Hoshizaki CR1A-FS, CR1A-HS, CF1A-FS, CF1A-HS SERVICE MANUAL

Hoshizaki

Hoshizaki America, Inc.

Commercial Series

Refrigerated Kitchen Equipment

Model

Reach-In

“A Superior Degree

of Reliability”

www.hoshizaki.com

SERVICE MANUAL

Number: 73179

Issued: 6-18-2010

IMPORTANT

Only qualied service technicians should install, service, and maintain the

unit. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number __________________________

• Serial Number __________________________

• Complete and detailed explanation of the problem.

2

IMPORTANT

This manual should be read carefully before the unit is serviced or maintenance

operations are performed. Only qualied service technicians should install,

service, and maintain the unit. Read the warnings contained in this booklet

carefully as they give important information regarding safety. Please retain this

booklet for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 5

I. Specications ...................................................................................................................... 6

A. Nameplate Ratings ........................................................................................................ 6

B. Dimensions ................................................................................................................... 6

1. Refrigerated Volume and Shelf Space ..................................................................... 6

2. One Section/Two Section ........................................................................................ 7

II. General Information ........................................................................................................... 8

A. Construction .................................................................................................................. 8

1. One Section ............................................................................................................. 8

2. Two Section ............................................................................................................. 9

B. Sequence of Operation ............................................................................................... 10

1. Sequence Cycles and Shutdown ........................................................................... 10

a) Refrigerator ...................................................................................................... 10

b) Freezer ..............................................................................................................11

2. Sequence Flow Charts .......................................................................................... 12

a) Refrigerator ...................................................................................................... 12

b) Freezer ............................................................................................................. 13

C. Display Module............................................................................................................ 14

1. Display Module Layout ........................................................................................... 14

2. Controls and Adjustments ...................................................................................... 15

D. Control Module ............................................................................................................ 16

1. Control Module Layout ........................................................................................... 16

2. Alarm Safeties ....................................................................................................... 17

F. Compressor Overload and Short Cycle Protection ...................................................... 18

G. Mullion/Perimeter Heater ............................................................................................ 18

H. Thermistors ................................................................................................................. 18

III. Technical Data ................................................................................................................ 19

A. Wiring Diagrams .......................................................................................................... 19

IV. Service Diagnosis ........................................................................................................... 23

A. Diagnostic Procedure .................................................................................................. 23

1. Refrigerator ............................................................................................................ 24

2. Freezer .................................................................................................................. 25

B. Control Module Check ................................................................................................. 28

C. Thermistor Check ........................................................................................................ 29

D. Diagnostic Chart ......................................................................................................... 30

1. Unit Not Cooling ..................................................................................................... 30

2. Evaporator is Frozen Up ........................................................................................ 32

3. Defrost Fails to Terminate ...................................................................................... 32

4. Other ...................................................................................................................... 32

3

V. Removal and Replacement of Components .................................................................... 33

A. Service for Refrigerant Lines ....................................................................................... 33

1. Refrigerant Recovery ............................................................................................. 33

2. Brazing .................................................................................................................. 34

3. Evacuation and Recharge ..................................................................................... 34

B. Removal and Replacement of Compressor ................................................................. 36

C. Removal and Replacement of Evaporator................................................................... 37

D. Removal and Replacement of Condenser................................................................... 39

E. Removal and Replacement of Expansion Valve (2-Section Freezer) .......................... 40

F. Removal and Replacement of Evaporator Fan Motor .................................................. 41

G. Removal and Replacement of Condenser Fan Motor ................................................. 41

H. Removal and Replacement of Control Module ............................................................ 42

I. Removal and Replacement of Thermistors ................................................................... 43

J. Removal and Replacement of Condensate Pump ....................................................... 45

K. Removal and Replacement of Door Gasket ................................................................ 46

L. Door Re-Hinging .......................................................................................................... 46

VI. Cleaning Instructions ...................................................................................................... 46

4

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

CAUTION Indicates a situation which could result in damage to the unit.

IMPORTANT Indicates important information about the use and care of the

unit.

WARNING

This unit should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore

dangerous. The manufacturer cannot be held responsible for eventual damage

caused by improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or re, follow

basic precautions including the following:

• This unit requires an independent power supply. See the nameplate for proper

voltage and breaker/fuse size. Failure to use a proper breaker or fuse can

result in a tripped breaker, blown fuse, or damage to existing wiring. This

could lead to heat generation or re.

• THIS UNIT MUST BE GROUNDED: This unit is equipped with a 3-prong

grounding plug to reduce the risk of potential shock hazards. It must be

plugged into a properly grounded, independent 3-prong wall outlet. If the

outlet is a 2-prong outlet, it is your personal responsibility to have a qualied

electrician replace it with a properly grounded, independent 3-prong wall

outlet. Do not remove the ground prong from the power cord and do not use

an adapter plug.

• Do not use an extension cord.

• Make sure the power switch is in the "OFF" position before plugging in or

unplugging the unit to reduce the risk of electric shock.

• Do not use a unit with a damaged power cord. The power cord should not be

altered, jerked, bundled, weighed down, pinched, or tangled. Such actions

could result in electric shock or re. To unplug the unit, be sure to pull the

plug, not the cord, and do not jerk the cord.

• To reduce the risk of electric shock, do not touch the plug or power switch with

damp hands.

• This unit should be disassembled or repaired only by qualied service

personnel to reduce the risk of electric shock, injury, or re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, re, or damage to the unit.

5

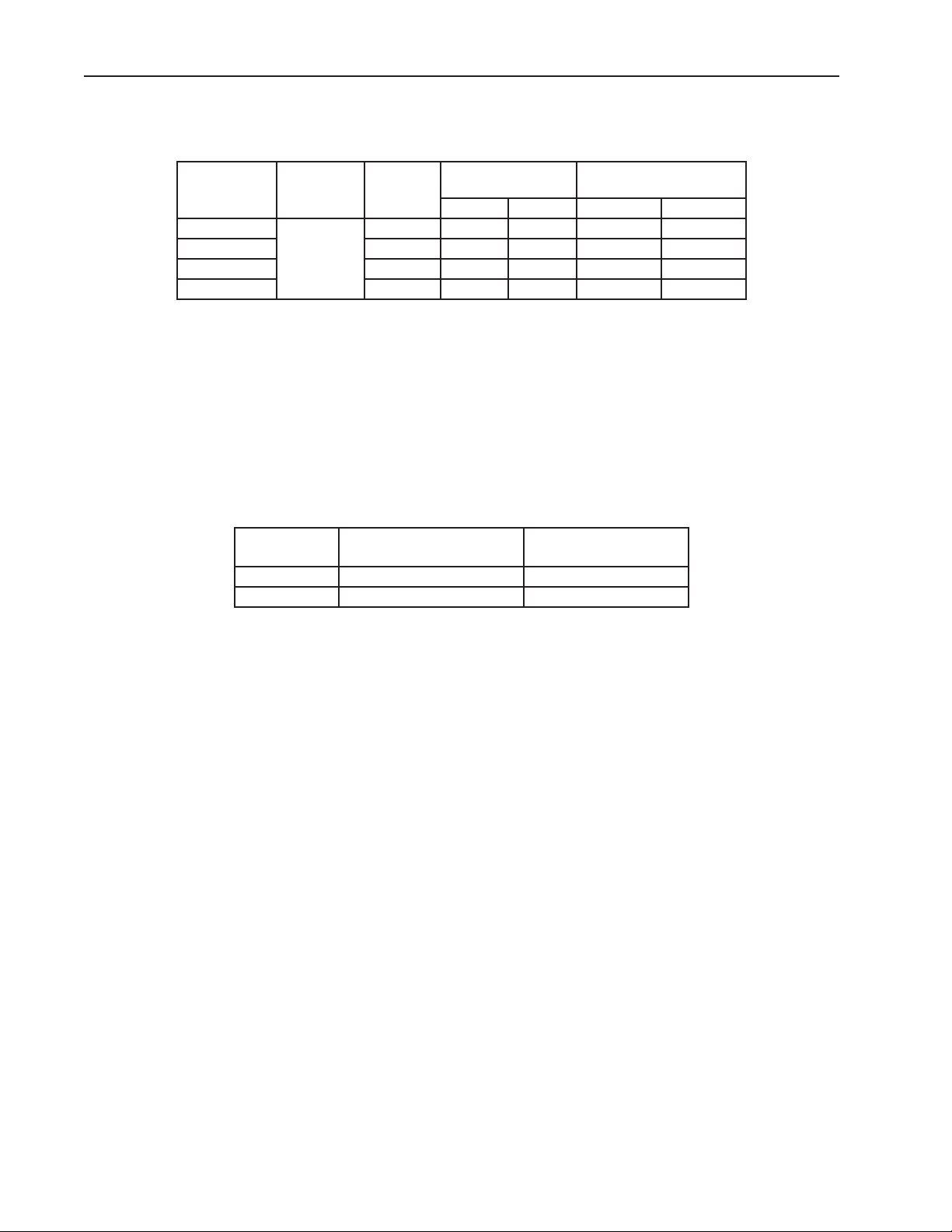

I. Specications

A. Nameplate Ratings

Design Pressure

AC Supply

Model

CR1A-FS/HS

CF1A-FS/HS 8.1 450 250 - 13

CR2A-FS/HS 8 240 120 12.5 CF2A-FS/HS 12 450 250 - 16.9

Voltage Amperes

4.8 240 120 10.6 -

115/60/1

(PSIG) Refrigerant (oz.)

HIGH LOW R-134a R-404A

See the nameplate for electrical and refrigeration specications. The nameplate is located

on the inner right side wall of the cabinet behind the front panel.

Note: We reserve the right to make changes in specications and design without prior

notice.

B. Dimensions

1. Refrigerated Volume and Shelf Space

Total Refrigerated

Model

C_1A-FS/HS 20 11.5

C_2A-FS/HS 45 24.6

Volume ft

3

Total Shelf Space

2

ft

Note: We reserve the right to make changes in specications and design without prior

notice.

6

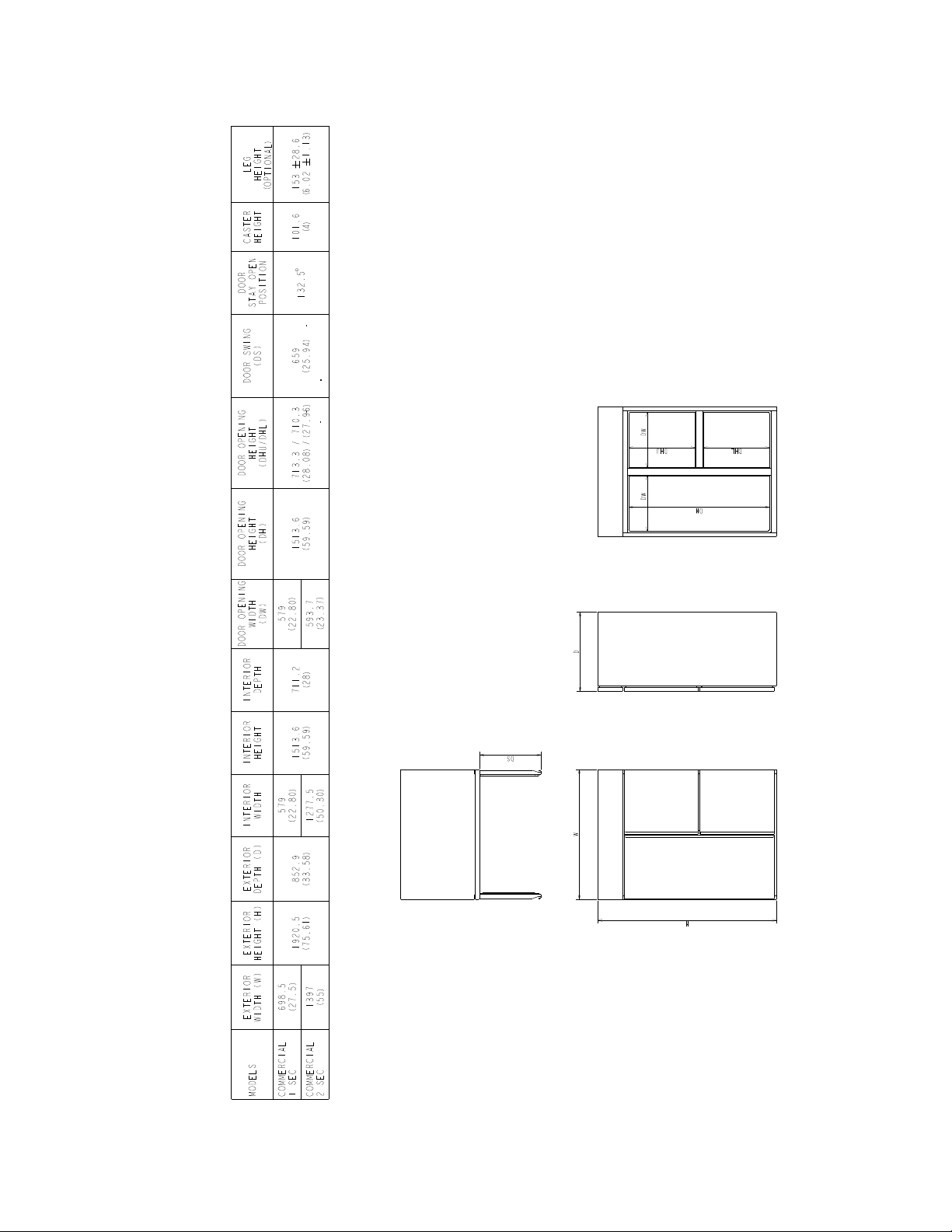

2. One Section/Two Section

Unit: mm (in.)

LEG

HEIGHT

CASTER

HEIGHT

DOOR

POSITION

STAY OPEN

(DS)

DOOR SWING

HEIGHT

(DHU/DHL)

DOOR OPENING

(DH)

HEIGHT

DOOR OPENING

1.13

153 28.6

6.02

4

101.6

132.5

659

25.94

713.3 / 710.3

28.08 / 27.96

59.59

1513.6

DHL DHU

DW DW

DH

579

(DW)

WIDTH

DOOR OPENING

DEPTH

INTERIOR

HEIGHT

INTERIOR

579

WIDTH

INTERIOR

EXTERIOR

DEPTH (D)

EXTERIOR

HEIGHT (H)

698.5

EXTERIOR

WIDTH (W)

22.80

711.2

1513.6

22.80

852.9

1920.5

27.5

593.7

28

59.59

1277.5

33.58

75.61

1397

23.37

D

DS

50.30

W

H

55

MODELS

COMMERCIAL

1 SEC

COMMERCIAL

2 SEC

7

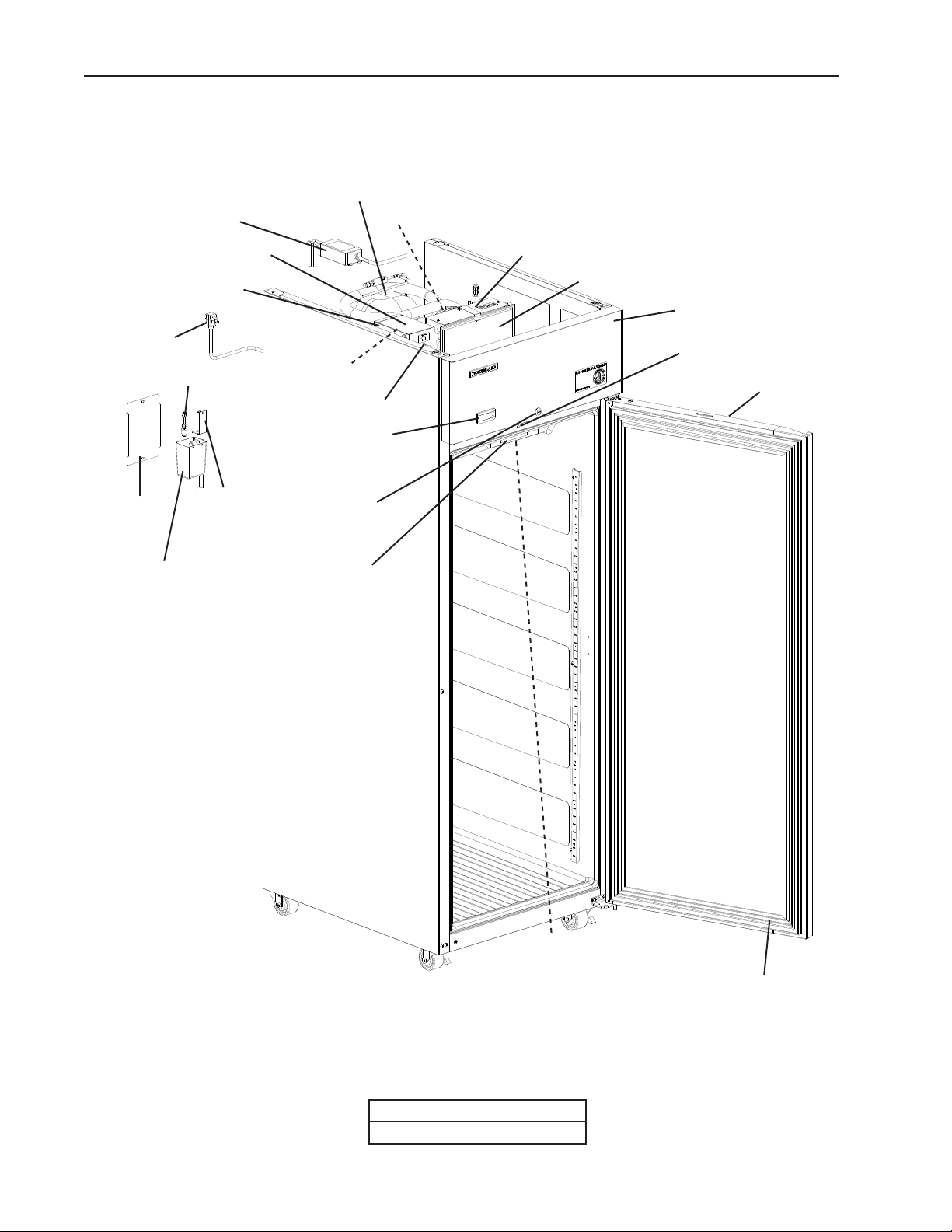

II. General Information

A. Construction

1. One Section

Compressor

Condensate Pump

Condenser Fan Motor

Control Box Cover

Power Cord

Reservoir

Cover

Reservoir

Control Box

Float Switch

Float

Switch

Bracket

Control Module

Power Switch

Display Module

Door Lock

Light

Condenser

Air Filter

Front Panel

Door Switch

Door

• Evaporator

• Cabinet Thermistor

• Defrost Thermistor

• Evaporator Fan Shroud

Model Shown: CR1A-FS

Models

CR1A-FS/HS and CF1A-FS/HS

8

Door Gasket

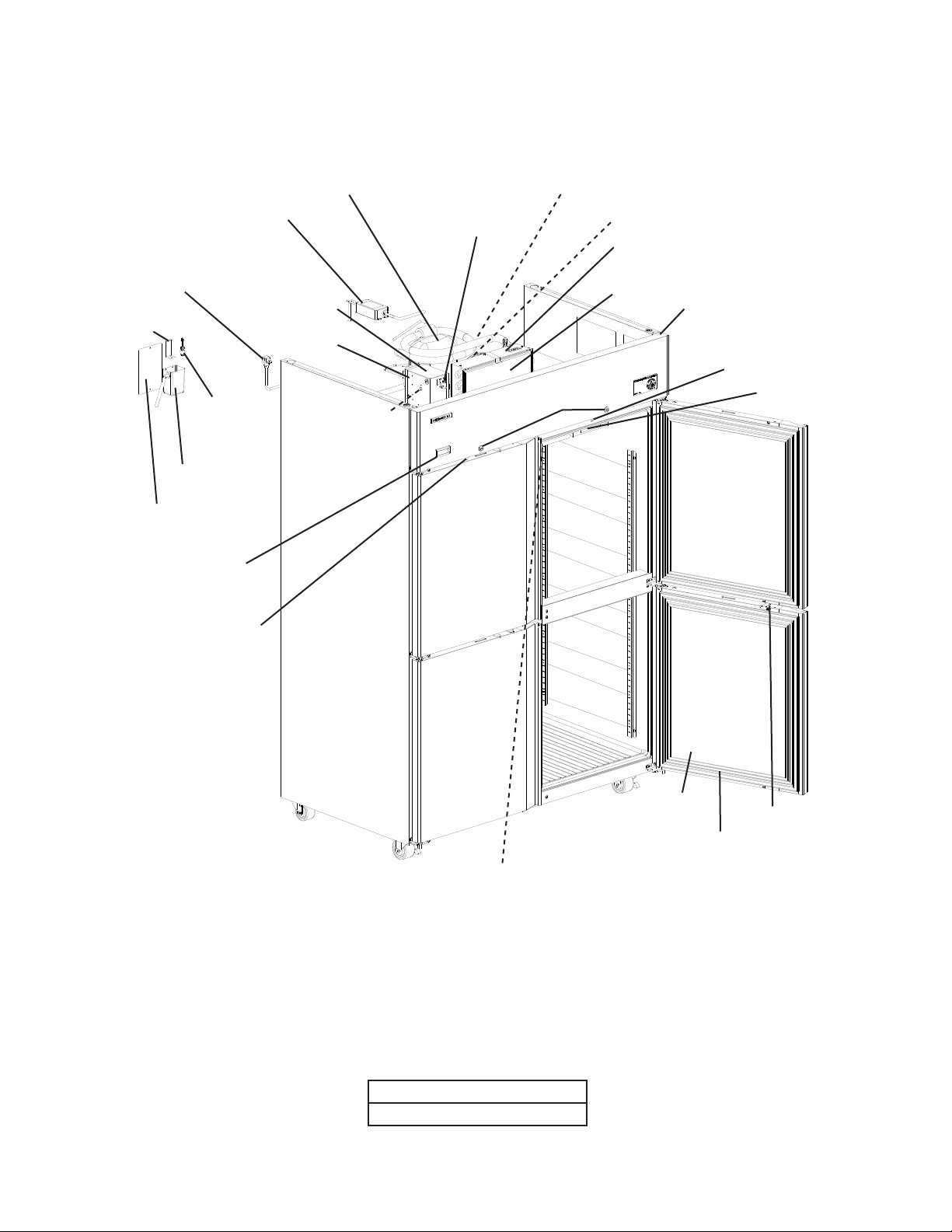

2. Two Section

Condensate Pump

Power Cord

Float Switch

Bracket

Reservoir Cover

Display Module

Door Switch

Control Box Cover

Control Box

Float Switch

Reservoir

Compressor

Control Module

Power Switch

Thermostatic Expansion Valve (CF2A-FS/HS)

Condenser Fan Motor

Condenser

Air Filter

Front Panel

Door Switch

Door Lock

Light

• Evaporator

• Cabinet Thermistor

• Defrost Thermistor

• Evaporator Fan Shroud

Model Shown: CF2A-HS

Models

CR2A-FS/HS and CF2A-FS/HS

9

Door

Door Latch

Door Gasket

B. Sequence of Operation

1. Sequence Cycles and Shutdown

The steps in the sequence are as outlined below.

Note: 1. There is a slight delay at startup.

2. There is a 2-minute minimum Comp on time and a 2-minute minimum Comp off

time.

3. EvapFM de-energizes when door is opened on FS and when upper door is

opened on HS.

4. A oat-switch controlled condensate pump (located on top of the unit) is used to

pump evaporator condensation to the condensate pan.

5. On freezers, EvapFM is de-energized during defrost.

a) Refrigerator

1. Startup/Cool Down

EvapFM, MH, and PH energize. There is a slight delay before cabinet temperature

appears on DMand Comp and ConFM energize.

2. Cool Down Achieved

CM monitors cooling of the cabinet via CTh. CTh cools to 3°F (1.7°C) below setpoint.

EvapFM, MH, and PH continue. Comp and ConFM de-energize.

3. Cool Down Restart

CTh warms to 3°F (1.7°C) above setpoint. EvapFM, MH, and PH continue. Comp and

ConFM energize.

4. Defrost

"dEF" is displayed during defrost. There is a 20-minute minimum defrost time and a

1-hour maximum defrost time.

a) Temperature Initiation: When DThcools to 8.6°F (-13°C) defrost begins. EvapFM, MH,

and PH continue. Comp and ConFM de-energize.

b) Manual Initiation: Manual defrost may be initiated by pressing and holding the lower

button until "dEF" appears on DM. EvapFM, MH, and PH continue. Comp and ConFM

de-energize.

c) Termination: DTh warms to 40°F (4.4°C). EvapFM, MH, and PH continue. Comp and

ConFM energize, 2-minute temperature display delay timer starts.

2-minute temperature display delay timer terminates and temperature display returns

to DM.

Note: There is a 2-hour minimum defrost interval.

Legend: CM–control module; Comp–compressor; ConFM–condenser fan motor;

CTh–cabinet thermistor; DM–display module; DTh–defrost thermistor;

EvapFM–evaporator fan motor; MH–mullion heater; PH–perimeter heater

10

b) Freezer

1. Startup/Cool Down

MH and PH energize. There is a slight delay before cabinet temperature appears on DM

and Comp, ConFM, and EvapFM energize.

2. Cool Down Achieved

CM monitors cooling of the cabinet via CTh. CTh cools to 3°F (1.7°C) below setpoint.

EvapFM, MH, and PH continue. Comp and ConFM de-energize.

3. Cool Down Restart

CTh warms to 2°F (1.1°C) above setpoint. EvapFM, MH, and PH continue. Comp and

ConFM energize.

4. Defrost

"dEF" is displayed during defrost. There is a 5-minute minimum defrost time and a 1-hour

maximum defrost time.

a) Temperature/Time Initiation: DTh cools to 32°F (0°C), then a 4-hour cumulative Comp

run timer starts. Once 4-hour cumulative Comp run timer terminates and DThis at or

below 32°F (0°C), defrost begins. DH energizes, MH and PH continue, Comp, ConFM,

and EvapFM de-energize.

b) Manual Initiation: Manual defrost may be initiated by pressing and holding the lower

button until "dEF" appears on DM. MH and PH continue. DH energizes, Comp, ConFM,

and EvapFM de-energize.

c) Termination

(1) After Temperature/Time Initiation: DTh warms to 59°F (15°C). 3-minute Comp delay

timer starts, 8-minute EvapFM delay timer starts, and 13-minute temperature display

delay timer starts. MH and PH continue, DHde-energizes.

3-minute Comp delay timer terminates. Comp and ConFM energize. 5 minutes later,

8-minute EvapFM delay timer terminates and EvapFM energizes. 5 minutes after

EvapFM energizes, 13-minute temperature display delay timer terminates and cabinet

temperature returns to DM.

(2) After Manual Initiation: DTh warms to 59°F (15°C). MH and PH continue, DH

de-energizes. 3-minute Comp/EvapFM delay timer starts, 13-minute temperature

display delay timer starts.

3-minute Comp delay timer terminates. Comp, ConFM, and EvapFM energize.

10minutes later, 13-minute temperature display delay timer terminates and cabinet

temperature returns to DM.

Note: There is a 4-hour minimum defrost interval.

Legend: CM–control module; Comp–compressor; ConFM–condenser fan motor;

CTh–cabinet thermistor; DH–defrost heater; DM–display module; DTh–defrost

thermistor; EvapFM–evaporator fan motor; MH–mullion heater; PH–perimeter

heater

11

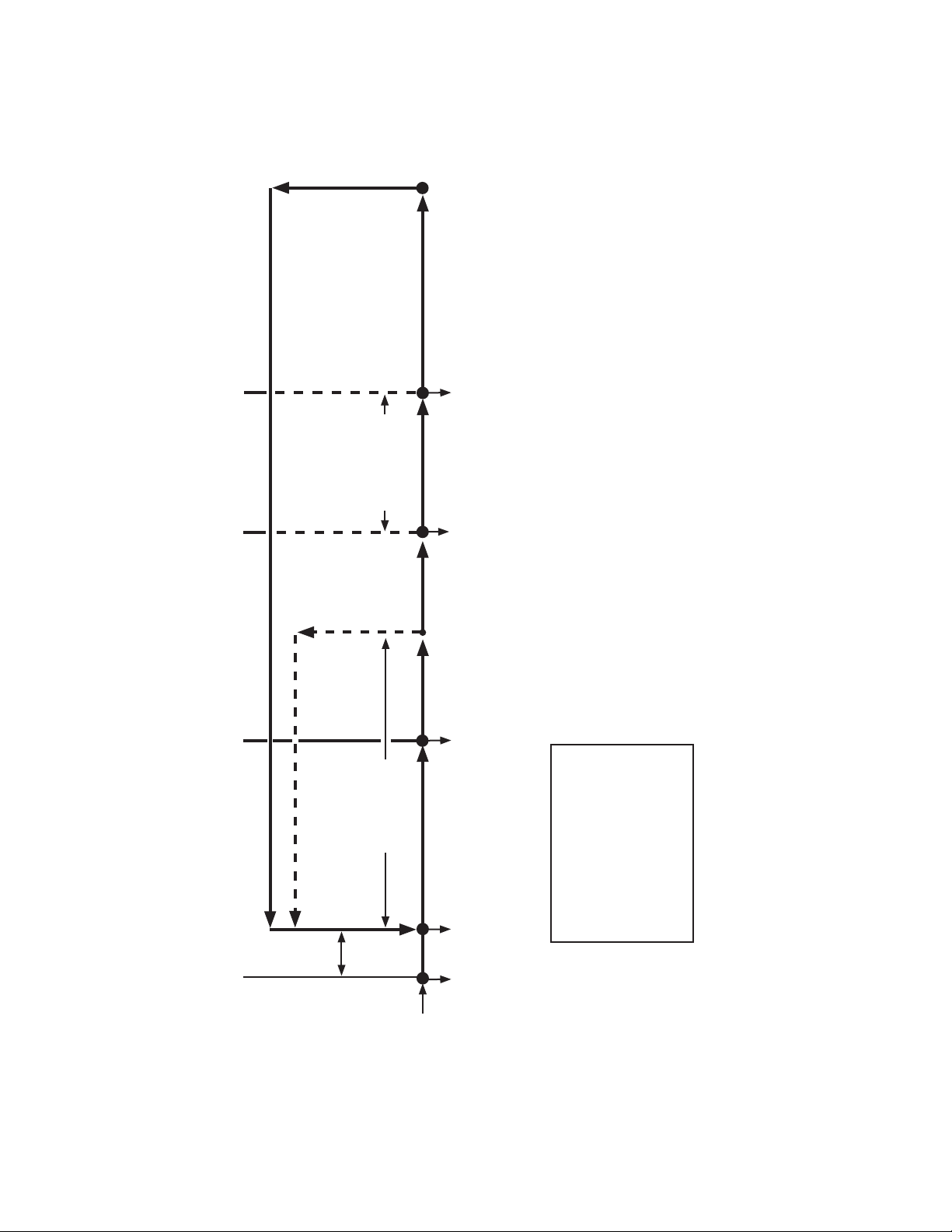

2. Sequence Flow Charts

a) Refrigerator

5. Defrost Termination

4. Defrost

2-min. temperature display

DTh warms to

40°F (4.4°C)

DTh cools to

8.6°F(-13°C)

delay timer starts

Comp energized

ConFM energized

EvapFM energized

MH energized

PH energized

DTh in control

EvapFM energized

MH energized

PH energized

Comp de-energized

ConFM de-energized

CTh warms

to 3°F (1.7°C)

above

setpoint

Note:

a) EvapFM de-energizes when door is opened on FS and when

upper door is opened on HS.

b) 2-minute minimum Comp on timer starts when Comp energizes.

c) 2-minute minimum Comp off timer starts when Comp de-energizes.

d) 2-minute temperature display delay timer starts when defrost

termination temperature is met.

e) 20-minute minimum defrost time.

f) 1-hour maximum defrost time.

CTh cools

to 3°F (1.7°C)

below setpoint.

Factory default

2. Cool Down Achieved

36°F (2°C)

2-min. Comp off

timer starts

EvapFM energized

MH energized

PH energized

Comp de-energized

ConFM de-energized

Refrigerator Sequence Flow Chart

3. Cool Down Restart

1. Startup/Cool Down

Slight

Delay at

Startup

CTh in control

2-min. Comp on

timer starts

Power on

Comp energized

EvapFM energized

ConFM energized

MH energized

EvapFM energized

PH energized

MH energized

PH energized

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DTh-defrost thermistor

EvapFM-evaporator fan motor

MH-mullion heater

PH-perimeter heater

12

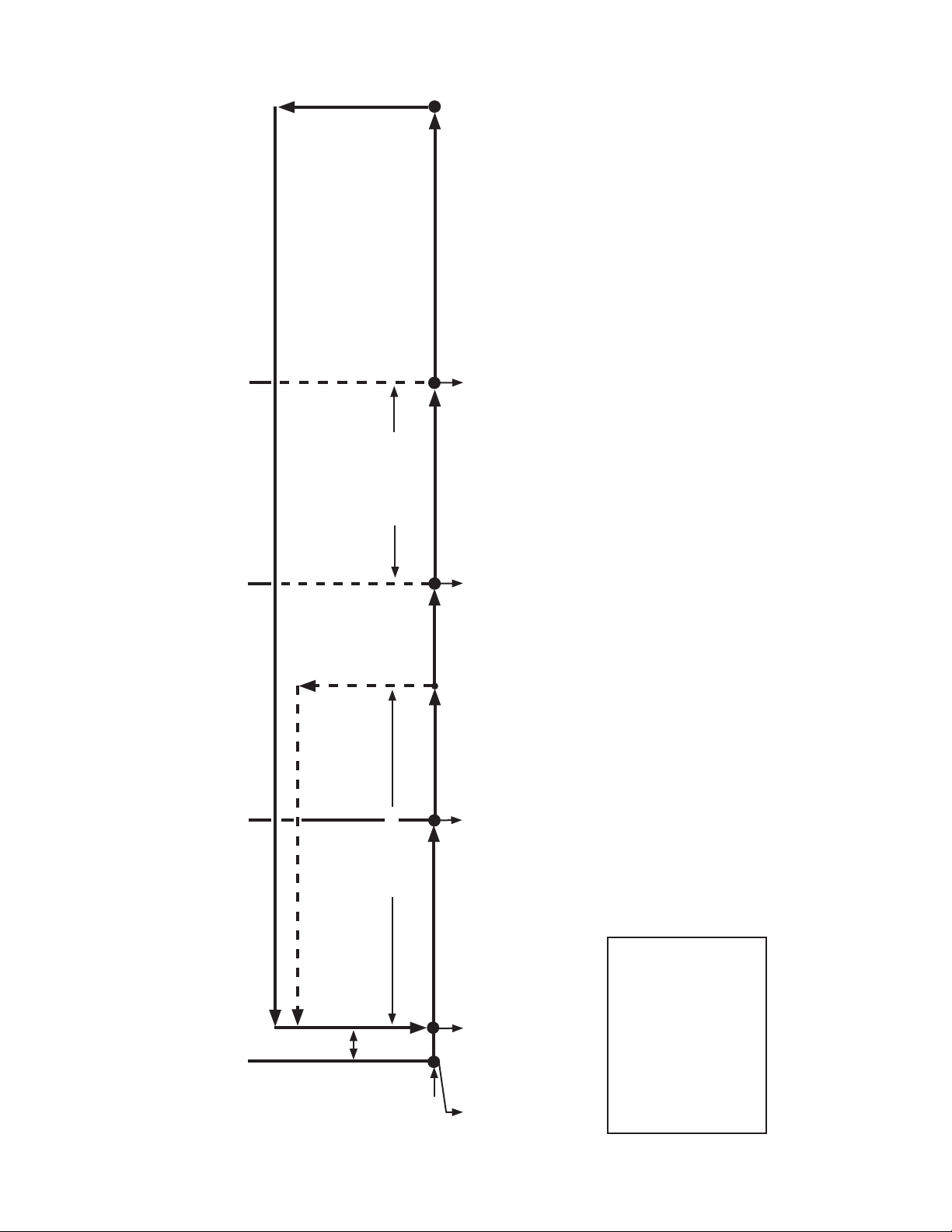

b) Freezer

DTh warms to 59°F (15°C)

5. Defrost Termination

3-min. Comp delay timer starts

(EvapFM starts with Comp on manual

13-minute temperature display

(except on manual defrost restarts)

delay timer starts

DTh in control

MH energized

PH energized

DH de-energized

defrost restart)

8-min. EvapFM delay timer starts

DTh is at or below 32°F (0°C)

and 4-hour cumulative Comp

4. Defrost

run timer terminates

CTh warms

to 2°F (1.1°C)

above setpoint

DH energized

MH energized

PH energized

Comp de-energized

ConFM de-energized

EvapFM de-energized

Freezer Sequence Flow Chart

CTh cools to

3°F (1.7°C)

below setpoint.

Factory default

-4°F (-20°C)

2-min. Comp off

CTh in control

2-min. Comp on

timer starts

timer starts

EvapFM energized

MH energized

PH energized

Comp de-energized

ConFM de-energized

Note:

a) EvapFM de-energizes when door is opened on FS and when upper door is opened on HS.

b) 2-minute minimum Comp on timer starts when Comp energizes.

c) 2-minute minimum Comp off timer starts when Comp de-energizes.

d) 3-minute Comp delay timer starts when defrost termination temperature is met.

e) 8-minute EvapFM delay timer starts when defrost termination temperature is met.

f) 13-minute temperature display delay timer starts when defrost termination temperature is met.

g) 5-minute minimum defrost time.

h) 1-hour maximum defrost time.

Comp energized

ConFM energized

EvapFM energized

MH energized

PH energized

2. Cool Down Achieved

1. Startup/Cool Down

3. Cool Down Restart

DTh reaches 32°F (0°C),

then 4-hour cumulative

Comp run timer starts

Slight

Delay at

Startup

Power on

13

MH energized

PH energized

Legend:

Comp-compressor

ConFM-condenser fan motor

CTh-cabinet thermistor

DH-defrost heater

DTh-defrost thermistor

EvapFM-evaporator fan motor

MH-mullion heater

PH-perimeter heater

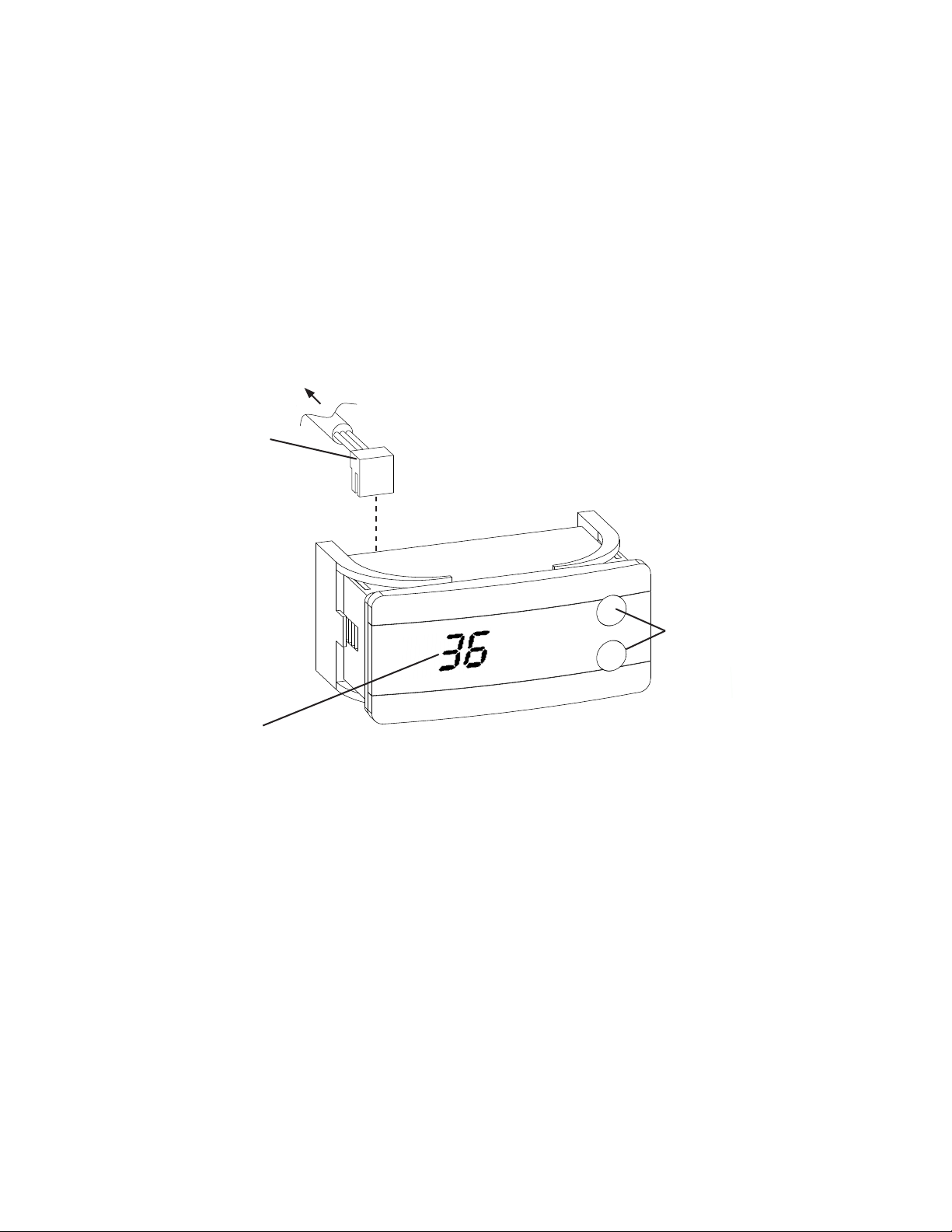

C. Display Module

When the power switch is moved to the "ON" position there is a slight delay, then the

current cabinet temperature is displayed. From the display module, the cabinet setpoint

and temperature display scale can be changed. For further details, see "II.C.2. Controls

and Adjustments."

1. Display Module Layout

Display Module

To Control Module

Display Cable

LED Display

Upper and Lower

Buttons

Fig. 1

14

Loading...

Loading...