Page 1

NO. L009-872

ISSUED: JUN.1,2012

REVISED:

HOSHIZAKI

CUBELET ICE DISPENSER

MODEL

DCM-60KE

DCM-60KE-P

DCM-120KE

DCM-120KE-P

SERVICE MANUAL

Page 2

CONTENTS

I. SPECIFICATIONS-------------------------------------------------------------------------------------- 1

1. DIMENSIONS/SPECIFICATIONS ----------------------------------------------------------------- 1

[a] DCM-60KE (L013: Continental) ---------------------------------------------------------------- 1

[b] DCM-60KE (L013-C101: UK) ------------------------------------------------------------------- 2

[c] DCM-60KE (L013-C201: Oceania) ------------------------------------------------------------ 3

[d] DCM-60KE (L013-C301: China)---------------------------------------------------------------- 4

[e] DCM-60KE (L013-C130: Middle East)-------------------------------------------------------- 5

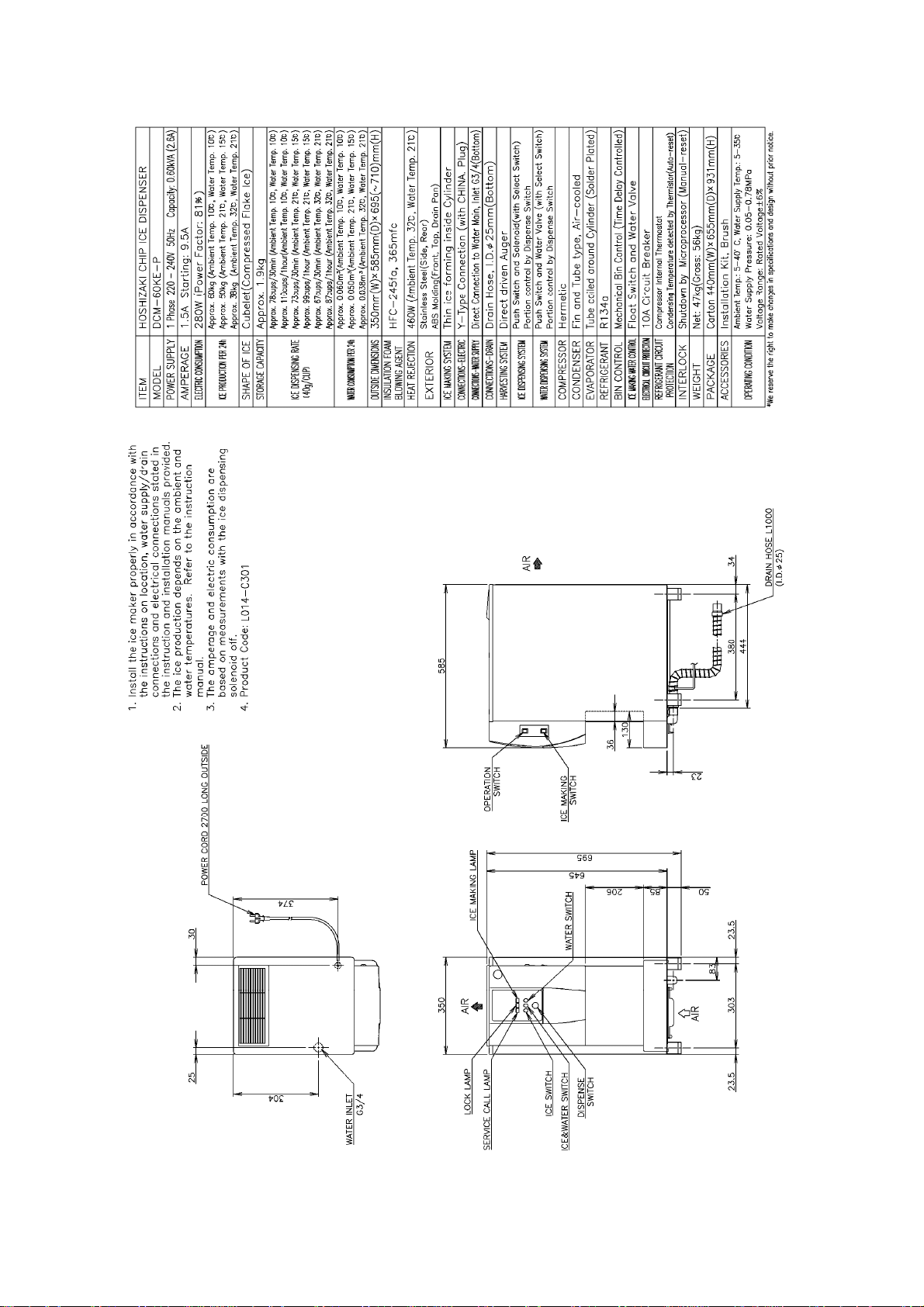

[f] DCM-60KE-P (L014: Continental) -------------------------------------------------------------- 6

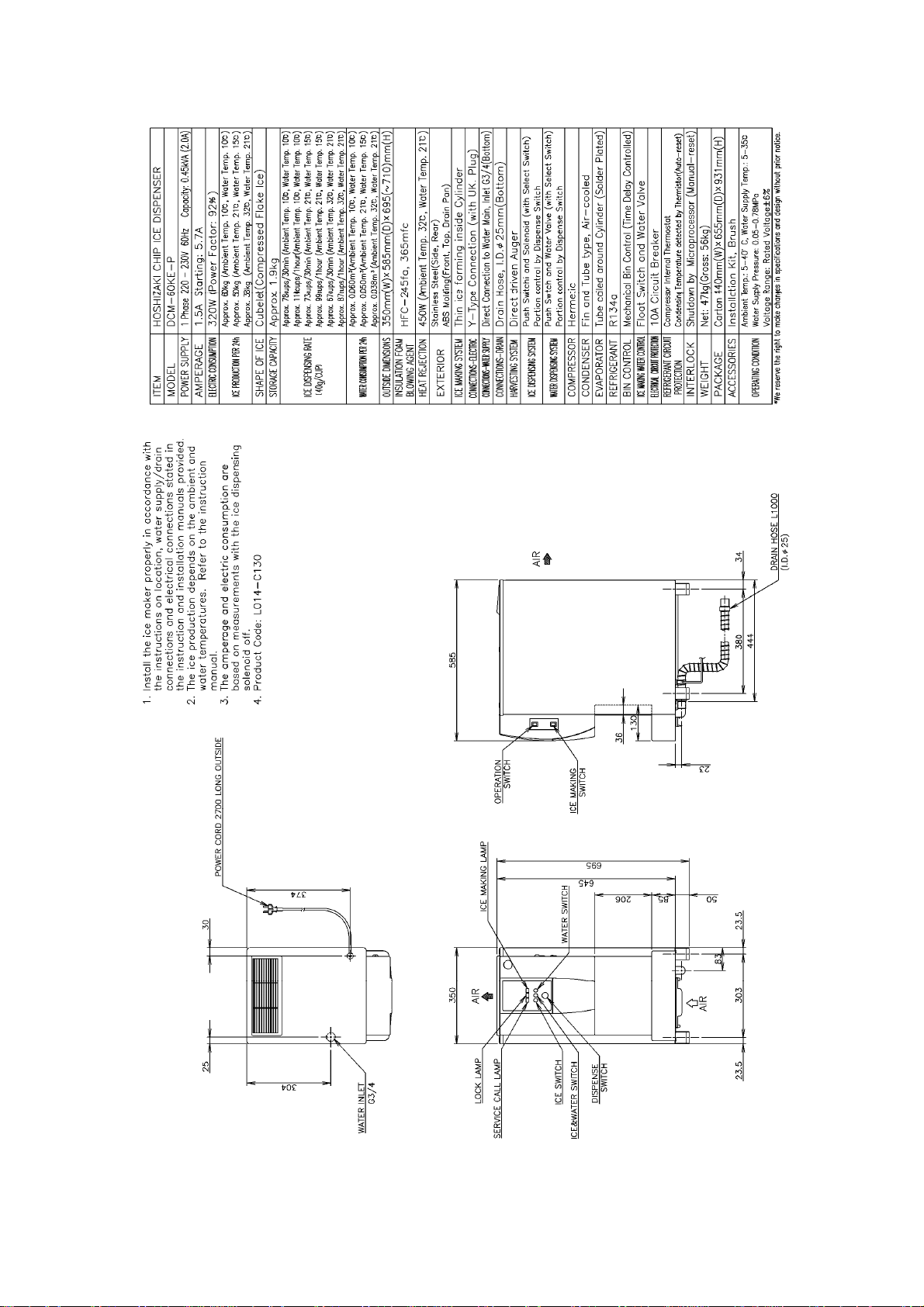

[g] DCM-60KE-P (L014-C101: UK) ---------------------------------------------------------------- 7

[h] DCM-60KE-P (L014-C201: Oceania) --------------------------------------------------------- 8

[i] DCM-60KE-P (L014-C301: China)-------------------------------------------------------------- 9

[j] DCM-60KE-P (L014-C130: Middle East)-----------------------------------------------------10

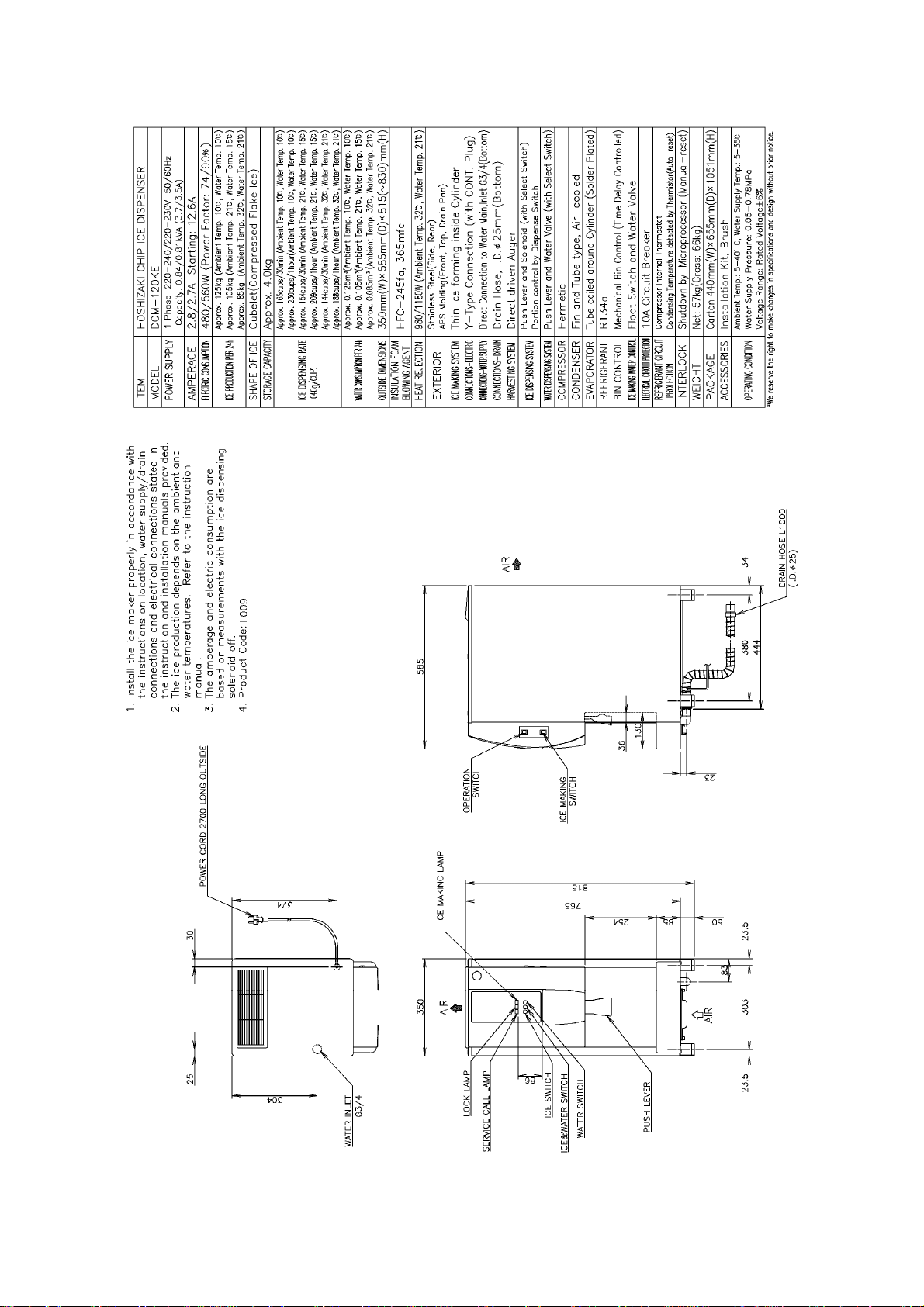

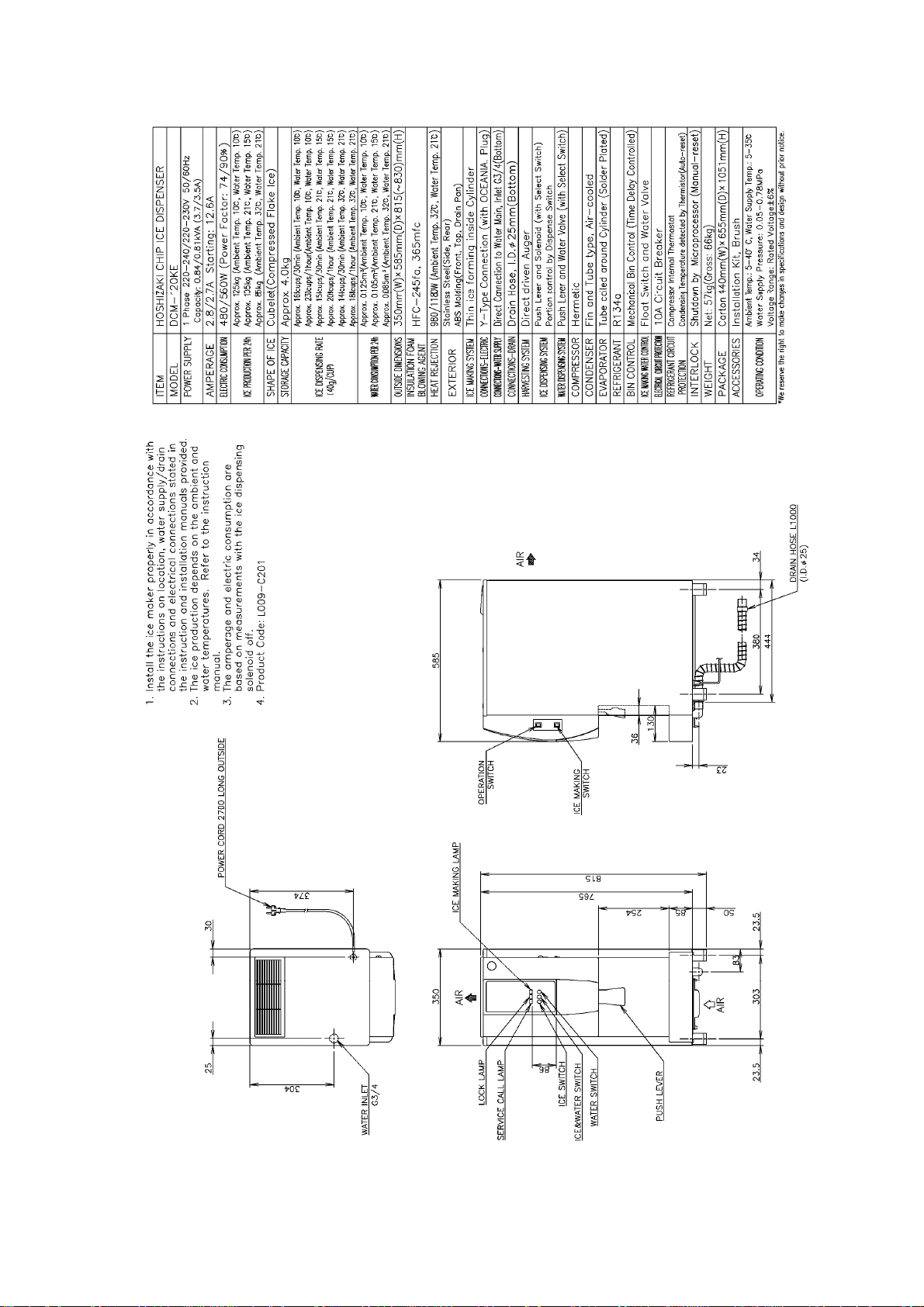

[k] DCM-120KE (L009: Continental)--------------------------------------------------------------11

[l] DCM-120KE (L009-C101: UK)------------------------------------------------------------------12

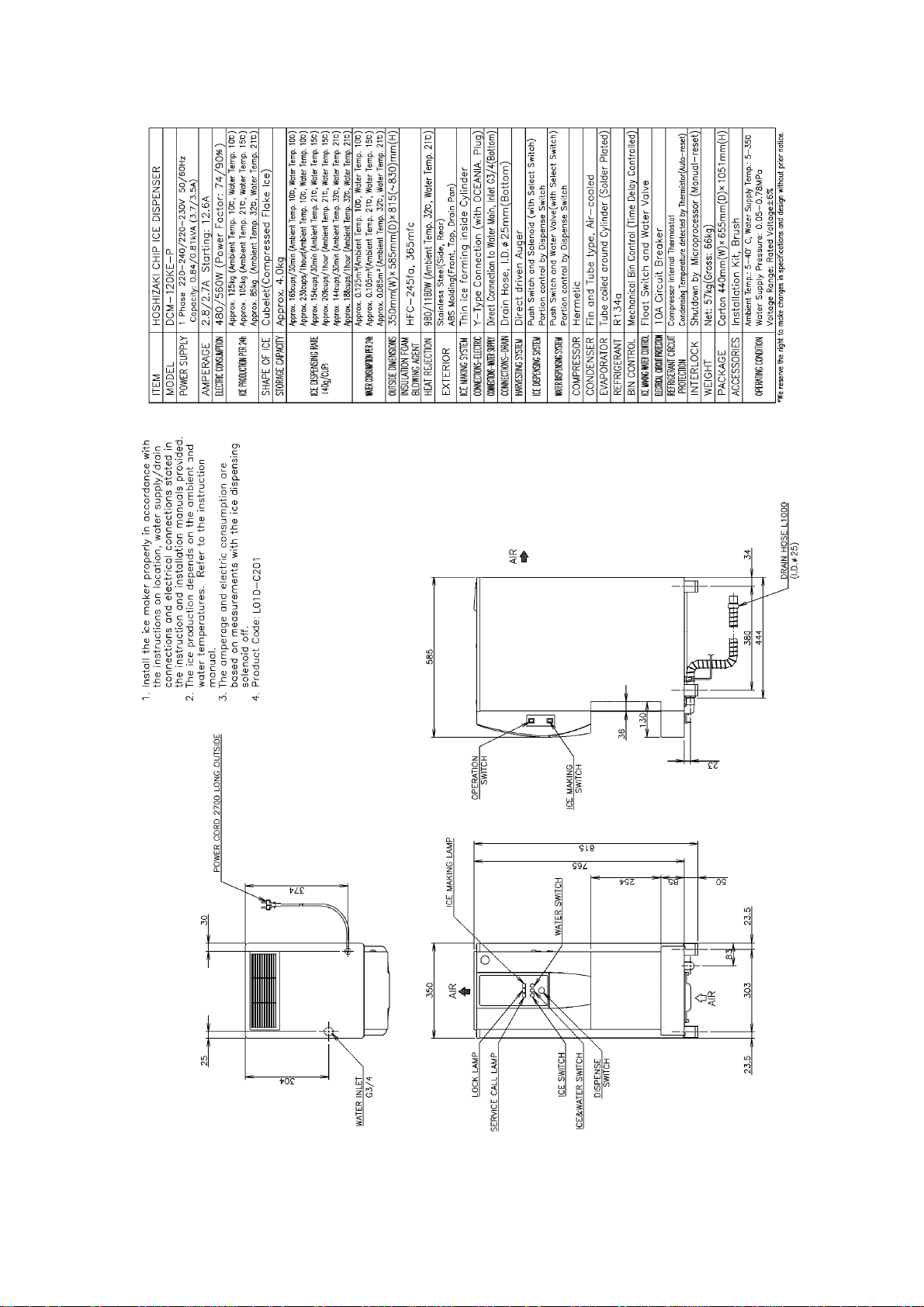

[m] DCM-120KE (L009-C201: Oceania)---------------------------------------------------------13

[n] DCM-120KE (L009-C301: China)-------------------------------------------------------------14

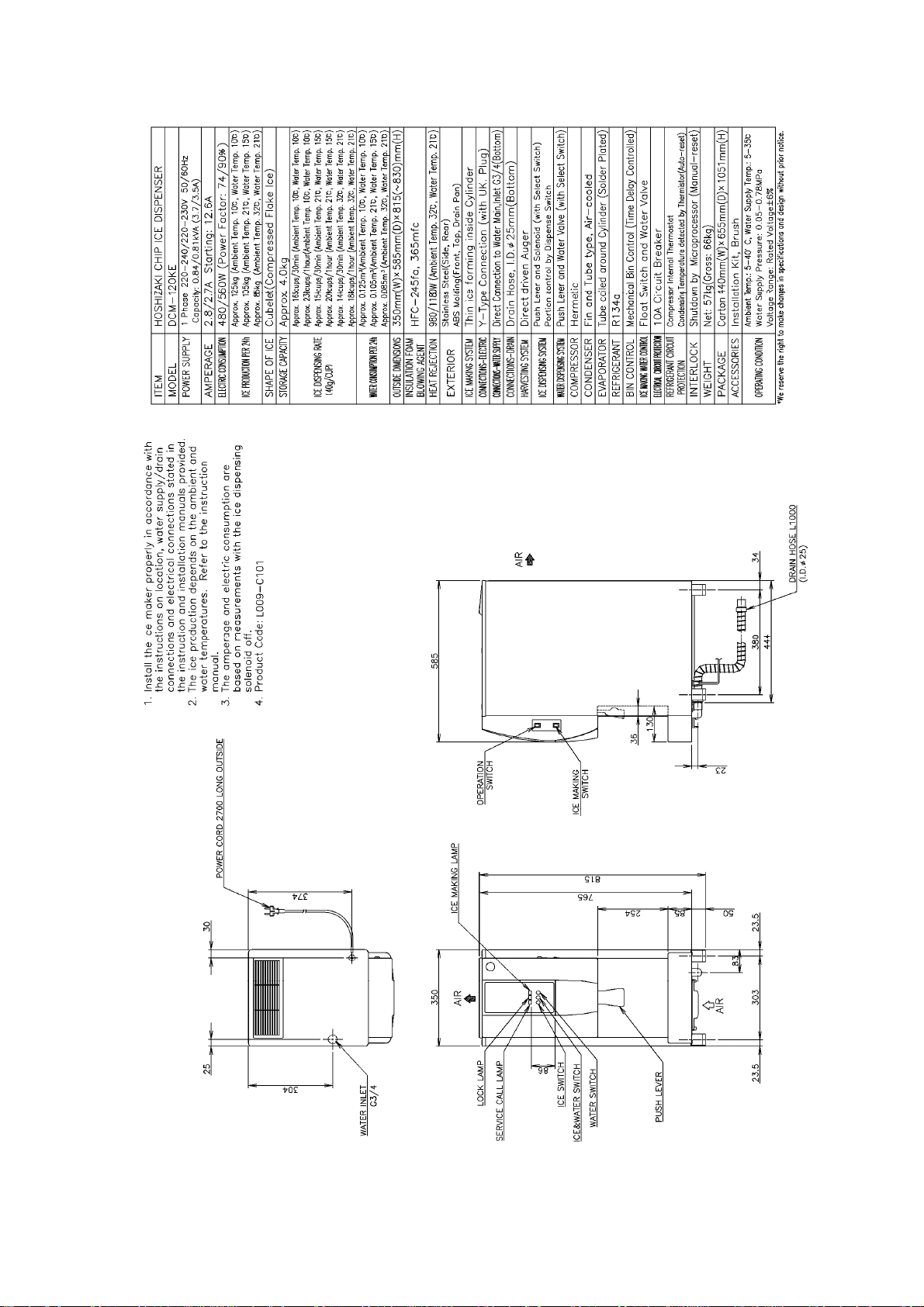

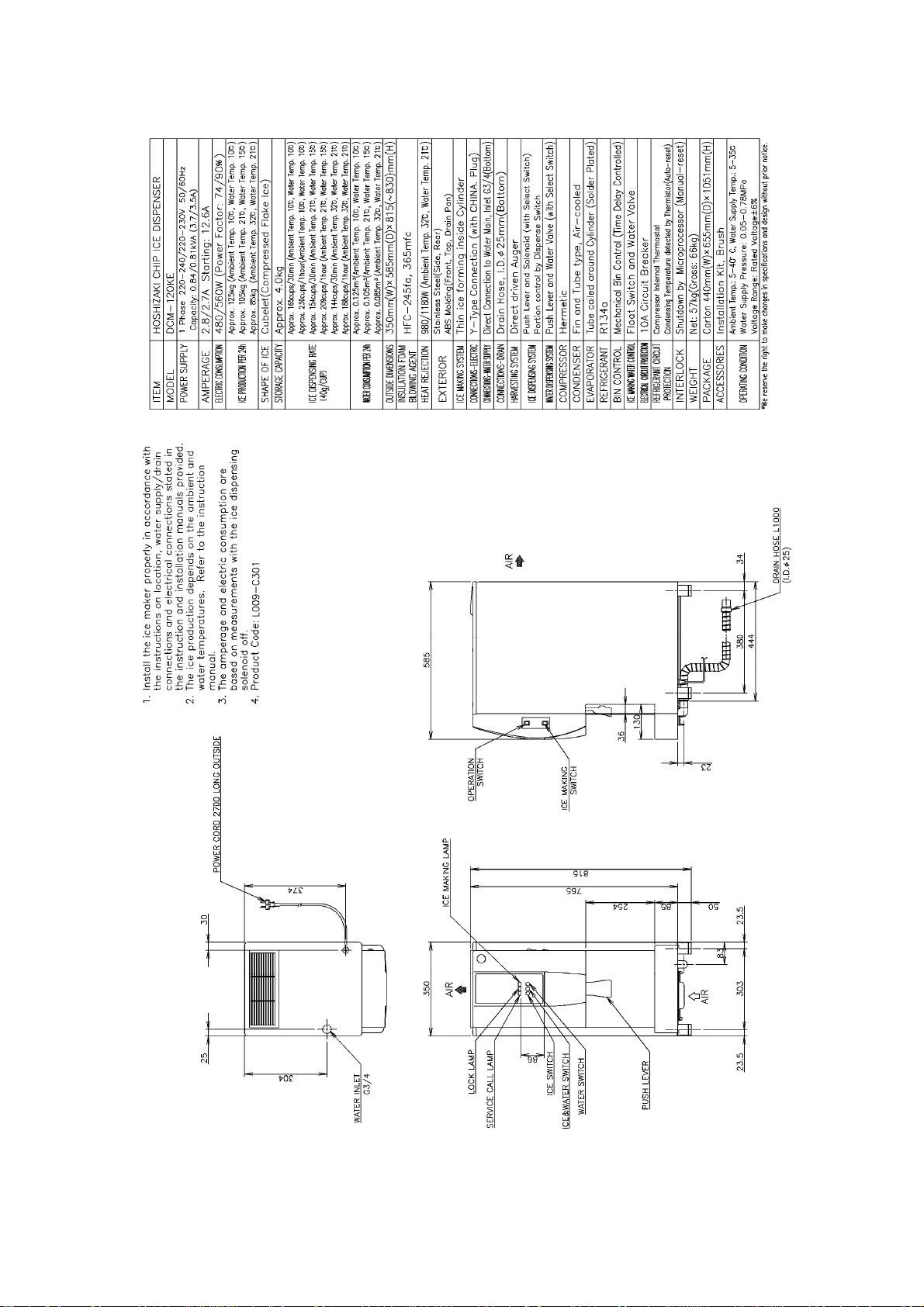

[o] DCM-120KE-P (L010: Continental)-----------------------------------------------------------15

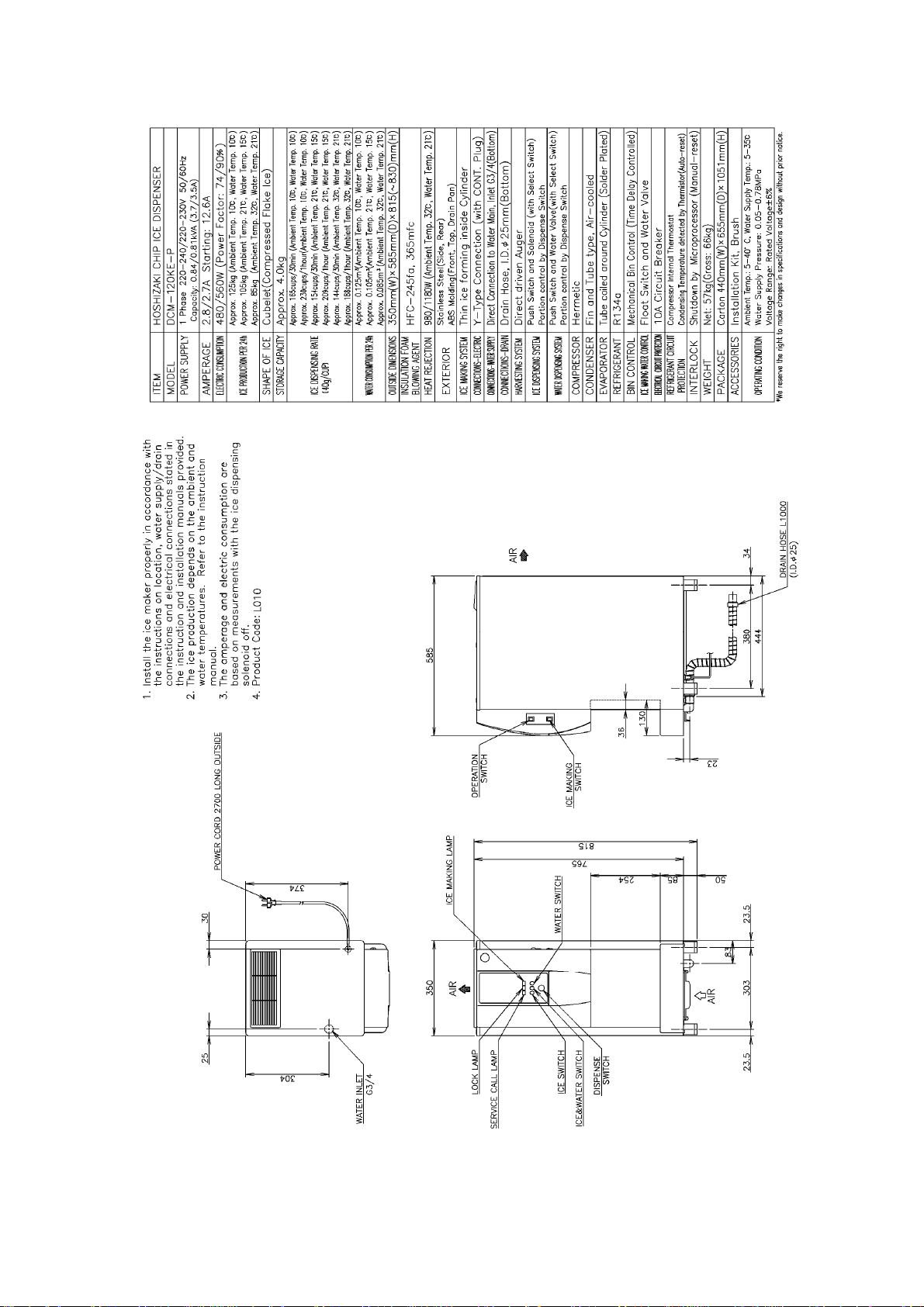

[p] DCM-120KE-P (L010-C101: UK)--------------------------------------------------------------16

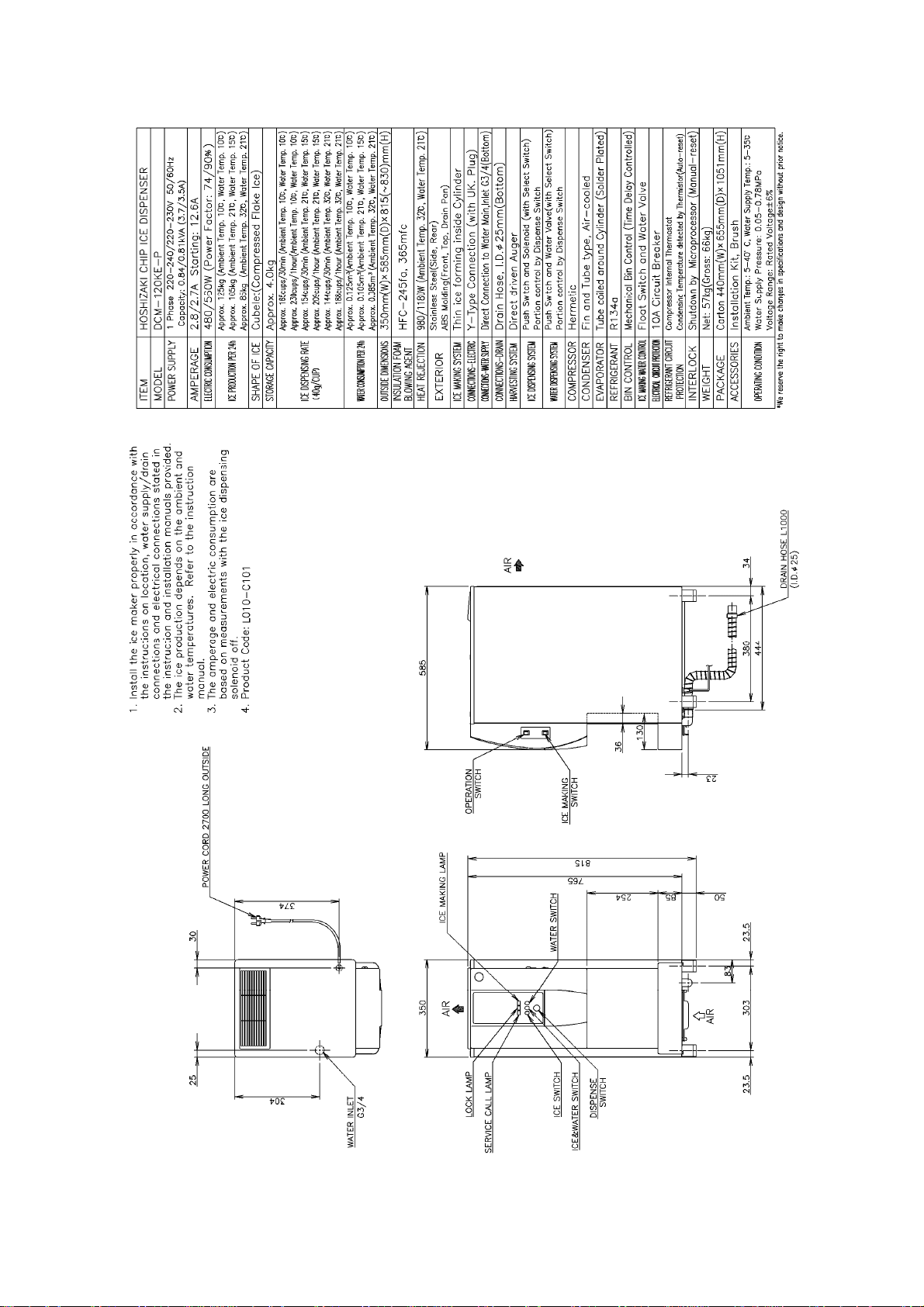

[q] DCM-120KE-P (L010-C201: Oceania)-------------------------------------------------------17

[r] DCM-120KE-P (L010-C301: China)-----------------------------------------------------------18

2. CONSTRUCTION-------------------------------------------------------------------------------------19

II. MAINTENANCE AND CLEANING INSTRUCTIONS-----------------------------------------21

1. EXTRUDING HEAD (UPPER BEARING), HOUSING (LOWER BEARING) -----------21

2. MECHANICAL SEAL---------------------------------------------------------------------------------21

3. GEAR MOTOR-----------------------------------------------------------------------------------------22

4. CONDENSER------------------------------------------------------------------------------------------22

5. AIR FILTER---------------------------------------------------------------------------------------------22

6. CONTROL WATER VALVE AND WATER DISPENSE VALVE ---------------------------23

7. CLEANING OF WATER SYSTEM----------------------------------------------------------------24

III. TECHNICAL INFORMATION----------------------------------------------------------------------27

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT-------------------------------------------27

2. WIRING DIAGRAM -----------------------------------------------------------------------------------28

3. ICEMAKING MECHANISM -------------------------------------------------------------------------29

[a] EVAPORATOR (CASING)----------------------------------------------------------------------30

[b] AUGER----------------------------------------------------------------------------------------------30

[c] EXTRUDING HEAD (BEARING)--------------------------------------------------------------30

[d] HOUSING-------------------------------------------------------------------------------------------30

[e] MECHANICAL SEAL-----------------------------------------------------------------------------30

[f] COUPLING (SPLINE JOINT)-------------------------------------------------------------------30

[g] GEAR MOTOR ------------------------------------------------------------------------------------30

[h] SEALING BOLT-----------------------------------------------------------------------------------31

4. ELECTRIC CIRCUIT ---------------------------------------------------------------------------------32

[a] BASIC OPERATION -----------------------------------------------------------------------------32

[b] TIMING CHART -----------------------------------------------------------------------------------33

PAGE

i

Page 3

5. OPERATION BOARD--------------------------------------------------------------------------------34

[a] DISPLAYING COMPRESSOR OPERATING HOURS ---------------------------------- 34

[b] DISPLAYING CYCLE TIME--------------------------------------------------------------------34

[c] DISPLAYING MODEL NUMBER--------------------------------------------------------------35

[d] SETTING MODEL NUMBER-------------------------------------------------------------------35

[e] DISPLAYING CONTROLLER BOARD SOFTWARE VERSION----------------------36

[f] DISPLAYING OPERATION BOARD SOFTWARE VERSION--------------------------36

[g] DISPLAYING ERROR LOG AND ONGOING ERROR----------------------------------36

[h] RESETTING ERROR LOG---------------------------------------------------------------------37

[i] REDUCING COMPRESSOR STARTING TIME-------------------------------------------- 37

[j] RESETTING COMPRESSOR OPERATING HOURS ------------------------------------ 37

6. ERROR CODES---------------------------------------------------------------------------------------38

7. PERFORMANCE DATA-----------------------------------------------------------------------------41

[a] DCM-60KE(-P): 50Hz----------------------------------------------------------------------------41

[b] DCM-60KE(-P): 60Hz----------------------------------------------------------------------------42

[c] DCM-120KE(-P): 50Hz---------------------------------------------------------------------------43

[d] DCM-120KE(-P): 60Hz --------------------------------------------------------------------------44

IV. SERVICE DIAGNOSIS ----------------------------------------------------------------------------- 45

1. NO ICE PRODUCTION------------------------------------------------------------------------------45

2. LOW ICE PRODUCTION----------------------------------------------------------------------------47

3. FAULTY DISPENSER--------------------------------------------------------------------------------47

4. OTHERS-------------------------------------------------------------------------------------------------48

V. REMOVAL AND REPLACEMENT----------------------------------------------------------------49

1. FRONT COVER ---------------------------------------------------------------------------------------49

[a] REMOVAL------------------------------------------------------------------------------------------49

[b] REPLACEMENT ----------------------------------------------------------------------------------51

2. SERVICE FOR REFRIGERANT LINES ---------------------------------------------------------52

[a] SERVICE INFORMATION----------------------------------------------------------------------52

[b] REFRIGERANT RECOVERY------------------------------------------------------------------53

[c] EVACUATION AND RECHARGE-------------------------------------------------------------53

3. BRAZING------------------------------------------------------------------------------------------------54

4. COMPRESSOR----------------------------------------------------------------------------------------54

5. DRIER----------------------------------------------------------------------------------------------------55

6. EXPANSION VALVE ---------------------------------------------------------------------------------56

7. FAN MOTOR -------------------------------------------------------------------------------------------57

8. EVAPORATOR ASSEMBLY -----------------------------------------------------------------------57

9. CONTROL WATER VALVE AND WATER DISPENSE VALVE ---------------------------59

10. FLUSH WATER VALVE -----------------------------------------------------------------------------60

11. CONTROLLER BOARD -----------------------------------------------------------------------------61

[a] MODIFICATION-----------------------------------------------------------------------------------61

[b] REPLACEMENT ----------------------------------------------------------------------------------61

12. BIN CONTROL SWITCH ASSEMBLY -----------------------------------------------------------62

13. STORAGE BIN ASSEMBLY------------------------------------------------------------------------63

14. AGITATOR AND DRIP RING-----------------------------------------------------------------------63

ii

Page 4

I. SPECIFICATIONS

1. DIMENSIONS/SPECIFICATIONS

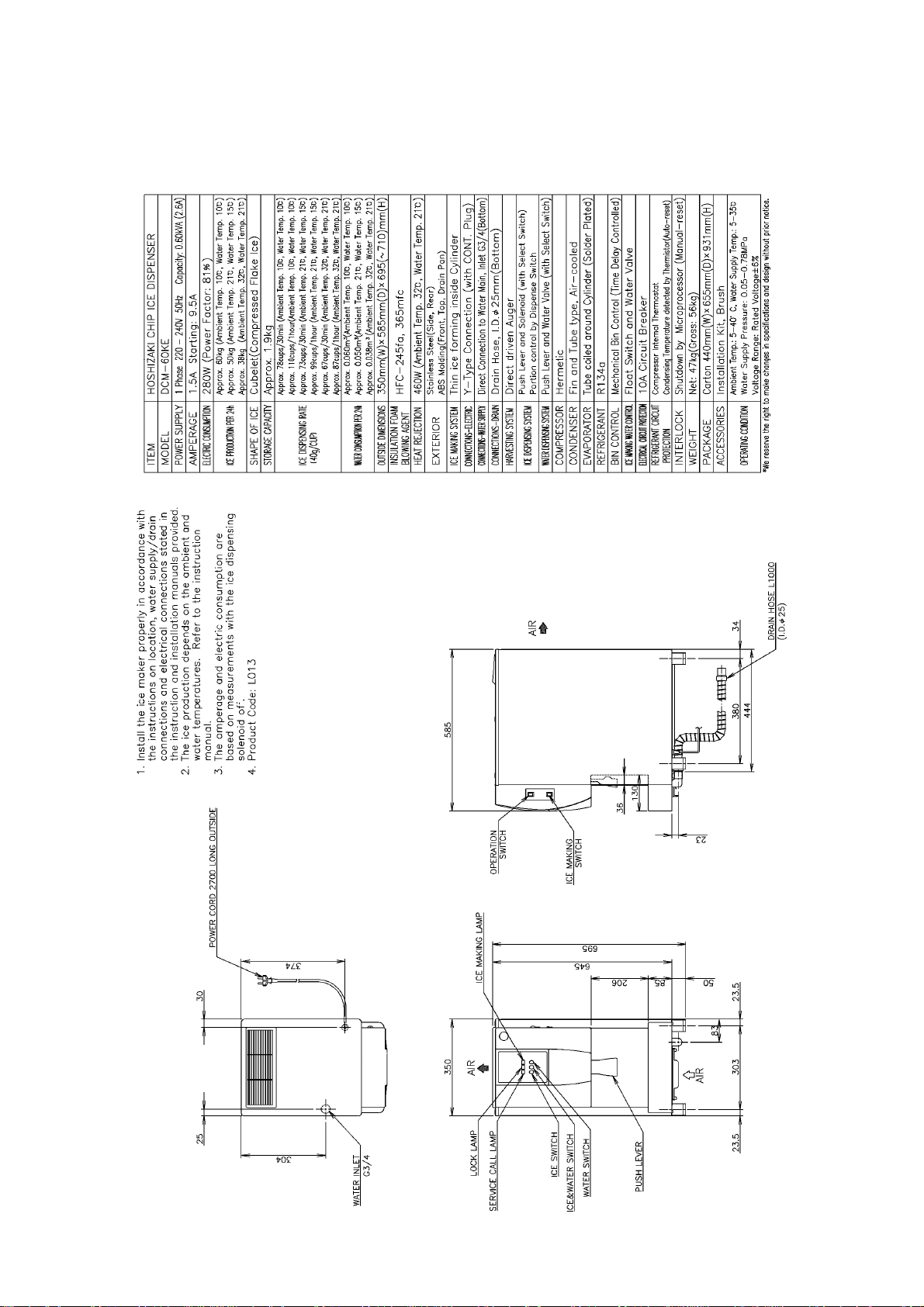

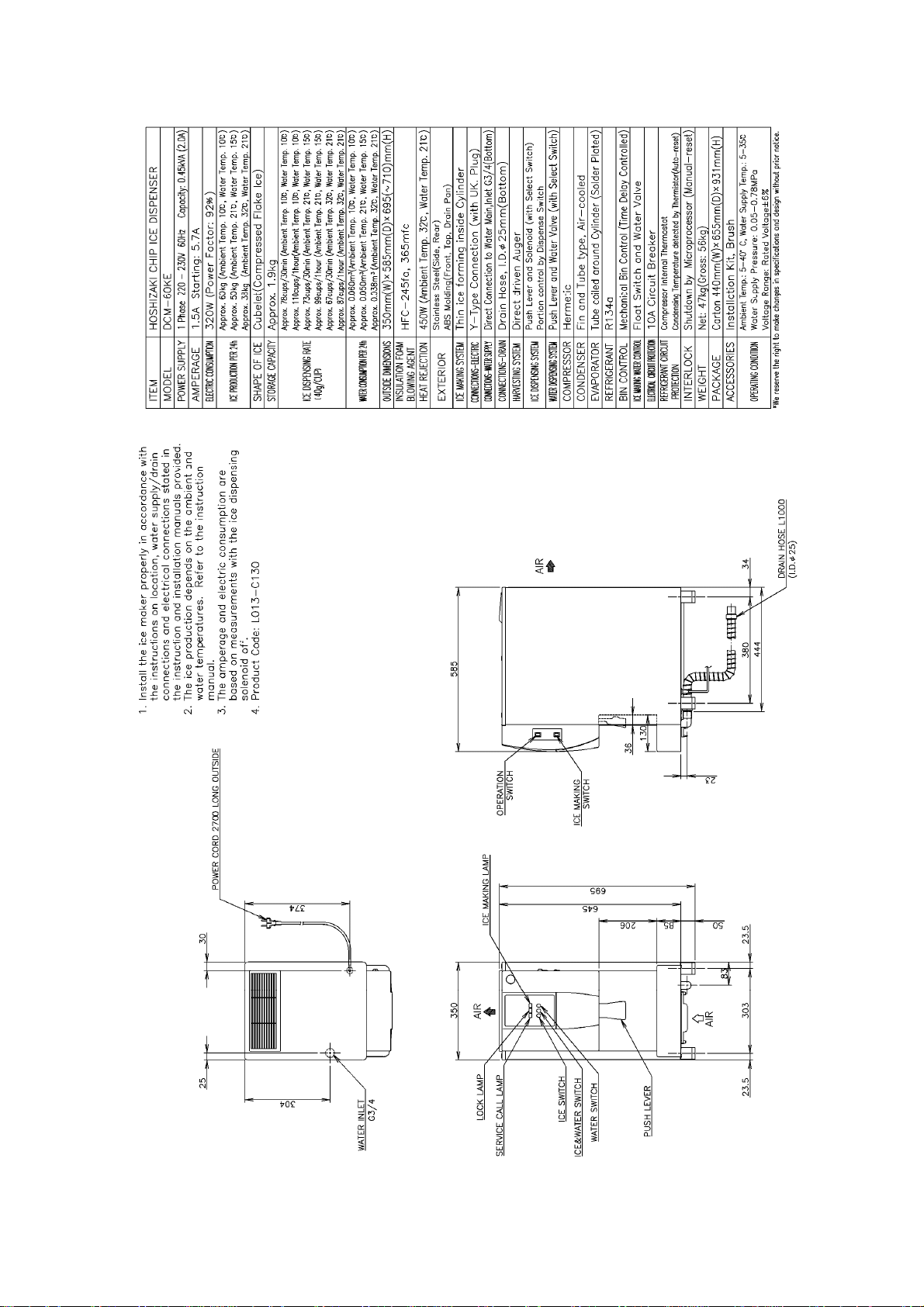

[a] DCM-60KE (L013: Continental)

1

Page 5

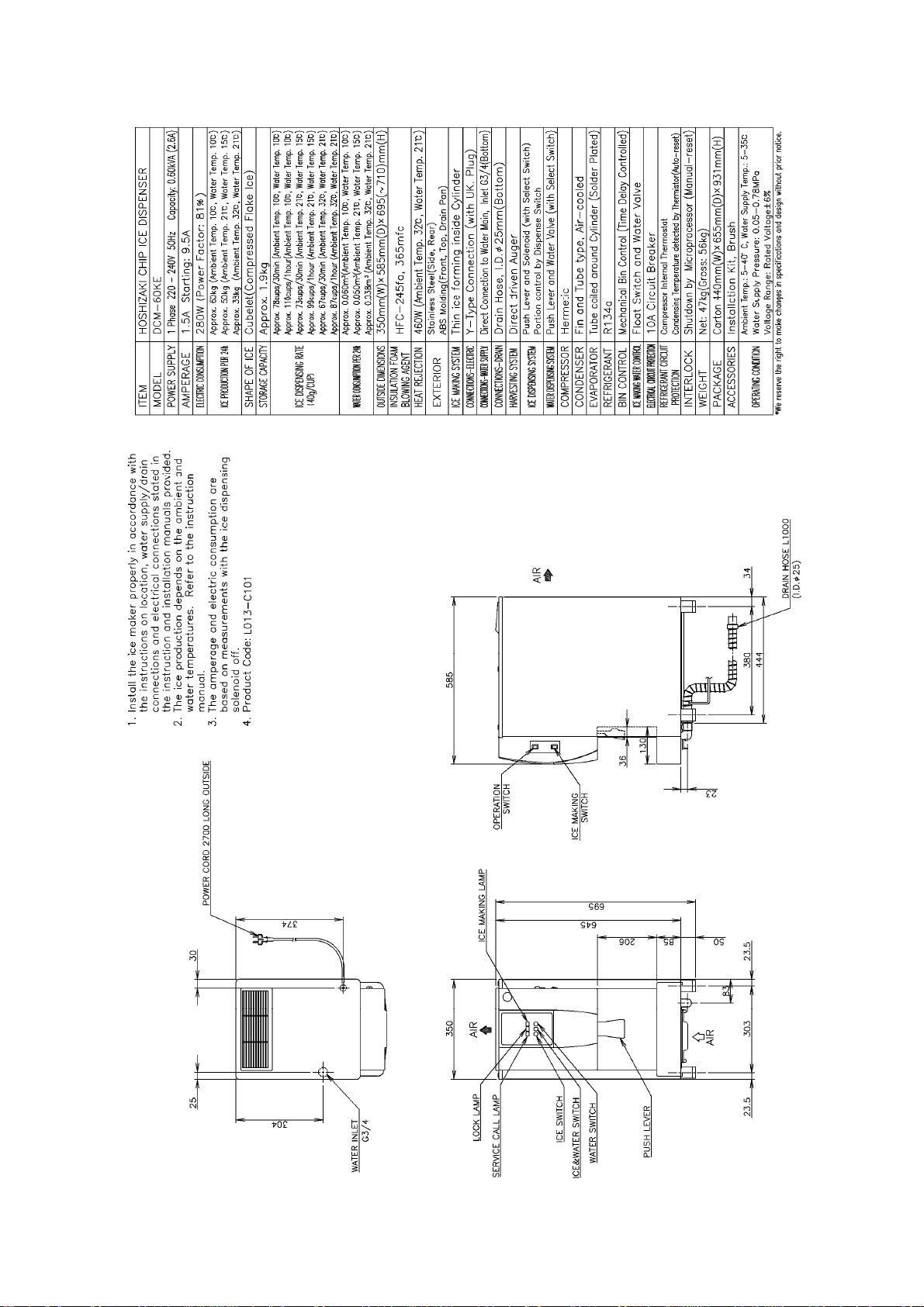

[b] DCM-60KE (L013-C101: UK)

2

Page 6

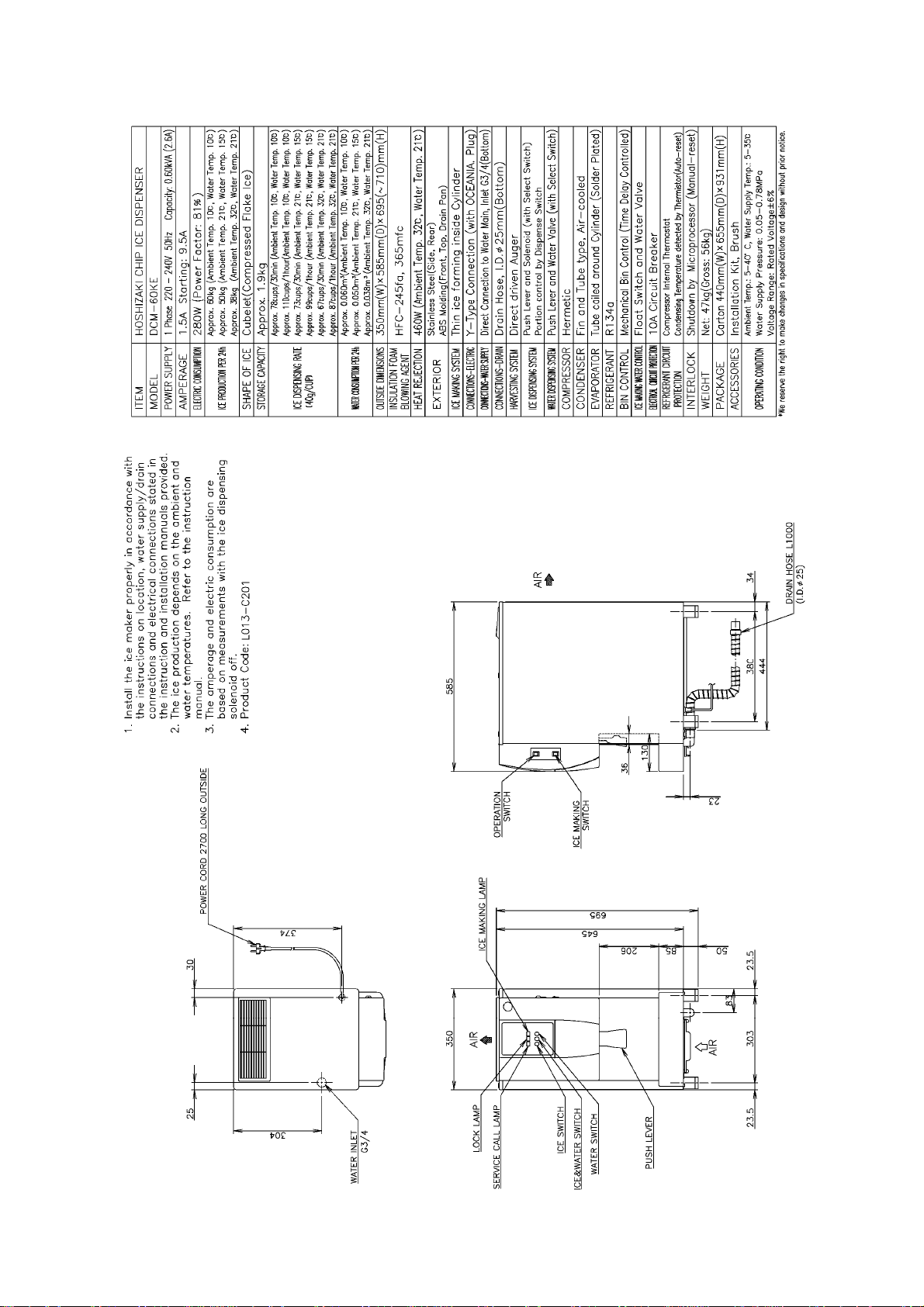

[c] DCM-60KE (L013-C201: Oceania)

3

Page 7

[d] DCM-60KE (L013-C301: China)

4

Page 8

[e] DCM-60KE (L013-C130: Middle East)

5

Page 9

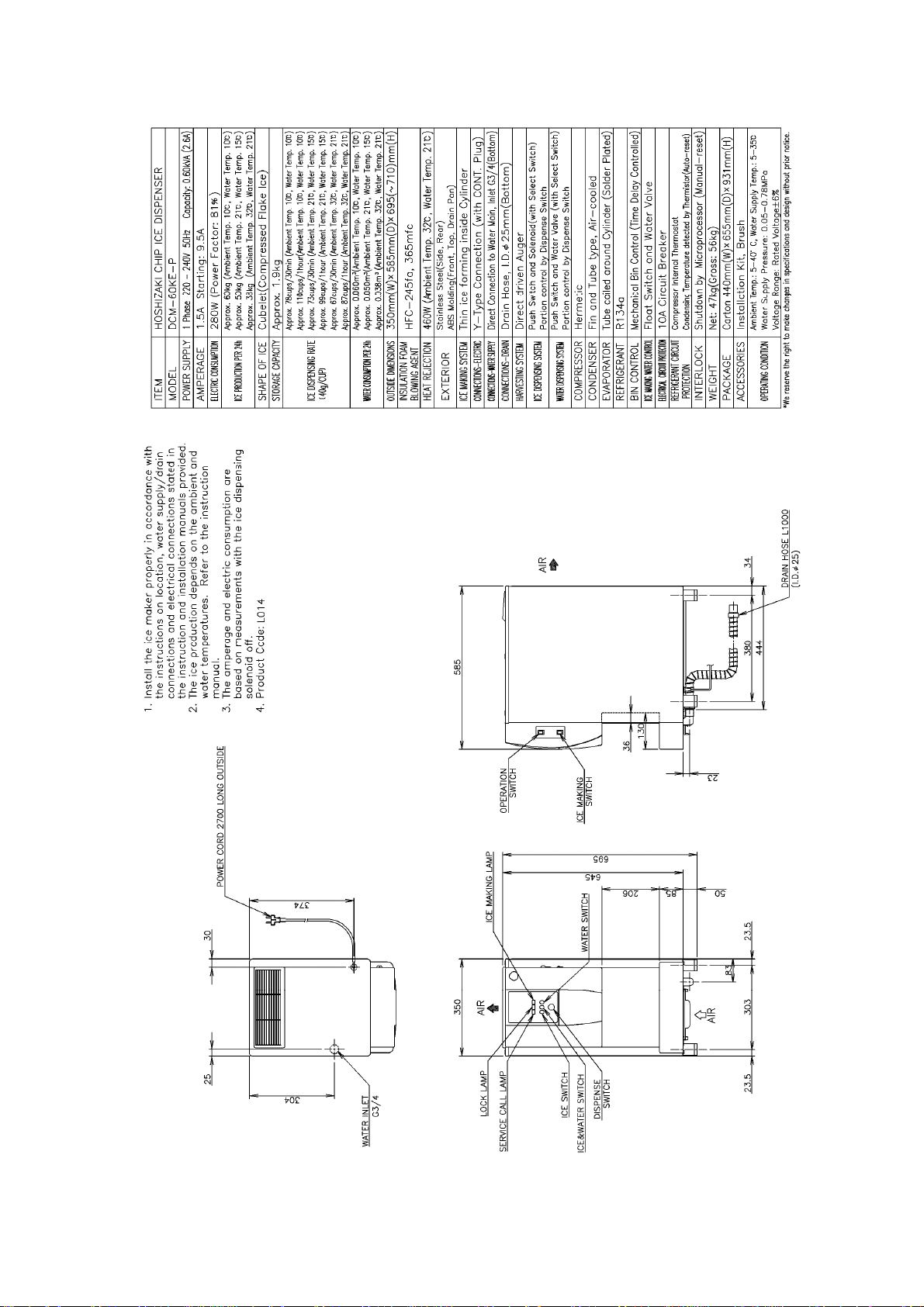

[f] DCM-60KE-P (L014: Continental)

6

Page 10

[g] DCM-60KE-P (L014-C101: UK)

7

Page 11

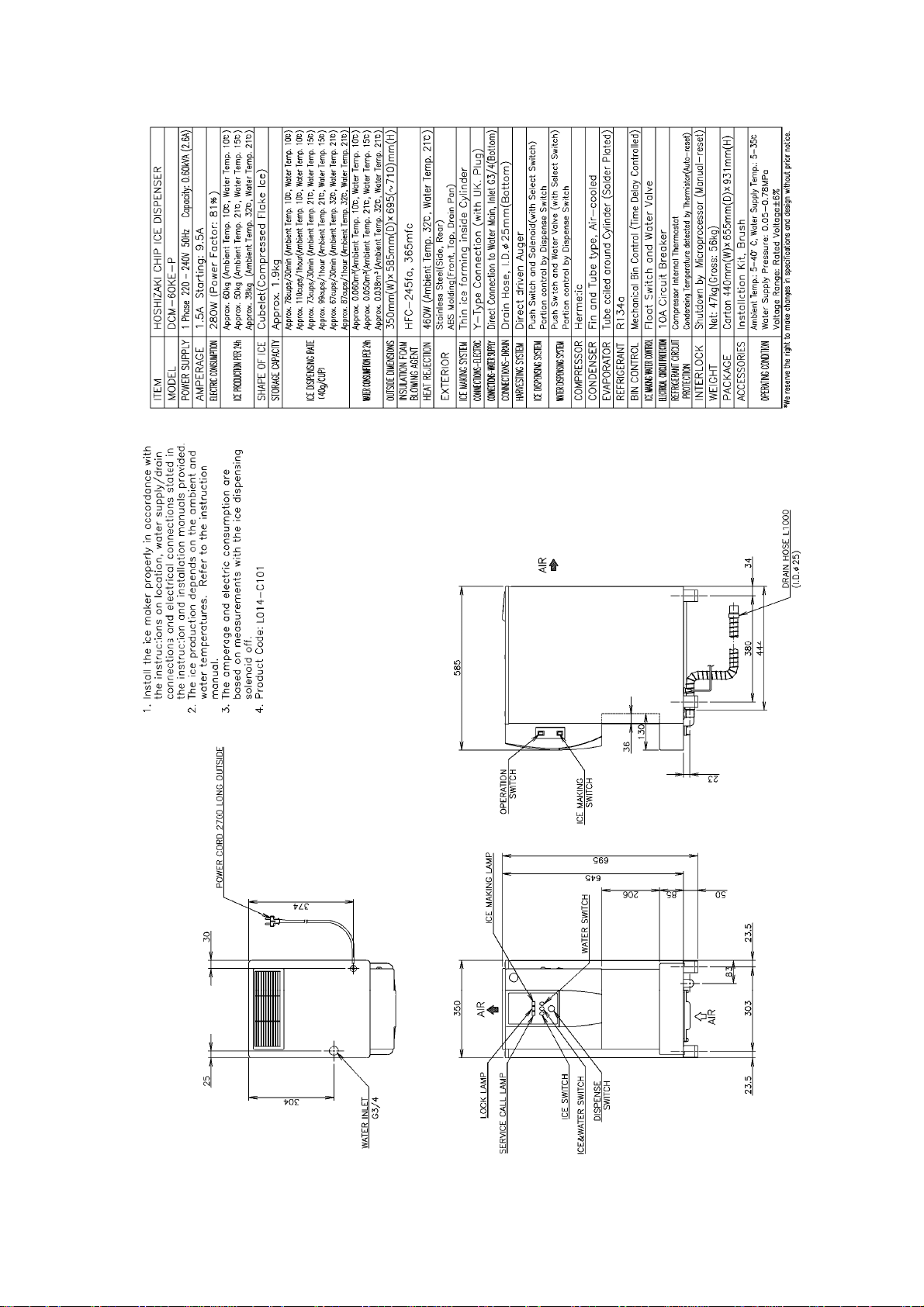

[h] DCM-60KE-P (L014-C201: Oceania)

8

Page 12

[i] DCM-60KE-P (L014-C301: China)

9

Page 13

[j] DCM-60KE-P (L014-C130: Middle East)

10

Page 14

[k] DCM-120KE (L009: Continental)

11

Page 15

[l] DCM-120KE (L009-C101: UK)

12

Page 16

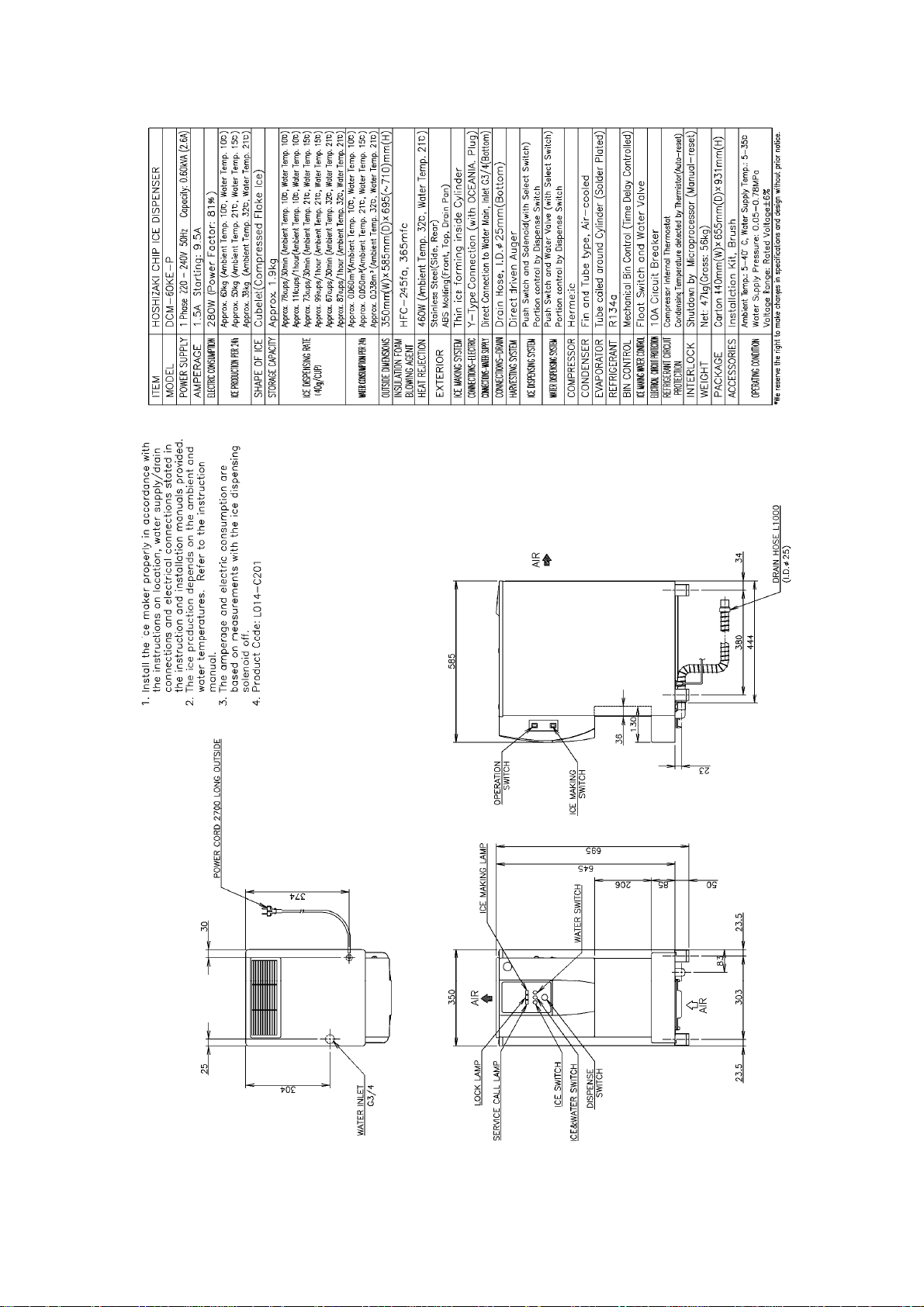

[m] DCM-120KE (L009-C201: Oceania)

13

Page 17

[n] DCM-120KE (L009-C301: China)

14

Page 18

[o] DCM-120KE-P (L010: Continental)

15

Page 19

[p] DCM-120KE-P (L010-C101: UK)

16

Page 20

[q] DCM-120KE-P (L010-C201: Oceania)

17

Page 21

[r] DCM-120KE-P (L010-C301: China)

18

Page 22

2. CONSTRUCTION

Bin Control

Switch

Ice Storage

Bin

Control Water

Valve

Float Switch

Reservoir

Shutter

Water Dispense

Valve

Operation Board

Dispense Switch

*DCM-60/120KE-P

Safety Switch

Front Cover

Spout

Push Lever

*DCM-60/120KE

Water Supply Inlet

Grille

Drain Pan

Air Filter Leg

19

Page 23

Operation

Switch

Ice Making

Switch

Expansion

Valve

Evaporator

Control Box

Controller Board

Transformer

Compressor

Lever Switch

*DCM-60/120KE

Flush Water

Valve

Gear Motor

Drier

Fan Motor

Thermistor

Condenser

Drain Outlet

20

Page 24

II. MAINTENANCE AND CLEANING INSTRUCTIONS

IMPORTANT

1. This ice dispenser must be maintained individually, referring to the instruction

manual and labels provided with the ice dispenser.

2. To achieve optimum ice dispenser performance, the following parts need periodic

inspection and maintenance:

Extruding head (upper bearing)

Housing (lower bearing)

Mechanical seal

These parts should be inspected after two years from installation or 10,000 hours of

operation, whichever comes first, and once a year thereafter. Their service life,

however, depends on water quality and environment. More frequent inspection and

maintenance are recommended in bad or severe water conditions.

1. EXTRUDING HEAD (UPPER BEARING), HOUSING (LOWER BEARING)

These parts should be replaced if a diametrical gap

of more than 0.5 mm is found when at least three

spots are checked by changing the direction of the

auger on each bearing.

It depends on the water quality and conditions, but

normally the bearings should be checked for wear

after a total of 8,000 - 10,000 hour operation from

installation date.

Note: The clearance between the auger blades

and the evaporator interior is 0.4 - 0.5 mm. If

the bearings and rotating parts are worn out

to create a larger clearance, the evaporator

interior may be damaged. (The diameters

(May differ from actual design)

differ by 0.8 - 1.0 mm.)

If the auger surfaces against which the bearings contact are no longer smooth or

show any burrs or abrasions during the above inspection, replace the auger.

0.5 mm Round Stock

or Pin Gauge

For reference only

Auger

Extruding

Head

2. MECHANICAL SEAL

The mechanical seal prevents water leaks from between the auger and the housing bearing

and gradually wears out to reduce its watertightness. Check the amount of water leakage

from the drain pipe located at the side of the gear case to determine the necessity of

replacement.

Total operation time Water leakage

3,000 hours 0.1 mL/h

10,000 hours 0.5 mL/h

21

Page 25

Note: The water leakage will exceed the above amount with scale/dirt build up or damage

on the mating surface. Replace the mechanical seal when the water leakage exceeds

0.5 mL/h.

3. GEAR MOTOR

After the following hours of operation, check the gear motor for excessive noise caused by

increased torque or deterioration of mechanical parts.

Bearing, gear and other mechanical parts: 10,000 hours

Oil seal: 5 years

Note: When the output shaft oil seal is exposed to a large amount of water at one time,

water may enter the gear case. Always drain the water circuit before removing the

auger for service.

4. CONDENSER

Check the condenser once a year, and clean if required by using a brush or vacuum cleaner.

More frequent cleaning may be required depending on the location of the ice dispenser.

5. AIR FILTER

Plastic mesh air filters remove dirt or dust from the air, and keep the condenser from getting

clogged. If the filters get clogged, the ice dispenser’s performance will be reduced. Remove

and clean the air filter(s) at least twice per month:

1) Pull out the air filter from the bottom of the drain pan.

2) Clean the air filter by using a vacuum cleaner. When severely clogged, use warm water

and a neutral cleaner to wash the air filter.

3) Rinse and dry the air filter thoroughly, and place it in position.

Air Filter

Handle

22

Page 26

6. CONTROL WATER VALVE AND WATER DISPENSE VALVE

1) Unplug the ice dispenser.

2) Close the water supply tap.

3) Disconnect the fitting from the valve.

4) Clean the filter packing using a brush.

5) Replace the filter packing and fitting in their correct positions.

6) Open the water supply tap.

7) Plug in the ice dispenser.

8) Check for leaks.

Fitting

Filter Packing

Control Water Valve /

Water Dispense Valve

23

Page 27

7. CLEANING OF WATER SYSTEM

WARNING

1. HOSHIZAKI recommends cleaning this unit at least twice a year. More frequent

cleaning, however, may be required in some existing water conditions.

2. Do not touch the operation switch and ice making switch with damp hands.

3. Always wear rubber gloves, eye protectors, apron, etc. for safe handling of the

cleaner and sanitiser.

4. Use the cleaners and sanitisers recommended by Hoshizaki. Contact your local

Hoshizaki office for further details. (The instructions below give an example of

those recommended cleaners and sanitisers.)

5. Never mix cleaning and sanitising solutions in an attempt to shorten cleaning time.

6. Wipe off any splashed or spilt cleaner/sanitiser immediately.

7. Do not use any ammonia type cleaners on any part of the ice dispenser.

CAUTION

Do not use ice produced with cleaning and sanitising solutions. Be sure none remains

in the storage bin on completion of cleaning.

<STEP 1>

Dilute the solutions with water as follows:

Cleaning solution: “Nickel-Safe Ice Machine Cleaner” by The Rectorseal Corporation or

similar. Prepare approximately 5 L of solution as directed on the

container.

Sanitising solution: 30 mL of 5.25% sodium hypochlorite with 7.6 L of water or the

Hoshizaki recommended sanitiser as directed on the container.

IMPORTANT

For safety and maximum effectiveness, use the solutions immediately after dilution.

<STEP 2>

Use the cleaning solution to remove lime deposits in the water system.

1) Move the ice making switch to the “OFF” position.

2) Press the push lever or dispense switch to dispense ice, and remove all ice from the

storage bin.

24

Page 28

3) Press the drain switch on the control panel. The display illuminates “DRAIN” during the 1

minute drain cycle.

4) Unplug the ice dispenser.

5) Remove the top panel and storage bin cover.

6) Pour the cleaning solution carefully into the opening in the center of the storage bin (top

of the evaporator) to an overflow level (surplus solution will be seen overflowing into the

drain pan).

Note: The overflow will be from the water reservoir and indicates that it is full.

7) Allow the cleaning solution to stand for 10 minutes. During this time, take a small brush

or a cloth and clean the inside of the storage bin with the remaining solution.

8) Refit the storage bin cover, and loosely fit the machine’s top panel.

9) Plug in the ice dispenser to make ice with the cleaning solution.

10) With the water supply tap open, move the ice making switch to the “ON” position. Allow

the machine to continue ice making for a further 20 minutes.

11) Move the ice making switch to the “OFF” position.

12) Press the drain switch on the control panel.

13) While the display illuminates “DRAIN” during the 1 minute drain cycle, pour warm water

into the storage bin to melt any ice down the drain.

Note: 1. If the machine has heavy deposits of scale, repeat the complete cleaning

procedure.

2. Do not increase the proportion of cleaning solution to shorten cleaning times, as

this may lock the auger when completing item 7).

<STEP 3>

Note: Sanitising should always be completed after cleaning or alternately as an individual

procedure if conditions exist to make it necessary.

Use 2.8 litres of the sanitising solution to sanitise the ice dispenser.

14) Unplug the ice dispenser.

15) Remove the top panel and storage bin cover.

16) Pour the sanitising solution carefully into the reservoir through the opening in the center

of the storage bin up to an overflow level.

25

Page 29

17) Wait for 10 minutes. During this time, use a clean cloth and some of the remaining

solution to wipe the inside of the storage bin and the bin cover. (Do not fit the agitator or

the drip ring.)

18) Refit the storage bin cover, and loosely fit the machine’s top panel.

19) Plug in the ice dispenser to make ice with the sanitising solution.

20) With the water supply tap open, move the ice making switch to the “ON” position. Allow

the machine to continue ice making for a further 20 minutes.

21) Move the ice making switch to the “OFF” position.

22) Press the drain switch on the control panel.

23) While the display illuminates “DRAIN” during the 1 minute drain cycle, pour clean warm

water carefully into the bin to melt any ice and into the opening in the center to an

overflow level. Be careful not to wet the bin control switch on the storage bin cover.

24) Unplug the ice dispenser.

25) Remove the top panel and storage bin cover.

26) Remove the agitator by unscrewing counterclockwise. Lift out the drip ring.

27) Take a clean cloth and a pan of fresh cold water to wipe/rinse thoroughly the bin liner

and storage bin cover.

28) Wash the agitator and drip ring with a neutral cleaner. Rinse thoroughly.

29) Immerse the agitator and drip ring into the remaining sanitising solution. Rinse

thoroughly.

30) Refit the removed parts in reverse order.

26

Page 30

III. TECHNICAL INFORMATION

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT

Control Water Valve

Water

Supply

Inlet

Water Dispense

Valve

Float Switch

Reservoir

Freezer

(Evaporator)

Flush Water Valve

Storage Bin

Expansion

Valve

Gear Motor

Drier

Condenser

Thermistor

Fan

27

Compressor

Water Circuit

Refrigerant Circuit

Page 31

2. WIRING DIAGRAM

28

Page 32

3. ICEMAKING MECHANISM

Bracket - Solenoid

Solenoid

Shutter Assembly

Ice Chute

Bin Control Switch

O-ring

Extruding Head

Sealing Bolt

Ice Storage Bin

Storage Bin Cover

Inside Cover

Balance Plate (B)

Agitator

Drip Ring

Insulation

Evaporator Top Cover

Auger

Evaporator

Mechanical Seal

Housing

Gear Motor

Water Supply Pipe

O-ring

Coupling

29

Page 33

[a] EVAPORATOR (CASING)

The evaporator consists of a stainless steel icemaking cylinder coiled with a refrigeration

pipe and wrapped together with a polyurethane foam insulation material. Water coming from

the inlet into the evaporator will be frozen into ice. The ice spout is located on top of the

evaporator.

[b] AUGER

The stainless steel auger is supported by the upper and lower bearings of the evaporator

and slowly rotated by the gear motor, while scraping off the ice forming on the inner wall of

the cylinder and pushing up to the ice spout.

[c] EXTRUDING HEAD (BEARING)

The stainless steel extruding head is provided with a press-fit plastic bearing inside and fixed

on top of the evaporator. The extruding head functions as the auger bearing and

compresses the sherbet ice carried up by the auger into a column shape with the path

resistance.

[d] HOUSING

The cast bronze housing is provided with a press-fit plastic bearing inside and fixed on the

bottom of the evaporator for connection with the gear motor.

[e] MECHANICAL SEAL

The mechanical seal on the lower auger bearing prevents icemaking water leaks into the

evaporator. The mating surfaces are made of ceramic and carbon.

[f] COUPLING (SPLINE JOINT)

The auger bottom and gear motor output shaft are splined and connected with the spline

joint.

[g] GEAR MOTOR

The gear motor consists of a 200W 1 phase 240V or 80W 1 phase 220 - 240 / 220V drive

motor integrated with a decelerator and provided with a built-in auto-reset thermal protector.

When the thermal protector trips, the controller board will stop the gear motor. The thermal

protector trips when the gear motor mechanism is overloaded or when excessively high or

low voltage is applied on the gear motor. The electrical capacity must be increased if a large

current flows through the surrounding equipment.

30

Page 34

[h] SEALING BOLT

Sometimes the icemaking operation may produce white solids on the drip pan. They are

deposits of silica and calcium contents in the icemaking water leaking from the sealing bolt.

The bolt is provided with retaining and sealing functions, which may be reduced by the load

and vibration during a freeze cycle. Do not reuse a removed sealing bolt.

Solids deposited from

sealing bolt

31

Page 35

A

A

4. ELECTRIC CIRCUIT

CAUTION

Reassemble all the components as they were after servicing the unit according to a

service call.

[a] BASIC OPERATION

The ice dispenser starts water supply when the operation switch and ice making switch are

moved to the “ON” position. On completion of water supply, the gear motor starts

immediately. After 5 minutes the compressor starts to begin icemaking operation.

In normal operation, the ice dispenser shuts down when the storage bin fills up to trip the bin

control switch or the ice making switch is moved to the “OFF” position.

Operation switch "ON"

Ice making swtch "ON"

Water supply starts

Wate r supply ends

Gear monor starts

fter 5 min

Compressor starts

(Freeze cycle starts)

Bin full

Less than 3 hrs

after bin full

Drain

Water supply ends

Water supply starts

3 hrs or more

after bin full

Low ice bin level

Gear motor stops

fter 1 min

* Low ice bin level

DCM-60KE: 400g less ice than bin full

DCM-120KE: 800g less ice than bin full

(Microprocessor calculates amount of ice

melt and dispensed)

Compressor stops

32

Page 36

p

p

[b] TIMING CHART

(Resume ice production after automatic flush)

Reset

Bin Cont rol ( mor e than 3 hrs)

Tri

1min

Reset after a certain

amount of ice reduction

10sec

60min

1min

0sec

If no ice is dispensed for 60 min,

gear motor runs for 10 sec (repeat)

OFF

60KE: 400g

120KE: 800g

Ice Making Switch

ON

ON

5min 5min 5min

1mi n 1mi n

5min

ON

OFF

Reset after a certain

amount of ice reduction

90sec

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

Reset

Bin Control

Tri

Ice Making Switch

ON

Low

ON

ON

OFF

High

OFF

Middle

ON

ON

OFF

OFF

Ice M a ki ng Switch

Contro l Water Valve

Wa t e r L e vel

Float Switch (Upper)

Float Switch (Lower)

33

Compressor

Gear Motor

Bin Control Switch

Fan Motor

Flush Water Valv e

Ice Making Lamp

"Bin Full" Indication

"Drain" Indication

Page 37

5. OPERATION BOARD

[a] DISPLAYING COMPRESSOR OPERATING HOURS

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

Note: The display shows the compressor operating hours in six digits divided into three

parts (two digits for 2 seconds each time).

Then, “- -” appears in the display (to show the end of the compressor operating hours

display mode).

e.g. 3527 hours = “00”, “35”, “27”, “- -“

[b] DISPLAYING CYCLE TIME

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

3) While still holding down the lock switch, press the drain switch once.

4) The display shows the cycle time.

Note: The display shows the cycle time in four digits divided into two parts (first minutes

then seconds, for 2 seconds each time) from the latest record (5 records at

maximum).

Then, “- -“ appears in the display (to show the end of the cycle time display mode).

If no cycle time is recorded, the display shows “- -“ only.

Minutes are indicated as follows:

o 0 to 9 = 0 to 9 minutes

A 0 to 9 = 10 to 19 minutes

b 0 to 9 = 20 to 29 minutes

C 0 to 9 = 30 to 39 minutes

d 0 to 9 = 40 to 49 minutes

E 0 to 9 = 50 to 59 minutes

Seconds are indicated as 0 to 5 0 to 9.

e.g. o9 48 = 9 minutes 48 seconds b7 36 = 27 minutes 36 seconds

34

Page 38

By using the freeze cycle time, approximate ice production capacity can be calculated.

Ice production capacity (kg/d) = 24,000 / cycle time (sec)

* If the automatic drain pan flush is activated, the cycle time becomes longer because the

drain pan is flushed at the same time as water is supplied to the reservoir.

[c] DISPLAYING MODEL NUMBER

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

3) While still holding down the lock switch, press the drain switch twice.

4) The display shows the model number.

Note: The display shows two digits.

* The model number is specified on the wiring label.

[d] SETTING MODEL NUMBER

The model number setting is required at the time of replacement of the controller board

(not required at the time of replacement of the operation board only).

Without this setting, the ice dispenser will display “EP” and will not work.

Check the model number specified on the wiring label. Improper setting may result in

failure or inoperability. Check for the correct model number after this setting.

Operation SW

Ice SW

Water SW

1) Press and hold the portion control switch, and turn on the operation switch.

2) The display shows current model number, and the water switch and ice switch flash.

3) Press the water switch to increase the number, or press the ice switch to decrease the

number until it matches the model number on the wiring label.

4) Press the portion control switch to complete the setting.

35

Page 39

[e] DISPLAYING CONTROLLER BOARD SOFTWARE VERSION

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

3) While still holding down the lock switch, press the drain switch three times.

4) The display shows the software version of controller board.

Note: The display shows the software version divided in three parts.

e.g. Ver. 1-1-1 = “ 1”, “-1”, “-1”

[f] DISPLAYING OPERATION BOARD SOFTWARE VERSION

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

3) While still holding down the lock switch, press the drain switch four times.

4) The display shows the software version of operation board.

Note: The display shows the software version divided in three parts.

e.g. Ver. 1-0-0 = “ 1”, “-0”, “-0”

[g] DISPLAYING ERROR LOG AND ONGOING ERROR

1) Press and hold the lock switch.

2) After 3 seconds, the display shows the compressor operating hours.

3) While still holding down the lock switch, press the portion control switch once.

4) The display shows error log.

5) When the display shows “- -” to indicate the end of the error log display mode, press the

portion control switch once.

36

Page 40

6) The display shows ongoing error.

Note: 1. The display shows up to eight errors from the latest error.

2. If there is no error log, the display shows “- -”.

3. Ongoing errors appear from the smallest error code, not from the latest error.

[h] RESETTING ERROR LOG

Operation SW

1) Press and hold the lock switch and portion control switch together, and turn on the

operation switch.

2) Error log is reset.

[i] REDUCING COMPRESSOR STARTING TIME

Operation SW

1) Press and hold the lock switch, and turn on the operation switch.

2) The display shows the model number, and the compressor starts running.

Note: The compressor startup delay time is reduced from 5 minutes to 2 minutes.

[j] RESETTING COMPRESSOR OPERATING HOURS

Operation SW

1) Press and hold the drain switch, lock switch and portion control switch together, and turn

on the operation switch.

2) The display shows “FA” and then the model number.

3) The compressor operating hours are reset.

4) Turn off the operation switch.

Note: Be sure to turn off the operation switch once, otherwise malfunction may occur.

37

Page 41

6. ERROR CODES

Interlock Errors

Code Error Condition Operation Reset Check/Repair

Water leak from

Icemaking

E0

Water Leak

Low Ice

E1

Production

Float Switch

E2

Error

Gear Motor

E3

Error

Abnormal High

E4

Side Pressure

Gear Motor

Drive Element

E5

Error

Condenser

Thermistor

Eb

Circuit Open

Operation

Board

Ed

Communication

Error

Gear Motor

EE

Error

c0 error occurs 2 times in a

row.

c8 error occurs 2 times in a

row.

With flush water valve OFF,

float switch trips at both

upper and lower float levels

for 2 seconds.

Gear motor relay is ON with

gear motor protective circuit

detector OFF.

c2 error occurs 5 times in 1

hour of compressor

operation.

Gear motor relay is OFF

with gear motor protective

circuit detector ON.

Condenser thermistor

circuit is open.

Operation board fails to

communicate with controller

board for more than 1

second.

c5 error occurs 5 times.

Service call lamp

blinks.

E0 blinks.

Whole unit stops.

Dispensing not

available.

Service call lamp

blinks.

E1 blinks.

Whole unit stops.

Dispensing not

available.

Service call lamp

blinks.

E2 blinks.

Whole unit stops.

Dispensing not

available.

Service call lamp

blinks.

E3 blinks.

Whole unit stops.

Dispensing not

available.

E4 blinks. N/A

Service call lamp

blinks.

E5 blinks.

Whole unit stops.

Dispensing not

available.

Service call lamp

blinks.

Eb blinks.

Whole unit stops.

Dispensing not

available.

Service call lamp

blinks.

Whole unit stops.

Dispensing not

available

Service call lamp

blinks.

EE blinks.

Whole unit stops.

Dispensing not

available

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

Power supply,

Turn OFF Turn ON

water circuit

(reservoir, inlet

hose, outlet hose,

hose joint,

mechanical seal,

flush water valve),

float switch

Gas leak, control

water valve not

closing, vapor lock,

freeze, float switch,

bin control switch

Float switch

Gear motor

protective circuit

(TPO, overload,

etc.), gear motor

relay

Fan motor,

refrigeration circuit,

condenser

clogged,

installation

conditions

Miswiring, gear

motor relay

Replace controller

board.

Condenser

thermistor

Controller board,

operation board,

communication line

between operation

board and

controller board

Gear motor locked,

hunting or

overloaded, supply

voltage, high

ambient

temperature

38

Page 42

Code Error Condition Operation Reset Check/Repair

Service call lamp

Abnormal Low

EF

Voltage

c3 error occurs 3 times in 24

hours.

blinks.

EF blinks.

Whole unit stops.

Dispensing not

Power supply,

Turn OFF Turn ON

Supply voltage

available

While compressor is

EL

Bin Control

Switch Error

running, number of water

supply cycles reaches in a

row:

DCM-60KE(-P) 12 times

DCM-120KE(-P) 24 times

* This count is reset when

ice is dispensed or

Service call lamp

blinks.

EL blinks.

Whole unit stops.

Dispensing not

available

Power supply,

Turn OFF Turn ON

Bin control switch

compressor stops.

Service call lamp

Model Setting

EP

No. Error

Controller board model

number is not set.

blinks.

EP blinks.

Whole unit stops.

Dispensing not

Power supply,

Turn OFF Turn ON

Controller board

model setting

available

Service call lamp

EU

Controller

Board Error

Controller board IC fails.

blinks.

EU blinks.

Whole unit stops.

Dispensing not

Power supply,

Turn OFF Turn ON

Replace controller

board.

available

Service call lamp

Power supply,

Turn OFF Turn ON

Electric leak, fuse

None

Electric Leak

Short Circuit

Electric leak or overcurrent.

blinks.

Whole unit stops.

Dispensing not

available

Non-Interlock Errors

Code Error Condition Operation Reset Check/Repair

Error records and

CM

Time

“- -”

c0

c1

Microcomputer

Read/Write

Error

Icemaking

Water Leak

Low Water

Microcomputer fails to

read/write properly.

After initial water supply, float

switch trips at lower float level

within 5 minutes after gear

motor starts and before

compressor starts.

Water supply continues for

more than 90 seconds, or float

switch trips at lower float level

and does not reset for more

than 60 seconds after water

supply.

Memory circuit

not available.

Whole unit stops.

Flush water

valve turns ON

for 1 second,

then turns OFF.

Unit restarts.

Ice making lamp

blinks. Whole

unit stops.

Dispensing is not

available until

reservoir fills up.

Only control

water valve

operates

intermittently for

5 minutes.

Replace

controller

board.

Error record

only.

Automatically

resets after

reservoir fills

up.

compressor

operating hours not

available on

display

Water leak from

water circuit

(reservoir, hoses,

mechanical seal,

flush water valve),

float switch

Water supply

interruption, control

water valve not

opening, flush

water valve not

closing, float

switch, water leak

39

Page 43

Code Error Condition Operation Reset Check/Repair

Automatically

resets after

Abnormal High

c2

Side Pressure

Abnormal Low

c3

Voltage

Drain Error

c4

Gear Motor

c5

Error

Low Ice

c8

Production

Condenser thermistor reads

higher than set point for 5

seconds.

Voltage stays below setting for

more than 1 second.

* For 15 seconds after

compressor starts, abnormal

low voltage is not detected.

After drain cycle, float switch

trips at lower float level and

upper float level (reservoir

full).

While gear motor is running

(at least 10 seconds after gear

motor starts), voltage

detection signal is not input to

controller board.

Interval between reservoir

water supplies exceeds:

DCM-60KE(-P)

1st freeze cycle 40 minutes

2nd cycle or later 20 minutes

DCM-120KE(-P)

1st freeze cycle 30 minutes

2nd cycle or later 15 minutes

Ice making lamp

blinks.

Whole unit stops.

Dispensing not

available.

Ice making lamp

blinks.

Whole unit stops.

Dispensing not

available.

N/A

Ice making lamp

blinks.

Whole unit stops.

Dispensing not

available.

Whole unit stops,

then

automatically

restarts.

pressure

switch turns

ON or

condenser

outlet

thermistor

reads lower

than set point.

Automatically

resets after

voltage stays

above reset

setting for 2

minutes.

Error record

only.

Automatically

resets after 30

minutes.

Error record

only.

Fan motor,

refrigeration circuit,

condenser

clogged,

installation

conditions

Supply voltage

Flush water valve

not opening,

control water valve

not closing

Gear motor locked,

hunting or

overloaded, supply

voltage, high

ambient

temperature

Water leak from

water circuit

(reservoir, inlet

hose, outlet hose,

hose joint,

mechanical seal,

flush water valve),

float switch

40

Page 44

7. PERFORMANCE DATA

[a] DCM-60KE(-P): 50Hz

70

60

0.07

0.06

/day]

3

Ice Produc tion Capaci ty [kg/day]

Am perage [A]

50

40

30

20

0 10203040

1.60

1.55

1.50

1.45

1.40

1.35

0 10203040

0.05

0.04

0.03

0.02

0 10203040

8.0

7.5

7.0

6.5

6.0

5.5

0 10203040

Water Cons umption [ m

Wattage [kWh/day]

1400

1200

1000

Head Pres sure [k P a]

800

600

400

200

0 10203040

The horizontal axis shows the ambient temperature

It refers to data of at/wt=10/10, 21/15, 32/21

140

130

120

110

100

90

80

0 10203040

Suction Pressure [kPa]

41

Page 45

[b] DCM-60KE(-P): 60Hz

Ice P roducti on Capacity [ kg/ day]

Am perage [ A ]

70

60

50

40

30

20

0 10203040

1.60

1.55

1.50

1.45

1.40

0.07

0.06

0.05

0.04

0.03

0.02

0 10203040

8.0

7.5

7.0

6.5

6.0

/day]

3

Water Cons um pt i on [m

Watt age [kWh/day]

1400

1200

1000

Head Pressure [kPa]

1.35

800

600

400

200

0 10203040

0 10203040

0 10203040

010203040

The horizontal axis shows the ambient temperature

It refers to data of at/wt=10/10, 21/15, 32/21

5.5

140

130

120

110

100

90

80

Suction Pressure [kPa]

42

Page 46

[c] DCM-120KE(-P): 50Hz

140

0.14

Ice Produc tion Capaci ty [kg/day]

Am perage [A]

130

120

110

100

90

80

70

0 10203040

2.95

2.90

2.85

2.80

2.75

2.70

0 10203040

0.13

0.12

0.11

0.10

0.09

0.08

0.07

0 10203040

12.5

12.0

11.5

11.0

10.5

10.0

0 10203040

/day]

3

Water Cons umption [ m

Watt age [ kWh/day]

Head Pressure [kPa]

1400

1200

1000

800

600

400

200

010203040

0 10203040

The horizontal axis shows the ambient temperature

It refers to data of at/wt=10/10, 21/15, 32/21

130

120

110

100

90

80

70

Suction Pressure [kPa]

43

Page 47

[d] DCM-120KE(-P): 60Hz

140

130

120

0.14

0.13

0.12

/day]

3

110

100

Ice Production Capacity [kg/day]

Amperage [A]

90

80

70

0 10203040

2.75

2.70

2.65

2.60

2.55

2.50

0 10203040

0.11

0.10

0.09

0.08

0.07

0 10203040

14.5

14.0

13.5

13.0

12.5

12.0

0 10203040

Water Cons um pt i on [ m

Wattage [kWh/day]

Head Pressu re [ kPa]

1400

1200

1000

800

600

400

200

0 10203040

0 10203040

The horizontal axis shows the ambient temperature

It refers to d ata of at/wt=10/10, 21/15, 32/21

130

120

110

100

90

80

70

Sucti on P ress ure [ kPa ]

44

Page 48

IV. SERVICE DIAGNOSIS

Display error records by operating the operation board (see “III. 5. [g] DISPLAYING ERROR

LOG AND ONGOING ERROR”). Check for a possible cause and service the unit.

1. NO ICE PRODUCTION

PROBLEM POSSIBLE CAUSE REMEDY

[1] The ice

dispenser will

not start.

[2] Water does not

stop, and the ice

dispenser will

not start.

[3] Water has been

supplied, but the

ice dispenser will

not start.

a) Power supply

b) Fuse 1. Blown out. No

c) Transformer

receptacle

e) Transformer 1. Coil winding opened. 1. Replace.

f) Water valve 1. Coil winding opened. 1. Replace.

receptacle (control

box)

i) Overload protector 1. Tripped. 1. Reset.

j) Model number 1. Incorrect. 1. Set correct number. See “III. 5.

relay (controller

board)

b) Float switch

c) Flush water valve 1. Valve seat clogged

d) Hoses 1. Disconnected. 1. Connect.

e) Mechanical seal 1. Water leaks. 1. Replace.

f) Reservoir 1. Cracked. 1. Replace.

a) Bin control 1. Bad contacts. 1. Check for continuity and

b) Gear motor

protector (thermal

breaker)

c) Controller board 1. Defective. 1. Replace.

1. OFF position. 1. Move to ON position.

2. Loose connections. 2. Tighten.

3. Bad contacts. 3. Check for continuity and

replace.

4. Blown fuse. 4. Replace.

5. Voltage too low. 5. Get recommended voltage.

1. Locate and resolve the cause

indication on

operation board.

1. Disconnected. 1. Connect.

1. OFF position. 1. Move to ON position. d) Operation switch

2. Bad contacts. 2. Check for continuity and

1. Closed. 1. Open. g) Water supply tap

2. Water failure. 2. Wait till water is supplied.

1. Disconnected. 1. Connect. h) Plug and

2. Terminal out of plug

or receptacle.

1. Contacts fused. 1. Replace controller board. a) Water control

2. Coil winding opened. 2. Replace controller board.

1. Bad contacts. 1. Check for continuity and

2. Float does not move

freely.

and water leaking.

1. Tripped. 1. Find out the cause, resolve it,

of short circuit (ex. control

water valve, flush water

valve), and replace.

replace.

2. Insert terminal back in

position.

[d] SETTING MODEL

NUMBER.

replace.

2. Clean or replace.

1. Clean or replace.

replace.

and press reset button on

motor protector.

45

Page 49

PROBLEM POSSIBLE CAUSE REMEDY

[3] (Continued)

d) Condenser

thermistor

1. Dirty condenser fins. 1. Clean.

2. Ambient temperature

too warm.

2. Check for recommended

temperature.

3. Fan not rotating. 3. Replace.

4. Condenser water

pressure too low or off.

5. Water regulating valve

4. Check and get recommended

pressure.

5. Clean.

clogged.

6. Refrigerant

6. Recharge.

overcharged.

7. Refrigerant line or

7. Clean and replace drier.

components plugged.

8. Bad contacts. 8. Check for continuity and

replace.

9. Loose connections. 9. Tighten.

1. Coil winding opened. 1. Replace. e) Gear motor

protect relay

2. Bad contacts. 2. Check for continuity and

replace.

f) Capacitor 1. Defective 1. Replace.

[4] Gear motor

starts, but

compressor will

not start or

operates

intermittently.

a) Ice making switch 1. OFF position 1. Move to ON position.

b) X3 relay

(controller board)

1. Bad contacts. 1. Check for continuity and

replace controller board.

2. Coil winding opened. 2. Replace controller board.

c) Compressor

1. Loose connections. 1. Tighten.

2. Motor winding opened

2. Replace.

or earthed.

3. Motor protector

tripped.

d) Power supply 1. Circuit ampacity too

low.

3. Find out the cause of overheat

or overcurrent.

1. Install a larger-sized

conductor.

e) Controller board 1. Defective. 1. Replace.

f) Starter 1. Defective. 1. Replace.

g) Start capacitor or

1. Defective. 1. Replace.

run capacitor

[5] Gear motor and

compressor

start, but no ice

is produced.

a) Refrigerant line

1. Gas leaks. 1. Check for leaks with a leak

detector. Reweld leak, replace

drier and charge with

refrigerant. The amount of

refrigerant is marked on

nameplate or label.

2. Refrigerant line

clogged.

2. Replace the clogged

component.

46

Page 50

2. LOW ICE PRODUCTION

PROBLEM POSSIBLE CAUSE REMEDY

[1] Low ice

production

a) Refrigerant line

b) High-side

pressure too high

c) Expansion valve

(not adjustable)

d) Evaporator 1. Evaporator pipe

1. Gas leaks. 1. See 1 - [5] - a).

2. Refrigerant line

clogged.

3. Overcharged. 3. Recharge.

1. Dirty air filter or

condenser.

2. Ambient or condenser

water temperature too

warm.

3. Fan rotating too slow. 3. Replace.

4. Bad ventilation. 4. Remove anything blocking

5. Less than 15 cm

clearance at rear,

sides and top.

1. Low-side pressure

exceeding the limit.

crushed.

2. Replace the clogged

component.

1. Clean.

2. Check for recommended

temperature.

vents.

5. Allow proper clearance for

ventilation.

1. Replace.

1. Replace.

3. FAULTY DISPENSER

PROBLEM POSSIBLE CAUSE REMEDY

[1] No ice is

dispensed.

[2] No water is

dispensed.

[3] Ice keeps being

dispensed.

a) Storage bin 1. Ice block or bridge. 1. Remove all ice from storage

bin when not using ice

dispenser for a long time.

b) Agitator 1. Deformed due to ice

block or bridge.

c) Solenoid 1. Coil winding opened. 1. Replace.

d) Lever switch 1. Bad contacts. 1. Check for continuity and

1. Clogged filter. 1. Clean. a) Water valve

(dispensing)

b) Lever switch 1. Bad contacts. 1. Check for continuity and

a) Shutter 1. Faulty adjustment. 1. With shutter closed, lock

b) Lever switch 1. Contacts fused. 1. Replace.

2. Coil winding opened. 2. Replace.

1. Replace.

replace.

replace.

shutter in place by securing

with two screws at the lower

part of solenoid and two

screws under solenoid.

47

Page 51

4. OTHERS

PROBLEM POSSIBLE CAUSE REMEDY

[1] Abnormal noise

[2] Overflow from

reservoir (Water

does not stop.)

[3] Gear motor

protector

operates

frequently.

a) Fan motor

(condenser unit)

b) Compressor

c) Refrigerant lines 1. Rub or touch lines or

d) Gear motor (ice

making)

e) Evaporator

a) Water supply

b) Water valve

c) Float switch

a) Power supply

voltage

b) Evaporator assy 1. Bearings or auger

1. Bearing worn out.

2. Fan blade deformed. 2. Replace fan blade.

3. Fan blade does not

move freely.

1. Bearings worn out, or

cylinder valve

defective.

2. Mounting pad out of

position.

other surfaces.

1. Bearing or gear

wear/damage.

1. Low-side pressure too

low.

2. Scale on inside wall of

freezing cylinder.

1. Water pressure too

high.

1. Diaphragm does not

close.

1. Bad contacts.

1. Too high or too low.

worn out.

1. Replace.

3. Replace.

1. Replace.

2. Reinstall.

1. Replace.

1. Replace.

1. See if expansion valve bulb is

mounted properly, and replace

the valve if necessary.

2. Remove auger. Use a solution

of lime removing cleaner to

clean periodically. If water is

found to surpass the following

levels, install a conditioner.

Hardness 50 ppm

Silica 30 ppm

1. Install a pressure reducing

valve.

1. Clean or replace.

1. Check for continuity and

replace.

1. Connect the unit to a power

supply of proper voltage.

1. Replace bearing or auger.

48

Page 52

V. REMOVAL AND REPLACEMENT

1. FRONT COVER

[a] REMOVAL

1) Remove the top panel.

2) Remove the two screws at the top of the front cover and the screw at the back of the ice

spout.

3) Pull the top of the front cover forward.

(Hooks are provided at the bottom of the front cover.)

Hook

49

Page 53

4) Disconnect the two connectors.

5) Lift off the front cover.

50

Page 54

[b] REPLACEMENT

1) Replace the removed parts in the reverse order of which they were removed.

Note:

1. Before installing the front cover, put the water pipe through the front cover.

Water Pipe

2. Hook the bottom of the front cover as shown below, and push it in hard.

51

Page 55

2. SERVICE FOR REFRIGERANT LINES

[a] SERVICE INFORMATION

1) Allowable Compressor Opening Time and Prevention of Lubricant Mixture [R134A]

The compressor must not be opened more than 15 minutes in replacement or service. Do

not mix lubricants of different compressors even if both are charged with the same

refrigerant, except when they use the same lubricant.

2) Treatment for Refrigerant Leak [R134A]

If a refrigerant leak occurs in the low side of an ice dispenser, air may be drawn in. Even if

the low side pressure is higher than the atmospheric pressure in normal operation, a

continuous refrigerant leak will eventually lower the low side pressure below the

atmospheric pressure and will cause air suction. Air contains a large amount of moisture,

and ester oil easily absorbs a lot of moisture. If an ice dispenser charged with R134A has

possibly drawn in air, the drier must be replaced. Be sure to use a drier designed for R134A.

3) Handling of Handy Flux [R134A]

Repair of the refrigerant circuit requires brazing. It is no problem to use the same handy flux

that has been used for the current refrigerants. However, its entrance into the refrigerant

circuit should be avoided as much as possible.

4) Oil for Processing of Copper Tubing [R134A]

When processing the copper tubing for service, wipe off oil, if any used, by using alcohol or

the like. Do not use too much oil or let it into the tubing, as wax contained in the oil will clog

the capillary tubing.

5) Service Parts for R134A

Some parts used for refrigerants other than R134A are similar to those for R134A. But never

use any parts unless they are specified for R134A because their endurance against the

refrigerant has not been evaluated. Also, for R134A, do not use any parts that have been

used for other refrigerants. Otherwise, wax and chlorine remaining on the parts may

adversely affect R134A.

6) Replacement Copper Tubing [R134A]

The copper tubes currently in use are suitable for R134A. But do not use them if oily inside.

The residual oil in copper tubes should be as little as possible. (Low residual oil type copper

tubes are used in the shipped units.)

7) Evacuation, Vacuum Pump and Refrigerant Charge [R134A]

Never allow the oil in the vacuum pump to flow backward. The vacuum level and vacuum

pump may be the same as those for the current refrigerants. However, the rubber hose and

gauge manifold to be used for evacuation and refrigerant charge should be exclusively for

R134A.

52

Page 56

8) Refrigerant Leak Check

Refrigerant leaks can be detected by charging the unit with a little refrigerant, raising the

pressure with nitrogen and using an electronic detector. Do not use air or oxygen instead of

nitrogen for this purpose, or rise in pressure as well as in temperature may cause R134A to

suddenly react with oxygen and explode. Be sure to use nitrogen to prevent explosion.

[b] REFRIGERANT RECOVERY

The refrigerant must be recovered if required by an applicable law. Recover the refrigerant

from the access valve, and store it in a proper container. Do not discharge the refrigerant

into the atmosphere.

When replacing the drier, take the opportunity to also fit a low-side access valve and a

high-side access valve for ease of charging liquid refrigerant.

[c] EVACUATION AND RECHARGE

1) Attach a charging hose of a gauge manifold to a vacuum pump and the low-side access

valve (to be fitted by service personnel).

2) Open the low-side valve on the gauge manifold, and turn on the vacuum pump.

3) Allow the vacuum pump to pull down to a 760 mmHg vacuum. Evacuating period

depends on the pump capacity.

4) Close the low-side valve on the gauge manifold.

5) Disconnect the vacuum pump, and attach a refrigerant charging cylinder to accurately

weigh in the liquid charge. Remember to purge any air from the charging hose. See the

nameplate for the required refrigerant charge.

6) Open the low-side valve on the gauge manifold and the valve on the charging cylinder.

7) When no more refrigerant is drawn in, turn on the ice dispenser. When the required

amount of refrigerant has been charged, close the valve on the charging cylinder and

turn off the ice dispenser.

8) Close the low-side valve on the gauge manifold.

9) Disconnect the charging hose from the access valve. Always cap the access valve to

prevent a refrigerant leak.

10) Always thoroughly leak test all joints and valve caps.

11) Avoid charging large quantities of liquid into the low side in case of damage to the

compressor.

53

Page 57

3. BRAZING

DANGER

1. Refrigerant R134A itself is not flammable, explosive and poisonous. However, when

exposed to an open flame, R134A creates phosgene gas, hazardous in large

amounts.

2. Always recover the refrigerant and store it in a proper container, if required by an

applicable law. Do not discharge the refrigerant into the atmosphere.

3. Do not use silver alloy or copper alloy containing arsenic.

4. In its liquid state, the refrigerant can cause frostbite because of the low temperature.

4. COMPRESSOR

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened. Do not

replace the drier until after all other repair or replacement has been made.

1) Unplug the ice dispenser.

2) Remove the panels.

3) Remove the terminal cover on the compressor, and disconnect the compressor wiring.

4) Recover the refrigerant and store it in a proper container, if required by an applicable law

(See “2. [b] REFRIGERANT RECOVERY”).

5) Remove the discharge, suction and access pipes from the compressor using brazing

equipment.

WARNING

When repairing a refrigerant system, be careful not to let the burner flame contact any

electrical wires or insulation.

6) Remove the bolts and rubber grommets.

7) Slide and remove the compressor. Unpack the new compressor package. Install the

new compressor.

8) Attach the rubber grommets of the previous compressor.

9) Clean the suction and discharge pipes with an abrasive cloth/paper.

54

Page 58

10) Place the compressor in position, and secure it using the bolts and washers.

11) Remove plugs from the discharge, suction and access pipes.

12) Braze the access, suction and discharge pipes (Do not change this order) with nitrogen

gas flowing at the pressure of 0.2 - 0.3 bar.

13) Install the new drier (See "5. DRIER").

14) Check for leaks using nitrogen gas (10 bar) and soap bubbles.

15) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge (See “2. [c] EVACUATION AND RECHARGE”).

16) Connect the terminals to the compressor, and replace the terminal cover in its correct

position.

17) Refit the panels in their correct position.

18) Plug in the ice dispenser.

5. DRIER

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened. Do not

replace the drier until after all other repair or replacement has been made.

1) Unplug the ice dispenser.

2) Remove the front cover.

3) Recover the refrigerant and store it in a proper container, if required by an applicable law

(See “2. [b] REFRIGERANT RECOVERY”).

4) Remove the drier using brazing equipment.

5) Install the new drier with the arrow on the drier in the direction of the refrigerant flow. Use

nitrogen gas at the pressure of 0.2 - 0.3 bar when brazing the tubings.

6) Check for leaks using nitrogen gas (10 bar) and soap bubbles.

7) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge (See “2. [c] EVACUATION AND RECHARGE”).

8) Refit the front cover in its correct position.

9) Plug in the ice dispenser.

55

Page 59

6. EXPANSION VALVE

IMPORTANT

Sometimes moisture in the refrigerant circuit exceeds the drier capacity and freezes up

at the expansion valve. Always install a new drier every time the sealed refrigeration

system is opened. Do not replace the drier until after all other repair or replacement

has been made.

1) Unplug the ice dispenser.

2) Remove the front cover.

3) Recover the refrigerant and store it in a proper container, if required by an applicable law

(See “2. [b] REFRIGERANT RECOVERY”).

4) Remove the expansion valve bulb at the evaporator outlet.

5) Remove the expansion valve cover, and disconnect the expansion valve using brazing

equipment.

6) Braze the new expansion valve with nitrogen gas flowing at the pressure of 0.2 - 0.3 bar.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve from

overheating. Do not braze with the valve body exceeding 120°C.

7) Install the new drier (See "5. DRIER").

8) Check for leaks using nitrogen gas (10 bar) and soap bubbles.

9) Evacuate the system, and charge it with refrigerant. See the nameplate for the required

refrigerant charge (See "2. [c] EVACUATION AND RECHARGE").

10) Attach the bulb to the suction line. Be sure to secure the bulb using a wire or clamp and

replace the insulation.

11) Place the new set of expansion valve covers in position.

12) Refit the front cover in its correct position.

13) Plug in the ice dispenser.

56

Page 60

7. FAN MOTOR

1) Unplug the ice dispenser.

2) Remove the cabinet.

3) Disconnect the lead wires at their connection.

4) Take out the fan motor with its bracket from the unit.

Remove 4 screws.

Remove fan motor from unit.

5) Remove the fan motor from the fan motor bracket.

6) Assemble the removed parts in the reverse order of which they were removed.

8. EVAPORATOR ASSEMBLY

See the exploded view under “III. 3. ICEMAKING MECHANISM”.

1) Move the ice making switch to the “OFF” position.

2) Press the push lever or dispense switch to dispense ice, and remove all ice from the

storage bin.

3) Press the drain switch on the control panel. The display illuminates “DRAIN” during the 1

minute drain cycle.

4) Unplug the ice dispenser.

5) Remove the panels.

6) Remove the storage bin assembly (See “13. STORAGE BIN ASSEMBLY”).

EXTRUDING HEAD

7) Remove the sealing bolts, and lift off the extruding head.

8) Check the bearing inside the extruding head. If it is worn out or scratched, replace the

bearing.

57

Page 61

Note: Replacing the bearing needs a fitting tool. If it is not available, replace the whole

extruding head.

AUGER

9) Lift out the auger. Check the top and bottom areas in contact with the bearings. If the

surface is scratched or pitted, replace the auger. Check the blade edge of the auger. If it

is scratched or worn where it has contacted the evaporator, replace it.

EVAPORATOR

Note: Skip the following steps 10) through 15) when the evaporator does not need

replacement.

10) Recover the refrigerant and store it in a proper container, if required by an applicable law

(See "2. [b] REFRIGERANT RECOVERY").

IMPORTANT

Always install a new drier every time the sealed refrigeration system is opened. Do not

replace the drier until after all other repair or replacement has been made.

11) Remove the bulb of the expansion valve.

12) Disconnect the brazing connections of the expansion valve and the copper tube - low

side from the evaporator, using brazing equipment.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve from

overheating. Do not braze with the valve body exceeding 120°C.

13) Disconnect the hoses from the evaporator.

14) Remove the four socket head cap screws securing the evaporator with the housing.

15) Lift off the evaporator.

HOUSING AND MECHANICAL SEAL

16) The mechanical seal consists of two parts. One part rotates with the auger, the other is

static and is fitted into a top recess in the housing. If the contact surfaces of these two

parts become worn or scratched, the mechanical seal may leak water and should be

replaced.

17) Remove the O-ring on the top outer edge of the housing.

58

Page 62

18) Remove the four bolts and lift the housing clear of the gear motor. Check the bearing

inside the housing. If it is worn or scratched, replace it using a fitting tool. Carefully ease

out the lower part of the mechanical seal before replacing the bearing.

Note: If a fitting tool is not available, replace the whole lower housing complete with

bearing.

GEAR MOTOR

19) Cut the connectors.

20) Remove the three socket head cap screws securing the gear motor.

21) Assemble the removed parts in the reverse order of which they were removed.

WARNING

Be careful not to scratch the surface of the O-ring, or it may cause water leaks. Handle

the mechanical seal with care not to scratch nor to contaminate its contact surface.

22) When replacing the evaporator:

(a) Braze the new evaporator with nitrogen gas flowing at the pressure of 0.2 - 0.3 bar.

(b) Replace the drier.

(c) Check for leaks using nitrogen gas (10 bar) and soap bubbles.

(d) Evacuate the system, and charge it with refrigerant. See the nameplate for the

required refrigerant charge (See "2. [c] EVACUATION AND RECHARGE").

23) Refit the panels in their correct position.

24) Plug in the ice dispenser.

9. CONTROL WATER VALVE AND WATER DISPENSE VALVE

1) Unplug the ice dispenser.

2) Close the water supply tap.

3) Remove the panels.

4) Disconnect the terminals from the valve.

5) Loosen the fitting nut on the valve inlet, and remove the valve. Do not lose the packing

inside the fitting nut.

59

Page 63

6) Install the new valve.

7) Assemble the removed parts in the reverse order of which they were removed.

8) Open the water supply tap.

9) Plug in the ice dispenser.

10) Check for water leaks.

11) Refit the panels in their correct position.

10. FLUSH WATER VALVE

1) Move the ice making switch to the “OFF” position.

2) Press the drain switch on the control panel. The display illuminates “DRAIN” during the 1

minute drain cycle.

3) Unplug the ice dispenser, and close the water supply tap.

4) Remove the panels.

5) Remove the clamp and disconnect the hose from the flush water valve.

Note: Water may still remain inside the evaporator. Be sure to drain the water into the

drain pan.

6) Disconnect the terminals from the flush water valve.

7) Remove the flush water valve from the bracket.

8) Remove the drain pipe from the flush water valve.

9) Connect the drain pipe to the new flush water valve, and place the valve in position.

10) Connect the hose to the flush water valve, and secure it with the clamp.

11) Pour water into the reservoir, and check for water leaks on the flush water valve.

12) Open the water supply tap.

13) Plug in the ice dispenser.

14) Check for water leaks.

15) Push the drain switch, and make sure water is flushing.

16) Refit the panels in their correct position.

60

Page 64

11. CONTROLLER BOARD

IMPORTANT

A single type controller board is supplied as a service board. Some modifications and

adjustment will be required to fit the ice dispenser models. Do not repair any parts and

electronic devices on the controller board in the field. Replace the whole board with a

new service board.

[a] MODIFICATION

1) Check that the service board package includes:

Controller board 1 pc. Instruction sheet 1 pc.

2) Modify the service board referring to the instruction sheet attached (Set the model number

according to "III. 5. [d] SETTING MODEL NUMBER").

[b] REPLACEMENT

1) Unplug the ice dispenser.

2) Remove the panels.

3) Remove the control box.

4) Disconnect the connectors and board support from the controller board.

5) Remove the controller board from the control box.

6) Install the new controller board and reassemble the control box in the reverse order of the

removal procedure.

7) Replace the panels in their correct position.

8) Plug in the ice dispenser.

61

Page 65

12. BIN CONTROL SWITCH ASSEMBLY

r

r

1) Unplug the ice dispenser.

2) Remove the top panel.

3) Remove the storage bin cover.

4) Remove the bin control switch.

5) Remove the snap pin and E-ring, and disassemble the balance plate (B) and shaft.

6) Install the new bin control switch assembly.

7) Assemble the removed parts in the reverse order of which they ware removed.

8) Plug in the ice dispenser, and check that the bin control switch works normally.

DCM-60KE(-P)

Bin Control Switch

Shaft

Storage Bin Cove

Balance Plate (B)

DCM-120KE(-P)

Bin Control Switch

Shaft

Storage Bin Cove

Balance Plate (B)

Tie

Tie

62

Page 66

13. STORAGE BIN ASSEMBLY

1) Move the ice making switch to the “OFF” position.

2) Press the push lever or dispense switch to dispense ice, and remove all ice from the

storage bin.

3) Press the drain switch on the control panel. The display illuminates “DRAIN” during the 1

minute drain cycle.

4) Unplug the ice dispenser.

5) Remove the panels.

6) Remove the storage bin cover.

7) Remove the agitator, drip ring and shutter assembly.

8) Remove the three sealing bolts, and lift off the storage bin assembly.

9) Install the new storage bin assembly.

10) Assemble the removed parts in the reverse order of which they were removed.

11) Plug in the ice dispenser.

12) Mover the shutter to check for proper operation.

14. AGITATOR AND DRIP RING

1) Move the ice making switch to the “OFF” position.

2) Press the push lever or dispense switch to dispense ice, and remove all ice from the

storage bin.

3) Unplug the ice dispenser.

4) Remove the top panel.

5) Remove the storage bin cover.

6) Rotate the agitator counterclockwise, and lift off.

7) Rotate the dip ring about 30 degrees clockwise, and lift out.

8) Install the new drip ring and agitator.

9) Assemble the removed parts in the reverse order of they were removed.

10) Plug in the ice dispenser.

63

Loading...

Loading...