Shocker XL Installation Instructions

Planning Your Installation

If this isn’t the second time you’re reading the instructions, keep reading!

• Plan out the location of each component before starting your installation.

• Make sure you have enough airline and wire to install the system before beginning.

• Make sure mounting locations are secure and void of debris. The horns are ideal for mounting under the

cab, along the frame rails, in front of your radiator, etc. To prevent your horns from being muffled, leave

plenty of space in front of them to allow them to project (horns facing down is ideal).

• The electric valve may be mounted anywhere in-line between the air tank and the horns but the less

tubing used between the valve and horns, the sharper the crisp!

• The horns should not be mounted where they will be submerged or will receive any kind of impact.

Installing Your Horns

ning the panel nut for the rear mount and the nut for the front mount, torque only enough to secure the

horn firmly in place.

• Drill a 7/16” hole for the rear mount first, then mark a location for the 3/16” front mount hole. When tighte

Installing Your Valve

from your tank and towards your horns. On some valves the inlet port may also be marked as ‘in’ or ‘inlet’.

The air valve may be mounted in any direction but it is recommended that it is mounted vertically.

• Locate the directional arrow on the valve body, for the direction of air flow. The arrow should point away

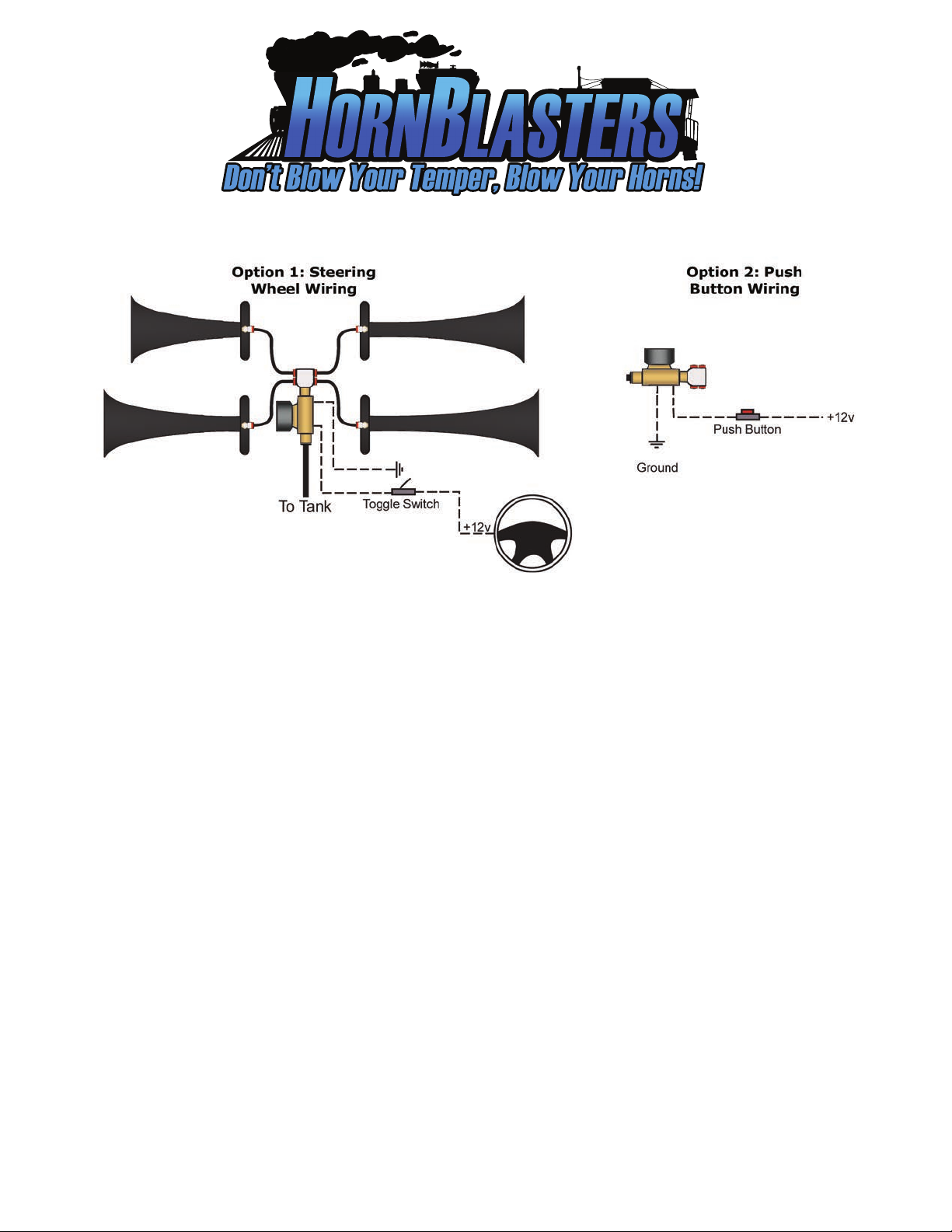

Wiring Your Valve

Once you have grounded one of the valve terminals, please choose one of the next two options for the switch.

• Option 1 (using a toggle switch & steering wheel): Wire the other terminal to a toggle switch and then into

your electric horn 12 volt line under the hood. This will let you blow the horns from the steering wheel

button with an On/Off switch.

• Option 2 (use a push-button switch): Wire the other terminal to a momentary button switch in a convenient

location and wire the other side of the switch to a 12 volt power source.

Test your solenoid valve by activating the switch. This should cause the valve to click if wired correctly.

Running Air Line the the Horns

It is very important to turn o all compressors and drain the tanks before you start connecting the horns. Before

cutting any air tubing, make sure to double check your measurements. Make sure to cut equal lengths of air line to connect

each horn to the manifold or the horns may sound at dierent times. We recommend cutting your lengths with at least an

extra inch per line just to be safe. Unlike compression ttings, the push to pull connectors can be used multiple times. The air

valve should connect to the center tting of the 4-point banjo tting. When threading any ttings make sure to use Teon

tape or lock-tight to prevent air leaks. Some ttings may already have pipe sealant applied on their threads for your convenience. The air valve may be mounted in any direction but it is preferred that it is mounted vertically.

Air Horns to Tank:

[Air Tank] » [1/2” NPT M to 1/2” PTC Fitting] » [1/2” Air Line] » [1/2” NPT M to 1/2” PTC Fitting] » [Air Valve] » [1/2” to 4x

5/16” NPT M Banjo Fitting] » [5/16” Air Line] » [5/16in P2P to 1/8in NPT F Elbow] » [Rear Horn Mount]

1. Plan out the ttings placement before you begin and make sure you understand the correct order.

2. Make sure that your tank is empty of air and that the compressor is not running during installation.

3. Start by cutting equal lengths of 5/16” tubing to run from each horn to the banjo tting.

4. Install your banjo tting into the outlet port of your 1/2” air valve. If the valve has a directional arrow on its body, the

arrow starts with the inlet and points out the outlet; the arrow should point towards your horns.

5. Plumb each horn to the banjo tting, making sure that the lines are inserted rmly into their sockets. You do not use

Teon tape or pipe sealant with the PVC ttings.

6. Finally connect your air valves inlet port to your air tank using 1/2” air line using the 1/2” M NPT to 1/2” PTC ttings. Make

sure to use a side or top port on your tank so that condensation will not drain in to your air valve.

Finishing Up

The nal step is testing your installation! Turn you air system back on and once the tank is full, check for air leaks on the ttings

throughout the whole system. If you see any problems, re-plumb those ttings as you deem neccessary. You’re almost done!

Get Involved In The Train Horn Community

No matter what your take is on your new train horn kit, it’s always good to have someone to share your stories with.

Trainhornforums.com is the largest train horn community online and provides a place to share photos of your ride, post

videos, catch up with other train horn and HornBlasters fans, meet other train horn enthusiasts, or even nd help with a

complicated question.

Go online to www.trainhornforums.com and sign up today!

@hornblasters #hornblasters

/hornblasters

Make sure to follow us on all the popular social media! Facebook, Vine, Twitter, Youtube, and Instagram. Show o your

install and tag us in all your photos!

HornBlasters, Inc.

39440 Pattie Road

Zephyrhills, FL 33540

Phone: +1 (877) 209-8179

Fax: +1 (813) 783-2407

email: sales@hornblasters.com

Loading...

Loading...