Page 1

NO:

ISSUED:

REVISED:

73113

June 7, 2004

June 15, 2005

HOSHIZAKI

MODULAR FLAKER

MODEL

F-801MAH/-C

F-801MWH/-C

SERVICE MANUAL

Page 2

IMPORTANT

Only qualified service technicians should attempt to service or maintain this

icemaker. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: HOSHIZAKI Technical Support Department

Phone: 1-800-233-1940 Technical Service

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

Web Site: www.hoshizakiamerica.com

Note: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

Page 3

Please review this manual. It should be read carefully before the icemaker is serviced or

maintenance operations are performed. Only qualified service technicians should service

and maintain the icemaker. This manual should be made available to the technician prior

to service or maintenance.

CONTENTS

I. Specification ...................................................................................................................... 5

1. Icemaker ....................................................................................................................... 5

F-801MAH.................................................................................................................. 5

F-801MWH ................................................................................................................. 6

F-801MAH-C .............................................................................................................. 7

F-801MWH-C ............................................................................................................. 8

II. General Information .......................................................................................................... 9

1. Construction .................................................................................................................9

F-801MAH/-C ............................................................................................................. 9

F-801MWH/-C .......................................................................................................... 10

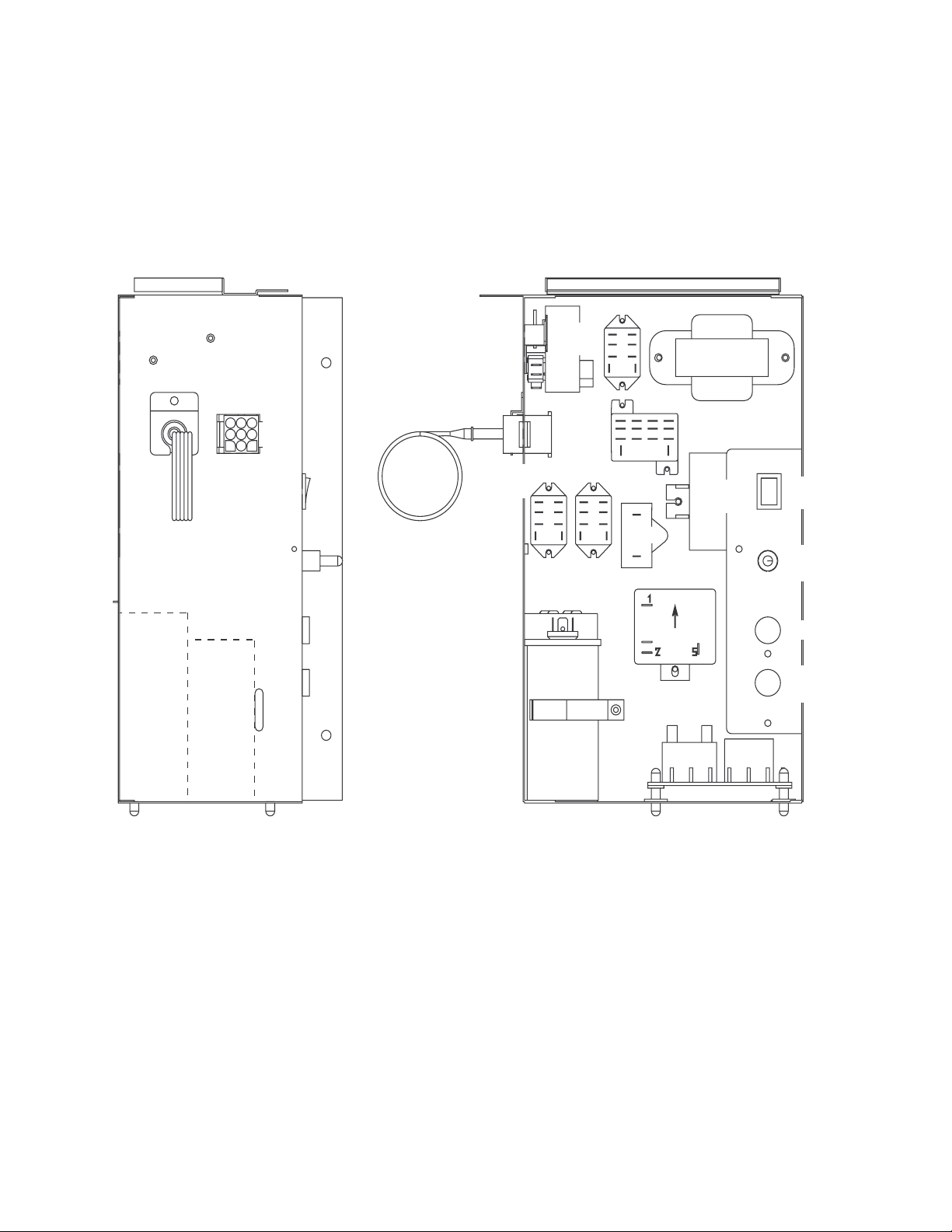

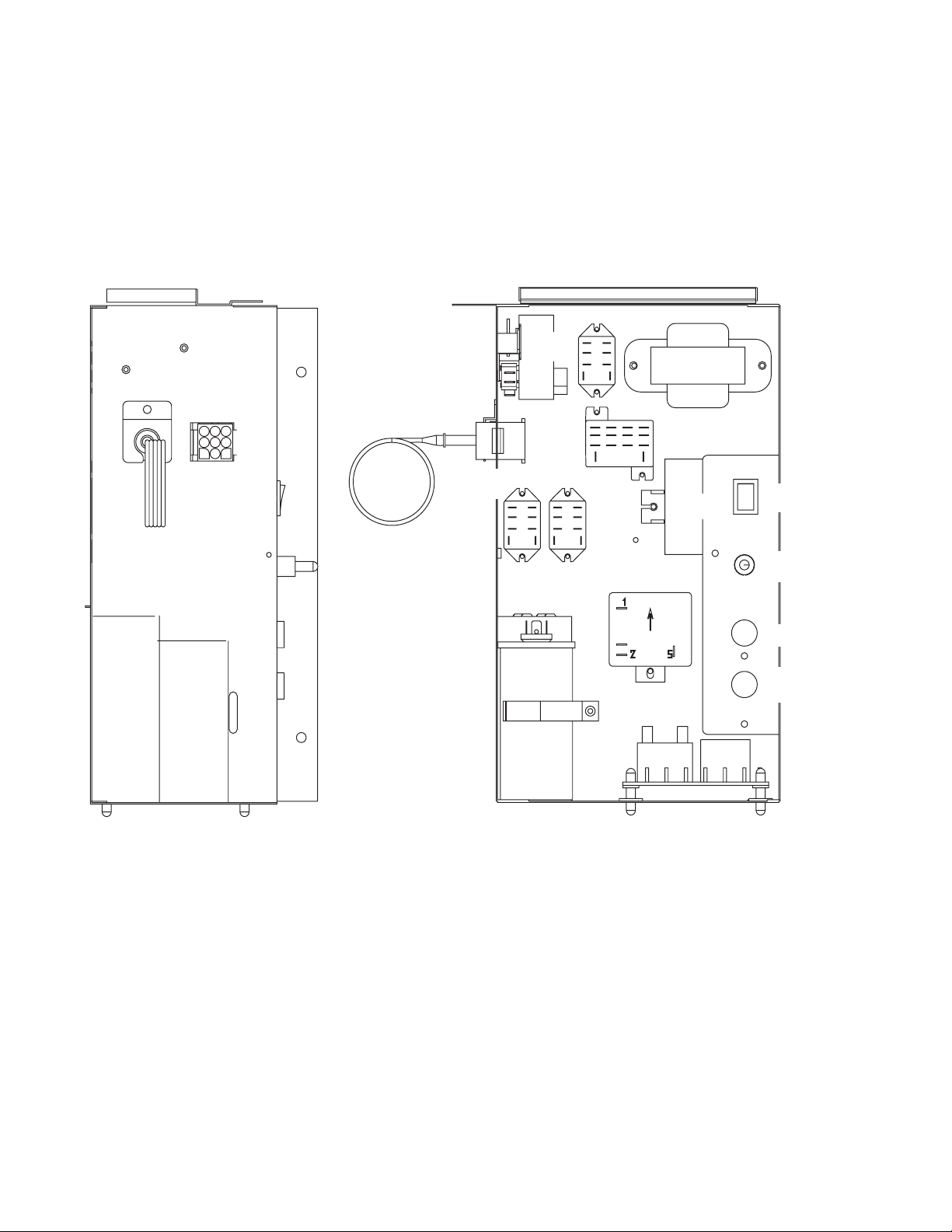

2. Control Box Layout ..................................................................................................... 11

F-801MAH/-C ........................................................................................................... 11

F-801MWH/-C .......................................................................................................... 12

III. Technical Information ..................................................................................................... 13

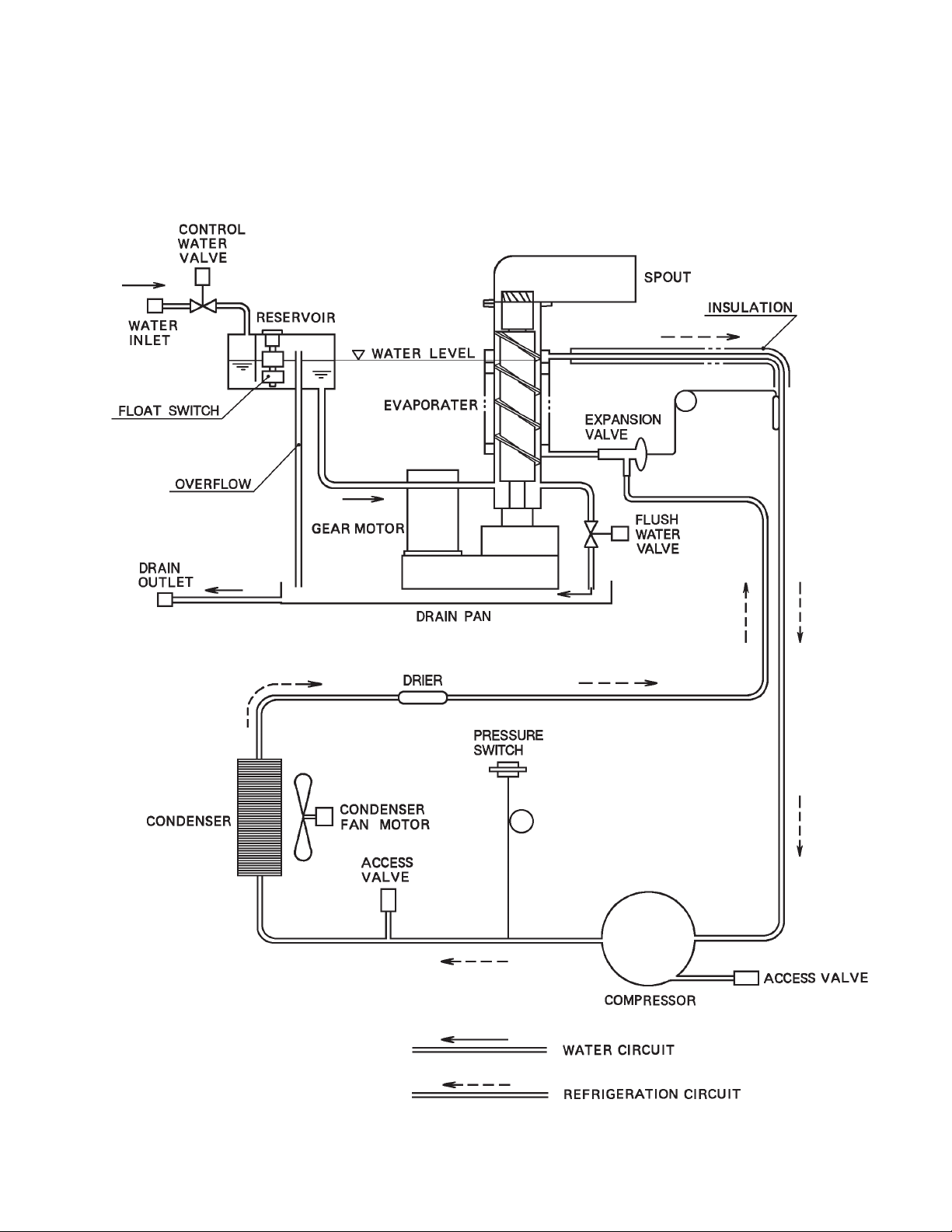

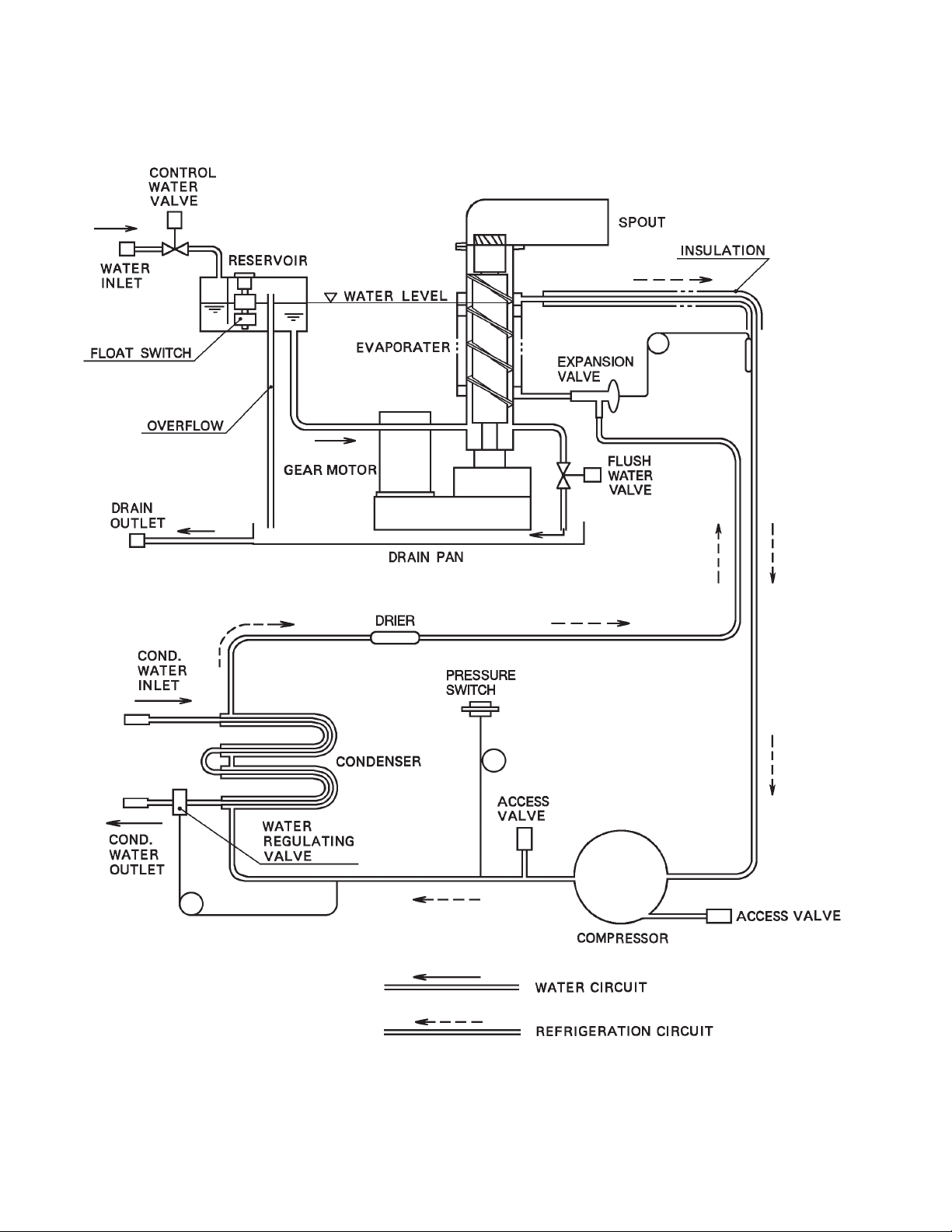

1. Water Circuit and Refrigeration Circuit........................................................................ 13

F-801MAH/-C ........................................................................................................... 13

F-801MWH/-C .......................................................................................................... 14

2. Wiring Diagrams ......................................................................................................... 15

F-801MAH/-C, F-801MWH/-C .................................................................................. 15

3. Sequence of Electrical Circuit .................................................................................... 16

4. Timing Chart ............................................................................................................... 26

5. Performance Data ....................................................................................................... 29

F-801MAH................................................................................................................ 29

F-801MWH ............................................................................................................... 30

F-801MAH-C ............................................................................................................ 31

F-801MWH-C ........................................................................................................... 32

IV. Adjustment of Components ............................................................................................ 33

1. Adjustment of Water Regulating Valve (water-cooled model only) .............................. 33

2. Adjustment of Flake Size ............................................................................................ 34

V. Service Diagnosis ........................................................................................................... 35

1. No Ice Production ....................................................................................................... 35

2. Low Ice Production ..................................................................................................... 37

3. Other ........................................................................................................................... 38

VI. Removal and Replacement of Components .................................................................. 39

1. Service for Refrigerant Lines ...................................................................................... 39

[a] Refrigerant Recovery........................................................................................... 39

[b] Evacuation and Recharge [R-404A] .................................................................... 39

2. Brazing ....................................................................................................................... 40

3. Removal and Replacement of Compressor ................................................................ 41

4. Removal and Replacement of Drier ........................................................................... 42

3

Page 4

5. Removal and Replacement of Expansion Valve......................................................... 43

6. Removal and Replacement of Water Regulating Valve (water-cooled model only) .... 44

7. Removal and Replacement of Evaporator Assembly ................................................. 45

8. Removal and Replacement of Fan Motor ................................................................... 49

9. Removal and Replacement of Control Water Valve .................................................... 49

10. Removal and Replacement of Flush Water Valve ..................................................... 50

VII. Cleaning and Maintenance .......................................................................................... 51

1. Preparing the Icemaker for Long Storage ................................................................... 51

2. Cleaning and Sanitizing Instructions .......................................................................... 52

[a] Cleaning Solution ................................................................................................ 52

[b] Cleaning Procedure ............................................................................................ 53

[c] Sanitizing Solution............................................................................................... 54

[d] Sanitizing Procedure - Initial................................................................................ 54

[e] Sanitizing Procedure - Final ................................................................................ 55

3. Maintenance ............................................................................................................... 57

4

Page 5

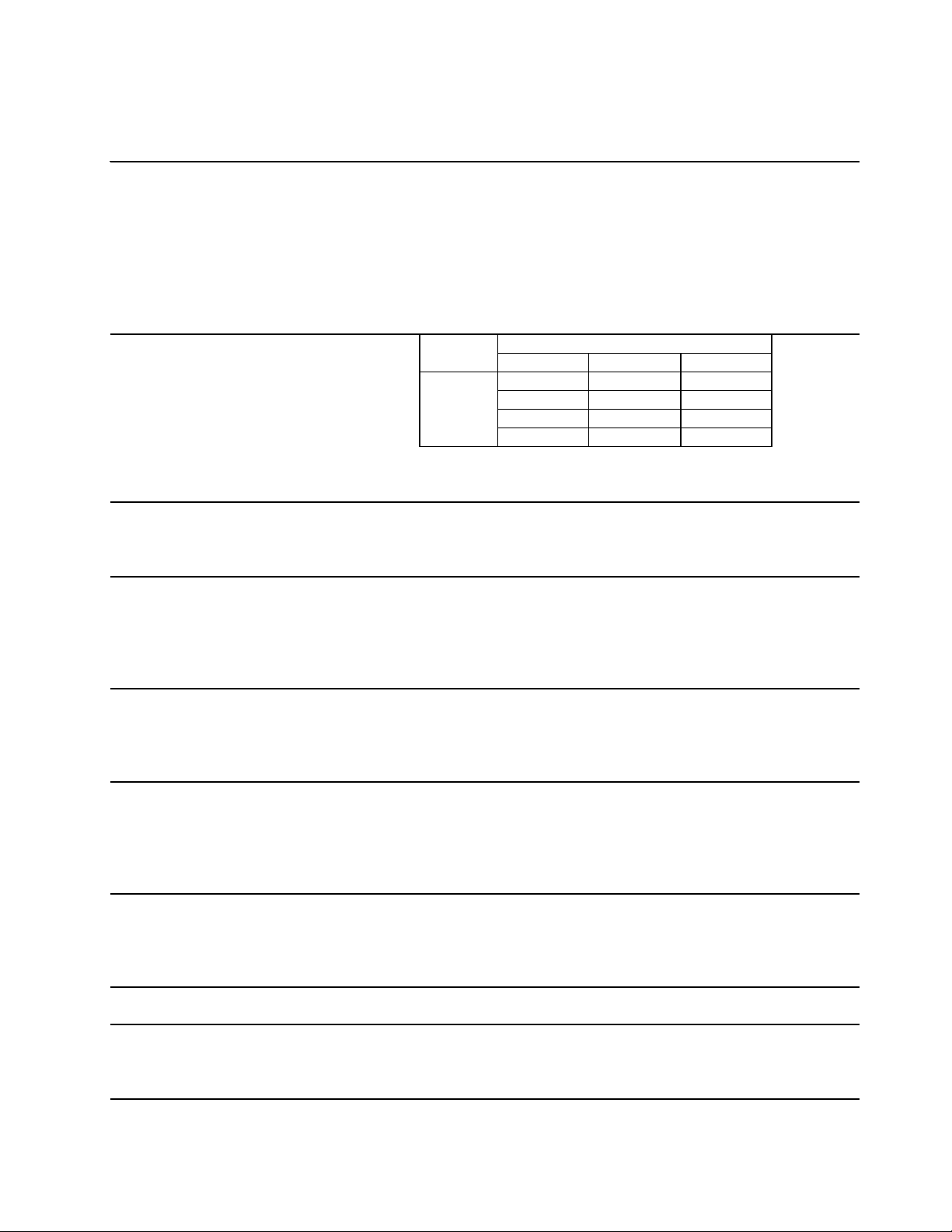

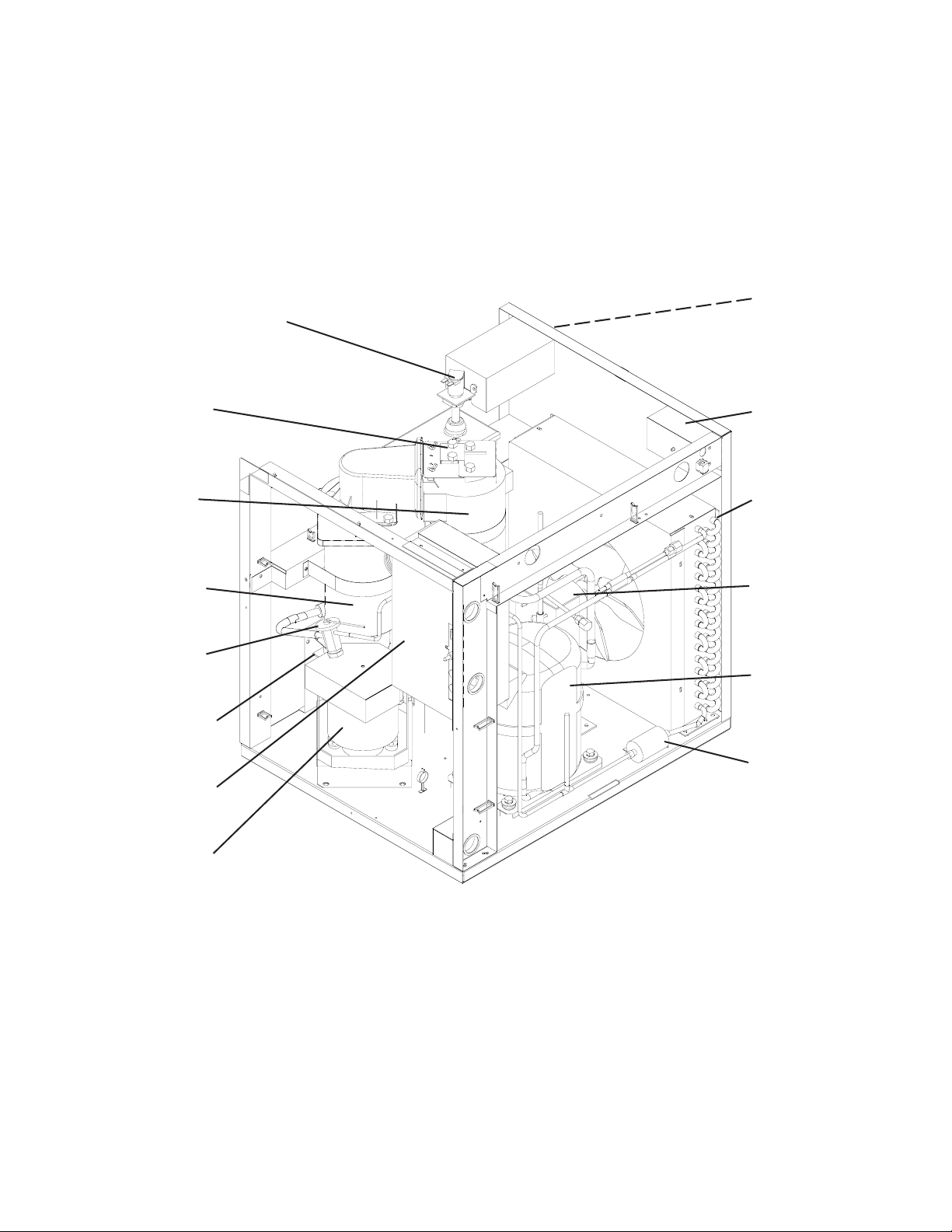

I. Specification

T

r

1. Icemaker

F-801MAH

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 9.4 RLA 51 LRA

GEAR MOTOR 120 V 3 FLA 1/4 HP

FAN MOTOR 115 V 0.85 FLA 1/15 HP

OTHER 120 V 0.03 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient

PER 24 HR. Temp.(°F)

lbs./day ( kg/day ) 70 * 823 (373) 786 (357) 748 (339)

Reference without *marks 80 711 (323) 677 (307) 644 (292)

90 613 (278) * 599 (272) 555 (252)

100 528 (239) 502 (228) * 471 (214)

SHAPE OF ICE Flake

ICE QUALITY Approx. 70%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1131 (4.5) 1089 (3.2)

POTABLE WATER 72 (12) 99 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 22" x 27-3/8" x 25-15/16" (560 x 695 x 658mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 176 lbs. ( 80 kg ), Shipping 207 lbs. ( 94 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FP

- DRAIN Outlet 3/4" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4HP Gear Motor )

ICE MAKING W ATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic , Model RS43-C2E-CAA

CONDENSER Air-cooled, Fin and Tube Type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, (800 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

PC BOARD CIRCUIT PROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Fuse (3A)

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pres sure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

1lb 12oz

WATER TEMP. (°F)

50

70 90

We reserve the right to make changes in specifications and design without prior notice.

5

Page 6

F-801MWH

T

r

r

r

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 8.5 RLA 51 LRA

GEAR MOTOR 120 V 3 FLA 1/4 HP

OTHER 120 V 0.03 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient

PER 24 HR. Temp.(°F)

lbs./day ( kg/day ) 70 * 720 (327) 693 (315) 677 (307)

Reference without *marks 80 661 (300) 646 (293) 630 (286)

90 616 (279) * 605 (274) 587 (266)

100 573 (260) 560 (254) * 520 (236)

SHAPE OF ICE Flake

ICE QUALITY Approx. 70%, Ice (90/70°F, Conductivity 200 µs/c m)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1078 (4.3) 1076 (3.6)

POTABLE WATER 72 (12) 86 (12)

WATER-COOLED CONDENSER 360 (60) 219 (31)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 22" x 27-3/8" x 25-15/16" (560 x 695 x 658mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 176 lbs. ( 80 kg ), Shipping 207 lbs. ( 94 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT Cond. Inlet 1/2" FPT

- DRAIN Outlet 3/4" FP

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4HP Gear Motor )

ICE MAKING WA TER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model RS43-C2E-CAA

CONDENSER Water-cooled, tube in tube type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Ex pansion Valve

REFRIGERANT CHARGE R-404A, (470 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

PC BOARD CIRCUIT P ROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Auto-reset Overload Protecto

GEAR MOTOR PROTECTION Fuse (3A)

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LO W W A TER P RO TECTIO N Float S wi tch and Tim e

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

1lb 1oz

WATER TEMP. (°F)

50

70 90

Cond. Outlet 3/8" FPT

We reserve the right to make changes in specifications and design without prior notice.

6

Page 7

F-801MAH-C

T

r

r

r

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 9.4 RLA 51 LRA

GEAR MOTOR 120 V 3 FLA 1/4 HP

FAN MOTOR 115 V 0.85 FLA 1/15 HP

OTHER 120 V 0.03 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient

PER 24 HR. Temp.(°F)

lbs./day ( kg/day ) 70 * 752 (341) 728 (330) 688 (312)

Reference without *marks 80 650 (295) 614 (279) 580 (263)

90 548 (249) * 552 (250) 490 (222)

100 463 (210) 437 (198) * 405 (184)

SHAPE OF ICE Cubelet

ICE QUALITY Approx. 80%, Ice (90/70°F, Conductivity 200 µs/c m)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1169 (5.1) 1110 (3.5)

POTABLE WATER 66 (12) 90 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 22" x 27-3/8" x 25-15/16" (560 x 695 x 658mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 176 lbs. ( 80 kg ), Shipping 207 lbs. ( 94 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FP

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4HP Gear Motor )

ICE MAKING WA TER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model RS43-C2E-CAA

CONDENSER Air-cooled, Fin and Tube Type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Ex pansion Valve

REFRIGERANT CHARGE R-404A, (800 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

PC BOARD CIRCUIT P ROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Auto-reset Overload Protecto

GEAR MOTOR PROTECTION Fuse (3A)

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LO W W A TER P RO TECTIO N Float S wi tch and Tim e

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

1lb 12oz

WATER TEMP. (°F)

50

70 90

We reserve the right to make changes in specifications and design without prior notice.

7

Page 8

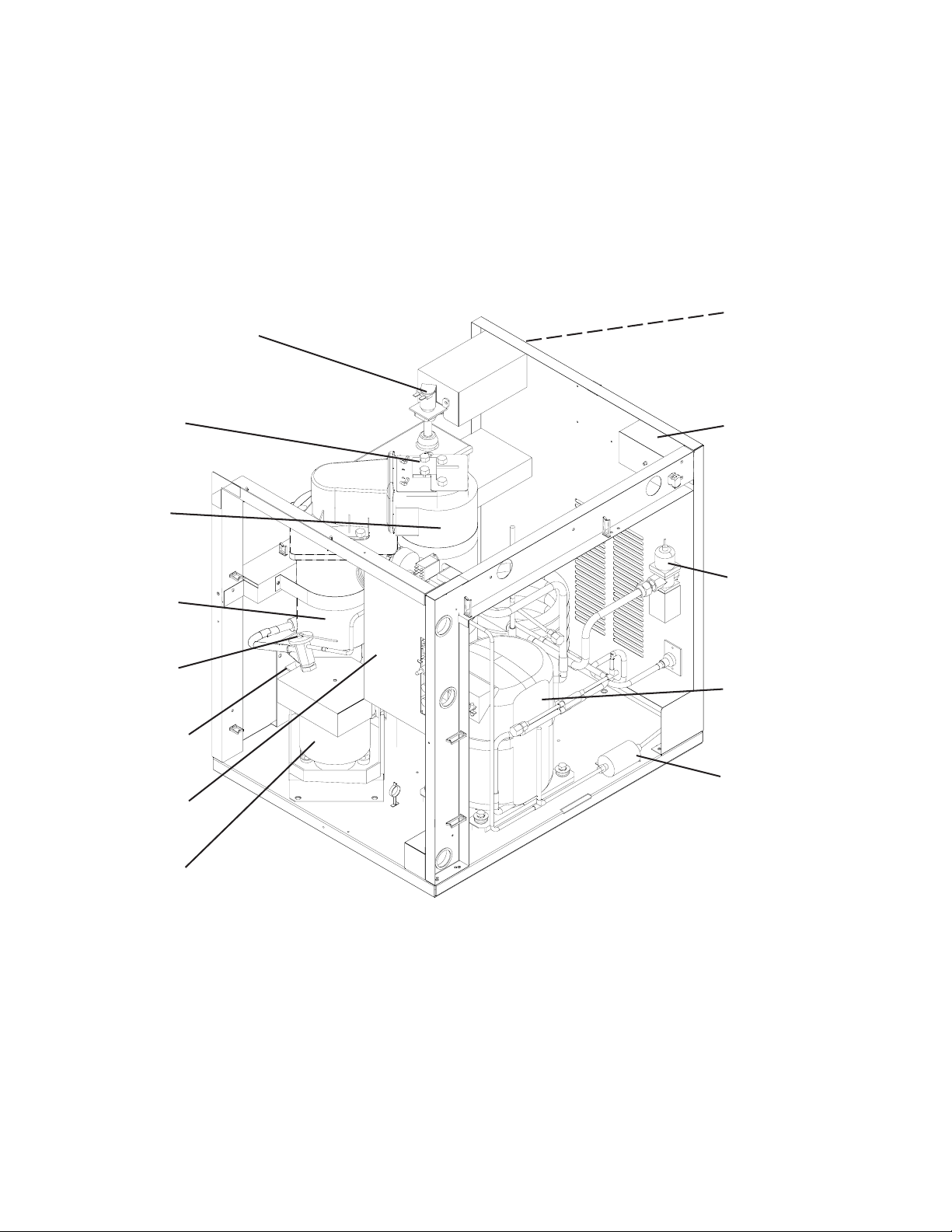

F-801MWH-C

T

T

T

r

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 8.5 RLA 51 LRA

GEAR MOTOR 120 V 3 FLA 1/4 HP

OTHER 120 V 0.03 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient

PER 24 HR. Temp.(°F)

lbs./day ( kg/day ) 70 * 645 (293) 620 (281) 608 (276)

Reference without *marks 80 596 (270) 585 (265) 574 (260)

90 563 (255) * 550 (249) 541 (246)

100 531 (241) 521 (236) * 485 (220)

SHAPE OF ICE Cubelet

ICE QUALITY Approx. 80%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY N/A

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1075 (4.7) 1083 (4.1)

POTABLE WATER 66 (12) 77 (12)

WATER-COOLED CONDENSER 302 (55) 199 (31)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 22" x 27-3/8" x 25-15/16" (560 x 695 x 658mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 176 lbs. ( 80 kg ), Shipping 207 lbs. ( 94 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FP

- DRAIN Outlet 3/4" FPT Cond. Outlet 3/8" FP

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4HP Gear Motor )

ICE MAKING W ATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRES SOR Hermetic , Model RS43-C2E-CAA

CONDENSER Water-cooled, tube in tube type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, (470 g)

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

PC BOARD CIRCUIT PROTECTION High Voltage Cut-off Relay

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Fuse (3A)

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pres sure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

We reserve the right to make changes in specifications and design without prior notice.

1lb 1oz

WATER TEMP. (°F)

50

70 90

Cond. Inlet 1/2" FP

8

Page 9

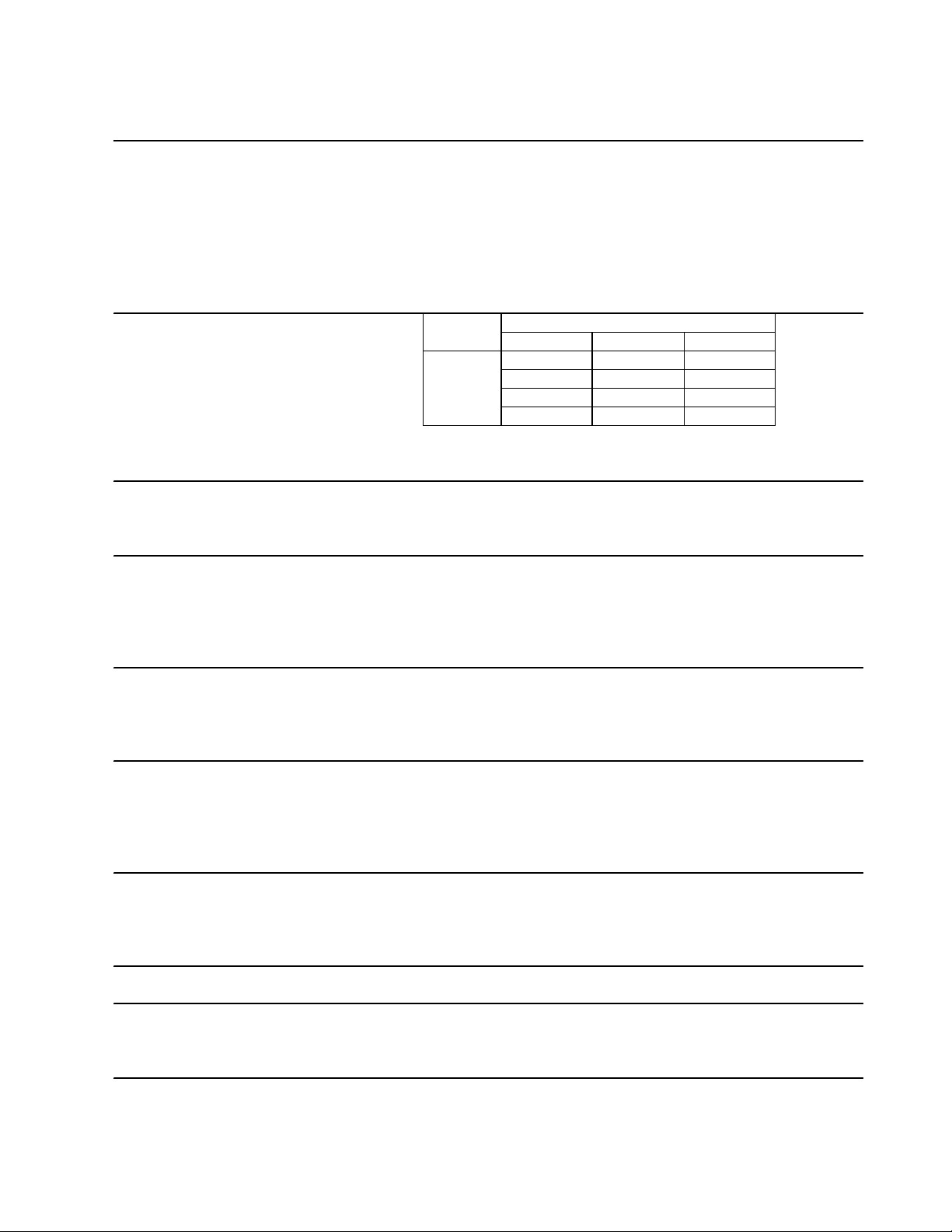

II. General Information

1. Construction

F-801MAH/-C

Control Water Valve

Water Supply

Inlet

Bin Control

Ice Chute

Evaporator

Expansion

Valve

Flush Water

Valve

Control Box

Gear Motor

Junction Box

Condenser

Fan Motor

Compressor

Drier

9

Page 10

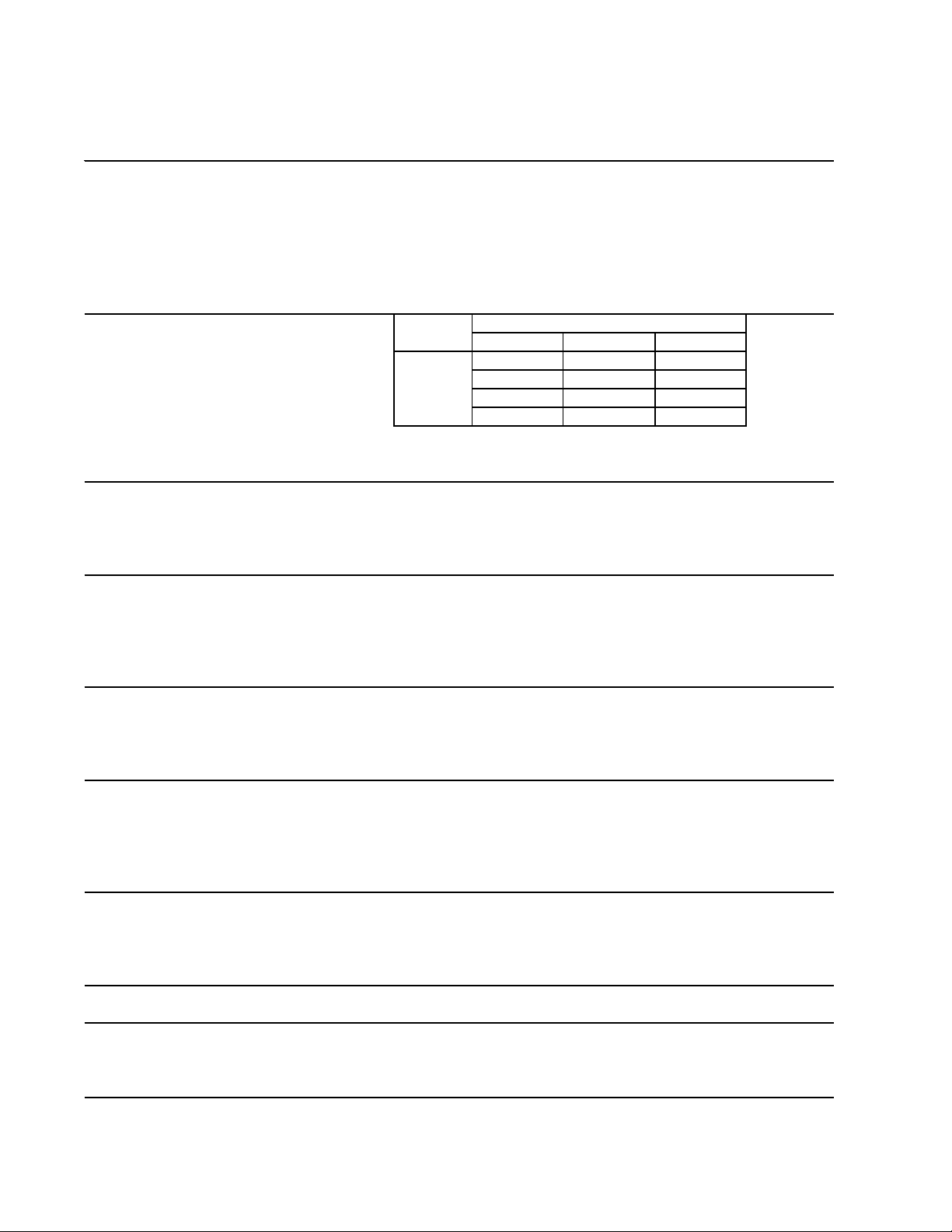

F-801MWH/-C

Control Water Valve

Water Supply

Inlet

Bin Control

Ice Chute

Evaporator

Expansion

Valve

Flush Water

Valve

Control Box

Gear Motor

Junction Box

Water

Regulator

Compressor

Drier

10

Page 11

2. Control Box Layout

)

F-801MAH/-C

CONNECTOR

PRESSURE

SWITCH

FLUSH

TIMER

GEAR

MOTOR

RELAY

CIRCUIT PROTECT

RELAY

GEAR MOTOR

PROTECT RELAY

WATER CONTROL

RELAY

FAN

MOTOR

CAP

STARTER

TRANSFORMER

FLUSH

GEAR

MOTOR

CAP.

FLUSH

SWITCH

ICE

POWER

SWITCH

START

CAPACITOR

RUN

CAPACITOR

CONTROL

TIMER

Note: The above component names are identical with the wiring label, but not with

the parts list.

FUSE

FUSE

(GEAR MOTOR

11

Page 12

F-801MWH/-C

CONNECTOR

PRESSURE

SWITCH

FLUSH

TIMER

GEAR

MOTOR

RELAY

CIRCUIT PROTECT

RELAY

GEAR MOTOR

PROTECT RELAY

WATER CONTROL

RELAY

STARTER

TRANSFORMER

GEAR

MOTOR

CAP.

FLUSH

ICE

FLUSH

SWITCH

POWER

SWITCH

START

CAPACITOR

RUN

CAPACITOR

CONTROL

TIMER

FUSE

FUSE

(GEAR MOTOR)

12

Page 13

III. Technical Information

1. Water Circuit and Refrigeration Circuit

F-801MAH/-C

13

Page 14

F-801MWH/-C

14

Page 15

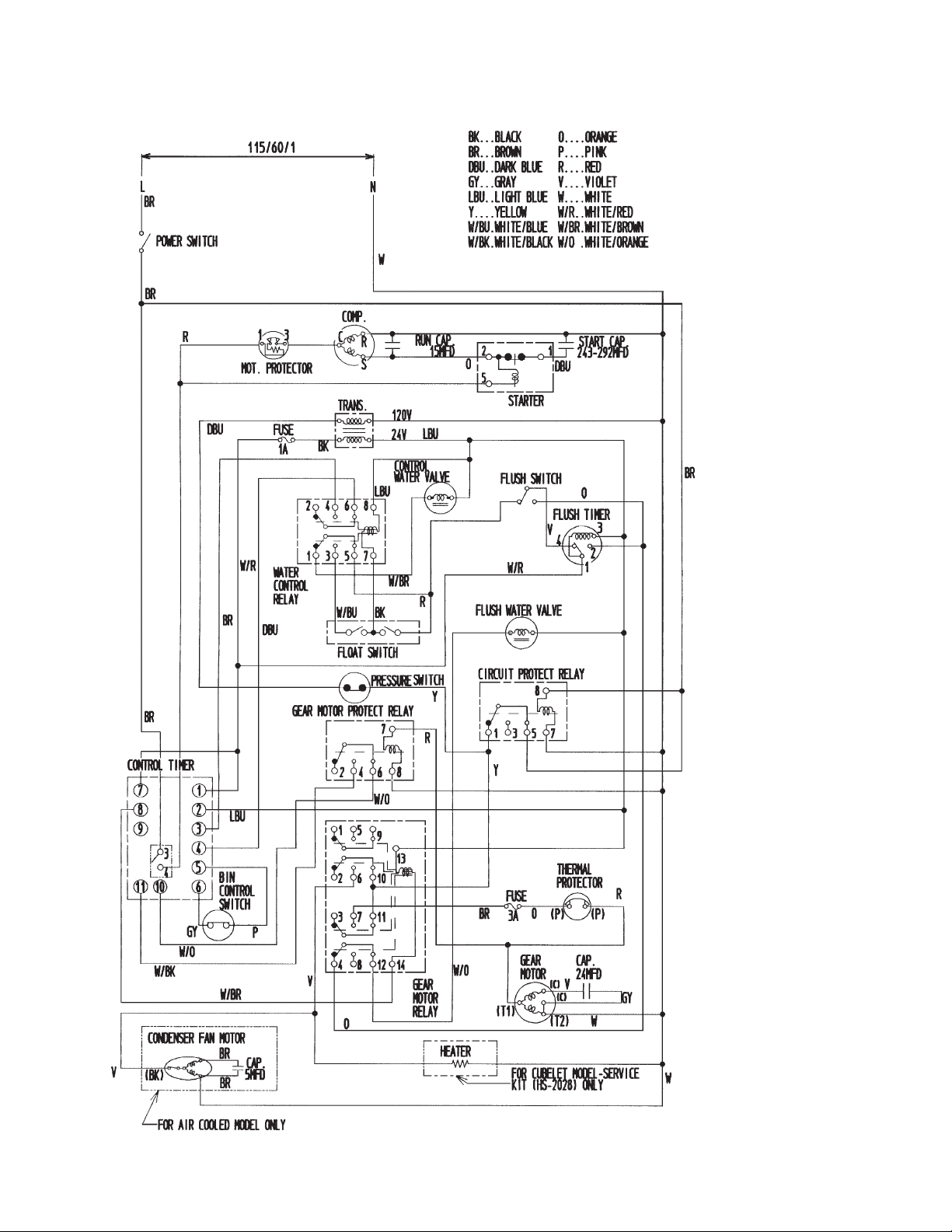

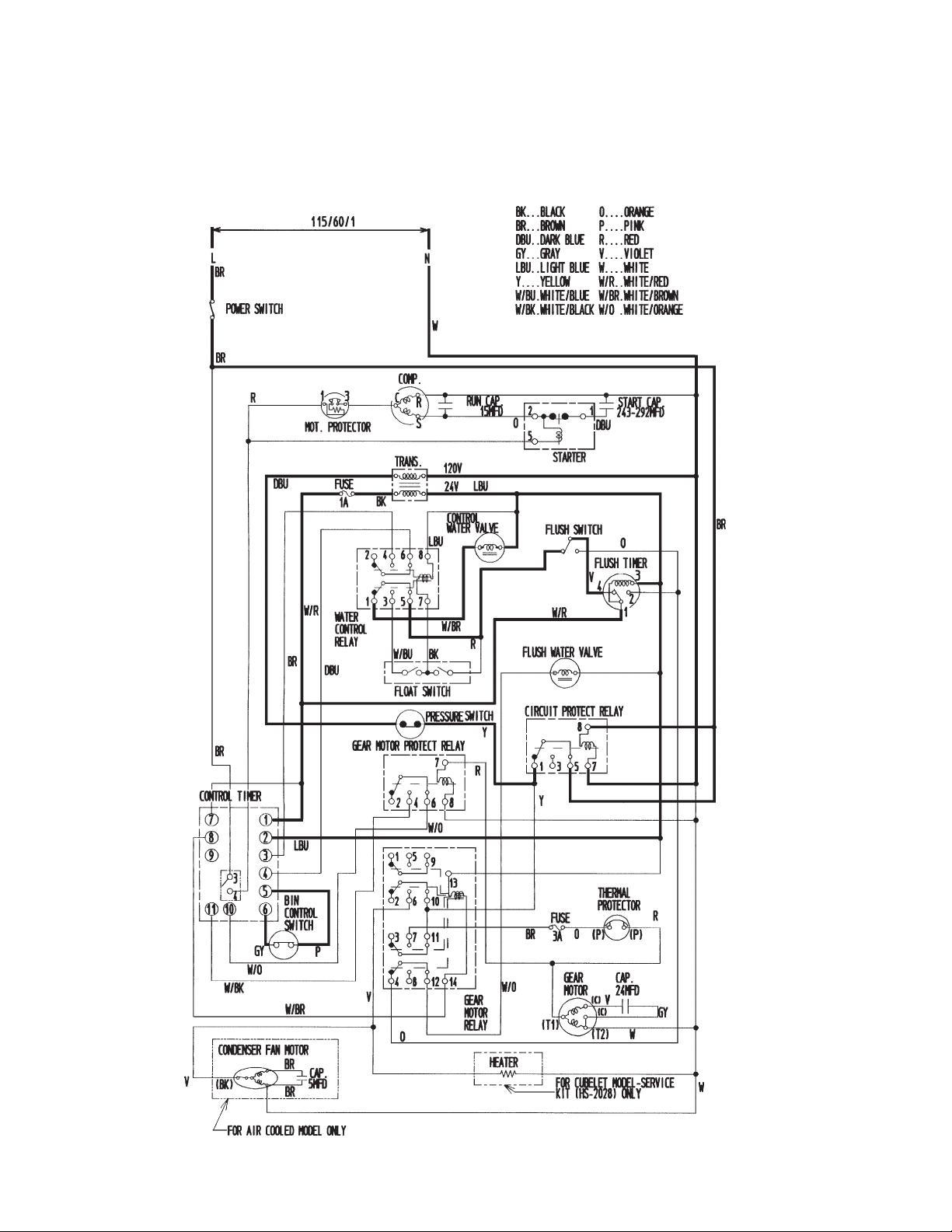

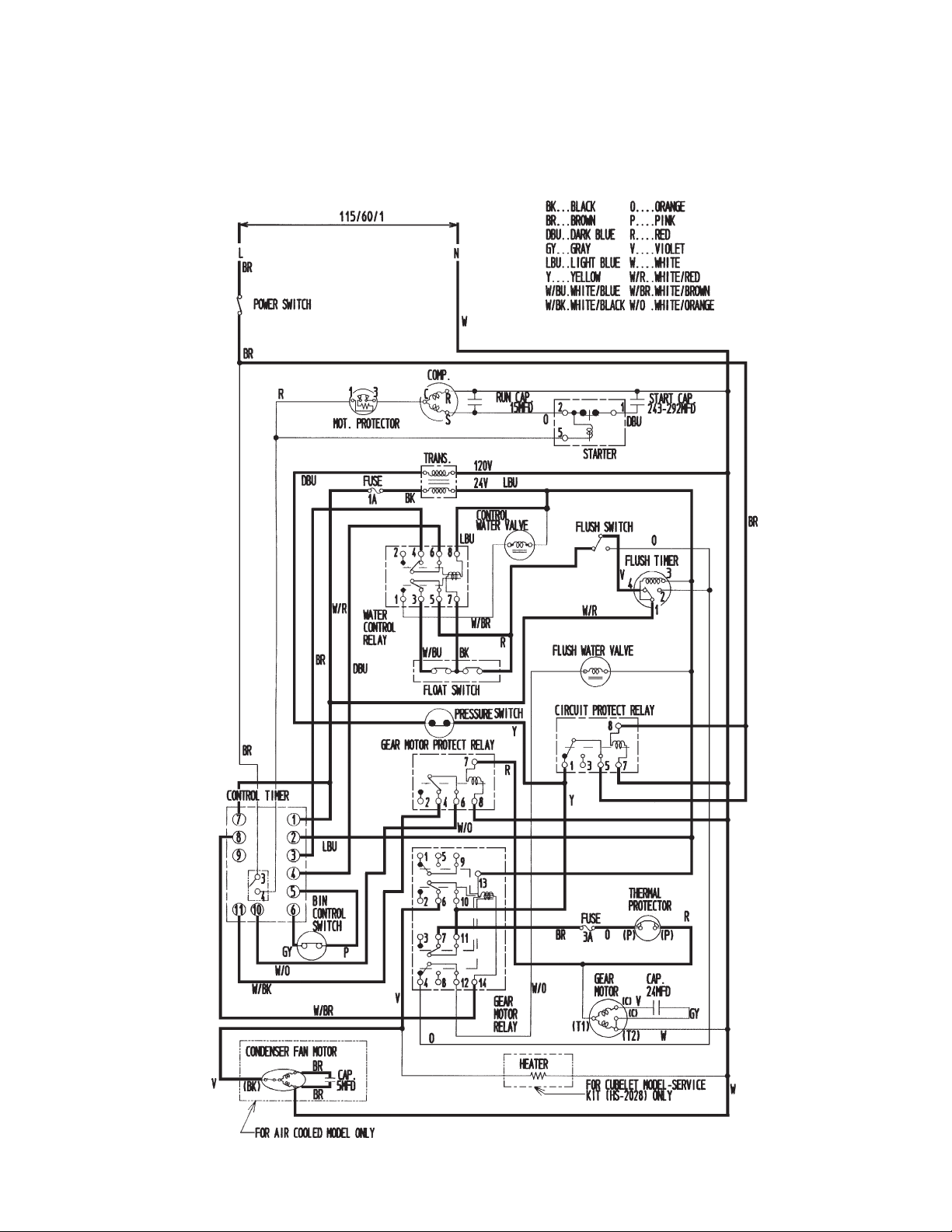

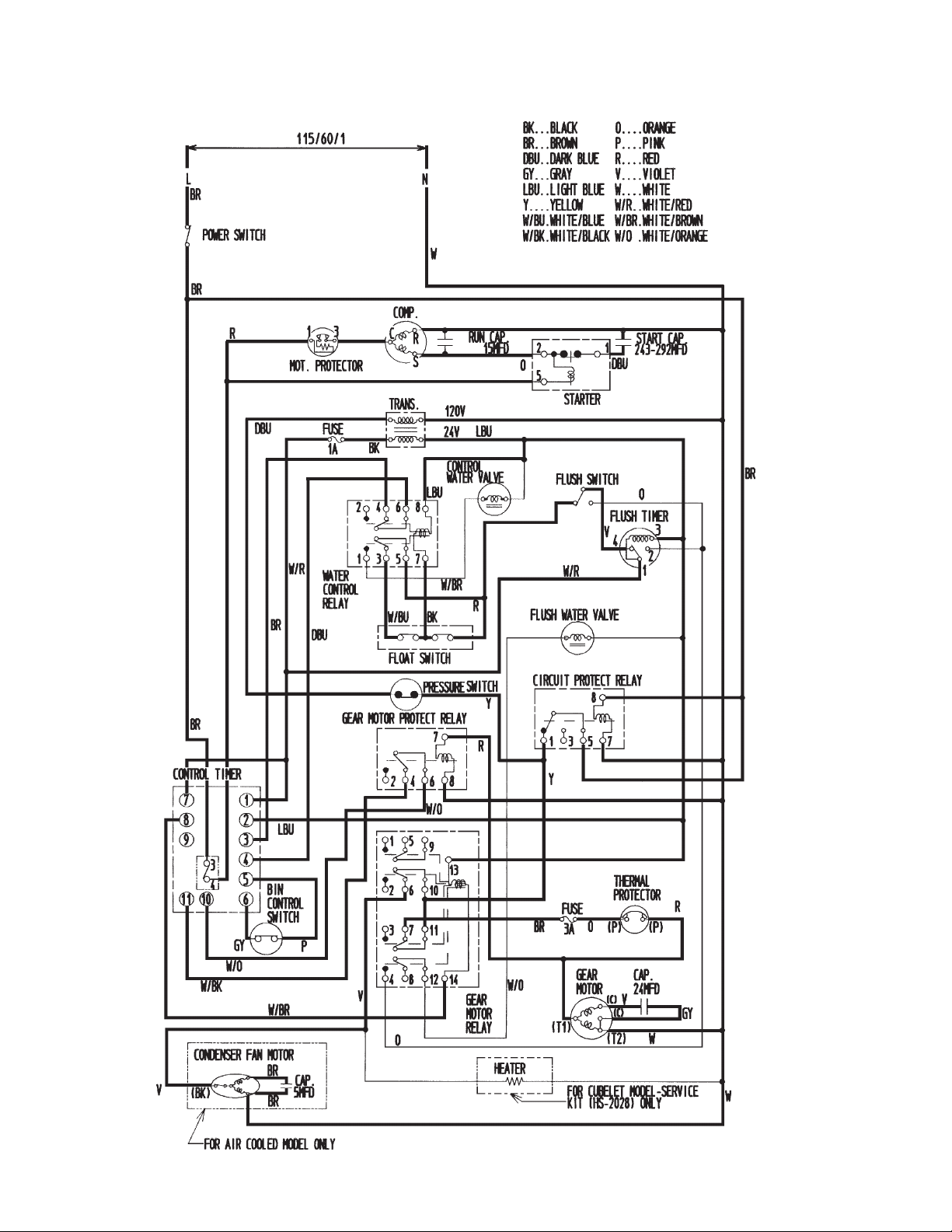

2. Wiring Diagrams

F-801MAH/-C, F-801MWH/-C

15

Page 16

3. Sequence of Electrical Circuit

[a] When power switch is moved to “ON” position and flush switch to “ICE” position,

water starts to be supplied to reservoir.

16

Page 17

[b] When reservoir has been filled, gear motor starts immediately.

17

Page 18

[c] Compressor starts about 60 sec. after gear motor starts.

18

Page 19

[d] Bin control operates, and about 6 sec. later, compressor and gear motor stop

simultaneously.

19

Page 20

[e] Low water (except water-cooled model).

20

Page 21

[f] Low water (water-cooled model), or dirty air filter (air-cooled model), pressure

switch to “OPEN”, compressor and gear motor operate intermittently.

21

Page 22

[g] When flush switch is moved to “FLUSH” position, flush water valve opens and

flushes reservoir and evaporator.

22

Page 23

[h] When flush timer operates (for 15 min. every 12 hours).

23

Page 24

[i] When 208-230V are supplied to circuit protect relay, it protects the circuit from

miswiring. If the power supply is properly connected, the contact of circuit protect

relay does not move even when the coil is energized.

24

Page 25

[j] When input voltage is too low, (less than 70%), gear motor fuse (1.5A) is blown

causing the compressor and gear motor to turn off immediately.

25

Page 26

4. Timing Chart

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

ON

OFF

UPPER

LOWER

BOTTOM

Miswiring. Circuit Protect Relay operates.)

Proper wiring. The unit starts.

BIN CONTROL

OFF ON

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

7. FLUSH SWITCH

8. FLUSH WATER

VALV E

9. BIN CONTROL

10. GEAR MOTOR

RELAY

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

FLUSH

ICE

ON

OFF

ON

OFF

ON

OFF

1 sec

6 sec 1 sec

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

14. PRESSURE

SWITCH

ON

OFF

ON

OFF

ON

OFF

ON

OFF

60 sec

60 sec

26

Page 27

LOW WATER

FLUSH TIMER

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

7. FLUSH SWITCH

ON

OFF

UPPER

LOWER

BOTTOM

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

FLUSH

ICE

21 min every 12 hr

8. FLUSH WATER

VALV E

9. BIN CONTROL

10. GEAR MOTOR

RELAY

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

14. PRESSURE

SWITCH

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

150 sec

90 sec 60 sec 90 sec 60 sec

1 sec

150 sec

1 sec

27

Page 28

FLUSH

FLUSH SWITCH PRESSURE SWITCH

ICE

OFF ON

1. CIRCUIT PROTECT

RELAY

2. WATER LEVEL

UPPER

3. FLOAT

SWITCH

LOWER

4. WATER CONTROL

RELAY

5. CONTROL WATER

VALV E

6. FLUSH TIMER

7. FLUSH SWITCH

ON

OFF

UPPER

LOWER

BOTTOM

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1 - 2

2 - 3

FLUSH

ICE

8. FLUSH WATER

VALV E

9. BIN CONTROL

10. GEAR MOTOR

RELAY

11. GEAR MOTOR

12. FAN MOTOR

13. COMPRESSOR

14. PRESSURE

SWITCH

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

150 sec

90 sec 60 sec

1 sec

1 sec

60 sec

28

Page 29

5. Performance Data

F-801MAH

APPROXIMATE Ambient Water Temp. (F)

ICE PRODUCTION Temp. (F)

PER 24 HR. 70 * 823 (373) 786 (357) 748 (339)

80 711 (323) 677 (307) 644 (292)

90 613 (278) * 599 (272) 555 (252)

lbs./day ( kg/day) 100 528 (239) 502 (228) * 471 (214)

APPROXIMATE ELECTRIC 70 * 1089 -- 1095 -- 1101 -CONSUMPTION 80 1107 -- 1113 -- 1119 --

90 1125 -- *1131 -- 1147 -watts 100 1164 -- 1181 -- *1197 -APPROXIMATE WATER 70 * 99 (374) 94 (357) 90 (340)

CONSUMPTION PER 24 HR. 80 85 (323) 81 (308) 77 (293)

(TOTAL) 90 74 (278) * 72 (272) 67 (252)

gal. / day (l/day) 100 63 (240) 60 (228) * 57 (214)

EVAPORATOR OUTLET TEMP. 70 * 15 (-10) 16 (-9) 16 (-9)

°F (°C) 80 16 (-9) 16 (-9) 17 (-8)

90 17 (-8) * 17 (-8) 18 (-8)

100 19 (-7) 19 (-7) * 20 (-7)

HEAD PRESSURE 70 * 204 (14.3) 266 (18.7) 302 (21.2)

80 204 (14.3) 266 (18.7) 302 (21.2)

PSIG (kg/cm

SUCTION PRESSURE 70 * 38 (2.7) 42 (3.0) 46 (3.3)

PSIG (kg/cm

TOTAL HEAT OF REJECTION

2

G)

2

G) 80 38 (2.7) 42 (3.0) 46 (3.3)

90 204 (14.3) * 266 (18.7) 302 (21.2)

100 204 (14.3) 266 (18.7) * 302 (21.2)

90 38 (2.7) * 42 (3.0) 46 (3.3)

100 38 (2.7) 42 (3.0) * 46 (3.3)

50 70 90

6398 BTU/h (AT 90°F / WT 70°F)

Note: The data without *marks should be used for reference.

We reserve the right to make changes in specifications and design without prior notice.

29

Page 30

F-801MWH

APPROXIMATE Ambient Water Temp. (F)

ICE PRODUCTION Temp. (F)

PER 24 HR. 70 * 720 (327) 693 (315) 677 (307)

80 661 (300) 646 (293) 630 (286)

90 616 (279) * 605 (274) 587 (266)

lbs./day ( kg/day) 100 573 (260) 560 (254) * 520 (236)

APPROXIMATE ELECTRIC 70 * 1076 -- 1076 -- 1076 -CONSUMPTION 80 1076 -- 1077 -- 1077 --

90 1077 -- *1078 -- 1076 -watts 100 1074 -- 1071 -- *1069 -APPROXIMATE W ATER 70 * 306 (1158) 397 (1504) 631 (2387)

CONSUMPTION PER 24 HR. 80 318 (1205) 415 (1571) 666 (2520)

(TOTAL) 90 331 (1251) * 433 (1638) 704 (2666)

gal. / day (l/day) 100 344 (1304) 457 (1728) * 778 (2944)

EVAPORATOR OUTLET TEMP. 70 * 17 (-8) 17 (-8) 18 (-8)

°F (°C) 80 19 (-7) 19 (-7) 20 (-7)

90 20 (-7) * 20 (-7) 20 (-7)

100 20 (-7) 20 (-7) * 21 (-6)

HEAD PRESSURE 70 * 265 (18.6) 265 (18.6) 266 (18.7)

80 265 (18.6) 265 (18.6) 266 (18.7)

90 265 (18.6) * 265 (18.6) 266 (18.7)

PSIG (kg/cm

2

G)

100 265 (18.6) 265 (18.6) * 266 (18.7)

SUCTION PRESSURE 70 * 42 (3.0) 43 (3.0) 44 (3.1)

PSIG (kg/cm

2

G) 80 42 (3.0) 43 (3.0) 44 (3.1)

90 42 (3.0) * 43 (3.0) 44 (3.1)

100 42 (3.0) 43 (3.0) * 44 (3.1)

WATER FLOW FOR CONDENSER 15 gal/h (AT 90°F / WT 70°F)

PRESSURE DROP OF COOLING WATER LINE Less than 7 PSIG

HEAT OF REJECTION FROM CONDENS ER

HEAT OF REJECTION FROM COMPRESSOR 1050 BTU/h (AT 90°F / WT 70°F)

50 70 90

5155 BTU/h (AT 90°F / WT 70°F)

Note: The data without *marks should be used for reference.

We reserve the right to make changes in specifications and design without prior notice.

30

Page 31

F-801MAH-C

APPROXIMATE Ambient Water Temp. (F)

ICE PRODUCTION Temp. (F)

PER 24 HR. 70 * 752 (341) 728 (330) 688 (312)

80 650 (295) 614 (279) 580 (263)

90 548 (249) * 552 (250) 490 (222)

lbs./day (kg/day) 100 463 (210) 437 (198) * 405 (184)

APPROXIMATE ELECTRIC 70 * 1110 -- 1112 -- 1124 -CONSUMPTION 80 1136 -- 1148 -- 1160 --

90 1172 -- *1169 -- 1196 -watts 100 1209 -- 1222 -- *1251 -APPROXIMATE W ATER 70 * 90 (342) 87 (331) 83 (313)

CONSUMPTION PER 24 HR. 80 78 (295) 74 (279) 70 (264)

(TOTAL) 90 66 (249) * 66 (251) 59 (222)

gal. / day (l/day) 100 56 (210) 52 (199) * 49 (184)

EVAPORATOR OUTLET TEMP. 70 * 14 (-10) 14 (-10) 14 (-10)

°F (°C) 80 14 (-10) 14 (-10) 14 (-10)

90 14 (-10) * 14 (-10) 16 (-9)

100 16 (-9) 18 (-8) * 18 (-8)

HEAD PRESSURE 70 * 200 (14.0) 212 (14.9) 219 (15.4)

80 226 (15.9) 233 (16.4) 241 (16.9)

90 249 (17.5) * 265 (18.6) 265 (18.6)

PSIG (kg/cm

2

G)

100 273 (19.2) 282 (19.8) * 296 (20.8)

SUCTION PRESSURE 70 * 38 (2.7) 41 (2.9) 42 (2.9)

2

PSIG (kg/cm

G) 80 42 (2.9) 42 (3.0) 42 (3.0)

90 43 (3.0) * 43 (3.0) 43 (3.0)

100 43 (3. 1) 44 (3.1) * 48 (3.3)

TOTAL HEAT OF REJECTION

6398 BTU/h (AT 90°F / WT 70°F)

50 70 90

Note: The data without *marks should be used for reference.

We reserve the right to make changes in specifications and design without prior notice.

31

Page 32

F-801MWH-C

APPROXIMATE Ambient Water Temp. (F)

ICE PRODUCTION Temp. (F)

PER 24 HR. 70 * 645 (293) 620 (281) 608 (276)

80 596 (270) 585 (265) 574 (260)

90 563 (255) * 550 (249) 541 (246)

lbs./day ( kg/day) 100 531 (241) 521 (236) * 485 (220)

APPROXIMATE ELECTRIC 70 * 1083 -- 1082 -- 1081 -CONSUMPTION 80 1080 -- 1078 -- 1077 --

90 1076 -- *1075 -- 1073 -watts 100 1072 -- 1070 -- *1068 -APPROXIMATE W ATER 70 * 276 (1046) 342 (1294) 579 (2192)

CONSUMPTION PER 24 HR. 80 287 (1086) 354 (1339) 605 (2291)

(TOTAL) 90 296 (1119) * 368 (1392) 633 (2397)

gal. / day (l/day) 100 305 (1156) 381 (1442) * 693 (2622)

EVAPORATOR OUTLET TEMP. 70 * 20 (-7) 20 (-7) 21 (-6)

°F (°C) 80 21 (-6) 21 (-6) 21 (-6)

90 21 (-6) * 21 (-6) 21 (-6)

100 21 (-6) 21 (-6) * 22 (-6)

HEAD PRESSURE 70 * 263 (18.5) 263 (18.5) 264 (18.6)

80 263 (18.5) 263 (18.5) 264 (18.6)

90 263 (18.5) * 263 (18.5) 264 (18.6)

PSIG (kg/cm

2

G)

100 263 (18.5) 263 (18.5) * 264 (18.6)

SUCTION PRESSURE 70 * 46 (3.2) 46 (3.3) 47 (3.3)

PSIG (kg/cm

2

G) 80 46 (3.2) 46 (3.3) 47 (3.3)

90 46 (3.2) * 46 (3.3) 47 (3.3)

100 46 (3.2) 46 (3.3) * 47 (3.3)

WATER FLOW FOR CONDENSER

PRESSURE DROP OF COOLING WATER LINE

HEAT OF REJECTION FROM CONDENS ER

HEAT OF REJECTION FROM COMPRESSOR 1050 BTU/h (AT 90°F / WT 70°F)

50 70 90

13 gal/h (AT 90°F / W T 70°F)

Less than 7 PSIG

5155 BTU/h (AT 90°F / WT 70°F)

Note: The data without *marks should be used for reference.

We reserve the right to make changes in specifications and design without prior notice.

32

Page 33

IV. Adjustment of Components

1. Adjustment of Water Regulating Valve (water-cooled model only)

The water regulating valve or also called “water regulator” is factory-adjusted. No adjustment

is required under normal use. Adjust the water regulator , if necessary, using the following

procedures.

1) Attach a pressure gauge to the high-side line of the system. Or prepare a thermometer to

check the condenser drain temperature.

2) Rotate the adjustment screw by using a flat blade screwdriver, so that the pressure gauge

shows 260 PSIG (R-404A models/-F type), or the thermometer reads 100 -104°F, in 5

minutes after the icemaking process starts. When the pressure exceeds 260 PSIG, or the

condenser drain temperature exceeds 104°F, rotate the adjustment screw counterclockwise.

3) Check that the pressure or the condenser drain temperature holds a stable setting.

Adjustment Screw

CW

CCW

Bottom View

CW - Higher

CCW - Lower

Adjustment Screw

33

Page 34

2. Adjustment of Flake Size

To adjust the flake size, change the direction of the cutter head on the top of the auger,

according to the following procedures:

1) Remove the bolt and the cutter head.

FINE

2) The cutter head has two holes, one for fine flake

and the other for coarse flake size. The unit is

shipped from the factory in the fine flake

COARSE

position.

3) Place the cutter head so that the pin on the top of the auger fits into the selected hole.

4) Secure the cutter head by the bolt.

34

Page 35

V. Service Diagnosis

1. No Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] The icemaker will

not start.

[2] Water flow does not

stop, and the

icemaker will not

start

[3] Water has been

supplied, but the

icemaker will not

start.

a) Power Supply 1. OFF position. 1. Move to ON position.

b) Power Switch

c) Fuse (Control Box) 1. Blown out. 1. Check for short circuit

d) Circuit Protect Relay 1. Miswiring. 1. Check power supply

e) Flush Timer 1. Flushing out. 1. Wait for 15 minutes.

f) Flush Switch 1. FLUSH position. 1. Move to ICE position.

g) Transformer 1. Coil winding opened. 1. Replace.

h) Control Water Valve 1. Coil winding opened. 1. Replace.

i) Shut-off Valve 1. Closed. 1. Open.

j) Plug and Receptacle

a) Water Control Relay 1. Contact fused. 1. Replace.

b) Float Switch 1. Bad contacts. 1. Check for continuity

c) Flush Water Valve 1. Valve seat clogged

d) Hoses 1. Disconnected. 1. Connect.

a) Water Control Relay 1. Bad contacts. 1. Check for continuity

b)

c) Gear Motor Relay 1. Coil winding opened. 1. Replace.

d) Control Timer

e) Gear Motor Protect

2. Loose connection. 2. Tighten.

3. Bad contacts. 3. Check for contintinuity

4. Blown fuse. 4. Replace.

(Control Box)

(Control Box)

Bin Control 1. Bad contacts. 1. Check for continuity

(Printed Circuit

Board)

Relay

1. Off position. 1. Move to ON position.

2. Bad contacts. 2. Check for continuity

2. Bad contacts. 2. Check for continuity

2. Bad contacts. 2. Check for continuity

2. Water failure. 2. Wait till water is

1. Disconnected. 1. Connect.

2. Terminal out of Plug

or Receptacle.

2. Coil winding opened. 2. Replace.

2. Float does not move

freely.

and water leaking.

2. Activator does not

move freely.

2. bad contacts. 2. Check for continuity

1. Broken. 1. Replace.

1. Coil winding opened. 1. Replace.

2. Bad contacts. 2. Check for continuity

and replace.

and replace.

and replace.

voltage and wire

properly.

and replace.

and replace.

supplied.

2. Insert Terminal back in

position

and replace.

2. Clean or replace.

1. Clean or replace

and replace.

and replace.

2. Clean Axle and its

corresponding holes

or replace Bin Control.

and replace.

and replace.

35

Page 36

PROBLEM POSSIBLE CAUSE REMEDY

[4] Water has been

supplied, Fan Motor

starts, but Gear

Motor and

Compressor will not

start.

[5] Gear Motor and

Compressor start

but operate

intermittently.

[6] Gear Motor starts,

but Compressor will

not start or operates

intermittently.

a) Gear Motor Fuse

(BUSSMAN GMD

1.5A)

b) Thermal Protector

(Gear Motor)

a) Pressure Switch 1. Dirty Air Filter or

a) X2 Relay on Control

Timer

b) Starter 1. Bad contacts. 1. Check for continuity

c) Start Capacitor or

Run Capacitor

d) Compressor 1. Loose connections. 1. Tighten.

1. Blown Fuse. 1. See "3. [3]." Find out

1. Bad contacts. 1. Check for continuity

Condenser.

2. Ambient or

condenser water

temperature too

warm.

3. Condenser water

pressure too low or

off. (Water-cooled

model only)

4. Water Regulating

Valve set too high.

(Water-cooled model

only)

5. Fan not rotating. 5. See "3. [1] a) Fan

6. Refrigerant

overcharged.

7. Refrigerant line or

components

plugged.

8. Bad contacts. 8. Check for continuity

9. Loose connections. 9. Tighten.

1. Bad contacts. 1. Replace.Check for

2. Coil winding opened. 2. Replace Timer.

2. Coil winding opened. 2. Replace.

3. Loose Connections. 3. Tighten.

1. Defective. 1. Replace.

the cause and replace

the Fuse.

and replace.

1. Clean.

2. Get cooler.

3. Check and get

recommended

pressure.

4. Adjust it lower.

Motor."

6. Recharge.

7. Clean and replace

drier.

and replace.

continuity and replace.

and replace.

[7] Gear Motor and

Compressor start,

but no ice is

produced.

2. Motor winding

opened or grounded.

3. Motor Protector

tripped.

e) Power Supply 1. Circuit Ampacity too

low.

a) Refrigerant Line 1. Gas leaks. 1. Check for leaks with a

2. refrigerant line

clogged.

2. Replace.

3. Find out the cause of

overheat or

overcurrent.

1. Install a larger-sized

conductor.

leak detector. Reweld

leak, replace drier and

charge with

refrigerant. The

amount of refrigerant

is marked on

Nameplate or Label.

2. Replace the clogged

component.

36

Page 37

2. Low Ice Production

PROBLEM POSSIBLE CAUSE REMEDY

[1] Low ice production a) Refrigerant Line 1. Gas leaks. 1. See "1. [5] a)

Refrigerant Line."

b) High-side Pressure

Too High

c) Expansion Valve

(not adjustable)

2. Refrigerant line

clogged.

3. Overcharged. 3. Recharge.

1. Dirty Air Filter or

Condenser.

2. Ambient or

condenser water

temperature too

warm.

3. Condenser water

pressure too low or

off. [Water-cooled

model only]

4. Fan rotating too

slow.

5. Water Regulating

Valve clogged.

[Water-cooled model

only]

6. Condensing unit out

of order.

1. Low-side pressure

too low.

2. Low-side pressure

too high.

2. Replace the clogged

component.

1. Clean.

2. Get cooler.

3. Check and get

recommended

pressure.

4. See "3 [1] a) Fan

Motor."

5. Clean.

6. Check condensing

unit.

1. Replace.

2. See if Expansion

Valve Bulb is mounted

properly, and replace

the valve if necessary.

37

Page 38

3. Other

PROBLEM POSSIBLE CAUSE REMEDY

[1] Abnormal noise a) Fan Motor 1. Bearing worn out. 1. Replace.

2. Fan blade deformed. 2. Replace fan blade.

[2] Overflow from

Reservoir (Water

does not stop.)

[3] Gear Motor Fuse

blown frequently.

3. Fan blade does not

move freely.

b) Compressor 1. Bearings worn out,

or cylinder valve

broken.

2. Mounting pad out of

position.

c) Refrigerant Lines 1. Rub or touch lines or

other surfaces.

d) Gear Motor (Ice

Making)

e) Evaporator 1. Too much pressure

a) Water Supply 1. Water pressure too

b) Control Water Valve 1. Diaphragm does not

c) Float Switch 1. Bad contacts. 1. Check for continuity

a) Power Supply

Voltage

b) Ice Making Unit 1. Bearings or Auger

c) Bin Control 1. Bad contacts. 1. Check for continuity

1. Bearing or Gear

worn out / damaged.

loss.

2. Scale on inside wall

of Freezing Cylinder.

high.

close.

1. Too high or too low. 1. Connect the unit to a

worn out.

2. Activator does not

move freely.

3. Replace.

1. Replace.

2. Reinstall.

1. Replace.

1. Replace.

1. Replace.

2. Remove Auger. Use

"SCALE AWAY" or

"LIME-A-WAY"

solution to clean

periodically. If the

water is found hard by

testing, install a

softener.

1. Install a pressure

Reducing Valve

1. Clean or replace.

and replace.

power supply of

proper voltage.

1. Replace Bearing or

Auger.

and replace.

2. Clean Axle and its

corresponding holes

or replace Bin Control.

38

Page 39

VI. Removal and Replacement of Components

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place

after the equipment is serviced.

IMPORTANT

1. The Polyolester (POE) oils used in R-404A units can absorb moisture

quickly. Therefore it is important to prevent moisture from entering the

system when replacing or servicing parts.

2. Always install a new filter drier every time the sealed refrigeration system

is opened.

3. Do not leave the system open for longer than 15 minutes when replacing

or servicing parts.

1. Service for Refrigerant Lines

[a] Refrigerant Recovery

The icemaker unit is provided with two refrigerant access valves - one on the low-side and

one on the high-side line. Using proper refrigerant practices recover the refrigerant from the

access valves and store it in an approved container. Do not discharge the refrigerant into

the atmosphere.

[b] Evacuation and Recharge [R-404A]

1) Attach charging hoses, a service manifold and a vacuum pump to the system. Be sure

to connect charging hoses to both high-side and low-side access valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump. Never allow the oil in the vacuum pump to flow backward.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period

depends on pump capacity.

39

Page 40

4) Close the low-side valve and high-side valve on the service manifold.

5) Disconnect the vacuum pump, and attach a refrigerant service cylinder to the highside line. Remember to loosen the connection, and purge the air from the hose. See

the nameplate for the required refrigerant charge. Hoshizaki recommends only virgin

refrigerant or reclaimed refrigerant which meets ARI Standard No. 700-88 be used.

6) A liquid charge is recommended for charging an R-404A system. Invert the service

cylinder. Open the high-side, service manifold valve.

7) Allow the system to charge with liquid until the pressures balance.

8) If necessary, add any remaining charge to the system through the low-side. Use a

throttling valve or liquid dispensing device to add the remaining liquid charge

through the low-side access port with the unit running.

9) Close the two refrigerant access valves, and disconnect the hoses and service

manifold.

10) Cap the access valves to prevent a possible leak.

2. Brazing

1. Refrigerant R-404A itself is not flammable at atmospheric pressure and

temperatures up to 176° F.

2. Refrigerant R-404A itself is not explosive or poisonous. However, when

exposed to high temperatures (open flames) R-404A can be decomposed

to form hydrofluoric acid and carbonyl fluoride both of which are

hazardous.

3. Always recover the refrigerant and store it in an approved container. Do

not discharge the refrigerant into the atmosphere.

4. Do not use silver alloy or copper alloy containing arsenic.

5. Do not use R-404A as a mixture with pressurized air for leak testing.

Refrigerant leaks can be detected by charging the unit with a little

refrigerant, raising the pressure with nitrogen and using an electronic leak

detector.

DANGER

40

Page 41

3. Removal and Replacement of Compressor

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repairs or replacement

have been made.

1) Turn off the power supply, and remove the panels.

2) Remove the terminal cover on the compressor, and disconnect the compressor wiring.

3) Recover the refrigerant and store it in an approved container, if required by an applicable

law.

4) Remove the discharge, suction and access pipes from the compressor using brazing

equipment.

WARNING

When repairing a refrigerant system, be careful not to let the burner flame

contact any electrical wires or insulation.

5) Remove the bolts and rubber grommets.

6) Slide and remove the compressor. Unpack the new compressor package. Install the new

compressor.

7) Attach the rubber grommets of the prior compressor.

8) Sandpaper the discharge, suction and access pipes.

9) Place the compressor in position, and secure it using the bolts.

10) Remove plugs from the discharge, suction and access pipes.

11) Braze the access, suction and discharge lines (Do not change this order), while purging

with nitrogen gas flowing at the pressure of 3 - 4 PSIG.

12) Install the new drier.

13) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

41

Page 42

14) Evacuate the system, and charge it with refrigerant. For the air-cooled and water-cooled

models, see the nameplate for the required refrigerant charge and type. For the remote aircooled models, see the label on the control box.

15) Connect the terminals to the compressor, and replace the terminal cover in its correct

position.

16) Replace the panels in their correct position, and turn on the power supply.

4. Removal and Replacement of Drier

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repairs or replacement

have been made.

1) Turn off the power supply, and remove the panels.

2) Recover the refrigerant and store it in an approved container, if required by an applicable

law.

3) Remove the drier using brazing equipment.

4) Install the new drier with the arrow on the drier in the direction of the refrigerant flow. Use

nitrogen gas at the pressure of 3 - 4 PSIG when brazing the tubings.

5) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

6) Evacuate the system, and charge it with refrigerant. For the air-cooled and water-cooled

models, see the nameplate for the required refrigerant charge and type. For the remote

air-cooled models, see the label on the control box.

7) Replace the panels in their correct position, and turn on the power supply.

42

Page 43

5. Removal and Replacement of Expansion Valve

IMPORTANT

Sometimes moisture in the refrigerant circuit exceeds the drier capacity and

freezes up at the expansion valve. Always install a new drier every time the

sealed refrigeration system is opened. Do not replace the drier until after all

other repairs or replacement have been made.

1) Turn off the power supply, and remove the panels.

2) Recover the refrigerant and store it in an approved container, if required by an applicable

law.

3) Remove the expansion valve bulb at the evaporator outlet.

4) Remove the expansion valve cover, and remove the expansion valve using brazing

equipment.

5) Braze the new expansion valve with nitrogen gas flowing at the pressure of 3 - 4 PSIG.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve from

overheating. Do not braze with the valve body exceeding 250°F.

6) Install the new drier.

7) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

8) Evacuate the system. Charge it with refrigerant. For the air-cooled and water-cooled

models, see the nameplate for the required refrigerant charge and type. For the remote

air-cooled models, see the label on the control box.

9) Attach the bulb to the suction line. Be sure to secure the bulb using a band and to insulate

it.

10) Place the new set of expansion valve covers in position.

11) Replace the panels in their correct position, and turn on the power supply.

43

Page 44

6. Removal and Replacement of Water Regulating Valve (water-cooled model only)

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repairs or replacement

have been made.

1) Turn off the power supply, remove the panels and close the water supply line shut-off

valve.

2) Recover the refrigerant and store it in an approved container.

3) Disconnect the capillary tube using brazing equipment.

4) Disconnect the flare-connections of the valve.

5) Remove the screws and the valve from the bracket.

6) Install the new valve, and braze the capillary tube.

7) Install the new drier.

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Connect the flare-connections.

10) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge and type.

11) Open the water supply line shut-off valve, and turn on the power supply.

12) Check for water leaks.

13) See “IV. 1. Adjustment of Water Regulating Valve.” If necessary, adjust the valve.

14) Replace the panels in their correct position.

44

Page 45

7. Removal and Replacement of Evaporator Assembly

1) Turn off the power supply.

2) Remove the panels.

3) Move the flush switch to the "FLUSH" position.

4) Turn on the power supply and drain out all water from the water line.

5) Turn off the power supply.

6) Remove the strap connecting the spout to the chute assembly.

7) Remove the three thumbscrews and take off the spout from the evaporator.

Cutter

8) Remove the bolt and lift off the cutter.

9) Remove the rubber O-ring and the nylon ring at the top of the evaporator.

Extruding Head

10) Remove the four socket head cap screws and lift off the extruding head.

11) Replace the bearing inside the extruding head, if it exceeds the wear tolerance of 0.02"

or is scratched.

Note: Replacing the bearing requires a bearing press adaptor. If it is not available,

replace the whole extruding head.

Auger

12) Lift off the auger. If the area in contact with the bearing is worn out or the blade scratched,

replace the auger.

Evaporator

Note: Skip the following steps 13) through 15) when the evaporator does not need

replacement.

45

Page 46

13) Recover the refrigerant and store it in an approved container, if required by an applicable

law.

IMPORTANT

Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repairs or replacement

have been made.

14) Remove the bulb of the expansion valve.

15) Disconnect the brazing-connections of the expansion valve and the copper tube -low

side from the evaporator, using brazing equipment.

16) Remove the two truss head machine screws and the strap securing the evaporator.

17) Disconnect the three hoses from the evaporator.

18) Remove the four socket head cap screws securing the evaporator with the bearinglower.

19) Lift off the evaporator.

Bearing-Lower and Mechanical Seal

20) The mechanical seal consists of two parts. One moves along with the auger, and the

other is fixed on the bearing-lower. If the contact surfaces of these two parts are worn or

scratched, the mechanical seal may cause water leaks and should be replaced.

21) Remove the O-ring on the bearing-lower.

22) Remove the four bolts and the bearing-lower from the gear motor. Replace the bearing

inside the bearing-lower, if it exceeds the wear tolerance of 0.02" or is scratched.

Note: Replacing the bearing requires a bearing press adaptor. If it is not available,

replace the whole bearing-lower.

Gear Motor

23) Remove the coupling-spline on the gear motor shaft.

24) Remove the barrier on the top of the gear motor.

25) Remove the three socket head cap screws securing the gear motor.

46

Page 47

26) Assemble the removed parts in the reverse order of the above procedure.

WARNING

Be careful not to scratch the surface of the O-ring, or it may cause water leaks.

Handle the mechanical seal with care not to scratch nor to contaminate its

contact surface.

27) When replacing the evaporator;

(a) Braze the new evaporator with nitrogen gas flowing at the pressure of 3 - 4 PSIG.

(b) Replace the drier.

(c) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

(d) Evacuate the system. Charge it with refrigerant. For the air-cooled and water-cooled

models, see the nameplate for required refrigerant charge and type. For the remote

air-cooled models, see the label on the control box.

28) Move the flush switch to the "ICE" position.

29) Replace the panels in their correct position.

30) Turn on the power supply.

47

Page 48

Rubber O-ring

Nylon Ring

Bolt

Washer

Auger

Mechanical

Seal

O-ring

Bearing

- Lower

Cutter

Extruding

Head

Washer

Socket Head

Cap Screw

Evaporator

Bolt

Washer

Coupling

- Spline

Washer

Socket Head

Cap Screw

Barrier

Gear Motor

48

Page 49

8. Removal and Replacement of Fan Motor

1) Turn off the power supply and remove the panels.

2) Remove the wire connectors from the fan motor leads.

3) Remove the fan motor bracket and fan motor.

4) Install the new fan motor.

5) Replace the fan motor bracket and the wire connectors.

6) Replace the panels in their correct position, and turn on the power supply.

9. Removal and Replacement of Control Water Valve

1) Turn off the power supply, remove the panels and close the water supply line shut-off

valve.

2) Disconnect the terminals from the control water valve.

3) Loosen the fitting nut on the control water valve inlets, and remove the control water

valve. Do not lose the packings inside the fitting nut.

4) Remove the water supply hose from the control water valve.

5) Install the new control water valve.

6) Assemble the removed parts in the reverse order of the above procedure.

7) Open the water supply line shut-off valve.

8) Check for water leaks.

9) Replace the panels in their correct position, and turn on the power supply.

49

Page 50

10. Removal and Replacement of Flush Water Valve

1) Turn off the power supply, remove the panels and close the water supply line shut-off

valve.

2) Remove the clamp and disconnect the hose from the flush water valve.

Note: Water may still remain inside the evaporator. Be sure to drain the water into the

drain pan.

3) Disconnect the terminals from the flush water valve.

4) Remove the flush water valve from the bracket.

5) Remove the drain pipe from the flush water valve.

6) Connect the drain pipe to the new flush water valve, and place the valve in position.

7) Connect the hose to the flush water valve and secure it with the clamp.

8) Pour water into the reservoir, and check for water leaks on the flush water valve.

9) Open the water supply line shut-off valve, and turn on the power supply.

10) Move the flush switch to the "ICE" position.

11) Check for water leaks.

12) Move the flush switch to the "FLUSH" position, and make sure water is flushing.

13) Move the flush switch to the "ICE" position.

14) Replace the panels in their correct position.

50

Page 51

VII. Cleaning and Maintenance

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after

any maintenance or cleaning is done to the equipment.

1. Preparing the Icemaker for Long Storage

WARNING

When shutting off the icemaker for an extended time, drain out all water from the

water line and remove the ice from the storage bin. The storage bin should be

cleaned and dried. Drain the icemaker to prevent damage to the water supply

line at sub-freezing temperatures, using air or carbon dioxide. Shut off the

icemaker until the proper ambient temperature is resumed.

[Air-Cooled and Remote Air-Cooled Models]

1) Run the icemaker with the water supply line shut-off valve closed.

2) Open the drain valve and blow out the water inlet line by using air pressure.

3) Turn off the power supply.

4) Remove the front panel.

5) Move the flush switch on the control box to the

“FLUSH” position.

6) Turn on the power supply, and then drain out all

water from the water line.

7) Turn off the power supply.

8) Turn off the power switch on the control box.

Air or CO2

9) Replace the front panel in its correct position.

Shut-off Valve

Drain Valve

10) Close the drain valve.

11) Remove all ice from the storage bin, and clean the bin.

51

Page 52

[Water-Cooled Models]

1) Turn off the power supply and wait for 3 minutes.

2) Turn on the power supply and wait for 20 seconds.

3) Close the water supply line shut-off valve.

4) Open the drain valve and quickly blow the water supply line from the drain valve to drain

water in the condenser.

5) Follow the above steps 3) through 11) in [Air-Cooled and Remote Air-Cooled Models].

2. Cleaning and Sanitizing Instructions

WARNING

1. HOSHIZAKI recommends cleaning this unit at least once a year. More

frequent cleaning, however, may be required in some existing water

conditions.

2. To prevent injury to individuals and damage to the icemaker, do not use

ammonia type cleaners.

3. Always wear liquid-proof gloves to prevent the cleaning and sanitizing

solutions from coming into contact with skin.

[a] Cleaning Solution

Dilute 4.8 fl. oz. (142 ml) of recommended cleaner Hoshizaki “Scale Away” or

“LIME-A-WAY” (Economics Laboratory, Inc.) with 0.8 gallons (3 l) of warm water. This is a

minimum amount. Make more solution if necessary.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

52

Page 53

[b] Cleaning Procedure

The cleaning process will remove lime deposits from the water system.

1) Remove the front panel and top panel, then turn off the power supply.

2) Close the water supply line shut-off valve.

3) Remove all ice from the storage bin.

4) Move the flush switch to the “FLUSH” position.

5) Turn on the power supply and drain out all water from the water line.

6) Turn off the power supply.

7) Remove the strap connecting the spout to the chute assembly.

8) Remove the thumbscrews securing the spout and lift it off.

9) Pour the cleaning solution over the extruding head until the evaporator assembly and the

reservoir are filled and the solution starts to overflow into the drain pan.

Note: If there is excess scale on the extruding head, fill the evaporator assembly and

reservoir as described above, then use a clamp on the reservoir hose between the

reservoir and evaporator assembly to block flow. Pour additional cleaning fluid

over the extruding head until the evaporator assembly is completely full.

10) Replace the spout and strap in their correct positions.

11) Allow the icemaker to sit for about 10 minutes before operation. If you placed a clamp on

the reservoir hose in step 9, remove it before operation.

12) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

13) Remove the front panel.

14) Move the flush switch to the “FLUSH” position to drain the remainder of the solution.

15) After the solution is drained, move the flush switch to the “ICE” position.

16) Replace the front panel in its correct position.

17) Open the water supply line shut-off valve and supply water to the reservoir.

18) When the gear motor starts, remove the front panel and turn off the power supply.

19) Drain out all water from the water line. See 4) through 6).

53

Page 54

[c] Sanitizing Solution

Dilute 2.5 fl. oz. (74 ml or 5 tbs) of IMS-II Sanitizer or a 5.25% sodium hypochlorite solution

(chlorine bleach) with 5 gallons (19 l) of warm water.

IMPORTANT

For safety and maximum effectiveness, use the solution immediately after

dilution.

[d] Sanitizing Procedure - Initial

The sanitizing process will sanitize the icemaker.

1) Close the water supply line shut-off valve.

2) Remove the strap connecting the spout to the chute assembly.

3) Remove the thumbscrews securing the spout and lift it off. Remove the rubber O-ring and

nylon O-ring at the top of the cylinder and also remove the packing between the spout

and the chute.

4) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

5) Remove the two thumbscrews securing the proximity switch to the chute assembly.

6) Remove the chute assembly from the icemaker.

7) Remove the packing at the bottom of the ice chute.

8) Remove the three ties and the chute insulation.

9) Remove the six wing nuts and two baffles.

10) Remove the two thumbscrews, the plate and the packing from the top of the ice chute,

then remove the bin control assembly by sliding it slightly toward the chute opening and

lifting it off.

11) Disassemble the bin control assembly by removing the two snap pins, shaft and

actuator.

12) Soak the removed parts in .25 gallons (1 l) of sanitizing solution for 10 minutes then

wipe them down.

13) Rinse the parts thoroughly.

If the solution is left on these parts, they will rust.

IMPORTANT

54

Page 55

14) Replace all parts in their correct positions.

IMPORTANT

When installing the baffles, make sure that the bent surface (the one without the

studs) faces the actuator so that the bent surface can guide the ice to the center

of the actuator.

15) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

[e] Sanitizing Procedure - Final

1) Remove the front panel and top panel, then turn off the power supply.

2) Move the flush switch to the “FLUSH” position.

3) Turn on the power supply and drain out all water from the water line.

4) Turn off the power supply.

5) Remove the strap connecting the spout to the chute assembly.

6) Remove the thumbscrews securing the spout and lift it off.

7) Pour the sanitizing solution over the extruding head until the evaporator assembly and

the reservoir are filled and the solution starts to overflow into the drain pan.

8) Replace the spout and strap in their correct positions.

9) Allow the icemaker to sit for about 10 minutes before operation.

10) Move the flush switch to the “ICE” position, then turn on the power supply. Replace the

top panel and front panel in their correct positions. Make ice using the solution until the

icemaker stops making ice.

11) Remove the front panel.

12) Move the flush switch to the “FLUSH” position to drain the remainder of the solution.

13) After the solution is drained, move the flush switch to the “ICE” position.

14) Replace the front panel in its correct position.

15) Open the water supply line shut-off valve and supply water to the reservoir.

55

Page 56

16) When the gear motor starts, remove the front panel and turn off the power supply.

17) Drain out all water from the water line. See 2) and 3).

18) Move the flush switch to the “ICE” position and run the icemaker.

19) Turn off the power supply after 30 minutes.

20) Pour warm water into the storage bin to melt all ice, and then clean the bin liner with the

solution.

21) Flush out any solution from the storage bin.

22) Turn on the power supply and start the automatic icemaking process.

IMPORTANT

1. After cleaning, do not use ice made from the sanitizing solution. Be careful

not to leave any solution in the storage bin.

2. Follow carefully any instructions provided with the bottles of cleaning or

sanitizing solution.

3. Never run the icemaker when the reservoir is empty.

56

Page 57

3. Maintenance

1. This icemaker must be maintained individually, referring to the instruction

manual and labels provided with the icemaker.

2. To have the optimum performance of this icemaker, the following

consumable parts need periodical inspection, maintenance and

replacement:

These parts should be inspected at least once a year or every 10,000 hours

of operation. Their service life, however, depends on water quality and

environment. More frequent inspection and maintenance are recommended.

IMPORTANT

Extruding Head

Housing

Gear Motor

Auger

Mechanical Seal

Consult with your local distributor about inspection and maintenance

service. To obtain the name and phone number of your local distributor, call

Hoshizaki Technical Support at 1-800-233-1940.

1) Stainless Steel Exterior

To prevent corrosion, wipe the exterior occasionally with a clean and soft cloth. Use

a damp cloth containing a neutral cleaner to wipe off oil or dirt build up.

2) Storage Bin and Scoop

* Wash your hands before removing ice. Use the plastic scoop provided (bin

accessory).

* The storage bin is for ice use only. Do not store anything else in the bin.

* Keep the scoop clean. Clean using a neutral cleaner and rinse thoroughly.

* Clean the bin liner using a neutral cleaner. Rinse thoroughly after cleaning.

57

Page 58

3) Air Filter (air-cooled model only)

A plastic mesh air filter removes dirt or dust from the air, and keeps the condenser

from getting clogged. As the filter gets clogged, the icemaker’s performance will be

reduced. Check the filter at least twice a month. When clogged, use warm water and

a neutral cleaner to wash the filter.

4) Condenser (except water-cooled model)

Check the condenser once a year, and clean if required by using a brush or vacuum

cleaner. More frequent cleaning may be required depending on the location of the

icemaker.

58

Loading...

Loading...