Hoshizaki DCM-240BAF Service Manual

NO.:

ISSUED:

REVISED:

73067

JUNE 23, 1998

DEC. 15, 2003

HOSHIZAKI

CUBELET ICE DISPENSER

MODEL

DCM-240BAF

SERVICE MANUAL

IMPORTANT

Only qualified service technicians should attempt to service or maintain this ice dispenser. No service or maintenance should be undertaken until the

technician has thoroughly read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the dispenser.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City , GA 30269

Attn: HOSHIZAKI T echnical Support Dep artment

Phone: 1-800-233-1940 T echnical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: T o expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

• Please review this manual. It should be read carefully before the ice dispenser is

serviced or maintenance operations performed. Only qualified service technicians

should service and maintain the dispenser. This manual should be made available to the

technician prior to service or maintenance.

CONTENTS

PAGE

I. SPECIFICATIONS ........................................................................................................... 5

1. DCM-240BAF (Air-cooled) .......................................................................................... 5

II. GENERAL INFORMATION.............................................................................................. 6

1. CONSTRUCTION ....................................................................................................... 6

2. OPERATION - How it works ....................................................................................... 7

III. TECHNICAL INFORMATION.......................................................................................... 8

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT...................................................... 8

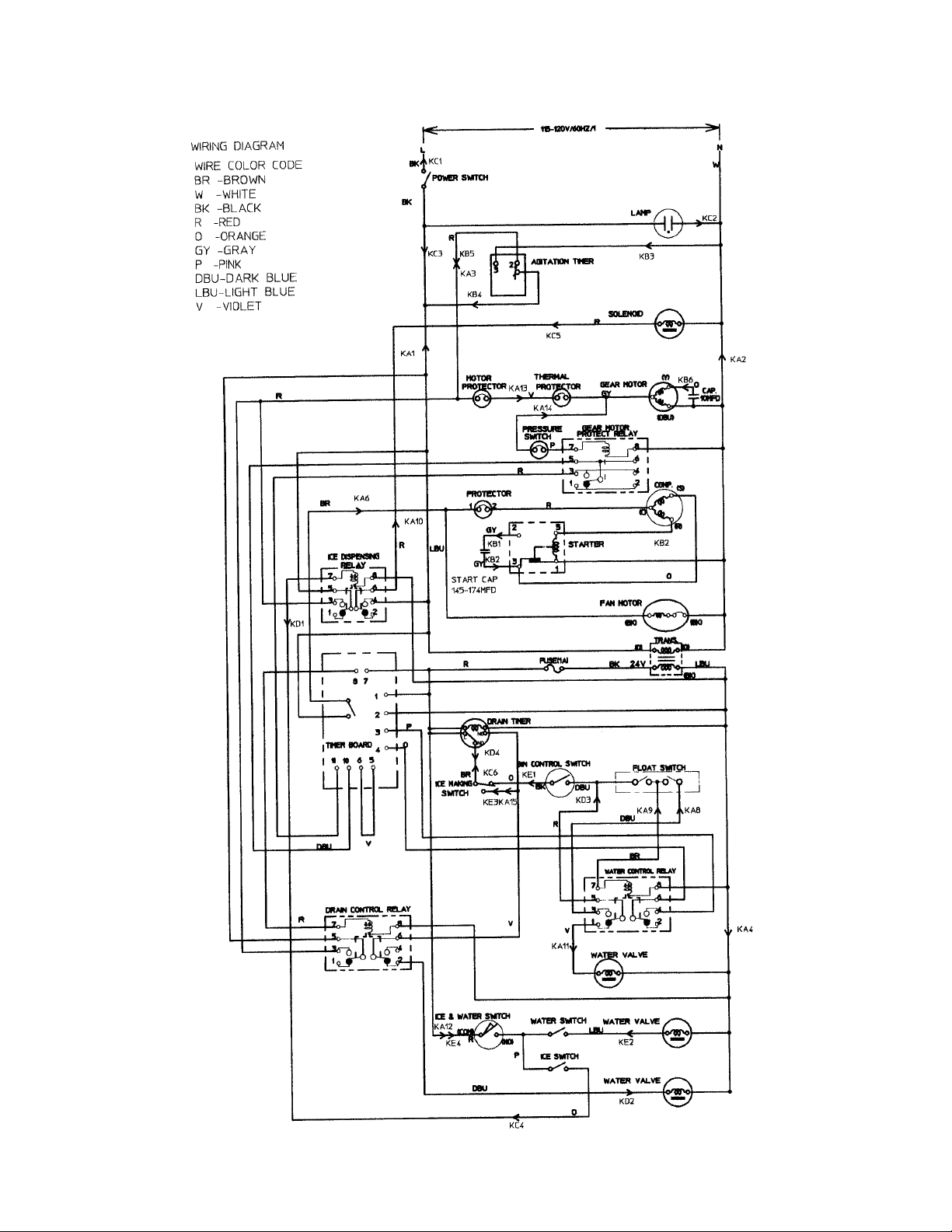

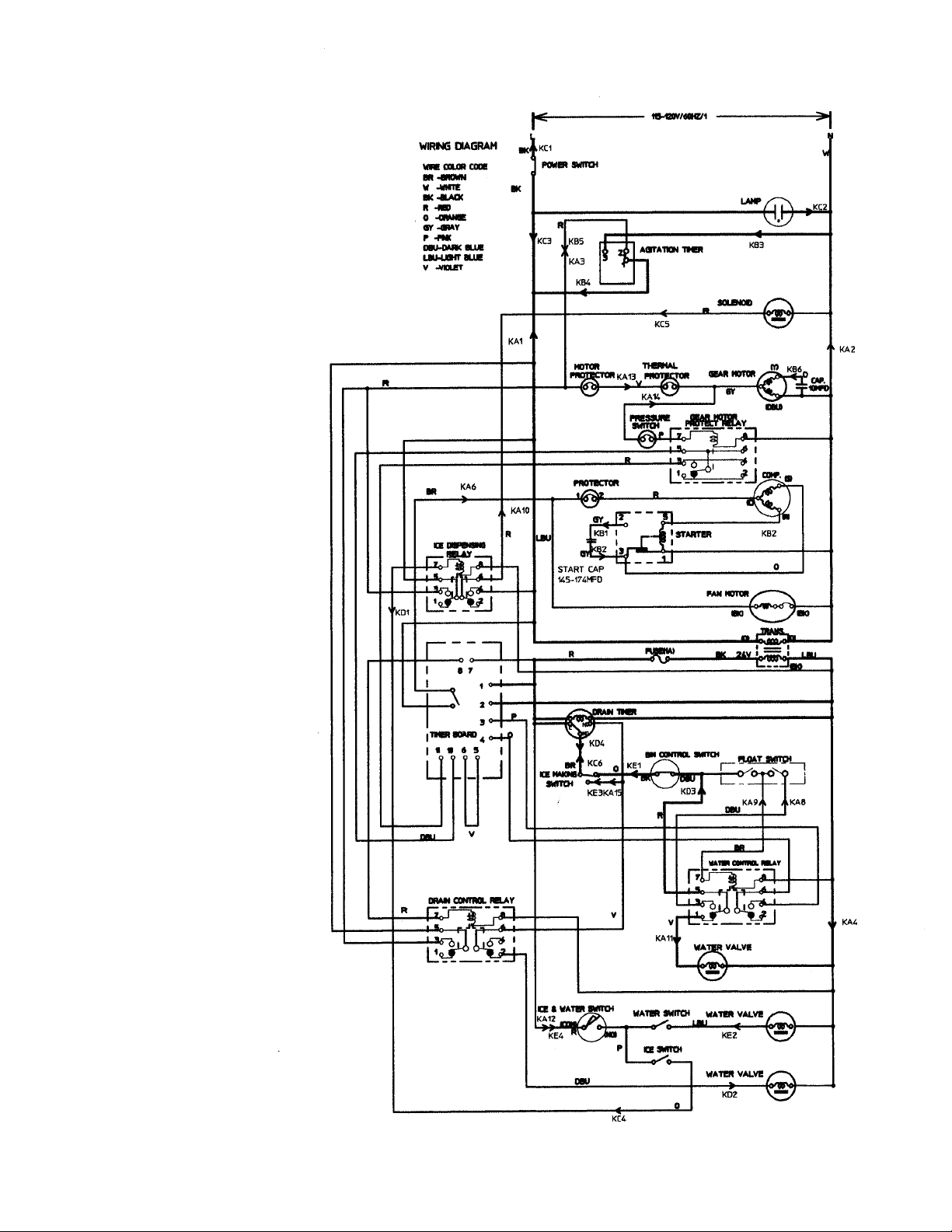

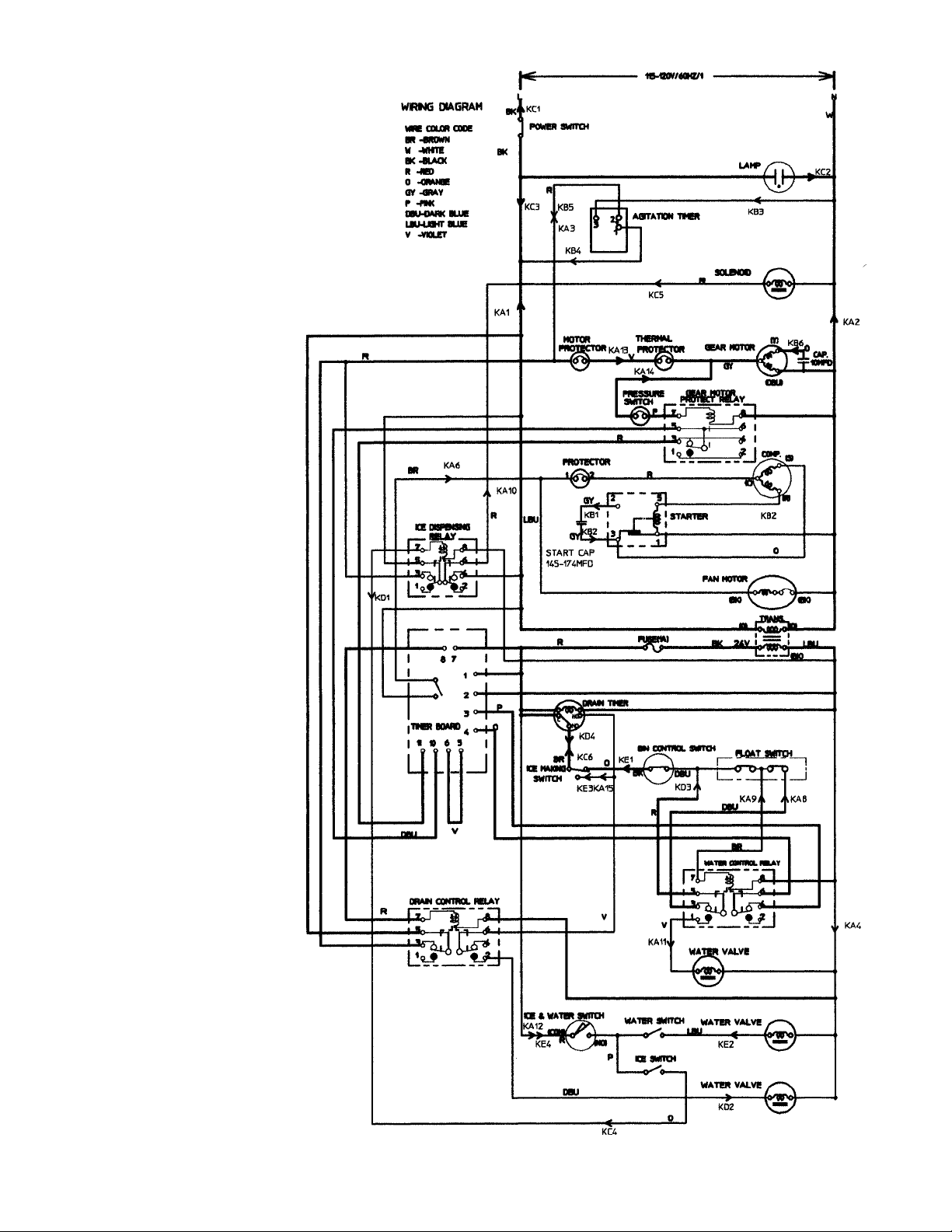

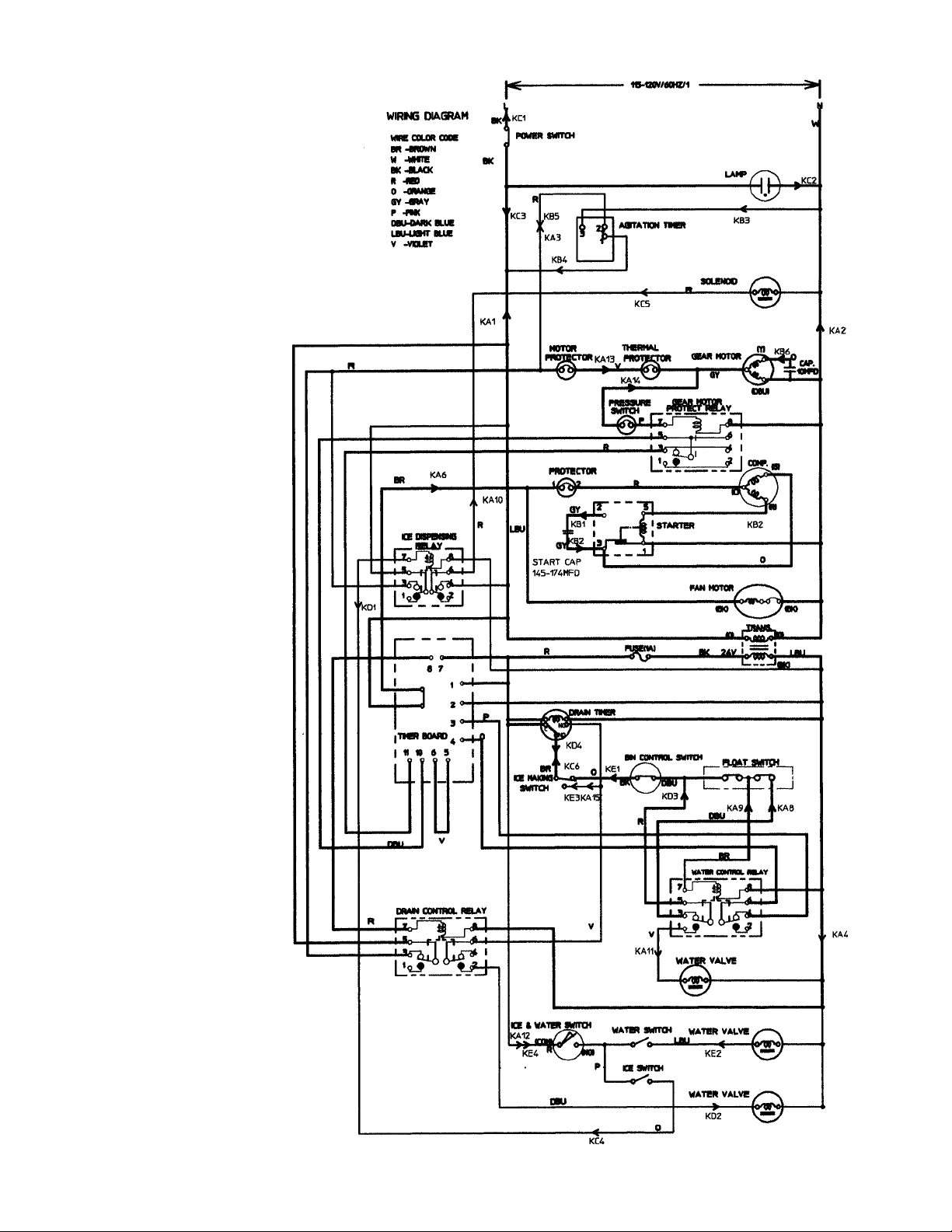

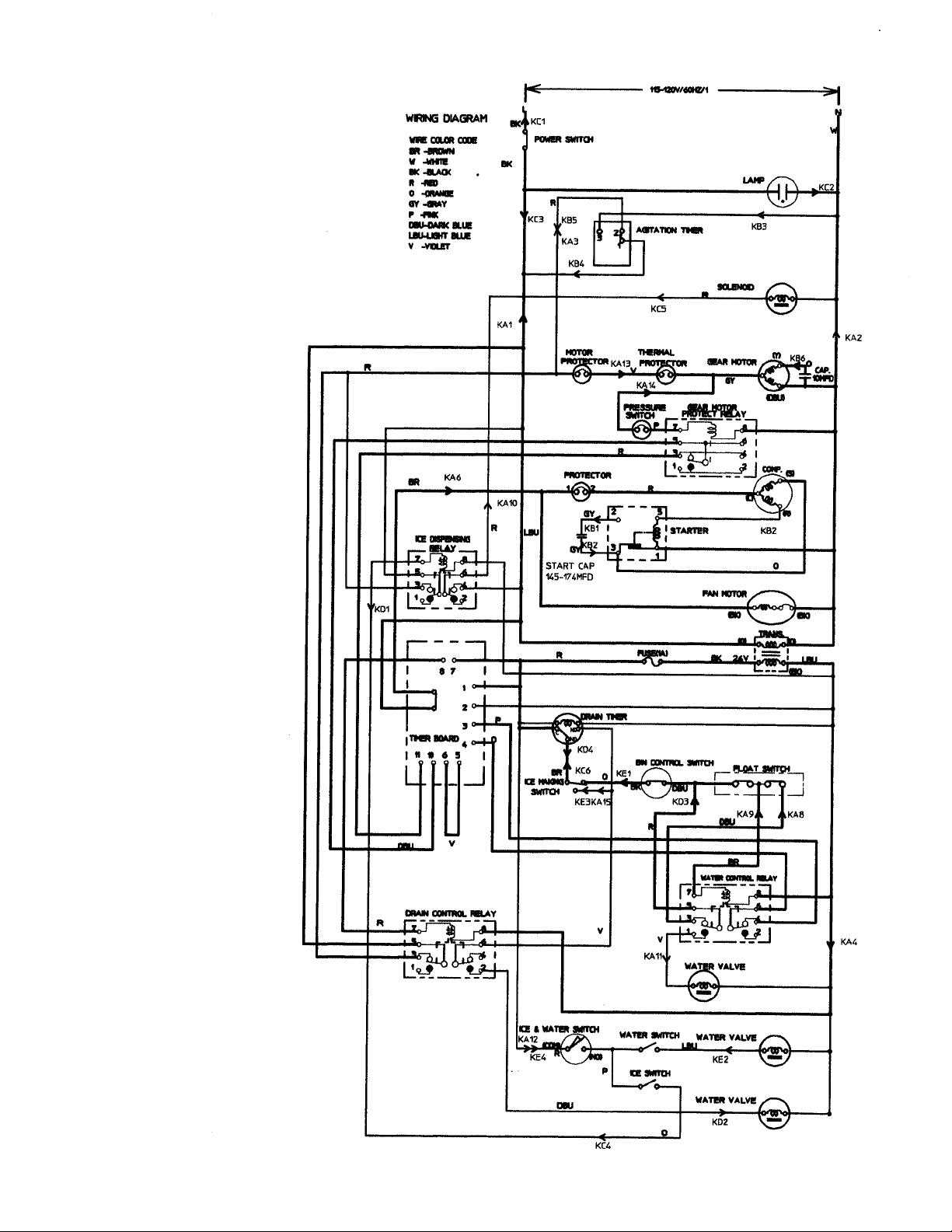

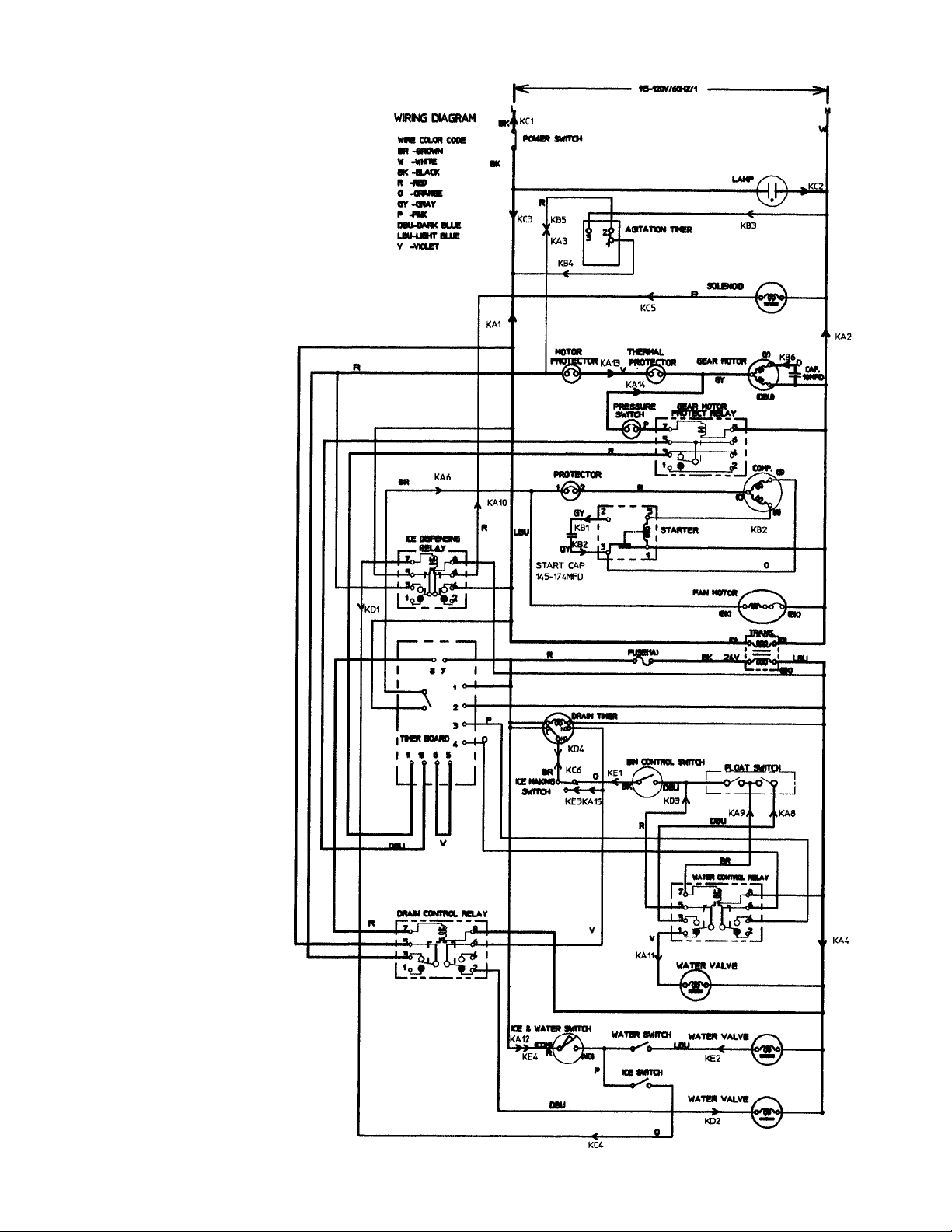

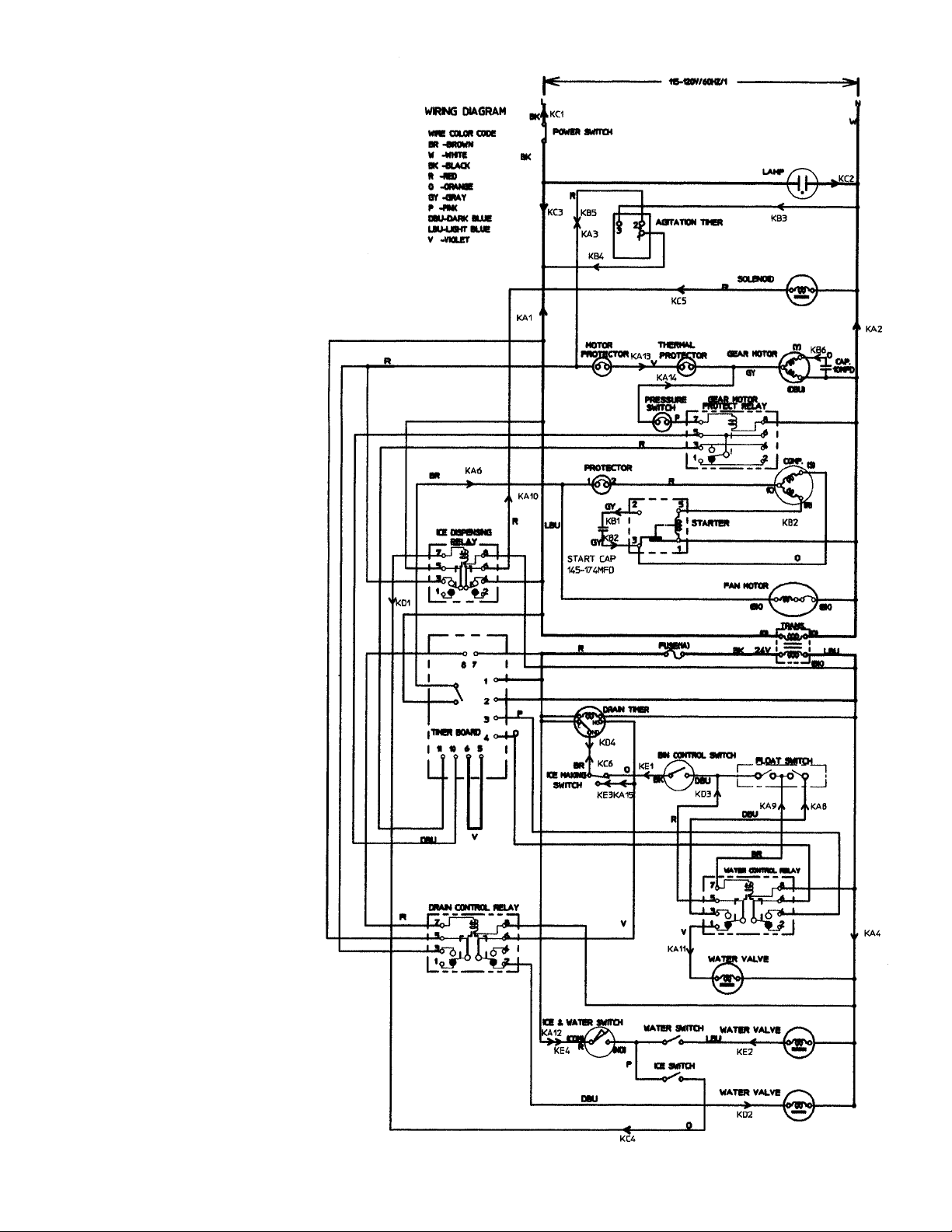

2. WIRING DIAGRAM..................................................................................................... 9

3. SEQUENCE OF ELECTRICAL CIRCUIT.................................................................. 10

4. PERFORMANCE DATA ............................................................................................ 22

IV. SERVICE DIAGNOSIS ................................................................................................ 23

1. NO ICE PRODUCTION............................................................................................. 23

2. LOW ICE PRODUCTION.......................................................................................... 25

3. FAULTY DISPENSER ............................................................................................... 26

4. OTHERS ................................................................................................................... 27

V. REMOVAL AND REPLACEMENT OF COMPONENTS................................................ 28

1. SERVICE FOR REFRIGERANT LINES ..................................................................... 28

[a] REFRIGERANT RECOVERY.............................................................................. 28

[b] EVACUATION AND RECHARGE [R-404A] ........................................................ 28

2. BRAZING .................................................................................................................. 29

3. REMOVAL AND REPLACEMENT OF COMPRESSOR............................................. 30

4. REMOVAL AND REPLACEMENT OF DRIER............................................................ 31

5. REMOVAL AND REPLACEMENT OF THERMOSTATIC EXPANSION VALVE

6. REMOVAL AND REPLACEMENT OF PRESSURE SWITCH .................................... 33

7. REMOVAL AND REPLACEMENT OF WATER VALVE ............................................. 34

8. REMOVAL AND REPLACEMENT OF FLOAT SWITCH ............................................ 35

9. REMOVAL AND REPLACEMENT OF BIN CONTROL SWITCH ASSEMBLY ...... 36

10. REMOVAL AND REPLACEMENT OF STORAGE BIN ASSEMBLY .......................... 37

11. REMOVAL AND REPLACEMENT AGITATOR AND DRIP RING............................... 38

12. REMOVAL AND REPLACEMENT OF EVAPORATOR ASSEMBLY .......................... 39

32

3

VI. CLEANING AND MAINTENANCE INSTRUCTIONS.................................................... 42

1. PREPARING THE ICE DISPENSER FOR LONG STORAGE .................................. 42

2. CLEANING INSTRUCTIONS .................................................................................... 44

[a] CLEANING PROCEDURE .................................................................................. 44

[b] SANITIZING PROCEDURE ................................................................................ 46

3. MAINTENANCE INSTRUCTIONS............................................................................. 48

4

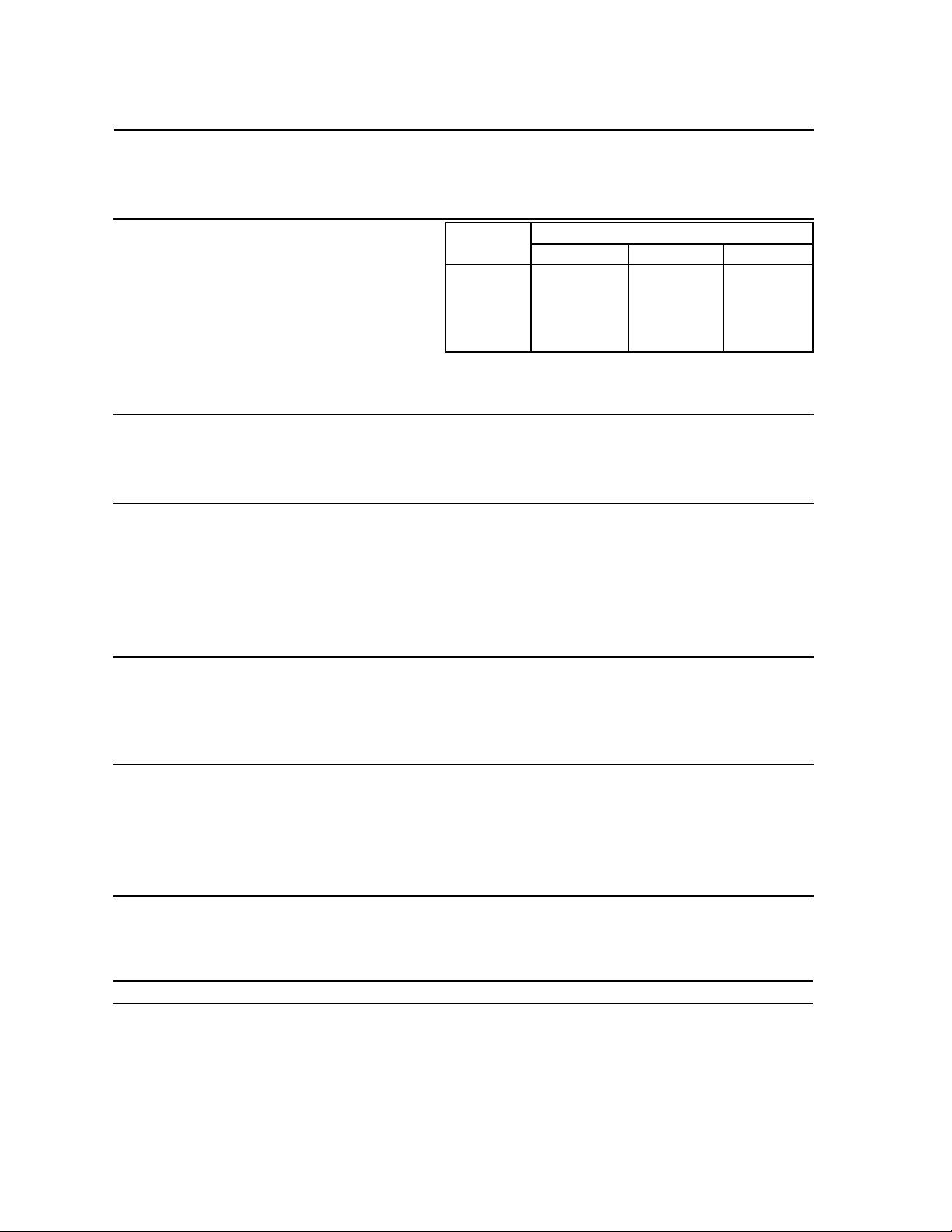

I. SPECIFICA TIONS

1. DCM-240BAF (Air-cooled)

AC SUPPLY VOLTAGE

AMPERAGE

MINIMUM CIRCUIT AMPACITY

MAXIMUM FUSE SIZE

APPROXIMATE ICE PRODUCTION

PER 24 HR.

lbs./day ( kg/day )

Reference without *marks

SHAPE OF ICE

ICE QUALITY

APPROXIMATE STORAGE CAPACITY

ELECTRIC AND WATER CONSUMPTION

ELECTRIC W (kWH/100 lbs.)

POTABLE WATER

gal./24hr. (gal./100 lbs.)

EXTERIOR DIMENSIONS ( W x D x H )

EXTERIOR FINISH

WEIGHT

CONNECTIONS - ELECTRIC

- WATER SUPPLY

- DRAIN

ICE MAKING SYSTEM

HARVESTING SYSTEM

ICE MAKING WATER CONTROL

COOLING WATER CONTROL

BIN CONTROL SYSTEM

COMPRESSOR

CONDENSER

EVAPORATOR

REFRIGERANT CONTROL

REFRIGERANT CHARGE

DESIGN PRESSURE

COMPRESSOR PROTECTION

GEAR MOTOR PROTECTION

REFRIGERANT CIRCUIT PROTECTION

LOW WATER PROTECTION

ACCESSORIES - REQUIRED

OPERATING CONDITIONS

115/60/1

8.5 A [ AT 104°F (40°C) / WT 80°F (27°C) ]

N/A

N/A

Ambient Water Temp. (°F/°C)

Temp (°F/°C) 50/10 70/21 90/32

70/21

80/27

90/32

100/38

Cubelet (compressed flake ice)

Approx. 90% ice ( 90/70°F, conductivity 200µs/cm. )

8.8 lbs

90/70°F 70/50°F

700 ( 8.0) 670 ( 5.9 )

25.6 ( 12.2 ) 32.8 ( 12.0 )

16 9/16" x 24 3/16" x 31 7/8" ( 420 x 615 x 809 mm. )

Stainless steel, plastic top

Net 152 lbs. ( 69 kg. ) Shipping 170 lbs ( 77 kg. )

Cord Connection

Inlet 1/2" NPT

Drain pan 3/4" FPT

Bin drain 3/4" MPT

Auger type

Direct driven auger ( 80 W gear motor )

Float switch

N/A

Mechanical bin control (micro-switch)

Hermetic, Model JS25CIE-IAA-252

Air-cooled, fin and tube type

Copper tube on cylinder

Thermostatic expansion valve

R404A, 15.5 oz. ( 440 g )

High 444 PSIG, Low 230 PSIG

Auto-reset overload protector

Manual reset circuit breaker

Auto-reset high pressure control switch

Float switch and timer

N/A

VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 45 - 100°F

WATER SUPPLY TEMP. 45 - 90°F

WATER SUPPLY PRESS. 10 - 113 PSIG

*275 ( 125 )

240 (110 )

215 ( 98 )

190 ( 87 )

265 ( 120 )

230 ( 105 )

*210 ( 95 )

190 ( 86 )

250 ( 111 )

215 ( 98 )

200 ( 90 )

*175 ( 78 )

* We reserve the right to make changes in specifications and design without prior notice.

5

II. GENERAL INFORMATION

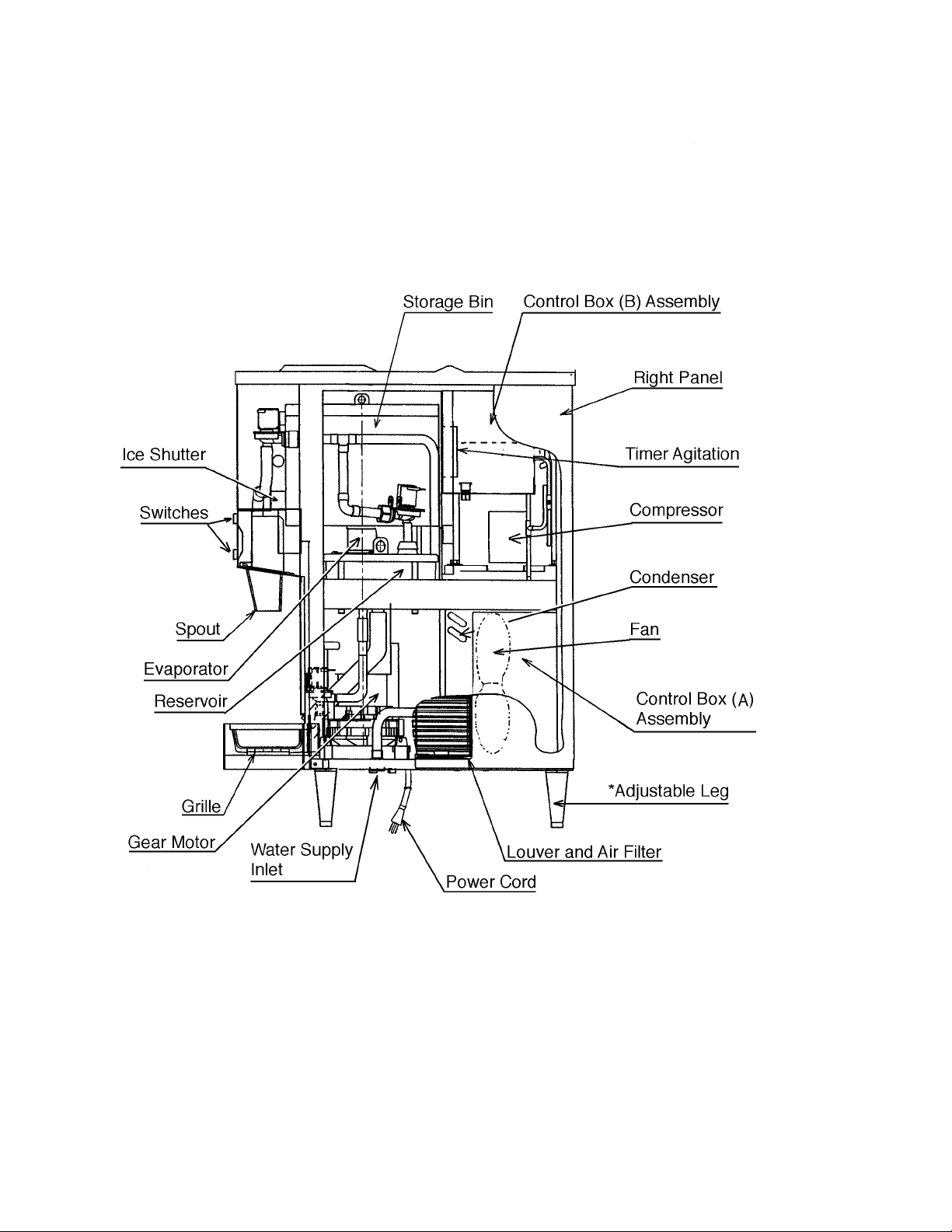

1. CONSTRUCTION

Hoshizaki Cubelet Ice Dispenser, model DCM-240BAF includes Water Supply, Freezer,

Condensing, Storage, Dispensing and Control Assemblies.

Note: *Adjustable Legs

Minimum height - 4"

Maximum height - 5.3"

Do not adjust exceeding the above recommendation.

Fig. 1

6

A2AAA0269804

2. OPERA TION - How it works

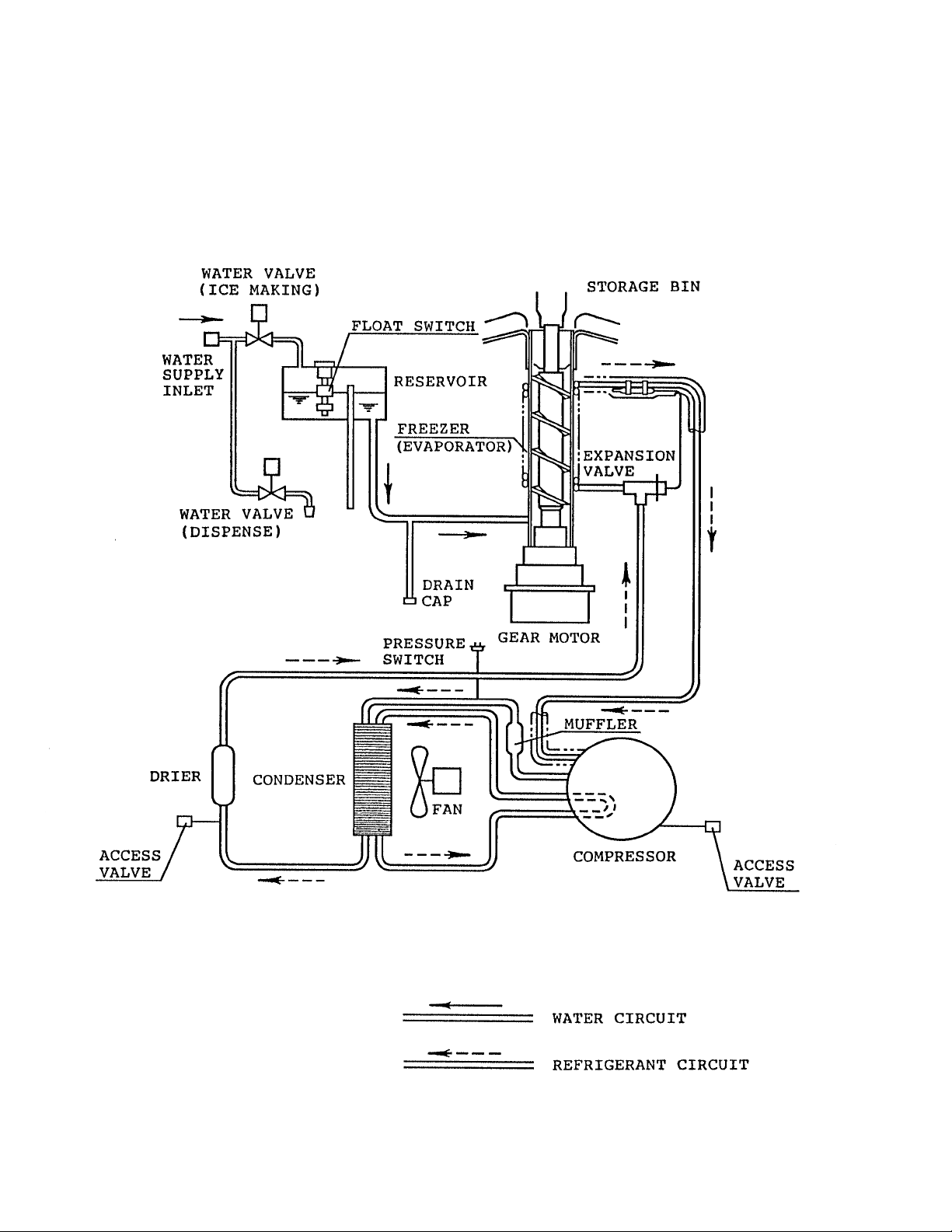

Water flows from the potable water source through the Water Supply Line Shut-off Valve,

enters at the Water Inlet fitting and into the Water Reservoir. The Water Reservoir functions to maintain a constant water level inside the Freezer Assembly. Water from the

Water Reservoir enters at the bottom of the Freezer. Heat is removed by the refrigeration

process and ice forms inside the Freezer.

A stainless steel Auger, located inside the Freezer, is direct-driven by the Gear Motor, and

the rotating Auger carries the ice upward to the end of the Auger, where excess water is

pressed out of the ice, as the ice is extruded and broken into cubelet ice (compressed ice)

and then pushed out into the Storage Bin.

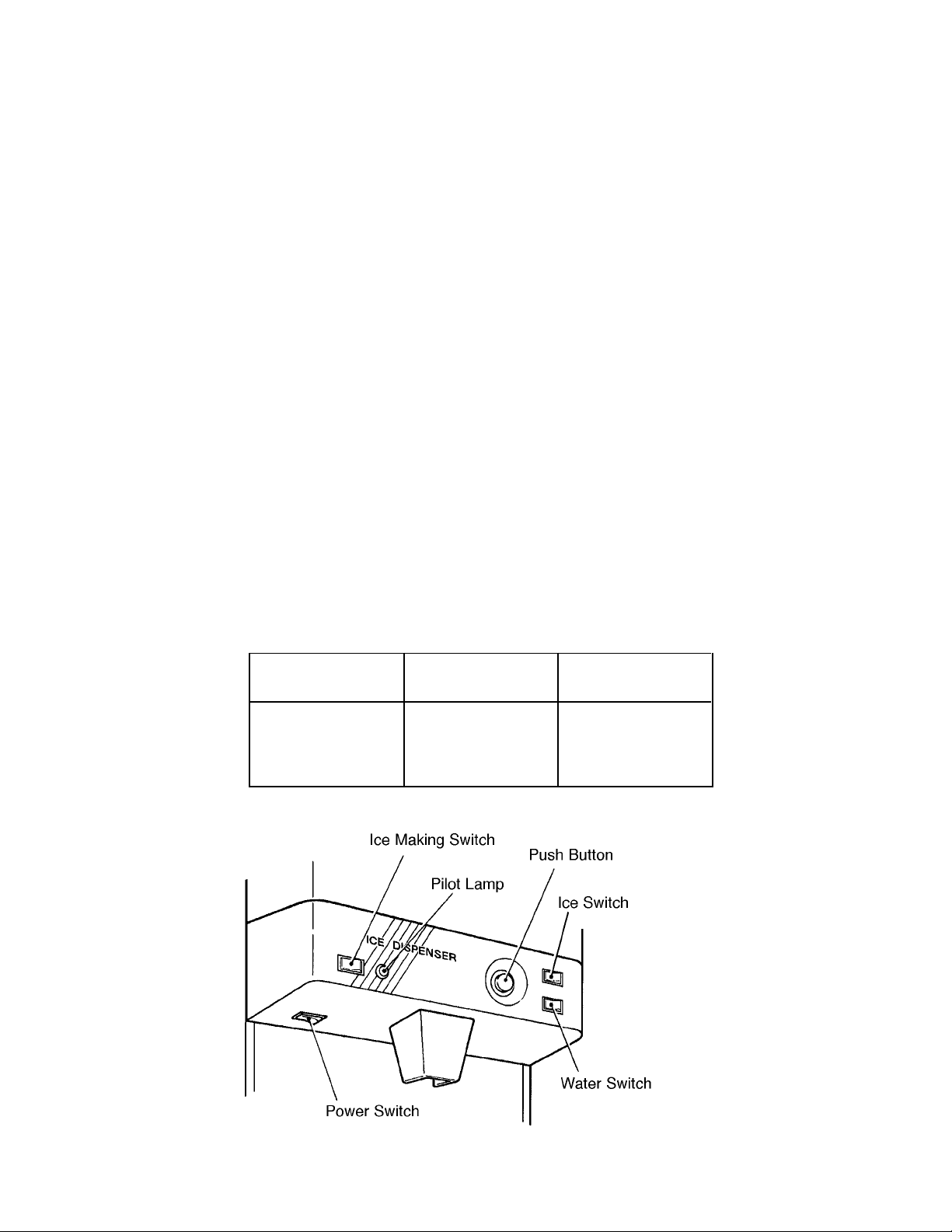

Moving the Power Switch and the Ice Making Switch, on the left of the Middle Front Panel,

to the “ON” position starts the automatic and continuous icemaking process. When the Ice

Storage Bin is filled with ice, the Bin Control Switch will shut off the icemaking process. As

the ice is removed from the Storage Bin, the Bin Control Switch resets automatically and

restarts the icemaking process.

Moving the Ice Switch and the Water Switch, located on the right of the Middle Front Panel,

to the “ON” and/or “OFF” positions gives the user a convenient 3-way dispensing.

The Agitator in the Storage Bin keeps the ice from clustering so that the ice can move

easily through the Spout.

Choice Ice Switch Water Switch

Ice Only

Water Only

Ice and Water

ON

OFF

ON

OFF

ON

ON

Fig. 2

A2AAA0269804

7

III. TECHNICAL INFORMA TION

1. W ATER CIRCUIT AND REFRIGERANT CIRCUIT

8

A2AAA0269804

2. WIRING DIAGRAM

A2AAA0269804

9

3. SEQUENCE OF ELECTRICAL CIRCUIT

POWER ON

WATER STARTS TO BE

SUPPLIED TO RESERVOIR

AGITATION TIMER ON - (2 SEC.)

10

A2AAA0269806

RESERVOIR FILLS UP

GEAR MOTOR TURNS ON

A2AAA0269806

11

COMPRESSOR STARTS

@ 60 SEC. AFTER

GEAR MOTOR

12

A2AAA0269806

ICE MAKING CONTINUES

A2AAA0269806

13

BIN CONTROL SWITCH

TRIPPED

COMPRESSOR STOPS

@ 90 SEC. LATER

14

A2AAA0269806

GEAR MOTOR STOPS

@ 60 SEC. AFTER

COMPRESSOR

A2AAA0269806

15

Loading...

Loading...