Page 1

Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

Standard

SPF9 Stapler-Folder

&

FC9 Trimmer

Service Manual

Page 2

SERVICE MANUAL

Standard Horizon SPF-9/FC-9 Stapler-Folder

Fore-Edge Trimmer

SM_SPF9/FC9

Read this manual, and thoroughly

familiarize yourself with its

contents before operating or

servicing this equipment.

Page 3

Page 4

I

STAPLER & FOLDER

FORE-EDGE TRIMMER

US501009-01171808/SPF9FC9/01E/DV

Important Information

- This manual is designed to help you to maintain and repair Stapler & Folder SPF-9 and

Fore-edge Trimmer FC-9. Read, understand and keep this manual in a safe and convenient

place.

- Do not maintain or repair SPF-9/FC-9 until you read and understand the instructions in

this manual.

- Horizon International Inc. shall not be liable for incidental consequential damages

resulting from : improper or inadequate maintenance by customer; unauthorized modification or misuse; operation outside of the environmental specifications for the product.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to

change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or

translated to another language without the prior written consent of Horizon International Inc.

SPF-9/FC-9

Page 5

II

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in damage on machines. It may also be used to alert against unsafe

practices.

- Read and understand all safety instructions with signal word such as WARNING and

CAUTION. If safety instructions are ignored, personal injury may result.

- Horizon International Inc. cannot anticipate every possible situation that might involve

a potential hazard. The instructions in this manual and warning labels on the machine are

therefore not all inclusive.

- Do not operate the machines when any covers are removed.

- Some of the drawings in this manual show the machine uncovered for explaining the

detail or inside of machine.

Page 6

III

Use the following tools for maintenance and repair.

1. Screw Driver No. 2

2. Screw Driver 6 to 7 mm

3. Allen Wrenches 1.5, 2, 2.5, 3, 4, 5, and 6 mm

4. Open-ended Wrench 5.5 x 7 mm 8 x 10 13 x 17

5. Box Wrench 5.5 mm

6. Snap-ring Expander

1. The following signs in this manual

represent wire color.

Sign Color

BRN Brown

RED Red

ORN Orange

YEL Yellow

GRN Green

BLU Blue

VIO Violet

GRY Gray

WHT White

BLK Black

2. The following abbreviations in this manual

represent electronic and electrical parts.

Abbreviation Meaning

CL Clutch

BK Brake

SW Switch

mSW Microswitch

M Motor

LED Light Emitted Diode

VR Potentiometer

RY Relay

I. Necessary Tool for Maintenance and Repair

II. Signs and Abbreviations in This Manual

Page 7

IV

Contents

Important Information ..........................................................................................................I

Safety Precautions ..................................................................................................................II

I. Necessary Tool for Maintenance and Repair.....................................................................III

II. Signs and Abbreviations in This Manual ......................................................................... III

1. Specifications ...................................................................................................................1

2. Operation Overview ........................................................................................................3

3. Sheet Flow ........................................................................................................................4

4. Drive Section ....................................................................................................................7

5. How to Remove Covers...................................................................................................9

6. Knife Replacement ..........................................................................................................11

7. Troubleshooting...............................................................................................................13

8. Electronic Parts Layout ..................................................................................................21

9. Control Panel LED Descriptions ................................................................................... 23

10. Line Diagram ................................................................................................................. 25

Page 8

1

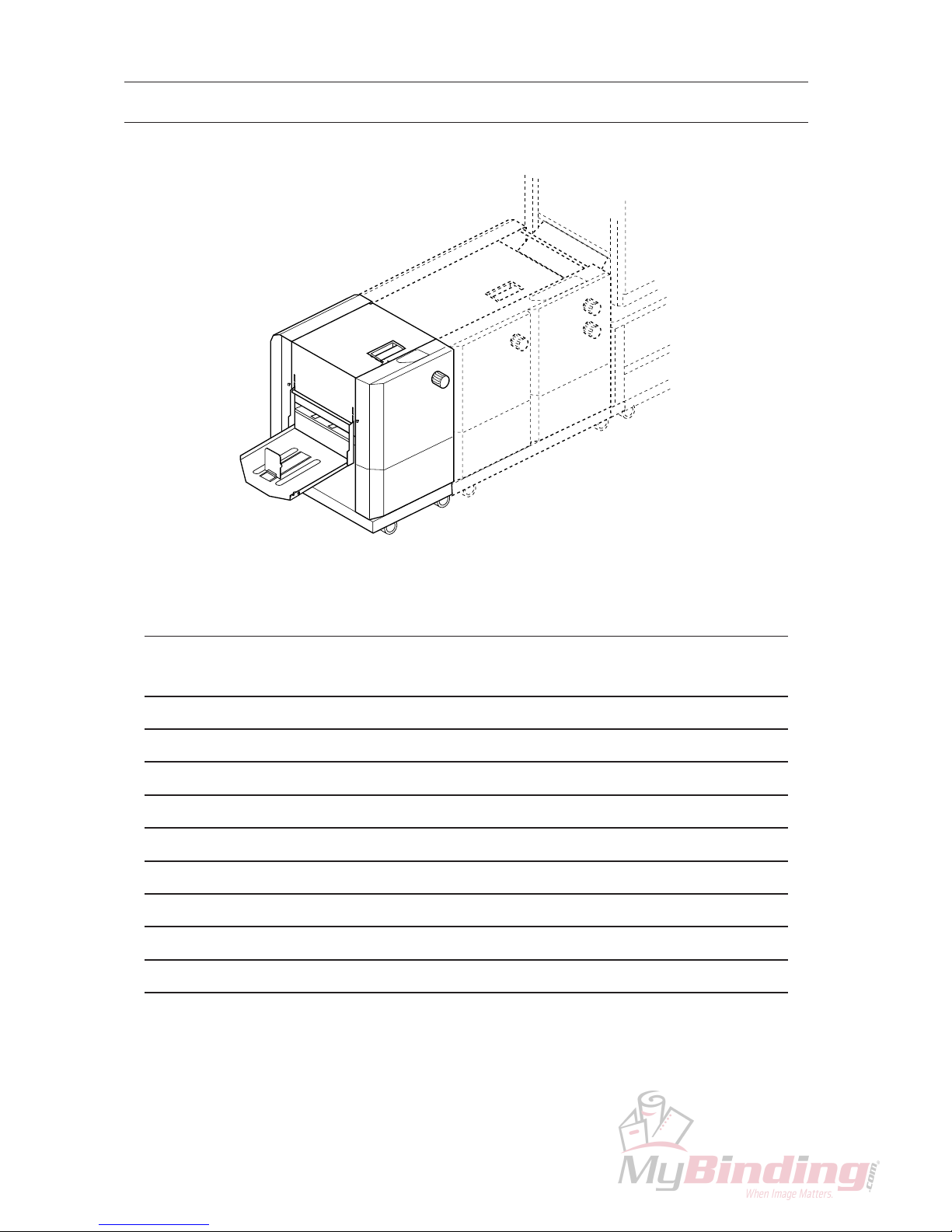

1. Specifications

1-1 SPF-9

Function Stapling and Folding, Side Stapling, Corner Stapling, Folding

Sheet Size Stapling and Folding : A3, A4 (11" x 17", 8.5" x 11")

Side Stapling/Corner Stapling : A4 (8.5" x 11")

Sheet Weight 64 gsm ~ 130 gsm (16# Bond to 36# Bond)

Stapling and Folding Thickness

up to 20 sheets of 64 gsm / up to 10 sheets of 130 gsm

(14 sheets of 20# Bond)

Side Stapling Thickness up to 20 sheets of 130 gsm (36# Bond)

Corner Stapling Thickness up to 20 sheets of 130 gsm (36# Bond)

Production Speed 2,000 booklets / hour

Stacker Pile Height Stapling and Folding : 40 booklets (A3 - 64 gsm, 10 sheets)

Side Stapling : 100 booklets (A4 - 64 gsm, 10 sheets)

Staple Distance 120 mm (4.7") (Fixed)

Staple Cartridge type, 5,000 staples

Sensor No Staple, Sheet Jam, Misfeed on Collator

Counter 4 digits (No memory)

Machine Size (W x D x H) 1,240 x 621 x 796 mm (48.8" x 24.4" x 31.3")

Machine Weight 154 kg (339.2 lb)

Power 220-240 V 50 Hz, 115-120 V 60 Hz, 100 V 50/60 Hz

Power Consumption 60 Hz : 410 W 50 Hz : 375 W

Options Fore-edge Trimmer FC-9, Delivery Conveyor ED-9

Page 9

2

1. Specifications

1-2 FC-9

Sheet Size A3, A5, 11" x 17", 5.5" x 8.5"

Trimmed Size Maximum : 323 x 225 mm (12.7" x 8.8")

Minimum : 180 x 105 mm (7" x 4.2")

trimming Thickness 64 gsm 40 sheets (16# Bond : 40 sheets)

Trimming Width Maximum : 13 mm (0.5")

Production Speed 2,000 books/hour

Detector Sheet Jam, Knife Lock, full Trimming

Counter Total Counter

Machine Size (W x D x H) 445 x 621 x 796 mm (17.6" x 24.5" x 31.4")

Machine Weight 101 kg (221 lb)

Power 220-240 V 50 Hz, 115-120 V 60 Hz, 100 V 50/60 Hz

Power Consumption 150 W

The machine design and specifications are subject to change without any notice.

Page 10

3

2. Operation Overview

2-1 SPF-9

Connecting cable on SPF-9 is connected to collator.

1. Turn on power switch on SPF-9.

On operation panel,

- automatic mode lamp will illuminate.

- stapling & folding lamp will illuminate.

2. Turn on power switch on collator.

3. Pile sheets into collator and set required set up on SPF-9 following "2-1 Operation Procedure"

procedure 5 to 20 (page15 to 18) in SPF-9 Operation Manual.

4. Select automatic mode with function mode select button.

5. Press start button on collator.

- Sheets delivered from collator will be stapled automatically.

6. Press stop button on collator to stop SPF-9.

SPF-9 will stop without pressing stop button in the following cases.

- Sheet jam, misfeed, and double feed occur in collator. Collator lamp on SPF-9 illuminates.

- Sheets are jammed in SPF-9. Sheet jam lamp on SPF-9 illuminates.

- Sheet jam, misfeed and double feed occur

in collator.

- Sheets are jammed in SPF-9.

- Sheets are jammed in FC-9.

- Upper knife stops at the middle of cutting

process.

Cable on FC-9 is connected to SPF-9.

1. Turn on power switch on SPF-9.

2. Turn on power switch on collator.

3. Pile sheets into collator and set required set up on SPF-9 and FC-9 following "2-1 Operation

Procedure" 5 to 20 (page 15 to 18) in SPF-9/FC-9 Operation Manual.

4. Select automatic mode with function mode select button.

5. Press start button on collator.

- Sheet delivered from collator will be stapled and folded in SPF-9 and be cut in FC-9 automatically.

6. Press stop button on collator to stop SPF-9.

SPF-9 will stop without pressing stop button in the following cases.

- Collator lamp in SPF-9 will illuminate.

- Sheet jam lamp on SPF-9 will illuminate.

- Jam lamp will illuminate.

- Knife lock lamp will illuminate.

2-2 FC-9

Page 11

4

3. Sheet Flow

3-1 SPF-9

There are 2 ways in sheet flow.

I. When "stapling & folding" or "folding" mode is selected with operation mode select

button

1. Sheets enter and hit staple and fold stopper.

2. Sheets are jogged by jog plate and jog guide (F).

3. Sheets are stapled in staple & fold mode.

4. Transport roller (F) unit and transport roller (R) unit lower at the same time staple and fold

stopper rises, and transport belt transports sheets.

5. Sheets pass under gate and stop by hitting stopper in fold section.

6. Fold knife pushes fold part of sheets and fold roller nips sheets and then press rollers press

sheets and sheets are ejected.

II. When "side stapling" or "corner stapling" mode is selected with operation mode select

button

1. Sheets enter and hit side staple stopper.

2. Sheets are jogged by jog plate and jog guide (F).

3. Sheets are stapled.

4. Transport roller (F) unit and transport roller (R) unit lower at the same time staple and fold

stopper lowers, and transport belt transports sheets.

5. Sheets pass above gate and are ejected.

Page 12

5

Top View from Operation Side

Transport Roller (F) Unit

Staple Unit

Jog Guide (R)

Jog Guide (F)

Jog Roller

Jog Plate

Jog Unit

Operation Side View

Press Roller

Fold Roller

Sheet Hold Roller

Staple & Fold Stopper Unit

Staple & Fold Stopper

Transport Roller (F) Unit

Transport Roller (R) Unit

Side Staple Stopper Unit

Staple Unit

Side Staple Stopper

Jog Roller

Jog Plate

Sheet Feed Guide A

Fold Knife

Gate

Stopper

Sheet Exit

Sheet Entrance

Transport Belt

3. Sheet Flow

Page 13

6

Upper Transport Belt

3. Sheet Flow

3-2 FC-9

There are two ways in sheet flow.

I. When "stapling & folding" mode is selected with operation mode select button

1. Sheets from sheet entrance hit stopper.

2. Belt stops and sheets are trimmed.

3. Stopper lowers, belt rotates, and then sheets are ejected.

II. When "side stapling" or "corner stapling" mode is selected with operation mode select

button

1. Sheets from sheet entrance pass through FC-9.

Exit Side

Entrance Side

Delivery Belt

Stopper

Stopper Unit

Lower Knife

Upper Knife

Lower Transport Belt

Hold Roller

Page 14

7

4. Drive Section

4-1 SPF-9

1. Electricity is charged by turning on power switch. Motor will rotate with hand feed mode.

(In automatic mode, motor will rotate as soon as collator starts.)

2. Motor drives reduction belt and reduction pulley. At this point, speed of reduction pulley will

be 1/3 of motor speed.

3. Reduction pulley drives fold rollers and press rollers. When clutch is on, transport belt will be

rotated by clutch pulley.

4. When clutch is turned off, transport belt will stop.

Operation Side View

Timing Belt

Press Roller

Fold Roller

Clutch Pulley

Reduction Pulley

Motor

Reduction Belt

Transport Belt

Transport Roller (9 pcs)

Page 15

8

Delivery Belt

4. Drive Section

4-2 FC-9

1. Electricity is charged by turning on power switch. Motor will rotate with hand feed mode. (In

automatic mode, motor will rotate as soon as collator starts.)

2. Motor drives reduction belt and reduction pulley. At this point, speed of reduction pulley will

be 40 percent of motor speed.

3. Reduction pulley drives upper transport belt and lower transport belt with drive belt. And also

reduction pulley drives delivery belt.

Motor

Reduction Belt

Lower

Transport Belt

Upper Transport Belt

Drive Belt

Reduction Pulley

Hold Roller

Page 16

9

Bind Screw

(M4 x 6) (5 pcs)

Bind Screw

(M4 x 6) (4 pcs)

Bind Screw

(M4 x 6) (4 pcs)

Lower part of side

cover is placed

on two hook plates .

Lower part of side

cover is placed

on two hook plates .

5. How to Remove Covers

5-1 SPF-9

WARNING

- Turn power off before removing any

covers.

Page 17

10

(1)

(2)

(3)

(4)

(5)

WARNING

- Turn power off before removing any

covers.

5. How to Remove Cover

5-2 FC-9

Remove five covers as follows.

(1) Bind Screw M4 x 6 (2 pcs)

The lower part of rear cover is placed on

two hook plates.

(2) Bind Screw M4 x 6 (2 pcs)

(3) Bind Screw M4 x 6 (2 pcs)

The lower part of front cover (L) is placed

on two hook plates.

(4) Bind Screw M4 x 6 (2 pcs)

The lower part of cover (FL) is placed on

two hook plates.

(5) Bind Screw M4 x 6 (2 pcs)

Page 18

11

6. Knife Replacement

6-1 Upper Knife

Fix Screw

WARNING

- Take care when replacing knife.

Sharp knife can cause severe personal

injury.

1.Remove two cables and slide FC-9 left to

access upper knife.

2.Turn air nozzle up. (2 fix screws)

3.Remove 3 fix screws and take out upper

knife from upper side.

4. Attach new/resharpened knife in the reverse

order of removal.

NOTE

- Apply a small amount of grease on mark

part of knife when upper knife is installed.

Air Nozzle

Fix Screw

Cables

Page 19

12

6. Knife Replacement

6-2 Lower Knife

Align

1.Remove upper knife referring to page 6.

2.Remove entrance guide. (2 fix screws)

3.Re move 2 entrance lower belts.

Remove sensor connector and entrance

table (4 screws).

4.Remove 4 fix screws and take out lower

knife from lower side.

5.Install new/resharpened knife with reverse

order of removal.

NOTE

- Flash top surface of lower knife with trim

table with knife height adjust screws.

Knife Height Adjust Screw

Fix Screws

Sensor Connector

Entrance

Lower Belts

Entrance Table

Entrance Guide

Page 20

13

Top View from Operation Side

Adjust Bolt C

Stopper must be

parallel with sheets.

Adjust Bolt B Adjust Bolt A

Rear Frame

Font Frame

Adjust Bolt C

Staple & Fold Stopper

Jog Guide (R)

Jog Guide (F)

Jog plate must be

parallell with sheets.

Jog Plate

Adjust Bolt D

Adjust Bolt D

7. Troubleshooting

7-1 Finishing quality is not good.

7-1-1 Sheets are not jogged neatly.

(Cause)

Jog guide (F), jog guide (R),

jog plate or staple & fold

stopper is (are) skewed.

(Remedy)

Adjust jog guide (F), jog guide (R), jog plate or staple &

fold stopper so that they are parallel with sheets.

1. Adjust jog guide (F) and jog guide (R) so that they

are parallel with front frame and rear frame respectively

with adjust bolts A and B.

2. Adjust staple & fold stopper so that it is parallel with

sheets with adjust bolt Cs.

3. Adjust jog plate so that it is parallel with sheets with

adjust bolt D.

- In case that sheets are still not jogged neatly, refer to

the next troubleshooting. (6-1-2 to 6-1-5)

Page 21

14

Delivery Side of SPF-9

Stopper

Bind Screw

Nut

Bolt

Transporting Direction of Sheets

L1

L2

7. Troubleshooting

7-1-2 Sheets are not folded correctly.

(Cause 1)

Sheets are not cut exactly square.

(Cause 2)

Stopper in fold section is skewed.

Measure the length of L1 and L2 of

ejected sheets as shown in the drawing

below.

(Remedy 1)

Fold sheet by hand and check that sheets are cut

exactly square.

(Remedy 2)

Loosen nut which fixes stopper and adjust

stopper with bolt so that L1 is equal with L2.

1. Remove lower side cover at delivery side.

2. Loosen bind screws on stopper. (2 pcs)

3. Loosen nuts. (2 pcs)

4. Raise/lower stopper with bolt.

5. Install side cover with the reverse procedure

of removing.

NOTE

- Determine whether stopper is raised or lowered according to length of L1 and L2.

- When L1 is longer than L2, raise left bolt or

lower right bolt.

- When L1 is shorter than L2, lower left bolt or

raise right bolt.

Page 22

15

Operation Side View

Joint Belt

Timing Belt

Timing Belt

Staple & Fold Stopper

Stopper in Fold Section

Top View from Operation Side

Joint Belt

Timing Belt

Staple & Fold Position

Adjust Pulley

Staple & Fold Stopper

Staple & Fold Stopper Handle Shaft

Transporting Direction of Sheets

Folding Line

Staple

7. Troubleshooting

7-1-3 Sheets are folded correctly, but staples are not on folding line.

(Cause)

Either staple & fold stopper or stopper in

fold section is not positioned correctly.

(Remedy)

Adjust either staple & fold stopper or stopper

in fold section position with staple & fold

position adjust pulley.

1. Measure the distance between staple and

folding line.

2. Loosen two fix screws on staple & fold

position adjust pulley.

3. Move staple & fold stopper either delivery

side or entrance side by measured length,

holding staple & fold stopper shaft with your

right hand.

- To delivery side, when staple and folding

line are as shown in the left drawing.

- To entrance side, when staple and folding

line are opposite from the position shown in

the left drawing.

NOTE

Staple & fold stopper and stopper in fold

section are activated together through joint

belt.

Page 23

16

Pin Hole (R)

Pin Hole (F)

Joint Plate F

Top View from Operation Panel

Joint Plate R

Rear Side

Front Side

Bolts M5-15

Bolts M5-15

Staple Base

Staple Unit

Transporting Direction of Sheets

Folding Line

Staples

(Remedy)

Adjust staple positions by moving staple unit

base.

NOTE

- When the positions of staples and folding line

is as shown in the above drawing, move the

rear side of the staple base to the right or move

the front side of the staple base to the left.

- When the positions of staples and folding line

is opposite from the positions as shown in the

above drawing, move the rear side of the staple

base to the right or move the front side of the

staple base to the left.

1. Insert pin into pin hole (F) at the front side.

Shaft (No.5) can be used instead of pin.

2. Loosen four M5-15 bolts.

3. Adjust staple base referring to NOTE above.

4. Fasten hour bolts.

5. Pull out pins.

7. Troubleshooting

7-1-4 Sheets are folded correctly, but staples are skewed.

(Cause)

Staple unit is skewed against sheets.

Page 24

17

Transporting Direction of Sheets

Aligned

Not Aligned

Aligned

Folding Line

Folding line and staples are aligned.

7. Troubleshooting

7-1-5 SPF-9 is set up correctly and folding is not skewed. But the result of folding is

as shown below.

(Cause)

Position of staple & fold

stopper indicator, jog indicator, staple & fold stopper unit,

and jog unit is not correct.

7-2 Ejected booklet is smeared.

(Remedy)

Move staple & fold stopper indicator or replace scale, or

move jog indicator or replace scale.

(Remedy)

Clean press rollers with alcohol-soaked cloth.

(Cause)

Press rollers are dirty.

Page 25

18

Spring 1

Spring 2

Nut

Bolt

Fold Roller

Press Roller B

Press Roller A

Timing Belt

Front Frame from Operation Side View

7. Troubleshooting

7-3 Sheet jam causes a stop of press rollers during folding operation, or

booklet is not ejected by pressing eject button even though press rollers are

rotating.

(Cause)

Pressure between press rollers A and B

is not proper.

(Remedy)

1. Remove cover.

2. Remove two spring 1 and two spring 2 on

both front and rear frame.

3. Loosen nut.

4. Adjust pressure of press roller by turning

adjust bolt.

5. Fasten nut and install springs 1 and 2.

NOTE

- Excessive pressure between press rollers A

and B causes sheet jam without sheets' passing

through press rollers.

- Weak pressure (much clearance) between

pressure rollers A and B causes slip and sheets

are not ejected.

CAUTION

- When press rollers stop, turn power

off immediately.

Page 26

19

Solenoids

Staple & Fold Stopper Unit

Stopper Guides

(4 pcs)

Side Staple Stopper

Solenoid

Side Staple Stopper Unit

7. Troubleshooting

7-4 Slow movement of side staple stopper causes sheet jam when side stapling

or corner stapling is performed.

(Cause)

The position of solenoid in side

staple stopper unit is too high, solenoid cannot pull up stopper.

(Remedy)

Lower the position of solenoid.

(Cause)

Clearance between stopper guides

and side staple stopper unit is too

narrow.

(Remedy)

Widen two lower guides of four guides. Adjust

position of two lower guides for smooth up/down

movemnt of side staple stopper.

7-5 Finished booklets have scratches when side stapling or corner stapling is

performed.

(Cause)

The position of solenoid in staple &

fold stopper unit is too low, booklet

hits staple & fold stopper when

ejected.

(Remedy)

Raise the position of solenoid.

Scratch

Transporting Direction of Sheets

Page 27

20

7. Troubleshooting

7-8 FC-9 Stopper does not work smoothly.

(Cause)

Stopper shafts are twisted at the position of

end shaft.

(Remedy)

Loosen fix screws at the top of stopper

shafts screws and adjust stopper shafts so

that they are not twisted. Stopper shafts

twist can be checked by use of two holes

(No.3). Check that stopper is parallel to

lower knife when fix screws are fastened.

Holes (No.3)

Stopper Shaft

Sheet Forwarding Direction

Stopper Unit

Fix Screw (Adjustable Side)

Fix Screw (Fixed Side)

Stopper

End Shaft

Stopper

(Cause 1)

Sheets do not hit stopper properly because

sheets slip on belt or curling sheets are

caught at transport section.

(Remedy 1)

Clean belt so that sheets are transported

smoothly.

(Cause 2)

Stopper is not parallel to lower knife if

sheets hit stopper properly.

(Remedy 2)

Adjust stopper so that it will be parallel to

lower knife.

- Loosen fix screw on stopper at adjusting

side. (Hole at adjusting side is larger than

that at fixed side.)

- Place a exact-square sheet as shown in

the drawing.

- Fasten fix screw. Check that stopper

shafts can be moved when screw is fastened.

7-9 Sheets are trimmed askew.

Page 28

21

8. Electronic Parts Layout

8-1 SPF-9

Sheet Presence Sensor

Terminal Block (Drive Motor)

Transport Belt Drive Motor

Drive Relay

Receptacle

Top Cover Microswitch

Sheet Pass Sensor

Panel P.C.B. QPW-461

Power Switch

Breaker

Upper : 2A 24 V

Middle : 2A Knife Motor

Lower : 5A Power

Power Supply 24V

Power Supply 5V

Brake P.C.B. QPW-465

Control P.C.B. QPW-460

Knife Home Position Sensor

Eject Guide Open Microswitch

Booklet Presence

in Folding Section

Page 29

22

8. Electrical Parts Layout

8-2 FC-9

Stopper Section Sensor

Motor Relay

Receptacle

Transport Section Sensor

Panel P.C.B. QPW-477

Power Supply 24 V

Power Supply 5 V

Knife Motor Driver

Breaker 3A

Stopper Solenoid

SSR

Page 30

23

L3 Collating

L4 Collator's Feed Error

L5 Transport Belt Drive Motor

L6 Knife Motor

L7 Jog Button

L8 Eject Button

L9 Operation Mode Select Button

L10 Function Moder Select Button

L11 Sheet Pass Sensor

L12 Sheet Presence Sensor

L13 Knife Home Position Sensor

L14 Booklet Presence in Fold Section

L15 Upper Cover Sensor

Not illuminate during collating.

Not illuminate when collator feed error occurs.

Illuminates during rotating.

Illuminates during rotating.

Illuminates when pressed.

Illuminates when pressed.

Illuminates when pressed.

Illuminates when pressed.

Illuminates when sheet exists on sensor.

Illuminates when sheet exists on sensor.

Illuminates when knife is at home position.

Illuminates when sheet exists on sensor.

Illuminates when cover is open.

L16

L15 Not Used

L18

CON1

L7 L8 L9 L10

CON13

CON3

CON11CON10

L3 L4 L5 L6

CON5CON4

CON12

CON2 CON8 CON7 CON6 CON9

CON9

Control P.C.B. QPW460

L11 L12 L13 L14

L15 L16 L17 L18

9. Control Panel LED Descriptions

9-1 SPF-9

Page 31

24

L13

L12

L11

L10

L9

L8

L7

L6

L1 L2 L3 L4

L5

9. Control Panel LED Descriptions

9-2 FC-9

L1 Stapling & Folding Mode (SPF-9) Illuminates when "stapling & folding" mode is selected.

L2 Collating Not illuminate in collating.

L3 Hand Feed Mode(SPF-9) Not illuminate when sheets are fed manually.

L4 Transport Motor Illuminates while transport motor is activated.

L5 Not used

L6 Knife Inching Button Illuminates when knife inching button is pressed.

L7

Sheet Presence in Transport Section

Illuminates when sheets exist in transport section.

L8

Sheet Presence in Stopper Section

Illuminates when sheets exist in stopper section.

L9 Trimmings Box Illuminates when trimmings box is open.

L10 Knife Sensor Illuminates when knife reaches the upper limit position.

L11 Door Illuminates when door is open.

L12 Not used

L13 Not used

QPW-467

Page 32

25

Upper Cover seonsor

Jog Guide Solenoid

Jog Plate Solenoid

Staple & Fold Stopper Solenoid

Connector for Collator

Connecting Cable for FC-9Staple (Drive Side)

Staple (Operation Side)

Noise Filter

Lower Breaker 5A

Drive Motor Relay

Relay

Upper Breaker 2A

Drive Motor

Middle Breaker 2A

CON1 CON13 CON3

CON11CON10CON5CON4

CON12

CON2 CON8 CON7 CON6 CON9

CON9

Side Staple Stopper Solenoid

Gate

Clutch

Transport Solenoid F

Transport Solenoid R

Drive Motor Relay

Panel P.C.B. QPW-461

Control P.C.B.

QPW-460

Break P.C.B. QPW-465

Knife Motor

Ejecting Guide sensor

Sheet Pass Sensor

Sheet Presence Sensor

Booklet Presence Sensor

Knife Home Position Sensor

5V Power Supply

24V Power Supply

Upper

Upper

Lower

Lower

10. Line Diagram

10-1 SPF-9

Page 33

26

CON8

CON2CON3

CON1

CON5 CON6

CON4

CON7

10. Line Diagram

10-2 FC-9

Control P.C.B.

QPW-476

Door Microswitch

Door Relay

Connecting Cable

Counter

Stopper Solenoid

Entrance Section Sensor

Knife Upper Limit Sensor

Stopper Section Sensor

Knife Motor Driver

Trimmings Box Open Microswitch

Power Supply 24 V

Power Supply 5 V

SSR for Power Switch

Transport Motor Relay

Receptacle with Noise Filter

Breaker 3 A

Transport Motor

Transport Motor Relay

Knife Motor Driver

Terminal Board

Door Relay

Power Supply 24 V

Power Supply

5 V

SSR

Page 34

Page 35

SM_SPF9/FC9

10 Connector Road, Andover, MA 01810

Revision 1

Standard Business Systems

(978) 470-1920 (978) 470-2771

Loading...

Loading...