Page 1

NO. J002-794

ISSUED: APR. 1, 2011

REVISED: SEP. 6, 2011

MODEL

HOSHIZAKI

DISHWASHER

JWE-2400CUA-L-25B

JWE-2400CUA-R-25B

SERVICE MANUAL

Page 2

IMPORTANT

Only qualifi ed service technicians should install, service, and maintain the

unit. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualifi ed service technicians in the

maintenance and service of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

Page 3

IMPORTANT

This manual should be read carefully before the unit is serviced or maintenance

operations are performed. Only qualifi ed service technicians should install,

service, and maintain the unit. Read the warnings contained in this booklet

carefully as they give important information regarding safety. Please retain this

booklet for any further reference that may be necessary.

CONTENTS

I. Specifi cations ------------------------------------------------------------------------------------------------ 1

A. Specifi cation Sheet ------------------------------------------------------------------------------------- 1

1. JWE-2400CUA-L-25B ------------------------------------------------------------------------------ 1

2. JWE-2400CUA-R-25B ------------------------------------------------------------------------------2

B. Nameplate Rating --------------------------------------------------------------------------------------- 3

C. Dimensions/Connections ------------------------------------------------------------------------------ 4

1. JWE-2400CUA-L-25B ------------------------------------------------------------------------------ 4

2. JWE-2400CUA-R-25B ------------------------------------------------------------------------------5

II. General Information ---------------------------------------------------------------------------------------- 6

A. Construction ---------------------------------------------------------------------------------------------- 6

1. Dishwasher -------------------------------------------------------------------------------------------- 6

2. Booster Tank ------------------------------------------------------------------------------------------7

3. Control Box -------------------------------------------------------------------------------------------- 8

B. Functions -------------------------------------------------------------------------------------------------- 9

1. Increasing Rinse Water Flow Rate -------------------------------------------------------------- 9

C. Sequence of Operation -------------------------------------------------------------------------------- 9

1. Auto Fill Cycle ----------------------------------------------------------------------------------------- 9

2. Ready Cycle (Unit Inactive) ----------------------------------------------------------------------10

3. Wash Cycle/Rinse Cycle --------------------------------------------------------------------------10

4. Table Limit Switch -----------------------------------------------------------------------------------11

5. Emergency Stop Button ---------------------------------------------------------------------------11

6. Drain----------------------------------------------------------------------------------------------------11

D. Sequence of Operation Flow Chart ----------------------------------------------------------------12

E. Timing Chart ---------------------------------------------------------------------------------------------13

1. Auto Fill Cycle ----------------------------------------------------------------------------------------13

2. Wash Cycle/Rinse Cycle --------------------------------------------------------------------------14

F. Control Board and Operation Board ---------------------------------------------------------------15

1. Control Board Location ----------------------------------------------------------------------------15

2. Control Board Layout ------------------------------------------------------------------------------16

3. Control Board Diagram ----------------------------------------------------------------------------17

4. Operation Panel Layout ---------------------------------------------------------------------------18

5. Features -----------------------------------------------------------------------------------------------18

6. Controls, Adjustments, and Lamps -------------------------------------------------------------18

7. Service Menu and Error Log ---------------------------------------------------------------------19

8. Temperature Display -------------------------------------------------------------------------------21

9. Error Codes ------------------------------------------------------------------------------------------21

10. Buzzer -------------------------------------------------------------------------------------------------21

11. Operation Time Display ----------------------------------------------------------------------------22

i

Page 4

12. Special Modes ---------------------------------------------------------------------------------------22

III. Service Diagnosis ----------------------------------------------------------------------------------------24

A. Diagnostic Procedure ---------------------------------------------------------------------------------24

B. Error Codes ----------------------------------------------------------------------------------------------26

1. Error Code Table ------------------------------------------------------------------------------------26

2. Error Code Log --------------------------------------------------------------------------------------27

3. Error Code Details ----------------------------------------------------------------------------------28

C. Service Flow Charts -----------------------------------------------------------------------------------41

1. Unit Will Not Start -----------------------------------------------------------------------------------41

2. Dishes Not Clean -----------------------------------------------------------------------------------43

3. Inadequate Rinse -----------------------------------------------------------------------------------45

4. Dishwasher Will Not Start Wash/Rinse Cycle -----------------------------------------------46

5. No or Inadequate Detergent/Rinse Aid Supply ----------------------------------------------47

6. Wash Tank Water Boils ----------------------------------------------------------------------------47

7. Wash Tank Water Not Draining ------------------------------------------------------------------48

D. Float Switch Check and Cleaning ------------------------------------------------------------------49

1. Float Switch Check ---------------------------------------------------------------------------------49

2. Float Switch Cleaning ------------------------------------------------------------------------------49

E. Thermistor Check --------------------------------------------------------------------------------------50

IV. Removal and Replacement of Components -------------------------------------------------------51

A. Removal of Panels -------------------------------------------------------------------------------------51

B. Removal and Replacement of Wash Pump Motors -------------------------------------------51

C. Removal and Replacement of Rinse Pump Motor ---------------------------------------------52

D. Removal and Replacement of Gear Motor ------------------------------------------------------55

E. Removal and Replacement of Conveyor ---------------------------------------------------------56

F. Removal and Replacement of Crankshaft --------------------------------------------------------57

G. Removal and Replacement of Control Box ------------------------------------------------------58

H. Removal and Replacement of Thermistor -------------------------------------------------------58

I. Removal and Replacement of Control Board or Operation Board --------------------------59

1. Control Board ----------------------------------------------------------------------------------------59

2. Operation Board -------------------------------------------------------------------------------------60

J. Removal and Replacement of Heater -------------------------------------------------------------61

K. Removal and Replacement of Float Switch -----------------------------------------------------62

L. Removal and Replacement of Thermostat -------------------------------------------------------63

V. Cleaning and Maintenance Instructions -------------------------------------------------------------64

A. Daily Maintenance -------------------------------------------------------------------------------------64

B. Weekly Maintenance ----------------------------------------------------------------------------------69

1. Heater --------------------------------------------------------------------------------------------------69

2. Exterior ------------------------------------------------------------------------------------------------69

C. Monthly Maintenance ---------------------------------------------------------------------------------69

1. Water Supply Line ----------------------------------------------------------------------------------69

D. Descaling (As Required) -----------------------------------------------------------------------------70

E. Shutdown -------------------------------------------------------------------------------------------------70

F. Long Storage, Relocation, Disposal, Transfer ---------------------------------------------------72

VI. Operating Instructions -----------------------------------------------------------------------------------72

VII. Technical Information -----------------------------------------------------------------------------------73

A. Water Circuit ---------------------------------------------------------------------------------------------73

B. Wiring Diagram -----------------------------------------------------------------------------------------74

ii

Page 5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING

NOTICE

Indicates a situation which could result in damage to the unit or

IMPORTANT

This product should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore

dangerous. The manufacturer cannot be held responsible for injury or damage

resulting from improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or fi re, follow

basic precautions including the following:

• Only qualified service technicians should install, service, and maintain the

unit.

• Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or severe damage to

equipment.

• This unit requires independent power supplies for the dishwasher and for the

booster tank. See the nameplate for proper voltage and breaker/fuse sizes.

Failure to use proper breakers or fuses can result in tripped breakers, blown

fuses, or damage to existing wiring. This could lead to heat generation or fi re.

• THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit could

result in death or serious injury.

• Use the “ON/OFF” button on the operation panel to turn off the unit, then turn

off the dishwasher and booster tank power supplies before servicing. Lockout/

Tagout to prevent the power supplies from being turned back on inadvertently .

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, fi re, or damage to the unit.

• To avoid possible burns and spills, be sure to drain the wash tank and internal

booster tank and let the components cool before servicing. When draining the

internal booster tank, wait until the water temperature falls below 104°F (40°C).

• When disassembling components that have been in contact with detergent,

wear rubber gloves and goggles. Before starting disassembly, thoroughly

read the detergent safety instructions. Contact with skin may cause irritation

and contact with eyes may cause blindness.

• When using an acidic descaling cleaner, wear rubber gloves and goggles.

Contact with skin may cause irritation, and contact with eyes may cause

blindness. Do not use or mix with a dishwashing detergent. Some detergents

may generate toxic chlorine gas.

Indicates a hazardous situation which could result in death or

serious injury.

property.

Indicates important information about the use and care of the

unit.

WARNING

iii

Page 6

I. Specifi cations

A. Specifi cation Sheet

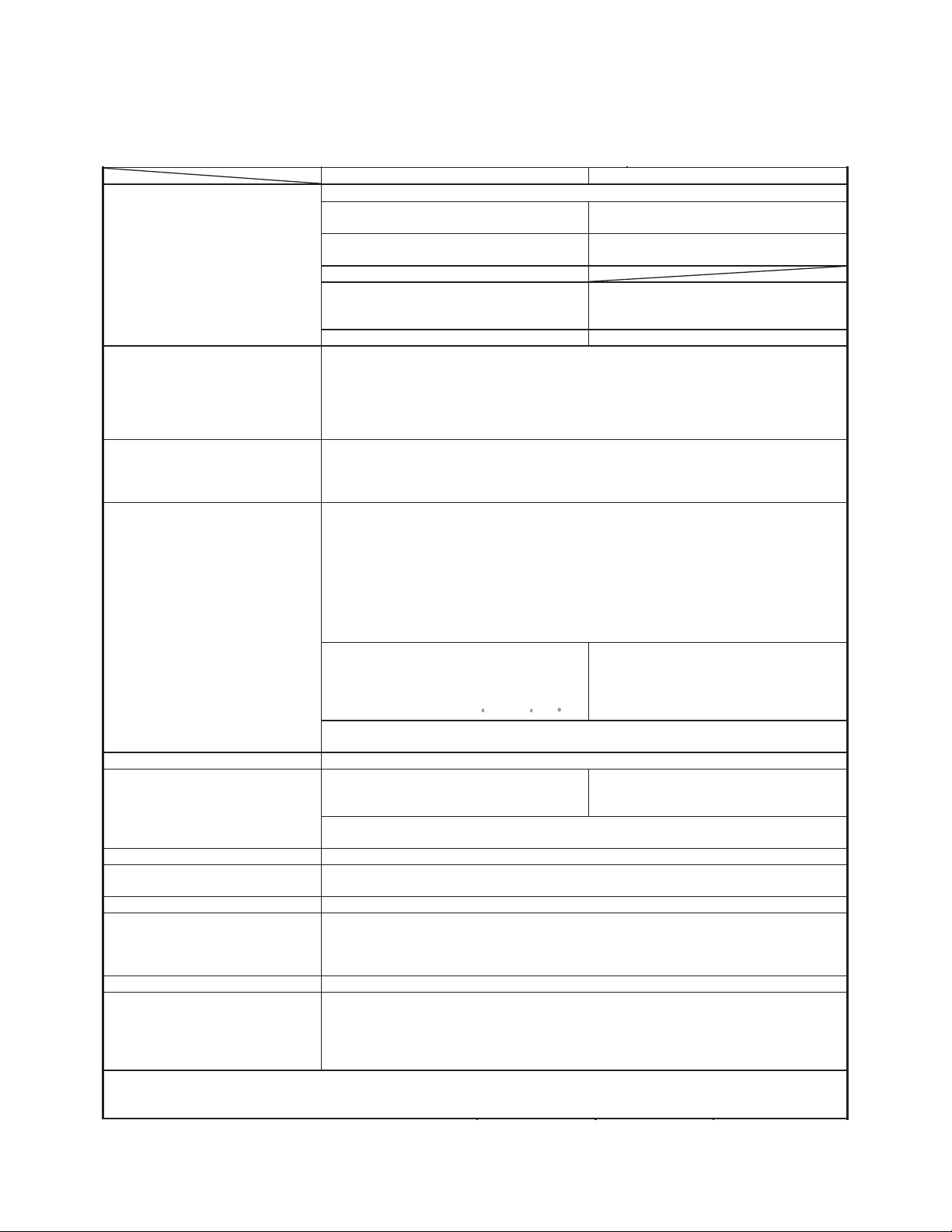

1. JWE-2400CUA-L-25B

DISHWASHER SIDE BOOSTER SIDE

AC SUPPLY VOLTAGE

POWER SUPPLY CAPACITY

AMPERAGE

STARTING AMPERAGE

ELECTRICAL COMSUMPTION

HEATER

RACK SIZE

NUMBER OF LARGE DISHES / RACK

CAPACITY

WATER COMSUMPTION

PASSING HEIGHT

DIRECTION OF OPERATION

OUTSIDE DIMENSIONS

EXTERIOR

DOOR

LEG

WASH SYSTEM ,RINSE SYSTEM

PUMP

DRAIN SYSTEM

START

DRY SYSTEM

REFUSE DISPOSAL

DETERGENT

DISPLAY

TANK CAPACITY

HOT WATER SUPPLY

TEMPERATURE CONTROL

CONNECTION – WATER SUPPLY

– DRAIN

CONTROL Microprocessor control

BOIL – DRY PROTECTION

SAFETY SYSTEM

WEIGHT Net 430lb (195kg) / Gross 584lb (265kg)

PACKAGE

CERTIFICATION

ACCESSORIES-SUPPLIED

ACCESSORIES-REQUIRED Universal rack (addition), Ventilation hoods x 2, Drain Tempering Kit

OPERATION CONDITIONS

* The rated properties are based on measurements at ambient temperature of 86ºF (30ºC) according to the Technical

Requirements for Electrical Appliances.

* We reserve the right to make changes in specifications and design without prior to notice.

3 phase 3-wire 208-230V/60Hz (±10%) /

208V : 18.4kVA(51.1A)

230V : 22.1kVA(55.5A)

Max Running 51.2A

Rated Motor 9.0A

26.0A

Max 19.86kW

Rated Motor 3.06kW

Power Factor 84%

16.80kW(230V) 25.20kW(230V)

19-3/4" × 19-3/4"(500 × 500mm)

16 plates (9.1” DIA)

240/200/160racks/hour㩷adjustable in 3 steps (rotary switch)

114Gal/hour(432L/hour), 0.48 Gal/rack(1.8L/rack) - at 240rack/hour

20.5" (520mm)

Left to Right

W57.3" × D27.6" × H58.1" (W1,455 × D700 × H1,475mm)

Stainless Steel

Vertically Sliding Service Panel(Opening:W25.6" × H18.9")

Stainless Steel Adjustable 9.4" - 11.0"

Upper and Lower Fixed Spray

Wash 1HP x 2, Rinse 0.134HP

Draw Out Overflow Pipe, Overflow Drain

Rack Detection (Wash/Rinse)

Residual Heat Drying

Filter Collection

Not Provided

Wash Water Temperature / Rinse Water Temperature (selectable by switch)

Ready, Auto Fill, Wash, Error Code

27.2Gal (103L)

Automatic Hot Water Supply by

Microprocessor Control

Wash: 160ºF (71ºC) min.

Thermistor Control: 163ºF(73㩷C) – 168㩷㪝(76C)

Inlet: 3/4"FPT

Outlet: 1-1/2"MPT

Water Level Switch,

Bimetal Thermostat (Manual - Reset),

Thermistor (Auto - Reset)

Service Panel Switch, Emergency Stop by Microprocessor Control

Table Limit Switch, Emergency Stop Button, Conveyor Overload Protector

Carton + Crate

W62.6"×D32.9"×H65.9" (W1,590mm ×D 835mm × 1,675mm)

NSF ANSI-3, ETL, cETL, Energy Star

Universal rack (19-3/4" x 19-3/4"), Instruction manual, Installation manual

Maintenance sheet, Curtain(L), Curtain(S) x 2, Shaft - curtain(L), Shaft - curtain (S) x 2

Guard(L), Guard(R), Hook - Drain, Table limit Switch, Upper wash spray arm,

Operation box assembly, Cable cover, Inlet water strainer & Packing

Ambient Temperature: 41 - 95ºF (5ºC - 35ºC), Voltage Range: Rated Voltage ±10%

Recommends Water Hardness : 4gpg (grains per gallon) (68.5ppm) or less

Water Supply Temperature: 110 - 167ºF (43ºC - 75ºC) ( Recommends 140 ºF (60ºC))

Water Supply Pressure (Gauge Static Pressure): 10 - 70PSIG (0.07 - 0.48 MPa)

Exhaust Requirements : 200CFM(Entrance End),400CFM(Discharge End)

2 power supply lines

208V : 20.6kVA(57.2A)

230V : 25.3kVA(63.5A)

Max Running 63.3A

Max 25.20kW

12.4Gal (47L)

Automatic Hot Water Supply by

Water Valve

Rinse: 180ºF (82ºC) min.

Thermistor Control: 182ºF(83ºC)-185ºF (85ºC)

Float Switch,

Bimetal Thermostat (Manual - Reset),

Thermistor (Auto - Reset)

㩷

1

Page 7

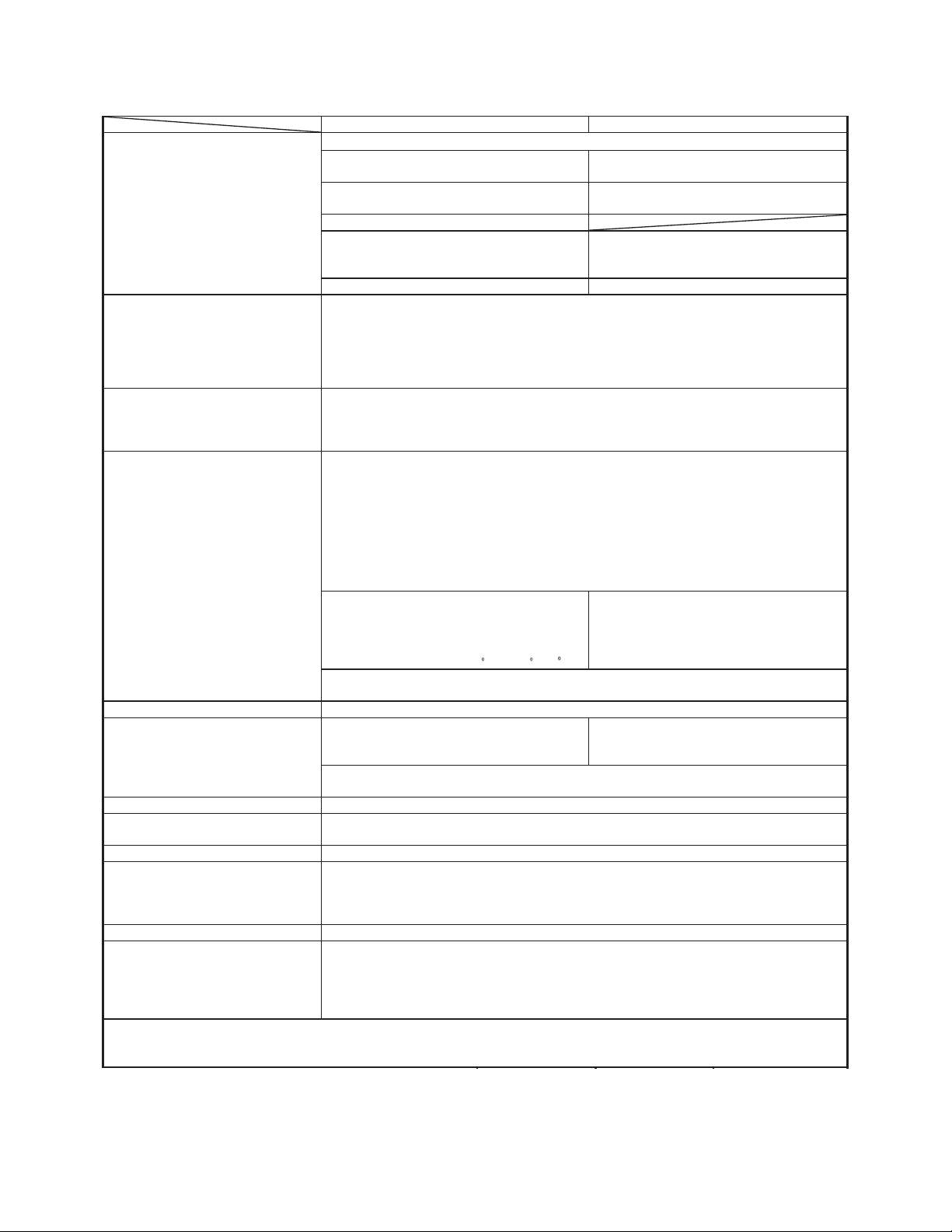

2. JWE-2400CUA-R-25B

DISHWASHER SIDE BOOSTER SIDE

AC SUPPLY VOLTAGE

POWER SUPPLY CAPACITY

AMPERAGE

STARTING AMPERAGE

ELECTRICAL COMSUMPTION

HEATER

RACK SIZE

NUMBER OF LARGE DISHES / RACK

CAPACITY

WATER COMSUMPTION

PASSING HEIGHT

DIRECTION OF OPERATION

OUTSIDE DIMENSIONS

EXTERIOR

DOOR

LEG

WASH SYSTEM ,RINSE SYSTEM

PUMP

DRAIN SYSTEM

START

DRY SYSTEM

REFUSE DISPOSAL

DETERGENT

DISPLAY

TANK CAPACITY

HOT WATER SUPPLY

TEMPERATURE CONTROL

CONNECTION – WATER SUPPLY

– DRAIN

CONTROL Microprocessor control

BOIL – DRY PROTECTION

SAFETY SYSTEM

WEIGHT Net 430lb (195kg) / Gross 584lb (265kg)

PACKAGE

CERTIFICATION

ACCESSORIES-SUPPLIED

ACCESSORIES-REQUIRED Universal rack (addition), Ventilation hoods x 2, Drain Tempering Kit

OPERATION CONDITIONS

* The rated properties are based on measurements at ambient temperature of 86ºF (30ºC) according to the Technical

Requirements for Electrical Appliances.

* We reserve the right to make changes in specifications and design without prior to notice.

3 phase 3-wire 208-230V/60Hz (±10%) /

208V : 18.4kVA(51.1A)

230V : 22.1kVA(55.5A)

Max Running 51.2A

Rated Motor 9.0A

26.0A

Max 19.86kW

Rated Motor 3.06kW

Power Factor 84%

16.80kW(230V) 25.20kW(230V)

19-3/4" × 19-3/4"(500 × 500mm)

16 plates (9.1” DIA)

240/200/160racks/hour㩷adjustable in 3 steps (rotary switch)

114Gal/hour(432L/hour), 0.48 Gal/rack(1.8L/rack) - at 240rack/hour

20.5" (520mm)

Right to Left

W57.3" × D27.6" × H58.1" (W1,455 × D700 × H1,475mm)

Stainless Steel

Vertically Sliding Service Panel(Opening:W25.6" × H18.9")

Stainless Steel Adjustable 9.4" - 11.0"

Upper and Lower Fixed Spray

Wash 1HP x 2, Rinse 0.134HP

Draw Out Overflow Pipe, Overflow Drain

Rack Detection (Wash/Rinse)

Residual Heat Drying

Filter Collection

Not Provided

Wash Water Temperature / Rinse Water Temperature (selectable by switch)

Ready, Auto Fill, Wash, Error Code

27.2Gal (103L)

Automatic Hot Water Supply by

Microprocessor Control

Wash: 160ºF (71ºC) min.

Thermistor Control: 163ºF(73㩷C) – 168㩷㪝(76C)

Inlet: 3/4"FPT

Outlet: 1-1/2"MPT

Water Level Switch,

Bimetal Thermostat (Manual - Reset),

Thermistor (Auto - Reset)

Service Panel Switch, Emergency Stop by Microprocessor Control

Table Limit Switch, Emergency Stop Button, Conveyor Overload Protector

Carton + Crate

W62.6"×D32.9"×H65.9" (W1,590mm ×D 835mm × 1,675mm)

NSF ANSI-3, ETL, cETL, Energy Star

Universal rack (19-3/4" x 19-3/4"), Instruction manual, Installation manual

Maintenance sheet, Curtain(L), Curtain(S) x 2, Shaft - curtain(L), Shaft - curtain (S) x 2

Guard(L), Guard(R), Hook - Drain, Table limit Switch, Upper wash spray arm,

Operation box assembly, Cable cover, Inlet water strainer & Packing

Ambient Temperature: 41 - 95ºF (5ºC - 35ºC), Voltage Range: Rated Voltage ±10%

Recommends Water Hardness : 4gpg (grains per gallon) (68.5ppm) or less

Water Supply Temperature: 110 - 167ºF (43ºC - 75ºC) ( Recommends 140 ºF (60ºC))

Water Supply Pressure (Gauge Static Pressure): 10 - 70PSIG (0.07 - 0.48 MPa)

Exhaust Requirements : 200CFM(Entrance End),400CFM(Discharge End)

2 power supply lines

208V : 20.6kVA(57.2A)

230V : 25.3kVA(63.5A)

Max Running 63.3A

Max 25.20kW

12.4Gal (47L)

Automatic Hot Water Supply by

Water Valve

Rinse: 180ºF (82ºC) min.

Thermistor Control: 182ºF(83ºC)-185ºF (85ºC)

Float Switch,

Bimetal Thermostat (Manual - Reset),

Thermistor (Auto - Reset)

㩷

2

Page 8

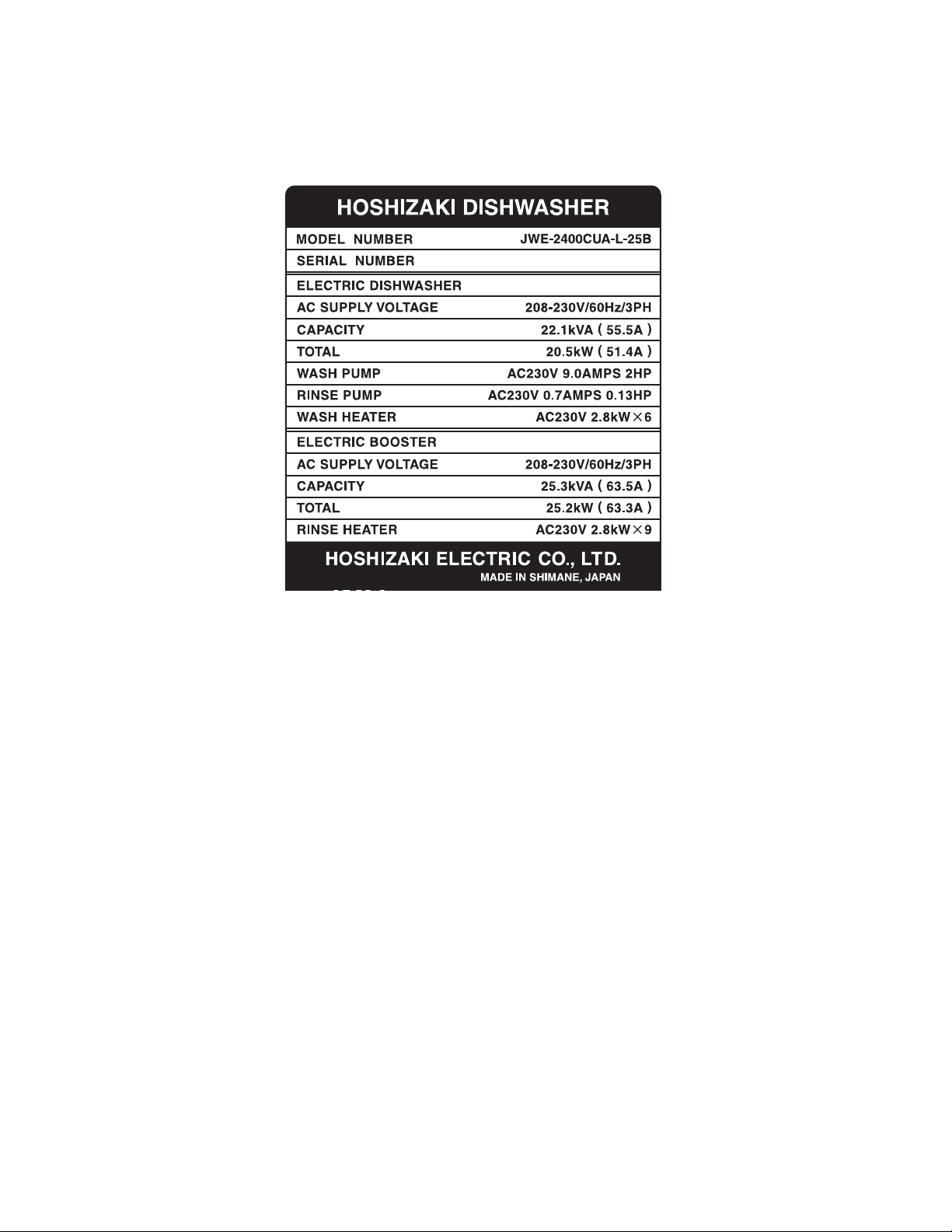

B. Nameplate Rating

For certifi cation marks, see the nameplate on the dishwasher.

We reserve the right to make changes in specifi cations and design without prior notice.

3

Page 9

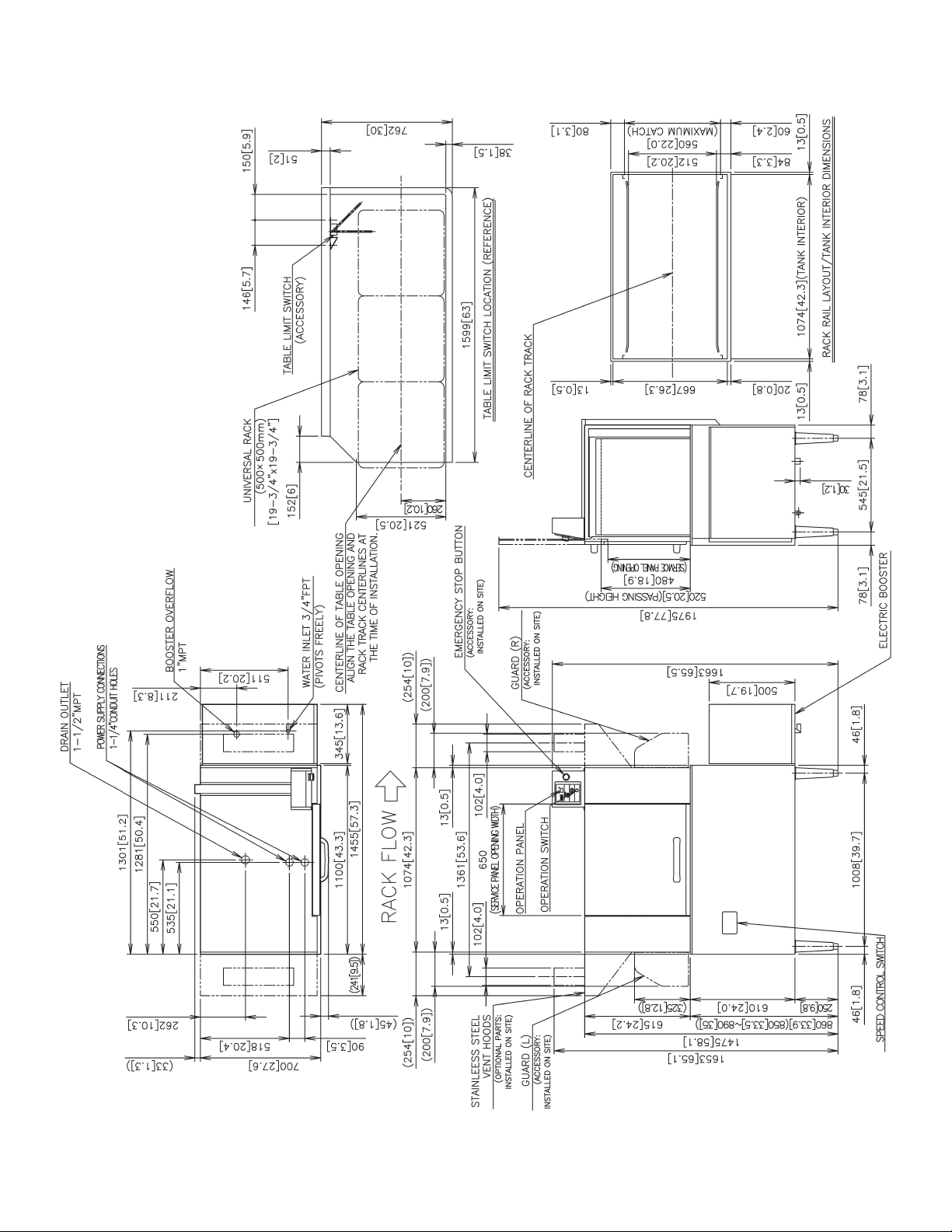

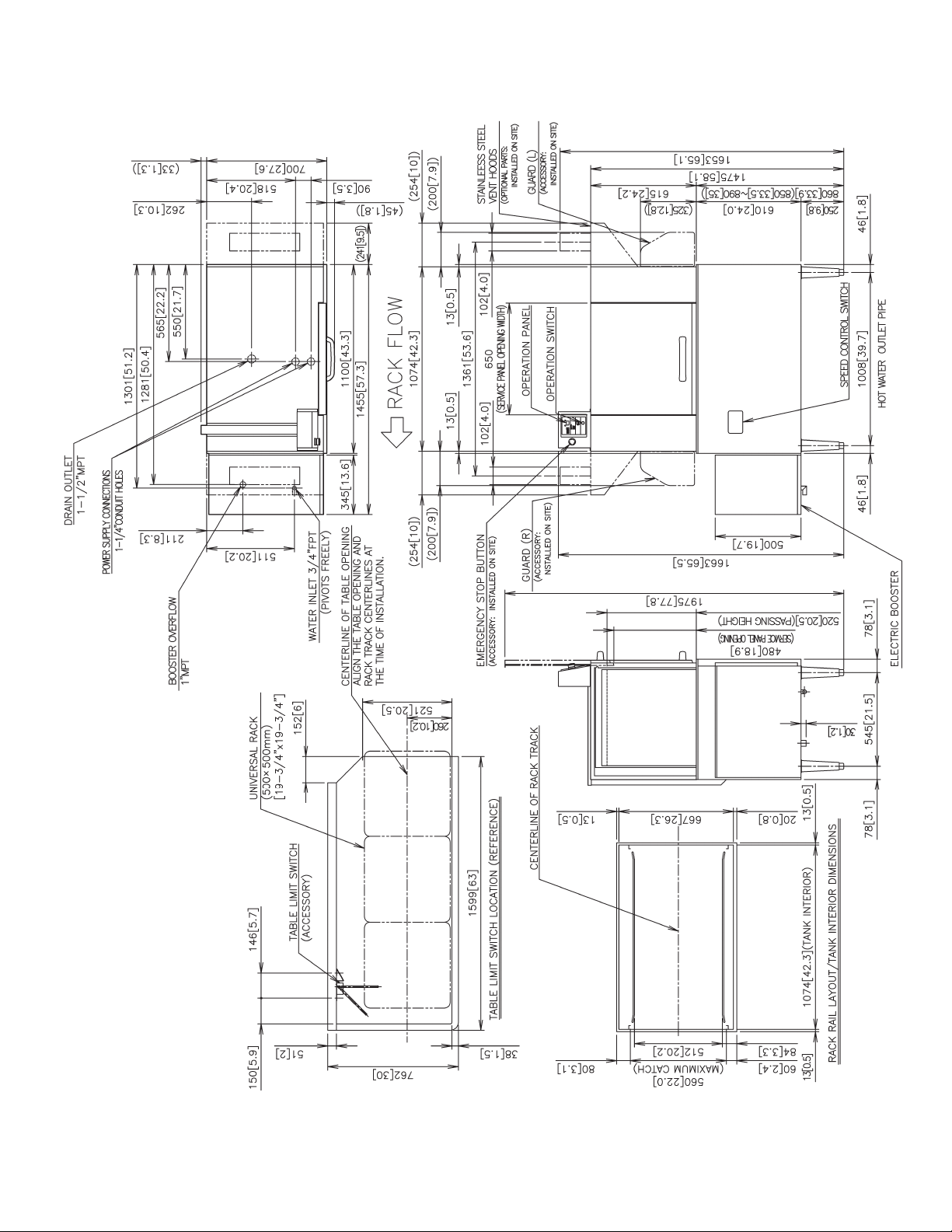

C. Dimensions/Connections

1. JWE-2400CUA-L-25B

Units: mm [in.]

4

Page 10

2. JWE-2400CUA-R-25B

Units: mm [in.]

5

Page 11

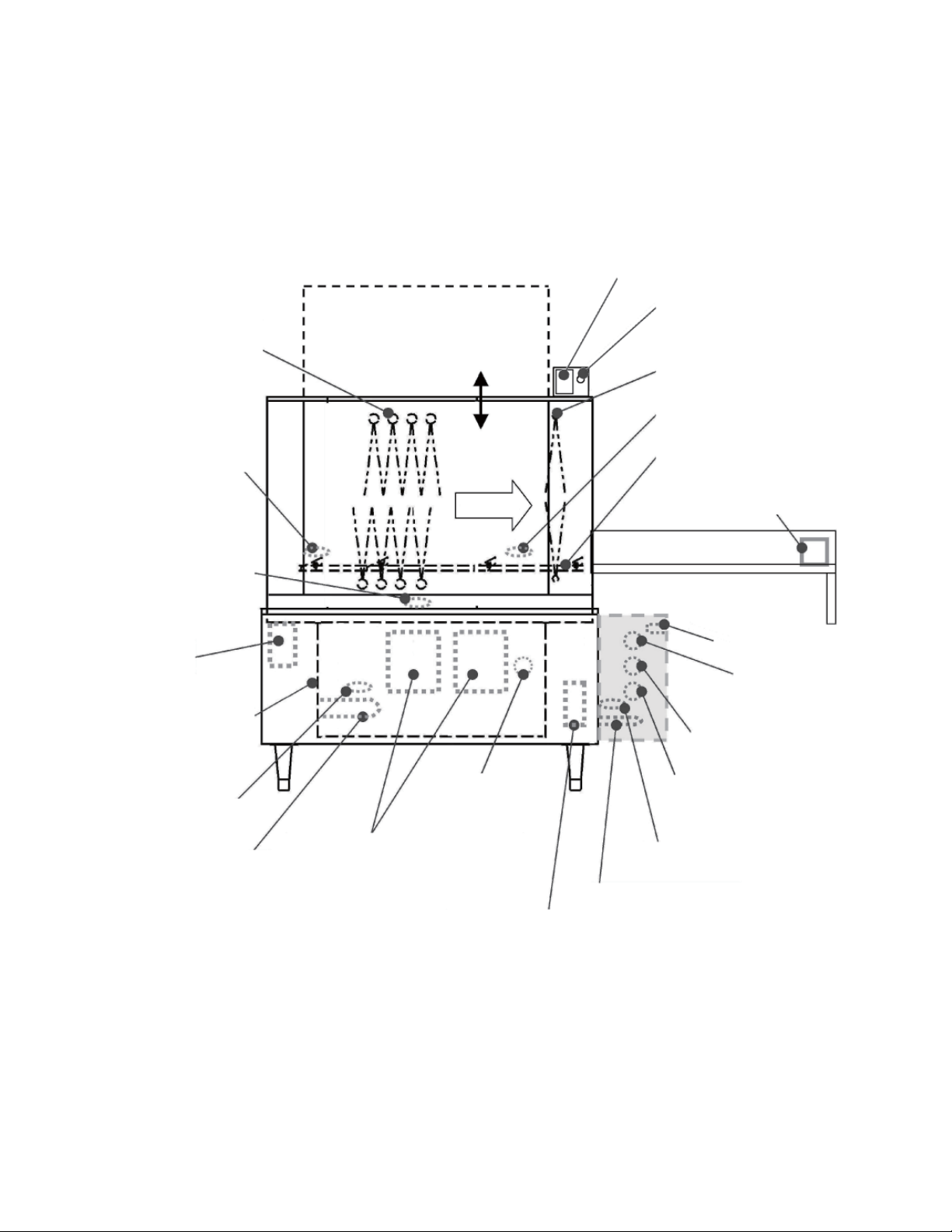

II. General Information

A. Construction

1. Dishwasher

The illustration below shows JWE-2400CUA-L-25B (left-to-right rack fl ow).

Operation Panel

Vertically Sliding

Wash Spray Arm (stationary)

Service Panel

Emergency Stop Button

Rinse Spray Arm (stationary)

Rinse Start Switch

Wash Start Switch

Service Panel Switch

Conveyor Motor

Wash Tank (26 gallons)

Wash Tank Thermistor

Wash Tank Heater

Rack Flow

Water Level Sensor

Wash Pump

(Upper/Lower Spray Arm)

Rinse Pump

Conveyor

Table Limit Switch

Booster Tank

Water Valve

Backup Water

Level Float Switch

Water Level Float Switch

Water Level Safety

Float Switch

Booster Tank Thermistor

Booster Tank Heater

6

Page 12

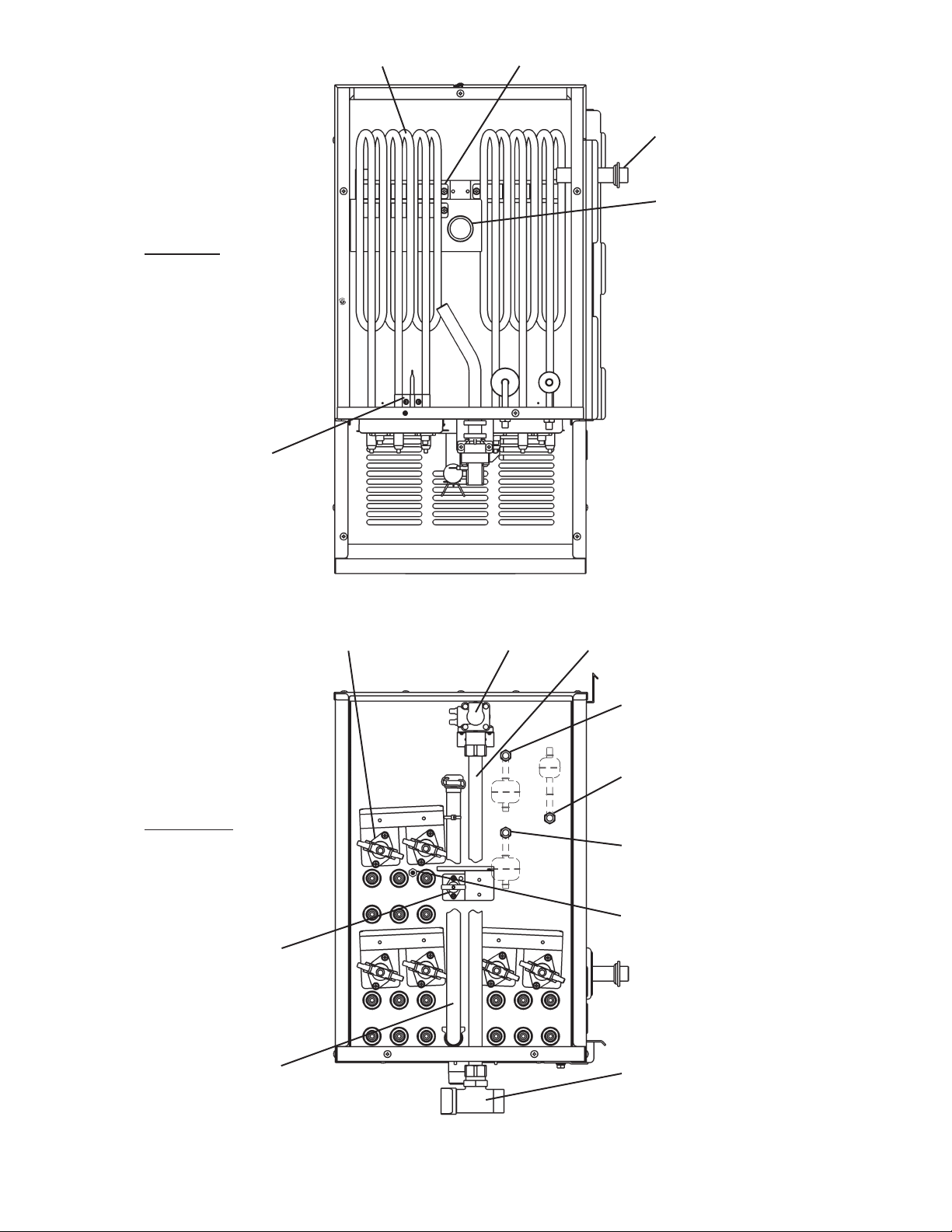

2. Booster Tank

Top View

Thermostat Plate

Sheathed Heater [H7 - 15]

Band Heater

Hot Water Outlet Pipe

Overfl ow Pipe

Thermal Protector [TH7 - 12]

(heater boil dry protection)

Front View

Thermal Protector [TH14]

Drain Hose

Inlet Water

Valve [WV]

Inlet Pipe

Water Level Float Switch [FS1]

(downward end)

Backup Water Level Float Switch [FS2]

(upward end)

Water Level Safety Float Switch [FS3]

(downward end)

Thermistor [TH2]

(hot water temperature control)

Strainer

7

Page 13

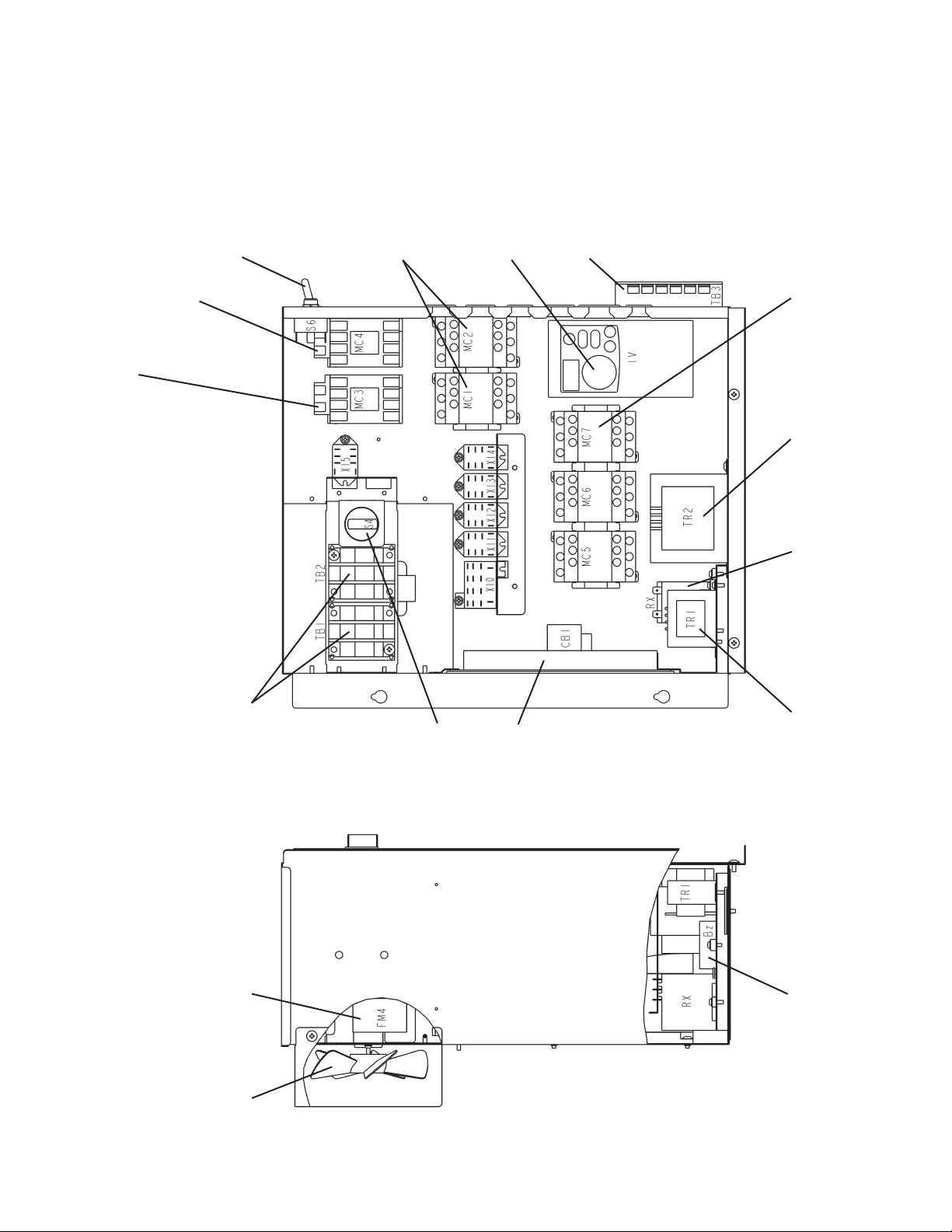

3. Control Box

Magnetic Contactor

(Upper Wash Spray Arm PM)

Magnetic Contactor

(Lower Wash Spray Arm PM)

Voltage Tap Switch

Magnetic Contactor

MC1, 2: Wash Tank Heater Control

(MC1: right, MC2: left)

not change settings.

Terminal Block

Inverter

* NOTICE: To prevent failure, do

TB3: Detergent/Rinse Aid Feeder

Magnetic Contactor

MC5 - 7: Booster Tank Heater Contactors

(MC5: upper, MC6: lower left, MC7: lower

right)

Main Transformer

(Control Supply)

Relay

X10: Rinse PM Control

X11: Service Panel Switch

X12: Phase Reversal Relay

X13: Booster Tank Water Valve

X14: Conveyor Drive Signal

X15: Booster Tank Heater Control Relay

Terminal Block

TB1: For Dishwasher

TB2: For Booster Tank

Fan MotorFan

Control Board

Conveyor Speed

Switch

Phase Reversal Relay

Control Transformer

(Control Board)

Buzzer

8

Page 14

B. Functions

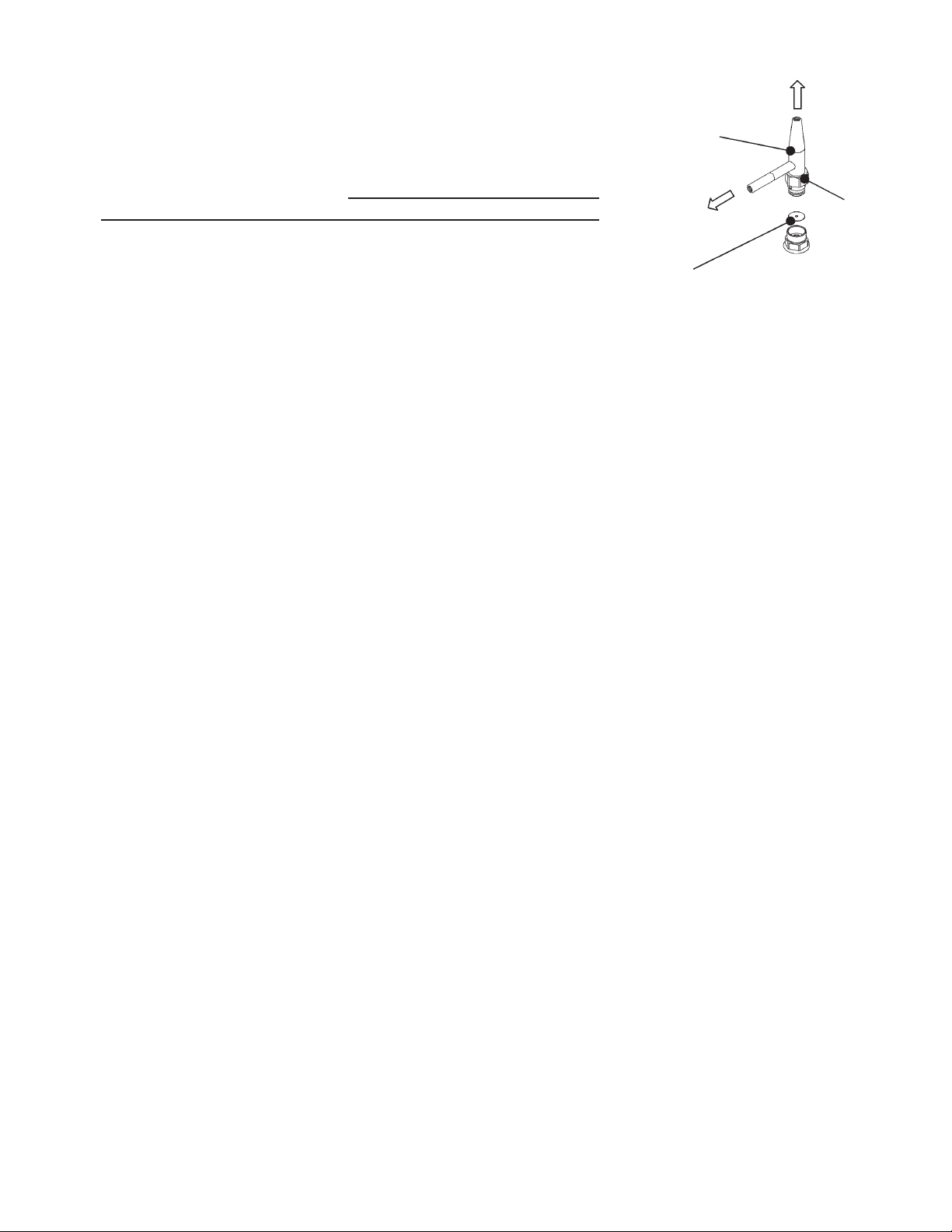

1. Increasing Rinse Water Flow Rate

Upper Rinse Spray Arm

The rinse water fl ow rate is factory adjusted to 1.90 gal/min

Clean Pipe

(7.2 L/min). To increase the fl ow rate to 3.17 gal/min (12 L/

min), follow the steps below. Hot water supply of at least

3.44 gal/min (13 L/min) and 113°F (45°C) will be required.

Lower Rinse

Spray Arm

1) Remove the upper and lower rinse spray arms.

2) Loosen the clean pipe nut, and remove the clean pipe.

Spacer

3) Remove the spacer (with 4.5 mm DIA hole) from the nut at the unit side.

4) Replace the clean pipe and the upper and lower rinse spray arms in their correct positions.

C. Sequence of Operation

The steps in the sequence are as outlined below.

1. Auto Fill Cycle

"AUTO FILL" lamp fl ashing and "RINSE TEMP." or "WASH TEMP." lamp on.

If BT WLF/S is open when the "ON/OFF" button is pressed, WV energizes after BT auto fi ll

delay time (factory default: 10 seconds).

When BT WLF/S closes, WV de-energizes, the "AUTO FILL" lamp fl ashes and the auto fi ll

cycle starts.

RPM energizes for length of time set by the auto fi ll cycle rinse time setting (factory default:

13 minutes). For details, see "Auto Fill Cycle Rinse Time" (service menu item 03) in "II.F.7.b)

Service Menu Chart."

At the end of the auto fi ll cycle, there is a 5-second dwell time. CB checks WT WLS. If WT

WLS is closed, BZ beeps, the "AUTO FILL" lamp goes off and the "READY" lamp comes

on. If WT WLS is open, BZ beeps continuously, the "AUTO FILL" lamp goes off and "A1"

fl ashes in the display. For details, see "III.B.3.a) Auto Fill Error (A1)."

If the BT water level goes down and BT WLF/S opens during the auto fill cycle, WV

energizes after BT auto fi ll delay time (factory default: 10 seconds). For adjustment of this

delay time, see "Booster Tank Auto Fill Delay Time" (service menu item 08) in "II.F.7.b)

Service Menu Chart." If delay time is set shorter, WV energizes/de-energizes frequently

and BT may not supply hot water of proper temperature.

If SP is opened during the auto fi ll cycle, SPS opens, RPM de-energizes. The "AUTO FILL"

lamp keeps flashing and the rinse cycle time keeps counting down. When SPS closes

again, RPM energizes.

If WLS is closed when the "ON/OFF" button is pressed, the "READY" lamp comes on and

the unit is ready to start.

Nut

Note:

1. If SP is opened during the auto fi ll cycle, RPM de-energizes to stop hot water supply.

If SP is left open for a long time, WT may not fi ll by the end of the auto fi ll cycle. In this

case, WT WLS opens when the unit starts, and the supplementary fi ll cycle begins.

2. WTH is energized when WT WLS closes during the auto fi ll cycle.

3. BTH is energized during the auto fi ll cycle if WLSF/S is closed.

9

Page 15

4. If BT WLF/S fails, BT BUWLF/S assumes control. If BT BUWLF/S remains closed for 1

minute, o1 or o2 error appears in the display. For details, see "III.B. Error Codes."

5. The wash/rinse start switch is inactive during the auto fi ll cycle.

2. Ready Cycle (Unit Inactive)

"READY" lamp and "RINSE TEMP." or "WASH TEMP." lamp on.

WT WLS closed. After a rinse cycle, RPM de-energizes, and the "READY" lamp comes on.

WTH energizes when WT water temperature is at the wash temperature setpoint or

lower. WTH de-energizes when WT water temperature is 5°F (3°C) above the setpoint.

For details, see "Wash Temperature Setpoint" (service menu item 04) in "II.F.7.b) Service

Menu Chart."

BTH energizes when BT water temperature is 3°F (2°C) below the rinse temperature

setpoint or lower. BTH de-energizes when BT water temperature reaches the setpoint.

WV energizes/de-energizes when BT WLF/S opens/closes. For details, see "Rinse

Temperature Setpoint" (service menu item 05) in "II.F.7.b) Service Menu Chart."

Note:

1. The thermistors control WT and BT water temperatures.

2. If one of the thermistors has an open or short circuit, WTH or BTH de-energizes and an

error code appears in the display.

3. WTH and BTH are controlled regardless of SPS operation.

3. Wash Cycle/Rinse Cycle

"WASH" lamp and "RINSE TEMP." or "WASH TEMP." lamp on.

When a rack is loaded from the wash compartment entrance and the wash start switch

closes, WPM energizes, power is supplied to DFT and the "WASH" lamp comes on. WPM

draws water from WT and sends it through the wash spray arms. The upper spray arm

WPM starts fi rst, followed by the lower spray arm WPM. Then, the conveyor starts to move

the rack. After the wash start switch opens and the extended wash cycle time (factory

default: 30 seconds) has expired, WPM de-energizes and power is cut to DFT. For details,

see "Extended Wash Cycle Time" (service menu item 01) in "II.F.7.b) Service Menu Chart."

When the rinse start switch closes, RPM energizes and power is supplied to RFT. RPM

draws water from BT and sends it through the rinse spray arms. Rinse aid is fed into the

rinse water line and sprayed from the rinse spray arms together with rinse water. Any

excess water in WT drains through the overfl ow pipe. After the rinse start switch opens

and the extended rinse cycle time (factory default: 15 seconds) has expired, RPM deenergizes, power is cut to RFT, the "WASH" lamp goes off and the "READY" lamp comes

on. For details, see "Extended Rinse Cycle Time" (service menu item 02) in "II.F.7.b)

Service Menu Chart."

After both WPM and RPM de-energize, the conveyor stops. If SP is opened during

operation, SPS opens, WPM and RPM de-energize and the conveyor stops. If the wash/

rinse start switch is closed when SPS closes, WPM and RPM energize and the conveyor

restarts.

Note:

1. If WT WLS opens after WPM energizes, WPM de-energizes and RPM energizes for

the supplementary fi ll cycle time (factory default: 450 seconds) to supply hot water into

10

Page 16

WT. The conveyor does not start during the supplementary fi ll cycle. "A3" appears in the

display and the "AUTO FILL" lamp fl ashes. BZ beeps three times only at the beginning.

If WT WLS is still open after the supplementary fi ll cycle, another cycle starts. If WT

WLS still does not close, "A3" appears in the display, BZ beeps and the unit shuts down.

For adjustment of the supplementary fi ll cycle time, see "Supplementary Fill Cycle Time"

(service menu item 07) in "II.F.7.b) Service Menu Chart." For details, see "III.B.3.c)

Wash Tank Water Level Error (A3)."

2. If WT WLS and the wash start switch are closed after RPM runs for the supplementary

fi ll cycle time, WPM energizes and the conveyor starts.

3. If SP is opened and closed during operation and the wash/rinse start switch is open, the

unit does not resume operation. Load another rack to close the wash start switch. The

unit resumes operation if SP is closed during the extended wash/rinse cycle time.

4. Table Limit Switch

If a rack reaches the end of the clean dishtable and actuates TLS lever (TLS closed),

WPM and RPM de-energize, the conveyor stops and "L1" appears in the display. When

the rack is removed and TLS lever returns to the original position (TLS open), WPM and

RPM energize and the conveyor starts after 3 seconds unless the wash/rinse start switch

is open.

5. Emergency Stop Button

To shut down the unit in case of emergency, press ESB on top of the unit (wash

compartment exit side). To resume operation, turn ESB clockwise to unlock and press the

"ON/OFF" button on the operation panel.

Note: The unit is inoperative without ESB connected at the time of installation.

6. Drain

This unit does not have a drain valve.

The overfl ow pipe in WT drains excess water from WT. To completely drain WT, remove

the overfl ow pipe.

To drain BT, use the “ON/OFF” button on the operation panel to turn off the unit, then turn

off the dishwasher and booster tank power supplies. Lockout/Tagout to prevent the power

supplies from being turned back on inadvertently.

Use BT drain hose to drain BT. WARNING! To avoid possible burns, allow BT water

temperature to fall below 104°F (40°C) before draining.

Legend: BT–booster tank; BTH–booster tank heater; BUWLF/S–backup water level fl oat

switch; BZ–buzzer; CB–control board; DFT–detergent feeder terminals (detergent

feeder not provided by Hoshizaki); DS–door switch; ESB–emergency stop button;

RFT–rinse aid feeder terminals (rinse aid feeder not provided by Hoshizaki);

RPM–rinse pump motor; SP–service panel; SPS–service panel switch; WLSF/

S–water level safety float switch; TLS–table limit switch; WLF/S–water level

fl oat switch; WLS–water level sensor; WPM–wash pump motor; WT–wash tank;

WTH–wash tank heater; WV–inlet water valve

11

Page 17

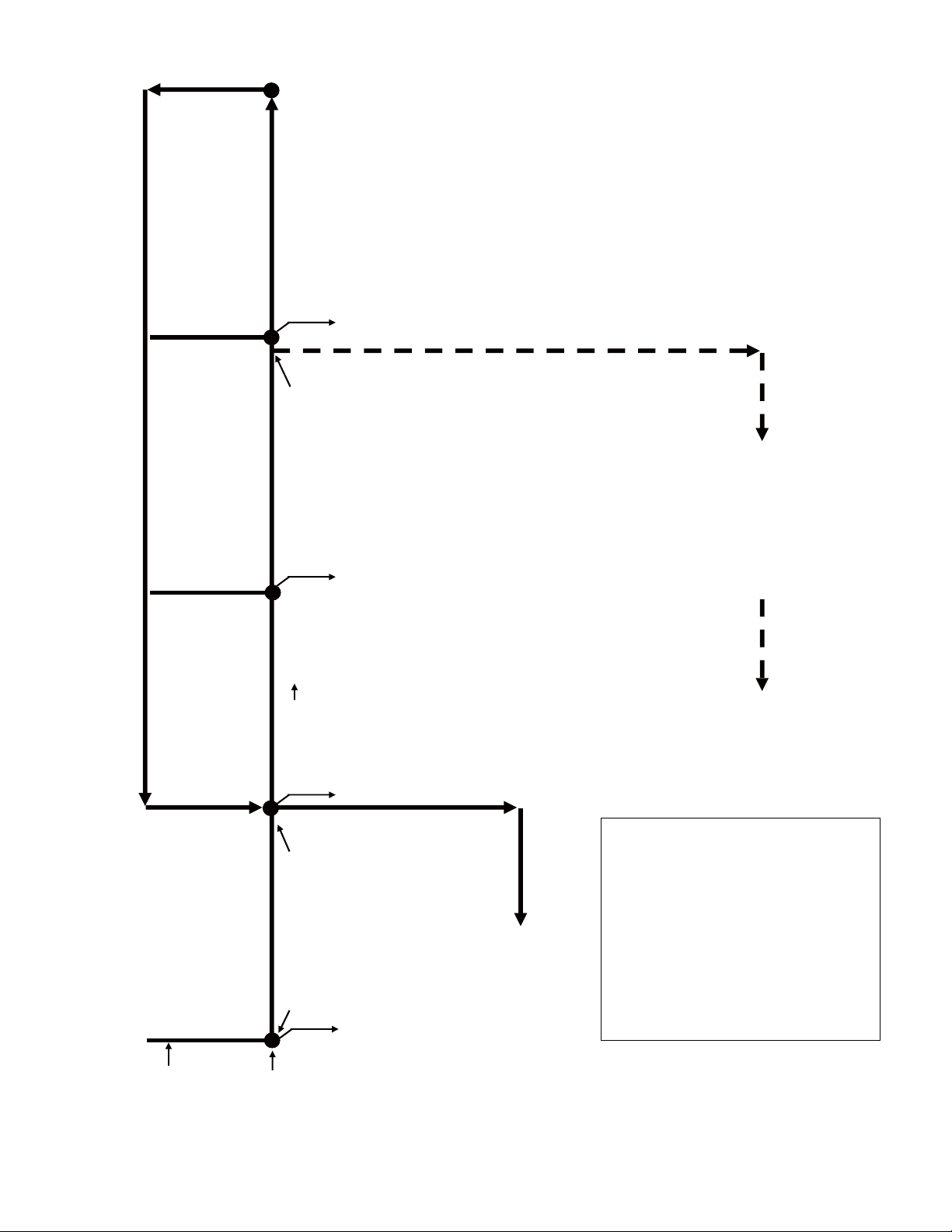

D. Sequence of Operation Flow Chart

p

g

y

g

g

y

g

g

(

g

(

g

(

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

y

g

g

g

g

g

g

g

g

g

y

g

g

y

g

g

g

p

g

p

g

g

g

ized

ens

ized

BT WLF/S

ized b

followed by the lower spray arm WPM

JWE-2400CUA-25B

WT WLS

monitored

during Wash

power supplied to RFT

ized when RSS opens

ized

power supplied to DFT RPM ener

ized when WSS opens RPM de-ener

ized

WPM de-ener

and the extended wash cycle time and the extended rinse cycle time

ized when WT water temp. at

ized while WPM and RPM ener

ized GM ener

ized when WT water temp. at WTH ener

ized when WPM ener

GM ener

WTH ener

de-energized) de-energized)

ized when WT water temp.

ized when WT water temp. WTH de-ener

WTH de-ener

wash temp. setpoint (service menu item wash temp. setpoint (service menu item

is 5ºF (3ºC) above wash temp. setpoint is 5ºF (3ºC) above wash temp. setpoint

ized b

ized when BT water temp.

ized when BT water temp. 3ºF

ized when BT water temp. BTH de-ener

ized when BT water temp. 3ºF BTH ener

BTH de-ener

menu item 05) or lower menu item 05) or lower

ized when BT WLSF/S

ized/de-ener

BT WLF/S WV ener

ized b

ized when BT WLSF/S BTH de-ener

ized/de-ener

WV ener

BTH de-ener

reaches rinse temp. setpoint (service reaches rinse temp. setpoint (service

menu item 05) menu item 05)

opens opens

ized when WT WLS o

ized when WTH ener

FCT ener

ens WTH de-ener

WT WLS

ized when WT WLS o

ized when WPM

FCT ener

WTH de-ener

energized

WPM and GM de-energized

RPM energized

(time=service menu item 07)

WT WLS open

"A3"error appears in display.

repeats twice

ized when WT water

Dishwasher Sequence Flow Chart

WT WLS closed

WT WLS

WT WLS check.

• SPS must be closed for RPM to energize • Cycle started by wash start switch • Cycle started by rinse start switch

• RPM time: (service menu item 03) • SPS must be closed for WPM to energize • SPS must be closed for RPM to energize

• RFT de-energized during Auto Fill Cycle • The upper spray arm WPM starts first,

ins here

Cycle Steps 1. Auto Fill Cycle 2. Ready Cycle (Unit Inactive) 3. Wash Cycle 4. Rinse Cycle

Initial startu

be

ized when WT water temp. WPM ener

WTH de-ener

WTH ener

item 04) or lower

check

ized b

time=service menu

ized

ized/de-ener

cle if closed.

BT WLF/S at wash temp. setpoint (service menu when WPM energized) when RPM energized)

RPM ener

item 03)

WV ener

Go to Ready

C

temp. is 5ºF (3ºC) above wash temp. (service menu item 01) has expired (service menu item 02) has expired

ized when BT WLSF/S

closed setpoint (service menu item 04) (power cut to DFT when WPM (power cut to RFT when RPM

BTH ener

ized when BT water

ized when BT water temp.

BTH de-ener

temp. reaches rinse temp. setpoint 04) or lower 04) or lower

(service menu item 05) or lower

ized when RPM

ized when WT WLS BTH ener

FCT ener

WTH ener

closed 3ºF (2ºC) below rinse temp. setpoint

energized

ized when BT WLSF/S BTH ener

ized/de-ener

WV ener

(service menu item 05)

BT WLF/S (service menu item 04) (service menu item 04)

BTH de-ener

WT WLS open

"A1" error appears

in display.

ized

ized when WT WLS

"A3"error appears

FCT de-ener

WTH de-ener

opens (2ºC) below rinse temp. setpoint (service (2ºC) below rinse temp. setpoint (service

opens

Legend:

BT–internal booster tank

BTH–internal booster tank heater

DFT–detergent feeder terminals

GM-gear motor (conveyor)

RFT–rinse aid feeder terminals

RPM–rinse pump motor

RSS-rinse start switch

in display.

SPS–service panel switch

VFCT-vent fan control terminals

WLF/S–water level float switch

unit shuts down

WLS–water level sensor

WLSF/S-water level safety float switch

WPM–wash pump motor

WSS-wash start switch

WT–wash tank

WTH–wash tank heater

WV–inlet water valve

12

Page 18

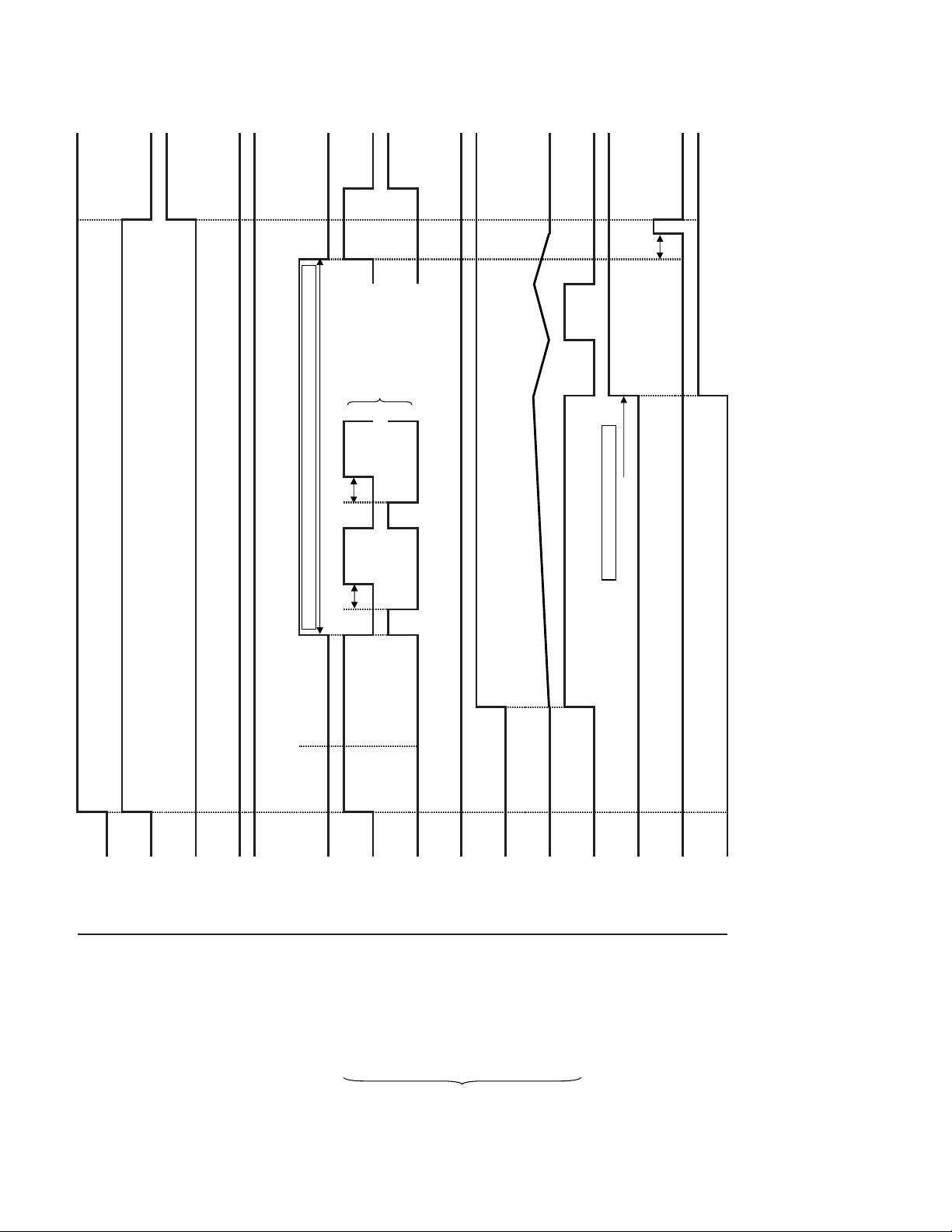

E. Timing Chart

u

1. Auto Fill Cycle

Note 2

(Repeat)

Service menu item 03

Approx. 13 gal (50L) water level

Note 1 Note 1

Auto Fill Cycle Rinse Time (*13 min) 2 gal (7.8L)/min x 13 min = 20 gal (101L)

Note 3

If the booster tank water level float switch does not close after 10 minutes in booster tank auto fill, error code "A2" (booster tank auto

Booster tank auto fill delay time (*10 seconds): If auto fill cycle starts immediately after the booster tank water level float switch opens,

the booster tank fills up too soon, and the water valve energizes/de-energizes frequently, resulting in no hot water supply.

Note 1:

After the rinse pump motor de-energizes, there is a 5-second dwell time to stabilize the water level before checking the water level

Note 2:

* Factory default, adjustable by service men

OFF

OFF

OFF

OFF

OPEN

OFF

OFF

OPEN

CLOSED

OPEN

CLOSED

OPEN

OFF

OPEN

OFF

OFF

fill error) appears in the display, and the unit shuts down.

sensor status.

Note 3:

"ON/OFF" Button ON

"AUTO FILL" Lamp ON

"READY" Lamp ON

"WASH" Lamp ON

Service Panel Switch CLOSED

Rinse Pump ON

Water Valve ON

Water Level Float Switch CLOSED

Backup Water Level

Float Switch

Water Level Safety Float

Switch

Booster Tank Thermistor Setpoint

Booster Tank Heater ON

Water Level Sensor CLOSED

Buzzer ON

Wash Tank Heater ON

Booster Tank

13

Page 19

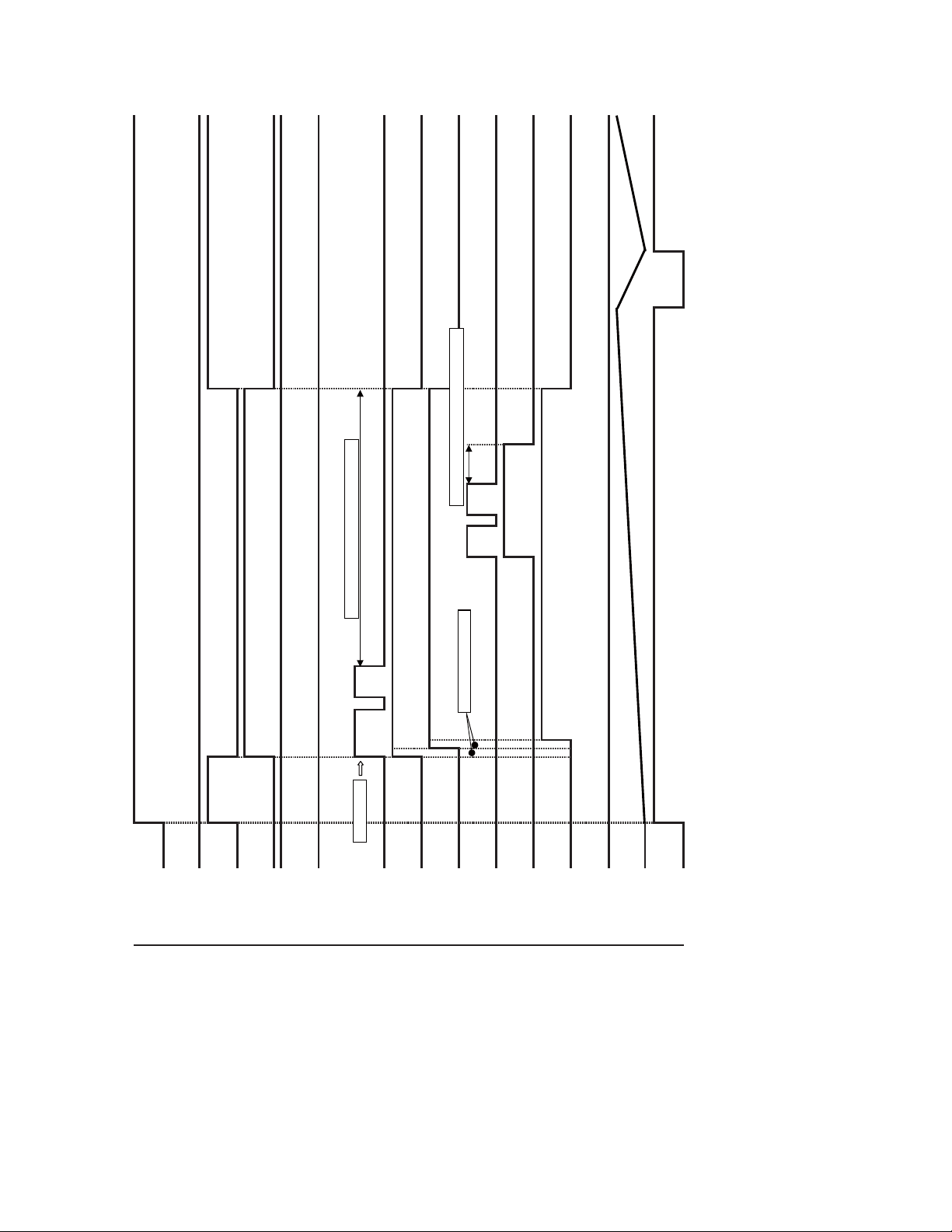

2. Wash Cycle/Rinse Cycle

u

y

g

g

y

g

y

y

(

)

Note 3

Service menu item 02

cle continuesNote 1:

cle continues

ize

Extended Rinse Cycle Time (*15 sec)

Note 2

Service menu item 01

Extended Wash Cycle Time (*30 sec)

Note 1

Note 4

Load rack

Note 4

0.5 sec

Time

Dela

this time to close the wash start switch, wash c

this time to close the rinse start switch, rinse c

or stops when both the wash pump and the rinse pump de-ener

* Factory default, adjustable by service men

If another rack is loaded durin

wash/rinse cycle.

Note 2: If another rack is loaded durin

Note 3: The conve

Note 4: The rack handle shape opens the wash/rinse start switch for a moment. But the extended wash/rinse cycle time prevents interruption of the

OFF

OFF

OFF

OFF

OPEN

OPEN

OPEN

OFF

OFF

OPEN

OFF

OFF

OFF

Setpoint

OFF

"ON/OFF" Button ON

"AUTO FILL" Lamp ON

"READY" Lamp ON

"WASH" Lamp ON

Service Panel Switch CLOSED

Water Level Sensor CLOSED

Wash Start Switch CLOSED

Upper Wash Pump ON

Lower Wash Pump ON

Rinse Start Switch CLOSED

Rinse Pump ON

Conveyor (Gear Motor) ON

Buzzer ON

Wash Tank Thermistor

Wash Tank Heater ON

14

Page 20

F. Control Board and Operation Board

• A Hoshizaki exclusive solid-state control board and operation board are employed in all

Hoshizaki dishwasher units.

• All models are pretested and factory set.

NOTICE

1. The control board and operation board are fragile; handle very carefully.

2. The control board and operation board contain integrated circuits, which

are susceptible to failure due to static discharge. It is especially important to

touch the metal part of the unit when handling or replacing the control board

or operation board.

3. Do not touch the electronic devices on the control board or operation board

or the back of the control board or operation board.

4. Do not attempt to repair the control board or operation board.

5. Do not short out power supply to test for voltage.

1. Control Board Location

The control box is located behind the front panel. Follow the instructions and warnings for

safe and effi cient operation of the unit.

Control Box

15

Page 21

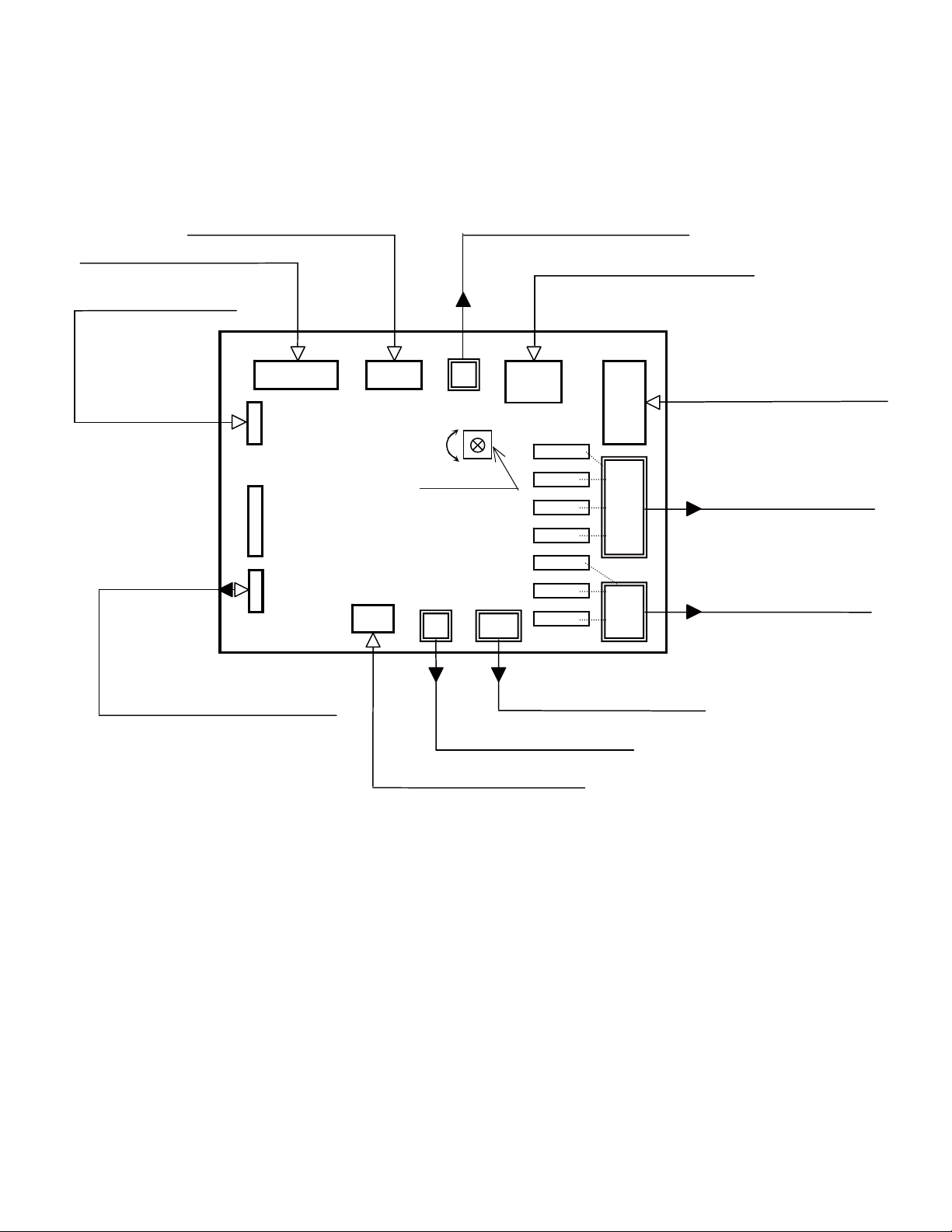

2. Control Board Layout

Inputs and outputs are laid out on the control board as illustrated below.

Signal Input XA Connector (10P)

Signal Input XA Connector (6P)

Thermistor Signal Input

XA Connector (4P)

4

1

8

1

5

1

1

CN7

CN6

CN5

CN8

10

1

CN11

3

CN9

Low

Buzzer Volume

CN13

Buzzer Output XA Connector (2P)

Power Input VH Connector (4P)

2

16

CN10

High

112

VR1

CN12

1 4

CN1

X1

X2

X3

X4

X5

X6

X7

13

CN2

1

6

1

7

CN3

1

5

CN4

Power Input VH Connector (6P)

Output VH Connector (7P)

Output VH Connector (5P)

Operation Board XA Connector (5P)

XH Connector (3P): not in use

XH Connector (2P): not in use

Booster Tank Water Level Safety

Signal Input XA Connector (3P)

16

Page 22

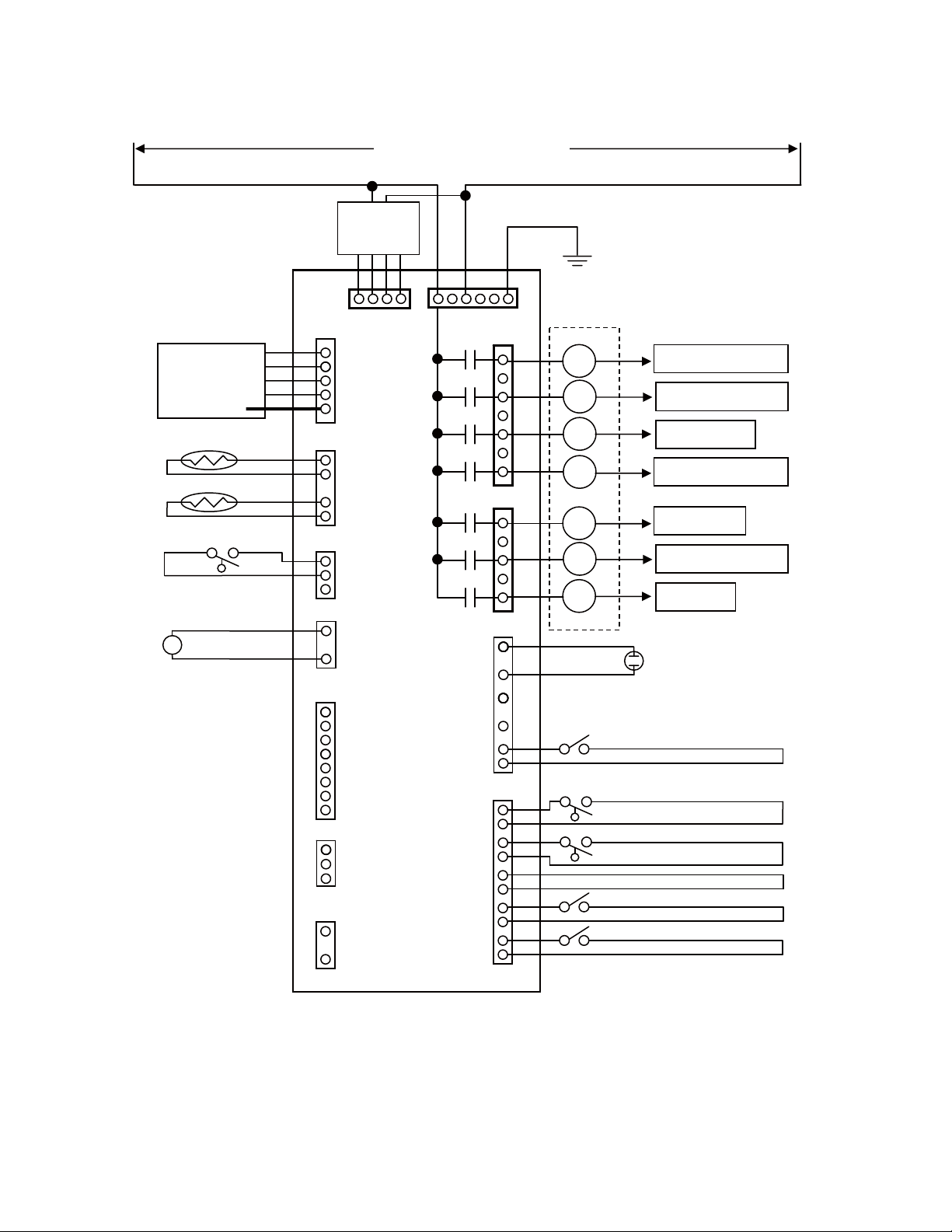

3. Control Board Diagram

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

1

y

200VAC from Transformer

Transformer

11V 7.7V

[Communication]

Operation Panel

Board

Shielded Wire

Wash Tank Thermistor

Booster Tank Thermistor

Booster Tank Water

Level Safet

Float Switch

Buzzer Output

1(CN1)41 (CN2)6

1

5

CN5

1

4

CN7

3

2

CN11

1

2

CN10

X1

X2

X3

X4

X5

X6

X7

CN3

CN4

2

1

X15

3

MC1

5

X10

7

MC3

1

X13

3

MC4

5

X14

Booster Tank Heater

Wash Tank Heater

Rinse Pump

Upper Wash Pump

Water Valve

Lower Wash Pump

Conveyor

Wash Tank Electrode

(Water Level Sensor)

Connector Voltages

5

6

CN9

1

CN6

Table Limit Switch + Conveyor Overload

Booster Tank Water Level Float Switch

Booster Tank Backup Water Level Float Switch

CN2 : 200VAC

CN3 : 12VDC

CN4 : 12VDC

CN5 : 5VDC

CN7 : 5VDC

CN8 : 12VDC

CN9 : 1-2: 6VAC

5-6: 12VDC

CN12

CN13

10

CN8

Wash Start Switch

Rinse Start Switch

CN10 : 12VDC

CN11 : 12VDC

*1 Connectors CN 1 - 4 are VH Connectors

17

Page 23

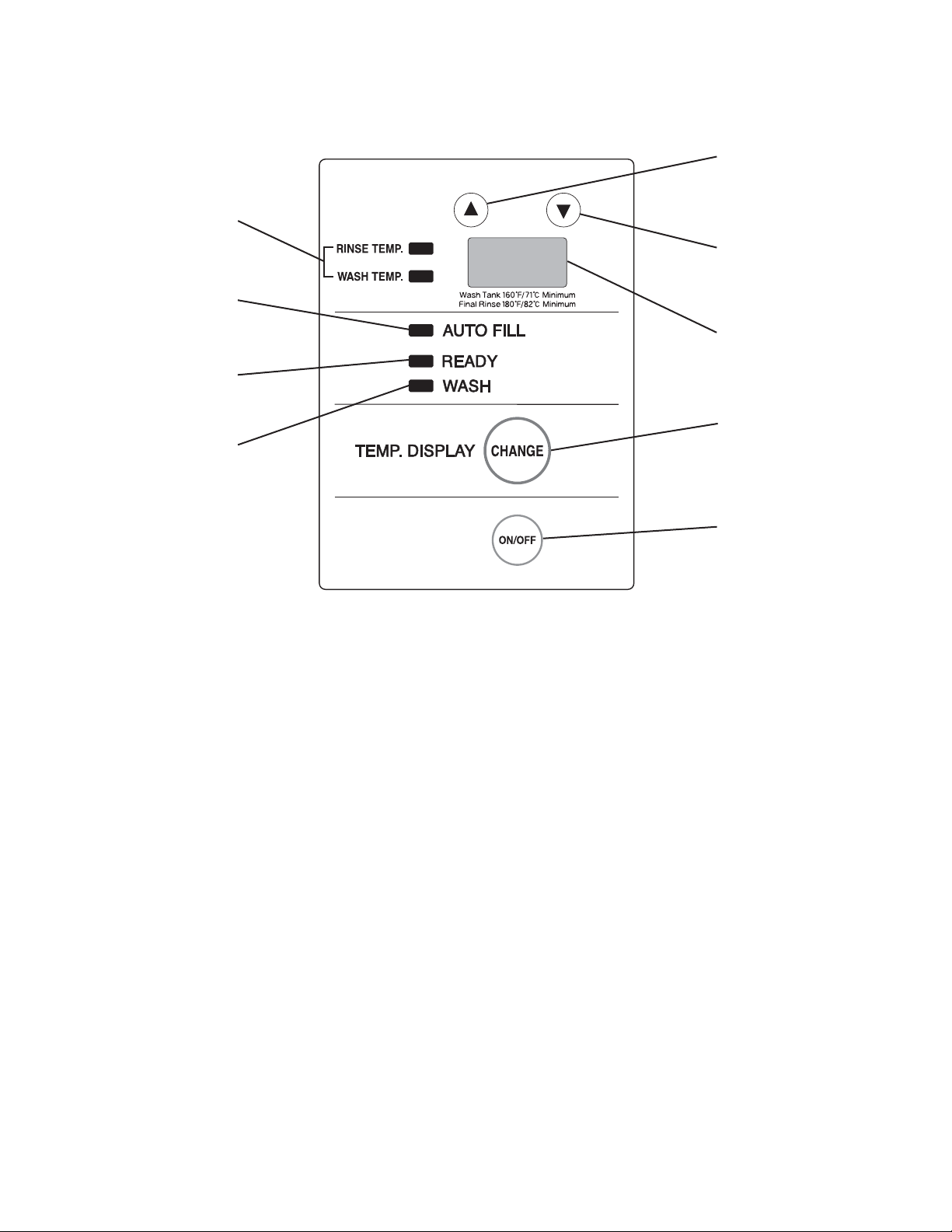

4. Operation Panel Layout

The operation panel is mounted

on top of the unit (wash compartment exit side) and is

connected to the CN5 connector on the control board.

Water Temperature

Lamps

"AUTO FILL" Lamp

"READY" Lamp

"WASH" Lamp

Up Button

Down Button

Display

"CHANGE" Button

"ON/OFF" Button

5. Features

a) Display

This operation board uses an LED display to show system details and diagnostic

information.

b) Service Menu and Error Log

A service menu ("01" to "19" and "21" to "25") allows for viewing and setting of system

operating details and parameters. See "II.F.7. Service Menu and Error Log."

c) Error Codes

Error codes ("A1" to "A3," "H1" to "H6," "L1," "L2," "b1," "b2," "o1," "o2") are designed to

protect the unit. These codes give information or warnings in the event the unit is operating

out of acceptable parameters. See "III.B. Error Codes."

6. Controls, Adjustments, and Lamps

a) Water Temperature Lamps

Light up to indicate the water temperature shown in the display.

b) "AUTO FILL" Lamp

Flashes during the auto fi ll cycle, and goes off at the end of the cycle.

18

Page 24

"READY" Lamp

c)

Lights up when the auto fi ll cycle completes and the dishwasher is ready to wash.

"WASH" Lamp

d)

Lights up during washing operation.

e) Up Button, Down Button

Indicates the total hours of operations in six digits by two digits each time.

Example: 123,456 hours are indicated by

Press to stop the beep in case of error.

Service personnel also use these buttons to change the controller settings.

f) Display

Indicates wash water temperature in wash cycle, rinse water temperature in rinse cycle,

and error codes in case of trouble.

"CHANGE" Button

g)

Press to change the wash water temperature shown in the display to the rinse water

temperature.

"ON/OFF" Button

h)

Turns on/off the power for operation.

i) Conveyor Speed Switch

Located on front panel. Changes the rack conveyor speed in three levels (high = 240

racks/hour, medium = 200 racks/hour, low = 160 racks/hour).

7. Service Menu and Error Log

The service menu ("01" to "19" and "21" to "25") may be used to change settings, acquire

diagnostic information, and to view error history.

a) Service Menu Access

• Enter Service Menu: Use the "ON/OFF" button to turn off the unit. Press and hold the

"CHANGE" button, then press the "ON/OFF" button. "01" should appear on the display.

• Scroll: Use the up and down arrow buttons to scroll through the service menu list, settings,

and data.

• View Service Menu Setting: Press the "CHANGE" button to view the selected menu

setting.

• Change Setting: Use the up and down arrow buttons to change the setting value.

• Return to Service Menu List: Press the "CHANGE" button once again to return to the main

service menu list.

• Exit Service Menu and Save Settings: Press the "ON/OFF" button to exit the service menu

and save the settings. The display goes blank.

19

Page 25

b) Service Menu Chart

Service

Menu

01 Extended Wash Cycle Time 1 to 99 seconds

02 Extended Rinse Cycle Time 1 to 99 seconds

03 Auto Fill Cycle Rinse Time 0 to 99 minutes

04 Wash Temperature Setpoint Fahrenheit 32 to 176

05 Rinse Temperature Setpoint Fahrenheit 32 to 185

06 Booster Tank Heating Time 0 to 99 seconds

07 Supplementary Fill Cycle Time 0 to 990 seconds

08 Booster Tank Auto Fill Delay Time 0 to 99 seconds

09 Water Temperature Display ON: wash water temperature

10 Booster Tank Auto Fill Timer 1 to 99 minutes

11 Booster Tank Temperature Correction Fahrenheit 0 to 9R

12 Water Temperature Display Change ON: alternate

13 Temperature Display Scale Fahrenheit or Celsius

14 Water Temperature Display Change

Cycle Time

15 Low Water Temperature Lock Function ON: lock function on

16 Wash Tank Refi ll Alert ON: alert on

17 Total Operation Time Before Alert 10 to 600 minutes 1 to 60 12 (2h)

18 Display Hold Function ON: stays on

19 Power Supply Lock Function ON: "Ch" keeps fl ashing until

21

Error Log

through

Note: To erase the log, press and hold the

25

up and down buttons for 3 seconds with

one of the error codes displayed. The unit

beeps once and the entire log clears.

Item and Details Setting Range Display

1 to 99 30

(in 10 second steps)

1 to 99 15

(in 1 second steps)

0 to 99 13

(in 1 minute steps)

°F

(in 1

°F steps)

Celsius 0 to 80

(in 1°

(in 1

Celsius 0 to 85

(in 1°

(in 10 second steps)

(in 10 second steps)

(in 1 second steps)

OFF: rinse water temperature

(in 1 minute steps)

(in 1

Celsius 0 to 5K

(in 1K steps)

OFF: fi xed

1 to 10 seconds

(in 1 second steps)

OFF: lock function off

OFF: alert off

OFF: goes off after preset time

electrode is turned off

OFF: "Ch" goes off when "ON/

OFF" button is switched off

NA Most Recent

°

C steps)

°F

°F steps)

°

C steps)

R steps)

32 to 176 163

0 to 80 73

32 to 185 185

0 to 85 85

0 to 99 0

0 to 99 450

0 to 99 10

on or oF on

1 to 99 20

0 to 9 0

0 to 5 0

on or oF on

°F or °C °F

1 to 10 5

on or oF oF

on or oF oF

on or oF oF

on or oF oF

Errors

21 is most recent.

"--" is displayed if

the log is empty.

Factory

Default

NA

20

Page 26

8. Temperature Display

• Indicates the average water temperature read by the wash tank or booster tank thermistor.

Indicates water temperature selected by the water temperature lamps beside the display.

The factory default setting is to indicate wash water temperature and rinse water temperature

alternately every 5 seconds. To adjust the display change cycle time, or to fi x the temperature

display for either wash or rinse water temperature and indicate the other temperature while

the "CHANGE" button is pressed, see service menu items 09, 12 and 14 in "II.F.7.b) Service

Menu Chart."

• The temperature display range is 32°F to 199°F (0°C to 99°C). To change the display scale,

see "Temperature Display Scale" (service menu item 13) in "II.F.7.b) Service Menu Chart."

• The temperature display updates every 5 seconds for the wash tank and the booster

tank.

9. Error Codes

In the event of operation outside of normal parameters, the control board identifi es the issue

with an error code and beeps. If more than one error occurs, the display cycles through the

relevant error codes. For service corrections, see "III.B. Error Codes."

Error Codes

A1

Wash Tank Auto Fill Error

A2

Booster Tank Auto Fill Error

A3

Wash Tank Water Level Error

Booster Tank Water Level Error 1

o1

(Booster Tank Water Level Float Switch Closed)

Booster Tank Water Level Error 2

o2

(Booster Tank Water Level Float Switch Open)

H1

Wash Tank Thermistor Error (short)

H2

Wash Tank Thermistor Error (open)

H3

Booster Tank Thermistor Error (short)

H4

Booster Tank Thermistor Error (open)

H5

ROM/RAM Error

H6

EEPROM Error

L1

Conveyor Overload or Table Limit Error 1

L2

Conveyor Overload or Table Limit Error 2

b1

Booster Tank Error

b2

Booster Tank Water Level Safety Error

10. Buzzer

• At the end of an auto fi ll cycle or other mode operation, the buzzer turns on for 0.1 second

and off for 0.1 second 10 times.

• In case of an error, the buzzer turns on for 0.1 second and off for 0.9 second repeatedly

until the error is reset. To turn off the beep, press the down button.

• When a button is pressed, the buzzer turns on for 0.1 second.

• To adjust the buzzer volume, use the volume control on the control board.

21

Page 27

11. Operation Time Display

To indicate the total hours of operation in the display, press the up button on the operation

panel. The number appears from the hundred-thousands place by two digits each for 1

second. The maximum number is 999,999 hours, and the display does not change for the

higher numbers.

Example: 19,302 hours are indicated as

12. Special Modes

OFF OFF

a) Continuous Wash Mode

The continuous wash mode (also used when descaling) allows the wash pump motor to

run continuously. In this mode, the wash tank heaters and booster tank heaters remain deenergized.

To enter the continuous wash mode, use the "ON/OFF" button to turn off the unit. Press

and hold the up and down buttons and the "CHANGE" button for 3 seconds and press the

"ON/OFF" button. As long as the service panel switch and wash tank water level sensor are

closed, the wash pump motor runs

and power is supplied to the detergent feeder terminals.

"PC" (preventative cleaning) appears in the display and the lamps are off.

To cancel the continuous wash mode, press the "ON/OFF" button.

b) Low Water Temperature Lock Function

To ensure the NSF specifi ed minimum wash water temperature of 160°F, this unit is provided

with a function to lock the washing operation until water in the wash water tank reaches 160°F

even if a rack is loaded (factory default: OFF).

To activate this function, set service menu item 15 to "ON" referring to "II.F.7.a) Service Menu

Access." The minimum temperature of 160°F cannot be changed.

c) Alert Function

To keep water in the wash water tank clean, this unit is provided with functions to beep and

fl ash "Ch" (= Change) in the display when wash water should be changed and to continue

this alert until the wash water tank is refi lled (factory default: OFF).

To activate this function, set service menu items 16, 17, 18 and 19 referring to "II.F.7.a)

Service Menu Access."

1) Set service menu item 16 to ON to activate this function (factory default: OFF).

2) Set service menu item 17 to the desired total operation time before alert [number in display

x 10 minutes] (factory default: 12 (2 hours)). Change this setting according to the advice

of the relevant health department and customer demands.

3) Set service menu item 18 to either OFF ["Ch" goes off after 10 minutes] or ON ["Ch" keeps

fl ashing] (factory default: OFF). Even if set to ON, "Ch" goes off when the "ON/OFF" button

on the operation panel is switched off.

22

Page 28

4) Set service menu item 19 to ON to stop the beep when the "ON/OFF" button is switched

off but to resume fl ashing "Ch" when the "ON/OFF" button is switched back on unless the

wash water tank is refi lled (factory default: OFF). Press the emergency stop button or turn

off the external power supply to stop both the beep and "Ch" indication.

Set service menu item 19 to OFF to stop both the beep and "Ch" indication once the "ON/

OFF" button is switched off.

If service menu item 19 is set to ON, "Ch" keeps fl ashing even if service menu item 18 is

set to OFF.

Alert Function Setting Flow

Wash Tank Refi ll Alert

Total Operation Time

Before Alert

Display Hold Function

Service Menu 16

ON

Service Menu 17

1 to 99

Service Menu 18

ON

Set service menus

17 to 19

Alert starts after number in display

(1 to 99) x 10 minutes

[factory default: 12 (2 hours)]

"Ch" keeps fl ashing

(until "ON/OFF" button is switched off)

OFF

* OFF

Alert function OFF

[factory default]

"Ch" goes off after 10 minutes

[factory default]

Power Supply Lock

Function

Service Menu 19

* ON

* "Ch" keeps fl ashing even if

service menu 18 is set to OFF

Switching off "ON/OFF" button cancels beep

but not "Ch" until wash water tank is refi lled

23

OFF

Beep stops and "Ch" goes off when

"ON/OFF" button is switched off

[factory default]

Page 29

III. Service Diagnosis

WARNING

1. This unit should be diagnosed and repaired only by qualified service

personnel to reduce the risk of death, electric shock, serious injury, or fi re.

2. Risk of electric shock. Use extreme caution and exercise safe electrical

practices.

3. Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

4. Do not make any alterations to the unit. This could cause water leak, electric

shock, or fi re.

5. To help reduce the risk of electric shock, do not touch switches with damp

hands.

A. Diagnostic Procedure

The diagnostic procedure is a sequence check of the switches and sensors while operating

the unit, by using the switch open/closed display mode.

Switch Open/Closed Display Mode

The switch open/closed display mode indicates when the wash start switch, rinse start switch,

wash tank water level sensor, booster tank water level fl oat switch, and booster tank backup

water level fl oat switch are open or closed.

To enter the switch open/closed display mode, use the "ON/OFF" button to turn on the

unit. Press and hold the up and down buttons for 3 seconds. The following appears in the

display:

Load a rack to engage the wash start switch and start a cycle. The display indicates whether

a switch is open or closed. When a switch is closed, its corresponding segment is illuminated

in the display. See the illustration below.

To resume the normal display, press the down button.

Booster Tank Backup Water Level Float Switch

Wash Start Switch

Booster Tank Water Level Float Switch

Rinse Start Switch

Wash Tank Water Level Sensor

24

Page 30

It is recommended to conduct this sequence check in the auto fi ll cycle after draining the

wash tank and booster tank. See “II.C. Sequence of Operation” for further details.

1) Use the “ON/OFF” button on the operation panel to turn off the unit.

2) Pull out the overfl ow pipe to drain the wash tank.

3) Drain the booster tank through the drain hose.

4) Replace the overfl ow pipe and drain hose in their correct positions.

5) Enter the switch open/closed display mode according to the above procedure.

6) Auto Fill Cycle

a. After the service panel is closed and the “ON/OFF” button is pressed, the inlet water

valve in the booster tank opens in 10 seconds to start water supply.

b. After a while, the booster tank water level float switch closes, segment C in the

display comes on, and the inlet water valve closes to stop water supply.

c. The rinse pump starts to feed water to the wash tank. When the booster tank water

level goes down, the water level fl oat switch opens, segment C in the display goes

off, and the inlet water valve opens to start water supply.

d. After the rinse pump is energized for a preset time to fi ll the wash tank, the wash

tank water level sensor closes, and segment E in the display comes on.

e. In normal operation, the booster tank backup water level fl oat switch does not close,

and segment A in the display stays off. If the booster tank water level fl oat switch

fails or the booster tank water level reaches the overfl ow level, segment A comes on.

7) Wash Cycle/Rinse Cycle

a. When a rack is loaded from the wash compartment entrance and the wash start

switch closes, segment B in the display comes on and the wash pump starts the

wash cycle for a preset time. When the conveyor moves the rack forward and the

wash start switch opens, segment B goes off and the wash pump stops after the

preset time. Segment E in the display stays on.

b. If the booster tank is below the predetermined water level, segment C in the display

stays off. The inlet water valve stays open until segment C comes on.

c. When the wash cycle ends and the rinse start switch closes, segment D in the

display comes on and the rinse pump starts the rinse cycle for a preset time. When

the rinse start switch opens, segment D goes off and the rinse pump stops after the

preset time. When the rinse cycle starts, the booster tank water level goes down and

segment C in the display goes off. The inlet water valve stays open until segment C

comes on.

Diagnosis: If any problem is found by the above sequence check, refer to “III.B. Error

Codes,” “III.C. Service Flow Charts,” “III.D. Float Switch Check and Cleaning” and “III.E.

Thermistor Check.”

25

Page 31

B. Error Codes

In the event of operation outside of normal parameters, the control board identifi es the issue

with an error code. For further service information, see "III.C. Service Flow Charts."

1. Error Code Table

Error

Code

A1

A2

A3

o1

Problem Operation Reset

Wash Tank Auto Fill Error

Water level in wash tank does not reach

water level sensor after rinse pump has

run for preset time.

Booster Tank Auto Fill Error

In auto fi ll cycle, booster tank water level

fl oat switch does not close within 10

minutes (or 20 minutes in "READY" mode)

after inlet water valve is opened.

Wash Tank Water Level Error

Water level in wash tank goes below water

level sensor in "READY" mode or during

operation.

Booster Tank Water Level Error 1 (Booster

Tank Water Level Float Switch Closed)

Both booster tank water level fl oat switch

and booster tank backup water level fl oat

switch have remained closed for 1 minute.

Booster Tank Water Level Error 2 (Booster

Tank Water Level Float Switch Open)

Whole unit

stops

Whole unit

stops

Supplementary

fi ll cycle starts

(Whole unit

stops if water

level sensor

does not

close after two

cycles)

Whole unit

stops

Whole unit

stops

Use "ON/OFF" button to turn the unit

off and then back on.

Use "ON/OFF" button to turn the unit

off and then back on.

After supplementary fi ll cycle ends,

alarm resets.

(If whole unit stops, use "ON/OFF"

button to turn the unit off and then

back on.)

Use "ON/OFF" button to turn the unit

off and then back on.

Use "ON/OFF" button to turn the unit

off and then back on.

o2

Booster tank water level fl oat switch is

open and booster tank backup water

level fl oat switch has remained closed for

1 minute.

Wash Tank Thermistor Error (short)

H1

Thermistor senses abnormal temperature

(at or above 231°F (110°C)).

Wash Tank Thermistor Error (open)

H2

Thermistor senses abnormal temperature

(at or below -6°F (-21°C)).

Booster Tank Thermistor Error (short)

H3

Thermistor senses abnormal temperature

(at or above 231°F (110°C)).

Normal

(Wash tank

heaters off)

Normal

(Wash tank

heaters off)

Normal

(Booster tank

heaters off)

26

After replacing failed component,

alarm resets.

After replacing failed component,

alarm resets.

After replacing failed component,

alarm resets.

Page 32

Error

Code

H4

H5

H6

L1

L2

b1

b2

Problem Operation Reset

Booster Tank Thermistor Error (open)

Thermistor senses abnormal temperature

(at or below -6°F (-21°C)).

ROM/RAM Error

Control board ROM/RAM fails.

EEPROM Error

EEPROM fails.

Conveyor Overload or Table Limit Error 1

Inverter sends conveyor overload signal or

table limit switch closes.

Conveyor Overload or Table Limit Error 2

After unit stops with "L1" error and restarts,

another error signal is sent within 3

seconds.

Booster Tank Error

Booster tank error output contacts open.

Booster Tank Water Level Safety Error

Booster tank water level safety fl oat switch

opens after booster tank water level fl oat

switch closes.

Normal

(Booster tank

heaters off)

Whole unit

stops

Whole unit

stops

Unit stops After error signal stops, alarm resets.

Whole unit

stops

Normal After booster tank error is resolved,

Whole unit

stops

After replacing failed component,

alarm resets.

After replacing control board, alarm

resets.

After replacing control board, alarm

resets.

Use "ON/OFF" button to turn the unit

off and then back on.

alarm resets.

Use "ON/OFF" button to turn the unit

off and then back on.

2. Error Code Log

Use the "ON/OFF" button to turn off the unit. Press and hold the "CHANGE" button, then

press the "ON/OFF" button. "01" should appear on the display. Use the down arrow button to

scroll to service menu items 21 through 25. 21 is the most recent error. Press the "CHANGE"

button to view the selected service menu item. Press the "CHANGE" button once again to

return to the main service menu list. If no errors exist in the log, "--" is displayed.

Press the "ON/OFF" button to exit the service menu. The display goes blank.

To erase the log, press and hold the up and down buttons for 3 seconds with one of the error

codes displayed. The unit beeps once and the entire log clears.

27

Page 33

3. Error Code Details

r

a) Auto Fill Error (A1)

• If the water level sensor in the wash tank is not closed at the end of the auto fi ll cycle, the

unit shuts down, "A1" appears in the display, and the buzzer sounds.

• To reset, use the "ON/OFF" button to turn the unit off and then back on.

• See the chart below for possible causes and remedies.

Code Error

A 1

Wash tank water level sensor is open at the end

of the auto fill cycle.

Item Possible Cause Remedy

Overflow Pipe

Wash Tank Water Level

Senso

Out of position. Set in position.

Heavy scale or soil

buildup.

Connector not properly

connected.

Open circuit. Repair or replace.

Defective. Replace.

Operation

Unit stops.

Clean.

Reconnect.

Continue

Rinse Pump

Control Board

Open circuit. Repair or replace.

Control relay

defective.

Defective. Replace.

Improper setting. Readjust.

Connector not properly

connected.

Defective. Replace.

Replace.

Reconnect.

28

Page 34

Continue

Booster Tank Water

Level Float Switch

Sticking (with float in

“ON” position).

Defective (with internal

contacts in “ON”

position).

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

Replace.

29

Page 35

b) Booster Tank Auto Fill Error (A2)

• In the auto fi ll cycle, if the booster tank water level fl oat switch does not close within 10 minutes

(or 20 minutes in "READY" mode) after the cycle starts, the unit shuts down, "A2" appears

in the display, and the buzzer sounds.

• To reset, use the "ON/OFF" button to turn the unit off and then back on.

• See the chart below for possible causes and remedies.

Code Error

A 2

Booster tank water level float switch does not

close within 10 minutes (or 20 minutes in

“READY” mode) after the auto fill cycle starts.

Item Possible Cause Remedy

Booster Tank

Not ready for

operation.

Operation

Unit stops.

Get it ready.

Strainer

Water Valve

Booster Tank Water

Level Float Switch

Water supply pressure

too low.

Filter clogged. Clean.

Open circuit. Repair or replace.

Filter clogged. Clean.

Defective. Replace.

Connector not properly

connected.

Open circuit. Repair or replace.

Readjust.

Reconnect.

Control Board

Sticking.

Connector not properly

connected.

Defective. Replace.

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

Reconnect.

30

Page 36

c) Wash Tank Water Level Error (A3)

)

• If the water level in the wash tank goes below the water level sensor in "READY" mode or

during operation, the supplementary fi ll cycle starts, "A3" appears in the display, the "AUTO

FILL" lamp fl ashes, and the buzzer sounds three times only at the beginning.

•

If the wash tank water level sensor is closed after the supplementary fi ll cycle, the alarm

resets. If the wash tank water level sensor is still open after the supplementary fi ll cycle,

another cycle starts.

If the wash tank water level sensor is closed after the second cycle, the alarm resets. If the

wash tank water level sensor still does not close after the second cycle, the buzzer sounds,

and the unit completely shuts down.

• See the chart below for possible causes and remedies.

Code Error

A 3

Wash tank water level sensor opens in

“READY” mode or during operation.

Item Possible Cause Remedy

Operation

Auto fill cycle starts.

Overflow Pipe

Wash Tank Water Level

Sensor (Wash Tank

Electrode

Control Board

Out of position. Set in position.

Heavy scale or soil

buildup.

Connector not properly

connected.

Open circuit. Repair or replace.

Defective. Replace.

Connector not properly

connected.

Defective. Replace.

Clean.

Reconnect.

Reconnect.

Auto Fill Cycle

Water level too low.

See “A1.”

31

Page 37

d) Booster Tank Water Level Error 1 (Booster Tank Water Level Float Switch Closed)

(o1)

• If both the booster tank water level fl oat switch and the booster tank backup water level

fl oat switch have remained closed for 1 minute, the booster tank heaters de-energize, "o1"

appears in the display, and the buzzer sounds.

• The error resets if the booster tank backup water level fl oat switch opens or when the "ON/

OFF" button is used to turn the unit off and then back on.

• See the chart below for possible causes and remedies.

Code Error

o 1

Booster tank water level float switch and booster

tank backup water level switch have remained

closed for 1 minute.

Item

Water Valve

Booster Tank Water

Level Float Switch

Control relay contacts

fused.

Defective. Replace.

Sticking.

Possible Cause

Operation

Unit stops.

Remedy

Replace.

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

Defective. Replace.

Booster Tank Backup

Water Level Float

Switch

Control Board

Sticking.

Defective. Replace.

Defective. Replace.

Note: See “III.D. Float Switch Check and Cleaning.”

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

32

Page 38

e) Booster Tank Water Level Error 2 (Booster Tank Water Level Float Switch Open)

(o2)

• If the booster tank water level fl oat switch is open and the booster tank backup water level

fl oat switch has remained closed for 1 minute, the booster tank heaters de-energize, "o2"

appears in the display, and the buzzer sounds.

• The error resets if the booster tank backup water level fl oat switch opens or when the "ON/

OFF" button is used to turn the unit off and then back on.

• See the chart below for possible causes and remedies.

Code Error

o 2

Booster tank water level float switch is open and

booster tank backup water level switch has

remained closed for 1 minute.

Item Possible Cause Remedy

Operation

Unit stops

Booster Tank Water

Level Float Switch

Booster Tank Backup

Water Level Float

Switch

Control Board

Sticking.

Open circuit. Repair or replace.

Defective. Replace.

Sticking.

Defective. Replace.

Connector not properly

connected.

Defective. Replace.

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

Check and clean. See

“III.D. Float Switch

Check and Cleaning.”

Reconnect.

Note: See “III.D. Float Switch Check and Cleaning.”

33

Page 39

f) Wash Tank Thermistor Error (H1, H2)

• If the wash tank thermistor senses a temperature at or above 231°F (111°C) (2.4kΩ), the

thermistor leads are considered shorted and the wash tank heaters de-energize, "H1"

appears in the display, and the buzzer sounds.

• If the wash tank thermistor senses a temperature at or below -6°F (-21°C) (517kΩ), the

thermistor leads are considered open and the wash tank heaters de-energize, "H2" appears

in the display, and the buzzer sounds.

• After replacing the failed component, the alarm resets.

• See the chart below for possible causes and remedies.

Note: The auto fi ll cycle and the wash/rinse cycle will start even after this error occurs.

H 1 / H 2

Code Error

Thermistor senses abnormal temperature.

Item Possible Cause Remedy

Operation

Continues (wash tank

heater off).

Thermistor

Control Board

Connector not properly

connected.

Open circuit (H2). Replace.

Short circuit (H1). Replace.

Defective. Replace.

Connector not properly

connected.

Defective. Replace.

Reconnect.

Reconnect.

Note: See “III.E. Thermistor Check” and “IV.H. Removal and Replacement of Thermistor.”

34

Page 40

g) Booster Tank Thermistor Error (H3, H4)

• If the booster tank thermistor senses a temperature at or above 231°F (111°C) (2.4kΩ), the

thermistor leads are considered shorted and the booster tank heaters de-energize, "H3"

appears in the display, and the buzzer sounds.

• If the booster tank thermistor senses a temperature at or below -6°F (-21°C) (517kΩ),

the thermistor leads are considered open and the booster tank heaters de-energize, "H4"

appears in the display, and the buzzer sounds.

• After replacing the failed component, the alarm resets.

• See the chart below for possible causes and remedies.

Note: The auto fi ll cycle and the wash/rinse cycle will start even after this error occurs.

H 3 / H 4

Code Error

Thermistor senses abnormal temperature.

Item Possible Cause Remedy

Operation

Continues (booster

tank heater off).

Thermistor

Control Board

Connector not properly

connected.

Open circuit (H4). Replace.

Short circuit (H3). Replace.

Defective. Replace.

Connector not properly

connected.

Defective. Replace.

Reconnect.

Reconnect.

Note: See “III.E. Thermistor Check” and “IV.H. Removal and Replacement of Thermistor.”

35

Page 41