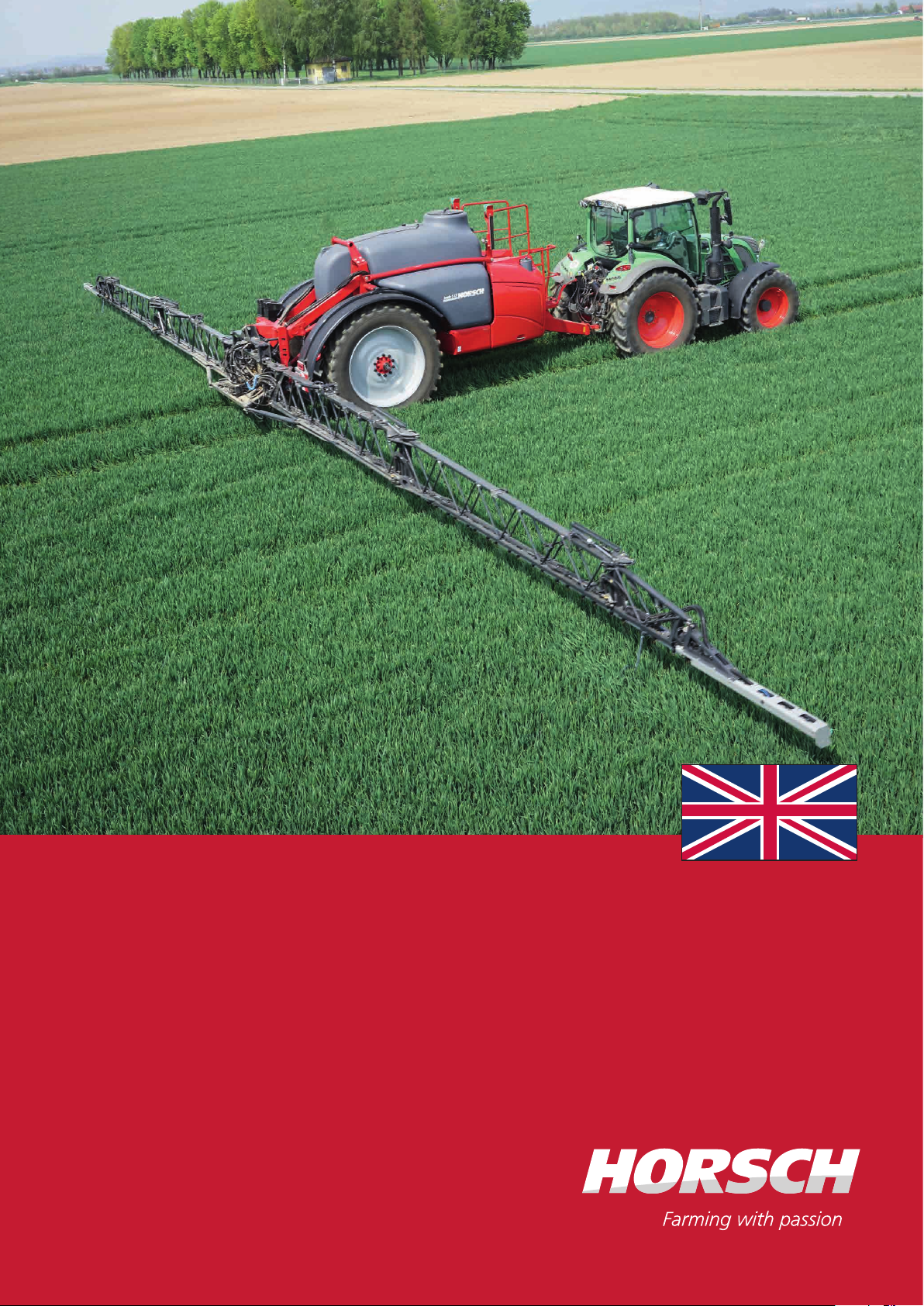

horsch LEEB 4 LT, LEEB 5 LT Operating Instructions Manual

OPERATING INSTRUCTIONS

LEEB 4 / 5 LT

READ CAREFULLY PRIOR TO STARTING UP!

KEEP OPERATING INSTRUCTIONS IN A SAFE PLACE!

ART.:

ISSUE:

80900208

03/2016

EC Declaration of Conformity

exchangeable equipment

(Directives 2006/42/EC and 2009/127/EC)

The manufacturer HORSCH LEEB Application Systems GmbH

Plattlinger Str. 21

D-94562 Oberpöring (Germany)

hereby declares, that the product,

Designation of machine: trailed crop protection device

Machine type: HORSCH LEEB 4 / 5 / 6 LT from chassis number: 36721250

this declaration refers to, conforms with all relevant fundamental health and safety requirements

of the EC directive 2006/42/EC and 2009/127/EC.

For proper implementation of the heath and safety requirements mentioned in the EC-directive,

the following standards and technical specications have been used:

EN ISO 4254-1 :05-2011

EN ISO 4254-6 :10-2011

EN ISO 12100 :03-2011

Documentation Representative:

Manfred Köbler

HORSCH Maschinen GmbH

Sitzenhof 1

D-92421 Schwandorf

Oberpöring, 10.02.2016

Place and date ____________________

Theodor Leeb

(CEO)

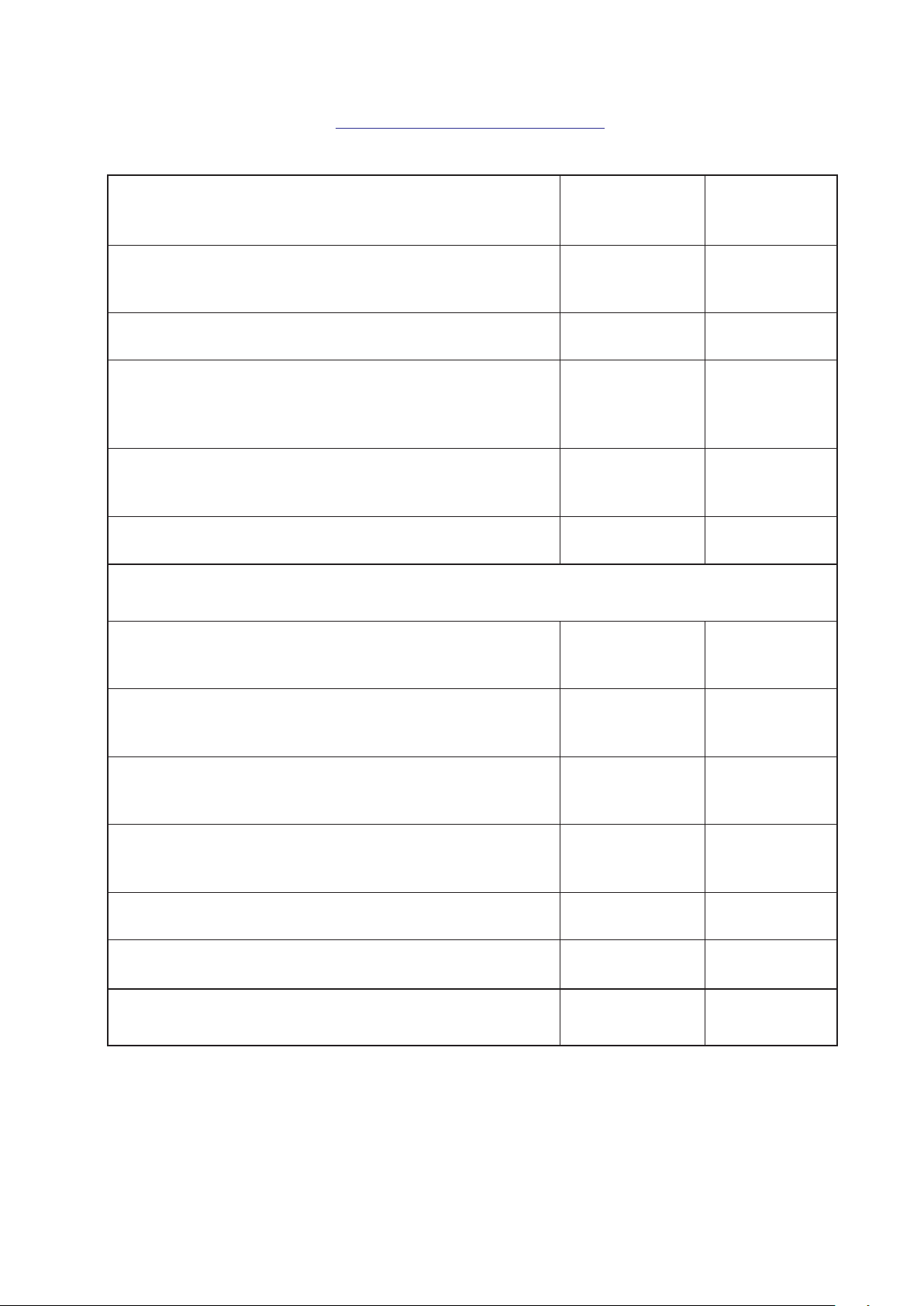

Vehicle handover certicate

Preparation of vehicle by customer service workshop carried out on Signature

Check oil level, correct if necessary:

Hydraulic oil circuits (PTO-shaft pump)

Lubricate vehicle according to lubrication plan, oil joints

Check Ackerman steering

Check tyre pressure

Check wheel nuts for tight t

Check the electric system

Check the error log

Brake test

Explanations during vehicle handover

Raise the attention for the safety notes in the operating

instructions

Inform about the necessity to comply with country specic

regulations concerning speed and trailer brake systems

Explain the following functional features in detail and

demonstrate their operation:

Operating controls, multiple display, commissioning,

connecting, parking, fault output, code table

Notes on customer service and maintenance

Handover of vehicle accessories

Handover performed:

Acknowledgement of receipt

No right to claim warranty if this acknowledgement of receipt has not been returned!

* Mandatory eld

To

Dealer

Cust. No.: .................................................

Company ..................................................*

Street: ..... ................................................. *

ZIP-Code: ................................................*

Place: .......................................................*

Country: ................................................... *

Machine type: ..........................................*

Serial number: ..........................................*

Service engineer

Name: ...................................................... *

First name: ...............................................*

Customer I:

Name/company: ......................................*

Name of contact: .....................................*

First name of contact: .............................. *

Road: ....................................................... *

ZIP-Code: ................................................*

Place: .......................................................*

Country: ................................................... *

Phone ......................................................*

Fax: ..........................................................

E-Mail: ......................................................*

Phone: .....................................................

Fax: ..........................................................

E-Mail: ......................................................

New machine sold to nal customer - Initial use*

Customer's machine - Relocation*

Demonstration machine - Initial use*

Demonstration machine - Relocation*

Demonstration machine sold to nal customer - Use*

Customer II:

Name/company: ......................................*

Name of contact: .....................................*

First name of contact: .............................. *

Road: ....................................................... *

ZIP-Code: ................................................*

Place: .......................................................*

Country: ................................................... *

Phone ......................................................*

Fax: ..........................................................

E-Mail: ......................................................*

"

I hereby conrm the receipt of the operating instructions and spare parts list for the machine specied above.

I have been instructed by an authorized dealer or a Service Engineer from HORSCH in the operation and functions as well as the safety related requirements of the machine.

I am aware, that the right to claim warranty will only be eective, if this form is returned to the

responsible dealer or handed over to the Service Engineer, properly completed immediately after

initial instruction.

........................................................................*

Place, date of initial instruction

........................................................................*

Signature of buyer

- Translation of the Original Operating Instructions -

Machine Identication

The corresponding data is to be entered into the list below upon receiving the machine:

Serial number: ..................................................

Machine type: ...................................................

Year of construction: ........................................

Initial installation: ..............................................

Fittings: .............................................................

..........................................................................

..........................................................................

..........................................................................

Publication date of Operation Manual: 03/2016

Latest change:

Address of Retailer: Name: ......................................................................

Road: ......................................................................

Town/City: ......................................................................

Tel.: ......................................................................

Customer No.:

Retailer: ......................................................................

Address of manufacturer: HORSCH LEEB Application Systems GmbH

Plattlinger Str. 21

D- 94562 Oberpöring (Germany)

Tel.: +49 (0) 99 37 - 95 96 30

Fax: +49 (0) 99 37 - 95 96 366

E-Mail: info.leeb@horsch.com

80900208 LEEB 4/5 LT en

Kd. Nr.: HORSCH: ......................................................................

Foreword

Please note:

Dear Customer,

Thank you for the trust in us you have expressed

by buying this machine.

In order to be able to use the trailed crop protection sprayer to your full advantage, you should

read these operating instructions with utmost

attention before you use the machine.

These operating instructions contain important

information for the proper use and the safe operation of the machine. By purchasing the crop

protection sprayer you have acquired a quality

product from HORSCH LEEB AS.

The LT trailed crop protection sprayer is a machine sprayer for the placing of crop protection

agents and liquid fertiliser in compliance with the

statutory directives for soil cultures.

The contents is structured in such a way that

you will be informed in detail about the required

activities in compliance with the work-related

sequence.

The manual provides you with comprehensive

notes and information concerning maintenance,

safe use of the machine, safe working methods,

special precautions and available accessories.

Compliance with these notes and information is

necessary, important and useful for operational

safety, reliability and conservation of value of the

crop protection sprayer.

Always keep these operating instructions with

the crop protection sprayer. The operating instructions are a component part of your machine.

HORSCH LEEB AS will not assume liability

for any damage or malfunctions resulting from

failure to comply with the operating instructions.

Upon delivery of the machine check for transport

damage or missing parts! Check the delivered

machine for completeness against the delivery

note, including optional equipment you have

ordered. Only immediately raised claims will

lead to compensation!

The operating instructions must be read and

strictly adhered to by all persons working on or

with the machine e.g.:

• Operation (including preparation, fault recti-

cation during work, care)

• maintenance (maintenance and inspection)

• Transport

You receive an acknowledgement of receipt

together with the operating instructions. The

trained personnel of our service and sales partners will train and instruct you in the operation

and care of your machine. After this you or the

sales or service partner should return the receipt

back to HORSCH. This conrms your formal

acceptance receipt of the machine.

The warranty period starts with the date of

delivery.

Only operate the machine after you have been

instructed and in full compliance with these operating instructions. This crop protection sprayer

must only be used by persons who are familiar

with the machine and have been informed about

any possible dangers that may arise from the

machine.

Strictly follow the safety notes! Follow also the

applicable accident prevention regulations as

well as other generally recognised safety, occupational heath and road trac related regulations.

8

Any information, illustrations and technical

specications in these operating instructions

are up-to-date at the time of publishing. We, at

any time, reserve the right for design changes,

technical and formal alterations to our products

for the purpose of improvement or to meet

changed legal regulations, without notication.

We will, of course, make up-to-date data available.

Any directions given in these operating instructions always refer to the travel direction of the

machine.

The illustrations in these operating instructions

show dierent versions of the implement and

dierent equipment variants.

Service

The company HORSCH LEEB AS would be

pleased, if your machine and our services would

meet your expectations.

If you encounter any problems, please feel free

to contact your sales partner.

The service sta of our sales partners and the

service employees at Horsch will always be

available for assistance.

In order to be able to solve technical problems

as quickly as possible, we ask you kindly to

support us.

Please help the service personnel by providing

the following information to avoid unnecessary

queries.

• Customer number

• Name of customer representative

• Name and address

• Machine model and serial number

• Purchasing date and operating hours or area

performance

• Type of problem

Compensation claims for damages which have

not been caused by the machine, are excluded.

This also means that any liability for consequential damages caused by travel and operating

faults is excluded.

Warranty claim processing

Warranty claim forms must be submitted through

your local HORSCH sales partner to the Service

Department of HORSCH LEEBG AS GmbH.

HORSCH LEEB Application Systems GmbH

Plattlinger Str. 21

D-94562 Oberpöring

Phone +49 (0) 99 37 . 95 96 30

Fax +49 (0) 99 37 . 95 96 366

www.horsch.com

All rights reserved

© 2015 HORSCH LEEB Application Systems GmbH

9

Table of contents

Foreword ......................................................8

1. Safety .......................................................14

1.1 Notes on representation .........................14

1.2 Qualication and training of personnel ...14

1.3 Work place of the operator .....................15

1.4 Danger caused by failing to comply

with the safety notes ...............................15

1.5 Safety conscious working .......................15

1.6 Safety notes for the operator ..................15

1.6.1 Safety and accident prevention

instructions ........................................15

1.6.2 Coupling and uncoupling the machine .. 16

1.6.3 Working with the machine .................17

1.6.4 Changing equipment.........................17

1.6.5 Transporting the machine .................18

1.6.6 Hydraulic system ..............................18

1.6.7 Electrical system ...............................19

1.6.8 Towed machines ...............................20

1.6.9 Brake system ....................................20

1.6.10 Pneumatic brake system ................20

1.6.11 Tyres ...............................................20

1.6.12 Handling crop protection agents .....21

1.6.13 Operating the crop protection sprayer ...21

1.6.14 Maintenance ...................................22

1.7 Loading and unloading ...........................23

1.8 Unauthorized conversion and

manufacture of spare parts.....................23

1.9 Impermissible operating modes..............24

1.10 Spare parts and wear items as

well as auxiliary materials .....................24

1.11 Working in the vicinity of high voltage

power lines ...........................................24

1.12 Phone and radio equipment .................24

1.13 Danger caused by residual energy .......25

1.14 Cleaning and waste disposal ................25

1.15 Intended use .........................................25

1.15.1 Specied equipment .......................26

1.15.2 Consequential damage ...................26

1.15.3 Effects when using certain

crop protection products .................26

1.15.4 Danger zones and danger points....27

1.15.5 Personal protection equipment .......28

1.15.6 Organizational measures ................28

1.15.7 Operating instructions .....................28

1.16 Safety notes on the machine ................29

1.17 Instruction sticker..................................29

1.18 Safety stickers ......................................29

1.19 Position of safety stickers .....................32

2. Product description ................................34

2.1 Overview.................................................34

2.2 Safety and protective features ................35

2.3 Fluid circuit LT CCS - components .........36

2.4 Fluid circuit LT CCS Pro - components ..37

2.5 Supply lines between tractor and machine ....38

2.6 Trafc-compliant equipment ...................38

2.7 Technical data .........................................39

2.7.1 Dimensions .......................................41

2.7.2 Permissible total weight and tyres ....42

2.8 Nose development data..........................45

2.9 Necessary tractor equipment..................45

3. Design and function ...............................47

3.1 Control unit .............................................47

3.2 Connections............................................47

3.3 Folding boom ..........................................47

3.4 Nozzles ...................................................48

3.5 Spraying line ...........................................48

3.6 Spraying control......................................48

3.7 CCS - continuous inside cleaning...........48

3.8 Fluid circuit - function..............................49

3.9 Induction hopper ....................................51

3.10 Spraying pump .....................................52

3.11 Piston diaphragm pump ........................ 53

3.12 Hand washing tank ...............................53

3.13 Agitator .................................................53

3.14 Filter......................................................54

3.15 External cleaning system (optional)......55

3.16 Hydraulic connections ..........................56

3.16.1 Coupling hydraulic hoses ...............56

3.16.2 Uncoupling hydraulic hoses ...........57

3.17 Pulling tool (optional) ............................57

3.18 Lifting points .........................................57

3.19 Transport, document and safety

container ..............................................58

10

3.20 Pneumatic brake system ......................58

3.20.1 Automatic load dependent

brake pressure regulator (ALB) .......60

3.20.2 Connecting the brake system .........60

3.20.3 Disconnecting the brake system .....61

3.21 Drawbar ................................................61

3.22 Automatic Ackerman steering ............... 62

3.22.1 Adjusting the mechanical

steering end stop ............................62

3.23 Suspension ...........................................63

3.24 Hydraulic support..................................63

3.25 Working platform with ladder ................64

3.26 Fresh water tank ......................................................64

3.27 Main control terminal ............................65

3.28 Multi-function handle ............................66

3.28.1 Assignment of multi-function handle ... 67

3.29 PTO-shaft pump (optional) ...................68

3.30 NightLight (optional) .............................69

3.31 Hydraulic compressor ...........................70

4. Design and Function of the Spraying

Boom ...........................................................72

4.1 Folding boom control ..............................72

4.1.1 BoomControl .....................................72

4.1.2 BoomControl modes .........................73

4.2 Folding and unfolding .............................73

4.3 Folding variants - folding boom ..............75

4.4 Adjusting the spraying height..................76

4.5 Transport lock .........................................76

4.6 Slope compensation / pendulum lock .....78

4.7 Collision protection .................................78

4.8 Spraying line ...........................................79

4.8.1 Circulation system ............................79

4.8.2 Cleaning nozzle tube and nozzles ....79

4.9 Nozzle body ............................................80

4.9.1 Single nozzle body with

pneumatic control valve ....................80

4.9.2 Multiple nozzle body manual 3-fold ..80

4.9.3 Multiple nozzle body pneumatic........81

4.9.4 Border nozzles, electric (option) .......81

4.10 Assembling and cleaning nozzles.........82

4.10.1 Assembling nozzles ........................82

4.10.2 Changing nozzles ...........................82

4.10.3 Cleaning nozzles ............................82

4.10.4 Disassembling the diaphragm

valve in case of dripping nozzles ....82

5. Commissioning .......................................83

5.1 Check suitability of the tractor ................83

5.2 Safeguarding tractor / machine ..............84

5.3 Initial commissioning of the service

brake system ..........................................85

5.4 Assemble the wheels ..............................85

5.5 Adjusting the hydraulic system

on the hydraulic valve block ...................85

6. Transport travels ....................................86

6.1 Safety notes............................................86

6.2 Transport lock .........................................87

6.2.1 Folding boom rest .............................87

6.2.2 Package lock ....................................88

6.2.3 Locking of slope compensation ........88

6.2.4 Locking of parallelogram...................89

7. Coupling and uncoupling the machine ...89

7.1 Coupling the machine .............................90

7.2 Uncoupling the machine .........................91

7.2.1 Manoeuvring the uncoupled machine .....91

8. Working with the machine .....................93

8.1 Preparing for spraying ............................94

8.2 Preparing the spraying mixture...............95

8.2.1 Calculating lling / relling quantities ...97

8.2.2 Filling table for residual areas ...........98

8.3 Filling with water .....................................99

8.3.1 Filling the spraying mixture tank

through the ller connection............100

8.3.2 Direct lling (external lling) ............100

8.3.3 Filling through the lling dome ........101

8.3.4 Filling the fresh water tank

through the ller connection ...........101

11

8.4 Flushing in preparations .......................102

8.4.1 Induction hopper .............................102

8.4.2 Flushing in liquid preparations

during the lling process ................103

8.4.3 Flushing in liquid preparations

full or partly lled solution tank ........104

8.4.4 Flushing in powdery preparations

and carbonyl diamide ......................104

8.4.5 Pre-cleaning the canister with

spraying mixture .............................105

8.4.6 Pre-cleaning the canister with

fresh water ......................................105

8.5 Spraying operation ...............................106

8.5.1 Special notes for spraying operation ... 106

8.5.2 Adjusting the spraying height ..........107

8.5.3 Spraying pressure, nozzle size,

application quantity, travel speed,

agitator ............................................107

8.5.4 Spraying ..........................................108

8.5.5 Measures for windward

drift reduction .................................108

8.5.6 Spraying with 25 cm nozzle

spacing and reduced target area

distance .........................................108

8.5.7 Emptying the spraying mixture

tank via the pressure outlet .............109

8.6 Residual quantities ...............................109

8.6.1 Technical residual quantity ..............109

8.6.2 Eliminating residual quantities ........ 110

8.6.3 Draining off technical residual

quantities ........................................ 110

8.6.4 Diluted residual quantities............... 111

8.7 Draining the fresh water tank................ 111

8.8 Troubleshooting .................................... 112

9. Sprayer cleaning, maintenance...........113

9.1 Cleaning ............................................... 115

9.1.1 CCS - Continuous inside cleaning

(Continuous Cleaning System) ....... 116

9.1.2 Cleaning the lters .......................... 117

9.1.3 Cleaning the sprayer with

the tank empty ............................... 118

9.1.4 Cleaning the sprayer with

the tank lled ................................... 119

9.1.5 Folding boom cleaning with

"Air Valve" (option) .......................... 11 9

10. Putting into storage ............................120

10.1 At the end of the spraying season ......120

10.2 Drainage .............................................120

10.2.1 Draining of solution container .......120

10.2.2 Drainage of spraying pump...........120

10.2.3 Draining the fresh water tank ........120

10.3 Putting the sprayer system in

to winter storage .................................121

10.4 Before the new season .......................124

11. Maintenance and care plan ................125

11.1 Lubrication instructions ....................... 127

11.1.1 Overview of lubrication

points basic machine ....................128

11.1.2 Overview of lubrication

points middle section ....................130

11.1.3 Overview of lubrication

points spraying boom ....................132

11.2 Drawbar ..............................................133

11.3 High pressure cleaner (optional) .........133

11.4 Ball-and socket-coupling .....................134

11.5 Axle and brake ....................................135

11.5.1 General visual inspection .............. 135

11.5.2 Checking the wheel hub

bearing play (workshop work) .......136

11.5.3 Replacing the grease of the

wheel hub bearing ........................136

11.5.4 Brake lining inspection .................. 137

11.5.5 Brake adjustment .......................... 137

11.5.6 Air vessel .......................................137

11.5.7 Test instructions for twin-line

brake system (workshop work) .....138

11.6 Tyres / wheels .....................................138

11.6.1 Air pressure in tyres ......................139

11.6.2 Assembling tyres (workshop work) ..139

11.7 Maintenance – hydraulics ................... 140

11.7.1 Identication of hydraulic hoses .... 141

11.7.2 Maintenance intervals ................... 141

11.7.3 Inspection criteria for hydraulic hoses ....141

11.7.4 Assembly and disassembly of

hydraulic hoses ..............................142

11.7.5 Oil change PTO-shaft pump .........142

11.8 Calibrating the ow meter ................... 143

12

11.9 Notes on crop sprayer test ..................144

11.9.1 Pump capacity test ........................ 144

11.9.2 Flow meter test .............................144

11.10 Electric lighting system .....................144

12. Nozzle selection..................................145

12.1 General ...............................................145

12.2 Procedure ...........................................145

12.2.1 With diagram and universal table ...145

12.2.2 With table of application

quantities ......................................148

12.3 Pressure ranges of different nozzles ...150

13. Liquid fertiliser operation ..................151

13.1 Conversion table for spraying

liquid fertiliser AHL ............................152

14. Waste disposal ...................................153

15. Tightening torques .............................154

Index ..........................................................156

13

1. Safety

1.1 Notes on representation

Warning notes

These operating instructions distinguish be-

tween three dierent types of warning notes.

The following signal words with warning symbols are used:

DANGER

Highlights a danger that will lead to death or

severe injury if it is not avoided.

WARNING

1.2 Qualication and

training of personnel

The crop protection sprayer must only be operated, serviced and repaired by persons who

are familiar with it and have been made aware

of the dangers involved. The owner is obliged

to exactly specify the area of responsibility,

competence and the monitoring of personnel.

If the personnel does not have appropriate

knowledge, it must be trained and instructed

accordingly. A person being instructed must only

work with or on the machine under the supervision of an experienced person.

The owner must further make sure that the personnel has read and understood the contents of

these operating instructions.

Maintenance work not described in these operating instructions must only be carried out in

authorized expert workshops.

Highlights a danger can lead to death or severe

injury if it is not avoided.

CAUTION

Highlights a danger that can lead to injury if it

is not avoided.

Please read the warning notes given in these

operating instructions!

Instructions

NOTE

Identies important notes.

Take-action instructions are indicated by arrow

points:

¾ ...

¾ Keep the order of the instructions. Alternatively,

instructions may be numbered consecutively.

Loading/

transport

Commissioning

Setup work

Operation

Maintenance

Troubleshooting

and fault

rectication

Waste disposal

Person

specially

instructed for

the activity

Instructed

operator

Persons with

professional

training

*

NOTE

* Maintenance and repair work on the machine

must only be carried out by a specialist workshop,

if the related work is identied with the sux

"Workshop work". Personnel in an expert workshop has the necessary knowledge and tools for

professional and safe execution of work.

The designations right, left, front and rear apply as

seen in travel direction.

14

1.3 Work place of the operator

The machine must solely be operated by one person and only from the driver's seat of the tractor.

When driving on public roads you must strictly

comply with the corresponding statutory regulations (in the Federal Republic of Germany the

StVZO and StVO).

When using public roads pay attention to the

relevant regulations!

1.4 Danger caused by failing to comply with the safety notes

Failing to comply with the safety notes can cause

danger for persons, but also for the environment

and the machine. Moreover, it can lead to the

loss of all compensation claims.

In detail, failing to comply with the safety regulations can lead to the following endangerments:

¾ Danger for persons caused by unsecured

working areas

¾ Failure of important machine functions

¾ Failure of specied methods for service and

maintenance

¾ Danger for persons caused by mechanical

and chemical eects

¾ Danger for the environment caused by hy-

draulic oil leaks

1.5 Safety conscious

Be prepared for emergencies. Always keep the

rst aid box close at hand.

Keep emergency numbers for physicians and

re ghters near the phone.

1.6 Safety notes for the operator

WARNING

Danger of crushing, cutting, being pulled in,

being caught and impact caused by missing

trafc and operational safety features.

Before each start, check the machine with re-

spect to safety in trac and operational safety!

1.6.1 Safety and accident prevention instructions

Besides the notices in these operating instructions you should also pay attention to the

generally valid safety and accident prevention

instructions!

working

The safety notes mentioned in these operating

instructions, any existing accident prevention

instructions and possibly existing internal work,

operating and safety instructions of the operator

must be strictly followed.

Besides the safety notes in these operating

instructions, the national and generally valid

occupational safety and accident prevention

instructions are also binding.

Follow the instructions given in the warning signs

to avoid dangers. The occupational safety and

accident prevention instructions issued by the

responsible liability association are binding.

¾ Before each commissioning of the machine all

safety and protective features must be properly assembled and fully functional. Check all

safety installations and protective features at

regular intervals.

¾ The attached warning and information decals

provide important notes for danger-free operation. Compliance serves your safety!

¾ When using public roads pay attention to the

relevant regulations!

¾ Faulty or disassembled safety installations

and protective features can lead to dangerous situations.

¾ Become familiar with all equipment and con-

trol elements as well as their functions before

starting work.

15

¾ It is prohibited to remain inside the working

range!

¾ Keep the machine clean and tidy to avoid

re hazards!

¾ Before drive o and before commissioning

check the immediate vicinity (children)! En-

sure sucient visibility!

¾ Couple the machine properly and use only

the specied facilities to fasten and secure

the machine!

¾ Pay attention to the permissible axle loads,

total weight and transport dimensions!

¾ Transport equipment, such as e.g. lighting,

warning facilities and possible protective features must be checked and installed!

¾ Operating elements (ropes, chains, linkages,

etc.) for remote controlled elements must be

routed in such a way, that they will not trigger

unintended movements in any transport and

working positions.

¾ Make equipment t for road travel and lock as

specied by the manufacturer!

¾ Always match the travel speed to the ambient

conditions!

¾ When driving up and down hill or across the

slope avoid sudden cornering!

¾ When driving on slopes – danger of tipping

over!

¾ Travel characteristics, steering and braking

ability are inuenced by attached or hitched

up equipment and ballasting weights. You

should therefore pay attention to sucient

steering and braking ability!

¾ Consider the overhang and/or centrifugal

mass of the machine when cornering.

¾ Only start operation of the machine after all

protective features have been installed and

are functional!

¾ Keep safety installations in good condition.

Replace missing or damaged parts.

¾ Using the machine for riding on or transporting

persons is prohibited!

¾ Do not remain in the turning and operating

range of the machine!

¾ The folding boom must only be operated when

there are no persons inside the slewing range!

¾ Parts actuated by external forces (e.g. hydrauli-

cally) have crushing and shearing points!

¾ When working on the crop protection sprayer

secure the machine with wheel chocks

against rolling away!

¾ Match your travel mode in such a way, that

you will at any time be able to securely control the tractor with hitched up or unhitched

machine at any time.

Be aware of your own abilities, account for the

road, trac, sight and weather conditions, the

driving characteristics of the tractor and the

inuences of the mounted or towed machine.

1.6.2 Coupling and uncoupling the machine

¾ Only couple the machine to such tractors and

transport it with tractors suitable for this purpose.

¾ Couple the machine properly to the specied

devices!

¾ By coupling the machine to the front and/or

rear of a tractor you must not exceed:

• the permissible total weight of the tractor

• the permissible tractor axle loads

• the permissible tyre load bearing capacities

of the tractor tyres

¾ Secure both tractor and machine against

unintended rolling away before coupling or

uncoupling the machine!

¾ Persons are not allowed to stand between

the machine to be hitched up and the tractor, while the tractor is moving towards the

machine!

Possibly assisting persons must stay besides

the vehicles and may only step between the

vehicles when these are at standstill.

¾ Lock the operating lever for the tractor hydrau-

lics in a position in which accidental lifting or

lowering is ruled out!

¾ When hitching and unhitching machines move

the supporting devices (if present) to the corresponding position (stability).

16

¾ When operating supporting devices there is

danger of injuring at crushing and shearing

points!

¾ Be particularly cautious when coupling and

uncoupling the machine to or from the tractor!

There are crushing and shearing points at the

coupling point between tractor and machine!

¾ Persons are not permitted to stand between

tractor and machine when the hydraulic system is operated!

¾ Coupled supply lines

• must easily follow all movements when

cornering without any tension, buckling or

chang.

• must not rub against other parts.

¾ Triggering ropes for quick release couplings

must hang down loosely and should not trigger any action when in lowest position!

¾ Always park unhitched machines in a stable

position!

¾ Never unhitch with an empty tank and un-

folded folding boom!

Negative drawbar load can cause the machine

to tip over!

1.6.3 Working with the machine

¾ Never climb onto a ,moving machine!

¾ Parts actuated by external forces (e.g. hydrau-

lically) have crushing and shearing points!

¾ Power operated machine parts must only be

actuated if persons keep a sucient safety

distances to the machine!

¾ Secure the tractor against unintended starting

and accidental rolling before leaving it.

To do so

• lower the machine to the ground

• apply the parking brake

• shut down the tractor engine

• Pull out the ignition key

1.6.4 Changing equipment

¾ Secure the machine against unintended roll-

ing away!

¾ Secure raised frame parts you have to work

under with suitable supports!

¾ Caution! Danger of injury caused by protrud-

ing parts (boom parts, etc.)!

¾ Do not step on moving or other rotating parts

to climb onto the machine. You could fall and

be seriously injured.

¾ Become familiar with all equipment and con-

trol elements of the machine as well as their

functions before starting work.

¾ Wear tight tting clothes! Loose clothes in-

crease the danger of being caught or pulled

in by rotating or moveable components.

¾ Only start operation of the machine, if all pro-

tective features have been installed and are

fully functional in protective position!

¾ Observe the maximum payload of the mount-

ed / hitched up machine and the permissible

axle and drawbar loads of the tractor. If necessary drive with the tank only partly lled.

¾ Persons are not permitted to stay inside the

working range of the machine!

¾ Persons are not permitted to stay inside the

turning and slewing range of the machine!

¾ Use accessing aids and steps only at stand-

still. During operation it is not permitted to ride

on the machine as a passenger!

17

1.6.5 Transporting the machine

¾ When driving on public roads comply with the

corresponding national road trac regulations!

¾ Before starting transport travels check the

correct connection of all supply lines:

• the light system for damage, function and

cleanliness

• the brake and hydraulic system for appar-

ent faults

• whether the parking brake is fully released

• the function of the brake system

¾ Always ensure sucient steering and braking

capacity of the tractor!

Machines attached to or towed by a tractor or

front or tail weights aect the driving properties as well as the steering and braking ability

of the tractor.

¾ Observe the maximum payload of the mount-

ed / hitched up machine and the permissible

axle and drawbar loads of the tractor!

¾ The tractor must secure the prescribed brak-

ing deceleration for the load carrying tractor/

machine combination!

¾ Check the braking eect before setting o!

¾ Consider the width and centrifugal mass of

the machine when cornering with the machine

attached or hitched up!

¾ Before starting transport travels move all sle-

wable machine parts into transport position!

¾ Before starting transport travels lock all sle-

wable machine parts in transport position to

prevent endangering position changes.

Use the dedicated transport locks for this

purpose!

¾ Before starting transport travels lock the con-

trol levers for the hydraulic system to prevent

accidental lifting or lowering of the attached

or hitched up machine!

¾ Before starting transport travels check wheth-

er the necessary transport equipment has

been correctly mounted to the machine, such

as e.g. lighting, warning signs and protective

features!

¾ Match the travel speed to the prevailing con-

ditions!

¾ Shift to a lower gear before driving downhill!

¾ Always switch o single wheel braking (lock

the pedals!) before starting transport travel!

¾ Pay attention to the notes in chapter Transport

travel.

1.6.6 Hydraulic system

WARNING

¾ The hydraulic system is under high pressure!

¾ Ensure correct connection of the hydraulic

hoses!

¾ When connecting hydraulic hoses make sure

that the hydraulic system has been depressurized on both tractor and machine side!

¾ Blocking actuators on the tractor, which serve

the purpose of directly executing hydraulic or

electric movements of components, such as

e.g. folding, slewing and pushing processes,

is prohibited.

The corresponding movements must automatically stop once you release the corresponding actuator. This does not apply for

equipment which

• are continuous or

• automatically controlled or

• require a oating or pressure position be-

cause of their function

¾ Before starting work in the hydraulic system

• lower the machine to the ground

• depressurize the hydraulic system

• shut down the tractor engine

• apply the parking brake.

• pull out the ignition key

18

¾ Pressure accumulator

Depending on the equipment of the machine,

the hydraulic system may have a pressure accumulator installed. Do not open or work (welding, drilling) on the pressure accumulator. Even

after being emptied, the tank is still preloaded

by gas pressure. Always depressurize the

pressure accumulator before starting work on

the hydraulic system. The pressure gauge (if

present) should not indicate any pressure. The

pressure in the pressure gauge must drop to 0

bar. Only then may work be carried out on the

hydraulic system.

¾ Have the hydraulic hoses inspected by an ex-

pert under occupational safety related aspects

at least once every year!

¾ Replace hydraulic hoses if damaged or exces-

sively aged! Use only genuine hydraulic hoses

from HORSCH LEEB AS!

¾ In order to avoid accidents caused by unde-

sired hydraulic movements or hydraulic movements triggered by other persons (children,

passenger), the control units on the tractor

must be secured and locked when not in use

or in transport position.

1.6.7 Electrical system

Always disconnect the battery (negative pole)

before starting work in the electric system!

¾ Use only the specied fuses! The use of too

strong fuses will destroy the electric system.

Fire hazard!

¾ Make sure that the battery is correctly con-

nected. Connect the plus pole rst and the

minus pole after. When disconnecting discon-

nect the negative pole rst and the positive

pole after!

¾ The utilization period of hydraulic hoses

should not exceed six years, including a possible storage time of maximum two years.

Even if properly stored and under permissible

stress, hoses and hose connections are subject to natural ageing, which limits their shelf

life and utilization period. Deviating from this,

the utilization period can also be determined

on the basis of empirical values, particularly

under due consideration of the endangering

potential. For hoses and hose lines made of

thermoplastics other guide values may be

decisive.

¾ Never try to seal o leaking hydraulic hoses

with your hands or ngers. Fluids (hydraulic

oil) escaping under pressure can penetrate

the skin and enter into the body causing severe injury! If injured by hydraulic oil, consult

a doctor immediately! Danger of infection!

¾ Due to the possible danger of severe infec-

tions, one must use appropriate auxiliary

means when looking for leakages!

¾ Power sockets and connectors (electric,

pneumatic) should be identied by colour to

rule out operating errors.

¾ Always cover the positive battery pole with the

dedicated covering. Danger of explosion in

case of short-circuit to ground!

¾ Avoid sparking and naked ames in the vicin-

ity of the battery! Danger of explosion!

¾ The machine can be equipped with electronic

components and parts, the function of which

can be aected by the transmission of electromagnetic waves from other equipment. Such

inuences can lead to the endangerment of

persons, if the following safety notes are not

complied with.

In case of a subsequent installation of electric

appliances and/or components on the machine, with connection to the on-board power

supply, the user in his own responsibility must

check whether this installation will cause

interferences in the vehicle electronics or in

other components.

Make sure that the subsequently installed

electric and electronic components are

in accordance with the valid issue of the

EMC directive 2014/30/EC and are identied

with the CE-sign.

19

1.6.8 Towed machines

1.6.10 Pneumatic brake system

¾ Pay attention to the permissible combinations

of hitching device on the tractor and drawbar

hitch on the machine!

Couple only permissible vehicle combinations

(tractor and towed machine).

¾ In case of single-axle machines pay attention

to the maximum permissible drawbar load of

the tractor on the hitching device!

¾ Always ensure sucient steering and braking

capacity of the tractor!

Machines mounted to or towed by a tractor

aect the travel behaviour as well as the steering and braking ability of the tractor, especially

single-axle machines with drawbar load applied to the tractor!

¾ For drawbars with drawbar load, the height

of the drawbar must only be adjusted in a

specialist workshop!

1.6.9 Brake system

¾ Only drive o with the hitched up machine af-

ter the operating pressure required to release

the brake has been reached (pressure gauge

on tractor).

¾ Before coupling the machine clean the seal

rings on the coupling heads of the supply and

brake line from possible contamination!

¾ Close the coupling heads on the tractor before

driving without machine!

¾ Close the coupling heads of supply and brake

lines and hook these into the brackets provided for this purpose!

¾ Drain the air vessel daily!

¾ The specied settings on the brake valves

must not be changed!

¾ Change the air vessel if it is loose in the ten-

sion straps, if it is damaged, the type plate is

corroded, loose or missing.

1.6.11 Tyres

¾ Adjustment and repair work on the brake

system must only be carried out in expert

workshops or established brake service

workshops.

¾ Immediately stop the tractor in case of brake

system malfunctions.

Have the malfunction remedied immediately.

¾ The brake system must be thoroughly

checked at regular intervals.

¾ Securely park the machine before starting

work in the brake system. Secure the machine

against unintended lowering and rolling away

(wheel chocks)!

¾ Be extra careful when performing welding,

ame cutting or drilling work near brake lines!

¾ After setup and repair work on the brake sys-

tem you must generally carry out a brake test!

¾ Pay attention to the corresponding regulations

(France) when changing the hydraulic oil!

¾ Only use the specied hydraulic oils (France)

when topping up or changing the hydraulic oil.

¾ When working on the tyres make sure that the

machine has been parked safely and properly

secured against rolling away and accidental

lowering (parking brake, wheel chocks).

¾ The assembly of wheels and tyres requires

profound knowledge and the use of proper

assembly tools!

¾ Repair work on tyres and wheels must only be

carried out by specialists and only with the appropriate assembly tools for this kind of work!

¾ Check the air pressure regularly! Pay attention

to the specied air pressure!

¾ Check the wheel nuts regularly and retighten

all fastening screws and nuts as specied by

HORSCH LEEB AS GmbH! Failing to do so

can lead to loosing wheels and thus to the

machine tipping over.

20

1.6.12 Handling crop protection agents

1.6.13 Operating the crop protection sprayer

¾ Follow the recommendations of the crop

protection agent manufacturers in regard to

• protective clothing.

• Warnings concerning the handling of crop

protection agents.

• Regulations for metering, use and cleaning.

¾ Store all relevant information about the used

crop protection agent (safety data sheets,

instructions for use, etc.) in the document

container.

¾ Pay attention to the notes in the “AID” publica-

tions - No. 1237 “Crop protection terminology”

and No. 1042 "Caution when handling crop

protection agents”. (Only available in German)

¾ The water quality (the water hardness and

mineral content in particular) inuences the

property of some fertilisers and crop protec-

tion agents. Precipitation and deocculation

can cause deposits in lters and nozzles.

Example: Extremely calciferous water reacts

with sulphate-bearing fertiliser to form calcium

sulphate (gypsum) and causes white deposits

in the lters.

Pay attention to the conditions of use and

the combination possibilities given by the

corresponding manufacturers to avoid such

problems!

¾ Observe the data on compatibility of crop

protection agents with materials of the crop

protection sprayer!

¾ Do not spray any crop protection agents that

have a tendency to agglutination or solidication!

¾ When handling crop protection agents wear

suitable protective clothing.

¾ Do not eat, drink or smoke while handling crop

protection agents!

¾ Keep crop protection equipment and crop

protection agents out of the reach of children!

¾ Always ensure a sucient water supply in the

machine to be able to wash o crop protection

agent in events of emergency.

¾ In case of physical contact with crop protection

products you may need to consult a physician.

¾ Thoroughly clean hands and face after the

end of work.

¾ Pay attention to the notes in the Plant Protec-

tion Act!

¾ Observe the notes in the publications of the

"Federal Ministry for food, agriculture and

consumer protection".

¾ Never open pressurized lines!

¾ Use only original spare hoses from HORSCH

LEEB AS, which will withstand the chemical,

mechanical and thermal loads. For assembly

you should generally use hose clamps made

of V2A.

¾ Repair work inside the spraying mixture con-

tainer must only be performed after thorough

cleaning and with a respirator. This work must

be monitored by a second person outside the

spraying mixture container for safety reasons.

Ensure sucient ventilation of the spraying

mixture container!

¾ Please pay attention to the following when

repairing crop protection sprayers which have

been used with ammonium nitrate - carbonyl

diamide solution:

by the evaporation of water, residues of ammonium nitrate - carbonyl diamide solution

can be form salt on or inside the spraying

mixture container. This results in pure ammonium nitrate and carbonyl diamide. In its pure

form, ammonium nitrate in connection with

organic matter , such as e.g. carbonyl diamide,

becomes explosive, if critical temperatures

(caused by e.g. welding work, grinding, ling)

are reached during repairs.

¾ By thorough washing o the spraying mixture

container or the parts to be repaired with

water, this endangerment can be eliminated,

because the salt of the ammonium nitrate carbonyl diamide solution is water soluble.

Therefore always clean the crop protection

sprayer thoroughly with water before starting

repair work!

¾ The rated volume of the spraying mixture

container must not be exceeded when lling!

¾ At the headland reduce the travel speed and

switch o the sprayer.

¾ Excessive, jerky steering movements at the

beginning and the end of a curve will put extreme loads on the folding boom.

21

¾ When applying small droplets under strong

wind, the chemical can be blown about and

thus cause damage for others!

¾ If the soil is very dry, the applied chemical

can be blown away together with dust and

cause damage. Always wait until the soil is

suciently moist!

¾ Check the following from time to time: Meter-

ing quantity, clogged nozzles, damage to

machine parts, leakage and cleanliness of

the machine.

¾ For tractors with cabins with ventilation fans

replace the fresh air lters with activatedcarbon lters!

¾ Ensure that the category of the tractor cabin

is approved for the respective crop protection

agent used.

¾ Do not ll crop protection sprayers with water

from open waterbodies - to protect man, animal and environment!

¾ Always ensure a sucient water supply in the

machine to be able to wash o crop protection

agent in events of emergency.

¾ When using these products strictly comply

with the instructions for use and the precautions listed issued by the crop protection

product manufacturer!

¾ Information concerning the preparations used

must always be kept in the transport box, so

that these are available for rescue services

in case of accidents.

¾ Fill the crop protection sprayer only through

original HORSCH LEEB AS lling equipment

and by gravity feed via the water mains!

¾ Never blow out nozzles and other small parts

with your mouth!

¾ Thoroughly clean hands and face after the

end of work.

1.6.14 Maintenance

WARNING

Danger of poisoning - Do not climb into the

spraying mixture container!

Only trained personnel with suitable protective

outt and securing devices may climb into the

tank for cleaning.

¾ Wear gloves to protect against sharp-edged

machine parts.

¾ Repair, maintenance and cleaning work as

well as the rectication of malfunctions must

generally be carried out with the engine shut

down! Pull the machine plug o the on-board

computer. Pull out the ignition key!

¾ Before starting maintenance work clean the

crop protection sprayer, especially all parts

which are contaminated by spraying mixture.

¾ Perform all specied adjustment, maintenance

and inspection tasks as scheduled.

¾ Secure all operating media like pneumatic

and hydraulic system against unintended

starting up.

¾ Secure the raised machine or raised machine

parts against accidental lowering before starting maintenance, repair and cleaning work!

¾ Safely take up and fasten large assembly

groups with lifting gear for replacement.

¾ Check nuts and screws regularly for tight t

and retighten as necessary!

¾ When exchanging cultivation tools use ap-

propriate tools and wear gloves!

¾ Dispose of oils, greases and lters according to

applicable regulations!

¾ Prior to working on the electrical system,

disconnect it from the electric current supply!

¾ Disconnect the cable from the generator

and the battery of the tractor before starting

electric welding work on tractor or connected

machines!

The ground connection must be as close as

possible to the welding point.

22

¾ If protective features are subjected to wear,

they must be inspected at regular intervals

and replaced in due time!

¾ Spare parts must at least meet the technical

requirements specified by the equipment

manufacturer! This is ensured when using

original spare parts from HORSCH LEEB AS!

¾ For the storage of gas use only nitrogen for

lling - danger of explosion!

1.7 Loading and unloading

WARNING

Danger of accident when using an inappropriate

tractor and if the brake system of the machine is

not connected with the tractor or not lled!

1.8 Unauthorized conversion and manufacture of spare parts

WARNING

Danger of crushing, cutting, being caught,

being pulled in and impact caused by the

breakage of load bearing components.

The following is generally prohibited:

¾ drilling in frame and undercarriage

¾ enlargement of existing bore holes on frame

and undercarriage

¾ welding on load bearing parts

Hitch the machine properly to the tractor be-

fore the machine is loaded on or o a transport

vehicle!

For loading and unloading the machine only

use a tractor which meets the specied power

requirements!

NOTE

Only start to drive with the coupled machine

after the operating pressure required to release

the pneumatic brake system has been reached

(pressure gauge on tractor).

Conversions or changes to the machine are only

permitted in agreement with the manufacturer.

Original spare parts and authorized accessories

serve your safety.

This also applies for welding work on load bear-

ing components.

The use of parts other than the ones specied

may result in the rejection of liability for result-

ing damage.

Use only conversion and accessory parts approved by HORSCH LEEB AS GmbH, e.g. to

maintain the validity of the type approval as per

national and international regulations.

The following machines must be in a condition

that is determined by the corresponding acceptance or approval:

¾ Vehicles with a governmental type approval

¾ facilities and equipment connected with a ve-

hicle with a valid type approval or an approval

for road trac.

23

1.9 Impermissible

1.11 Working in the

operating modes

The operational safety of the delivered machine

is only ensured in case of intended use as speci-

ed in the operating instructions.

The limit values specied in the data sheets must

under no circumstances be exceeded.

1.10 Spare parts and wear items as well as auxiliary materials

Machine parts in unacceptable condition

must be replaced immediately.

Use only original HORSCH LEEB AS spare parts

and wear items, to maintain the validity of the

type approval as per national and international

regulations.

When using spare parts and wear items from

third parties it cannot be ensured that these

have been designed and manufactured under

the aspects of expected loads and safety.

HORSCH LEEB AS GmbH does not assume

liability for damage resulting from the use of

unapproved spare parts and wear items or

auxiliary materials.

vicinity of high voltage

power lines

Be extra cautious when working under or within

the range of high voltage power lines.

WARNING

Danger of electric accidents by touching high

voltage power lines or voltage transfer via the

spraying boom!

¾ The total height of 4 m can also be consider-

ably exceeded during eld work. This can

occur with lifted parallelogram and angular

actuated boom wings.

Assess the situation before starting work.

¾ If you have to pass under overhead lines, you

must ask the owner of these overhead lines

about their rated voltage and minimum height.

¾ The safety distances specied in the table must

under no circumstances be fallen short of.

Rated voltage Safety distance from

overhead power lines

[kV] [m]

up to 1 1

1 to 110 2

110 to 220 3

220 to 380 4

1.12 Phone and radio equipment

Phones and radio equipment not connected to

an external aerial can disturb the function of

the vehicle electronics and thus endanger its

operational safety.

24

1.13 Danger caused by residual energy

Pay attention to the occurrence of mechanical,

hydraulic, pneumatic and electric/electronic

residual energies on the machine. Apply appropriate measures when instructing operating

personnel. You will nd detailed notes in the

corresponding chapters of the operating instructions.

1.14 Cleaning and waste disposal

Handle and dispose of used materials and

substances in a professional way (see chapter

“Waste disposal of crop protection sprayer”).

This applies in particular for work on the lubrication system and facilities and when cleaning

with solvents.

NOTE

Do not clean new machines with a steam jet of

a high pressure cleaner. The paint takes approx. 3 months to cure and could be damaged

before this time.

1.15 Intended use

Use of the crop protection sprayer is considered

as intended if the following points are accounted

for during operation of the machine. The manufacturer is not liable for damages from unintended

use. The risk will be borne solely by the user.

¾ The crop protection sprayer is intended for the

application of crop protection agents (insecticides, fungicides, herbicides, etc.) in form of

suspensions, emulsions and mixtures as well

as of liquid fertilisers.

¾ The sprayer is solely intended for agricultural

applications in the treatment of plantations. It

is compliant with the latest technical standard

and, when correctly set and adjusted and with

the correct metering, it ensures biological

success.

¾ The machine must only be operated for its

intended use if in a technically perfect condition, whilst being aware of safety and risks

and in strict compliance with the operating

instructions!

¾ The working machine is operated by one

person sitting in the cabin.

¾ The crop protection sprayer is a working ma-

chine, which must only be driven on public

roads in strict compliance with the permitted

axle loads.

¾ Any faults that could adversely aect opera-

tional safety must be eliminated immediately!

¾ Defective or excessively strained parts must

be replaced immediately. The machine must

otherwise not be operated.

¾ Use only genuine HORSCH-LEEB-AS spare

parts for repairs. Other spare parts have

not been tested and approved by HORSCH

LEEB AS and may have a negative inuence

on machine characteristics or severely aect

the safety.

¾ Changes to the machine, which may have a

negative eect on safety, are only permitted

with the consent of the manufacturer.

The equipment is suitable for terrain sloping in

¾ Layer line

travel direction to the left 15 %

travel direction to the right 15 %

¾ Slope line

Uphill 15 %

Downhill 15 %

Intended use also includes:

¾ paying attention to all notes in these operating

instructions.

¾ compliance with the specied inspection and

maintenance work.

¾ the sole use of genuine HORSCH LEEB AS

spare parts.

Any use different than described above is prohibited and is considered unintended.

25

For damage caused by unintended use

¾ mechanical damage (e.g. pump defects)

¾ the owner shall be solely responsible!

¾ HORSCH LEEB AS GmbH will not assume

any liability.

1.15.1 Specied equipment

The specied equipment of the crop protection

sprayer results from the combination of

¾ Basic equipment and undercarriage

¾ Tyres

¾ drawbar

¾ Pressure tting

¾ Pump equipment

¾ Spraying boom

¾ Spraying lines with section control and op-

tional equipment

Should one of our sales oces create an individual type, that is not listed hereunder, the sales

oce in question is obliged to issue the declaration required by § 25 of the plant protection act

from 15/09/1986, to the Julius-Kühn-Institute.

The forms required for this purpose are available from:

Julius Kühn-Institute

Federal Research Institute for Crops

Messeweg 11/12

D-38104 Braunschweig

1.15.2 Consequential damage

The machine has been manufactured by

HORSCH LEEB Application Systems GmbH

with great care. However, despite the intended

use deviations in placement quantity up to total

failure may be caused by e.g.:

¾ dierent compositions of crop protection agents

(insecticides, fungicides, herbicides etc.) in the

form of suspensions, emulsions and mixtures as

well as liquid fertilisers

¾ blockages and bridging (e.g. agglutination or

occulation of crop protection agents)

¾ wear of wear items

¾ incorrect application quantities and travel

speeds

¾ incorrect sprayer settings and non-compliance

with the "Good professional practice in crop

protection - fundamentals for execution"

¾ reaction of crop protection agents caused by

impermissible mixing of two or more dierent

crop protection agents (e.g. occulation of the

spraying mixture)

1.15.3 Effects when using certain crop protection products

At the time the crop protection sprayer is manufactured the manufacturer is aware of only a

few crop protection agents with BBA (Biological

Federal Institute for Agriculture and Forestry)

approval, which could have a damaging eect

on the materials used in the crop protection

equipment.

We would like to point out, that e.g. crop protection agents known to use, like Lasso, Betanal

and Tramal, Stomp, Iloxan, Mudecan, Elancolan

and Teridox will cause damage to hoses and

switching diaphragms, if these are exposed

to such products over a longer period of time

(20 hours). The listed examples do not claim

completeness.

We particularly warn against the use of non-

permitted mixtures of two or more dierent crop

protection agents. Substances with a tendency

to agglutination or solidication must not be

placed.

When using such aggressive crop protection

agents it is highly recommended to place these

immediately after the preparation of the spraying

mixture and thoroughly clean the system with

water after.

The materials and components used for the

HORSCH LEEB AS crop protection sprayers

are liquid fertiliser proof.

¾ damage caused by external eects (e.g.

ow meter)

26

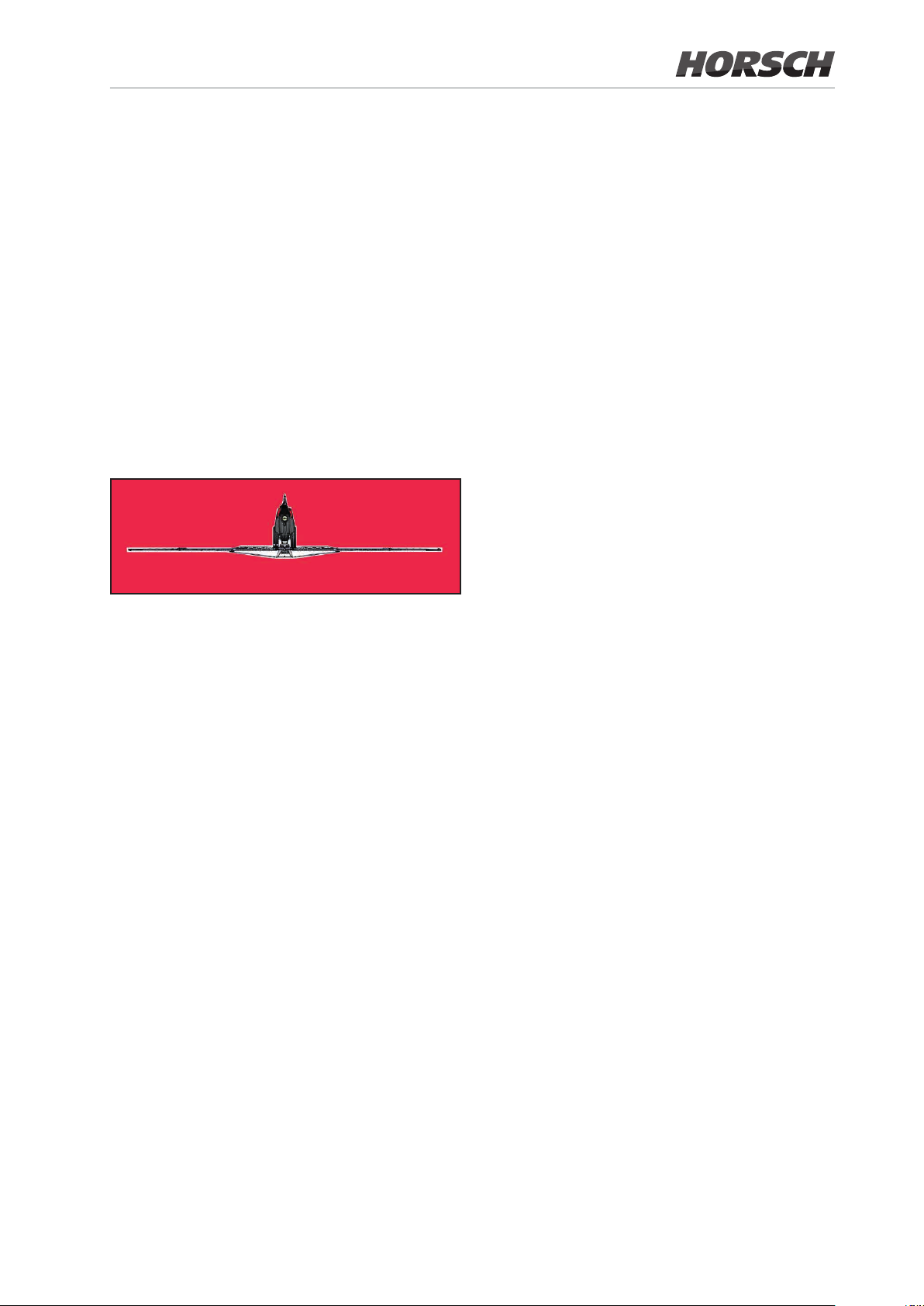

1.15.4 Danger zones and danger points

No persons are to remain within the danger zone

of the machine,

The danger zone is the area around the machine, in which persons could be reached

¾ by work related movements of the machine

and its cultivation tools

¾ by materials or foreign objects thrown out of

the machine

¾ accidentally lowering or lifted cultivation tools

¾ unintended rolling of the vehicle

The area marked red indicates the danger zone

of the machine:

The danger zone of the machine contains

dangerous spots with permanently existing or

unexpected dangers. These danger spots are

marked with warning signs, which warn against

residual dangers, that cannot be technically

eliminated by design. In these cases the special

safety regulations in the corresponding chapters

do apply.

¾ as long as the tractor engine is running with

the hydraulic system connected.

¾ as long as tractor and machine have not been

secured against unintended starting and accidental rolling away.

The operator must only move the machine or

change cultivation tools from transport to working position and vice-versa or drive these implements, if the danger zone of the machine is free

of persons.

Danger spots exist:

¾ between tractor and crop protection sprayer,

especially when coupling and uncoupling

¾ in the area of moving components.

¾ on the driving machine.

¾ in the slewing range of the spraying boom.

¾ in the spraying mixture container due to toxic

vapours.

¾ under the raised, but unsupported machine

or parts of the machine.

¾ when unfolding and folding the spraying boom

in the area of overhead lines by contacting

such power lines.

27

1.15.5 Personal protection equipment

WARNING

Health hazards caused by accidental contact

with crop protection products or spraying

mixture!

NOTE

Do not enter the tractor cabin with contami-

nated protective outt!

Take off the protective outt and store it

in the stowage box of the crop protection

sprayer.

Wear your own personal protection outt:

¾ when preparing the spraying mixture

¾ when cleaning / replacing the spray nozzles,

during spraying operation, during all work to

clean the crop protection sprayer after spraying operation.

When wearing the required protective clothing

you should always follow the information of

the manufacturer, the product information, the

instructions for use, the safety data sheet or the

operating instructions for the crop protection

product to be used.

Required equipment:

¾ chemicals resistant gloves

¾ chemicals resistant overall

¾ waterproof shoes

¾ face protection

¾ respirator

1.15.6 Organizational measures

NOTE

The owner must provide the necessary personal

protective outt as specied by the manufacturer

of the crop protection agent to be applied.

1.15.7 Operating instructions

¾ The operating instructions must always be

kept near the place of use of the machine!

¾ The operating instructions must always be

freely accessible for operator and maintenance

personnel!

NOTE

Check all existing safety features at regular

intervals!

¾ safety goggles

¾ skin care agent, etc.

Wear your safety gloves:

¾ before you start to process crop protection

agents,

¾ before starting work on the contaminated crop

protection sprayer or

¾ before cleaning the crop protection sprayer.

Wash off your safety gloves off with clear

water from the fresh water tank:

¾ immediately after any contact with crop pro-

tection products

¾ before taking o the protective gloves.

28

1.16 Safety notes on the

1.17 Instruction sticker

machine

The towed crop protection sprayer LT is

equipped with safety and protective features.

Not all danger spots on this machine can be

completely safeguarded under due consideration of the functionality of the machine. Corresponding safety notes on the machine point to

still remaining residual risks.

The danger notes are applied in the form of warning signs or safety stickers.

Their position and meaning is shown next!.

NOTE

Become familiar with the meaning of the

adjacent warning signs.

The opposite texts and the attachment

location on the machine provide information about the special danger spots on the

machine.

Keep all warning signs on the machine in

clean and legible condition! Replace illegible

warning signs!

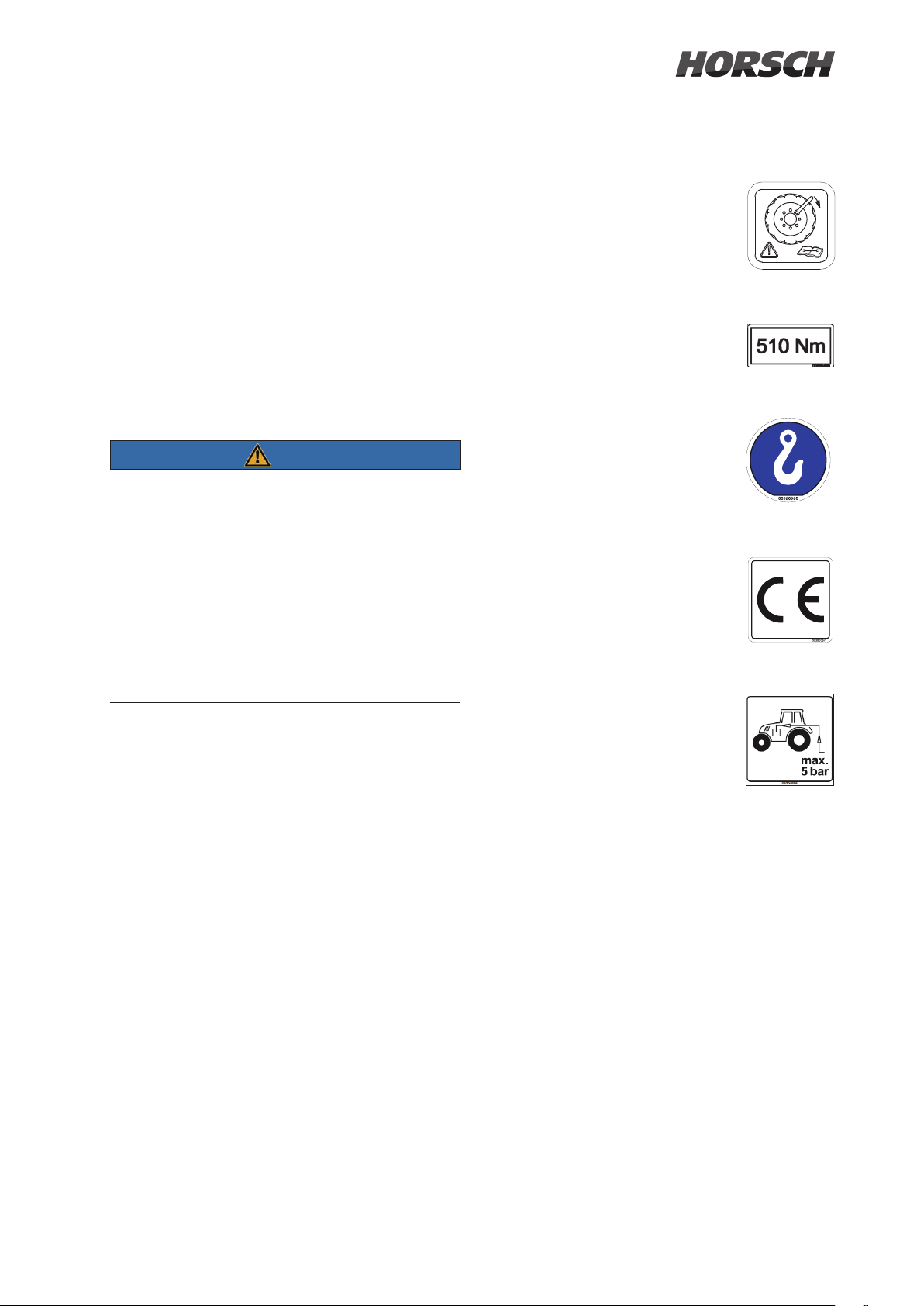

Check and retighten wheel nuts or

wheel bolts at regular intervals see maintenance overview!

00380359

00380359

Tightening torque for wheel studs /

wheel nuts - 510 Nm

00385489

Loading hook; attach lifting tackle

(chains, ropes, etc.) here when

performing loading work.

00380880

The CE-sign indicates that the machine complies with the basic health

and safety requirements.

00380067

The return pressure of the hydraulics from the crop protection sprayer

to the tractor must not exceed

5 bar.

04004899

1.18 Safety stickers

Safety stickers on the machine warn of hazards

at dangerous points and are an important part

of the safety equipment of the machine. Missing safety stickers increase the risk of severe or

even fatal physical injuries.

¾ Clean soiled safety stickers.

¾ Damaged or illegible safety stickers must be

replaced immediately.

¾ Provide spare parts with the specied safety

stickers.

29

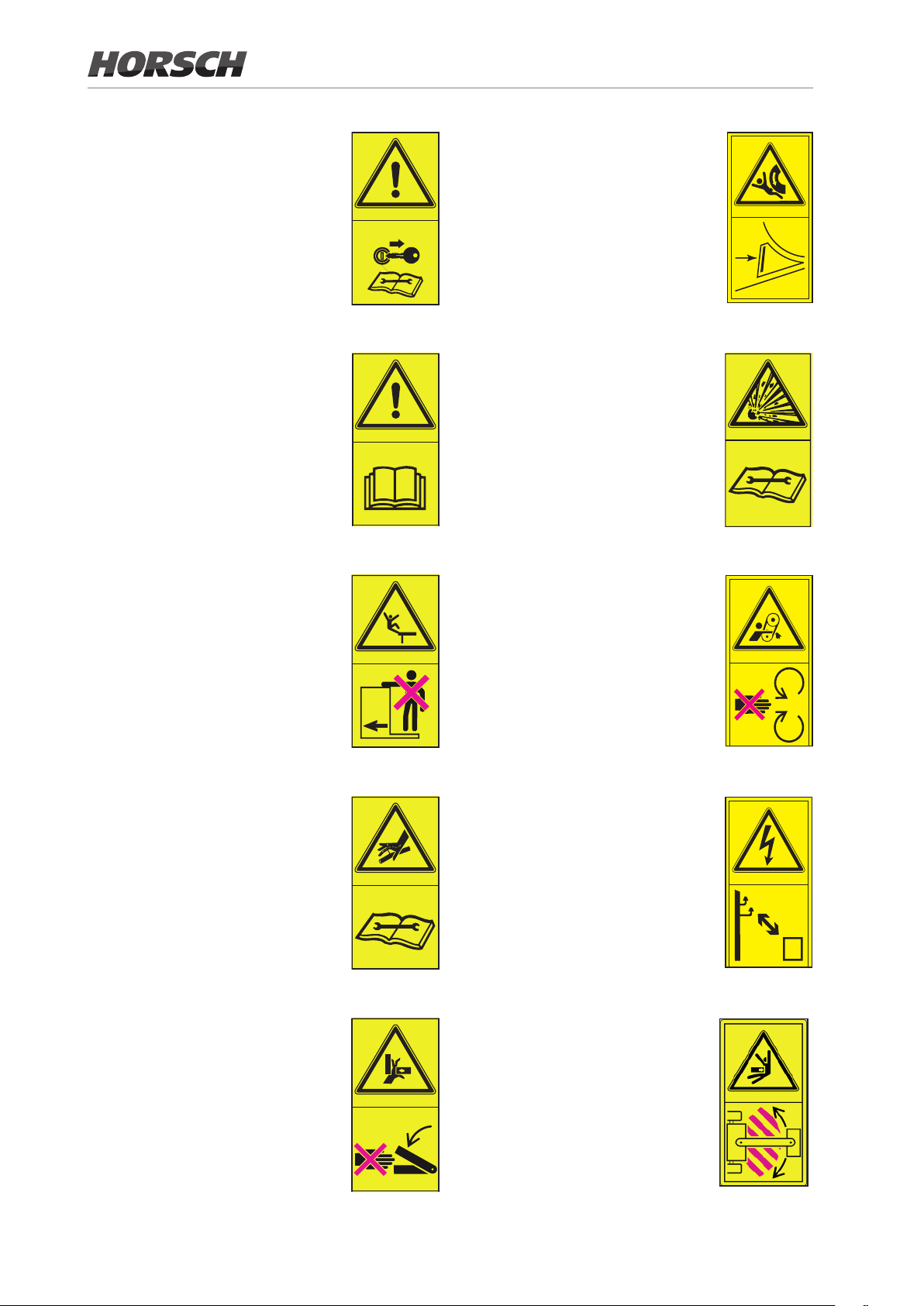

Switch the engine o and pull out

the key before starting maintenance

and repair work.

Endangerment caused by accidental movement of the machine!

Before commissioning the machine

you should read and follow the op

erating instructions!

No passengers are allowed to ride

on the machine!

04002983

-

04002983

04001455

04002983

The pressure accumulator is

charged with gas or oil pressure.

Dismantle and repair only in strict

compliance with the instructions in

the technical manual.

04001679

Do not open or remove protective

features while the engine is running!

04002983

Take care of emerging high pres-

sure uid! Follow the notes in the

operating instructions!

Never reach into areas where there

is a risk of crushing as long as parts

could still be moving!

04002983

04001683

Keep a sucient distance to electric

high voltage power lines!

04002983

Staying in the operating range of

the drawbar between tractor and

towed machine is prohibited!

04002622

30

Loading...

Loading...