Page 1

1

Page 2

CONTENTS

1. PREPARATION…………………………………………………………1

1.1 Precaution……………………………………………………………1

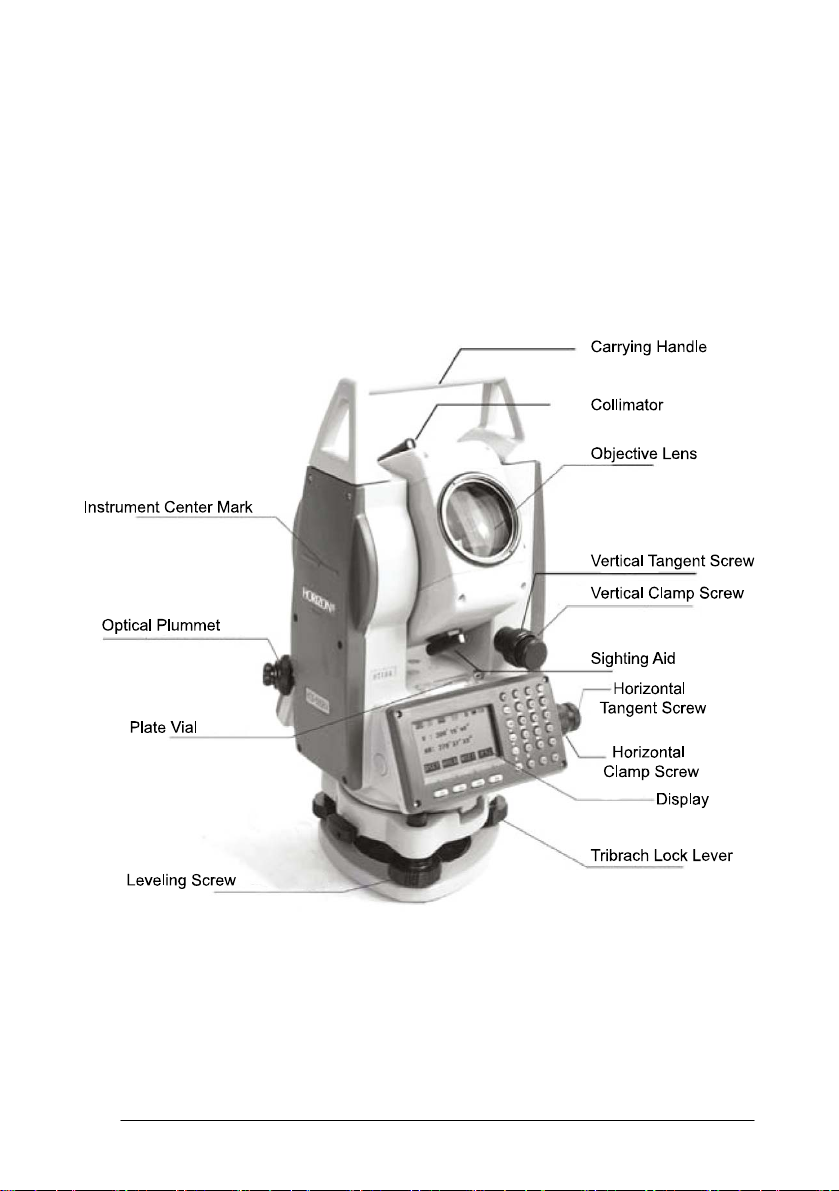

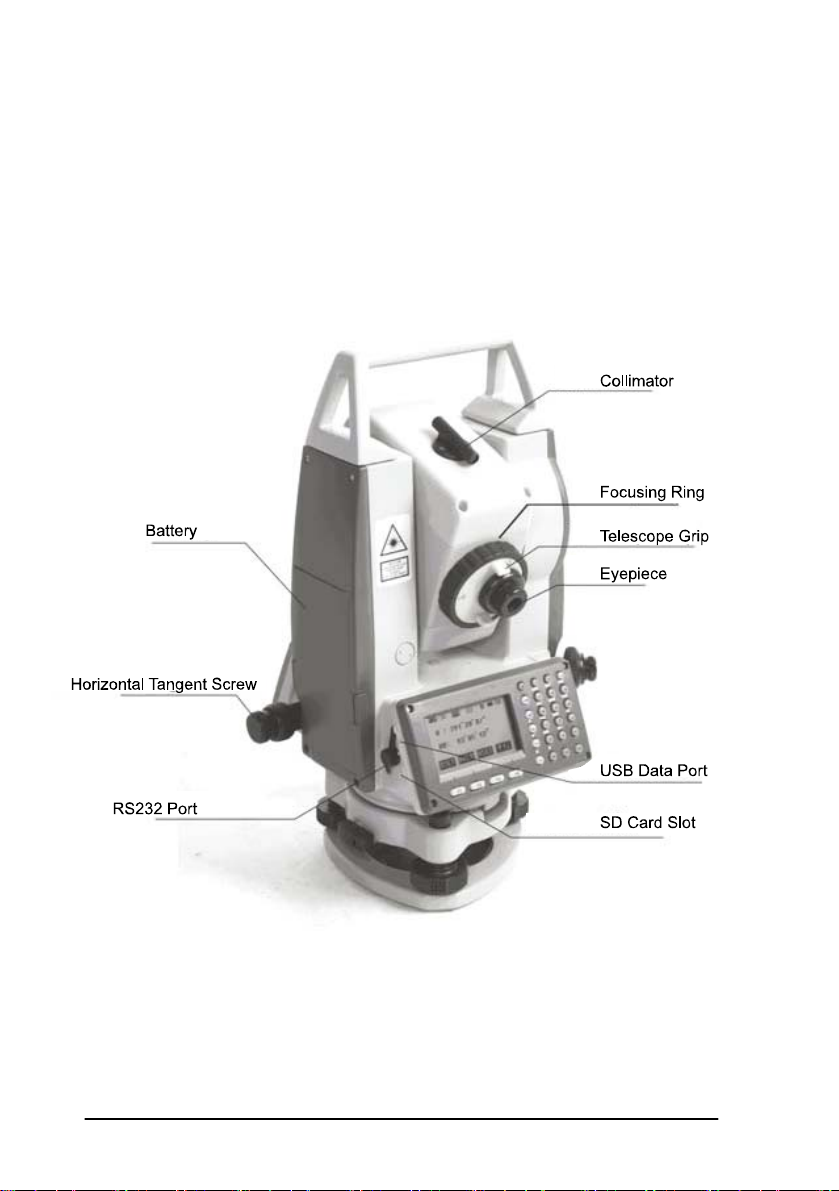

1.2 Nomenclature…………………………………………………………3

1.3 Unpacking and Storing of the Instrument……………………………5

1.4 Setting Up the Instrument …………………………………………5

1.5 Battery Removal & Insertion, Information and Recharging ………7

1.6 Reflector Prisms……………………………………………………9

1.7 Mounting and Dismounting Instrument from the Tribrach…………10

1.8 Eyepiece Adjustment and Object Sighting…………………………11

1.9 Turning On and Off………………………………………………11

1.10 How To Enter Alphanumeric Characters…………………………12

2. FUNCTION KEY AND DISPLAY……………………………………14

2.1 Operating Key……………………………………………………14

2.2 Function Key………………………………………………………16

2.3 Star-key Mode……………………………………………………19

2.4 Dot-key Mode……………………………………………………20

3. INITIAL SETTINGS…………………………………………………21

3.1 Setting of the Temperature and Air Pressure………………………21

3.2 Setting of the Atmospheric Correction……………………………22

3.3 Setting of the Prism Constant ……………………………………24

3.4 Setting of the Vertical Angle Tilt Correction………………………25

4. ANGLE MEASUREMENT……………………………………………26

4.1 Measuring Horizontal Angles Right and Vertical Angle……………26

4.2 Switching Horizontal Angle Right/Left……………………………28

4.3 Setting of the Horizontal Angle….………………………………29

2

Page 3

4.3.1 Setting by Holding the Angle………………………………29

4.3.2 Setting the Horizontal Angle from the Keypad………30

4.4 Vertical Angle Grade Percentage (%) Mode………………………31

4.5 Setting the Initial Zenith Angle…………………………………32

5. DISTANCE MEASUREMENT………………………………………33

5.1 Setting the Atmospheric Correction………………………………33

5.2 Setting the Prism Constant………………………………………33

5.3 Distance Measurement (Continuous Measurement)………………33

5.4 Changing the Distance Measurement Modes……

……………………

35

(repeat measurement / single measurement / track measurement)…35

5.5 Stake Out (S.O.)……………………………………………………36

5.6 Offset Measurement………………………………………………38

5.6.1 Angle Offset………………………………………………38

5.6.2 Distance Offset Measurement……………………………41

5.6.3 Plane Offset Measurement…………………………………43

5.6.4 Column Offset Measurement………………………………46

6. COORDINATE MEASUREMENT……………………………………49

6.1 Execution of Coordinate Measurement……………………………49

6.2 Setting the Coordinate Values of an Occupied Point……………51

6.3 Setting the Height of the Instrument……………………………53

6.4 Setting the Height of the Target (Prism Height)…………………54

7. SURVEYING PROGRAMS…………………………………………55

7.1 Remote Elevation Measurement (REM)…………………………55

7.2 Missing Line Measurement (MLM)……………………………59

7.3 Area Calculation………………………………………………65

7.4 Setting Z (elevation) Coordinate of an Occupied Point…………69

7.5 Point to Line Measurement……………………………………73

7.6 Road Measuring……………………………………………………77

3

Page 4

7.6.1 Designing Horizontal Alignment Projects………………77

7.6.2 Editing Horizontal Alignment Data………………………86

7.6.3 Importing Horizontal Alignment Data……………………88

7.6.4 Deleting Horizontal Alignment Data………………………91

7.6.5 Designing Vertical Curves…………………………………91

7.6.6 Editing Vertical Alignment Data…………………………94

7.6.7 Importing Vertical Alignment Data…………………………95

7.6.8 Deleting Vertical Alignment Data…………………………96

7.6.9 Generating a Road Coordinate File………………………97

7.6.10 Road Setting Out………………………………………97

7.6.11 Slope Setting Out………………………………………105

7.7 Layout ……………………………………………………………107

7.8 Resection…………………………………………………………107

7.9 Volume Calculation…………………………………………………108

7.10 Traverse Adjustment………………………………………………109

7.11 COGO…………………………………………………………115

7.11.1 Inverse Calculation ………………………………………115

7.11.2 Traverse Calculation………………………………………116

7.11.3 Intersection………………………………………………118

7.11.4 Calculating the bias point…………………………………121

7.11.5 Calculating the pedal………………………………………123

8. DATA COLLECTION…………………………………………………126

8.1 Operation procedure ………………………………………………127

8.2 Preparation…………………………………………………………128

8.2.1 Selecting a File for Data Collection…………………………128

8.2.2 Selecting a Coordinate File ………………………………129

8.2.3 Occupied Point and Backsight Point………………………130

8.2.4 Measuring and Memorizing the Data………………………135

4

Page 5

8.3 Data Collect Offset Measurement Mode…………………………140

8.3.1 Angle Offset………………………………………………140

8.3.2 Distance Offset Measurement……………………………143

8.3.3 Plane Offset Measurement…………………………………145

8.3.4 Column Offset Measurement………………………………148

8.4 Editing the PCODE Library [PCODE INPUT]………………………151

8.5 Setting the Parameters for Data Collection…………………………153

9. LAYOUT…………………………………………………………………154

9.1 Setting the Parameters for Data Collection………………………155

9.2 Preparation…………………………………………………………155

9.2.1 Setting the GRID FACTOR…………………………………155

9.2.2 Selecting the Coordinate Data File…………………………155

9.2.3 Setting the Occupied Point…………………………………157

9.2.4 Setting the Backsight Point…………………………………159

9.3 Executing a Layout…………………………………………………162

9.4 Setting a New Point…………………………………………………165

9.4.1 Side Shot Method……………………………………………165

9.4.2 Resection Method……………………………………………168

10. MEMORY MANAGEMENT MODE………………………………174

10.1 Choosing a Storage Medium……………………………………176

10.2 Displaying the Internal Memory Status…………………………177

10.3 Searching Data…………………………………………………177

10.3.1 Measured Data Search…………………………………178

10.3.2 Coordinate Data Search…………………………………181

10.3.3 PCODE LIBRARY Search

…………………………………

182

10.3.4 Plotting Points……………………………………………184

10.4 File Maintenance………………………………………………185

10.4.1 Renaming a File…………………………………………186

5

Page 6

10.4.2 Deleting a File……………………………………………187

10.5 Direct Key Input of Coordinate Data …………………………188

10.6 Deleting Coordinate Data from a File……………………………189

10.7 Editing the PCODE Library……………………………………191

10.8 Data Communication……………………………………………192

10.8.1 Data Communication using RS-232………………………193

10.8.1.1 Sending data……………………………………………194

10.8.1.2 Loading data……………………………………………195

10.8.1.3 Setting the parameters of data communication………197

10.8.2 Data Conversion using USB………………………………199

10.8.2.1 Data export……………………………………………199

10.8.2.2 Data import……………………………………………200

10.9 File Operation……………………………………………………200

10.9.1 Copy a file from the SD card to memory of the instrument…201

10.9.2 Copy a file from current work memory to the SD card…202

10.10 Initialization…………………………………………………………204

11. BASIC SETTINGS…………………………………………………206

11.1 Setting Units……………………………………………………206

11.2 Parameter Settings………………………………………………208

11.2.1 Setting of the Tilt Sensor …………………………………208

11.2.2 Setting of the W-Correction………………………………209

11.2.3 Setting of the Grid Factor…………………………………211

11.2.4 Setting of the Least Angle Display………………………213

11.2.5 Setting of the Vertical Angle Display……………………214

11.2.6 Setting of the plotting points number………………………214

11.2.7 Setting Distance Range Mode…………………………215

11.2.8 Automatic compensation for temperature and air pressure

…………………………………………………………………………216

6

Page 7

11.3 Setting Measuring Mode Display………………………………217

11.4 Setting the Shortcut Keys…………………………………………217

11.5 Other Settings……………………………………………………218

11.5.1 Auto Power Off……………………………………………218

11.5.2 Choosing the Battery Type………………………………219

11.5.3 Reset the Instrument to Factory Settings…………………220

11.5.4 Selecting a Language………………………………………220

11.6 Date and Time……………………………………………………221

11.7 Adjusting the LCD Display Contrast……………………………222

12. CHECK AND ADJUSTMENT………………………………………223

12.1 Plate Vial …………………………………………………………223

12.2 Circular Vial………………………………………………………224

12.3 Inclination of the Reticle…………………………………………225

12.4 Perpendicularity of the Line of Sight to the Horizontal Axis (2c)…226

12.5 Vertical Index Difference Compensation………………………227

12.6 Adjustment of Vertical Index Difference (I angle) and Vertical…228

12.7 Optical Plummet…………………………………………………230

12.8 Laser Plummet (optional)…………………………………………232

12.9 Instrument Constant (K)…………………………………………232

12.10 Parallel check for Line of Sight and Emitting Photoelectric

Axis …………………………………………………………………234

12.11 Tribrach Leveling Screw………………………………………234

13. ERROR DISPLAYS…………………………………………………235

14. SAFETY INSTRUCTIONS…………………………………………237

14.1

14.2 Laser Plummet……………………………………………………239

15. ACCESSORIES………………………………………………………240

Integrated EDM……………………………………………237

7

Page 8

1. PREPARATION

1.1 Precautions

1. Never point the instrument at the sun without a filter.

2. Never store the instrument in extreme temperatures and avoid sudden

changes of temperature.

3. When not using the instrument, place it in the case to avoid shock, dust, and

humidity.

4. If there is a Significant difference in temperature between the work site and

the instrument storage location leave the instrument in the case until it adjusts to the

temperature of the surrounding environment.

5. Please remove the battery for separate storage if the instrument is to be in

storage for an extended time. The battery should be charged once a month during

storage.

6. The instrument should be placed in its carrying case during transportation. It

is recommended that the original packing case be used for cushioning during

extended transportation.

7. Be sure to secure the instrument with one hand when mounting or removing

from the tripod.

8. Clean exposed optical parts with degreased cotton or lens tissue only.

9. Clean the instrument's surface with a woolen cloth when finished with use.

Dry it immediately if it gets wet.

10. Check the battery, functions, and indications of the instrument as well as its

initial setting and correction parameters before operating.

8

Page 9

11. Unless you are a maintenance specialist do not attempt to disassemble the

instrument for any reason. Unauthorized disassembly of the instrument can result in

a void warranty.

12. The HTS580AGX/ARX total stations emit a laser during operation. DO

NOT stare into the beam or laser source when instrument is operation.

9

Page 10

1.2 Nomenclature

10

Page 11

11

Page 12

1.3 Unpacking and Storage of the Instrument

Unpacking of the Instrument

Place the case lightly with the cover upward, unlock the case and take out the

instrument.

Storage of the Instrument

Replace the cover on the telescope lens, place the instrument into the case with

the vertical clamp screw and circular vial upward (objective lens toward the tribrach),

tighten the vertical clamp screw, close and lock the case.

1.4 Instrument Set Up

Mount the instrument onto the tripod and secure firmly. Level and center the

instrument precisely to ensure the best performance. Use a rugged tripod with a 5/8”

tripod screw. Our Fiberglass SL180FGB tripods are recommended.

Operation Reference: Leveling and Centering the Instrument

1). Setting up the tripod

First extend the extension legs to suitable length and tighten the screws, firmly

plant the tripod in the ground over the point of beginning.

2). Attaching the instrument to the tripod

Secure the instrument carefully on the tripod and slide the instrument by

loosening the tripod mounting screw. If the optical plumb site is positioned over the

center of the point tighten the mounting screw.

3). Roughly leveling the instrument by using the circular vial

Turn the leveling screw A and B to move the bubble in the circular vial, in

which case the bubble is located on a line perpendicular to a line running through

12

Page 13

the centers of the two leveling screw being adjusted. Turn the leveling screw C to

move the bubble to the center of the circular vial. Recheck the position of the

instrument over the point and adjust if needed.

4). Leveling by using the plate vial

Rotate the instrument horizontally by loosening the Horizontal Clamp Screw

and place the plate vial parallel with the line connecting leveling screws A and B,

then bring the bubble to the center of the plate vial by turning the leveling screws A

and B.

Rotate the instrument 90° (100g) around its vertical axis and turn the

remaining leveling screw or leveling C to center the bubble once more.

Repeat the procedures for each 90° (100g) rotation of the instrument and

check whether the bubble is correctly centered in all directions.

5). Centering by using the optical plummet(or laser plummet)

Adjust the eyepiece of the optical plummet telescope to your eyesight. Slide the

instrument by loosening the tripod screw; place the point on the center mark of the

optical plummet. Sliding the instrument carefully as to not rotate the axis will allow

you to get the least dislocation of the bubble.(Place star-key after power on, then

press F4(LASER)key, press F1(ON)key to turn on the laser plummet. Slide the

instrument by loosening the tripod screw; Place laser facular on the occupied

pointing, Sliding the instrument carefully as to not rotate the axis will allow you to

get the least dislocation of the bubble. The last, press ESC key, and laser plummet

turn off automatically.)

6). Complete leveling the instrument

Level the instrument precisely as in Step 4. Rotate the instrument and check to

see that the bubble is in the center of the plate level regardless of the telescope

13

Page 14

direction, then tighten the tripod screw firmly.

1.5 Battery Removal & Insertion - Information and

Recharging

Battery removal & insertion

Insert the battery into the battery slot and push the battery until it clicks.

Press the right and left buttons of the battery compartment to remove the

battery.

Battery information

------------- Indicates that battery is fully charged

------------- Indicates that the battery can only be used for

about 1 hour.

Recharge the battery or prepare a recharged battery for

use.

------------- Recharge the battery or prepare a recharged

battery for use.

Note: The working time of the battery is determined by environment conditions,

recharging time, and other factors.

Battery Recharging

14

Page 15

Battery should be recharged only with the charger supplied with the instrument.

Remove the on-board battery from instrument as instructed and connect to the

battery charger.

Battery Removal Caution

▲Before you take the battery out of the instrument, make sure that the power is

turned off. Otherwise the instrument can be damaged.

Recharging Caution:

▲The charger has built-in circuitry for protection from overcharging. However,

do not leave the charger plugged into the power outlet after recharging is completed.

▲Be sure to recharge the battery at a temperature of 0℃~45℃, recharging

may be abnormal beyond the specified temperature range.

▲When the indicator LED does not light after connecting the battery and

charger the battery or the charger may be damaged.

Storage Caution:

▲The rechargeable battery can be repeatedly recharged 300-500 times.

Complete discharge of the battery may shorten its service life.

▲In order to get the maximum service life be sure to recharge the battery at

least once a month.

15

Page 16

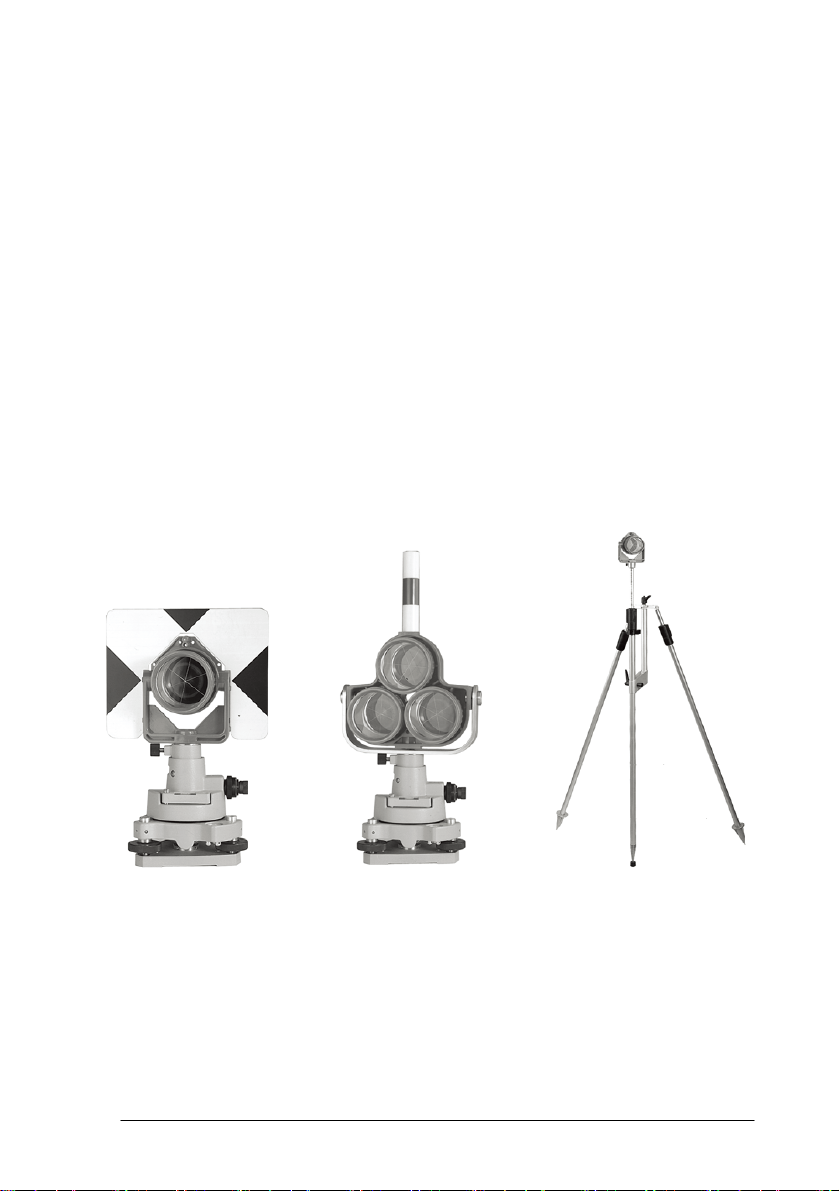

1.6 Reflector Prisms

When doing distance measuring in prism mode a reflector prism needs to be

placed as the target. Reflector systems can be single or multiple prisms which can be

mounted with a tripod/tribrach system or mounted on a prism pole. Unique mini

prism systems allow setups at corners that are hard to reach. Reflectorless targets

extend the range of the instrument when used in reflectorless mode.

Illustrated are some prisms and a reflector compatible with instruments:

16

Page 17

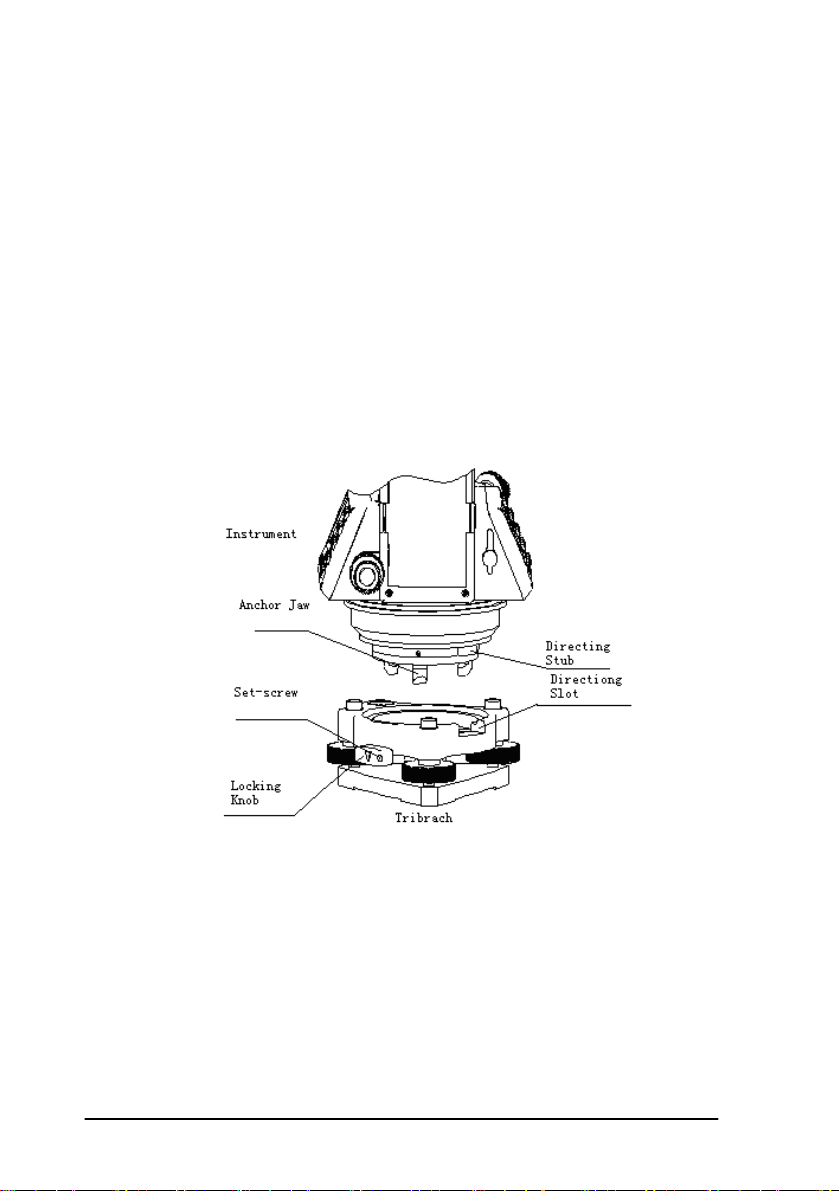

1.7 Mounting and Dismounting the Instrument from the

Tribrach

Dismounting

When necessary the instrument can be dismounted from the tribrach. Loosen

the tribrach locking screw in the locking knob with a screwdriver if necessary. Turn

the locking knob 180 degrees counter-clockwise to disengage anchor jaws and

remove the instrument from the tribrach.

Mounting

Insert three anchor jaws into holes in tribrach and line up the directing stub on

the instrument with the directing slot of the tribrach. Turn the locking knob 180

degrees clockwise and tighten the locking screw with a screwdriver.

17

Page 18

1.8 Eyepiece Adjustment and Object Sighting

Method of Object Sighting (for reference)

Sight the telescope to the sky and rotate the eyepiece tube to make the reticule

clear.

Collimate the target point with top of the triangle mark in the collimator.

(keep a certain distance between eye and the collimator).

Make the target image clear with the telescope focusing screw.

If there is parallax when your eye moves up and down or left and right this

indicates the diopter of the eyepiece lens or focus is not adjusted well and accuracy

will be effected. You should readjust the eyepiece tube carefully to eliminate the

parallax.

1.9 Turning the instrument On and Off

Power on

1. Be sure that the instrument is leveled.

2. Press and momentarily hold the power (POWER) key.

3. Rotate the EDM head in an upwards direction to initialize.

4. To turn OFF press and hold the power key until instrument powers down.

Be sure there is sufficient battery power. If 'Battery Empty' is shown on the

display, the battery should be recharged or replaced.

*** DO NOT remove the battery during measuring, otherwise the data will be lost

and the instrument could be harmed!! ***

18

Page 19

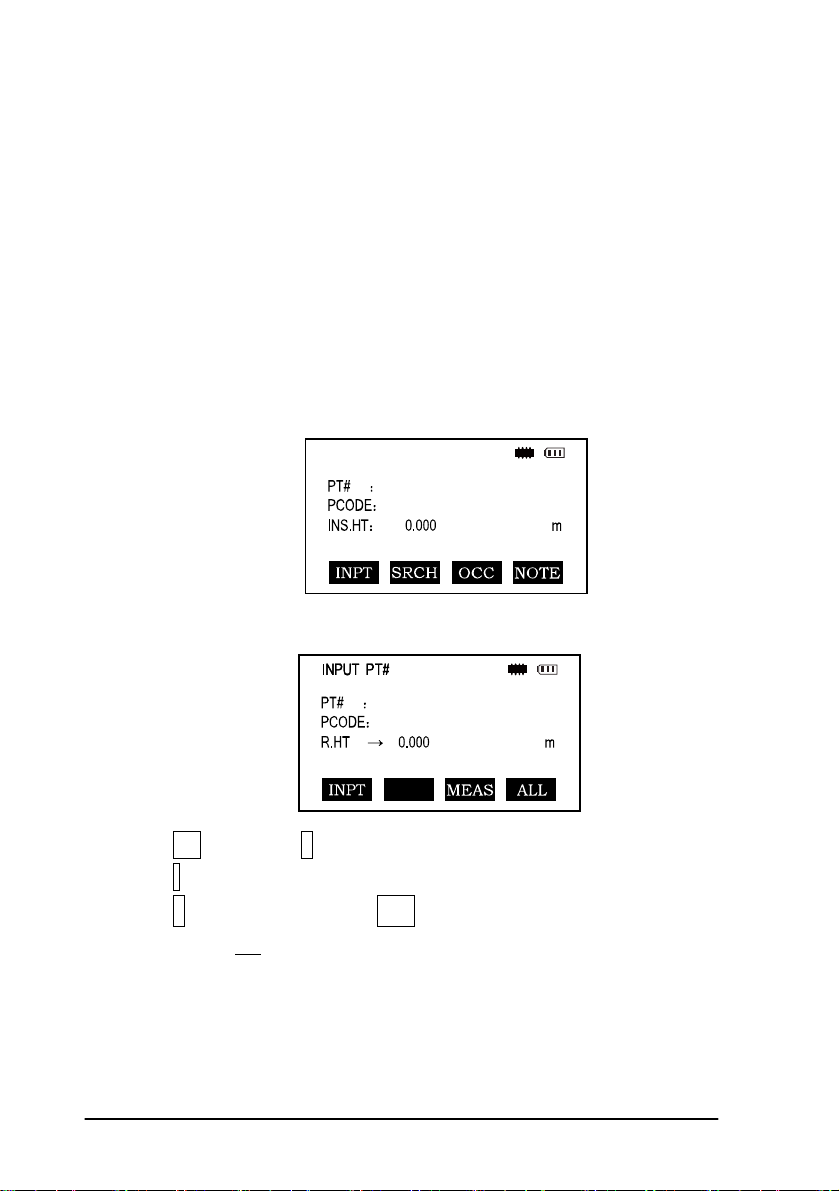

1.10 How To Enter Alphanumeric Characters

*How to select an item

[Example 1] Select INS.HT (instrument height) in the data collection mode

(first press the MENU button then F1: COLLECT DATA and then select the data file

desired. Press F2 to list, the arrow keys to choose and then F4 to select). Press F1

again for OCC.PT# INPUT.

The arrow (

line up or down

Press [▼] move->R..HT

Press F1 INPUT then 1 to input“1”

Press . to input “. ”

Press 5 to input “5 ”, press ENT

Then R. HT =1.5 m

→) indicates an item to enter. Press [▲] [▼] key to move the arrow

19

Page 20

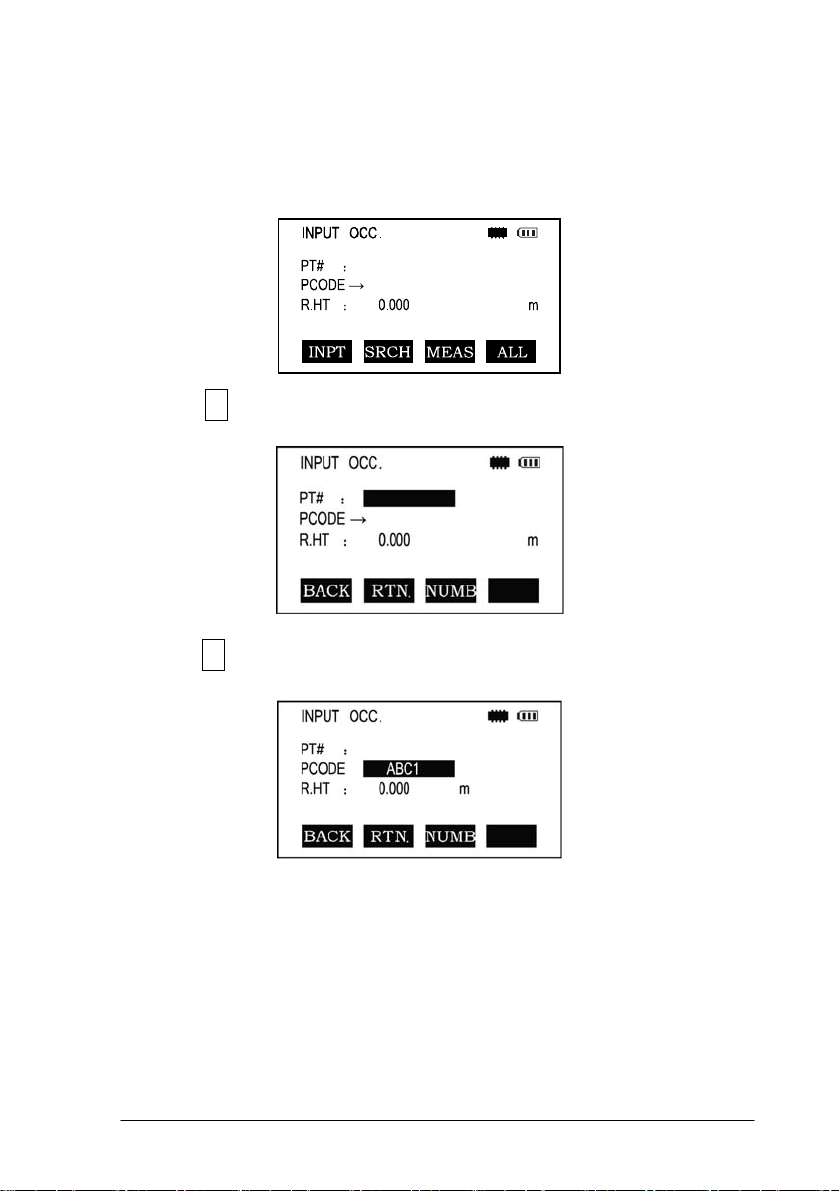

*How to enter characters

[Example 2] Input the code “ABC1”of instrument point in Data Collection Mode.

1.Move the arrow to PCODE using the [▲]or [▼]key

2.Press F1 (input) key

3.Press F1 key once

Press [7] key once for “A”

Press [7] key twice for “B”

Press [7] key three times for “C”

Press [1] key once for “1” (*Press F3 to switch to NUMB mode first)

Press enter key to finish input

20

Page 21

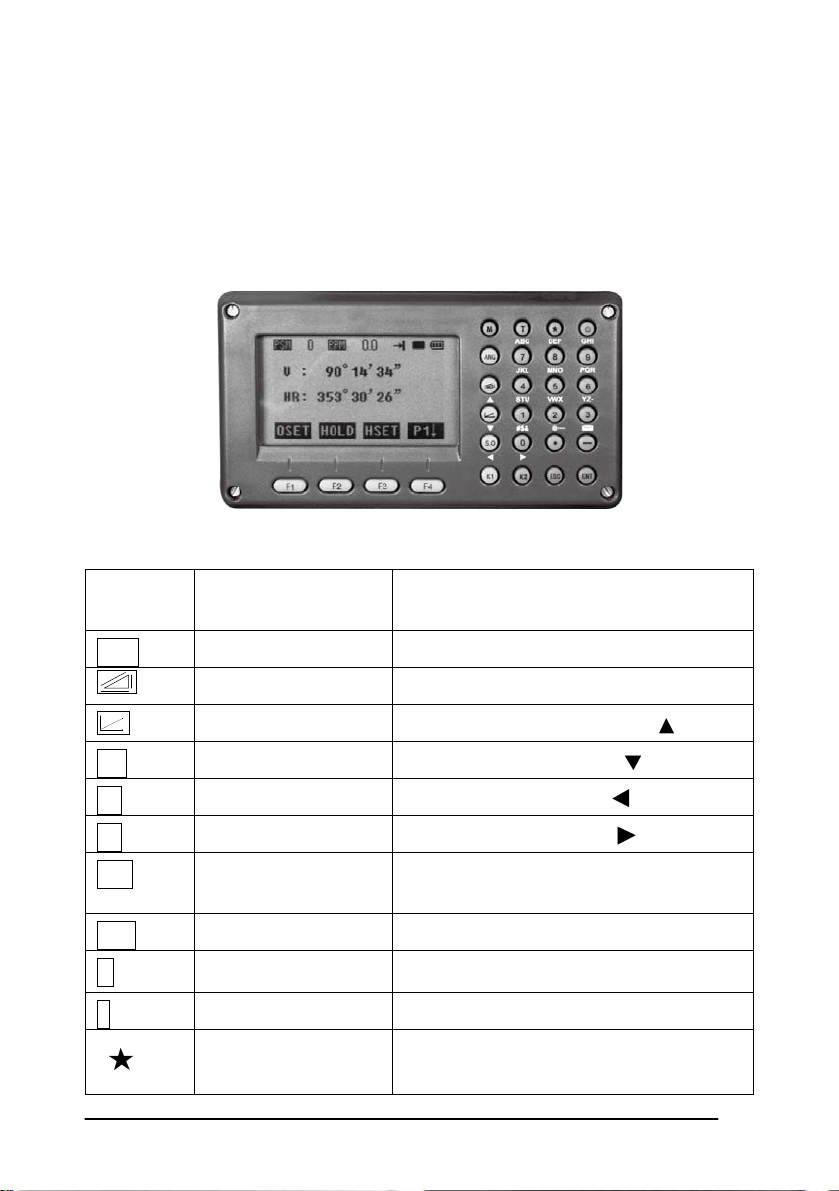

2. FUNCTION KEY AND DISPLAY

2.1 Operating Key

Keys Names Function

ANG Angle meas. key Angle measurement mode

Distance meas. key Distance measurement mode

Coordinate meas. key

Coordinate measurement mode (

Up)

S.O Layout key Layout measurement mode ( Down)

K1 Quick key1 User-defined quick key 1( Left)

K2 Quick key 2 User-defined quick key 2( Right)

ESC Escape key

ENT Enter key

M Menu key Switches menu mode and normal mode

T Shift key Shift distance measuring key

Star key

Return to the measurement mode or

previous layer mode.

Press after confirmation of inputting values

Press once to adjust contrast or twice for

illumination of keypad

21

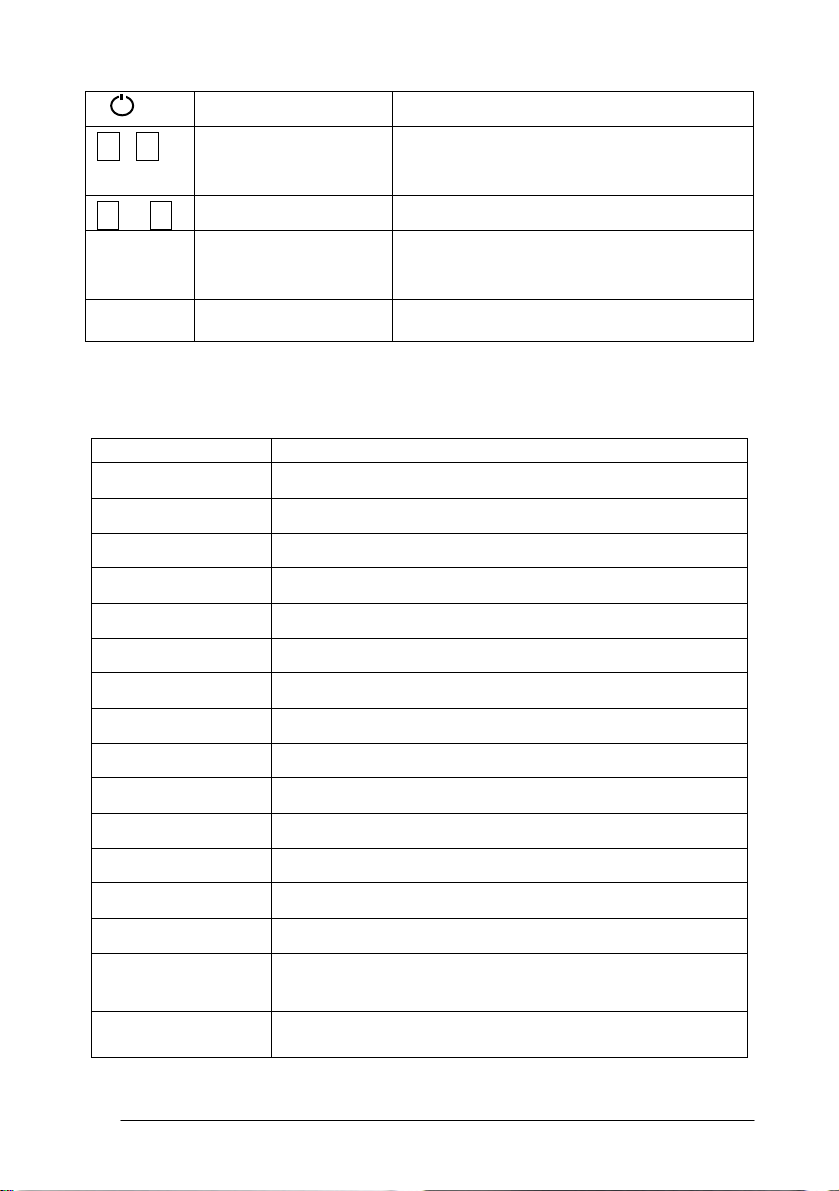

Page 22

Power key On / Off key press and hold

F1- F4 Soft key ( Function

key)

0- 9 Number key Input numbers

— Minus key Input minus sign, displays electronic

. Point key On / Off laser pointing function

Display marks:

Display Content

V Vertical angle

V% Vertical angle as a percentage (Gradient display)

HR Horizontal angle (right)

HL Horizontal angle (left)

HD Horizontal distance

VD Elevation difference

SD Slope distance

Responds to the message displayed

bubble

22

N North coordinate

E East coordinate

Z Z or elevation coordinate

* EDM working

m/ft Switches units between meters and feet

m Meter unit

S/A Sets temperature, air pressure, prism constant

PSM Prism constant (unit:mm)

PPM Atmospheric correction

Page 23

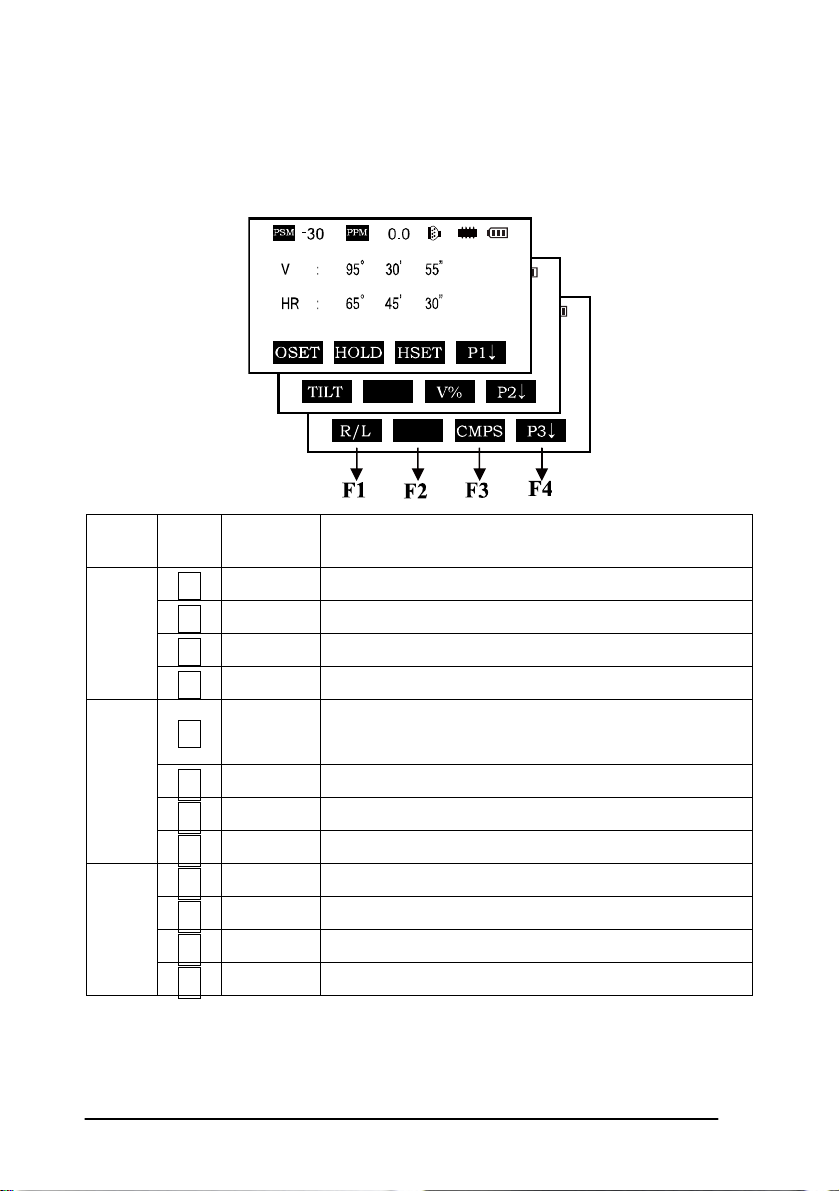

2.2 Function Key

Angle measurement mode (three-page menu)

Page Keys

P1

P2

P3

Display

marks

Function

F1 0SET Horizontal angle is set to 0°0′0″

F2 HOLD Hold the horizontal angle

F3 HSET Set a required horizontal angle by entering numbers

F4

F1 TILT

P1↓ Scroll to the next page (P2)

Tilt correction screen. If the correction is turned on

the display will show the tilt correction value.

F2

F3 V% Vertical angle percent grade (%) mode

F4

P2↓ Scroll to the next page (P3)

F1 R/L Switches Right/Left rotation of horizontal angle

F2

F3 CMPS Switches vertical angle “0” position

F4

P3↓ Scroll to the next page (P1)

23

Page 24

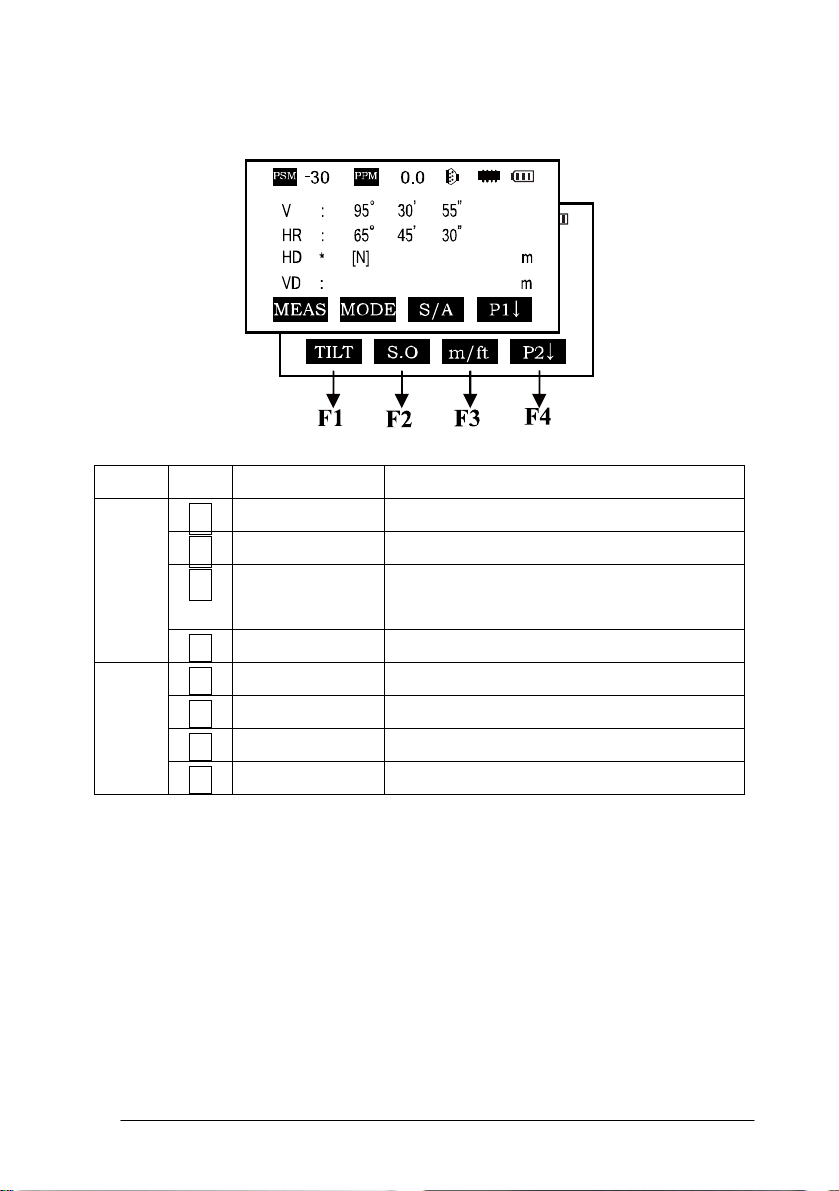

Distance measurement mode (two-page menu)

Page Keys Display marks Function

F1 MEAS Begin measuring

P1

F2 MODE Sets measuring mode, Fine/--/Tracking

F3 S/A Sets temperature, air pressure, prism

constant

P1↓ Scroll to the next page (P2)

P2

F4

F1 OFSET Selects Off-set measurement mode

F2 S.O. Selects Stake Out measurement mode

F3 m / ft Switches units between meters and feet

F4

P2↓ Scroll to the next page (P1)

24

Page 25

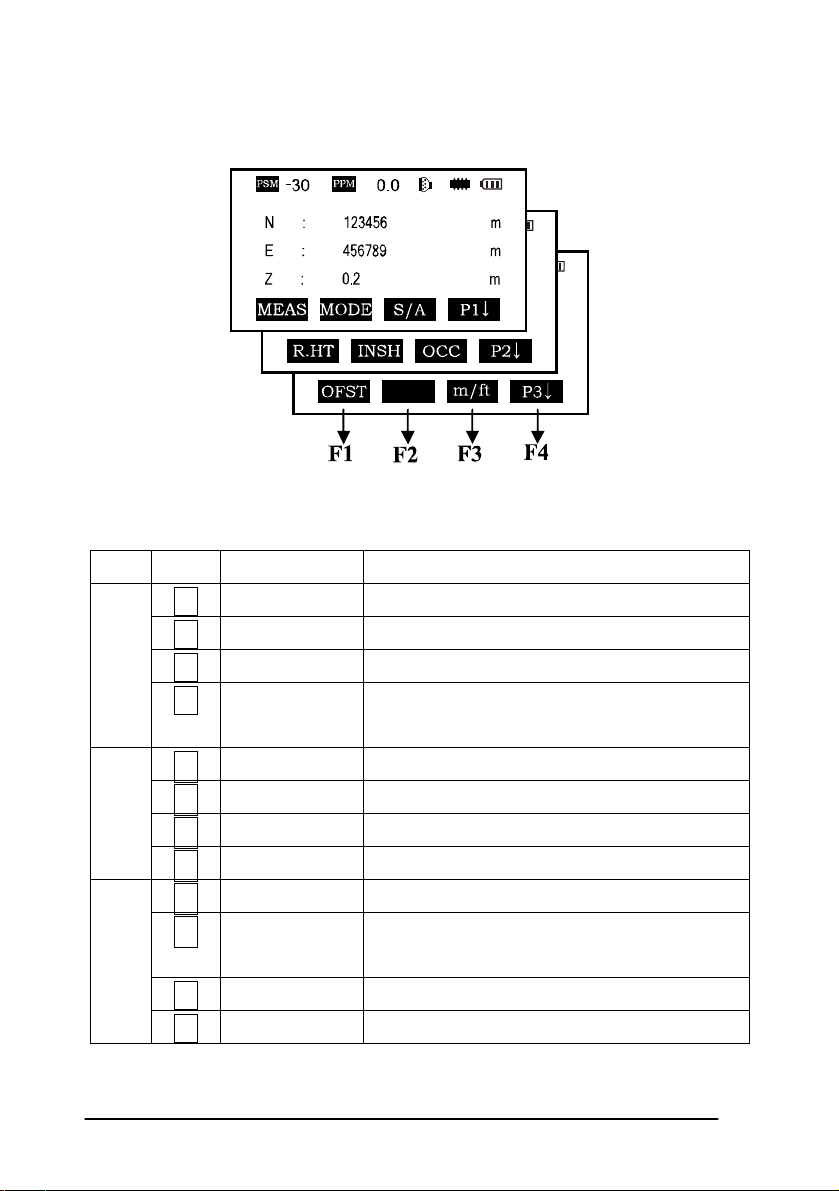

Coordinate measurement mode(three-page menu)

Page Keys Display marks Function

F1 MEAS Start measuring

P1

P2

P3

F2 MODE Sets a measuring mode, Fine/Tracking

F3 S/A Sets temperature, air pressure, prism constant

F4

P1↓ The function of soft keys is shown on next

page (P2)

F1 R.HT Sets prism height

F2 INSHT Sets instrument height

F3 OCC Sets instrument coordinate.

F4

P2↓ Shows the function of soft keys on page 3

F1 OFSET Off-set measurement mode

F2 BACKSIGHT Setting a direction angle for backsight

orientation

F3 m / ft Switches meter and feet unit.

F4

P3↓ Shows the function of soft keys on page1

25

Page 26

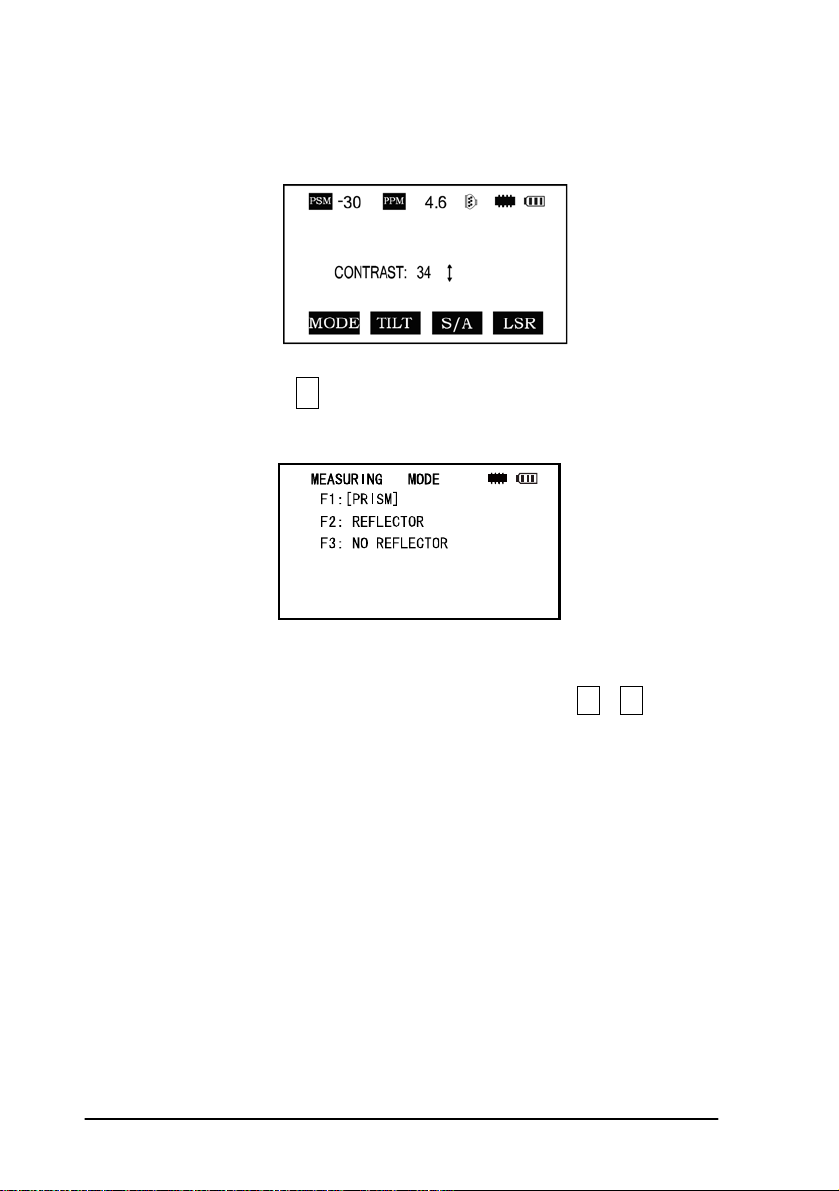

2.3 star-key mode

The total station(non-reflectorless):

Press the star key , following is displayed:

1. Contrat adjustment: After pressing star key, adjust the display contrast by

pressing [▲] or [▼] key.

2. Illumination: After pressing star key, select [Illumination] by pressing

F1(LAMP) key or press star key.

3. Tilt: After pressing star key, select [tilt] by pressing F2 (TILT) key, and

select ON or OFF by pressing F1 or F3 key, press F4 (ENT) key.

4. S/A: After pressing star key, select [S/A] by pressing F3 (S/A) key, then you

can set Prism contrast, air pressure and temperature.

5. Laser plummet: If total station has this function, after pressing star key,

select [laser] by pressing F4 (LSR) key, and select ON or OFF by pressing F1 or F2

key.

*In some interface, you can turn on or turn off panel backlight by press star key

directly.

26

Page 27

The total station(with reflectorless):

Press the star key , following is displayed:

1.Mode: Press the F1 (mode) key, the following is displayed :

You can select the type of measure mode by pressing the F1—F3 keys.

2.You can turn on the lamp by pressing the star key once more or by pressing

twice from any menu.

2.4 Dot-key Mode

The total station can function as a laser pointer

The laser pointer can be turned on or off by pressing the (.) dot key.

27

Page 28

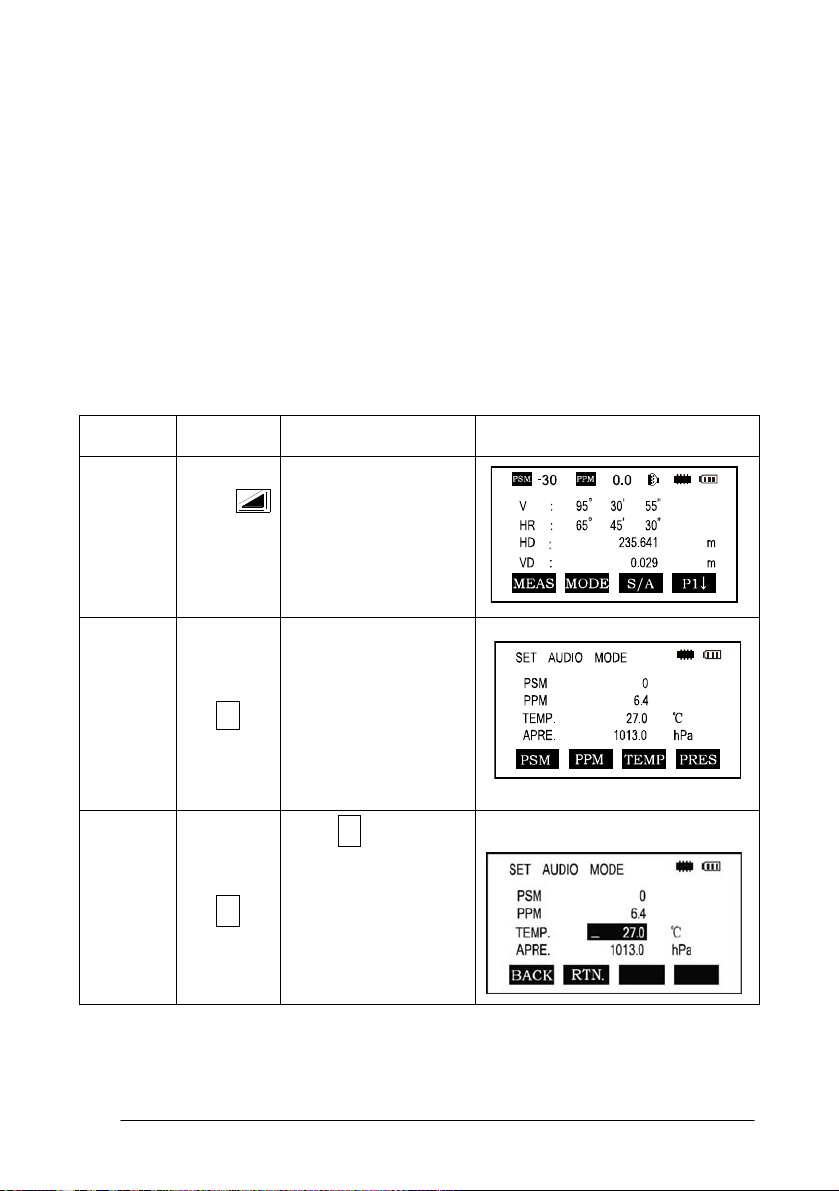

3. INITIAL SETTINGS

The series total station can be reset to the instruments original factory settings.

See Section 11 “Basic Settings”

3.1 Setting the Temperature and Atmospheric

Pressure

Measure the surrounding temperature and air pressure in advance. Example:

temperature +25°, air pressure 1017.5 hPa

Procedure

Temp.

Settings

Operation Operating procedure Display

F3

F3

Enter the Distance

Measurement Mode

Press F3 to enter the

S/A screen

Press F3 to enter

temperature section,

enter the correct

temperature, press

the ENT key to set

28

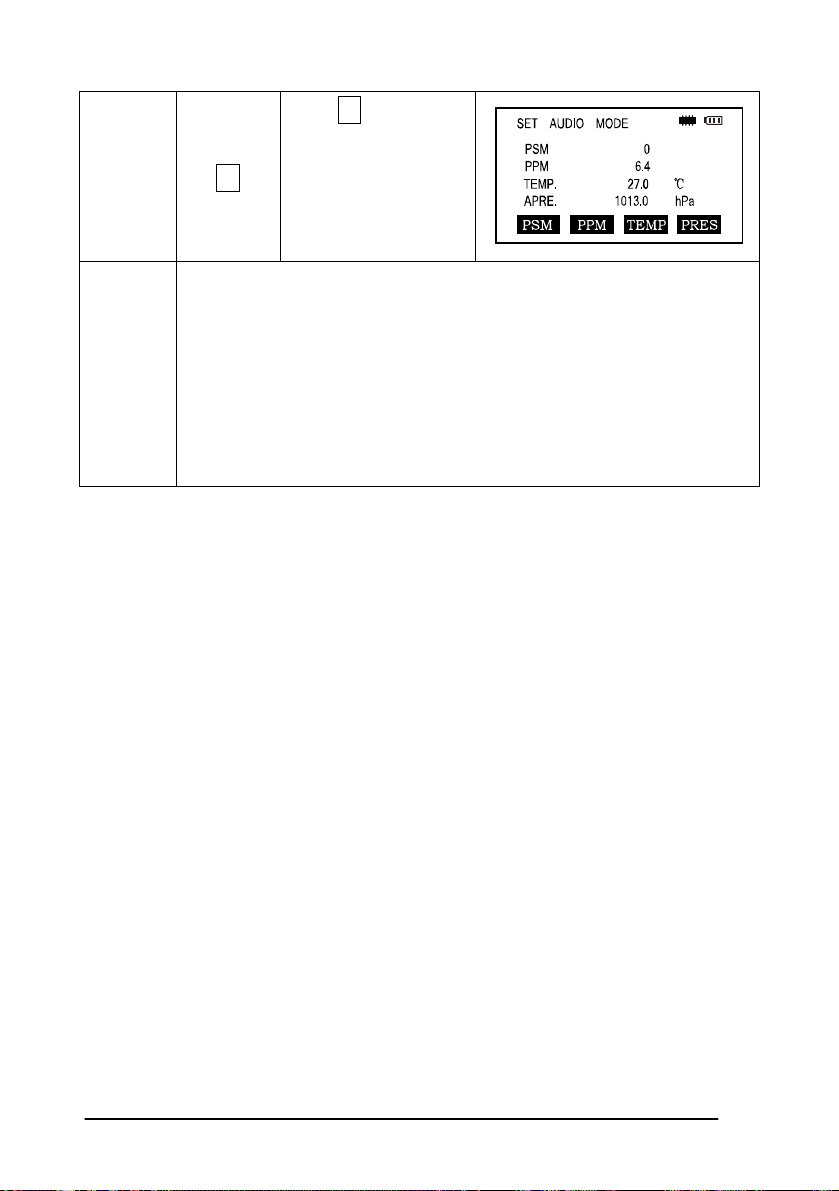

Page 29

Atms.

Pressure

F2

Press F2 key and

enter the air pressure,

press the ENT key to

confirm

Remar

ks

Temperature operating range:-30°~+60℃ or -22~+140℉

Air pressure:560~1066 hPa or 420~800 mmHg or 16.5~31.5 inHg

If the atmospheric correction value calculated from the temperature

and air pressure exceeds the range of ±999.9PPM,the operation will

return to step 4 automatically, and you should enter the data again.

3.2 Setting of the Atmospheric Correction

The infrared emitted by the Total Station varies with the air temperature and

pressure. Once the atmospheric correction value is set the instrument will correct

the distance measuring result automatically.

Air pressure: 1013hPa

Temperature: 20℃

The calculation of atmospheric correction :

ΔS =273.8 0.2900 P / ( 1 + 0.00366T )(ppm)

ΔS:Correction Coefficient (Unit ppm)

P: Air Pressure (Unit : hPa If the unit is mmHg , please convert using

1hPa = 0.75mmHg

T: temperature ( unit℃)

29

Page 30

Direct Setting Method of Atmosphere Correction Value

After measuring the temperature and air pressure the atmosphere correction

value can be obtained from an atmospheric correction chart or correction formula

(PPM).

Procedure

F2

*1)See 2.10“How to Enter Alphanumeric Characters”

Input range:-999. 9PPM to +999. 9 Step length: 0 .1PPM

*2) If Temperature and Atmospheric Pressure are reset, the PPM will be

recalculated automatically.

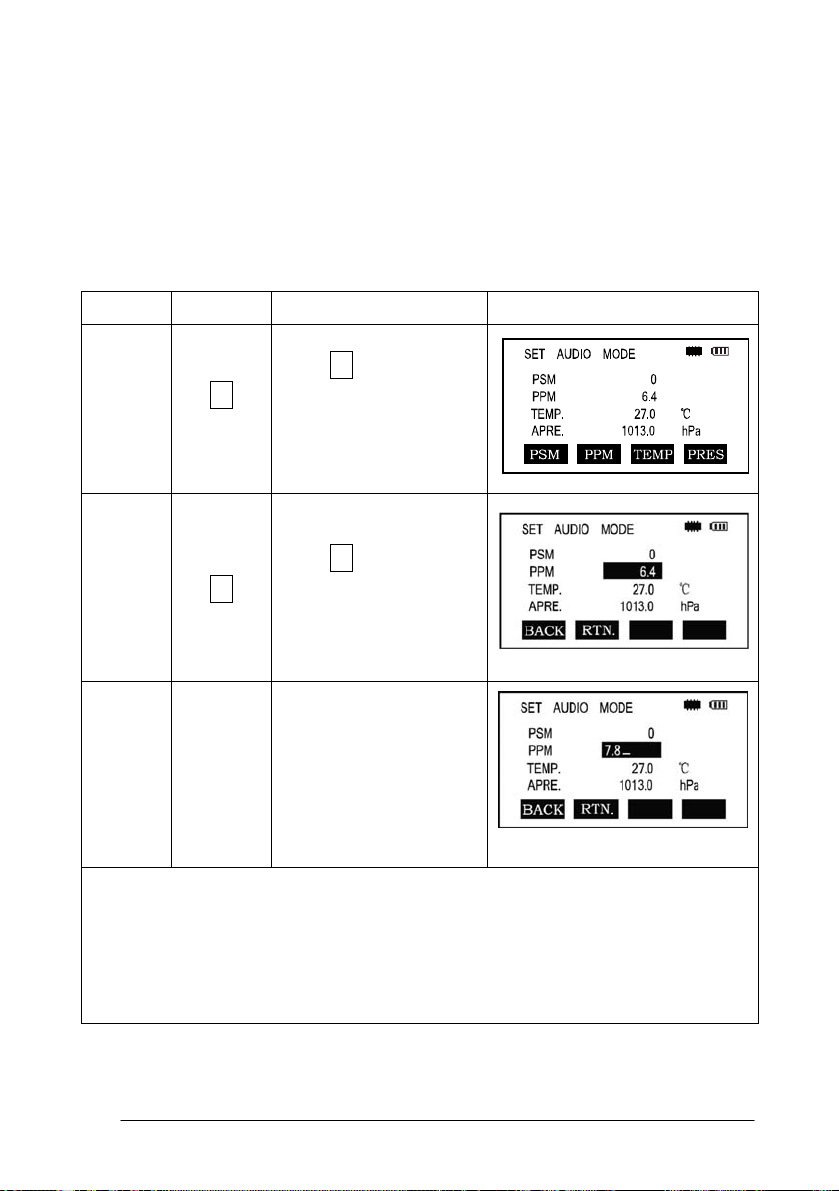

Operation

F3

Enter

value

Operation Procedure Display

Press F3 Key in

distance measurement

or coordinate

measurement mode

Press F2 [ppm] key,

which shows the current

setting value

Enter atmospheric

correction and press

ENT

30

Page 31

3.3 Setting of the Prism Constant

In the factory the prism constant for the total station is set at -30mm. If the

constant of the prism used is not -30mm, you must change this setting. Once the

prism constant is set it will become the new default value until changed.

Procedure Operation Operation Procedure Display

Press F3 ( S/A ) Key

in Distance

F3

② F1

③

Input range:-99. 9mm to +99. 9mm Step length 0. 1mm

Enter

data

Measurement Mode

or Coord.

Measurement Mode.

② Press F1(PRISM)

key

Press F1 (INPUT) key

to enter the Prism

Constant correction

value. *1, press F4 to

confirm and return to

the Setting Mode.

*The total station in reflectorless measuring mode sets the prism constant to 0

automatically.

31

Page 32

3.4 Setting of the Vertical Angle Tilt Correction

When the tilt sensor is activated the instrument automatically corrects the

vertical angle for mislevel. To ensure a precise angle measurement the tilt sensor

must be turned on. The tilt sensor display can also be used to fine level the

instrument. If the (“X TILT OVER”) display appears the instrument is out of the

automatic compensation range and must be leveled manually to within tolerances.

The instruments compensates the vertical angle reading due to inclination of

the standing axis in the X direction.

When the instrument is on an unstable footing or used during a windy day the

display of vertical angle can be unstable. You can turn off the auto tilt correction

function in this case.

Setting the tilt correction

The instrument memorizes the last setting for this feature. To insure the compensator

is on check this setting before operating the instrument.

For operation procedures refer to 11.2.1.

32

Page 33

4.ANGLE MEASUREMENT

4.1 Measuring Horizontal Angle Right and Vertical

Angles

Make sure the angle measurement mode is selected.

Operation procedure Operation

①Collimate the first target

Collimate A

(A)

To set horizontal angle of

target A at 0

00 ’ 00" press the F1

(0SET) key and then press

the F4 (YES) key

③ Collimate the second

target (B)

Collimate B

The required V/H angle to

target B will be displayed

Display

F1

F4

Note : The horizon angle will be saved when the instrument is powered off and

displayed when powered on.

33

Page 34

Reference: How to Collimate

Point the telescope toward a light surface or sky. Turn the diopter ring and adjust the

diopter so that the cross hairs are clearly observed.

Aim the target at the peak of the triangle mark of the sighting collimator. Allow a

certain space between the sighting collimator and yourself for collimating.

Focus the target with the focusing knob.

If parallax is created between the cross hairs and the target when viewing vertically

or horizontally while looking into the telescope, focusing is incorrect or diopter

adjustment is poor.

This adversely affects precision in measurement please eliminate the parallax by

carefully focusing and using the diopter adjustment.

34

Page 35

4.2 Switching Horizontal Angle Right/Left

Make sure the angle measurement mode is selected.

Operation procedure Operation

Press the F4 Key twice to get the

menu to page 3. (P3)

F4

twice

Display

Press the F1(R/L)key.

The Horizontal Right angle mode

F1

(HR) Switches to Horizontal Left

mode (HL)

Measure as HL mode

*Each time the F2 (R/L) key is pressed the HR/HL mode switches

35

Page 36

4.3 Setting of the Horizontal Angle

4.3.1 Setting by Holding the Angle

Make sure the angle measurement mode is selected.

Operation procedure Operation Display

①Set the required horizontal

Display

angle using the horizontal

angle

tangent screw

②Press the F2 (HOLD)key

③Collimate the target Collimate

④Press the F4 (YES) key to

finish holding the horizontal

angle, the display turns back to

the normal

angle measurement mode

*To return to the previous mode, press the ESC key.

F2

F4

36

Page 37

4.3.2 Setting the Horizontal Angle from the Keypad

Make sure the angle measurement mode is selected.

Operation procedure Operation

①Collimate the target Collimate

②Press the F3 (HSET) key

F3

③Input the required horizontal

angle by using the keys, for

example:

150.10.20, inputs

150.10.20

150 10′20″.

ENT

Press ENT

Carry on normal measurement

after entering the required

horizontal angle

Display

37

Page 38

4.4 Vertical Angle Percent Grade (%) Mode

Make sure the angle measurement mode is selected.

Operation procedure Operation

Press F4 key to get the

function on menu page

P2

Press the F3(V%)key * F3

*Each time the F3(V%)key is pressed the display mode switches.

When the angle measured is over 45°(100%)from the horizontal <OVERTOP>

is displayed.

F4

Display

38

Page 39

4.5 Setting the Initial Zenith Angle

Vertical angle is displayed as shown below:

Make sure the angle measurement mode is selected.

Operation procedure Operation Display

Press F4 key twice to get the

menu on page 3 (P3):

F4

twice

Press the F3(CMPS)key * F3

* Each time the F3 key is pressed the display mode switches.

39

Page 40

5. DISTANCE MEASUREMENT

When setting the atmospheric correction obtain the correction value by

measuring the temperature and pressure.

5.1 Setting of the Atmospheric Correction

When setting the atmospheric correction obtain the correction value by

measuring the temperature and pressure. Refer to Section 3.2 “Setting of the

Atmospheric Correction”.

5.2 Setting of the Correction for Prism Constant

The instrument is preset for a Prism Constant value of -30mm at the factory. If

the prism is of another constant the instrument needs to be updated with this

constant. Refer to Chapter 3.3 “Setting of the Prism Constant”. The updated value

is kept in the instrument memory after the power is shut off.

5.3 Distance Measurement (Continuous Measurement)

Make sure the angle measurement mode is selected.

Operation procedure Operation

Collimate the center of prism

*1

40

Collimate

Display

Page 41

Press the key, distance

measurement starts *2 *3;

③The measured distances are

shown (*4,*7) By pressing

the

changes to horizontal (HR),

vertical (V) angle, vertical

distance (VD) and slope

distance (SD)

*1)The total station prism mode collimate center of prism when measuring;

*2)When EDM is working, the “*” mark appears in the display. The total

stations will display “weak signal” when measuring if the signal is weak.

*3)To change the mode from Fine to Tracking, refer to section 5.4 “Fine mode /

Tracking Mode”. To set the distance measurement on when the instrument is

powered up, refer to Chapter 11 “Basic Settings”.

*4)The distance unit indicator "m" (for meter) or “ft” (for feet) appears and

disappears alternatively with a buzzer sounding at every renewal of distance data.

*5) Measurement may repeat automatically in the instrument if the result is

affected by external factors*.

*6)To return to the angle measuring angle mode from the distance-measuring

mode, press the ANG key.

*7)It is possible to choose the display order (HR,HD,VD) or (V, HR,SD) for initial

measuring mode. Refer to Chapter 11 "Basic Settings".

key again the display

41

Page 42

5.4 Changing the Distance Measurement Mode

(Repeat Measurement / Single Measurement/

Track Measurement)

Make sure the angle measurement mode is selected.

Operation procedure Operation Display

Collimate the center of the

prism

Press the key,Continuous

Measurement begins *1;

Press the F2 (MODE) key to

switch between Repeat

Measurement, Single

Measurement and Tracking

Measurement. [N], [1], [T]

Collimate

F2

F1

42

Page 43

*1 It is possible to set the measurement mode for N-times measuring mode or

continuous measurement mode when the power is turned on. Refer to Chapter 11

“Basic Settings”.

5.5 Stake Out (S.O.)

The difference between the measured distance and the input stake out distance

is displayed.

Measured distance - Stake out distance = Displayed value

In a stake out operation you can select either horizontal distance (HD), relative

elevation (VD), and slope distance (SD.)

Operation procedure Operation

Press the F4(↓) key in the distance

measuring mode to menu P2

Press the F2 (S.O) key

The data previously set is shown

F4

F2

Display

43

Page 44

Select the measuring mode by

pressing the F2 to F4 keys. F2:HD,

F3:VD,

F4:SD

F1

Pris

m

Enter 350

Enter the distance 350 , press F4

Collimate the target (Prism),

measurement starts. The difference

between the measured distance and

the

stake out distance is displayed.

Move the target until the difference

becomes 0.

To return to normal distance measurement mode, stake out distance to “0” or

switch to other measurement mode.

F4

Collimate

44

Page 45

5.6 Offset Measurement

There are four offset measurement modes:

1. Angle offset

2. Distance offset

3. Plane offset

4. Column offset

5.6.1 Angle Offset

This mode is useful when it is difficult to set up the prism directly on target; for

example at the center of a tree. Place the prism at the same horizontal distance from

the instrument as that of point A0 to measure. To measure the coordinates of the

center position use the offset measurement after setting the instrument height/prism

height.

When measuring coordinates of ground point AI: Set the instrument

height/Prism height

When measuring coordinates of point A0: Set the instrument height only (Set

the prism height to 0)

45

Page 46

Set the instrument height/prism height before proceeding to the offset

measurement mode.

When setting the coordinate value for the occupied station, refer to Section 6.2

“Setting Coordinate Values of an Occupied Point”.

Operation procedure Operation Display

Press the F4( ↓ ) key from

distance

measuring mode to get the

function on menu P2

F4

Press F1 (OFSET) key F1

46

Page 47

Press F1 (ANG.OFFSET) key F1

Collimate prism P, and press the

F1

(MEAS) key.

The horizontal distance from the

instrument to the prism will be

measured.

Collimate point AO using the

horizontal motion clamp and

horizontal tangent screw.

Show the north coordinate, east

coordinate and z coordinate of

waited measuring point by

pressing

To return to procedure 3, press F4 (NEXT) key

key.

Collimate

[P]

F1

Collimate

AO

To return to the previous mode, press ESC key

47

Page 48

5.6.2 Distance Offset Measurement

Measuring the distance and coordinate of a pond or a tree of which the radius is

known. Measuring the distance or coordinate to P0 point, input oHD value as an

offset value and measure P1 point as shown in the drawing. The display shows

distance or coordinate value to P0 point.

When setting the coordinate value for the occupied station, refer to Section 6.2

‘Setting Coordinate of Occupied Point’

Operation procedure Operation Display

①Press the F4 (↓) key from

distance measuring mode to get

the function on menu P2

48

F4

Page 49

②Press F1 (OFSET) key. F1

③Press F2 (DIST OFSET) key,

enter the measurement of

DIST.OFFSET

④Enter R HD,

press ENT key *1

⑤Enter forward HD,

press ENT key *2

⑥Collimate Prism P1, and press

F1 (MEAS) key.

F2

Enter R

HD

ENT

Enter

forward HD

ENT

Collimate

Measuring will start.

After measuring, the result

added

offset value will be show。

P1

F1

49

Page 50

⑦Show the coordinate of Point

P0

To return to procedure 4,press F1 (NEXT) key

To return to the previous mode, press ESC key

*1)*2)refer to section 8.3.2 “Distance Offset Measurement”

5.6.3 Plane Offset Measurement

Used to facilitate distance or coordinate measuring for a given plane.

Three random prism points (P1, P2, P3) on a plane will be measured at first in the

plane-offset measurement to determine the measured plane. Collimate the

measuring target point (P0) then the instrument will calculate and display coordinate

and distance values of the cross point between collimation axis and the plane.

50

Page 51

When setting the coordinate value for the occupied station, refer to Section 7.2

‘Setting Coordinate Value of Occupied Point’.

Operation procedure Operation Display

①Press the F4 (↓) key from

distance

F4

measuring mode to get the

function on page 2.

②Press F1 (OFSET) key F1

③Press F3 (PLANE OFSET) key

F3

④Collimate Prism P1, and press

F1 (MEAS) key.

Collimate

N-time measuring will start.

After measuring, the display will

show the second point

P1

F1

measurement.

51

Page 52

⑤Measure the second and third

points in the same way.

The instrument calculates and

displays coordinate and distance

values of the cross point between

the collimation axis and of the

plane *1*2

⑥Collimate the edge (P0) of the

plane *3*4

Collimate

P2

F1

Collimate

P3

F1

Collimate

P0

⑦By pressing key each

time,horizontal distance, relative

elevation and slope distance are

shown in sequence.

To show the coordinate of the

point (P0), press

52

key.

Page 53

*1 ) In case the calculation of plane was not successful by the measured three

points, error displays. Start measuring over again from the first point.

*2 ) Data display is the mode beforehand of offset measurement mode.

*3 ) Error will be displayed when collimated to the direction which does not cross

with determined plane.

*4 ) The reflector height of the target point P0 is set to zero automatically.

5.6.4 Column Offset Measurement

If it is possible to measure circumscription point (P 1) of Column directly the

distance to the center of the column (P0), coordinate and direction angle can be

calculated by measured circumscription points (P2) and (P3).

The direction angle of the center of the column is 1/2 of total direction angle of

circumscription points (P2) and (P3).

53

Page 54

When setting the coordinate value for the occupied station, refer to Section 6.2

‘Setting Coordinate Values of Occupied Point’.

Operation procedure Operation Display

Press the F4 (↓) key from

distance

measuring mode to get the

function on menu P2

F4

Press F1 (OFSET) key F1

Press F4 (COLUMN

OFFSET)key

Collimate the center of the

column

(P1) and press F1 (MEAS)

key

N-time measuring will start.

After the measurement,

angle-measuring display of

the left side (P2) will be

shown.

54

F4

Collimate

P1

F1

Page 55

Collimate the left side of

column(P2) and press F4

(SET) key.

After measurement, angle

measuring

display of the right side (P3)

will be shown.

⑥Collimate the right side of

the column (P3) and press

F4 (SET) key.

After measurement, the

distance between the

instrument and the center of

column (P0) will be

calculated.

To show the coordinate of

Collimate

P2

F4

Collimate

P3

F4

point P0,press key.

*1*2

*1)To return to procedure 5, press F4 (NEXT) key

*2)To escape the measuring,press ESC key,the display returns to the previous

mode.

55

Page 56

6. COORDINATE MEASUREMENT

6.1 Execution of Coordinate Measurement

Measure the coordinates by entering the instrument height and prism height,

coordinates of unknown Point will be measured directly.

* When setting coordinate values of occupied point, see Section 6.2 “Setting

Coordinate Values of Occupied Station Point”.

* When setting the instrument height and prism height, see Section 6.3

“Setting Height of the Instrument” and 6.4 “Setting Height of Target (prism

Height)”.

* To set backsight, determine the backsight azimuth or check the known

azimuth, coordinate and distance.

The coordinates of the unknown point are calculated as shown below and displayed:

Coordinates of occupied point:(N0,E0,Z0)

Instrument height :INS.HT

Prism height: R.HT

Vertical distance (Relative elevation):Z(VD)

Coordinates of the center of the prism, originated from the center point of the

instrument:(n,e,z)

Coordinates of unknown point:(N1,E1,Z1)

N1=N0+n

E1=E0+e

Z1=Z0+INS.HT+Z-R.HT

Center point of the instrument (N0, E0, Z0+INS.HT)

56

Page 57

When doing coordinate measurement coordinates of occupied point, the instrument

height, the prism height and back sight azimuth should be set.

Operation procedure Operation Display

Set the direction angle of

known

point A *1 )

Set

direction

angle

Collimate target prism B, and

press

key

Collimate

target

prism

*1Refer to Section 4.3 “Setting of Horizontal Angle”.

In case the coordinate of instrument point is not entered, (0,0,0) will be used as the

default for the instrument point. The prism height will be calculated as 0 when the

prism height is not set.

57

Page 58

6.2 Setting Coordinate Values of Occupied Point

Set the coordinates of the instrument (occupied point) according to known

values and the instrument automatically converts and displays the unknown point

(prism point) coordinates following the observation.

The instrument retains the coordinates of the occupied point after turning the

power off.

58

Page 59

Operation procedure Operation Display

Press the F4 (P1↓) key from

the

coordinate measurement mode

F4

to get the function on menu P2.

Press the F3(OCC)key F3

Enter

③Enter N coordinate value

data

ENT

④Enter E and Z coordinate

values in the same manner.

Enter

After entering the

data

values, the display returns to

ENT

the coordinate measuring

display menu.

Input range:-999999.999m/ft ≤ N、E、Z ≤ +999999.999m/ft

59

Page 60

6.3 Setting Height of the Instrument

The instrument height value will be retained after the instrument is powered off.

Operation procedure Operation Display

Press the F4 (P1↓) key from the

F4

coordinate measurement mode to

access the P2 menu screen.

② Press the F2 (I.HT) key,

F2

The current value is displayed.

Enter the instrument height and

press the ENT key to get to the

coordinate measuring display

Input range:

—999.999≤INS.HT≤+999.999m

60

Enter the

I.H.

ENT

Page 61

6.4 Setting Height of Target (Prism Height)

This mode can be used to obtain z coordinate values. The target height value

will be retained after the instrument is powered off.

Operation procedure Operation Display

Press the F4 (P1↓) key from the

coordinate measurement mode to

access the P2 menu screen.

②Press the F1 (R.HT) key

The current value is displayed.

Enter the prism height, then press

the ENT key to get to the

coordinate measuring display

Input range:

F4

F1

Enter the

prism

height

ENT

—999.999m≤prism height≤+999.999m/ft

61

Page 62

7. SURVEYING PROGRAM

Surveying Program Mode (programs)

By pressing the menu key M , the instrument will be in Menu Mode.

7.1 Remote Elevation Measurement(REM)

To obtain elevation of the point at which setting the target prism is not possible,

place the prism at any point on the vertical line from the target then carry out REM

procedure as follows.

62

Page 63

1)With prism height (h) input

Operation procedure Operation Display

Press the M Key

M

Press the F2 key,enter MEAS

F2

PROGRAM. menu

③Press the F1(REM)key F1

④Press the F1 key F1

⑤Enter prism height (1.3 is an

example in meters)

F1

Enter

prism

height

1.3

F4

63

Page 64

⑥Collimate prism

⑦Press the F1 (MEAS) key,

measurement starts. Horizontal

distance (HD) between the

instrument and prism will be

shown.

⑧Press the F4 (SET)

The prism position will be

decided.

⑨ Collimate target K.

Vertical distance

(VD) will be shown.

Collimate

Prism

F1

F4

Collimate

K

To return to procedure 5,press F2 (R.HT) key.

To return to procedure 6,press F3 (HD) key.

To return to PROGRAMS Menu, press the ESC key.

64

Page 65

2)Without prism height input

Operation procedure Operation Display

Press the M menu key M

Press the F2 key,enter the

F2

measure programs menu.

③Press the F1 (REM) Key. F1

④Press the F2 key to select the

F2

mode without prism height.

Collimate prism, press the F1

(MEAS) key. Measuring starts.

Collimate

Horizontal distance (HD)

between the instrument and

target

target will be shown..

65

Page 66

⑥Press the F4 (SET)

The target position will be

decided.

F4

Collimate ground point G ,

press the F4 (SET) key. The

position of

point G will be decided

Collimate target K

Vertical distance (VD) will be

shown

To return to procedure 5, press the F3 (HD) key.

To return to procedure 6, press the F2 (Vang) key.

To return to PROGRAMS Menu, press the ESC key.

F4

Collimate

K

7.2 Missing Line Measurement (MLM)

Measurement for horizontal distance (dHD) , slope distance (dVD),elevation

(dVR) and horizontal bearing (HR) between two target prisms.

It is possible to enter the coordinate value directly or calculate from coordinate

data file.

MLM Mode has two modes:

66

Page 67

1. MLM-1 (A-B, A-C): Measurement A-B, A-C, A-D

2. MLM-2 (A-B, B-C): Measurement A-B, B-C, C-D

It is necessary to set the direction angle of the instrument.

[Example] MLM-1 (A-B, A-C)

Procedure of MLM-2(A-B,B-C)mode is completely the same as that of

MLM-1 mode.

Operation procedure Operation Display

M

①Press the M menu key

67

Page 68

② Press the F2 key, enter

F2

MEAS PROGRAMS

③Press the F2 (MLM) key F2

Enter file

④Enter file name

name

⑤Press ENT key. ENT

⑥Press the F1 key F1

68

Page 69

⑦Collimate prism A, and press

the F1 (MEAS) key.

Horizontal distance (HD)

between the instrument and

target A will be shown.

⑧Press the F4 (SET) key

The position of the target is

confirmed.

⑨Collimate prism B and press

the F1 (MEAS) key. Horizontal

distance (HD) between the

instrument and target B will be

shown..

⑩Press the F4 (SET) key

The horizontal distance(dHD)

Collimate

A

F1

F4

Collimate

B

F1

and relative

elevation (dVD) between target

A and B.

⑾ To measure the distance

between points

A and C, press the F4 (NEXT)

key*1)

F4

F4

69

Page 70

⑿ Collimate point C (target C)

and press the F1 (MEAS) key.

Horizontal distance (HD)

between the instrument and

Collimate

C

F1

target C will be shown.

⒀Press the F4 (SET) key. The

horizontal distance (dHD) and

relative elevation (dvD) between

F4

taget A and C will be shown

⒁ To measure the distance

between points

A and D, repeat procedure 12

to 14 *

*To return to Previous mode , press the ESC key.

70

Page 71

HOW TO USE COORDINATE DATA

It is possible to input coordinate values directly or calculate from a coordinate

data file.

[Example] Input the data (NEZ) directly:

Operation procedure Operation Display

①Press the F3(NEZ) key F3

② Press the F4(coordinate)

F4

key

③Enter coordinate, press

ENT

ENT key to get to the second

point.

*To return to PROGRAMS Menu, press the ESC key.

71

Page 72

7.3 Area Calculation

This mode calculates the area of an enclosed figure.

There are two area calculation methods as follows:

1) Area calculation from Coordinate data file

2) Area calculation from measured data

Note:

Area is not calculated correctly if observed lines cross each other.

It is not possible to calculate area from a mix of coordinate file data and measured

data.

The number of points used for calculation is not limited.

The area to be calculated shall not exceed 200000 sqm. (approx. 49 acres)

1) Area calculation from Coordinate data file

Operation procedure Operation Display

①Press M menu key M

②Press the F2 key, enter the

F2

Measurement Program.

72

Page 73

③Press F3 (AREA) key F3

Press F1 (FILE DATA) key F1

Enter file name or press F2 for

LIST. Press ENT key, Initial

Enter

File name

display will be shown .

ENT

⑥Press F4 (NEXT) key

The top of the file data

(DATA-01) will be set and the

second point number will be

F4

shown.

Repeat pressing F4 (NEXT)

key to set required number of

the points. When 3 points are

set, the area surrounded by the

F4

points is calculated and the

result will be shown.

* To set the required point number, press F1 (PT#) key.

* To show the list of the coordinate data in the file, press F2 (LIST) key.

73

Page 74

2) Area calculation from measured data

Operation procedure Operation Display

①Press M menu key M

②Press the F2 key, enter the

F2

Measurement Program.

③Press F3 (AREA) key F3

Press the F2

(MEASUREMENT) key

F2

Collimate a target or prism and

press the F1 (MEAS) key.

Collimate

Prism

Measuring starts *

74

F1

Page 75

Press the F4 key to affirm F4

⑦Collimate a next prism and

press F1 (MEAS) key. When 3

points are set, the area

surrounded by the points is

calculated and the result will be

shown.

*1 Measurement is N-time measurement mode.

Collimate

F1

75

Page 76

7.4 Setting Z Coordinate of Occupied Point

Occupied point coordinate data and known point actual measuring data can be

utilized, zcoordinate of occupied point is calculated and reset.

Known point data from a coordinate file can used.

1 ) Setting z coordinate of occupied point

[Example setting] Using coordinate data file

Operation procedure Operation Display

①Press the M menu key M

②Press the F2 key ,enter

PROGRAMS

③Press the F4 (Z

COORDINATE key

76

F2

F4

Page 77

④Enter the File Name then

press ENT to affirm.

Press the F2 (REF. MEAS)

key and enter the point

number (press F2 for LIST)

After input the PT#, press

the ENT key, the coordinate

of this point is shown.

Input

File Name

ENT

F2

ENT

⑦Press the F4 (YES) key to

confirm instrument height

setting display will be shown.

F4

Enter the instrument height,

Enter

press ENT key. Press F1

INS.HT

(MEAS) for observation

ENT

results

For more information about data file, see chapter 10 “Memory Management

Mode”.

77

Page 78

2)Z coordinate calculation from known point measuring data

[Example setting] Using coordinate data file.

Operation procedure Operation Display

Press the M menu key M

Press the F2 key, enter MEAS

F2

PROGRAMS.

Press the F4 (Z

F4

COORDINATE) key

INPUT

Enter the File Name then

File Name

press ENT to affirm.

ENT

⑤Press the F2 key F2

78

Page 79

⑥Enter the point number in

coordinate data file, press

ENT to affirm.

Enter PT#

ENT

⑦Press the F4 (YES) key to

affirm

⑧Enter the height then press

the ENT to affirm.

⑨Collimate a prism on the

point and press the F1

(MEAS)key.

Measuring starts *1

F4

Enter R.HT

ENT

Collimate P

F1

⑩Press the F4 (CAL) key *2

Z: Z coordinate

F4

79

Page 80

⑾Press the F4 (SET) key *3

Z coordinate of the occupied

point will be set. Backsight

point masuring screen will be

shown.

⑿Press the F4 (YES) key.

Horizontal angle will be set.

The display returns to

Measurement Programs menu.

*1 Measurement is Fine Single measurement mode.

*2 To measure other points, press the F1 (NEXT) key.

*3 Pressing the F1 or F3 key, the display will be changed alternately.

F4

F4

7.5 Point to Line Measurement

This mode is used to obtain the coordinate data of an unknown occupied point

from a known point and a known line. An observation will need to be taken at the

known point A and along the line N designated for the example as B. After

measuring the 2 points the coordinate and the direction angle of the instrument will

be calculated and recorded.

80

Page 81

Operation procedure Operation Display

①Press the M menu key M

②Press the F2 key for the

F2

Measure Program menu

③Press the ▼ key ▼

81

Page 82

④Press F1 (POINT TO LINE)

key

⑤ Enter instrument height.

Press ENT

⑥Enter reflector (PI) height at

point A. Press ENT

F1

Enter

INS.HT

ENT

Enter

R.HT

ENT

⑦Collimate prism A (Origin)

and press F1 (MEAS) key.

Measuring starts.* 1 Press

F4

Input height of target B height

will be shown.

82

Collimate

P1

F1

F4

Page 83

⑧ Enter reflector height of

point B. Press ENT

Enter

INS.HT

ENT

⑨Collimate prism B (P2) and

press F1 (MEAS) key.

Measuring starts.* 1 Press

F4

The coordinate data and

direction angle of the

instrument is calculated and

recorded.

⑩ Press F1 (NEZ) key to

measure

other points *2 *3.

⑾Collimate prism, press F4

(MEAS) key. Measuring

starts *3)

The result will be shown.*4)

Collimate

P2

F1

F4

Collimate

P

F1

F4

*1)Measurement is N-time measurement mode.

*2)Press F2 (S.CO) key to show the new occupied data.

*3)Measurement is N-time measurement mode.

*4)To return to previous mode, press F1 (EXIT) key.

83

Page 84

7.6 Road Construction

By using this program you can define a straight line, a curve, or a transition curve as

a reference to make a measurement and set out. This program will do the

computation of coordinates and setting out of the design point according to the stake

number and deviation which are defined by the roads design.

In order to use this program the observation station coordinates and backsight

azimuth angle need to be set.

7.6.1 Design: Horizontal Alignment

Horizontal alignment consisted of following elements: start point, straight line,

circular curve , transition curve, INTG, WIDE and PEG.

The define option will prompt for the start details(chainage,NEZ,starting

azimuth).

Enter these details in the screen, press [ENT] key to show the mail input routine

screen:

84

Page 85

top right corner of the screen shows the number of horizontal alignment.

The main line input screen displays current chainage and the bearing angle (the

tangent line from the chainage) and the function key (For creating new line). System

provides three functions: defining straight line, circular curve, transition curve.

Select a function key, enter the detailed information of the chainage, the alignment

elements will be created. Press ENT key, the new chainage and bearing angle will be

calculated automatically and the main alignment screen will be restored. Now other

line style can be defined, the new elements can be added only in the end of the

original alignment file.

Operation procedure is as follows:

Operation procedure Operation Display

In main menu, press F2 key to

get MEAS PROGRAM menu,

press F4 key to get second page

of MEAS PROGRAM menu.

Press F2(ROAD MEASURE)

key

Enter file name, then press ENT

key.

F2

F4

F2

F2

85

Page 86

Press F1(ROAD DESIGN)key.

F1

Press F1(DESIGN H-LINE)

F1

key for the H-line menu.

Input starting chainage, northing

coordinate, easting coordinate

Input

starting

and starting azimuth. Press ENT

key to show the main input

routine screen.

data

ENT

In main input routine screen we can add straight line, circular curve and transition

curve to the end of current curve. Select the desired option by pressing F1-F3 keys.

Straight line

When the start point or other line style is well defined it allows you to easily define a

straight line. A straight line length value cannot be negative.

86

Page 87

Operation procedure Operation Display

Press F1(Line)key from HZ AL

F1

menu to get BEELINE.

Enter

After entering the length of the

line press ENT key.

length

ENT

Return to HZ AL menu.

Circular Curve

Press F2 key (ARC) in the “HZ AL Screen”, the circular curve can be defined.

Circular curves consists of Arc length and the Radius. The radius value rule:

Looking along the forward direction of the curve, when the curve rotates to right, the

radius value is positive. When the curve rotates to left, the radius value is negative.

The arc length cannot be negative.

87

Page 88

Operation procedure Operation Display

Press F2(ARC) key from

H-LINE menu to get ARC.

Input the radius of the ARC

(R) and press the ENT key.

Input the length of the ARC (L)

and press the ENT key.

Return to HZ AL menu with

calculated values.

88

F2

Input R

ENT

INPUT L

ENT

Page 89

Transition curve

Press F3 key in the “Main Line Input Screen” and a transition curve can be

defined. The inputting of transition curve consists of transition curve parameter

“A”,starting radius, and resending radius. If the input radius is ∞ you can

input 0 as its value.

The rule of transition curve parameter A : Looking along the forward direction of the

curve. When the curve rotates to right, the radius value is positive. When the curve

rotates to left, the radius value is negative.

Operation procedure Operation Display

Press F3 key from H-Line

F3

menu on page 1

Enter A

Input A,press ENT key.

Input radius,press ENT key.

ENT

Enter R

ENT

89

Page 90

Instrument returns to previous

mode with solution.

Stake Spacing(INTG)

Press F1 (INTG) on the second page of the main alignment screen then enter into the

setting interface of stake spacing interval which needs to be greater than 0.

Operation procedure Operation Display

Press F4 on the main

alignment screen (1/2) to enter

into the main alignment

screen (2/2)

Press F1 to enter into the

input interface of stakes space

Return to the main alignment

screen.

Remarks: the stake spacing can be input only once but can be modified during

editing of the horizontal alignment.

90

F4

Enter space

ENT

Page 91

Road Widening Stake Number(WIDE)

On the second page of the main alignment screen, press F2 (WIDE) to enter into the

road widening stake data input interface, and then input the stake number of

widening point, left road width and right road width.

Operation procedure Operation Display

Press F4 on the main

alignment screen (1/2) to enter

into the P2 alignment screen

(2/2).

Press F2 (WIDE) to enter into

the input interface of road

widening stake number.

Input the stake number, left

road width and right road

width, and press ENT to

confirm.

Remarks: The data of each road widening point will determine the road width

between this stake number and next widening point stake number.

F4

F2

Enter data

ENT

91

Page 92

Additional stake number(PEG)

On the second page of the main alignment screen, press F3 (PEG) to enter into the

input interface of addition stake data, and then input the stake number of the

additional staking point, left road width and right road width.

Operation procedure Operation Display

Press F4 on the main

alignment screen (1/2) to

enter into the main alignment

screen (2/2).

Press F3 (PEG) to enter into

the input interface of

additional stake number.

Input the stake number, left

road width and right road

width, and press ENT to

confirm.

Remarks: Two or more additional stake points can be input.

F4

F3

Enter data

ENT

92

Page 93

7.6.2 Editing horizontal alignment data

You can edit the horizontal alignment after input.

From the Road Design Menu select F2: EDIT H-LINE

The function of the soft keys are as follows:

[FST]:Press this key to go to the start of the file,and show the first alignment data;

[LST]:Press this key to go to the end of the file,and show the last alignment data;

[EDIT]:To edit the current alignment data;

[SRCH]:Search the alignment data by inputting chainage;

It is possible to edit data by using the above function keys. After entering the data to

be modified press [ENT] key to record the modified data.

93

Page 94

Operation procedure Operation Display

Press F2 (Edit horizontal

alignment) on the road design

menu to enter into the horizontal

alignment editing interface.

Through pressing [ ▲ ] or [▼],

select the alignment data which is

required to be modified, and press

F1 (edit) to edit it, and finally

press ENT (ENTER) to confirm.

*1)

Return to the alignment interface,

the modified alignment data will be

displayed, and then continue to

modify the other alignment data as

needed

F2

[▲]or[▼]

F1

Enter data

ENT

*1 Or press F4 (search), then input the stake number of the alignment data

(chainage) which is required to be modified.

94

Page 95

7.6.3 Receiving horizontal alignment

You upload a prepared file of horizontal alignment data from a computer for the

alignment work before setting out.

There are two methods to upload data to the instrument.

1. Directly upload the alignment data to the current operating internal memory

from a computer through a data cable (RS-232).

Refer to 10.8 for the operation method

2. Store the alignment data on an SD card, insert the SD card into the

instrument and then copy data from SD card to the memory.

Refer to 10.9 for the operation procedures.

The horizontal alignment data format is in the following format:

Number Data Format Meaning of Parameters

1 start Z,X,Y,a

Initial Point: Stake number of initial point Z, coordinate X,

coordinate Y, initial azimuth a

2 Line Lz Straight line data: the length of straight line Lz

3 spiral A,Rs,Re

4 arc R,Ly

5 wide Zi,wLi,wRi

Transition curve data: transition curve parameter A, radius

of initial point Rs, radius of end point Re.

Circular curve data: radius of circular curve R, curve

length Ly.

Widening point data: initiation stake number Zi, width of

left road wLi, width of right road wRi.

6 integer L0 Stake Space: the length of stake space is LO

7 peg Zj,wLj,wRj

Additional stake point data: additional stake number Zj,

left road width wLj, right road width wRj

95

Page 96

Explanation:

1. The data in the first row is the initial point data, and only one point can be

entered.

2. The data in the second, third, fourth rows is element data, any combination can be

input according to the requirements.

3. The data in the fifth, sixth, and seventh rows is auxiliary calculation data,

choosing whether to enter or not according to the requirements as an option, the

default step length is 20m. Only one staking space is available.

4. The transition curve parameter A and circular curve radius R as needed (sign as

per the direction of route, curve to left is negative, and curve to right is positive), all

other parameters are positive.

5. When the radius of circular curve is ∞, the input radius is 0.

Convert the designed alignment data into *.HAL file using transmission software,

then copy the data to SD card or the memory.

For example:

start 0,2541930.604,502841.293,191.5644

line 452.484

arc 1200,165.885

spiral -90,1e20,130

arc -130,214.928

spiral 110,1e20,280

arc 280,77.151

spiral 110,280,1e20

line 100.978

96

Page 97

integer 20

wide 0,0,6.5

wide 130.945,1.8,6.5

wide 400,4.5,4.5

wide 1040,0,6.5

peg 130.945,1.8,6.5

peg 220,1.8,0

peg 240,2.338,0

peg 260,2.878,0

peg 1000,4.5,5.28

peg 1020,4.5,6.038

peg 1033.721,4.5,6.48

97

Page 98

7.6.4 Deleting horizontal alignment data

The horizontal alignment data in the internal memory can be deleted with the

procedure as follows:

Operation procedure Operation Display

Press F2 (road measurement) in

the menu of Measurement

Program and choose a file.

Press F3 (DEL HZ AL DATA) F3

Press F4 (Yes), the current

selected horizontal alignment

data will be deleted.

F2

Select a file

ENT

7.6.5 DESIGN: VERTICAL CURVE

A vertical curve consists of series of intersection points. The intersection point

consists of a chainage, elevation and curve length. The start and end intersection

points must be a zero curve length.

98

Page 99

Intersection points can be entered in any order. After entering a point data press

ENT to save it and advance to enter the next point. Press ESC to exit without saving.

Operation procedure Operation Display

Press F2 key from the menu to

get MEAS PROGRAM. Press []

for page 2/2

Press F2(ROAD MEASURE)

key

Input file name, then press

ENT key

F2

F2

ENT

99

Page 100

Press F1(ROAD DESIGN)key

Press F3(DESIGN V AL)key F3

F1

Input the CH, H and L of the

first point,then press ENT

key *1

After inputting each point the

menu will advance to the next

point. ESC to exit.

*1 The start and end intersection points must be a zero curve length.

Enter data

ENT

100

Loading...

Loading...