Page 1

ISSUED: JAN. 22, 2 003

REVISED: JUN. 20, 2005

HOSHIZAKI

SELF-CONTAINED CUBER

MODEL

AM-100BAE

AM-150BAF

AM-150BWF

INSTRUCTION MANUAL

Page 2

FOREWORD

IMPORTANT

Only qualified serv ice technicians should attempt to install, ser vice or maintain this

icemaker. No such installati on, service or maintenance shoul d be undertaken until

the technician has thoroughl y read this Instruction Manual . Likewise , the owner/

manager should not pr oceed to operate the icemaker unti l the installer has

instructed them on its proper operati on.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

installation, maintenance and service of the icemaker.

Should the reader hav e any question s or concerns which have not been satisfactorily

addressed, please call or write to the H OSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtre e Cit y, GA 30269

Attn: HOSHIZA KI Technical Support Department

Phone: 1-800-233-1940 Technical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE:

To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

Page 3

IMPORTANT

1. This bookl et is an integral and essential part of the pr oduct and should be

handed over t o the user . Read the warning s contained in thi s booklet carefully

as they give important indications regarding the safety of the installation, use

and maintenance. Please preserv e this booklet for any further consultation

that may be necessar y .

2. This icemaker should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for

eventual damage c aused by impr oper , incor rect and unreasonabl e use.

CONTENTS

I. GE NERAL INFORMA TI ON ----------------------------------------------------------------------------1

1. CO NSTRUCT ION------------------------------------------------------------------------------------1

[a] AM-100BAE --------------------------------------------------------------------------------------1

[b] AM-150BAF --------------------------------------------------------------------------------------2

[c] AM-150BWF --------------------------------------------------------------------------------------3

II. I NST ALLA TIO N A ND OPE RA TING IN STRUCT IONS -------------------------------------------4

1. CHECKS BEFORE INSTALLATION------------------------------------------------------------4

2. LOCA TI ON --------------------------------------------------------------------------------------------5

3. SET UP ------------------------------------------------------------------------------------------------6

4. ELECTRICAL CONNECTIONS ------------------------------------------------------------------6

5. WA TER SUPPLY AN D DR AIN CONN ECTIONS ---------------------------------------------7

6. FINAL CH ECK LIST---------------------------------------------------------------------------------9

7. ST ART UP---------------------------------------------------------------------------------------------9

8. PREP ARING THE ICEM AKER FOR LONG STOR AGE (more than 1 day)---------- 10

III. MAINTENANCE AND CLEANING INSTRUCTIONS -----------------------------------------12

1. CL EANING IN STRUCTI ONS--------------------------------------------------------------------12

[a] WA TER SYSTEM------------------------------------------------------------------------------12

[b] STORAGE BIN, SLOPE, SCOOP, ETC.-------------------------------------------------13

2. MAINTENAN CE------------------------------------------------------------------------------------ 16

PAGE

SERV ICE INSTRU CTIONS---------------------------------------------------------------------------- 17

Page 4

I. GENERAL INFORMATION

1. CONSTRUCTION

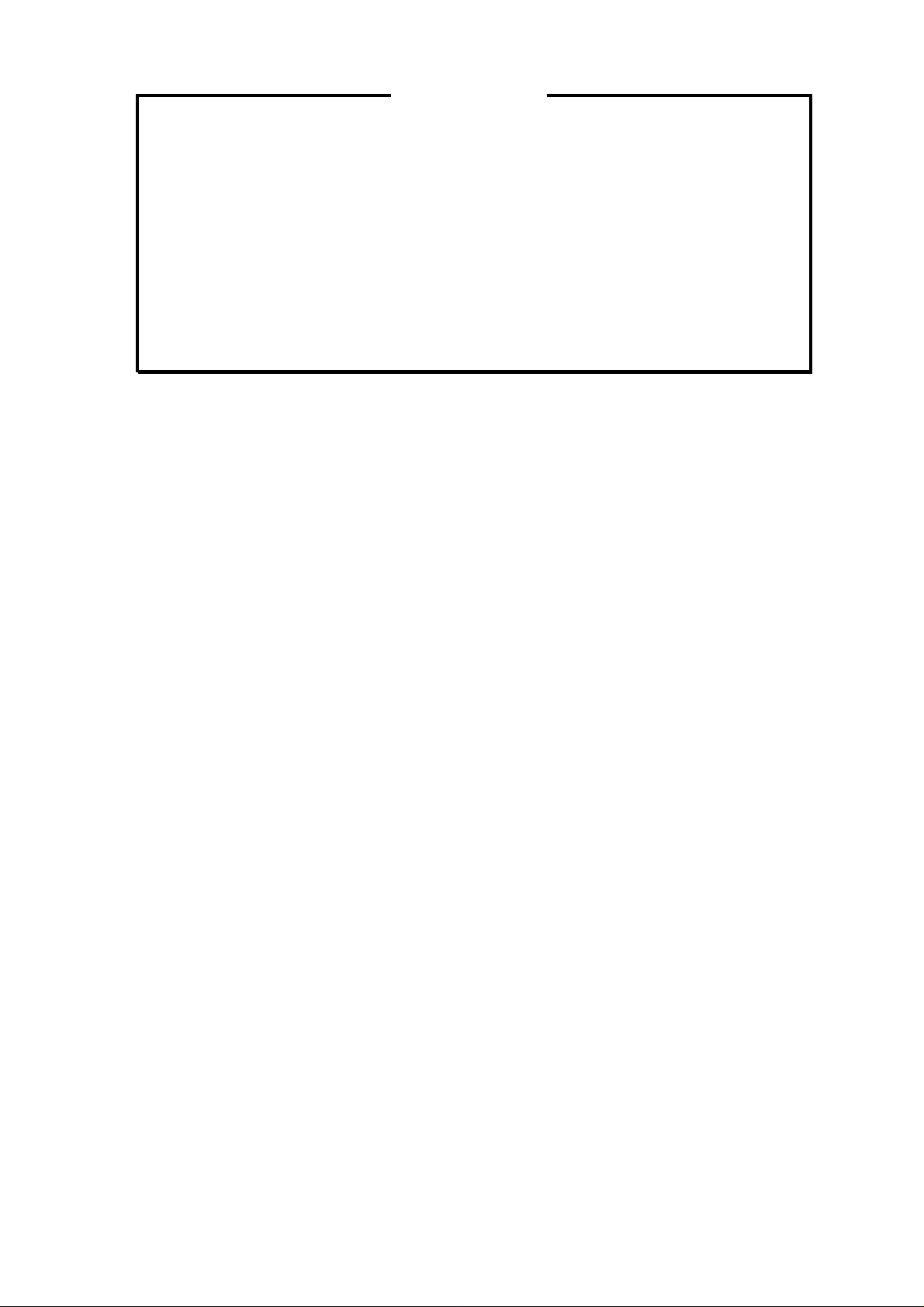

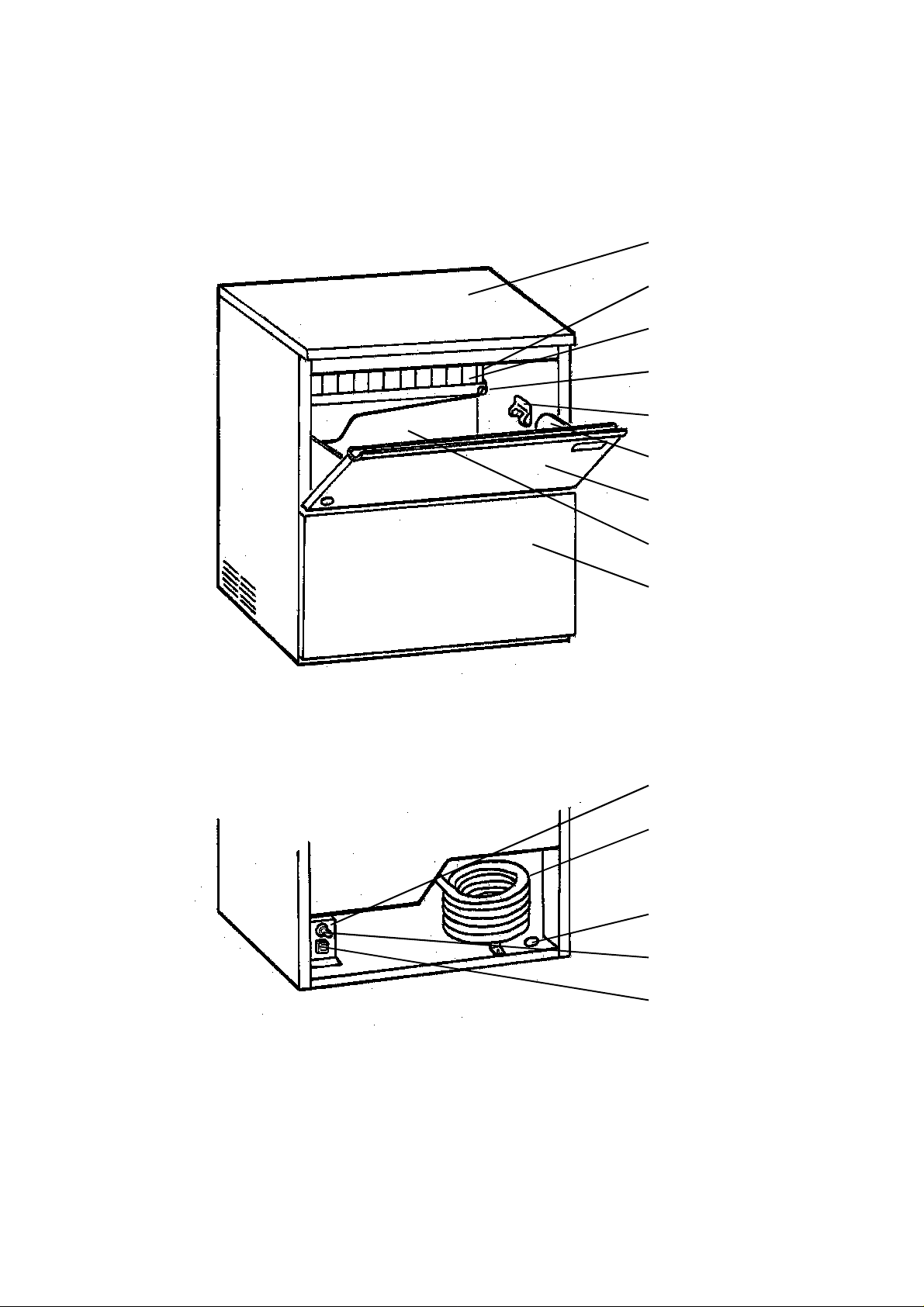

[a] AM-100BA E

Top Panel

Front Panel (Upper)

Ice Making Mechanism

Bin Control Thermostat

Storage Bin

Slope

Door

Front Panel (Lower)

Control Box

Condenser

Air Filter

Tapped Hole (Leg Moun ting)

Control Switch

Fuse

1

Page 5

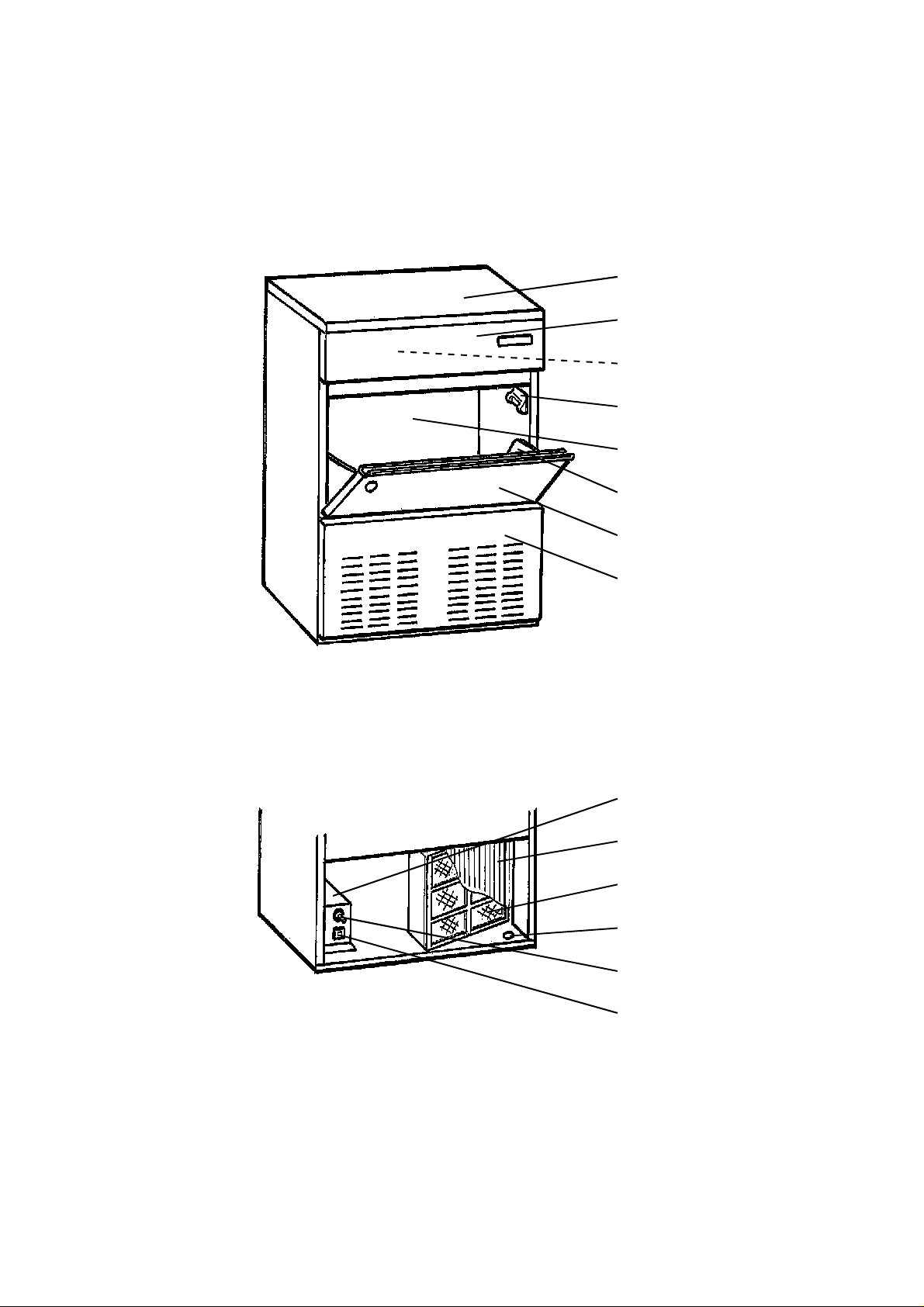

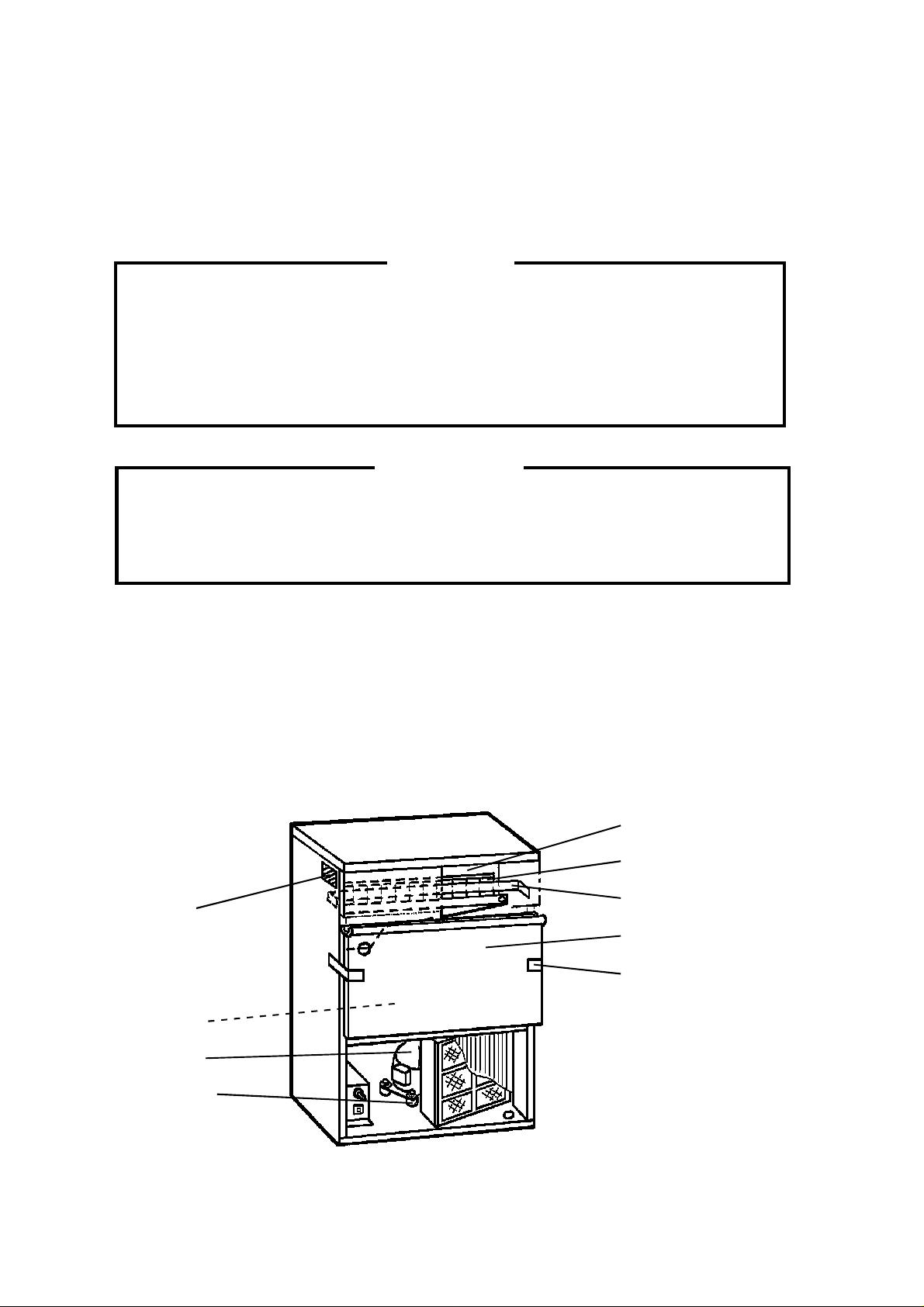

[b] AM-150BA F

Top Panel

Ice Making Mechanism

Separator

Water T ank

Bin Control Thermostat

Slope

Door

Storage Bin

Front Panel (Lower)

Control Box

Condenser

Air Filter

Tapped Hole (Leg Moun ting)

Control Switch

Fuse

2

Page 6

[c] AM-150BWF

Top Panel

Ice Making Mechanism

Separator

Water T ank

Bin Control Thermostat

Slope

Door

Storage Bin

Front Panel (Lower)

Control Box

Condenser

Tapped Hole (Leg Moun ting)

Control Switch

Fuse

3

Page 7

II. INSTALLATION AND OPERATING INSTRUCTIONS

1. CHECKS BEFORE INSTALLATION

* Visually inspect the exterior of the shipping container , and any severe damage noted should

be reported to the carrier.

W ARNING

1. Remove shipping t ape(s) and pack ing as fol lows . If any left i n the icem aker ,

it will not w ork proper ly .

2. Do not lift or carry t he unpacked ic emaker by us ing the bra ss fitting for water

supply at the r ear of the unit. The plasti c threads may be damaged.

IMPORTANT

1. Remove the shipping tapes holding the Door and Separator.

2. Ensure all components, fasteners an d thumbscr ews are securely in pl ace.

* Remove the package containing accessories.

* Check that refrig erant lines do n ot rub or touch li nes or other sur faces.

* Check that the Compr essor is snug on all mounting pads.

* See the Nameplate on the upper right part of the Left Side Panel, and check tha t your

voltage supplied cor responds with the voltage speci fied on the Nameplate.

Ice Making Mechanism

Separator

Nameplate

Shipping T ape

Door

Shipping T ape

Accessories

Compressor

Mounting Pad

Fig. 1

4

Page 8

2. LOCATION

W ARNING

This icemaker is not intended for outdoor use. Normal operating ambient

temperature should be within 50°F (10°C) to 100°F (38°C); Normal operating

water temp er a t ure should be within 41°F (5°C) to 90°F (32 °C). Operation of

the icemaker , for extended periods, outside of these normal temperature ranges

may affect production capaci ty .

For best operating results:

* The icemaker should not be located next to ovens, grills or other high heat producing

equipment.

* The location should provi de a firm foundation for the equipment. Lev el the i cemaker from

side to side and front to rear.

* Avoid a site w here drippi ng i s not allow ed.

* This icemaker will not work at subfreezing temperatures. To prevent damage to the water

supply line, drai n the icemaker when ai r temperature is below zero.

* The AM-100BAE icemaker requires no clearance at either side. But allow enough space

at rear for water supply and drain connections, at least 12” (approx. 30 cm) clearance at

front, and at least 0.6” (approx . 15 mm) cleara nce at top for main tenance.

* The AM-150BAF icemaker r equires 2” (approx . 5 cm) clearance at either side. Allow enoug h

space at rear for water supply and drain connections, at least 12” (approx. 30 cm) clearance

at front, and at least 0.6” (a pprox. 15 mm) cle arance at top for mai ntenance.

5

Page 9

3. SET UP

IMPORTANT

Do not place heavy objects exceeding 33 l bs (15 kg) on the Top Panel.

1) Unpack the icemaker, and remove all shipping cartons, tapes

and packing BEFORE operating the unit.

2) Position the i cemaker in a selected site. Clean the interior

with soap and w ater and rin se thoroughl y .

3) Level the ic emake r in bo th the l eft- to- r ig ht an d t he fr ont- t orear directions (when installed with or without legs). See Fig.

2.

4) When installing the unit without legs, the perimeter where the

machine touches the counter shoul d be sealed wi th silicone

to prevent wate r from leaking under the icemak er .

Max. 0.4” (1 c m)

Fig. 2

T apped Hole

(Leg Mounting)

5) When installin g the unit with legs on the botto m, use the four

accessory legs adjustable from 6” (15.2 cm) to 7” (17.8 cm).

Screw the legs tightly i nto the tapped holes in th e base (see

Fig. 3). Handle the icemaker carefully not to damage the

exterior.

Base

Adjustable Leg

Fig. 3

4. ELECTRICAL CONNECTIONS

W ARNING

THIS APPLIANCE MUST BE GROUNDED.

This icemaker requires a ground that meets the national and local electrical

code requirements. To prevent possib le severe electrical shock injury to

individuals or extensive damage to eq uipment, install a proper ground w ire to

this icemaker . Remove the plug from the mains socket before any maintenance,

repairs or cleaning is undertaken.

* This icemaker must be plug g ed i nto the separated power receptacle which has eno ugh

capacity. The maximum allow able vol tage v ariation should not exceed ± 10 percent of the

nameplate rating. See the Namepl ate.

* Usually an electrical permit and serv ices of a licensed electrician ar e required.

6

Page 10

5. WATE R SUPPLY AND DRAIN CONNECTIONS

W ARNING

To prevent damage to the freezer mechanism, do not operate this icemaker

when the w ater suppl y is OF F, or if the pr essure is below 10 PSIG (0. 7 bar), the

recommended water pressure. St op the icemaker until pr oper water pr essure

is resumed.

CAUTION

1. A brass fitting for the water supply line connection is attached to the 3/4” BSP

plastic threads to avoid cross-threading of the Water Valve possibly resulting

in leaks. The brass fitting allows connection of a 1/2” FPT that should be

connected to the potable w ater supply lin e.

2. While making the water supply line connection, use a wrench to hold the

brass fitting still to prevent overtightening and damage to the plastic threads.

* Water supply inlet for the i cemaker is 1/2” female pipe t hread (FPT).

Note: On water-cooled model, two water supply inlets are pro vided. One is for the i cemaker

(1/2” FPT), and the other is for the water -cooled condenser (1/2” FPT).

* The brass fitting is attached as shown in Fig. 4. The fitting size is a 1/2” FPT and must be

connected only to a pot able water supply.

* A water supply line shut-off valve and drain valve must be installed.

* Water supply pressure should be a mini mum of 10 PSIG (0.7 bar) and a maximum of 113

PSIG (7.5 bar). If the pressure exceeds 113 PSIG (7.5 bar), use a pressure reducing valve.

* Drain outlet for icemaker dump is 3/4” FPT.

Note: On water-cooled model, a 3/8” FPT is pr ovided for the con denser drain outlet. The

icemaker drain and the condenser drai n piping connecti ons must be made separate ly .

* Drain must be 1/4” fall per foot (2 cm fall per meter) on horiz ontal run s to get good flow.

* Keep a more than 2 vertical inch (5 vertical cm) air gap between the drain pipe end and the

sink.

* The drain pipe must be so laid as to prevent a backflow into the Storage Bin. Provide a trap

in the bin drain li ne to prev ent odor from flowi ng back into the S tor age Bin.

7

Page 11

* A plumbing permit and services of a licensed plumber may be required in some areas.

* This icemaker should be installed in accordance with applicable national, state and local

regulations.

AM-100BAE

AM-150BAF

Icemaker

Trap

1/4” fall per foot

Water Supply Inlet

3/4” BSP Threads

Brass fitting is attached

to Water Supply Inlet.

Fitting size is a 1/2” FPT.

Shut-off V alv e

Drain V alve

Bin Drain Outlet

3/4” FPT

AM-150BWF

Condenser Outlet

3/8” FPT

Water-cooled

Condenser Inlet

1/2” FPT

Drain V alve

T o approved floor drain

Icemaker

Water Supply Inlet

3/4” BSP Threads

Brass fitting is attached

to Water Supply Inlet.

Fitting size is a 1/2” FPT.

Shut-off V alve

Drain V alve

Bin Drain Outlet 3/4” FPT

1/4” fall per foot

T o approved floor drain

Shut-off V alv e

Trap

Fig. 4

8

Page 12

6. FINAL CHECK LIST

1) Is the icemaker lev el?

2) Is the icemaker in a site where the ambient temperature is within 50°F (10°C) to 100°F

(38°C) and the water temperature withi n 41°F (5°C) to 90°F ( 32°C) al l year ar ound?

3) Have all shipping tape(s), string and packing been removed from the icemaker?

4) Are all components, fastener s and thumbscrews se curely in place?

5) Have all electr ical and piping connections been made?

6) Has the power supply voltage been tested or checked against the nameplate rating?

Has a proper earth been installed to the icemaker?

7) Are the Water Supply Line Shut-off V alve and D rain V alve installed? Has the water supply

pressur e been che ck ed to en su re a mi ni mum o f 10 P SI G (0 .7 bar ) and a ma x i mum of

1 13 PSIG (7.5 bar)?

8) Have the Compressor hold-down bol ts and all refriger a nt l i ne s been check ed ag a i nst

vibration and possible failure?

9) Has the Bin Control Thermostat been checked for correct operation? When the icemaker

is running, cool the Detector of the Bin Control Thermostat. The icemaker should stop

within 10 seconds.

10)Has the user been given the Instr uction Manual and instructed on how to operate the

icemaker and the importance of periodic maintenance recommended?

11) Has the user been given the name and telephone number of the Autho rized Service

Agency?

7. START UP

* Check that shipping tape(s), str ing and packing are r emoved before starting the i cemaker .

1) Clean inside the Storage Bin and Door.

2) Open the Water Supply L ine Shut-of f V alv e and plug in the ice maker .

3) Remove the Fr ont Panel ( Lower) , and move the Control S witch on the Control Box t o the

“ICE” position.

* The freezing cycle w ill start automatically.

9

Page 13

8. PREPARI NG THE ICEM AKER FOR LONG STORAGE (more t han 1

day)

W ARNING

Drain the icemaker to prevent damage to the water supply line at subfreezing

temperatures, using air or carbon dioxide. Shut off the icemaker until proper air

temperature is resumed.

[1] On water- cooled model o nly, first remov e the wat er from the w ater-cool ed condenser:

1) Remove th e Front Panel (L ower).

Icemaker

2) Move the Control Switch, on the Control

Box, to the “OFF” position.

Potable Water

Supply Line

3) Wait 3 mi nutes.

Shut-off V alv e

4) Move the Control Switch to the “ICE”

position.

5) Allow 5 mi nutes for the icemaker to fill with

water and the Water Pump to start

operating.

6)Close the Water-cooled Condenser

Air or CO

Water-cooled Condenser

Water Supply Line

Drain V alve

2

Shut-off V alve

Water Supply Line Shut-off Valve.

7) Open the Drai n Val ve for the water- cooled

condenser w ater supply line.

8) Allow th e line to drai n by grav ity.

Air or CO

Fig. 5

Drain V alve

2

9) At tach co mpres sed air or carbon dioxide supply to the Co ndens er Wate r Line Drain

Valve.

10) Blow t he water- cooled condenser out usin g compres sed air or carbon diox ide until water

stops coming out.

[2] Remove t he wa ter from the potable water supply line and the Water Tank:

1) Close the Water Supply L ine Shut-of f V alv e, and open the D rain Valve.

2) Remove the Front Panel (Lower), and move the Control Sw itch, on the Control Box, to the

“OFF” position.

10

Page 14

3) Blow ou t the water sup ply lin e.

Note: This procedure i s necessary to protect the icemaker from freez ing up at subfreezing

temperature.

4) Unplug t he icemaker .

5) Remove all ice from the St orage Bin, and clean the Bin.

6) Drain an d clean the Water Tank . See “III. 1 . [b] STOR AGE BIN, SLO PE, SCOOP, ETC.”

7) Refit the Front Panel (Lower) in its correct posit ion.

8) Close the Drain Valve.

11

Page 15

III. MAINTENANCE AND CLEANING INSTRUCTIONS

IMPORTANT

Ensure all components, fastener s and thumbs crews ar e securely in place a fter

any maintenance or cleani ng is done t o the equi pment.

1. CLEANING INSTRUCTIONS

W ARNING

1. HOSHIZAKI recommends cleaning this unit at least once a year. More

frequent cleaning, however, may be required in some existing water conditions.

2. To prevent injury to individuals an d damage to th e icem aker, do not use

ammonia type cleaner s.

3. Always wear liquid-proof gloves for safe handling of the cleaning and sanitizing

solutions. This will prevent irritation in case the solution comes into contact

with skin.

[a] W ATER SYSTEM

1) Dilute approx imately 5 fl. oz . (148 ml) of recommended cl eaner Hoshiz aki “Scal e Away ”

or “LIME-A -WA Y ” (Economics Laborator y , Inc.) w ith 1 ga l. (3.8 li t.) of wat er .

2) Remove all i ce from the Evaporator and the Storage Bi n.

Note: To remove cubes on the Evaporator, remove the Front Panel (Lower), move the

Control Swi tch on the Cont rol Bo x to the “OF F” posi tion and mo v e it bac k to the

“ICE” position after 3 minutes. The defrost cycle starts and the cubes will be

removed from the Evap orator .

3) Move the Control Switch to the “OFF” po si t i on. Close the Water Supply Line Sh ut- o ff

Valve.

4) Remove the Water Tank to drain the water . Refit the Wa ter Tank in its correct positi on.

5) Slowly pour the cleaning solution into the Water Tank.

6) Move the Control Switch to the “WASH” position.

7) After circulating the cleaning solution for about 30 minutes, move the Control Swi tch to the

“OFF” position.

12

Page 16

8) Remove the Water T ank to drain the cleaning solution. Refit the Water T ank in it s correct

position.

9) Open the Shut-off Valve.

10) Move the Control Switch to the “WA SH” position to circulate clean water for a bout 5

minutes.

11) Move the Control Switch to the “OFF” position and immediately back to the “WASH”

position to rinse water .

12) Repeat the above ri nse procedure three more times to rin se thoroughly.

13) Dilute approximately 0.5 fl. oz. (14.8 ml) of 5.25% Sodium Hypochlorite (Chlorine Bleach)

with 1 gal. (3.8 lit.) of water.

14) Move th e Control Switch to the “ OFF” position. Close the Water Supply Line Shut-o f f

Valve.

15) Remove the Water Tank to drain the water . Refit the Water Tank in its correct positi on.

16) Slowly pour the san itizing solution in to the Water Tank.

17) Move the Control Switch to the “WASH” posi tion.

18) After circulating the sani tizing sol ution for about 15 minutes, move the Control Switch to

the “OFF” position.

19) Remove the Water T ank to drain the sanitizing solution. Refit the Water T ank in it s correct

position.

20) Open t he Shut-of f V alv e.

21) Move the Control Switch to the “WA SH” position to circulate clean water for a bout 5

minutes.

22) Move the Control Switch to the “OFF” position and immediately back to the “WASH”

position to rinse water .

23) Repeat the above rinse procedur e two more times to rinse thoro ughly.

24) Move the Control Switch to the “ICE” position, and start the automatic icemaking process.

Refit the Front Panel (Lower) in its correct position.

13

Page 17

[b] STORAGE BIN, SLOPE, SCOOP, ETC.

IMPORTANT

1. Wash your hands before removing ice. Use the Plastic Scoop provided to

remove ice.

2. Keep the Scoop clean. Clean i t by using a neutra l cleaner at least once a

day , and rinse thoroughly.

3. Close the Bin Door after removing ice to prevent entrance of dirt, dust or

insects into the Bin.

4. Clean the Bin Liner at least onc e a month by using a neutral cleaner. Rinse

thoroughly after cleaning.

5. The S torag e Bin is for ice use only. Do not store anything el se in the Bin.

6. Keep the area around the ic emaker clean. Dirt, dust or insects in the icemaker

could cause electrical damage to the equipment or harm to individual s.

1) Remove the Fr ont Panel (Low er), and move the Contr ol Swi tch on the Contr ol Box to the

“OFF” position.

2) Unplug the ic emaker .

3) Open the Bin Door , and remove ice from the S torage Bi n.

4) Remove the Slope by bending its center carefully and releasing it from th e two Slope

Shafts. Take out the Slope from the Sto rage Bin.

5) Thoroughly clean and sanitize the Storage Bin, Slope, Scoop and any parts normally

accessible from the Storage Bin.

6) Remove each Separator by lifting it to the

Separator

horizontal position and pushing it hard inwa rd.

Remove all the Separators in the same way,

and clean and san itize them.

7) Disconnect the Suction Tube from the Water

T ank to drain the T ank.

14

Water Tank

Suction Tube

Page 18

8) Remove the Thumbscrews on both sides of the

Water Tank, and pull it out toward you. Clean

and saniti ze the Wat er Tank.

Water Tank

Thumbscrew

9) Pull the Discharg e Tu be from the Water Plate.

Remove the Water Plate by pulling it toward you.

10) Remove the Caps to clean and sanitize the

Water Plat e. If the Noz zles are clogg ed, clean

them with a wir e or a suitable brush.

1 1) Refit the Caps on the C leaning Outlet s to seal

them off.

12) Slide in th e Water Plate al ong the M echanism

Base. Refit the Discharge Tube securely on

the Spray Outlet. A loose fitting may cause a

water leak.

Water Pla t e

Discharge Tube

Cap

Water Pla t e

Cap

Water Pla t e

Water Pla t e

13) Place th e rear of the Water Tank on the Water

Tank Rest at the bac k of the S torag e Bin. U se

the Thumbscrews to secure the f ront of the

Water Tank to the Mechanism Base.

14) Refit the Suction T ube on to the Water T ank Inlet.

A loose fitting may cause a water leak.

15

Water Tank

Mechan ism Ba se

Thumbscrew

Discharge Tube

Bin Rear

Tank Rest

Water Tank

Suction Tube

Page 19

15) Hook each Separator on to the Mechanism

Base, and pull it hard toward you until it locks in

place with a click. Refit all the Separators in

the same way.

16) Refit the Slope in its correct position.

17) Plug in the icemaker , and move the Contr ol Switch on the Control Box to the “ ICE” position

to start the automatic icemaking process.

18) Refit the Front Panel (Lower) in its correct position.

Separator

2. MAINTENANCE

IMPORTANT

This icemaker must be maintained indi vidually , referring to the instruction manual

and labels provided wi th the icemaker .

1) Exterior

To keep the exte rior cl ean, wi pe occasiona lly w ith a cl ean and soft cloth. U se a damp

cloth containing a neut ral cleaner t o wipe off all oil or dirt buil d-up.

2) Air F ilt er

A pla stic mesh air fil ter remov es di rt or dust from the air, and keeps the Condenser

from getting clogged. As the filter gets clogged, the icemaker’s performance will be

reduced. Check the filter at least twice a month. When clogged, use warm water and

a neutral cleaner to wash the filter.

3) Condenser

Check the Condenser once a year, and clean if required by us ing a brush or v acuum

cleaner. More frequent cleaning may be required dependi n g on the location of the

icemaker.

16

Page 20

(

)

A

Bin Control Thermostat Replacement Procedure

To ensure proper operation, follow the instructions below:

[AM-100BAE]

1) Make a 40 mm (1.6”) diameter loop.

2) Locate the loop below the Thermostat

Capillary (Bulb).

3) Manually bend the Capillary to keep it

15 mm (0.6”) forward from the through

hole position on the Holder.

4) Turn up the end of the Capillary.

Through Hole

Loop

40 mm (1.6”) DIA

Bin Control Thermostat Assembly Details

[NOTE]

1) Run Cord Heater along with Capillary of Thermostat and bind them tightly with

Aluminum Tape (Form end to end of Cord Heater).

2) Do not overheat Flexible Tube during shrinking process.

Capillary (Bulb)

Thermostat

Cord Heater

Flexible Tube

SERVICE INSTRUCTIONS

[AM-150BAF/BWF]

1) Make a 40 mm (1.6”) ID U-bend.

2) Locate the U-bend 60 mm (2.4”) below

the Thermostat Ca pillary (Bulb).

3) Manually bend the Capillary to keep it

15 mm (0.6”) forward from the through

hole position on the Holder.

4) Turn up the end of the Capillary.

Holder

Capillary (Bulb)

End

15 mm (0.6”)

Silicone Tube

DETAIL A

Through Hole

60 mm (2.4”)

40 mm (1.6”)

Silicone Tube

17

Seal

Capillary (Bulb)

150mm

210mm

Bracket - Holder

Holder

Capillary (Bulb)

End

15 mm (0.6”)

Capillary (Bulb)

(5.9”)

8.3”

Page 21

HOSHIZAKI AMERICA, INC.

618 HIGHWAY 74 SOUTH

PEACHTREE CITY , GA 30269

U.S.A.

PHONE: 770-487-2331

www.hoshizakiamerica.com

9117EA10H

Loading...

Loading...