Hoshizaki DCM-230FE-UK Service Manual

NO:

ISSUED:

REVISED:

73109

DEC. 23, 1998

JAN. 13, 2004

HOSHIZAKI

CUBELET ICE DISPENSER

MODEL

DCM-230FE

SERVICE MANUAL

FOREWORD

IMPORTANT

Only qualified service technicians should attempt to service or maintain this icemaker.

No service or maintenance should be undertaken until the technician has thoroughly

read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City , GA 30269

Attn: HOSHIZAKI T echnical Support Department

Phone: 1-800-233-1940 T echnical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: T o expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

Please review this manual. It should be read carefully before the icemaker is serviced

or maintenance operations are performed. Only qualified service technicians should

service and maintain the icemaker. This manual should be made available to the technician prior to service or maintenance.

CONTENTS PAGE

I. GENERAL INFORMATION .............................................................................................5

1. DIMENSIONS AND CONNECTIONS ........................................................................ 5

2. CONSTRUCTION ...................................................................................................... 6

3. OPERATION - How it works ......................................................................................7

4. TIMER BOARD ..........................................................................................................8

[a] SOLID-STATE CONTROL ..................................................................................8

[b] TIMER BOARD ................................................................................................... 8

[c] SEQUENCE ...................................................................................................... 10

II. INSTALLATION INSTRUCTIONS................................................................................12

1. UNPACKING............................................................................................................12

2. LOCATION...............................................................................................................13

3. INSTALLATION ....................................................................................................... 14

4. ELECTRICAL CONNECTION..................................................................................14

5. WATER SUPPLY AND DRAIN CONNECTIONS.....................................................15

III. OPERATING INSTRUCTIONS .................................................................................... 17

1. START UP ............................................................................................................... 17

2. CONTROLS AND ADJUSTMENTS ......................................................................... 19

3. PREPARING THE ICE DISPENSER FOR LONG STORAGE.................................19

IV. MAINTENANCE...........................................................................................................21

1. PERIODIC CLEANING ............................................................................................21

2. CLEANING OF WATER SYSTEM........................................................................... 22

V. TECHNICAL INFORMATION ....................................................................................... 2 7

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT..................................................27

2. WIRING DIAGRAM.................................................................................................. 2 8

3. TIMING CHART ....................................................................................................... 29

4. SPECIFICATIONS ...................................................................................................30

5. PERFORMANCE DATA........................................................................................... 31

6. ICE DISPENSING CAPACITY................................................................................. 3 2

VI. SERVICE DIAGNOSIS ...............................................................................................36

VII. REMOVAL AND REPLACEMENT OF COMPONENTS ............................................ 40

1. SERVICE FOR REFRIGERANT LINES................................................................... 40

[a] REFRIGERANT RECOVERY ........................................................................... 40

[b] EVACUATION AND RECHARGE (R-404A) .....................................................40

2. BRAZING .................................................................................................................41

3

3. REMOVAL AND REPLACEMENT OF COMPRESSOR ........................................... 42

4. REMOVAL AND REPLACEMENT OF DRIER.......................................................... 43

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE.................................... 44

6. REMOVAL AND REPLACEMENT OF ICE MAKING MECHANISM.............................

AND WATER SYSTEM............................................................................................. 45

7. REMOVAL AND REPLACEMENT OF ELECTRICAL SYSTEM ............................... 51

8. REMOVAL AND REPLACEMENT OF DISPENSING SYSTEM ............................... 53

9. BEFORE CALLING A SERVICE AGENT ................................................................. 54

10. WARRANTY ............................................................................................................. 54

4

I. GENERAL INFORMATION

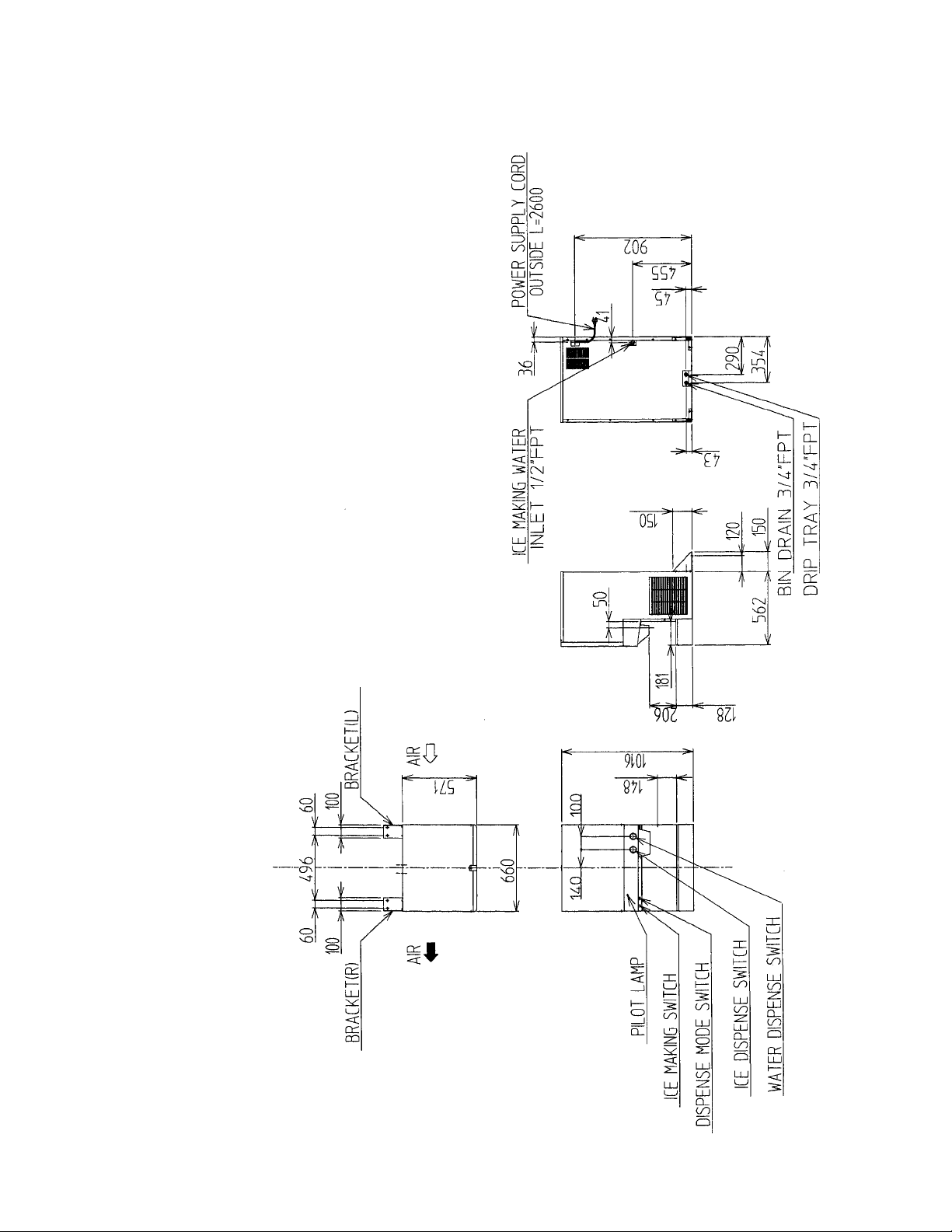

1. DIMENSIONS/CONNECTIONS

5

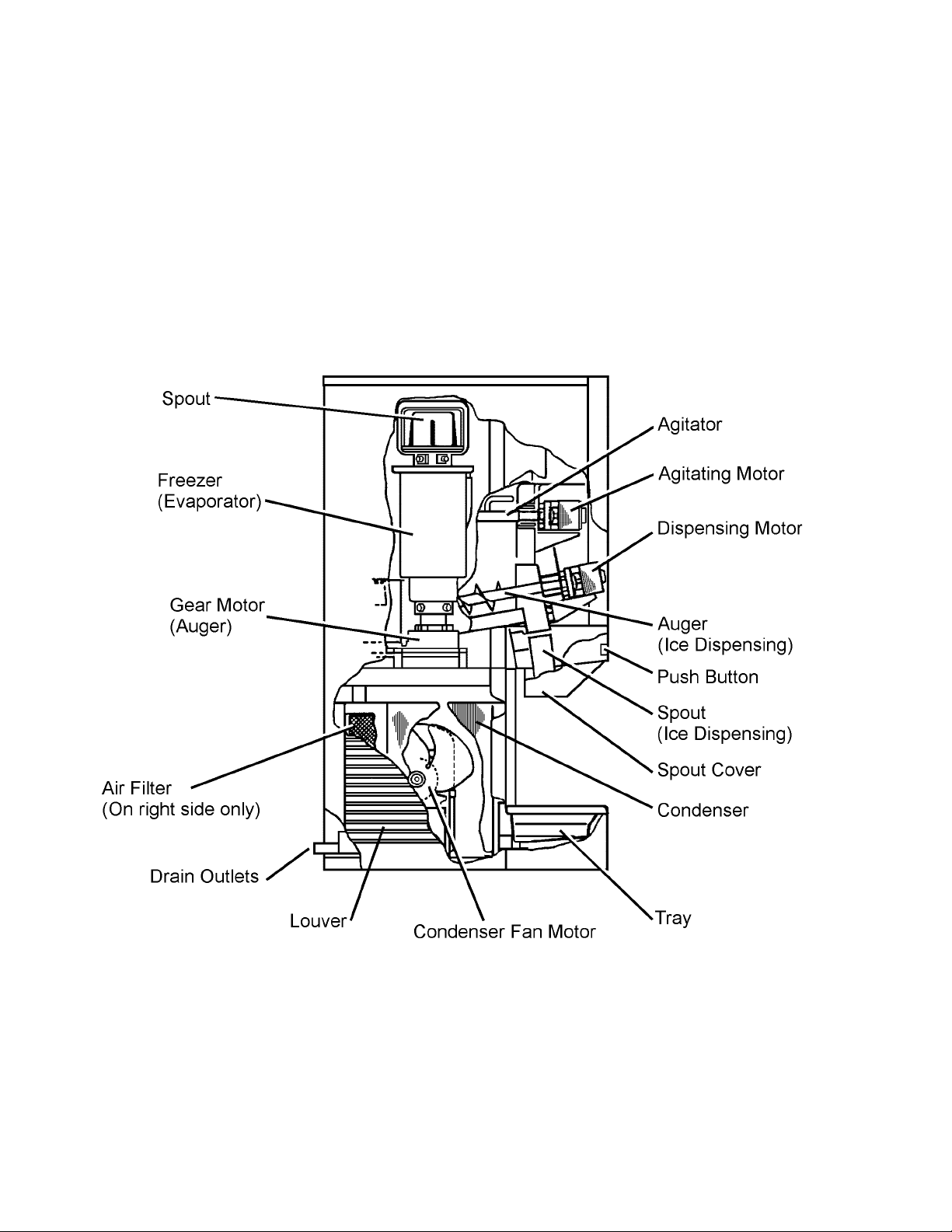

2. CONSTRUCTION

Hoshizaki Cubelet Ice Dispenser, model DCM-230FE includes Water Supply, Freezer,

Condensing, Storage, Dispensing and Control Assemblies.

6

3. OPERATION - How it works

Water flows from the potable water source through the Water Supply Line Shut-off Valve,

enters at the Water Inlet fitting and into the Water Reservoir. The Water Reservoir functions to maintain a constant water level inside the Freezer Assembly. Water from the

Water Reservoir enters at the bottom of the Freezer. Heat is removed by the refrigeration

process and ice forms inside the Freezer.

A stainless steel Auger, located inside the Freezer, is direct-driven by the Gear Motor, and

the rotating Auger carries the ice upward to the end of the Auger, where excess water is

pressed out of the ice, as the ice is extruded and broken into cubelet ice (compressed ice)

and then pushed out into the Ice Storage Bin through the Ice Spout.

Turning on the Power Switch on the Control Box starts the automatic and continuous

icemaking process. When the Ice Storage Bin is filled with ice, the Bin Control Switch,

located on the top of the Storage Bin, shuts off the icemaking process. As the ice is removed from the Storage Bin, the Bin Control Switch resets automatically and restarts the

icemaking process.

Moving the Dispense Mode Switch to the “PORTION” position gives the user a portioncontrolled mode, resulting in dispensing a certain amount of ice (See “IV. 2. CONTROLS

AND ADJUSTMENTS”) when the Push Button is pressed. Moving the switch to the “CONTINUOUS” position, gives a continuous dispensing mode, resulting in dispensing ice while

the Push Button is being pressed.

The Agitator in the Storage Bin keeps the ice from clustering so that the ice can move

easily through the Spout and prevents the formation of an ice block.

7

4. TIMER BOARD

[a] SOLID-STATE CONTROL

1) A HOSHIZAKI exclusive solid-state control is employed in the DCM-230FE cubelet ice

dispenser. This control includes a microprocessor (LSI) developed by HOSHIZAKI.

2) A Printed Circuit Board (hereafter called “Timer Board”) includes a stable and high quality

control system.

3) No adjustment is required.

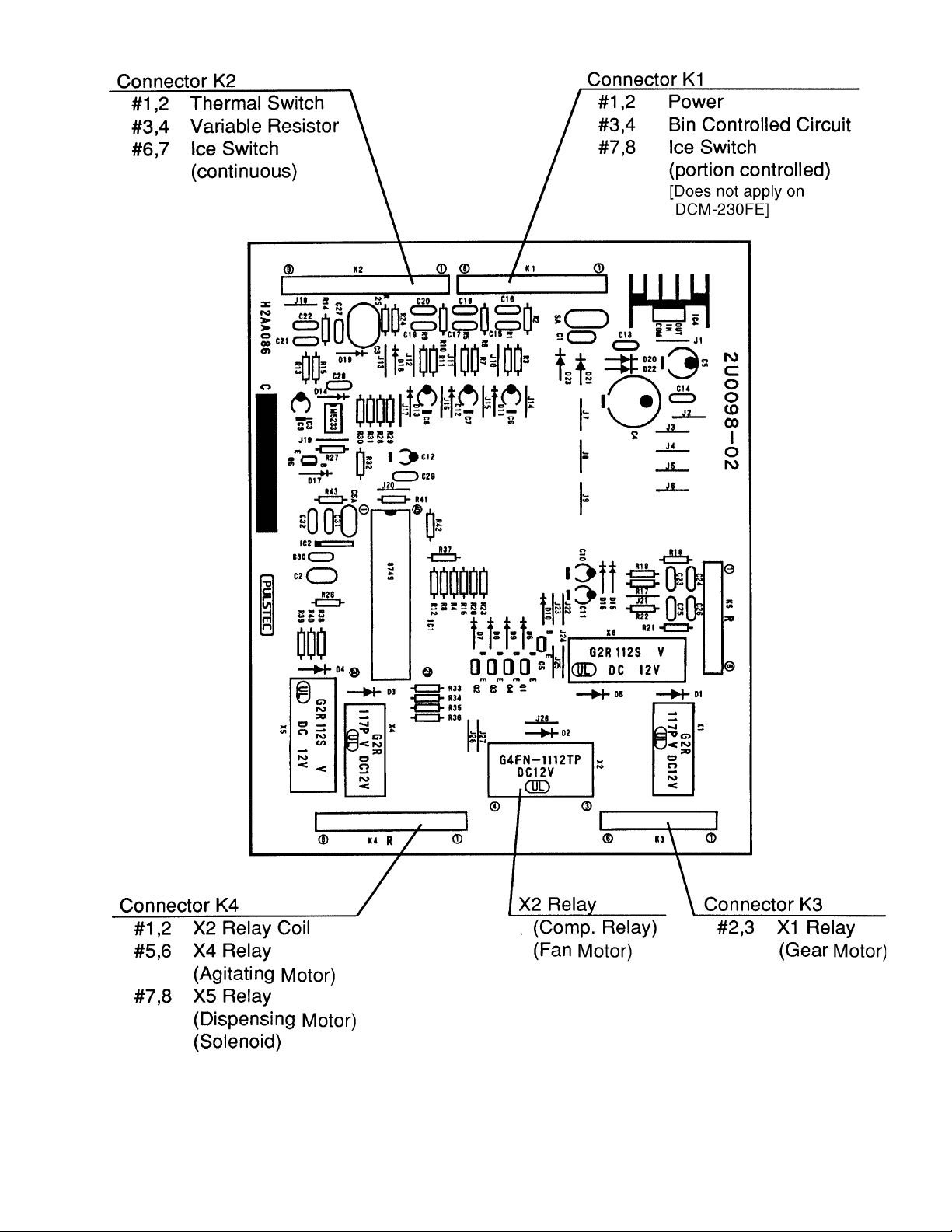

[b] TIMER BOARD

CAUTION

1. Fragile, handle very carefully.

2. A timer board contains CMOS (Complementary Metal-Oxide Semiconductor)

integrated circuits, which are susceptible to failure due to static discharge. It

is especially important to use an antistatic wrist strap when handling or

replacing the board.

3. Do not touch the electronic devices on the board or the back of the board to

prevent damage to the board.

4. Do not change wiring and connections. Especially, never misconnect K1,

K2, K3 and K4.

5. Do not fix the electronic devices or parts on the board in the field. Always

replace the whole board assembly when it goes bad.

A timer board, Part Code 2U0098-02 (Model H2AA086C03), is used for DCM-230FE.

8

9

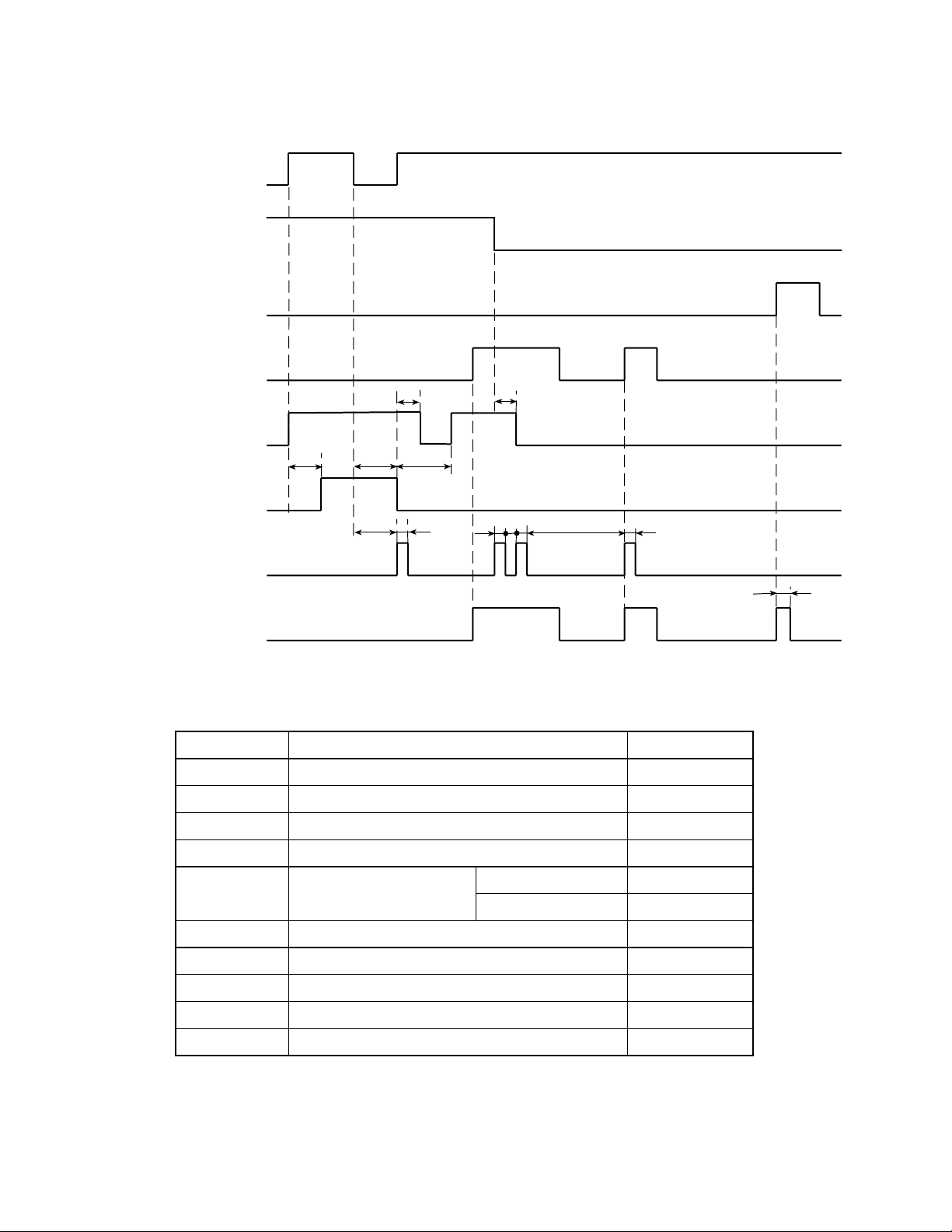

[c] SEQUENCE

ON

Bin Control

OFF

Pressure Switch

OFF

ON

Ice Switch

[portion controlled]

Ice Switch

[continuous]

X1 Relay

[Gear Motor]

X2 Relay

[Compressor Relay]

X4 Relay

[Agitating Motor]

X5 Relay

[Solenoid]

[Dispensing Motor]

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

t6

t3

t9 t9

t6

t7

t6

t5

t3

t1

t2

t8

t4

t10

KRAMMETIEMIT

1temiTyaled-NOyaleR2X.ces06

2temiTyaled-FFOyaleR2X.ces09

3temiTyaled-FFOyaleR1X.ces06

4temiTyaled-tratseRyaleR1X.ces021

muminiM.ces6.0

5temiTNOyaleR5X

mumixaM.ces02

6temiTtratser-itnAyaleR4X.ces21

7temiTteser-itnAyaleR4X.ces02

8temiTyaled-NOyaleR4X.ces09

9t)6tgnitelpmocretfa(emiTNOyaleR4X.ces6.0

01t)8tgnitelpmocretfa(emiTNOyaleR4X.ces6.0

10

Functions of Relays

1) X1

- makes just when the Bin Control Circuit closes.

- breaks t3 sec. after X2 breaks following the t2 sec. delay since the Bin Control Circuit

opens.

- will not make for t4 sec. after X2 breaks, even if the Bin Control Circuit closes.

2) X2

- makes t1 sec. after the Bin Control Circuit closes.

- breaks t2 sec. after the Bin Control Circuit opens.

- will not make while the Pressure Switch is OFF, whether the Bin Control Circuit is ON

or OFF.

3) X4

- makes for t10 sec. after the t8 sec. delay since the Bin Control Circuit closes.

- makes for t9 sec. after the t6 sec. delay since X5 is made by switching ON the Ice

Switch (portion controlled) or Ice Switch (continuous).

- makes just when X5 is made by switching ON the Ice Switch (portion controlled) or

Ice Switch (continuous), after t7 min. has passed since X4 breaks.

4) X5

- makes for t5 sec. after the Ice Switch (portion controlled) is switched ON.

- is ON while the Ice Switch (continuous) is ON.

11

II. INSTALLATION INSTRUCTIONS

WARNING

The installation must be carried out by qualified personnel, in accordance with

current regulations, according to the manufacturer’s instructions.

1. UNP ACKING

WARNING

Children should not be allowed in reach of the packaging elements (plastic

bags and expanded polystyrene) as they are potential sources of danger.

CAUTION

1. Remove shipping carton, tape(s) and packing. If packing material is left in the

ice dispenser, it will not work properly.

2. Ensure all components, fasteners and thumbscrews are securely in place.

1) After removing the packaging, make sure that the ice dispenser is in good condition. If in

doubt, please do not use the equipment but apply to professionally qualified personnel.

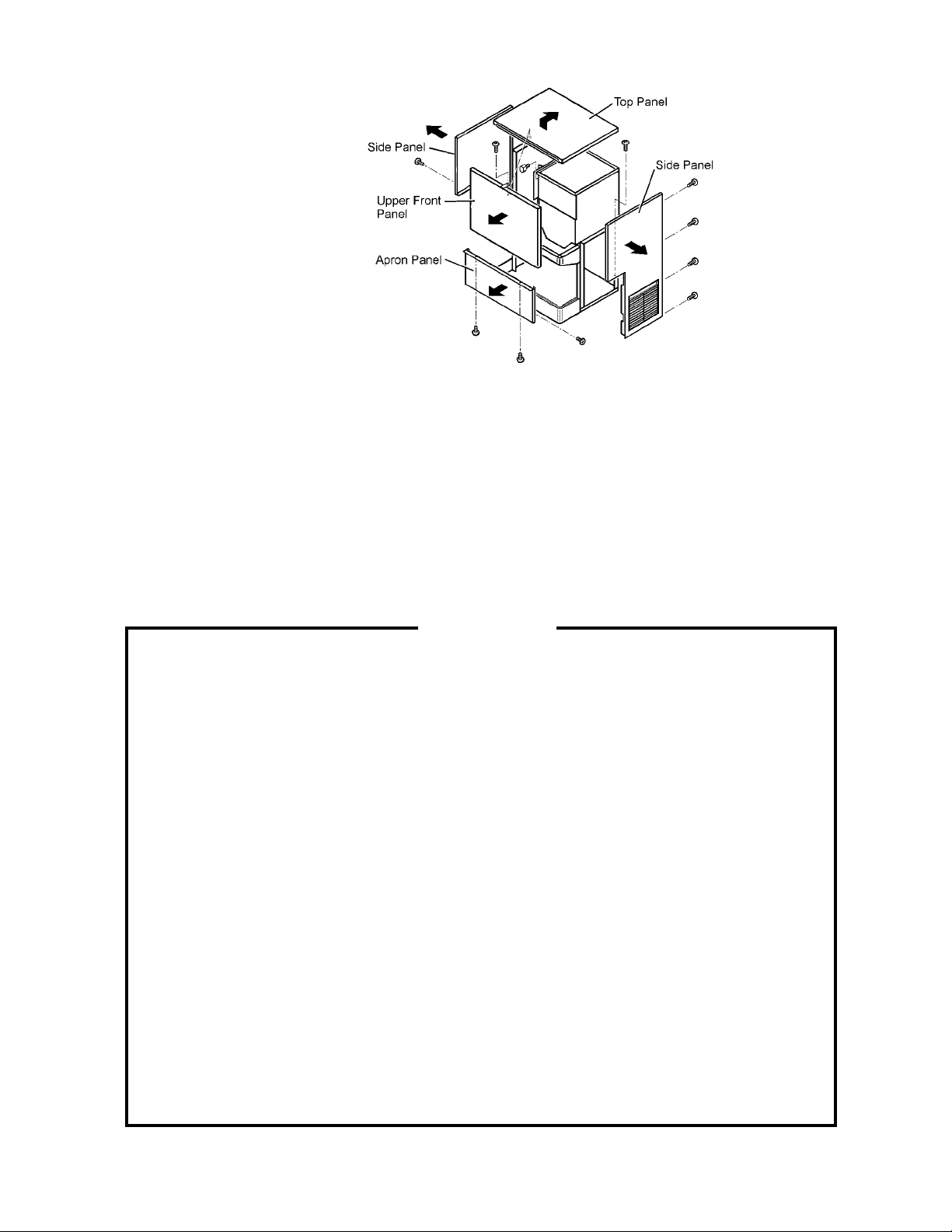

2) Remove the Upper Front, Top and Side Panels to prevent damage when installing the ice

dispenser. See Fig. 1.

3) Remove the package of accessories, and check the contents:

a) Installation Kit

Inlet Hose 1

Outlet Hose 2

1/2-3/4 Nipple 1

3/4-3/4 Nipple 2

b) Bracket 2

c) Fuse 3

4) Check for 10A, 1A and 0.5A spare fuses.

5) Remove the protective plastic film from the panels. If the ice dispenser is exposed to the

sun or to heat, remove the film after the ice dispenser cools.

12

Fig. 1

Upper Front Panel: Remove the screws. Pull the bottom toward you.

Top Panel: Remove the Thumbscrew. Lift up the front and push away.

Apron/Side Panel: Remove the screws and pull toward you.

2. LOCATION

IMPORTANT

1. This ice dispenser is not intended for outdoor use. Normal operating ambient temperature should be within +5°C to +40°C. Normal operating water

temperature should be within +5°C to +35°C. Operation of the ice dispenser,

for extended periods, outside of these normal temperature ranges may affect

production capacity.

2. The ice dispenser should not be located next to ovens, grills or other high

heat producing equipment.

3. The location should provide a firm and level foundation for the equipment at

normal counter top height.

4. Allow 15 cm clearance at rear, sides and top for proper air circulation and

ease of maintenance and/or service should they be required.

5. This appliance is not suitable for installation in an area where a water jet

could be used and where dripping is not allowed.

6. Do not place anything on top of the ice dispenser or in front of the Louver.

13

3. INST ALLATION

• Incorrect installation can cause harm to people, animals or things, for which the manufacturer cannot be held responsible.

1) Position the ice dispenser in the selected permanent site.

2) Level the ice dispenser in both the left-to-right and front-to-rear directions.

4. ELECTRICAL CONNECTION

WARNING

THIS APPLIANCE MUST BE EARTHED

This ice dispenser requires an earth that meets the national and local electrical code requirements. To prevent possible severe electrical shock to individuals or extensive damage to equipment, install a proper earth wire to the

ice dispenser. Remove the plug from the mains socket before any maintenance, repairs or cleaning is undertaken.

• This ice dispenser must have a separate power supply or receptacle of proper capacity.

See the Nameplate.

• The main control box fuses are rated at 10A, 1A and 0.5A and should only be replaced

by a qualified service engineer.

• Usually an electrical permit and services of a licensed electrician are required.

• If the supply cord and the plug should need to be replaced, it should only be done by a

qualified service engineer.

For the U.K. and the Republic of Ireland only

• The wires in the mains lead are coloured in accordance with the following code:

Green & Yellow = Earth

Blue = Neutral

Brown = Live

As the colours of the wire in the mains lead of this appliance may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured Green-and-Yellow must be connected to the terminal in the

plug which is marked with the letter E or by the symbol or coloured Green or Greenand-Yellow. The wire which is coloured Blue must be connected to the terminal which is

marked with the letter “N” or coloured Black. The wire which is coloured Brown must be

14

connected to the terminal which is marked with the letter L or coloured Red.

• Should the socket outlets in the installation site not be suitable for the plug supplied with

your product, the plug must be removed (cut off if it is moulded on plug) and an appropriate plug fitted.

If the non-rewirable has been cut from the power supply cord, it must be disposed of.

There should be no attempt to reuse it. Inserting such a plug into a socket elsewhere

presents a serious risk of electrical shock.

• The non-rewirable plug must never be used without a fuse cover being fitted.

The correct replacement for the detachable fuse cover is identifiable from the

manufacturer’s reference number stamped on the plug.

Supply of replacement fuse covers can be obtained from Hoshizaki Parts/Service Centres.

Fuses should be rated at 10A and approved to BS 1362.

5. WATER SUPPLY AND DRAIN CONNECTIONS

(For the U.K. only, the connections must be in accordance with current requirements of the Model

Water Byelaws 1986 SI No. 1147)

• Only potable water should be used for this ice dispenser.

• Water supply pressure should be minimum 0.5 bar and maximum 8 bar. If the pressure

exceeds 8 bar, use a pressure reducing valve. Do NOT throttle back the supply tap.

• A plumbing permit and services of a licensed plumber may be required in some areas.

• The ice dispenser drain is gravity flow, so ensure drainpipe has an adequate pitch or fall.

• Water should drain into an open trap.

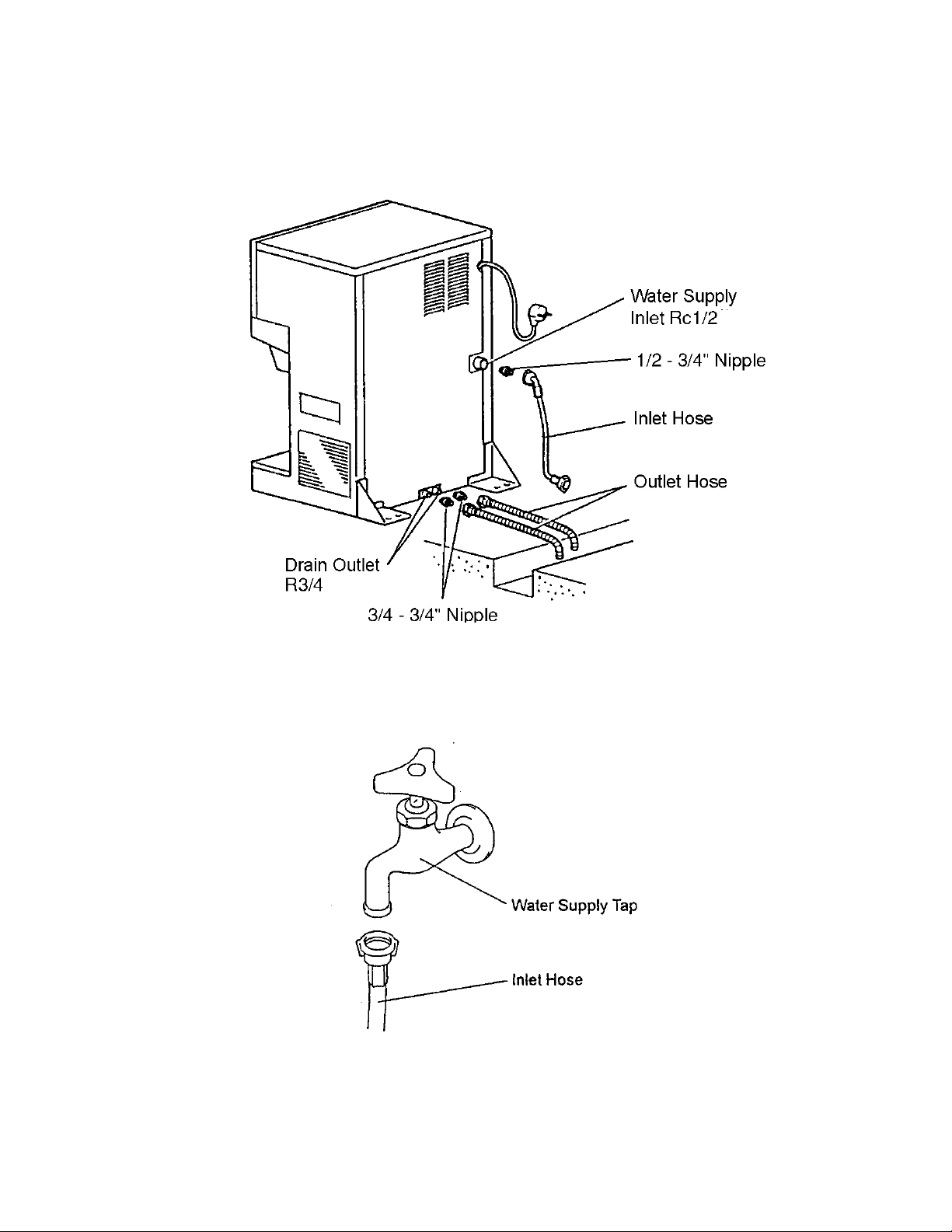

1) By means of a suitable spanner or wrench, tighten the 1/2-3/4 Nipple (accessory) into the

Rc1/2 fitting on the rear of the ice dispenser as indicated. P.T.F.E. tape and/or a suitable

sealing compound should be used to obtain a leak free joint.

Note: Jointing compounds should be approved and suitable for potable water use.

2) Attach angled end of white flexible inlet hose (accessory) to free end of 1/2-3/4 Nipple

ensuring rubber sealing washer is correctly positioned. Hand tighten sufficiently to provide

leak free joint.

3) Attach the other end of inlet hose to the water tap, noting washer is correctly positioned

before hand tightening as above.

15

4) Attach grey flexible outlet hoses (accessory) to the R3/4 fittings on the rear bottom of the

ice dispenser, confirming fitment of rubber washers before finally hand tightening the

joints. These pipes can be cut to length as necessary to suit position of main drain.

Fig. 2

Fig. 3

16

III. OPERATING INSTRUCTIONS

WARNING

1. This ice dispenser is designed to produce and store edible ice. To keep the

ice dispenser hygienic:

• Wash your hands before removing ice.

• Keep the Grille in the Tray clean. Clean it by using a neutral cleaner and

rinse thoroughly.

2. The use of any electrical equipment involves the observance of some

fundamental rules. In particular:

• Instances of high humidity and moisture increase the risk of electrical

short circuits and potential electrical shocks. If in doubt, disconnect the

ice dispenser.

• Do not pull the power cord in order to disconnect the ice dispenser from

the feed network.

• This appliance is not suitable for unsupervised use by young children,

aged or infirm persons.

3. All parts are factory-adjusted. Improper adjustments may result in failure.

4. If the unit is turned off, wait for at least 3 minutes before restarting the ice

dispenser to prevent damage to the Compressor.

5. Dispensing no ice for more than 5 or 6 hours could result in spouting wet

ice or making ice bridge. Turn off the Control Switch, and remove ice from

the Storage Bin within 2 hours. Soggy and sticky ice should be removed

continuously as produced.

1. ST ART UP

1) Clean the Storage Bin

2) Open the Water Supply Line Shut-off Valve.

3) Plug in the ice dispenser.

4) Remove the Front Panel.

5) Turn on the Power Switch on the Control Box.

17

Loading...

Loading...