Page 1

Service Manual

Commercial Series

Refrigerated Kitchen Equipment

Models

Undercounter

Worktop

Prep Table

hoshizakiamerica.com

Number: 73191

Issued: 9-29-2011

Revised: 5-1-2017

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No service should be undertaken until

the technician has thoroughly read this Service Manual. Failure to service and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage. Proper installation is the

responsibility of the installer. Product failure or property damage due to improper

installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service of the appliance.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read

the warnings and guidelines contained in this booklet carefully as they provide

essential information for the continued safe use, service, and maintenance of the

appliance. Retain this booklet for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 5

I. Construction and Refrigeration Circuit Diagram ................................................................. 8

A. Construction .................................................................................................................. 8

B. Refrigeration Circuit Diagram ........................................................................................ 9

II. Sequence of Operation and Service Diagnosis ............................................................... 10

A1. Thermostat Control Sequence of Operation Flow Chart ............................................ 10

1. Undercounter and Work Top: Refrigerator .............................................................. 10

2. Prep Table ...............................................................................................................11

3. Undercounter and Work Top: Freezer .....................................................................11

A2. Thermistor/Control Module Sequence of Operation Flow Chart ............................... 12

1. Undercounter and Work Top: Refrigerator .............................................................. 12

2. Prep Table .............................................................................................................. 13

3. Undercounter and Work Top: Freezer .................................................................... 14

B1. Thermostat Control Service Diagnosis ...................................................................... 15

1. Undercounter and Worktop: Refrigerator ................................................................ 15

2. Prep Table .............................................................................................................. 16

3. Undercounter and Worktop: Freezer ...................................................................... 17

B2. Thermistor/Control Module Service Diagnosis .......................................................... 19

C. Defrost Timer Check ................................................................................................... 23

D. Control Module Check ................................................................................................. 24

E. Diagnostic Table .......................................................................................................... 26

III. Controls and Adjustments ............................................................................................... 28

A. Temperature Settings .................................................................................................. 28

B. Defrost ......................................................................................................................... 28

C. Safety Devices ............................................................................................................ 30

D. Perimeter and Mullion Heaters .................................................................................... 30

IV. Refrigeration Circuit and Component Service Information.............................................. 31

A. Refrigeration Circuit Service Information .................................................................... 31

B. Component Service Information .................................................................................. 33

C. Door Reversal ............................................................................................................. 34

D. Door/Drawer Location Reversal .................................................................................. 37

V. Preparing the Appliance for Periods of Non-Use ............................................................. 48

VI. Disposal .......................................................................................................................... 49

3

Page 4

VII. Technical Information ..................................................................................................... 50

A. Electrical and Refrigerant Data ................................................................................... 50

B. Wiring Diagrams .......................................................................................................... 51

1a. Undercounter and Worktop: Refrigerator; Cabinet Thermostat ............................ 51

1b. Undercounter and Worktop: Refrigerator; Cabinet Thermistor/Control Module .... 52

2a. Prep Table; Cabinet Thermostat (Without Defrost Heater) ................................... 53

2b. Prep Table; Cabinet Thermostat (With Defrost Heater) ........................................ 54

2c. Prep Table; Cabinet Thermistor/Control Module ................................................... 55

3a. Undercounter and Work Top: Freezer; Cabinet Thermostat ................................. 56

3b. Undercounter and Work Top: Freezer; Cabinet Thermistor/Control Module ......... 57

4

Page 5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the use and care of the

appliance.

WARNING

This appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting from

improper, incorrect, and unreasonable use. Failure to service and maintain the

appliance in accordance with this manual will adversely affect safety, performance,

component life, and warranty coverage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service this appliance.

• This appliance must be installed in accordance with applicable national, state, and

local codes and regulations.

• To reduce the risk of electric shock, do not touch the plug with damp hands.

• Unplug the appliance before servicing.

• This appliance requires an independent power supply of proper capacity. See

the nameplate for electrical specications. Failure to use an independent power

supply of proper capacity can result in a tripped breaker, blown fuse, damage to

existing wiring, or component failure. This could lead to heat generation or re.

• THIS APPLIANCE MUST BE GROUNDED. This appliance is equipped with a

NEMA5-15 three-prong grounding plug

hazards. It must be plugged into a properly grounded, independent 3-prong wall

outlet. If the outlet is a 2-prong outlet, it is your personal responsibility to have

a qualied electrician replace it with a properly grounded, independent 3-prong

wall outlet. Do not remove the ground prong from the power cord and do not use

an adapter plug. Failure to follow these instructions may result in death, electric

shock, or re.

• Do not use an extension cord.

• Do not use an appliance with a damaged power cord. The power cord should not

be altered, jerked, bundled, weighed down, pinched, or tangled. Such actions

could result in electric shock or re. To unplug the appliance, be sure to pull the

plug, not the cord, and do not jerk the cord.

to reduce the risk of potential shock

5

Page 6

WARNING, continued

• The GREEN ground wire in the factory-installed power cord is connected to the

appliance. If it becomes necessary to remove or replace the power cord, be sure

to connect the power cord's ground wire.

• Do not splash, pour, or spray water directly onto or into the appliance. This might

cause short circuit, electric shock, corrosion, or failure.

• Do not make any alterations to the appliance. Alterations could result in electric

shock, injury, re, or damage to the appliance.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Children should be properly supervised around this appliance.

• Do not climb, stand, or hang on the appliance or door or allow children or animals

to do so. Do not climb into the appliance or allow children or animals to do so.

Death or serious injury could occur or the appliance could be damaged.

• Be careful not to pinch ngers when opening and closing the doors or rail cover

(prep table models). Be careful when opening and closing the doors or rail cover

when children are in the area.

• Open and close the doors and rail cover (prep table models) with care. Opening

the doors or rail cover too quickly or forcefully may cause injury or damage to the

appliance or surrounding equipment.

• Do not use combustible spray or place volatile or ammable substances in or near

the appliance. They might catch re.

• Keep the area around the appliance clean. Dirt, dust, or insects in the appliance

could cause harm to individuals or damage to the equipment.

• Do not throw anything onto the shelves or load any single shelf with more than

120lb. (54.5 kg) of product. They might fall off and cause injury.

• This appliance is designed only for temporary storage of food. Employ sanitary

methods. Use for any other purposes (for example, storage of chemicals or

medical supplies such as vaccine and serum) could cause deterioration of stored

items.

• Do not block air inlets or outlets, otherwise cooling performance may be reduced.

• Do not tightly pack the cabinet. Allow some space between items to ensure good

air ow. Also allow space between items and interior surfaces.

• Do not put warm or hot foods in the cabinet. Let them cool rst, or they will raise

the cabinet temperature and could deteriorate other foods in the cabinet or

overload the appliance.

6

Page 7

WARNING, continued

• All foods should be wrapped in plastic lm or stored in sealed containers.

Otherwise foods may dry up, pass their smells onto other foods, cause frost

to develop, result in poor appliance performance, or increase the likelihood of

cross-contamination. Certain dressings and food ingredients, if not stored in

sealed containers, may accelerate corrosion of the evaporator, resulting in failure.

• Do not store items near air outlets. Otherwise, items may freeze up and crack or

break causing a risk of injury or contamination of other food.

Additional Warnings for Prep Table Models

• The entire rail must always be covered by rail dividers and pans (1/6 size, up to

6"(15cm)deep). Otherwise, the appliance will not cool properly.

• Use only 1/6 size pans up to 6"(15cm) deep. Do not use damaged pans.

• Ingredients must be pre-chilled to 37°F (3°C) or less before placing in rail.

• Keep the rail cover closed when not actively preparing food.

• The rail is for keeping ingredients cool while preparing food. If not actively

preparing food for a long period such as overnight, seal pans with plastic

wrap in addition to closing the rail cover. Depending on conditions, the cabinet

temperature setting may need to be adjusted to prevent items from freezing.

Alternatively, seal ingredients and store them in a refrigerator or freezer.

NOTICE

• Protect the oor when moving the appliance to prevent damage to the oor.

• Keep ventilation openings, in the appliance enclosure or in the built-in structure,

clear of obstruction. Do not place anything on top of the appliance in an

undercounter installation. There must be at least 1.5" (4 cm) overhead clearance

for proper ventilation. The factory-installed rear bumpers must be in place

to ensure proper rear clearance. Blockage of airow could negatively affect

performance and damage the appliance.

• Do not allow the appliance to bear any outside weight.

• To prevent deformation or cracks, do not spray insecticide onto the plastic parts or

let them come into contact with oil.

• To avoid damage to the gasket, use only the door handle when opening and

closing.

• To avoid damage to the top seal, do not lift the appliance by the top panel or

remove the top panel.

Additional Notice for Prep Table and Mega Top Models

• Do not place anything on top of the rail hood or rail cover and do not lift the

appliance by the rail hood or rail cover. The rail hood and rail cover are not

designed to bear any outside weight.

• CRMR27-8(-12M) Auxiliary Code B-5 to C-7: Do not place anything on the air

distribution table beneath the pans. The air distribution table is not a load-bearing

surface.

7

Page 8

I. Construction and Refrigeration Circuit Diagram

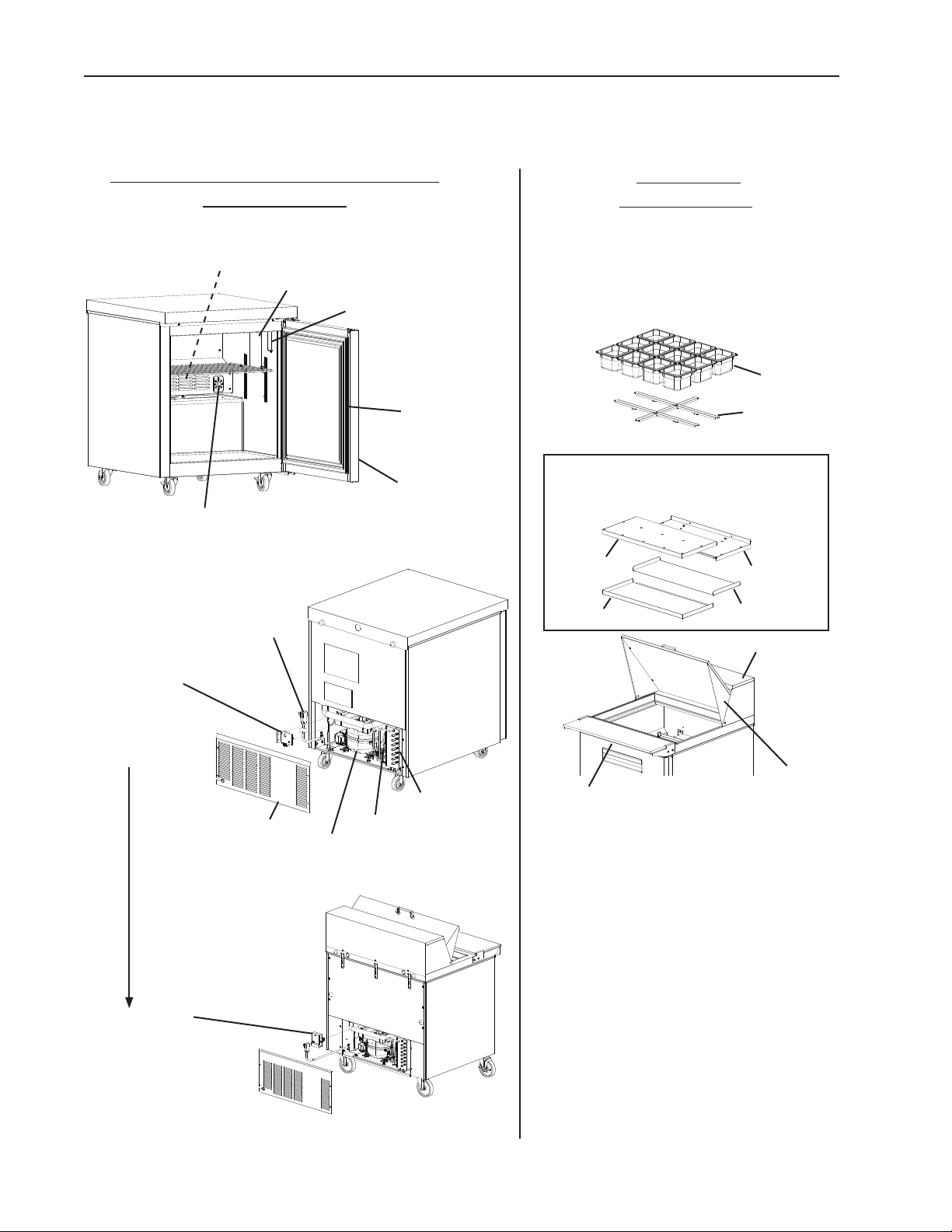

A. Construction

Undercounter, Worktop, Prep Table

Common Parts

• Evaporator

• Evaporator Fan

• Evaporator Fan Shroud

Nameplate

Thermometer

Door Gasket

Door

Cabinet Temperature Control Dial

(Cabinet Thermostat/Thermistor)

Verify Auxiliary Code in Parts List

for Change

Power Cord

Prep Table

Specic Parts

Air Distribution Table Panels

CRMR27-8, CRMR27-12M

Auxiliary Codes B-5 to C-7

Upper Front

Lower Front

Pans

Rail Dividers

Upper Rear

Lower Rear

Rail Hood

Defrost Timer:

Prep Table and

Freezer.

Verify Auxiliary

Code in Parts List

for Change

Rear Panel

Control Module:

Verify Auxiliary Code in

Parts List for Change

Condenser

Condenser Fan Motor

Compressor

Model Shown: CRMF27

Model Shown: CRMR36-10

Rail Cover

Cutting Board

Model Shown: CRMR27-12M

8

Page 9

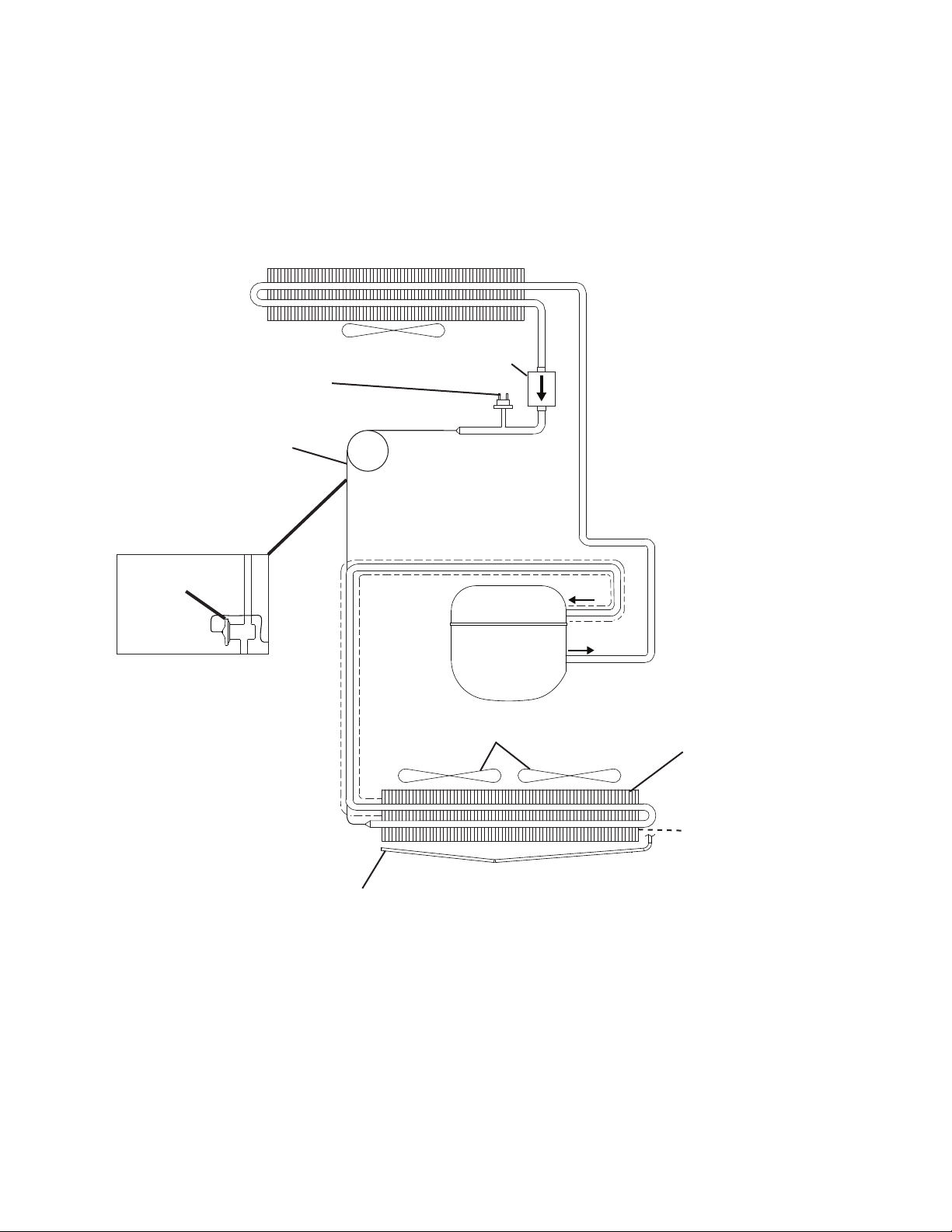

B. Refrigeration Circuit Diagram

1. Refrigerator and Freezer

Condenser

High-Pressure Switch

CRMR60 and CRMR72 Prep Table,

CRMF48, and CRMF60

Capillary Tube

Thermostatic

Expansion Valve

CRMF48(-W)

Auxiliary Code: A-5 and B-5

Condenser Fan

Evaporator Fans

(1, 2, or 3 depending on model)

Drier

Compressor

Evaporator

Cabinet Thermostat Bulb

Freezer and Prep Table Models: Defrost Heater, Defrost Safety Thermostat, and Defrost Thermistor

9

Page 10

II. Sequence of Operation and Service Diagnosis

The steps in the sequence are as outlined below.

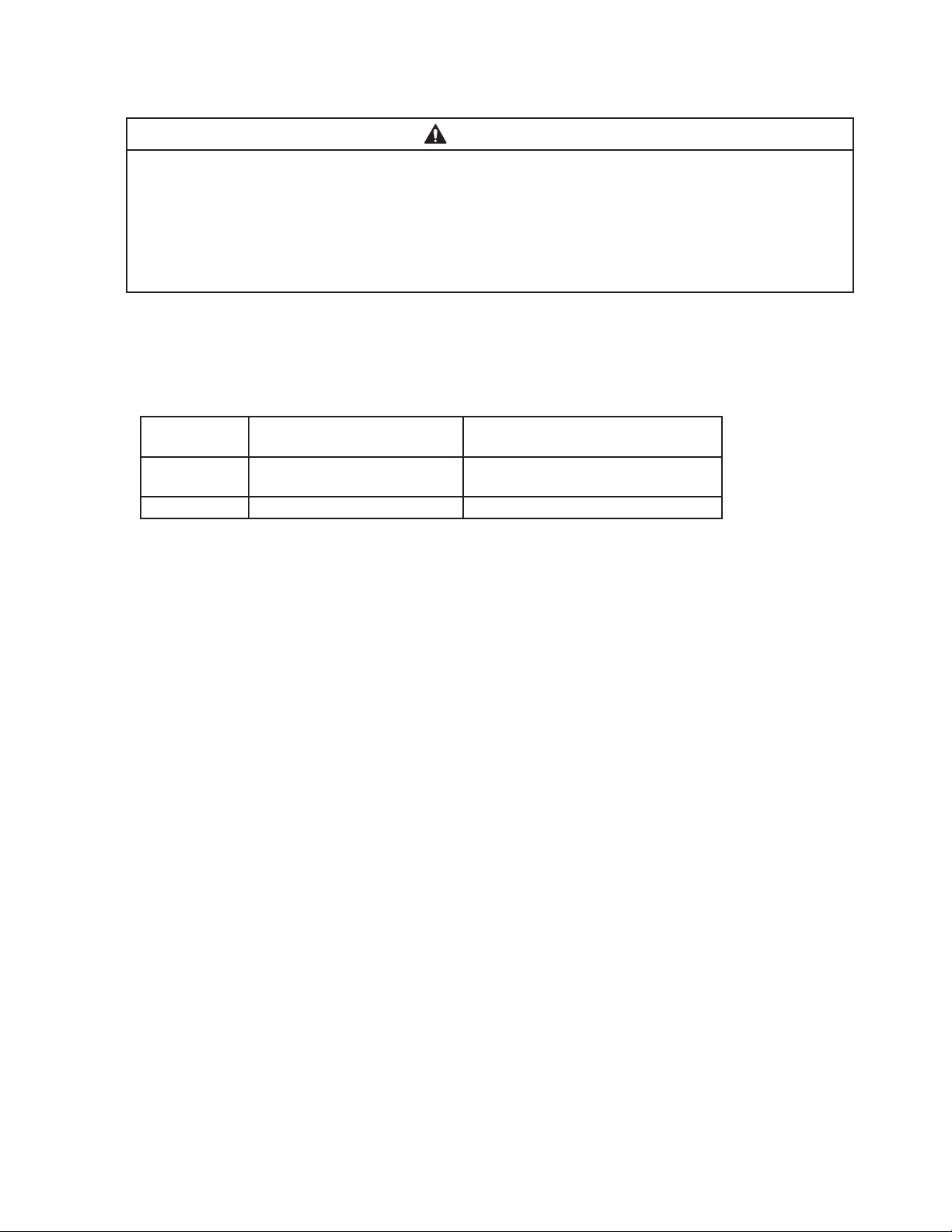

See the table for default cabinet temperature control settings.

Model Default Cabinet Temperature

Approximate Default Temperature

Control Setting

Undercounter

Worktop

Between 4 and 5 Refrigerator: 34°F (1°C)

Freezer: -5°F (-21°C)

Prep Table 6 34°F (1°C)

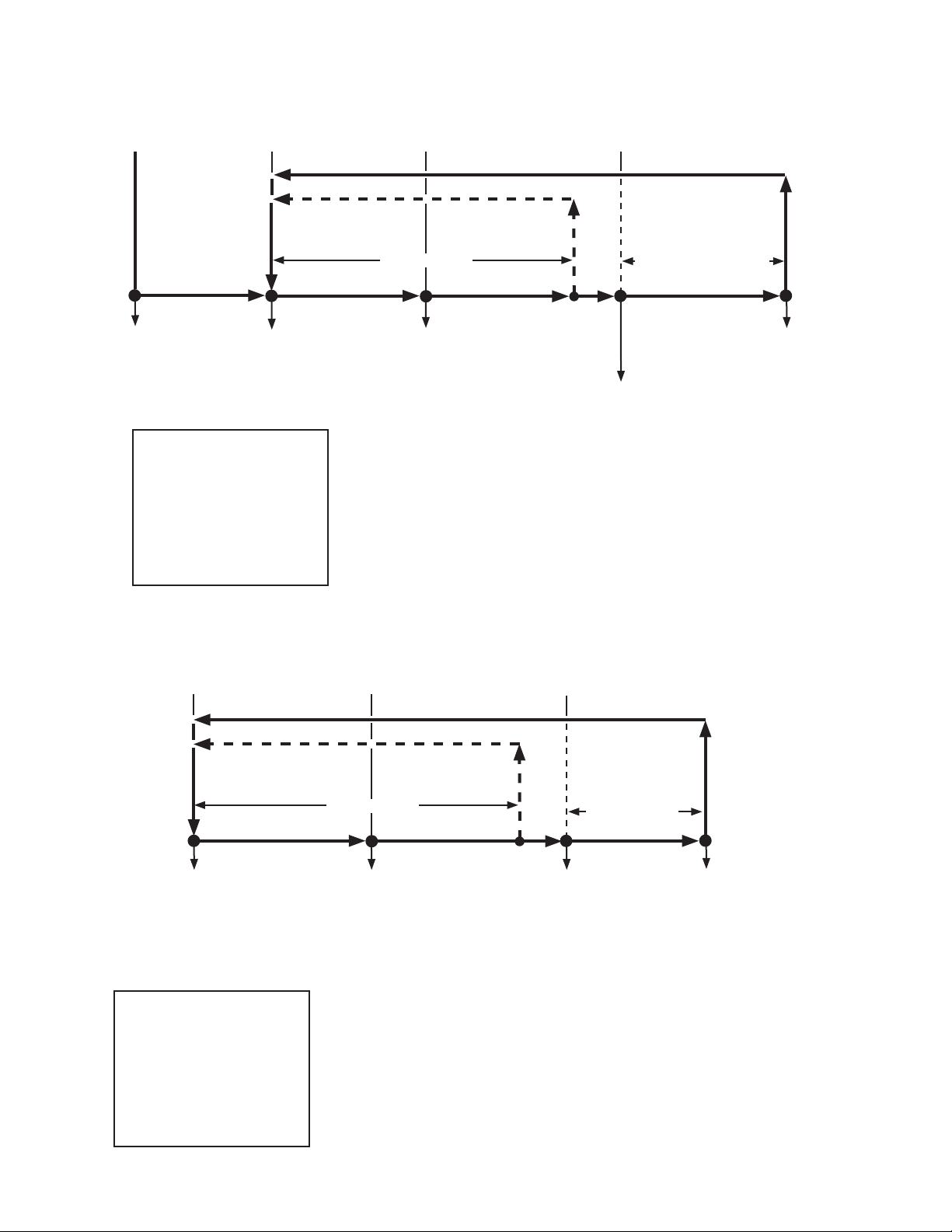

A1. Thermostat Control Sequence of Operation Flow Chart

1. Undercounter and Work Top: Refrigerator

Refrigerator Sequence Flow Chart

1. Startup/Cool Down

CTh above setpoint CTh cools to setpoint

CTh closed

Comp energized

ConFM energized

EvapFM energized

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermostat

EvapFM-evaporator fan motor

CTh open

EvapFM energized CRMR60 and CRMR72

Comp de-energized

ConFM de-energized

EvapFM de-energized CRMR27 and CRMR48

2. Cool Down Achieved

CTh in control

CTh above

Off cycle defrost

between run cycles.

setpoint

10

Page 11

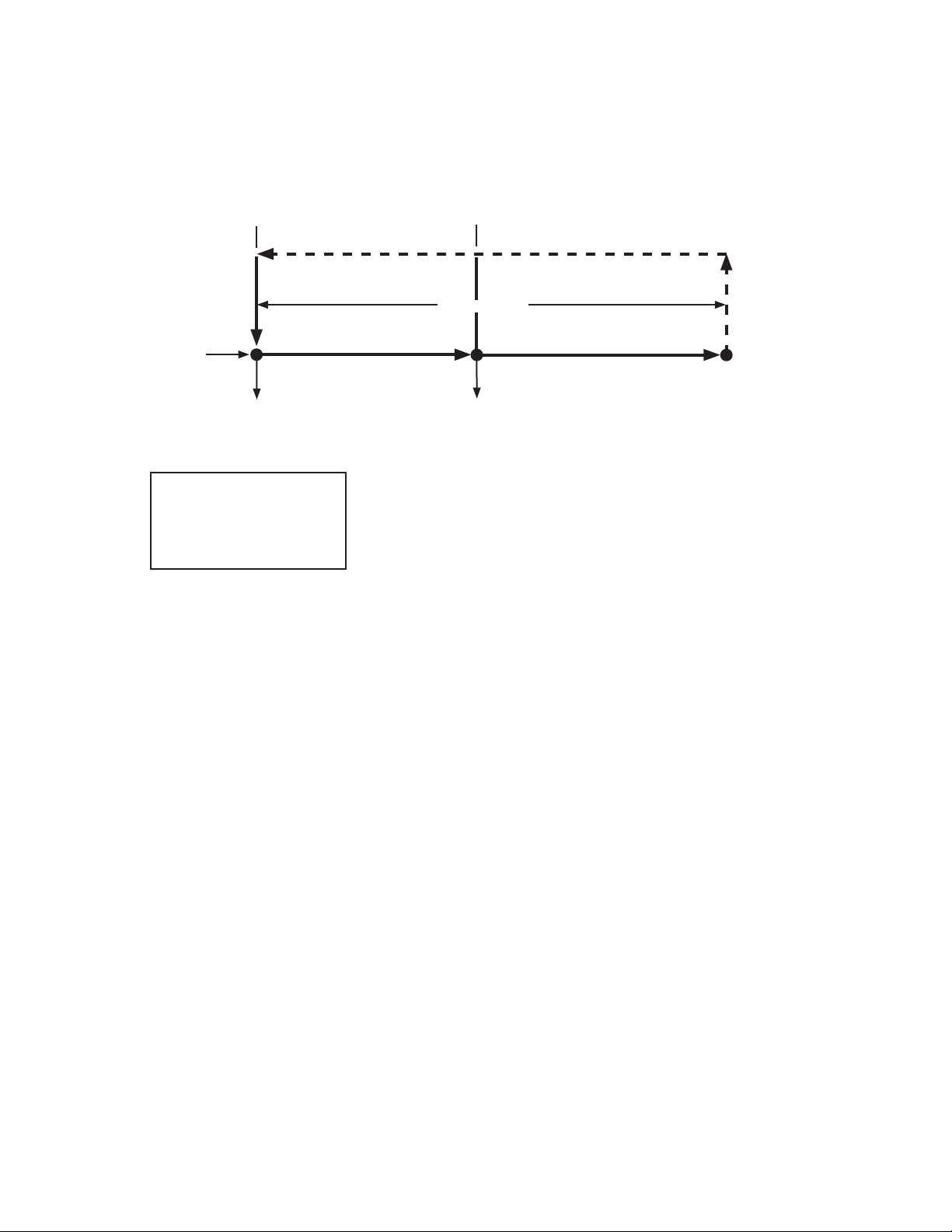

2. Prep Table

Prep Table/Mega Top Sequence Flow Chart

1. Startup

EvapFM energized

(without DH)

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DH-defrost heater

DTh-defrost thermistor

EvapFM-evaporator fan motor

MH-mullion heater

PH-perimeter heater

2. Cool Down

CTh above setpoint

CTh closed

Comp energized

ConFM energized

EvapFM energized

(with DH)

3. Cool Down Achieved

CTh cools to setpoint

CTh in control

CTh open

EvapFM energized

Comp de-energized

ConFM de-energized

4. Defrost

20 or 25 min. DT in

CTh above

8 or 6-hr. DT terminates

20 or 25-min. DT starts

DH energized

EvapFM energized (without DH)

Comp de-energized

ConFM de-energized

EvapFM de-energized (with DH)

control

setpoint

8 or 6-hr. DT terminates

20 or 25-min. DT starts

DH de-energized (if applicable)

CTh above

setpoint

3. Undercounter and Work Top: Freezer

Freezer Sequence Flow Chart

1. Startup/Cool Down

CTh above setpoint

CTh in control

CTh closed

Comp energized

ConFM energized

EvapFM energized

MH energized

PH energized

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DH-defrost heater

DTh-defrost thermistor

EvapFM-evaporator fan motor

MH-mullion heater

PH-perimeter heater

2. Cool Down Achieved

CTh cools to setpoint

CTh open

Comp de-energized

ConFM de-energized

EvapFM de-energized

MH de-energized

PH de-energized

3. Defrost

DT* in control

CTh above

setpoint

8 or 6-hr. DT terminates

20 or 25-min. DT starts

DH energized

Comp de-energized

ConFM de-energized

EvapFM de-energized

MH de-energized

PH de-energized

CTh above

setpoint

20 or 25-min. DT terminates

8 or 6-hr. DT starts

DH de-energized

11

Page 12

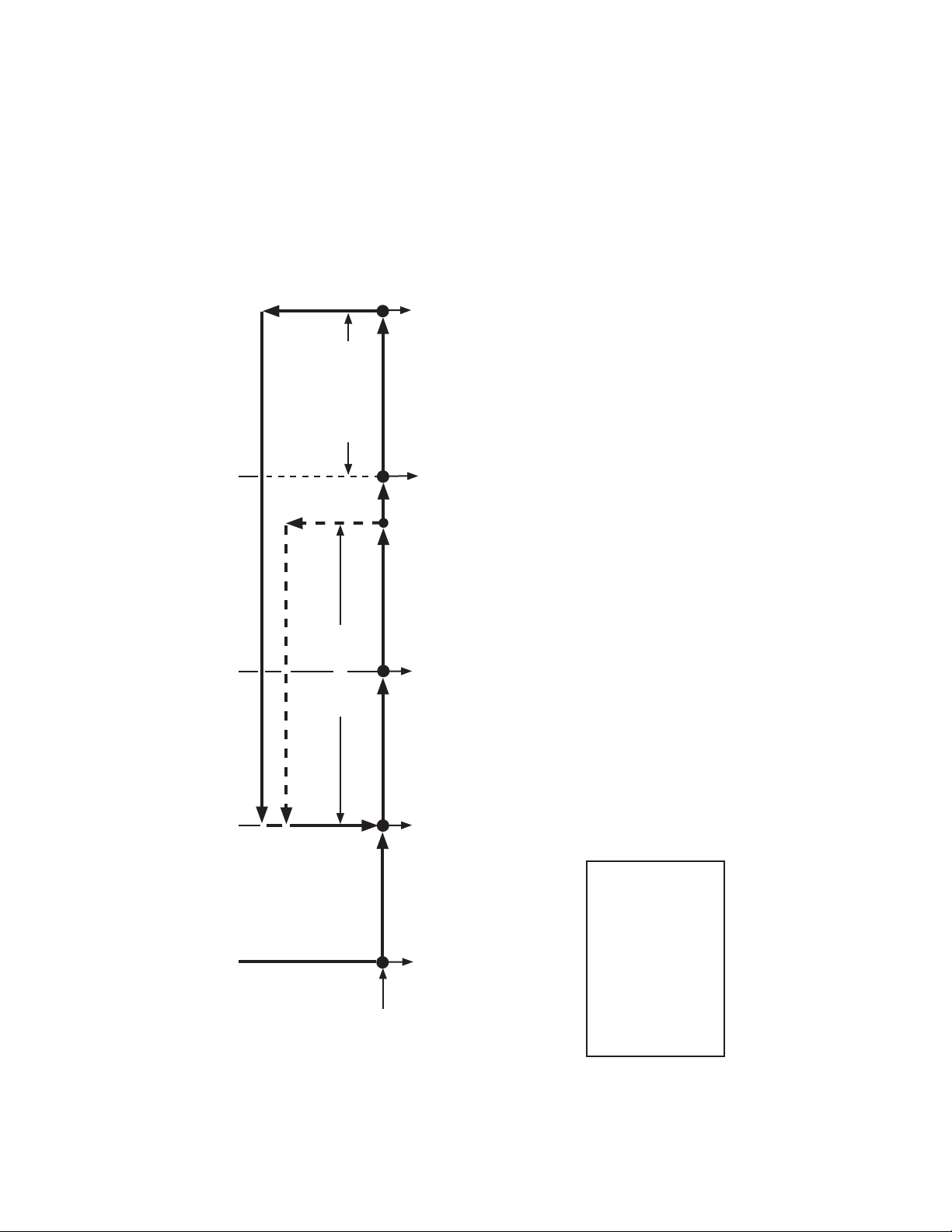

A2. Thermistor/Control Module Sequence of Operation Flow Chart

1. Undercounter and Work Top: Refrigerator

Refrigerator Sequence Flow Chart

1. Startup/Cool Down

CTh above setpoint

*

2-min. Comp

Power on

Red LED On

(5 sec. Delay)

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

EvapFM-evaporator fan motor

on timer starts

Green LED Flashes

If Red LED ashes, check CTh

Comp energized

ConFM energized

EvapFM energized

2. Cool Down Achieved

CTh cools to setpoint

CTh in control

*

2-min. Comp

off timer starts

Green LED Flashes

If Red LED ashes, check CTh

Comp de-energized

ConFM de-energized

EvapFM de-energized

Note: Delays

*

a) 2-min. minimum Comp on timer starts when Comp energizes.

b) 2-min. minimum Comp off timer starts when Comp de-energizes.

Off cycle defrost

between run cycles

CTh above

setpoint

12

Page 13

2. Prep Table

°F (4.4°C).

achieved

44°F (6.7°C)

4. Defrost

3. Cool Down Achieved

Defrost:

time/temp. initiated

temp. terminated

DTh in control

*

2-min. Comp off

CTh cools to setpoint

CTh in control

setpoint

CTh above

timer starts

DH de-energized

*

25-min. max. DT starts

ConFM de-energized

*

6-hr DT starts

After DOT Delay:

Comp energized

DH energized

Comp de-energized

ConFM de-energized

Evap. Temp.

reaches 44°F (6.7°C)

*

6-hr. DT terminates

5-min. min. DT starts

EvapFM energized

Comp de-energized

ConFM energized

EvapFM de-energized

*

After FDD

EvapFM energized

Prep Table Top Sequence Flow Chart

*

*

2-min. Comp on

2. Cool Down

CTh above setpoint

timer starts

a) 2-min. minimum Comp on timer starts when Comp energizes.

b) 2-min. minimum Comp off timer starts when Comp de-energizes.

c) 5-min. minimum defrost time.

d) 25-min. maximum defrost time.

e) DOT (drip off time) 1-min. Comp/ConFM delay timer starts when defrost termination temperature is met (drip off time (DOT)).

f) FDD (fan delay after defrost) EvapFM starts once 30-sec. EvapFM delay timer terminates or DTh reaches 40

Comp energized

ConFM energized

EvapFM energized

Note: Delays

g) If evaporator temperature raises above 50°F (10°C) during the cooling cycle, 6-hr. DT resets.

1. Startup

Red LED Off

Green LED Flashes

If Red LED Flashes,

check CTh or DTh

Power on

EvapFM energized

Red LED On

(5 sec. Delay)

13

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DH-defrost heater

DTh-defrost thermistor

EvapFM-evaporator fan motor

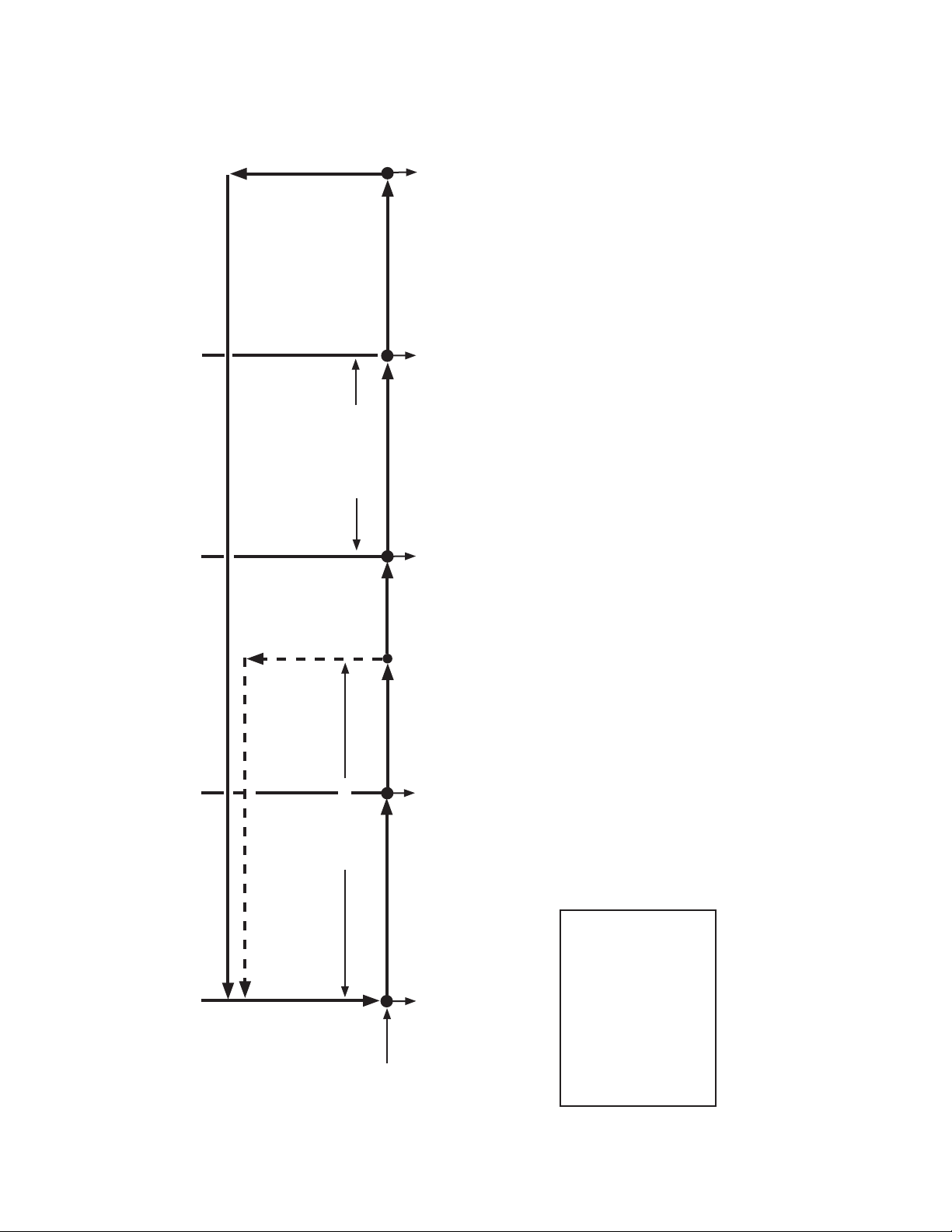

Page 14

3. Undercounter and Work Top: Freezer

5. Defrost Termination

Defrost Termination:

Temp. achieved:

45°F (7°C) or 50°F (°10C)

DTh in control

Defrost

DH de-energized

Terminated

6-hr. or 8-hr. DT starts

*

After DOT Delay:

Comp energized

ConFM energized

MH energized

PH energized

*

After FDD

EvapFM energized

Defrost Initiation:

3. Defrost

Time/Temp achieved.

CTh warms

above

setpoint

6-hr. or 8-hr. DT terminates

Evap. temp. below 41°F (5°C)

6-hr. or 8-hr. DT terminates

Evap. temp. below 41°F (5°C)

5-min. min. DT starts

60-min. max. DT starts

DH energized

Comp de-energized

ConFM de-energized

EvapFM de-energized

MH de-energized

PH de-energized

Freezer Sequence Flow Chart

2. Cool Down Achieved

Achieved

2-min. Comp off

timer starts

Comp de-energized

ConFM de-energized

EvapFM de-energized

MH de-energized

PH de-energized

Setpoint

*

CTh in control

a) 2-min. minimum Comp on timer starts when Comp energizes.

b) 2-min. minimum Comp off timer starts when Comp de-energizes.

c) 5-min. minimum defrost time.

d) 1-hr. maximum defrost time.

e) DOT (drip off time) 3-min. Comp/ConFM delay timer starts when defrost termination temperature is met (drip off time (DOT)).

f) FDD (fan delay after defrost) EvapFM starts once 7-minute EvapFM delay timer terminates or DTh reaches 25°F (-4°C).

1. Startup/Cool Down

Red LED off

Green LED Flashes

If Red LED ashes,

check CTh or DTh

6-hr. or 8-hr. DT starts

2-min. Comp on

timer starts

Note: Delays

Comp energized

Power on

Red LED On

(5 sec. Delay)

ConFM energized

EvapFM energized

14

MH energized

PH energized

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DH-defrost heater

DTh-defrost thermistor

EvapFM-evaporator fan motor

MH-mullion heater

PH-perimeter heater

Page 15

B1. Thermostat Control Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Use extreme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

• Make sure all food zones are clean after the appliance is serviced.

The diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation and proper

voltage per nameplate.

See the table for default cabinet temperature control settings.

Model Default Cabinet Temperature

Control Setting

Undercounter

Worktop

Prep Table 6 34°F (1°C)

Between 4 and 5 Refrigerator: 34°F (1°C)

Approximate Default Temperature

Freezer: -5°F (-21°C)

Note: When checking voltage (115VAC), always choose a white (W) neutral wire to

establish a good neutral connection.

1. Undercounter and Worktop: Refrigerator

1) Unplug the appliance from the electrical outlet.

2) Remove the rear panel.

3) Plug the appliance back into the electrical outlet.

4) Startup/Cool Down–Temperature above setpoint. CTh closed. Comp, ConFM, and

EvapFM energize. Diagnosis: Conrm that Comp, ConFM, and EvapFM energize.

Ifnot, conrm that temperature is above setpoint and CTh is closed. Check both

terminals of CTh (BK) or (BR) to a neutral (W) for 115VAC. If 115VAC is present on

one terminal and not the other, replace CTh. If 115VAC is present on both terminals,

Check voltage at Comp, external protector, and Comp terminals. Check Comp winding

continuity. Check voltage on ConFM and EvapFM. Check ConFM and EvapFM winding

continuity and check fan blades for binding.

If Comp, ConFM, and EvapFM are energized and the cabinet temperature does not

cool down, check for a restriction in the refrigeration circuit, low refrigerant charge, or

inefficient Comp.5)

5) Cool Down Achieved–Temperature cools to setpoint. CThopens. Comp, ConFM, and

EvapFM de-energize. Note: EvapFM continues on CRMR60 and CRMR72.

Diagnosis: If temperature has cooled to setpoint and Comp and ConFM do not

de-energize, check CTh continuity. If CTh defective, replace CTh.

Note: EvapFM de-energizes with Comp on CRMR27 and CRMR48 and continues on

CRMR60 and CRMR72.

15

Page 16

2. Prep Table

1) Unplug the appliance from the electrical outlet.

2) Remove the rear panel.

3) Plug the appliance back into the electrical outlet.

4) Startup/Cool Down–Temperature above setpoint. CTh closed. Comp, ConFM, and

EvapFM energize. Diagnosis: Check that Comp, ConFM, and EvapFM energize.

Ifnot, conrm that the appliance is not in a defrost cycle. DT is operating properly,

temperature is above setpoint, and CTh is closed. Check voltage on DT. In cooling,

115VAC is present on both DT terminal #1 (BK) and DT terminal #4(BK) or (BR) to a

neutral (W). If 115VAC is present on terminal #2 (R) to a neutral (W), advance DT out

of defrost cycle or replace DT. Check both terminals of CTh (BK) or (BR) to a neutral

(W) for 115VAC. If 115VAC is present on one terminal and not the other, replace CTh.

If115VAC is present on both terminals, check for voltage at Comp, external protector,

and Comp terminals. Check Comp winding continuity. Check voltage on ConFM and

EvapFM. Check ConFM and EvapFM winding continuity and fan blades for binding.

Note: CRMR60-xx and CRMR72-xx, also see "HPS Activation (CRMR60 and CRMR72

Prep Table)" below.

If Comp, ConFM, and EvapFM are energized and the cabinet temperature does not

cool down, check for a restriction in the refrigeration circuit, low refrigerant charge, or

inefficient Comp.

HPS Activation (CRMR60 and CRMR72 Prep Table): Check continuity of HPS.

If open, allow time for system pressure to equalize and HPS to reset. If HPS does

not reset, replace HPS and diagnose reason for HPS activation. Conrm ConFM is

energized and fan blade turns freely. Check that the condenser coil is not clogged or

restricted. Check that there are no restrictions in the refrigeration circuit (drier).

Conrm that the appliance location meets factory requirements:

• This appliance is not intended for outdoor use. Normal operating ambient temperature

should be within 45°F to 100°F (7°C to 38°C).

• The appliance should not be located next to ovens, grills, or other high heat producing

equipment.

6) Cool Down Achieved–Temperature cools to setpoint. CTh opens. EvapFM continues.

Comp and ConFM de-energize. Diagnosis: If cabinet temperature has cooled to

setpoint and Comp and ConFM do not de-energize, check CTh continuity. If CTh

defective, replace CTh.

7) Defrost–Defrost Initiation: DT terminates. EvapFM continues (auxiliary code C-5 and

earlier). If CTh closed, Comp and ConFM de-energize. EvapFM de-energizes (auxiliary

code C-6 and later) and DH energizes (CRMR48-xx aux. code C-7 and later. All others

aux. code D-8 and later).

Defrost Termination: DT terminates. EvapFM continues (auxiliary code C-5 and earlier).

If CTh closed, Comp and ConFM energize. EvapFM energizes (auxiliary code C-6

and later) and DHde-energizes (CRMR48-xx aux. code C-7 and later. All others aux.

code D-8 and later).

16

Page 17

Diagnosis: Defrost Initiation: Manually advance DT cam to terminate DT. Conrm

Comp and ConFM de-energize or remain de-energized and on auxiliary code C-6

and later, conrm EvapFM de-energizes. For CRMR48-xx aux. code C-7 and later

and all other aux. code D-8 and later, conrm DH energizes. If not, replace DT.

Defrost Termination: Advance DT cam to terminate DT. If CTh closed, conrm Comp

and ConFM energize and on auxiliary code C-5 and earlier, conrm EvapFM

energizes. For CRMR48-xx aux. code C-7 and later and all other aux. code D-8 and

later, conrm DH de-energizes. If not, check DT voltage terminal #2(R) to a neutral

(W). If115VAC is present, replace DT.

3. Undercounter and Worktop: Freezer

4) Startup/Cool Down–Temperature above setpoint. CTh closed. Comp, ConFM,

EvapFM, PH, and MH energize. Diagnosis: Check that Comp, ConFM, EvapFM,

PH, and MH energize. If not, conrm that the appliance is not in a defrost cycle, DT is

operating properly, temperature is above setpoint, and CTh is closed. Check voltage

onDT. In cooling, 115VAC is present on both DT terminal #1 (BK) and DT terminal

#4 (BK) to a neutral (W). If 115VAC is present on terminal #2 (R) to a neutral (W),

advance DT out of defrost cycle or replace DT. Check both terminals of CTh (BK) to a

neutral (W) for 115VAC. If 115VAC is present on one terminal and not the other, replace

CTh. If 115VAC is present on both terminals, check Comp, ConFM, and EvapFM. For

CRMF48(-01)(-W)(-W01) and CRMF60(-W), also see "HPS Activation (CRMF48(-01)

(-W)(-W01) and CRMF60(-W))" below.

Check voltage at Comp, external protector, and Comp terminals. Check Comp windings.

Check voltage on ConFM and EvapFM. Check ConFM and EvapFM windings. Check

fan blades for binding.

If Comp, ConFM, and EvapFM are energized and the cabinet temperature does not

cool down, check for a restriction in the refrigeration circuit, low refrigerant charge,

inefficient Comp, or defective TXV (CRMF48(-01)(-W)(-W01) auxiliary codes A-5 and

B-5).

HPS Activation (CRMF48 and CRMF60): Check continuity of HPS. If open, allow time

for system pressure to equalize and HPS to reset. If HPS does not reset, replace HPS

and diagnose reason for HPS activation. Conrm ConFM is energized and fan blade

turns freely. Check that the condenser coil is not clogged or restricted. Check that there

are no restrictions in the refrigeration circuit (drier, TXV (auxiliary codes A-5 and B-5)).

Conrm that the appliance location meets factory requirements:

• This appliance is not intended for outdoor use. Normal operating ambient temperature

should be within 45°F to 100°F (7°C to 38°C).

• The appliance should not be located next to ovens, grills, or other high heat producing

equipment.

• A minimum of 1.5" (4 cm) overhead clearance should be provided for proper

ventilation.

5) Cool Down Achieved–Temperature cools to setpoint. CTh opens. Comp, ConFM,

EvapFM, PH, and MH de-energize. Diagnosis: If temperature has cooled to setpoint

and Comp, ConFM, EvapFM, PH, and MH do not de-energize, check CTh continuity.

IfCTh defective, replace CTh.

17

Page 18

6a) Defrost

Early DT's were designed with 8-hr. interval and 20-min. defrost cycle.

Later DT's were designed with 6-hr. interval and 25-min. defrost cycle.

Manual advance in and out of defrost by turning the defrost dial is quickest way to

troubleshoot components.

Defrost Initiation: DT terminates. DH energizes. If CTh closed, Comp, ConFM,

EvapFM, PH, and MH de-energize.

Defrost Termination: DT terminates. DH de-energizes. If CTh closed, Comp, ConFM,

EvapFM, PH, and MH energize.

Diagnosis: Defrost Initiation: Manually advance DT cam to terminate DT. Conrm DH

energizes and Comp, ConFM, EvapFM, PH, and MH de-energize. If not, replace

DT. If Comp, ConFM, EvapFM, PH, and MH de-energize, check DH. Conrm DST is

closed. If not, let DH cool, then recheck DST. If DST is still open, replace DST. Check

DH amp draw and DH continuity.

Defrost Termination: Advance DT cam to terminate DT. If CTh closed, conrm Comp,

ConFM, EvapFM, PH, and MH energize. Conrm DH de-energizes. If not, check DT

voltage terminal #2 (R) to a neutral (W). If 115VAC is present, replace DT.

7) PH and MH Diagnosis: Check that PH and MH energize. Check for 115VAC at PH and

MH. If 115VAC is not present, check power supply. If 115VAC is present, check amp

draw of PH and MH. If an amp reading is not present, check the continuity of PH and

MH. If defective, replace PH or MH.

Legend: Comp–compressor; ConFM–condenser fan motor; CTh–cabinet thermostat;

DH–defrostheater; DST–defrost safety thermostat; DT–defrost timer;

EvapFM–evaporator fan motor; HPS–high-pressure switch; MH–mullion heater;

PH–perimeterheater; TXV–thermostatic expansion valve

18

Page 19

B2. Thermistor/Control Module Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Use extreme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

• Appliance is heavy. Use care when lifting or positioning. Work in pairs when

needed to prevent injury or damage.

• Make sure all food zones are clean after the appliance is serviced.

The diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation and proper

voltage per nameplate.

See the table for default cabinet temperature control settings.

Model Default Cabinet Temperature

Control Setting

Undercounter

Worktop

Prep Table 6 34°F (1°C)

Between 4 and 5 Refrigerator: 34°F (1°C)

Approximate Default Temperature

Freezer: -5°F (-21°C)

The diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation and proper

voltage per nameplate.

Conrm that the appliance location meets factory requirements:

• This appliance is not intended for outdoor use. Normal operating ambient

temperature should be within 45°F to 86°F (7°C to 30°C).

• The appliance should not be located next to ovens, grills, or other high heat

producing equipment. Check CM using the steps in "II.C. Control Module Check."

Note: • When checking voltage (115VAC), always choose a white (W) neutral wire to

establish a good neutral connection.

• CM has high and low voltage protection. If off on either protection, no LED is

visible and all components are off.

High Voltage: 135VAC

Low Voltage: 90VAC

• Solid red LED for 5 sec. at startup.

• Flashing green LED: Normal operation.

• Flashing red LED: check cabinet thermistor and defrost thermistor (if applicable).

• CM has a 2 min. minimum on time and 2 min. minimum off time for Comp.

1. Service Diagnosis: All Refrigerators, Prep Tables, and Freezers

1) Unplug the appliance from the electrical outlet.

2) Remove the rear panel.

19

Page 20

3) Plug the appliance back into the electrical outlet. If appliance was in defrost when power

supply was disconnected, defrost is terminated and normal cooling cycle begins when

power supply is reconnected.

4) Startup/Cool Down–There is a slight delay (solid red LED for 5 sec., then ashing

green LED). Temperature above setpoint at CTh and if applicable, conrm appliance is

not in a defrost cycle (PT and Freezers). Comp, CondFM, and EvapFM energize. 2-min.

Comp on timer starts.

Freezers: PH, and MH energize.

a) CTh Diagnosis: If CTh fails, a red LED ashes along with the green LED on the CM.

Conrm CTh is properly connected to CM. Check Ohm reading of CTh. Replace as

needed.

b) TD Diagnosis: Conrm TD is set between 4 and 5. Check Ohm reading of TD.

Replace as needed.

c) CM Diagnosis: Conrm green LED is ashing. If not, check for 115VAC between

CM 2 (L) black (BK) wire and CM 3 white (W) neutral wire. If 115VAC is not present,

check power cord connections and breaker/fuse. Conrm wiring connections are

secure for both CM 2 (L) black (BK) (power supply) and CM 3 white (W) (neutral).

If 115VAC is present and green LED is not ashing, replace CM.

d) Comp/CondFM Diagnosis: Check that Comp and ConFM energize. If not, conrm

that the temperature is above setpoint. Next, check for 115VAC at CM (C) 1 brown

(BR) wire to neutral (W) wire. If 115VAC is not present, replace CM. If 115VAC is

present, check HPS continuity (if applicable). See "f) HPS Activation" below.

Comp: If 115VAC is present, check Comp external overload, start cap, start relay, and

Comp motor windings. Replace as needed.

CondFM: If 115VAC is present, check fan blade for binding, then check ConFM motor

windings.

e) EvapFM Diagnosis: Check that EvapFM(s) energize. If not, check for 115VAC at

CM (F) 5 dark blue (DBU) wire to neutral (W) wire. If 115VAC is not present, replace

CM. If 115VAC is present, check fan blades for binding, then check EvapFM motor

windings.

f) HPS Activation (CRMR60 and CRMR72 Prep Table and Freezer Models):

Check continuity of HPS. If open, allow time for system pressure to equalize and

HPS to reset. If HPS does not reset, replace HPS and diagnose reason for HPS

activation. Conrm ConFM is energized and fan blade turns freely. Check that the

condenser coil is not clogged or restricted. Check that there are no restrictions in the

refrigeration circuit (drier).

g) PH and MH Diagnosis (Freezer only): PH and MH follow Comp operation. When

Comp is energized, PH and MH are energized. If 115VAC is present, check amp draw

of PH and MH. If an amp reading is not present, check the continuity of PH and MH.

If defective, replace PH or MH.

If Comp, ConFM, and EvapFM are energized and the cabinet does not cool down,

check for a restriction in the refrigeration circuit, low refrigerant charge, or inefficient

Comp.

20

Page 21

5) Cool Down Achieved–Temperature cools to setpoint. Comp and ConFM de-energize.

UC/WT Refrigerators and Freezers: EvapFM de-energizes.

Prep Table: EvapFM continues.

Diagnosis: If temperature setpoint achieved and Comp, ConFM, and EvapFM(except

PT models) does not de-energize, check CTh and TD continuity. If CTh or TD is

defective, replace. If CTh and TD are good and either the Comp, ConFM, and/or

EvapFM (except PT models) continue, or if EvapFM on PT models de-energizes,

replace CM.

6) Defrost–Manually initiated defrost, off cycle defrost, and time-initiated

temperature-terminated heated defrost.

1a) Manually-Initiated (All): Turn the TD all the way to the right. Wait 1 to 3 sec. then

back to original setting. Defrost initiated. If defrost does not initiate, wait 1 to 2 min.

and repeat process.

1b) Off Cycle-Initiated (UC/WT Refrigerators): Off cycle between cooling cycles.

CTh cools below TD setting. TD setting satised. Comp, CondFM, and EvapFM

de-energize.

1c) Time-Initiated (Heated) (Prep Table and All Freezers): 6-hr. DT terminates.

(1) Prep Tables: Comp and ConFM de-energizes, EvapFM continues. DH energizes.

5-min. minimum DT starts and 25-min. maximum DT starts.

(2) Freezers: Comp, ConFM, PH, MH, and EvapFM de-energize. DH energizes.

5-min. minimum DT starts and 1-hr maximum DT starts.

Note: When DTh is above 50°F on Prep Tables or above 41°F on Freezers, defrost

will not initiate and 6-hr. DT resets and starts once DTh temperature cools

below 50°F on Prep Tables and cools below 41°F on Freezers.

2a) Manually-Terminated: Turn the TD all the way to the right. Wait 1 to 3 sec. then

back to original setting. Defrost terminated. If DH continues or Comp does not

energize, make several more attempts of manual termination.

2b) Off Cycle-Terminated: CTh warms above TD setting. Comp, CondFM, EvapFM

energize.

2c) Temperature-Terminated: DTh achieves termination temperature or backup DT

terminates.

(1) Prep Tables: 44

°F achieved or 25-min. backup DT terminates. DH de-energizes.

IfCTh calling for cooling, 1-min. Comp delay timer starts (drip time) and 90-sec.

EvapFM delay timer starts. 1-min. Comp delay timer terminates. Comp and

ConFM energize. 30 sec. later, 90-sec. EvapFM delay timer terminates and

EvapFM energizes.

Note: If DTh achieves 40°F before 90-sec. EvapFM delay timer terminates,

90-sec. EvapFM delay timer terminates and EvapFM energizes.

(2) Freezers: 45°F achieved or 1-hr. DT terminates. DH de-energizes. If CTh calling

for cooling, 3-min. Comp delay timer starts (drip time) and 7-min. EvapFM delay

timer starts. 3-min. Comp delay timer terminates. Comp and ConFM energize. 4

min. later, 7-min. EvapFM delay timer terminates and EvapFM energizes.

Note: If DTh achieves 25°F before 7-min. EvapFM delay timer terminates, 7-min.

EvapFM delay timer terminates and EvapFM energizes.

21

Page 22

Defrost Diagnosis:

1) Manual-Initiation or Time-Initiation: TD rotated to max. position and back or

6-hr. or 80hr. DT terminates. After rotating TD several times and defrost still not

activated, wait 1 to 2 min. and repeat process. Replace TD as needed.

(2) CM Diagnosis: Conrm DH energizes (if applicable) and Comp, ConFM, and

EvapFM (if applicable) de-energize. If not, replace CM.

(3) Comp and ConFM Diagnosis: Conrm Comp and ConFM de-energize. If not,

check for 115VAC at CM 1 (C) (BR) to neutral (W). If 115VAC is present, Check

DTh continuity. Replace as needed. If DTh conrmed, replace CM.

(4) EvapFM (if applicable): Conrm EvapFM de-energizes. If not, check for 115VAC

at CM 5 (F) (DBU) to neutral (W). If 115VAC is present, conrm Comp and ConFM

de-energized. Next, check DTh continuity. Replace as needed. If DTh conrmed,

replace CM.

2) Off Cycle Defrost: Off cycle defrost. Has CTh warmed above temperature setpoint?

If not, conrm CTh continuity. Replace as needed. If CTh conrmed, replace CM.

3) Heated Defrost Diagnosis: Initiation; Conrm Comp is energized, then manually

initiate defrost. Rotate TD all the way to the right. Wait 1 to 5sec. then rotate back

to original setting. Defrost initiated.

a) Prep Table: Check that Comp and ConFM de-energize. DH energizes.

EvapFMcontinues.

b) Freezer: Check that Comp, ConFM, PH, MH, and EvapFM de-energize.

DHenergizes.

(1) TD: If Comp and ConFM continue, wait 1 to 2 min. and make several more

attempts of manual initiation. Ifmanual initiation fails, replace TD.

(2) CM: If TD conrmed and Comp and ConFM continue, replace CM.

(3) DH: If Comp and ConFM de-energize, check that DH energizes. Check for

115VAC at CM 4 (H) (R) to CM 3 (N) (W). If 115VAC is not present, replace CM.

If115VAC is present, and DH is not energized, check for 115VAC at DTS black (B)

wire to any white (W) neutral wire. If 115VAC is not present, DTS is open. Let cool

and reset. If DTS does not reset (close), replace DTS. If 115VAC is present, check

continuity of DH. Replace as needed.

4) Heated Defrost Diagnosis: Termination;

a) Prep Table

(1) DTh: DTh warms to 44°F (6.6°C). DH de-energizes. Conrm continuity of DTh.

Replace as needed. If DTh is good and DH continues after DTh achieves 44°F

(6.6°C), replace CM.

b) Freezer

(1) DTh: DTh warms to 45°F. (7°C) DH de-energizes. Conrm continuity of DTh.

Replace as needed. If DTh is good and DH continues after DTh achieves 45°F

(7°C), replace CM.

Legend: Comp–compressor; ConFM–condenser fan motor; CM–control module;

CTh–cabinet thermistor; TD–temperature dial; DH–defrostheater; DST–defrost

safety thermostat; DT–defrost timer; DTh–defrost thermistor; EvapFM–evaporator

fan motor; HPS–high-pressure switch; MH–mullion heater; PH–perimeterheater

22

Page 23

C. Defrost Timer Check

The defrost timer (DT) starts once the appliance in plugged into the electrical outlet.

There are 2 possible interval and defrost cycle times: 8-hr./20min. and 6-hr./25min.

1. Defrost Timer

Before replacing a DT that does not show a visible defect and that you suspect is bad,

conduct the folowing check procedure. This procedure will help you verify your diagnosis.

Always choose a neutral (W) to establish a good power supply and neutral connection to

DT: 115VAC at DT 1 (BK) to DT 3 (W).

2. Normal Operation

DT 8-hr. or 6-hr. interval timer starts. DT switch (internal) closed between DT 1 (BK)

and DT 4 (BK or BR) and open between DT 1 (BK) and DT 2 (R). Once DT terminates

DT switch (internal) opens. DT switch (internal) opens between DT4 (BK or BR) and

DT1(BK) and closes between DT 1 (BK) and DT 2 (R).

Diagnosis: In normal operation, Comp, ConFM, and EvapFM energized, check for

115VAC between DT1(BK) and neutral (W). Next, check for 115VAC at DT4 (BK or

BR) and neutral (W). If 115VAC is not present between DT4 (BK or BR) and neutral

(W) (Comp, ConFM, and EvapFM de-energized), check for 115VAC between DT 2 (R)

and neutral (W). If 115VAC is not present between DT4 (BK or BR) and neutral (W) or

between DT 2 (R) and neutral (W), DT switch (internal) defective. Replace DT. If 115VAC

is present between DT4 (BK or BR) and neutral (W) (Comp, ConFM, and EvapFM

energized), advance the cam dial on DT until it clicks (defrost initiated). Comp, ConFM,

and EvapFM de-energize. If not, replace DT. Next, check for 115VAC between DT 2 (R)

and neutral (W). If 115VAC is not present, replace DT.

Off Cycle Defrost: If 115VAC is present, off cycle defrost initiated and 20-min. or 25-min.

DT starts. After 20-min. or 25-min. defrost cycle terminates, Comp, ConFM, and EvapFM

energize. If not, replace DT.

Heated Defrost: If 115VAC is present, DH energized and 20-min. or 25-min. DT starts.

Once DST achieves termination temperature, DH de-energized. After 20-min. or 25-min.

defrost cycle terminates, Comp, ConFM, and EvapFM energize. If not, replace DT.

Legend: Comp–compressor; ConFM–condenser fan motor; CM–control module;

CTh–cabinet thermistor; TD–temperature dial; DH–defrostheater; DST–defrost

safety thermostat; DT–defrost timer; DTh–defrost thermistor; EvapFM–evaporator

fan motor; HPS–high-pressure switch; MH–mullion heater; PH–perimeterheater

23

Page 24

D. Control Module Check

1. Control Module

Before replacing a CM that does not show a visible defect and that you suspect is bad,

conduct the following check procedure. This procedure will help you verify your diagnosis.

Always choose a neutral (W) to establish a good power supply and neutral connection to

CM: 115VAC at CM 2 (L) (BR)

2. Startup/Cool Down

At startup, CM displays a solid red LED for 5 sed. After 5 sec. CM turns red LED off and

begins ashing a green LED. This is normal operation. If a red LED ashes (fault code),

check CTh or DTh for continuity and good connection to CM.

1) Check all wiring connections.

2) Be sure the power supply is connected to the electrical outlet.

3) Conrm the CTh and DTh are properly connected (no red LED ashing). A Red LED

turns on for 5 sec. at startup. After 5 sec. the red LED turns off and a green LED starts

ashing. This is normal operation. If the red LED starts ashing, check CTh and DTh

continuity. Replace as needed.

4) Check that Comp, ConFM, and EvapFM energize (PH and MH on freezers). If not check

CTh status. If CTh ohm reading is in proper range,

Comp and ConFM and PH and MH (freezers); check for 115VAC at CM 1 (C) (BR)

to neutral (W). If 115VAC is not present, replace CM. If 115VAC is present and Comp

energized and ConFM did not, check ConFM blades for binding and motor winding

continuity. If PH or MH (freezers) does not energize, check continuity, replace as

needed.

EvapFM; Check for 115VAC at CM 5 (F) (DBU) to neutral (W). If 115VAC is not present,

replace CM. If115VAC is present, check EvapFM blades for binding and motor winding

continuity.

3. Defrost initiation

5) Manual Defrost Check: Turn the TD all the way to the right. Wait 1 to 3 sec. then back

to original setting. Defrost initiated. If Comp and ConFM continue, wait 1 to 2 min. and

repeat process of manual initiation. If Comp remains energized, replace CM.

6) Conrm Comp, ConFM, EvapFM (UC/WT refrigerator and freezer), PH and MH

(freezers) de-energize. If not, for Comp, ConFM and PH and MH (freezers), check for

115VAC at CM 1 (C) (BR) to neutral (W) and for EvapFM (if applicable) CM 5 (F) (DBU)

to neutral (W). If 115VAC is present, replace CM. Note: EvapFM continues on Prep Table

models.

7) Heated Defrost: Conrm DH energizes. Check for 115VAC at CM 4 (H) (R) to neutral

(W). If 115VAC is not present, replace CM.

4. Defrost Termination

8) Check that all components restart after defrost termination.

a) UC/WT Refrigerator: CTh above setpoint. Cool cycle starts. Comp, ConFM, and

EvapFM energize.

24

Page 25

b) Prep Table: DTh warms to 44°F (6.6°C). DH de-energizes. Conrm continuity of

DTh. Replace as needed. If DTh is good and DH continues after DTh achieves

44°F (6.6°C), replace CM.

c) Freezer: DTh warms to 45°F (7°C) or 50°F (10°C). DH de-energizes. Conrm

continuity of DTh. Replace as needed. If DTh is good and DH continues after DTh

achieves 45°F (7°C) or 50°F (10°C), replace CM.

Legend: Comp–compressor; ConFM–condenser fan motor; CM–control module;

CTh–cabinet thermistor; DH–defrost heater; DTh–defrost thermistor;

EvapFM–evaporator fan motors, MH–mullion heater; PH–perimeter heater

25

Page 26

E. Diagnostic Table

Before consulting the diagnostic tables, check the following:

• Check the cabinet temperature control setting. See the table for default cabinet

temperature control settings.

Model Default Cabinet Temperature

Control Setting

Undercounter

Worktop

Prep Table 6 34°F (1°C)

Between 4 and 5 Refrigerator: 34°F (1°C)

Approximate Default Temperature

Freezer: -5°F (-21°C)

• Make sure the doors are not left open or opened too often and that they are sealing

properly.

• On prep tables, pans and rail dividers must be in place. Otherwise, the rail will not cool

properly.

• Make sure product is not blocking airow and that the cabinet is not overloaded with

warm or hot product. Product should be allowed to cool before putting in the appliance.

On prep tables, only load ingredients that have been pre-chilled to 37°F (3°C) or less.

• Check for correct installation and proper voltage per appliance nameplate. This

appliance is not intended for outdoor use. Normal operating ambient temperature:

– Undercounter and Worktop 45°F to 100°F (7°C to 38°C)

– Prep Table 45°F to 86°F (7°C to 30°C)

• The appliance should not be located next to ovens, grills, or other high heat producing

equipment. A minimum of 1.5" (38 mm) overhead clearance is required for proper

ventilation.

1. Appliance Not Cooling

Appliance Not Cooling - Possible Cause

Power Supply

1.

Power Supply Cord and Plug

2.

Wiring

3.

Cabinet Thermostat or Cabinet

4.

Thermistor

Cabinet Temperature Dial

5.

Defrost Timer or Control Module

6.

(if applicable)

Evaporator Fan Motor

7.

Condenser Fan Motor

8.

Unplugged, blown fuse, or tripped or defective circuit breaker.

a)

Loose connection.

b)

Not within specications.

c)

Loose connection.

a)

Defective.

b)

Loose connection or open.

a)

Faulty.

b)

Loose, disconnected, or defective.

a)

Loose, disconnected, or defective.

a)

Defrost timer defective. If applicable.

a)

Control module in alarm (red LED ashing). If applicable.

b)

Control module defective. If applicable.

c)

Defective.

a)

Fan blade binding.

b)

Defective.

a)

Fan blade binding.

b)

26

Page 27

Appliance Not Cooling - Possible Cause

Compressor External Protector

9.

a)

b)

c)

d)

e)

f)

Compressor

10.

Condenser

11.

Evaporator

12.

Refrigerant/Refrigerant Lines

13.

a)

a)

a)

a)

b)

High-Pressure Switch

10.

(if applicable)

a)

b)

c)

d)

e)

f)

Thermostatic Expansion Valve

11.

(not adjustable)

CRMF48(-01)(-W)(-W01)

(auxiliary codes A-5 and B-5)

a)

Dirty condenser.

Condenser fan motor not operating.

Defective.

Start relay defective.

Low charge.

Start capacitor (if applicable) defective.

Defective.

Dirty.

Dirty or frozen up.

Gas leak.

Refrigerant lines or components restricted.

Dirty condenser.

Ambient temperature too warm.

Condenser fan motor not operating.

Refrigerant overcharge.

Refrigerant lines or components restricted.

Bad contacts.

Defective.

2. Evaporator is Frozen Up

Evaporator is Frozen Up - Possible Cause

Evaporator

1.

Evaporator Fan Motor

2.

Refrigerant Charge

3.

Defrost Heater (if applicable)

4.

Defrost Timer or Control Module

5.

(if applicable)

Defrost Safety Thermostat Open

6.

(if applicable)

Thermostatic Expansion Valve

7.

(not adjustable)

CRMF48(-01)(-W)(-W01)

(auxiliary codes A-5 and B-5)

Dirty.

a)

Defective.

a)

Fan blade binding.

b)

Low.

a)

Defective.

a)

Defective.

a)

Defective.

a)

Defective.

a)

3. Defrost Fails to Initiate or Terminate

Defrost Fails to Initiate or Terminate - Possible Cause

Defrost Thermistor (if applicable)

1.

Defrost Timer or Control Module

2.

(if applicable)

Defrost Heater (if applicable)

3.

Defective.

a)

Defective.

a)

Defective

a)

27

Page 28

III. Controls and Adjustments

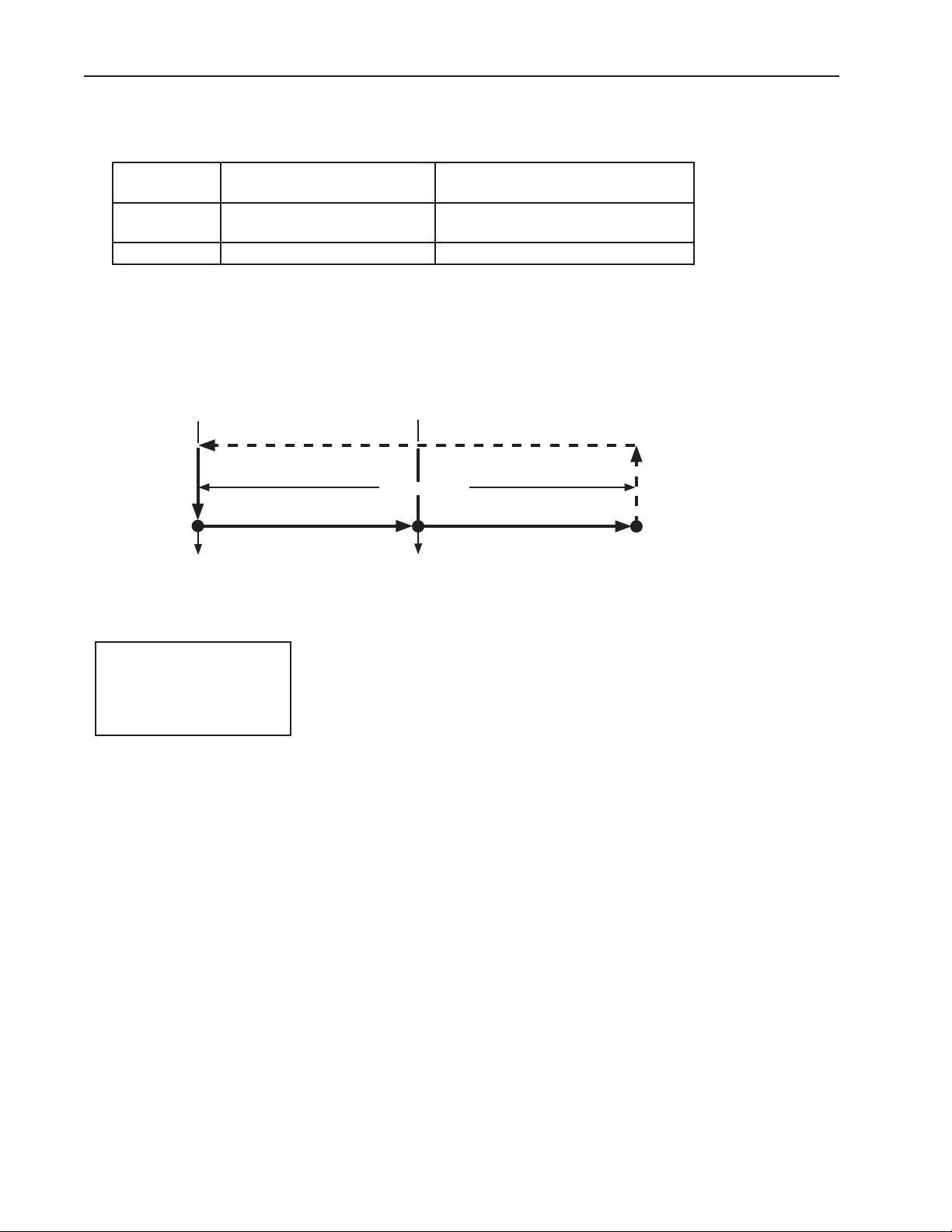

A. Temperature Settings

1. Temperature Reading

A thermometer with both °F and °C scales is mounted in the cabinet. See Fig. 1.

2. Cabinet Temperature

The appliance features a cabinet temperature control dial (TD). The warmest setting

is 1and the coldest setting is 7. See the table for default cabinet temperature control

settings.

Model Default Cabinet Temperature

Control Setting

Undercounter

Worktop

Prep Table 6 34°F (1°C)

Between 4 and 5 Refrigerator: 34°F (1°C)

Approximate Default Temperature

Freezer: -5°F (-21°C)

Fig. 1

Warmer Colder

Cabinet Temperature

Control Dial

B. Defrost

There are 2 types of defrost: Off Cycle Defrost and Heated Defrost.

Manual Initiation (All Models): Turn the TD all the way to the right. Wait 3 sec. then

back to original setting. Defrost initiated.

Automatic Initiation: 8-hr. or 6hr. Defrost timer terminates.

Manual Termination: Turn the TD all the way to the right. Wait 3 sec. then back to

original setting. Defrost terminated.

Automatic Termination: Cabinet temperature above setpoint, or defrost thermistor

above termination temperature, or back defrost timer terminates.

Thermometer

1. Undercounter and Worktop Refrigerators

Off-cycle defrost between run cycles.

28

Page 29

2. Prep Table and Freezer

Time-Initiated Defrost Cycle: 20-min. or 25-min. defrost cycle once every 8 or 6 hrs. (25/8

or 20/6). Defrost cycle initiation and termination are controlled by the defrost timer or

control module and defrost thermistor.

Prep Table Refrigerators: The evaporator fan motor remains energized and all other

components de-energize during the defrost cycle.

Freezers: The defrost heater energizes and all other components de-energize during the

defrost cycle. There is an in-line defrost safety thermostat.

a) Defrost Timer Defrost:

To initiate a manual defrost cycle follow the steps below.

1) Make sure the appliance is unplugged, then

remove the rear panel. See Fig. 2.

Defrost

Timer Cam

2) Rotate the defrost timer cam clockwise until

it clicks. When the appliance is plugged

in it will start a 20-min. or 25-min. defrost

Fig. 2

cycle. To bypass the defrost cycle and start

at the beginning of an 8-hr. or 6 hr. interval,

rotate the defrost timer cam clockwise until

nd

it clicks a 2

time.

Rear Panel

3) Replace the rear panel in its correct position.

4) Plug the appliance into the electrical outlet.

b) Control Module with Defrost Thermistor Defrost:

To initiate a manual defrost cycle follow the steps below.

1) Rotate TD all the way to the right. Wait 1 to 5sec. then rotate back to original setting.

Defrost initiated. See Fig. 3.

2) Repeat step 1 to terminate defrost.

Fig.3

29

Page 30

C. Safety Devices

1. Compressor External or Internal Protector (All Models)

If combined temperature/amperage value is above the limit specied by the

compressor manufacturer, the compressor protector operates independently to turn

off the compressor. The compressor protector de-energizes the compressor until the

temperature/amperage value returns to an acceptable level.

2. High-Pressure Switch

If pressure on the high-side of the appliance exceeds Hoshizaki specications, the

high-pressure switch activates and interrupts the compressor circuit, de-energizing the

compressor until the pressure returns to an acceptable level.

If the condenser fan motor is operating and the compressor is off, it is most likely that the

compressor protector opened. If both the compressor and condenser fan motor are off, it

is most likely the appliance is off or the high-pressure switch has opened.

D. Perimeter and Mullion Heaters

Freezers are equipped with perimeter and mullion heaters. If condensation occurs,

check continuity of heaters.

30

Page 31

IV. Refrigeration Circuit and Component Service Information

WARNING

• This appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• To reduce the risk of electric shock, do not touch the plug with damp hands.

• Unplug the appliance from the electrical outlet before servicing.

• Make sure all food zones in the appliance are clean after the appliance is

serviced.

A. Refrigeration Circuit Service Information

WARNING

• Repairs requiring the refrigeration circuit to be opened must be performed by

properly trained and EPA-certied service personnel.

• Use an electronic leak detector or soap bubbles to check for leaks. Add a trace

of refrigerant to the system (if using an electronic leak detector), and then raise

the pressure using nitrogen gas (140 PSIG). Do not use R-134a as a mixture with

pressurized air for leak testing.

NOTICE

• Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

• Do not leave the system open for longer than 15 minutes when replacing or

servicing parts. The Polyol Ester (POE) oils used in R-134a appliances can

absorb moisture quickly. Therefore it is important to prevent moisture from

entering the system when replacing or servicing parts.

• Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

1. Refrigerant Recovery

No refrigerant access valves are provided on this appliance. Using proper refrigerant

practices, utilize a temporary tap-line valve on the high side to recover the refrigerant.

Store the refrigerant in an approved container. Do not discharge the refrigerant into the

atmosphere.

After recovery is complete, replace the tap-line valve with a proper, permanent access

valve.

31

Page 32

2. Brazing

WARNING

• R-134a itself is not ammable at atmospheric pressure and temperatures up to

212°F (100°C).

• R-134a itself is not explosive or poisonous. However, when exposed to high

temperatures (open ames), R-134a can be decomposed to form hydrouoric

acid and carbonyl uoride both of which are hazardous.

• Do not use silver alloy or copper alloy containing arsenic.

• Use an electronic leak detector or soap bubbles to check for leaks. Add a trace

of refrigerant to the system (if using an electronic leak detector), and then raise

the pressure using nitrogen gas (140 PSIG). Do not use R-134a as a mixture with

pressurized air for leak testing.

1) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

NOTICE

• Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

2) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace

of refrigerant to the system (if using an electronic leak detector), and then raise

the pressure using nitrogen gas (140 PSIG). Do not use R-134a as a mixture with

pressurized air for leak testing.

3. Evacuation and Recharge (R-134a)

1) Attach a vacuum pump to the system. Be sure the high-side charging hose is connected

to the eld-installed high-side access valve.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump, then open the high-side valve on the gauge manifold. Never

allow the oil in the vacuum pump to ow backwards.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period depends

on pump capacity.

4) Close the high-side valve on the gauge manifold.

32

Page 33

5) Disconnect the gauge manifold hose from the vacuum pump and attach it to a

refrigerant service cylinder. Remember to loosen the connection and purge the air from

the hose. See the nameplate for the required refrigerant charge. Hoshizaki recommends

only virgin refrigerant or reclaimed refrigerant which meets the requirements of ARI

Standard 700 (latest edition) be used.

6) A liquid charge is recommended when charging an R-134a system. Place the service

cylinder on the scales; if the service cylinder is not equipped with a dip tube, invert the

service cylinder, then place it on the scales. Open the high-side valve on the gauge

manifold.

7) Allow the system to charge with liquid until the proper charge weight is met.

8) Close the high-side valve on the gauge manifold, then close the refrigerant access valve

(if applicable). Disconnect the gauge manifold hose.

9) Cap the access valve to prevent a possible leak.

B. Component Service Information

NOTICE

When replacing a component listed below, see the notes to help ensure proper

operation.

Component Notes

Compressor Install a new start relay and compressor external protector. WARNING! To reduce the

risk of electric shock, be sure to reconnect the compressor's ground wire.

Thermostatic

Expansion Valve

CRMF48(-01)

(-W)(-W01)

(auxiliary codes

A-5 and B-5)

• Attach the thermostatic expansion valve bulb to the suction line in the same location as

the previous bulb.

• The bulb should be between the 10 and 2 o'clock positions on the tube.

• Secure the bulb with the clamp and holder.

33

Page 34

C. Door Reversal

This appliance is provided with a cabinet design which, after being delivered to the

installation location, permits changing of the door swing from left to right or right to left. To

change the door swing, follow the steps below. Example shows change from right hinged

to left hinged.

WARNING

• Wear eye protection when reversing the doors.

• Keep ngers away from edge of upper hinge bracket. Spring cartridge can cause

the upper hinge bracket to move suddenly with extreme force.

Door and Lower Hinge Removal and Relocation

1) Remove all items from the appliance. Make sure the appliance is unplugged from the

electrical outlet. Move the appliance out for ease of access then lock the casters.

2) With the door closed, loosen, but do not remove, the upper hinge bracket outer screw.

See Fig. 4. Next, open the door to the fully open position and remove the upper hinge

bracket inner screw. See Fig. 5.

3) Slide the upper hinge bracket out from under the outer screw and remove the door.

WARNING! Keep away from upper hinge bracket. Upper hinge bracket may spring

closed.

4) Replace the upper hinge bracket inner screw in its original position and tighten, then

tighten the upper hinge bracket outer screw.

Upper Hinge Bracket

WARNING! Upper

hinge bracket may

spring closed

Upper Hinge

Bracket

Upper Hinge Bracket

Outer Screw

Door Closed

Fig. 4

Upper Hinge

Bracket Inner

Screw

Door Fully Open

Fig. 5

5) Remove the lower hinge bracket. See Fig. 6. Be sure to leave the thrust washer in place.

6) Clear the foam from the lower hinge bracket mounting holes prior to securing lower

hinge bracket in its new location. Install the lower hinge bracket in its new location.

Besure the lower hinge bracket is pushed all the way in and the thrustwasher is in its

original position.

Thrust

Washer

Lower Hinge

Bracket

Mounting Holes

Lower Hinge Bracket

Thrust Washer

Lower Hinge Bracket

Bolts

Fig. 6

34

Bolts

Page 35

Upper Hinge Bracket Removal and Spring Cartridge Relocation

7) While preventing the upper hinge bracket from rotating, remove the upper hinge bracket

from the spring cartridge. See Fig. 7. Note which side of the upper hinge bracket is

facing up.

8) Remove the ller cap, ller screws, and spring cartridge. See Fig. 16. Leave the thrust

washers in place on the spring cartridge. NOTICE! Spring cartridge may be difficult

to remove. Be careful not to damage the nish. See Fig. 8.

Upper Hinge

Bracket

Screw

Washer

Door

Filler Screws

Filler Cap

Door

Screws

Thrust Washers

Spring Cartridge

Fig. 7

Fig. 8

9) Clear foam from the spring cartridge hole to allow for spring cartridge installation.

See Fig. 9. Install the spring cartridge in its new location. Reinstall the ller cap and ller

screws on the opposite side of the door.

Screws

Spring Cartridge

Spring Cartridge Hole

Filler Screws

Door

Filler Cap

Fig. 9

Lower Door Prep and Upper Hinge Bracket Relocation

10) Remove the ller cap and nylon bearing from the bottom of the door. SeeFig.10.

Reinstall on the opposite side.

11) Make sure the thrust washers are in place on the spring cartridge, then ip the upper

hinge bracket over from its original position and install onto the spring cartridge in

the door open position. See Fig. 11. The upper hinge bracket should be positioned as

Filler Cap

shown.

Fig. 10

Upper Hinge

Bracket Outer

Screw Slot

Nylon Bearing

Screw

Washer

Upper Hinge

Bracket Inner

Screw Hole

Upper Hinge Bracket

Thrust Washers

Inside of

Door

Fig. 11

35

Page 36

Door Installation

12) Remove the black plastic ller cap located from the hole above where the spring

cartridge screw will line up. Note: The black plastic ller cap is not reusable.

13) Remove the upper hinge bracket screws from the new location and apply Loctite

Threadlocker Blue 242 or 243 to the threads. Next, start the upper hinge bracket

outer screw into the appliance. Rotate a few threads into the appliance; do not tighten

thescrew. See Fig. 12.

Upper Hinge Bracket

Outer Screw

Black Plastic Filler Cap

Upper Hinge

Bracket Inner

Screw

Upper Hinge

Bracket Outer

Screw

Fig. 12

14) Be sure the lower hinge bracket thrust washer is in place, then place the door on the

lower hinge bracket in the fully open position. Slide the door upper hinge bracket outer

slot onto the upper hinge bracket outer screw. See Fig. 13.

15) Install the upper hinge bracket inner screw and tighten.

Upper Hinge Bracket

Upper Hinge

Bracket

Outer Screw

Upper Hinge

Bracket Outer

Screw

Upper Hinge

Bracket

WARNING! Upper

hinge bracket may

spring closed

Door Fully Open

Lower Hinge Bracket

Thrust

Washer

Fig. 13

36

Upper Hinge

Bracket Inner

Screw

Door Fully Open

Page 37

16) Close the door and tighten the upper hinge bracket outer screw.

See Fig. 14.

Upper Hinge Bracket

Outer Screw

Upper Hinge

Bracket

Door Fully Closed

Fig. 14

17) Check the door operation to assure it opens and closes properly. Note: Hold door at

45°angle from closed position and release. Door should close on its own. If not, adjust

hinge bracket.

18) Unlock the casters and move the appliance back into its original position. Lock the

casters once in position, then plug the appliance back into the electrical outlet. Allow the

appliance to cool down prior to putting product back in.

D. Door/Drawer Location Reversal

The appliance is provided with a cabinet design which, after being delivered to the

installation location, permits changing of the drawer and door locations. To change the

drawer and door locations, follow the steps below. Example shows CRMR48-D2.

WARNING

• Wear proper PPE (personal protection equipment) when executing these

procedures (safety glasses and gloves).

• Keep ngers away from edge of upper hinge bracket. Spring cartridge can cause

the upper hinge bracket to move suddenly with extreme force.

Drawer and Drawer Frame Removal

1) Remove all items from the appliance. Make sure the appliance is unplugged from the

electrical outlet. Move the appliance out for ease of access then lock the casters.

See Fig. 15.

Model Shown: CRMR48-D2

Casters

Fig. 15

37

Page 38

2) Remove the drawers. Pull the drawer out to its fully extended position. Open the safety

clips (one on each side) by sliding them forward, then rotating them up. See Fig. 16.

Lift up on the handle slightly, then pull to disengage the drawer. Be sure to support the

rear and front of the drawer while removing it. WARNING! Be sure to close the safety

clips when reinstalling the drawer.

Safety Clip

Closed

Safety Clip

Open

Safety Clips

Drawer

Slides

Upper Drawer

Lower Drawer

Fig. 16

3) Remove the 4 horizontal mullion screws, then cut the horizontal mullion silicone loose

and remove the horizontal mullion. See Fig. 17.

Horizontal Mullion Screws

Horizontal Mullion Silicone

Horizontal Mullion

Silicone

Horizontal Mullion

Fig. 17

38

Page 39

4) Remove the hex-bolts from the 2 right (front and rear) and 2 left (front and rear) brackets

(2 hex-bolts per bracket), then remove the right and left drawer frames. See Fig. 18.

Right Drawer Frame

Right Rear

Hex-Bolts

Right Front

Hex-Bolts

Left

Rear

Bracket

Left Drawer Frame

Right

Rear

Bracket

Right Front

Bracket

Right Drawer Frame

Right

Rear

Bracket

Right Front

Bracket

Left Drawer

Frame

Left Front

Bracket

Fig. 18

Left

Rear

Bracket

Left Rear

Hex-Bolts

Left Front

Hex-Bolts

Left Drawer

Frame

Left Front

Bracket

Left

Rear

Bracket

Left Front

Bracket

Right Drawer

Frame

Right Front

Bracket

Right

Rear

Bracket

39

Page 40

Pilaster and Inner Brackets Relocation