Hoshizaki HWR96A, HUR96A, HWF40AD, HUF68A, HUF40AD Service Manual

...

Hoshizaki America, Inc.

Hoshizaki

Commercial Refrigerators & Freezers

Undercounter & Worktop Series

“A Superior Degree

of Reliability”

www.hoshizaki.com

Models

Refrigerators

HUR40A(-D) HWR40A(-D)

HUR68A(-D) HWR68A(-D)

HUR96A(-D) HWR96A(-D)

Freezers

HUF40A(-D) HWF40A(-D)

HUF68A(-D) HWF68A(-D)

SERVICE MANUAL

Number: 73123

Issued: 2-4-2005

Revised: 9-30-2008

IMPORTANT

Only qualied service technicians should attempt to service or maintain this

unit. No such service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

•ModelNumber__________________________

•SerialNumber__________________________

•Completeanddetailedexplanationoftheproblem.

ENERGY STAR

®

Products earning the ENERGY STAR prevent greenhouse gas emissions by meeting strict

energy efficiency guidelines set by the U.S. Environmental Protection Agency and the

U.S. Department of Energy. Several models of Hoshizaki undercounters have earned the

ENERGY STAR. To easily determine if your unit has earned the ENERGY STAR, see the

nameplate attached to the right wall on the inside of the cabinet.

2

Please review this manual. It should be read carefully before the unit is serviced or

maintenance operations are performed. Only qualied service technicians should service

and maintain the unit. This manual should be made available to the technician prior to

service or maintenance.

CONTENTS

I. Specications ...................................................................................................................... 5

A. Nameplate Ratings ........................................................................................................ 5

B. Dimensions ................................................................................................................... 5

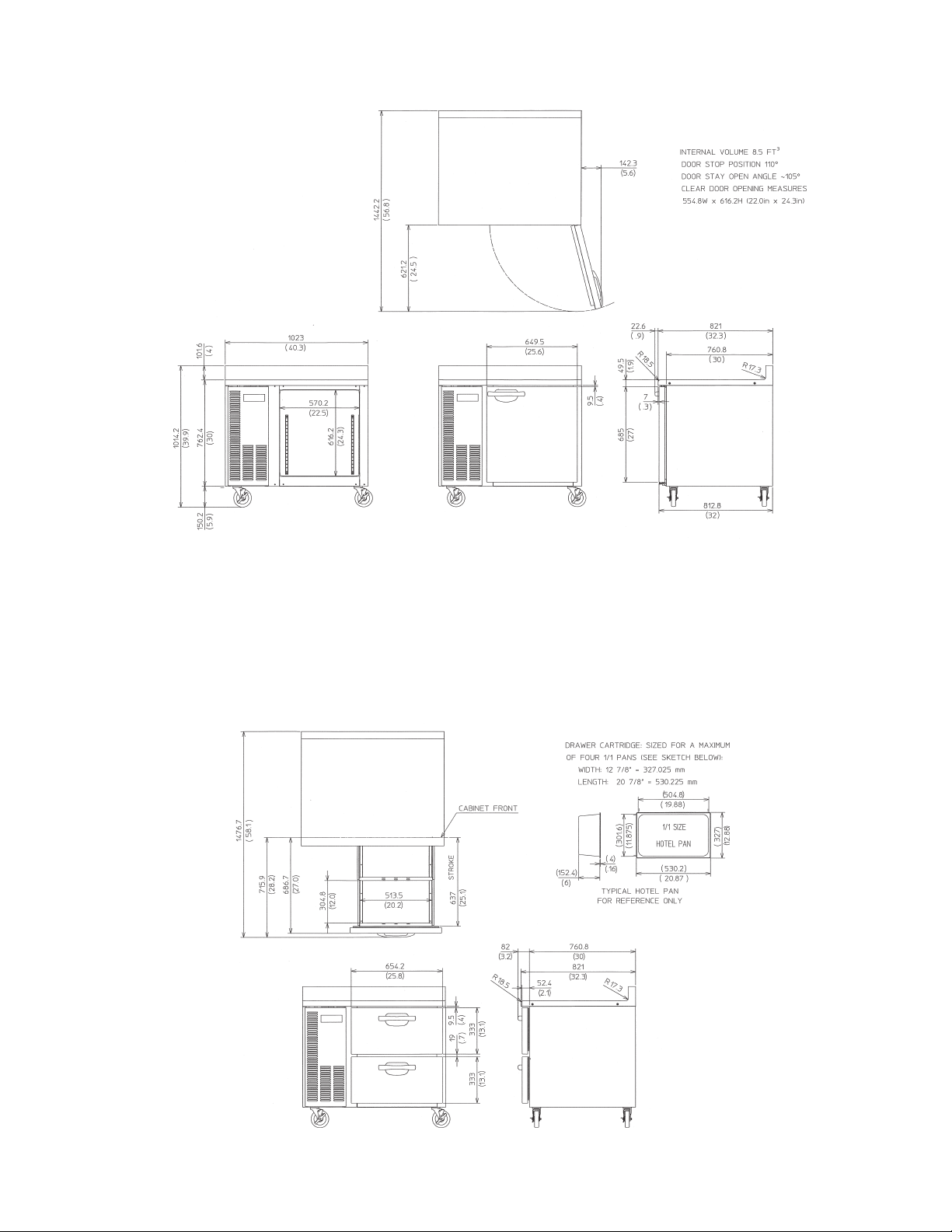

1. HUR40A, HUF40A ................................................................................................... 6

1a. HUR40A-D, HUF40A-D ......................................................................................... 6

2. HWR40A, HWF40A ................................................................................................. 7

2a. HWR40A-D, HWF40A-D ........................................................................................ 7

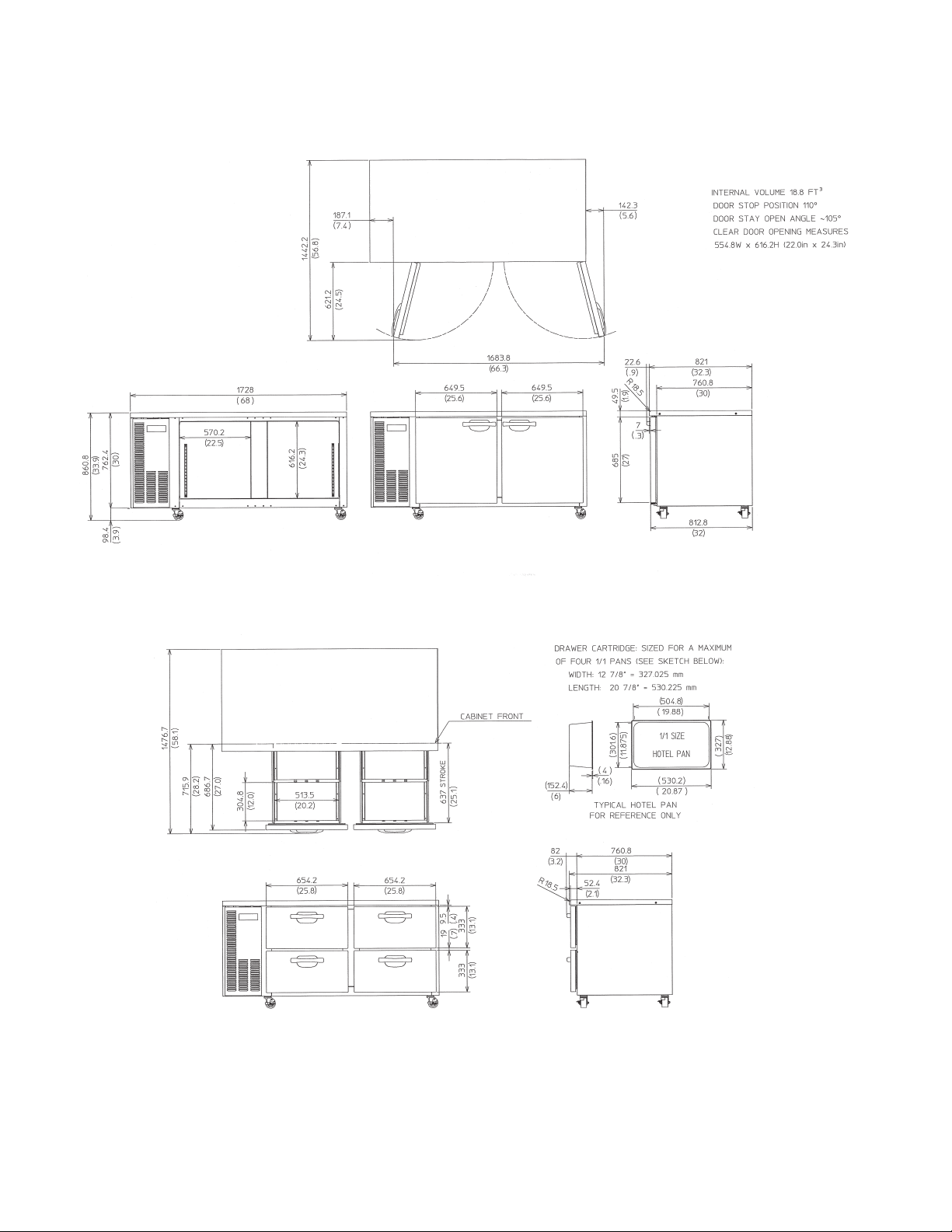

3. HUR68A, HUF68A .................................................................................................. 8

3a. HUR68A-D, HUF68A-D ......................................................................................... 8

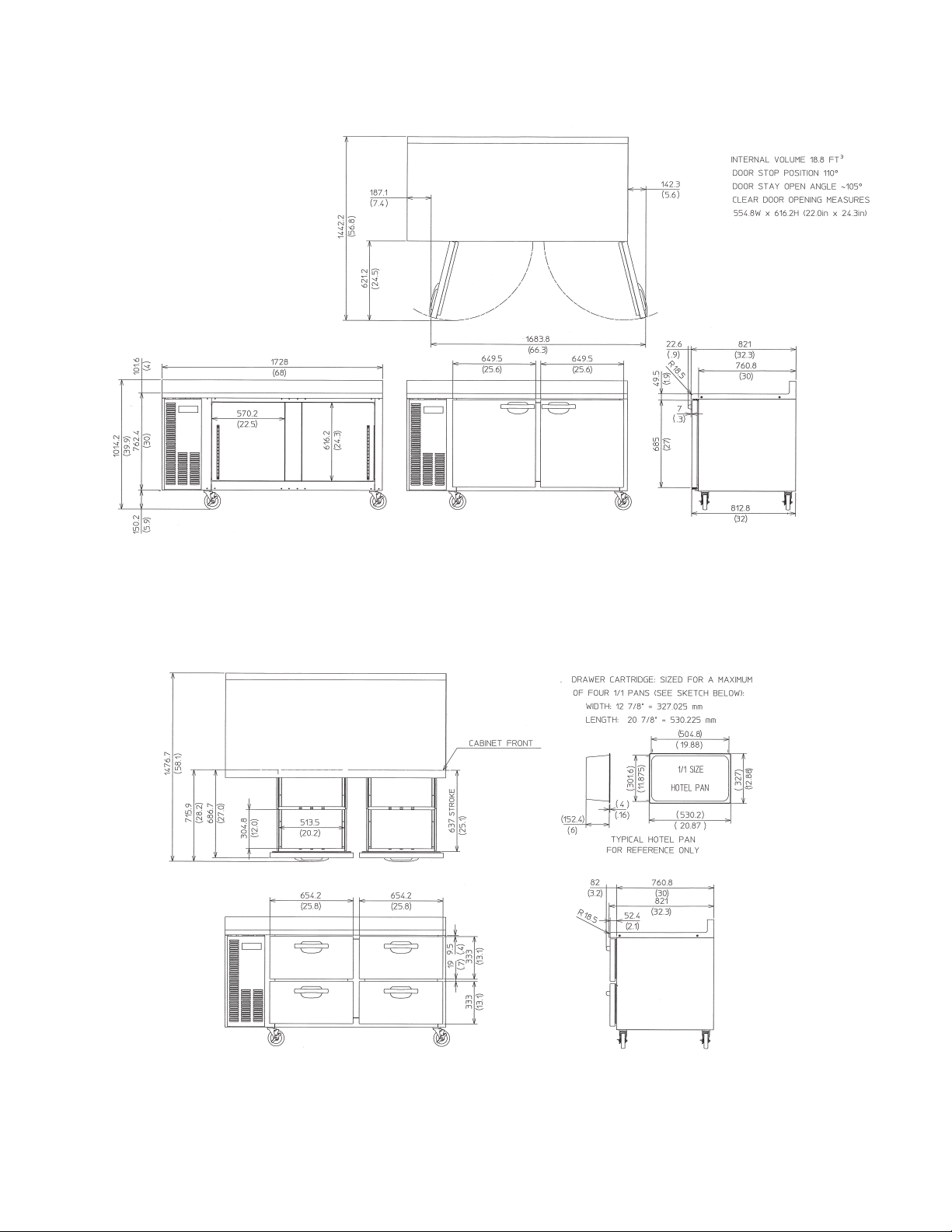

4. HWR68A, HWF68A ................................................................................................. 9

4a. HWR68A-D, HWF68A-D ........................................................................................ 9

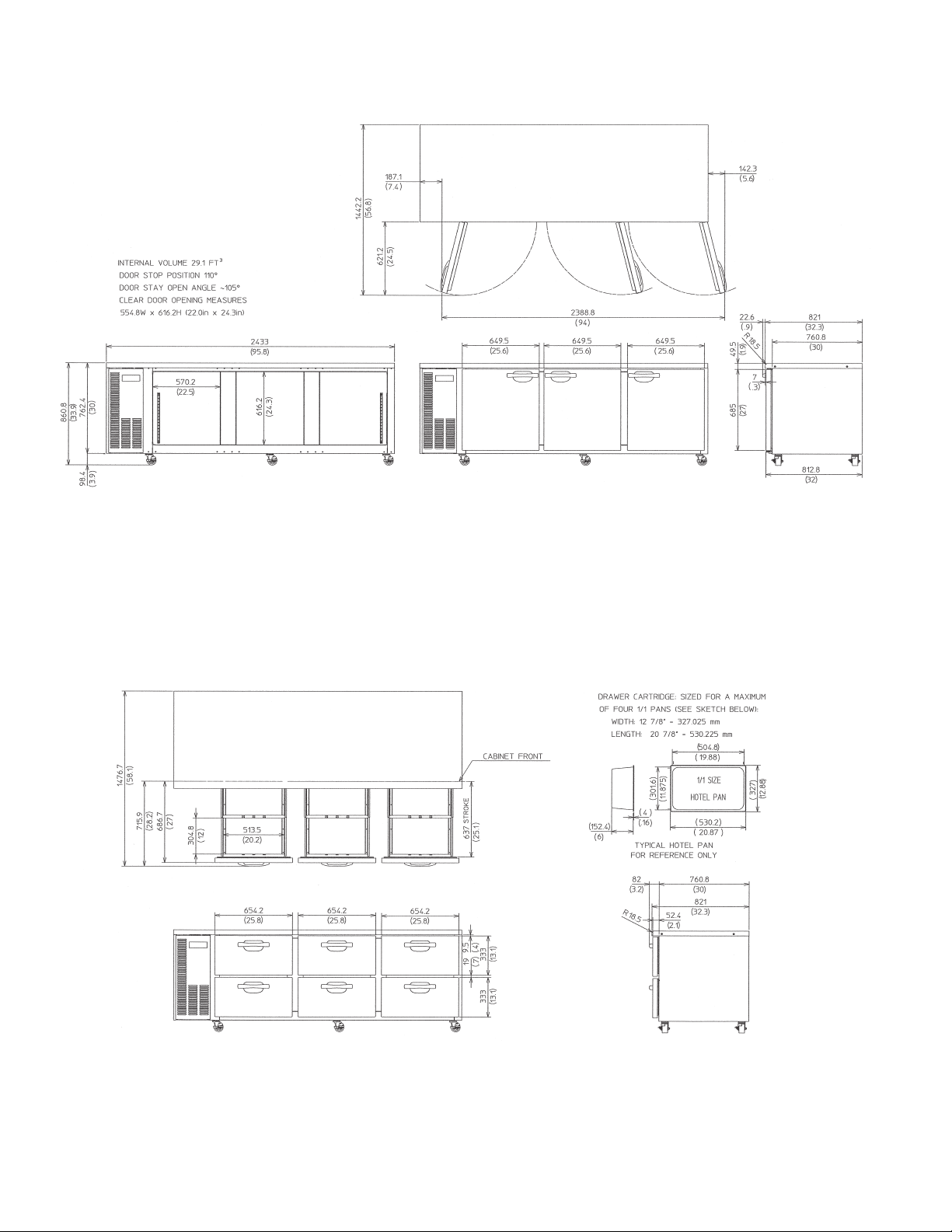

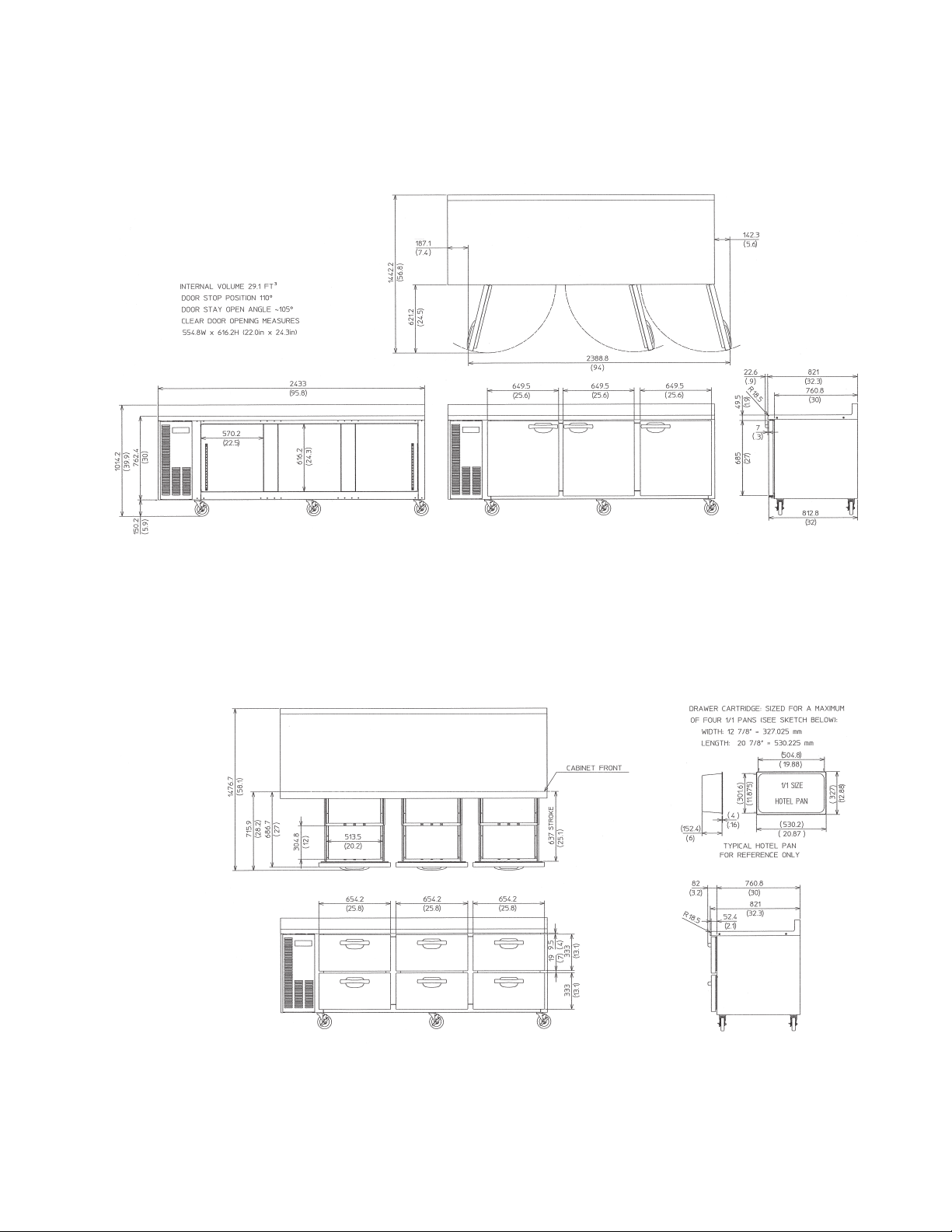

5. HUR96A ................................................................................................................ 10

5a. HUR96A-D ........................................................................................................... 10

6. HWR96A ................................................................................................................11

6a. HWR96A-D ...........................................................................................................11

II. General Information ........................................................................................................ 12

A. Construction ................................................................................................................ 12

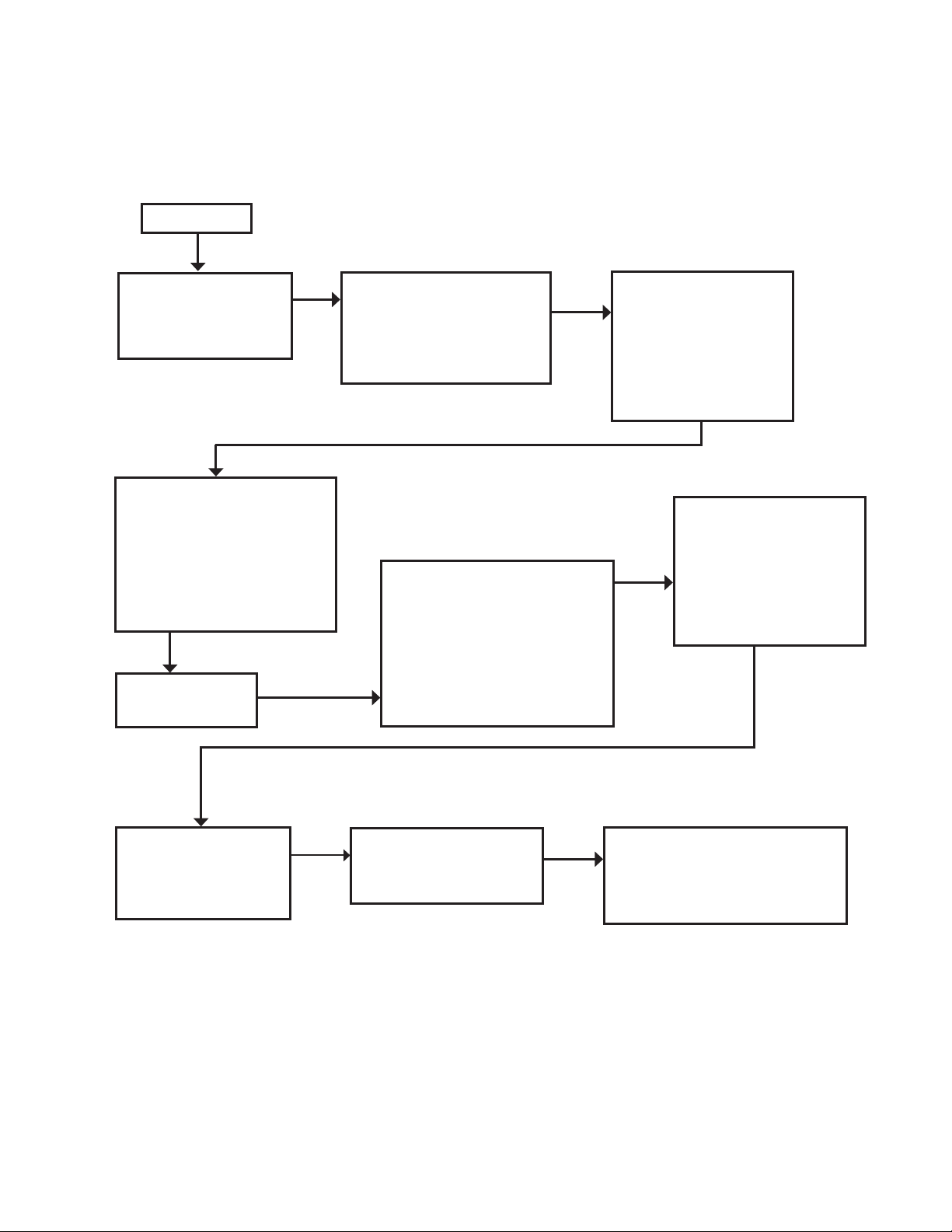

B. Sequence of Operation and Timing Charts ................................................................. 13

1. Refrigerators – Continuous Operating Mode ......................................................... 13

2. Freezers – Continuous Operating Mode .............................................................. 15

3. Refrigerators – Energy Saving Operating Mode ................................................... 17

4. Freezers – Energy Saving Operating Mode .......................................................... 19

C. Control Board .............................................................................................................. 21

1. Start-Up Delay........................................................................................................ 21

2. Control Board Layout ............................................................................................. 22

D. Settings and Diagnostics ............................................................................................. 23

1. Gaining Access to Settings and Diagnostics .......................................................... 23

2. Temperature Display .............................................................................................. 24

a) Switching the Display Between Fahrenheit and Celsius (F5) .......................... 24

b) Adjusting the Setpoint Temperature ................................................................. 24

c) Cabinet Temperature Correction (calibration factor) ......................................... 25

3. Settings and Diagnostics Menu ............................................................................. 26

a) Defrost Interval (F0) ......................................................................................... 27

b) Defrost Termination Temperature (F1) ............................................................. 27

c) Setpoint Temperature Differential (F2).............................................................. 28

d) High Temperature Alarm Delay Time (F3) ........................................................ 29

e) Low Temperature Alarm Delay Time (F4) ......................................................... 29

f) Temperature Display Scale (F5) ........................................................................ 30

g) Alarm History (F6) ............................................................................................ 30

h) Compressor Run Time (F7) ............................................................................. 31

3

4. Operating Modes ................................................................................................... 31

a) Continuous ....................................................................................................... 32

b) Energy Saving .................................................................................................. 32

c) Automatic Corrections Made During Energy Saving Operating Mode .............. 32

E. Perimeter Frame Heater .............................................................................................. 32

III. Service Diagnosis ........................................................................................................... 33

A. Alarm Codes ............................................................................................................... 33

1. Alarm Display Priority ............................................................................................. 34

2. Alarm Details and Countermeasures ..................................................................... 35

a. High Temperature Alarm (E1) ........................................................................... 35

b. Low Temperature Alarm (E2) ............................................................................ 36

c. Defrost Alarm (E3) ............................................................................................ 37

d. High Pressure Alarm (E4) ................................................................................. 37

e. Clogged Filter Alarm (E7) ................................................................................. 38

f. Defrost Temperature Sensor Malfunction Alarm (E8) ........................................ 39

g. Clogged Filter Sensor Malfunction Alarm (E9) ................................................. 40

h. Control Board Error Alarms (EA and ED) ......................................................... 41

B. Diagnosis Chart .......................................................................................................... 42

C. Thermistor Check ........................................................................................................ 45

IV. Removal and Replacement of Components ................................................................... 46

A. Service for Refrigerant Lines ....................................................................................... 46

1. Refrigerant Recovery ............................................................................................. 46

2. Brazing .................................................................................................................. 46

3. Evacuation and Recharge .................................................................................... 47

B. Removal and Replacement of Refrigeration Unit ........................................................ 48

C. Removal and Replacement of Compressor ................................................................ 48

D. Removal and Replacement of Evaporator ................................................................... 49

E. Removal and Replacement of Capillary Tube / Suction Line Assembly ...................... 51

F. Removal and Replacement of Thermistors .................................................................. 52

G. Removal and Replacement of Door Gasket ............................................................... 53

H. Removal and Replacement of Defrost Heater ............................................................. 53

I. Removal and Replacement of Control Board ............................................................... 54

J. Removal and Replacement of Fan Motors ................................................................... 55

K. Door Re-Hinging and Drawer Conversion ................................................................... 55

V. Cleaning and Maintenance Instructions ........................................................................... 56

A. Cleaning ...................................................................................................................... 56

B. Maintenance ................................................................................................................ 57

VI. Wiring Diagrams ............................................................................................................ 58

A1. HUR40A, HWR40A (auxiliary code Q5 and earlier) .................................................. 58

A2. HUR40A(-D), HWR40A(-D) (auxiliary code Q6 and later) ....................................... 59

B. HUF40A(-D), HWF40A(-D) ......................................................................................... 60

C1. HUR68A, HWR68A (auxiliary code Q5 and earlier) .................................................. 61

C2. HUR68A(-D), HWR68A(-D) (auxiliary code Q6 and later) ........................................ 62

D. HUF68A(-D), HWF68A(-D) ......................................................................................... 63

E. HUR96A(-D), HWR96A(-D)......................................................................................... 64

4

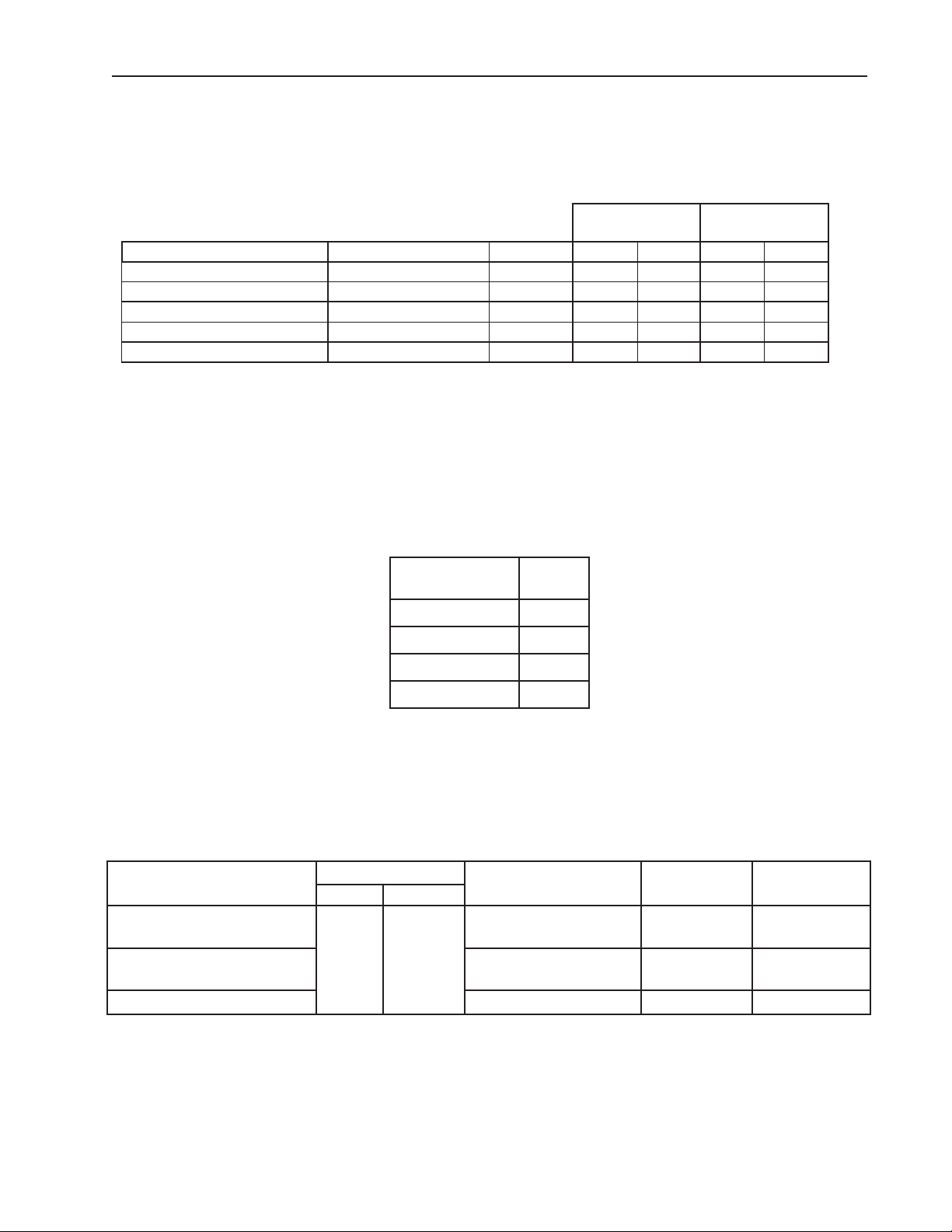

I. Specications

A. Nameplate Ratings

Design Pressure

(PSIG)

Model AC Supply Voltage Amperes HI LO 404A 134a

HUR40A(-D), HWR40A(-D) 115/60/1 5.0 240 120 15.2

HUR68A(-D), HWR68A(-D) 115/60/1 5.0 240 120 15.2

Refrigerant

(oz.)

HUR96A(-D), HWR96A(-D) 115/60/1 6.0 240 120 15.2

HUF40A(-D), HWF40A(-D) 115/60/1 5.5 450 250 14.1

HUF68A(-D), HWF68A(-D) 115/60/1 10.0 450 250 13.0

Undercounter Model Names

The undercounter models covered in this service manual initially had different model

names. If you have a unit with an auxiliary code of N-6 and a serial number ending in "H",

refer to the table below.

Model Name on

Nameplate

UR1-SSB HUR40A

UR2-SSB HUR68A

Current

Name

UF1-SSB HUF40A

UF2-SSB HUF68A

B. Dimensions

Door Opening mm Total Refrigerated

Model

HUR40A(-D), HWR40A(-D),

HUF40A(-D), HWF40A(-D)

HUR68A(-D), HWR68A(-D),

HUF68A(-D), HWF68A(-D)

HUR96A(-D), HWR96A(-D) 29.1 26.6 12

Width Height

570.2 616.2

Volume ft

18.8 1 7. 1 8

3

8.5 7. 6 4

Total Shelf

Space ft

2

Hotel Pan

Capacity (-D)

5

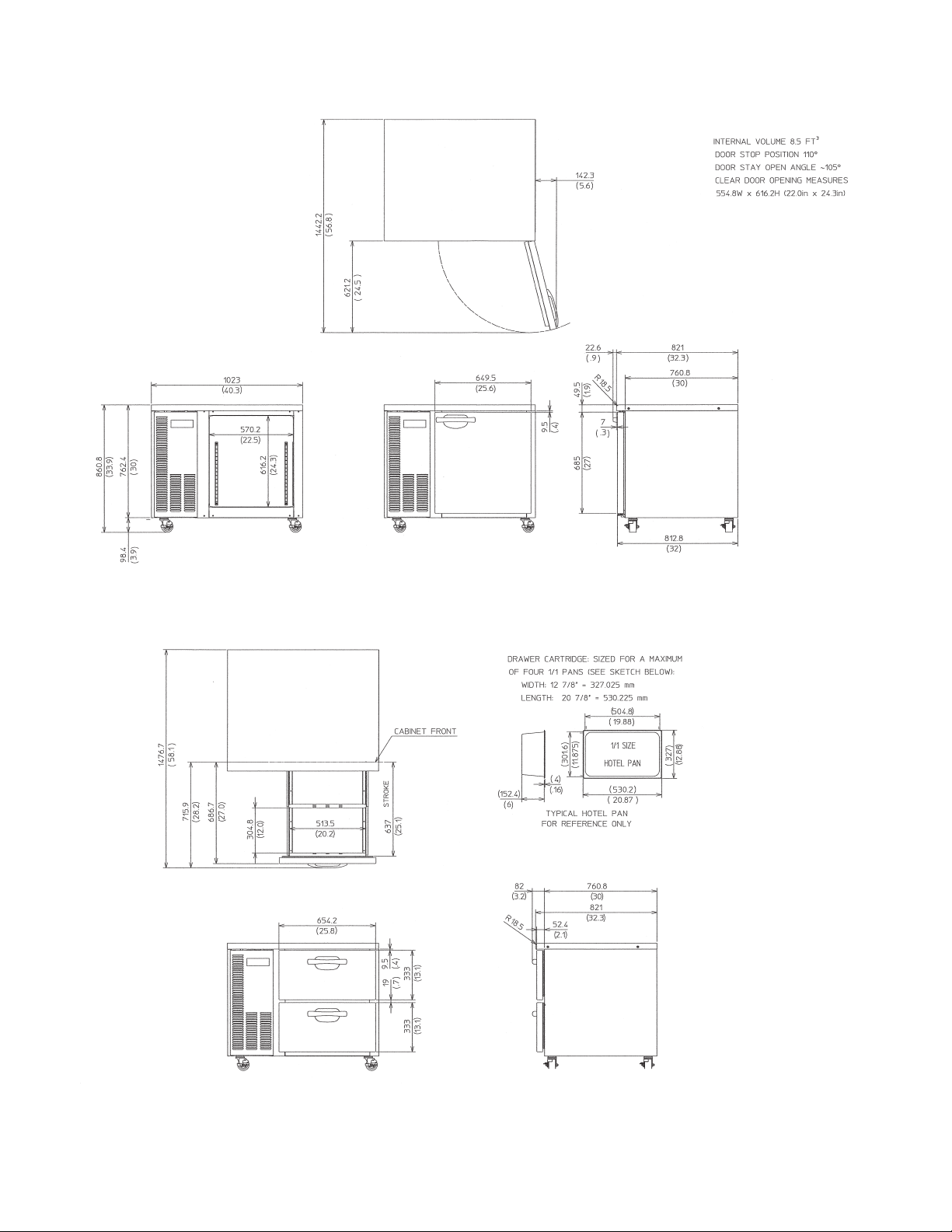

1. HUR40A, HUF40A

Units: mm (in.)

1a. HUR40A-D, HUF40A-D

6

2. HWR40A, HWF40A

Units: mm (in.)

2a. HWR40A-D, HWF40A-D

7

3. HUR68A, HUF68A

Units: mm (in.)

3a. HUR68A-D, HUF68A-D

8

4. HWR68A, HWF68A

Units: mm (in.)

4a. HWR68A-D, HWF68A-D

9

5. HUR96A

Units: mm (in.)

5a. HUR96A-D

10

6. HWR96A

Units: mm (in.)

6a. HWR96A-D

11

II. General Information

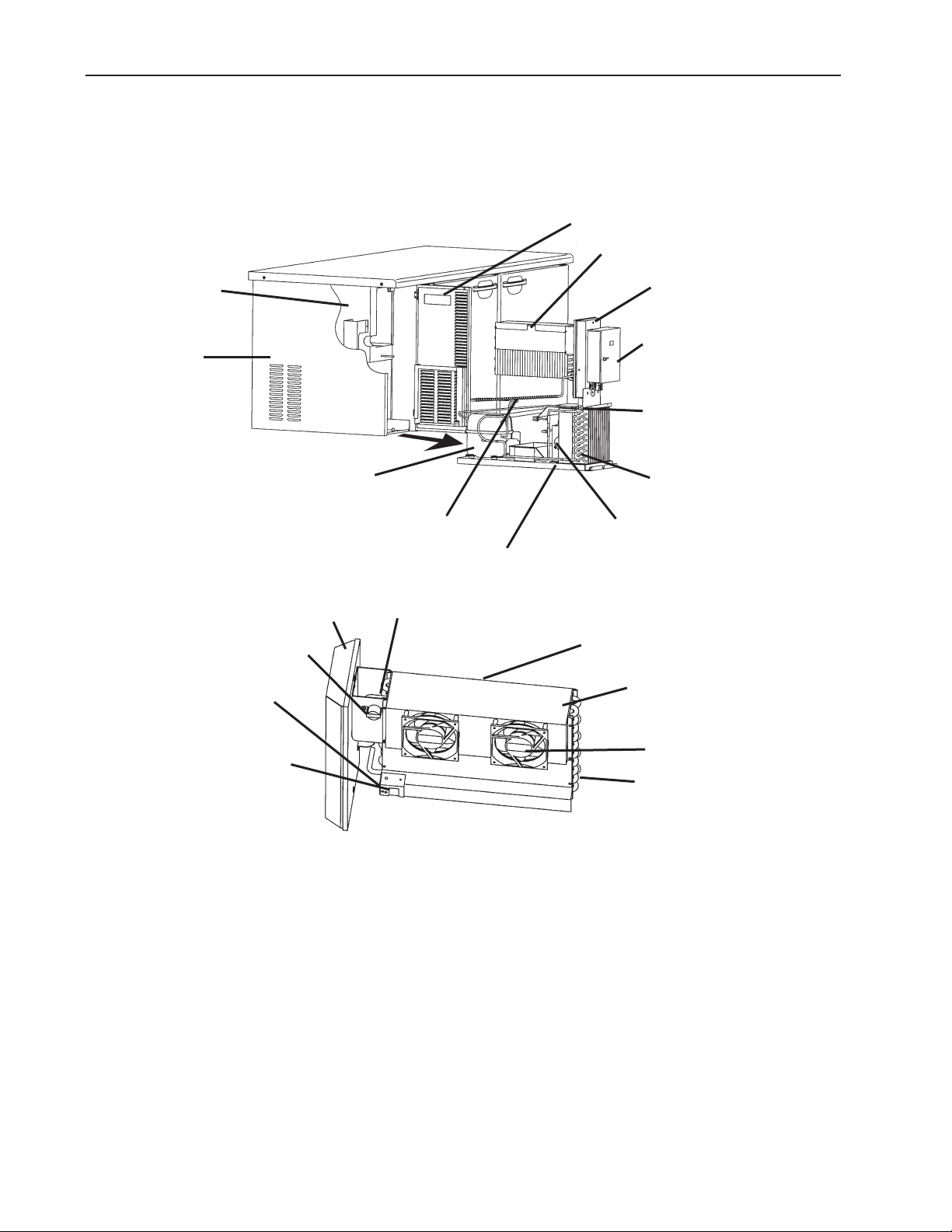

A. Construction

Hoshizaki undercounters feature a cartridge-type refrigeration unit that can be removed

without taking off the top and side panels.

Front Panel

Evaporator Assembly

Evaporator Case

Side Panel

Evaporator Case Cover

Defrost Thermostat

Defrost Heater

Compressor

Capillary Tube/Suction

Line Assembly

Thermal Fuse

Evaporator Case Cover

Control Box

Access Valve (Low-Side)

Condenser

Condenser Fan Motor

Compressor Base

Defrost Thermistor

Evaporator Shroud

Cabinet Thermistor

Evaporator Fan Motor

Evaporator

Evaporator Case

12

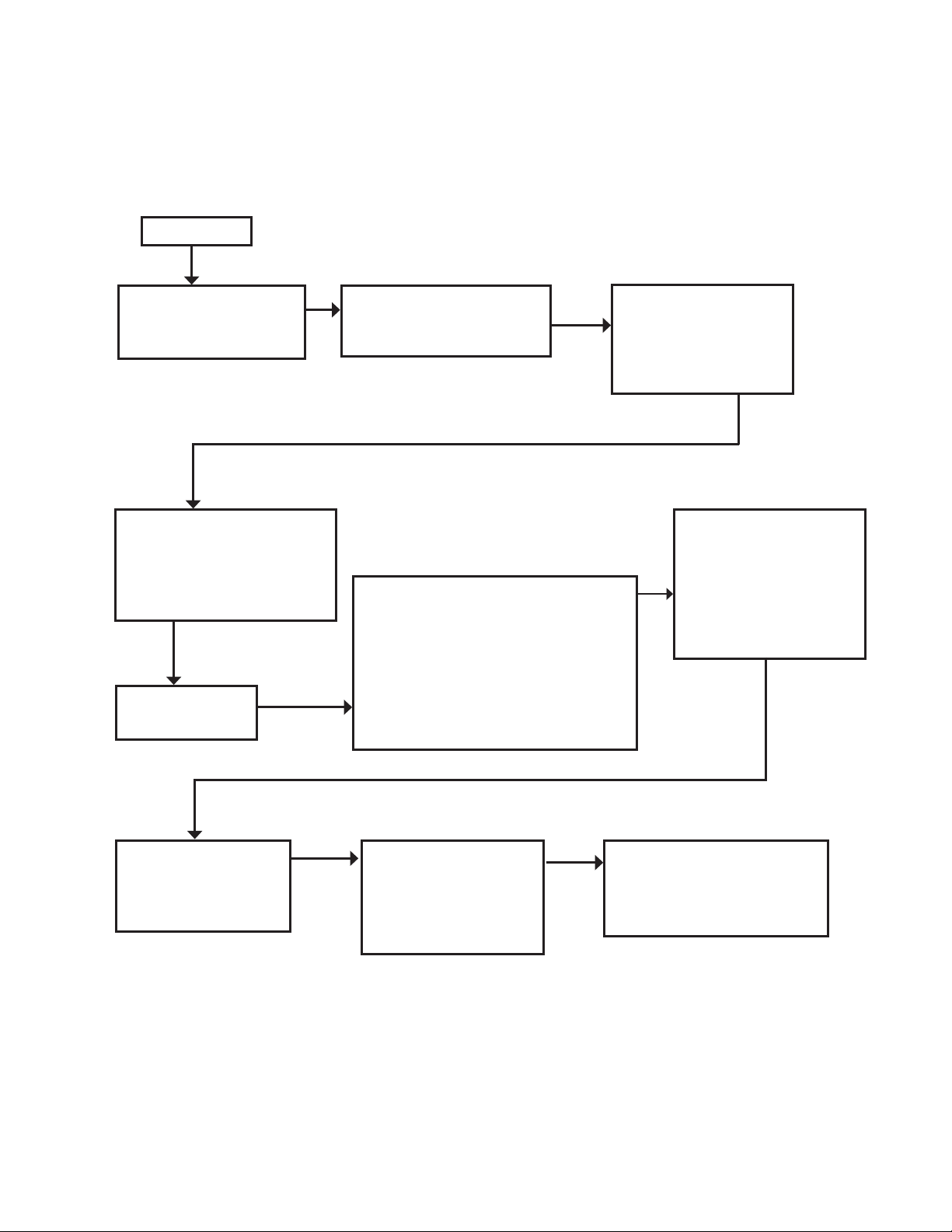

B. Sequence of Operation and Timing Charts

For details on operating modes, see "II.D.4. Operating Modes."

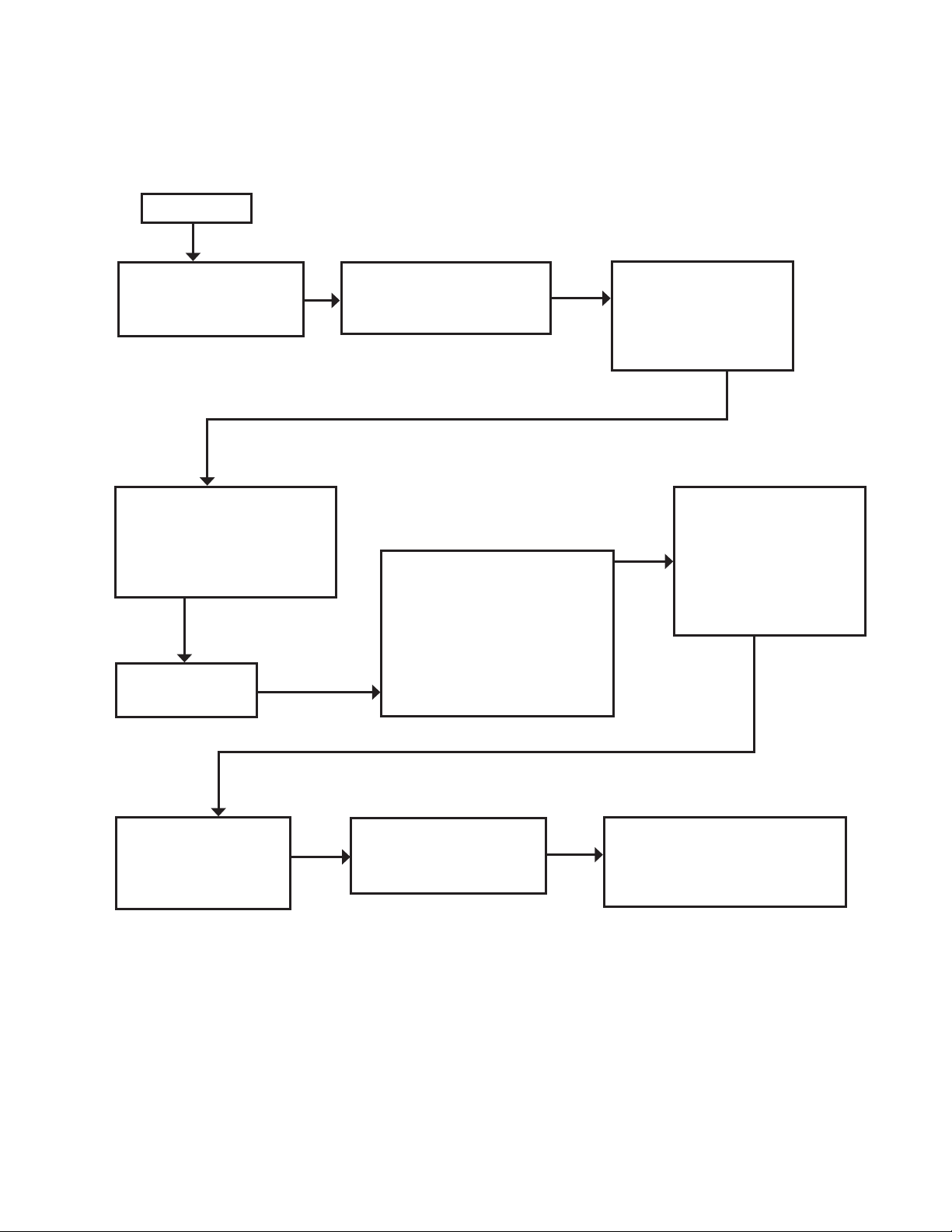

1. Refrigerators – Continuous Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

2. Evaporator fan(s) on

Cycle On (Cut-on

temperature reached)

[Minimum 2 minutes]

1. Compressor start-up

2. Condenser fan start-up

Continue as

normal cycling

2-minute Delay

1. Compressor start-up

2. Condenser fan start-up

Defrost Start

Preprogrammed time interval

1. Compressor off

2. Evaporator fan(s) off

3. Frame heater(s) off (Q6 and later)

4. Condenser fan off

5. Defrost heater on

6. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum 2 minutes]

1. Compressor off

2. Condenser fan off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

2. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

2. Frame heater(s) on

(Q6 and later)

One minute after evaporator

fan start-up "dF" no

longer displayed, cabinet

temperature displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the

"cabinet thermistor."

2) The defrost thermistor reads the evaporator temperature.

3) There is a ve second evaporator fan startup delay when the compressor and

fan would otherwise start together.

13

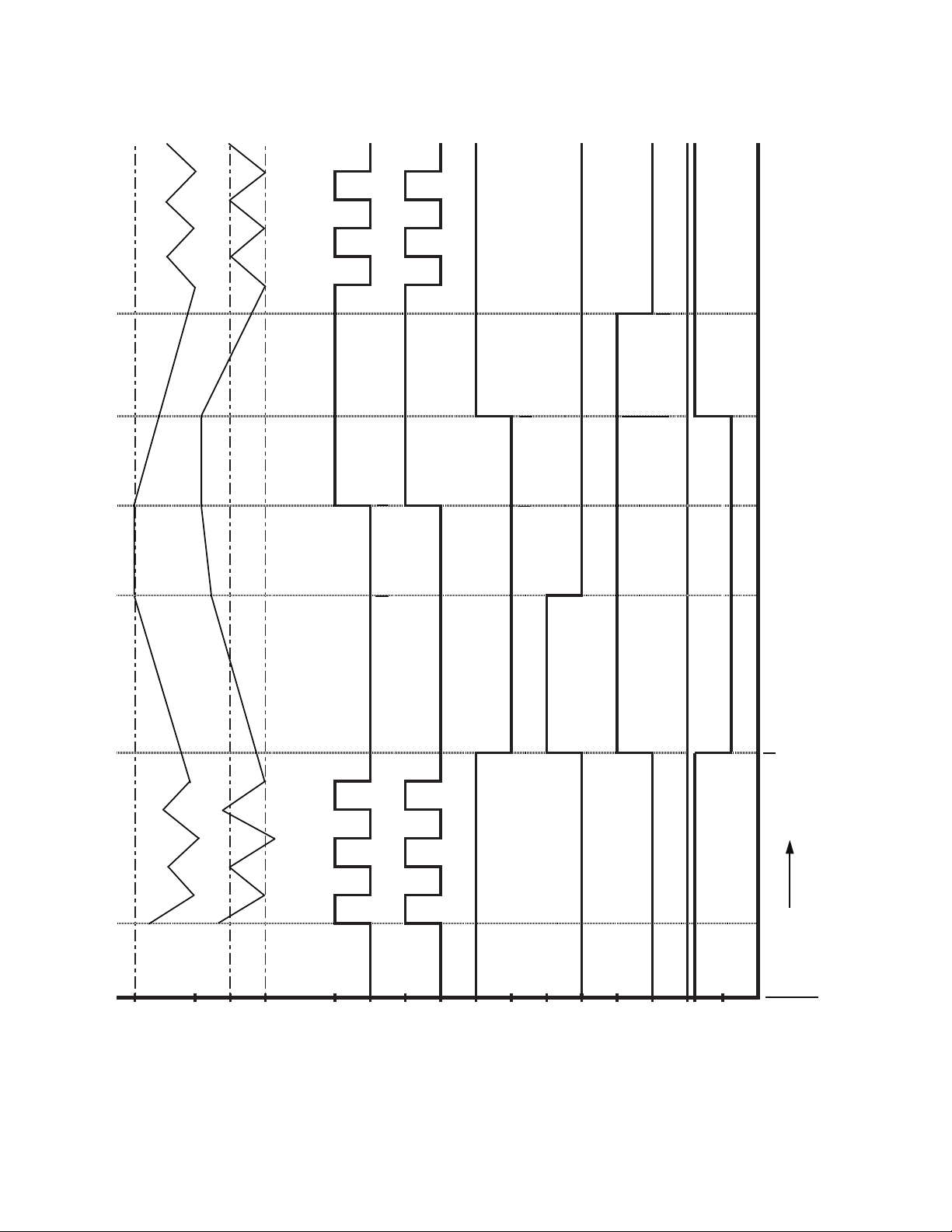

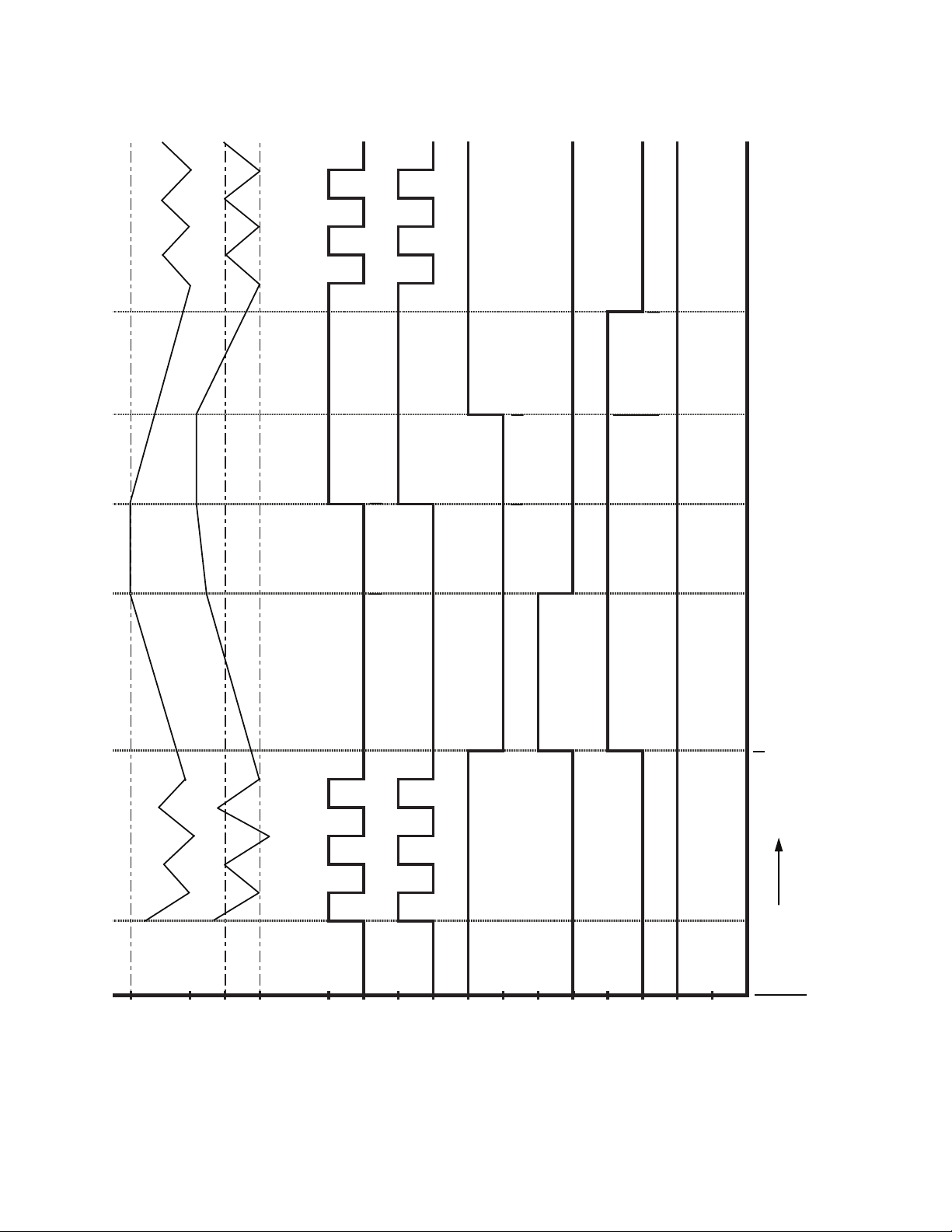

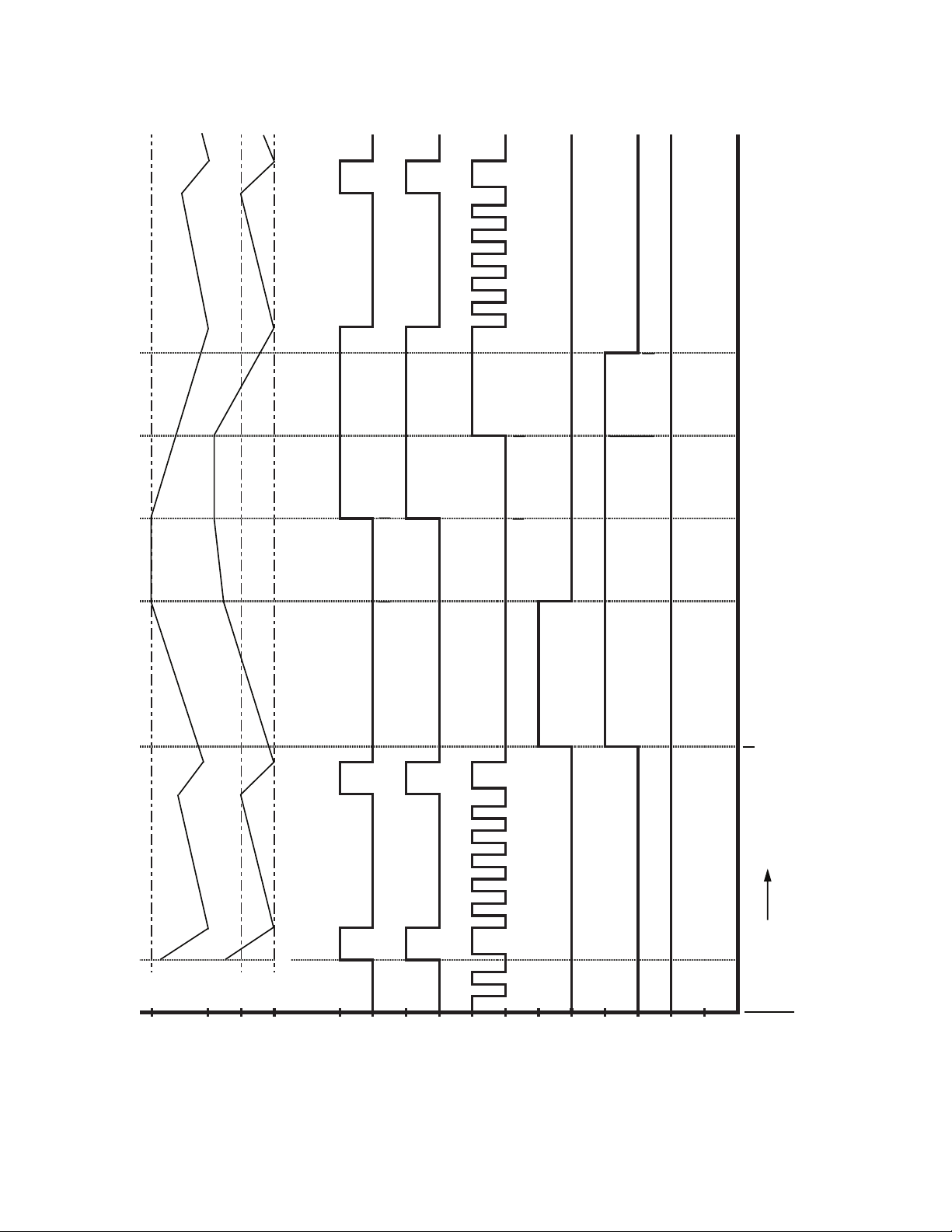

b) Timing Chart

r

TIME-TEMPERATURE CONTROL CHART ENERGY SAVING MODE

REFRIGERATORS

Refrigerators – Continuous Operating Mode

)yaleD niarD(

.nim 5

)yaleD naF(

.nim 5

)noitaruD tsorfeD .xaM(

.nim 06 <

)yaleD yalpsiD(

.nim 1

)elbatsujdA - tratS tsorfeD(

sruoh 6

Q6 and Later

Q5 and Earlier

)FFO .niM(

.nim 2

)NO .niM(

.nim 2

)yaleD tratS(

.nim 2

)+( laitnereffiD + tniopteS

gninaem oN

rotsimrehT tsorfeD

erutarepmeT noitanimreT tsorfeD

)--( laitnereffiD + tniopteS

rotsimrehT tenibaC

FFO

NO

osserpmoC

FFO

NO

naF resnednoC

FFO

NO

n(s)aF rotaropavE

retaeH tsorfeD

FFO

NO

rotacidnI tsorfeD

FFO

NO

FFO

NO

Frame Heater(s)

14

emiT

NO rewoP

2. Freezers – Continuous Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

2. Evaporator fan(s) on

Cycle On (Cut-on

temperature reached)

[Minimum 2 minutes]

1. Compressor start-up

2. Condenser fan start-up

Continue as

normal cycling

2 minute delay

1. Compressor start-up

2. Condenser fan start-up

Defrost Start

Preprogrammed time interval

1. Compressor off

2. Evaporator fan(s) off

3. Condenser fan off

4. Defrost heater on

5. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum 2 minutes]

1. Compressor off

2. Condenser fan off

Defrost end

Defrost thermistor

reaches defrost

termination

temperature, or defrost

timer reaches 1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

2. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

Eight minutes after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the

"cabinet thermistor."

2) The defrost thermistor reads the evaporator temperature.

3) There is a ve second evaporator fan startup delay when the compressor and

fan would otherwise start together.

15

b) Timing Chart

r

r

r

r

r

TIME-TEMPERATURE CONTROL CHART [NOT DURING ENERGY SAVING MODE] FOR

REFRIGERATORS & FREEZERS WITH AUXILIARY CODE _____ AND BEFORE

Freezers – Continuous Operating Mode

)yaleD naF(

.nim 5

)yaleD niarD(

.nim 5

)yaleD yalpsiD(

.nim 8

)noitaruD tsorfeD .xaM(

.nim 06 <

)FFO .niM(

.nim 2

)NO .niM(

.nim 2

)yaleD tratS(

.nim 2

)+( laitnereffiD + tniopteS

erutarepmeT noitanimreT tsorfeD

gninaem oN

otsimrehT tsorfeD

)--( laitnereffiD + tniopteS

otsimrehT tenibaC

FFO

NO

osserpmoC

FFO

NO

naF resnednoC

FFO

NO

n(s)aF rotaropavE

FFO

NO

etaeH tsorfeD

FFO

NO

otacidnI tsorfeD

FFO

NO

)elbatsujdA - tratS tsorfeD(

sruoh 6

emiT

NO rewoP

Frame Heater(s)

16

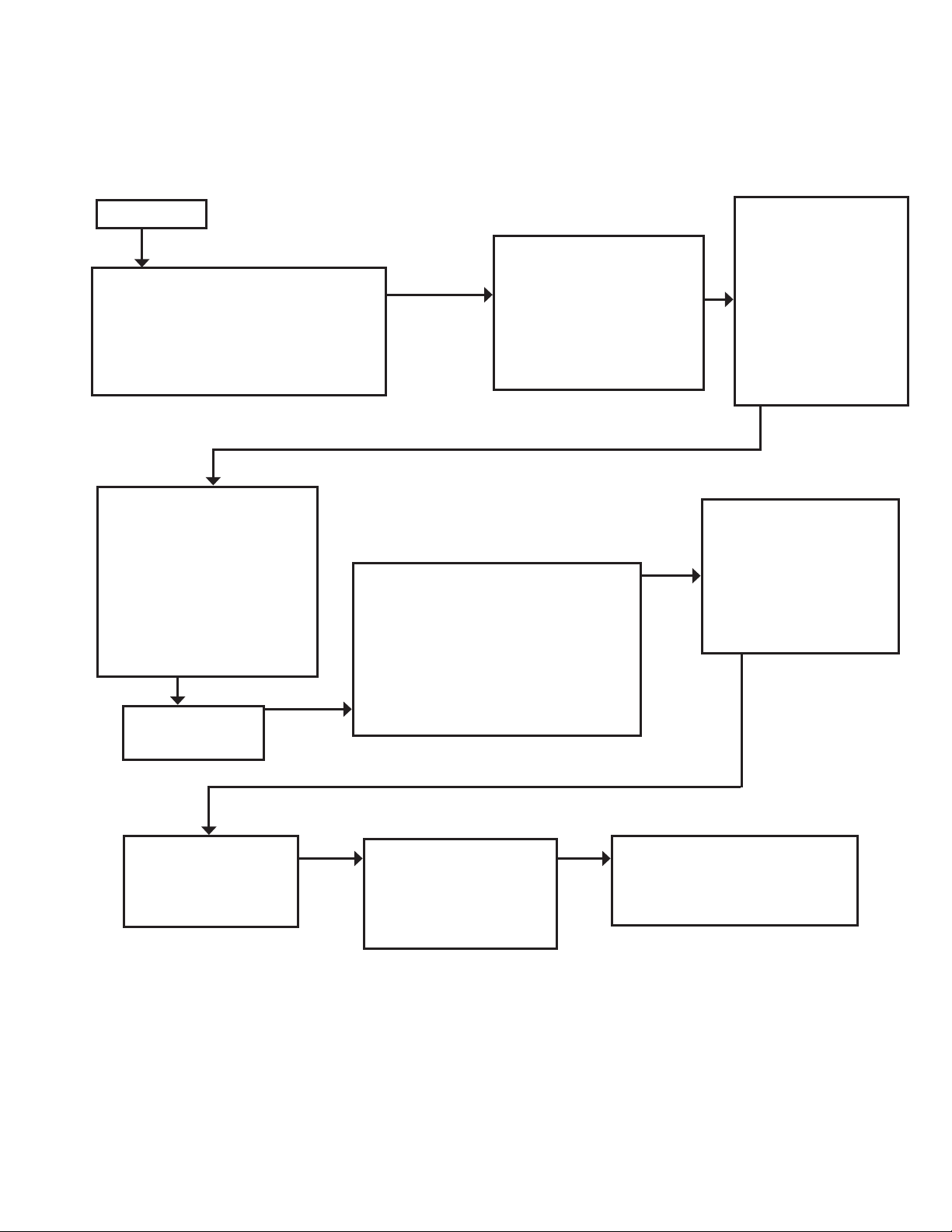

3. Refrigerators – Energy Saving Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on continuously

(Q5 and earlier)

Frame heater(s) cycle on and off

(Q6 and later)

2. Evaporator fan(s) cycles on and off

Cycle On (Cut-on

temperature reached)

[Minimum 2 minutes]

1. Compressor start-up

2. Condenser fan start-up

3. Frame heater(s) on

(continuously)

4. Evaporator fan(s) on

(continuously)

Continue as

normal cycling

Defrost Start

Preprogrammed time interval

1. Compressor off

2. Frame heater(s) off (Q6 and later)

3. Evaporator fan(s) off

4. Condenser fan off

5. Defrost heater on

6. "dF" displayed

2-minute Delay

1. Compressor start-up

2. Condenser fan start-up

3. Frame heater(s) on

(continuously)

4. Evaporator fan(s) on

(continuously)

Cycle Off (Cut-out

temperature reached)

[Minimum 2 minutes]

1. Compressor off

2. Condenser fan off

3. Frame heater(s)

cycle on and off

(Q6 and later)

4. Evaporator fan(s)

cycles on and off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

2. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

2. Frame heater(s)

on (Q6 and later)

One minute after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the "cabinet

2) The defrost thermistor reads the evaporator temperature.

thermistor."

17

b) Timing Chart

r

r

TIME-TEMPERATURE CONTROL CHART [DURING ENERGY SAVING MODE] FOR

REFRIGERATORS WITH AUXILIARY CODE _____ AND AFTER

Refrigerators – Energy Saving Operating Mode

)sdoireP FFO rosserpmoC llA(

*

tnettimretnI

noitarepO

)yaleD yalpsiD(

.nim 1

rehtegot trats esiwrehto dluow naf dna rosserpmoc

nehw yaled pu trats naf rotaropave dnoces eviF

*

)yaleD naF(

.nim 5

)yaleD niarD(

.nim 5

)noitaruD tsorfeD .xaM(

.nim 06 <

)elbatsujdA - tratS tsorfeD(

sruoh 6

Q6 and Later

Q5 and Earlier

)sdoireP FFO rosserpmoC llA(

*

tnettimretnI

noitarepO

)FFO .niM(

.nim 2

)NO .niM(

.nim 2

)yaleD tratS(

.nim 2

)--( laitnereffiD + tniopteS

)+( laitnereffiD + tniopteS

gninaem oN

rotsimrehT tsorfeD

erutarepmeT noitanimreT tsorfeD

rotsimrehT tenibaC

FFO

NO

osserpmoC

FFO

NO

naF resnednoC

NO

18

*

FFO

n(s)aF rotaropavE

FFO

NO

etaeH tsorfeD

rotacidnI tsorfeD

FFO

NO

FFO

NO

Frame Heater(s)

emiT

NO rewoP

4. Freezers – Energy Saving Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

2. Evaporator fan(s)

cycles on and off

Cycle On (Cut-on

temperature reached)

[Minimum 2 minutes]

1. Compressor start-up

2. Condenser fan start-up

3. Evaporator fan(s) on

(continuously)

Continue as

normal cycling

2-minute Delay

1. Compressor start-up

2. Condenser fan start-up

3. Evaporator fan(s) on

(continuously)

Defrost Start

Preprogrammed time interval

1. Compressor off

2. Evaporator fan(s) off

3. Condenser fan off

4. Defrost heater on

5. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum 2 minutes]

1. Compressor off

2. Condenser fan off

3. Evaporator fan(s)

cycles on and off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

2. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

Eight minutes after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the "cabinet

2) The defrost thermistor reads the evaporator temperature.

thermistor."

19

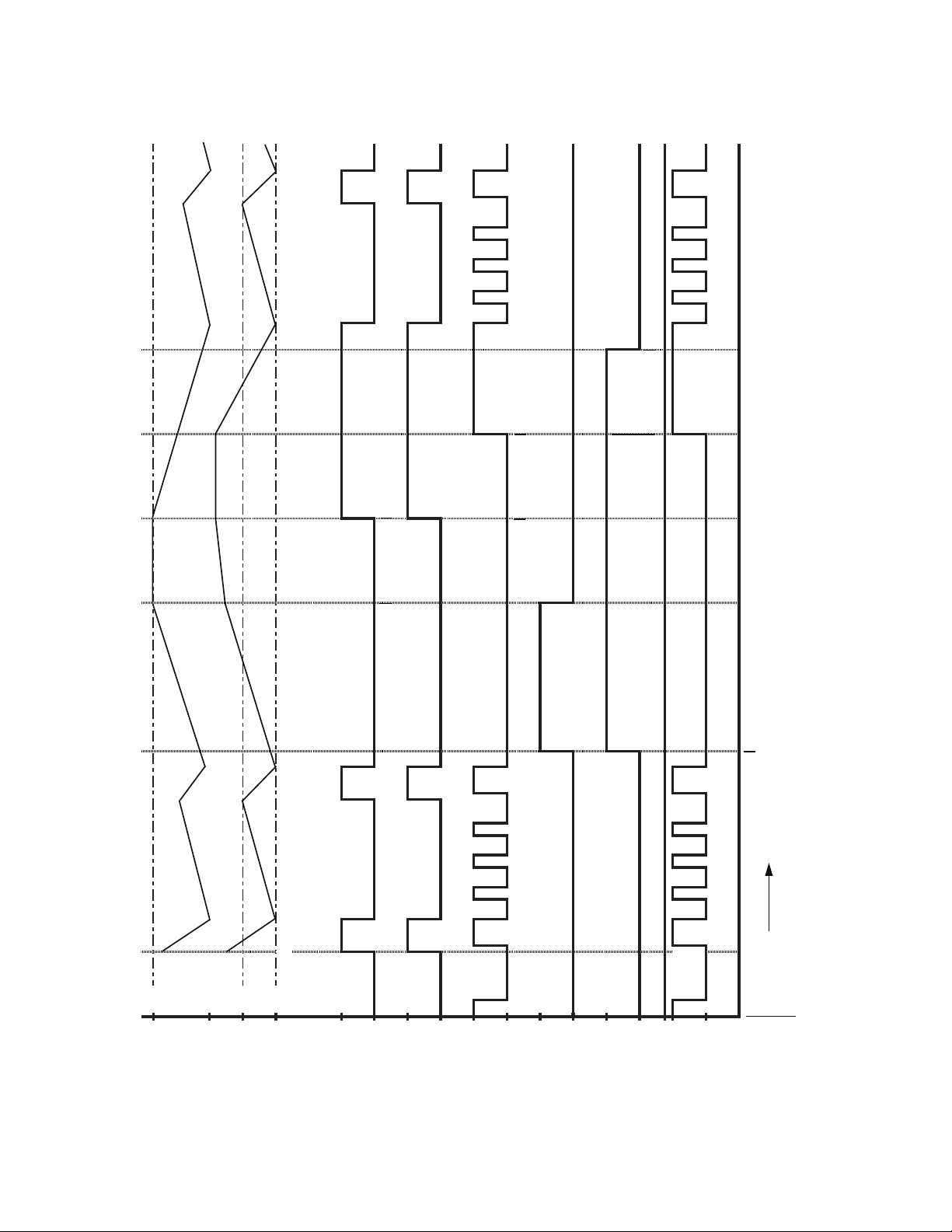

b) Timing Chart

)y

TIME-TEMPERATURE CONTROL CHART [DURING ENERGY SAVING MODE] FOR

FREEZERS (ALL UNITS)

Freezers – Energy Saving Operating Mode

*

)sdoireP FFO rosserpmoC llA(

tnettimretnI

noitarepO

)yaleD yalpsiD(

.nim 8

rehtegot trats esiwrehto dluow naf dna rosserpmoc

nehw yaled pu trats naf rotaropave dnoceseviF

*

)yaleD naF(

.nim 5

)yaleD niarD(

.nim 5

)noitaruD tsorfeD .xaM(

)elbatsujdA - tratS tsorfeD(

.nim 06 <

sruoh 6

*

)sdoireP FFO rosserpmoC llA(

tnettimretnI

noitarepO

)FFO .niM(

.nim 2

)NO .niM(

.nim 2

emiT

.nim 2

tratS(

aleD

)+( laitnereffiD + tniopteS

rotsimrehT tsorfeD

erutarepmeT noitanimreT tsorfeD

gninaem oN

)--( laitnereffiD + tniopteS

rotsimrehT tenibaC

rosserpmoC

FFO

NO

FFO

NO

naF resnednoC

NO

*

retaeH tsorfeD

FFO

n(s)aF rotaropavE

FFO

NO

rotacidnI tsorfeD

FFO

NO

FFO

NO

Frame Heater(s)

NO rewoP

20

Loading...

Loading...