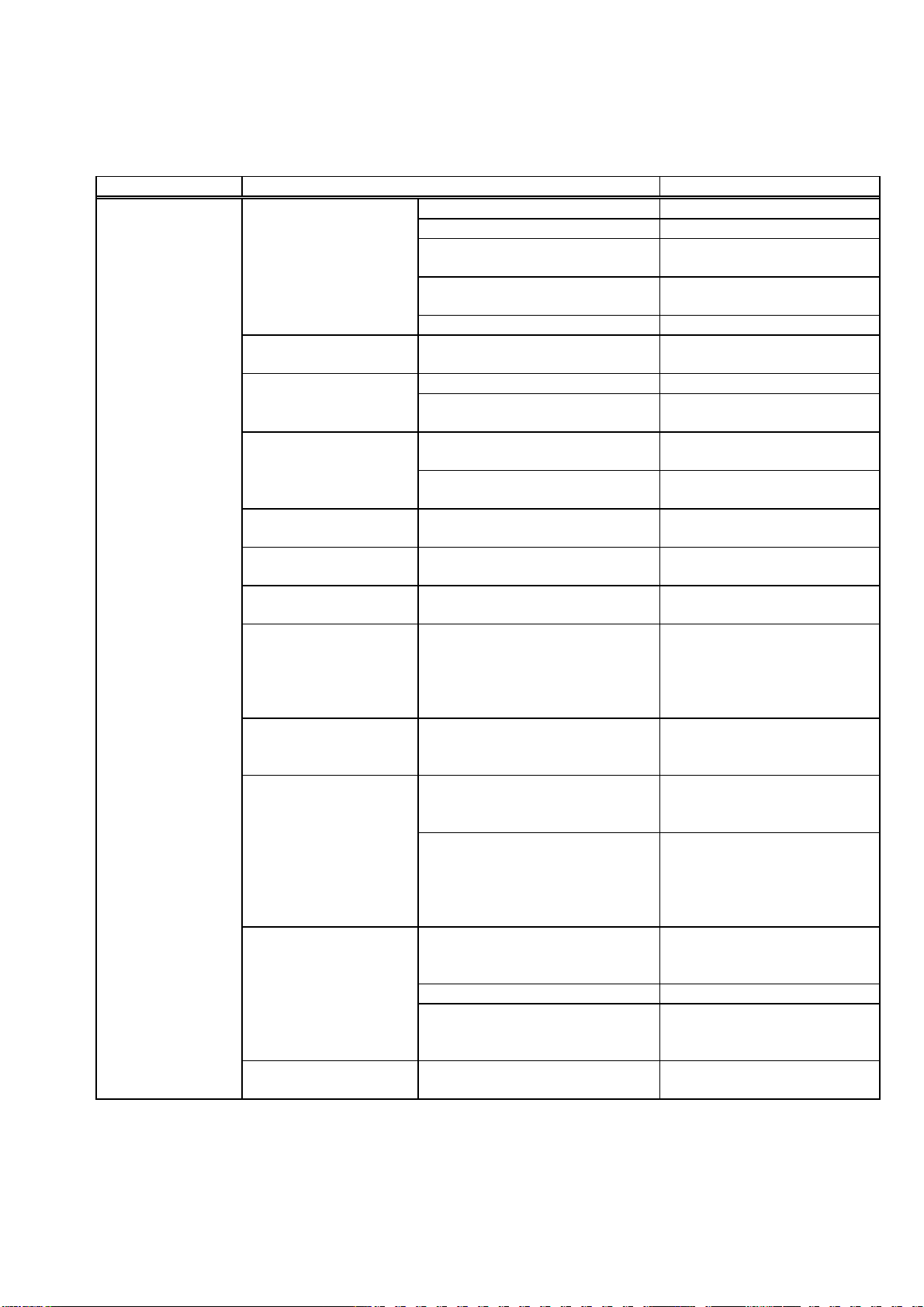

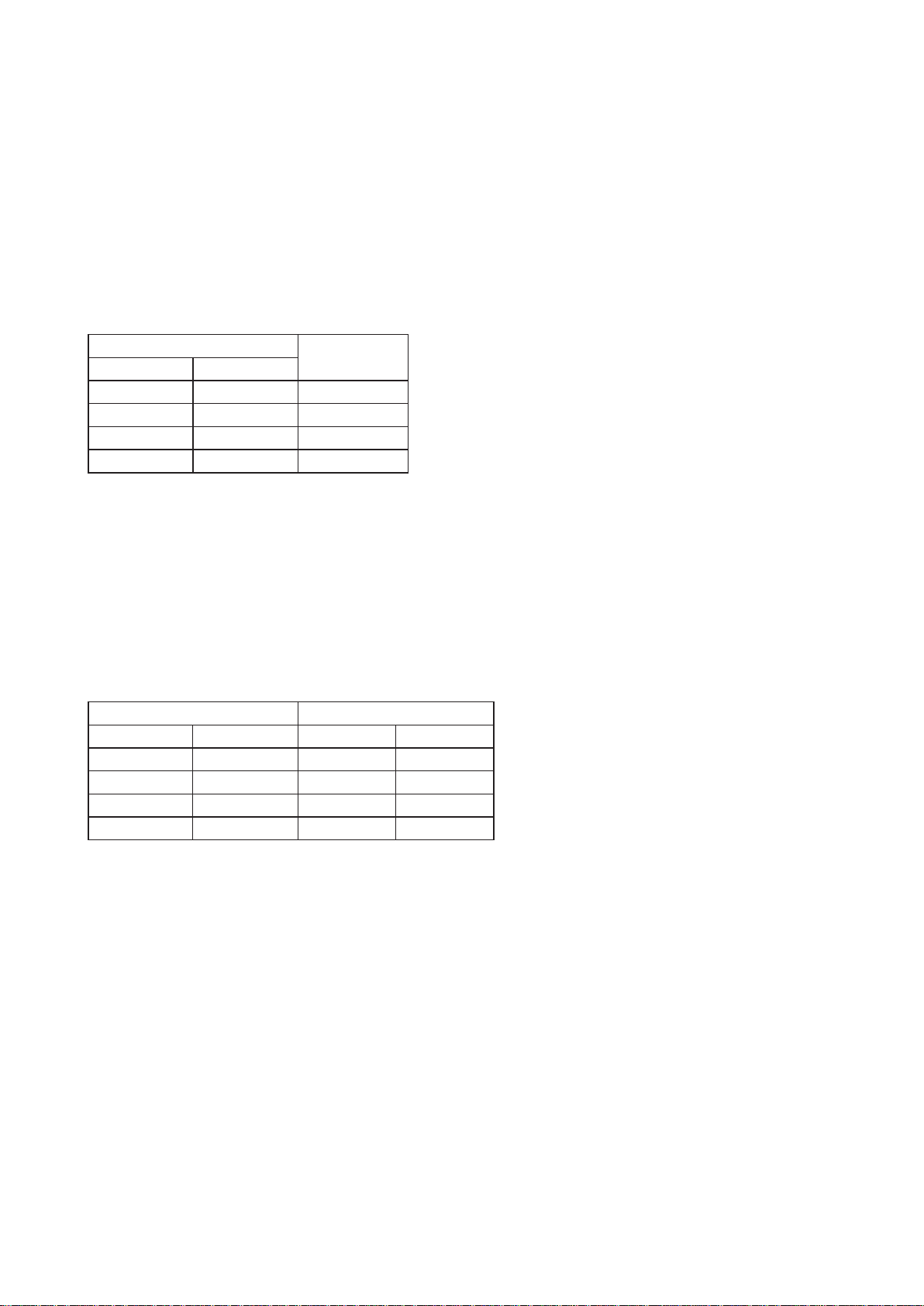

1. Default Dip Switch Settings

The dip switch is factory-adjusted to the following positions:

S1 Dip Switch No. 1 2 3 4 5 6 7 8 9 10

KM-230BAJ OFF OFF OFF OFF ON ON OFF ON OFF ON

KM-300BAJ OFF OFF OFF OFF ON ON ON OFF OFF ON

KM-300BWJ OFF OFF OFF OFF ON ON ON OFF ON OFF

S2 Dip Switch No. 1 2 3 4 5 6

KM-230BAJ ON OFF OFF OFF OFF ON

KM-300BAJ ON OFF OFF OFF OFF OFF

KM-300BWJ ON OFF OFF OFF OFF OFF

Do not adjust the S2 dip switch. These must be left in the factory default position, or

the unit will not operate properly. The S2 dip switch No. 6 is factory-adjusted to the

“ON” position for the auxiliary codes G1 and H0. Change it to the “OFF” position when

replacing the control board. This does not affect the product performance but prevents

cloudy ice even in poor water quality areas.

S1 Dip Switch S2 Dip Switch

Anti-Slush Control (6)

Freeze Timer (9 & 10)

Harvest Pump Timer (7 & 8)

Pump-Out Frequency Control

(5 & 6)

Pump-Out Timer (3 & 4)

Harvest Timer (1 & 2)

Overfreeze Detection Control (5)

Harvest Completion Detection

Control (4)

Rell Counter (3)

Harvest Promotion Control (2)

Pump-Out/Drain Selector (1)

Fig. 4 Fig. 5

2. Harvest Timer (S1 dip switch 1 & 2)

The harvest timer starts counting when the thermistor reached 48°F (9°C) at the

evaporator outlet and the control board reads 3.9 kΩ from the thermistor. The harvest

33

Page 35

timer is factory set, and generally no adjustment is required. However, a setting

longer than the factory setting may be advised in cases where the drain provided at

harvest needs to be prolonged for extra cleaning. Before changing this setting, contact

Hoshizaki Technical Support at 1-800-233-1940 for recommendations. Keep in mind that

setting the harvest timer to a longer setting decreases 24-hour production.

Note that the pump-out timer (S1 dip switch 3 & 4) acts in place of the harvest timer

during cycles with a pump out. For details, see “III. C. 3. Pump-Out Timer (S1 dip switch

3 & 4).“

Note: On models with a pump-out every cycle, the harvest timer is only relevant during

the initial harvest cycle since a pump out occurs every cycle there after.

Dip Switch Setting

No. 1 No. 2

OFF OFF 60

ON OFF 90

OFF ON 120

ON ON 180

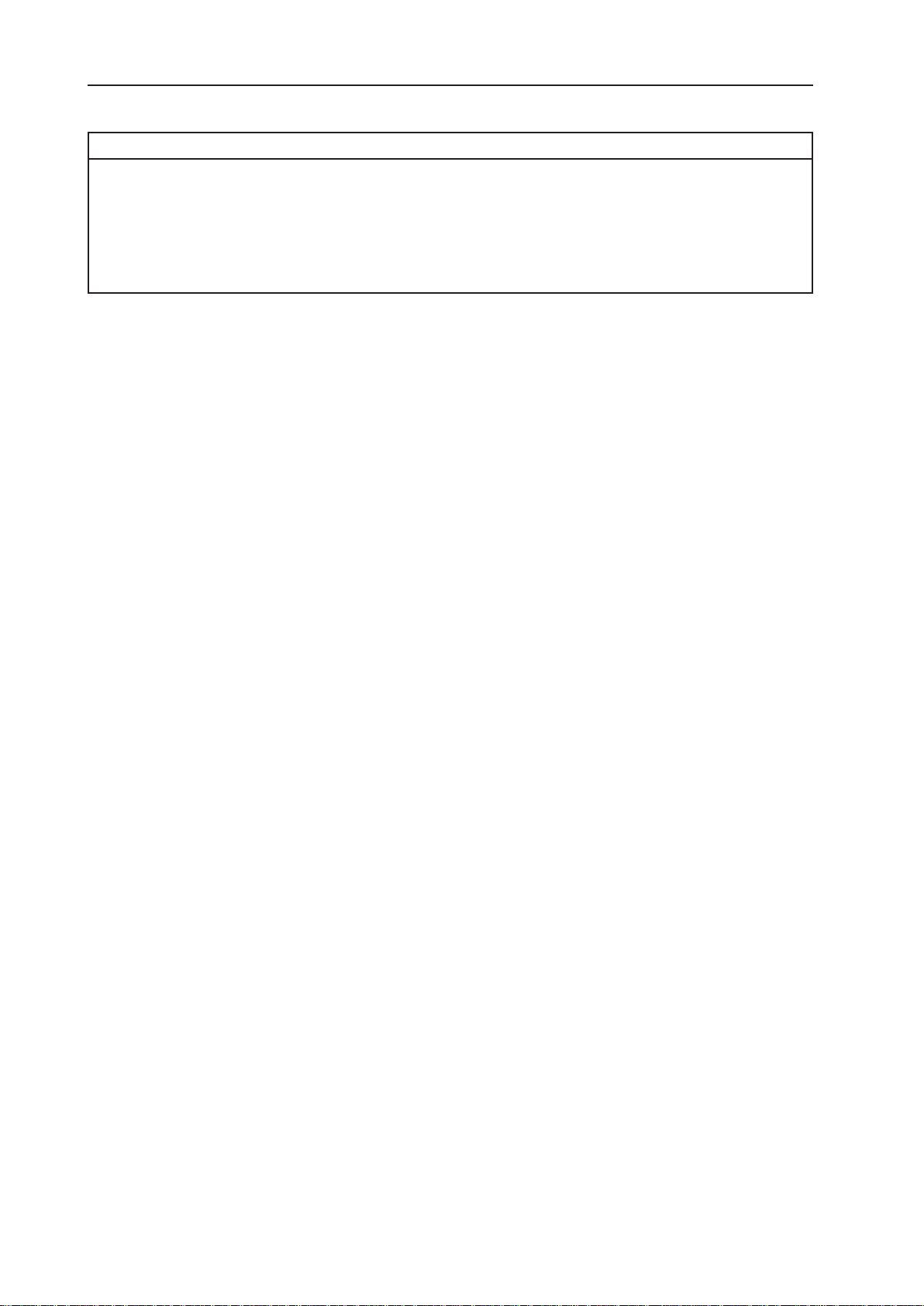

3. Pump-Out Timer (S1 dip switch 3 & 4)

When a pump-out is called for, the pump motor stops for 2 seconds, then the pump

motor and drain valve energize. Water is removed from the bottom of the water tank

and sent down the drain. The pump-out drains the water tank for the time determined

by the pump-out timer. The pump-out timer also acts in place of the harvest timer during

cycles with a pump-out. The pump-out timer is factory set, and generally no adjustment

is required. The pump-out timer control can be set to pump-out for 10 or 20 seconds.

Dip Switch Setting Time (seconds)

No. 3 No. 4 T1 T2

OFF OFF 10 120

ON OFF 20 160

OFF ON 20 120

ON ON 20 180

Time

(seconds)

T1: Time to drain the water tank

T2: Harvest timer at pump-out

4. Pump-Out Frequency Control (S1 dip switch 5 & 6)

The water tank drains at the frequency set by the pump-out frequency control.

The pump-out frequency control is factory-adjusted to drain the water tank every 10

cycles, and no adjustment is required. However, where water quality is bad and the

icemaker needs a pump-out more often, the pump-out frequency can be adjusted as

shown in the table below.

34

Page 36

Dip Switch Setting

No. 5 No. 6

OFF OFF every cycle

ON OFF every 2 cycles

OFF ON every 5 cycles

ON ON every 10 cycles

5. Harvest Pump Timer (S1 dip switch 7 & 8)

The harvest pump timer allows the water valve to close and the pump motor to circulate

water in the tank during the nal part of harvest. The water valve is open during harvest

for a maximum of 6 minutes or the length of harvest minus 0, 10, 30, or 50 seconds

(determined by the harvest pump timer setting), whichever is shorter. When the water

valve closes, the pump motor energizes and runs for the time determined by the harvest

pump timer setting.

The harvest pump timer is factory-adjusted, and no adjustment is required.

Frequency

Dip Switch Setting

No. 7 No. 8

OFF OFF 0

ON OFF 10

OFF ON 30

ON ON 50

6. Freeze Timer (S1 dip switch 9 & 10)

Time

(seconds)

NOTICE

Adjust to proper specication, or the unit may not operate correctly.

The freeze timer setting determines the maximum allowed freeze time to prevent

possible freeze-up issues. Upon termination of freeze timer, machine initiates the

harvest cycle. After 2 consecutive timer terminations, machine will shut down, possibly

indicating a problem.

The freeze timer is factory adjusted, and no adjustment is required.

Dip Switch Setting

No. 9 No. 10

OFF OFF 60

ON OFF 50

OFF ON 70

ON ON 100

Time

(minutes)

35

Page 37

7. Pump-Out/Drain Selector (S2 dip switch 1)

The pump-out/drain selector setting determines whether the pump motor energizes

(pump-out) or stays off (drain) after a 2-second delay at the beginning of the pump-out

cycle or at shutdown. Regardless of the pump-out/drain selector setting, the drain valve

energizes after a 2-second delay at the beginning of the pump-out cycle or at shutdown.

When the pump-out/drain selector is set to pump-out, the pump motor takes water from

the tank and forces it through the drain valve and down the drain. When the pump-out/

drain selector is set to drain, water drains by gravity through the drain valve.

S2 Dip Switch Setting

No. 1

OFF Drain

ON Pump-out

8. Harvest Promotion Control (S2 dip switch 2)

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

When activated, this control promotes harvest of ice on the evaporator that is hard to

remove. If the harvest cycle exceeds 6 minutes, the pump motor starts to operate for a

maximum of 3 minutes.

S2 Dip Switch Setting

No. 2

OFF Activated

ON Deactivated

9. Rell Counter (S2 dip switch 3)

Pump Operation Setting

Harvest Promotion

Control

Do not adjust. This must be left in the factory default position or the unit will not operate

properly. The KM-230BAJ and KM-300BAJ/BWJ do not rell.

10. Harvest Completion Detection Control (S2 dip switch 4)

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

It is deactivated on the KM-230BAJ and KM-300BAJ/BWJ.

When activated, this control determines whether ice remains on the evaporator at the

end of a harvest cycle and at the beginning of a freeze cycle. If ice drops and activates

the bin control switch in the last 10 seconds of a harvest cycle, the control determines

that ice still remains on the evaporator and extends the harvest cycle for 30 seconds.

If the bin control switch is activated at the beginning of a freeze cycle, the control

determines that ice still remains on the evaporator and starts a harvest cycle after the

minimum freeze cycle time has passed.

36

Page 38

S2 Dip Switch Setting

No. 4

OFF Deactivated

ON Activated

11. Overfreeze Detection Control (S2 dip switch 5)

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

It is deactivated on the KM-230BAJ and KM-300BAJ/BWJ.

When activated, the thermistor detects the temperature of the evaporator outlet to nd

overfreeze in a harvest cycle and at the beginning of a freeze cycle. If the difference

between the maximum temperature after the harvest pump timer starts counting and the

temperature at the end of a harvest cycle is 7.2°F (4°C) or more and if the temperature

at the end of a harvest cycle is 48°F (9°C) or less, the harvest cycle is extended for 30

seconds. If the difference between the temperature at the beginning of a freeze cycle

and the minimum temperature after 30 seconds in the freeze cycle is 2.5K or more

and less than 3.5K, the next harvest cycle is extended for 30 seconds. If the above

conditions occur in succession, the number of occurrence times 30 seconds will be

added to the harvest cycle time. If the above temperature difference is 3.5K or more, the

freeze cycle ends after the minimum freeze cycle time and a harvest cycle starts.

If the evaporator outlet temperature is more than 3.5°C but not more than 5°C at the end

of harvest cycle, the harvest cycle is extended for 50 seconds before moving on to the

freeze cycle. If the evaporator outlet temperature is 3.5°C or less, another harvest cycle

starts. The harvest cycle does not repeat more than three times. The freeze cycle starts

even if the evaporator outlet temperature is 3.5°C or less at the end of the third harvest

cycle.

Harvest Completion

Detection Control

S2 Dip Switch Setting

No. 5

OFF Deactivated

ON Activated

12. Anti-Slush Control (S2 dip switch 6)

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

When activated (Ver. 1.1), the thermistor located on the suction line checks for a 41°F

(5°C) temperature as the evaporator cools. When 41°F (5°C) is reached, a 4.8 kΩ signal

causes the control board to de-energize the pump motor for 10 seconds.

When activated (Ver. 2.0), the thermistor located on the suction line checks for a 50°F

(10°C) temperature as the evaporator cools. When 50°F (10°C) is reached, a 3.9 kΩ

signal causes the control board to de-energize the pump motor for 10 seconds and

energize it for 50 seconds repeatedly. When 34°F (1°C) is reached, a 5.9 kΩ signal

causes the control board to de-energize the pump motor for 10 seconds, energize it for

50 seconds, de-energize it again for 10 seconds, then energize it continuously.

Overfreeze Detection

Control

37

Page 39

S2 Dip Switch Setting

No. 6

Anti-Slush Control

OFF Activated (Ver. 1.1)

ON Activated (Ver. 2.0)

13. Control Board Replacement

The dip switches should be adjusted to the factory default settings as outlined in this

manual.

D. Switches

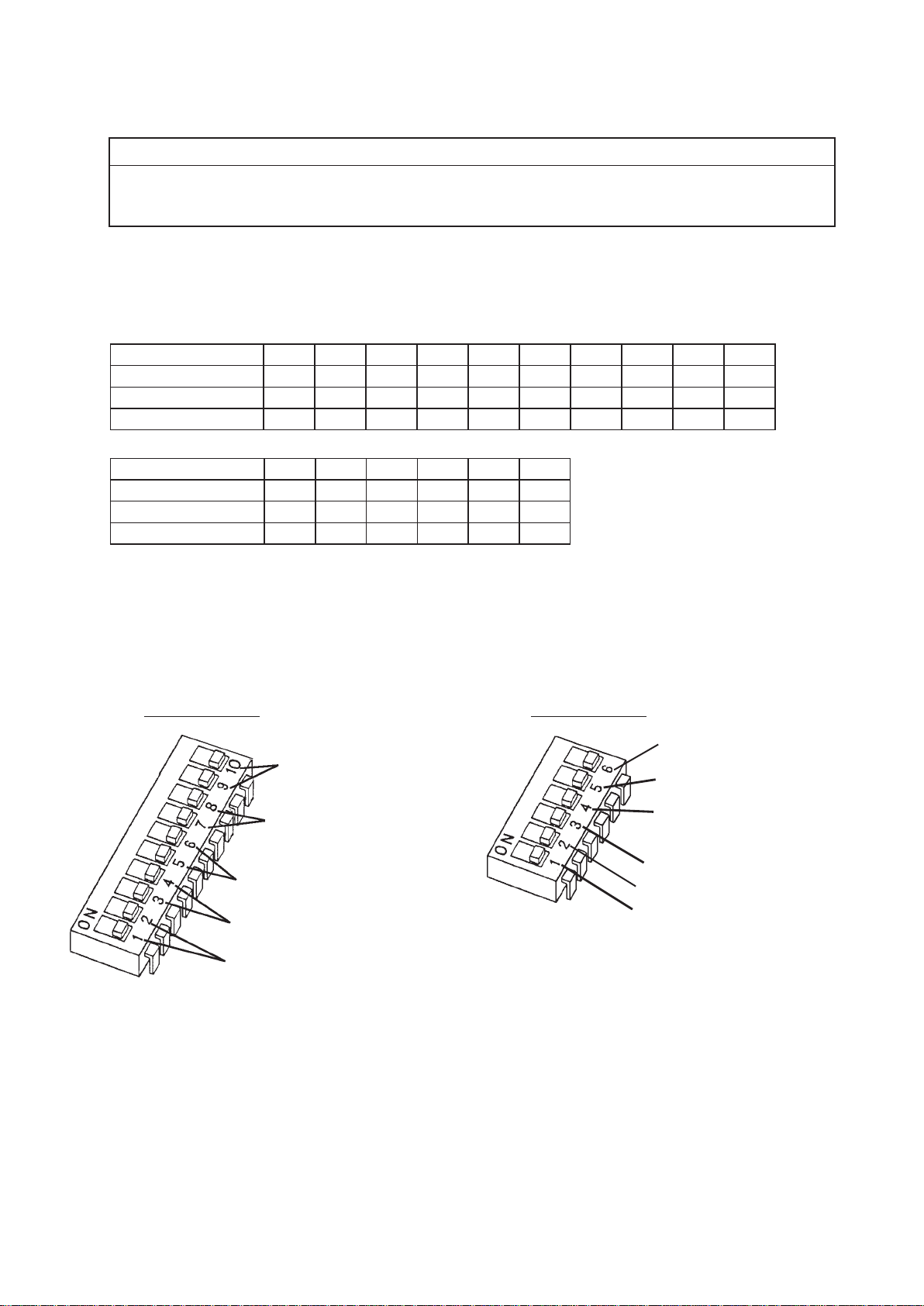

Two different control switches are used for operation. They are located on the right side

of the control box which becomes accessible when the front louver is removed. The

upper is the control switch, and the lower is the service switch.

1. Control Switch

This switch is used to place the machine into one of three modes: “OFF” (center

position), “ICE” (upper position), and “SERVICE” (lower position).

2. Service Switch

When the control switch is in the “SERVICE” position, the control switch supplies power

to the service switch and the machine is in service mode. The service switch has three

positions: “DRAIN”, “CIRCULATE”, and “WASH”. See the information below for details

of each function.

Note: 1. When the service switch is activated, power is supplied to the water pump in

all three positions.

2. When the control switch is in the “OFF” position or in the “ICE” position, the

service switch has no power and can be left in any position.

1) DRAIN

This machine utilizes a pump-out drain

system. When the service switch is active

and placed in the “DRAIN” position, power is

supplied to the pump and drain valve.

ICE

OFF

SERVICE

WASH

CIRCULATE

DRAIN

Control Switch

Service Switch

38

Fig. 6

Page 40

2) CIRCULATE

When the service switch is active and placed in the “CIRCULATE” position, power is

supplied to the pump only. This operation can be used to circulate cleaner for extended

periods of time over the outside surface of the evaporator.

3) WASH

This machine utilizes a solenoid operated wash (bypass) valve. When the service switch

is active and placed in the “WASH” position, power is supplied to the pump and cleaning

valve. This operation is used to circulate cleaner and sanitizer over both the inside and

outside of the evaporator.

39

Page 41

IV. Refrigeration Circuit and Component Service Information

WARNING

• This appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• To reduce the risk of electric shock, do not touch the control switch or plug with

damp hands. Make sure the control switch is in the "OFF" position before plugging

in or unplugging the appliance.

• Move the control switch to the "OFF" position and unplug the appliance from the

electrical outlet before servicing.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after any maintenance is done to the appliance. Make sure that

none have fallen into the storage bin.

• Make sure all food zones in the icemaker and storage bin are clean after service.

A. Refrigeration Circuit Service Information

WARNING

• Repairs requiring the refrigeration circuit to be opened must be performed by

properly trained and EPA-certied service personnel.

• Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). Do not use R-404A as a mixture with

pressurized air for leak testing.

NOTICE

• Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

• Do not leave the system open for longer than 15 min. when replacing or servicing

parts. The Polyol Ester (POE) oils used in R-404A applications can absorb

moisture quickly. Therefore it is important to prevent moisture from entering the

system when replacing or servicing parts.

• Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

40

Page 42

1. Refrigerant Recovery

The icemaker is provided with a low-side refrigerant access valve. Using proper

refrigerant practices, recover the refrigerant from the access valve and store it in an

approved container. Do not discharge the refrigerant into the atmosphere. After recovery

is complete, install a proper, permanent high-side access valve.

2. Brazing

WARNING

• R-404A itself is not ammable at atmospheric pressure and temperatures up to

176°F (80°C).

• R-404A itself is not explosive or poisonous. However, when exposed to high

temperatures (open ames), R-404A can be decomposed to form hydrouoric acid

and carbonyl uoride both of which are hazardous.

• Do not use silver alloy or copper alloy containing arsenic.

1) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4

PSIG.

Note: Because the pipes in the evaporator case are specially coated to resist

corrosion, it is important to make connections outside the evaporator case

when possible. If it is necessary to braze inside the evaporator case, use

sandpaper to remove the coating from the brazing connections before

unbrazing the components.

NOTICE

• Always install a new drier every time the sealed refrigeration system is opened.