Page 1

*UM206030*

Sheet Cutter

SmartStacker

User’s Manual

Important Information

- This manual is designed to help you to operate and maintain the Smart-

Stacker. Please read and understand this manual, and keep it in a safe and

convenient place.

- Do not operate the SmartStacker until you read and understand the in-

structions in this manual.

- Horizon International Inc. shall not be liable for incidental consequential

damages resulting from: improper or inadequate maintenance by the cus-

tomer, unauthorized modication or misuse, or operation outside of the

environmental specications for the product.

- Horizon International Inc. pursues a policy of continuing improvement in

design and performance of the product. Therefore, the product design and

specications are subject to change without prior notice and without our

legal obligation.

- All rights are reserved. No part of this manual may be photocopied, repro-

duced or translated to another language without the prior written consent

of Horizon International Inc.

170107/HN,CF,AT,RN/IDCS5.5/ICS5/PXI

UM206030-10(000)

Page 2

Safety Precautions

Safety precautions are indicated in this manual as follows:

The term WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

The term CAUTION indicates a potentially hazardous situation which, if not avoided,

may result in serious injury, or damage to the machine.

This symbol indicates a note which includes important information. Follow the note to

operate the machine safely.

This symbol indicates a prohibited action. Do not perform any prohibited action.

This symbol indicates an essential procedure. Follow the procedure to operate the machine safely.

This will help you to avoid an incorrect operation which may cause

Important

Attention

Note

Additional Information

➡

- Horizon International Inc. cannot anticipate every possible situation that might involve a potential

hazard. Therefore, the instructions in this manual and warning labels on the machine are not allinclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation

when such operation could cause injury to personnel. Do not attempt to operate any switch, valve,

or other energy isolating device when it has been locked or tagged out.

- Do not operate the machine when any covers are removed.

- Some of the drawings in this manual show the machine with the covers removed to help in

explaining the details inside the machine.

problems with the machine, or make it necessary to go back to a

previous step.

This explains functional limitations and restrictions on the operation

of the machine.

This indicates a helpful hint.

This indicates additional information which will help you to operate

the machine efciently.

This explains what the machine will do after you operate it as instructed.

2 SmartStacker User's Manual

Page 3

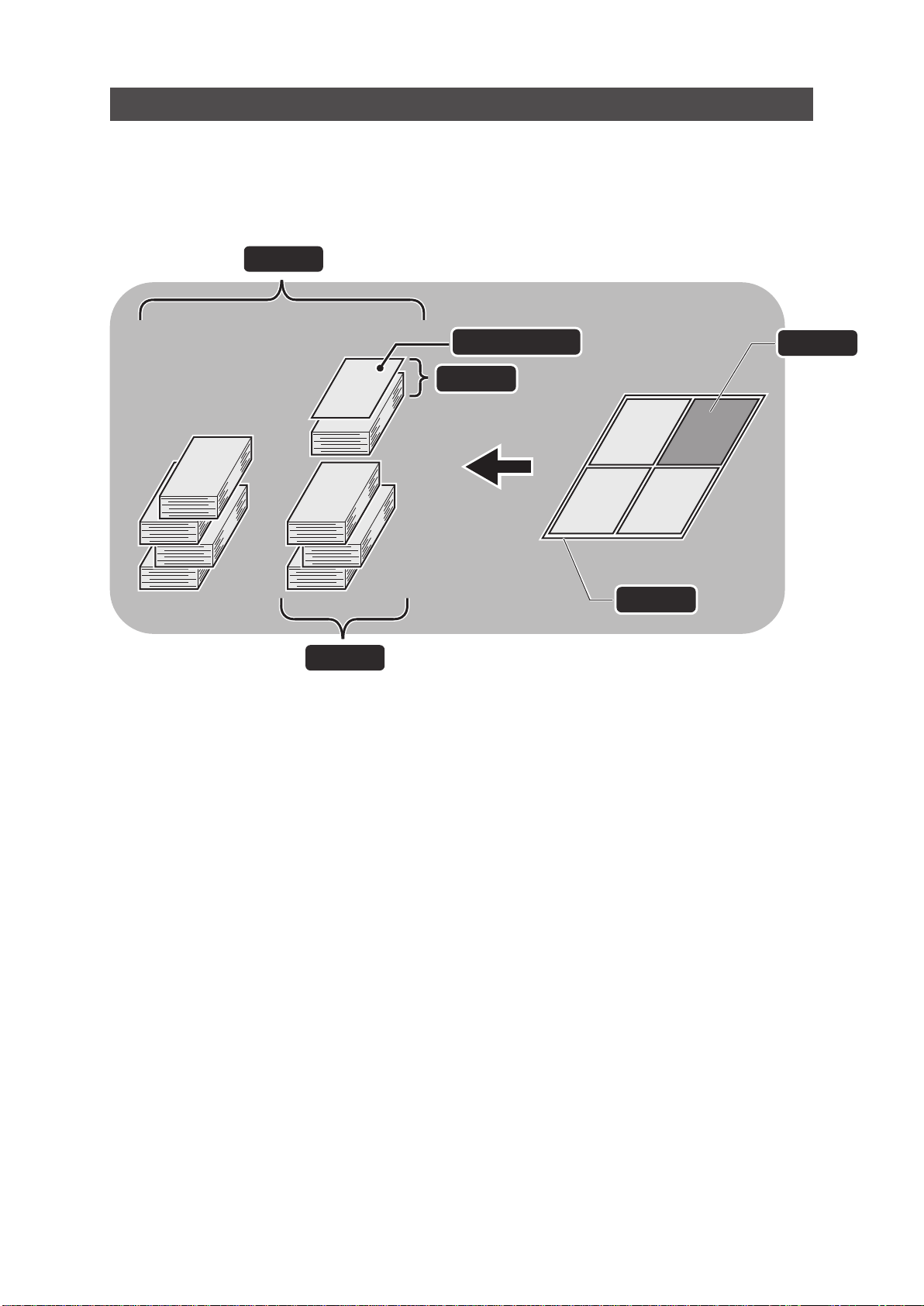

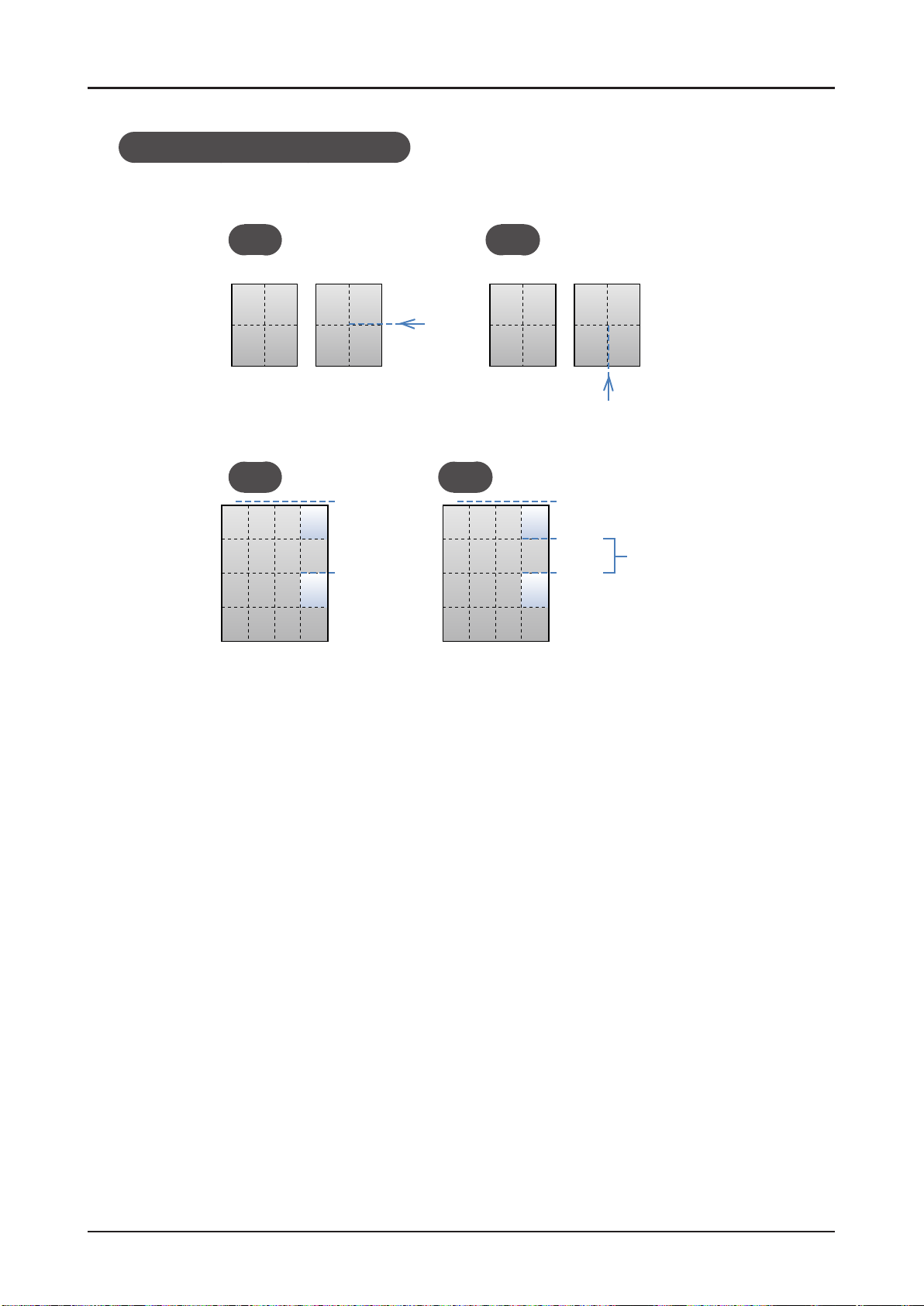

Glossary

The drawing below shows the terms we will use in this manual.

Job

Stack

Page / Piece

Block

Sheet

26030

10101A1

Page

3SmartStacker User's Manual

Page 4

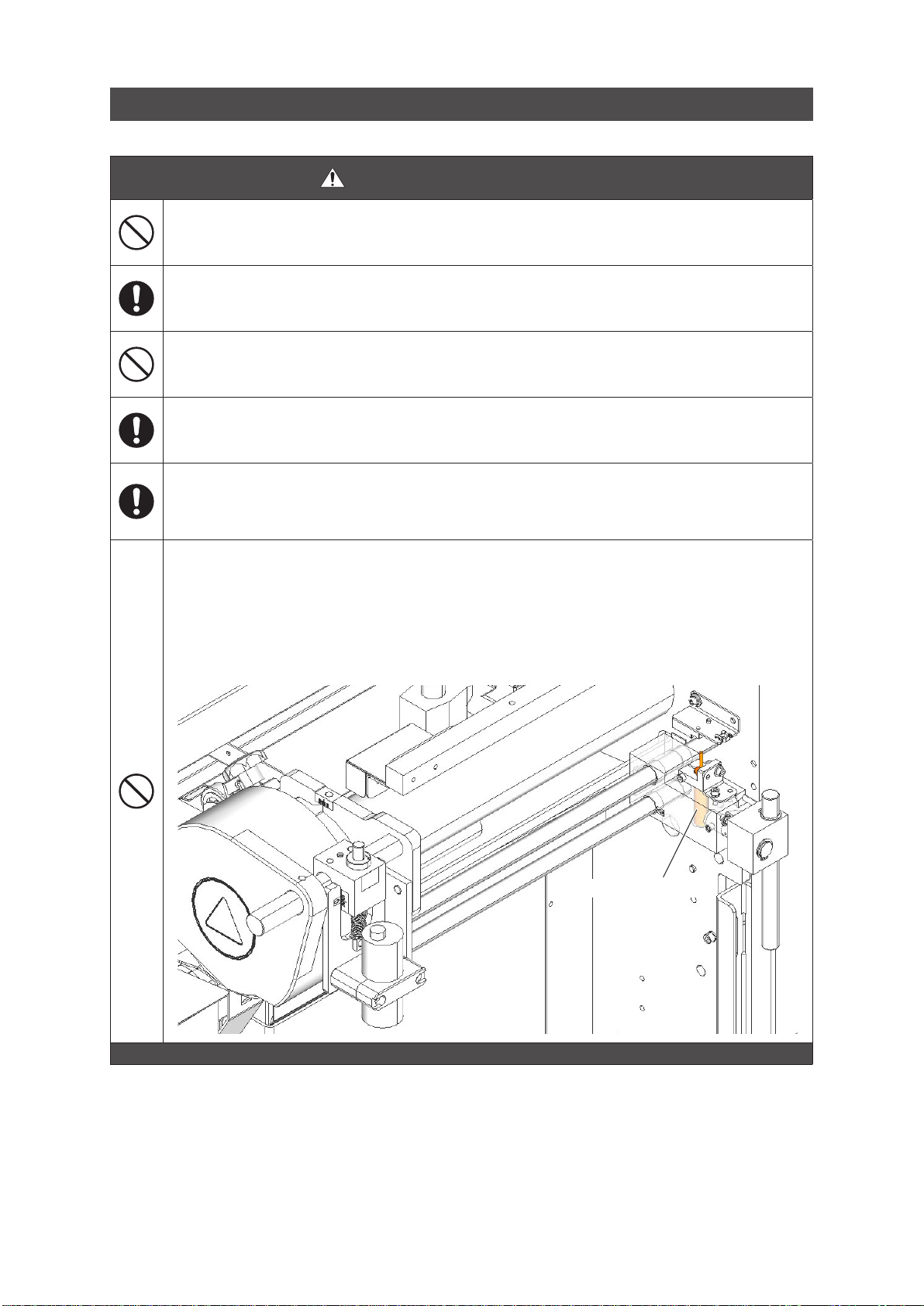

Basic Safety Precautions

WARNINGS for Operation

Keep your hands and ngers outside of the safety cover and away from any moving parts

while the machine is running. Otherwise, moving parts can cause severe personal injury.

Work alone when you operate the machine. Letting someone else operate the machine

could cause it to start suddenly without warning, causing severe personal injury.

Do not remove or bypass any safety features. Without these protective features, moving

parts can cause severe personal injury.

Be sure all other operators are clear of the machine before turning the handwheel. If someone else has their hands in the machine, turning the handwheel could cause personal injury.

As the working condition may include exposure to high noise levels which can lead to hearing damage, the employer and operator should ensure that any necessary hearing protection is provided and used by the operator and others in the work area.

Only for optional Sheet Feeder :

• Do not stare into beam of sheet edge indicator (class 1 laser product*1).

Otherwise, light beam can cause severe personal injury.

*1 This laser meets the IEC standards, 60825-1: 2007,class 1 LASER product.

• Use of controls or adjustments or performance of procedures other than these specied

here in may result in hazardous radiation exposure.

Sheet Edge Indicator

4 SmartStacker User's Manual

Page 5

WARNINGS for Operation

When you lower the feed table, do not place your feet under the table.

Press the Emergency Stop button before turning the drive handwheel. If the machine

accidentally starts suddenly, this can cause severe personal injury.

Turn off the power switch before adjusting the machine unless instructed otherwise. If the

Start button is pressed when the power is on, the machine may cause severe personal injury.

CAUTIONS for Operation

If you turn off the Power switch, wait about ten seconds before turning it on again. Otherwise, a circuit board may be damaged.

If a jam occurs, remove all the jammed sheets before you start the operation again. Otherwise the machine may be damaged.

Do not use the machine for any improper purpose. Otherwise, the performance of the machine cannot be guaranteed.

5SmartStacker User's Manual

Page 6

Sheet Feeder

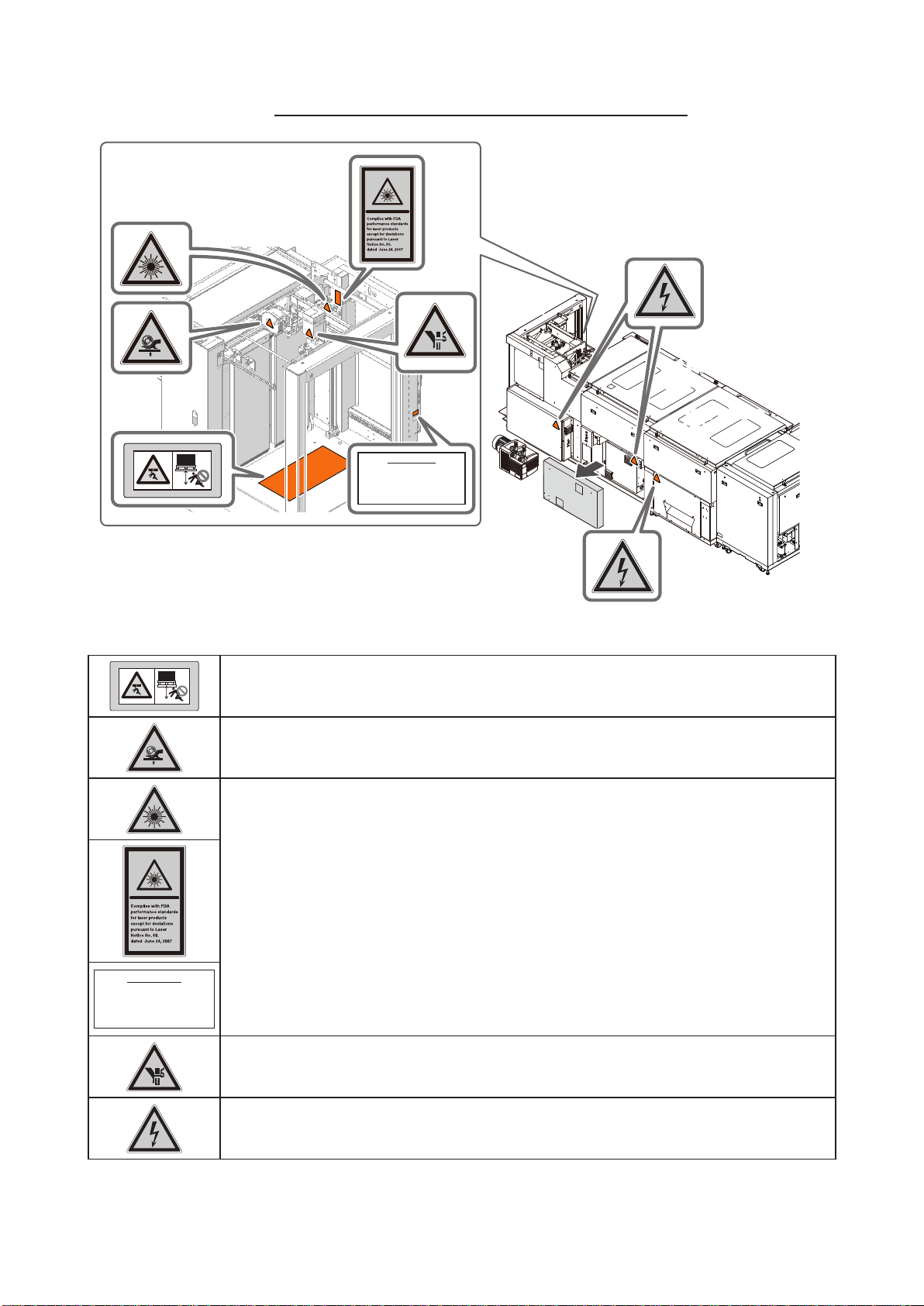

Warning Label Locations and Meanings

Feeder

1st Regist

Unit

Identification Label

Taiyo Seiki Co., Ltd.

1600 Aza-Shironoshita, Asahi, Shin-asahi-cho,

Takashima, Shiga 520-1501, Japan

Biwako Factory

Manufactured: 1.2014

1st Process

Unit

Identification Label

Taiyo Seiki Co., Ltd.

1600 Aza-Shironoshita, Asahi, Shin-asahi-cho,

Takashima, Shiga 520-1501, Japan

Biwako Factory

Manufactured: 1.2014

Do not get into under the feed table. Otherwise, you may be injured

Do not approach your hands and ngers while the roller is rotating.

Otherwise your hands and ngers may be caught by the rotating roller.

Do not stare into beam of sheet edge indicator (class 1 laser product*1).

Otherwise light beam can cause severe personal injury.

*1 This laser meets the IEC standards, 60825-1: 2007, class 1 LASER product.

Laser Diode Wavelength: 625-640 nm

Maximum Power: 5 mW

Do not approach your hands and ngers to the suction head while the feed table is

moving. Otherwise your hands and ngers may be caught by the suction head.

There are electric parts inside. Take care when opening the cover.

Otherwise, high voltage can cause severe personal injury.

6 SmartStacker User's Manual

Page 7

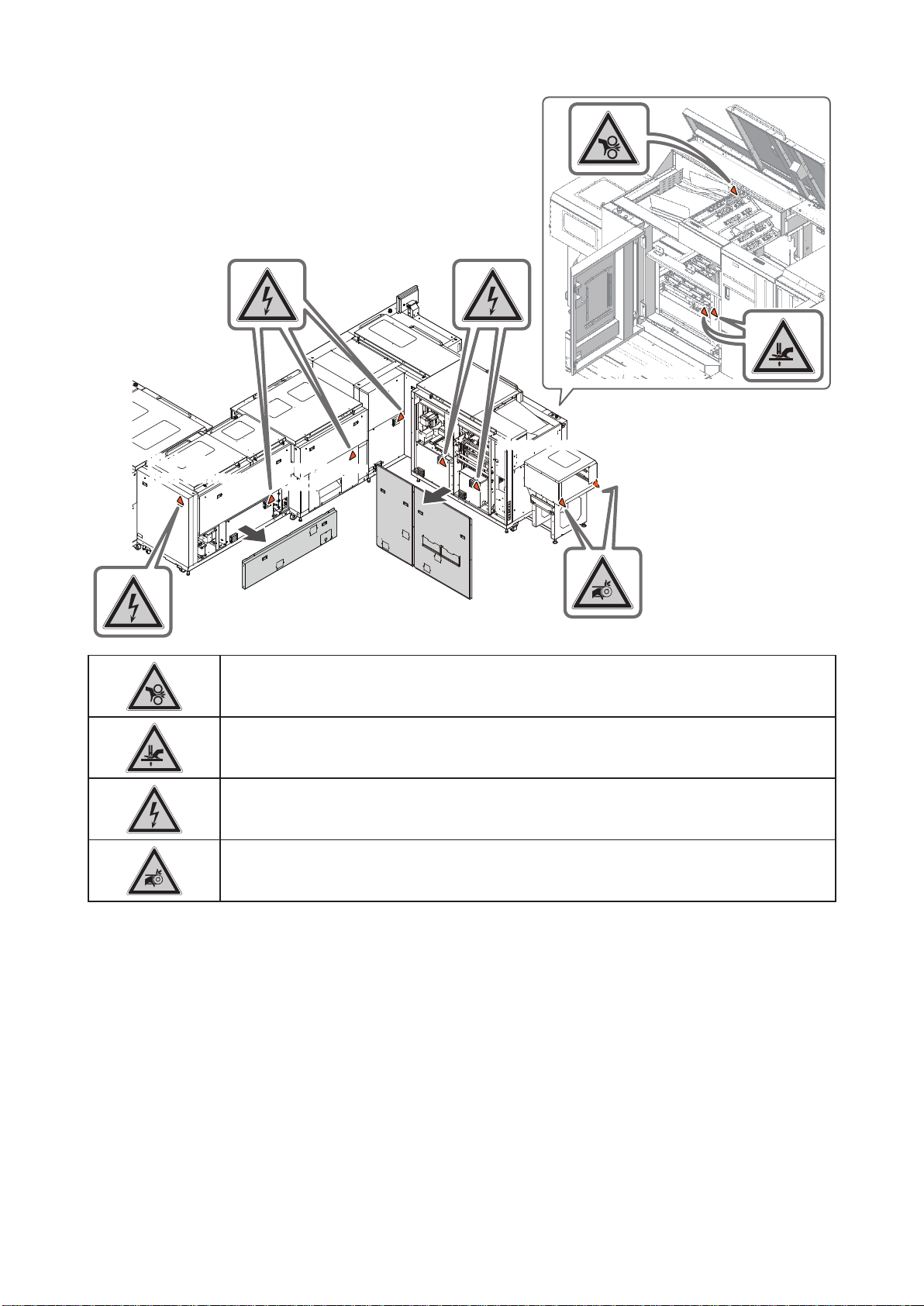

90-degree

Turn Conveyor

Keep your hands and ngers away from the rollers while they are turning.

Otherwise your hands and ngers may be caught by the moving rollers.

Merge

Conveyor

Merge Stacker

Merge Stacker

2nd Process

Unit

Do not approach your hands and ngers while the stack table of the Merge Stacker is

moving. Otherwise your hands and ngers may be caught by the stack table.

There are electric parts inside. Take care when opening the cover.

Otherwise, high voltage can cause severe personal injury.

Keep your hands and ngers away from the belts and rollers while the belts are

moving. Otherwise your hands and ngers may be caught by these parts.

7SmartStacker User's Manual

Page 8

Contents

Important Information ........................................................................................................................1

Safety Precautions ............................................................................................................................2

Glossary ............................................................................................................................................3

Basic Safety Precautions...................................................................................................................4

Warning Label Locations and Meanings ...........................................................................................6

1 Machine Description

1-1 Features of the Machine .....................................................................................14

1-1-1 SmartStacker Conguration ................................................................................14

1-1-2 Directions described in this manual .....................................................................15

1-1-3 Sheet Flow ...........................................................................................................16

1-1-4 Delivery ................................................................................................................19

1-1-5 Supported Jobs ...................................................................................................22

1-1-6 Capability of Each Line ........................................................................................26

1-1-7 The Role of Panels of the SmartStacker and the FLC ........................................27

1-2 SmartStacker Screen Descriptions .....................................................................28

1-2-1 Run - Main Screen - Part 1 ..................................................................................28

1-2-2 Run - Main Screen - Part 2 ..................................................................................29

1-2-3 Run - Main Screen - Part 3 ..................................................................................30

1-2-4 Run - Main Screen - Part 4 ..................................................................................31

1-2-5 Run - Main Screen - Part 5 (for Merge Stacker) ..................................................32

1-2-6 Run - Main Screen - Part 6 (for B2 Stacker) ........................................................33

1-2-7 Run - Setting Screen - Part 1 ..............................................................................34

1-2-8 Run - Setting Screen - Part 2 (for Merge Stacker) ..............................................35

1-2-9 Run - Setting Screen - Part 3 (for B2 Stacker) ....................................................36

1-2-10 Run - Setting Screen - Part 4 (for B2 Stacker) ....................................................37

1-2-11 Run - Fine Adjustment Screen - Part 1 ................................................................38

1-2-12 Run - Fine Adjustment Screen - Part 2 ................................................................39

1-2-13 Run - Fine Adjustment Screen - Part 3 (for B2 Stacker) ......................................40

1-2-14 Run - Page Size Fine Adjustment Screen - Part 1 (for Merge Stacker) ....................41

1-2-15 Run - Page Size Fine Adjustment Screen - Part 2 (for B2 Stacker) ....................42

1-2-16 Run - Cutter Position Fine Adjustment - 1st Process Unit Fine Adjustment Screen ..............43

1-2-17 Run - Cutter Position Fine Adjustment - 2nd Process Unit Fine Adjustment Screen .............44

1-2-18 Run - Scoring Position Fine Adjustment Screen (Optional) .................................45

1-2-19 Setting - Size Setting Screen - Only for Ofine System- Part 1 ...........................46

1-2-20 Setting - Size Setting Screen - Only for Ofine System - Part 2 ..........................47

1-2-21 Setting - Size Setting Screen - Only for Ofine System - Part 3 ..........................48

1-2-22 Setting - Size Setting Screen - Only for Ofine System - Part 4 (for B2 Stacker) ..............49

1-2-23 Trim Guide Setting Screen ..................................................................................50

1-2-24 Memory - Main Screen - Part 1............................................................................51

1-2-25 Memory - Main Screen - Part 2............................................................................52

1-2-26 Information - Main Screen - Part 1 ......................................................................53

1-2-27 Information - Main Screen - Part 2 ......................................................................54

1-2-28 Information - Input Monitor Screen - Part 1 .........................................................55

1-2-29 Information - Input Monitor Screen - Part 2 .........................................................56

1-2-30 Information - Input Monitor Screen - Part 3 .........................................................57

1-2-31 Information - Input Monitor Screen - Part 4 .........................................................58

8 SmartStacker User's Manual

Page 9

1-2-32 Information - Input Monitor Screen - Part 5 .........................................................59

1-2-33 Information - Input Monitor Screen - Part 6 (for B2 Stacker) ...............................60

1-2-34 Information - Signal I/O Monitor Screen ..............................................................61

1-2-35 Information - Single Operation Screen - Part 1 ...................................................62

1-2-36 Information - Single Operation Screen - Part 2 ...................................................63

1-2-37 Information - Single Operation Screen - Part 3 ...................................................64

1-2-38 Information - Single Operation Screen - Part 4 ...................................................65

1-2-39 Information - Error History Screen .......................................................................66

1-2-40 Information - Administrator - Main Screen ...........................................................67

1-2-41 Information - Administrator - Administrator Setting Screen - Part 1 ...........................68

1-2-42 Information - Administrator - Administrator Setting Screen - Part 2 ...........................69

1-2-43 Information - Administrator - Input Signal Enable Settings Screen - Part 1 ...........................70

1-2-44 Information - Administrator - Input Signal Enable Settings Screen - Part 2 ...........................71

1-2-45 Information - Administrator - Input Signal Enable Settings Screen - Part 3 ...........................72

1-2-46 Information - Administrator - Motor Enable Settings Screen - Part 1 ..............................................73

1-2-47 Information - Administrator - Motor Enable Settings Screen - Part 2 ..............................................74

1-2-48 Information - Administrator - Motor Enable Settings Screen - Part

1-2-49 Information - Administrator - Adjustment Mode Screen .......................................76

1-2-50 Information - Administrator - Network Conguration Screen ...............................77

1-2-51 Error - Main Screen .............................................................................................78

1-2-52 Error - Unit Screen ...............................................................................................79

3 ....................................75

1-3 Finishing Line Controller Screen Descriptions ....................................................80

1-3-1 Run - Main Screen - Part 1 ..................................................................................80

1-3-2 Run - Main Screen - Part 2 ..................................................................................81

1-3-3 Run - Main Screen - Part 3 ..................................................................................82

1-3-4 Run - Main Screen - Part 4 ..................................................................................83

1-3-5 Run - Main Screen - Part 5 ..................................................................................84

1-3-6 Run - Main Screen - Part 6 ..................................................................................85

1-3-7 Run - Main Screen - Part 7 ..................................................................................86

1-3-8 Run - Main Screen - Part 8 ..................................................................................87

1-3-9 Run - Main Screen - Part 9 ..................................................................................88

1-3-10 Run - Main Screen - Part 10 ................................................................................89

1-3-11 Run - Main Screen - Part 11 ................................................................................90

1-3-12 Run - Main Screen - Part 12 ................................................................................91

1-3-13 Run - Main Screen - Part 13 ................................................................................92

1-3-14 Run - Job Details Screen .....................................................................................93

1-3-15 Run - Diagnostic Tool Screen ..............................................................................94

1-3-16 Setting - General(1) Screen - Part 1 ....................................................................95

1-3-17 Setting - General(1) Screen - Part 2 ....................................................................96

1-3-18 Setting - General(1) Screen - Part 3 ....................................................................97

1-3-19 Setting - General(1) Screen - Part 4 ....................................................................98

1-3-20 Setting - General(2) Screen - Part 1 ....................................................................99

1-3-21 Setting - General(2) Screen - Part 2 ..................................................................100

1-3-22 Setting - Job List Screen ...................................................................................101

1-3-23 Setting - Line Screen .........................................................................................102

1-3-24 Setting - Banner Screen Part 1 ..........................................................................103

1-3-25 Setting - Banner Screen Part 2 ..........................................................................104

1-3-26 Setting - About the FLC Screen .........................................................................105

9SmartStacker User's Manual

Page 10

2 Procedures for Near Line Operation

2-1 Daily Safety Check ............................................................................................108

2-2 Changeover .......................................................................................................112

2-2-1 Before a Changeover ........................................................................................ 112

2-2-2 Starting the Changeover .................................................................................... 114

2-2-3 Setting the Trim Guides for the Gutter Trim ....................................................... 116

2-2-4 Recalling Fine Adjustment Values .....................................................................117

2-3 Loading the Sheets on the Sheet Feeder ......................................................... 118

2-3-1 Loading the Sheets on the Feed Table ..............................................................118

2-4 Starting a Job ....................................................................................................122

2-5 Pausing and Resuming a Job ...........................................................................123

2-5-1 Pausing and Resuming a Job Using the FLC ....................................................123

2-5-2 Holding and Resuming a Job Using the FLC ....................................................124

2-5-3 Removing Any Blank Pages ..............................................................................126

2-6 Reprint - When using the Merge Stacker ..........................................................127

2-6-1 Selecting the Reprint List Preparation Method ..................................................127

2-6-2 Deciding How to Handle Reprinting ...................................................................128

2-6-3 How the Stack is Delivered If a Jam Occurs .....................................................129

2-6-4 Reprinting the Whole Job from the Beginning ...................................................131

2-6-5 Reprinting Only the Bad Stack ..........................................................................133

2-6-6 Reprinting Only the Bad Block ...........................................................................137

2-6-7 Reprinting Only the Bad Sheet ..........................................................................140

2-7 Error Recovery - When using the B2 Stacker ..........................................................143

2-7-1 How the Sheets are Delivered If a Jam Occurs .................................................143

2-7-2 Resuming the Job ..............................................................................................144

2-8 Changing the Setting of Handy Scanner for FLC ..............................................145

2-8-1 Turning down the beep sound ...........................................................................145

2-8-2 Turning off the automatic scan mode ................................................................145

2-8-3 Returning to default settings ..............................................................................145

3 ProceduresforOfineOperation

3-1 Setting the Control Panel - When using the Merge Stacker................................................148

3-1-1 Setting the Job ...................................................................................................148

3-1-2 Setting the Delivery Action .................................................................................153

3-1-3 Starting a Job ....................................................................................................155

3-2 Setting the Control Panel - When using the B2 Stacker .........................................156

3-2-1 Setting the Job ...................................................................................................156

3-2-2 Setting the Delivery Action .................................................................................159

3-2-3 Starting a Job ....................................................................................................162

3-3 Saving, Loading, and Deleting Jobs ..................................................................163

3-3-1 Saving a Job ......................................................................................................163

10 SmartStacker User's Manual

Page 11

3-3-2 Loading a Job ....................................................................................................164

3-3-3 Deleting a Job ....................................................................................................165

3-3-4 Protecting the Job Data .....................................................................................166

3-3-5 Exporting the Job Data ......................................................................................167

3-3-6 Recalling Exported Jobs ....................................................................................168

4 Procedures for Inline

Operation

4-1 Daily Safety Check ............................................................................................172

4-2 Changeover .......................................................................................................175

4-2-1 Setting the Trim Guides for the Gutter Trim .......................................................175

4-3 Reprint - When using the Merge Stacker ..........................................................176

4-3-1 How the Stack is Delivered If a Jam Occurs .....................................................176

4-3-2 Restarting the Operation ...................................................................................177

4-4 Post Processing ................................................................................................178

4-4-1 Removing Any Blank Pages ..............................................................................178

5 Fine Adjustments

5-1 Adjusting the Sheet Feeder ...............................................................................180

5-1-1 Adjusting the Position of the Suction Head .......................................................180

5-1-2 Adjusting the Feed Table Position .....................................................................180

5-1-3 Setting the Suction Head ...................................................................................181

5-1-4 Setting the Side Air ............................................................................................185

5-1-5 Adjusting the Table Guide and the Rear Guide .................................................187

5-1-6 Feed Rotor Adjustments ....................................................................................188

5-2 Adjusting the Cutting Positions .........................................................................190

5-2-1 Adjusting the Length and Width of the Finished Size ........................................190

5-2-2 Adjusting the Trim Width - Short Edge ..............................................................191

5-2-3 Adjusting the Trim Length - Long Edge .............................................................192

5-2-4 Adjusting Individual Trim Positions ....................................................................193

5-3 Adjusting the Guide Positions ...........................................................................196

5-3-1 Adjusting the Register Guide for the 1st Regist Unit .........................................196

5-3-2 Adjusting the Ejecting Gates on the 2nd Process Unit ......................................198

5-3-3 Adjusting the Angle Adjusting Guides on the Merge Conveyor .........................199

5-3-4 Adjusting the Stopper on the Merge Stacker .....................................................200

5-3-5 Adjusting the Pressure of the Sheet Hold-Down Plates in the Merge Stacker ........201

5-3-6 Adjusting the Stopper on the B2 Stacker ...........................................................202

5-3-7 Adjusting the Pressure of the Sheet Hold-Down Plates in the B2 Stacker ..............203

5-4 Adjusting the Optional Scoring Unit ..................................................................204

5-4-1 Adjusting the Scoring Positions .........................................................................204

5-4-2 Adjust the Scoring Depth ...................................................................................205

6 Troubleshooting

6-1 If an Error Icon Appears ....................................................................................208

11SmartStacker User's Manual

Page 12

6-2 If an Error Code Is Displayed on SmartStacker ................................................ 211

6-3 If a Warning Screen is Displayed on SmartStacker ..........................................345

6-4 If an Error Code Is Displayed on FLC ...............................................................349

6-5 If a Warning Message Is Displayed on FLC ......................................................354

6-6 Pole Lamp and Up/Down Buttons .....................................................................355

6-6-1 Pole Lamp .........................................................................................................355

6-6-2 Up/Down Buttons ...............................................................................................355

6-7 Problems with Cutting Quality ...........................................................................356

6-7-1 Cutting is Skewed in the 1st Process Unit .........................................................356

6-8 Problems with the Sheet Feeder .......................................................................357

6-8-1 Misfeeding .........................................................................................................357

6-8-2 Double Feeding .................................................................................................360

6-9 If a Jam Occurs .................................................................................................363

6-9-1 Clearing the sheets after a jam ..........................................................................363

6-9-2 Removing the jammed sheets ...........................................................................364

7 Maintenance

7-1 SmartStacker ....................................................................................................370

7-1-1 Cleaning the Sensors ........................................................................................370

7-1-2 Cleaning the Air Filter ........................................................................................375

7-1-3 Cleaning the Belts .............................................................................................377

7-1-4 Lubrication .........................................................................................................380

7-1-5 Checking the Sheet Guide .................................................................................382

7-1-6 Checking the Rollers .........................................................................................386

7-2 Optional Sheet Feeder ......................................................................................387

7-2-1 Cleaning the Vacuum Piston and Air Filter ........................................................387

7-2-2 Replacing the Separator and Suction Rubbers .................................................389

8 Appendix

8-1 Specications ....................................................................................................392

8-1-1 Specications of SmartStacker ..........................................................................392

8-1-2 Specication Requirement on PC for FLC .........................................................395

8-2 Accessories .......................................................................................................396

8-2-1 SmartStacker Accessories ................................................................................. 396

8-2-2 Optional Sheet Feeder Accessories ..................................................................401

8-2-3 Component parts for FLC-H ..............................................................................404

8-2-4 Optional B2 Stacker Accessories ......................................................................405

12 SmartStacker User's Manual

Page 13

1 Machine Description

This chapter explains the main features on

the machine, the touch panel screen on

the SmartStacker and the screen on the

Finishing Line Controller.

1

Page 14

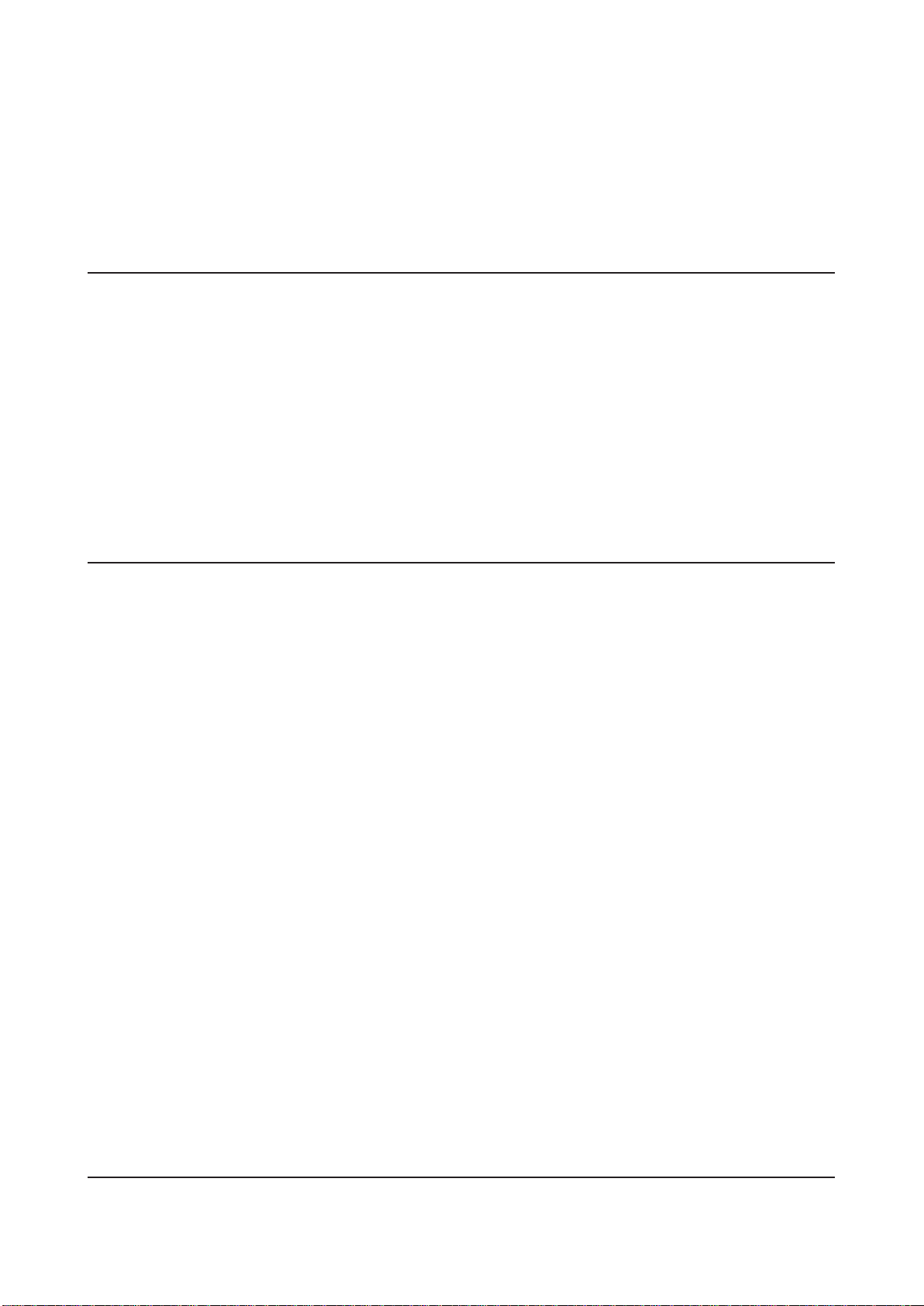

1-1

123456789

10

11

Features of the Machine

1-1-1

SmartStacker Configuration

Here are the sections included in a typical production line, along with the abbreviations we will use in this

manual.

1 Sheet Feeder (SF) (Option)

2 1st Regist Unit (1Reg)

3 1st Process Unit (1Pro)

4 90-degree Turn Conveyor (TC)

5 2nd Regist Unit (2Reg)

6 2nd Process Unit (2Pro)

7 Merge Conveyor (MC)

8 Merge Stacker (MS)

9 Output Shift Conveyor

10

1m Conveyor

11

B2 Stacker (BS)

14 SmartStacker User's Manual

Page 15

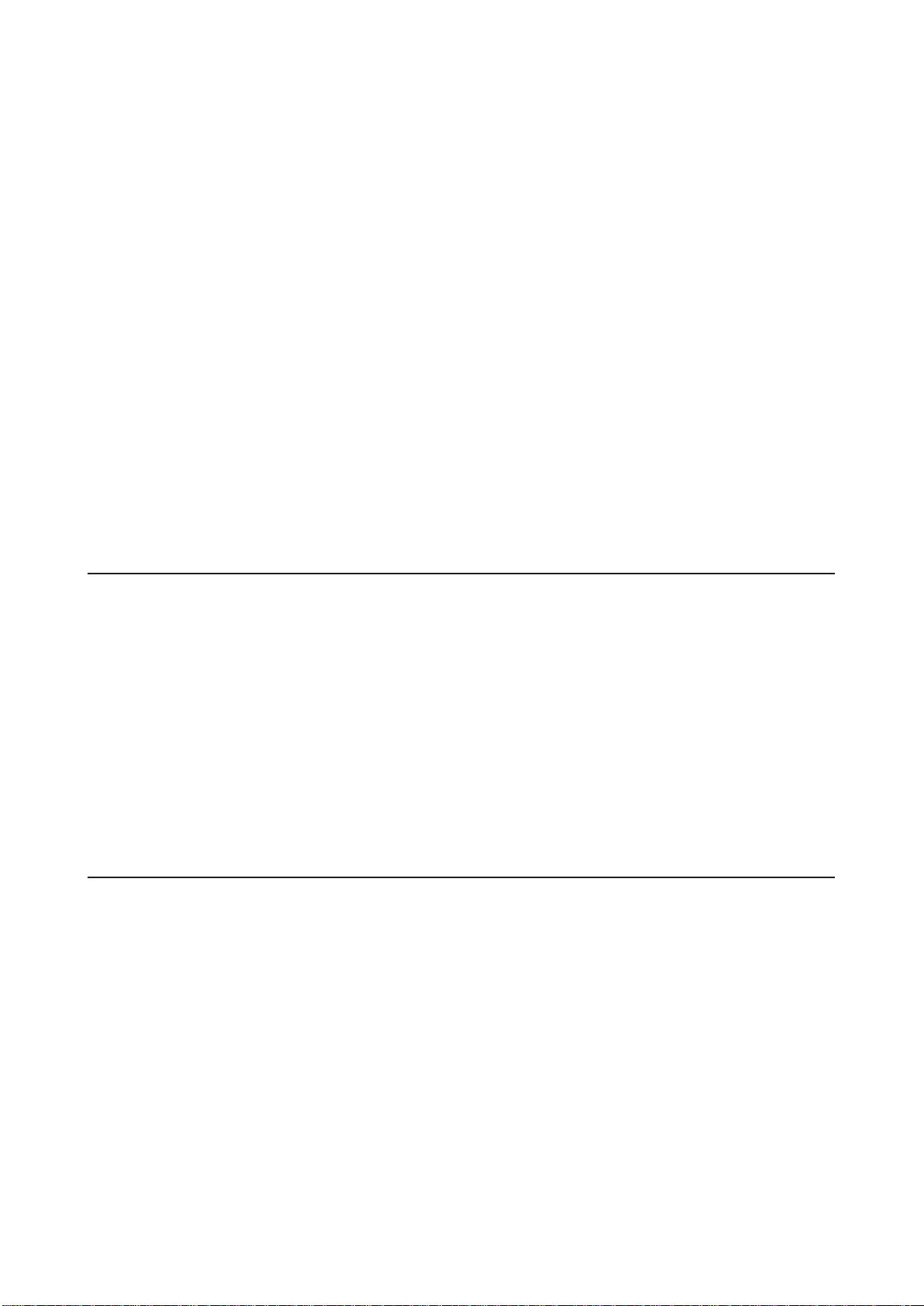

Features of the Machine

1-1-2

Delivery Side

Delivery

Side

Directions described in this manual

Infeed Side

Drive Side

Drive Side

Delivery

Operator Side

Operator Side

Drive Side

Delivery

Side

Side

Infeed

Infeed Side

Side

Operator SideOperator Side

Infeed Side

Operator SideOperator Side

Delivery Side

Operator Side

Operator Side

Drive Side

Infeed

Side

15SmartStacker User's Manual

Page 16

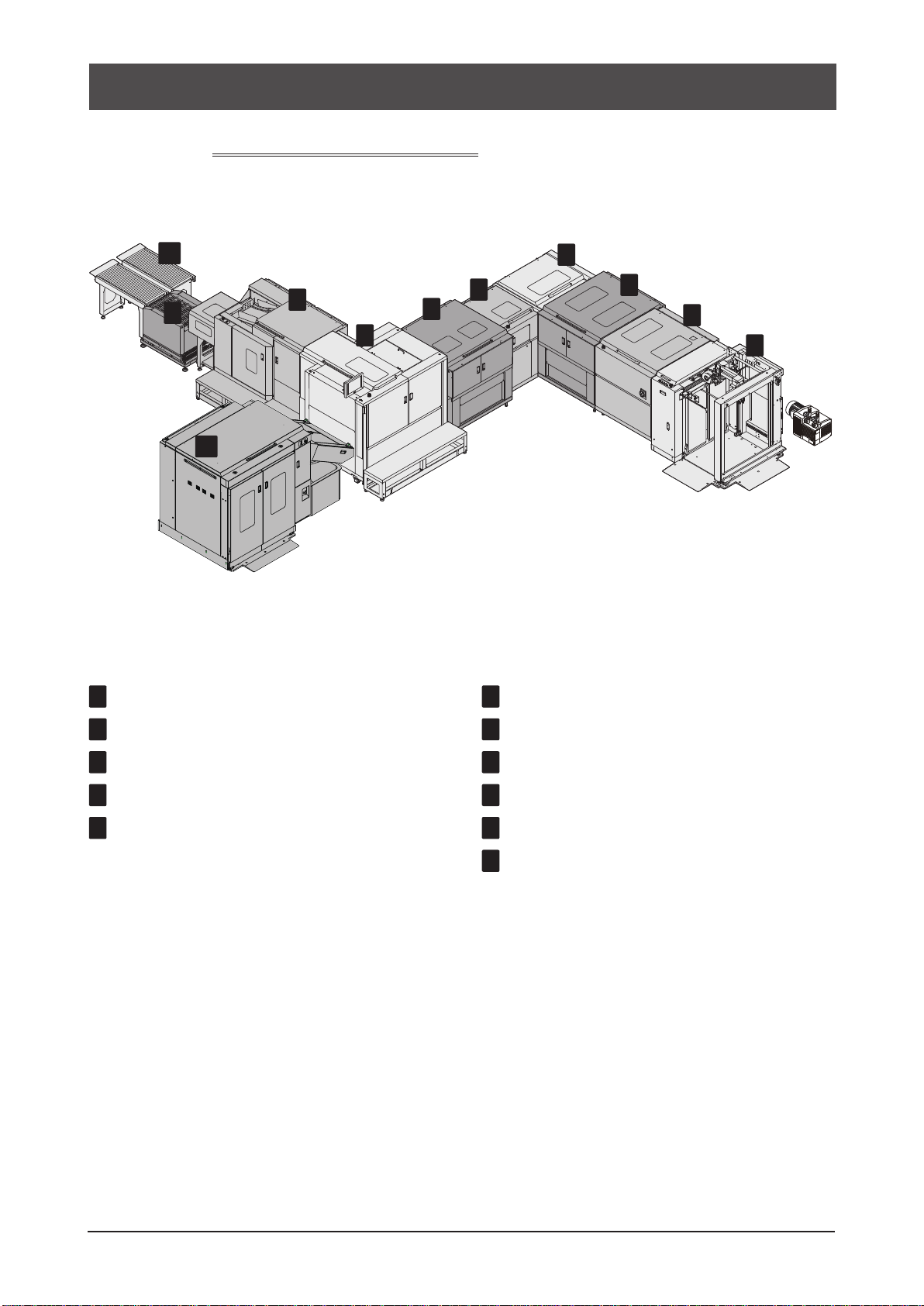

Features of the Machine

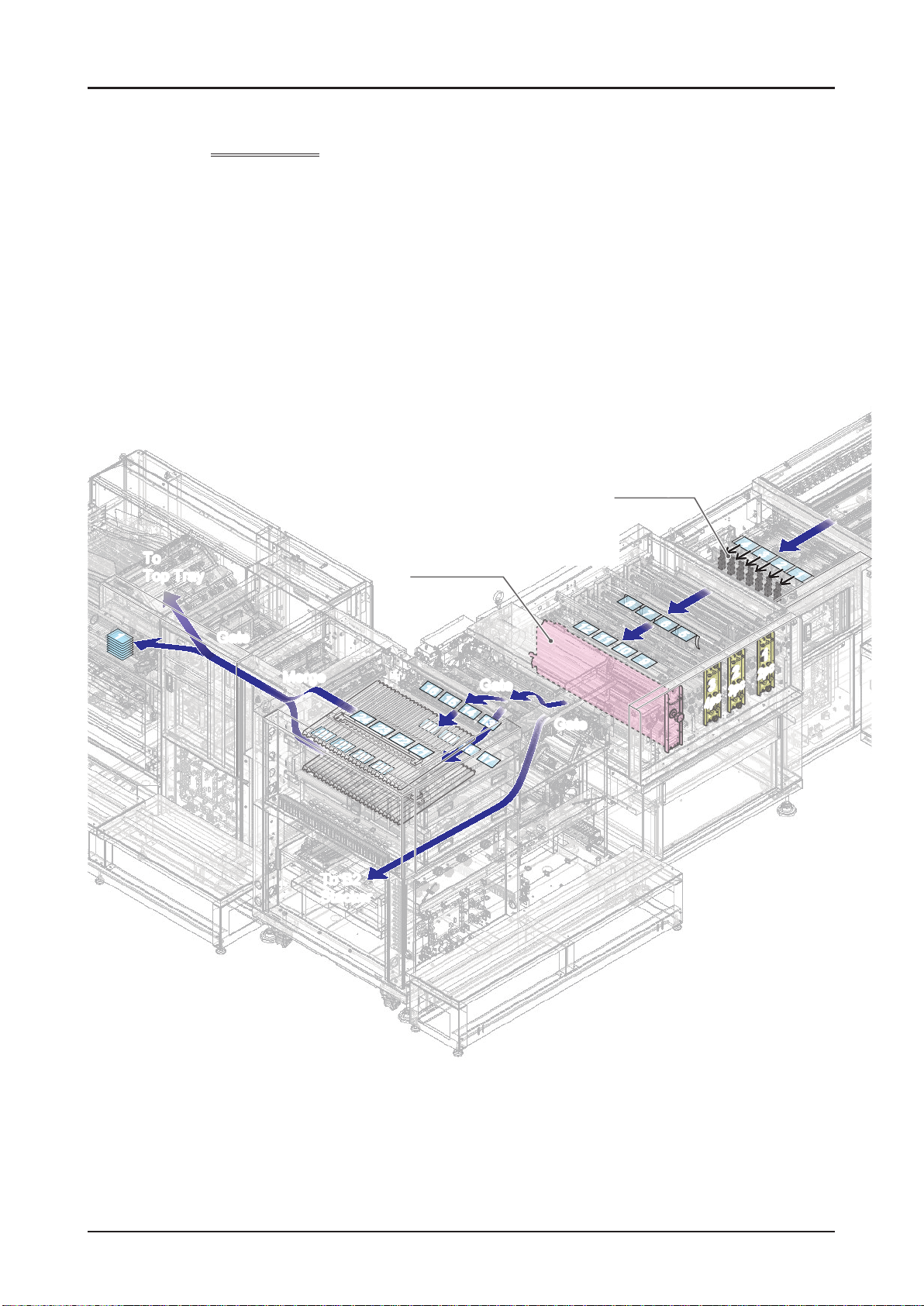

1-1-3

To

To

Top Tray

Top Tray

11

Sheet Flow

GateGate

MergeMerge

24 23 22 2124 23 22 21

28 27 26 2528 27 26 25

Scoring Unit

(Optional)

16 15 14 1316 15 14 13

20 19 18 1720 19 18 17

Gate

Gate

2nd Process

(9 Cutters)

12 11 10 912 11 10 9

Gate

Gate

2nd Regist

8 7 6 58 7 6 5

33

4pc4pc

4 3 2 1

4 3 2 1

11

22

2pc2pc

3pc3pc

To B2

To B2

Stacker

Stacker

16 SmartStacker User's Manual

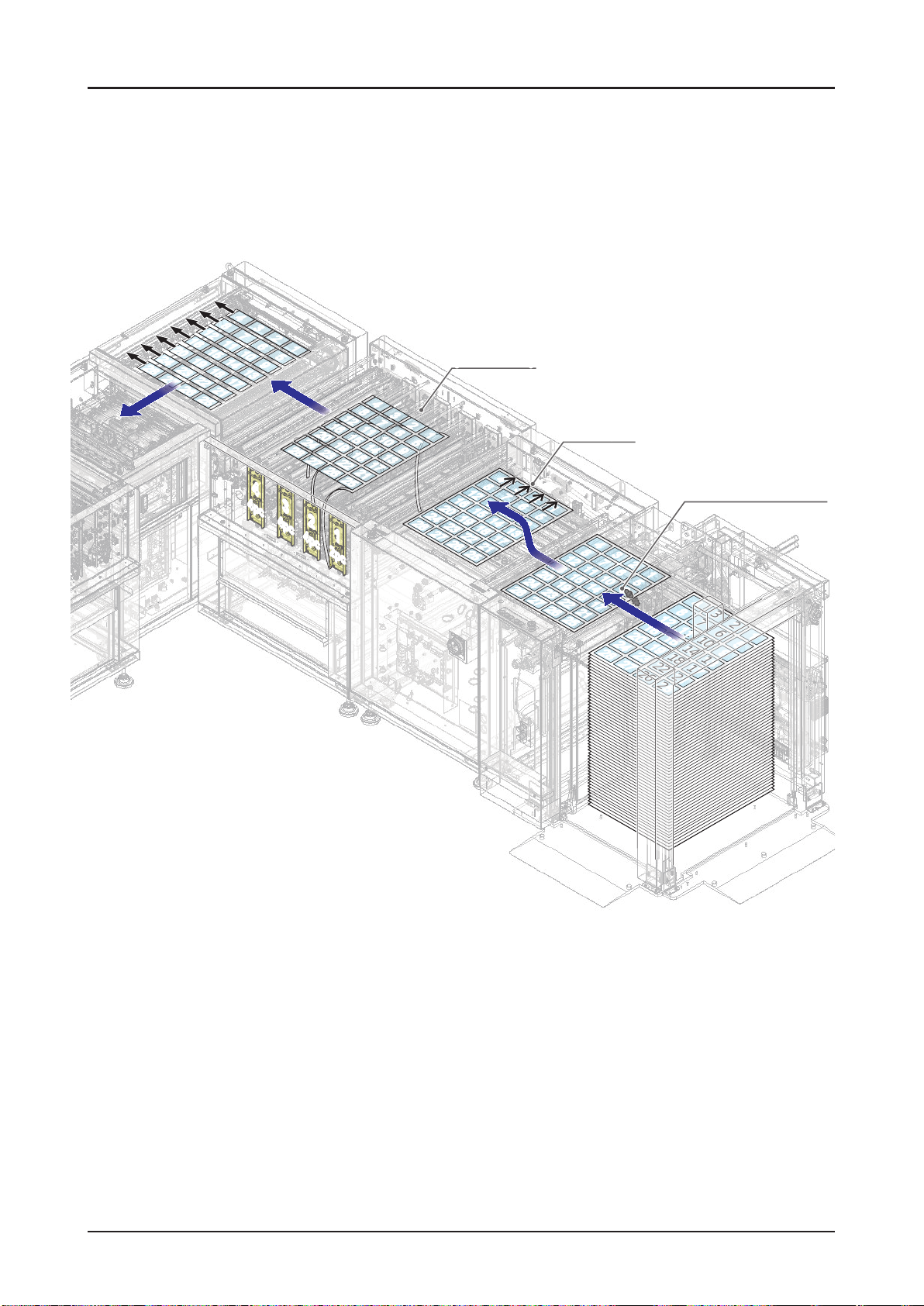

Page 17

16 15 14 13

16 15 14 13

20 19 18 17

20 19 18 17

24 23 22 21

24 23 22 21

28 27 26 25

28 27 26 25

4 3 2 14 3 2 1

8 7 6 5

8 7 6 5

12 11 10 9

12 11 10 9

4pc4pc

Features of the Machine

1st Process

(14 Cutters)

4

4

8

8

3

15

15

18

18

21

21

11

11

14

14

17

17

3

7

7

2

2

6

6

1

10

10

13

13

1

5

5

9

9

4

4

8

8

3

28

28

24

24

27

27

20

20

23

23

26

26

16

16

19

19

22

22

25

25

12

12

15

15

18

18

21

21

11

11

14

14

17

17

3

7

7

10

10

13

13

28

28

6

6

9

9

24

24

27

27

2

2

1

1

5

5

16

16

20

20

19

19

23

23

26

26

1st Regist

4

4

8

8

12

12

7

7

11

11

15

15

10

10

14

14

18

18

13

13

22

22

17

17

21

21

25

25

28

28

3

3

6

6

24

24

9

9

27

27

2

2

20

20

5

5

23

23

26

26

Double Feed Detect

Ultrasonic Sensor

1

1

4

4

8

8

3

15

15

18

18

21

21

11

11

14

14

17

17

7

7

10

10

13

13

3

2

2

6

6

9

9

16

16

19

19

22

22

12

12

25

25

1

1

5

5

12

12

16

16

20

20

24

24

19

19

28

28

23

23

27

27

22

22

26

26

25

44

25

33

22

4pc

4pc

4pc4pc

11

2pc2pc

17SmartStacker User's Manual

Page 18

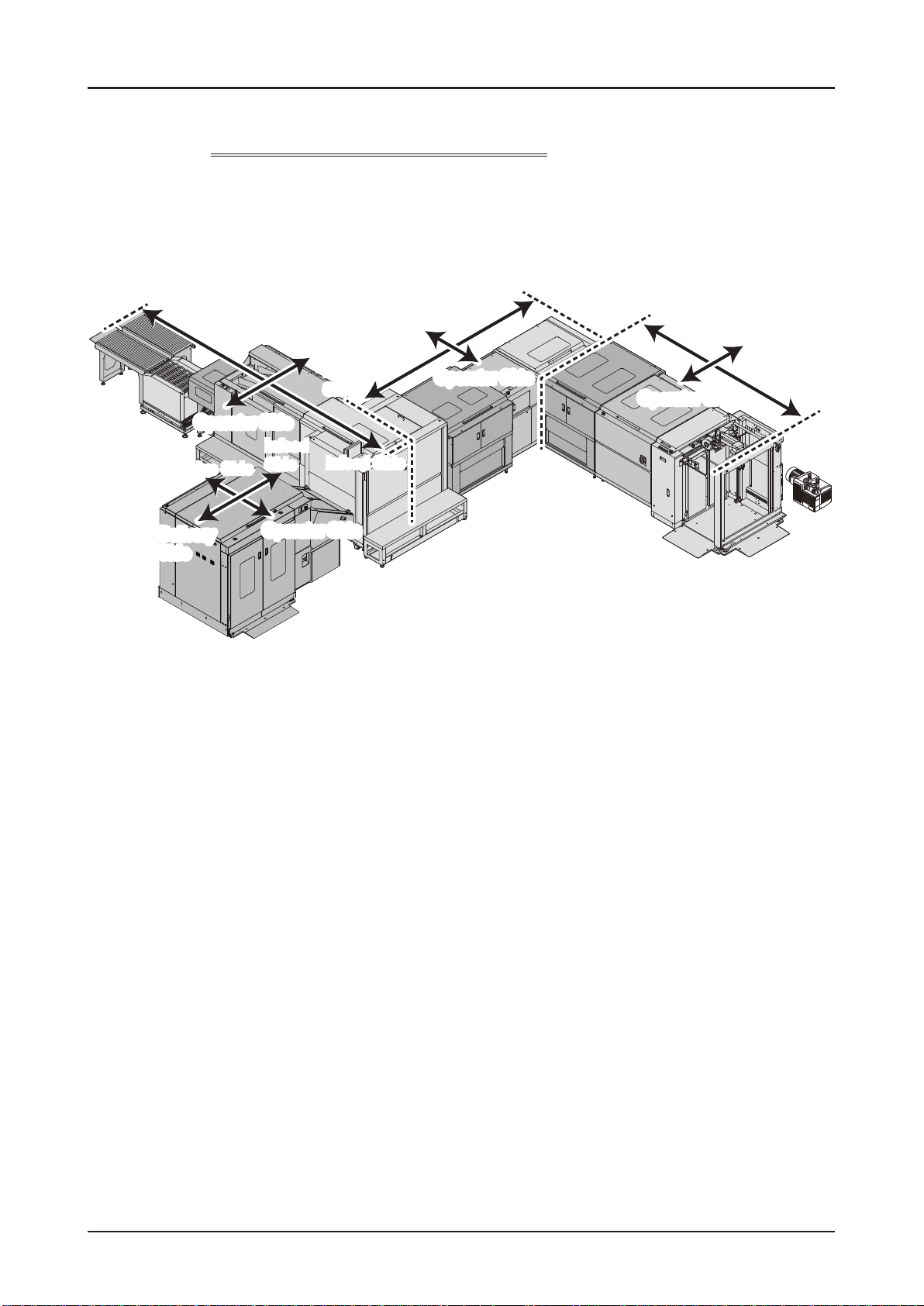

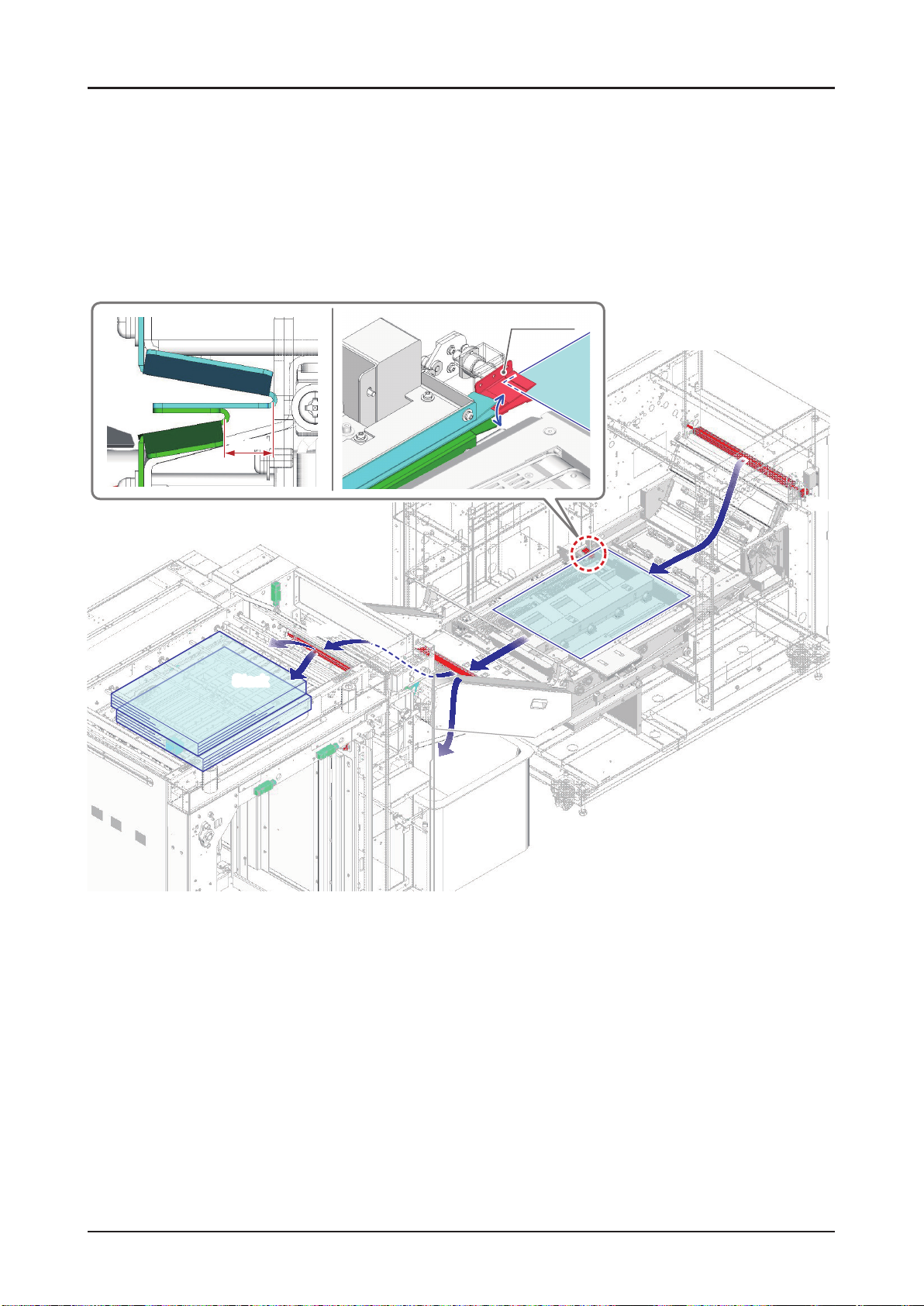

Features of the Machine

10 mm

Offset Guide

GateGate

Stack

Stack

Gate

Gate

Gate

Gate

Eject

Eject

26030

10103C1

18 SmartStacker User's Manual

Page 19

Features of the Machine

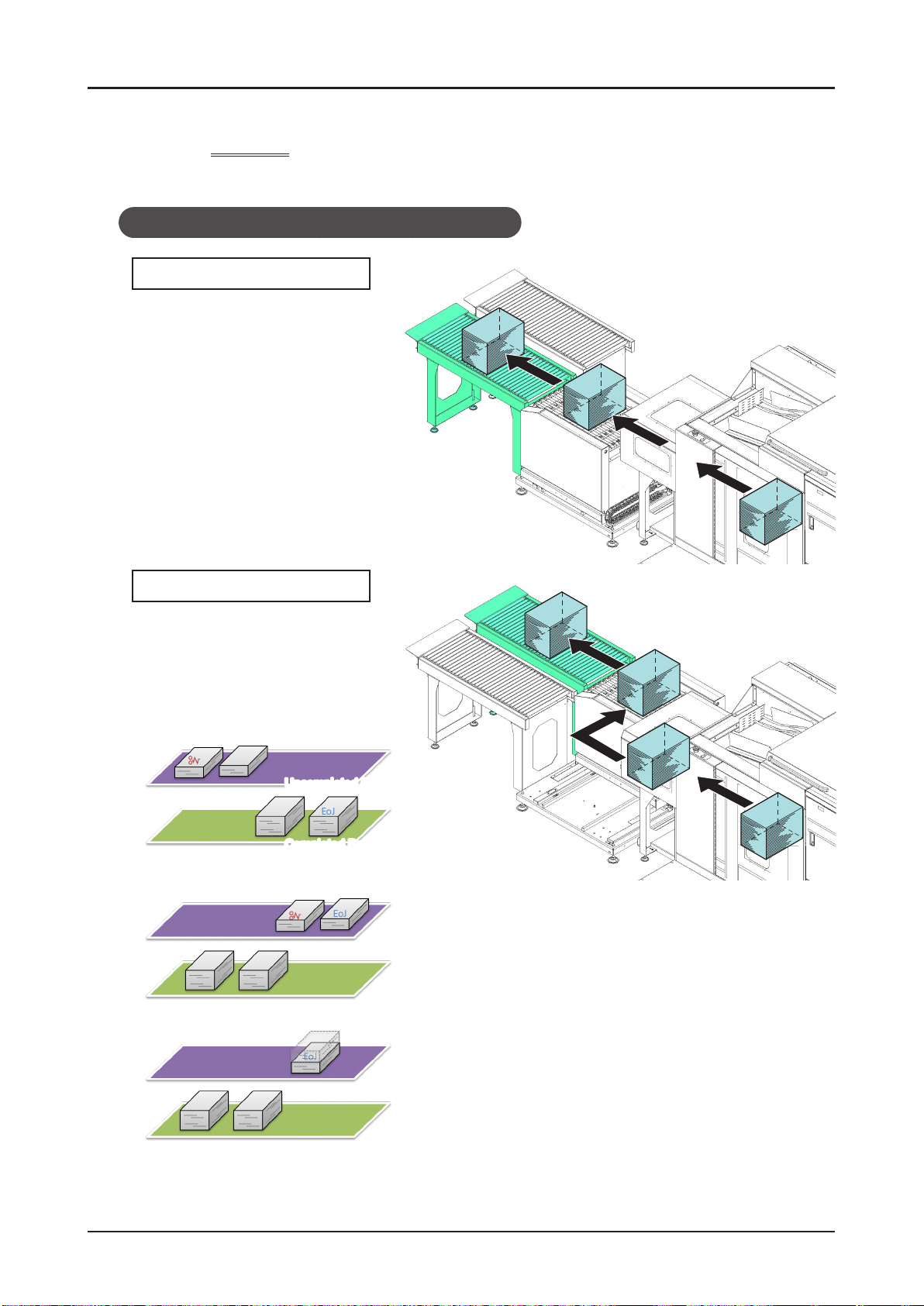

1-1-4

The processed stacks will be delivered to either of two destinations.

Delivery

When Using in the Near Line or Inline System

To Completed Conveyor

The stack goes to the complete

conveyor in case that the stack is

reached to the planned number of

sheets.

To Uncompleted Conveyor

A stack which is less than the

planned number of sheets goes to the

uncompleted box in all cases.

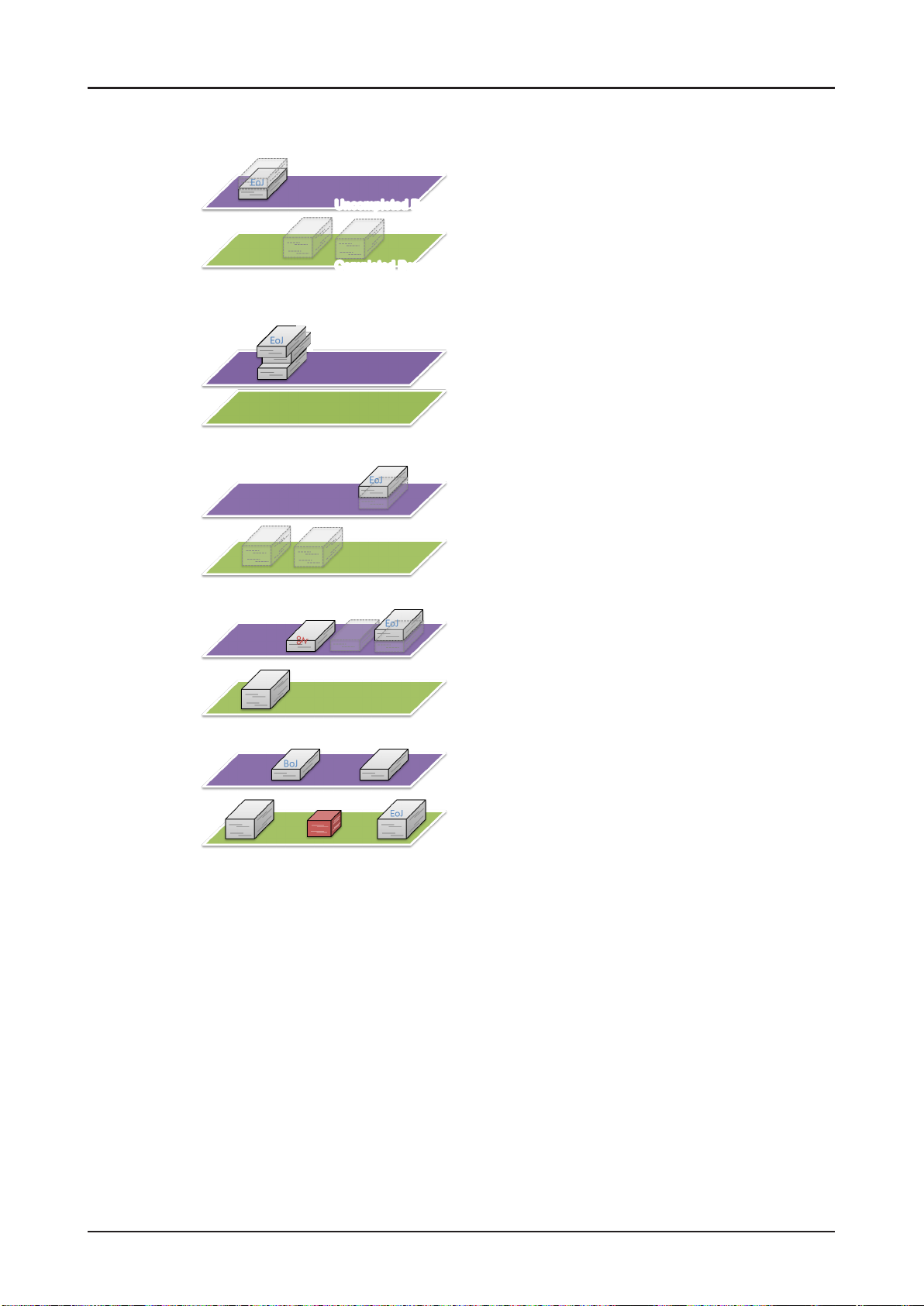

For Example of 3 stacks in job

• A jam on middle of the rst stack

Uncompleted Box

Completed Box

(Eoj = End of Job)

• A jam on middle of the last stack

• The job end on middle of the last stack

19SmartStacker User's Manual

Page 20

Features of the Machine

• The job end on middle of the rst stack

• If the “Offset” or “None” is selected for the operations after job processing on the FLC screen, the

previous job is not delivered, and the Line Clear button is pressed

• The user changes starting sheet number (from the Press UI)

• The user changes starting sheet number after the jam

Uncompleted Box

Completed Box

• Break of a job with changeover

20 SmartStacker User's Manual

Page 21

Features of the Machine

When using in the ofine system

To Completed Conveyor

The stack goes to the completed conveyor in case that the stack reaches the planned number of

sheets.

The block whose number of sheets reaches the planned number goes to the completed conveyor.

To Uncompleted Conveyor

A stack which is less than the planned number of sheets goes to the uncompleted box in all cases.

• The jam occurs at rst block of the second stack when the job is set in 3 stacks.

Fist Block

Uncompleted Box

Completed Box

Second and After Block

21SmartStacker User's Manual

Page 22

Features of the Machine

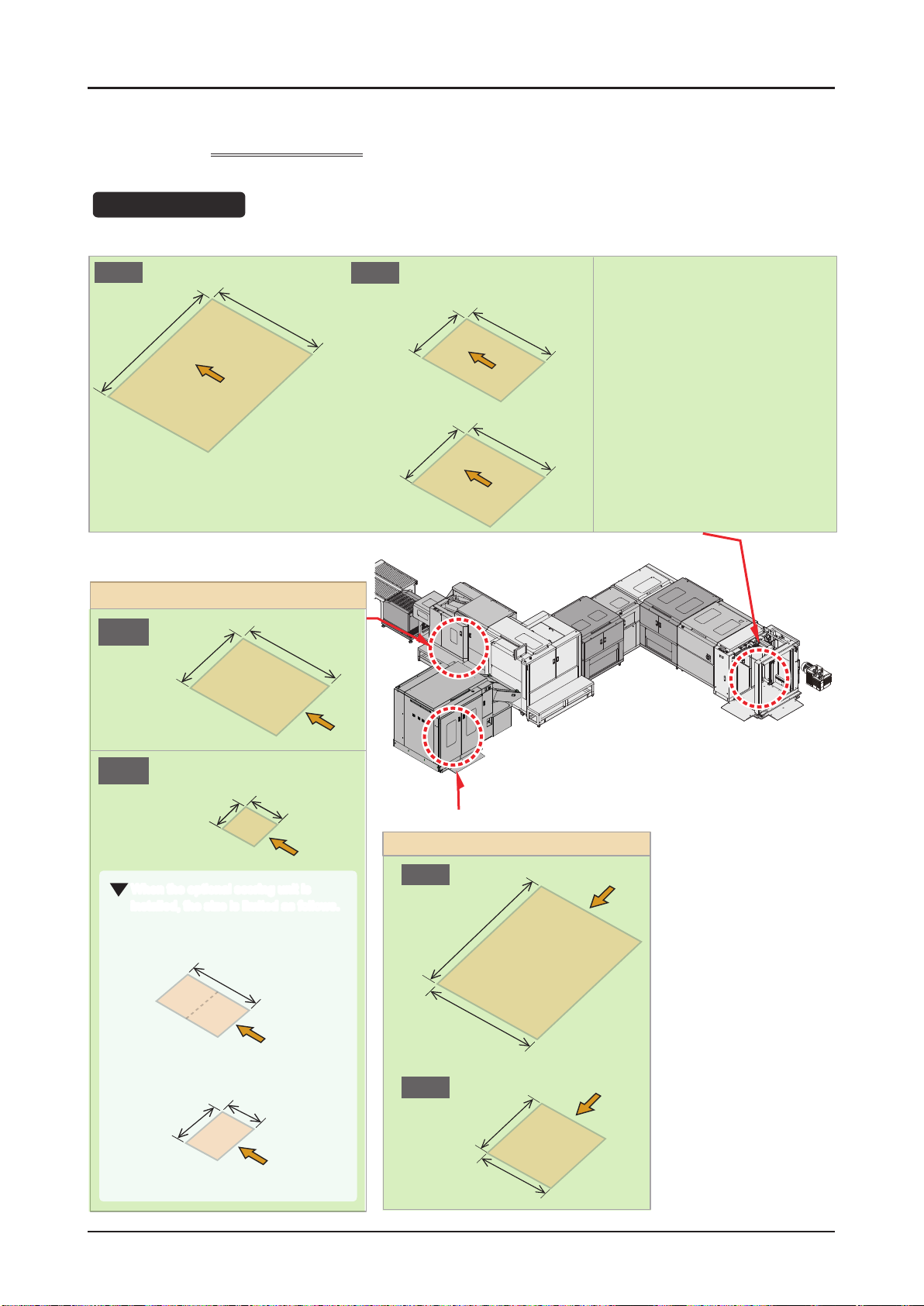

1-1-5

Sheet Size

Uncut Size

Max.

762 mm

30.000”

Finished Size

Supported Jobs

530 mm

20.865”

Min.

When delivered to Merge Stacker

279.4 mm

11.000”

When delivered to B2 Stacker

380mm

14.965”

330 mm

12.995”

330mm

12.995”

Standard Size

ISO A Series: A2 / A3

ISO B Series: B2 / B3

Inch Series: 18” x 24” / 17” x 22” /

13” x 19”

Merge Stacker

Max.

381 mm

15.000”

Min.

100 mm

3.940”

When the optional scoring unit is

installed, the size is limited as follows.

With Scoring

Without Scoring

148 mm

5.83”

177.8

7”

through

(Min.)

105 mm

4.13”

530 mm

20.865”

105 mm 4.135”

through

265 mm

10.43”

Finished Size

B2 Stacker

Max.

762 mm

30.000”

530mm

20.865”

Min.

380 mm

14.965”

210 mm

8.270”

22 SmartStacker User's Manual

Page 23

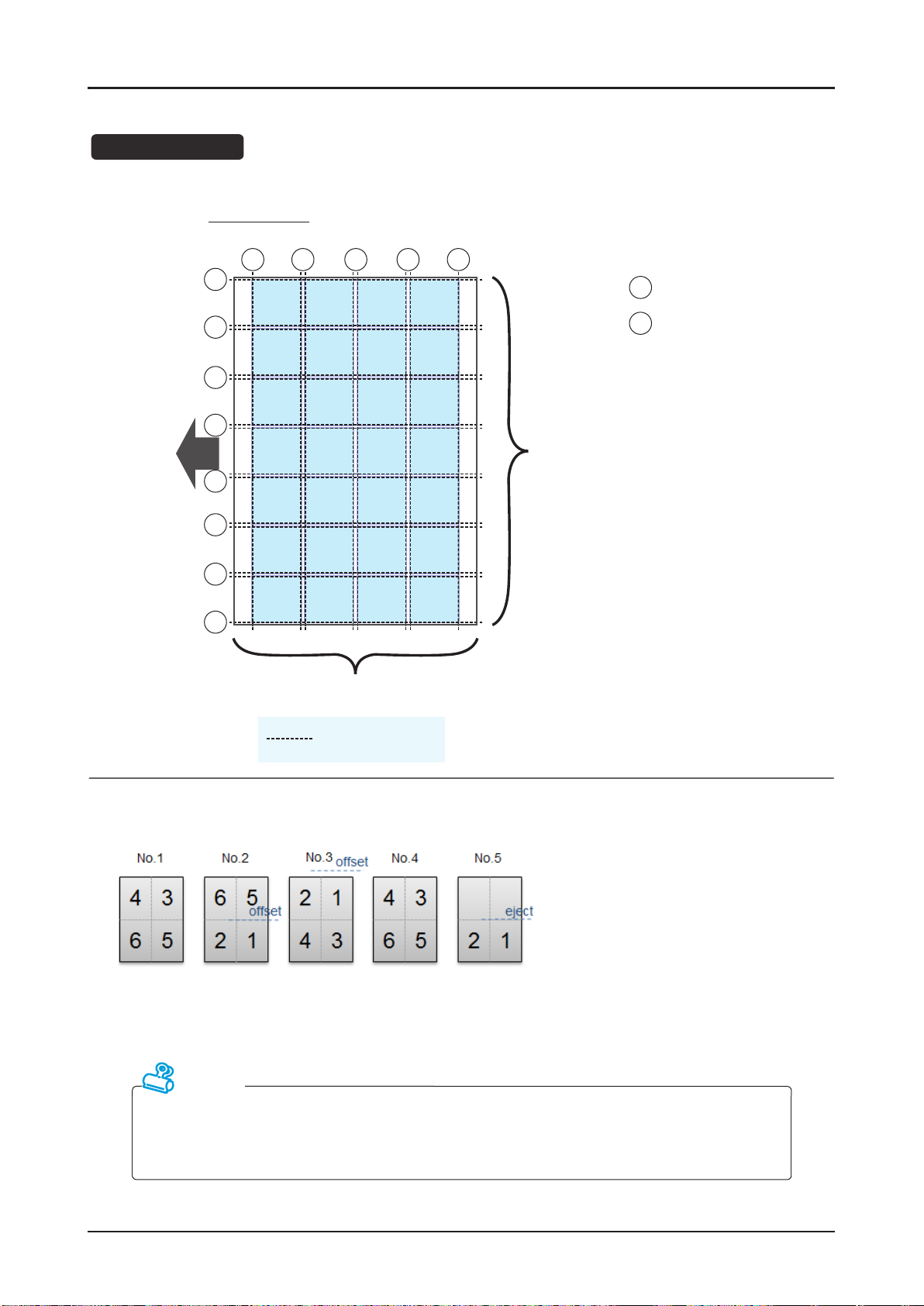

Number of Cuts

28-up (Max)

Features of the Machine

Feed

Direction

E

G

G

G

G

G

G

E

G G G

1234

5678

9101112

13141516

17181920

21222324

25262728

1 to 4 rows (8 cutters)

E E

: Edge Trim

E

(Bleed Trim)

: Gutter Trim

G

1 to 7 columns (14 cutters)

Slit Positions

Several blocks can be included in a job.

(The system can feed sheets with different numbers of pages.)

Attention

The maximum number of sheets which is capable in one job is as following:

• For near line operation: 100,000 sheets

• For inline operation: 50,000 sheets

23SmartStacker User's Manual

Page 24

Features of the Machine

Limitations of offset and delivery

The offset function and delivery function can be set in parallel to the feeding direction. They cannot

be set in perpendicular.

OK NG

The ejection operation can be done after the last row and other one row.

No.1

23

45

OK NG

No.2

45

offset

1

eject

123

4567

eject

123

4567

No.1

123

123

No.2

23

45

eject

eject

1234

eject

34

51

offset

The ejecting operation

cannot be done twice

except after the last row.

4567

24 SmartStacker User's Manual

Page 25

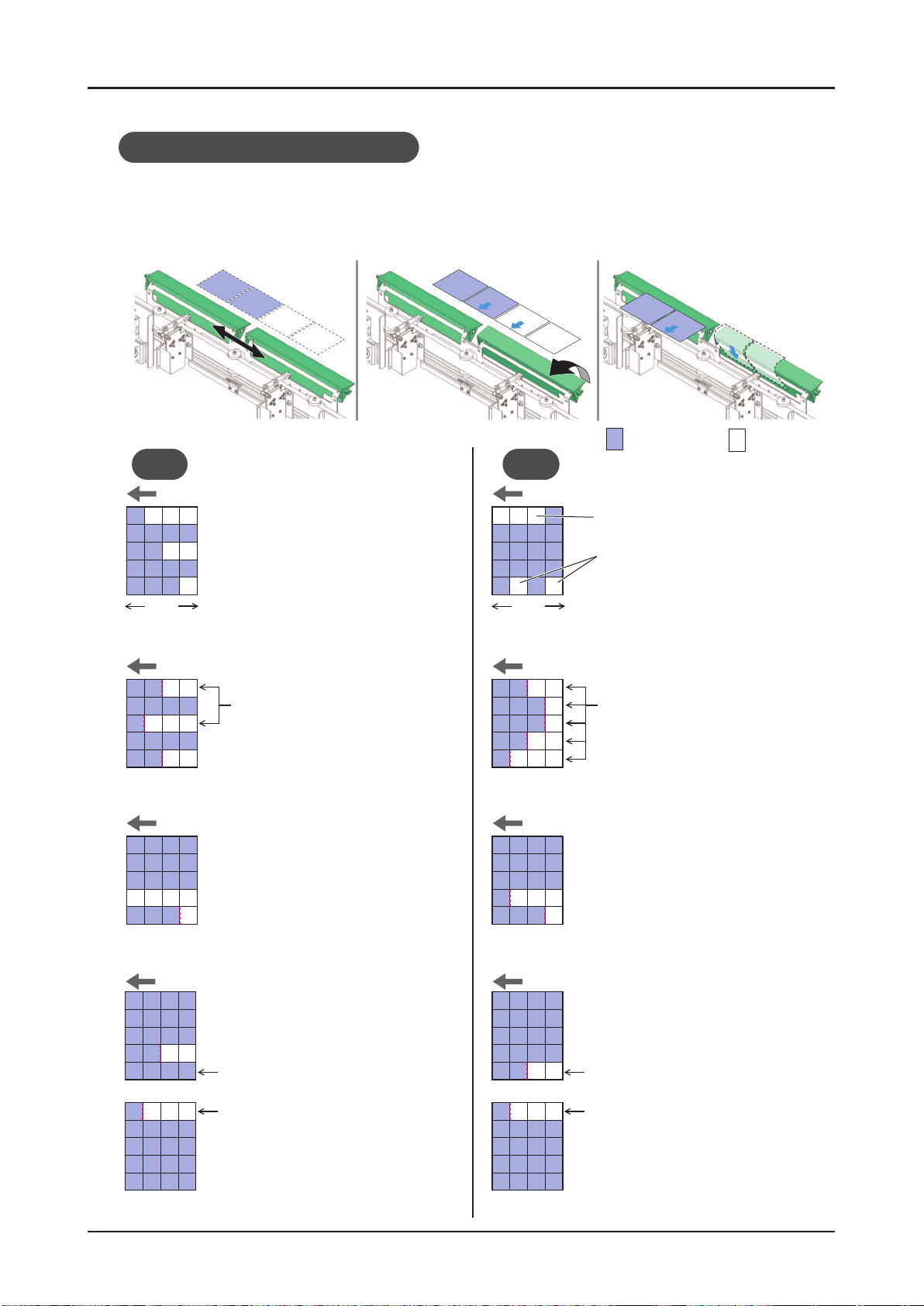

Limitation for blank page removal

Mechanism of Blank Page Removal

Features of the Machine

1. The gates slide to the

2. The gates open. 3. The blank pages which are

position where the blank

pages will pass.

OK NG

Feed direction Feed direction

The blank pages must be arranged

from the tail edge along the feeding

direction so that the several pages

can be removed at once.

Leading

edge

Tail

edge

Leading

edge

hit against the gates will be

ejected.

Printed page Blank page

The blank pages are arranged in the

leading edge.

The blank pages are not continued from the tail edge.

Tail

edge

Feed direction Feed direction

If there are at least one row

between the blank pages as this

drawing, the blank page can be

ejected.

Feed direction Feed direction

However, in case that the blank pages are continued against the feeding

direction of the 2nd process unit, if

all the pages on the next row is blank

pages, the removal is possible.

Feed direction Feed direction

If there are at least one row

between the blank pages as

this drawing, the blank page

can be ejected.

Next sheet

Next sheet

First

row

Last

row

In case that several rows which

have different separation position

are continued, the SmartStacker

cannot eject the blank pages.

In case of this drawing, the SmartStacker cannot eject the blank

pages. Because two rows which

have different separation position

are continued.

In case of this drawing, the

SmartStacker cannot eject

the blank pages. Because

First

row

Last

row

two rows which have different separation position are

continued.

Next sheet

Next sheet

25SmartStacker User's Manual

Page 26

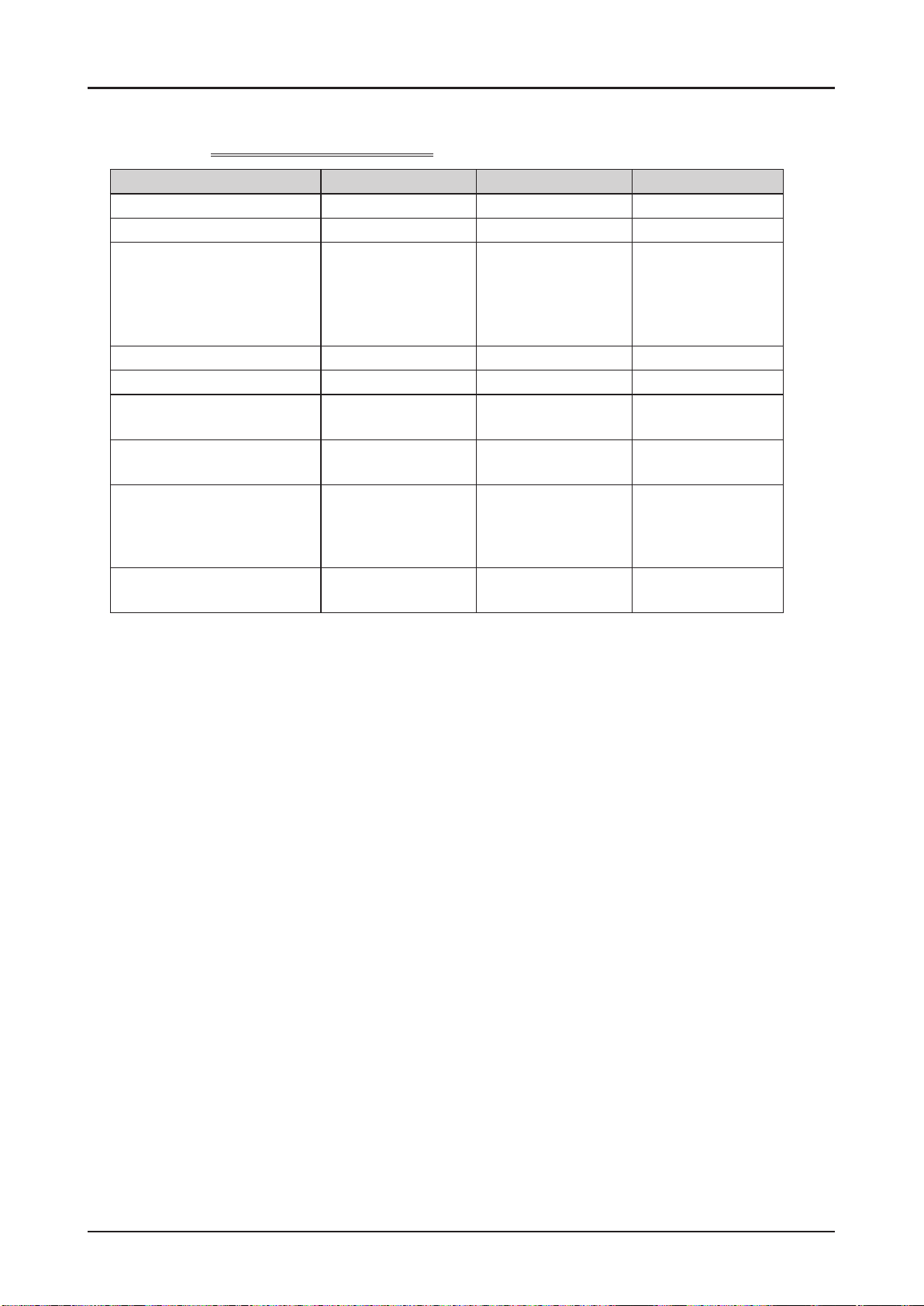

Features of the Machine

1-1-6

Functions Ofine Near line Inline

Sheet Cut and Stack Enable Enable Enable

Create a Job Enable Disable Disable

Fine Adjustment of

the Job Setting

JDF-based Operation Disable Enable Enable

Blank Page Rejection Disable Enable Enable

Operation Using the

Banner Sheet

Continuous Operation

of Multiple Jobs

Reprint Process

after an Error

Progress Report to the

Upstream System

Capability of Each Line

Enable

Disable Enable Enable

Disable

Disable

Disable Disable Enable

Enable

but ag is

necessary to set

Enable

using banner sheet

Enable

(You print the reprint

list and pass it to an

operator for press.)

Enable

but the ne-

adjustment should

be made before

printing is started

Enable

Enable

• Ofine and Near line can be switched just by pressing a button, but to use as the Inline system, the machine

should be installed again.

26 SmartStacker User's Manual

Page 27

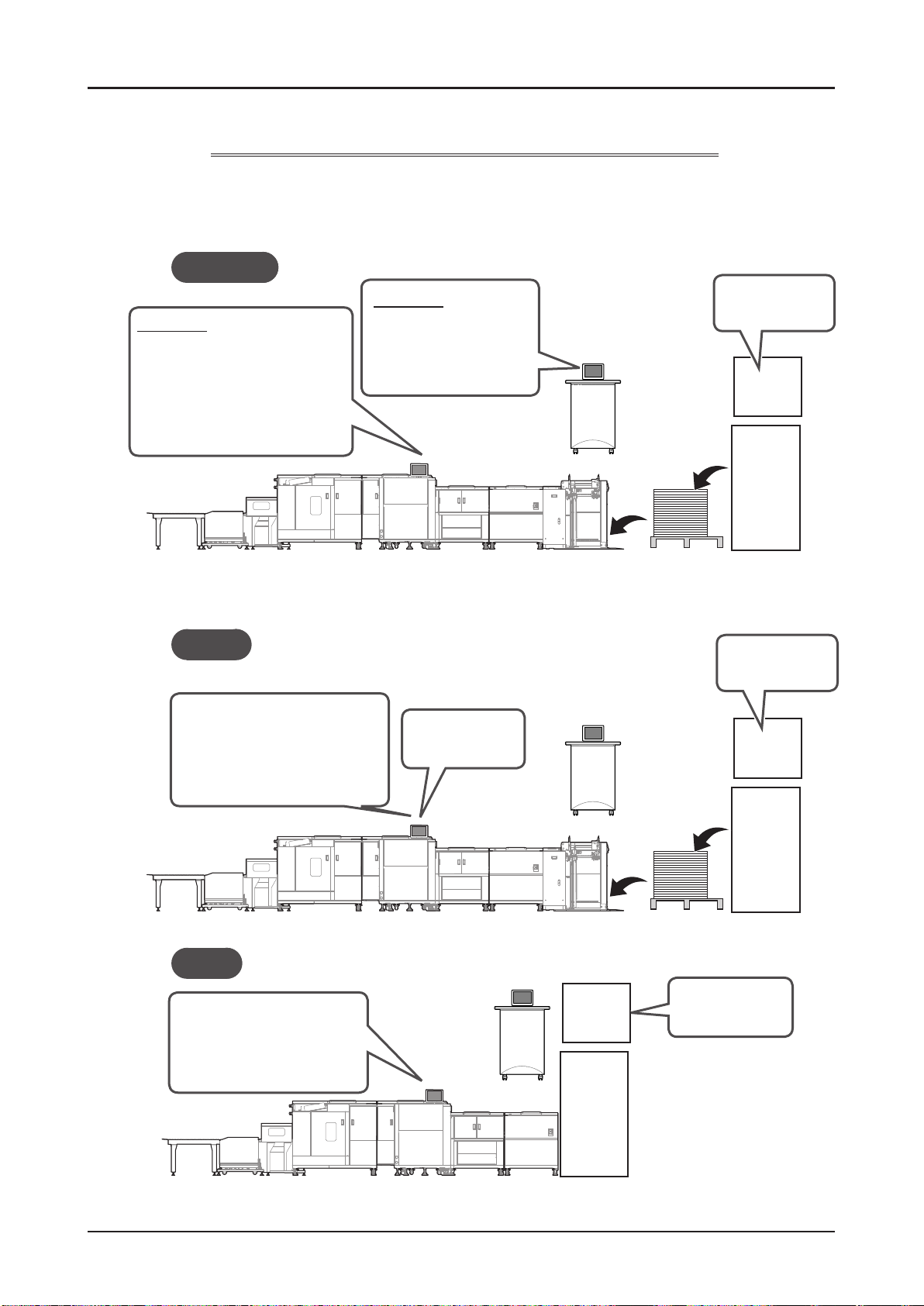

Features of the Machine

1-1-7

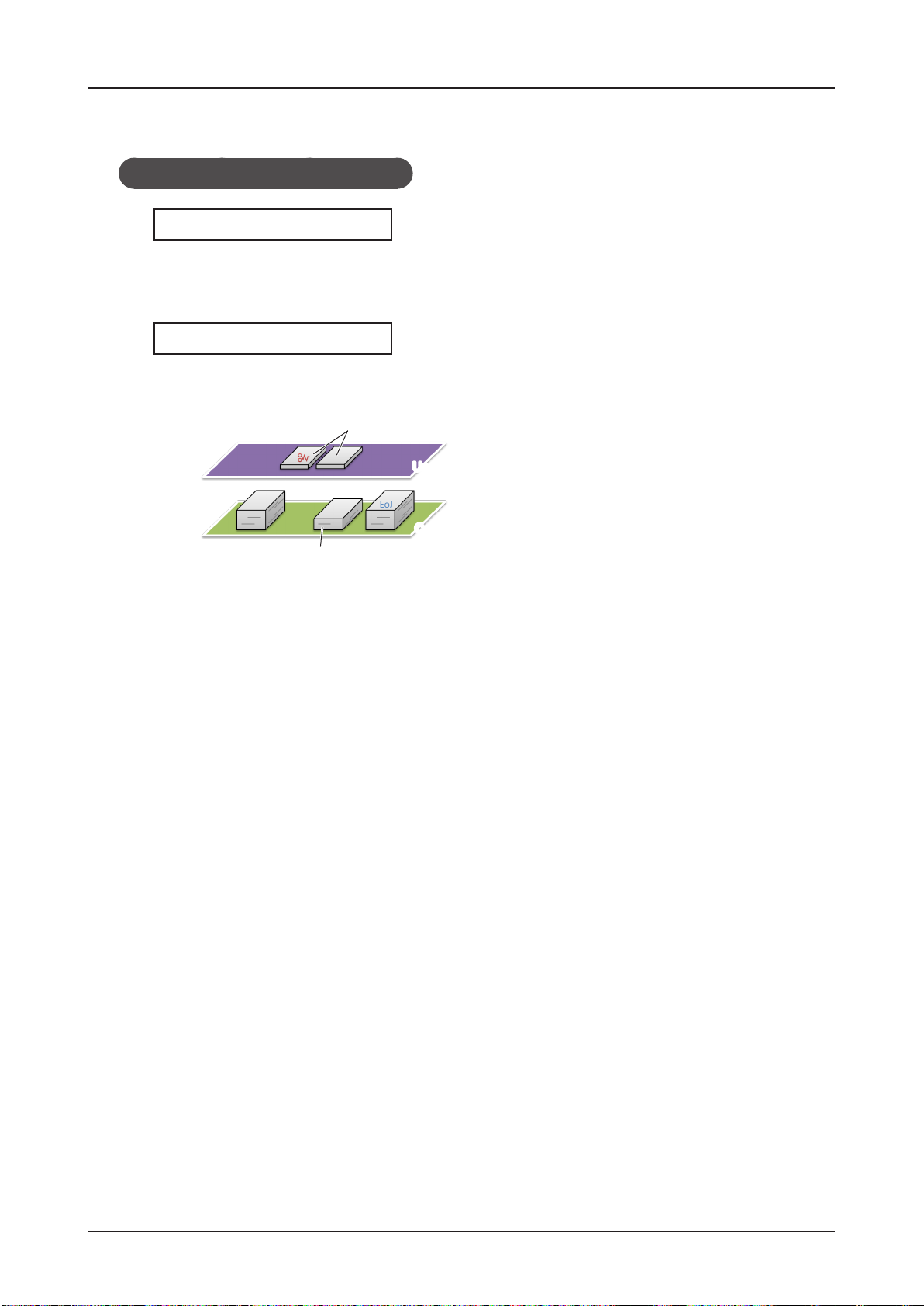

The Role of Panels of the SmartStacker and the FLC

The role of panels of the SmartStacker and the FLC, the procedure to create and start a job, and also to

make the ne adjustment are different depending on the conguration of line. The outline is shown below.

Near Line

Main Role

Saving the ne adjustment

•

values to the memory

beforehand

Recalling the saved adjustment

•

before running the job that was

set the ag

Main Role

Starting the job

•

Setting the ag on the

•

job

Creating the reprint list

•

Panel

FLC

FeederSmartStacker

Pallet

Creating the job

DFE

(UBM)

Press

Ofine

Saving the ne adjustment

•

values to the memory

beforehand

Recalling the saved job setting

•

Inline

Enter the values for the ne

•

adjustment before starting

the operation so that the

ne adjustment values are

carried over.

Panel

Panel

Creating the job

•

Starting the job

•

FLC

FeederSmartStacker

FLC

DFE

(UBM)

Press

Pallet

Creating the job

•

Starting the job

•

Creating and starting

the job for print

DFE

(UBM)

Press

SmartStacker

27SmartStacker User's Manual

Page 28

1-2

SmartStacker Screen Descriptions

1-2-1

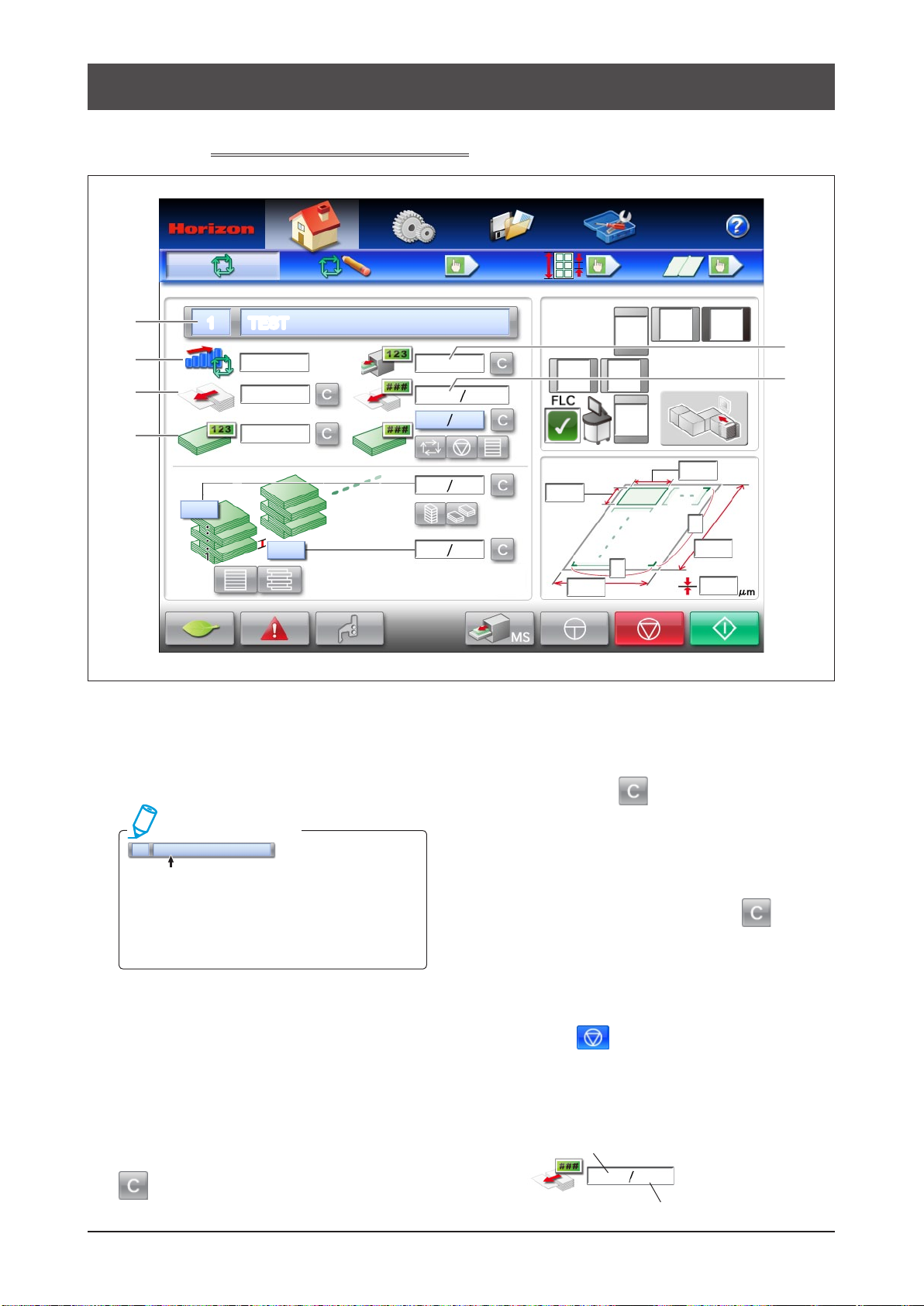

1

2

3

4

Run - Main Screen - Part 1

1 TEST

5

pieces/hr

6

Job Name

1

When you recall a job from the job memory in the

ofine system, the current job number and name are

displayed here.

Additional Information

1 TEST

If you change the settings or ne adjustment

settings after recalling the job from the memory

screen, the name of the job shown in the draw-

ing above will change to red. Save the modied

job with a different name if necessary.

Production Speed Indicator

2

The current operation speed (number of pages per

hour) is shown here.

Feed Counter for Uncut Sheets

3

The total number of fed uncut sheets is displayed

here. This number is saved even if the power is

turned off. If you are using this machine in the

ofine mode and want to change the job, press

(Clear) to reset the counter to zero.

Delivered Block Counter

4

This shows the number of blocks that have been

delivered. The number is saved even if the power is

turned off. Press

zero.

Counter for Delivered Pages (Pieces)

5

The total number of delivered pages is displayed

here. Every piece is counted. The number is saved

even if the power is turned off. Press

reset the counter to zero.

Preset Counter for the Number of Uncut

6

Sheets

If you are using the machine in the ofine mode, and

you press

sheets is displayed. The number of uncut sheets

which should be fed is calculated automatically using

the counter for the number of pages in each block

and the preset counter for the total number of blocks.

Number of sheets already fed

(Clear) to reset the counter to

(Stop), the preset number of uncut

0

10

Total number of sheets to be fed

(Clear) to

28 SmartStacker User's Manual

Page 29

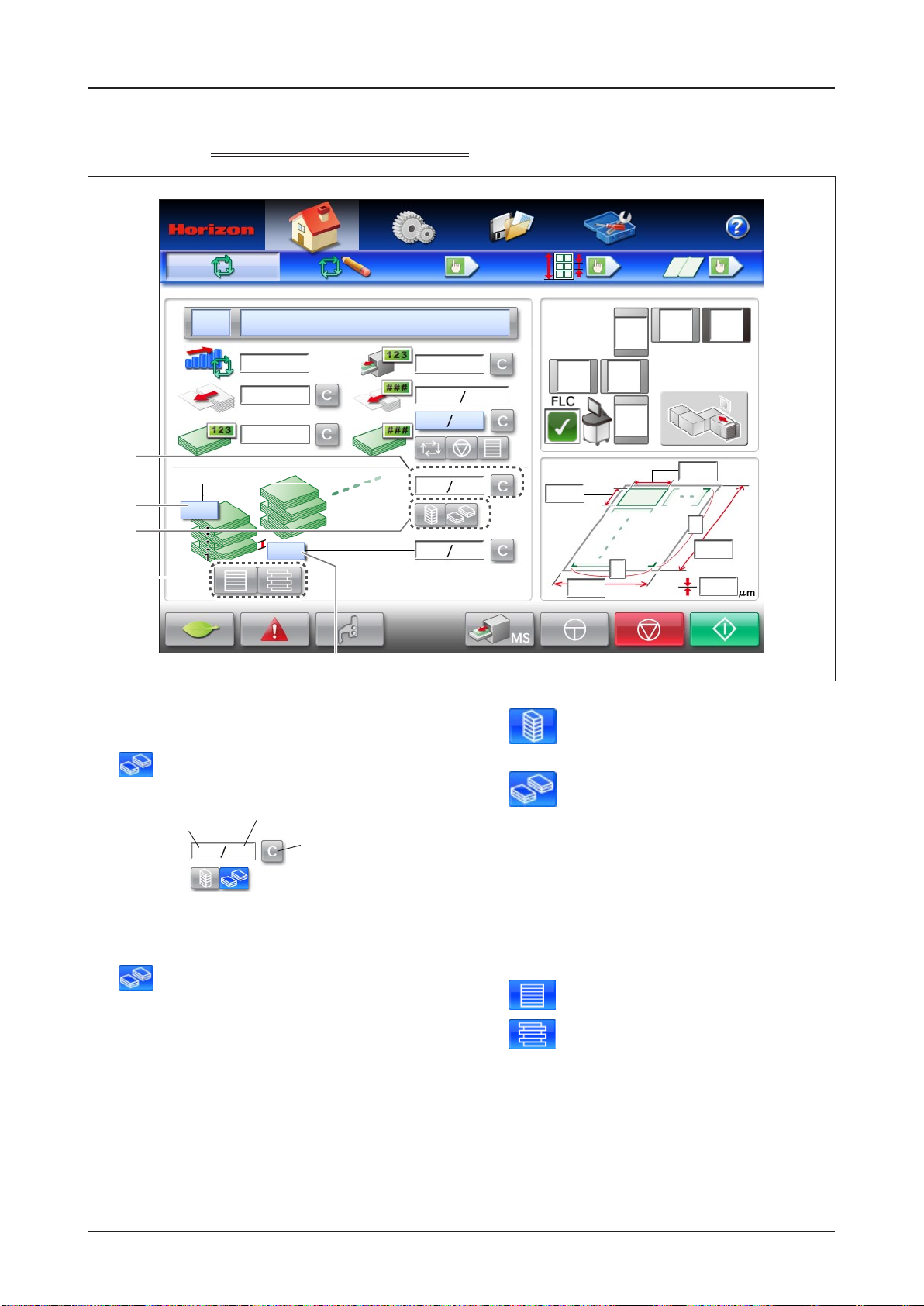

SmartStacker Screen Descriptions

1-2-2

1

2

3

4

Run - Main Screen - Part 2

pieces/hr

5

Counter for the Number of Blocks in Each Stack

1

When the machine is used in an ofine system and

is selected for the stack function, the number

of blocks stacked is displayed.

Number of blocks

already stacked

Number of Blocks in Each Stack

2

When the machine is used in an ofine system and

is selected for the stack function, enter the

number of blocks in each stack.

Stack Function On/Off

3

Use this to set how many blocks should be stacked in the

stacker before the blocks are delivered.

If you are using the machine in an inline system

or a near line system, the setting on the press is

displayed and this function cannot be set from this

screen. If you are using the machine in the ofine

mode, set this function on this screen.

Number of blocks in each stack

0 5

Press this button to

clear the number of

blocks which have

already been stacked.

This turns off the stack function. The machine will

continue feeding the uncut sheets until the pages

reach the upper limit of the Merge Stacker.

This turns on the stack function. The

machine will stop after feeding the number

of blocks in one stack.

Offset Function On/Off

4

Use this setting to set whether or not each block is

offset by the stacker.

If you are using the machine in an inline system or a near

line system, the setting on the press is displayed and this

function cannot be set from this screen. If you are using the

machine in the ofine mode, set this function on this screen.

The offset function is turned off (straight stacking).

All of the blocks of pages are stacked without any offset.

The offset function is turned on.

One block is offset to the right, and the next

block is offset to the left.

Number of Sheets for One Block

5

Enter the number of sheets for one block.

If you are using the machine in an inline system or a

near line system, the setting on the press is displayed

and this function cannot be set from this screen. If

you are using the machine in the ofine mode, set this

function on this screen.

29SmartStacker User's Manual

Page 30

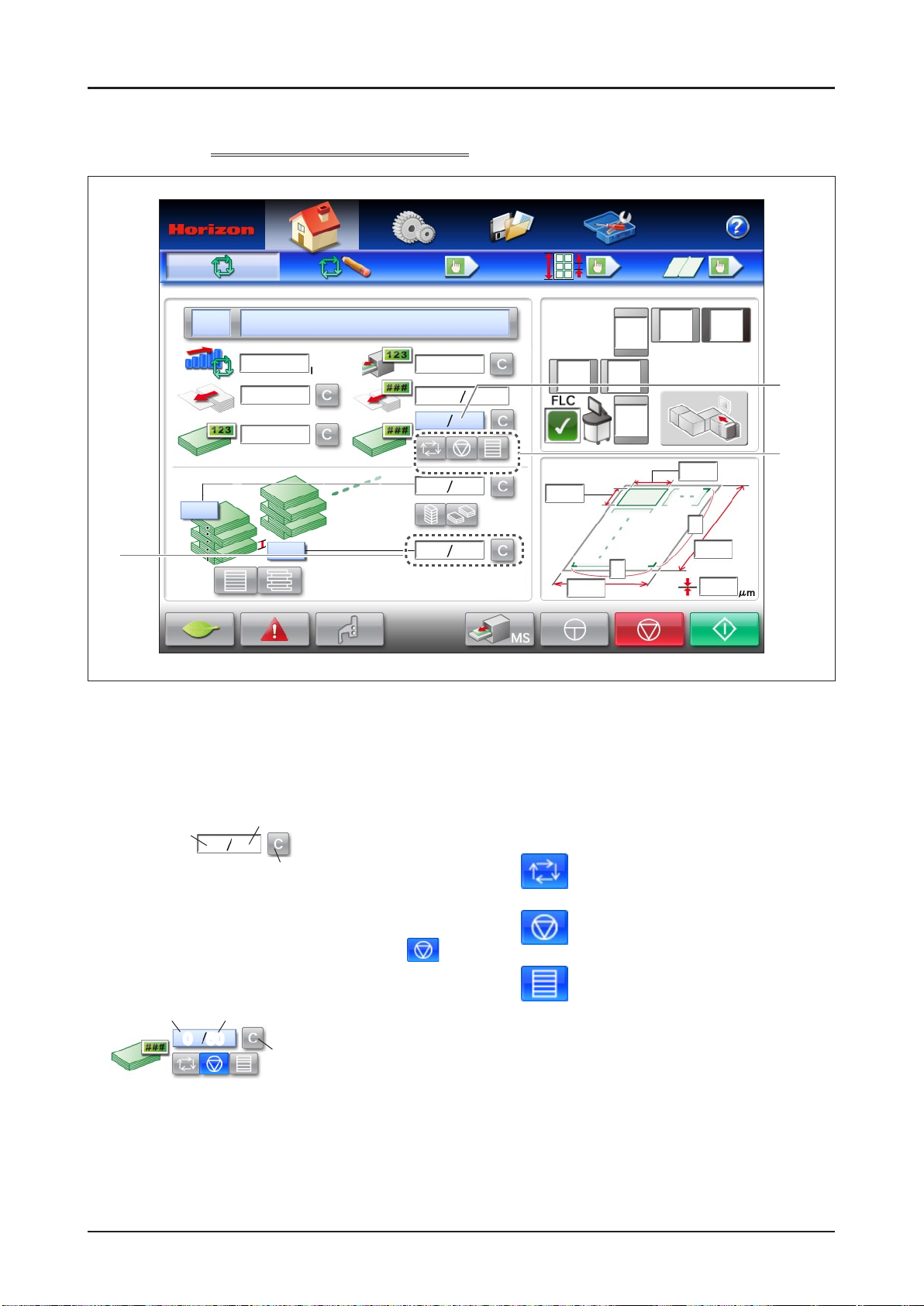

SmartStacker Screen Descriptions

1-2-3

1

Run - Main Screen - Part 3

pieces/hr

2

3

Counter for the Number of Pages

1

(Pieces) in Each Block

This indicates the number of pages included in one

block, and the number of pages already stacked.

Number of pages

already stacked

0 5

Press this button to clear the number of

pages which have already been stacked.

Preset Counter for the Total Number of Blocks

2

If you are using the machine in the ofine mode and select

(stop) for the preset function, enter the preset number of blocks.

Number of blocks

already delivered

0 50

Number of pages included

in one block

Total preset number of blocks

Press this button to clear the

number of blocks which have

already been delivered.

Total Preset Function On/Off

3

Use this setting to set how many blocks should be

delivered before the machine stops. If you are using the

machine in an inline system or a near line system, the

setting on the press is displayed and this function cannot

be set from this screen. If you are using the machine in the

ofine mode, set this function on this screen.

The preset function is turned off. The machine

continues feeding the uncut sheets until the

Stop button is pressed or the sheets run out.

The preset function is turned on. The machine

stops after feeding the number of blocks which

has been set on the preset counter.

All of the blocks are stacked without offsetting.

When the top of the stack reaches to the

upper limit of the Merge Stacker, the sets are

delivered.

30 SmartStacker User's Manual

Page 31

SmartStacker Screen Descriptions

1-2-4

Run - Main Screen - Part 4

pieces/hr

1

2P

SF1P

2

3

MCMS

4

5

6

7

Help Button

1

Press this button to see explanations of each of the

icons on the screen.

Status Icon

2

Status icons are displayed for each machine.

Running

Interlock Circuit Open

(This icon means that the

Emergency Stop button has been

pressed or the safety cover has

been opened.)

Not Ready (An error occurred

during the changeover and the

machine is stopped.)

No Icon: Stopping

Internal Network Communication Error Icon

3

The icon is displayed if there is a problem with the

network communications.

The communication network has a

problem.

The machine is checking if the

communication device exists.

External Network Communication Error Icon

4

The icon is displayed if there is a problem with the

network communication between the systems.

Line System Icon

5

These icons show how the unit will operate with the

rest of the production line.

Ofine

Near line

Inline

Status of FLC and Line System

6

This icon is displayed when the FLC is connected

with an Inline system or with a Near Line system.

See page 83 for details of icon.

Sheet Size

7

This indicates the current sheet size and thickness.

31SmartStacker User's Manual

Page 32

SmartStacker Screen Descriptions

1-2-5

Run - Main Screen - Part 5 (for Merge Stacker)

2P

pieces/hr

MCMS

1

Power Saving Mode

1

When this button is pressed, the machine goes into

power saving mode. The display on the touch panel

disappears. When you touch the panel again, the

machine returns to the normal mode.

Go to the Error Screen

2

Press this button to display the Error screen. See

page 78 for details.

Trim Guide Setting Screen Display

3

2

Button

Press this button to display the Trim Guide Setting

screen. Use this button to check wether the trim

guide is set for the current job. See page 50 for

details.

Block Delivery Button

4

Press this button to deliver the block from the Merge

Stacker. Use this button after an error occurs and

the machine stops.

Jog Button

5

Press and hold this button to move the sheets

forward. Use this button after an error occurs and

the machine stops.

4

Stop Button

6

If the machine is used in an ofine system or a

near line system, press this button to stop feeding.

Any sheets which are in-process are nished and

delivered, and the machine is stopped.

`Immediately` is selected for the Stop Timing).

When the machine is used in a Near Line system,

the timing to stop the machine can be changed.

See page 81 for details.

Start Button

7

This button is used if the machine is used in an ofine

system or a near line system.

If the machine is used in an ofine system, press this

button to start the feeding and cutting operations.

If the machine is used in a near line system, press

this button to do the changeover, the feeding and

cutting operation following the information of read

barcode. If the job does not have a barcode, the

system runs following the information of the Pending

job that is selected on the screen of FLC.

5

Attention

6

73

(when

32 SmartStacker User's Manual

Page 33

SmartStacker Screen Descriptions

1-2-6

See

page 28.

See

page 29.

Run - Main Screen - Part 6 (for B2 Stacker)

pieces/hr

See

page 31.

See

page 30.

See page 32.

33SmartStacker User's Manual

Page 34

SmartStacker Screen Descriptions

1-2-7

1

2

3

Run - Setting Screen - Part 1

Feed Speed

1

This sets the number of uncut sheets to be

processed per hour.

Feed Rotor Suction Length

2

This sets the suction length of the feed rotor. If the

machine misfeeds, make the length longer. If the

machine double-feeds, make the length shorter.

Amount of Downward Vacuum of the

3

Transport Roller Section

T

his sets the amount of vacuum provided by the fans below the

transport rollers in the Merge Conveyor.

Increase the vacuum air if the sheets do not align with the angle

adjusting guide and result in misaligned stack of sheets.

Adjust the air if the sheets do not run on the transport rollers

smoothly and result in an error, the error code 340 / 350; Sheet

has not arrived at upper / lower transport section sheet pass

sensor, or the error code 341 / 351; Sheet remains at upper /

lower transport section sheet pass sensor.

(Reduce the air for light sheets such as normal paper.

Increase the air for heavy sheets such as coated paper.)

Angle Adjusting Guide

Fans

34 SmartStacker User's Manual

Page 35

SmartStacker Screen Descriptions

1-2-8

Run - Setting Screen - Part 2 (for Merge Stacker)

1

2

3

4

Supporting Air

1

When the vacuum belts are transporting a sheet

to the top of the stack in the Merge Stacker, air is

supplied to support sheet. The amount of air can be

adjusted here.

Use the smallest amount of air that will provide

reliable operation. If you are running thin or soft

sheets, and they are bent and do not stack correctly,

increase the amount of air.

Amount of Upward Vacuum of the

2

Vacuum Belt

This sets the amount of vacuum provided by the

vacuum belt in the Merge Stacker.

Usually this should be set to maximum.

If you are running thin sheets which do not separate

from the belt when they reach the stopper, reduce

the vacuum.

Jogging Motion On/Off

3

This turns the jogging motion in the Merge Stacker

on or off.

This is the standard setting. The stopper

will jog every sheet.

The stopper will not jog the sheets.

Bypass for the Merge Stacker

4

This turns the jogging motion in the Merge Stacker

on or off.

Sheets are stacked on the merge stacker.

Normally, select this button.

This button is currently not available.

35SmartStacker User's Manual

Page 36

SmartStacker Screen Descriptions

1-2-9

3

Run - Setting Screen - Part 3 (for B2 Stacker)

1

2

Supporting Air

1

When the vacuum belts are transporting a sheet to

the top of the stack in the B2 Stacker, air is supplied

to support sheet. The amount of air can be adjusted

here.

Usually this should be set to maximum. Use

the large amount of air that will provide reliable

operation. If you are running thin or soft sheets, and

they are bent and do not stack correctly, increase

the amount of air.

Adjustment of Upward Vacuum of the

2

Vacuum Belt

This sets the amount of vacuum provided by the

vacuum belt in the B2 Stacker.

If the sheet does not reach the stopper in the stack

section, press

vacuum. If you are running thin sheets which do not

separate from the belt when they reach the stopper,

or if a jam occurs, reduce the vacuum.

to increase the amount of

Amount of Downward Vacuum of the

3

Register Guide Section

This sets the amount of vacuum provided by the fans

below the register section in the Merge Conveyor. Increase

the vacuum air if the sheets do not align with the register

guide and result in misaligned stack of sheets.

If a jam caused by hitting the register guide (any scratches or

transport error caused by sheet bent) occurs, press

reduce the vacuum.

Register Guide

Register Section

You can see the sheet ow from above the sheet receiving

section of the Merge Conveyor and the B2 Stacker. Check that

the sheet is aligned to the guide.

to

36 SmartStacker User's Manual

Page 37

SmartStacker Screen Descriptions

1-2-10

Run - Setting Screen - Part 4 (for B2 Stacker)

1

Bypass for the B2 Stacker

1

This turns the jogging motion in the B2 Stacker on or

off.

Sheets are stacked on the B2 stacker.

Normally, select this button.

This button is currently not available.

37SmartStacker User's Manual

Page 38

SmartStacker Screen Descriptions

1-2-11

The sheet feeder is optional.

Run - Fine Adjustment Screen - Part 1

3

4

5

1

2

Option

6

7

Sheet Feeder Table Guide Position

1

The table guide position can be adjusted here. The

tail edges of the sheets are registered by this guide

when they are loaded into the table.

Sheet Feeder Suction Head Position

2

The suction head position can be adjusted here.

Position the suction head so that the set register pin

of the suction head ts against the tail edge of the

stack of sheets.

Sheet Feeder Rear Guide Position

3

The rear guide position can be adjusted here.

1st Regist Unit Register Guide Position

4

The register guide position can be adjusted here.

The sheets move to the rear and are positioned by

this guide.

2nd Process Unit Gate Position

5

The blank page ejecting gate position can be

adjusted here. When the pages are delivered to the

waste tray, if the edges hit the gate and jam, adjust

the position of the gate.

Merge Conveyor Upper Stopper and

6

Angle Adjusting Guide Position

The upper stopper and angle adjusting guide

position can be adjusted here.

After the sheets were delivered onto the transport

roller section and turned the direction, they are

aligned with the angle adjusting guide while they are

transported through between the stopper and the

angle adjusting guide.

Adjust the guide if the sheets from upper section and

the sheets from lower section of Merge Conveyor are

regularly misaligned in a stack.

Merge Conveyor Lower Stopper and

7

Angle Adjusting Guide Position

The lower stopper and angle adjusting guide position

can be adjusted here.

After the sheets were delivered onto the transport

roller section and turned the direction, they are

aligned with the angle adjusting guide while they are

transported through between the stopper and the

angle adjusting guide.

Adjust the guide if the sheets from upper section and

the sheets from lower section of Merge Conveyor are

regularly misaligned in a stack.

38 SmartStacker User's Manual

Page 39

SmartStacker Screen Descriptions

1-2-12

The sheet feeder is optional.

Run - Fine Adjustment Screen - Part 2

1

2

Option

Merge Stacker Stopper Position

1

The stopper position can be adjusted here. The

head of the stack is held by this stopper while the

pages are stacked.

Merge Stacker Sheet Holding Plates

2

Pressure

The sheet holding plates prevent the sheets from

bouncing back from the stopper.

This pressure is automatically adjusted according to

the thickness of sheet. (The pressure is reduced for

thin sheets, and increased for thick sheets.) If you

want to change the pressure, make the adjustment

here.

If a sheet does not reach the stopper and causes a

jam, decrease the pressure.

If the front and rear edges of the stack are not

aligned correctly, increase the pressure.

39SmartStacker User's Manual

Page 40

SmartStacker Screen Descriptions

1-2-13

The sheet feeder is optional.

Run - Fine Adjustment Screen - Part 3 (for B2 Stacker)

Option

Option

B2 Stacker Stopper Position

1

The stopper position can be adjusted here. The

head of the stack is held by this stopper while the

pages are stacked.

B2 Stacker Sheet Separate Plates Pressure

2

The sheet separate plates prevent the sheets from

bouncing back from the stopper.

This pressure is automatically adjusted according to

the thickness of sheet. (The pressure is reduced for

thin sheets, and increased for thick sheets.) If you

want to change the pressure, make the adjustment

here.

If a sheet does not reach the stopper and causes

a jam, decrease the pressure. If the front and

rear edges of the stack are not aligned correctly,

increase the pressure.

1 2

40 SmartStacker User's Manual

Page 41

SmartStacker Screen Descriptions

1-2-14

1

2

3

4

Run - Page Size Fine Adjustment Screen - Part 1 (for Merge Stacker)

5

Page Length

1

The page length can be adjusted. If the cut sheets

are longer or shorter equally than the desired

dimension, adjust the page length setting here.

Value Before Fine Adjustment

V alue After Fine Adjustment

Bleed Trim Length

2

If the bleed and gutter trim position of all of the

pages is shifted to the right or left, adjust the length

here.

Bleed Trim Width

3

If the bleed and gutter trim position of all of the pages

is shifted up or down, adjust the width here.

Feed

Direction

Page Width

4

The page width can be adjusted. If the width of all of

the pages is too wide or too narrow, adjust the width

here.

Feed

Direction

Go to the 1st Process Unit Fine

5

Adjustment Screen

41SmartStacker User's Manual

Page 42

SmartStacker Screen Descriptions

1-2-15

1

2

3

4

Run - Page Size Fine Adjustment Screen - Part 2 (for B2 Stacker)

5

Page Length

1

The page length can be adjusted. If the cut sheets

are longer or shorter equally than the desired

dimension, adjust the page length setting here.

Value Before Fine Adjustment

V alue After Fine Adjustment

Bleed Trim Length

2

If the bleed trim position is shifted to the right or left,

adjust the length here.

Bleed Trim Width

3

If the bleed trim position is shifted up or down, adjust

the width here.

Feed

Direction

Page Width

4

The page width can be adjusted. If the width of all of

the pages is too wide or too narrow, adjust the width

here.

Feed

Go to the 1st Process Unit Fine

Direction

5

Adjustment Screen

42 SmartStacker User's Manual

Page 43

SmartStacker Screen Descriptions

1-2-16

1

2

Run - Cutter Position Fine Adjustment - 1st Process Unit Fine Adjustment Screen

3

5

Simultaneous Adjustment Button

1

Separately Adjustment:

The cutters are adjusted individually.

Simultaneous Adjustment:

When one of cutters is adjusted, all the

cutters in front than the adjusted cutter

are automatically adjusted along with the

adjusted cutter.

Cutter Position Fine Adjustment

2

If the one of bleed or gutter trim positions is shifted

up or down, adjust the position of the affected cutter.

Cutters which are not used for the selected job

cannot be adjusted.

Feed

Direction

Cutter Position Indication

3

This indicates which cutter positions are adjustable,

depending on the selected job.

Go to the 2nd Process Unit Fine

4

Adjustment Screen

Return to the Run - Page Size Fine

5

Adjustment Screen

4

43SmartStacker User's Manual

Page 44

SmartStacker Screen Descriptions

1-2-17

1

2

Run - Cutter Position Fine Adjustment - 2nd Process Unit Fine Adjustment Screen

3

5

Simultaneous Adjustment Button

1

Separately Adjustment:

The cutters are adjusted individually.

Simultaneous Adjustment:

When one of cutters is adjusted, all the

cutters in front than the adjusted cutter

are automatically adjusted along with the

adjusted cutter.

Cutter Position Fine Adjustment

2

If the one of the bleed or gutter trim position is

shifted to the right or left, adjust the position of the

affected cutter.

Cutters which are not used for the selected job

cannot be adjusted.

4

Cutter Position Indication

3

This indicates which cutter positions are adjustable,

depending on the selected job.

Go to the 1st Process Unit Fine

4

Adjustment Screen

Return to the Run - Page Size Fine

5

Adjustment Screen

Feed

Direction

44 SmartStacker User's Manual

Page 45

SmartStacker Screen Descriptions

1-2-18

1

Run - Scoring Position Fine Adjustment Screen (Optional)

2

Fine Adjustment of the Scoring

1

Position - Far Side

Each sheet is cut into two parts in the 2nd Process Unit.

If the scoring position is shifted from the desired position

on the far side of the page, adjust the position here.

Feed

Direction

Fine Adjustment of the Scoring Position

2

- Operator Side

Each sheet is cut into two parts in the 2nd Process Unit.

If the scoring position is shifted from the desired position

on the operator side of the page, adjust the position here.

Feed Direction

45SmartStacker User's Manual

Page 46

SmartStacker Screen Descriptions

1-2-19

8

7

6

5

4

3

Setting - Size Setting Screen - Only for Offline System- Part 1

1

2

Sheet Width

1

Enter the width of the sheet.

Allowable range for the sheet width:

279.4 to 762 mm / 11” to 30”

Division Number - Long Side

2

Enter the number of parts into which you want to

divide the long side of the sheet.

Allowable range for the division number - long side:

1 through 7

Sheet Length

3

Enter the length of the sheet.

Allowable range for the sheet length:

330 to 530 mm / 12.99” to 20.87”

Division Number - Short Side

4

Enter the number of parts into which you want to

divide the short side of the sheet.

Allowable range for the division number - short side:

1 through 4

Gutter Trim On/Off - Long Side

5

This is used to set whether to trim the gutter of the long side.

On: The gutter is trimmed

Off: No gutter trim

If you change this setting, the Trim Guides

Setting screen will be displayed when you do the

changeover. See page 50 for details.

Gutter Trim Width - Long Side

6

If you have turned on the gutter trim function, this is

used to set the gutter trim width.

Allowable range for the gutter trim width:

6 to 15 mm / 0.24” to 0.6”.

Page Width

7

Enter the page width.

Page Length

8

Enter the page length.

46 SmartStacker User's Manual

Page 47

SmartStacker Screen Descriptions

1-2-20

1

2

3

Setting - Size Setting Screen - Only for Offline System - Part 2

4

5

6

Long Edge Trim On/Off

1

This sets the trim function when the long edge of

sheet is cut.

Long Edge Trim Width (Register side)

2

When the long edge trim function is turned on, enter

the value of the long edge trim width on the register

side (rear side).

Long Edge Trim Width (Non-registered

3

side)

When the long edge trim function is turned on,

the value of the long edge trim width on the nonregistered side (front side) is displayed.

The value is decided according to the sheet size

(untrimmed sheet), nished sheet width, division

number, long edge trim width (register side).

If you enter a value which is out of range, the value

will be displayed in red.

On: Edge is trimmed.

Off: Edge is not trimmed.

Short Edge Trim On/Off

4

This sets the trim function when the short edge of

sheet is cut.

Short Edge Trim Width (Register side)

5

When the short edge trim function is turned on, enter

the value of the short edge trim width on the register

side (rear side).

Short Edge Trim Width (Non-registered

6

side)

When the short edge trim function is turned on,

the value of the short edge trim width on the nonregistered side (front side) is displayed.

The value is decided according to the sheet size

(untrimmed sheet), nished sheet length, division

number, short edge trim width (register side).

If you enter a value which is out of range, the value

will be displayed in red.

On: Edge is trimmed.

Off: Edge is not trimmed.

47SmartStacker User's Manual

Page 48

SmartStacker Screen Descriptions

1-2-21

Setting - Size Setting Screen - Only for Offline System - Part 3

1

2

3

4

5

Gutter Trim Width - Short Side

1

If you have turned on the gutter trim function, this is

used to set the gutter trim width.

Allowable range for the gutter trim width:

6 to 15 mm / 0.24” to 0.6”

Gutter Trim On/Off - Short Side

2

This is used to set whether to trim the gutter of the

short side. See the explanation for item number 5 on

the page 46.

Scoring On/Off (Option)

3

This can be set only if you plan to divide the short

side of the sheet into two parts. Once you turn on this

function, the positive score can be made on the center

of the sheet.

Sheet Thickness

4

Enter the thickness in µm of the sheet to be run.

This setting is used to adjust the how long to stack

table lowers in the Merge Stacker, to predict how

many pages can be stacked before the stacker is

full, and to determine the timing for delivery of the

pages.

6

Fine Adjustment Carry Over

5

Select this to carry over the ne

adjustment settings from the previous

job.

Use this for a new job, so the ne

adjustment values are cleared to zero.

Starting the Changeover After Home

6

Positioning

If this is selected, all of the parts of the machine

return to their home positions before the changeover

begins.

When the sheets on the feed table is raised to the

upper position and the changeover is started, the

buzzer sounds and the feed table is lowered for the

specied amount. After the changeover, the feed

table will be rising.

Starting the Changeover

7

If this is selected, the changeover starts immediately,

without the parts returning to their home positions.

When the sheets on the feed table is raised to the

upper position, the machine performs as same as

described above.

7

48 SmartStacker User's Manual

Page 49

SmartStacker Screen Descriptions

1-2-22

See page 47.

See page 46.

Setting - Size Setting Screen - Only for Offline System - Part 4 (for B2 Stacker)

See page 48.

49SmartStacker User's Manual

Page 50

SmartStacker Screen Descriptions

1-2-23

If you turn the gutter trim function On or Off, the Trim Guide Setting screen will be displayed when you

do the changeover. It’s also possible to display this screen from the Run screen.

Trim Guide Setting Screen

1

2

3

4

Trim Guide Setting Positions

1

Set the trim guides in the positions shown in red.

Installing Trim Guide

2

This drawing is displayed when the gutter trim function

is changed from Off to On. Loosen the locking screws

and install the trim guide as shown in the drawing.

Important

If a trim guide should be installed, but is not,

the trim will not be removed. This can cause

a jam.

32

Removing Trim Guide

3

This drawing is displayed when the gutter trim function

is changed from On to Off. Loosen the locking screws

and remove the trim guide as shown in the drawing.

Important

If a trim guide should be removed, but is

not, the guide scratches and breaks the

moving sheets. This can cause a jam.

Return to the Setting - Size Setting

4

Screen

If this screen is displayed from the Run screen, you

will return to the Run screen when you press this

button.

OK Button

5

Press this button after completing the settings for the

trim guides. The changeover will continue.

5

50 SmartStacker User's Manual

Page 51