Hoshizaki DCM-750BAF, DCM-500BAF SERVICE MANUAL

NO:

ISSUED:

REVISED: DEC. 17, 2003

MAR. 11, 1999

73071

HOSHIZAKI

CUBELET ICE DISPENSER

MODEL

DCM-500BAF

DCM-500BWF

DCM-750BAF

DCM-750BWF

SERVICE MANUAL

IMPORTANT

Only qualified service technicians should attempt to service or maintain this icemaker.

No service or maintenance should be undertaken until the technician has thoroughly

read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City , GA 30269

Attn: HOSHIZAKI T echnical Support Department

Phone: 1-800-233-1940 T echnical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: T o expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

• Please review this manual. It should be read carefully before the ice dispenser is

installed and operated. Only qualified service technicians should install, service and

maintain the ice dispenser. This manual should be made available to the technician

prior to installation, service or maintenance.

CONTENTS PAGE

I. SPECIFICATIONS ............................................................................................................ 5

1. DCM-500BAF (Air-cooled) .......................................................................................... 5

2. DCM-500BWF (Water-cooled) .................................................................................... 6

3. DCM-750BAF (Air-cooled) .......................................................................................... 7

4. DCM-750BWF (Water-cooled) .................................................................................... 8

II. GENERAL INFORMATION .............................................................................................. 9

1. CONSTRUCTION ....................................................................................................... 9

DCM-500BAF, DCM-750BAF ..................................................................................... 9

DCM-500BWF, DCM-750BWF ................................................................................. 10

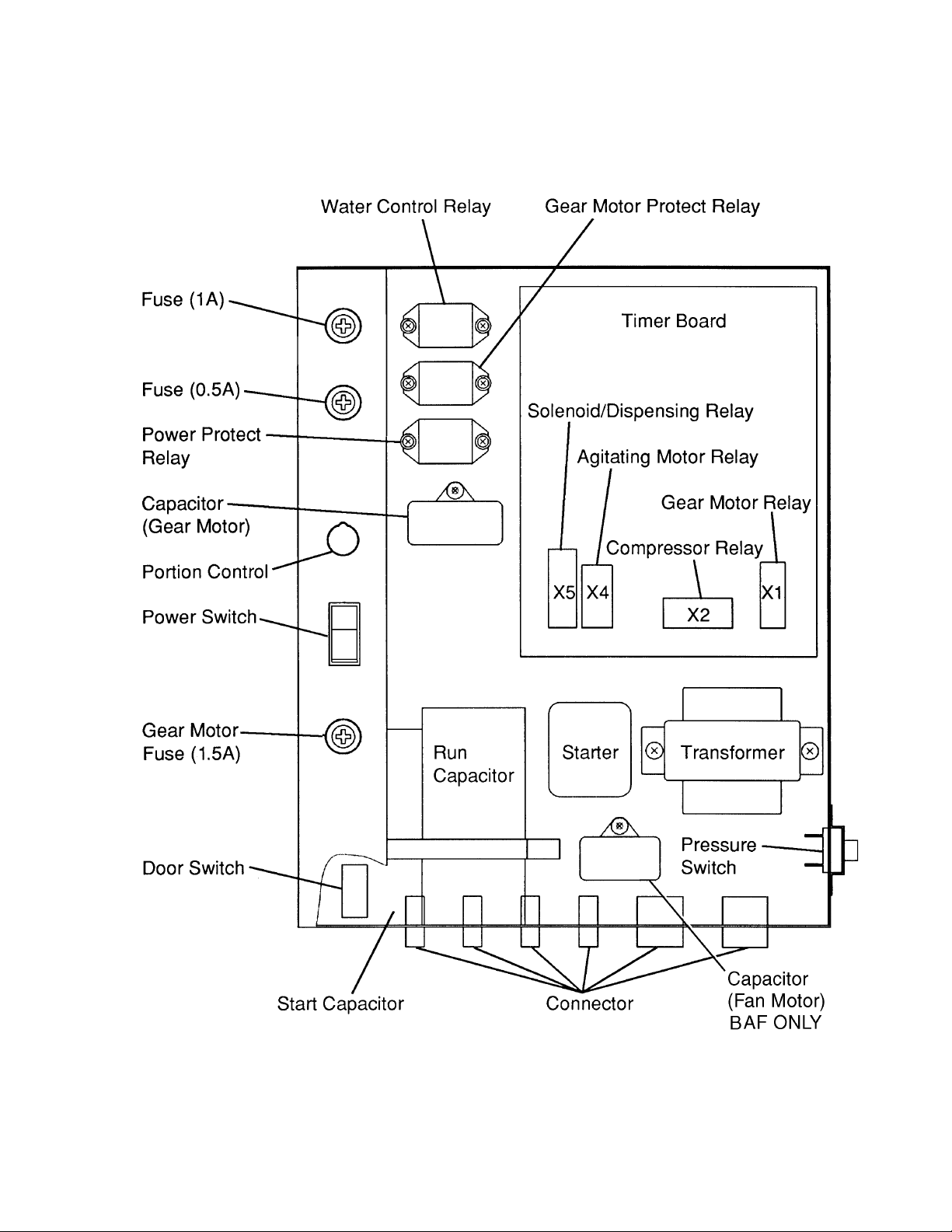

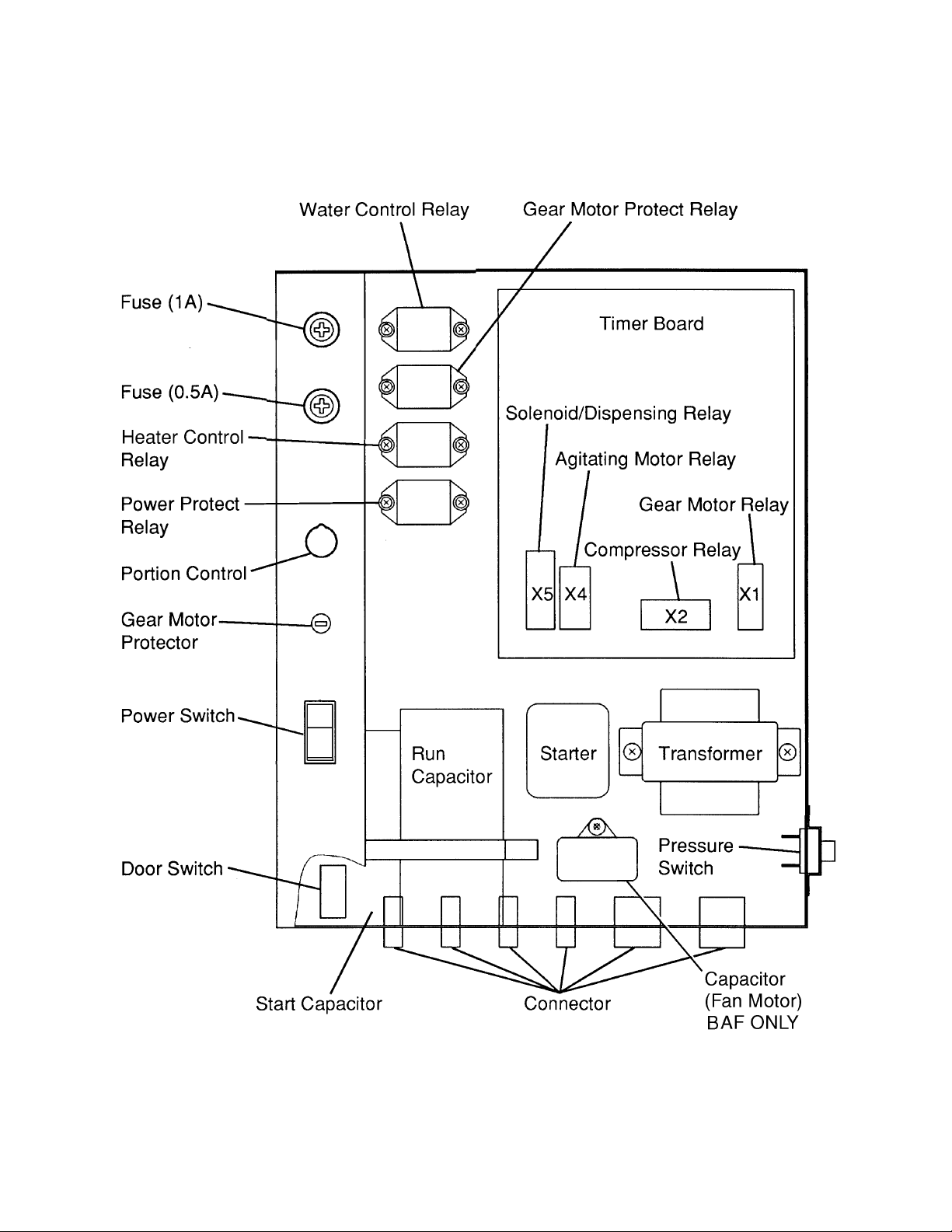

2. CONTROL BOX LAYOUT......................................................................................... 11

DCM-500BAF, DCM-750BAF ................................................................................... 11

DCM-500BWF, DCM-750BWF ................................................................................. 12

3. CABINET STAND ..................................................................................................... 13

III. TECHNICAL INFORMATION........................................................................................ 16

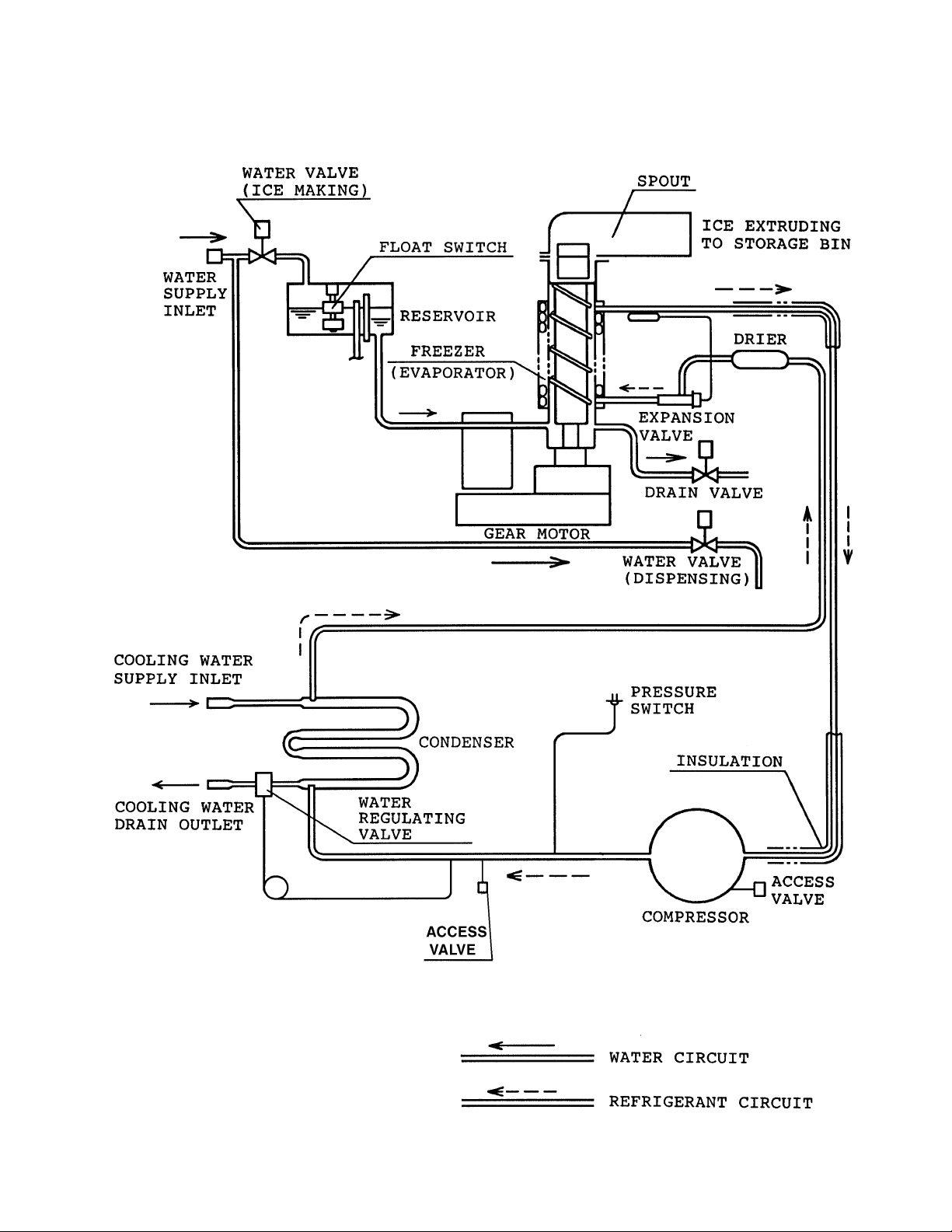

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT................................................... 16

DCM-500BAF (Air-cooled) ........................................................................................ 16

DCM-500BWF (Water-cooled) .................................................................................. 17

DCM-750BAF (Air-cooled) ........................................................................................ 18

DCM-750BWF (Water-cooled) .................................................................................. 19

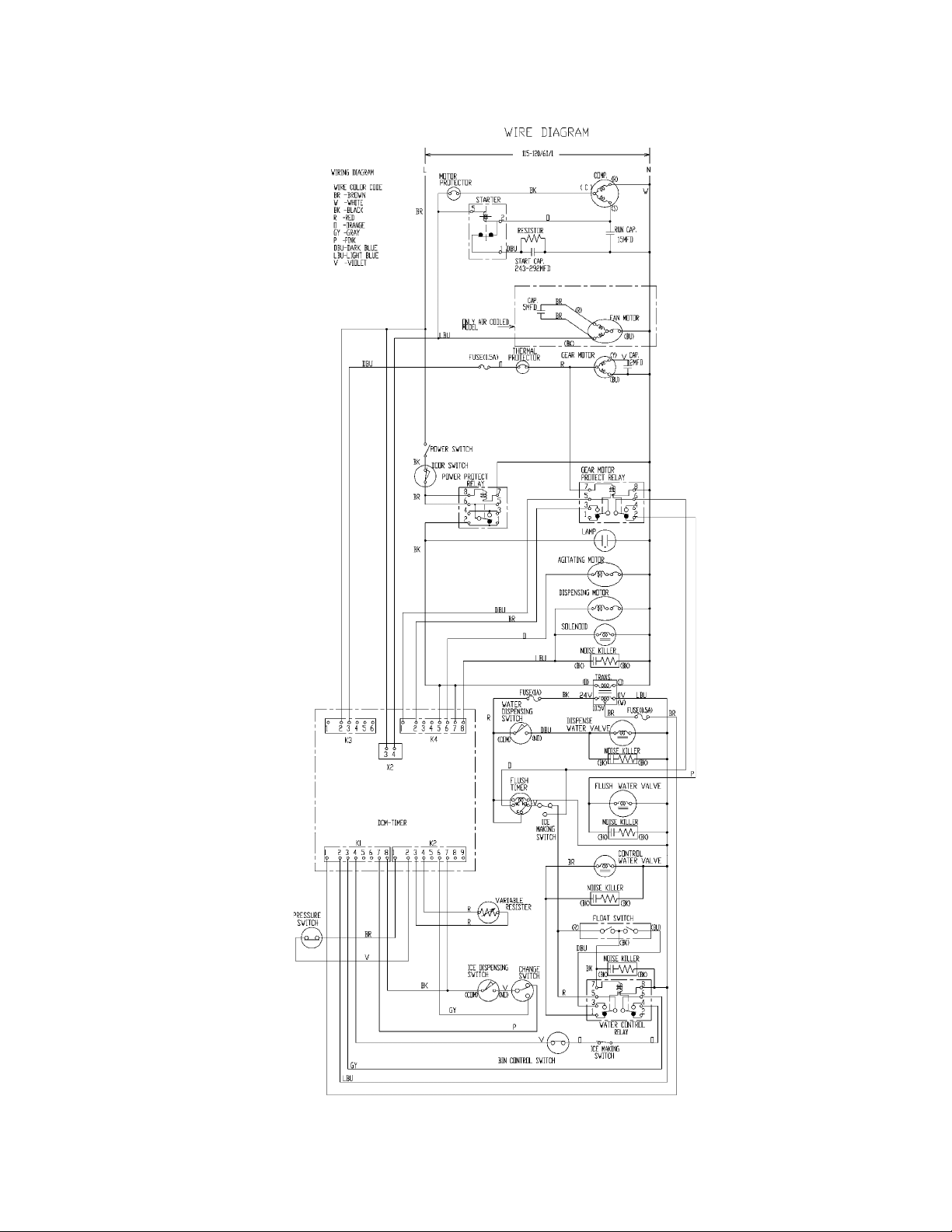

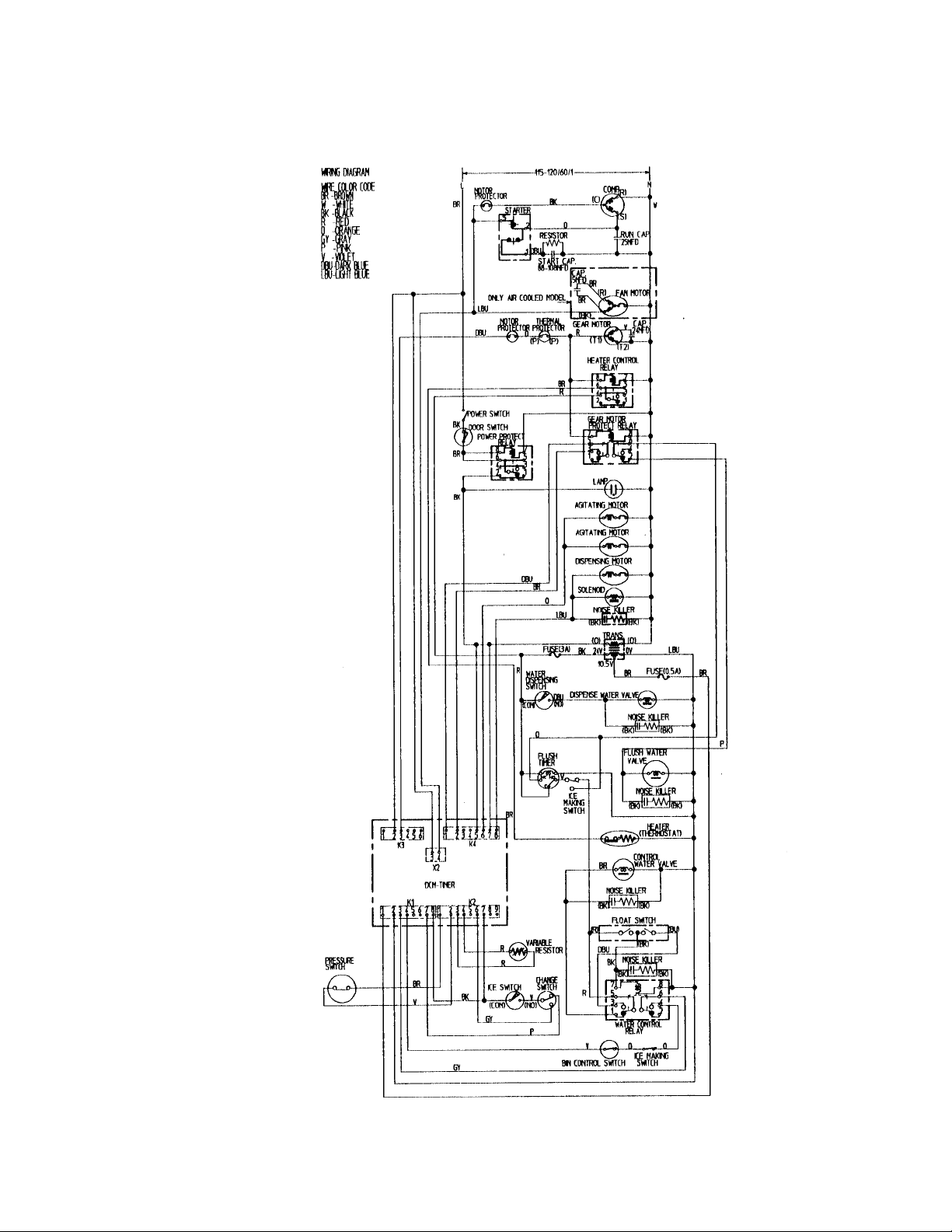

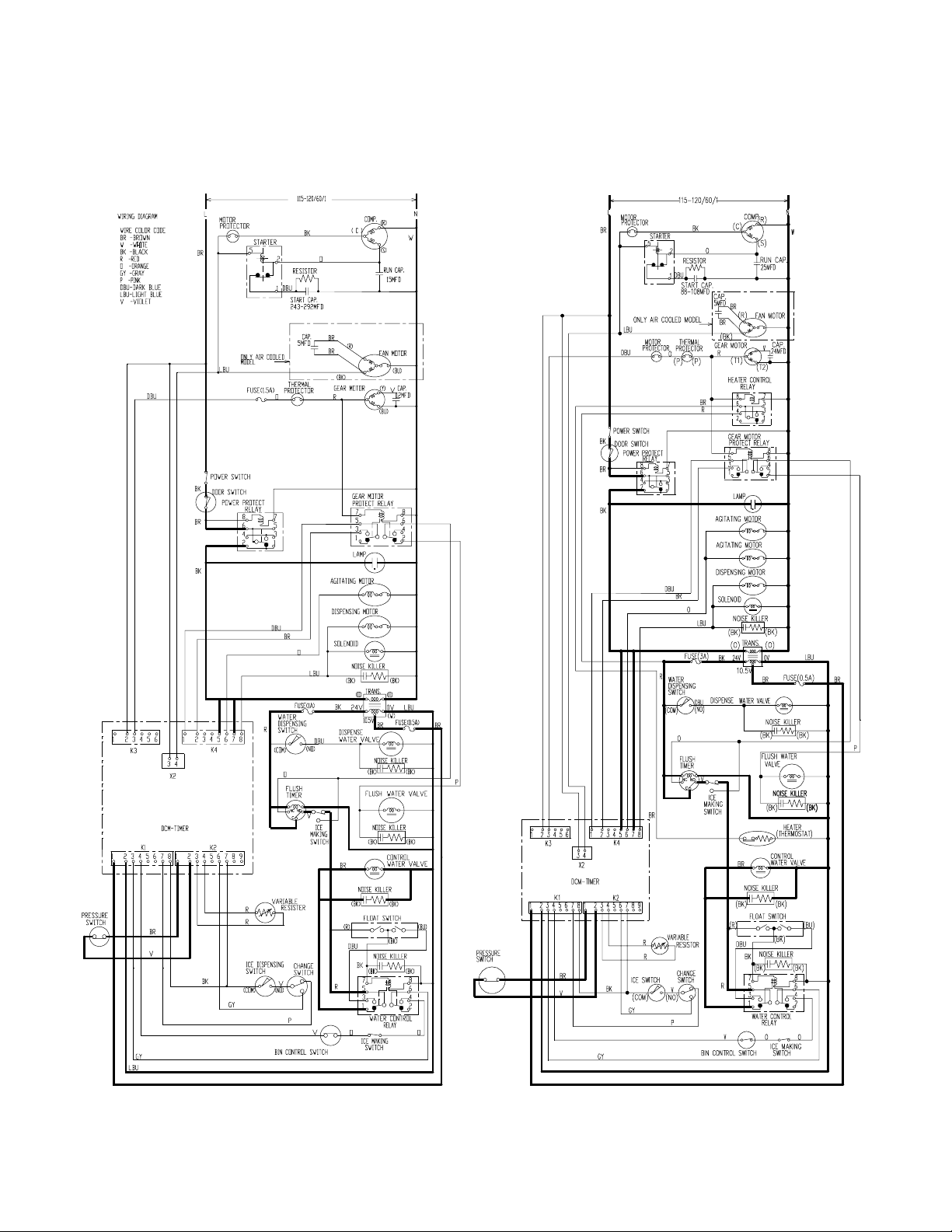

2. WIRING DIAGRAM................................................................................................... 20

DCM-500BAF, DCM-500BWF .................................................................................. 20

DCM-750BAF, DCM-750BWF .................................................................................. 21

3. SEQUENCE OF ELECTRICAL CIRCUIT ................................................................. 22

4. TIMING CHART ........................................................................................................ 36

5. TIMER BOARD ......................................................................................................... 37

6. PERFORMANCE DATA............................................................................................ 4 1

IV. ADJUSTMENT OF COMPONENTS ............................................................................ 45

ADJUSTMENT OF WATER REGULATING VALVE

- WATER-COOLED MODEL ONLY ............................................................................ 45

V. SERVICE DIAGNOSIS ................................................................................................. 46

3

VI. REMOVAL AND REPLACEMENT OF COMPONENTS .............................................. 50

1. SERVICE FOR REFRIGERANT LINES..................................................................... 50

[a] REFRIGERANT RECOVERY ............................................................................. 50

[b] EVACUATION AND RECHARGE [R-404A]........................................................ 50

2. BRAZING .................................................................................................................. 51

3. REMOVAL AND REPLACEMENT OF COMPRESSOR ............................................ 5 2

4. REMOVAL AND REPLACEMENT OF DRIER........................................................... 53

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE ................................... 54

6. REMOVAL AND REPLACEMENT OF WATER REGULATING VALVE ................... 55

7. REMOVAL AND REPLACEMENT OF EVAPORATOR ASSEMBLY......................... 56

8. REMOVAL AND REPLACEMENT OF FAN MOTOR ................................................ 61

9. REMOVAL AND REPLACEMENT OF CONTROL/DISPENSING WATER VALVE 61

10. REMOVAL AND REPLACEMENT OF FLOAT SWITCH ........................................... 62

11. REMOVAL AND REPLACEMENT FLUSH WATER VALVE..................................... 62

12. REMOVAL AND REPLACEMENT OF ELECTRICAL SYSTEM ............................... 63

13. REMOVAL AND REPLACEMENT OF DISPENSING SYSTEM ............................... 64

VII. CLEANING AND MAINTENANCE INSTRUCTIONS.................................................. 66

1. PREPARING THE ICE DISPENSER FOR LONG STORAGE.................................. 66

2. CLEANING INSTRUCTIONS.................................................................................... 68

[a] WATER SYSTEM ............................................................................................... 68

[b] STORAGE BIN.................................................................................................... 70

[c] WATER VALVE................................................................................................... 72

[d] STRAINER.......................................................................................................... 73

3. MAINTENANCE INSTRUCTIONS ............................................................................ 75

4

I. SPECIFICATIONS

(

g)

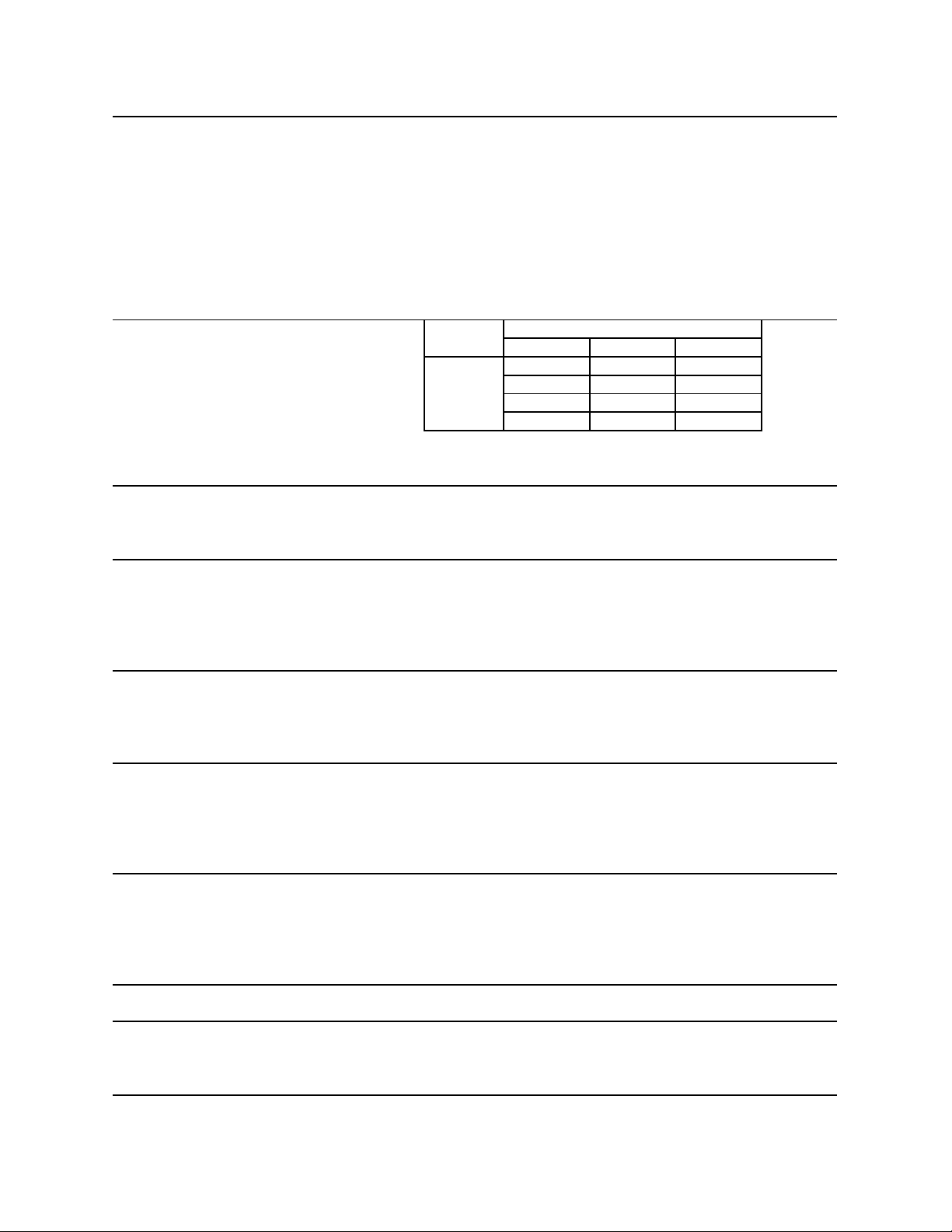

1. DCM-500BAF (Air-cooled)

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 7.9 RLA 51 LRA

GEAR MOTOR 120 V 1.6 FLA 1/6 HP

FAN MOTOR 120 V 0.6 FLA 30W

AGITATING MOTOR 120 V 0.9 FLA 55 W

DISPENSING MOTOR 120 V 0.9 FLA 55 W

OTHERS 120 V 0.2 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BRE AKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F)507090

lbs./day ( kg/day ) 70 *525 (243) 510 (231) 485 (220)

Reference without *marks 80 461 (209) 438 (199) 416 (189)

90 396 (179) *385 (175) 358 (162)

100 340 (154) 323 (147) *304 (138)

SHAPE OF ICE Cubelet (Compressed Flake Ice)

ICE QUALITY Approx. 90%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY 40 lbs.

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1055 (6.6) 985 (4.4)

POTABLE WATER 46 (11.9) 64 (11.9)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 26" x 22-1/2" x 40" (661 x 571 x 1016 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 251 lbs. ( 114 kg ), Shipping 276 lbs. ( 125 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT x2

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/6 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model R43C1E-CAA-219

CONDENSER Air-cooled, Fin and tube type

EVAPORATOR Copper Tube on Cylinder

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A,

DESIGN PRESSURE High 460 PSIG, Low 290 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out Relay

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Auto-reset Thermal Protector

Manual reset Circuit Breaker or Fuse

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Con trol Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES -SUPPLIED Spare Fuse

-REQUIRED Legs

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

DRAWING NO. (DIMENSION) 340147S--

1 lb. 4.1 oz.

570

We reserve the right to make changes in specifications and design without prior notice.

5

2. DCM-500BWF (Water-cooled)

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 7.9 RLA 51 LRA

GEAR MOTOR 120 V 1.6 FLA 1/6 HP

AGITATING MOTOR 120 V 0.9 FLA 55 W

DISPENSING MOT OR 120 V 0.9 FLA 55 W

OTHERS 120 V 0.2 A

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ONLY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE IC E PRO DUC TION Am bi ent WATER TEMP. (°F )

PER 24 HR. Temp. ( ° F ) 50 70 90

lbs./day ( kg/day ) 70 *545 (247) 526 (239) 515 (233)

Reference without *marks 80 503 (228) 493 (223) 482 (219)

90 471 (214) *465 (211) 451 (205)

100 441 (200) 432 (196) *400 (181)

SHAPE OF ICE Cubelet (Compressed Flake Ice)

ICE QUALITY Approx. 90%, Ice (90/70°F, Conductivity 200 µs/cm)

APPROXIMATE STORAGE CAPACITY 40 lbs.

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 930 (4.8) 985 (4.0)

POTABLE WATER 56 (12) 65 (12)

WATER-COOLED CONDENSER 465 (100) 285 (52)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 26" x 22-1/2" x 40" (661 x 571 x 1016 mm)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 245 lbs. ( 111 kg ), Shipping 269 lbs. ( 122 kg )

CONNECTIONS - ELECTRIC Permanent - Connection

- WATER SUPPLY Inlet 1/2" FPT Condenser Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT x2 Condenser Outlet 3/8" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/6 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTRO L Automatic Water Regulator

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model R43C1E-CAA-219

CONDENSER Water-cooled, Double Tube Type

EVAPORATOR Copper Tube on Cylinder

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A,

DESIGN PRESSURE High 460 PSIG, Low 290 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out Relay

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Auto-reset Thermal Protector

Manual-reset Circuit Breaker or Fuse

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES -SUPPLIED Spare Fuse

-REQUIRED Legs

OPERATING CONDITIONS VOLTAGE RANGE 104-127 V

AMBIENT TEMP. 45-100° F

WATER SUPPLY TEMP. 45-90° F

WATER SUPPLY PRESSURE 10-113 PSIG

DRAWING NO. (DIMENSION) 340148S--

We reserve the right to make changes in specifications and design without prior notice.

13.4 oz. (380g)

6

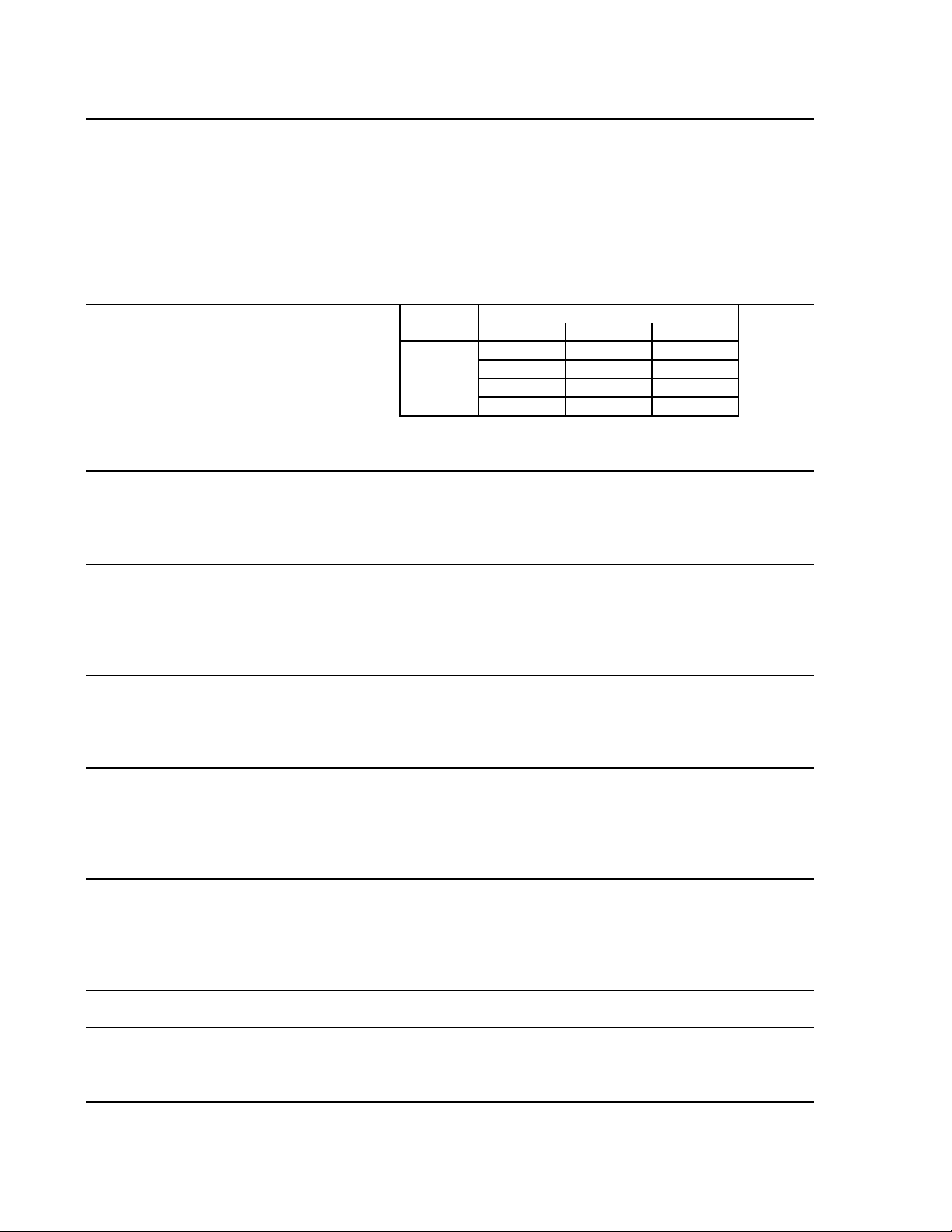

3. DCM-750BAF (Air-cooled)

A

A

A

A

Y

Y

r

y

r

r

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 11.1 RLA 60 LRA

GEAR MOTOR 120 V 3 FL

FAN MOTOR 120 V 0.85 F L

AGITAT ING MOTOR 120 V 1.8 FLA (Total) 110 W

DISPENSING MOTOR 120 V 0.9 FL

OTHER 120 V 0.6

MAXIMUM FUSE SIZE 20 A

MAX. HACR BREAKER (USA ONLY) 20 A

MAX. CIRC. BREAKER (CANADA ON LY) 20 A

MINIMUM CIRCUIT AMPACITY 20 A

APPROXIMATE ICE PRODUCTION Ambient WA TER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 * 803 (364) 770 (349) 726 (329)

Reference without *marks 80 684 (310) 645 (293) 608 (276)

90 573 (260) * 567 (257) 509 (231)

100 480 (218) 452 (205) * 423 (192)

SHAPE OF ICE Cubelet (Compressed Flake Ice)

ICE QUALIT

APPROXIM ATE STORAGE C APACIT

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1481 (6.3) 1449 (4.3)

POTABLE WATER 68 (12) 96 (12)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 34-1/16" x 28-1/2" x 48-1/16" (865 x 723 x 1221 mm)

EXTERIOR FINISH Stainless Steel; Galvanized Steel (Rear)

WEIGHT Net 375 lbs. ( 170 kg ), Shipping 405 lbs. ( 184 kg )

CONNECTIONS - ELECTRIC Permanent Connection

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Drain Pan 3/4" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Mechanical Bin Control ( Proximity Sw. )

COMPRESSOR Hermetic, Model RS55C1E-PAA

CONDENSER Air-cooled, Fin and tube type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, 1 lb. 7.1 oz. (660 g)

DESIGN PRESSURE High 460 PSIG, Low 290 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-off Rela

COMPRESSOR PROTECTION Auto-reset Overload Protecto

GEAR MOTOR PROTECTION Manual reset Circuit Breaker

REFRIGER ANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Time

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Legs

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

DRAW ING NO. (DIMENSIONS) 340969---

Approx. 90%, Ice (90/70°F, Conductivity 200 µs/cm )

95 lbs.

Bin Drain 3/4" FPT

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

1/4 HP

1/15 HP

55 W

We reserve the right to make changes in specifications and design without prior notice.

7

4. DCM-750BWF (Water-cooled)

A

A

A

A

A

A

A

Y

A

Y

Y

A

r

y

AC SUPPLY VOLTAGE 115/60/1

COMPRESSOR 120 V 10 RL

GEAR MOTOR 120 V 3 FL

AGITATING MOTOR 120 V 1.8 FLA (Total) 110 W

DISPENSING MOTOR 120 V 0.9 FL

OTHER 120 V 0.6

MAXIMUM FUSE SIZE 20

MAX. HACR BREAKER (USA ONLY) 20

MAX. CIRC. BREAKER (CANADA ONLY) 20

MINIMUM CIRCUIT AMPACIT

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 * 879 (399) 851 (386) 830 (376)

Reference without *marks 80 809 (367) 789 (358) 770 (349)

SHAPE OF ICE Cubelet (Compressed Flake Ice)

ICE QUALIT

APPROXIMATE STORAGE CAPACIT

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 1349 (4.3) 1348 (3.7)

POTABLE WATER 89 (12) 105 (12)

WATER - COOLED CONDENSER 624 (83.7) 421 (47.9)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDxH) 34-1/16" x 28-1/2" x 48-1/16" (865 x 723 x 1221 mm)

EXTERIOR FINISH Stainless Steel; Galvanized Steel (Rear)

WEIGHT Net 375 lbs. ( 170 kg ), Shipping 405 lbs. ( 184 kg )

CONNEC TIONS - ELECTRIC Permanent Connection

- WATER SUPPLY Inlet 1/2" FPT Condenser Inlet 1/2" FPT

- DRAIN Drain Pan 3/4" FPT Condenser Outlet 1/2" FPT

ICE MAKING SYSTEM Auger type

HARVESTING SYSTEM Direct Driven Auger ( 1/4 HP Gear Motor )

ICE MAKING WATER CONTROL Float Switch

COOLING WATER CONTROL Water Regulating Valve

BIN CONTROL SYS TEM Mechanical Bin Control ( Pro ximity Sw. )

COMPRESSOR Hermetic, Model RS55C1E-PA

CONDENSER Water-cooled, Double tube type

EVAPORATOR Copper Tube on Cylinde

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE R-404A, 1 lb. 1.7 oz. (500 g)

DESIGN PRESSURE High 460 PSIG, Low 290 PSIG

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-off Rela

COMPRESSOR PROTECTION Auto-reset Overload Protector

GEAR MOTOR PROTECTION Manual reset Circuit Breaker

REFRIGERANT CIRCU IT PROTEC TION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION Float Switch and Timer

ACCESSORIES - SUPPLIED Spare Fuse

- REQUIRED Legs

OPERATING CONDITIONS VOLTAGE RANGE 104 - 127 V

DRAWING NO. (DIMENSIONS) 340970---

20

90 751 (341) * 746 (338) 714 (324)

100 697 (316) 679 (308) * 628 (285)

Approx. 90%, Ice (90/70°F, Conductivity 200 µs/cm)

95 lbs.

Bin Drain 3/4" FPT

AMBIENT TEMP. 45 - 100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

60 LRA

1/4 HP

55 W

We reserve the right to make changes in specifications and design without prior notice.

8

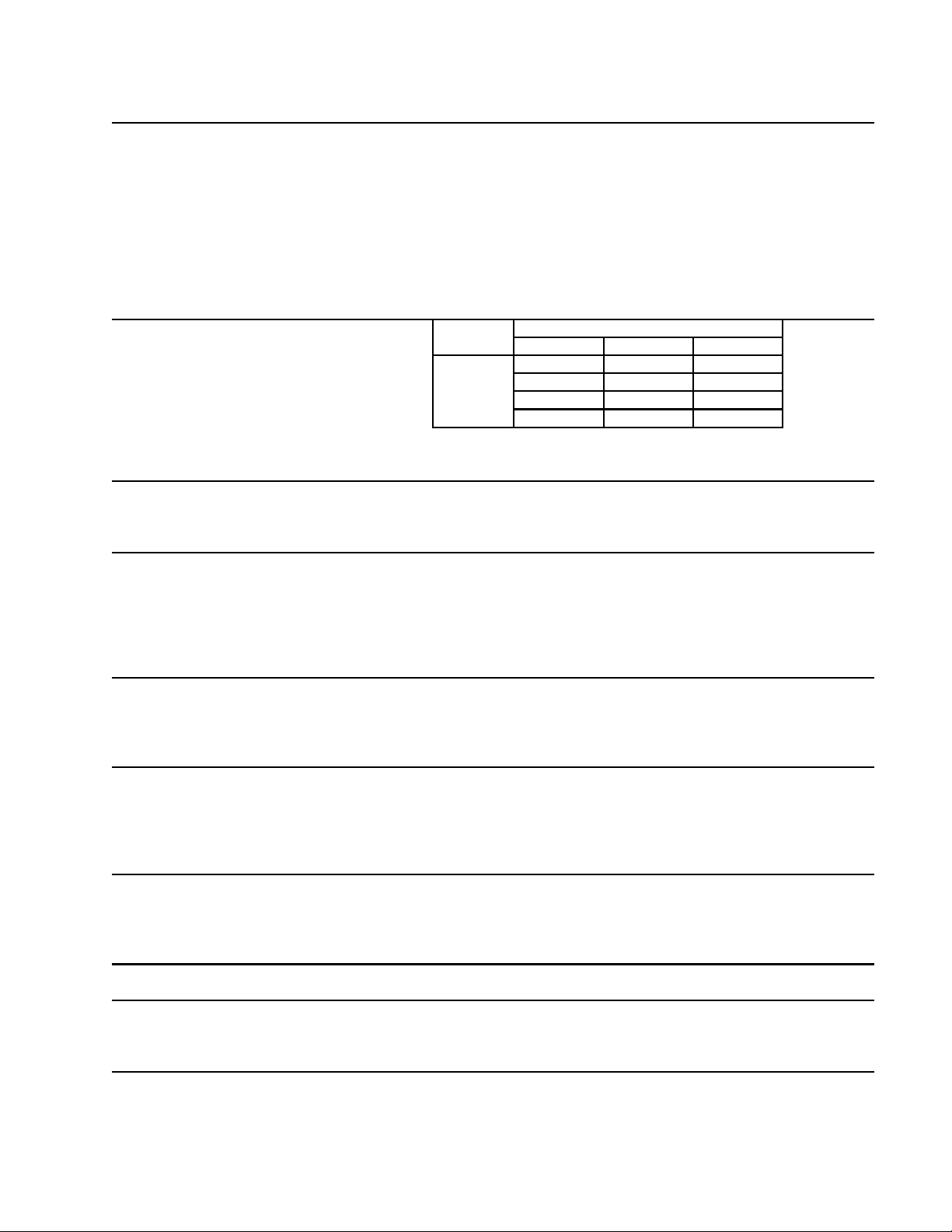

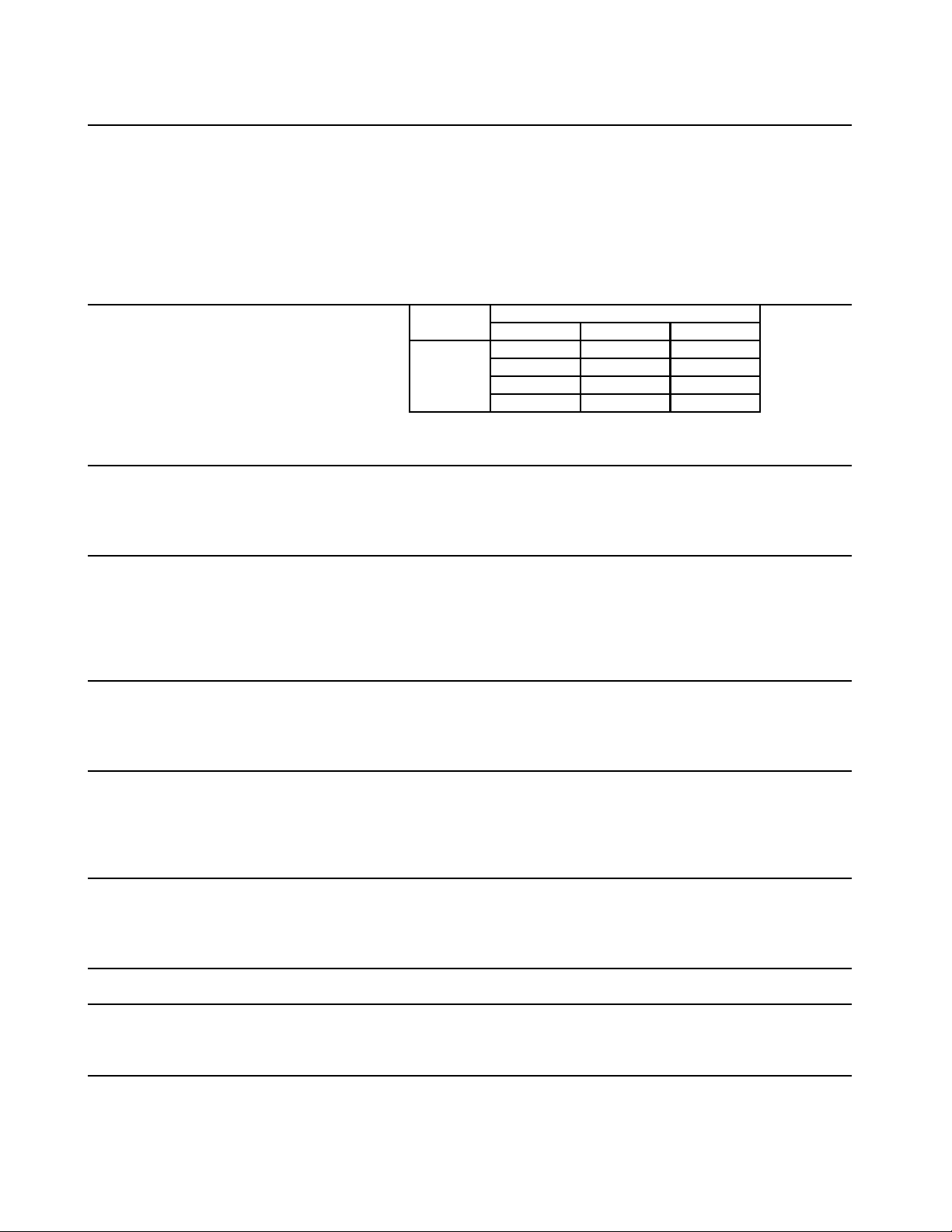

II. GENERAL INFORMATION

1. CONSTRUCTION

DCM-500BAF, DCM-750BAF

9

DCM-500BWF, DCM-750BWF

10

2. CONTROL BOX LAYOUT

DCM-500BAF, DCM-500BWF

11

DCM-750BAF, DCM-750BWF

12

5. CABINET STAND

When placing the ice dispenser on the Cabinet Stand:

1) Attach four adjustable legs to the Cabinet Stand. (Cabinet Stand accessory)

2) Remove the protective plastic film from the panels.

3) Remove the Front Panel by lifting up and pulling toward you.

4) Place the ice dispenser on the Cabinet Stand.

Combination: SD-450 . . . . . . DCM-500BAF, BWF

SD-700 . . . . . . DCM-750BAF, BWF

5) You must secure the ice dispenser to the Cabinet Stand with four bolts (Cabinet Stand

accessory).

6. Seal the seam all around between the dispenser and the Cabinet Stand with food grade

silicone. See Fig. 1

7) Replace the Front Panel.

Fig. 1

13

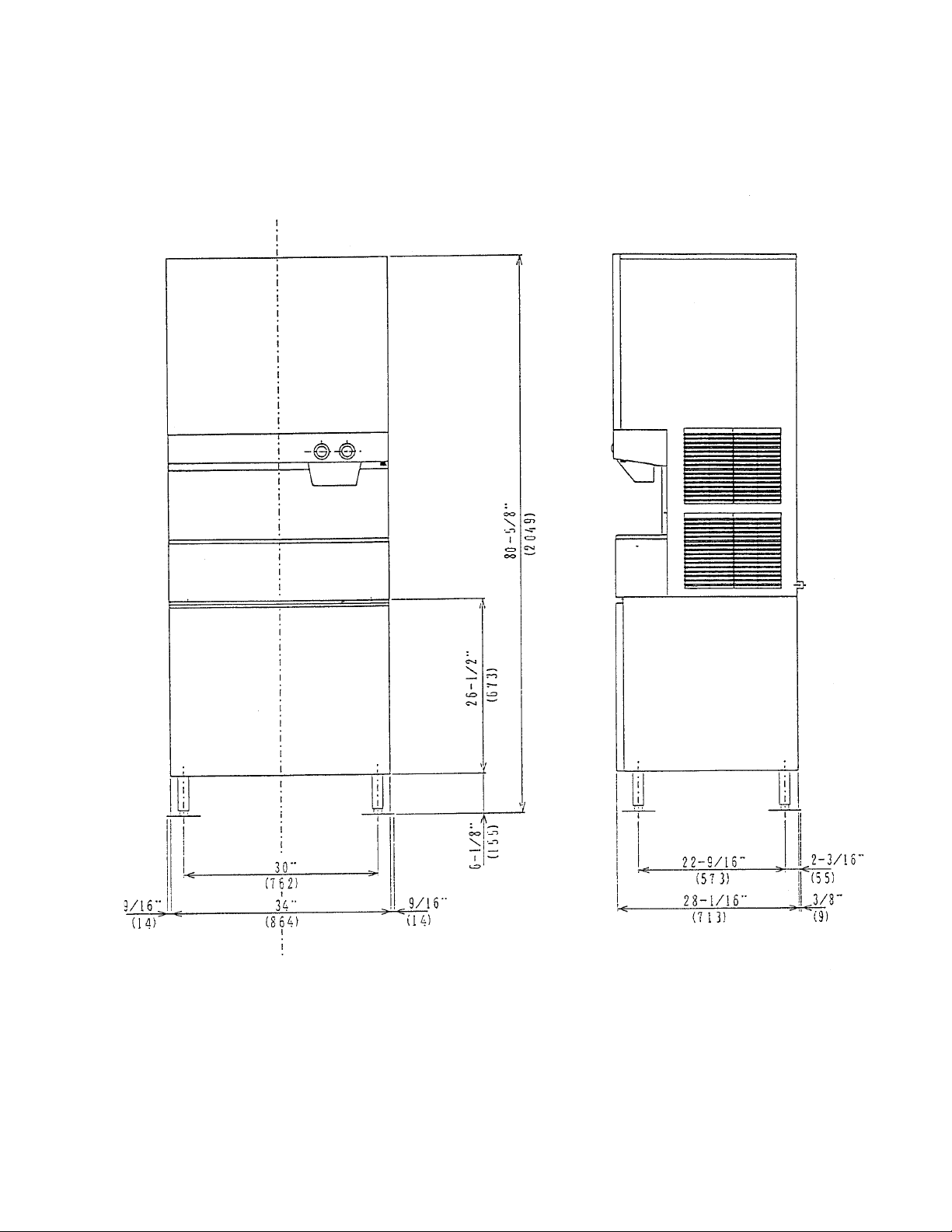

DIMENSIONS WITH DCM-500BAF ON SD-450

Unit: inch (mm.)

Fig. 2

14

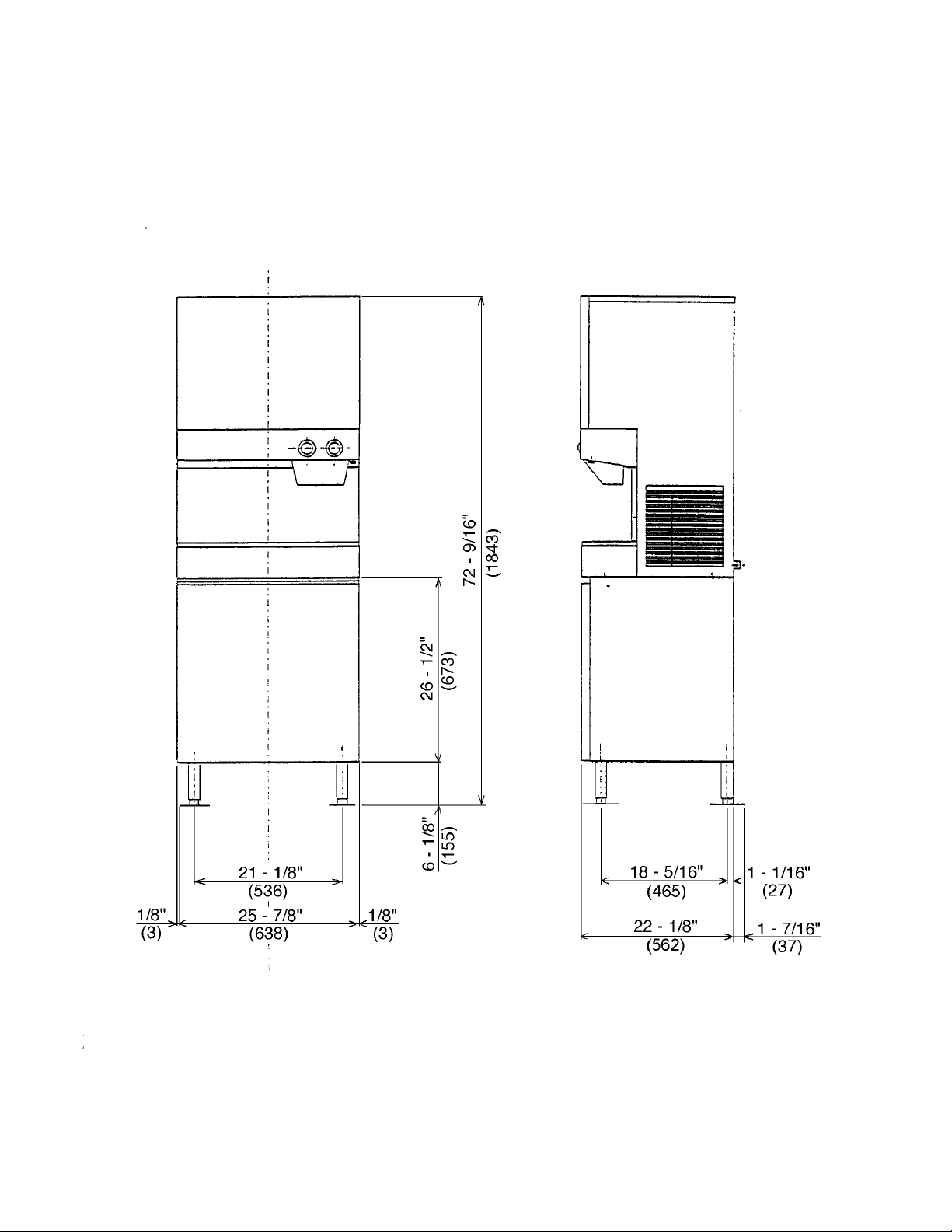

DIMENSIONS WITH DCM-750BAF ON SD-700

Unit: inch (mm.)

Fig. 3

15

III. TECHNICAL INFORMATION

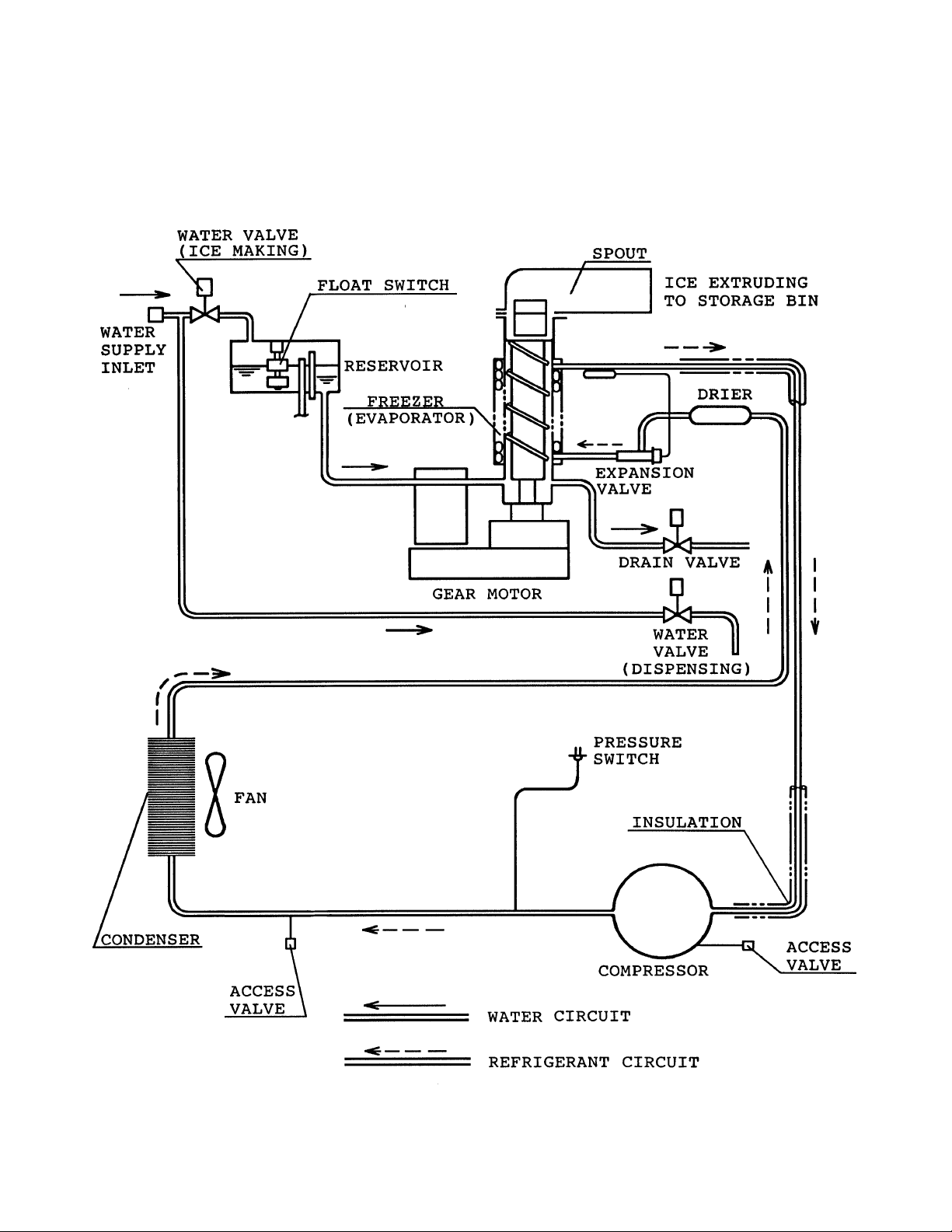

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT

DCM-500BAF

16

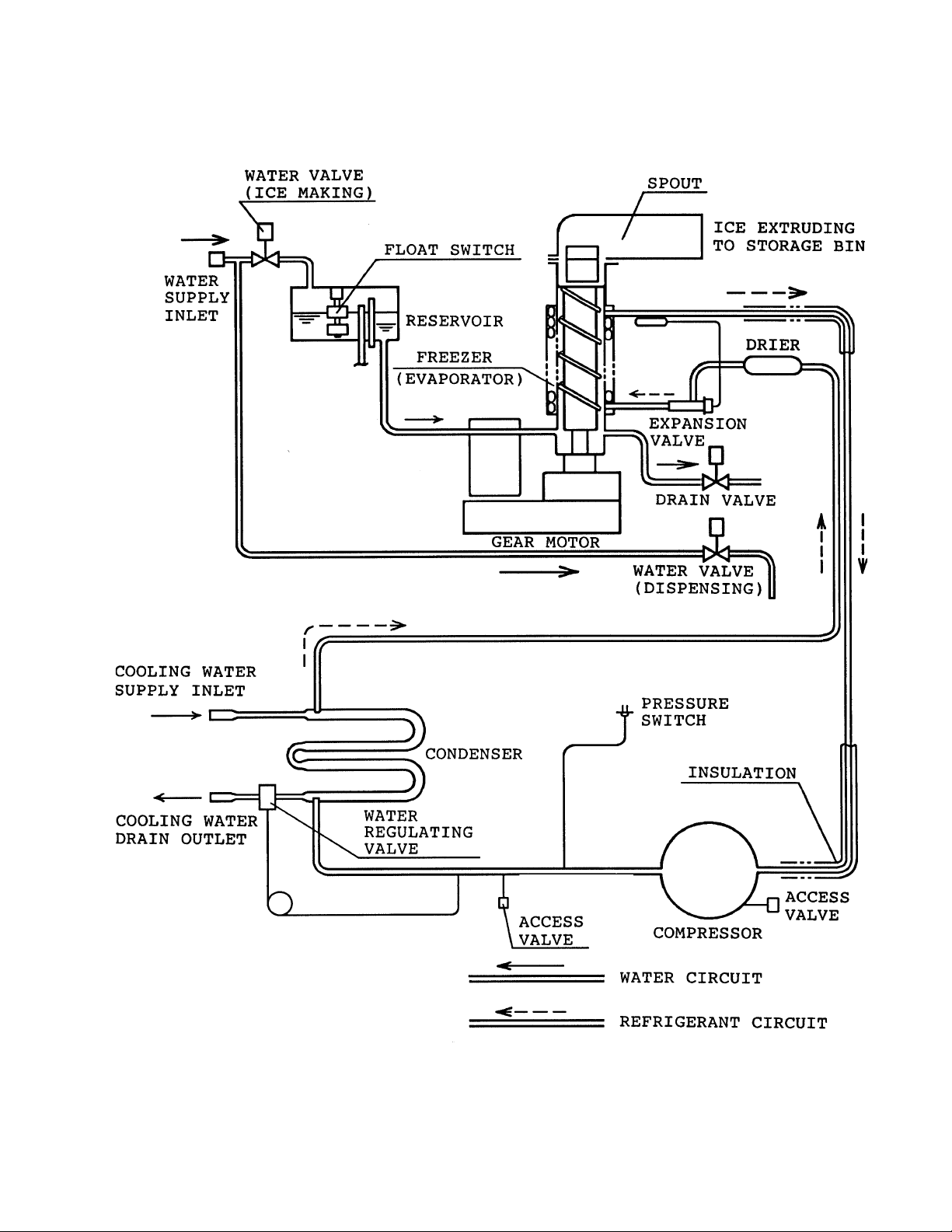

DCM-500BWF

17

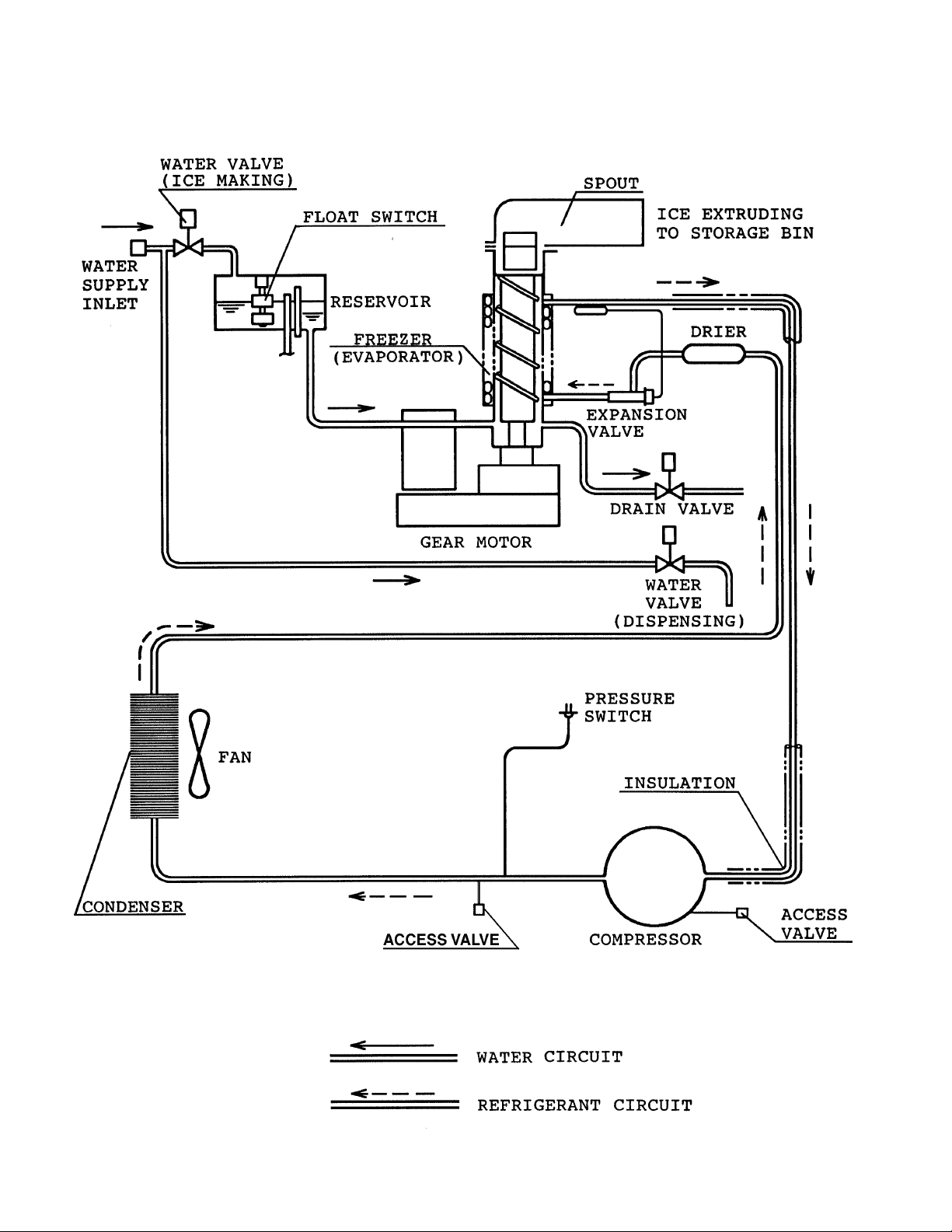

DCM-750BAF

18

DCM-750BWF

19

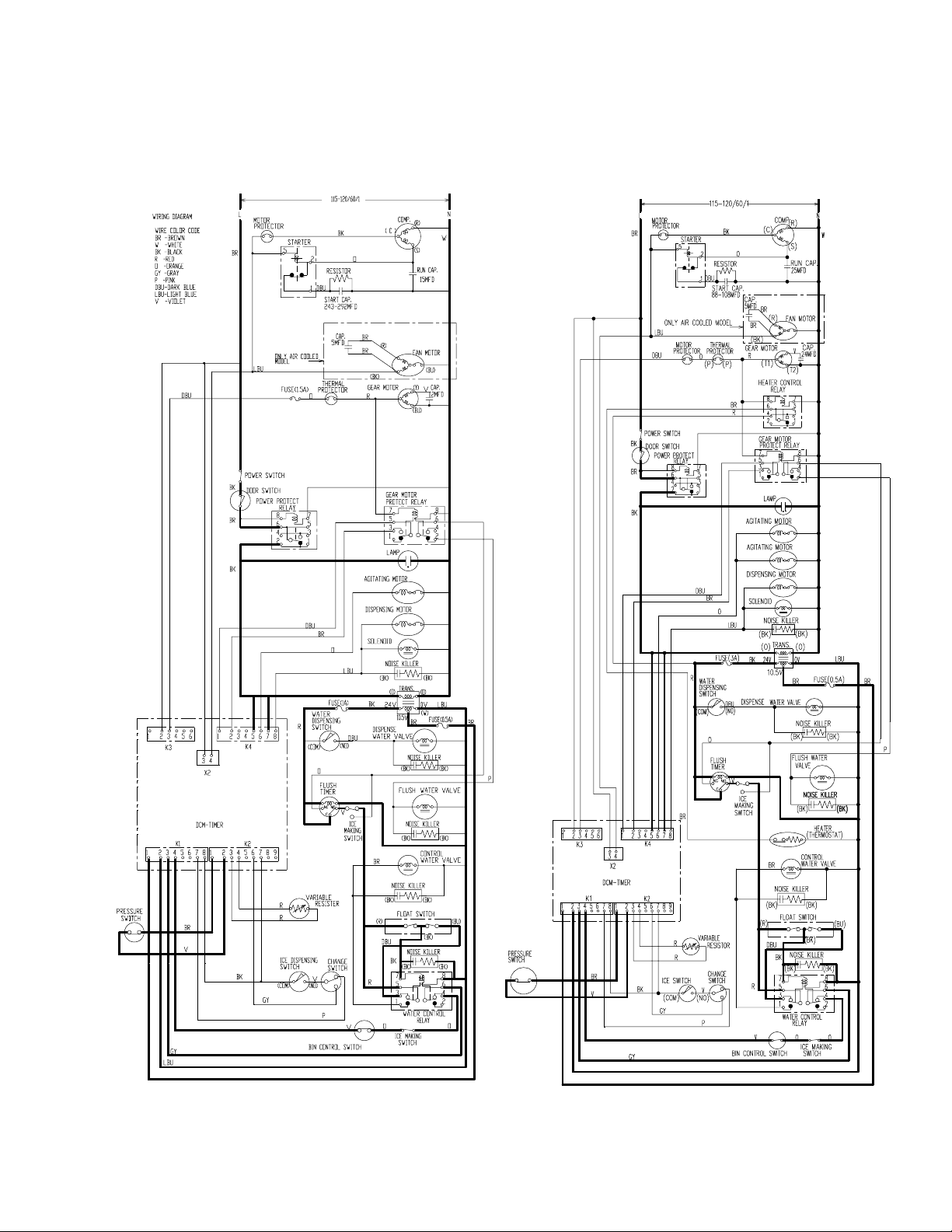

2. WIRING DIAGRAM

DCM-500BAF,

DCM-500BWF

20

DCM-750BAF,

DCM-750BWF

21

3. SEQUENCE OF ELECTRICAL CIRCUIT

[a] When Power Switch and ICE MAKING SWITCH are moved to “ON” position, water

starts to be supplied to Reservoir.

[DCM-500]

[DCM-750]

22

[b1] When Reservoir has been filled up, Gear Motor starts immediately. (Reservoir filled)

[DCM-500] [DCM-750]

23

Loading...

Loading...