Page 1

Standard PS-P610

Corner Side Stapler for

QC Collators

Instruction Manual

Page 2

PUNCH STAPLE

PS-P61

Important Information

- This manual is designed to help you to install, operate and maintain Punch Staple PS-

P61. Read, understand and keep this manual in a safe and convenient place.

- Do not operate PS-P61 until you read and understand the instructions in this manual.

- Horizon International Inc. shall not be liable for incidental consequential damages resulting from : improper or inadequate maintenance by customer; unauthorized modification or

misuse; operation outside of the environmental specifications for the product.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to

change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or translated to another language without the prior written consent of Horizon International Inc.

070720/PSP61/09E/DV UM201013-09

I

Page 3

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in damage on machines. It may also be used to alert against unsafe

practices.

- Read and understand all safety instructions with signal word such as WARNING and

CAUTION. If safety instructions are ignored, personal injury may result.

- Horizon International Inc. cannot anticipate every possible situation that might involve

a potential hazard. The instructions in this manual and warning labels on the machine are

therefore not all inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inad-

vertent operation when such operation could cause injury to personnel. Do not attempt to

operate any switch, valve, or other energy isolating device where it is locked or tagged out.

- Do not operate the machines when any covers are removed.

- Some of the drawings in this manual show the machine uncovered for explaining the

detail or inside of machine.

II

Page 4

Contents

Important Information .....................................................................I

Safety Precautions ...........................................................................II

1. Before You Begin ..................................................... 1

This section explain parts and their function of PS-P61.

1-1 Specifications ............................................................................2

1-2 Accessories ...............................................................................3

1-3 Accessories (Option).................................................................4

1-4 Consumption Parts ....................................................................5

1-5 Machine Descriptions ............................................................... 6

1-5-1 Machine Descriptions ......................................................6

1-5-2 Operation Panel Descriptions ..........................................7

2. How to Operate........................................................ 9

This section instructs how to set up and operate PS-P61.

2-1 Operation Procedure ................................................................. 10

2-2 To Staple Custom Size Sheets .................................................. 14

2-3 Installation of Punch Unit (Option) .......................................... 15

3. Troubleshooting ....................................................... 19

This section shows remedies for simple malfunctions.

When Monitor Lamp Illuminates / Flashes and Machine Stops .........

3-1

3-1-1 When Sheet Jam 1 Lamp Illuminates ..............................20

When Sheet Jam 2 Lamp / Sheet Jam 3 Lamp Illuminates.......

3-1-2

3-1-3 When Punch Trouble Lamp Flashes ...............................22

3-1-4 When No Staple/Staple Trouble Lamp Illuminates ........23

3-1-5 When No Staple / Staple Trouble Lamp Flashes ............23

3-1-6 When Door Lamp Illuminates .........................................24

3-1-7 When Receiving Tray Lamp Illuminates ........................24

20

21

III

Page 5

3-2 When Sheets Are Delivered without Stapling ..........................25

3-2-1 When Collating Continues .............................................. 25

3-2-2 When Collating Stops......................................................27

3-3 When Circuit Breaker Trips ......................................................28

4. Maintenance and Parts ........................................... 29

This section shows how to maintain PS-P61.

4-1 How to Remove Jammed Staples .............................................30

4-2 How to Refill Staples ................................................................32

4-3 How to Clean Sensors ...............................................................34

5. Installation Instructions.......................................... 35

This section shows how to install PS-P61

5-1 Installation Instructions............................................................. 35

IV

Page 6

1. Before You Begin

1. Before You Begin

This section explain parts and their function of PS-P61.

1-1 Specifications ......................................................................................... 2

1-2 Accessories ............................................................................................. 3

1-3 Accessories (Option).............................................................................. 4

1-4 Consumption Parts................................................................................ 5

1-5 Machine Descriptions............................................................................ 6

(1)

Page 7

1. Before You Begin

1-1 Specifications

Functions

Sheet Size

Sheet Weight Range Normal Paper 53 to 127 gsm (Up to 104 gsm on Punching)

Stitch Thickness

Stitch Distance

Stapling Wire No.510 Cartridge Type (5,000 staples/cartridge)

Error Detector / Indicator

Production Speed

Top Stapling, Angled Corner Stapling, Straight Corner Stapling, Other

Side Corner Stapling, Two Hole Punching (option)

Max. W 300 x L 432 mm

Min. W 182 x L 257 mm

Top Stapling : A4 / 8.5" x 11"/ 8.5" x 14"

Angled Corner Stapling : A3 / A4 / 11" x 17" / 8.5" x 11"/ 8.5" x 14"

Straight Corner Stapling : A3 / A4 / 11" x 17" / 8.5" x 11"/ 8.5" x 14"

Other Side Corner Stapling : A4 / 8.5" x 11"/ 8.5" x 14"

Two Hole Punching (option) : A4 / 8.5" x 11"/ 8.5" x 14"

Side or Corner Stapling : Max. 10 sheets (Normal Paper 127 gsm)

Optional Punch Capability : Max. 10 sheets (Normal Paper 104 gsm)

Staple Distance : 148 mm (A4), 8.14" (8.5" x 14"), 5.13" (11" x 8.5")

Corner Staple Angle : 0 degree or 30 degree selectable

Sheet Jam, No Staple, Stapler Error, Cover Open, Sheets Full on Delivery

Tray

Side Stapling : Max. 12 sets / min.

Corner Stapling : Max. 25 sets / min.

Voltage/Frequency

Rated Current 230V, 50 Hz : 0.8 A

Heat Out Put 400 kJ (90 kcal)

Machine Dimensions

Machine Weight 74 kg (163.2 lb)

Options Punch Unit

Single Phase 115V, 60 Hz

Single Phase 230V, 50 Hz

1,115 (W) x 562 (D) x 580 (H) mm (with Delivery Tray)

(43.9" x 22.2" x 22.9")

The machine design and specifications are subject to change without any notice.

(2)

Page 8

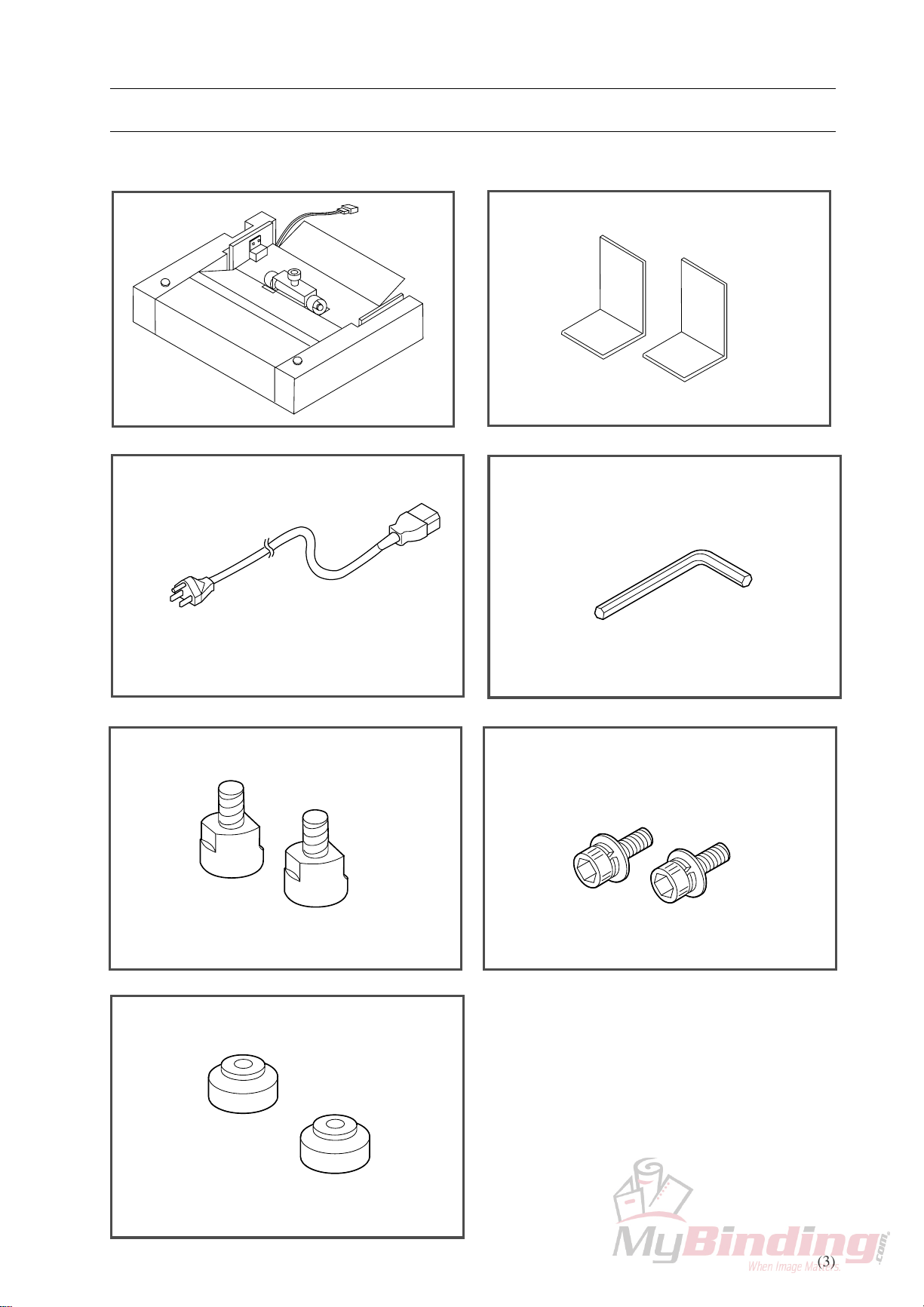

1-2 Accessories

1. Before You Begin

Sheet Guide 1 unit

Power Cord (4-007736-00) 1 pc

Receiving Sheet Guides (M901253-10) 2 pcs

Allen Wrench 3 mm 1 pc

Collator Lock Bolts 2 pcs

Plastic Mounts 2 pcs

SB Screws 2 pcs

(3)

Page 9

1. Before You Begin

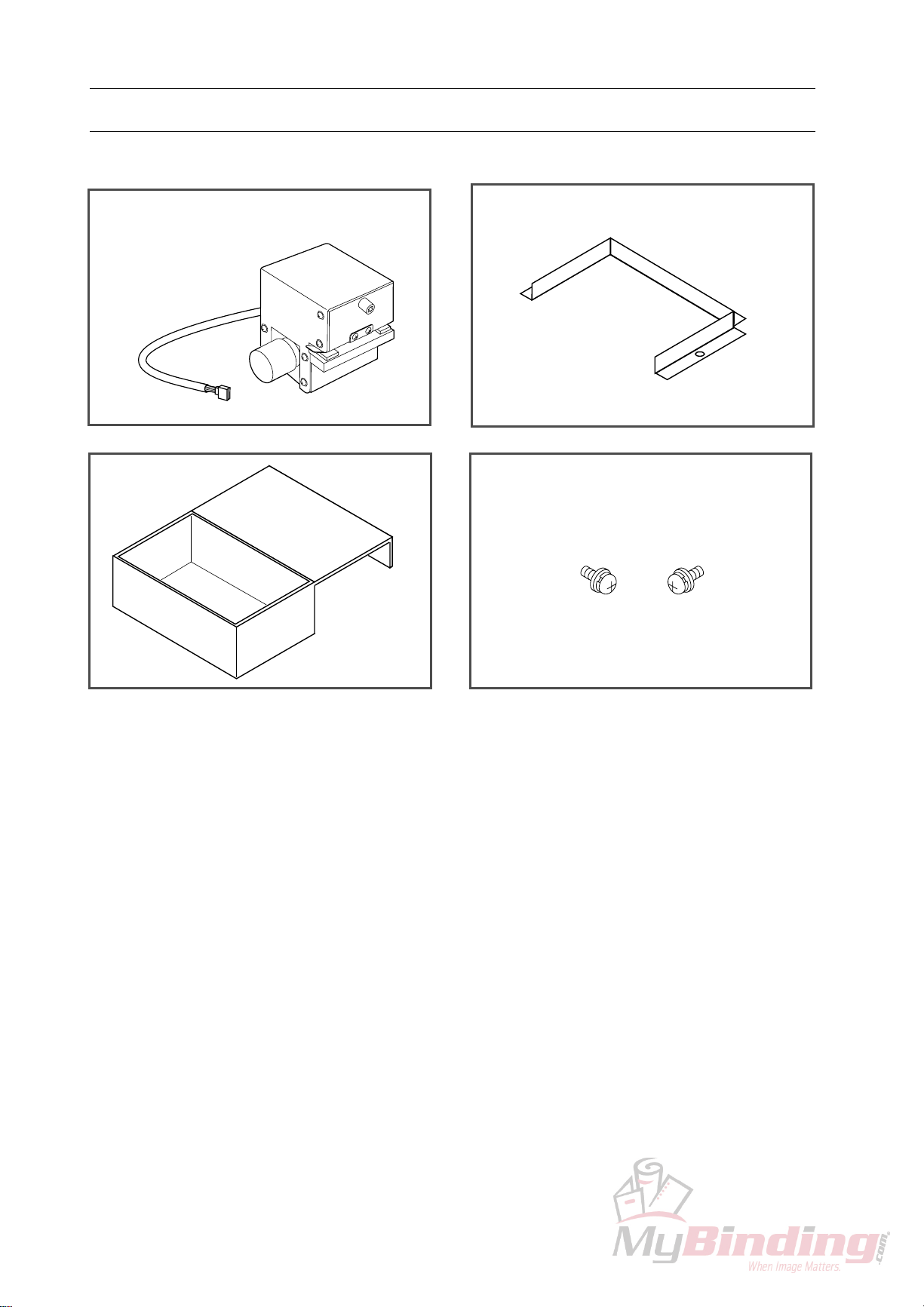

1-3 Accessories (Option)

Punch Unit (A903222-00) 1 pc

Box (M041594-20) 1 pc

Guide (M041593-11) 1 pc

Screw 2 pcs

(4)

Page 10

1-4 Consumption Parts

Staple Cartridge (No. 500) 1 pc

1. Before You Begin

(5)

Page 11

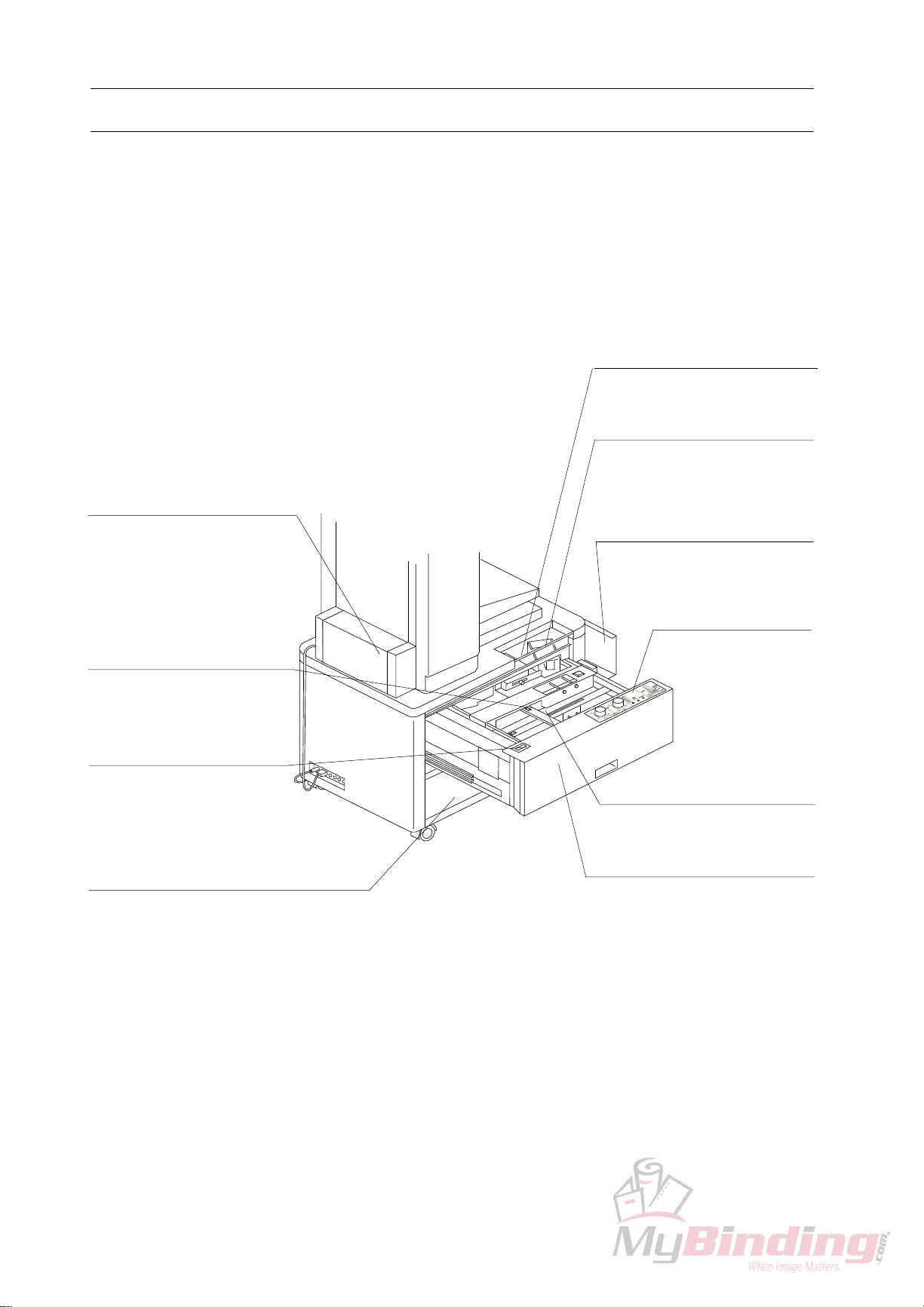

1. Before You Begin

1-5 Machine Descriptions

1-5-1 Machine Descriptions

Transport Unit

This unit transports collated

sheets to staple section of

PS-P61.

Punch Unit

This unit punches two holes.

Staple Unit

This unit staples sheets.

It has two staple angle

positions.

Receiving Tray

Stapled/ Punched sheets

are delivered in this tray.

Jog Guide Scale

This scale shows positions

of jog guide.

Counter

This counter shows total

number of books made.

(For maintenance)

Bottom cover

Tray for punch chip is housed in this

cover.

Operation Panel

Jog Guide

This guide jogs sheets.

Staple Cabinet

Sheets are jogged, and

stapled/ punched here.

(6)

Page 12

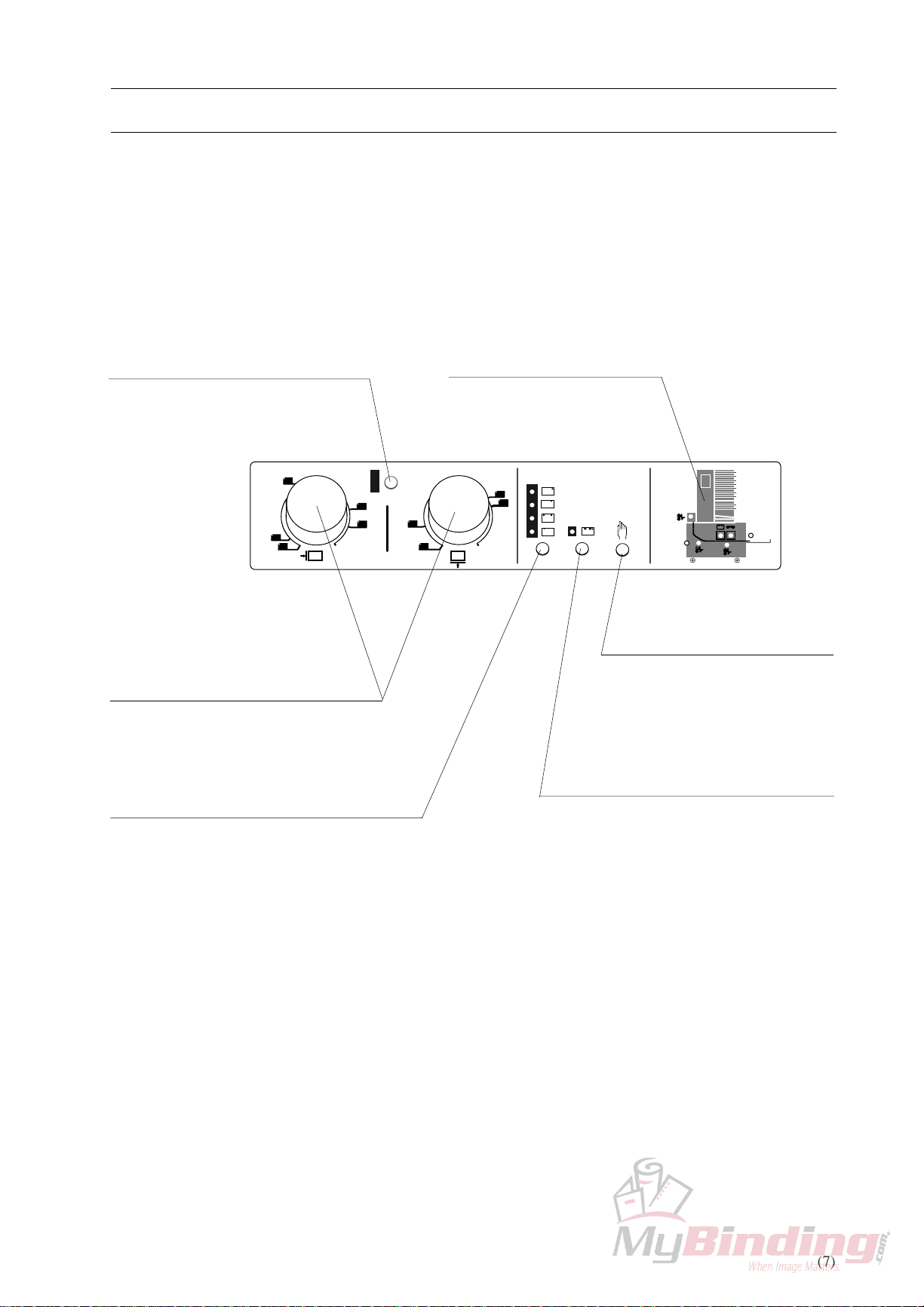

1-5 Machine Descriptions

1-5-2 Operation Panel Descriptions

1. Before You Begin

Jog Button

This button is used to select jog

time, 1 time or 2 times. Standard

setting is 1.

14"

A3

17"

1

2

A4

11"

Jog Guide Knob

This knob is used to adjust jog

guide position. Push and turn it.

Stapling Mode Button

This button is used to select stapling

modes, corner stapling (angled/straight/

other side) or side stapling.

Monitor Lamp

This lamp flashes when

troubles happen.

8.5

"

A4

11"

A3

Eject Button

This button is used to eject

sheets staying in machine.

Also, used to reset punch or/

and staple.

Punch Button

This button is used to punch mode,

punch ON or OFF.

(7)

Page 13

2. How to Operate

2. How to Operate

This section instructs how to set up and operate PS-P61.

2-1 Operation Procedure........................................................................... 10

2-2 To Staple Custom Size Sheets ............................................................ 14

2-3 Installation of Punch Unit (Option)................................................... 15

(9)

Page 14

2. How to Operate

2-1 Operation Procedure

1.Plug power cord of collator into outlet.

2.Turn on power switch of collator.

3.Pile sheets on collator.

NOTE

- Pile sheets on the bottom bin to be used

then pile sheets on the upper bin.

- Pile sheets with their face down.

- Refer to collator operation manual to

operate collator.

- Pile sheets as shown in the right drawing.

01PSP61A03

P10

P1

B5

A4

B4

(10)

A3

01PSP61A05

Page 15

A3

A3

A4

A4

B5

B4

B4

2-1 Operation Procedure

4. Select the left collating direction with

the collating direction button of the

collator (QC-S10/ QC-S100).

2. How to Operate

QC-S10

QC-S100

5. Push and turn jog guide knobs and

position jog guides according to sheet

size.

NOTE

- Set jog guide at the position you hear click

when knobs are turned for regular size

sheets (A3, B4, A4, B5).

- Refer to "2-2 To Staple Custom Size

Sheets" (page 12).

6. Press punch button and select ON

when punch unit (option) is installed

and used.

NOTE

Top stapling and other side corner stapling

cannot be performed when punch unit (Option) is installed. Refer to "2-3 Installation

of Punch Unit (Option)"( page 13).

Jog Guide Knob

A4

1

B4

A3

B4

2

A4

A3

B5

7. Select staple mode with stapling mode

button.

NOTE

Top stapling and other side corner stapling

on A3 or custom size sheets cannot be performed.

(11)

Page 16

2. How to Operate

2-1 Operation Procedure

8. Open staple cabinet.

9. Check whether sheet guide is positioned

properly with arrow marks of jog guide.

11" 8.5"

300 250 200

A3B4A4 B5

Staple Cabinet

Jog Guide

17"

A3

400

350

14"

300

11"

B5A4B4

10.

Adjust punch unit to sheet size by pull-

ing and sliding punch position knob on

punching.

NOTE

Punch unit can be set at only B4, A4 and B5

positions.

11.

Close staple cabinet.

12.

Set receiving tray and receiving tray

guide according to sheet size.

NOTE

Set receiving sheet guide wider than sheet

size to prevent sheets from hitting guides.

17"

A3

400350300

11" 8.5"

300 250 200

A3B4 A4B5

B4 A4 B5

Punch Position

Knob

B4

14"

A4

11"

B5

Receiving Tray

Receiving Tray Guide

(12)

Page 17

2-1 Operation Procedure

2. How to Operate

13.

Press check button twice.

Press the check button once to set bins to

feed position and then press the check

button again. One set of sheets will be

collated on the receiving tray. Pressing

the check button is to memorize the sheet

thickness and the number of used bins.

NOTE

Check up delivered sheets.

14.

Press start button to start collating.

QC-S10

QC-S100

QC-S10

QC-S100

15.

When all of set sheets are finished

collating, collating stops.

NOTE

Press stop button of collator when you want

to stop collating.

16.

When your job is completed, turn off

power switch and pull out power cord

from outlet.

QC-S10

Stop Button

QC-S100

(13)

Page 18

2. How to Operate

2-2 To Staple Custom Size Sheets

This section show how to set up parts to

staple custom size sheets.

NOTE

Only angled and straight corner staplings

can be performed when custom size sheets

are used.

1. Measure sheet size.

2. Open Staple cabinet.

01PSP61A14

3. Push and turn jog guide knobs to posi-

tion arrow marks to sheet size.

4. Close staple cabinet.

5. Select staple angle with stapling mode

button.

NOTE

Only angled and straight corner staplings

can be selected.

17" 14"

A3

400 350 300

B4

11" 8.5"

300 250 200

A3 B4 A4 B5

Jog Guide Knob

A4

11"

B5

Staple Cabinet

Jog Guide

6. Now set up is completed. Refer to "2-1

Operation Procedure", 12 to 16 (page 10

and 11).

(14)

Page 19

2-3 Installation of Punch Unit (Option)

This section shows how to install punch unit

(Option) to punch sheets.

WARNING

Turn off power switch and unplug

power cord before installing punch

unit.

NOTE

- B4, A4 and B5 sheets can be punched.

- Top stapling and other side corner stapling

cannot be performed when punch unit is

installed.

2. How to Operate

01PSP61A26

1. Turn off power switch.

2. Open rear cover.

3. Install punch unit by inserting punch

position knob into slot of punch position

plate.

Rear Cover

Punch Unit

4. Connect connector of punch unit.

5. Close rear cover.

Connector

(15)

Page 20

2. How to Operate

2-3 Installation of Punch Unit (Option)

6. Open staple cabinet.

7. Set punch unit with punch position knob

according to sheet size.

300 250 200

NOTE

- Punch unit can be set only on B4, A4, B5

position.

- Follow the reverse procedure of installation when punch unit is removed.

A3 B4 A4 B5

11" 8.5"

17"

A3

400 350 300

B4

14"

A4

11"

B4 A4 B5

Staple Cabinet

B5

8. Remove lower rear cover.

9. Fix guide with two screws.

Punch Position Knob

Rear Cover

(16)

Guide

Screws

Page 21

2-3 Installation of Punch Unit (Option)

10.

Place box on guide.

11.

Install rear cover with screws.

2. How to Operate

Box

Rear Cover

(17)

Page 22

3. Troubleshooting

3. Troubleshooting

This section shows remedies for simple malfunctions.

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops .... 16

3-2 When Sheets Are Delivered without Stapling .................................. 21

3-3 When Circuit Breaker Trips .............................................................. 24

(19)

Page 23

3. Troubleshooting

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops

3-1-1 When Sheet Jam 1 Lamp Illuminates

[Cause]

Sheets are jammed in transport unit or

transport unit is open.

CAUTION

While sheet jam 1 lamp is flashing, do

not open staple cabinet until jammed

sheets are removed. Otherwise, machine may be broken.

[Remedy]

1. Open transport unit.

2. Remove jammed sheets.

3. Close transport unit.

Transport Unit

(20)

Page 24

3. Troubleshooting

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops

3-1-2 When Sheet Jam 2 Lamp / Sheet Jam 3 Lamp Illuminates

[Cause]

Sheets are jammed in staple cabinet.

CAUTION

Do not close staple cabinet with support guide unit raised. Otherwise,

machine may be broken.

[Remedy]

1. Press eject button.

2. Pull out staple cabinet in case sheets are

not ejected by pressing eject button.

3. Remove jammed sheets.

NOTE

- In case sheet jam 3 lamp flashes, lift support guide unit, remove jammed sheets and

lower delivery unit.

4. Close staple cabinet.

Staple Cabinet

Support Guide Unit

(21)

Page 25

3. Troubleshooting

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops

3-1-3 When Punch Trouble Lamp Flashes

[Cause]

Punch unit is locked.

[Remedy]

1. Turn off power switch of collator , then

turn on again after a few seconds.

2. Press eject button. Punch unit is

reset.

3. Open staple cabinet.

4. Remove jammed sheets.

5. Close staple cabinet.

01PSP61A22

(22)

Staple Cabinet

Page 26

3. Troubleshooting

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops

3-1-4 When No Staple/Staple Trouble Lamp Illuminates

[Cause]

Out of staples.

[Remedy]

Refill staples.

See "4-2 How to Refill Staples" (page 32).

3-1-5 When No Staple / Staple Trouble Lamp Flashes

[Cause]

Staple unit is locked because of staple jam.

[Remedy]

1. Turn off power switch of collator.

2. Open staple cabinet.

3. Remove jammed sheets.

4. Remove jammed staples referring to

"4-1 How to Remove Jammed

Staples"(page 30).

5. Close staple cabinet.

6. Turn on power switch of collator.

Staple Cabinet

7. Depress eject button, and staple unit is

reset.

8. Check for proper stapling by collating

several sets (7 to 8 sets).

(23)

Page 27

3. Troubleshooting

3-1 When Monitor Lamp Illuminates / Flashes and Machine Stops

3-1-6 When Door Lamp Illuminates

[Cause]

Staple cabinet or rear cover is open.

[Remedy]

Close staple cabinet or rear cover.

01PSP61A27(E)

3-1-7 When Receiving Tray Lamp Illuminates

[Cause]

Receiving tray is full, or sheets are not

delivered completely.

[Remedy]

Remove sheets from receiving tray, or

delivery area.

(24)

Page 28

3-2 When Sheets Are Delivered without Stapling

3-2-1 When Collating Continues

[Cause]

Staples are not fed to stapling section

of staple unit.

[Remedy 1]

Set unnecessary sheets on bin, and check

for proper stapling by collating several sets

(7 to 8 sets).

[Remedy 2]

1. Open staple unit.

3. Troubleshooting

2. Pull up and release staple cartridge.

3. Clean staple feed roller with alcoholic

soaked cloth.

NOTE

- If oil stains the staple feed roller, the staple

sheet slips while being delivered, and misstitching occurs. Do not lubricate the stapler

unit.

Staple Cabinet

Staple Cartridge

Staple Feed

Roller

(25)

Page 29

3. Troubleshooting

3-2 When Sheets Are Delivered without Stapling

4. Lift the face plate holder and pull up the

face plate to the top.

5. Remove jammed staples, or restore the

sheet staples inside the sheet holder.

Face Plate Holder

Face Plate

Sheet Staple

6. Remove the jammed staples from the

staple unit.

7. Push down the face plate until you hear

a click.

Face Plate

(26)

Page 30

3-2 When Sheets Are Delivered without Stapling

8. Push down staple cartridge until you

hear click.

9. Close staple cabinet.

10. Check for proper stapling by collating

several sets (7 to 8 sets).

3-2-2 When Collating Stops

3. Troubleshooting

[Cause]

Collated sheets are not jogged neatly.

[Remedy 1]

Open staple cabinet and check whether

jog guide is positioned to sheets size

properly.

[Remedy 2]

Straighten curled sheets, and fan them

well.

Jog Guide

17"

A3

400

350

51

B

0

0

2

4

A

"

.5

0

5

2

4

B

" 8

1

0

0

3

3

A

14"

300

11"

B5A4B4

[Remedy 3]

Depress jog switch and select 2.

A4

Jog Time

01PSP61A32

1

2

B4

A3

01PSP61A33(E)

(27)

Page 31

3. Troubleshooting

3-3 When Circuit Breaker Trips

CAUTION

In case circuit breaker trips again

immediately after resetting, turn off

power switch, and call for your local

dealer to avoid serious damage to your

PS-P61.

1. Turn off power switch of collator.

2. Check inside of SPF-9 for obvious

problems such as jammed sheets. If

there is a problem, remove the cause.

01PSP61A34

3. Reset circuit breaker a few minutes after

turning off power switch.

- Push two left breakers to reset.

- Push up two right breakers to reset.

Breakers(Left)

Breakers(Right)

01PSP61A35

(28)

Page 32

4. Maintenance and Parts

4. Maintenance and Parts

This section shows how to maintain PS-P61.

4-1 How to Remove Jammed Staples....................................................... 30

4-2 How to Refill Staples ........................................................................... 32

4-3 How to Clean Sensors ......................................................................... 34

(29)

Page 33

4. Maintenance and Parts

4-1 How to Remove Jammed Staples

1. Open the staple unit.

2. Pull up the staple cartridge.

Staple Cartridge

Staple Unit

3. Lift the face plate holder and pull up the

face plate to the top.

4. Remove jammed staples, or restore the

sheet staples inside the sheet holder.

Face Plate Holder

Face Plate

Sheet Staple

(30)

Page 34

4-1 How to Remove Jammed Staples

5. Remove the jammed staples from the

staple unit.

6. Push down the face plate until you hear

a click.

4. Maintenance and Parts

Face Plate

7. Install staple cartridge in staple unit and

push it until you hear a click.

8. Close the staple unit.

(31)

Page 35

4. Maintenance and Parts

4-2 How to Refill Staples

1. Open the staple unit.

2. Pull up the staple cartridge.

Staple Cartridge

Staple Unit

3. Press the button and pull out the sheet

holder.

4. Insert staple refill to the back end

of case.

NOTE

- Set staple refill so that the arrow direction

of staple refill matches to that of case.

Button

Sheet Holder

Arrow

Staple

Refill

(32)

Page 36

4-2 How to Refill Staples

5. Lift the sheet holder tab.

6. Pull out the tab backward with the band.

4. Maintenance and Parts

Tab

7. Install staple cartridge in staple unit and

push it until you hear a click.

8. Close the staple unit.

(33)

Page 37

4. Maintenance and Parts

4-3 How to Clean Sensors

If paper dust collects on sheet jam sensors,

sheet jam lamp will stay illuminated or

sheets are delivered without stapling though

they are jogged neatly.

1. Open staple unit.

2. Clean two sensors with clean cloth.

3. Close staple unit.

Staple Unit

350

14"

300

11"

B5A4B4

Sensors

(34)

Page 38

5. Installation Instructions

5. Installation Instructions

This section shows how to install PS-P61.

5-1 Installation Instructions...................................................................... 34

(35)

Page 39

5. Installation Instructions

5-1 Installation Instructions

WARNING

- Place the collator on a flat and steady

area. Otherwise the collator may be

topped.

- When collator is laid on its side or on

PS-P61, more than three persons are

needed.

Collator : QC-S10 weight is 61 kg (135

lb).QC-S100 weight is 69 kg (152 lb).

- Be sure to push the bottom of transport door side of the collator when

moving the collator and the PS-P61.

Do not push the bin side. It may cause

fall over the collator.

1. Lay collator with transport unit door

down.

2. Install two lock bolts with spanner.

The Side of Transport Unit Door

Lock Bolts

(36)

Page 40

5-1 Installation Instructions

3. Remove two rubber mounts with allen

wrench and install two plastic mounts at

the same position. The plastic mounts is

fixed with the fix screws of rubber

mounts.

NOTE

Install the operation side of two plastic

mounts into the inside of holes.

4. Install collator on PS-P61 so that plastic

mounts are placed into dents of PS-P61.

5. Installation Instructions

Plastic Mounts

Install plastic mount

inside of hole.

Rubber Mounts

Install plastic mount

inside of hole.

Plastic

Mounts

5. Remove two fix plates. (4 fix screws

each.)

6. Open rear cover.

Fix Screw

Fix Plates

Rear Cover

(37)

Page 41

5. Installation Instructions

5-1 Install Instructions

7. Open staple cabinet.

8. Fix collator and PS-P61 with two fix

screws.

Staple Cabinet

9. Close staple cabinet.

10.

Remove two spacers.

11.

Remove lock bolt.

Rear Cover

Spacers

(38)

Lock Bolts

Page 42

NK cramp

Throug

5-1 Install Instructions

12.

Remove both side covers of transport

unit. (One fix screw each)

13.

Install transport unit with four fix

screws.

5. Installation Instructions

Transport Unit

Side Covers

Lock

Bolts

NOTE

Insert cord of transport unit into PS-P61.

14.

Connect cord of transport unit.

CAUTION

- Connect the cord through the NK

cramp shown to the right. Otherwise, a

jam may occur because the cord is

caught when the stitch unit is drawn

forth or fit in.

NK cramp

Through the

cord here

Transport

Unit

NK cramp

Pass the cord

through here

15.

Install side cover of transport unit. (One

fix screw each)

16.

Close rear cover.

(39)

Page 43

5. Installation Instructions

5-1 Install Instructions

17.

Connect connector cable to collator.

- Connect the connector cable to collator

QC-P66.

- Remove the left receptacle cover on the

drive side of the collator QC-S10 or QCS100 and then connect the connector

cable to collator.

Connector Cable

Power Cord

18.

Plug power cord on collator into outlet

of PS-P61.

QC-S10/

QC-S100

(40)

Loading...

Loading...