Page 1

DISHWASHER

INSTALLATION MANUAL

JWE-620UA-6B

FOR QUALIFIED INSTALLER ONLY

9280VC10B (041111)

Page 2

IMPORTANT

Only qualified service technicians should install, service and maintain the

product. No installation, service or maintenance should be undertaken until

the technician has thoroughly read this Installation Manual. Likewise, the

owner/manager should not proceed to operate the product until the installer

has instructed them on its proper operation. Failure to install, operate, and

maintain the equipment in accordance with this manual may adversely affect

safety, performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualified service technicians in the

installation, maintenance, and service of the product.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

* Model Number

* Serial Number

* Complete and detailed explanation of the problem.

i

Page 3

IMPORTANT

This manual should be read carefully before the product is installed and

operated. Only qualified service technicians should install, service, and

maintain the product. Read the warnings contained in this booklet carefully as

they give important information regarding safety. Please retain this booklet for

any further reference that may be necessary.

CONTENTS

1. MOVING---------------------------------------------------------------------------------------------------1

2. INSTALLATION ------------------------------------------------------------------------------------------1

[a] SHIPPING TAPE ------------------------------------------------------------------------------------2

[b] CHECKS BEFORE INSTALLATION -----------------------------------------------------------3

[c] PROTECTIVE FILM --------------------------------------------------------------------------------3

[d] OPERATION PANEL -------------------------------------------------------------------------------3

[e] CONNECTION TO A DISHTABLE -------------------------------------------------------------4

[f] RACK GUIDE ----------------------------------------------------------------------------------------6

3. VENTILATION -------------------------------------------------------------------------------------------7

4. WATER SUPPLY AND DRAIN CONNECTIONS ------------------------------------------------7

[a] WATER HEATER CONNECTION --------------------------------------------------------------7

[b] PRESSURE REDUCING VALVE ---------------------------------------------------------------7

[c] WATER SOFTENER -------------------------------------------------------------------------------8

[d] STRAINER -------------------------------------------------------------------------------------------9

[e] HOT WATER SUPPLY CONNECTION -------------------------------------------------------9

[f] DRAIN CONNECTION (WASH TANK DRAIN)-------------------------------------------- 10

PAGE

5. ELECTRICAL CONNECTION --------------------------------------------------------------------- 10

6. PHASE REVERSAL CHECK ---------------------------------------------------------------------- 12

7. DETERGENT/RINSE AID FEEDER ------------------------------------------------------------- 13

8. TRIAL RUN --------------------------------------------------------------------------------------------- 14

[a] CHECKS BEFORE TRIAL RUN -------------------------------------------------------------- 14

[b] PREPARING HOT WATER SUPPLY -------------------------------------------------------- 15

[c] FINAL CHECKS ----------------------------------------------------------------------------------- 15

[d] AFTER TRIAL RUN ------------------------------------------------------------------------------ 16

[e] ADJUSTMENT ------------------------------------------------------------------------------------ 17

9. RELOCATION ----------------------------------------------------------------------------------------- 17

ii

Page 4

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING

CAUTION

Indicates a situation which could result in damage to the unit.

IMPORTANT

This product should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for injury

or damage resulting from improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or fi re, follow

basic precautions including the following:

• Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or severe damage to

equipment.

• This unit requires independent power supplies for the dishwasher and for the

booster tank. See the nameplate for proper voltage and breaker/fuse sizes.

Failure to use proper breakers or fuses can result in tripped breakers, blown

fuses, or damage to existing wiring. This could lead to heat generation or

fi re.

• THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit

could result in death or serious injury.

• This unit should be disassembled or repaired only by qualified service

personnel to reduce the risk of electric shock, injury, or fi re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, fi re, or damage to the unit.

Indicates a hazardous situation which could result in death or

serious injury.

Indicates important information about the use and care of the

unit.

WARNING

iii

Page 5

1. MOVING

WARNING

When handling the unit (unloading from pallet,

moving, installing), do not hold the door or handle, or

the door will open. Hold the parts indicated by arrows

only.

Do not remove the shipping band securing the door until the end of installation.

WARNING

1. Do not lay down the unit. The door may open and cause injury.

2. This is a heavy unit. Handle and move it with care to prevent injury.

3. When unpacking or moving the unit, be careful not to damage the parts on

the bottom.

2. INSTALLATION

WARNING

1. This product must be installed in accordance with applicable national, state,

and local regulations.

2. To prevent possible water leak, electric shock or fi re, the installation must be

carried out by qualifi ed personnel according to this manual. On completion

of the installation, start up the unit to check for any abnormalities, and

instruct the user on how to use and maintain the unit in accordance with the

instruction manual.

3. This unit is not intended for outdoor use. Exposure to rain may cause electric

leakage or shock.

4. To prevent fire, electric shock, injury or water leak, this unit should be

1

Page 6

disassembled, repaired or modifi ed only by qualifi ed service personnel.

5. The location should provide a fi rm and level foundation for the unit to avoid

the risk of water leaks or injury caused by overturn or fall.

6. Avoid a site where dripping is not allowed. The unit may drip water onto the

fl oor.

7. Ambient temperature should be within 41 to 95°F (5 to 35°C). Operation of

the unit for extended periods outside of this normal temperature range may

affect performance.

8. Do not install the unit where there is a risk of freezing. If there is a possibility

that the ambient temperature may fall below 32°F (0°C) and freeze the unit,

be sure to drain the unit. The water supply line could be damaged and leak

water, resulting in damage to the surrounding property.

9. Install the unit where high temperatures and steam are allowed. During

operation, the surface temperature will reach around 176°F (80°C), and

steam will come out from between the door and body.

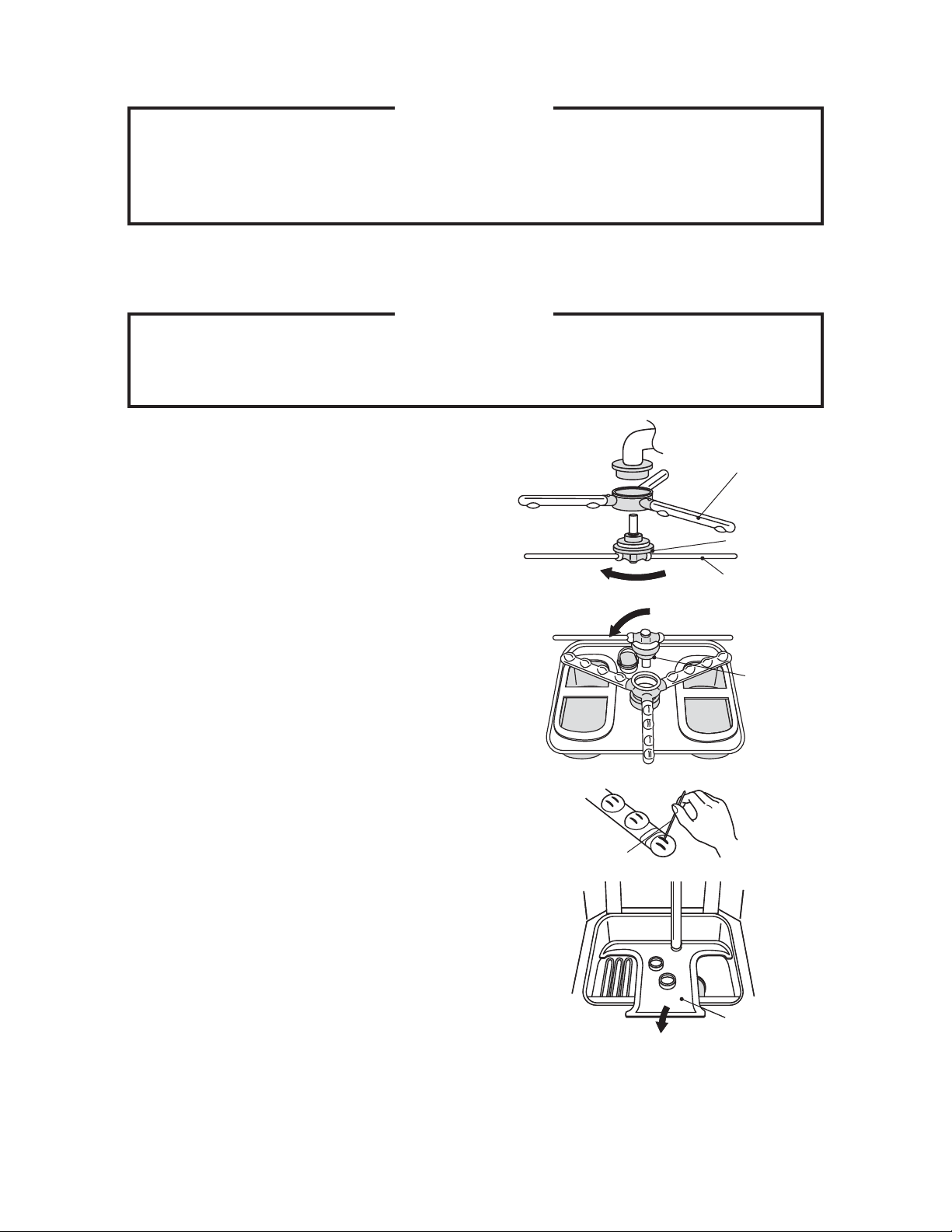

[a] SHIPPING TAPE

1) Remove the shipping band from the door.

2) Remove the shipping tape from the exterior.

3) Remove the shipping band from the rack

and package of accessories.

4) Remove the shipping tape from the rack rail.

5) Remove the shipping tape from the upper

and lower spray arms.

6) Remove the shipping tape from the tank

filters and separator. Take out the tank

fi lters.

IMPORTANT

Do not remove the labels.

Upper Wash

Spray Arm

Upper Rinse

Spray Arm

Rack Rail

Lower Rinse

Spray Arm

Lower Wash

Spray Arm

Door

Accessories

in Rack

Separator

Tank Filter

Pump Filter

Front Panel

Adjustable Leg

2

Page 7

[b] CHECKS BEFORE INSTALLATION

1) Check the exterior including the front panel and door for damage.

2) Check the internal parts including the spray arms and fi lters for damage or clogging.

3) The accessories except the rack are provided in the package. Check that all the

accessories listed in the instruction manual (see “1. [c] ACCESSORIES”) are included

and not damaged.

IMPORTANT

1. Visually inspect the exterior of the shipping container and immediately report

any damage to the carrier. Upon opening the container, any concealed

damage should also be immediately reported to the carrier.

2. The instruction manual should be handed over to the user.

[c] PROTECTIVE FILM

Be sure to remove the protective plastic film from the door and other parts which may

become hot during operation. Otherwise the adhesive on the fi lm will make the stainless

steel exterior look unclean.

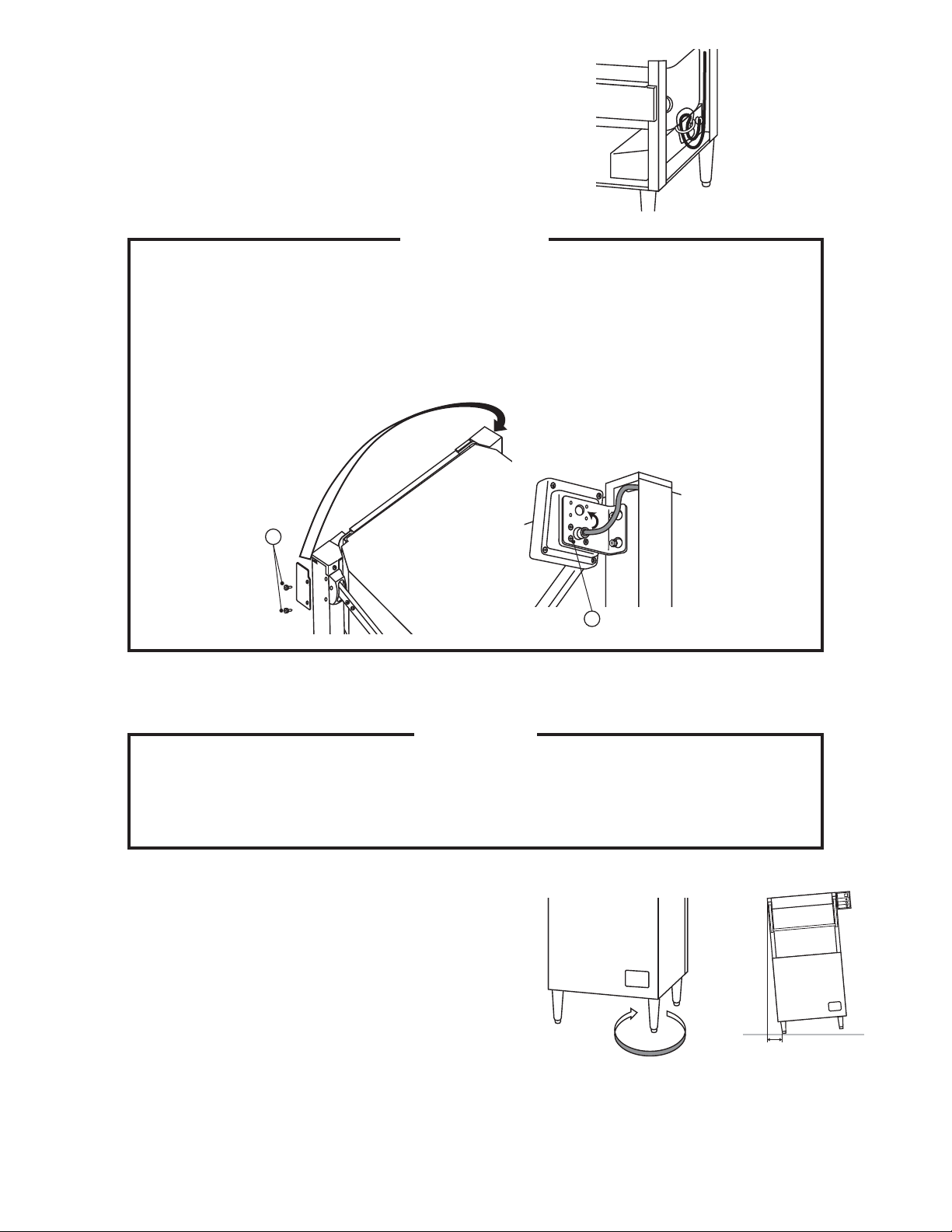

[d] OPERATION PANEL

Be sure to attach the operation panel before installing the unit. It is prepared at the factory

to be attached to the right side of the unit.

1) Loosen screws A on the pillar at the right side

Frame Cover

of the body (no need to remove). Then, remove

screw B at the front of the pillar to take off the

frame cover.

㪙

㪘

㪚

2) Insert the operation panel cable into the frame

(C), and route it into the machine compartment.

Then, attach the operation panel. Be careful not

to let the wiring touch the door opener.

3) Remove the front panel, and pull the cable from

the back of the machine compartment.

㪚

4) Remove the plastic bag from the operation

panel connection cable coming out of the

control box, and connect these cables.

3

Door Opener

Page 8

5) Cover the cable connection with the plastic

bag, and tie it upward as illustrated. Refi t the

front panel in its correct position.

IMPORTANT

To attach the operation panel to the left side, remove screws D from the

operation panel, turn the bracket upside down, and reattach it using the other

holes. Remove screws E and the cover, then attach them to the right side pillar.

Make sure that the wiring inside the machine compartment is clear of all moving

parts (i.e., fan motor).

㪜

㪛

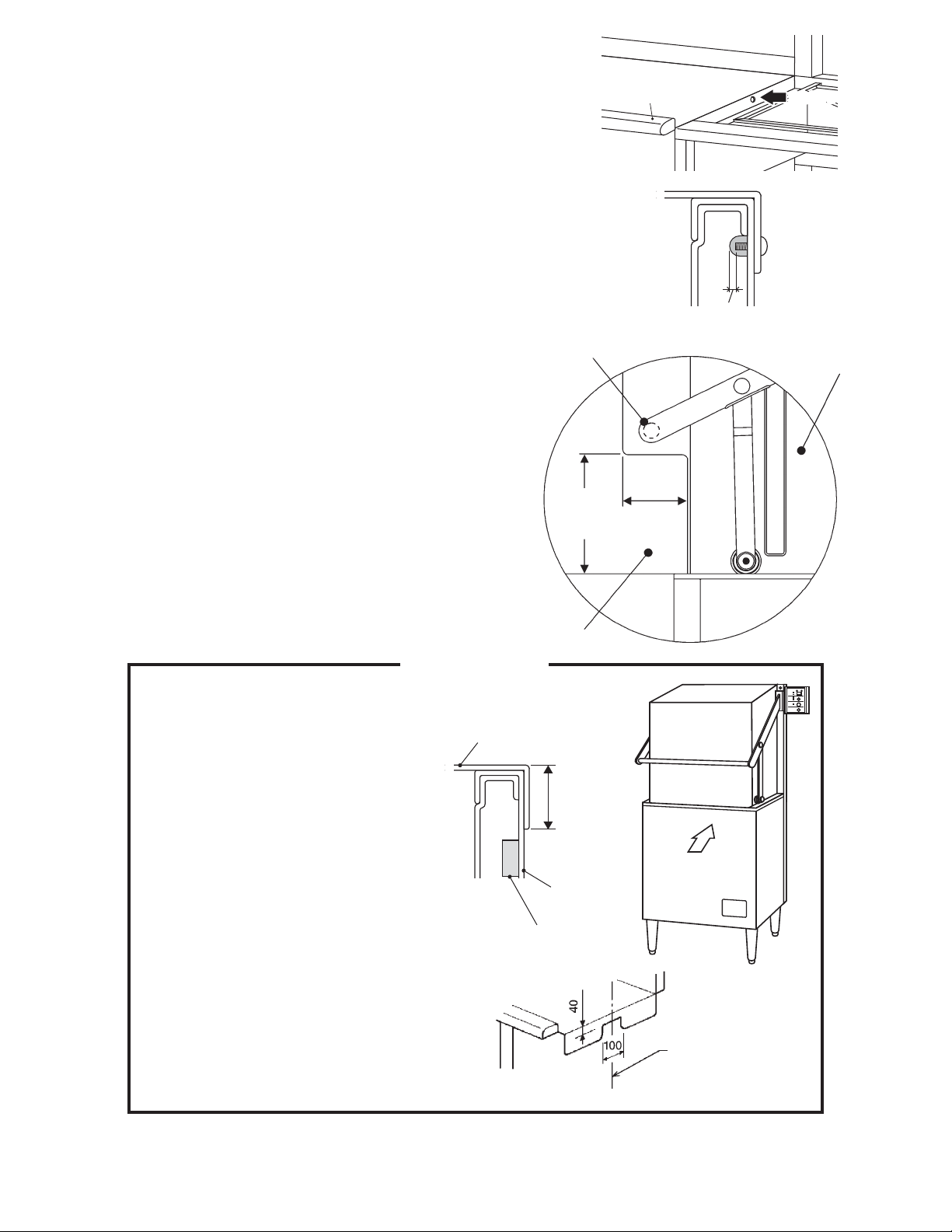

[e] CONNECTION TO A DISHTABLE

CAUTION

When connecting a dishtable, apply silicone sealant to a thickness of at least

1/2” (12.7 mm) to the end of the mounting screw to prevent water leaks resulting

in electric leakage or shock.

A dishtable facilitates loading and unloading of the

rack.

1) Remove the side panel where the dishtable is

to be installed.

2) Use the adjustable legs of the dishtable and

dishwasher to level them in both the left-to-right

and the front-to-rear directions. The unit must

not tilt more than 1/2” (12.7 mm) as shown in

the illustration.

4

Adjustable

Leg

Turn clockwise

1/2" (12.7mm)

to adjust higher

Page 9

3) Hook the dishtable on the wash tank. Drill a hole in the

wash tank to match the mounting hole in the dishtable.

4) Secure the dishtable to the dishwasher with a screw.

Apply silicone sealant to the screw threads as shown

on the right and between the dishtable and the wash

tank.

Dishtable

Dishwasher

ⓣࠍߌࠆ

Drill a hole

5) Refi t the side panel in its correct position.

6) For corner installation, if the side of the

dishtable located at the front of the dishwasher

is 9” (229 mm) or higher, the door handle will

hit the dishtable. In this case, make a notch in

the dishtable as shown on the right.

Make additional adjustments to the dishtable,

if necessary, to improve the tightness between

the dishtable and the dishwasher or to facilitate

loading and unloading of the rack.

IMPORTANT

1. To prevent possible corrosion,

do not leave any shavings after

drilling the hole in the wash tank.

Dishtable

Min 1/2"

(12.7mm)

Door Handle

Door

5"

(127mm)

9"

(229mm)

Dishtable

2. To connect a dishtable to the

front of the dishwasher, keep the

hook on the wash tank within 1.6”

(40 mm) from the rim. Otherwise

the built-in door switch may not

operate properly.

If this is not practical, make a

notch as shown on the right.

3. See “DISHTABLE REFERENCE

DRAWINGS” D05003, D05004,

D05005, and D05006 at the end

of the service manual (80VC-782)

for details.

Max 1.6"

(40mm)

Front

Tank

Door Switch

Dishwasher front

center line

5

Page 10

[f] RACK GUIDE

The rack guide helps ease the load and unload the rack smoothly. It is provided in the

package of accessories together with the securing bolts.

The rack guide location depends on the installation conditions.

Straight Installation

Dishwasher

Rear

Dishtable

Front

Rack Guide

Dishtable

Corner Installation

Dishwasher

Dishtable

Rack Guide

Rear

Front

Secure the rack guide tightly with the two hexagon bolts.

Dishwasher

Dishtable

Front

Rack Guide

Rear

Rack Guide

6

Page 11

3. VENTILATION

WARNING

1. Installation must be in accordance with applicable national, state, and local

regulations.

2. If an exhaust hood is required to discharge steam from the dishwasher, it

should provide a minimum 450 CFM and be a listed and labeled factory-built

commercial exhaust hood tested in accordance with UL Standard 710 by a

nationally recognized testing laboratory.

It must be installed according to the terms of its listing and the manufacturer’s

installation instructions.

3. To use a gas water heater, thoroughly read its instruction manual. Ensure

adequate air intake and exhaust systems and exhaust hoods in accordance

with applicable national, state, and local regulations for the type and capacity

of the heater to prevent dangerous conditions due to lack of oxygen and toxic

gas generation.

Only qualifi ed service personnel should install the above systems.

4. WATER SUPPLY AND DRAIN CONNECTIONS

WARNING

Plumbing connections must comply with applicable sanitary, safety and

plumbing codes.

CAUTION

To prevent water leaks resulting in damage to the surrounding property, make

proper water supply and drain connections according to this manual.

[a] WATER HEATER CONNECTION

Make the water heater connection according to its instruction manual.

[b] PRESSURE REDUCING VALVE

Keep the water supply pressure within 10 to 70 PSIG.

If the water pressure is too high, a pressure reducing valve (not supplied) must be installed

in the water line just ahead of the dishwasher.

7

Page 12

CAUTION

The pressure reducing valve must have a relief by-pass. Failure to use the

proper type of pressure reducing valve may result in damage to the unit.

[c] WATER SOFTENER

If water hardness exceeds 4 grains per gallon, a water softener (not supplied) must be

installed in the primary circuit (water supply inlet) of the water heater.

IMPORTANT

The recommended water hardness of not more than 4 grains per gallon is for

the dishwasher. If the required water hardness for the water heater is lower,

meet that requirement.

* External fi lters and strainers may be required depending on water quality. Contact your

local Hoshizaki distributor for recommendations.

* Sediment, silica, chlorides or other dissolved solids may lead to a recommendation for

particulate fi ltration or reverse osmosis treatment.

* If an inspection of the dishwasher or booster heater reveals lime build-up after the

equipment has been in service, in-line water treatment should be considered, and, if

recommended, should be installed and used as directed.

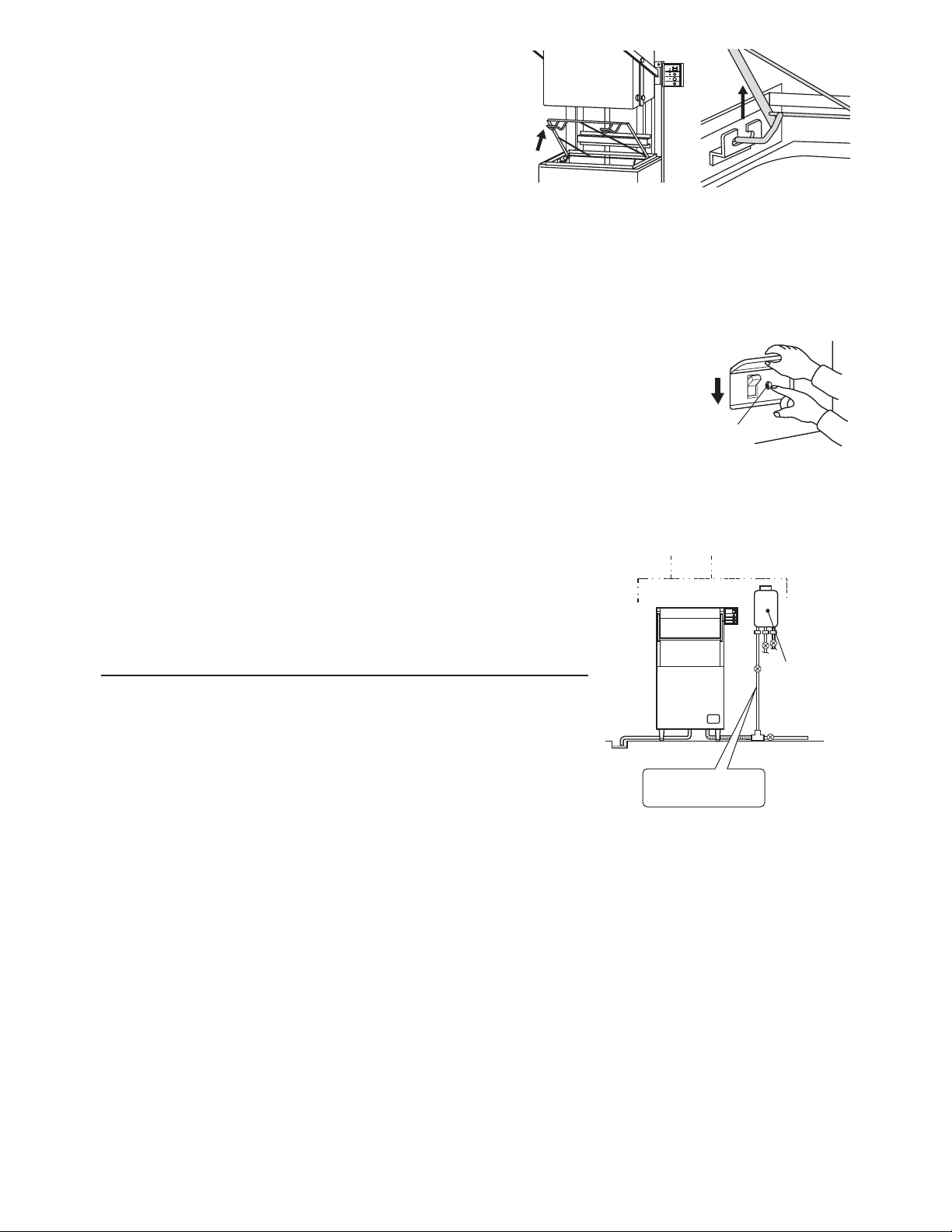

Water

Heater

Water Softener

Water Supply Line

Shut-off Valve

Water

Strainer

(3/4" FPT)

Wash Tank

Drain Pipe

Dishwasher

Water Supply

Valve

Water

Hammer

Arrestor

Gas

Gas Supply Line

Shut-off Valve

Wash Tank Drain Hose

Fitting (1-1/2" MPT)

Drain Valve

Pressure Reducing

Valve with By-pass

8

Page 13

[d] STRAINER

Attach the strainer (accessory) to the water supply

pipe on the bottom front of the unit. To prevent water

leaks, be sure to insert the rubber gasket (accessory)

between the water supply pipe nut and the strainer.

Tighten Loosen

Gasket (accessory)

Water Supply Pipe

FPT

NPT

Strainer (accessory)

Bottom

[e] HOT WATER SUPPLY CONNECTION

WARNING

To reduce the risk of burns, the hot water supply line must be thermally

insulated. Hot water around 167°F (75°C) will fl ow inside.

* Where there is a risk of water hammer, it is recommended to install a water hammer

arrestor between the dishwasher and water heater.

* Required incoming water temperature:

Incoming Water Temperature

Minimum Recommended Maximum

110

°F (43°C)

140

°F (60°C)

If water is supplied at a temperature below 110°F (43°C), the dishwasher cannot maintain

the proper rinse water temperature and may require a longer wash cycle time than the 53

second cycle. In such case, consult with an authorized Hoshizaki service company.

167

°F (75°C)

Wash Temperature Rinse Temperature

Minimum Recommended Minimum Recommended

°F (66°C) 150°F (66°C) 180°F (82°C) 180°F (82°C)

150

* Optional connection for low temperature conditions:

Where there is a risk of freezing, install a drain valve (shut-off valve) between the water

supply valve and dishwasher.

IMPORTANT

When an instantaneous water heater is used, it must be an exclusive type for a

dishwasher and provided with an end stop system.

9

Page 14

[f] DRAIN CONNECTION (WASH TANK DRAIN)

CAUTION

To ensure proper draining, do not route the drain pipe where it can be stepped

on.

* Drain line should be pitched (1/4” per foot) to the floor

drain. An air gap of a minimum of 2 vertical inches (5 cm)

Drain Pipe

(pitched)

should be between the end of the drain pipe from the

dishwasher and the fl oor drain.

* If a grease trap is required in the drain line by regulations,

Floor Drain

check that it is present at the time of installation.

5. ELECTRICAL CONNECTION

WARNING

1. Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or extensive damage

to equipment.

2. This unit requires an independent power supply. See the nameplate for

proper voltage and breaker/fuse size. Failure to use a proper breaker or fuse

can result in a tripped breaker, blown fuses, or damage to existing wiring.

This could lead to heat generation or fi re.

Min 2"

(5cm)

3. THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit could

result in death or serious injury.

4. Make sure the power supply is off before making any electrical connections

to prevent possible electric shock. Lockout/Tagout to prevent the power from

being turned back on inadvertently.

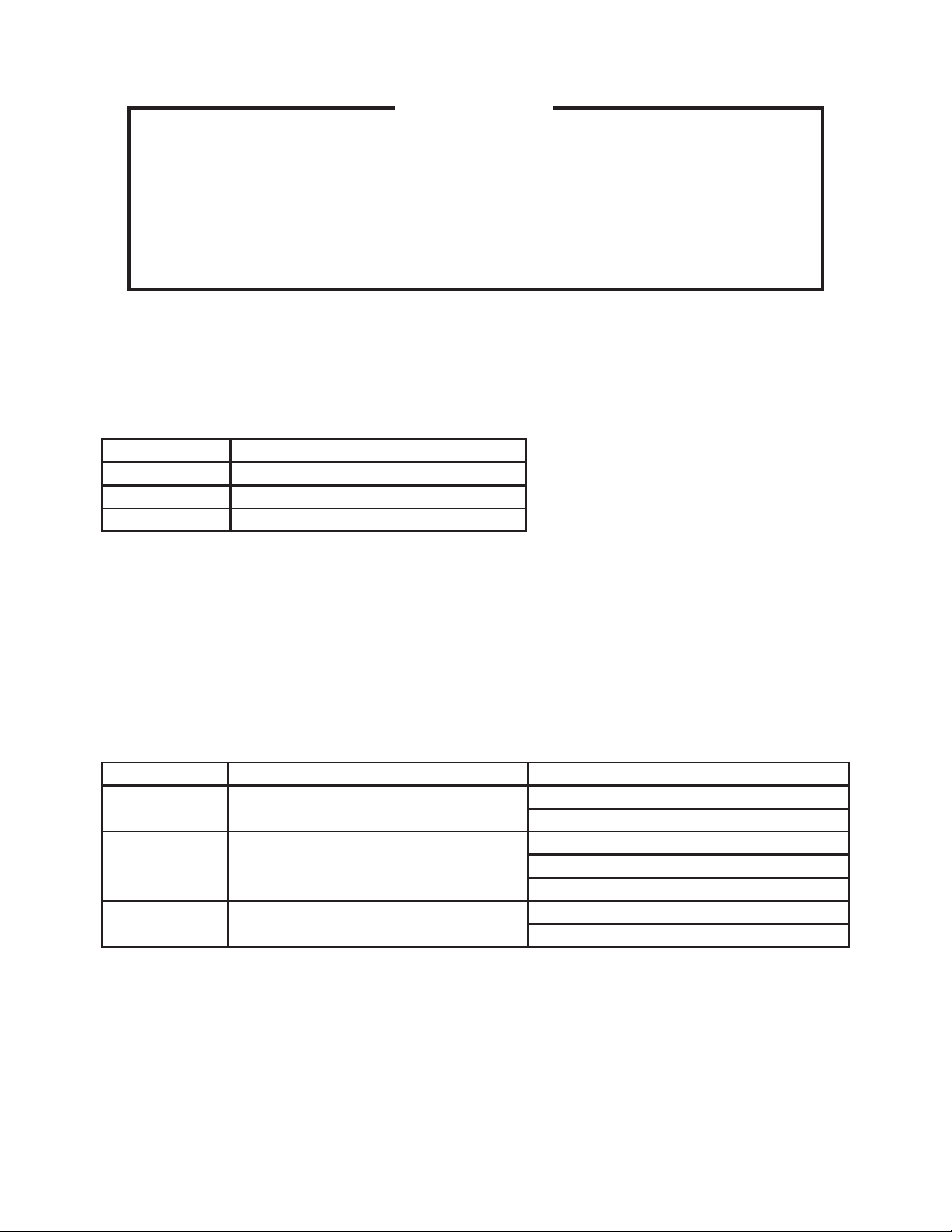

Electrical Specifi cations

(Also Refer to the Dishwasher Nameplate)

AC Supply Voltage Maximum Breaker/Fuse Size Minimum Circuit Ampacity

208 - 230V / 60Hz / 3Ph 50A 50A

* Usually an electrical permit and services of a licensed electrician are required.

10

Page 15

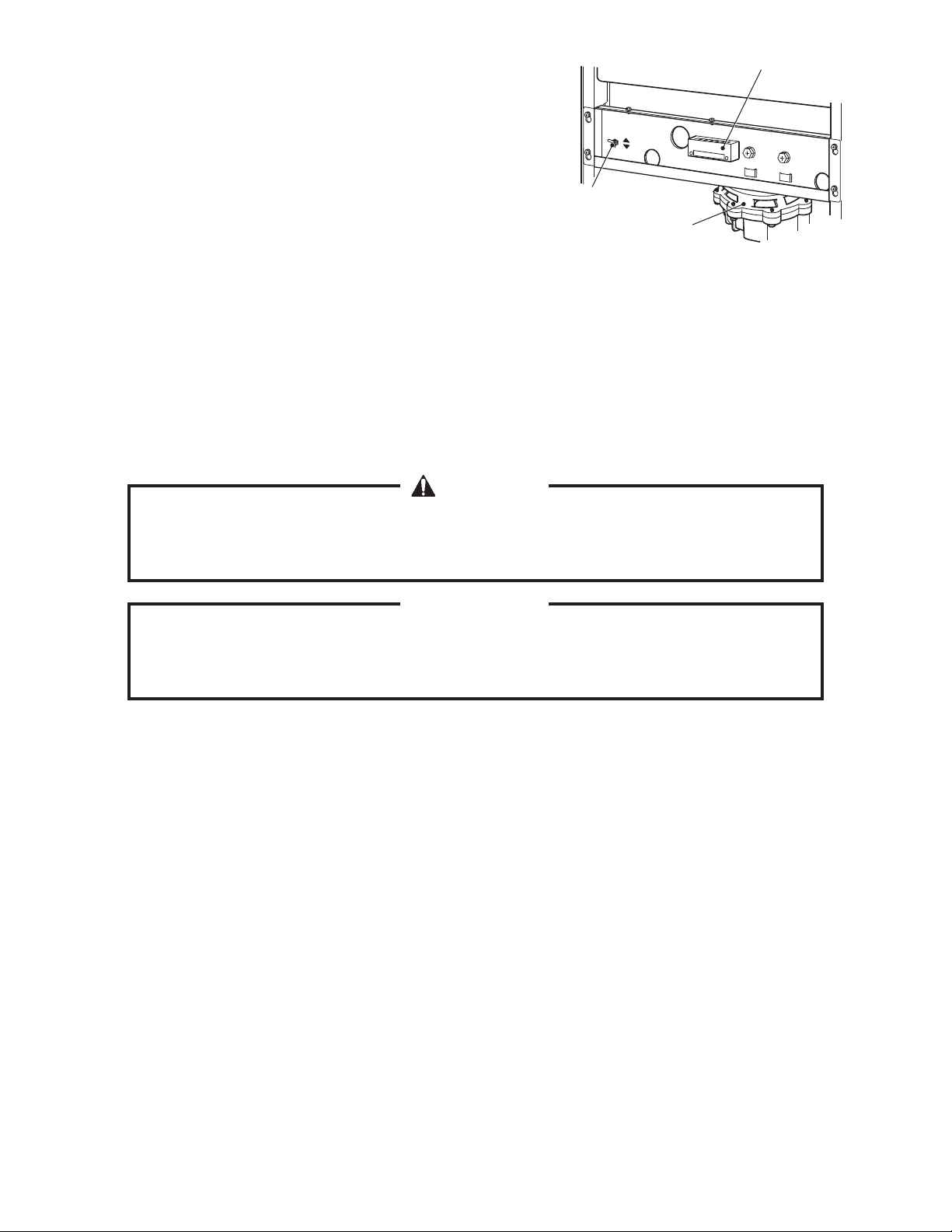

* The maximum allowable voltage variation is ±10

percent of the nameplate rating.

Terminal Block

* The voltage tap switch in the unit must be

positioned to match incoming voltage at startup

230V

208V

(factory default: 230V).

Voltage Tap Switch

* The opening for the power supply connection is

1.11” DIA to fi t a 3/4” trade size conduit.

Pump Motor

1) Remove the front panel.

2) Remove the 3 screws securing control box cover (A), then remove the cover.

3) Connect the ground wire to the ground screw in the base.

4) Route the 3 power wires through the 27.5” (700 mm) UL tube provided and then through

the strain relief in the control box next to the power switch (GFCI).

WARNING

The UL tube must slope downward from the strain relief to prevent entrance of

water through the strain relief into the control box.

IMPORTANT

Do not cut the UL tube. The extra length allows the control box to be pulled out

for service after installation.

5) Securely connect M8 ring terminals to the ends of the wires, then connect the ring

terminals to the terminals on the power switch (GFCI).

6) If the control box has been moved, carefully slide the control box into its correct position

while taking care not to catch the wires. Make sure the rear of the control box has

engaged the tab in the base.

7) Make sure the strain relief is in its proper position, then secure control box cover (A)

using the 3 screws.

8) Use the wire retainer in front of the rinse pump motor to secure the UL tube.

9) Reattach the front panel.

11

Page 16

Downgrade

Control Box Cover (A)

* Remove 3 screws

Wire

Retainer

UL T ube

Conduit

Grounding

Grommet

Cable Tie

6. PHASE REVERSAL CHECK

The unit is provided with a phase reversal relay to prevent operation in case of phase

reversal. To check for phase reversal, follow the steps below.

1) Make sure all wiring connections have been properly made. For details, see “5.

ELECTRICAL CONNECTION”.

2) Turn on the power supply, then move the power switch (GFCI) to the “ON” position.

3) If the display is blank, move the power switch (GFCI) to the “OFF” position, turn off the

power supply, then skip to the next section. If the display shows “H7”, move the power

switch (GFCI) to the “OFF” position, then proceed to step 4.

4) Turn off the power supply. Lockout/Tagout to prevent the power from being turned back

on inadvertently.

5) Swap 2 of the power wires attached to the power switch (GFCI).

6) Turn the power supply back on, then move the power switch (GFCI) to the “ON” position.

Confi rm that the display does not show “H7”.

7) Move the power switch (GFCI) to the “OFF” position, then turn off the power supply.

12

Page 17

7. DETERGENT/RINSE AID FEEDER

WARNING

1. Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or extensive damage

to equipment.

2. THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit could

result in death or serious injury.

This dishwasher must be operated with an automatic detergent feeder and an automatic

rinse aid feeder, including a visual means to verify that detergents/rinse aids are delivered

or to signal if detergents/rinse aids are not available for delivery.

Any feeders provided by a detergent supplier must be installed in the location shown

below. For electrical and plumbing connections, follow the instructions in this manual and

the manual supplied with the feeder. Consult with the detergent supplier or an authorized

Hoshizaki service company for further details.

The dishwasher uses 0.53 gallons of rinse water per rack. This information is use when

setting a detergent/rinse aid pump.

Concentration Sensor Detergent Inlet Terminal Block* Rinse Aid Inlet

(one on each side)

Tank

Interior

22mm

hole

Cap

Nut

O-ring

Tank

Wall

Nut

22mm

hole

Tank Wall

Tank

Exterior

O-ring

Tank

Interior

Cap

1/8-27 NPT

* Connect external detergent and rinse

aid feeders to this terminal block.

Terminal Block

Wash Pump

Use insulated terminals.

Power supply for the detergent and

rinse aid feeders is available with this

Rinse Pump

terminal block. For details, see the

wiring diagram below.

Plug

Booster Tank

Control Box

Rinse Aid Inlet

13

Page 18

IMPORTANT

1. Be sure to use detergent and rinse aid feeders with protective fuses.

2. Ensure the power supply capacity of 208 to 230VAC, 1A or less, and use

insulated terminals to connect the feeders to the terminal block.

* MC2 is synchronized with wash pump and X13 with rinse

External Detergent

and Rinse Aid Feeder

pump (except auto fi ll). See wiring label for details.

Dishwasher

6

5

4

3

2

1

Rinse Aid Solenoid

L3-230VAC

From X13 (#3)

L3-230VAC

From MC2 (#14)

Detergent Solenoid

Available If Needed

Available If Needed

Detergent and Rinse Aid

Terminal Block

If a hole is necessary in the side panel to allow the detergent

inlet to the wash tank, take off the side panel, and remove the

aluminum foil tape and hole cover.

8. TRIAL RUN

L2-230VAC (BR)

L3-230VAC (BK)

From X13 (#3) (W/R)

From MC2 (#14) (W/BK)

Hole Cover

Rinse Cycle

Wash Cycle

WARNING

To reduce the risk of electric shock, do not touch the attachment plug, power

switch (GFCI), or other electrical parts with damp hands.

[a] CHECKS BEFORE TRIAL RUN

1) Check that the door, upper and lower wash/

rinse spray arms, power switch cover, and

other moving parts move smoothly.

2) Fit the separator in the wash tank, and

install the tank fi lters.

Separator

14

Tank Filter

Page 19

3) Insert the drain pipe securely.

4) Lower the rack rail. With the rack rail lifted

Insert drain pipe

securely

up, the door cannot be closed and the unit

will not operate.

[b] PREPARING HOT WATER SUPPLY

1) If the optional drain valve for low temperature conditions is installed, close the drain

valve provided to prevent freezing.

2) Open the water supply valve.

3) Follow the instructions in the water heater’s instruction manual.

[c] FINAL CHECKS

1) Is an independent three-phase 208 to 230V disconnect used?

2) Is the voltage tap switch behind the front panel set to the proper voltage?

3) Is the power cord connected securely to the disconnect?

4) Has a proper ground connection been made?

5) Have all electrical, hot water, drain, and gas connections been made? Do electrical,

hot water, drain, and gas connections meet all national, state, and local code and

regulation requirements?

6) Are the gas and water supplies to the water heater turned on?

7) Turn on the water heater, move the power switch (GFCI) of the dishwasher to the “ON”

position, then press the “ON/OFF” button on the operation panel. Has the display lit

up?

* If yes, the auto fi ll cycle begins when the door is closed.

15

Page 20

8) Is the display showing “H7”? If yes, correct the reverse phase connection according to “6.

PHASE REVERSAL CHECK”.

9) Has the operation (auto fi ll, wash, rinse, mode selection) been checked against the

instruction manual?

10) Remove the front panel. Make sure there are no water leaks in the machine

compartment.

11) Does a sufficient amount of detergent and rinse aid remain in the tanks? Are they

properly supplied to the dishwasher?

12) Has the user been instructed on proper operation of the dishwasher?

13) Have the instruction and installation manuals been given to the user?

[d] AFTER TRIAL RUN

WARNING

When cleaning the strainer at the end of installation, wait until the surface

temperature falls below 104°F (40°C) to avoid the risk of burns.

CAUTION

Do not install the unit where there is a risk of freezing. If there is a possibility

that the ambient temperature may fall below 32°F (0°C) and freeze the unit, be

sure to drain the unit. The water supply line could be damaged and leak water,

resulting in damage to the surrounding property.

1) Press the “ON/OFF” button, and move the power switch (GFCI) to the “OFF” position.

2) Pull out the drain pipe to drain wash water from the wash tank.

3) Turn off the water heater according to its instruction manual.

4) Clean the strainer to remove any debris from the

water supply and drain connections. To remove

the strainer, turn the cap counterclockwise.

Strainer

Cap

Mesh

5) Use a dry soft cloth to wipe moisture off the

exterior and washing compartment.

16

Page 21

[e] ADJUSTMENT

If any adjustment is required to the wash or rinse cycle time or temperature setting, contact

an authorized Hoshizaki service company.

9. RELOCATION

WARNING

1. Make sure the power supply is off before making any electrical connections

to prevent possible electric shock. Lockout/Tagout to prevent the power from

being turned back on inadvertently.

2. When draining the booster tank and hot water supply line at the time of

relocation, wait until the surface temperature falls below 104°F (40°C) to

avoid the risk of burns.

1) Shut down and clean the unit according to the instruction manual.

2) Ask the detergent supplier to treat the detergent and rinse aid tanks and pipes.

3) To drain the booster tank, remove the front

panel, take out the end of the drain hose, and

remove the plug.

4) Disconnect the electrical, water supply and

drain connections.

Booster Tank

5) Move the unit with care not to damage it.

Drain Hose

6) Reinstall the unit properly according to this

installation manual.

Band

Plug

17

Page 22

DISHWASHER

INSTRUCTION MANUAL

JWE-620UA-6B

FOR END USER

9180VC10B (041111)

Page 23

IMPORTANT

Only qualified service technicians should install, service and maintain the

product. No installation, service or maintenance should be undertaken until

the technician has thoroughly read this Instruction Manual. Likewise, the

owner/manager should not proceed to operate the product until the installer

has instructed them on its proper operation. Failure to install, operate, and

maintain the equipment in accordance with this manual may adversely affect

safety, performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualified service technicians in the

installation, maintenance, and service of the product.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

* Model Number

* Serial Number

* Complete and detailed explanation of the problem.

i

Page 24

IMPORTANT

This manual should be read carefully before the product is installed and

operated. Only qualified service technicians should install, service, and

maintain the product. Read the warnings contained in this booklet carefully as

they give important information regarding safety. Please retain this booklet for

any further reference that may be necessary.

CONTENTS

1. CONSTRUCTION --------------------------------------------------------------------------------------1

[a] GENERAL --------------------------------------------------------------------------------------------1

[b] OPERATION PANEL -------------------------------------------------------------------------------3

[c] ACCESSORIES -------------------------------------------------------------------------------------4

2. CHECKS BEFORE OPERATION -------------------------------------------------------------------4

[a] CHECKS AFTER INSTALLATION --------------------------------------------------------------5

[b] WATER REQUIREMENTS -----------------------------------------------------------------------5

[c] CHECKS BEFORE OPERATION---------------------------------------------------------------5

3. CHECKING DETERGENT TANK AND RINSE AID TANK ------------------------------------6

4. PREPARING THE WASH COMPARTMENT -----------------------------------------------------6

[a] AUTO FILL -------------------------------------------------------------------------------------------8

5. LOADING -------------------------------------------------------------------------------------------------8

[a] PREWASH -------------------------------------------------------------------------------------------8

[b] LOADING DISHES ---------------------------------------------------------------------------------9

[c] LOADING RACK ------------------------------------------------------------------------------------9

PAGE

6. WASH AND RINSE ----------------------------------------------------------------------------------- 10

[a] OPERATING TEMPERATURES -------------------------------------------------------------- 10

[b] MODE SETTING --------------------------------------------------------------------------------- 10

7. UNLOADING --------------------------------------------------------------------------------------------11

8. INSUFFICIENT WASHING RESULTS------------------------------------------------------------11

9. SHUTDOWN ------------------------------------------------------------------------------------------- 12

10. INTERRUPTION -------------------------------------------------------------------------------------- 13

11. STANDBY/CLEANING BUTTON ----------------------------------------------------------------- 14

12. INTERNAL BOOSTER TANK ENERGY SAVING CONTROL ----------------------------- 14

ii

Page 25

13. LOW WATER TEMPERATURE LOCK FUNCTION ------------------------------------------ 14

14. ALERT FUNCTION ----------------------------------------------------------------------------------- 14

15. DAILY MAINTENANCE ----------------------------------------------------------------------------- 15

16. SELF-CLEANING ------------------------------------------------------------------------------------- 17

17. WEEKLY MAINTENANCE -------------------------------------------------------------------------- 18

[a] HEATER -------------------------------------------------------------------------------------------- 18

[b] EXTERIOR ----------------------------------------------------------------------------------------- 18

[c] WASH COMPARTMENT ------------------------------------------------------------------------ 19

18. MONTHLY INSPECTION --------------------------------------------------------------------------- 19

[a] POWER SWITCH (GROUND FAULT CIRCUIT INTERRUPTER) ------------------- 19

[b] WATER SUPPLY LINE -------------------------------------------------------------------------- 19

19. DESCALING (AS REQUIRED) -------------------------------------------------------------------- 20

20. TROUBLESHOOTING ------------------------------------------------------------------------------ 21

[a] TROUBLES REQUIRING IMMEDIATE SERVICE CALL -------------------------------- 21

[b] TROUBLES REQUIRING CHECK BY USER ---------------------------------------------- 21

[c] TROUBLES WITHOUT ERROR CODE INDICATION -----------------------------------22

21. LONG STORAGE, RELOCATION, DISPOSAL, TRANSFER ----------------------------- 23

iii

Page 26

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING

CAUTION

Indicates a situation which could result in damage to the unit.

IMPORTANT

This product should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for injury

or damage resulting from improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or fi re, follow

basic precautions including the following:

• Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or severe damage to

equipment.

• This unit requires independent power supplies for the dishwasher and for the

booster tank. See the nameplate for proper voltage and breaker/fuse sizes.

Failure to use proper breakers or fuses can result in tripped breakers, blown

fuses, or damage to existing wiring. This could lead to heat generation or

fi re.

• THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit

could result in death or serious injury.

• This unit should be disassembled or repaired only by qualified service

personnel to reduce the risk of electric shock, injury, or fi re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, fi re, or damage to the unit.

Indicates a hazardous situation which could result in death or

serious injury.

Indicates important information about the use and care of the

unit.

WARNING

iv

Page 27

1. CONSTRUCTION

[a] GENERAL

[5]

[6]

[1]

[4]

Rear View

[3]

[2]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

1

Page 28

[1] Upper Rinse Spray Arm, Lower Rinse Spray Arm

Rotates and sprays rinse water onto dishes to rinse off detergent.

[2] Upper Wash Spray Arm, Lower Wash Spray Arm

Rotates and sprays wash water onto dishes to remove stains.

[3] Heater

Keeps wash water at a proper temperature.

[4] Water Level Sensor

Detects wash water level.

[5] Handle

[6] Door

[7] Operation Panel

See “[b] OPERATION PANEL”.

[8] Rack Rail

[9] Drain Pipe

Pull out to drain.

[10] Separator

[11] Tank Filter

Separates wash water and scraps.

[12] Pump Filter

Prevents scraps from being drawn into the pump.

[13] Power Switch (Ground Fault Circuit Interrupter)

Move the lever to start up or shut down the unit. Automatically turns off the power in

case of a ground fault.

[14] Vent

2

Page 29

[b] OPERATION PANEL

[1]

[2]

[3]

[5]

[6]

[7]

[8]

[4]

[9]

[1] “READY” Lamp

Lights up when the auto fi ll cycle completes and the dishwasher is ready to wash.

[2] “AUTO FILL” Lamp

Flashes during the auto fi ll cycle, and goes off at the end of the cycle.

[3] Mode Lamps

Light up to indicate the selected operation mode, and fl ash during operation.

[4] Standby Lamp

Lights up when the dishwasher is in the standby mode. The unit will not start even

when the door is closed with this lamp on. See “11. STANDBY/CLEANING BUTTON”.

3

Page 30

[5] Up Button, Down Button

Indicates the total number of operation in six digits by two digits each time.

Example: 123,456 times are indicated by

Press to indicate rinse water temperature instead of wash water temperature while

the dishwasher is on standby.

Serv

[6] Display

Indicates wash water temperature in wash cycle, rinse water temperature in rinse

[7] “MODE” Button

Press to change the selected operation mode. See “6. WASH AND RINSE”.

[8] “STANDBY/CLEANING” Button

Press to make the dishwasher inoperable even when the door is closed. See “11.

Press and hold to start self-cleaning with the “ON/OFF” button off. See “16. SELF-

[9] “ON/OFF” Button

Turns on/off the power for operation.

ice personnel also use these buttons to change the controller settings.

cycle, and error codes in case of trouble. See “20. TROUBLESHOOTING”.

STANDBY/CLEANING BUTTON”.

CLEANING”.

[c] ACCESSORIES

Instruction manual x 1 Installation manual x 1

Universal rack x 1 Maintenance sheet x 1

Required for installation:

Operation panel x 1 Plate - rack guide x 1

Screw - bolt (stainless steel 5x12) x 2 Inlet water strainer & gasket x 1

2. CHECKS BEFORE OPERATION

WARNING

1. To prevent possible water leak, electric shock or fi re, the installation must be

carried out by qualifi ed personnel.

2. To use a gas water heater, thoroughly read its instruction manual. Ensure

adequate air intake and exhaust systems and exhaust hoods in accordance

with applicable laws for the type and capacity of the heater to prevent

dangerous conditions due to lack of oxygen and toxic gas generation.

4

Page 31

[a] CHECKS AFTER INSTALLATION

* In the presence of the installer, check for proper installation according to the installation

manual provided.

* Receive the installation manual from the installer, and keep it for later reference.

[b] WATER REQUIREMENTS

* Proper water quality can improve warewashing performance by reducing spotting,

lowering chemical supply costs, improving productivity and extending equipment life.

Local water conditions vary. The recommended proper water treatment for effective and

effi cient use of this equipment will also vary depending on the local water conditions. Ask

your municipal water supplier for details about local water specifi cs prior to installation.

* Recommended water hardness is not more than 4 grains of hardness per gallon.

Chlorides must not exceed 50 parts per million. Water hardness above 4 grains per gallon

should be treated by a water softener or in-line treatment. Water treatment has been

shown to reduce costs associated with machine cleaning, reduce the need for deliming

the dishwasher, reduce detergent usage and reduce corrosion of metallic surfaces in the

internal booster tank and dishwasher.

* Sediment, silica, chlorides or other dissolved solids may lead to a recommendation for

particulate fi ltration or reverse osmosis treatment.

* If an inspection of the dishwasher or internal booster tank reveals lime build-up after

the equipment has been in service, in-line water treatment should be considered, and,

if recommended, should be installed and used as directed. Contact an authorized

Hoshizaki service company for specifi c recommendations.

[c] CHECKS BEFORE OPERATION

* Ambient temperature should be within 41 to 95°F (5 to 35°C). Operation of the unit for

extended periods outside of this normal temperature range may affect performance.

WARNING

To avoid the risk of corrosion, clogging and health problems, be sure to use

potable water.

* To prevent water leaks resulting in damage to the surrounding property, keep the water

supply pressure within 10 to 70 PSIG. If the water pressure is too high, a pressure

reducing valve (option) must be installed according to the water heater’s instruction

manual.

5

Page 32

* The power supply voltage and capacity must be as follows:

Power supply voltage: 208 - 230V / 60Hz / 3Ph

Operating limits: 187 - 253V

Maximum breaker/fuse size: 50A

Minimum circuit ampacity: 50A

* The wash compartment has been cleaned before shipping. But clean it again before

starting up the unit, and check for proper installation of each part. See “15. DAILY

MAINTENANCE”.

* Check the electrical, water, and drain connections before starting up the unit. See “18.

MONTHLY INSPECTION”.

* Always use a dishwasher detergent instead of a neutral detergent for kitchen use.

(Some dishwasher detergents are not suitable. Contact an authorized Hoshizaki service

company for further details.)

3. CHECKING DETERGENT TANK AND RINSE AID TANK

* Follow the instructions of the detergent and rinse aid suppliers to check the detergent

tank and rinse aid tank safely.

IMPORTANT

Be sure to read the warning and caution labels attached to the detergent tank

and rinse aid tank.

4. PREPARING THE WASH COMPARTMENT

* Check that the wash compartment has been cleaned with all the parts in place. If not,

clean the wash compartment according to “13. DAILY MAINTENANCE”, and install the

parts following the instructions below.

6

Page 33

Upper Wash Spray Arm

Upper Spray Arm Holder

Drain Pipe

Dishtable

Upper Rinse

Spray Arm

Lower Wash Spray Arm

Lower Rinse Spray Arm

Wash Compartment

Tank Filter

Dishtable

Pump Filter

Power Switch (GFCI)

1) Check that the tank fi lters and drain pipe are

in place.

Insert drain pipe

securely

Place left and right

tank fi lters in

position

2) Lower the rack rail. With the rack rail lifted

up, the door cannot be closed and the unit

will not operate.

3) Turn on the power supply to the water heater.

4) Open the cover in the front, and move the power switch (GFCI) to the “ON” position.

5) Press the “ON/OFF” button. The display lights up. (If the door is closed, the auto fi ll

cycle begins.)

7

Page 34

[a] AUTO FILL

The auto fi ll cycle refers to automatically repeated starts and stops of the unit to fi ll the

wash tank with enough hot water for washing. The unit starts and stops about 24 times

and the cycle takes around 11 minutes (supply voltage: 208V, hot water supply: 24 PSIG,

143°F). Then, the dishwasher is ready for washing.

1) Close the door. The “AUTO FILL” lamp fl ashes, and the auto fi ll cycle starts.

2) After the auto fi ll cycle completes, the unit stops, the “READY” lamp lights up (“AUTO

FILL” lamp goes off), and the buzzer sounds.

IMPORTANT

If the dishwasher has been drained

out to prevent freezing, close the

drain valve before opening the water

supply line shut-off valve. With the

drain valve left open, hot water will

be wasted.

Gas Supply Line

Shut-off Valve

Water Supply Line

Shut-off Valve

Water Supply Valve

Water Heater

Water

Gas

Drain Valve

Dishwasher

5. LOADING

[a] PREWASH

1) Remove any leftovers (ex. meat, fi sh, vegetables), chopsticks, toothpicks, straws, paper

products and plastics from the dishes. Never use steel wool on ware to be loaded into

the dishwasher.

CAUTION

Do not put these scraps in the dishwasher, as this may cause reduction in wash

performance or failure.

2) To remove heavy soils such as baked gratin and steamed egg or rice, soak the dishes in

hot water before loading them in the dishwasher.

IMPORTANT

1. Do not allow a large amount of neutral detergent in the dishwasher.

2. Use a suitable rack for dishes.

8

Page 35

[b] LOADING DISHES

1) Place the rack on the dishtable.

2) Keep the dishes within the rack, otherwise they

may be damaged.

3) Do not stack the dishes, otherwise they cannot be

washed properly.

Correct

Incorrect

Stacked Sticking out

Facing up

4) Load glasses upside down into the glassware

rack, otherwise they cannot be washed properly

Correct

Incorrect

Water remains

and rinsed thoroughly or they may touch each

other and be damaged.

Dishes or cups with a deep bottom rim cannot be

rinsed thoroughly with wash water left inside the

rim. Load them as shown below.

Correct

Incorrect

Water remains

If the above loading is not practical, the rinse cycle

time must be extended. Contact an authorized

Hoshizaki service company for further details.

5) The door opening is about 18” (457 mm) high. Keep the loaded rack lower than this

height. Do not force large items into the dishwasher, otherwise they may be damaged or

block the spray arms.

[c] LOADING RACK

1) Slowly open the door.

2) Push the rack into the center of the dishwasher until it touches the rack guide at the

back. Otherwise, the rack and dishes may get caught on the back of the door, resulting

in damaging the wash and rinse spray arms and dishes.

CAUTION

Do not stack racks. Otherwise, this will

cause reduction in wash performance

or failure.

9

Door

Rack

Page 36

6. WASH AND RINSE

[a] OPERATING TEMPERATURES

Operating temperatures are as follows:

Wash Temperature Rinse Temperature

Minimum Recommended Minimum Recommended

°F (66°C) 150°F (66°C) 180°F (82°C) 180°F (82°C)

150

[b] MODE SETTING

Standard mode: Normal soils (about 53 seconds)

Long mode: Heavy soils (about 122 seconds)

Rinse mode: Rinse only (6 seconds)

1) Press the “MODE” button until the desired mode is selected and its lamp lights up.

2) Slowly close the door. The selected mode lamp fl ashes (“READY” lamp goes off), and

washing operation (wash and rinse) starts.

3) When the washing operation completes, the “READY” lamp lights up (mode lamp goes

off), and the buzzer sounds.

IMPORTANT

1. To change the duration of each mode, contact an authorized Hoshizaki

service company.

2. If the display has changed from temperature indication to

circling indication, the dishwasher is waiting for water supply.

In a wash cycle, the unit will automatically extend the wash

cycle and start a rinse cycle after completion of water supply.

In the rinse mode, the unit will wait for the water supply cycle

to complete and start a rinse cycle.

3. In case washing operation is interrupted by power failure or other reasons,

restart the washing operation from the beginning or select the rinse mode to

rinse off any detergent remaining on the dishes.

10

Page 37

7. UNLOADING

1) Slowly open the door.

2) Slide the rack onto the dishtable.

WARNING

1. To prevent the risk of burns, do not touch the hot water [140 to 176°F (60 to

80°C)] inside the wash tank directly.

2. When opening the door, be careful not to burn yourself with dripping hot

water.

3. To prevent possible burns, handle the rack, dishes, and interior parts [around

176°F (80°C)] with care after washing.

IMPORTANT

When carrying a loaded rack, use both hands to keep it level.

8. INSUFFICIENT WASHING RESULTS

If washing results seem insuffi cient, check for the following possible causes:

* Small items such as chopsticks and spoons or part of the dishes stick out of the rack to

block the spray arms. Remove the projecting items.

* The dishes are packed and stacked in the rack. Reload the dishes. See “5. [b] LOADING

DISHES”.

* The tank fi lters or pump fi lter is clogged. Clean them. See “15. DAILY MAINTENANCE”.

* The spray arm nozzles are clogged. Clean them. See “15. DAILY MAINTENANCE”.

* The upper and lower headers (spray arm shafts) are clogged

with small objects such as toothpicks. Clean them.

* The detergent tank is out of detergent. Replace it with a new

tank. See “3. CHECKING DETERGENT TANK AND RINSE

AID TANK”.

* Wash water is not clean. Press the “ON/OFF” button, check that the display goes off, and

pull out the drain pipe to drain the wash water. Reinsert the drain pipe, then press the “ON/

OFF” button to supply fresh wash water.

11

Header

Page 38

* The wash water temperature is too low.

* The dishes are heavily soiled. Preclean before loading the dishes.

* Iron or tannin content in wash water turns the dishes yellowish or faintly black. Soak the

dishes in a plastic bucket containing hot water and commercial bleach.

* White spots left on clear glassware can be caused by different reasons. Consult with an

authorized Hoshizaki service company or the detergent supplier.

* Adjustments of the wash and rinse cycle times, hot water temperature, and detergent

concentration may be required depending on the water quality, dish types and materials,

and soil conditions.

9. SHUTDOWN

CAUTION

If there is a possibility that the ambient

temperature may fall below 32°F (0°

C) and freeze the unit, be sure to drain

the unit. The water supply line could be

damaged and leak water, resulting in

damage to the surrounding property.

To drain out the water heater, close the

water supply line shut-off valve, and

open the drain valve and water supply

valve.

Gas Supply Line

Shut-off Valve

Water Supply Line

Shut-off Valve

Water Supply Valve

Water Heater

Water

Gas

Drain Valve

Dishwasher

1) Press the “ON/OFF” button on the operation panel. The display and lamps go off.

2) Open the cover in the front panel, then move the power switch (GFCI) to the “OFF”

position.

3) Turn off the water heater.

4) Turn off the gas and water supplies.

IMPORTANT

To operate the water heater, follow its instruction manual.

12

Page 39

5) Tilt back the rack rail.

IMPORTANT

The rack rail may fall down if tilted more than 10°. Do not hang anything from it

or hit it hard.

6) Pull out the drain pipe to drain water from the

wash tank.

7) Remove the right tank fi lter and then the left

tank fi lter without spilling scraps inside.

WARNING

When pulling out the drain pipe, be careful not to touch the wash water. It may

cause burns or skin irritation. Turn the drain pipe if it is hard to pull out.

10. INTERRUPTION

WARNING

To prevent hot water from splashing and causing burns, do not open the door

while the unit is running. Wait until the buzzer sounds 1 second after the unit

stops.

To interrupt washing operation, press the “ON/OFF” button on the operation panel. The

display and lamps go off, and the unit stops.

To resume operation, press the “ON/OFF” button.

13

Page 40

11. STANDBY/CLEANING BUTTON

The “STANDBY/CLEANING” button is used to keep wash water hot. It will cool more

quickly if the door is left open.

1) Press the “STANDBY/CLEANING” button on the operation panel. The standby lamp

lights up (“READY” lamp goes off). The unit will not start even when the door is opened

or closed.

2) To resume operation, press the “STANDBY/CLEANING” button on the operation panel.

The “READY” lamp lights up (standby lamp goes off). Now the dishwasher is ready to

wash.

IMPORTANT

The “STANDBY/CLEANING” button function is not available during washing

operation. Press it while the “READY” lamp is on.

12. INTERNAL BOOSTER TANK ENERGY SAVING CONTROL

The internal booster tank water temperature in the standby mode can be set lower to save

energy. For further details, consult with an authorized Hoshizaki service company.

13. LOW WATER TEMPERATURE LOCK FUNCTION

To ensure the NSF specified minimum wash and rinse water temperatures, this unit is

provided with functions to lock the washing operation until wash water reaches 150°F and

to extend the washing operation until rinse water reaches 180°F (factory default: OFF). For

further details, consult with an authorized Hoshizaki service company.

14. ALERT FUNCTION

To keep water in the wash tank clean, this unit is provided with functions to beep and fl ash

“Ch” (= Change) in the display when wash water should be changed and to continue this

alert until the wash water tank is refi lled (factory default: OFF). For further details, consult

with an authorized Hoshizaki service company.

14

Page 41

15. DAILY MAINTENANCE

IMPORTANT

Be sure to clean the dishwasher after closing time every day. It is diffi cult to

remove heavy soils left overnight. In high temperature conditions, food scraps

will rot and affect sanitary operation.

1) Take out scraps from the removed tank fi lters, and wash them clean with a scourer.

IMPORTANT

To prevent damage, do not hit the fi lters on the sink to drop scraps or to drain

the fi lters.

2) Turn and loosen the upper spray arm nut

in the direction of the arrow. Support the

upper rinse spray arm, and remove it

together with the upper wash spray arm.

3) Turn and loosen the lower spray arm nut in

the direction of the arrow. Lift off the lower

rinse spray arm, and remove the lower

wash spray arm.

4) If the wash spray arm and rinse spray arm

nozzles are clogged, use a wire or brush to

unclog and wash them clean.

5) Clean the wash compartment by lifting off

the separator toward you. Remove any

scraps from inside the wash compartment

and wash tank. Use a scourer to wash off

heavy soils.

Upper Wash Spray Arm

Spray Arm Nut

Upper Rinse Spray Arm

Spray Arm Nut

Wire

15

Separator

Page 42

IMPORTANT

To prevent damage, do not hit the separator on the sink to drop scraps or to

drain the separator.

6) Check the pump fi lter inside the wash tank.

If it is clogged, clean it with a scourer.

7) Check the water level sensor. If it is dirty,

clean it with a soft brush.

Water Level Sensor Location

Pump Filter

Water Level Sensor

Front

IMPORTANT

Do not use a metal brush to clean the water level sensor. The surfaces may be

damaged, or metal particles attached to the sensor may cause malfunction.

8) Replace the separator in its correct position.

Separator

9) Install the left and right tank fi lters.

16

Page 43

10) Use one hand to hold the upper wash spray

arm on the upper spray arm shaft, and use

the other hand to tighten the upper spray

arm nut in the direction of the arrow.

11) Place the lower wash spray arm on the

lower spray arm shaft, and tighten the lower

spray arm nut in the direction of the arrow.

12) Check that the wash spray arms and rinse

spray arms can be turned easily by hand.

13) Insert the drain pipe securely.

Insert Drain Pipe

securely

14) Lower the rack rail. With the rack rail lifted

up, the door cannot be closed and the unit

will not operate.

16. SELF-CLEANING

The self-cleaning function is to rinse the wash compartment with hot water. Use this

function after step 7) of “15. DAILY MAINTENANCE”.

CAUTION

If a portion control detergent feeder other than concentration sensitive type is

used, turn off the power to the detergent feeder. Otherwise the detergent may

be supplied during the self-cleaning cycle. After the cycle completes, turn the

detergent feeder back on. If this is not practical, consult with an authorized

Hoshizaki service company.

17

Page 44

1) Turn on the gas and water supplies and water heater.

2) Pull out the drain pipe.

3) Install the upper and lower rinse spray arms

only, and lower the rack rail. With the rack rail

lifted up, the door cannot be closed and the

Upper Rinse Spray Arm

unit will not operate.

4) With the door open, move the power switch

Rack Rail

(GFCI) to the “ON” position, then press and

hold the “STANDBY/CLEANING” button for 3

seconds. “SC” appears in the display.

Lower Rinse Spray Arm

5) Close the door. “SC” and the “AUTO FILL” lamp start fl ashing, and the self-cleaning

cycle begins. The buzzer sounds and the operation panel turns off when the cycle ends.

Move the power switch (GFCI) to the “OFF” position. Turn off the water heater, and the

gas and water supplies.

6) Open the door, an

d remove the upper and lower rinse spray arms. Go on to step 8) of “15.

DAILY MAINTENANCE”.

17. WEEKLY MAINTENANCE

[a] HEATER

WARNING

To prevent burns, wait for 10 minutes after draining the unit to clean the interior.

Soft Brush

Remove any scraps from the heater, and

use a soft brush to wash off residue.

Heater

Do not use a metal

brush which may

damage the surface.

[b] EXTERIOR

1) Wipe the exterior with a soft cloth.

2) Use a damp cloth containing a neutral cleaner to wipe off dirt. Then wipe away the

residue with a clean cloth.

18

Page 45

[c] WASH COMPARTMENT

1) Tilt back the rack rail, and lift it off the notch.

2) Remove any scraps from the wash tank.

18. MONTHLY INSPECTION

[a] POWER SWITCH (GROUND FAULT CIRCUIT INTERRUPTER)

1) Open the cover at the front, and move the power switch (GFCI)

to the “ON” position.

2) Press the test switch. The power switch (GFCI) should switch

from “ON” to “OFF”.

3) If not, move the power switch (GFCI) to the “OFF” position, and

contact an authorized Hoshizaki service company.

[b] WATER SUPPLY LINE

Check the water supply line for damage, deformation, or

water leak marks (stains). If any of these conditions are

found, contact an authorized Hoshizaki service company.

Recommendation of safety inspection by service personnel

Even if there is no problem with its use, a product out of

warranty may have a risk of electric shock, fi re, or water

leak due to insulation degradation or aging of the electrical

parts. Ask an authorized Hoshizaki service company for the

following inspections (charged):

ON

OFF

Test Switch

Water Heater

Damage, deformation

or water leaks

* Dust and dirt build-up or water leak inside the unit

* Aging conditions of the unit and its components

* Scale, silica, lime or other foreign matter in the water circuit

19

Page 46

19. DESCALING (AS REQUIRED)

* Use a descaler according to the supplier’s instructions.

WARNING

1. Carefully follow any instructions provided with the descaler.

2. Always wear liquid-proof gloves and goggles to prevent the descaler from

coming into contact with skin or eyes.

3. To prevent generation of toxic chlorine gas, do not mix a descaler with a

chlorinated cleaner.

1) Pull out the drain pipe to drain water from the wash tank. Start the auto fi ll cycle to fi ll

the wash tank with hot water.

2) Use the “ON/OFF” button to turn off the unit. Refer to the descaler's directions and add

the proper amount of descaler to the wash tank. The wash tank holds 14.3 gallons of

water.

3) Keep the door open. Press and hold the up and down buttons and the “MODE” button,

then press the “ON/OFF” button to select the “PC” (Preventative Cleaning) mode.

4) Close the door to start preventative cleaning.

5) Refer to the descaler's directions for the proper durationof cleaning. When the proper

amount of time has passed, press the “ON/OFF” button to stop cleaning.

6) Open the door, then check the wash tank interior. Repeat steps 1) through 5) if

necessary.

WARNING

Be careful not to burn yourself with the hot water or parts in the wash tank.

7) Drain the wash tank, then start the auto fi ll cycle. Run the dishwasher to rinse the wash

tank thoroughly. Drain the wash tank.

20

Page 47

20. TROUBLESHOOTING

IMPORTANT

If something seems wrong with the unit, check for possible causes according

to the following instructions. If the problem still exists, immediately contact an

authorized Hoshizaki service company.

When contacting a service company, let them know the model name, serial

number, date of installation (see warranty card) and type of trouble (ex. error

code).

[a] TROUBLES REQUIRING IMMEDIATE SERVICE CALL

When one of the following error codes fl ashes in the display, move the power switch (GFCI)

to the “OFF” position, and immediately contact an authorized Hoshizaki service company.

Error Code Problem

o1, o2 Booster tank water level switch

H1 - H4 Thermistors

H7 Reverse phase connection

[b] TROUBLES REQUIRING CHECK BY USER

When one of the following error codes fl ashes in the display, check for possible causes.

After the problem has been resolved, press the “ON/OFF” button on the operation panel to

resume operation. The error code disappears, and the buzzer stops.

If the error code appears again, move the power switch (GFCI) to the “OFF” position, and

immediately contact an authorized Hoshizaki service company.

Error Code Problem Possible Cause

A1 Auto fi ll

A2 Water supply from water heater

A3

Low wash water level in operation

or standby mode

Drain pipe disconnected

Dirty water level sensor

Water failure

Water supply valve closed

Water supply line shut-off valve closed

Drain pipe disconnected

Tank fi lter out of position

21

Page 48

[c] TROUBLES WITHOUT ERROR CODE INDICATION

Problem Possible Cause Remedy

Open the cover in the front panel, and move the power

Unit fails to

operate

Unit is not

operable by

opening/closing

door

Abnormal noise

(vapor lock)

Power switch

(GFCI) off

“ON/OFF”

button off

Power failure

Main power

supply off

Standby lamp

on

Bubbling

compartment

Pump fi lter

clogged

switch (GFCI) to the “ON” position. If it switches off again,

there is a risk of electric leakage. Immediately contact an

authorized Hoshizaki service company.

Check that the display on the operation panel is off and

the power switch (GFCI) is on. Press the “ON/OFF”

button. If the display and “READY” lamp light up, the unit

is ready. If the auto fi ll cycle is not complete, the unit will

start water supply and then enter the ready mode. In the

ready mode, operation can be started by opening and

closing the door.

If the power switch (GFCI) and “ON/OFF” button are on

but the display does not light up, check for power failure.

In case of power failure, move the power switch (GFCI)

to the “OFF” position and wait. When the power resumes,

start up the unit according to sections 3 - 6.

If the power does not resume on the same day, shut

down the unit according to section 9.

Turn on the main power supply. If it is already on or

switches off again, immediately contact an authorized

Hoshizaki service company.

The unit is not operable by opening/closing the door

while the standby lamp on the operation panel is on. To

cancel the standby mode and resume operation, follow

the instructions in section 11.

If the standby mode cannot be cancelled, or the unit is

still inoperable, move the power switch (GFCI) to the

“OFF” position, and immediately contact an authorized

Hoshizaki service company.

When a detergent other than dishwasher detergents is

used, or a large amount of neutral detergent for kitchen

use is mixed in from prewash, the wash compartment

bubbles heavily, resulting in insufficient washing due

to wash pump vapor lock. In this case, replace the

detergent with a dishwasher detergent, and refill the

wash tank.

Vapor lock also occurs when the pump fi lter at the pump

suction inlet is dirty or clogged. Clean the pump filter

according to step 6) of section 13.

22

Page 49

21. LONG STORAGE, RELOCATION, DISPOSAL, TRANSFER

When preparing the unit for long storage, shut down and clean the unit according to

sections 9 and 13 - 17. Move the power switch (GFCI) to the “OFF” position and turn off

the power supply.

If something seems wrong when restarting the unit after long storage, turn off the power

supply, and immediately contact an authorized Hoshizaki service company.

WARNING

1. When restarting the unit after long storage, contact an authorized Hoshizaki

service company. To prevent electric shock, do not restart the unit by yourself.

2. In case of relocation, contact an authorized Hoshizaki service company.

Improper installation may cause water leak, electric shock or fi re.

3. When disposing of the unit, contact an authorized Hoshizaki service company.

Leaving the unit may violate laws or cause an unexpected accident.

CAUTION

When selling or transferring this product, tape this instruction manual and the

installation manual to the exterior to provide the new owner with information on

safe and proper use of the product.

23

Loading...

Loading...