Hoshizaki AM-100BAE, AM-150BAF, AM-150BWF Manuel de service

NO. 17EA-622 / 73106

ISSUED: FEB. 25, 2003

REVISED: JAN. 12, 2007

HOSHIZAKI

SELF-CONTAINED CUBER

MODEL AM-100BAE

AM-150BAF

AM-150BWF

SERVICE MANUAL

IMPORT ANT

Only qualified service technicians should attempt to service or maintain this icemaker.

No such service or maintenance should be undertaken until the technician has

thoroughly read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the service

and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: HOSHIZAKI Technical Support Dep artment

Phone: 1-800-233-1940 Technical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

CONTENTS PAGE

I. SPECIFICA TIONS ------------------------------------------------------------------------------------- 1

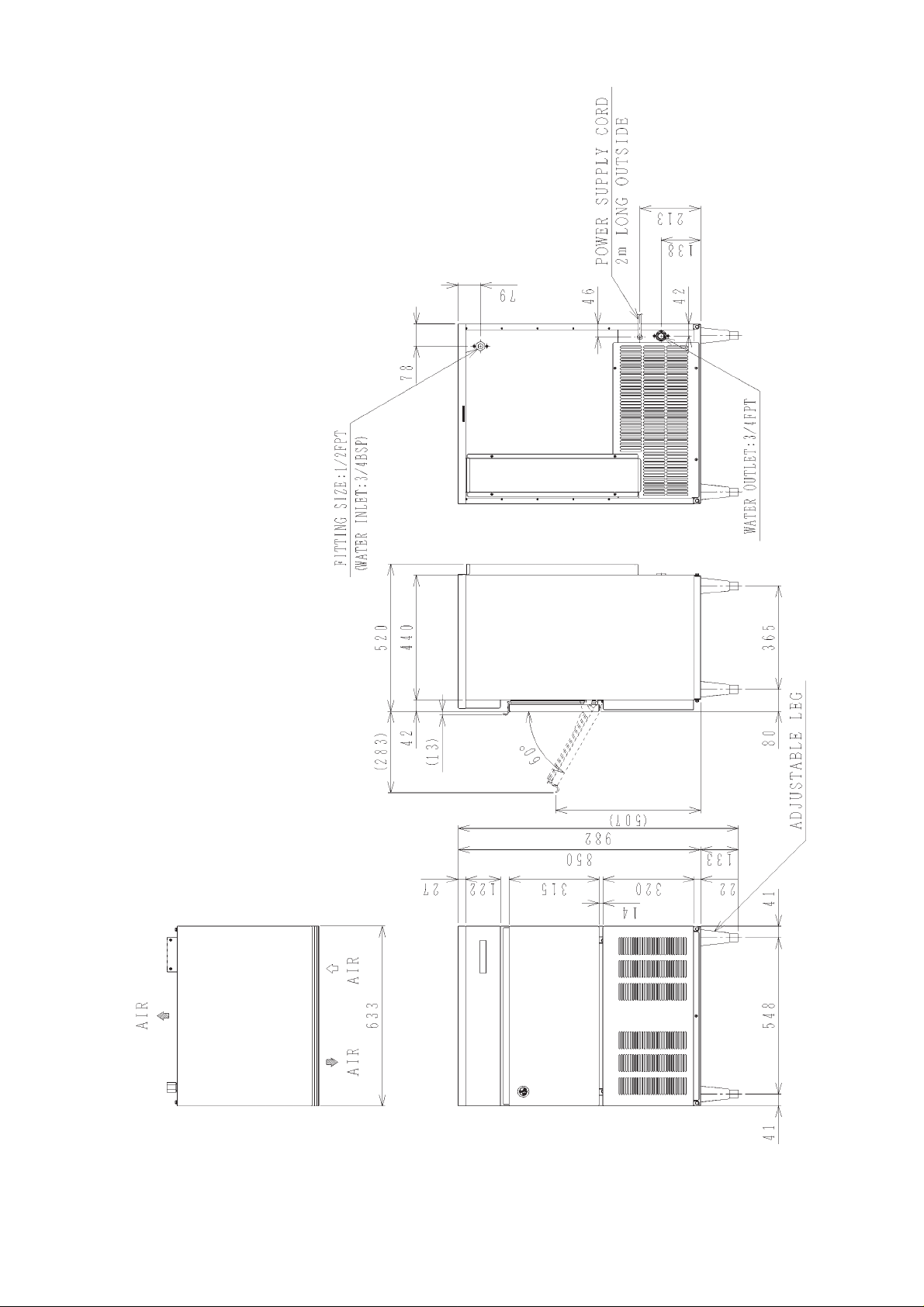

1. DIMENSIONS/CONNECTIONS----------------------------------------------------------------- 1

[a] AM-100BAE ------------------------------------------------------------------------------------ 1

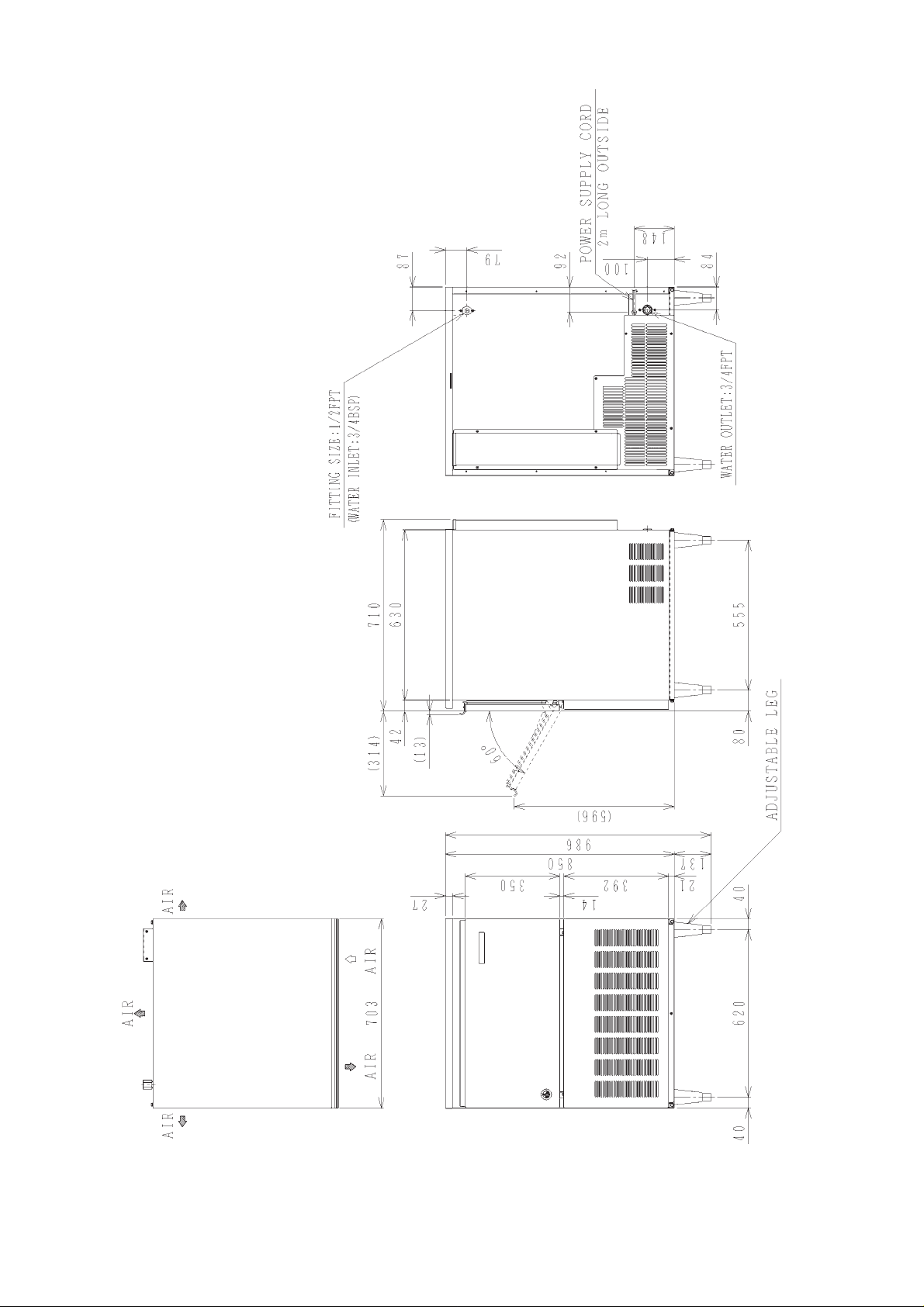

[b] AM-150BAF------------------------------------------------------------------------------------- 2

[c] AM-150BWF ------------------------------------------------------------------------------------ 3

2. SPECIFICA TIONS --------------------------------------------------------------------------------- 4

[a] AM-100BAE ------------------------------------------------------------------------------------ 4

[b] AM-150BAF------------------------------------------------------------------------------------- 5

[c] AM-150BWF ------------------------------------------------------------------------------------ 6

II. GENERAL INFORMA TION -------------------------------------------------------------------------- 7

1. CONSTRUCTION ---------------------------------------------------------------------------------- 7

[a] AM-100BAE ------------------------------------------------------------------------------------ 7

[b] AM-150BAF------------------------------------------------------------------------------------- 8

[c] AM-150BWF ------------------------------------------------------------------------------------ 9

2. ICEMAKING COMP ARTMENT ----------------------------------------------------------------10

III. INST ALLATION AND OPERA TING INSTRUCTIONS ---------------------------------------- 11

1. CHECKS BEFORE INST ALLATION---------------------------------------------------------- 11

2. LOCA TION------------------------------------------------------------------------------------------12

3. SET UP----------------------------------------------------------------------------------------------13

4. ELECTRICAL CONNECTIONS----------------------------------------------------------------13

5. WATER SUPPLY AND DRAIN CONNECTIONS-------------------------------------------14

6. FINAL CHECK LIST ------------------------------------------------------------------------------16

7. STAR T UP ------------------------------------------------------------------------------------------16

8. PREP ARING THE ICEMAKER FOR LONG ST ORAGE (more than 1 day)----------17

IV . MAINTENANCE AND CLEANING INSTRUCTIONS ----------------------------------------19

1. CLEANING INSTRUCTIONS -------------------------------------------------------------------19

[a] WA TER SYSTEM-----------------------------------------------------------------------------19

[b] STORAGE BIN, SLOPE, SCOOP, ETC. ------------------------------------------------21

2. MAINTENANCE-----------------------------------------------------------------------------------23

3. WATER VALVE------------------------------------------------------------------------------------24

4. BIN CONTROL THERMOSTAT ----------------------------------------------------------------25

V . TECHNICAL INFORMA TION ----------------------------------------------------------------------26

1. WA TER CIRCUIT AND REFRIGERANT CIRCUIT -----------------------------------------26

[a] AM-100BAE -----------------------------------------------------------------------------------26

[b] AM-150BAF------------------------------------------------------------------------------------27

[c] AM-150BWF -----------------------------------------------------------------------------------28

2. WIRING DIAGRAM -------------------------------------------------------------------------------29

[a] AM-100BAE -----------------------------------------------------------------------------------29

[b] AM-150BAF------------------------------------------------------------------------------------30

[c] AM-150BWF -----------------------------------------------------------------------------------31

i

3. CONTROLS ----------------------------------------------------------------------------------------32

[a] ICEMAKING CONTROL---------------------------------------------------------------------32

[b] DEFROST CONTROL-----------------------------------------------------------------------32

[c] NO ADJUSTMENT REQUIRED -----------------------------------------------------------32

[d] ADJUSTMENT A T PAR T REPLACEMENT --------------------------------------------32

4. TIMING CHART------------------------------------------------------------------------------------34

5. PERFORMANCE DATA-------------------------------------------------------------------------35

[a] AM-100BAE -----------------------------------------------------------------------------------35

[b] AM-150BAF------------------------------------------------------------------------------------36

[c] AM-150BWF -----------------------------------------------------------------------------------37

VI. SERVICE DIAGNOSIS ----------------------------------------------------------------------------38

1. NO ICE PRODUCTION --------------------------------------------------------------------------38

2. LOW ICE PRODUCTION------------------------------------------------------------------------40

3. ABNORMAL ICE ----------------------------------------------------------------------------------40

4. OTHERS --------------------------------------------------------------------------------------------41

VII. ADJUSTMENT --------------------------------------------------------------------------------------42

1. EXP ANSION VAL VE - AM-150BAF ONL Y--------------------------------------------------42

2. WATER REGULATING VALVE - W ATER-COOLED MODEL ONLY ------------------43

VIII. REMOV AL AND REPLACEMENT-------------------------------------------------------------44

1. SERVICE FOR REFRIGERANT LINES -----------------------------------------------------44

[a] SERVICE INFORMA TION ------------------------------------------------------------------44

[b] REFRIGERANT RECOVERY --------------------------------------------------------------45

[c] EV ACUATION AND RECHARGE---------------------------------------------------------46

2. COMPRESSOR-----------------------------------------------------------------------------------47

3. DRIER -----------------------------------------------------------------------------------------------48

4. EV APORATOR ------------------------------------------------------------------------------------49

5. HOT GAS VALVE---------------------------------------------------------------------------------50

6. PUMP MOTOR ------------------------------------------------------------------------------------51

7. F AN MOT OR---------------------------------------------------------------------------------------51

8. WATER VALVE------------------------------------------------------------------------------------52

9. CONTROLLER BOARD-------------------------------------------------------------------------52

10. THERMISTOR FOR CUBE CONTROL ------------------------------------------------------53

1 1. BIN CONTROL THERMOST A T ----------------------------------------------------------------54

12. EXPANSION V A LVE - AM-150BAF/BWF ONLY ------------------------------------------55

13. WATER REGULATING VALVE - W ATER-COOLED MODEL ONLY ------------------56

[a] VALVE BODY ---------------------------------------------------------------------------------56

[b] WHOLE VALVE-------------------------------------------------------------------------------57

ii

I. SPECIFICATIONS

1. DIMENSIONS/CONNECTIONS

[a] AM-100BAE

1

[b] AM-150BAF

2

[c] AM-150BWF

3

2. SPECIFICATIONS

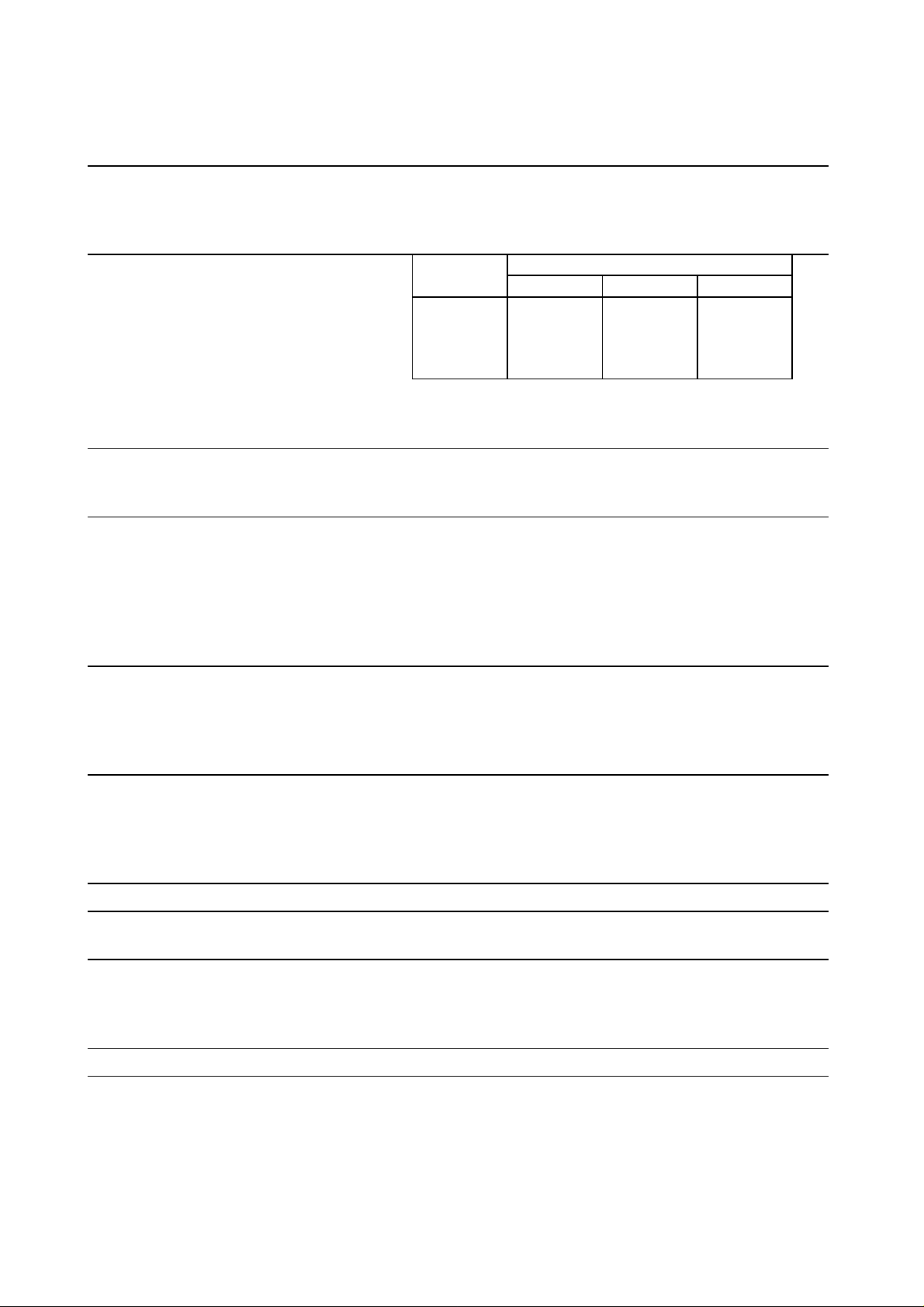

[a] AM-100BAE

AC SUPPLY VOLTAGE 115/60/1

AMPERAGE 6.5A (5 Min. Freeze AT 104°F/ WT 80°F)

MINIMUM CIRCUIT AMPACITY N/A

MAXIMUM FUSE SIZE N/A

APPROXIMATE ICE PRODUCTION Ambient Water Temp. (°F)

PER 24 HR. Temp. (°F) 50 70 90

lbs./day (kg/day) 70 105 (48) 103 (47) 96 (43)

80 96 (44) 93 (42) 86 (39)

90 86 (39) 83 (38) 76 (35)

100 67 (31) 66 (30) 61 (28)

SHAPE OF ICE Cube ø20 x H27mm

ICE PRODUCTION PER CYCLE 1.54 lbs. (0.70 kg) 60 pcs.

APPROXIMATE STORAGE CAPACITY 44 Ibs.

ELECTRIC & WATER CONSUMPTION 90°F/70°F 70°F/50°F See details of

ELECTRIC W (KWH/100 lbs.) 490 (15.7) 430 (9.9) PERFORMANCE DATA

WATER gal./24HR (gal./100 lbs.) 31 (38) 38 (37) No. SS-01129

EXTERIOR DIMENSIONS (W x D x H) 24.9” x 20.5” x 38.7” (633 x 520 x 982mm)

Includes 6” leg

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 110 lbs. (50 kg) Shipping 150 lbs. (68 kg)

CONNECTIONS - ELECTRIC Cord Connection

- WATER SUPPLY Inlet Fitting size is a 1/2” FPT (Water Inlet 3/4” BSP)

- DRAIN Outlet 3/4” FPT

CUBE CONTROL SYSTEM Thermistor, Timer

HARVESTING CONTROL SYSTEM Hot gas, Thermistor

ICE MAKING WATER CONTROL Timer

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model QA110K27CAU6

CONDENSER Air-cooled, Fin and Tube type

EVAPORATOR Tin-plated copper tube on sheet and cells

REFRIGERANT CONTROL Capillary Tube

REFRIGERANT CHARGE R134a 6.6 oz. (185 g)

COMPRESSOR PROTECTION Auto-reset Overload Protector

ACCESSORIES - SUPPLIED Ice Scoop, 6” Leg (4 pcs)

- REQUIRED N/A

OPERATION CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 50 - 100°F

WATER SUPPLY TEMP. 41 - 90°F

WATER SUPPLY PRESS. 7 - 113 PSIG

DRAWING NO. (DIMENSIONS) 3X6975

* We reserve the right to make changes in specifications and design without prior notice.

4

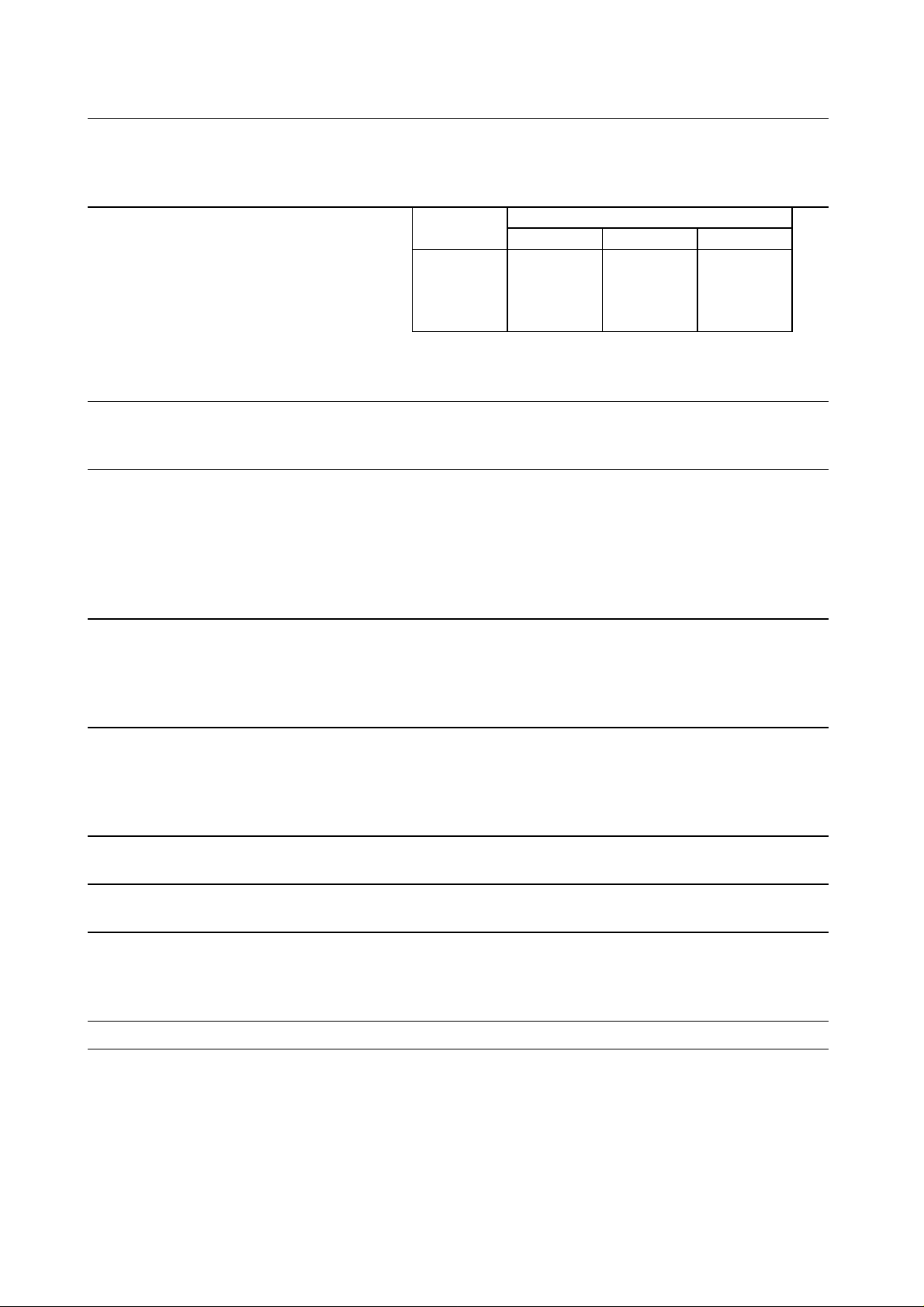

[b] AM-150BAF

AC SUPPLY VOLTAGE 115/60/1

AMPERAGE 8.8A (5 Min. Freeze AT 104°F/ WT 80°F)

MINIMUM CIRCUIT AMPACITY N/A

MAXIMUM FUSE SIZE N/A

APPROXIMATE ICE PRODUCTION Ambient Water Temp. (°F)

PER 24 HR. Temp. (°F) 50 70 90

lbs./day (kg/day) 70 150 (68) 140 (64) 130 (59)

80 140 (64) 130 (59) 120 (55)

90 130 (59) 120 (55) 110 (50)

100 110 (51) 105 (48) 100 (45)

SHAPE OF ICE Cube ø20 x H27mm

ICE PRODUCTION PER CYCLE 1.87 lbs. (0.85 kg) 60 pcs.

APPROXIMATE STORAGE CAPACITY 88 Ibs.

ELECTRIC & WATER CONSUMPTION 90°F/70°F 70°F/50°F See details of

ELECTRIC W (KWH/100 lbs.) 710 (14.2) 660 (10.6) PERFORMANCE DATA

WATER gal./24HR (gal./100 lbs.) 36 (31) 44 (31) No. SS-01131

EXTERIOR DIMENSIONS (W x D x H) 27.7” x 28” x 38.8” (703 x 710 x 986mm)

Includes 6” leg

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 143 lbs. (65 kg) Shipping 185 lbs. (84 kg)

CONNECTIONS - ELECTRIC Cord Connection

- WATER SUPPLY Inlet Fitting size is a 1/2” FPT (Water Inlet 3/4” BSP)

- DRAIN Outlet 3/4” FPT

CUBE CONTROL SYSTEM Thermistor, Timer

HARVESTING CONTROL SYSTEM Hot gas, Thermistor

ICE MAKING WATER CONTROL Timer

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model ASE24C3E

CONDENSER Air-cooled, Fin and Tube type

EVAPORATOR Tin-plated copper tube on sheet and cells

REFRIGERANT CONTROL Expansion Valve

REFRIGERANT CHARGE R404A 9.5 oz. (270 g)

COMPRESSOR PROTECTION Auto-reset Overload Protector

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

ACCESSORIES - SUPPLIED Ice Scoop, 6” Leg (4 pcs)

- REQUIRED N/A

OPERATION CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 50 - 100°F

WATER SUPPLY TEMP. 41 - 90°F

WATER SUPPLY PRESS. 7 - 113 PSIG

DRAWING NO. (DIMENSIONS) 3X6976

* We reserve the right to make changes in specifications and design without prior notice.

5

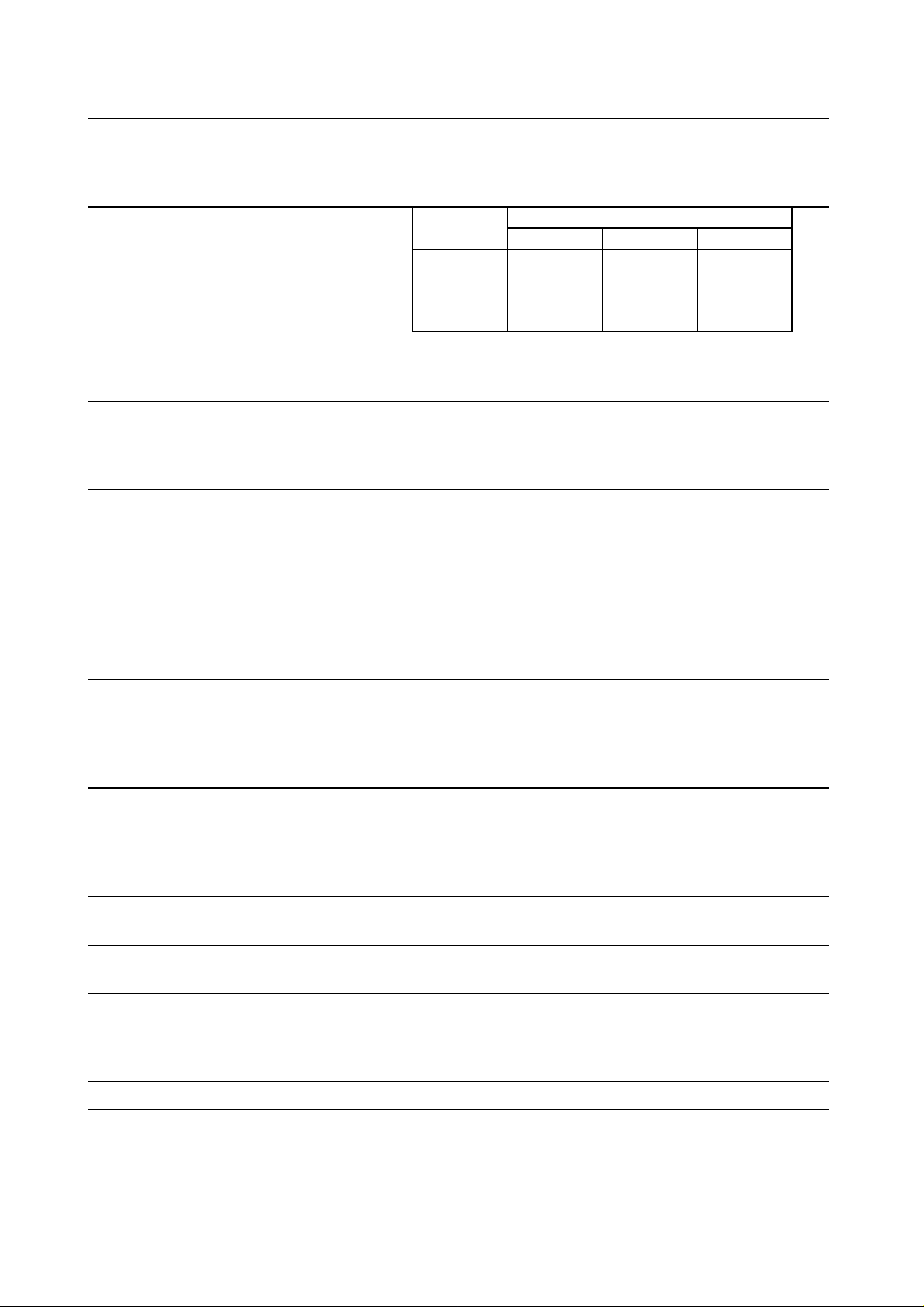

[c] AM-150BWF

AC SUPPLY VOLTAGE 115/60/1

AMPERAGE 7.0A (5 Min. Freeze AT 104°F/ WT 80°F)

MINIMUM CIRCUIT AMPACITY N/A

MAXIMUM FUSE SIZE N/A

APPROXIMATE ICE PRODUCTION Ambient Water Temp. (°F)

PER 24 HR. Temp. (°F) 50 70 90

lbs./day (kg/day) 70 150 (68) 140 (64) 130 (60)

80 150 (68) 140 (64) 130 (60)

90 145 (66) 140 (64) 130 (60)

100 145 (66) 135 (62) 125 (58)

SHAPE OF ICE Cube ø20 x H27mm

ICE PRODUCTION PER CYCLE 1.78 lbs. (0.81 kg) 60 pcs.

APPROXIMATE STORAGE CAPACITY 88 Ibs.

ELECTRIC & WATER CONSUMPTION 90°F/70°F 70°F/50°F See details of

ELECTRIC W (KWH/100 lbs.) 560 (9.5) 560 (9.0) PERFORMANCE DATA

WATER gal./24HR (gal./100 lbs.) 43 (31) 48 (31) No. SS-01769

WATER-COOLED CONDENSER 196 (140) 138 (92)

EXTERIOR DIMENSIONS (W x D x H) 27.7” x 28” x 38.8” (703 x 710 x 986mm)

Includes 6” leg

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT Net 138 lbs. (63 kg) Shipping 180 lbs. (82 kg)

CONNECTIONS - ELECTRIC Cord Connection

- WATER SUPPLY Inlet Fitting size is a 1/2” FPT (Water Inlet 3/4” BSP)

- DRAIN Outlet 3/4” FPT

- COOLING WATER Inlet 1/2” FPT

Outlet 3/8” FPT

CUBE CONTROL SYSTEM Thermistor, Timer

HARVESTING CONTROL SYSTEM Hot gas, Thermistor

ICE MAKING WATER CONTROL Timer

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM Thermostat

COMPRESSOR Hermetic, Model ASE24C3E

CONDENSER Water-cooled, Tube in Tube type

EVAPORATOR Tin-plated copper tube on sheet and cells

REFRIGERANT CONTROL Expansion Valve

REFRIGERANT CHARGE R404A 9.5 oz. (270 g)

COMPRESSOR PROTECTION Auto-reset Overload Protector

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

ACCESSORIES - SUPPLIED Ice Scoop, 6” Leg (4 pcs)

- REQUIRED N/A

OPERATION CONDITIONS VOLTAGE RANGE 104 - 127 V

AMBIENT TEMP. 50 - 100°F

WATER SUPPLY TEMP. 41 - 90°F

WATER SUPPLY PRESS. 7 - 113 PSIG

DRAWING NO. (DIMENSIONS) 3X6976

* We reserve the right to make changes in specifications and design without prior notice.

6

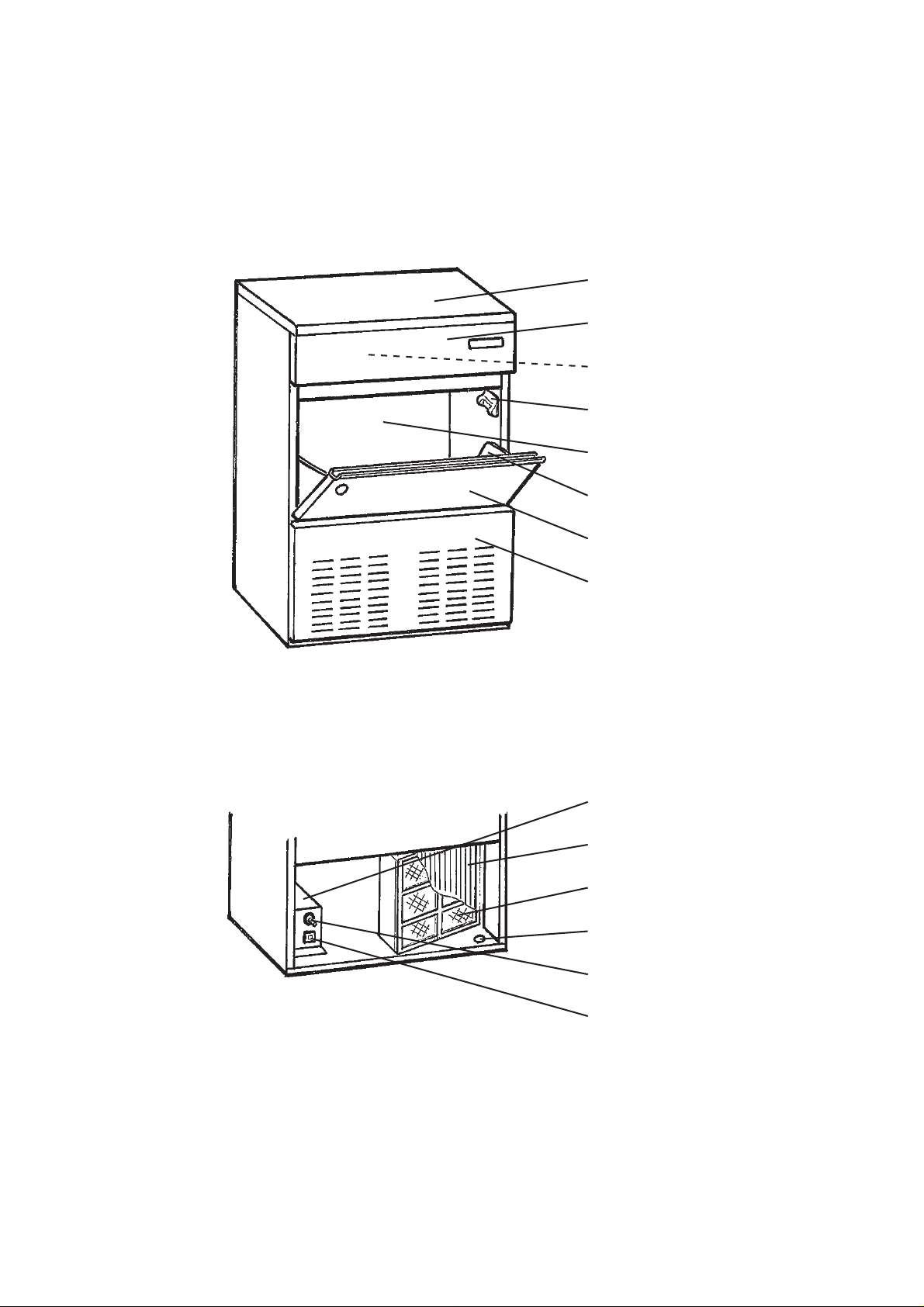

II. GENERAL INFORMATION

1. CONSTRUCTION

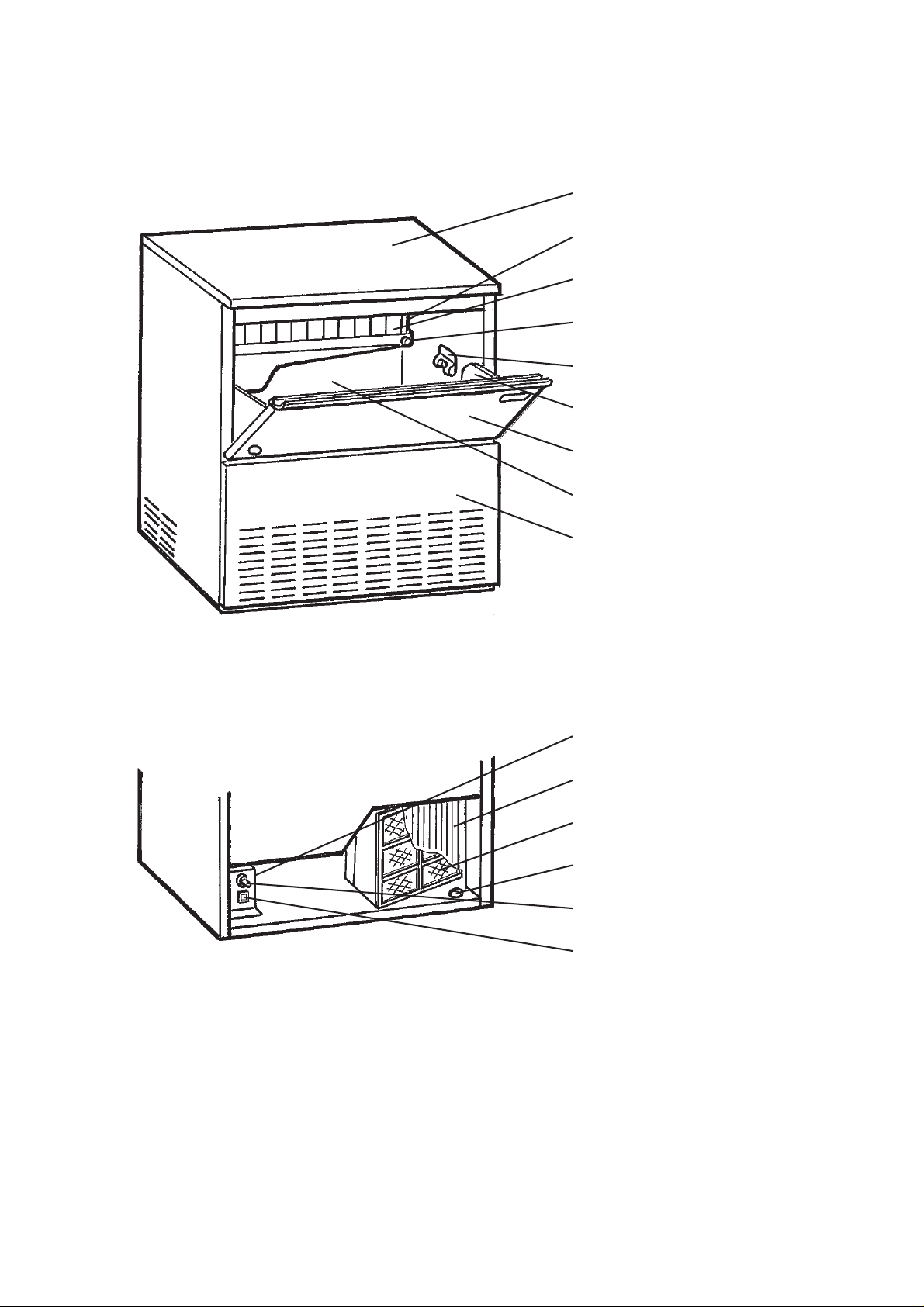

[a] AM-100BAE

Top Panel

Front Panel (Upper)

Ice Making Mechanism

Bin Control Thermostat

Storage Bin

Slope

Door

Front Panel (Lower)

Control Box

Condenser

Air Filter

Tapped Hole (Leg Mounting)

Control Switch

Fuse

7

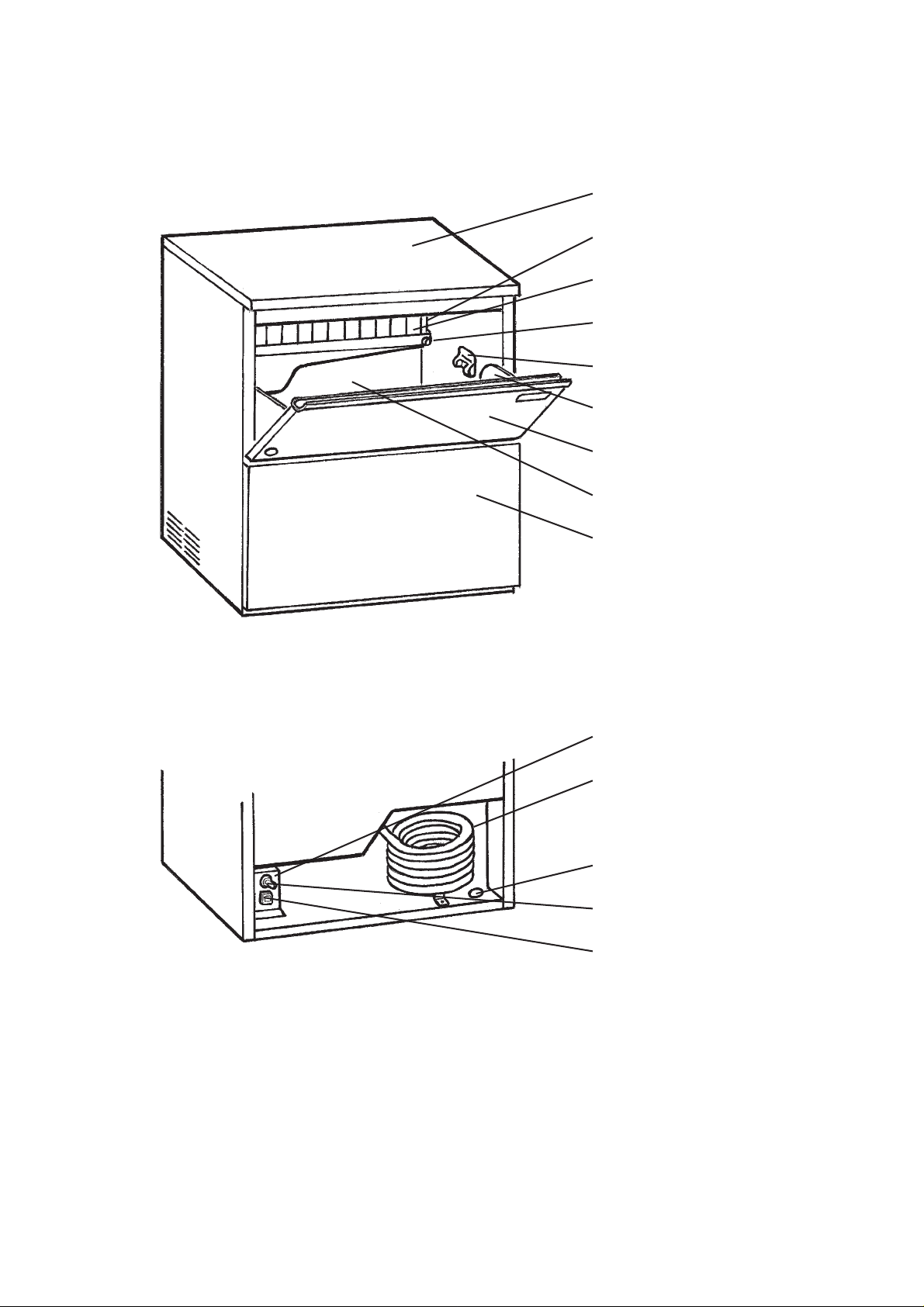

[b] AM-150BAF

Top Panel

Ice Making Mechanism

Separator

Water T ank

Bin Control Thermostat

Slope

Door

Storage Bin

Front Panel (Lower)

Control Box

Condenser

Air Filter

Tapped Hole (Leg Mounting)

Control Switch

Fuse

8

[c] AM-150BWF

Top Panel

Ice Making Mechanism

Separator

Water T ank

Bin Control Thermostat

Slope

Door

Storage Bin

Front Panel (Lower)

Control Box

Condenser

Tapped Hole (Leg Mounting)

Control Switch

Fuse

9

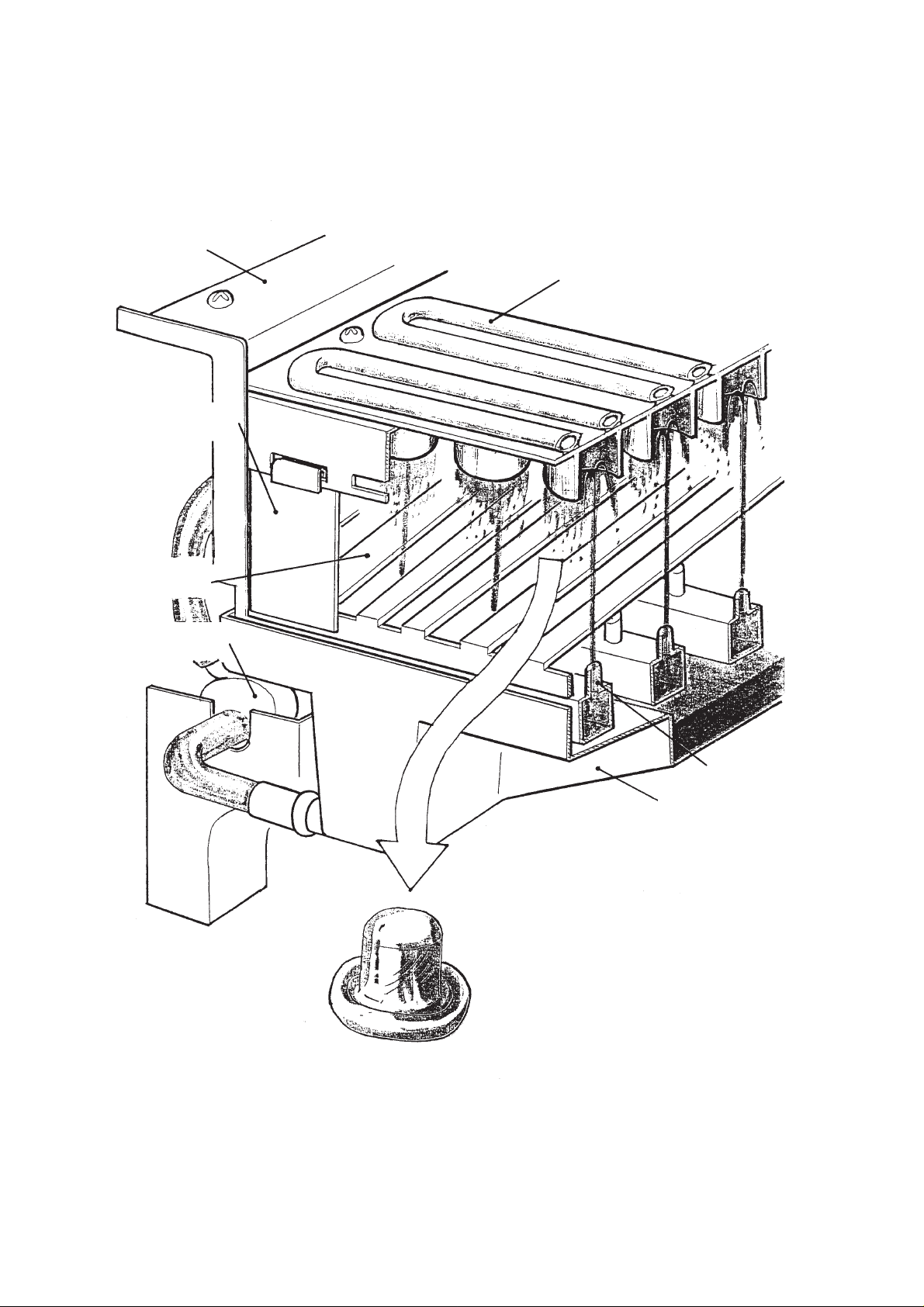

2. ICEMAKING COMPARTMENT

Bracket

Separator

Evaporator

Ice Chute

Pump Motor

Water Plate

Water Tank

10

III. INSTALLATION AND OPERATING INSTRUCTIONS

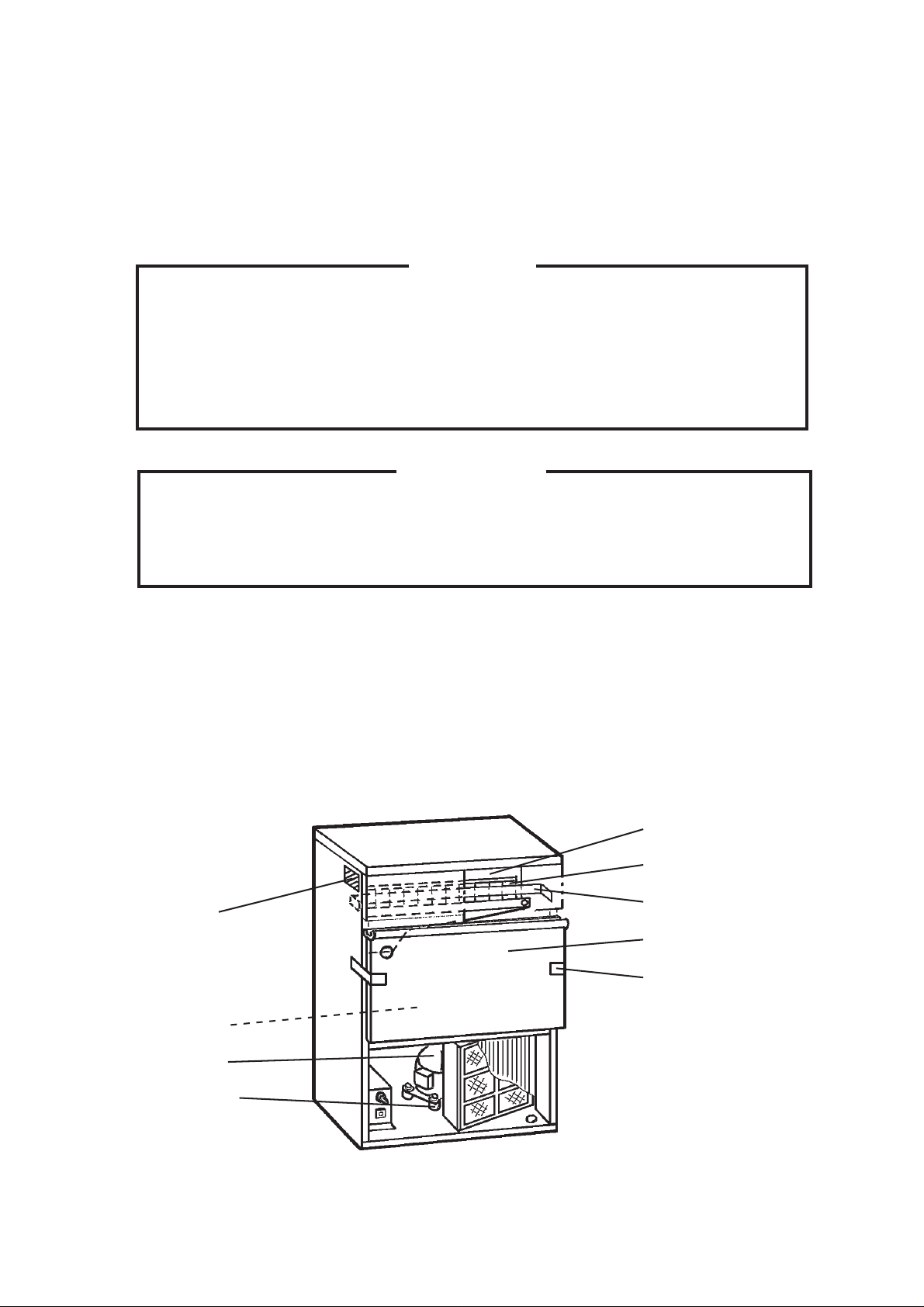

1. CHECKS BEFORE INSTALLATION

* Visually inspect the exterior of the shipping container , and any severe damage noted should

be reported to the carrier.

W ARNING

1. Remove shipping tape(s) and packing as follows. If any left in the icemaker ,

it will not work properly .

2. Do not lift or carry the unpacked icemaker by using the brass fitting for water

supply at the rear of the unit. The plastic threads may be damaged.

IMPORTANT

1. Remove the shipping tapes holding the Door and Separator .

2. Ensure all components, fasteners and thumbscrews are securely in place.

* Remove the package containing accessories.

* Check that refrigerant lines do not rub or touch lines or other surfaces.

* Check that the Compressor is snug on all mounting pads.

* See the Nameplate on the upper right part of the Left Side Panel, and check that your

voltage supplied corresponds with the voltage specified on the Nameplate.

Ice Making Mechanism

Separator

Nameplate

Shipping T ape

Door

Shipping T ape

Accessories

Compressor

Mounting Pad

Fig. 1

11

2. LOCATION

W ARNING

This icemaker is not intended for outdoor use. Normal operating ambient

temperature should be within 50°F (10°C) to 100°F (38°C); Normal operating

water temperature should be within 41°F (5°C) to 90°F (32°C). Operation of

the icemaker, for extended periods, out side of these normal temperature ranges

may affect production capacity.

For best operating results:

* The icemaker should not be located next to ovens, grills or other high heat producing

equipment.

* The location should provide a firm foundation for the equipment. Level the icemaker from

side to side and front to rear.

* A void a site where dripping is not allowed.

* This icemaker will not work at subfreezing temperatures. To prevent damage to the water

supply line, drain the icemaker when air temperature is below zero.

* The AM-100BAE icemaker requires no clearance at either side. But allow enough space at

rear for water supply and drain connections and at least 12” (approx. 30 cm) clearance at

front.

* The AM-150BAF icemaker requires 2” (approx. 5 cm) clearance at either side. Allow enough

space at rear for water supply and drain connections and at least 12” (approx. 30 cm)

clearance at front.

12

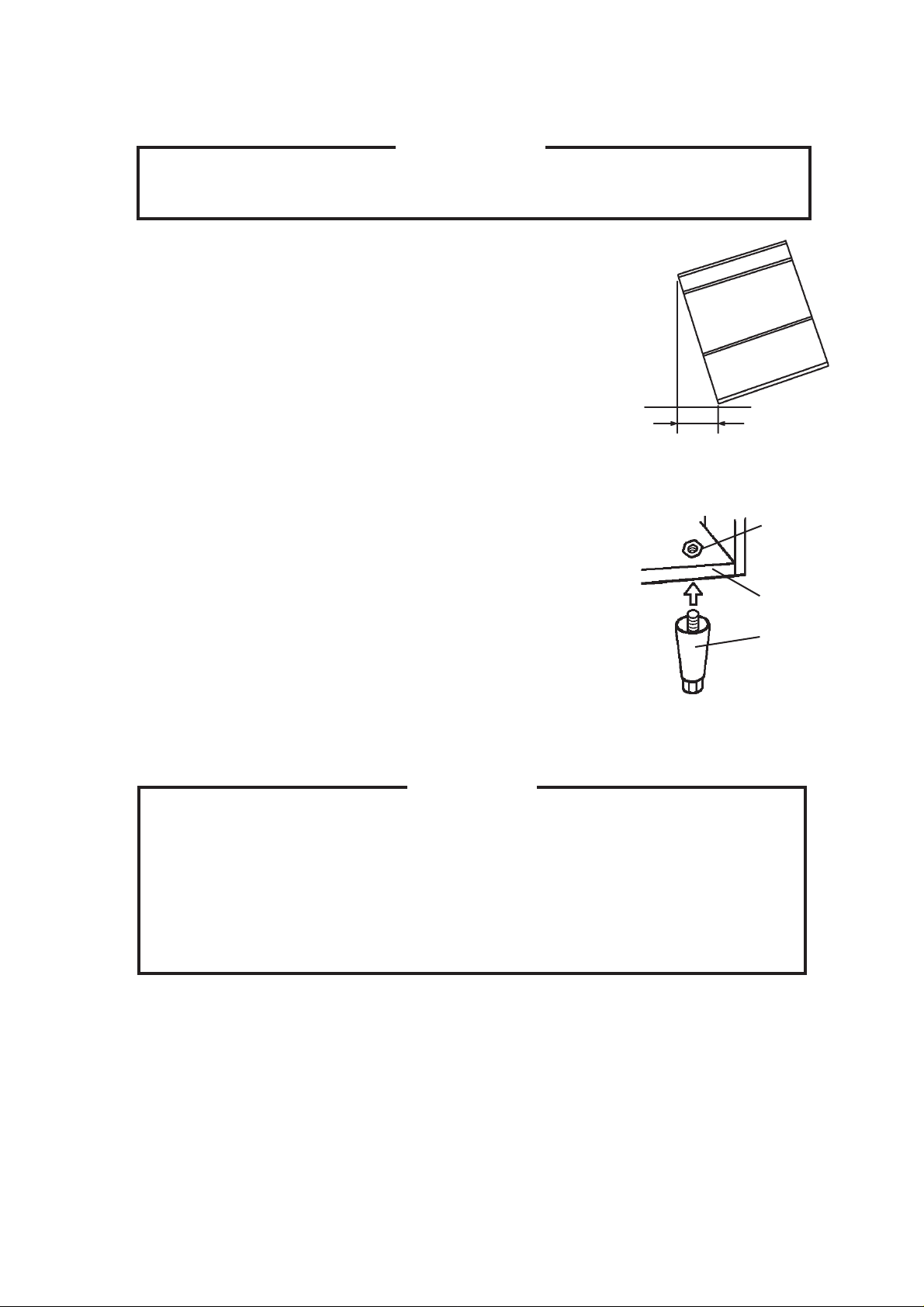

3. SET UP IMPORTANT

Do not place heavy objects exceeding 33 lbs (15 kg) on the Top Panel.

1) Unpack the icemaker , and remove all shipping cartons, tapes

and packing BEFORE operating the unit.

2) Position the icemaker in a selected site. Clean the interior

with soap and water and rinse thoroughly .

3) Level the icemaker in both the left-to-right and the front-torear directions (when installed with or without legs). See Fig.

2.

4) When installing the unit without legs, the perimeter where the

machine touches the counter should be sealed with silicone

to prevent water from leaking under the icemaker .

Max. 0.4” (1 cm)

Fig. 2

T apped Hole

(Leg Mounting)

5) When installing the unit with legs on the bottom, use the four

accessory legs adjustable from 6” (15.2 cm) to 7” (17.8 cm).

Screw the legs tightly into the tapped holes in the base (see

Fig. 3). Handle the icemaker carefully not to damage the

exterior.

Base

Adjustable Leg

Fig. 3

4. ELECTRICAL CONNECTIONS

W ARNING

THIS APPLIANCE MUST BE GROUNDED.

This icemaker requires a ground that meets the national and local electrical

code requirements. To prevent possible severe electrical shock injury to

individuals or extensive damage to equipment, install a proper ground wire to

this icemaker. Remove the plug from the mains socket before any maintenance,

repairs or cleaning is undertaken.

* This icemaker must be plugged into the separated power receptacle which has enough

capacity . The maximum allowable voltage variation should not exceed ± 10 percent of the

nameplate rating. See the Nameplate.

* Usually an electrical permit and services of a licensed electrician are required.

13

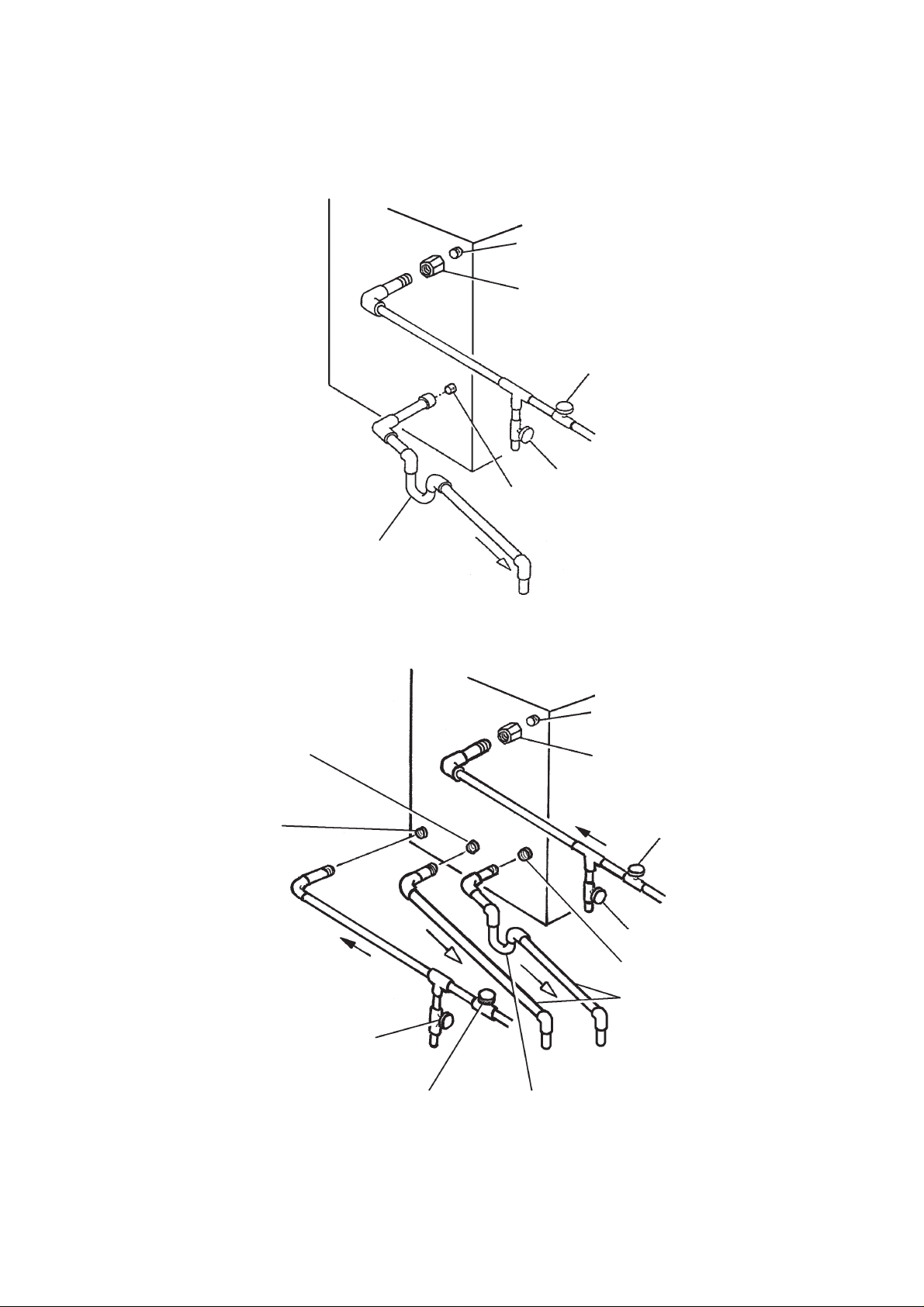

5. WATER SUPPLY AND DRAIN CONNECTIONS

W ARNING

To prevent damage to the freezer mechanism, do not operate this icemaker

when the water supply is OFF , or if the pressure is below 10 PSIG (0.7 bar), the

recommended water pressure. Stop the icemaker until proper water pressure

is resumed.

CAUTION

1. A brass fitting for the water supply line connection is attached to the 3/4” BSP

plastic threads to avoid cross-threading of the Water V alve possibly resulting

in leaks. The brass fitting allows connection of a 1/2” FPT that should be

connected to the potable water supply line.

2. While making the water supply line connection, use a wrench to hold the

brass fitting still to prevent overtightening and damage to the plastic threads.

* Water supply inlet for the icemaker is 1/2” female pipe thread (FPT).

Note: On water-cooled model, two water supply inlets are provided. One is for the icemaker

(1/2” FPT), and the other is for the water-cooled condenser (1/2” FPT).

* The brass fitting is attached as shown in Fig. 4. The fitting size is a 1/2” FPT and must be

connected only to a potable water supply .

* A water supply line shut-off valve and drain valve must be installed.

* Water supply pressure should be a minimum of 10 PSIG (0.7 bar) and a maximum of 1 13

PSIG (7.5 bar). If the pressure exceeds 1 13 PSIG (7.5 bar), use a pressure reducing valve.

* Drain outlet for icemaker dump is 3/4” FPT .

Note: On water-cooled model, a 3/8” FPT is provided for the condenser drain outlet. The

icemaker drain and the condenser drain piping connections must be made separately .

* Drain must be 1/4” fall per foot (2 cm fall per meter) on horizontal runs to get good flow.

* Keep a more than 2 vertical inch (5 vertical cm) air gap between the drain pipe end and the

sink.

* The drain pipe must be so laid as to prevent a backflow into the S torage Bin. Provide a trap

in the bin drain line to prevent odor from flowing back into the Storage Bin.

14

* A plumbing permit and services of a licensed plumber may be required in some areas.

* This icemaker should be installed in accordance with applicable national, state and local

regulations.

AM-100BAE

AM-150BAF

Icemaker

Trap

1/4” fall per foot

Water Supply Inlet

3/4” BSP Threads

Brass fitting is attached

to Water Supply Inlet.

Fitting size is a 1/2” FPT.

Shut-off V alve

Drain V alve

Bin Drain Outlet

3/4” FPT

AM-150BWF

Condenser Outlet

3/8” FPT

Water-cooled

Condenser Inlet

1/2” FPT

Drain V alve

T o approved floor drain

Icemaker

Water Supply Inlet

3/4” BSP Threads

Brass fitting is attached

to Water Supply Inlet.

Fitting size is a 1/2” FPT.

Shut-off V alve

Drain V alve

Bin Drain Outlet 3/4” FPT

1/4” fall per foot

T o approved floor drain

Shut-off V alve

Trap

Fig. 4

15

Loading...

Loading...