Page 1

I Introduction

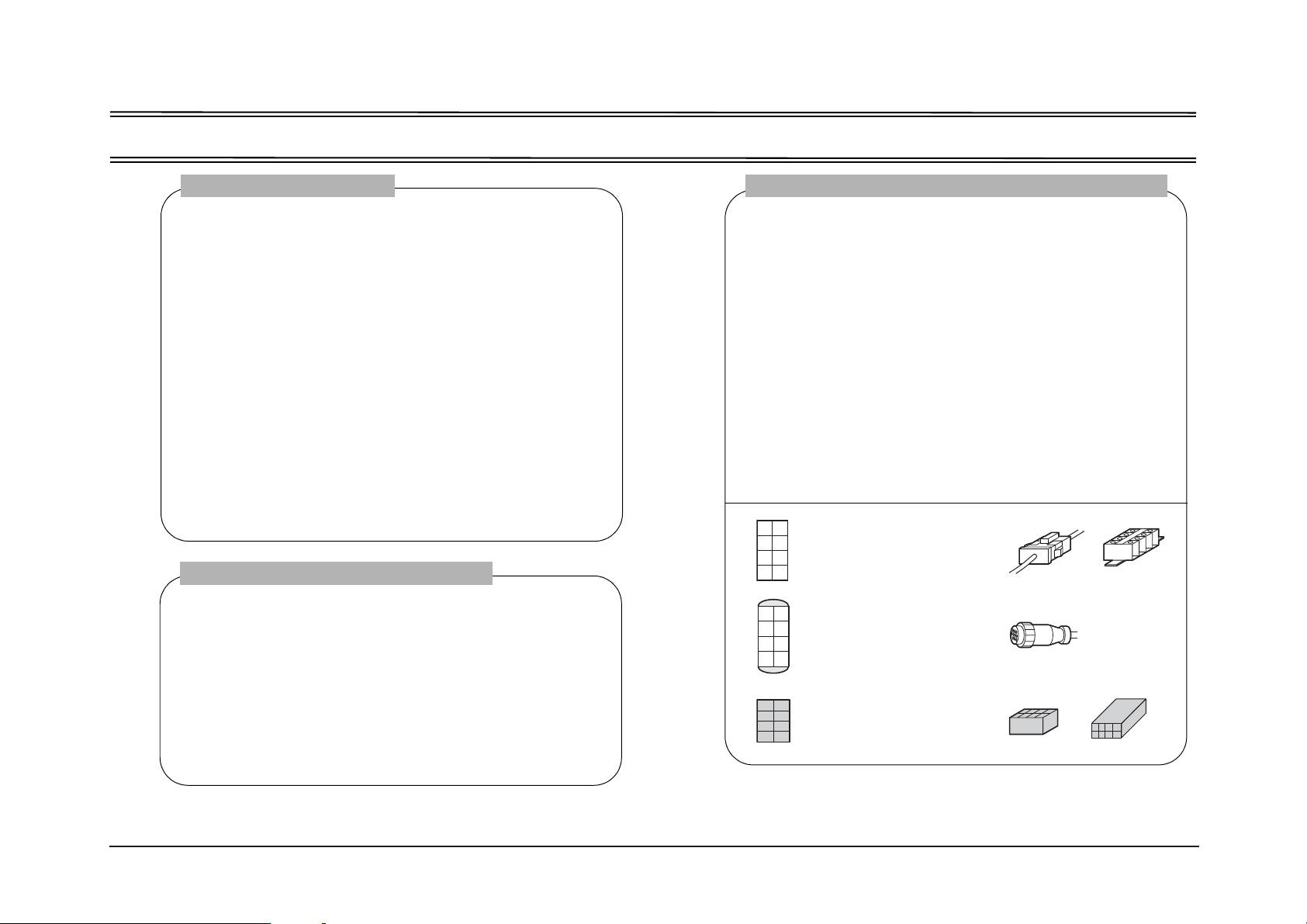

• This service manual is for the following product.

Paper Folder PF-P3100

• Prior consent

This service manual is intended for use when repairing and maintaining this

machine to keep it in top working condition. In order for you to safely perform

repair and maintenance work on this machine, please make sure that you fully

read and understand all of the notes related to safety that are written throughout this service manual.

- Horizon International, INC. cannot accept responsibility for any loss, damage, or

injury as a result of unauthorized modification, misuse, or use outside the

machine’s specifications, or any unsuitable or inadequate maintenance performed

by you or by authorized service personnel.

- Horizon International, INC. is continuously working to improve the design and

performance of all of its products. Consequently, the contents of this service

manual may be changed at any time in the future without prior notice.

Furthermore, Horizon International, INC. bears no additional liability for any added

contents.

- All rights with regards to copyrights are reserved. The copying or distribution of

any part or whole of this manual is strictly prohibited unless prior written

permission is obtained directly from Horizon International, INC.

• Caution when undertaking service operations

- When replacing parts or performing other such maintenance operations, switch

the power supply Off before starting unless it is necessary to keep the power on.

Also, remove the power cable from the socket before starting for additional safety.

- When removing covers, be extremely cautious of rotating objects such as belts

and pulleys, and of electrical wiring etc.

- Always perform operations alone. This manual is written on the assumption that

operations will be performed by one person.

- Make sure that other people do not touch the machine during operation.

- When turning the power back on, wait for approximately 10 seconds after turning

the power Off before switching it On again.

- When replacing parts, use the parts shown in the parts book unless commercially

available parts with exactly the same functions and performance can be obtained.

• Safety precautions

- In order to perform repair or maintenance work safely on this machine, thoroughly

read all of the warnings and cautions related to safety that are written in this

service manual BEFORE commencing any operation. Failing to heed the safety

precautions in this manual may lead to accidents resulting in injury or death.

- The maintenance procedures and safety precautions described in this service

manual are only effective if the repair/maintenance procedures specified for this

machine are followed.

- Precautions that if not followed correctly may lead to accidents resulting in injury

or death are indicated by this heading.

- Precautions that if not followed correctly may lead to accidents resulting in

machine damage or malfunctions are indicated by this heading.

- It is impossible for Horizon International, INC. to prevent all possible dangers

related to this product and its use. Therefore, the precautions shown in this service

manual and warning labels displayed on the product do not completely warn

against all possible dangers.

- Some of the diagrams in this service manual are drawn with covers removed to

describe the details or internal sections of the machine.

Edited and Published by Horizon International, INC.

070608/PFP3100/00E/TM/HI,MT US503013-00

WARNING

CAUTION

I

Page 2

II Symbols used in this manual

1. Wiring color character code

Single color wire color Compound line symbol

BRN = Brown = Brown PW = Power system Cabtire

RED = Red = Red GY = Heater system Likal wire

ORN = Orange = Orange SD = Cap for stepping motor

YEL = Yellow = Yellow Tire

GRN = Green = Green IO = Cabtire for I/O signal

BLU = Blue = Blue IL = Interlock system Cabtire

VIO = Violet = Violet CC = Each unit junction cord

GRY = Grey = Grey

WHT = White = White

BLK = Black = Black

PIN = Pink = Pink

SKY = Sky = Sky blue

BRNNE = The [NE] that follows the color mark is the dark gray band that

is attached to one of the wires for identification purposes when there are

2 of the same color wires within the same bundle of wires.

RED/BLU = The /BLU that follows the color mark indicates that the

mother color of the wire is blue, and that on top there is a RED colored

stripe.

2. Identification characters of electrical parts

A** = Inverter/driver NF** = Noise filter

B** = Sensor PW** = Power cable No.

C** = Capacitor Q** = Circuit protector/

E** = Heater Breaker

F** = Fuse QPM** = (multi layer) board

G** = Power supply QPW** = (Single layer) board

H** = Indicating lamp S** = Switch

HS** = Temperature sensor T** = Transformer

K** = Connector X** = Terminal board

L** = Lamp Y** = Solenoid/clutch/

M** = Motor Valve etc.

3. Circuit configuration identification characters and symbols

AC = Alternating current MS = Micro-switch

BK = Brake MOD = Module connector

BL = Short circuit connector NF = Noise filter

CL = Clutch NC = Normal [closed] contact

terminal

CN = Connector NO = Normal [open] contact

terminal

COM = Common terminal SSR = Solid state relay

CON = Connector VR = Volume

CW = Clockwise direction SL = Solenoid

CCW = Counterclockwise SIG = Signal voltage

direction

DC = Direct current S/N = Machine number

DSW = Dip switch RAP = Trouble recovery procedure

F.G = Frame ground BSD = Electric block diagram

GND = Ground *X## = * Connector

JSW =Jumper switch

1

1

Junction connector, or

2

2

terminal board

3

3

4

4

1

1

2

2

Round connector

3

3

4

4

Short circuit connector

BL

II

Page 3

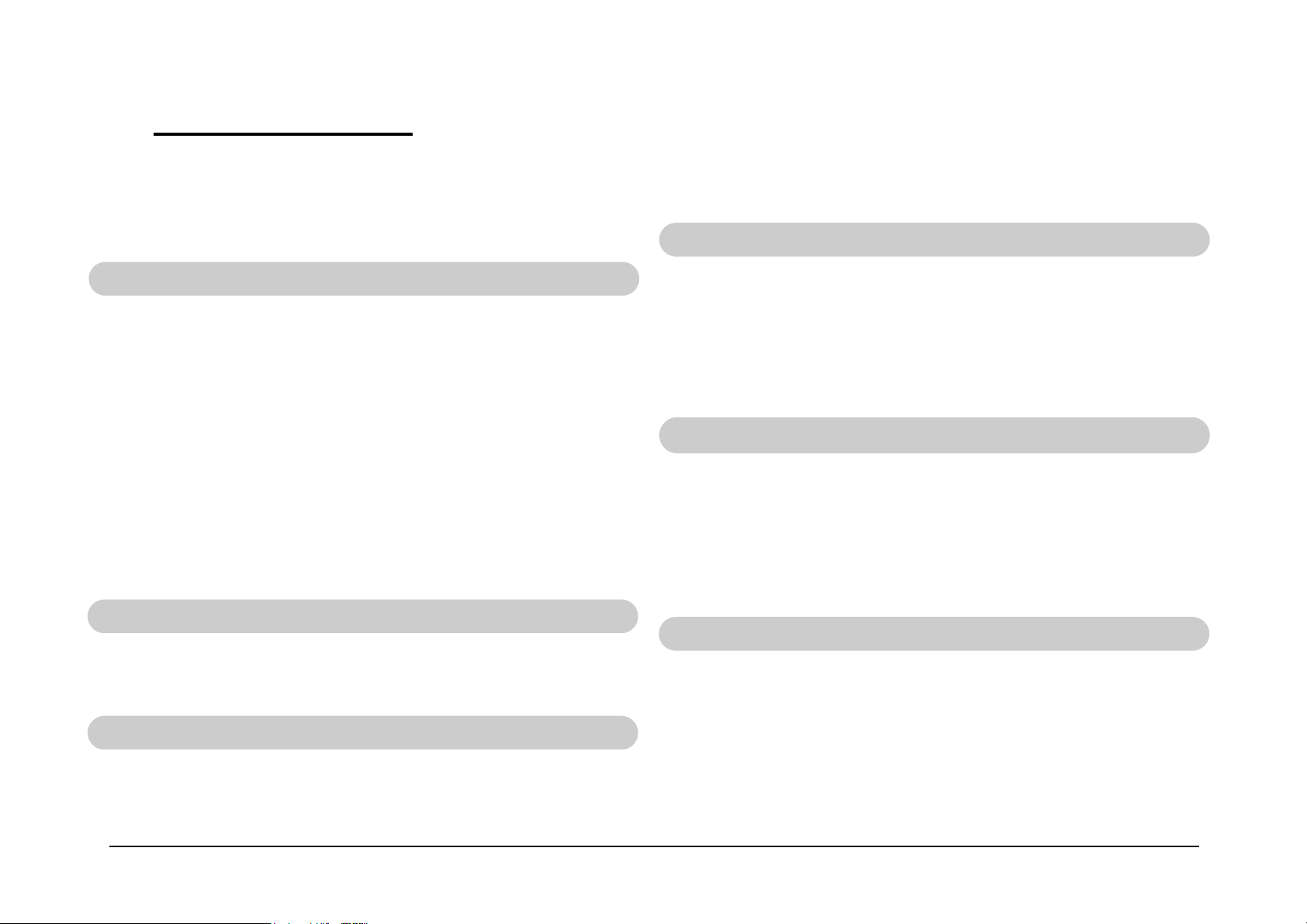

III Cautions when handling the print board and ROM

Even an small amount of static electricity that it cannot be felt by people will damage the board or ROM.

Exercise caution on the following points when handling the board or ROM.

Shield Bag

P.C.Board

Conductive

Sponge

Shield Bag

Keep Board in a

shield bag.

Put the ROM on a

conductive sponge

and keep in a shield

bag.

Clip

Wrist

Strap

Acrylic

Cover

Machine

Frame

Do not put Board and ROM on the

machine, especially on the acrylic

cover. (No problem on the

conductive plate.)

And keep the Board and ROM away

from the insulators.

Insulators: Plastic, form polystyrene,

chemical fiber fabric,

dry paper, etc.

When replacing the Board and

ROM, or setting the dip switches

and volumes on the Board, wear a

wrist strap, and connect the clip to

the machine frame (not painted

surface).

III

Page 4

Table of Contents

I Introduction ........................................................................I

II Symbols used in this manual..........................................II

III Cautions when handling the print board and ROM.....III

3-3 Tray Gate Position Adjustment ...........................................3-4

3-4 Belt Tension Adjustment .....................................................3-5

3-5 Delivery Belt Replacement..................................................3-6

3-6 Micro-switch Adjustment .....................................................3-7

4 Mechanical Troubleshooting............................. 4-1

1 Installation and Mechanism.............................. 1-1

1-1 Installation .......................................................................... 1-2

1-2 Main Cover Removal.......................................................... 1-3

1-3 Buckle Chute Removal....................................................... 1-4

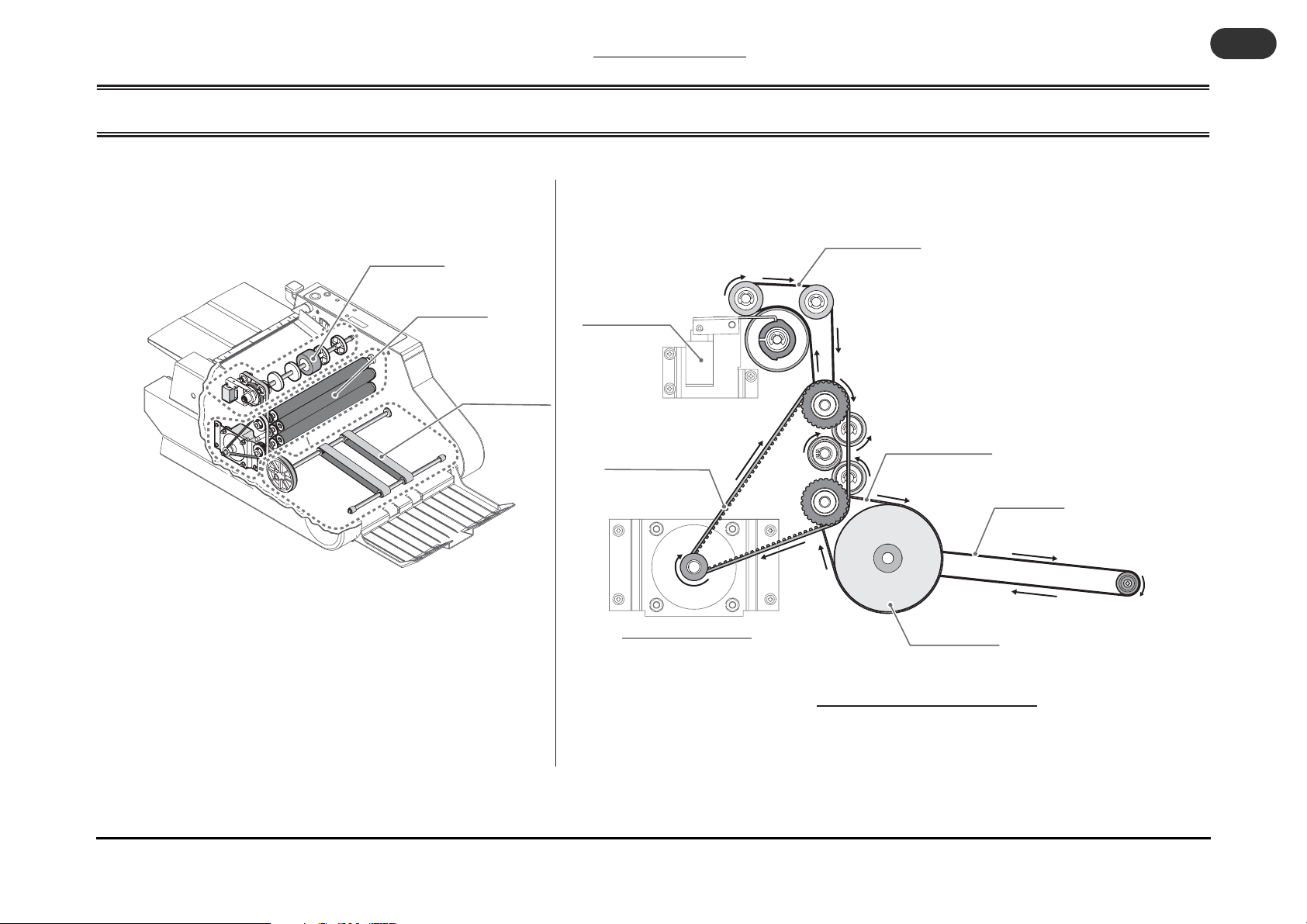

1-4 Mechanism of Folding ........................................................ 1-5

1-5 Feed Table ......................................................................... 1-6

1-6 Table Up/Down Mechanism ............................................... 1-7

1-7 Drive Section...................................................................... 1-8

1-8 Feed Roller Section............................................................ 1-9

1-9 Double Feed Stop Section ............................................... 1-10

1-10 Fold Roller Section......................................................... 1-11

1-11 Tray Gate Section .......................................................... 1-12

1-12 Delivery Section ............................................................. 1-13

1-13 Buckle Chute Section..................................................... 1-14

2 Service Mode and Error Code.......................... 2-1

2-1 Functions of Service Mode................................................. 2-2

2-2 Error Code Chart................................................................ 2-3

3 Adjusting and Checking Procedures ................ 3-1

3-1 Buckle Chute Stopper Angle Adjustment ........................... 3-2

3-2 Feed Clutch Unit Adjustment ............................................. 3-3

4-1 Machine Is Not Powered On ...............................................4-2

4-2 M10 Main Motor Does Not Rotate ......................................4-3

4-3 Tray Gate Malfunctions.......................................................4-4

4-4 Y01 Clutch Solenoid Does Not Activate..............................4-5

4-5 Buckle Chute Proximity Sensor Error .................................4-6

4-6 Delivery Belt Does Not Move ..............................................4-7

5 Folding Quality Troubleshooting.......................5-1

5-1 Sheets Are Wrinkled ...........................................................5-2

5-2 Corner of the Sheets Are Folded (Dog Ear)........................5-3

5-3 Uneven Folding...................................................................5-4

5-4 Fold Skewing ......................................................................5-5

5-5 Delivered Sheets Are Not Neatly Stacked ..........................5-6

5-6 Sheet Jams at the Tray Gate ..............................................5-7

6 Electrical Circuit................................................6-1

6-1 Electrical Parts Location and Description ...........................6-2

6-2 Power Circuit Wiring Diagram and Interlock Circuit ............6-5

6-3 QPM-243 Control P.C.B......................................................6-6

6-4 QPW-767/QPW-768 Buckle Chute LED P.C.B...................6-8

6-5 Firmwae Update................................................................6-10

IV

Page 5

1 Installation and Mechanism

1-1............... Installation ............................................................................ 1-2

1-2............... Main Cover Removal ........................................................... 1-3

1-3............... Buckle Chute Removal ........................................................ 1-4

1-4............... Mechanism of Folding .......................................................... 1-5

1-5............... Feed Table............................................................................ 1-6

1-6............... Table Up/Down Mechanism.................................................. 1-7

1-7............... Drive Section........................................................................ 1-8

1-8............... Feed Roller Section.............................................................. 1-9

1-9............... Double Feed Stop Section.................................................... 1-10

1-10............. Fold Roller Section............................................................... 1-11

1-11 ............. Tray Gate Section................................................................. 1-12

1-12............. Delivery Section.................................................................... 1-13

1-13............. Buckle Chute Section........................................................... 1-14

1

Installation and Mechanism

1-1

Page 6

1 Installation and Mechanism

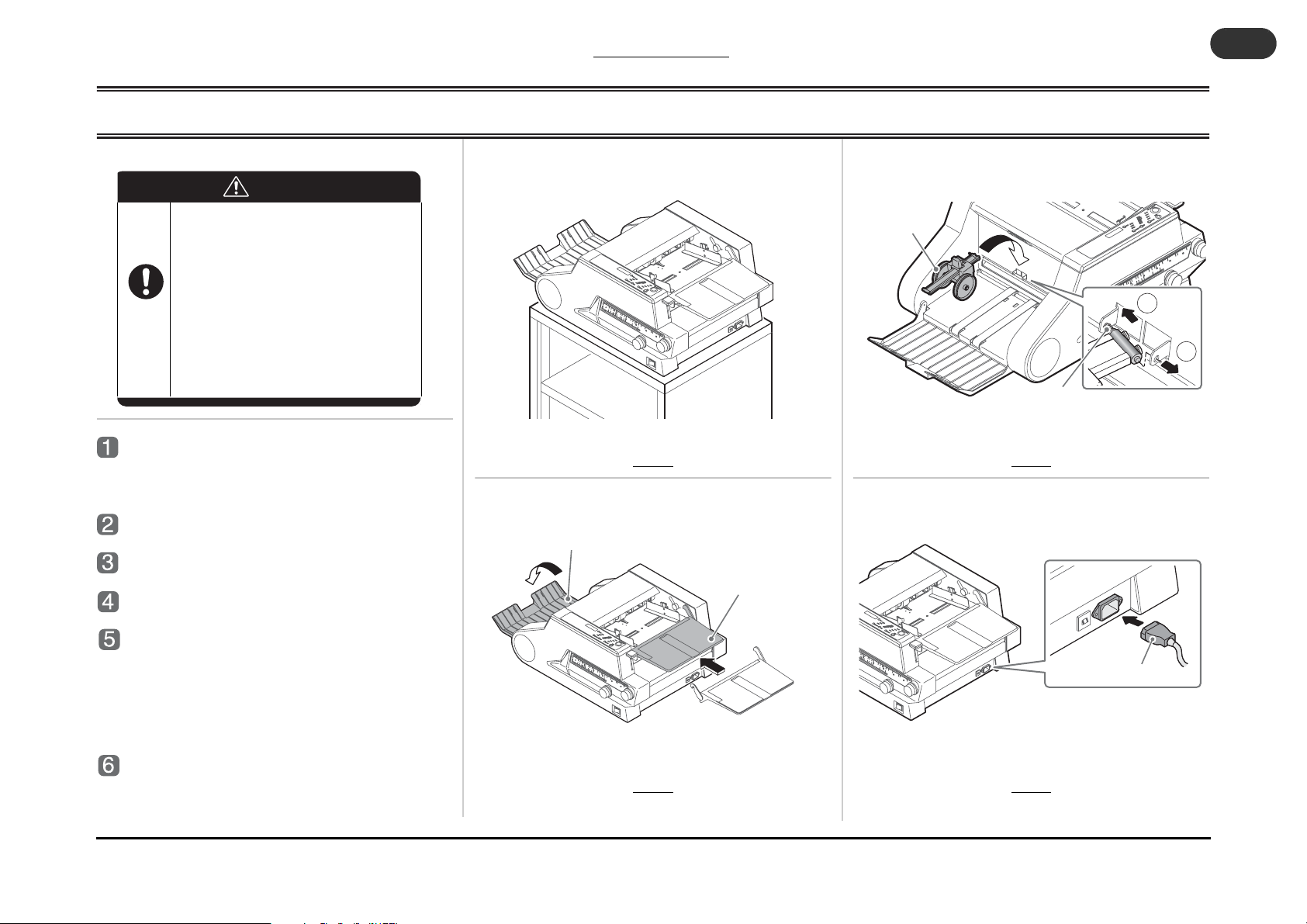

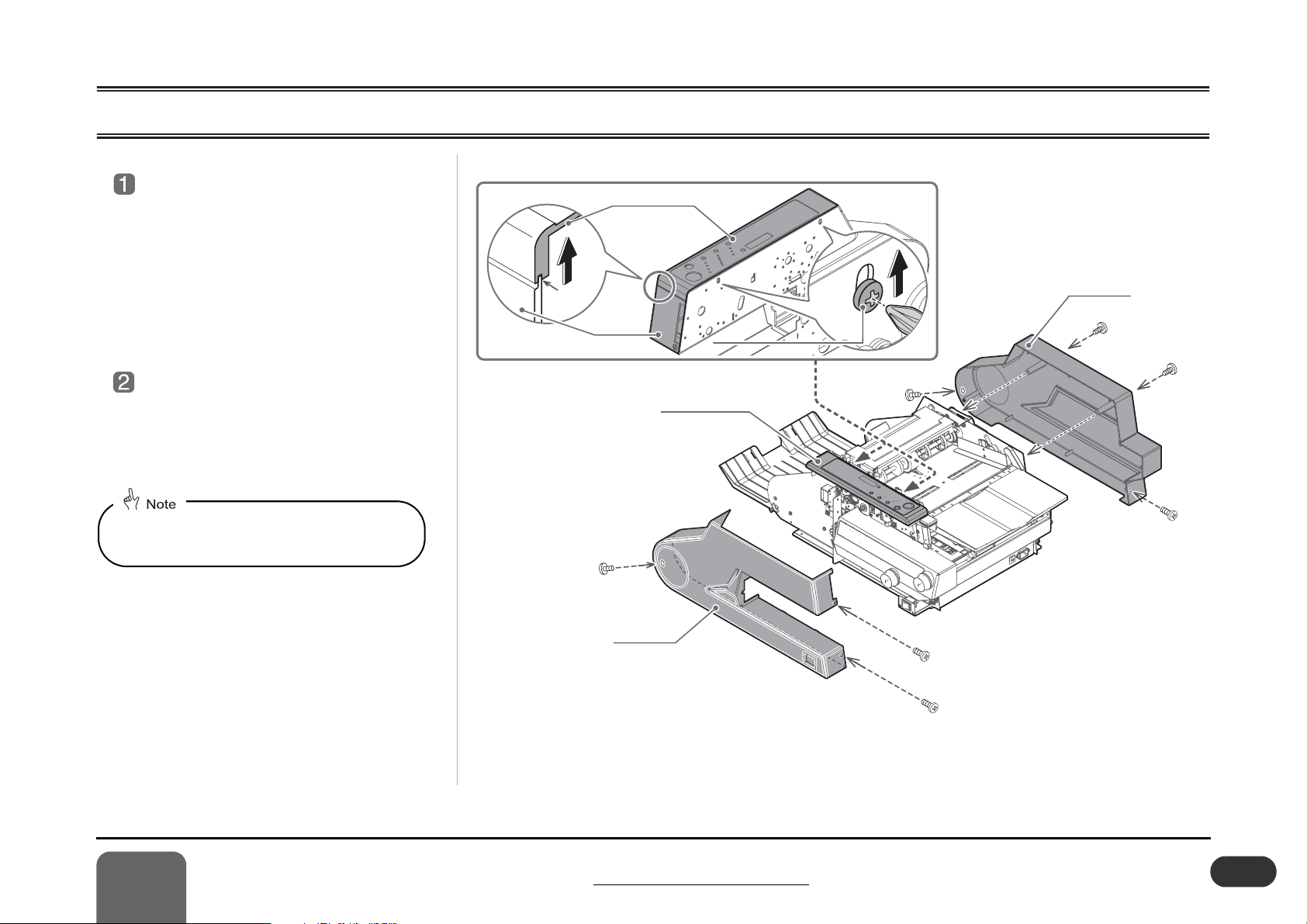

1 - 1 Installation

Caution

- Do not install the PF-P3100 on an

unstable or tilted floor. Otherwise,

the folder may fall over or the

machine frame may be distorted,

and this could affect the machine

performance.

- The PF-P3100 weighs 37kg (81.4 lb.).

Install the PF-P3100 on the table

which can support this weight.

- This machine must be moved by at

least two people.

1 - 1 Installation

503013

1_1_1A

Delivery Roller

Assembly

Pin

1-2

1

2

503013

1_1_1B

Open the package and take the folder

out of the box.

- Take all the accessories out of the box, too.

Place the folder on the table. (Fig.1)

Attach the support table. (Fig. 2)

Open the delivery tray. (Fig. 2)

Attach the delivery roller assembly.

(Fig. 3)

- Insert the rear end of the pin in the rear hole, and

push back in the direction shown by arrow 1. Pull

the front end of the pin into the front hole in the

direction shown by arrow 2.

Plug the power cable to the PF-P3100.

(Fig. 4)

Delivery Tray

Fig.1

Fig.2

Support Table

503013

1_1_1C

Fig.3

Fig.4

Power Cable

503013

1_1_1D

Page 7

1 Installation and Mechanism

Lock Screw for Control Panel

B4-8B

1 - 2 Main Cover Removal

Remove the cover F.

- Remove three lock screws.

- Loosen two lock screws of the control

panel.

- Lift the control panel, and disengage the

control panel from the cover F.

- Remove the cover F.

Remove the cover R.

- Remove four lock screws.

- Remove the cover R.

When attaching the cover, it is easier to attach

the cover once the buckle chute unit is

removed.

Engagement

Control Panel

Cover F

Cover F

Lock Screw for Control Panel

Lock Screw for Control Panel

Control Panel

B4-8B

B4-8B

Cover R

B4-8Bx4

1

Installation and Mechanism

1 - 2 Main Cover Removal

B4-8Bx3

503013

1_2_1A

1-3

Page 8

1 Installation and Mechanism

A

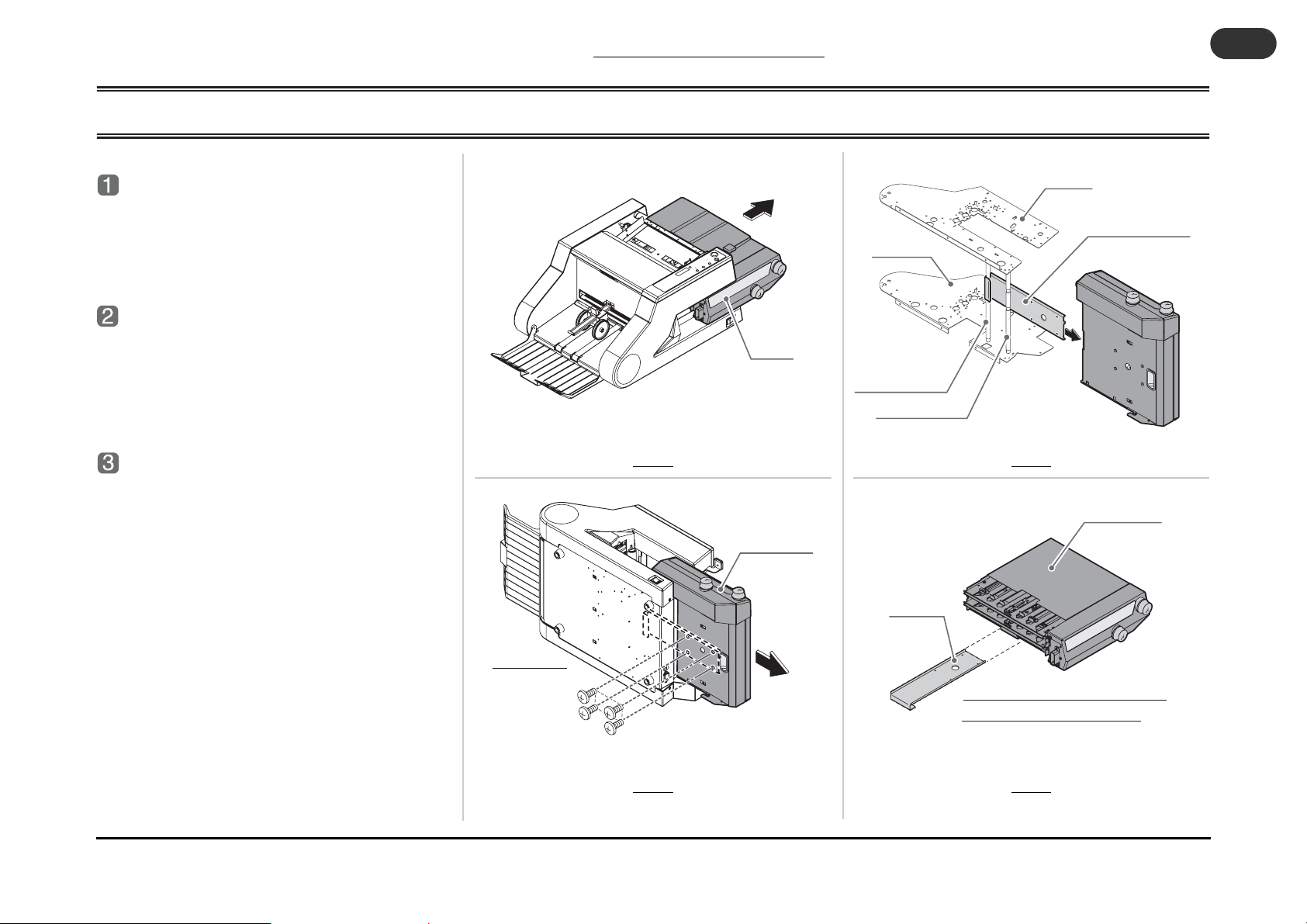

1 - 3 Buckle Chute Removal

1 - 3 Buckle Chute Removal

1-4

Pull out the buckle chute.

- Pull out the buckle chute to the arrow direction

slowly until it stops. (Fig. 1)

Remove the stopper bracket.

- Remove four lock screws of the stopper bracket

on the buckle chute at the bottom of the buckle

chute. (Fig. 2)

Remove the buckle chute.

- Pull out the buckle chute to the arrow direction to

remove. (Fig. 3)

- Remove the stopper bracket from the main body.

(Fig. 3)

Fig.1

Buckle

Chute

503013

1_3_1

Buckle Chute

Frame R

Support Shaft 1

Support Shaft 2

Stopper

Bracket

Fig.3

Frame F

Stopper Bracket

Buckle Chute

503013

1_3_1C

Bottom Plane

Buckle Chute and Stopper Bracket

503013

Lock Screws

B4-6B4

1_3_1B

Fig.2

separated from the main body

Fig.4

503013

1_3_1D

Page 9

1 Installation and Mechanism

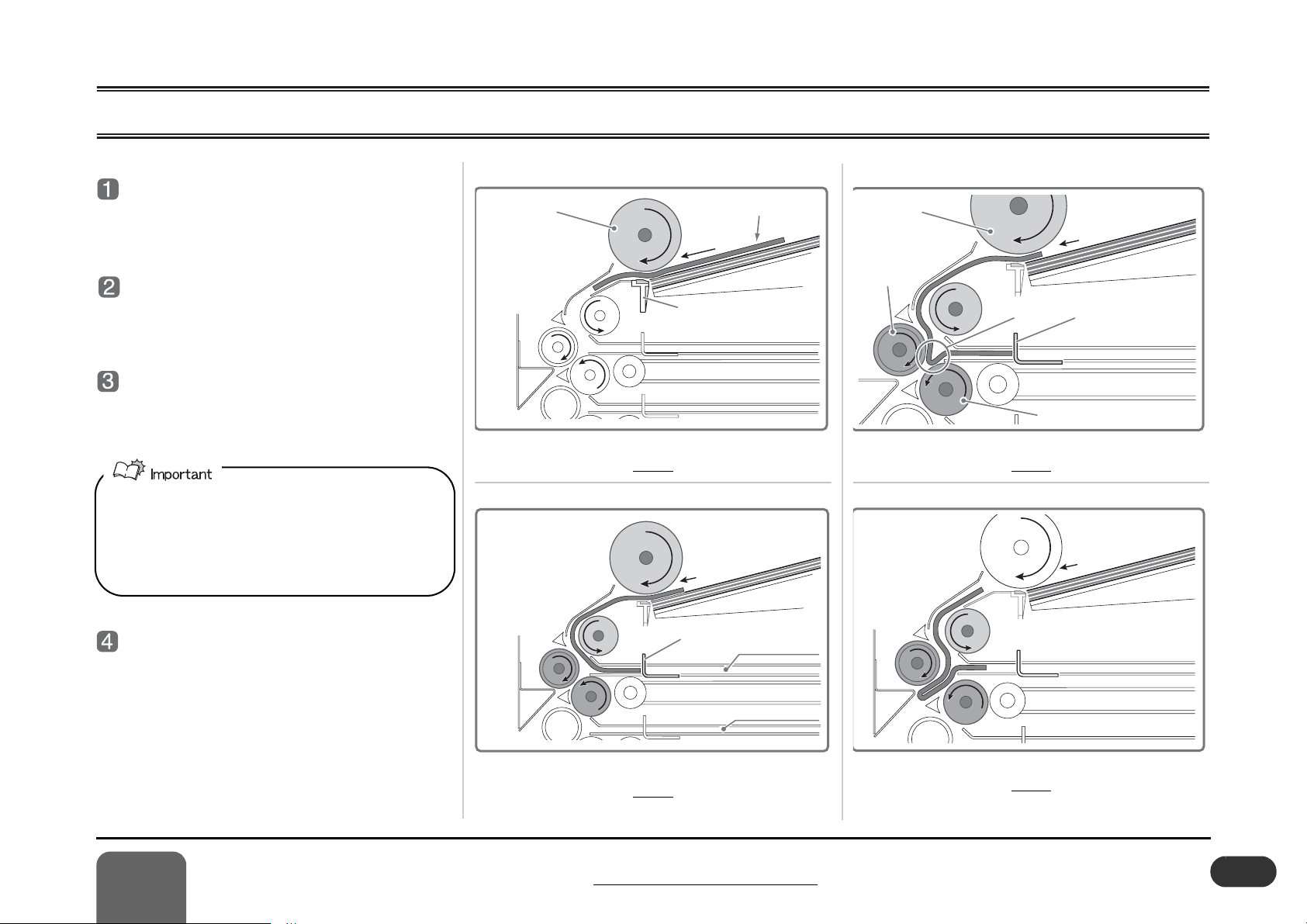

1 - 4 Mechanism of Folding

Sheets are fed.

- The feed roller rotates and feeds sheet one by one

to the buckle chute. (Fig. 1)

The sheet hits the stopper.

- The sheet hits the stopper on the 1st buckle chute

and stops. (Fig. 2)

The sheet is bent slightly.

- The sheet stopped by the stopper is bent, and the

fold rollers catch the sheet bend. (Fig. 3)

- When the folding speed is set to “High”, the amount of

sheet bend is slightly changed. Set the stopper position 1 mm (0.04”) shorter than the normal setting.

- When the heavier sheet is folded, the amount of sheet

bent becomes smaller. Set the folding speed to “High”

to create bigger sheet bend.

The sheet is folded.

- The fold rollers catch the bending part of sheet

and sheet is folded.

- The fold position changes depending on the stopper position.

Feed Roller

Fig.1

Sheets

Double Feed Stop Plate

Stopper

1st Buckle Chute

2nd Buckle Chute

503013

1_4_1A

Feed Roller

Fold Roller

Bending Part

Fold Roller

Fig.3

Stopper

503013

1_4_1B

1

Installation and Mechanism

503013

1_4_1C

Fig.2

1 - 4 Mechanism of Folding

Fig.4

503013

1_4_1D

1-51-5

Page 10

1 Installation and Mechanism

A

Slide Spring

1 - 5 Feed Table

Feed Table Sheet

Actuator

Sheet Guide

Support Table

1 - 5 Feed Table

The sheet guides can be

adjusted on this pivot.

Slide Spring

Slide Spring

1-6

Feed Angle

Adjusting Mechanism

Feed Table Sheet

Actuator

S12

Sheet Detection

Switch

This rod is

eccentric.

Feed Angle Adjusting Mechanism

Eccentric Rod

Lever Knob

Guide Shaft

The lever knob plates hold

the guide shaft and this fix

the guide position.

Slide Block

Guide Shaft

Slide SpringSlide Spring

503013

1_5_1

Page 11

1 Installation and Mechanism

(Strong)

(Normal)

Section B

Section A

Section A

Section B

1 - 6 Table Up/Down Mechanism

Feed Roller

Feed Table

Feed Table

Fulcrum Shaft

Section A

Section A

Feed Table

Pressure Adjusting Lever

Feed Roller

Section A

Section A

(Strong)

(Strong)

(Normal)

(Normal)

Feed Table

Pressure Adjusting Lever

Pressure Lever

Feed Tray Lever

Feed Table

Pressure Spring

Pressure Lever

Lever Cam Spring

Section B

Section B

Feed Table

Feed Table

Pressure Spring

Feed Tray Lever Cam

Feed Tray

Lever

Feed Table

The tip of the feed table lowers

when the feed tray lever pushes

this shaft down.

This switch detects

that the feed table

is lowered.

Set the lever to "Strong" to

increase the feed table pressure.

Section B

Section B

Feed Tray Lever

S12

Feet Table

Pushdown Shaft

503013

1_6_1A

1

Installation and Mechanism

1 - 6 Table Up/Down Mechanism

1-7

Page 12

1 Installation and Mechanism

M10 Main Motor

(DC brushless motor)

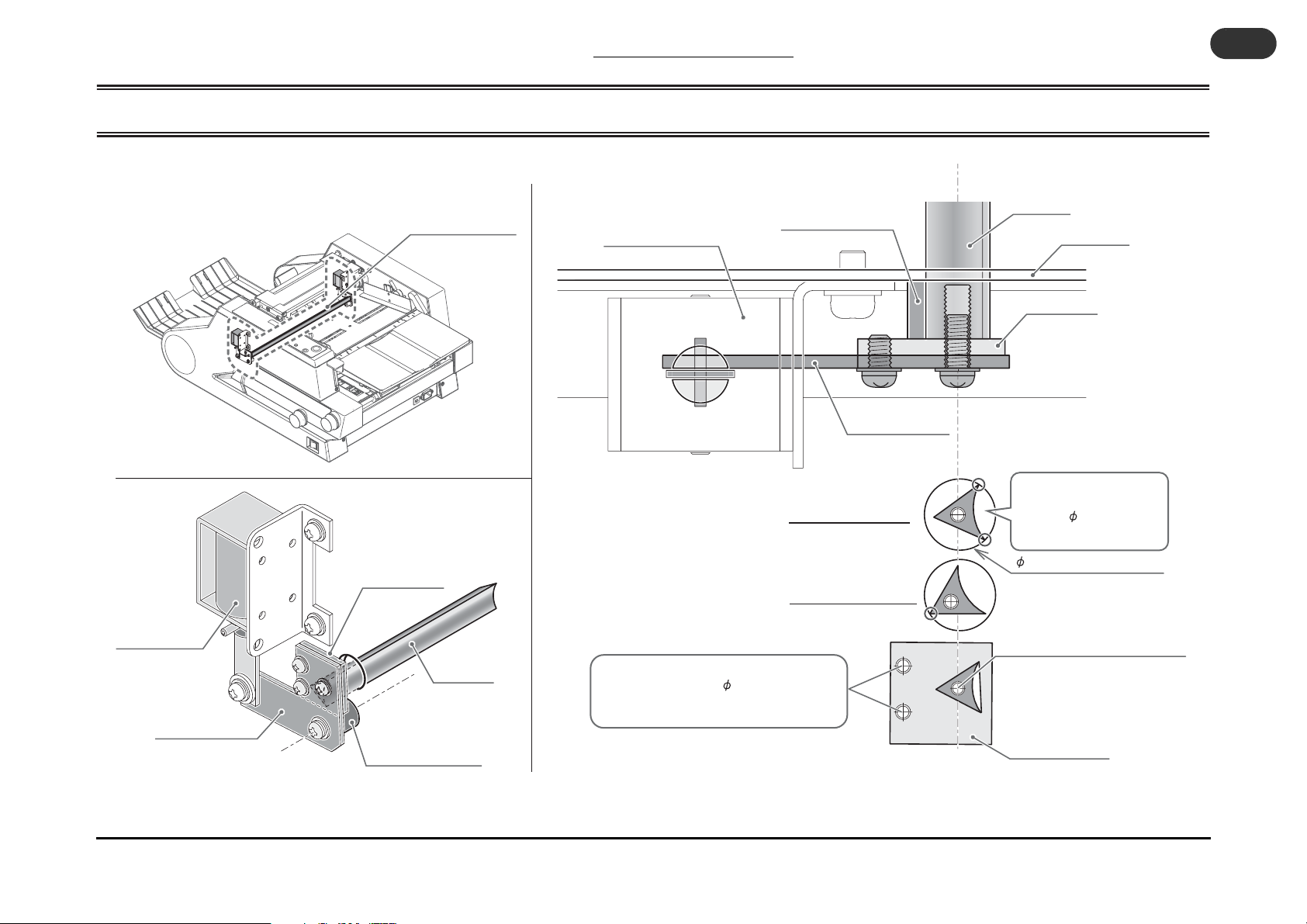

1 - 7 Drive Section

Feed Roller

1 - 7 Drive Section

1-8

Feed Drive Belt

Fold Roller

Delivery Section

Clutch Solenoid

Drive Timing Belt

M10 Main Motor

(DC brushless motor)

Delivery Drive Belt

Delivery Belt

Conveyor Pulley

Power Transport System

503013

1_7_1A

Page 13

1 Installation and Mechanism

A

Inner diameter of the clutch spring

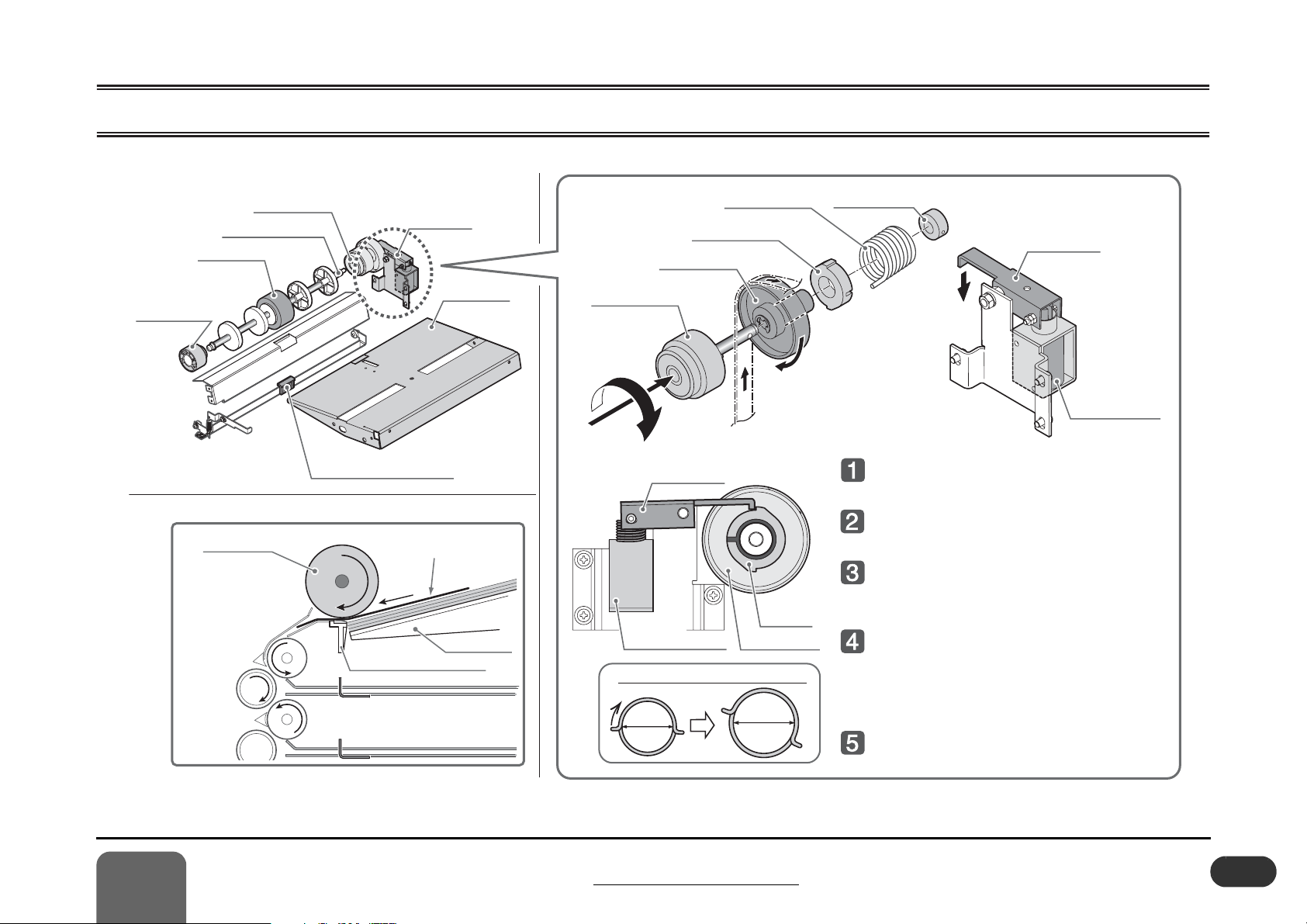

1 - 8 Feed Roller Section

Free Bearing

Fixed Bearing

Feed Roller Shaft

Feed Roller

Feed Roller

Clutch Unit

Double Feed Stop Plate

Sheet

Double Feed Stop Plate

Feed Table

Feed Table

Clutch Stopper

Clutch Pulley

Fixed Bearing

Feed Roller

Insert the feed roller shaft.

Clutch Lever

Clutch SolenoidClutch Solenoid

Inner diameter of the clutch spring

Twist

Inner

Diameter

Clutch Spring

Clutch

Stopper

Clutch Pulley

Enlarged

Inner

Diameter

Clutch Bushing

Clutch Lever

Clutch

The feed roller rotates to the

arrow direction and feeds sheet.

The rotation of the clutch stopper

stops when the clutch lever lowers.

The clutch spring is twisted to

the arrow direction, and the inner

diameter of

the clutch spring is enlarged.

Since the inner diameter of the

clutch spring is enlarged, the power

transmission to the feed roller shaft is

shut off, and the clutch bushing is

slipped on the clutch pu

lley.

The feed roller does not rotate although

the clutch pulley rotates.

Solenoid

503013

1_8_1

1

Installation and Mechanism

1 - 8 Feed Roller Section

1-9

Page 14

1 Installation and Mechanism

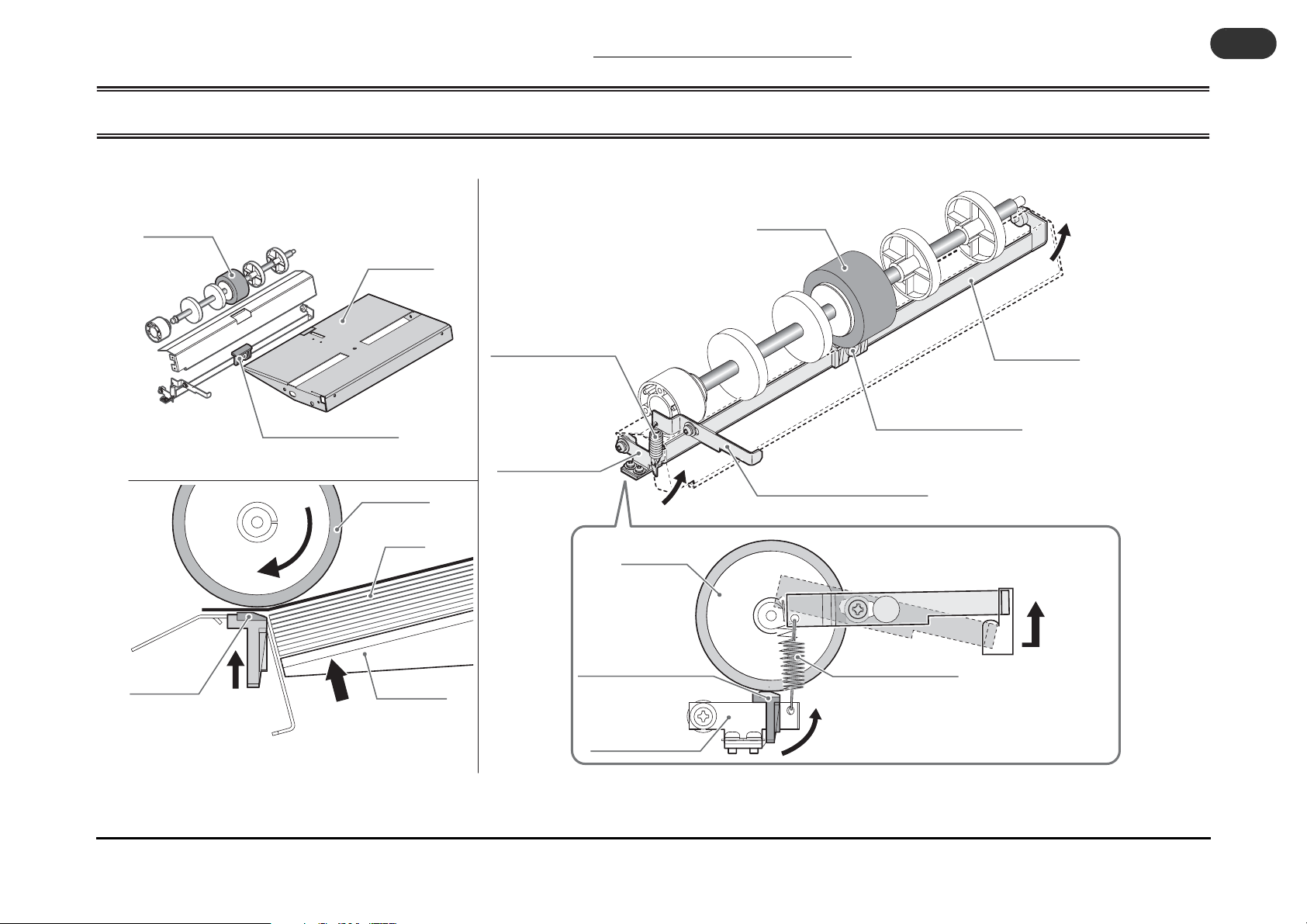

1 - 9 Double Feed Stop Section

1 - 9 Double Feed Stop Section

1-10

Feed Roller

Double Feed

Stop Plate

Double Feed Stop Plate

Double Feed

Stop Pressure

Feed

Pressure

Feed Table

Feed Roller

Sheet

Feed Table

Plate Pressure Spring

Plate Stand Lever

Double Feed Stop Plate

Plate Bracket Lever

Feed Roller

Feed Roller

Double Feed Stop Plate

Plate Pressure Adjusting Plate

Plate Pressure Spring

Second sheet is stopped by the

friction of the double feed stop plate.

Plate Bracket

Plate Pressure Adjusting Plate

Plate Pressure

Low"

"

503013

1_9_1A

Page 15

1 Installation and Mechanism

Solenoid O

N =

When the tray gate

is at right.

- When the solenoid

turns ON, the tray gate

comes close to the third

roller.

- The sheet that comes

through the second and

third

roller goes over

the tray gate and is

delivered.

Solenoid OFF =

When the tray gate is at left.

-

When the solenoid

turns OFF, the tray gate

moves to the left and

makes a space between

the tray gate and the

third roller.

- The sheet that comes

through the second and

third roller deflects at

the tray gate, then goes

to the second buckle

chute through the third

and fourth roller.

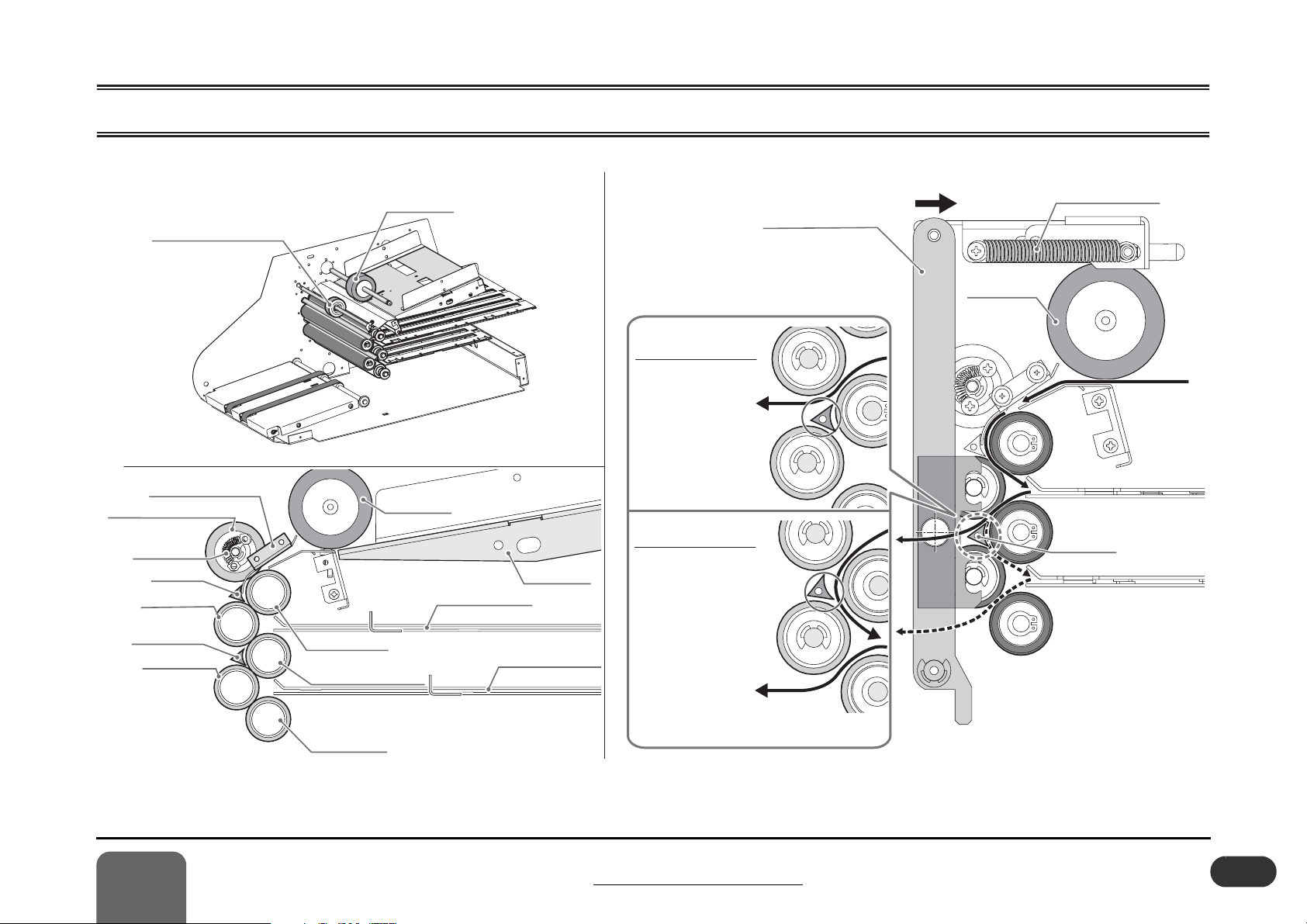

1 - 10 Fold Roller Section

Transport Rubber Roller

Upper Guide Plate

Transport Rubber Roller

Hold Spring

R Gate

Fold Roller 2

Tray Gate

Fold Roller 4

1

Installation and Mechanism

2

4

1

3

5

Fold Roller 1

Fold Roller 3

Fold Roller 5

Feed Roller

Feed Roller

1st Buckle Chute

Solenoid O

When the tray gate

- When the solenoid

turns ON, the tray gate

comes close to the third

roller.

- The sheet that comes

through the second and

third

Feed Table

2nd Buckle Chute

roller goes over

the tray gate and is

delivered.

Solenoid OFF =

When the tray gate is at left.

When the solenoid

turns OFF, the tray gate

moves to the left and

makes a space between

the tray gate and the

third roller.

- The sheet that comes

through the second and

third roller deflects at

the tray gate, then goes

to the second buckle

chute through the third

and fourth roller.

1 - 10 Fold Roller Section

N =

is at right.

Press the fold driven rollers.

Roller Pressure Link

2

4

2

4

Fold Roller Spring

Feed Roller

Sheet

3

1

2

3

Tray Gate

3

4

1st Buckle

nd Buckle

2

5

5

503013

1_10_1A

1-11

Page 16

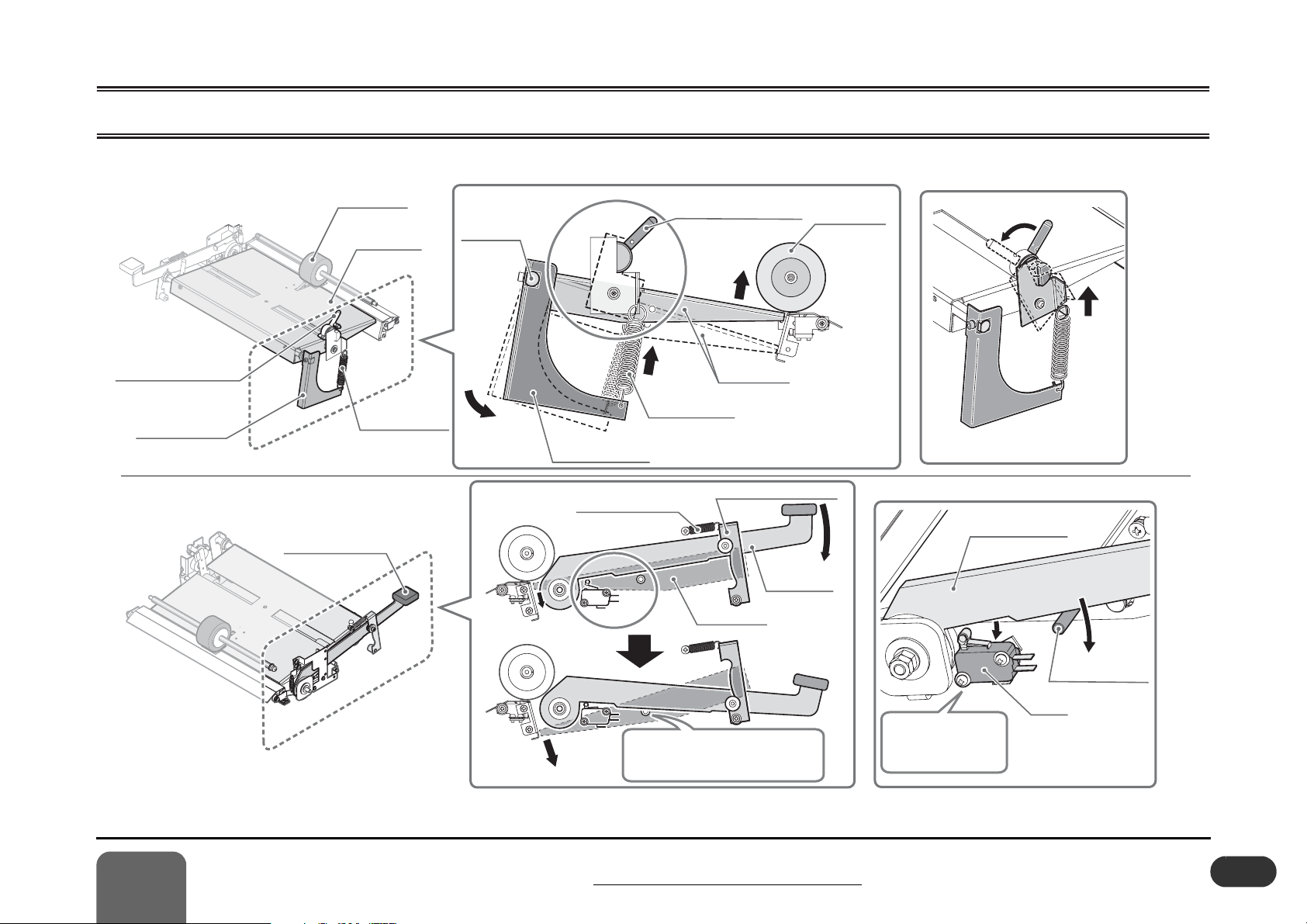

1 Installation and Mechanism

A

When Solenoid ON:

When Solenoid OFF:

1 - 11 Tray Gate Section

1 - 11 Tray Gate Section

1-12

Gate Solenoid

(front)

Gate Lever (front)

Tray Gate Section

Gate Bracket

Tray Gate

Gate Fulcrum Shaft

Gate Fulcrum Shaft

Gate Solenoid (front)

When Solenoid ON:

When Solenoid OFF:

Adjust the tilt of the tray gate and the

internal contact with the 14 hole by adjusting

the tray gate bracket using these two holes.

Gate Lever (front)

Tray Gate

Side Plate

Gate Bracket

The stop position of the tray

gate is where the gate hits

inside the 14 hole on the

side plate.

14 hole on the side plate

Lock the tray gate with this screw.

Tray Gate Bracket

503013

1_11_1

Page 17

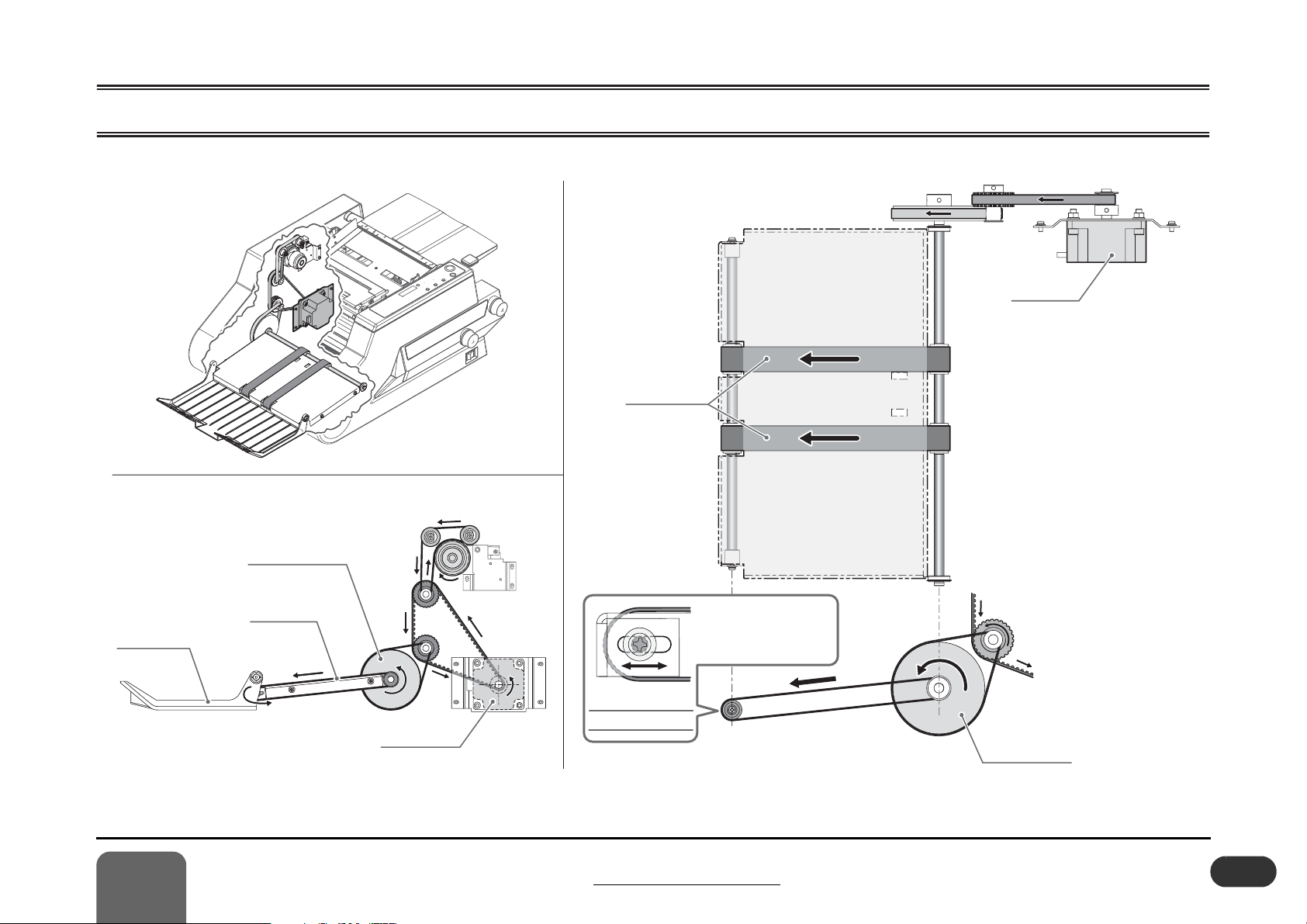

1 Installation and Mechanism

A

M10

M10M10M10M10M10M10

M10

Tension Adjustment

of the Delivery Belt

1 - 12 Delivery Section

M10

M10

M10M10M10

Main Motor

M10

M10

Delivery Tray

Conveyor Pulley

Delivery Belt

Main Motor

M10M10

Delivery Belts

Tension Adjustment

of the Delivery Belt

Adjust the belt tension

by fixing position of the

shaft.

Conveyor Pulley

503013

1_12_ 1

1

Installation and Mechanism

1 - 12 Delivery Section

1-13

Page 18

1 Installation and Mechanism

Timing Belt

1st Stopper

Stopper

2nd Buckle

LEDLED

1st Buckle

Home Position of Buckle Chute

21

1st Buckle

Chute Stopper

2nd Buckle Chute Stopper

Stopper Unit

21

22

Proximity Sensor Unit

Home Position of Buckle Chute Stopper

2nd Buckle

Section A

Section A

Lock Screws

Lock

Screws

Lock

Screws

Stopper

1 - 13 Buckle Chute Section

1 - 13 Buckle Chute Section

1-14

Home Position of Buckle Chute Stopper

Set the first and second stopper at 57 mm (2.2") from the

entrance of the buckle chute. Align the stopper pointer to the leftmost LED on the buckle chute.

57 mm (2.2")

Stopper

Stopper

Stopper

Stopper

57 mm (2.2")

Buckle Chute

Section

Stopper Pointer

LED

LED

Stopper Pointer

1st Buckle

2nd Buckle

2nd Buckle

Home Position of Buckle Chute

Stopper

Move Shaft

Timing Pulley

Timing Belt

Timing Belt

Handwheel

Handwheel

1st Stopper

1st Stopper

Timing Pulley

2nd Buckle

2nd

Stopper

1st Buckle

Stopper

Move Shaft

Section A

Section A

Proximity Sensor: B21

Lock Screws

Lock Screws

Lock

Lock

Screws

Screws

Section A

Section A

Sensor Bracket

Proximity Sensor Unit

2nd Buckle Chute Stopper

Loosen the lock screws,

and then adjust the position

of the stopper pointer.

Stopper Unit

Proximity Sensor for 1st Buckle Chute : B21

Proximity Sensor for 2nd Buckle Chute : B22

When the stopper moves

forward to the gate of the

buckle chute, the whole

sensor bracket slide to the

Slide

1st Buckle

Chute Stopper

arrow direction.

Sensor

Spring

503013

1_13_1A

Page 19

2 Service Mode and Error Code

2-1............... Functions of Service Mode .................................................. 2-2

2-2............... Error Code Chart.................................................................. 2-3

2

Service Mode and Error Code

2-1

Page 20

2 Service Mode and Error Code

2 - 1 Functions of Service Mode

2 - 1 Functions of Service Mode

2-2

The service mode is the functions listed in the chart to

the right can be performed by pressing the power

switch and the other buttons together.

To exit the service mode, turn off the power switch.

Start/Stop Button

Display

Sheet Size Select Button

Clear Button

Test Button

Power Switch : ON

503013

2_1_1A

Service Mode How to Enter What You Can Do in This Mode

Memory writing

error reset mode

Life counter check

mode

Software version

check mode

Error-ignoring

check mode

S13: Feed Table

Sheet Detection

switch ignoring

mode

S12: Feed Bar

switch ignoring

mode

Turn on the power switch while pressing

the Start/Stop, Test and Clear buttons on

the control panel simultaneously, and hold

down the buttons for 5 seconds until

buzzer sounds.

Turn on the power switch while pressing

the Start/Stop button on the control panel,

and hold down the button for 5 seconds

until buzzer sounds.

Turn on the power switch while pressing

the Start/Stop, Test and Sheet Size Select

buttons on the control panel simultaneously, and hold down the buttons for 5

seconds until buzzer sounds.

Turn on the power switch while pressing

the Start/Stop and Test buttons on the control panel simultaneously, and hold down

the buttons for 5 seconds until buzzer

sounds.

1. Enter into the error-ignoring check

mode.

2. Press the Clear button for 5 seconds

until buzzer sounds.

1. Enter into the error-ignoring check

mode.

2. Press the Start/Stop button for 5 seconds until buzzer sounds.

When “E7” (memory error) occurs, and the

machine is not recovered by turning the power

off and on, the memory can be reset in this

mode. (This memory will be returned to the

default value.)

Life counter can be displayed. The last two

digits are not indicated.(For example “10” is

indicated when 1,000 sheets were folded.)

The life counter is cleared to “0” by pressing

the Clear button for 5 seconds.

Current software version is displayed, for

example “v0.77”.

In this mode, error is not detected at all. Operation can be performed as usual. (“8888” is

displayed when the Clear button is pressed.)

In this mode, the folder can be used even if

S13 Feed Table Sheet Detection switch is broken down.

In this mode, operator can use the folder even

if S12 Feed Bar switch is broken down.

Page 21

2 Service Mode and Error Code

2 - 2 Error Code Chart

Error

Code

E1

E2

E3

E4

E5

Cause and Solutions

[Cause] The fold section cover opens while the motor rotates. (The S10 fold section cover switch turns Off.)

[Solution] Close the fold section cover. If the same error still occurs, check wiring/connection between S10 and QPM-243. If the S10 fold section cover switch is On,

LED L27 on QPM-243 turns off. If the same error still occurs, replace S10. If the same error still occurs, replace the QPM-243 control board.

[Cause] The X20 buckle connector is removed while the motor rotates. (The buckle chute is removed from the X20 buckle connector.)

[Solution] Insert the buckle chute so that the X20P connector on the buckle chute is connected to the X20R connector on the folder correctly. If the same error still

occurs, check wiring/connection between X20 and QPM-243. If the buckle chute is inserted properly, LED L26 on QPM-243 lights. If the same error still

occurs, replace the QPM-243 control board.

[Cause] The A10 motor driver alarms. (The M10 main motor is overloaded.)

[Solution] Check if a sheet is not caught between the mechanical sections driven by the M10 main motor. Check if the drive shaft of the M10 main motor tries to rotate

when the power is applied. Check if the drive shaft of the M10 can be rotated smoothly by hand when the drive belt is removed. If it is OK, check wiring/connection between M10 and A10, and A10 and QPM-243. If it is OK, replace the A10 motor driver. If it is OK, replace the QPM-243 control board.

[Cause] The F2 fuse (3.15 A) on the QPM-243 control board is blown. (24VDC circuit from the control board shorts out, or the fuse is deteriorated.)

[Solution] Check if the wiring is not caught in the machine covers and does not short out. Replace the F2 fuse. (If the fuse is not blown, LED L24 on QPM-243 lights.)

[Cause] The third and fourth contact point for the K01 interlock relay is welded. (Short-out condition) ---------- The interlock relay is defective.

[Solution] Replace the K01 interlock relay.

E6

[Cause] The third and fourth contact point for the K01 interlock relay is not connected. (Open condition) ---------- The interlock relay is defective.

[Solution] Replace the K01 interlock relay.

2

Service Mode and Error Code

2 - 2 Error Code Chart

2-3

Page 22

2 Service Mode and Error Code

2 - 2 Error Code Chart

[Cause] Memory reading error: EPROM information can not be read when turning on the power switch.

2-4

E7

[Solution] Reset the memory using the “Memory Reading Error Reset Mode” in the service function, and operates the folder with the default setting. If the same error

still occurs, replace the QPM-243 control board.

Page 23

3 Adjusting and Checking Procedures

3-1............... Buckle Chute Stopper Angle Adjustment.............................. 3-2

3-2............... Feed Clutch Unit Adjustment ............................................... 3-3

3-3............... Tray Gate Position Adjustment ............................................ 3-4

3-4............... Belt Tension Adjustment ...................................................... 3-5

3-5............... Delivery Belt Replacement .................................................. 3-6

3-6............... Micro-switch Adjustment ...................................................... 3-7

3

Adjusting and Checking Procedures

3-1

Page 24

3 - 1 Buckle Chute Stopper Angle Adjustment

A

SheetSheetSheet

1st buckle adjustment

Do not loosen.

2nd buckle adjustment

Do not loosen.

Stopper

2nd Buckle

LEDLED

Stopper

3 Adjusting and Checking Procedures

3 - 1 Buckle Chute Stopper Angle Adjustment

3-2

- Check the fold skew.

- Determine which stopper requires adjustment.

- Pull out the buckle chute and open the top cover. (Fig.1)

- Loosen the timing pulley on the rear of the 1st buckle

- Loosen the timing pulley on the rear from the square

- Insert the scale from the entrance of the buckle chute

- Align the stopper pointer to the left-most lamp on the

503013

5_4_1

Check the folded sheets which was fed

correctly.

Adjust the 1st buckle chute stopper

angle.

chute and adjust the stopper angle. (Fig.2) (Do not

loosen the timing pulley on the handwheel side as it

is a reference side.)

Adjust the 2nd buckle chute stopper

angle.

window for adjustment at the bottom of the buckle

chute unit, and adjust the stopper angle. (Fig.3) (Do

not loosen the timing pulley on the handwheel side as

it is a reference side.)

Check the stopper home position.

and set the stopper at 57 mm (2.2"). The stopper should

be leveled at the front and rear.

buckle chute. (See Section 1 - 13 for pointer adjustment)

(Fig.4)

Pull out the buckle chute to the arrow direction

slowly until it stops. See Section 1-3-1 for

buckle chute separation.

Fig.1 Buckle Chute

1st buckle adjustment

Adjust the stopper angle

using the timing pulley on the rear.

Sheet

Sheet

Stopper

Do not loosen.

503013

3_1_1B

Fig.2 Angle Adjustment 1

Top Cover

Buckle Chute

503013

3_1_1A

Timing Pulley

Allen Wrench

(2mm/0.08")

This is

registering

side.

2nd buckle adjustment

Bottom Plane

Square window for 2nd stopper

adjustment

Do not loosen.

This is the

reference side.

Timing Pulley

Allen Wrench

(2mm/0.08")

Adjust the stopper

angle using the timing

pulley on the rear.

503013

3_1_1C

Fig.3 Angle Adjustment 2

Set the first and second stopper at 57 mm (2.2")

from the inner side of the buckle chute. Align the

stopper to the left-most lamp on the buckle chute.

See Section 1-13.

57 mm (2.2")

Stopper

Stopper

Stopper

Stopper

57 mm (2.2")

Stopper Pointer

LED

LED

Stopper Pointer

1st Buckle

2nd Buckle

2nd Buckle

503013

3_1_1D

Fig.4 Buckle Chute Stopper Home Position

Page 25

3 Adjusting and Checking Procedures

Plunger

Clutch

Solenoid

When Y01 is On

G

FC-6

SARI-10

When Y01 turns to Off

G

G

G

G

3 - 2 Feed Clutch Unit Adjustment

- The feed clutch activates when start and stop

feeding the sheet, and Short fold and Accordion

fold, which the sheet enters into the first buckle

chute deeply, are selected.

- The feed clutch activates every time the clutch

stopper rotates, and waits until the former sheet

passes so that the second sheet does not hit the

first sheet and jams. (The feed clutch does not

activate for the continuous feeding on other fold

patterns.)

Check and adjust the gap between

the clutch lever and the clutch stop-

per.

Support Roller

Feed Roller Shaft

Feed Roller

Free Bearing

Fixed Bearing

Clutch Unit

Clutch Housing

Fixed

Bearing

FC-6

Roller

Clutch

Bearing

W8

SARI-10

Free Bearing Spring

Clutch Bush

Clutch Stopper

Clutch Pulley

"G" shows grease supply point.

Free

Bearing

Bearing

Clutch Spring

- Remove the rear cover to access the clutch section.

- Turn off the power switch.

- Check that the clutch stopper is stopped by the

clutch lever when the Y01 clutch solenoid is Off.

(Fig.2)

- Adjust the position of the solenoid bracket so that

when the plunger of Y01 is pushed down and the

solenoid Y01 is turned on, the gap between the

circumference of the clutch stopper and the tip of

the clutch lever becomes 0.5 to 1.0 mm (0.02" to

0.04").

- Lock the bracket using the bracket locking screw.

(Fig.3)

3

Clutch Lever

Y01

When Y01 turns to Off

1. The tip of the clutch lever is caught by the step of the clutch stopper.

2. The clutch stopper stops rotating.

3. The inner diameter of the clutch spring enlarges.

4. Torque to the feed roller is not transmitted.

Adjusting and Checking Procedures

Clutch Pulley

Fixed Bearing

Clutch Stopper

Clutch Spring

When Y01 is On

Loosen the bracket locking screw and adjust the position of the

solenoid bracket so that the gap between the clutch

lever and the clutch stopper becomes 0.5 to 1.0 mm (0.02" to 0.04").

3 - 2 Feed Clutch Unit Adjustment

Y01

Clutch Lever

Plunger

Plunger

Clutch

Clutch

Solenoid

Solenoid

Solenoid Bracket

Gap 0.5 to 1.0 mm

(0.02" to 0.04")

Clutch Spring

Clutch Stopper

Bracket Locking Screw

503013

3_2_1A

3-3

Page 26

3 Adjusting and Checking Procedures

Y02

No.3No.3

No.5No.5

When Y02 (Y03 on far side) is On,

the tray gate comes close to the third roller.

ON

Solenoid ON:

Solenoid OFF:

Y02

No.3No.3

No.5No.5

When Y02 (Y03 on far side) is Off,

the tray gate comes off from the third roller.

OFF

4

3 - 3 Tray Gate Position Adjustment

Depending on the position of the tray gate, sheets are

delivered, or folded again.

The stop position of the tray gate is where the gate

hits inside the 14 hole on the side plate.

Y02

Y02

Remove the second and fourth rollers.

3 - 3 Tray Gate Position Adjustment

No.3

No.3

Y02

Y02

No.3

No.3

3-4

Loosen the locking screws on the gate

holder. (Fig.2)

Lock the gate holder.

- Press the gate holder to the third roller direction and

tighten the locking screws. (Fig.4)

Adjust the solenoid position.

- Position the Y02 (Y03) solenoid so that when the plunger

of the solenoid is pushed in, two tip of the gate touches

the 14 hole on the side plate. Tighten the locking

screws in that position. (Fig.4)

Check the position of the tray gate.

- Remove the drive timing belt. Keep pushing plunger of

the Y02 (Y03) solenoid in and turn the third roller manually. Check that the roller turns without any noise by hitting the gate on the roller.

ON

Tray Gate

When Y02 (Y03 on far side) is On,

the tray gate comes close to the third roller.

Fig.1

Gate Solenoid (front)

503013

3_3_1B

Gate Fulcrum Shaft

Gate Holder Locking Screw

Gate Lever (front)

Solenoid ON:

Solenoid OFF:

(except for single fold)

Touch in one place

Fig.2

No.5

No.5

Tray Gate

Side Plate

Gate Holder

The stop position of

the tray gate is

where the gate hits

inside the 14 hole

on the side plate.

(Two places)

14 Side Plate Hole

503013

3_3_1A

OFF

Tray Gate

When Y02 (Y03 on far side) is Off,

the tray gate comes off from the third roller.

Fig.3

1

Y02Y02

2

Push In

Solenoid

Locking

Screw

Fig.4

3

These screws can also adjust

the tilt of the gate.

No.5

No.5

503013

3_3_1C

503013

3_3_1D

Touches the 14 hole

(two places)

14

Lock the Y02 (Y03)

solenoid when top

of the tray gate

touch the side

plate in two places.

Page 27

3 Adjusting and Checking Procedures

Tension Adjustment

Drive Timing Belt

Feed Drive Belt

Delivery Drive Belt

3 - 4 Belt Tension Adjustment

Drive Timing Belt Tension

The tension of the drive timing belt is

adjusted by the mounting position of the

drive motor (M10).

If the belt is tightened too much, it may

cause vibration of the belt by the motion of

the machine. Do not tighten the belt too

much.

Drive Timing Belt

When the belt is pushed by 200

gW at its center, the belt bends

by 3 to 4 mm (0.12" to 0.16").

Feed Drive Belt Tension

The tension of the feed drive belt is adjusted by

the attaching position of the tension roller. The

hole to fix the tension roller on the side plate is a

slotted hole.

Adjust by the tension roller.

Feed Drive Belt

When the belt is pushed by 500

gW at its center, the belt bends

by 3 to 4 mm (0.12" to 0.16").

Delivery Drive Belt

The tension of this belt

cannot be adjusted. Attach

only by the belt tension.

Delivery Belt Tension

The delivery belts are stretch, therefore, the belt

tension is not necessary to be adjusted for normal use. Lock the delivery roller shaft at the

center of the slot on the belt bottom plate.

If the delivery belt slips due to the long-time use,

set the delivery roller shaft at exit side of the

slot.

Delivery Belt

Belt Bottom Plate

503013

3_4_1B

Tension Adjustment

Adjust by the

mounting position

of the motor.

3

M10M10

Adjusting and Checking Procedures

Delivery Belt

503013

3_4_1A

3 - 4 Belt Tension Adjustment

Lock at the

center of the

slot.

Exit Side

3-5

Page 28

3 Adjusting and Checking Procedures

Delivery Drive Belt

Conveyor Pulley

Space

3 - 5 Delivery Belt Replacement

3 - 5 Delivery Belt Replacement

3-6

If the delivery belt slips, set the delivery roller shaft at

exit side of the slot on the belt bottom plate.

If the delivery belt slips even with setting the delivery roller

shaft at the exit side of the slot, replace the delivery belt.

Remove the cover F, R and the support

table.

Loosen two locking screws for the

delivery roller shaft.

- Loosen the locking screws for the delivery roller shaft at

exit side on the belt bottom plate. (Fig.2)

Remove the conveyor pulley.

- Remove the delivery drive belt.

- Remove the C snap ring for the conveyor pulley, and pull

out the conveyor pulley. (Fig.2)

- Pull out the PP4-18 parallel pin.

Displace the delivery roller drive shaft

to the front.

- Displace the delivery roller drive shaft to the front, and

make a space for belt replacement. (Fig.3)

Remove the belt bottom plate with the

delivery belt.

- Remove four locking screws on the belt bottom plate,

and remove the belt bottom plate with the delivery belt.

(Fig.4)

Attach new delivery belt in the reverse

order of removal.

- Lock the delivery roller shaft at the center of the slot on

the belt bottom plate.

Set Screws for

Delivery Roller Shaft

Belt Bottom

Plate

C Snap Ring

(STW-10)

Remove the snap

ring and pull out the

conveyor pulley.

Delivery Belt

Remove the

delivery drive

belt.

Pull out the

PP4-18

parallel pin.

Delivery Drive Belt

Delivery Drive Belt

Fig.1

Loosen the

locking screws

for the delivery

roller shaft.

Fig.2

Conveyor Pulley

Conveyor Pulley

Delivery Roller

503013

Drive Shaft

3_5_1A

503013

3_5_1B

Approach the

delivery belt to the

space on the back

for removal.

When attaching new

belt, align the arrow

direction with the

delivery direction.

Remove the delivery

belt and the belt bottom

plate from the frame.

Space

Space

Fig.3

Fig.4

Displace the delivery

roller drive shaft to the

front, and make a space

for belt replacement.

503013

3_5_1C

503013

3_5_1D

Locking Screw

Remove four

locking screws on

the belt bottom plate.

Page 29

3 Adjusting and Checking Procedures

0.5mm

(0.02")

0.5mm 0.5mm

0.5mm

(0.02")

: Fold Section Cover Switch

: Feed Bar Switch

: Feed Table Sheet Detection Switch

2

to 52 to

5

3 - 6 Micro-switch Adjustment

This section indicates the standard position for the

attachment of the three micro-switches used in this

machine.

S10: Fold Section Cover Switch

S10: Fold Section Cover Switch

- ON: When the fold section cover is closed.

- The actuator is pushed by the projection on the fold section cover.

- Attach with another 0.5 mm (0.02") push-in margin

when the actuator is pressed.

S12: Feed Bar Switch

- OFF: When the feed tray lever is pushed down.

- The actuator is pushed by the feed tray lever.

- Attach with another 0.5 mm (0.02") push-in margin

when the actuator is pressed.

S13: Feed Table Sheet Detection Switch

- The switch is activated when the actuator is pushed

down by the sheet on the feed table.

- The actuator is pushed by the detection lever.

- Attach with another 0.5 mm (0.02") push-in margin

when the actuator is pressed.

S10

0.5mm

Actuator

0.5mm

(0.02")

(0.02")

Check the clicking

sound when opening

the fold section cover

slowly.

503013

3_6_1A

S13

Fold Section

Cover

S12: Feed Bar Switch

There should be another 0.5 mm

(0.02") push-in margin when the

actuator is pressed.

Feed Tray Lever

S12

Feed Table

Pushdown Shaft

S13: Feed Table Sheet Detection Switch

5

5

to

to

2

2

mm

(0.08"

- 0.20")

ON when the actuator

is pushed by

2 - 5 mm (0.08" - 0.20").

3

Adjusting and Checking Procedures

3 - 6 Micro-switch Adjustment

3-7

Page 30

3 Adjusting and Checking Procedures

3-8

This page is intentionally left blank.

Page 31

4 Mechanical Troubleshooting

4-1 ............... Machine Is Not Powered On................................................. 4-2

4-2 ............... M10 Main Motor Does Not Rotate ....................................... 4-3

4-3 ............... Tray Gate Malfunctions ........................................................ 4-4

4-4 ............... Y01 Clutch Solenoid Does Not Activate................................ 4-5

4-5 ............... Buckle Chute Proximity Sensor Error................................... 4-6

4-6 ............... Delivery Belt Does Not Move................................................ 4-7

4

Mechanical Troubleshooting

4-1

Page 32

4 Mechanical Troubleshooting

0V

5V

4 - 1 Machine Is Not Powered On

The power cable is

unplugged from the outlet.

The power cable is

unplugged from the inlet.

Q01

circuit protector

is tripped.

The machine power

is not turned on.

Power is not

supplied to the outlet.

4 - 1 Machine Is Not Powered On

CN2

GND

GND

24V

24V

GND

GND

5V

5V

AC

100-240V

CN1

G01

Switching

Power Supply

5 VDC is generated

from the switching

power supply.

Tester

4-2

5V

Fuse on the QPM-243 control

P.C.B is blown.

(Refer to 6-3-1 for replacement.)

QPM-243 control board

is defective.

Wiring between the switching

power supply and the control

board is defective.

S00

power switch is not

turned on.

Power cable contact failure

Other

Tester

5 VDC is not generated

from the switching

power supply.

P.C.B. connector is

disconnected or not

connected correctly.

G01

switching power supply is

defective.

S00

power switch is defective.

Z01

noise filter is defective.

503013

4_1_1A

Page 33

4 Mechanical Troubleshooting

COM

NO

NC

Fold Section

Cover Switch

24V

GND

24V

24V

GND

X12

CON9CON9

CON10CON10

CON1CON1

S10

CN3

CN1

Motor Driver

A10

M10

24V

GND

X10

24V

GND

Buckle Chute

Connector

K01

X20

Interlock

Relay

DC Brushless Motor

SIG X20[L26]

SIG S10[L27]

QPM-243

Control Control

P.C.B.P.C.B.

50W

M10 : Main Motor Does Not Rotate

24 VDC Circuit

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

RED

BLK

ORN

ORN

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

BRN

RED

ORN

YEL

GRN

BLU

VIO

BRN

GRY

WHT

BLK

BRN

RED

ORN

GRN

YEL

BLU

VIO

GRY

M10

ORN

BLU

ORN

BLU

RED

BLK

24V

GND

CN1CN1

CN2CN2

CN3CN3

A10

CON10

CON11

X10

X11

YEL

K01

Interlock Relay

DC

Brushless

Motor

Motor DriverMotor Driver

[LED1]

SIG M10[L23]

QPM-243

Control

P.C.B

50W

A10 : Motor driver alarms

Interlock is activated

4 - 2 M10 Main Motor Does Not Rotate

M10 : Main Motor Does Not Rotate

24 VDC Circuit

503013

4_2_1A

Check the followings:

1. A sheet is not caught inside the mechani-

cal sections driven by the M10 main motor.

2. The drive shaft of the M10 main motor

tries to rotate when the power is applied.

The locking screws on timing pulley of the

M10 are not loosened.

3. The A10 motor driver does not send an

alarm out and stopped.

4

A10 : Motor driver alarms

1. LED L23 on QPM-243 control P.C.B. is not

turned off. (Normally lit)

2. LED1 on the A10 motor driver is not blink-

ing. (Normally lit)

3. LED1 is turned off when the A10 motor

driver is powered off.

Number of

blinks

2

3

4

5

Mechanical Troubleshooting

Signal Circuit

503013

4_2_1B

Check the followings:

Alarm

Stop with the overload-protection

function

One of the motor cable is disconnected

Overvoltage-protection function,

more than 27.6 VDC.

Undervoltage-protection function,

less than 18 VDC.

4 - 2 M10 Main Motor Does Not Rotate

Interlock is activated

Interlock Circuit

24V

COM

Fold Section

S10:

Cover Switch

NO

2

Buckle Chute

X20:

4

1

K01:

2

Connector

Interlock Relay

Motor

Driver

24V

3

4

A10

503013

GND

GND

4_2_1C

Check the followings:

1. The fold section cover is closed. (S10 is

not turned off.)

2. The X20 buckle chute connector is

inserted all the way (Pin 1 and 3, 2 and 4

of X20 is connected.)

3. The third and fourth contact point is not

opened by the K01 interlock relay activation.

4-3

Page 34

4 Mechanical Troubleshooting

Delivery

4 - 3 Tray Gate Malfunctions

- Tray gate closes (= Solenoid Y02 and Y03 turn On)

only while the single folding operation. To perform

the single folding, the tray gate comes close to the

third roller and the folded sheet is delivered to the

delivery belt.

4 - 3 Tray Gate Malfunctions

Do solenoids Y02 and Y03 function correctly?

Y03

Y02

4-4

Does the tray gate mechanism malfunction?

Locking Screws

Y02

Tray Gate

2

Delivery

3

4

Is a jammed sheet left inside?

Check the followings:

Tray Gate

503013

4_3_1A

1. There is no jammed sheet between the

tray gate and the fold roller.

[Confirmation]

Turn off the power switch and remove the

second and fourth rollers. Put your hand from

the delivery side, and check if the sheet is

jammed between the roller and the tray gate

on the infeed side by sliding your finger along

this gap.

Tray Gate

503013

4_3_1B

Check the followings:

1. When selecting single fold for the fold pat-

tern while the motor is rotating and the

feed table is raised, the plungers of Y02

and Y03 are pulled in.

2. When performing step 1, 24 VDC is mea-

sured on the connector XY02 and XY03.

3. Wiring and connection between Y02 -

XY02 - Pin 1 and 2 of CON8 on QPM-243,

and Y03 - XY03 - Pin 5 and 6 of CON8 on

QPM-243 are OK.

Plunger

Link

Gate Lever

In case either Y02 or Y03 malfunctions, the

tray gate can be switched by the other solenoid. Although, this makes the space

between the tray gate and roller at the side

where the solenoid malfunctions, and may

cause sheet jam.

Gate Fulcrum

Shaft

503013

4_3_1C

Check the followings:

1. The locking screw on the gate fulcrum

shaft is not loosened.

2. The connection of the gate lever and the

plunger is not loosened.

3. While the power is Off, the plunger can be

moved smoothly by hand.

4. The spring on the plunger is not cut. The

spring is not deformed and falls into the

plunger hole in the solenoid.

5. The locking screws of Y02 and Y03 are

fully tightened.

Page 35

4 Mechanical Troubleshooting

Plunger

Solenoid

Spring

BLU

BLU

BLU

BLU

BLU

CON8CON8

XY02

XY01XY01

XY03

Y02

Y01

Y03

BLU

BLU

BLU

BLU

BLU

BLU

BLU

QPM-243

Control

P.C.B

Clutch Clutch

SolenoidSolenoid

4 - 4 Y01 Clutch Solenoid Does Not Activate

- When Y01 clutch solenoid is On,

the feed roller rotates continuously to feed sheets.

When Y01 is Off,

the clutch lever stops the clutch stopper rotation, and

the feed roller stops.

- When performing short fold and accordion fold, sheet

enters into the first buckle chute deeply. To prevent

the second sheet from hitting the first sheet and

causing jam, “Intermittent feeding”

Other fold patterns

When performing single fold, letter fold, cross fold

and gate buckle fold, continuous feeding

- When performing short fold and accordion fold,

Y01 is turned off every time the clutch stopper

rotates and operate “Intermittent feeding”.

- When performing single fold and other folding

patterns, Y01 is On for continuous feeding.

4

is operated.

is operated.

Mechanical Troubleshooting

Does the feed clutch mechanism malfunction?

Gap

0.5-1.0mm

(0.02" - 0.04")

Spring

Spring

Clutch Lever

Plunger

Plunger

Y01

Clutch Stopper

Bracket Locking Screw

Solenoid

Solenoid

503013

4_4_1A

Check the followings:

1. When Y01 is On, the gap between the

clutch stopper and the clutch lever is 0.5

mm (0.02") to 1.0 mm (0.04").

2. The bracket locking screw is not loosened.

3. While the power is Off, the plunger can be

moved smoothly by hand.

4. The spring of the plunger is not deformed

and falls into the plunger hole in the solenoid.

5. The locking screws for Y01 are not loos-

ened.

4 - 4 Y01 Clutch Solenoid Does Not Activate

Does the solenoid Y01 malfunction?

503013

4_4_1B

Check the followings:

1. When short fold and accordion fold are

selected, Y01 turns OFF while feeding.

2. 24 VDC is measured on the connector

XY01 for the clutch solenoid. (0V when

operating intermittent feeding and Y01

turns off.)

3. Wiring and connection between the Y01 -

XY01- Pin 3, 4 of CON8 on QPM-243 is

OK.

4-5

Page 36

4 - 5 Buckle Chute Proximity Sensor Error

4 Mechanical Troubleshooting

4 - 5 Buckle Chute Proximity Sensor Error

4-6

- The proximity sensor inside the buckle chute detects

a sheet and counts the number of feeding. If there is

paper dust on the sensor detecting area, the

machine may not operate correctly.

- B22, 2nd buckle chute proximity sensor also decides

the operating timing of the feed clutch solenoid.

- B21/22 1st/2nd buckle chute proximity sensors are

positioned in front of the buckle chute stopper, and

slow down the feed speed right before the sheet hits

against the stopper to reduce shock and noise.

503013

4_5_1A

- Be sure to remove jammed sheets in the buckle

chute completely. Otherwise, it can cause the

machine malfunction.

Is a piece of paper left in the buckle chute?

Clean the sensor for the

second stopper from here.

B22B22

Clean the sensor for the

first stopper from the top.

B21B21

Second Stopper

First Stopper

503013

4_5_1B

Check the followings:

1. There is no paper dust around the sen-

sors.

2. The locking screws of the sensors are not

loosened.

3. Wiring and connection among B21 prox-

imity sensor 1, B22 proximity sensor 2 and

Pin 5, 6, 7, 8, 9, 10 of X20 buckle connector and Pin 5, 6, 7, 8, 9, 10 of CON4 on

QPM-243 are OK.

Does the sensor detecting area get dirty?

Proximity Sensor

B21B21

Cotton

Swab

Detecting Area

503013

4_5_1C

Check the followings:

1. If the sensor activates when there is no

paper dust around the sensor, check if the

detecting area of the sensor does not get

dirty with dust.

2. Clean the detecting area using a cotton

swab, and check if the sensor activates

correctly.

3. The sensor connector is connected cor-

rectly.

4. When activating the B21 using a piece of

paper, LED L22 on QPM-243 lights.

4. The sensor bracket is not tilted.

Page 37

4 Mechanical Troubleshooting

M10

4 - 6 Delivery Belt Does Not Move

Is the tension of delivery belt loosened?

Delivery Belts

Delivery Roller

Belt Bottom Plate

Tighten the

screw at the

center of this

slot.

Tension

Shaft

503013

4_6_1A

Check the followings:

1. The tension adjusting screw is tightened in

correct position.

- If the delivery belt is loose even through the

adjusting screw is set at the farther end (exit side)

of the slot, replace the belt.

Does the delivery belt drive mechanism

malfunction?

Delivery Roller Drive Shaft

Delivery Pulley

Delivery Belts

Main Motor

M10

M10

Conveyor Pulley

503013

4_6_1B

C Snap Ring(STW-10)

Check the followings:

1. The C snap ring (STW-10) at the end of

the conveyor pulley is not removed.

2. The delivery pulley is locked using the par-

allel pin.

4

3. The delivery belt does not slip due to the

stretch.

Mechanical Troubleshooting

4 - 6 Delivery Belt Does Not Move

4-7

Page 38

4 Mechanical Troubleshooting

4-8

This page is intentionally left blank.

Page 39

5 Folding Quality Troubleshooting

5-1............... Sheets Are Wrinkled ............................................................ 5-2

5-2............... Corner of the Sheets Are Folded (Dog Ear)......................... 5-3

5-3............... Uneven Folding..................................................................... 5-4

5-4............... Fold Skewing ....................................................................... 5-5

5-5............... Delivered Sheets Are Not Neatly Stacked ........................... 5-6

5-6............... Sheet Jams at the Tray Gate ............................................... 5-7

5

Folding Quality

Troubleshooting

5-1

Page 40

5 Folding Quality Troubleshooting

A

5 - 1 Sheets Are Wrinkled

5 - 1 Sheets Are Wrinkled

5-2

503013

5_1_1

Are the sheets curled or concaved?

Curled Concaved

- The sheets immediately after printed or left in the

humid place for long time may change shape as

shown above. If these sheets pass through the rubber

rollers, sheets may get wrinkles. Instruct the operator

to flatten the sheet out or dry the sheets before folding.

503013

5_1_1B

Is the buckle chute unit installed incorrectly?

Positioning Shaft

Buckle Chute

Push the buckle chute

unit until it hits against the positioning

shaft and stops. (Buckle chute is

locked by the support shaft.)

- If the buckle chute is installed incorrectly, space

made by the fold rollers and buckle chute entrance is

increased and causes wrinkles and double step folding.

- Push the buckle chute until U-shaped gutter on the

side of the buckle chute hits against the positioning

shaft and stops.

Support Shaft

503013

5_1_1C

Is the tray gate deformed?

Tray Gate

At Center

503013

5_1_1D

Tray Gate

- If the tray gate is deformed and does not align with

the fold roller at the center, the sheet path becomes

narrower at a certain place and the resistance for

sheet transportation is greater, and cause sheet wrinkles. Remove the tray gate and correct the deformation. (Distortion: within 0.1 mm [0.004"])

- If jammed sheet on the tray gate is removed forcibly,

the tray gate can be deformed. Instruct the operator

how to remove the jammed sheet.

Third Fold Roller

IncorrectCorrect

- The wrapping of the sheets blocks the humidity. If

the wrapping is opened and left for a long time,

the sheet becomes damp from outside but dry

inside. Therefore, the sheet becomes concave.

- The recycled papers are more likely to be effected

by the humidity.

Downward

deformation

503013

5_1_1D

If the entrance of the first buckle chute is

deformed downward, folded sheet is wrinkled.

(Flatten the buckle chute.)

Upward deformation within 0.5 mm (0.02")

is not a cause for wrinkles.

Page 41

5 Folding Quality Troubleshooting

A

5 - 2 Corner of the Sheets Are Folded (Dog Ear)

Is the tray gate deformed?

503013

5_2_1

Are the jammed sheets left on the sheet path?

Joint the torn pieces of

jammed sheets together.

- When removing the jammed sheet, remove it completely without any chip left inside. When the chip of

paper is left on the sheet path, the delivered sheet

hits it and the corner is folded (dog ear).

- Instruct the operator to joint the torn pieces of sheets

together and make sure to remove all the jammed

sheets completely.

503013

5_2_1B

Tray Gate

503013

5_2_1C

At Center

Correct

Tray Gate

Third Fold Roller

Incorrect

- If the tray gate is deformed and does not align with

the folded roller at the center, the sheet path becomes

narrower at a certain point and the resistance for

sheet transportation is greater. This skews the sheet

traveling direction and the eiher corner of the sheet

hits the tray gate and folded. Remove the tray gate

and correct the deformation. (Distortion: within 0.1

mm [0.004”])

- If jammed sheet on the tray gate is removed forcibly,

the tray gate can be deformed. Instruct the operator

how to remove the jammed sheet.

5

Folding Quality

Troubleshooting

5 - 2 Corner of the Sheets Are Folded (Dog Ear)

5-3

Page 42

5 Folding Quality Troubleshooting

5 - 3 Uneven Folding

5 - 3 Uneven Folding

5-4

The sheet edges do not

align even though correct

503013

5_3 1_A

size sheet is folded in

correct setting.

Is the sheet sticky because of static?

- The sheet immediately after printed by the laser

printer at high printing speed is hot and dry because it

is compressed and delivered by the toner transferring

rollers.

Especially in winter season, the sheet becomes static

and is sticks on the metal part, such as buckle chute,

and can not reach the buckle chute stopper. In case

of the short folding pattern that the large part of the

sheet enters the buckle chute, the sheet is more likely

to be effected by the static.

[Remedy]

- The sheet printed by the high speed laser printer

should be left for a while to cool it down and adapt to

the temperature and humidity in a room before folding.

- The static is reduced by jogging the sheet using the

jogging machine.

- Lower the printing speed on the laser printer.

- Fold sheets in the silent mode (low speed).

Is the jammed sheet left in the buckle chute?

- If a chip of sheet is left in the buckle chute while

removing a jammed sheet, the folded sheets do not

hit the buckle stopper completely and the sheet is

folded incorrectly.

Does the sheet have the cross grain direction?

Cross

Grain

Direction

503013

5_3_1B

- The cross grain direction sheet as shown in the figure

above is easy to break against the feed direction. If

there is another problem such as static, the sheet

may not reach the stopper resulting in incorrect folding.

Is the sheet size incorrect?

- Measure the sheet.

The correct sheet size (long edge) is shown below.

A3 420mm

A4 297mm

B3 515mm

B4 364mm

Does stopper drive mechanism malfunction?

2nd

Buckle Chute

Handwheel

1st Buckle Chute

Handwheel

503013

5_3_1C

Check the followings:

1. The locking screw on the drive timing pulley (rear) is

fully tightened.

2. The locking screw on the drive timing pulley (front) is

fully tightened.

3. The locking screws (rear) on the stopper belt are fully

tightened.

4. The locking screws (front) on the stopper belt are fully

tightened.

5. The drive shaft collar on the second stopper is fully

tightened.

6. The drive shaft collar on the first stopper is fully tight-

ened.

503013

5_3_1D

Collar

Drive

Shaft

First Handwheel

Wave

Wave

Washer

Washer

When the stopper moves by

folding a thick sheet, tighten

the wave washer. (Reduce

the gap.)

0..5-0.8 mm

(0.02" - 0.03")

Collar

Drive

Shaft

Second

Handwheel

Page 43

5 Folding Quality Troubleshooting

A

Fold Skew

Correction Lever

5 - 4 Fold Skewing

503013

5_4_1

Are sheet guides not at right angle against the

front stop or not parallel each other?

Sheet Guide

Front Stop

Fold Skew

Fold Skew

Correction Lever

Correction Lever

Front Stop

- When a sheet is loaded along the front stop and the

sheet guides are aligned with the sheet edge, the

guides should be parallel to the sheet.

- If the sheet guides are not parallel to the sheets,

adjust the skew using the fold skew correction lever.

(Standard position of the lever is middle.)

Sheet Guide

Sheet Guide

Fold Skew

Correction Lever

Sheet Guide

503013

5_4_1B

Is the roller pressure (spring force) not even

at front and rear?

Clamp Handle

Fold Roller Spring

Roller Link

1

2

4

- The pressure of the fold roller is produced by the fold

roller spring of the roller link. If the roller shaft is positioned incorrectly in the roller support and the roller

link is pulled up forcibly using the clamp handle while

installing the second and fourth fold rollers, the fold

roller spring will be deformed. In that case, replace

the fold roller spring.

Roller Pressure

3

Roller Pressure

5

Roller Support

Fulcrum Shaft

503013

5_4_1C

Is the stopper tilted?

Sheet

Stopper

503013

5_4_1D

- Fold a sheet and adjust the stopper tilt angle,

depending on the skew of the folded sheet.

Are the fold rollers stained?

- If the duplicator printed sheet is folded before it dries

out, the ink transfers to the fold roller and changes the

friction, then results in incorrect folding.

Instruct the operator to clean the fold rollers following

the “Maintenance” in the user’s manual.

If the fold roller is worn out or deformed, sheet may be

folded askew. Check the roller condition.

5

Folding Quality

Troubleshooting

5 - 4 Fold Skewing

5-5

Page 44

5 - 5 Delivered Sheets Are Not Neatly Stacked

A

M10

Main Motor

Delivery Belts

5 Folding Quality Troubleshooting

5 - 5 Delivered Sheets Are Not Neatly Stacked

5-6

503013

5_5_1

Does the folded sheet stick each other

because of static?

- If the static is built up on sheets, they stick each other

and are not neatly stacked.

Fan the sheet well to reduce the static electricity

before folding.

503013

5_5_1B

Does the delivery belt slip?

Delivery Belts

Tension

Delivery Belt

Drive Shaft

Conveyor Pulley

Delivery

Drive Belt

Timing Belt

Main Motor

M10

M10

Drive

503013

5_5_1C

Check the followings:

1. The delivery belt is not cut.

2. The delivery belt is tensed correctly.

3. The delivery drive belt is not cut or not removed from

the conveyor pulley.

4. The set screw on the conveyor pulley is not fully tight-

ened, and the conveyor pulley slips on the delivery

belt drive shaft.

Are antistatic tapes attatched correctly?

Delivery

Section Cover

Upper Guide

Lower Guide

Antistatic Tapes

- The antistatic tapes are attached on the exit sides of

the upper/lower guides in the delivery section.

503013

5_5_1D

Page 45

5 Folding Quality Troubleshooting

5 - 6 Sheet Jams at the Tray Gate

Does tray gate mechanism malfunction?

503013

5_6_1A

Y02/Y03Y02/Y03

Plunger

Lever Bracket

Gate Lever (front)

Fulcrum Shaft

Tray Gate

Gate Holder

Check the followings:

1. The locking screws on the tray gate are not loosened.

2. The locking screw on the tray gate lever is not loos-

ened.

3. The connecting screw on the tray gate lever is not

loosened.

4. The pin which is connecting the plunger of the Y02/

Y03 solenoid and the lever bracket is not removed.

5. The locking screws on the Y02/Y03 solenoid are not

loosened.

Is the tray gate deformed?

Tray Gate

At Center

503013

5_1_1D

- If the tray gate is deformed and does not align with

the folded roller at the center, the sheet path becomes

narrower at a certain point and the delivered sheet

hits the deformed tray gate and jams. Remove the

tray gate and correct the deformation. (Distortion:

within 0.1 mm [0.004”])

- If jammed sheet on the tray gate is removed forcibly,

the tray gate can be deformed. Instruct the operator

how to remove the jammed sheet.

Tray Gate

Third Fold Roller

IncorrectCorrect

- When pushing in the plunger of the Y02/Y03 by finger, the tray gate moves smoothly.

- When changing the fold patterns by pressing the fold

pattern selecting button, the Y02/Y03 moves correctly.

5

Folding Quality

Troubleshooting

5 - 6 Sheet Jams at the Tray Gate

5-7

Page 46

5 Folding Quality Troubleshooting

5-8

This page is intentionally left blank.

Page 47

6 Electrical Circuit

6-1............... Electrical Parts Location and Description............................. 6-2

6-2............... Power Circuit Wiring Diagram and Interlock Circuit.............. 6-5

6-3............... QPM-243 Control P.C.B........................................................ 6-6

6-4............... QPW-767/QPW-768 Buckle Chute LED P.C.B..................... 6-8

6-5............... Firmware Update.................................................................. 6-10

6

Electrical Circuit

6-1

Page 48

6 - 1 - 1 Electrical Parts Location (1/3)

A

6 Electrical Circuit

6 - 1 Electrical Parts Location and Description

6-2

6 - 1 -

Electrical Parts Location (1/3)

1

S13

S10

Y02

S12

Y03

Y01

Code Name

M10 Main Motor DC 50W 6-3-2

Y01 Feed Solenoid 24 VDC 6-3-2

Y02 Gate Solenoid (front) 24 VDC 6-3-2

Y03 Gate Solenoid (rear) 24 VDC 6-3-2

S00 Power Switch

S10 Fold Section Cover Switch

S12 Feed Bar Switch - 6-3-2

Feed Table Sheet Detection Switch

S13

B21