Page 1

BOOK BINDER

BOOK BINDER

BQ-260/260L

Important Information

- This manual is designed to help you to install, operate and maintain Perfect Binder BQ-

260/260L. Read, understand and keep this manual in a safe and convenient place.

- Do not operate BQ-260/260L until you read and understand the instructions in this

manual.

- Horizon International Inc. shall not be liable for incidental consequential damages resulting from : improper or inadequate maintenance by customer; unauthorized modification or

misuse; operation outside of the environmental specifications for the product.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to

change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or translated to another language without the prior written consent of Horizon International Inc.

060404/BQ260/06E/DV UM202001-06

I

Page 2

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in damage on machines. It may also be used to alert against unsafe

practices.

- Read and understand all safety instructions with signal word such as WARNING and

CAUTION. If safety instructions are ignored, personal injury will result.

- Horizon International Inc. cannot anticipate every possible situation that might involve

a potential hazard. The instruction in this manual and warning labels on the machine are

therefore not all inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation could cause injury to personnel. Do not attempt to

operate any switch, valve, or other energy isolating device where it is locked or tagged out.

- Do not operate the machines with any covers being removed.

- Some of the drawings in this manual shows the machine uncovered for explaining the

detail or inside of machine.

II

Page 3

CONTENTS

Important Information ............................................................................................I

Safety Precautions....................................................................................................II

1. Machine Parts Descriptions

1-1 General View of BQ-260 ...................................................................................2

1-2 Control Panel .....................................................................................................3

1-3 Operation Panel .................................................................................................5

1-4 Accessories and Tools ........................................................................................6

1-5 Accessory Tools..................................................................................................7

2. Installation Instructions

2-1 Installation Instructions ....................................................................................10

2-1-1 Installing Place ...............................................................................................10

2-1-2 Installing BQ-260 ...........................................................................................10

2-1-3 Releasing Transport Lock Nut .......................................................................11

2-1-4 Connecting Power Cord ................................................................................. 12

3. Before Starting Operation

3-1 Safety Device Function Check ..........................................................................13

3-1-1 Stop Button ..................................................................................................... 13

3-1-2 Safety Cover ...................................................................................................16

3-2 Every Day Check Up .........................................................................................18

3-2-1 Glue Level Check ...........................................................................................18

3-2-2 Level Plate Cleaning Check ...........................................................................18

3-2-3 Nipper Unit Check..........................................................................................19

3-2-4 Dust Bag Check .............................................................................................. 19

4. Set Up BQ-260

4-1 Nipper Unit Set Up ............................................................................................21

4-1-1 Nipper Unit Set Up for Stock Thickness ........................................................ 21

4-1-2 Cover Positioning Set Up ...............................................................................24

III

Page 4

4-2 Clamper Unit Set Up .........................................................................................26

4-3 Milling Unit Set Up............................................................................................27

4-3-1 Milling Guide Set Up .....................................................................................27

4-3-2 Milling Depth Set Up .....................................................................................28

4-4 Vertical Stacker Unit Set Up ............................................................................29

4-5 Melt Tank Unit Set Up ......................................................................................30

4-6 Operation Switches Set Up ...............................................................................32

4-7 Test Binding .......................................................................................................33

4-7-1 Test Binding for With Milling Binding..........................................................33

4-7-2 Pad Binding ....................................................................................................35

5. Operation Procedure

5-1 With Cover Binding Operation ........................................................................37

5-2 Pad Binding ........................................................................................................39

6. Special Binding Method

6-1 Small Size Binding .............................................................................................43

6-1-1 Register Shaft Position Adjustment ...............................................................43

6-1-2 Cover Position Register Block Installation ....................................................45

6-1-3 Small Cover Stopper Installation ...................................................................46

6-1-4 Shooter Attachment ........................................................................................47

6-2 To Increase Glue Film Thickness.....................................................................48

6-2-1 Spacer Plate Attachment ................................................................................48

6-2-2 Melt Tank Height Adjustment........................................................................51

6-3 To Adjust Condition of Spine ...........................................................................52

7. After Binding Finish

7-1 Glue Supply ........................................................................................................53

7-2 Clean Up While Power On................................................................................55

7-2-1 Nipping Plate and Nipper Jaw Clean Up........................................................55

7-2-2 Level Plate Clean Up......................................................................................56

7-3 Clean Up after Power Off .................................................................................58

7-3-1 Dust Bag Clean Up ......................................................................................... 58

7-3-2 Vertical Stacker Unit Clean Up ...................................................................... 58

7-4 Clean Up after Power Off .................................................................................59

7-4-1 Milling Unit Clean Up....................................................................................59

7-4-2 Gluing Length Sensor Clean Up ....................................................................60

7-4-3 Cover Sensor Clean Up ..................................................................................60

IV

Page 5

8. Maintenance

8-1 Once A Month ....................................................................................................61

8-1-1 Lubrication on Melt Tank Unit ......................................................................62

8-1-2 Greasing on Clamper Rail ..............................................................................62

8-1-3 Oiling on Nipper Unit.....................................................................................62

8-2 As Required........................................................................................................63

8-2-1 Milling Cutter Replacement ...........................................................................63

8-2-2 Roughening Cuter Replacement.....................................................................64

8-2-3 Glue Draining .................................................................................................66

9.

Installation of Suction Cover Feeder CF-260(Optional Equipment)

9-1 Before You Begin ...............................................................................................67

9-1-1 Specifications ................................................................................................. 68

9-1-2 Machine Descriptions and Functions .............................................................68

9-1-3 Descriptions and Functions of Operation Panel .............................................69

9-1-4 Tools and Accessories ....................................................................................70

9-2 Set Up and Operation........................................................................................71

9-2-1 Cover Piling....................................................................................................71

9-2-2 Open/Close of Sucker Valve ..........................................................................72

9-2-3 Cover Feeder Position Set Up ........................................................................72

9-2-4 Support Plate Set Up ...................................................................................... 72

9-2-5 Attachment of Accessories .............................................................................73

9-2-6 Feeding Test ...................................................................................................74

9-2-7 Cover Piling....................................................................................................74

9-2-8 Binding Finish ................................................................................................75

9-3 Trouble Shooting ...............................................................................................76

9-3-1 When Misfeed Occurs. ...................................................................................76

9-3-2 When Two Covers are fed at the same time...................................................77

9-4 CF-220 Accessories ............................................................................................78

10.

Installation of Friction Cover Feeder CF-220(Optional Equipment)

10-1 CF-220 Accessories ..........................................................................................79

10-2 Set Up................................................................................................................81

10-3 Installation of CF-220......................................................................................88

V

Page 6

This page is intentionally left blank.

VI

Page 7

1. Machine Parts Descriptions

1. Machine Parts Descriptions

1-1 General View of BQ-260 ......................................................................... 2

1-2 Control Panel ........................................................................................... 3

1-3 Operation Panel ....................................................................................... 5

1-4 Accessories and Tools.............................................................................. 6

1-5 Accessory Tools........................................................................................ 7

1

Page 8

1. Machine Parts Descriptions

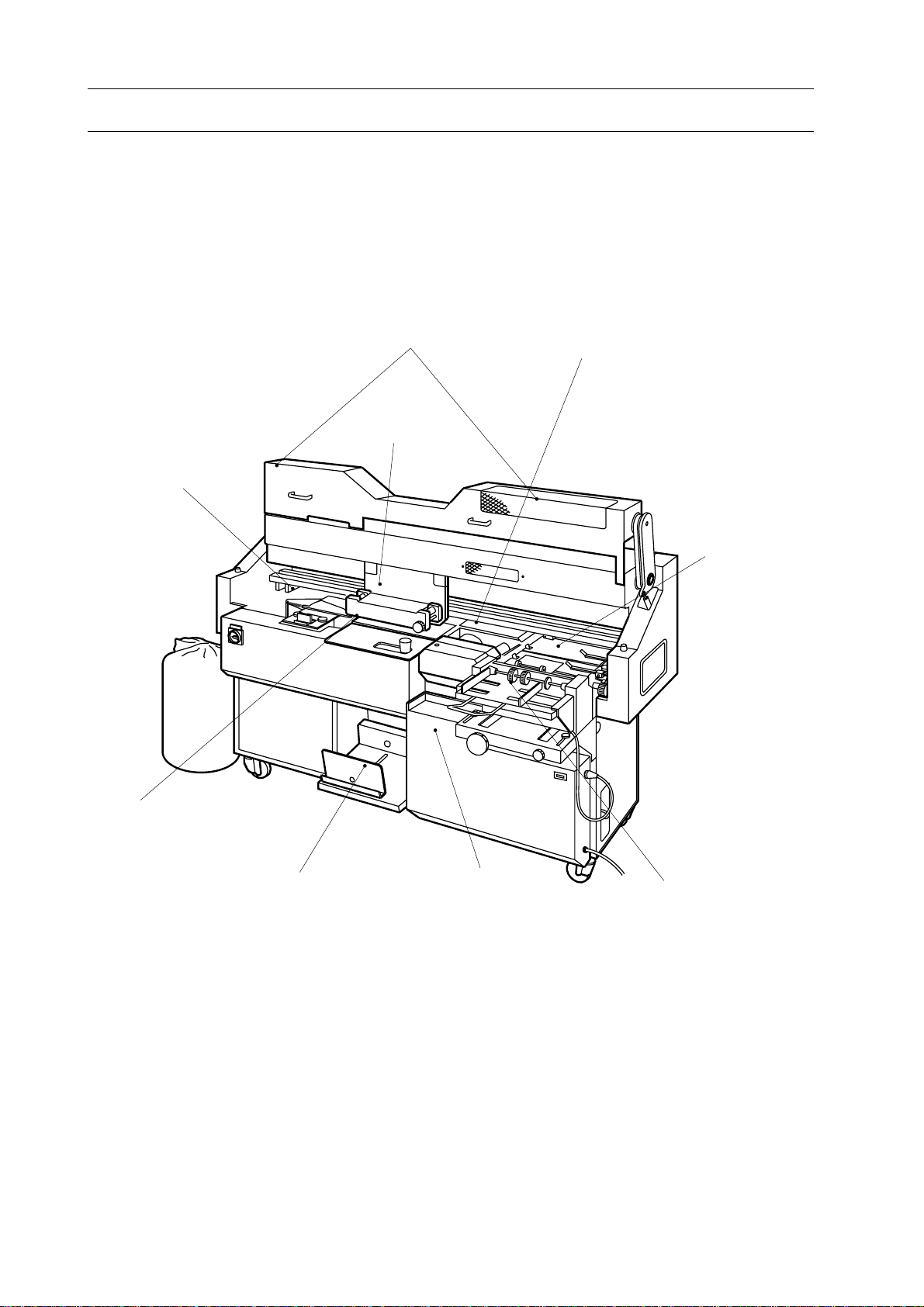

1-1 General View of BQ-260

Milling Unit

Safety Cover

Clamper Unit

Melt Tank Unit

Nipping Unit

Level Plate

Vertical Stacking Section

Control Panel

Cover Feeding Unit

(Option)

2

Page 9

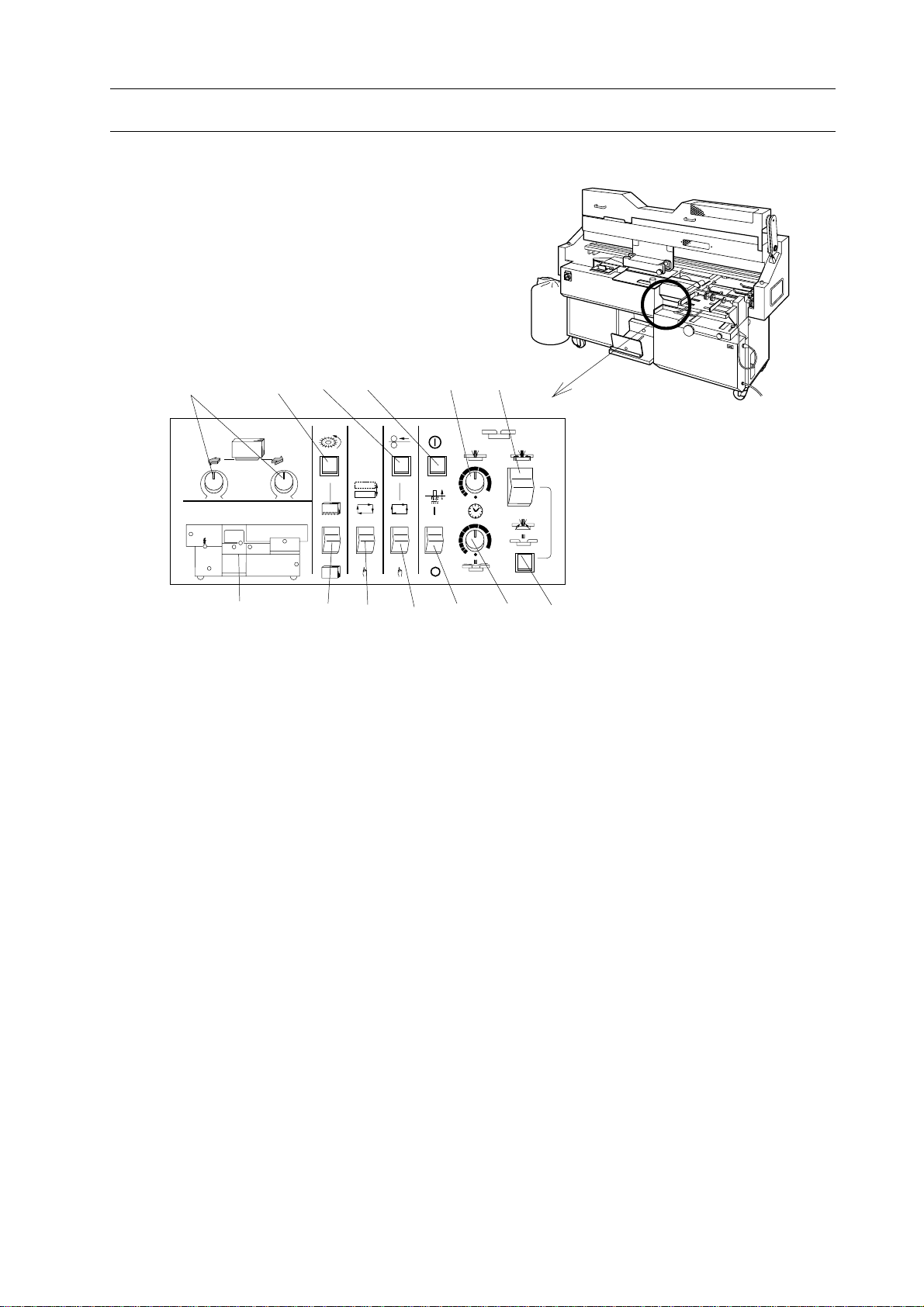

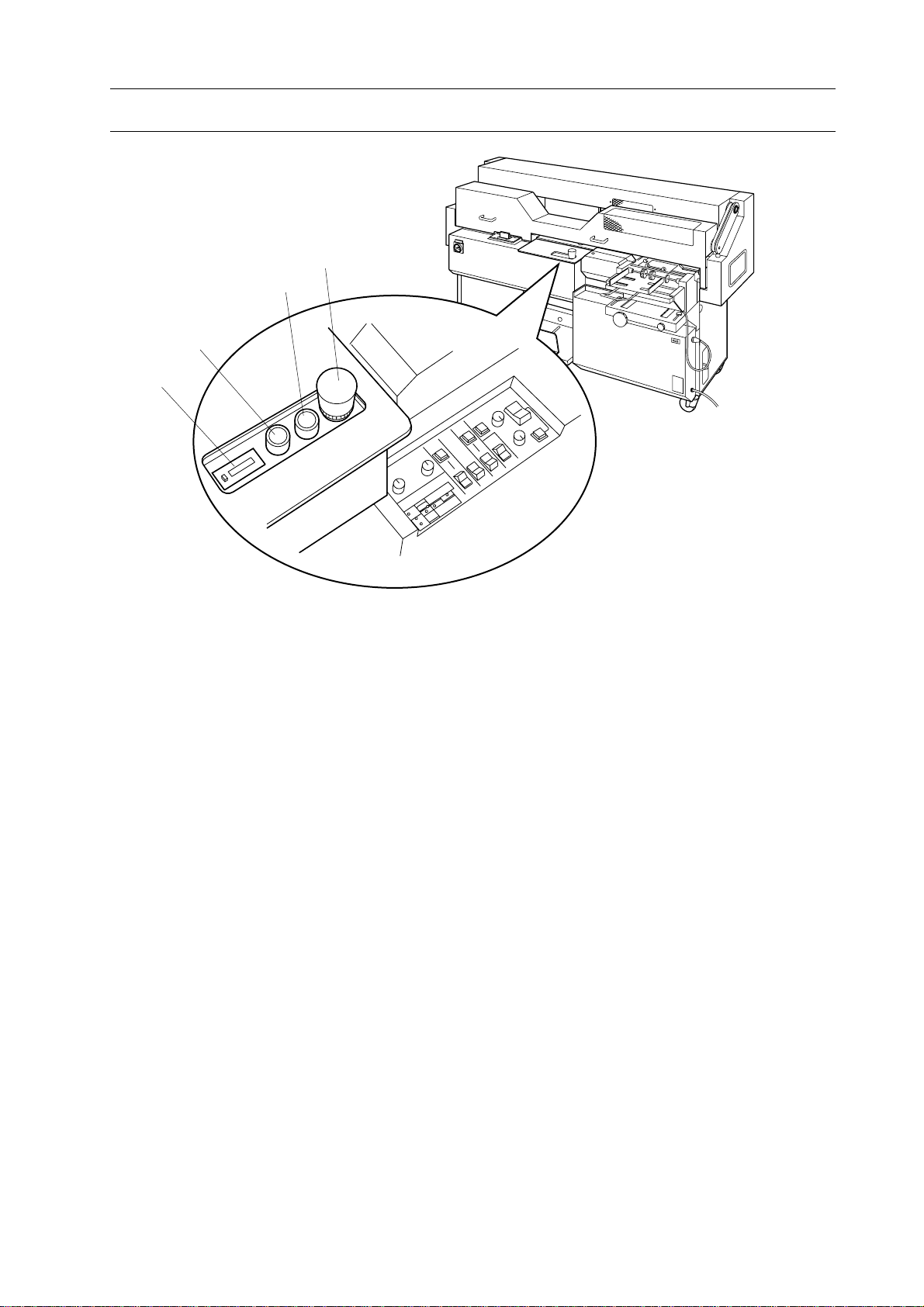

1-2 Control Panel

1 234 56

Trouble Monitor

1. Machine Parts Descriptions

7 8 9 10111213

1.Gluing Length Adjusting Knobs

Used to adjust spine glue length.

2.Milling Start Button

Used to start to rotate milling cutter.

3.Cover Single Feed Button

Used to feed one cover sheet from cover

feeder with automatic cover feeding

mode.

4.Nipper Up/Down Button

Used to raise or lower nipper unit for

setting up nipping unit.

5.Nipping Time Control Knob

Used to control nipping time.

6.Nipping Mode Select Switch

Used to select nipping mode. Three

different modes, With milling binding

mode, Signature binding mode and Pad

binding mode can be selected.

7.Trouble Monitor

(Please refer to next page.)

8.Milling Mode Select Switch

Used to select milling mode, with milling

or without milling.

9.Level Plate Mode Select Switch

Used to select reset mode of Level Plate

after one complete cycle of binding

automatic or manual.

10. Cover Feed Mode Select Switch

Used to select cover feed mode, automatic or manual

11.Clamper Pin On/OFF Switch

Used to turn on/off clamper pin which

holds stock in clamper when without

milling mode is selected..

12.Nipping Delay Time Control Knob

Used to control nipping delay time

length.

13.Pad Binding Lamp

This lamp turns on when pad binding

mode is selected.

3

Page 10

1. Machine Parts Descriptions

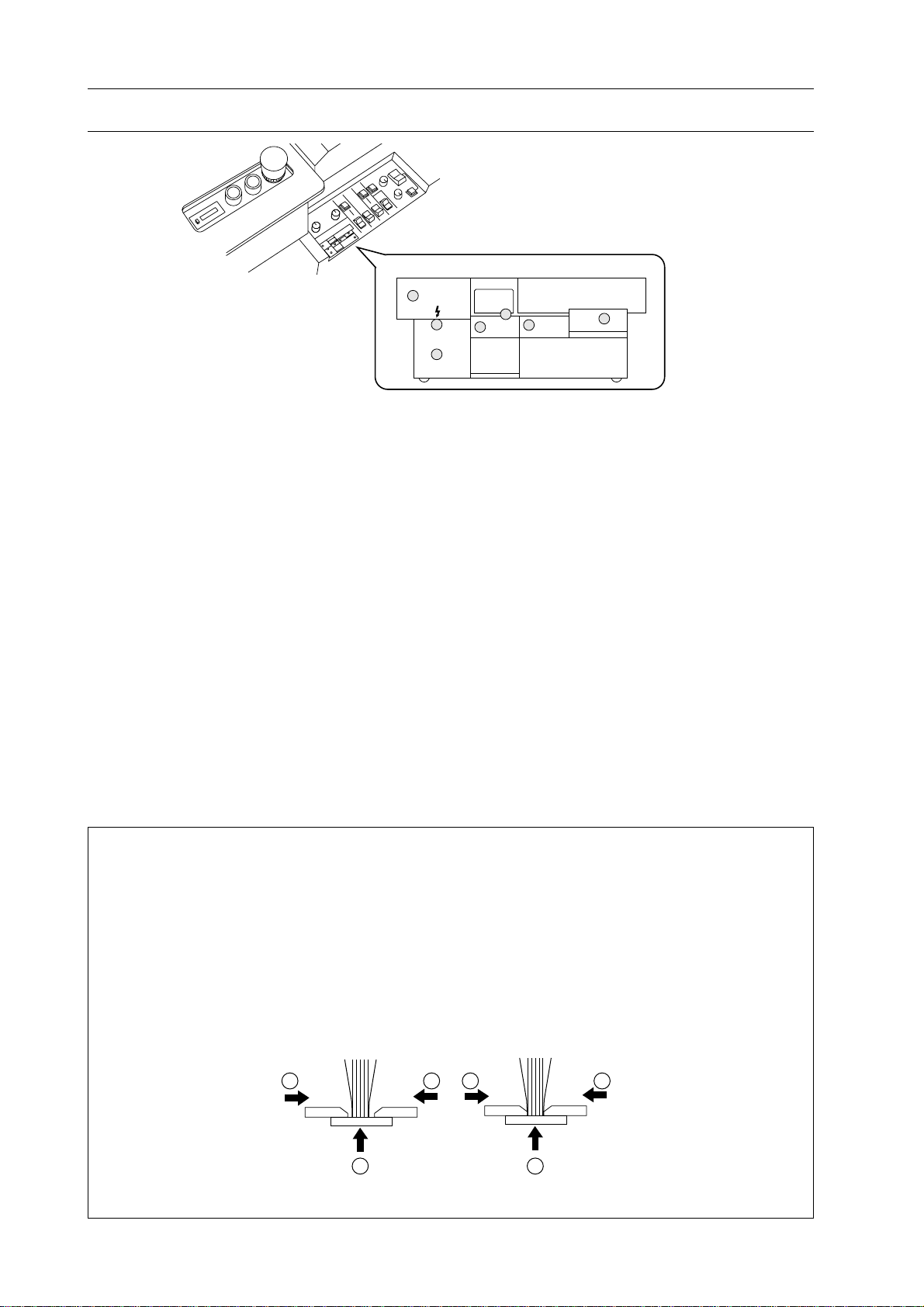

1-2 Control Panel

(1)

Trouble Monitor

(3)

(6)

Trouble Monitor

Indicates incorrect point on BQ-260.

When one of them turns on except power

lamp, BQ-260 can not be started.

Each LED turns on when :

(1) safety cover opens.

- Close safety cover.

(2) milling cutter does not rotate although

with milling binding mode is selected.

- Depress milling cutter start button to

rotate milling cutter.

(3) level plate opens.

- Depress start button to reset level plate.

(4) emergency stop switch is depressed.

- Pull up emergency stop switch to release it.

(7)

(2)

(5)

(4)

(5) glue is not ready for biding.

- Wait until glue will be melted.

(6) cover is not fed to stopper.

- Feed cover completely until it gets

stopped against stopper.

(7) main power is on.

NOTE : Difference of Nipper Movement

Nipping unit has two different movements, with milling binding mode and signature bind-

ing mode. In with milling binding mode, nipper plate raises at first and then front and back

nipper jaws nip stock. So, this binding mode is suitable for binding milled stock or cut sheet

stock. In signature binding mode, nipper plate and two nipper jaws raise and nip stock at

same time. So this binding mode is suitable for binding signature which spine is shaped

thicker because of folded edge. Book spine will be formed too sharp or destroyed when

spine is pressed at first as in with milling binding mode. Binding quality or book spine

shape bound with signature binding mode is not affected so much by folding.

2 211 1

1

With Milling Binding Mode Signature Binding Mode

4

Page 11

1-3 Operation Panel

4

3

2

1

1. Machine Parts Descriptions

1.Counter (with reset button)

Used to count amount of binding. When

reset button is set at far side, number in

counter can not be reset.

2.Level Plate Button

Used to open and reset level plate manually

when level plate switch is set at manual

operation mode.

3.Start Lamp and Start Button

Lamp indicates that BQ-260 is ready to

bind.

4.Stop Button

5

Page 12

1. Machine Parts Descriptions

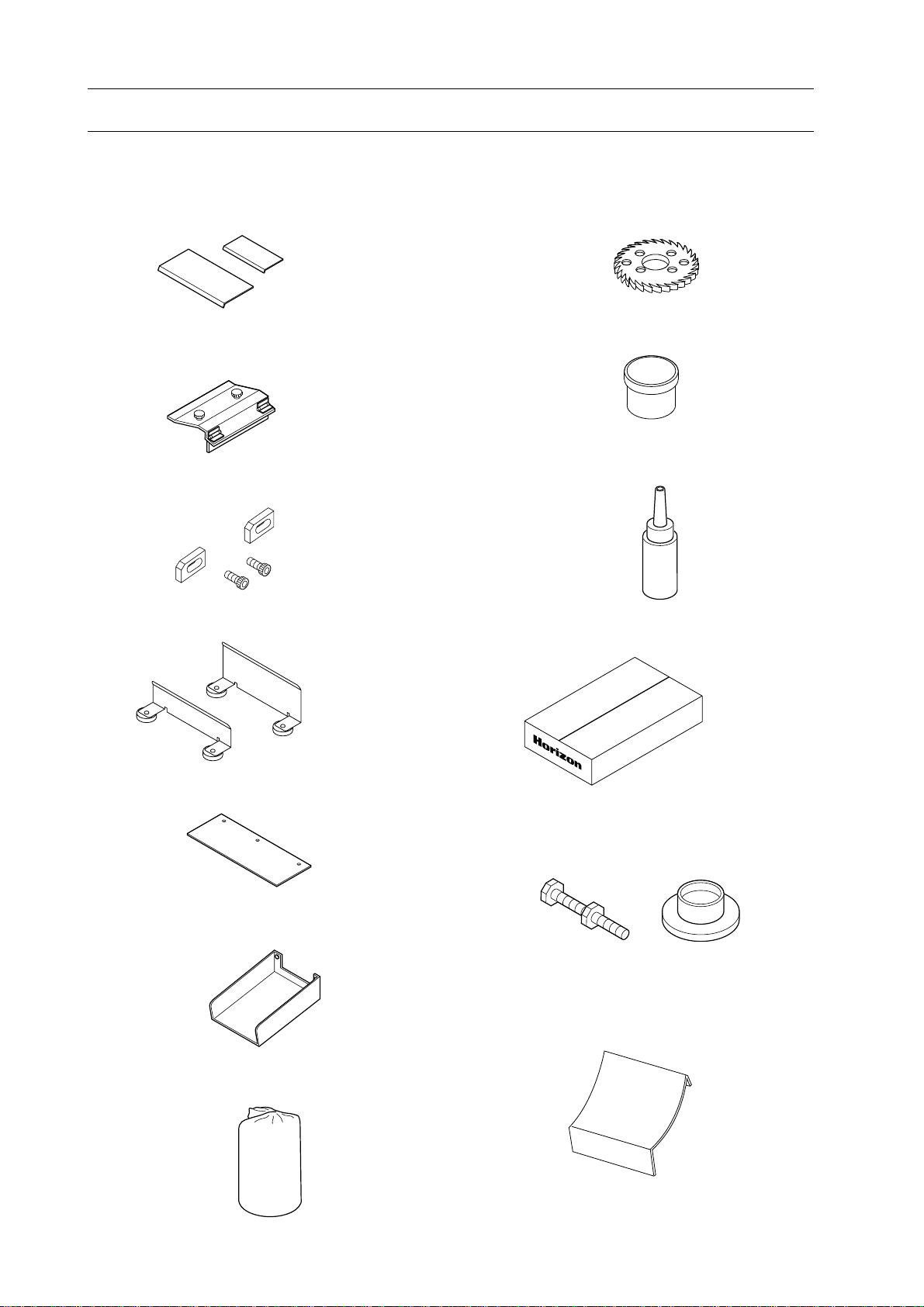

1-4 Accessories and Tools

Check all accessories are supplied with your BQ-260 when you open package.

1. Support Plates for Cover Feeder Unit

Large :1 pc

Small :1 pc

2. Small Cover Stopper (1 pc)

3. Small Cover Position Register (2 sets)

4. Clamper Support Guide

Large :1 pc

Normal : 1pc

8. Milling Cutter (1 pc)

9. Grease (1 pc)

10. Chain Oil (1 pc)

11. Hot Melt HM-110 (5 kg)

5. Space Plate (1 pc)

6. Drain for Glue Replacement (1 pc)

7. Dust Bag (1 pc)

H

M

-1

1

0

5

k

g

12. Mount Base with Leveling Bolt (3 sets)

13. Chute for small book (1 pc)

6

Page 13

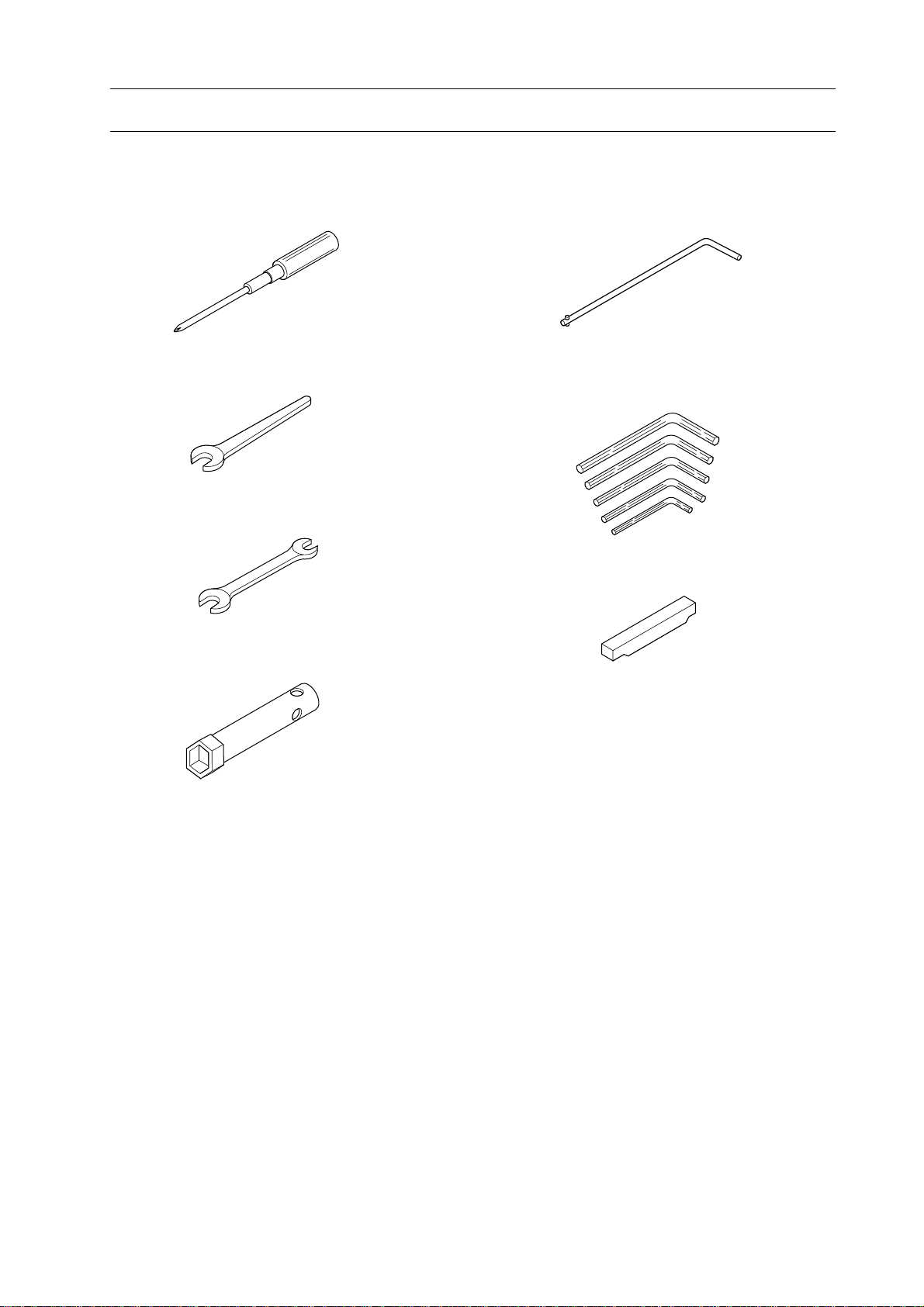

1-5 Accessory Tools

Check all tools supplied with your BQ-260 when you open package.

1. Machine Parts Descriptions

1. Screw Driver (1 pc)

2. Spanner (30 mm) (1 pc)

3. Spanner (13/17 mm) (1 pc)

4. Box Wrench ( 30 mm) (1 pc)

5. Special Wrench (1 pc)

6. Allen Wrench (2.5, 3, 4, 5, 6 mm)

(1 pc of each)

7. Roughening Cutter Height Gauge (1 pc)

.8

0

.5

0

7

Page 14

1. Machine Parts Descriptions

This page is intentionally left blank.

8

Page 15

2. Installation Instructions

2. Installation Instructions

2-1 Installation Instructions.......................................................................... 10

9

Page 16

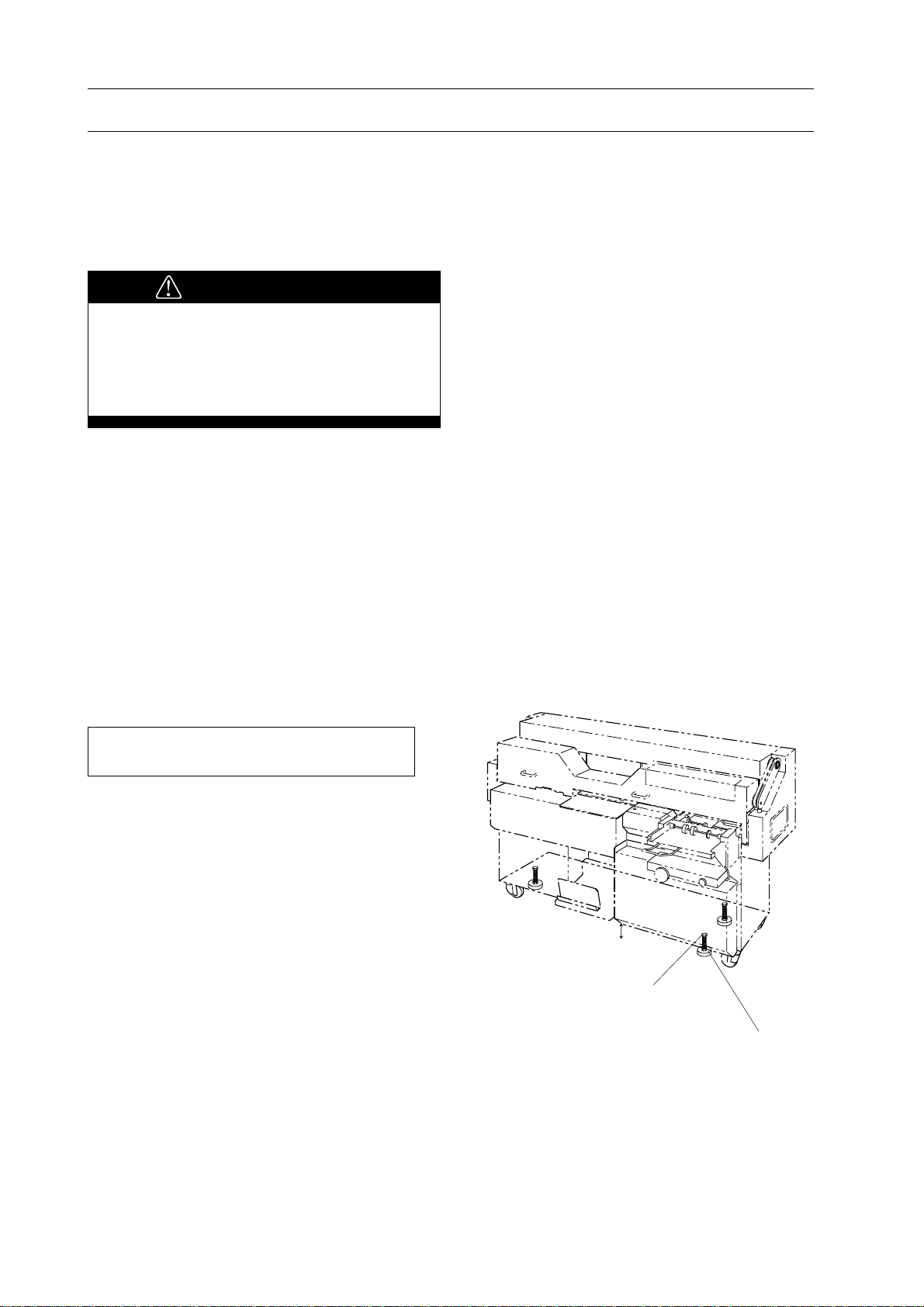

2. Installation Instructions

2-1 Installation Instructions

2-1-1 Installing Place

This section shows condition of installing

place for BQ-260.

WARNING

Weights of BQ-260 is about 500 kg.

Pay attention enough to transportation.

BQ-260 could fall down or catch a

person with something like wall.

1. Select a flat, rigid floor free from vibra-

tion.

2. Select a place free from direct exposure

to sun light.

3. Select a place free from extremely high

temperature and humidity.

2-1-2 Installing BQ-260

This section shows how to install BQ-260.

Necessary Tools : Spanner (19 mm)

1. Place BQ-260 on installation place.

2. Place 3 mount base under levelling bolts.

3. Turn leveling bolts with spanner clock-

wise until bottom of BQ-260 is 120 mm in

height.

4. Fasten 3 lock nuts on 3 leveling bolts.

120 mm

Leveling Bolt

Mount

10

Page 17

2-1 Installation Instructions

2-1-3 Releasing Transport Lock Nut

2. Installation Instructions

Melt Tank lock nut is installed to prevent

melt tank moving up and down during transportation.

1. Loosen melt tank lock nut.

NOTE

- It is not necessary to remove transport lock

nut. Remain it loosen.

- Remain height adjust bolt loosen unless

melt tank height adjustment is required.

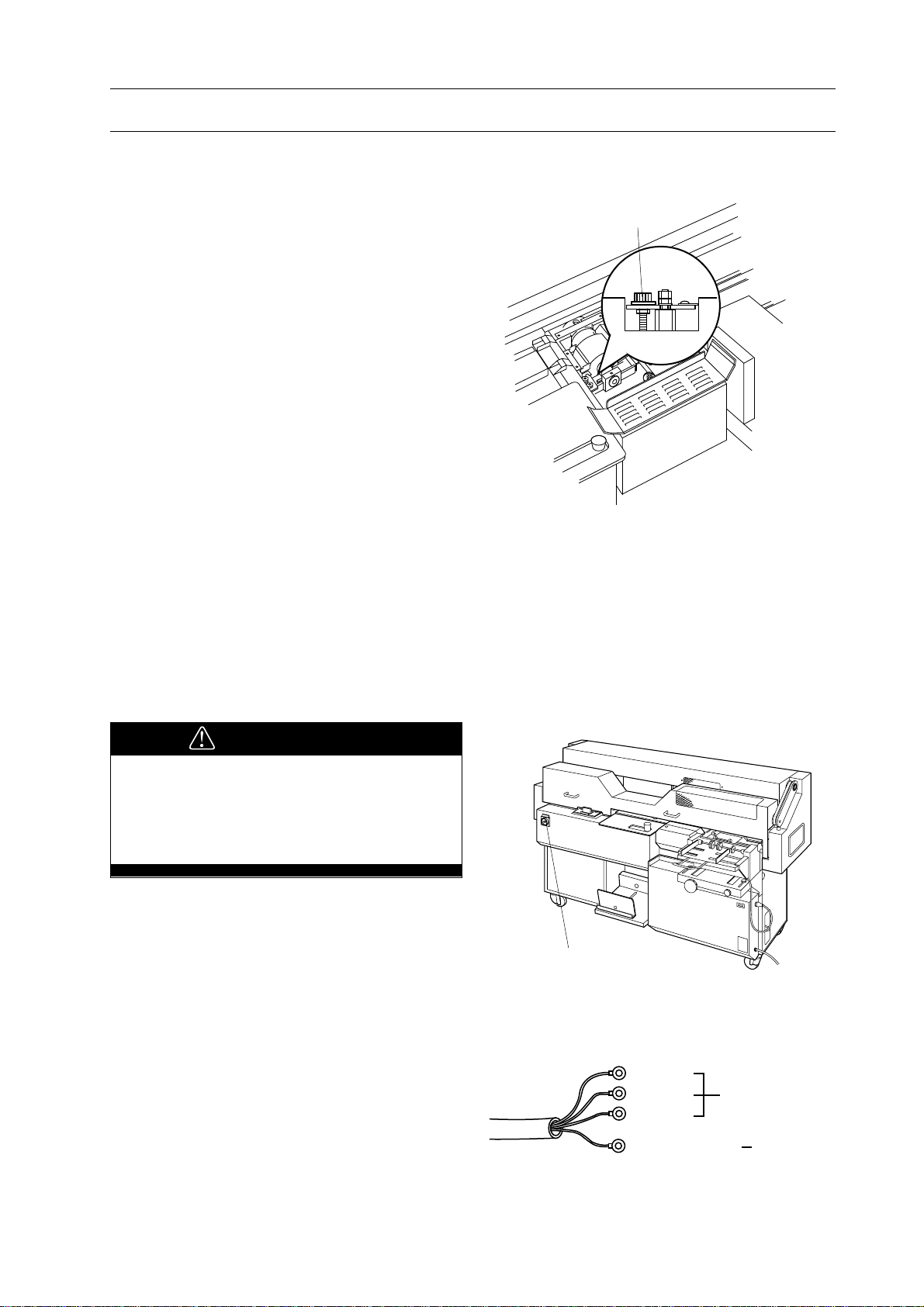

2-1-4 Connecting Power Cord

Height Adjust Bolt

Lock

This section shows how to connect power

cord on BQ-260.

WARNING

- Be sure to depress stop button to

prevent sudden work of BQ-260.

- Confirm voltage and frequency to be

used on your BQ-260 are correct.

1. Depress stop button.

2. Make sure that power switch is off.

3. Turn off main power or breaker in your

shop.

4. Attach power cord to 3-phase power

source.

Main Switch

Blue

Brown 3-Phase

Black

11

Green/Yellow Ground

Page 18

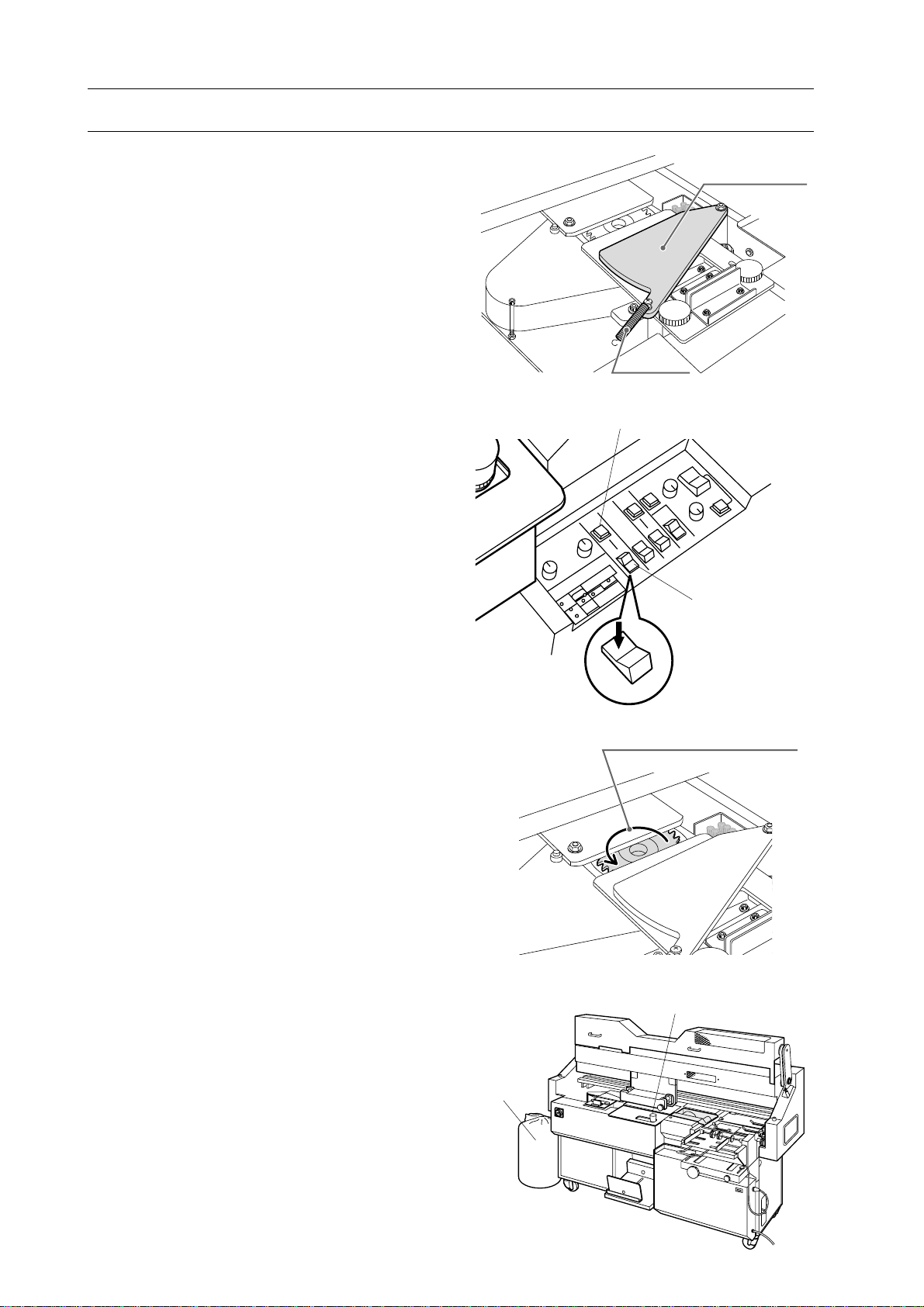

2. Installation Instructions

2-1 Installation Instructions

5. Turn on main power or breaker in your

shop.

6. Turn on power switch on BQ-260.

7. Remove the spring and open the shutter

plate.

8. Pull up stop button.

9. Depress milling mode select switch to

far side to select with milling mode.

10. Depress milling start button.

- Blower will start at the same time.

11. Depress milling mode select switch to

near side to stop the milling cutter, watching the rotating milling cutter from above.

- Check the rotating direction of the milling

cutter.

- The milling cutter should rotate counterclockwise.

Shutter Plate

Spring

Milling Start Button

Milling Mode

Select Switch

With Milling Mode

Normal Rotating Direction

12. If the milling cutter rotates clockwise,

stop immediately and perform as follows:

- Turn off power on BQ-260 and main

power or breaker in your shop.

- Change wiring on 3-phase terminal and

perform step 5 through 12.

13. Depress stop button after connecting

power cord correctly.

wat

Stop button

Dust Bag

12

Page 19

3. Before Starting Operation

3. Before Starting Operation

3-1 Safety Device Function Check................................................................ 14

3-2 Every Day Check Up............................................................................... 18

13

Page 20

3. Before Starting Operation

3-1 Safety Device Function Check

This section shows how to check safety device

function. Check all safety device function

before starting operation on BQ-260.

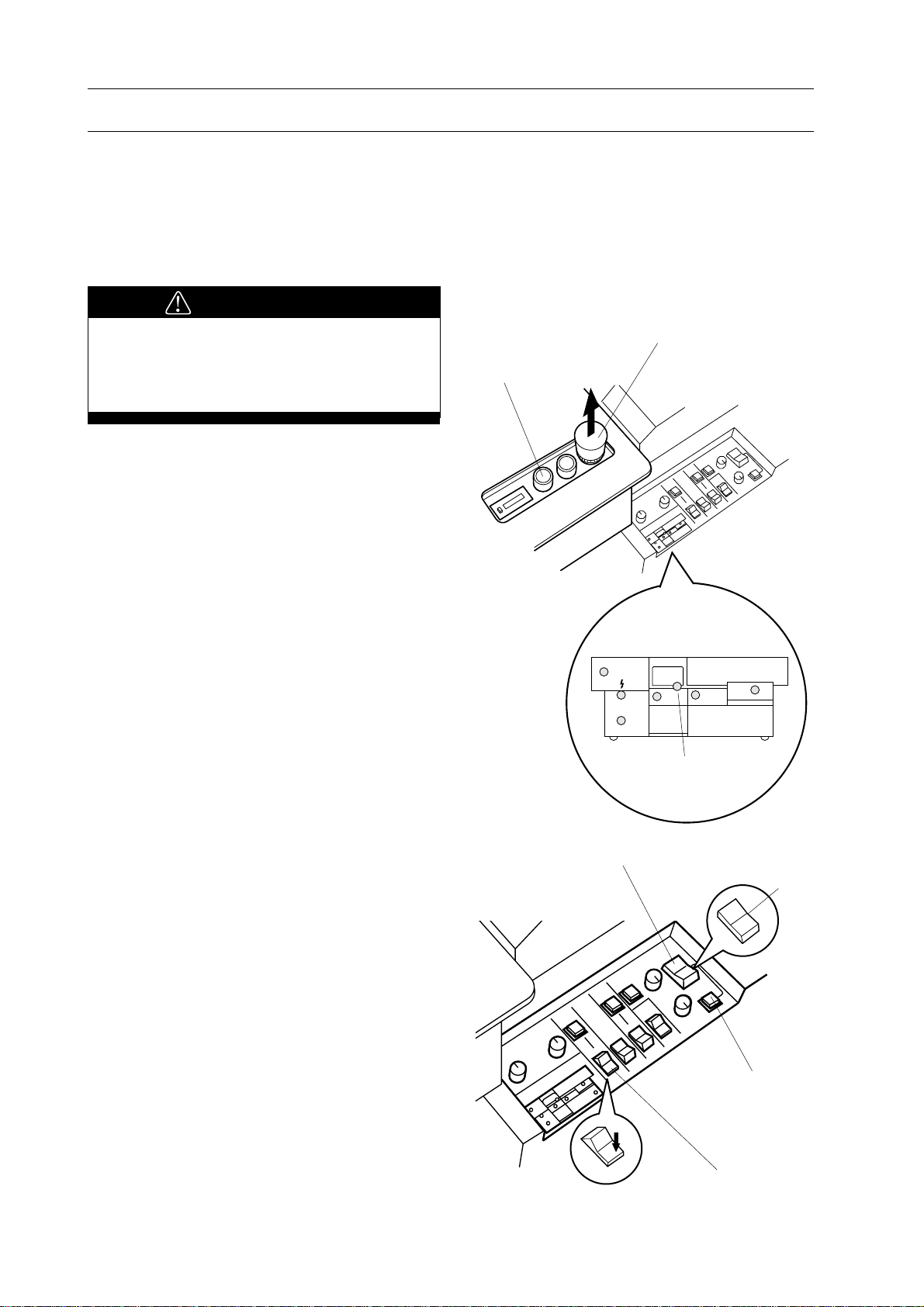

3-1-1 Stop Button

WARNING

Do not touch clamper while clamper is

moving. Moving clamper can cause

severe personal injury.

1. Pull up stop button. LED on monitor for

stop button turns off.

Stop Button

Start Button

2. Set nipping mode select switch to center

position to select pad binding mode.

- Pad binding lamp on control panel turns

on to indicate that pad binding is selected.

3. Select without milling mode with milling

mode select switch.

- Confirm lamp on start button is ON.

NOTE

Depress level plate control button when start

lamp is not on.

LED for Stop Button

Nipping Mode Select Switch

Pad Binding

Lamp

Near Side

Milling Mode

Select Switch

Center

14

Page 21

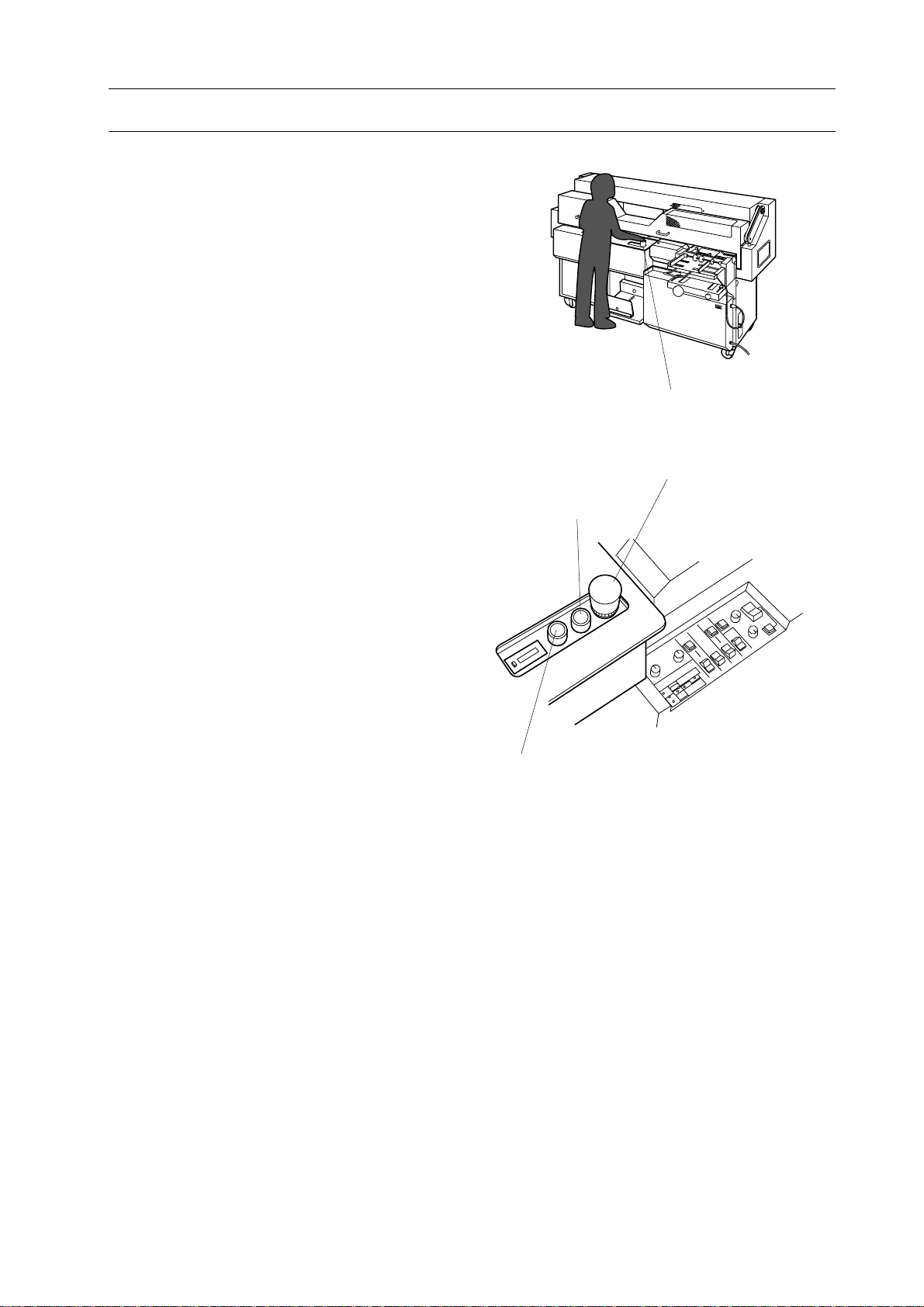

3-1 Safety Device Function Check

4. Check emergency stop function.

- Stand in front of operation panel.

- Hold top of stop button with your right

hand to prepare to depress stop button

immediately.

- Depress start button and depress stop

button 1 second after start button was

depressed.

- Clamper will stop in a moment to show

that emergency stop function works

correctly.

NOTE

When clamper does not stop in a moment

even if stop button is depressed, turn off main

power and call your local dealer.

3. Before Starting Operation

Stop Button

Stop Button

5. Move clamper to home position.

- Pull up stop button.

- Depress start button to move clamper to

its original position. Clamper will stop

over nipping unit for 10 seconds.

6. Reset level plate.

- When clamper returns to home position,

depress level plate button once to reset

level plate.

- Start button will turn on to indicate

level plate is reset.

7. Depress stop button to prevent BQ-260

works suddenly by mistake.

Start Button

Level Plate Button

15

Page 22

3. Before Starting Operation

3-1 Safety Device Function Check

This section shows how to check safety device

function. Check all safety device function

before starting operation on BQ-260.

3-1-2 Safety Cover

WARNING

Do not touch clamper while clamper is

moving. Moving clamper can cause

severe personal injury.

1. Pull up stop button. LED on monitor for

stop button turns off.

Stop Button

Start Button

2. Set nipping mode select switch to center

position to select pad binding mode.

- Pad binding lamp on control panel turns

on to indicate that pad binding is selected.

3. Select without milling mode with milling

mode select switch.

- Confirm lamp on start button is ON.

NOTE

Depress level plate control button when start

lamp is not on.

LED for Stop Button

Nipping Mode Select Switch

Pad Binding

Lamp

Near Side

Milling Mode

Select Switch

Center

16

Page 23

3-1 Safety Device Function Check

3. Before Starting Operation

4. Check safety cover function.

- Stand in front of operation panel.

- Hold handle on safety cover with your

both hand to prepare to open safety cover

immediately

- Depress start button and open safety cover

1 second after start button was depressed.

- Clamper will stop in a moment to show

that safety cover function works correctly.

NOTE

When clamper does not stop in a moment

even if safety cover is opened, turn off main

power and call your local dealer.

5. Move clamper to home position.

- Close safety cover.

- Depress start button to move clamper to

its original position. Clamper will stop

over nipping unit for 10 seconds.

Safety Cover

Start Button

Handles

6. Reset level plate.

- When clamper returns to home position,

depress level plate button once to reset

level plate.

- Start button will turn on to indicate

level plate is reset.

7. Depress stop button to prevent BQ-260

works suddenly by mistake.

Level Plate

Button

Stop Button

LED for Stop Button

Clamper

Cover Feeder

Unit

17

Page 24

3. Before Starting Operation

3-2 Every Day Check Up

3-2-1 Glue Level Check

Before start binding, glue level in melt tank

must be checked.

WARNING

Keep off your hands or fingers from

melt tank. Melt tank is heated up to

around 200˚C. High temperature can

cause severe skin burn.

CAUTION

Do not supply glue more than Red Line

on melt tank glue level scale.

NOTE

Check glue level when glue is melted.

1. When glue lower limit mark in melt tank

appears, glue level is not enough for binding.

NOTE

See "7-1 Glue Supply" (Page 54) when you

supply glue.

3-2-2 Level Plate Cleaning Check

Melt Tank Glue Level Scale

Glue Lower Limit Mark

Red Line

CAUTION

Keep glue level

below red line.

Before start binding, surface of level plate

must be cleaned.

1. Check level plate with your eyes

whether paper dust or glue stick on level

plate.

NOTE

See "7-2-2 Level Plate Clean Up" (Page 56)

when cleaning of level plate is necessary.

Level Plate

18

Page 25

3-2 Every Day Check Up

3-2-3 Nipper Unit Check

Before start binding, surface of nipper plate

and nipper jaw must be cleaned.

1. Check nipper plate and nipper jaws with

your eyes whether paper dust or glue stick

to nipper plate and nipper jaws.

NOTE

See "7-2-1 Nipping Plate and Nipper Jaw

Clean Up" (Page 55 ) when you clean nipper

unit.

3. Before Starting Operation

Nipper Plate

Nipper Plate

3-2-4 Dust Bag Check

Before start binding, dust bag must be empty.

1. Check dust bag with your hands whether

it is empty or not.

NOTE

See "7-3-1 Dust Bag Clean Up" (Page 58 )

when you clean dust bag.

Dust Bag

19

Page 26

3. Before Starting Operation

This page is intentionally left blank.

20

Page 27

4. Set Up BQ-260

4. Set Up BQ-260

4-1 Nipper Unit Set Up .................................................................................. 21

4-2 Clamper Unit Set Up............................................................................... 26

4-3 Milling Unit Set Up ................................................................................. 27

4-4 Vertical Stacker Unit Set Up .................................................................. 29

4-5 Melt Tank Unit Set Up............................................................................ 30

4-6 Operation Switches Set Up ..................................................................... 32

4-7 Test Binding ............................................................................................. 33

21

Page 28

4. Set Up BQ-260

4-1 Nipper Unit Set Up

NOTE

When your binding job is pad binding

(without cover), nipper unit set up is not

necessary to perform. Select pad binding

mode with nipping mode select switch. Then

proceed to "4-2 Clamper Unit Set Up" in

Page 26.

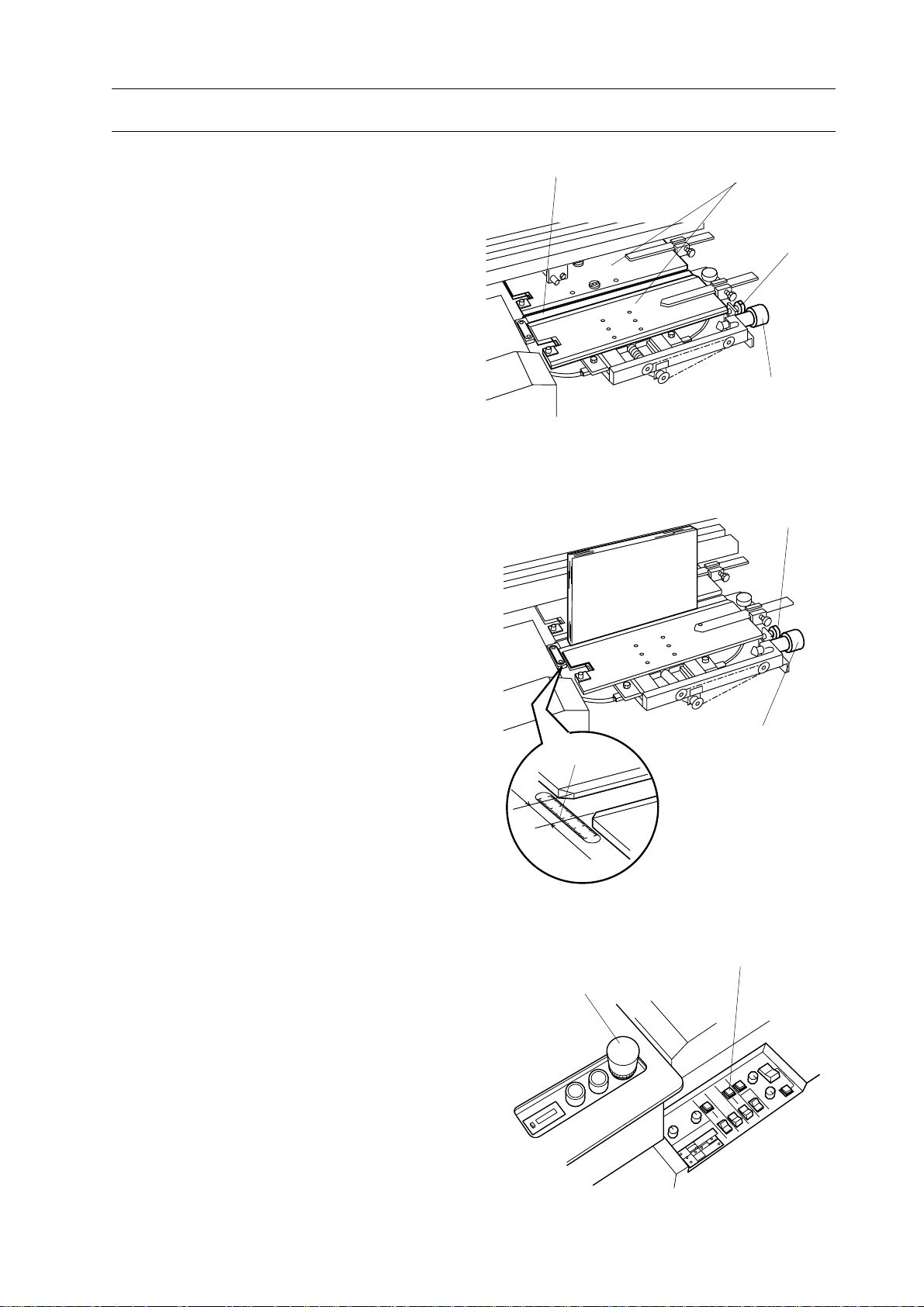

4-1-1 Nipper Unit Set Up for Stock Thickness

This section shows how to adjust nipping

width against stock thickness.

Nipper Up/Down Button

WARNING

Do not touch melt tank unit when

adjusting nipper unit. Melt tank is

heated up around 200˚C. High temperature can cause severe skin burn.

1. Select either with milling or without

milling binding mode by nipping mode

select switch.

Near Side : for signature binding

Far Side : for with milling binding

Center : for pad binding

2. Depress nipper up/down button to raise

nipper plate. Nipper plate stop at upper

position.

NOTE

- Nipper jaw's width must be adjusted when

nipper unit is at upper position.

- When nipper up/down button is depressed

with nipper being up position, nipper unit will

be down.

- Nipper is at lower position when 5 screws

on nipper plate appear.

Nipping Mode

Select Switch

Screws

3. Depress stop button.

22

Page 29

4-1 Nipper Unit Set Up

4. Set Up BQ-260

4. Hold 2 handles on safety cover with your

both hands and open safety cover.

5. Turn fix knob counterclockwise to

unlock nipping width adjusting knob.

6. Turn nipping compression adjusting

knob counterclockwise to open nipper jaws

until stock can be placed on nipper plate.

7. Place stock on nipper plate.

8. Turn nipping width adjusting knob

clockwise to nip stock.

9. Read scale on nipping unit. This mea-

surement will be used for setting up

clamper.

Nipping Plate Nipper Jaws

Lock Knob

Nipping Width

Adjusting Knob

Lock Knob

Stock

10. Slightly turn nipping width adjusting

knob counterclockwise to release the stock.

- Nipping width adjusting knob must be

turned back clockwise to secure the

adjusted width of nipper jaws.

11. Turn fix knob Clockwise to lock nipping

width adjusting knob.

12. Close safety cover.

13. Pull up stop button.

14. Depress nipper up/down button to lower

nipper unit.

15. Depress stop button to prevent BQ-260

works suddenly by misoperation.

Scale

Stop Button

Nipping Width

Adjusting Knob

Cover Single Feed Button

23

Page 30

4. Set Up BQ-260

4-1 Nipper Unit Set Up

4-1-2 Cover Positioning Set Up

This section shows how to adjust cover stopper and guide.

1. Pull up stop button.

2. Depress nipper up/down button to raise

nipper unit. Nipper unit stops at upper

position.

NOTE

Set up cover position when nipper unit is at

lower position.

Nipper Up/Down Button

3. Hold handles on safety cover with both

hands and open safety cover.

4. Prepare one cover sheet and mark center

point inside both edges of cover sheet.

5. Loosen two fix knobs for movable cover

guide.

6. Slide cover guides right to provide space

to place cover on nipper unit.

Cover Registers

Center Point

Movable Cover Guides

Fix Knobs

24

Page 31

4-1 Nipper Unit Set Up

4. Set Up BQ-260

7. Place cover inside up on nipper unit, so

that far side and left side slightly touch

cover stopper and cover registers.

NOTE

Register side of cover must be placed against

cover registers.

8. Turn cover stopper adjusting knob so

that marks on cover is positioned just on

center of nipper plate.

NOTE

Push or pull cover at the same time when

cover stopper is adjusted.

9. Slide movable cover guide against cover

to fix cover position. And then fasten fix

knobs for movable cover guide.

Cover Stopper Adjusting Knob

Movable Cover Guides

Cover

Cover Registers

Nipping Plate

Cover Stopper

Lock Knob

NOTE

- Clearance between cover and movable cover

guide must be less than 0.5 mm.

- Check whether cover does not bend or does

not have play more than 0.5 mm.

10. Close safety cover.

11. Depress nipper up/down button to lower

nipper unit.

NOTE

Cover can be fed only when nipper unit is at

lower position.

0.5 mm

Movable

Cover Guide

Cover

0.5 mm

Nipper Up/Down Button

25

Page 32

4. Set Up BQ-260

4-2 Clamper Unit Set Up

This section shows how to adjust clamper

unit opening.

WARNING

Depress stop button before setting up

clamper. Sudden start of clamper can

cause severe personal injury.

1. Depress stop button.

2. Hold two handles on safety cover with

your both hands and open safety cover.

3. Loosen lock knob on clamper.

Stop Button

Scale

4. Turn clamper opening adjusting knob to

adjust with the same measurement as in

nipper unit adjustment.

5. Fasten fix knob on clamper firmly.

6. Close safety cover.

NOTE

- Attach book guide (Accessory) on safety

cover when longer stock is placed.

Thinner book binding .. on clamper

Thicker book binding .. on safety cover

- Select guide large or small according to

stock size.

Clamper Opening

Adjusting Knob

Lock Knob

Book Guide

26

Page 33

4-3 Milling Unit Set Up

NOTE

When milling is not required on your binding, milling unit set up is not necessary to

perform.

Select without milling mode and proceed to

"4-4 Cover Feeder Unit Set Up" (Page 29).

4-3-1 Milling Guide Set Up

This section shows how to adjust milling

guide position.

1. Depress emergency stop switch.

4. Set Up BQ-260

Safety Cover

Stop Button

2. Loosen two lock knobs on front milling

guide.

3. Hold holder on stock thickness caliper

and open stock thickness caliper more than

stock thickness.

4. Place stock in stock thickness caliper.

NOTE

Use stock which will be bound.

5. Hold holder on stock thickness caliper

and push it to stock so that caliper guides

hold stock.

6. Fasten two lock knobs on front milling

guide firmly.

Holder Lock Knobs

Lock Knobs

Stock Thickness Caliper

Stock

Milling Guide

7. Take out stock from stock thickness

caliper.

27

Page 34

4. Set Up BQ-260

4-3 Milling Unit Set Up

4-3-2 Milling Depth Set Up

WARNING

Be sure to depress stop button before

adjusting milling depth and do not

touch milling cutter. Sharp cutter can

cause severe personal injury.

Necessary Tools : Allen Wrench (6 mm)

Pipe Wrench and Special

Wrench

1. Depress stop button.

2. Open safety cover.

3. Loosen lock screw on milling depth

adjusting bolt with allen wrench (6 mm).

Safety Cover

Stop Button

4. Adjust milling depth.

- Turn milling depth adjusting bolt with

pipe wrench to select milling depth.

- Align number on scale with pointer bar to

select required milling depth.

NOTE

- Unit on scale is mm.

- Milling depth is adjusted to 2 mm before

shipment.

5. Fasten fix screw on milling depth adjust-

ing bolt with allen wrench.

6. Close safety cover.

Pointer Bar

Milling Depth

Adjusting Bolt

28

Lock Screw

Scale

Allen Wrench

Pipe Wrench

Fix Screw

2.1

21

3

2.5

Page 35

4-4 Vertical Stacker Unit Set Up

This section shows how to adjust vertical

stacker.

1. Push stopper on vertical stacker unit

fully inside.

4. Set Up BQ-260

Stopper

29

Page 36

4. Set Up BQ-260

4-5 Melt Tank Unit Set Up

This section shows how to set up glue film

thickness and glue temperature.

WARNING

- Depress stop button before adjusting

melt tank.

- Ware gloves on your hands when you

set up melt tank unit. Melt tank is

heated up to around 200˚C. High temperature can cause severe skin burn.

CAUTION

Do not turn glue film thickness adjust

screw until glue is ready for binding.

Necessary Tool : Allen Wrench (5 mm)

1. Depress stop button.

2. Open safety cover. And then open melt

tank cover.

Stop Button

30

Melt Tank Cover

Page 37

4-5 Melt Tank Unit Set Up

3. Turn glue film thickness adjust screw

with allen wrench to point number 1.5 on

scale.

NOTE

Unit on scale is mm. Standard thickness of

glue film is 1.5 mm.

4. Close melt tank cover.

1.5

4. Set Up BQ-260

Scale

2

0.5

1

5. Turn glue temperature adjust knob to

select glue temperature.

NOTE

- Unit for temperature used on glue tempera-

ture indicator is centigrade degree.

- Standard temperature for glue is 180

degrees.

- Glue applied on book spine will be dry

quicker when you set glue temperature

lower. Low glue temperature is recommended

for applying thick glue film.

6. Pull up stop button.

Melt Tank Cover

Glue Temperature

Adjust Knob

Stop Button

31

Page 38

4. Set Up BQ-260

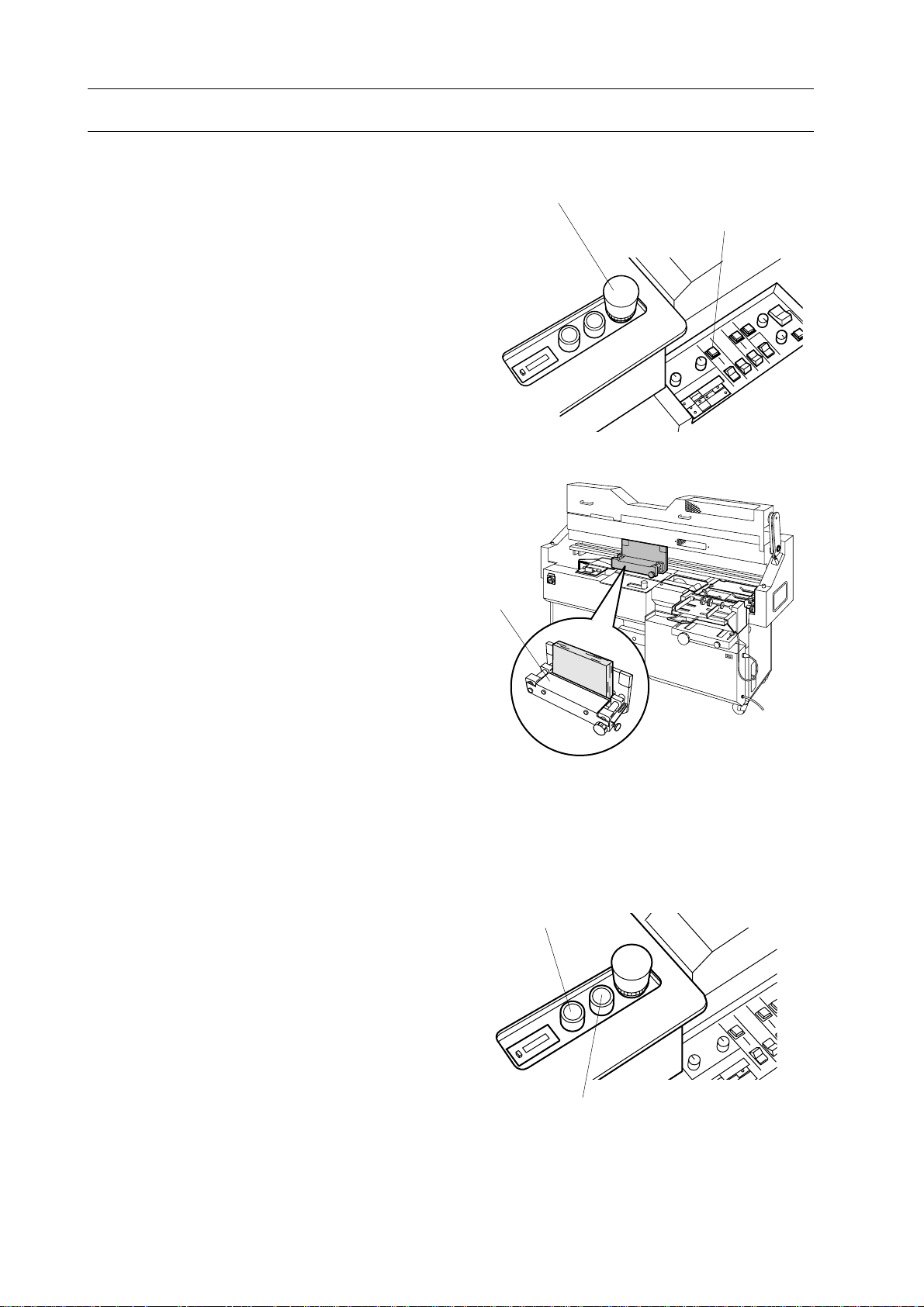

4-6 Operation Switches Set Up

This section shows how to set each switch on

operation panel.

1. Select nipping mode with nipping mode

select switch.

Far Side : With milling binding

Cut sheet binding

Near Side : Without milling binding

Signature binding

Center : Pad binding (without

cover)

Nipping Mode

Select Switch

2. Set nipping time.

- Turn nipping time control knob and

nipping delay time control knob fully

counterclockwise.

3. Select cover feed mode with cover feed

mode select switch.

Far side : Automatic feed

Near side : Manual feed

4. Select level plate reset mode with level

plate reset mode select switch.

Far side : Automatic Reset

Near side : Manual Reset

(After booklet is removed by hand, reset

level plate with level plate button.)

Far Side

Nipping Time

Control Knob

Cover Feed Mode Select Switch

Gluing Length Adjusting Knob

Nipping Delay Time

Control Knob

Near Side

5. Select milling mode with milling mode

select switch.

Far side : With Milling

Near side : Without Milling

6. Set both gluing length adjusting knobs at

12 o'clock.

Level Plate Reset

Mode Select Switch

Milling Mode Select Switch

32

Page 39

4-7 Test Binding

4-7-1 Test Binding for With Milling Binding

Test binding is necessary to confirm each

unit is set up properly.

1. Prepare stock for test binding.

NOTE

Stock for test binding must be same stock as

your job.

2. Confirm that cover is fed on nipping unit

and LED for cover on monitor is off.

4. Set Up BQ-260

Cover Single Feed Button

NOTE

When cover is not fed properly on nipping

unit and LED for cover on monitor is on, set

up cover so that cover edge touches to stopper.

3. True up stock and insert stock into

clamper. Left side of stock must touch

register shaft in clamper.

NOTE

Left side of stock must be register side. Spine

of stock must face down.

LED for Cover

Clamper

33

Page 40

4. Set Up BQ-260

4-7 Test Binding

4-1 When with milling mode is selected,

depress milling start button.

- Lamp in milling start button will turn off

and milling cutter will start rotating.

- Blower pump will start at same time and

dust bag swells with air.

4-2 When without milling mode is selected,

lamp in milling start button will not be on.

5. Depress start button.

- Confirm that lamp on start button is on

and then depress start button.

- Clamper will start for binding and returns

to its home position (start position) after

binding.

Milling Start Button

Level Plate Button

Start Button

Stop Button

6. Confirm that book is ejected at vertical

stacker unit after binding finished.

7. Check binding.

- When binding result does not satisfy your

requirement, perform "4-1" to "4-7" (page

22 to 34) again to readjust each unit on

binder.

8. Depress stop button.

9. Take out book from vertical stacker unit.

Vertical Stacker Unit

34

Page 41

4-7 Test Binding

4-7-2 Pad Binding

Test binding is necessary to confirm each

unit is set up properly.

1. Prepare stock for test binding.

NOTE

Stock for test binding must be same as your

job.

4. Set Up BQ-260

2. True up stock and insert stock into

clamper. Left side of stock must touch

register shaft in clamper.

NOTE

Left side of stock must be register side for

cover and stock. Spine of stock must face

down.

3-1 When with milling mode is selected,

depress milling start button.

- Lamp on milling start button will turn off

and milling cutter start rotating.

- Blower pump will start at same time and

dust bag swells with air.

3-2 When without milling mode is selected,

lamp in milling start button will not be on.

4. Depress start button.

- Confirm that lamp on start button is on

and then depress start button.

- Clamper will start for binding and returns

to its home position (start position) after

padding.

Clamper

Milling Start Button

Stop Button

5. Take out book from clamper and check

binding.

- When binding result does not satisfy your

requirement, perform "4-1" to "4-7" (page

22 to 35) again to readjust each unit on

binder.

6. Depress level plate button to reset level

plate.

7. Depress stop button.

Start Button

Level Plate Button

35

Page 42

4. Set Up BQ-260

This page is intentionally left blank.

36

Page 43

5. Operation Procedure

5. Operation Procedure

5-1 With Cover Binding Operation.............................................................. 38

5-2 Pad Binding.............................................................................................. 39

37

Page 44

5. Operation Procedure

5-1 With Cover Binding Operation

This section shows binding operation for with

cover binding.

1. Pull up stop button.

2. Depress milling start button.

NOTE

When without milling binding mode is selected, milling start button is not necessary to

depress.

Stop Button

Milling Start Button

3. True up stock and insert stock into

clamper. Left side of stock must touch

register shaft in clamper.

NOTE

Left side of stock must be register side. Spine

of stock must face down.

4. Confirm that lamp on start button is on

and then depress start button.

Clamper

Level Plat Button

38

Start Button

Page 45

5-1 With Cover Binding Operation

5-1 Followings are process of binding (with

milling).

1) Stock is clamped with clamper and

transported to milling unit and milled off

spine.

2) Stock is transported to home position and

clamper is automatically opened on level

plate to rejog stock.

3) Stock is applied glue on melt tank unit.

4) Stock applied glue is transported to

nipping unit. Nipping unit raises, sticks

cover to stock spine and nips them

strongly.

5. Operation Procedure

5) Stock formed spine is transported to

home position through over lowered melt

tank unit. Cover for next binding is fed on

nipping unit at same time.

6) Stock is released from clamper and falls

into vertical stacker unit.

5-2 Followings are process of binding (with-

out milling).

1) Stock is clamped with clamper and

transported to melt tank unit.

2) Glue is applied on spine at melt tank

unit.

3) Stock applied glue is transported to

nipping unit. Nipping unit raises, sticks

cover to stock spine and nips them

strongly.

4) Stock formed spine is transported to

home position through over lowered melt

tank unit. Cover for next binding is fed on

nipping unit at same time.

5) Stock is released from clamper and falls

into vertical stacker unit.

39

Page 46

5. Operation Procedure

5-2 Pad Binding

This section shows binding operation for pad

binding.

1. Pull up stop button.

2. When milling is required, depress mill-

ing start button.

Stop Button

Milling Start Button

3. True up stock and insert stock into

clamper. Left side of stock must touch

register shaft in clamper.

NOTE

Left side of stock must be register side. Spine

of stock must face down.

4. Confirm that lamp on start button is on

and then depress start button.

Clamper

Start Button

Level Plate Button

40

Page 47

5-2 Pad Binding

5-1 Followings are process of pad binding

(with milling).

1) Stock is clamped with clamper and

transported to milling unit and milled off

spine.

2) Stock is transported to home position and

clamper is automatically opened on level

plate to rejog stock.

3) Stock is applied glue on melt tank unit.

4) Stock is stopped over nipping unit for

several seconds to dry glue.

5) Stock is transported to home position

through over lowered melt tank unit.

5. Operation Procedure

6) Stock is released from clamper.

5-2 Followings are process of pad binding

(without cover)

1) Stock is clamped with clamper and

transported to melt tank unit.

2) Stock is applied glue on melt tank unit.

3) Stock is stopped over nipping unit for

several seconds to dry glue.

4) Stock is transported to home position

through over lowered melt tank unit.

5) Stock is released from clamper.

41

Page 48

5. Operation Procedure

This page is intentionally left blank.

42

Page 49

6. Special Binding Method

6. Special Binding Method

6-1 Small Size Binding................................................................................... 44

6-2 To Increase Glue Film Thickness .......................................................... 48

6-3 To Adjust Finish Condition of Spine..................................................... 52

43

Page 50

6. Special Binding Method

6-1 Small Size Binding

6-1-1 Register Shaft Position Adjustment

This section shows how to set up register

shaft when spine length of stock is shorter

than 130 mm (5.1").

WARNING

Depress stop button when you replace

register bar position. Clamper can

cause severe personal injury.

Necessary Tool : Special Wrench

(Accessory)

1. Depress stop button.

2. Remove register shaft in clamper with

special wrench.

NOTE

Do not fall removed register bar while it is

removed.

3. Fix register shaft with special wrench on

position indicated in drawing.

Stop Button

Clamper

Special Wrench

44

Register Shaft Position for

Smaller Size Binding

Page 51

6-1 Small Size Binding

6-1-2 Cover Position Register Block Installation

This section shows how to install register

block when spine length of cover is shorter

than 130 mm (5.1").

WARNING

Depress stop button when you attach

cover position register blocks. Nipper

unit can cause severe personal injury.

NOTE

Cover position register block is not required

for pad binding.

6. Special Binding Method

Necessary Tools : Allen Wrench (3 mm)

1. Depress stop button.

2. Attach cover position register blocks on

nipper.

NOTE

- Attach cover position register blocks so that

beveled corner faces to right-near side.

- Fix cover position register blocks so that it

is parallel with nipper jaw edge.

- Fix cover position register blocks so that

screw comes at center of groove.

- The blocks can be slid right and left within

10 mm.

Stop Button

Nipper Jaws

45

Cover Position

Register Block

Beveled Corner

Page 52

6. Special Binding Method

6-1 Small Size Binding

6-1-3 Small Cover Stopper Installation

This section shows how to install small cover

stopper.

WARNING

- Depress stop button when small cover

stopper is installed. Nipper can cause

severe personal injury.

- Turn off power switch when back

cover is opened.

Necessary Parts : Small cover stopper

Cover Stopper Adjusting Knob

1.

Depress stop button.

2. Turn cover stopper adjusting knob fully

clockwise.

3. Hold back cover with your hand and

loosen two lock screws.

4. Open back cover.

5. Fix small cover stopper on cover stopper

with two lock screws.

NOTE

- When small cover stopper is installed, cover

sensor recognizes as if cover sheet is always

placed. Confirm whether cover is fed properly

on nipper unit before you start binding.

- Cover must be fed manually when small

cover stopper is mounted on cover stopper.

Lock Screws

Back Cover

Lock Screws

Small

Cover

Stopper

Sensor

6. Close back cover and fix with two lock

screws.

46

Page 53

6-1 Small Size Binding

6-1-4 Shooter Attachment

This section shows how to install shooter

when spine length of stock is shorter than

160 mm.

NOTE

Any type of binding requires shooter when

stock spine length is shorter than 160 mm.

Necessary Parts : Shooter (Accessory)

1. Depress stop button.

6. Special Binding Method

Stop Button

2. Pull out stopper on vertical stacker unit

fully to near side.

3. Hung shooter on holes on stacker.

4. Keep stopper at the near side position.

Stopper

Shooter

47

Page 54

6. Special Binding Method

6-2 To Increase Glue Film Thickness

6-2-1 Spacer Plate Attachment

This section shows how to install spacer plate

on level pate to increase glue film thickness.

WARNING

Do not touch clamper when start button is depressed. Clamper can cause

severe personal injury.

Necessary Tool : Screw Driver

1. Pull up stop button.

- LED for stop button on monitor turns off.

2. Set nipping mode select switch at middle

position to select pad binding mode.

- Pad binding lamp turns on.

Stop Button

Level Plate Button

Start Button

LED for Stop Button

3. Depress milling mode select switch to

select with milling mode.

4. Confirm lamp on start button turns on.

NOTE

Depress level plate control button when lamp

on start button does not turn on.

Milling Mode

Select Switch

48

Center

Nipping Mode

Select Switch

Far Side

Page 55

6-2 To Increase Glue Film Thickness

5. Stand in front of operation panel.

6. Place your right hand on stop button.

7. Depress stop button when clamper

reaches to nipping section.

Level Plate Button

6. Special Binding Method

Stop Button

Start Button

8. Confirm level plate is clean.

NOTE

If it is not clean, see "7-2-2 Level Plate Clean

Up" (Page 56) and clean level plate.

9. Loosen three screws on level plate with

screw driver.

Screws

49

Level Plate

Page 56

6. Special Binding Method

6-2 To Increase Glue Film Thickness

10. Place spacer plate on level plate and fix

spacer plate with three screws.

11. Pull up stop button.

- LED for stop button on monitor turns off.

Level Plate Button

Spacer Plate

Stop Button

12. Depress start button to move clamper its

original position.

13. Depress level plate button once to reset

level plate.

- Start lamp will turn on to indicate level

plate is reset.

14. Depress stop button.

Start Button

LED for Level Plate

50

Page 57

6-2 To Increase Glue Film Thickness

6-2-2 Melt Tank Height Adjustment

This section shows how to adjust melt tank

height to increase glue film thickness by

lowering a melt tank unit.

WARNING

Put gloves on your hands when you set

up melt tank unit height. Melt tank is

heated up to around 200 degrees. High

temperature can cause severe skin

burn.

Necessary Tools : Allen Wrench (5 mm)

Screw Driver

6. Special Binding Method

1. Depress stop button.

2. Open melt tank cover.

3. Turn clockwise melt tank up/down screw

with Allen wrench until melt tank rises 1 to

2 mm.

4. Loosen fix screw on spacer until spacer

can be moved.

5. Turn spacer clockwise to insert it under

stopper. Confirm spacer is inserted under

stopper completely and then fasten fix

screw with screw driver.

6. Loosen melt tank up/down screw with

Allen wrench.

Melt Tank Cover

Fix Screw

Spacer

Stopper

Melt Tank Up/down Screw

7. Close melt tank cover.

51

Page 58

6. Special Binding Method

6-3 To Adjust Finish Condition of Spine

This section shows how to adjust finish

condition of spine by changing nipping

height or angle when the spine corner is too

sharp, or spine corner is round.

NOTE

Sheet quality and glue application thickness

influence the finish condition of spine.

1. Move cover feeding unit to the front side

to provide access space under nipping unit.

2. Turn adjust bar to the required direction

with spanner (17 cm).

Lower Section of

Nipping Unit

Adjust Bar

Dial

Hand

3. Make sure of the finish condition by test

binding. After that, set cover feeding unit.

Dial Number

0 : Standard

- : Nipper lowers by turning adjust bar counterclockwise (arrowed direction)

and spine becomes rounder.

+ : Nipper rises by turning adjust bar clockwise and spine becomes sharper.

Adjustment of the

Right Side of Nipper

Adjustment of the

Left Side of Nipper

52

Page 59

7. After Binding Finish

7. After Binding Finish

7-1 Glue Supply.............................................................................................. 53

7-2 Clean Up While Power On ..................................................................... 55

7-3 Clean Up after Power Off....................................................................... 58

7-4 Clean Up after Power Off....................................................................... 59

53

Page 60

7. After Binding Finish

7-1 Glue Supply

Glue must be supplied in melt tank when

binding finished.

WARNING

- Put gloves on your hands when you

supply glue in melt tank which is

heated up to around 200 degrees. High

temperature can cause severe skin

burn.

- Depress emergency stop switch before

supplying glue.

1. Open malt tank cover.

2. Place glue on supply area in melt tank.

NOTE

- Supply glue into melt tank piece by piece

not to supply glue over maximum glue level.

- Glue level must be lower than RED line on

glue level indicator.

- Use only Horizon Glue (HM-110).

3. Close melt tank cover.

Melt Tank Cover

Melt Tank Glue Supply Area

54

Page 61

7-2 Clean Up While Power On

7-2-1 Nipping Plate and Nipper Jaw Clean Up

Nipping plate or nipper jaws must be cleaned

after binding finished.

WARNING

- Depress stop button before cleaning.

- Put gloves on your hands. You might

unexpectedly touch melt tank which is

heated up to around 200 degrees. High

temperature can cause severe skin

burn.

7. After Binding Finish

Clamper

Stop Button

Necessary Tool : Cloth

1. Depress stop button.

2. Confirm clamper stops over level plate.

3. Confirm nipping unit is at lower point.

NOTE

- If nipping unit is at upper position, release

emergency stop, close safety cover and depress nipping unit up/down button once to

lower nipping unit.

- When nipping unit is at lower position, five

screws on nipping unit appear.

Nipper Plate

Screws

Nipper Up/Down Button

Stop Button

4. Wipe off dust such as glue or paper dust

on nipping plate and nipper jaws with

cloth.

55

Page 62

7. After Binding Finish

7-2 Clean Up While Power On

7-2-2 Level Plate Clean Up

Level plate must be cleaned after binding

finished.

WARNING

- Depress stop button to prevent personal injury after step 4.

- Ware gloves on your hands. You

might unexpectedly touch melt tank

which is heated up to around 200

degrees. High temperature can cause

severe skin burn.

Necessary Tool : Cloth

1. Pull up stop button.

2. Select pad binding mode.

- Set nipping mode select switch to center.

Pad binding lamp in start button will turn

on.

Stop Button

Start Button

Nipping Mode Select Switch

Center

56

Pad Binding Lamp

Page 63

7-2 Clean Up While Power On

3. Move clamper

- Depress start button to move clamper to

nipping unit. And then depress stop

button when clamper come over nipping

unit.

NOTE

Application roller in melt tank keeps to rotate

even if stop button is depressed. (for about 30

seconds)

4. Clean level plate with cloth.

7. After Binding Finish

Stop Button

Start Button

Level Plate

5. Pull up stop button.

6. Depress start button to return clamper to

home position.

7. Depress level plate control button once

to reset level plate after clamper returned to

home position.

8. Depress stop button.

NOTE

Occasionally application roller in melt tank

unit keeps to rotating.

Stop Button

Start Button

Level Plate

Button

57

Page 64

7. After Binding Finish

7-3 Clean Up after Power Off

7-3-1 Dust Bag Clean Up

Dust bag must be empty after binding finished.

1. Remove dust bag and dump dust from

dust bag.

2. Knot strings of dust bag on exhaust duct

on BQ-260.

Dust Bag

7-3-2 Vertical Stacker Unit Clean Up

Stacker must be cleaned after power off.

1. Pull out stacker fully to outside.

2. Clean stacker with soft cloth.

Exhaust Duct

Strings

Stacker

58

Page 65

7-4 Clean Up after Power Off

7-4-1 Milling Unit Clean Up

Milling unit must be cleaned after power off.

7. After Binding Finish

WARNING

Do not touch milling cutter or roughening cutter with your hands or fingers.

Sharp cutter can cause severe personal

injury.

1. Open safety cover.

2. Hold holder on front milling guide and

pull front milling guide fully to near side.

Safety Cover

3. Clean paper dust on milling unit surface

with vacuum cleaner.

4. Close safety cover.

Holder

Front Milling Guide

59

Page 66

7. After Binding Finish

7-4 Clean Up after Power Off

7-4-2 Gluing Length Sensor Clean Up

Gluing length sensor must be cleaned after

power off.

WARNING

- Clean up gluing length sensor after

melt tank cooled down.

- Ware gloves on your hand to prevent

accidental touch on warm melt tank

unit.

1. Open safety cover.

Glue Length Sensor

2. Clean gluing length sensor with soft

cloth or brush.

3. Close safety cover after cleaning.

7-4-3 Cover Sensor Clean Up

Cover sensor must be cleaned after power off.

1. Open back cover.

2. Turn cover stopper adjusting knob to

move cover stopper most backward position.

Cover Stopper Sensor

Cover Stopper

3. Clean cover stopper sensor with soft

brush.

4. Close back cover after cleaning.

60

Page 67

8. maintenance

8. Maintenance

8-1 Once A Month.......................................................................................... 62

8-2 As Required.............................................................................................. 63

61

Page 68

8. Maintenance

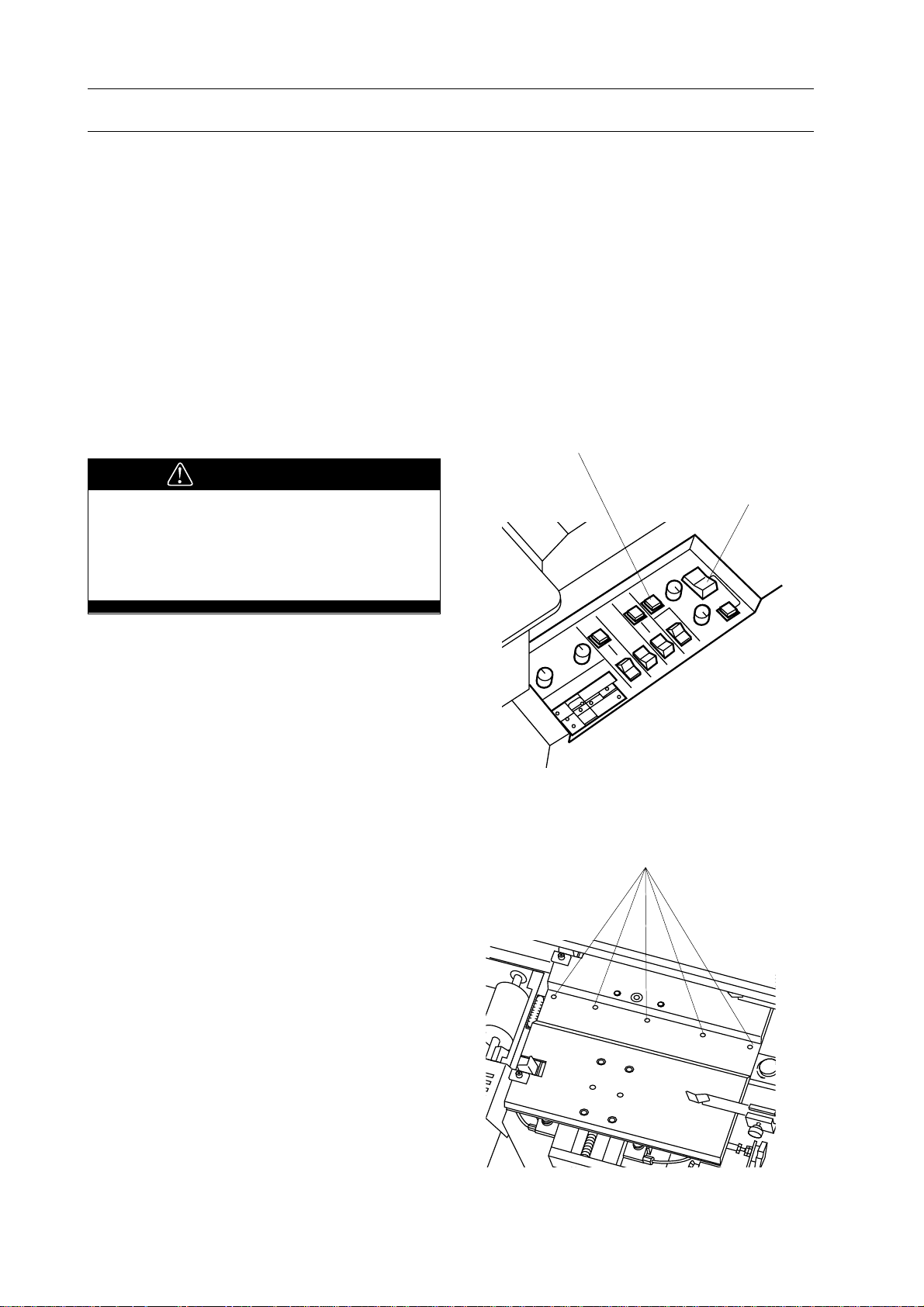

8-1 Once A Month

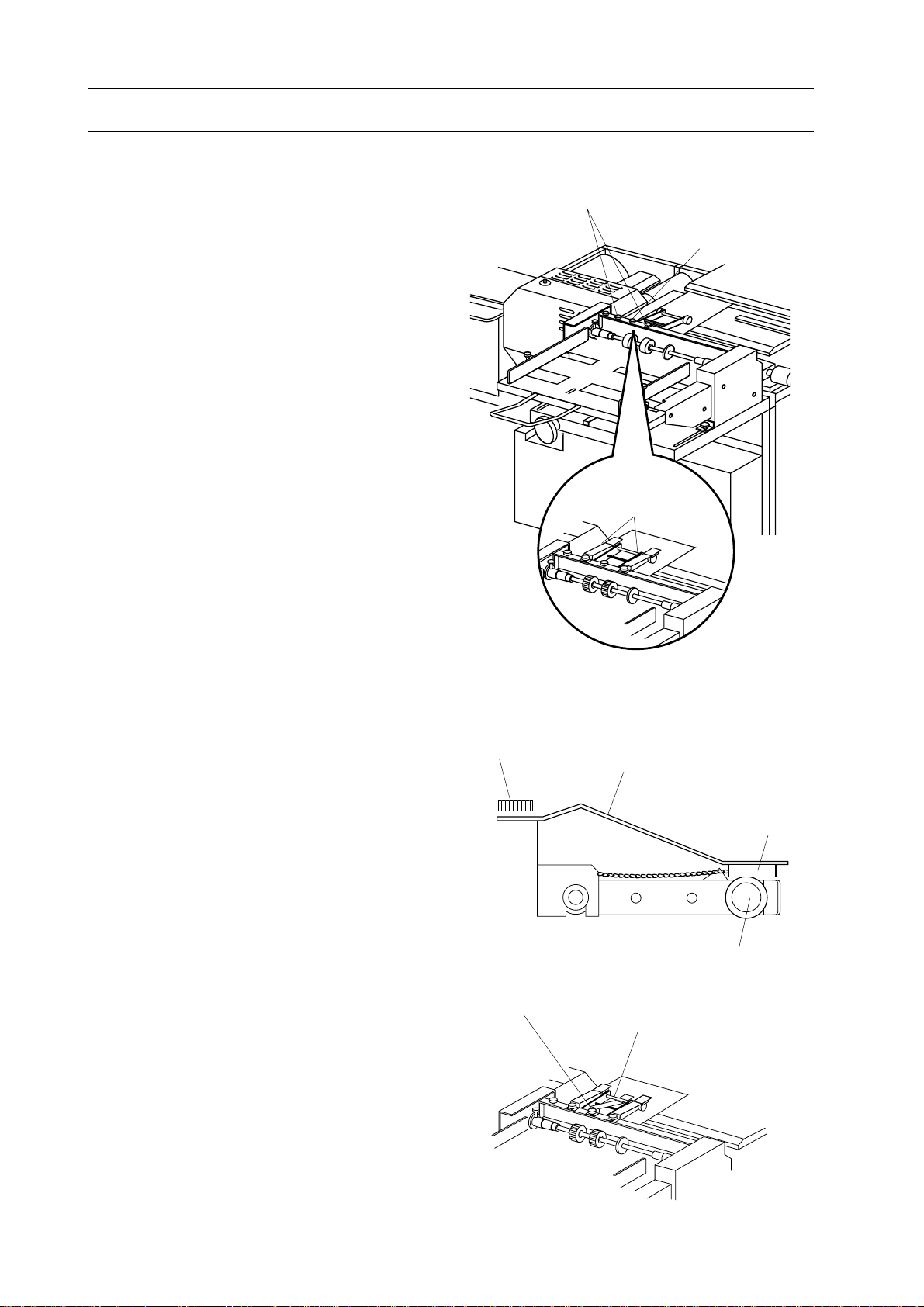

8-1-1 Lubrication on Melt Tank Unit

This section shows required maintenance

once in a month.

WARNING

Ware gloves on your hands when melt

tank is lubricated. Melt tank is heated

up to 200˚C.

1.Open safety cover.

2. Lubricate marked parts of melt tank unit

with a supplied melt tank chain oil.

8-1-2 Greasing on Clamper Rail

Wipe off all dust on clamper rail.

1.

2. Grease both back and front of clamper

rail.

Lubrication Points

Clamper Rail

8-1-3 Oiling on Nipper Unit

1. Pull oil pump lever once to lead oil to

slide part of nipper unit.

NOTE

It is not necessary to push oil pump lever.

Lever will move back automatically.

Oil Pump Lever

62

Page 69

8-2 As Required

8. maintenance

8-2-1 Milling Cutter Replacement

Continuous use of dull milling cutter will

effect on binding finish quality. Replace

milling cutter as required.

WARNING

- Turn off main power before replacing

milling cutter.

- Ware gloves on your hands when

milling cutter is replaced. Cutter will

cause severe personal injury.

Necessary Tools : Double-ended Spanner

(13 mm)

Allen Wrench (4 mm)

Thick Cloth

Hook Bolt

Spring White Cutter Guard

Front Milling Guide Rear Milling Guide

1. Turn off main power.

2. Access to milling cutter.

- Open safety cover.

- Remove spring on white cutter guard

from hook bolt.

- Remove both front and rear milling

guides.

3. Remove milling cutter.

- Place thick cloth to hold milling cutter.

- Loosen four fix screws on milling cutter

and remove milling cutter.

4. Install new or resharpened milling cutter

with reverse order of removing.

5. Install milling guides.

- Install rear milling guide so that guide

aligned with three positioning pins.

- Install front milling guide.

- Hook spring on white cutter guide to

cover milling section.

Thick Cloth

Hook Spring

Allen Wrench

Milling Cutter

Positioning Pins

63

Page 70

8. Maintenance

8-2 As Required

8-2-2 Roughening Cuter Replacement

Continuous use of dull roughening cutter will

effect on binding finish quality. Replace

roughening cutter as required.

WARNING

- Turn off main power before replacing

milling cutter.

- Ware gloves on your hands when

roughening cutter is replaced. Cutter

will cause severe personal injury.

Necessary Tools : Allen Wrench (5 mm)

Thick Cloth

Milling Cutter

1. Turn off main power.

2. Access to roughening cutter.

- Open safety cover.

- Open front milling guide.

- Remove spring on white cutter guard

from hook bolt.

3. Open P.C.B. cover.

- Remove four fix screws and tilt down

P.C.B. cover.

4. Depress release button to release brake

on milling cutter motor.

Spring

White Cutter Guard

Front Milling Guide

5. Turn milling cutter slowly by hand to

access to roughening cutter lock screw.

P.C.B. Cover

64

Release Button

Page 71

8-2 As Required

6. Remove roughening cutter.

- Hold tip of roughening cutter with thick

cloth.

- Loosen roughening cutter lock screw with

allen wrench.

- Pull out roughening cutter.

NOTE

- Spring under roughening cuter will jump

out. Remove roughening cutter slowly.

- Roughening cutter is reversible parts.

Roughening Cutter

Height Gauge

8. maintenance

Allen Wrench

7. Install new or reversed roughening

cutter.

- Push down roughening cutter with thick

cloth and fix lock screw.

- Place roughening cutter height gauge over

roughening cutter.

NOTE

Select either 0.5 mm or 0.8 mm for required

height of cutter.

- Loosen lock screw once. Roughening

cutter will move up. Then fix lock screw

firmly.

8. Close all safety and P.C.B. cover.

Roughening

Cutter

Roughening

Cutter

Screw

Spring

65

Page 72

8. Maintenance

8-2 As Required

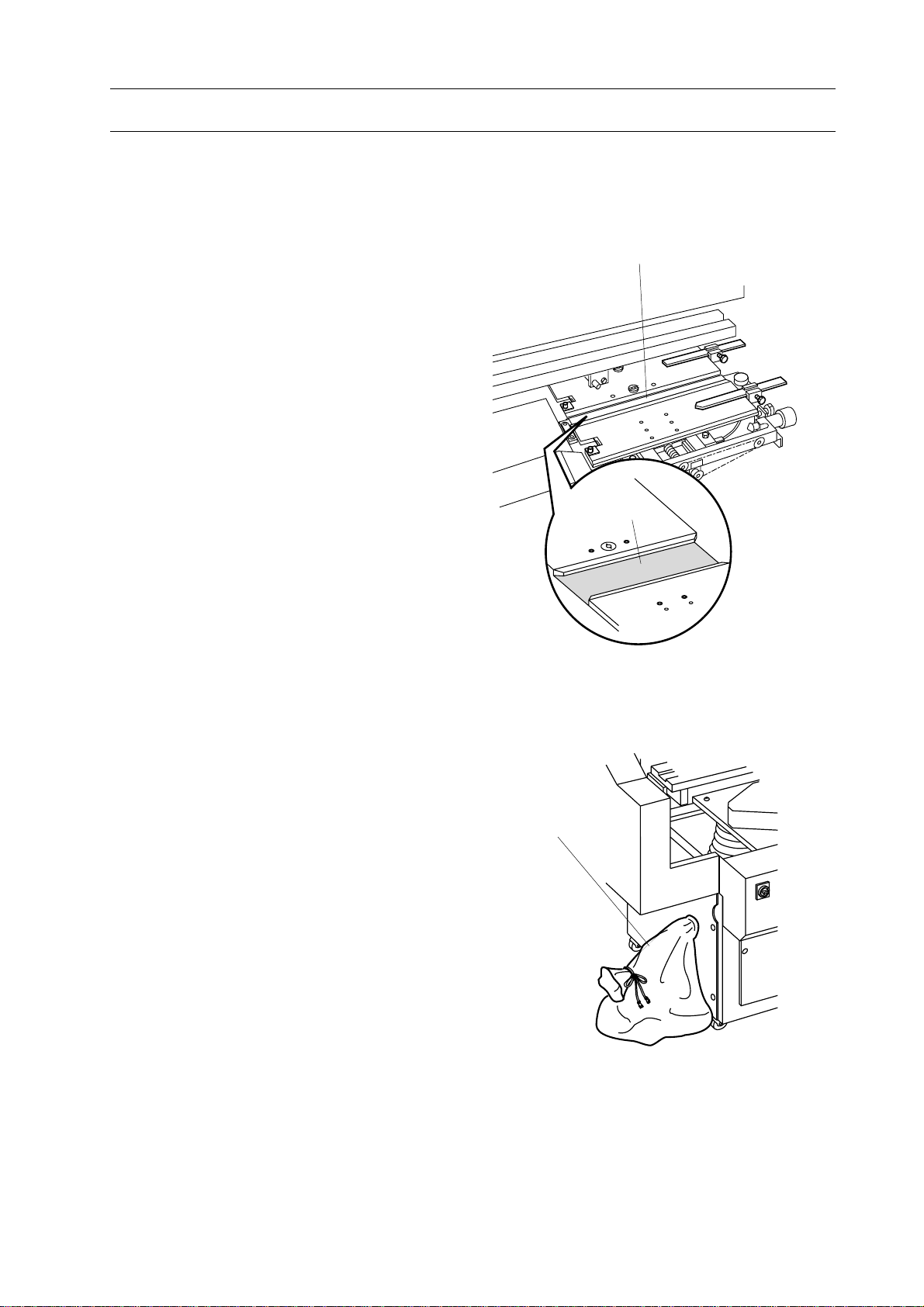

8-2-3 Glue Draining

This section shows how to drain glue in melt

tank. Deteriorated glue because of long

heating will cause decrease of adhesive

strength.

WARNING

Ware gloves on your hands when glue

is drained. Melted glue temperature is

200˚C. It can cause sever skin barn.

NOTE

Glue can only be drained when it is melted.

1. Melt glue.

- Turn on main power and wait until LED

for melt tank on monitor turns off.

2. Attach glue drain.

- Remove melt tank cover.

- Open control box.

- Attach glue drain under drain plate.

3. Provide a box for receiving glue (2 liter

capacity).

4. Drain glue

- Remove drain plug. Glue will come out

from melt tank.

- Fasten drain plug after all glue are

drained.

Met Tank Cover Control Box

Drain Plate

Glue Drain

5. Close covers

- Remove glue drain.

- Close control box , melt tank cover and

safety cover.

Box

66

Page 73

9. Installation of Suction Cover Feeder CF-260

9. Installation of Suction Cover Feeder CF-260

(Optional Equipment)

9-1 Before You Begin..................................................................................... 68

9-2 Set Up and Operation ............................................................................. 71

9-3 Trouble Shooting ..................................................................................... 76

9-4 Installation of BQ-260 ............................................................................. 78

67

Page 74

9. Installation of Suction Cover Feeder CF-260

9-1 Before You Begin

9-1-1 Specifications

Model Name CF-260

Maximum Cover Size 500 ~ 380 mm (19.7" x 15")

Minimum Cover Size 260 ~ 180 mm (10.2" x 7.1")

Cover Pile Height 100 mm (3.9")

Cover Thickness 80 to 300 gsm

Power Source 3-phase 200 V 50/60 Hz, 220 V 60 Hz, 400 V 50 Hz 0.65A

Power Consumption 0.4 kw

Motor 0.2 kw x 1, 25 w x 1, 15 w x 1

Machine Dimension 700 (W) x 690 (D) x 840 (H) mm

Machine Weight 110 kg (243 lb)

The machine design and specifications are subject to change without any notice.

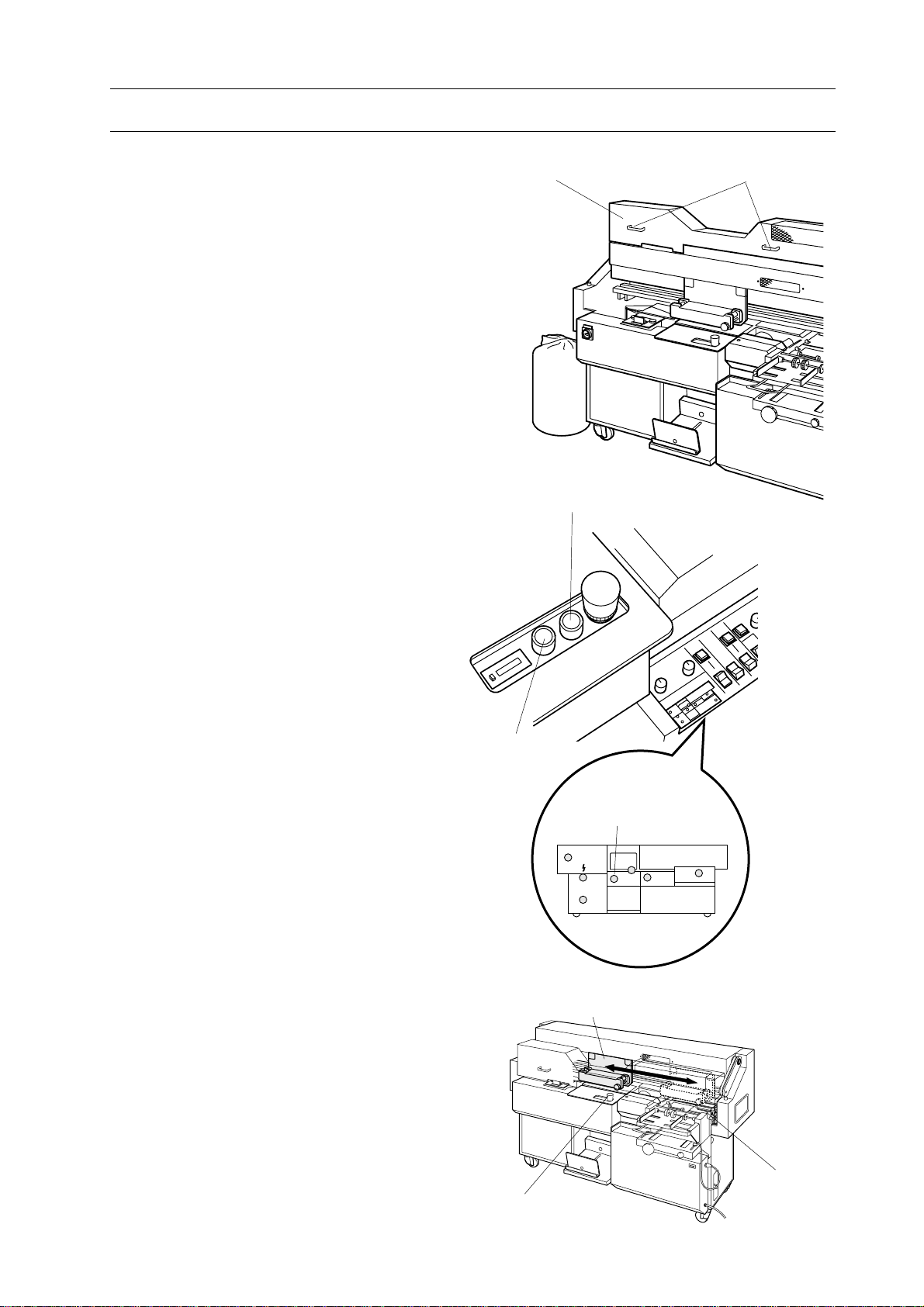

9-1-2 Machine Descriptions and Functions

Operation Panel

Front Guide

Back Guide

Side Guide

68

Table Height Adjusting Knob

Skew Adjusting Knob

Table Forward/Backward Handle

Power Switch

Page 75

9. Installation of Suction Cover Feeder CF-260

9-1 Before You Begin

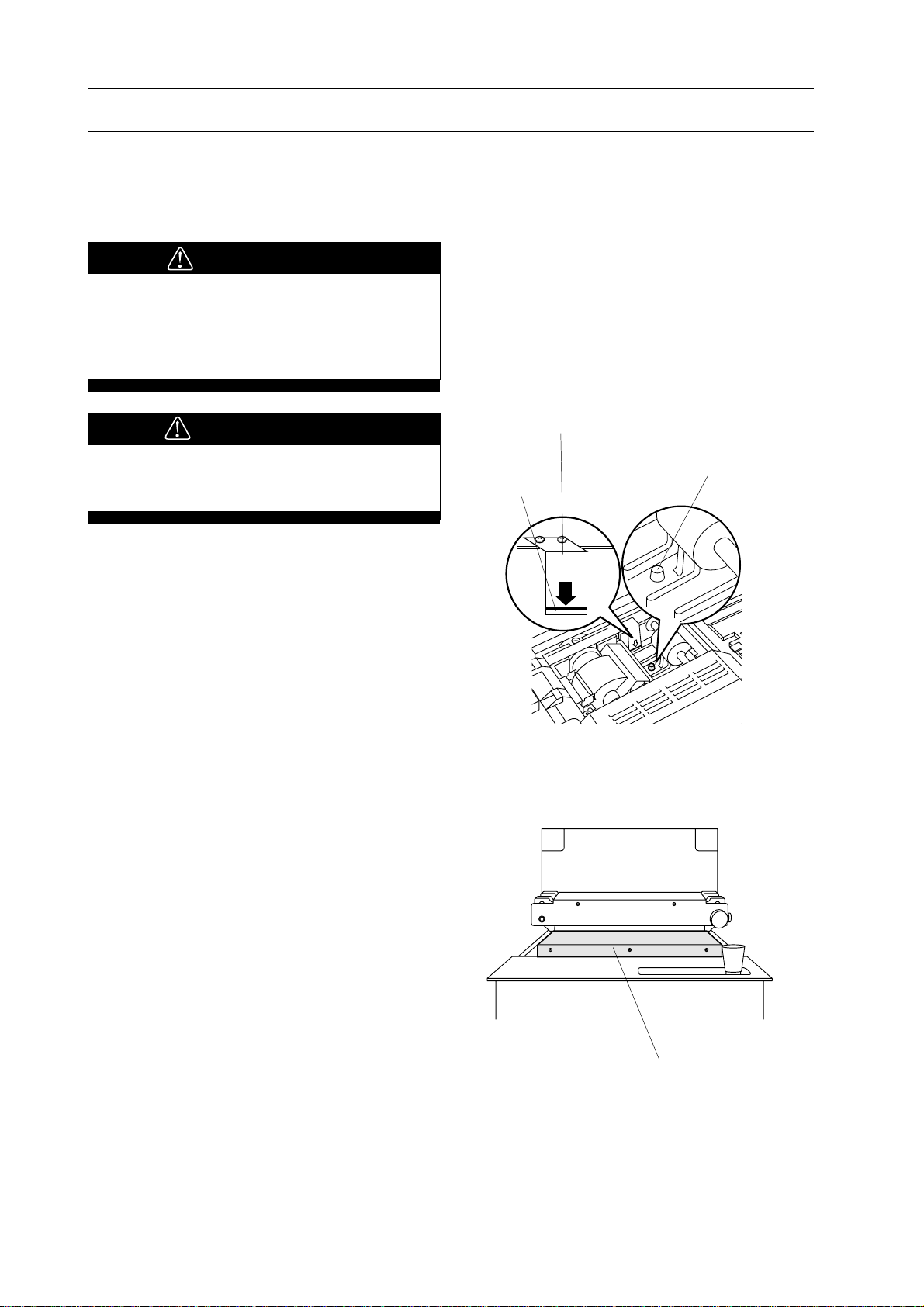

9-1-3 Descriptions and Functions of Operation Panel

Table Up Button

This button is used to raise table, and

to stop lowering table.

Sucker Bar Inching Button

This button is used to inch sucker bar.

Sucker bar stops at home position by

pressing this button coutinuously.

Compressor OFF Button

This button is used to turn off feed roller and

air pump.

Compressor ON Button

This button is used to turn on

feed roller and air pump.

Power Lamp

This lamp turns on when

power is on.

One Cycle Button

This button is used to operate sucker bar

one cycle. Sucker bar stops at home

position after one cycle.

Table Down Button

This button is used to lower table, and

to stop raising table.

69

Page 76

9. Installation of Suction Cover Feeder CF-260

9-1 Before You Begin

9-1-4 Tools and Accessories

Cover (M032435-00) 1 pcSucker (M014852-02) 14 pcs

Back Guide (M032433-00) 1 pc

Support Plate(S) (A933418-00) 1 pc

Support Plate(L) (A933416-00) 1 pc

(S)

Roller Cleaner(A933417-00) 2pcs

(L)

Adapter (A303401-00) 1 pc

Sucker Close/Open Tool 1 pc

(4010658-00)

Cover Sheet Holder(M032810-00) 1pc

Screw(M002000-01) 3pcs Sub Table 1pc

70

Page 77

9-2 Set Up and Operation

9-2-1 Cover Piling

This procedure shows cover piling before

starting binding.

WARNING

Do not touch moving parts parts. Moving parts may cause severe personal

injury.

CAUTION

Do not place books, tools and so on

under table. They may cause machine

damage.

9. Installation of Suction Cover Feeder CF-260

Table Lower Button

Front Guide

1. Turn on power switch.

-Power lamp turns on.

2. Press table lower button.

-Table lowers and stops at lowest position.

3. Pile covers so that covers touch front

guide and side guide.

NOTE

- Straighten covers before piling. Wavy or

curled cover will cause inferior feeding such

as misfeed.

- Do not pile covers more than 10 cm.

4. Place back guide at right corner of cover

on table.

5. Press table up button.

-Table rises and stops at feeding position.

Side Guide

Back Guide

Bin Up Button

One Cycle Button

6. Press one cycle button. Sucker bar

moves forward and then stops.

71

Page 78

9. Installation of Suction Cover Feeder CF-260

9-2 Set Up and Operation

9-2-2 Open/Close of Sucker Valve

This procedure shows how to set up suckers

for deifferent size of cover.

1. Pick up suckers which are going to suck

cover.

NOTE

Do not pick up suckers which does not completely placed on cover.

2. Open those sucker valve with sucker

open/close tool.

Close other sucker valve.

Sucker Valve

9-2-3 Cover Feeder Position Set Up

This procedure shows cover feeder set up

according to cover size.

1. Set up nipper referring to "4-1 Nipper

Unit Set Up"(page 22).

2. Make sure that nipper is at lower posi-

tion.

3. Place one cover on nipper.

4. Turn table forward/backward handle

until the clearance between cover and feed

roller is 2 to 3 mm.

9-2-4 Support Plate Set Up

This procedure shows how to set support

plate.

Feed Roller

2 ~ 3 mm

Cover

Nipper

1. Select suitable size of support plate and

place it on nipper so that the clearance

between cover feeder and support plate is

20 mm.

NOTE

When the size of cover is B4 (10.1" x 14.3")

or larger than B4 use the support plate (L).

72

20 mm

Supprt Plate

Page 79

9-2 Set Up and Operation

9-2-5 Attachment of Accessories

9. Installation of Suction Cover Feeder CF-260

- To prevent misfeeding of cover caused by

dart on support roller, support roller cleaner

is recommended to use.

- To prevent cover moves back, cover feeding

supporter is recommended to use.

NOTE

Supply a few drops of alcohol on cloth of

support roller cleaner.

1. Loosen fix screws on feed support roller

cleaners and cover feeding supporter.

Fix Screws

Fix Screw

Support Roller

Cleaner

2. Place support roller cleaner so that pad is

placed on roller and the other end is placed

under fix screw. And then fasten fix screw.

3. Attach cover feeding supporter under

middle fix screw and fasten fix screw.

Fix Screw

Middle Fix Screw

Support Roller Cleaner

Pad

Support Roller

Cover Feeding Supporter

73

Page 80

9. Installation of Suction Cover Feeder CF-260

9-2 Set Up and Operation

9-2-6 Feeding Test

This procedure shows test feeding of cover.

1. Press air pump ON button.

-Rollers rotates and air pump is turned on.

2. Press one cycle button and feed one

cover to check the cover is fed on nipper

smoothly.

3. If cover is not fed straightly and touches

some guides on nipper, adjust cover feeding direction with skew adjustment knob.

4. Try feeding covers a few times. When

covers are fed smoothly, leave only one

cover on nipper and start binding.

9-2-7 Cover Piling

This procedure shows the cover piling during

your binding job.

Compressor ON Button

One Cycle Button

Skew Adjustment Knob

WARNING

Do not pile cover during binder works.

Moving parts may cause severe personal injury.

CAUTION

Lower table when cover is piled. Ignoring the procedure may cause severe

machinery damage.

1. Press table lower button.

-Table lowers and stops at lowest position.

2. Pile covers so that covers touch front

guide and side guide.

3. Press table up button. Table rises and

stops at feeding position.

Table Up Button

One Cycle Button

4. Press one cycle button. Sucker bar

moves forward and stops.

74

Page 81

9-2 Set Up and Operation

9-2-8 Binding Finish

Turn power switch off after finishing binding.

1. Press table down button.

- Table lowers and stops at lowest position.

2. Remove cover from table.

9. Installation of Suction Cover Feeder CF-260

3. Turn power switch off.

Table Down Button

Table

Power Switch

75

Page 82

9. Installation of Suction Cover Feeder CF-260

9-3 Trouble Shooting

9-3-1 When Misfeed Occurs.