Page 1

AM SERVICE TRAINING

Featuring the

AM-50BAE, AM -100BAE, AM-150BAF

AM-50BAE

AM-100BAE AM-150BAF

80047 www.hoshizakiamerica.com 5-20-04

Page 2

25mm

All AM models have similar sequence of operation. This manual is designed as a

generic AM Training manual.

The Hoshizaki AM series ice machine uses a

horizontal evaporator design which forms a

unique cube shape.

20mm

The compact AM-50BAE unit is 14 7/8”w x

22 5/8”d x 33 1/2”h and is designed for

counter-top, under-counter, or freestanding

installations with up to 51 pounds of

production and 30 pounds of storage

The AM-100 and AM-150 are for under

counter or free standing applications .

The AM-100 dimensions are 24 15/16”w x

20 1/2”d x 39”h with 6” legs and can

produce up to 105 and pounds with 44

pounds of storage.

The AM150 measures 27 11/16”w x 27

15/16”d x 39”h with 6” legs and production

up to 150 pounds with 88 pounds of storage.

- 2 -

Page 3

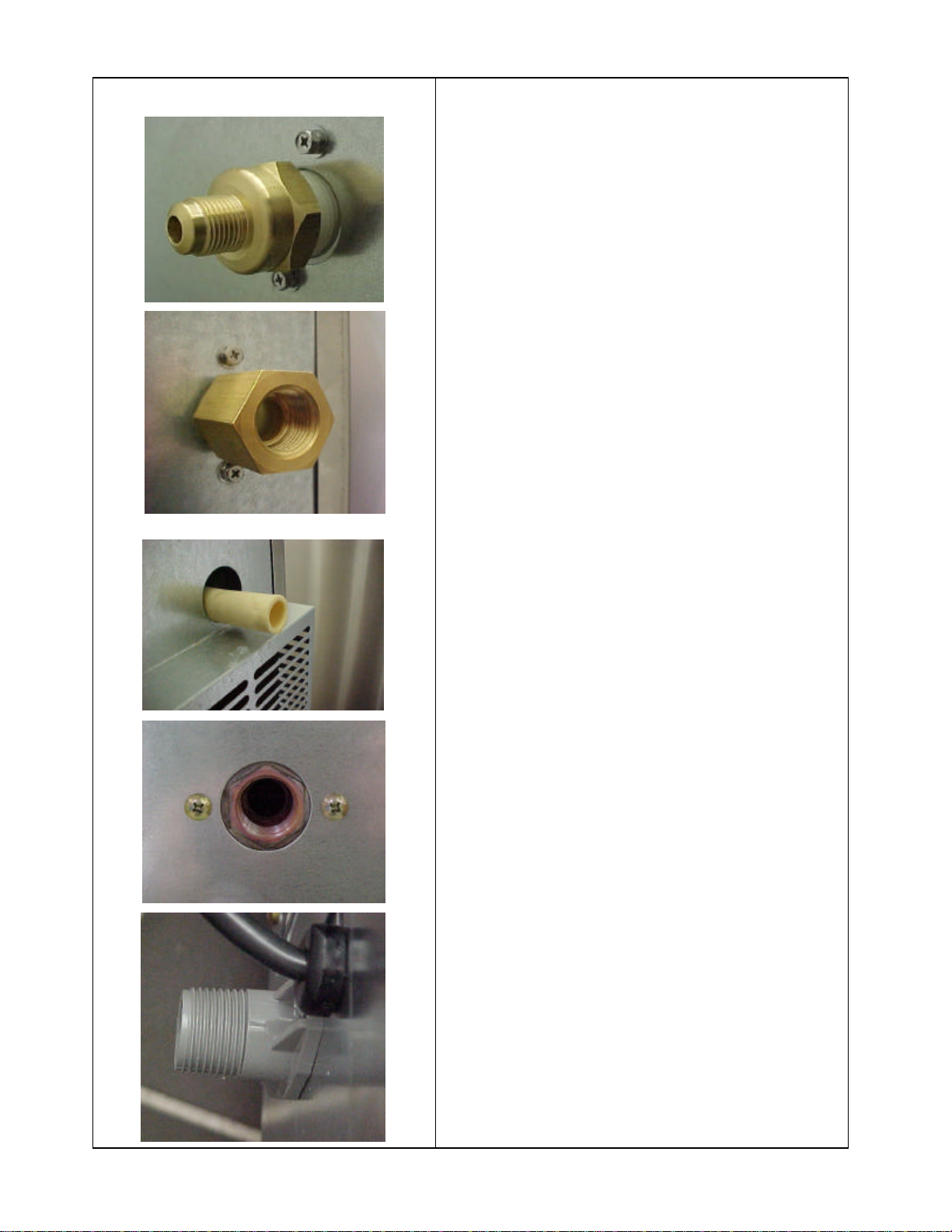

DRAIN

CONNECTIONS

4A32

40-01 1/2” FPT

1/2” FPT

5/8” I.D. rubber hose

WATER INLET CONNECTIONS

3/8” Male flare

4A3207-01

(AM-50 through April

2004)

AM-50 from May 2004

3/4” MPT

(AM-100 & AM-150)

A standard 120-volt power cord provides the

electrical connection. The unit is designed to

operate on a separate 15-amp circuit.

Inlet Water Line Connection

• 1st production units had a 3/4" BSP

connection directly to the inlet water

valve. (DO not connect with 3/4" FIP)

• Fitting (4A3207-01) and gasket

413854-01 were used from May

through July production. (Through

August on the AM -100BAE and AM150 BAF)

• Fitting (4A3240-01) and gasket

413854-01 were added in August 03

on the AM-50BAE and September 03

on the AM-100BAE and AM150BAF.

If no fitting is included, order either fitting

/gasket above or use 3/4" hose type fitting to

make this connection.

A minimum 3/8” water line is required for

proper operation.

Drain line connection

The drain connection for the AM-50 was

5/8” I.D. hose until April of 2004 and was

located on the left rear of the unit. A

standard 3/4” male insert fitting can be used

to connect this drain. From May 2004 the

drain fitting is 1/2” FPT. A minimum 1/2”

I.D. vented drain is required when making

this connection.

The drain for the AM-100 and AM-150 is a

3/4” MPT.

Since the unit will likely be enclosed, it is

recommended to use flexible, supply and

drain connections. This will allow easy

removal if service is necessary.

- 3 -

Page 4

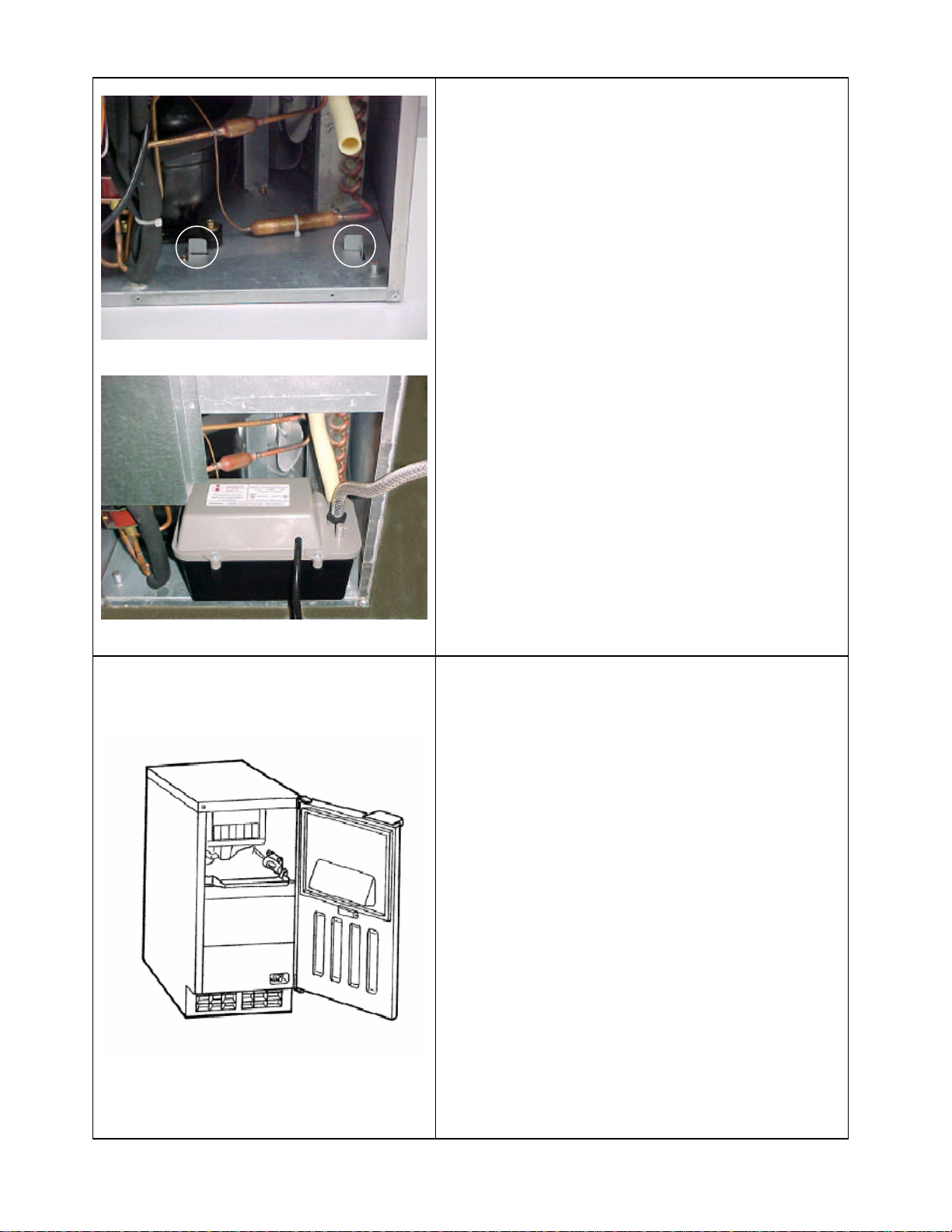

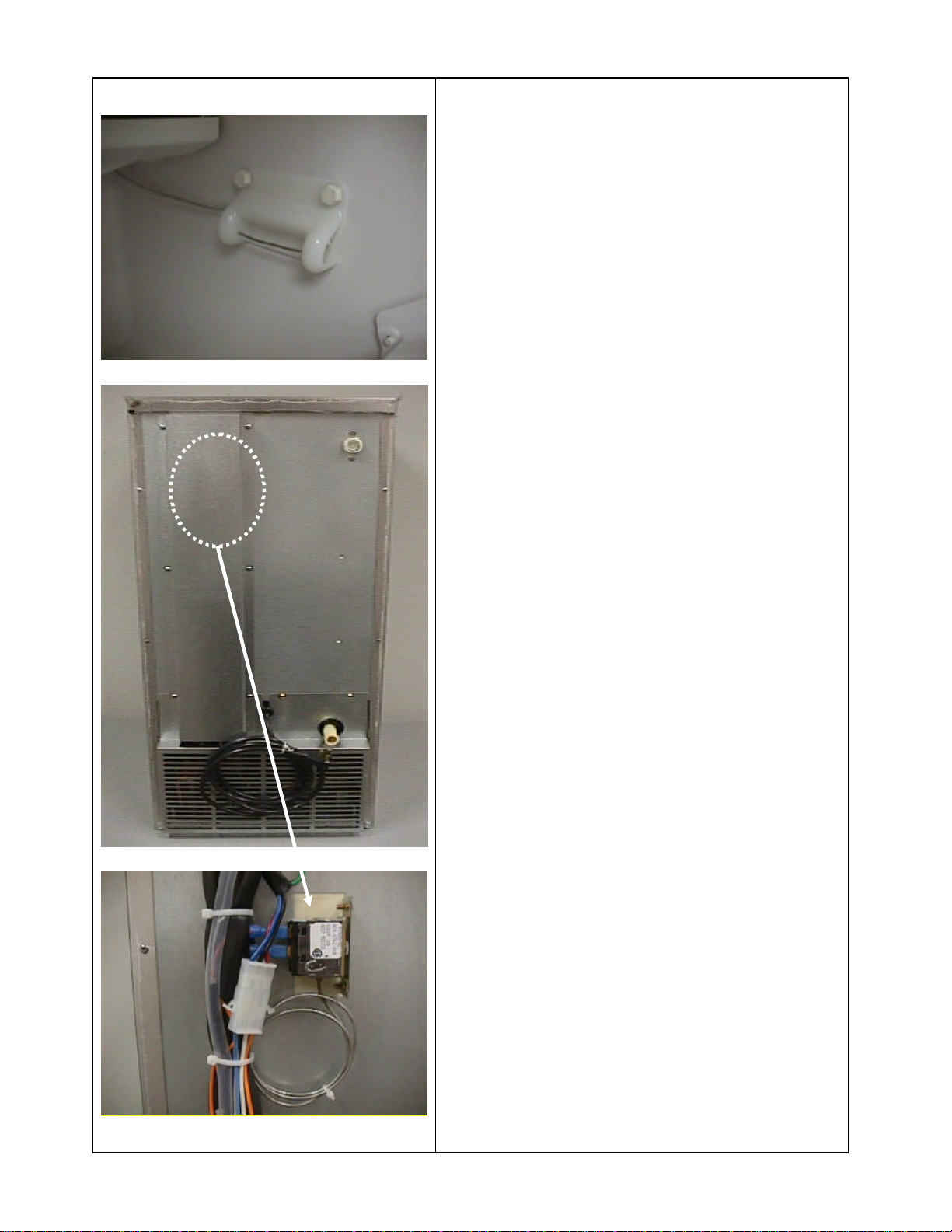

In the case of an AM-50 if a drain is not

located in an area that will allow for the

proper fall, there is an optional condensate

pump available that can be installed directly

into the unit. After removing the louvered

rear panel the pump location is defined by

the two metal tabs. This pump has a built in

safety that will shut the AM-50 down in the

event of a pump problem. This pump is

available as an accessory through your local

distributor. Simply follow the instructions

included with the pump for details on the

installation.

The AM-50 door can be field converted from

the standard right hinged door to a left

hinged door without the use of any additional

hinge kits. The AM-100 and AM-150 use a

spring loaded drop down door design

therefore can not be reversed.

This procedure for reversing the AM-50 door

is shown in the Instruction Manual provided

with the unit. View this manual at

www.hoshizaki.com.

- 4 -

Page 5

(AM

-

50)

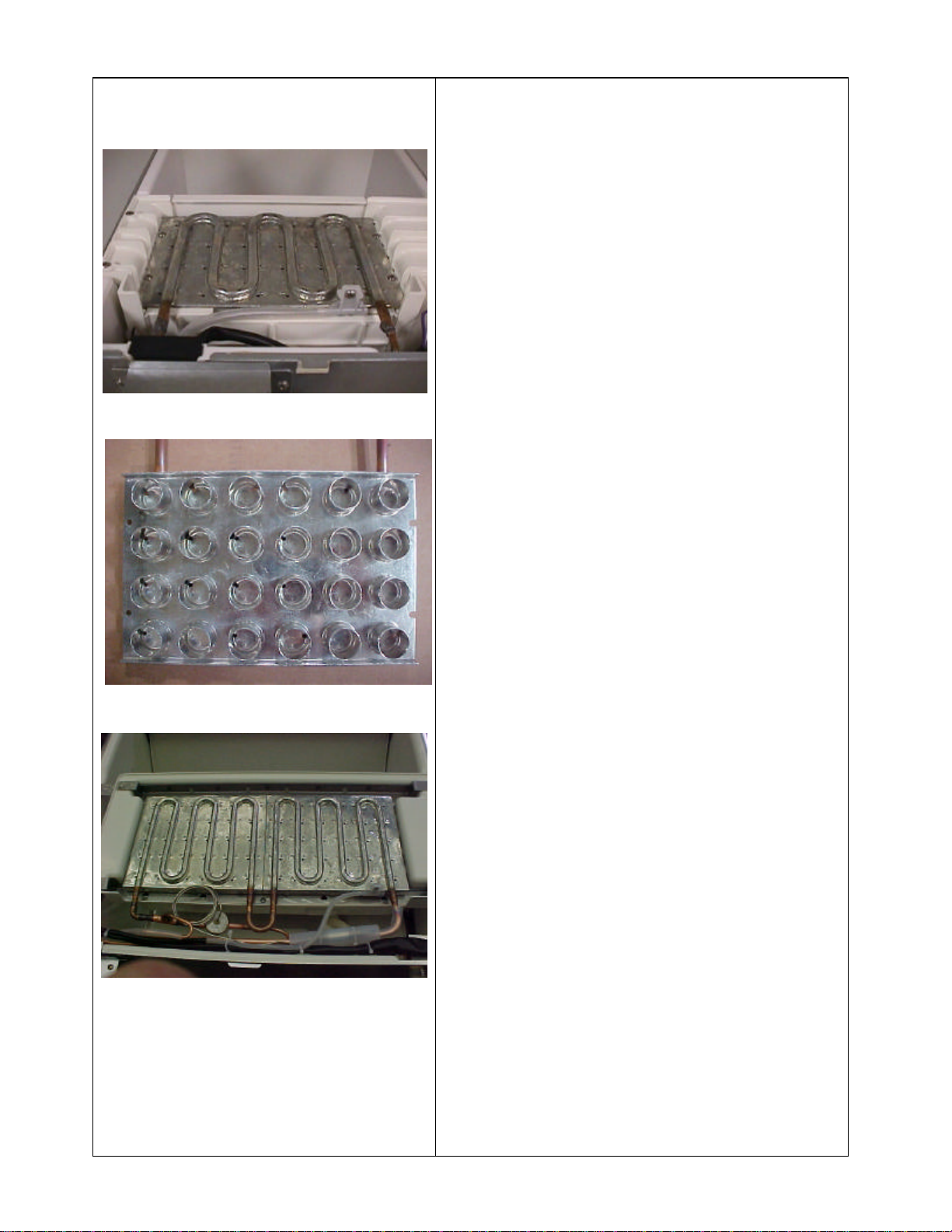

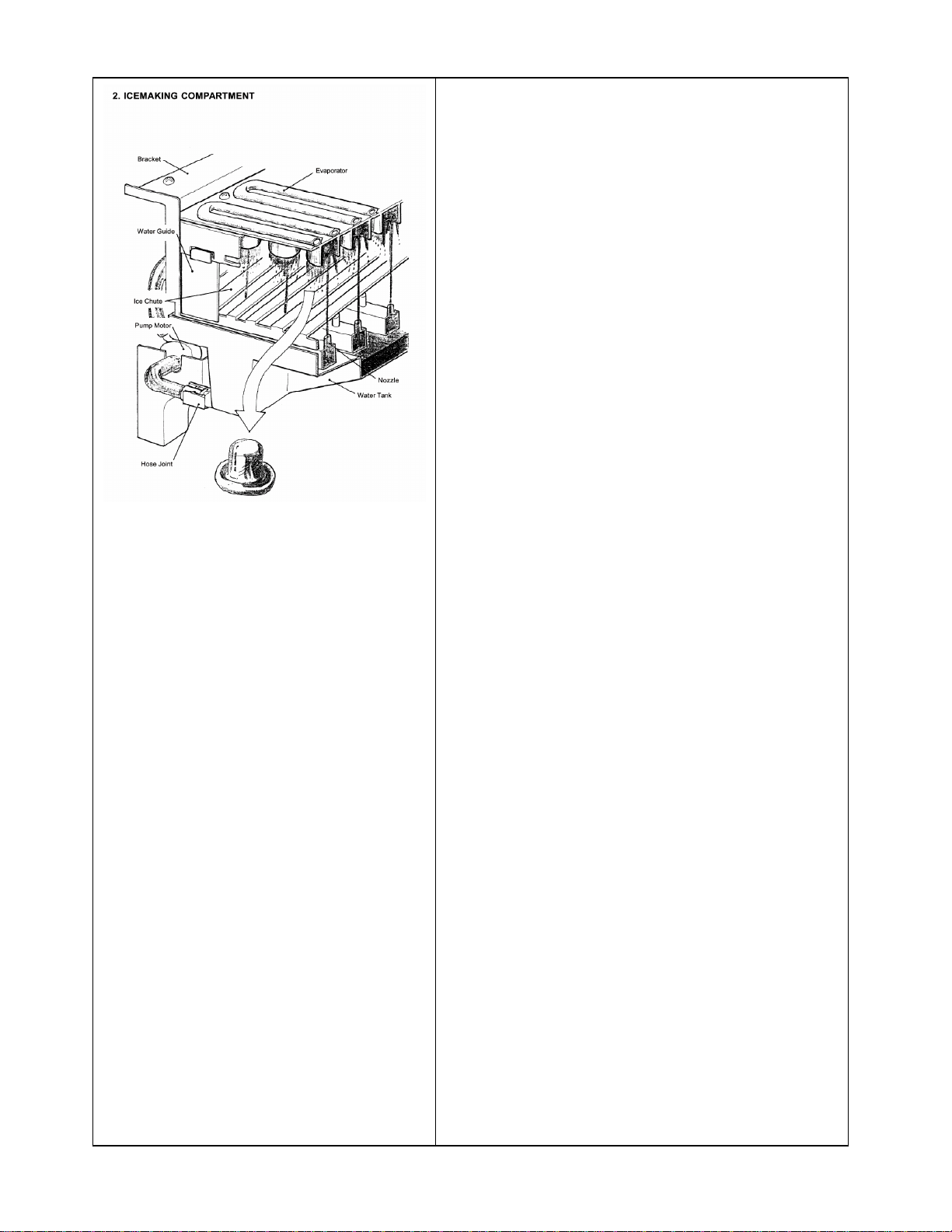

The horizontal evaporator and water

distribution system are unique to the

Hoshizaki AM and IM series. The AM and

the IM series are similar in the fact that they

both make ice on a horizontal evaporator.

The AM evaporator design however is

different, as shown in the center picture. The

moving IM water plate and associated parts

are eliminated with this simple design.

The AM-50BAE produces 24 cubes and .60

pounds per cycle. The AM-100BAE and

AM-150BAF produce 60 cubes and 1.54

pounds per cycle.

The AM series sequence of operation is also

different. The sequence of operation for the

AM series will be explained in the following

pages.

(AM-100 & AM-150)

- 5 -

Page 6

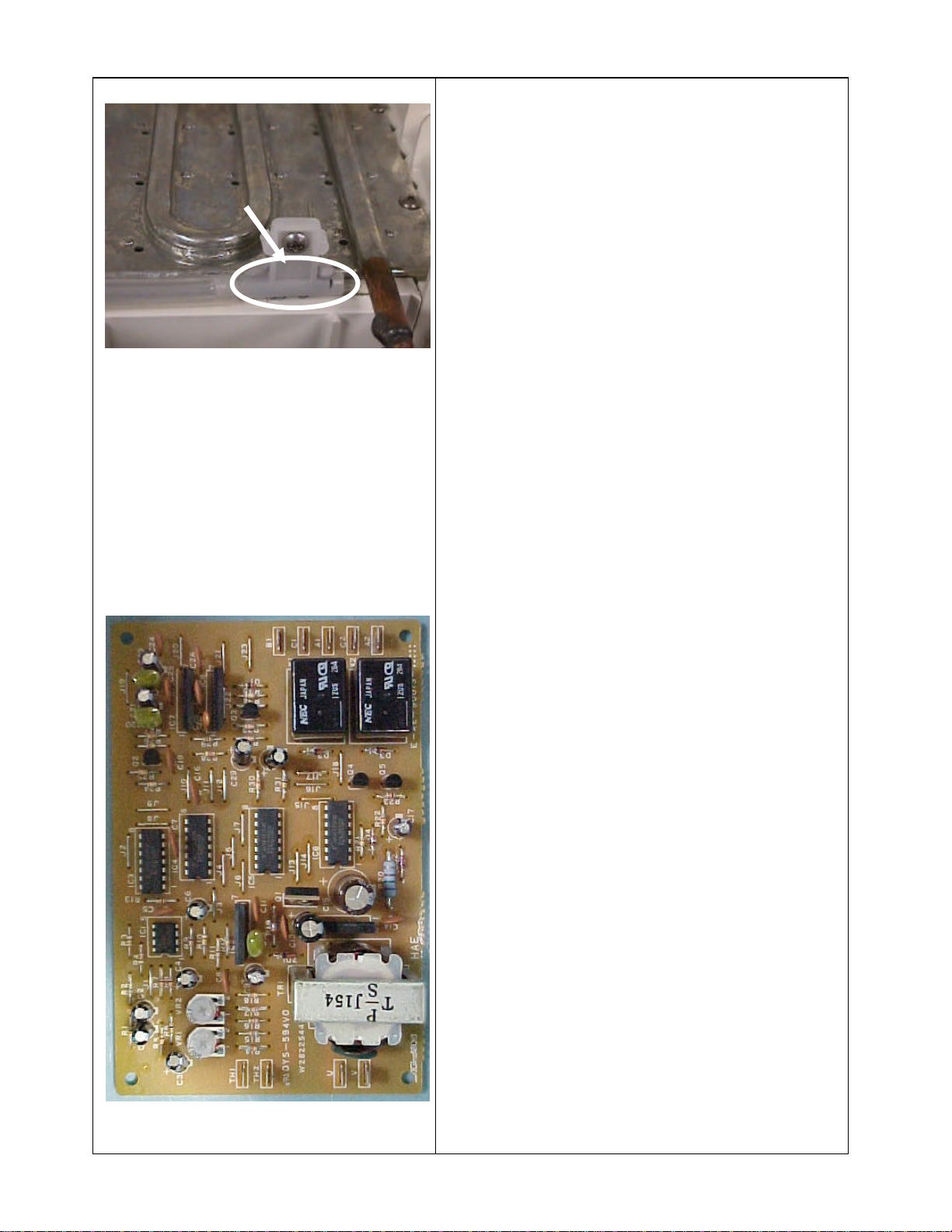

THERMISTOR

The AM series uses a combination

thermistor and control board to control the

sequence of operation. When the toggle

switch is placed in the “ON” position and

the bin control calls for ice, the unit will

begin in the initial harvest cycle. Starting

Thermistor

the unit in harvest allows the compressor to

start in an unloaded condition, greatly

extending the life of the compressor. This

operation is common among all Hoshizaki

cube icemakers.

During the initial harvest, the compressor,

hot gas valve and water valve will be

energized. The initial harvest is a timed

harvest. After 50 seconds, the control board

will energize the X1 board relay to start the

pump motor and condenser fan motor,

switching the unit into the freeze cycle.

After the initial harvest, the X2 board relay

will remain energized during the freeze

cycle. This allows the water valve to feed

fresh water for an additional 50 seconds.

This extended fill, only takes place when the

unit has restarted from a power interruption

or when the bin control calls for ice. During

the normal harvest cycle the water valve

will de-energize at the beginning of freeze

or in the event of long harvest the valve will

have a maximum open time of 102 seconds.

This could occur in the event of operation in

low water and ambient temperatures. During

normal operating conditions the unit will

run approximately 2~4 minutes in the

harvest cycle.

- 6 -

Page 7

Note:

*A thermistor temperature of

minute

A thermistor temperature of

will start the 50

26.6°F (-3°C) will start 8

freeze completion timer.

*

44.6°F (7°C)

second defrost completion timer.

* 26.6°F (-3°C) = 6.8KΩ

thermistor resistance.

* 44.6°F (+7°C) = 4.5KΩ

thermistor resistance.

Throughout the freeze cycle, which

normally last 14~33 minutes, depending on

model and operating conditions, the unit

will continue to circulate the water from the

reservoir to the horizontal evaporator,

through the spray tubes. When the

temperature of the evaporator has reached

approximately 26.6°F (-3°C) and the

thermistor signals approximately 6. 8KΩ the

freeze completion timer will start and count

down 8 minutes.

The control board will then switch to normal

harvest, re-energize the X2 relay and deenergize the X1 relay. This opens the hot

gas valve and water valve and de-energizes

the condenser fan motor and water pump. A

normal harvest is temperature and time

terminated and uses the same thermistor

used to terminate the freeze cycle. After the

evaporator warms to approximately 44.6°F

(+7°C) the thermistor signals the control

board with a resistance of approximately

4.5KΩ. The control board then starts the

harvest completion timer, which is set at 50

seconds. When this timer completes 50

seconds, it ends the harvest cycle and begins

freeze.

The unit will continue to cycle between

freeze and harvest until the bin control

opens, signaling a full bin or until power is

interrupted

- 7 -

Page 8

seconds after ice contacts the bulb.

The AM series uses a thermostatic bin

control located on the right rear side of the

ice storage compartment. This control will

open when ice touches the sensing bulb and

the unit will shut down

This control includes a small heater to

eliminate the control opening due to low

ambient temperatures in the bin.

Access the control by removing the wiring

channel from the rear of the unit.

The thermostatic bin control is factory set

and should shut down the unit within 10

Adjustment may be necessary in higher

altitudes.

- 8 -

Page 9

the louvered panel must be removed.

(AM-50BAE)

AM-50BAE: The control switch is marked

“ICE- OFF-WASH” and is located on the

lower right front of the unit .

AM-100 & AM-150: The control switch is

located on the control box which is located

behind the front panel on the left hand side

of the unit .

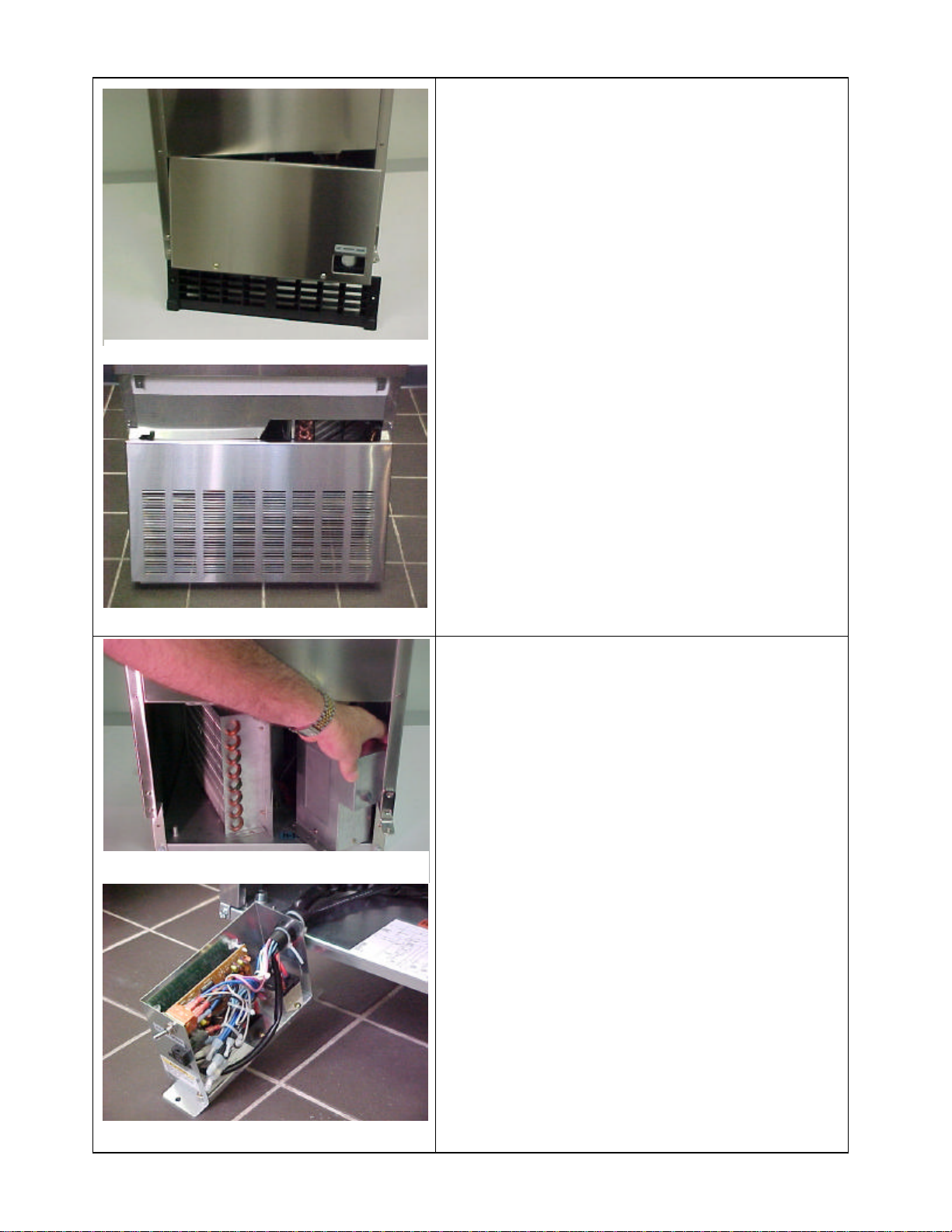

If it is necessary to gain access to the control

box,

AM-50BAE: This can be done by removing

the two screws from the lower portion of the

front panel and pulling the panel down

slightly to dis-engage the mounting tabs.

AM-100 & AM-150: Remove the middle

screw at the bottom of the front panel and lift

off.

(AM-100 & AM-150)

(AM-50BAE)

The control box is held in place with 2 hex

head bolts. Once the bolts are removed,

AM-50BAE: The control box can be rotated

approximately 45° CCW allowing easier

access to the control box cover and control

board.

AM-100 & AM-150: The control box can be

pulled out to the front of the unit after the

two bolts have been removed.

(AM-100 & AM-150)

- 9 -

Page 10

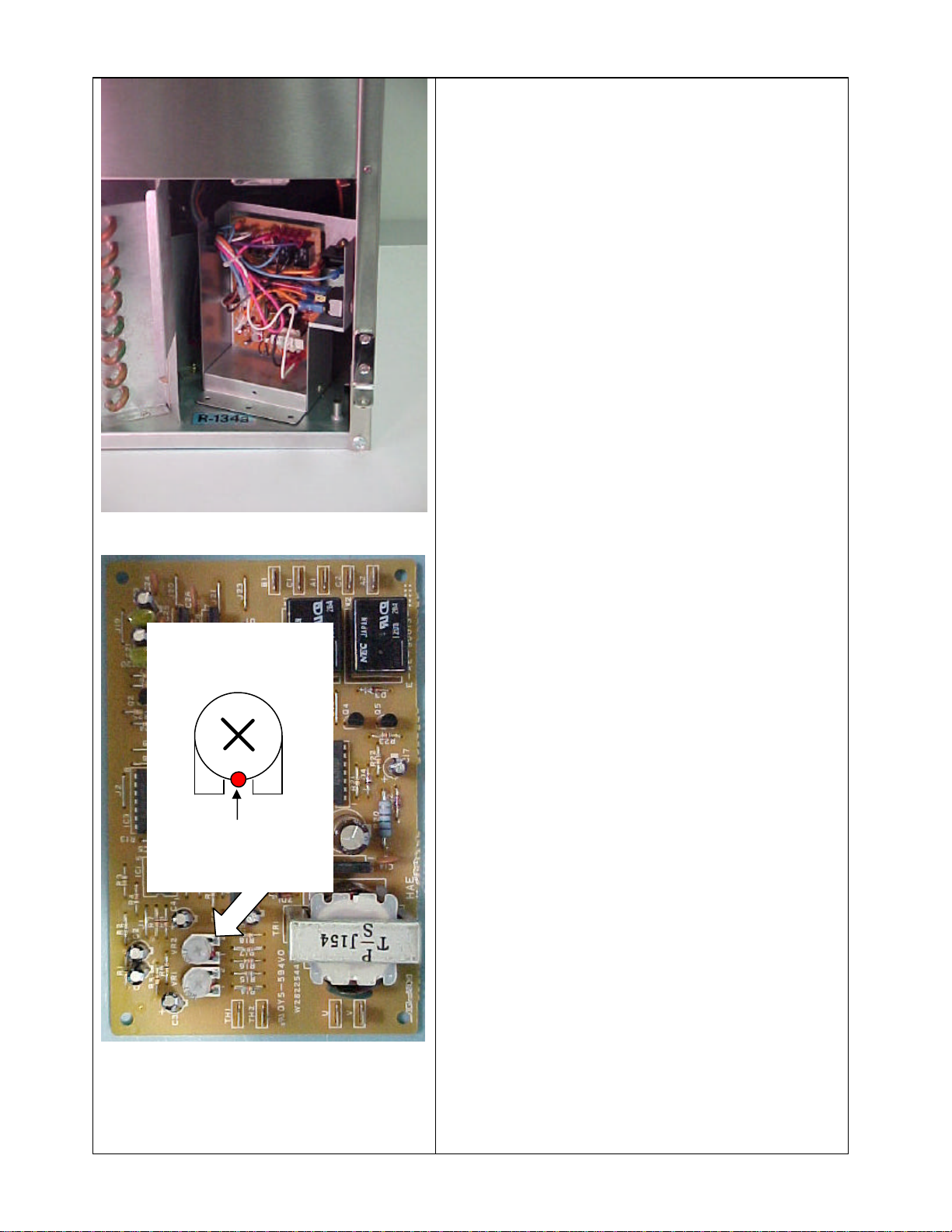

CONTROL BOARD:

A solid state board controls the AM

operation. The control board is factory

adjusted to produce consistent ice in all

ambient conditions.

“NO SEASONAL

ADJUSTMENTS ARE

REQUIRED”

There are no adjustments needed, however

VR1 & VR2

are factory adjusted.

Red paint seals the

setting for VR1 &

VR2 at this point.

there are two variable resistors on the control

board. The first resistor VR1 is used to fine

tune the harvest termination temperature

adjustment when the control board is

manufactured. The adjustment is sealed with

red paint and should always remain in the

factory setting.

VR2 is set from the factory so that the ice

machine will perform at the optimum level.

This resistor adjusts the freeze cycle

termination setting so the proper cube size is

obtained. The VR2 setting is also sealed with

red paint and should not be changed.

If you find that the red seal is broken, the

board will need to be replaced since these

settings cannot be correctly adjusted in the

field. The replacement board will be factory

set and sealed for proper operation.

- 10 -

Page 11

Preventative maintenance for the AM is

simple. Follow these steps to allow the unit

to operate efficiently.

1. Clean the condenser once a year using a

brush or vacuum.

2. Check and clean the inlet water valve

screen as needed to assure proper water

flow.

*Remember that the original fitting is a 3/4” BSP

and the use of a standard MPT fitting will

damage the threads. In May of 2003, this fitting

was changed to 3/8” male flare. After August

and September of 2003, this fitting was changed

to a 1/2" FPT.

3. Clean and sanitize the water distribution

system annually using the recommended

cleaner. (See the next page for detailed

information on cleaning the water

system)

4. Wipe down the exterior using a soft cloth

and neutral cleaner.

The AM ser ies uses a magnetic pump. This

style of pump allows the water portion of the

pump to be completely sealed from the

motor. This eliminates the need for a

mechanical seal and eliminates the

possibility of water entering the pump

through the pump end.

If the pump does not pump and is being

energized then remove the four screws from

the front of the pump and check for any

debris that may be binding the impeller

- 11 -

Page 12

Cleaning tips:

• A detailed cleaning label is located on the

back of the icemaker door of the AM50BAE or on the back of the bin baffle of

the AM-100 & AM-150. More detailed

instructions are included in the customers

Instruction Manual or in the product

Service Manual. This manuals can be

viewed at www.hoshizaki.com

• Always follow the cleaning instructions

and use the recommended ice machine

cleaner.

The following instructions provide

information on the disassembly of the water

Water circuit disassembly

circuit. Before starting these steps it will be

necessary to remove the hinged slope from

the pins at the front edge of the bin.

Remove each Separator by lifting it to the

horizontal position and pushing it hard

inward. Remove all the separators the same

way, clean and sanitize them

- 12 -

Page 13

(AM

-

50)

(AM

-

100 & AM

-

150

)

(AM

-

50BAE)

Disconnect the suction tube that connects

the pump motor to the sump tank.

The AM -50BAE has a locking tabs that can

be released by compressing both plastic tabs

to unlock the joint in the direction of the

black arrows and pulling the pipe clear to

drain the Tank.

AM-100BAE & AM-150BAF simply pull

the pipe of the connector

AM-50: Spread out the tabs on both sides to

unlock the water tank, and pull it out toward

you. Clean and sanitize the water tank.

AM-100 & AM-150: Remove the

thumbscrews on both sides of the water tank

and pull it out toward you. Clean and

(AM-100 & AM-150)

sanitize the water tank

- 13 -

Page 14

(AM

-

50)

AM-50BAE: Lift off the ice chute from the

front frame pipe and then from the rear

frame pipe clean and sanitize the ice chute

The AM-100 & AM-150: ice chute is

incorporated into the wat er plate and will be

removed as one assembly in the next step.

Check to see if cube guide pulls out with

sump tank

Pull the discharge tube from the spray

assembly. Remove the assembly by pulling

it toward you.

(AM-100 & AM-150)

(AM-50)

Remove the caps to clean and sanitize the

spray assembly. If the nozzles are clogged,

clean them with a small wire or suitable

brush.

(AM-100 & AM-150)

- 14 -

Page 15

(AM

-

50)

(AM

-

50)

Refit the caps on the cleaning outlets to seal

them off.

(AM-100 & AM-150)

AM-50: Slide in the spray assembly along

the rails on the right and left brackets. Refit

the discharge tube securely on the spray

outlet. Note: A loose fitting may cause a

water leak and improper water spray during

freeze.

AM-100 & AM-150: Slide the water plate

(AM-100 & AM-150)

along the mechanism base. Refit the

discharge tube securely on the spray outlet.

A loose fitting may cause a water leak.

- 15 -

Page 16

(AM

-

50)

AM-50: Position and lock the ice chute on to

the front and rear frame pipes by pushing the

chute down until it clicks

AM-100 & AM-150: Place the rear of the

water tank on the water tank rest at the back

of the storage bin. Use the thumbscrews to

secure the front of the water tank to the

mechanism base.

(AM-100 &AM-150)

AM-50: Slide in the water tank along the

rails at the bottom of the right and left

brackets until it clicks into place

- 16 -

Page 17

(AM-50)

AM-50BAE: Refit the suction tube on to the

water tank inlet by pushing the joint to lock

it securely in the arrow directions.

The AM-100 & AM-150 uses a simple push

on suction hose.

Note: A loose fitting may cause a water

(AM-100 & AM-150)

leak.

Hook each separator on the rail and pull it

hard toward you until it locks in place with a

click. Refit all the separators in the same

way.

Refit the bin slope in its correct position

- 17 -

Page 18

AM

-

50BAE

- 18 -

Page 19

- 19 -

Page 20

- 20 -

Page 21

Electrical Specifications:

AM-50BAE

The unit is 115 volt/ 60 hz. /1ph.

The AM-Series should be connected to a separate 15Amp circuit.

- 21 -

Page 22

Electrical Specifications:

AM-100BAE

The unit is 115 volt/ 60 hz. /1ph.

The AM-Series should be connected to a separate 15Amp circuit.

- 22 -

Page 23

Electrical Specifications:

AM-150BAF

The unit is 115 volt/ 60 hz./1ph.

The AM-Series should be connected to a separate 15Amp circuit.

- 23 -

Page 24

High side process tube

Thermistor

AM-50BAE R

-

134a 4.2 oz

AM-50BAE & AM-100BAE

AM-100BAE R-134a 6.6 oz

Low side process tube

Note: All Hoshizaki ice machines are critically charged. Since the AM- series have small refrigeration circuits and the AM100 and AM-150 use cap tube systems this is especially true. The AM- series does not come from the factory with any type

of refrigeration system access. In the event that the system must be accessed for troubleshooting it will be necessary to

install piercing type “saddle valve” on the system. These valves should only be installed on the process tubes provided on

the low side and high side of the system. After the repair has been made to the unit, sweat type schraders should be installed

in place of the piercing valves.

Again, these units are critical charged. Every precaution should be taken to insure that the exact charge of R134a for the

AM-50 and AM-100 and R-404a for the AM-150 is weighed into the system. Due to the very small charge of these units ,

extra care must be taken to avoid any refrigerant loss when removing gauges.

- 24 -

Page 25

AM

-

150BAF

system. These valves should only be installed on the process tubes provided on the low side and high side of the system.

High side process tube

WATER AND REFRIGERATION CIRCUIT

AM-150BAF 9.5oz R-404a

Low side process tube

Note: All Hoshizaki ice machines are critically charged. Since the AM-series have small refrigeration circuits this is

especially true. The AM-series does not come from the factory with any type of refrigeration system access. In the event

that the system must be accessed for troubleshooting it will be necessary to install piercing type “saddle valve” on the

After the repair has been made to the unit, sweat type schraders should be installed in place of the piercing valves.

Again, these units are critical charged. Every precaution should be taken to insure that the exact charge of R134a for the

AM-50 and AM-100 and R-404a for the AM-150 is weighed into the system. Due to the very small charge of these units,

extra care must be taken to avoid any refrigerant loss when removing gauges.

- 25 -

Page 26

Freeze time

= T

hermistor reads 26.6º

F (-3ºC) then completes 8 minute Freeze cycle comple

tion timer

.

Harvest time = Thermistor reads 44.6ºF (+7ºF) then completes 50 second defrost completion timer.

- 26 -

Page 27

SERVICE DIAGNOSIS

- 27 -

Page 28

- 28 -

Page 29

- 29 -

Page 30

AM SERIES REVIEW QUIZ

Choose the best answer for each question below.

1. The AM control board is located in the rear or the unit.

True False

2. The AM unit uses a thermostatic bin control.

True False

3. The bin control switch must OPEN or CLOSE to shut the unit down?

4. The AM-150BAF series uses R-404a or R-134a refrigerant.

5. The AM Series only uses one thermistor located on the evaporator?

True False

6. The freeze cycle is temperature and time terminated.

True False

7. On the initial freeze cycle the water valve will remain open for 50 seconds.

True False

8. The water valve will remain energized for the entire harvest cycle regardless of

how long.

True False

9. The AM-50BAE makes a square cube.

True False

NOTE: Quiz answers are at the bottom of next page.

- 30 -

Page 31

(NOTES)

Quiz answers:

1.False, 2. True, 3. Open, 4. R-404a, 5. True, 6. True, 7. True, 8. False., 9. False

- 31 -

Loading...

Loading...