Page 1

A

PC-61 Revision Control List

x

1-9,1-10,1-11,2

Manual No. Date Bulletin Code S/N applied History

US504004-00 Jan/17/2001 (First Edition)

1.Correcting the description of "2-11 Hydraulic Pressure Does not Operate." 2-20

2.Correcting the Hydraulic Circuit to (For S/N 100001 to 122899) and (For S/N

123001 or above). 5-3.4

US504004-01 Jun/4/2001 1.Adding precautions on P.C.board and ROM IV

2.Adding the relay in the control bo

3.Correcting producers No. for the rlay 7-8

4.Correcting wiring diagrams 7-6, 7-10, 7-11

US504004-03 Feb/27/2008 1. Adding the 61II-related pages.

2. Correcting the term "cut knife" to the "cutting knife".

3. Correcting the term "back gauge" to the "backgauge".

Page

6-4

23,2-24,2-25,226,2-27,2-28,316,3-17,6-5,6-6,67,6-8,6-9,7-14,715,7-16,7-17,718,7-19

All Page

All Page

Page 2

Page 3

FOREWORD

Paper Cutter

Model APC-61

Important Information

This service manual is designed to help you to repair and maintain the APC-61 in order to keep it in good operating condition.

Please read and understand the instructions in this service manual before performing any repair or maintenance.

- Horizon International Inc. shall not be liable for incidental or consequential damages resulting from: improper or inadequate

maintenance by the customer; unauthorized modification or misuse; or operation outside of the environmental specifications

for the product.

- Horizon International Inc. follows a policy of continuing improvement in design and performance of the product. Therefore,

the product design and specifications are subject to change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or translated to another language without the

prior written consent of Horizon International Inc.

US504004-03080131/APC61/03E/KY/NT/P6/I9/P7

1

Page 4

Safety Precautions

- Please read and understand all safety instructions which include the terms WARNING, and CAUTION. If these safety instruc-

tions are ignored, personal injury may result.

- The repair, maintenance and safety instructions in this manual are valid only when the repair or maintenance work is performed

according to the procedures described in this manual.

- The term WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- The term CAUTION indicates a potentially hazardous situation which, if not avoided, may result in damage on machines. It may

also be used to alert against unsafe practices.

- Horizon International Inc. cannot anticipate every possible situation that might involve a potential hazard. The instructions in this

manual and the warning labels on the machine are therefore not all-inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation, repair

or maintenance could cause injury to personnel. Do not attempt to operate any switch, valve, or any electrical device when it has

been locked or tagged out.

- Some of the drawings in this manual show the machine uncovered for explanations of the details inside the machine.

2

Page 5

I. Necessary Tools for Maintenance and Repair

9

n

n

n

K

e

y

n

n

a

y

)

.C

B

.

b

alue

ef

e

f

otal Counts Setting

e

CA

UTION

umeric

e

umbers

par

n

g

Use the following tools for maintenance and repair.

1. Screw Driver No. 2

2. Screw Driver 6 to 7 mm

3. Allen Wrenches 1.5, 2, 2.5, 3, 4, 5, and 6 mm

4. Open-ended Wrench 5.5 x 7, 8 x 10, 13 x 17 mm

5. Box Wrench 5.5 mm

6. Snap-ring Expander

II. Abbreviations in This Manual

2. The following abbreviation represent electronic and electrical parts.

Abbreviation

Meaning

CL Clutch

BK Brake

SW Switch

PS Proximity Switch

mSW Micro-switch

M Motor

1. The following abbreviations represent wire colors.

Abbreviation

Color

Abbreviations

Color

BRN Brown PNK Pink

RED Red LBL Light Blue

ORN Orange YEG Yellow Green

YEL Yellow YEO Yellow Orange

GRN Green LYE Light Yellow

BLU Blue GND Ground

VIO Violet

GRY Gray

WHT White

BLK Black

LED Light Emitting Diode

VR Potentiometer

RY Relay

AS Assembly

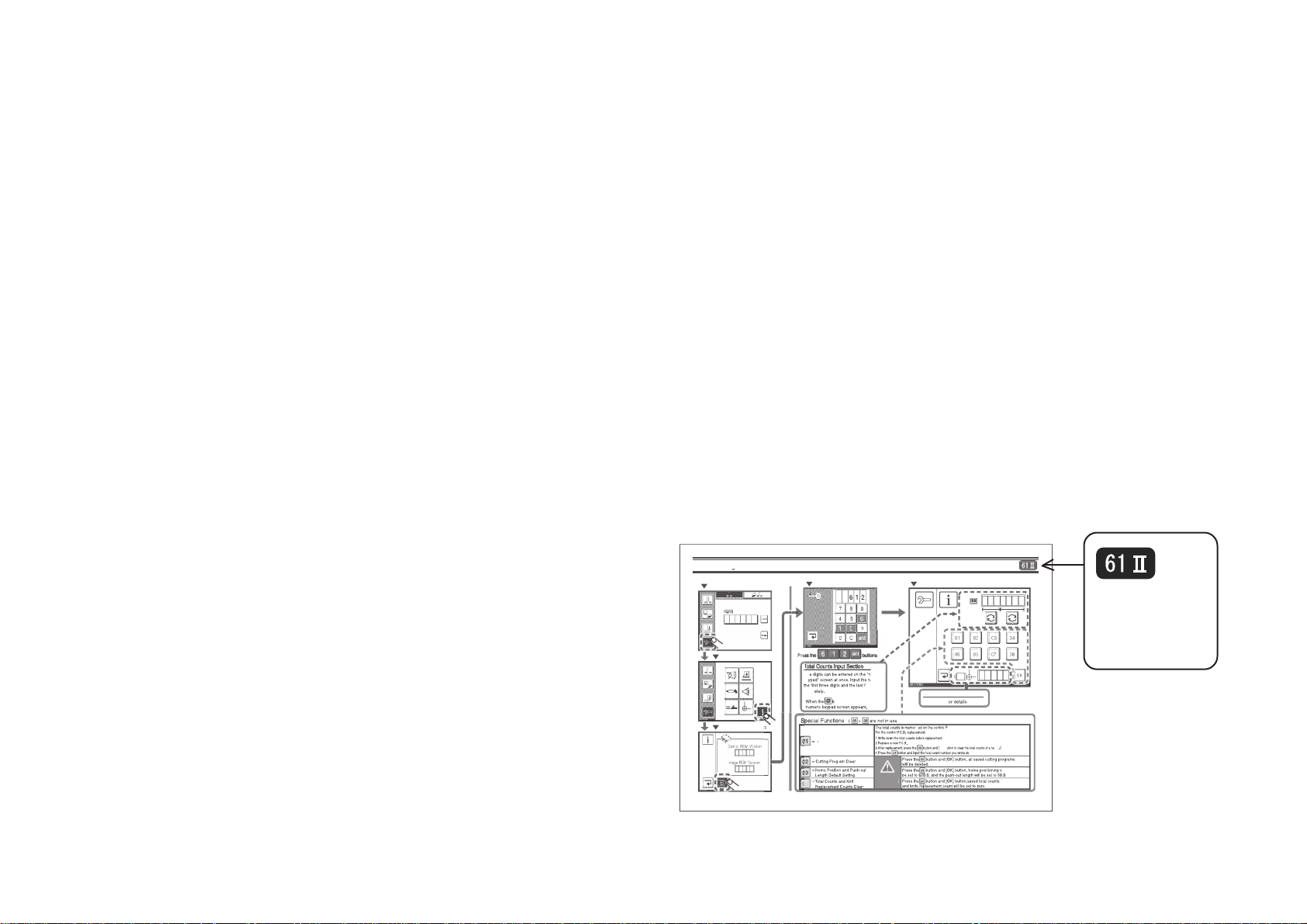

1-5 Entering Service Scree

"Numeric

"Normal Cutting" Scree

"Maintenance" Scree

"ormation" Scree

pad" Scree

se

our digits

utton is pressed,the

1-

.

"Service" Scree

Moter Home Position Displ

R

r to 1-7

iz

OK]

.

means

a page that is

related to

APC-61II.

will

3

Page 6

Contents

FOREWORD........................................................................... 1

Paper Cutter ............................................................................ 1

Model APC-61 ......................................................................... 1

Important Information ........................................................... 1

I. Necessary Tools for Maintenance and Repair .................. 3

II. Abbreviations in This Manual .......................................... 3

1. Machine Parts Descriptions

1-1 General View ..................................................................... 1-2

1-2 Operation Panel Descriptions (T61)................................ 1-5

1-3 Operation Panel Descriptions (M61) .............................. 1-7

1-4 Cover Descriptions............................................................ 1-8

1-5 Entering Service Screen (61II)......................................... 1-9

1-6 Calibration of Home position (61II)................................ 1-10

1-7 Checking Motor Home Position Distance (61II)............ 1-11

2. Troubleshooting

2-1 blinks on the Display (Backgauge Does Not Operate)

Part 1 ................................................................................. 2-2

Part 2 ................................................................................. 2-3

Part 3 ................................................................................. 2-4

Part 4 ................................................................................. 2-5

2-2 Cut Size is Not Equal

Part 1 ................................................................................. 2-6

Part 2 ................................................................................. 2-7

2-3 Knife Does Not Lower (Clamp Does Not Lower Either)

Part 1 ................................................................................. 2-8

Part 2 ................................................................................. 2-9

Part 3 ................................................................................. 2-10

2-4 Knife Does Not Lift

Part 1 ................................................................................. 2-11

Part 2 ................................................................................. 2-12

2-5 Clamp Lowers but Knife Does Not Lower ..................... 2-13

2-6 Clamp Does Not Lower Though Foot Pedal

Is Stepped On................... 2-14

2-7 Backgauge Does Not Operate

Part 1 ................................................................................. 2-15

Part 2 ................................................................................. 2-16

2-8 Backgauge Does Not come Forward

(But goes backward) .......... 2-17

2-9 Backgauge Operates By Itself.......................................... 2-18

2-10 Nothing Is Shown on Displays ....................................... 2-19

2-11 Hydraulic Pressure Does Not Operate.......................... 2-20

2-12 Knife Is Down before Operation ................................... 2-21

2-13 Knife Lower Limit Position Varies ............................... 2-22

2-14 Backgauge Does Not Move (61II) ................................. 2-23

2-15 Error Code (61II)............................................................ 2-24

4

Page 7

3.Adjustment

3-1 Fine Adjustment of Cut Size

(Different is about 0.1 mm) ................. 3-2

3-2 Adjustment of Cut Size

(Different is about between 0.1 and 0.2 mm)................. 3-3

3-3 Rough Adjustment of Cut Size

(Different is about 0.5 mm) ................. 3-4

3-4 Adjustment of Electromagnetic Brake Gap................... 3-5

3-5 Adjustment of Electromagnetic Clutch Gap .................. 3-6

3-6 Adjustment of Knife Replacement Position ................... 3-7

3-7 Adjustment of Knife Lower Limit Position.................... 3-8

3-8 Adjustment of Cutting Line Width ................................. 3-9

3-9 Release of Locked Knife................................................... 3-10

3-10 Pressure Adjustment of Hydraulic Pump .................... 3-12

3-11 Right Angle Adjustment of Backgauge to the Table....... 3-13

3-12 Horizontal Adjustment of Backgauge to the Table ..... 3-14

3-13 Parallel Adjustment of Backgauge to the Knife .......... 3-15

3-14 Backgauge Drive Section Mechanism (61II) ............... 3-16

3-15 Spindle Section Mechanism (61II)................................ 3-17

4.Repair

4-1 Replacing Knife Holder.................................................... 4-2

4-2 Replacing Clamp............................................................... 4-5

4-3 Replacing Backgauge........................................................ 4-8

4-4 Replacing Backgauge Block............................................. 4-9

4-5 Replacing Knife Link A and B......................................... 4-10

4-6 Replacing Clamp Link A and B....................................... 4-11

4-7 Replacing Joint (For Clamp) ........................................... 4-13

4-8 Replacing Joint (For Knife) ............................................. 4-14

4-9 Replacing Rod End ........................................................... 4-16

4-10 Replacing Rod ................................................................. 4-17

4-11 Replacing Encoder .......................................................... 4-18

4-12 Replacing Electromagnetic Brake................................. 4-19

4-13 Replacing Electromagnetic Clutch................................ 4-20

4-14 Replacing Belt (For High Speed)................................... 4-21

4-15 Replacing Belt (For Low Speed).................................... 4-22

4-16 Replacing Motor (For High Speed)............................... 4-23

4-17 Replacing VC Relay and Contactor .............................. 4-24

4-18 Replacing Sensors (Detecting Knife Replacement

Position, Knife Lower Limit Position) ..... 4-25

4-19 Replacing Power Supply ................................................ 4-26

4-20 Replacing Operation Panel ............................................ 4-27

4-21 Replacing Control Board ............................................... 4-28

4-22 Replacing Fuse and Resetting Thermal Relay ............. 4-29

4-23 Replacing Limit Switches............................................... 4-30

4-24 Replacing Knife Holder Upper Limit Position Sensor 4-31

4-25 Replacing Limit Switch

for Clamp Upper Limit Position.................. 4-32

4-26 Replacing Cutting Line Bulb ......................................... 4-33

4-27 Replacing Electromagnetic Valve.................................. 4-34

5

Page 8

5.Hydraulic Parts

5-1 Hydraulic Parts Description

(For S/N 100001 or above) ............................................... 5-2

5-2 Hydraulic Circuit .............................................................. 5-3

(For S/N 100001 to 122899) .............................................. 5-3

(For S/N 123001 or above) ................................................ 5-4

5-3 Hydraulic Parts Descriptions

(For S/N 099999 or below) ................................................ 5-5

5-4 Hydraulic Circuit (For S/N No.099999 or below) .......... 5-6

6. Electrical Parts Description

6-1 Identification and Location of Motors and Encoder ..... 6-2

6-2 Identification and Location of Sensors and Switches .... 6-3

6-3 Identification and Location

of Components in the Control Box .... 6-4

6-4 Location and Name of Pairs in Control Box(61II) ........ 6-5

6-5 Panel Internal Layout and Name (61II) ......................... 6-6

6-6

Hydraulic Pressure and Motor Unit Layout and Name (61II) ..

6-7 Backgauge Motor Section Layout and Name (61II) ...... 6-8

6-8 Parameter Settings of Amplifier

for Servo Motor (61II) ........................ 6-9

6-7

7-4 Control Board (QPW-153D), LED and Main Parts ...... 7-5

7-5 Control Board (QPW-153D) Connector Layout ............ 7-6

7-6 Foot Switch Control Board (QPW-155A) ...................... 7-7

7-7 Foot Switch Control Board (QPW-155A) ...................... 7-8

7-8 Control Box Schematic Diagram ..................................... 7-9

7-9 Wiring Diagram ................................................................ 7-10

7-10 Terminal-1 ....................................................................... 7-11

7-11 Terminal-2 Wiring Diagram (Inside of Control Box) . 7-12

7-12

LED and DSW of Control P.C.B. P083411(QPM-195) (61II) ....

7-13

LED and DSW of Panel P.C.B. P071811(QPM-157) (61II)..

7-14 P083411(QPM-195) Connector Connection (61II) ...... 7-16

7-15 New Circuit (Power System) (61II) ............................... 7-18

7-16 Safety Circuit Performance (61II) ................................ 7-19

7-14

7-15

7. System Wiring and Connections

7-1 Board Connections ............................................................ 7-2

7-2 CPU Board (QPW-162) .................................................... 7-3

7-3 Display Board M61:QPW-175, T61:QPW-176 .............. 7-4

6

Page 9

1.Machine Parts Descriptions

1-1 Machine Parts Descriptions ........................................................................... 1-2

1-2 Operation Panel Descriptions (T61) ..............................................................1-5

1-3 Operation Panel Descriptions (M61) .............................................................1-7

1-4 Cover Descriptions ..........................................................................................1-8

1-5 Entering Service Screen (61II) .......................................................................1-9

1-6 Calibration of Home Position (61II) ............................................................1-10

1-7 Checking Motor Home Position Distance (61II) ........................................ 1-11

1-1

Page 10

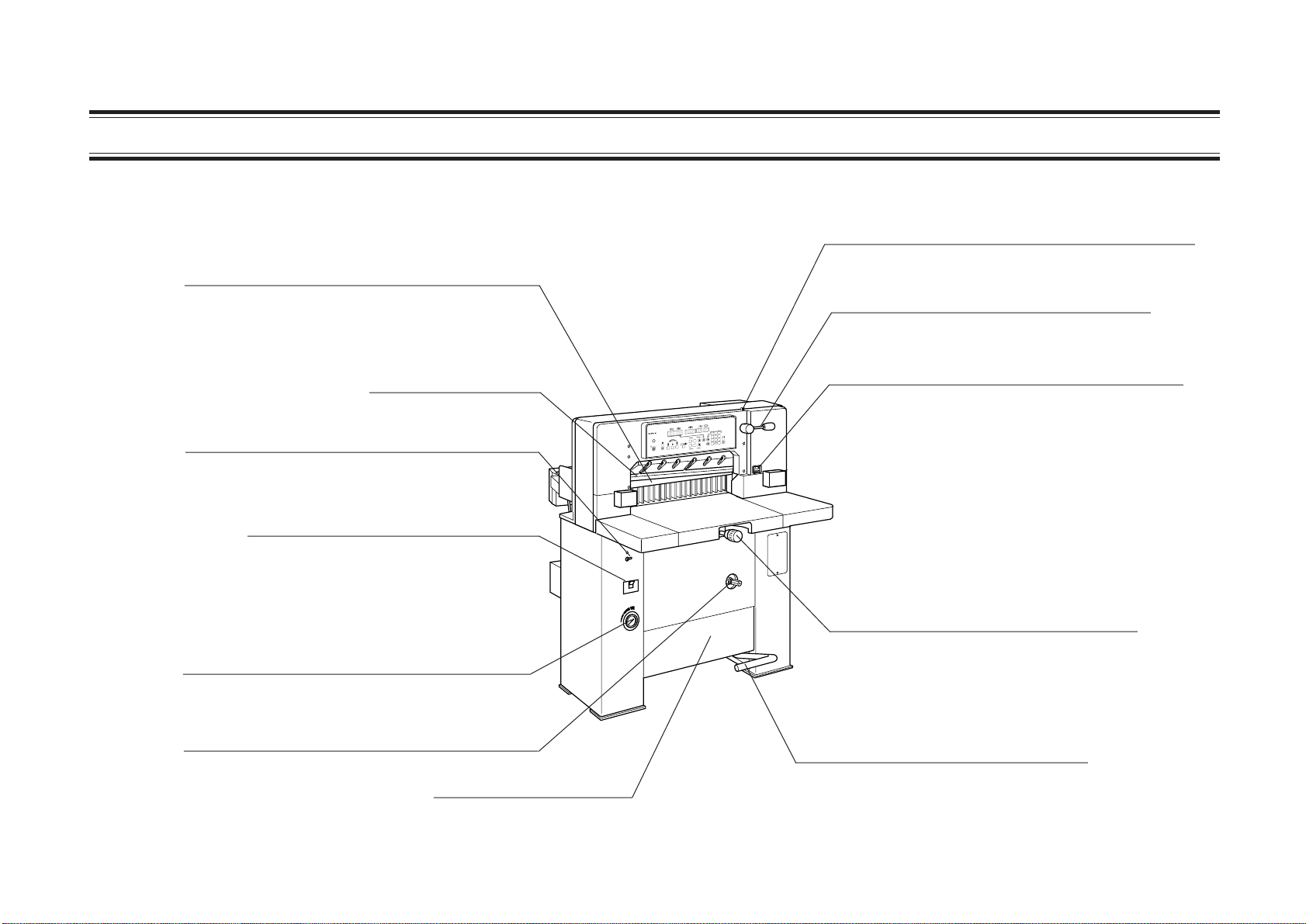

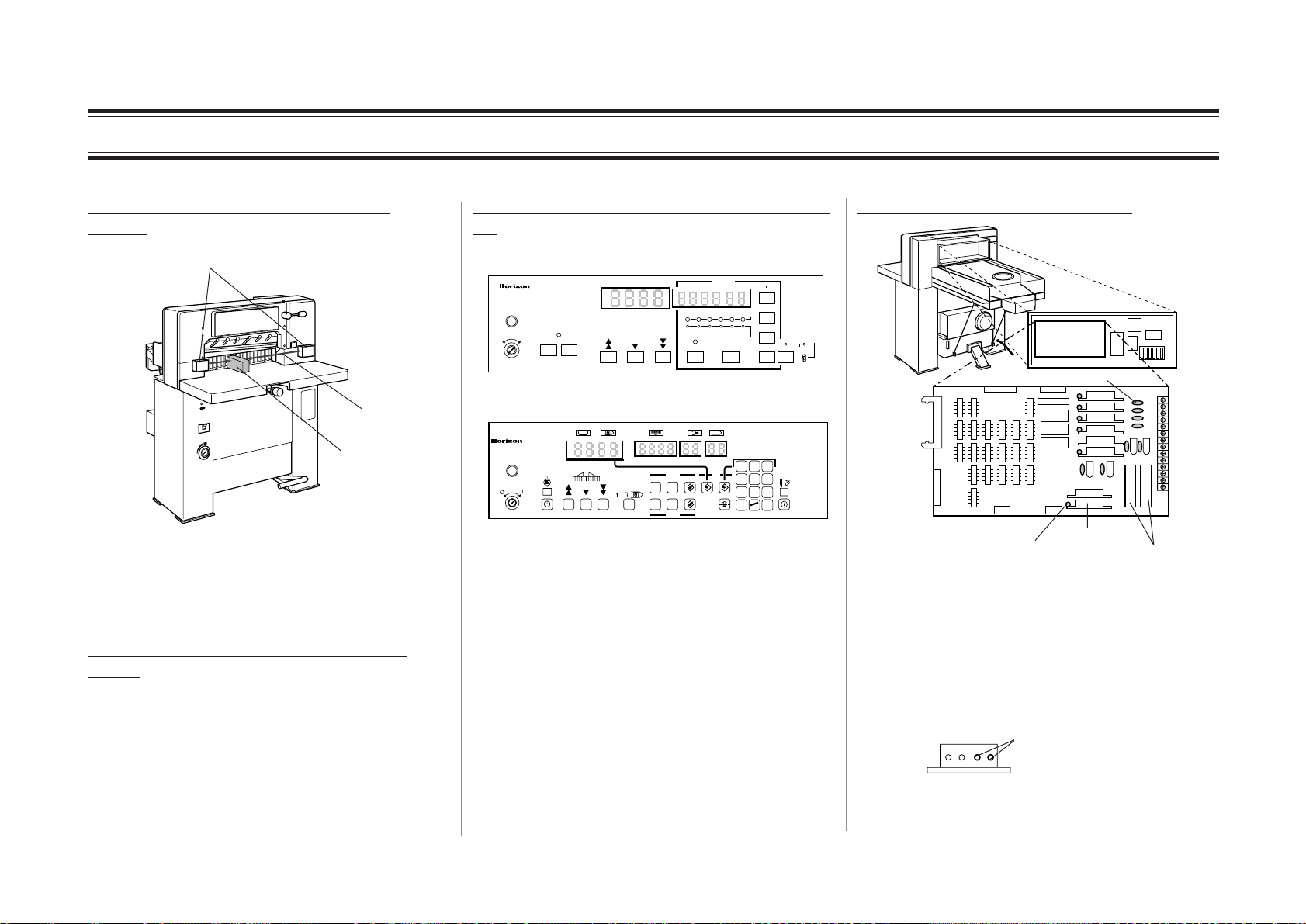

APC-T61

HYDRULIC CUTTER

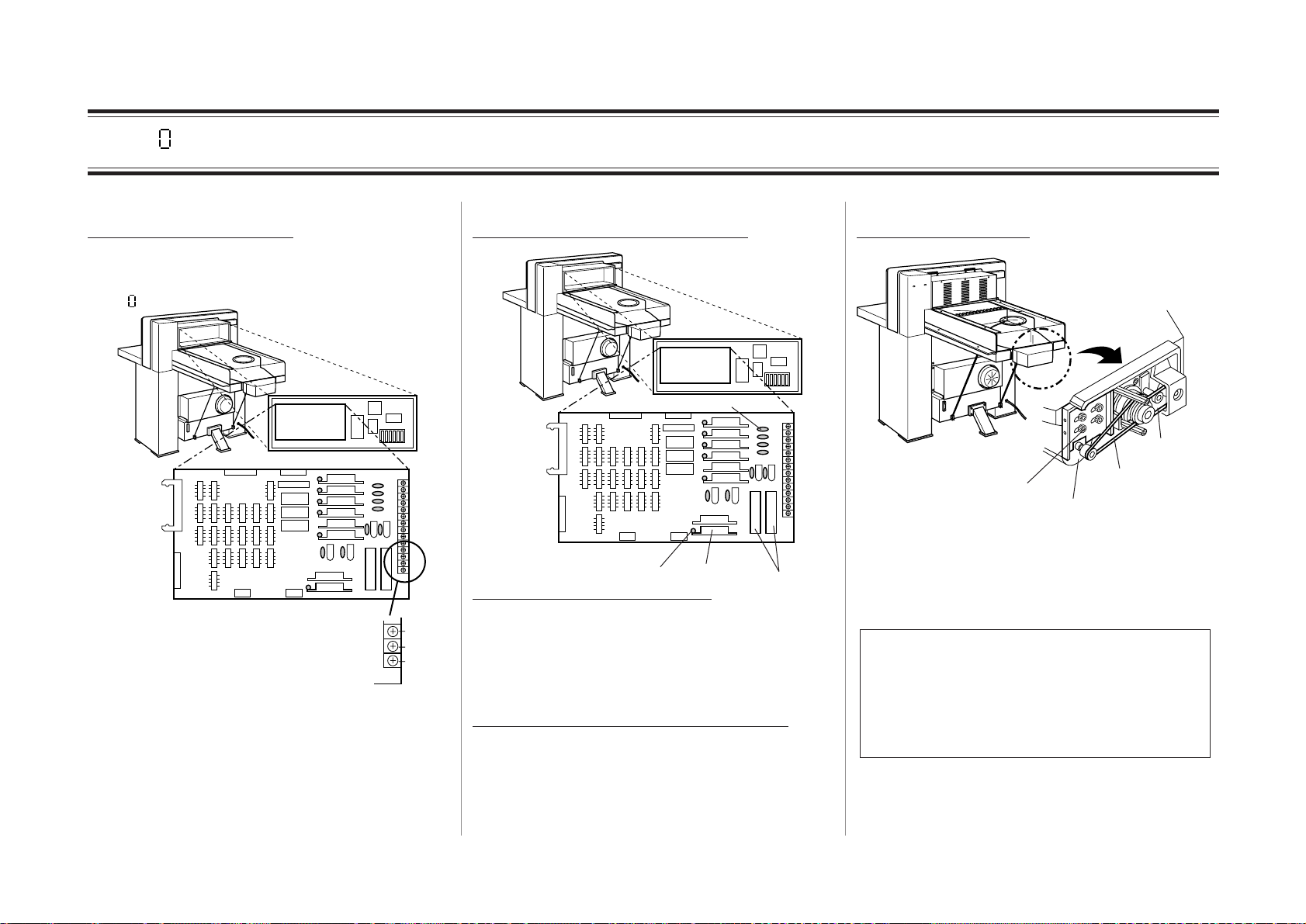

1-1 General View

Clamp

This clamp holds sheets not to move the sheets

when they are cut.

(500 to 1,700kg/cm )

Knife Angle Adjust Lever Fix Screw

Knife angle adjust lever is fixed with this screw.

Knife Angle Adjust Lever

2

The knife angle adjusted with this lever.

Cutting Knife

Cutting Depth Adjust Dial

This dial is used to adjust the knife lower limit

position only when Knife Operation Mode

Select Switch is turned off.

Cutting Knife ON/OFF Switch and Lamp

?

?

APC-T61

HYDRULIC CUTTER

7 8 9

4 5 6

1 2 3

-

P

+

P

.

E

c

0

-

S

+

S

When this switch is turned up, only clamping

will be performed with lamp lighting.

Power Switch

The type of this switch is the breaker.

Backgauge Adjust Knob

This knob is used to adjust backgauge.

Paper Clamp Pressure Indicator

Paper Clamp Pressure Adjusting Knob

Foot Pedal

This pedal is used to lower clamp.

Oil Tank

It can contain 40 liter of oil.

1-2

Page 11

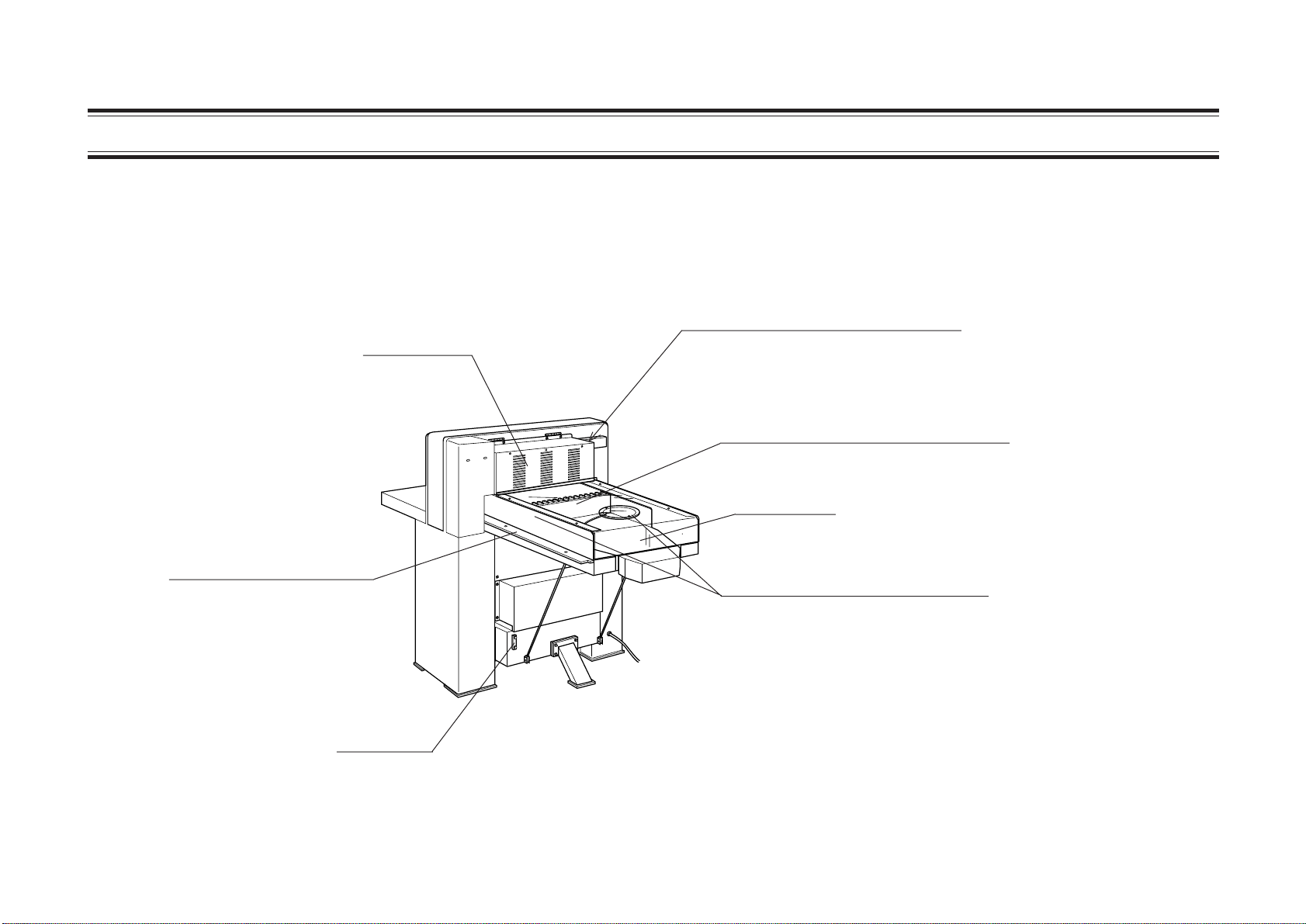

1-1 General View

Pressure Support Plate

Control Box

Light Switch

When turning up the lever, the table is

lightened up, but it becomes difficult to

see the cut line.

Backgauge

This backgauge is the back stop of

sheets to be cut.

Back Table

Side Guides

These guides are register plates for

preparing the sheets right angle

against cutting knife.

Oil Gauge

1-3

Page 12

APC-T61

HYDRULIC CUTTER

1-1 General View

Cutting Button A

Key Switch

Photoelectric Guard

When there is a foreign object

on the optical line between

?

?

APC-T61

HYDRULIC CUTTER

7 8 9

4 5 6

1 2 3

-

P

+

P

.

E

c

0

-

S

+

S

photoelectric guards, the ray is

blocked and safety function

operates. Therefore, knife and

clamp does not lower.

Oil Feed Cover For Backgauge

Backgauge Cover

Cutting Button B

This button and cutter A

button must be pressed

simultaneously to start

to cutting operation.

1-4

Motor encoder Section

The high speed motor, low speed motor,

electromagnetic clutch, brake and encoder are housed.

Page 13

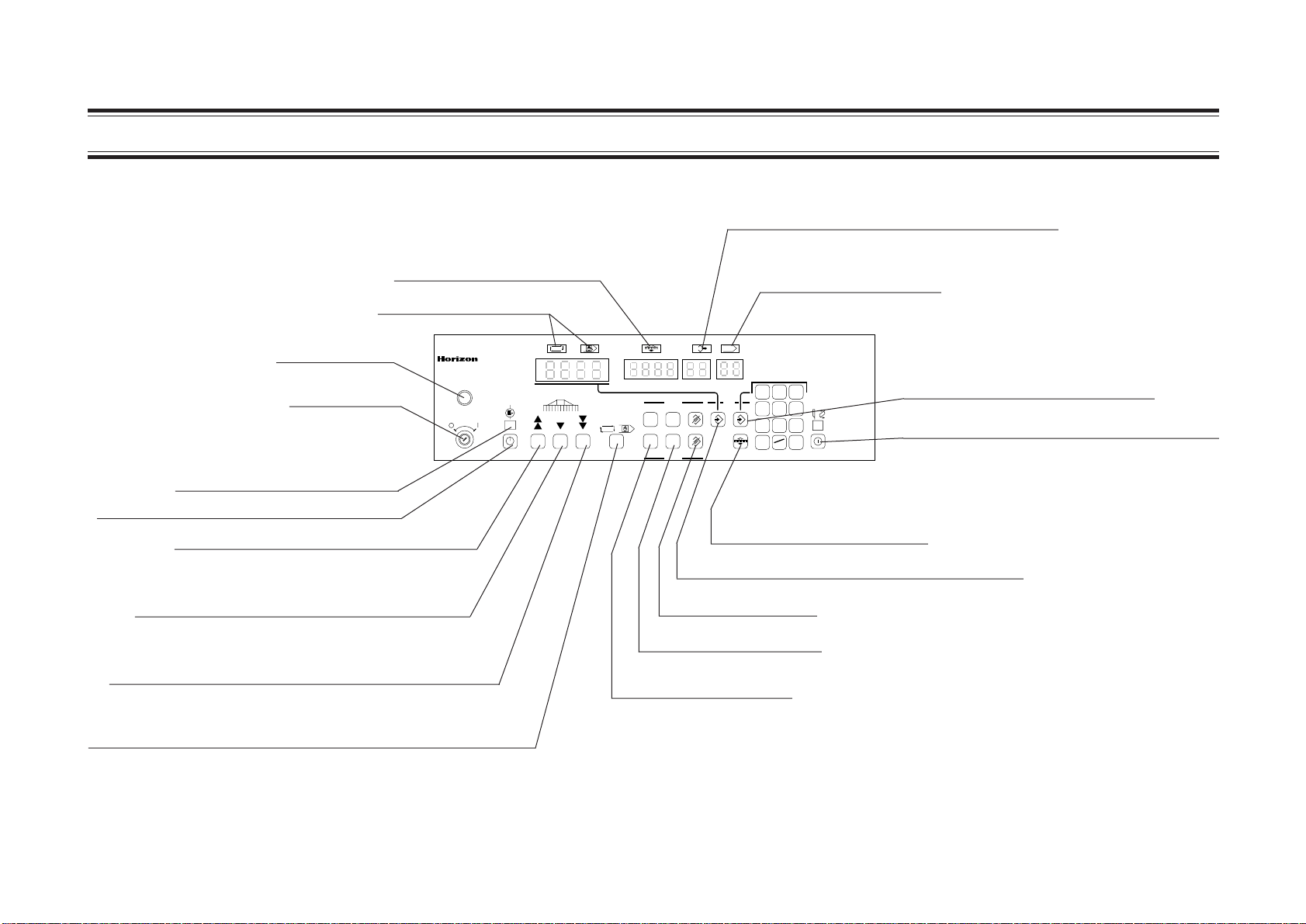

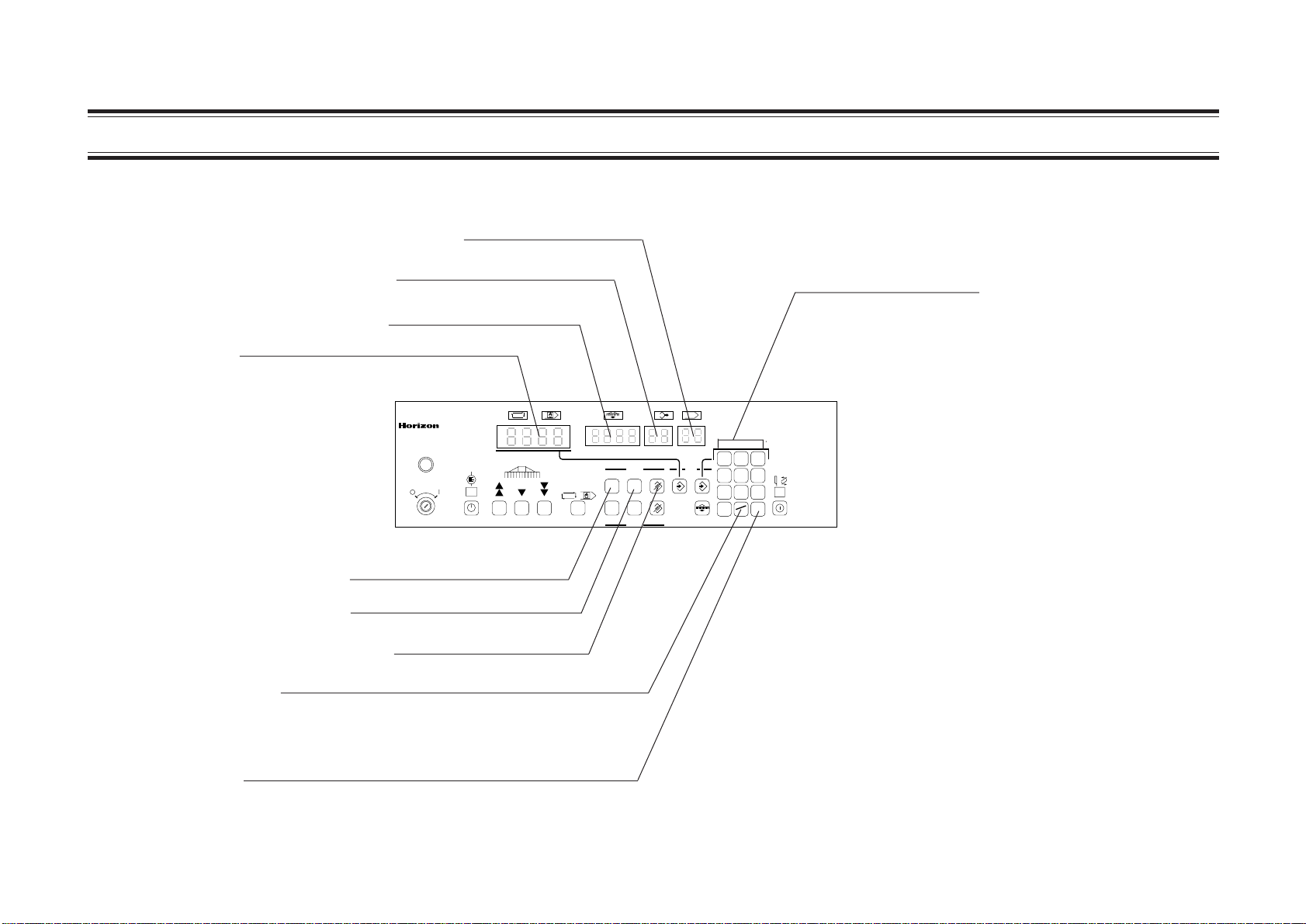

1-2 Operation Panel Descriptions (T61)

APC-T61

HYDRULIC CUTTER

Full Memory Lamp

This lamp lights when input memory is full.

Push-out Memory Lamp

Repeat/Setup Lamp

Power Lamp

HYDRULIC CUTTER

Key Switch

Hydraulic Pressure Lamp

Hydraulic Pressure ON/OFF Switch

High Speed Backward Button

This button is used to move backgauge

backward at high speed.

Low Speed Forward Button

This button is used to move backgauge

forward at low speed.

High Speed Forward Button

This button is used to move backgauge forward at

high speed.

Repeat/Setup Select Button

In normal operation, this switch must be set to the repeat

mode. (The above repeat lamp lights up.) The size memory

button must be set to the setup mode.(The above setup Lamp

lights up.)

Repeat

Current position

Setup

Put-out

Memory

Presetting

P

S

Program

P+-

S+-

Setup

No More

Memory Opar Error

?

Program No.

Delete

Memory Button (for the Current Position)

Step Delete Button

Step Backward Button

Step Forward Button

Operation Error Lamp

?

Step.No.

Memory

Push-out

789

456

123

.

0

E

c

Replacing

knife

ON

Memory Button (for the Keypad Input)

Knife Operation Mode Select Switch

This switch is used select knife operation

mode, cutting mode or knife replace

mode. In normal operation, this switch

must be set to the cutting mode.

Push-out Memory Button

1-5

Page 14

APC-T61

HYDRULIC CUTTER

1-2 Operation Panel Descriptions (T61)

Step Number Display

Program Number Display

Presetting Size Display

Current Position Display

This display shows the backgauge

current position.

Repeat

Current position

HYDRULIC CUTTER

Program Forward Button

Program Backward Button

Program Delete Button

Decimal Point/Clear Key

The decimal point is input in the first press and

the number is deleted for the delete key in the

second press.

Numeric Keypad

Setup

Put-out

Memory

Presetting

P

S

Program

P+-

S+-

Setup

No More

Memory Opar Error

?

Program No.

Delete

Step.No.

Memory

?

Push-out

789

456

123

.

0

E

c

Replacing

knife

ON

Enter Key

When this key pressed after inputting the number,

the backgauge moves to the set position.

1-6

Page 15

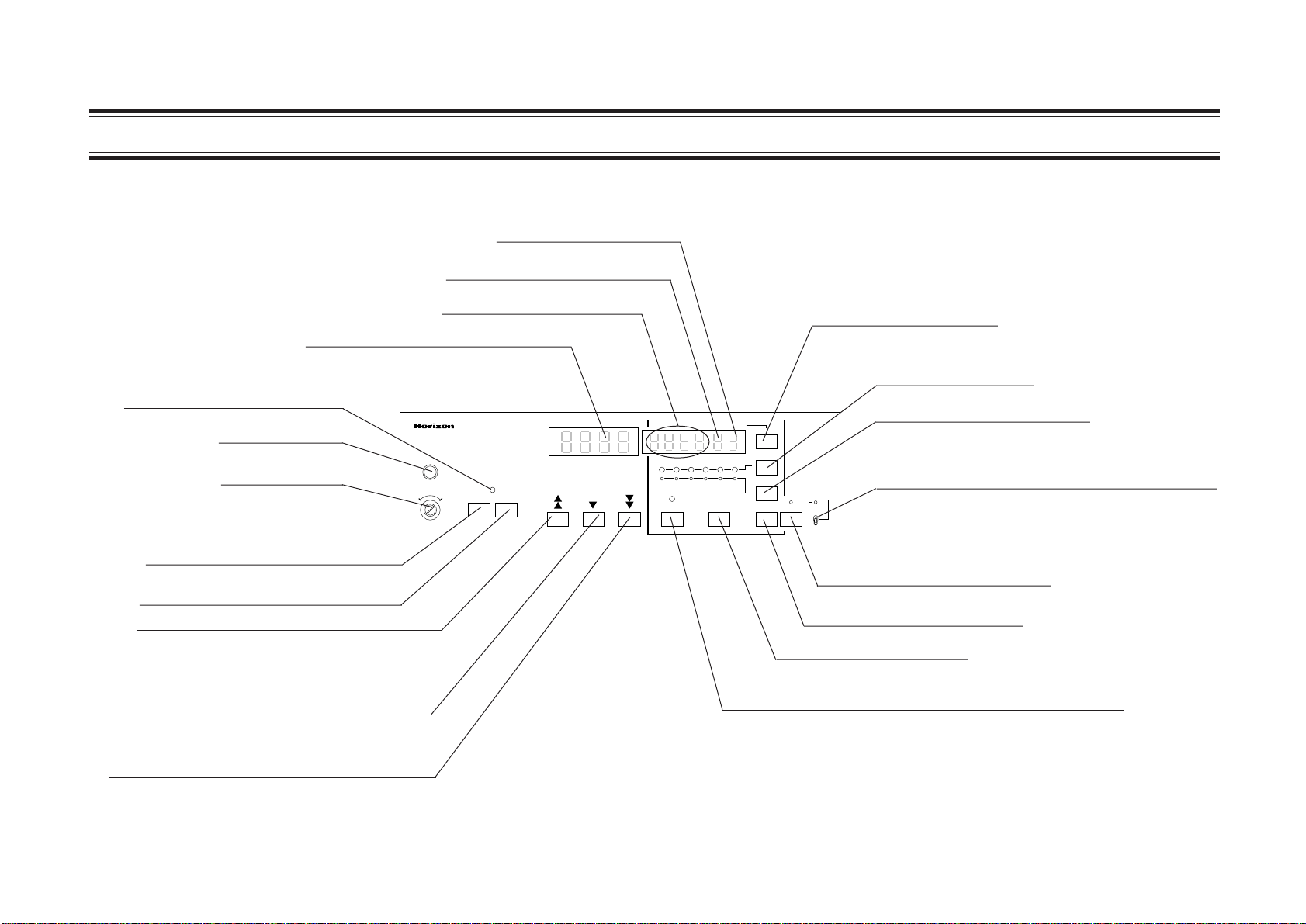

APC-M61

HYDRULIC CUTTER

1-3 Operation Panel Descriptions (M61)

Program Number Display

Step Number Display

Current Position Display

This display shows the backgauge

current position.

Hydraulic Pressure Lamp

Power Lamp

Key Switch

Hydraulic Pressure ON Button

Hydraulic Pressure OFF Button

High Speed Backward Button

This button is used to move

backgauge backward at high

speed.

Low Speed Forward Button

This button is used to move backgauge

forward at low speed.

High Speed Forward Button

This button is used to move backgauge

forward at high speed.

Presetting Size Display

Current Position Display

Power

Hydraulic

Backgauge Travel

Memory

Program No. Step No.

Presetting

Step

1 2 3 4 5 6

Memory Delete

Repeat / Setup

Step Forward Button

Size Memory Button

Push-out Memory Button

Knife Operation Mode Select Switch

This switch is used to replace knife.

In normal operation, this switch must be set

Step Forward

Size

Memory

Push-out

Memory

Program

Forward

Replacing Knife

Be sure to set "knife Angle

Adjustmant" knob and "Knife

Operation Mode" select

switch to each "Replacing

Knife"Position

Cutting Operation & Knife

Vertical Adjustment

Be sure to set "knife

Operation Mode" select

switch to "cutting"

position

knife Operation

Program Extension

Mode

Replacing

Knife

Cutting

to the cutting mode.

Program Extension Button

Program Forward Button

Memory Delete Button

Repeat/Setup Select Button

In normal operation, this switch must be set to the

repeat mode. The above repeat/Setup Lamp lights up.

The size memory button must be set to the setup mode.

(The above setup Lamp lights up.)

1-7

Page 16

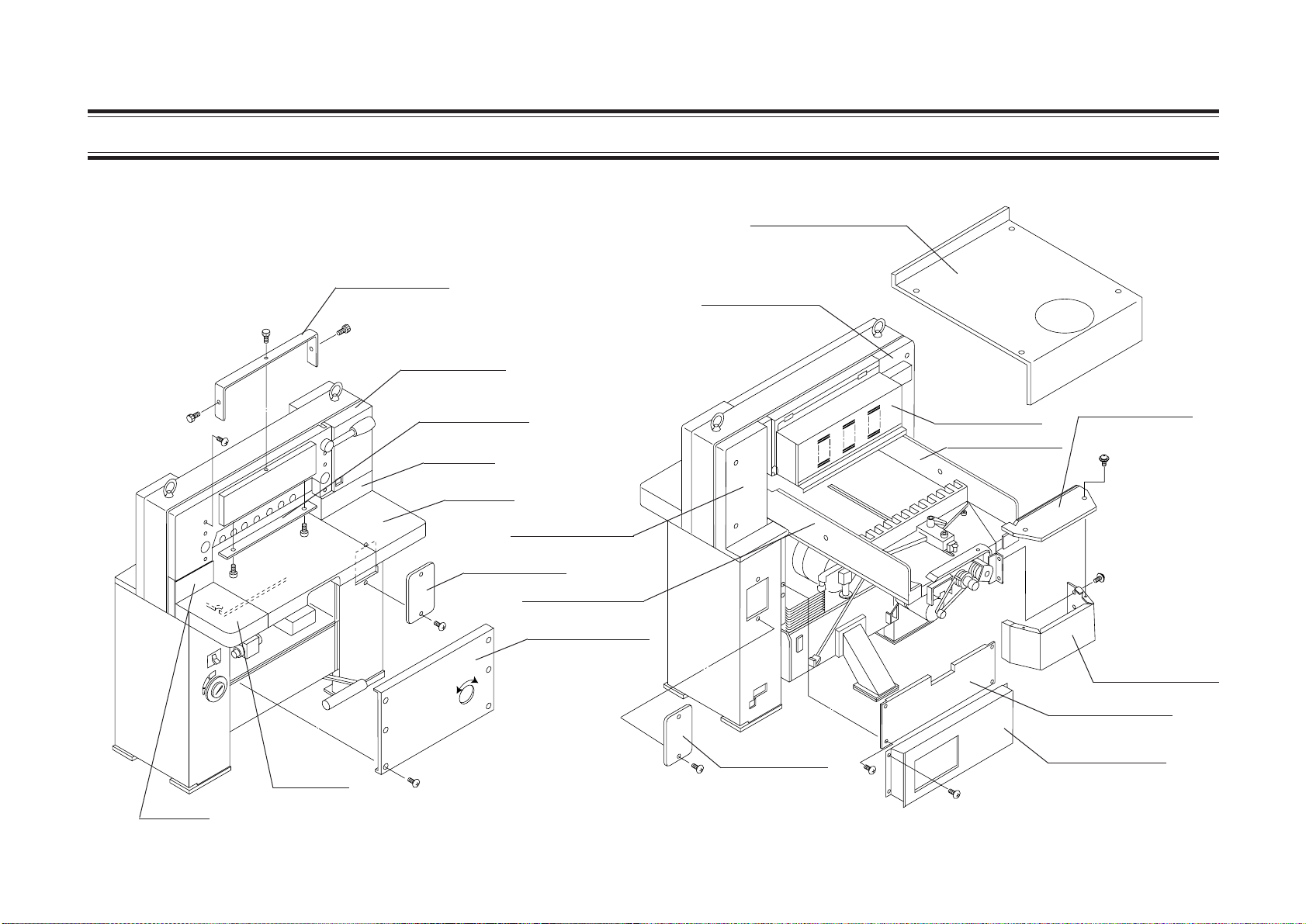

1-4 Cover Descriptions

Backgauge Cover

M013345-02

Upper Cover

Rear Cover L

Front Cover

Plate L

Table L

Lower Cover

Plate R

Table R

Small Cover

Rear Cover R

Side Gauge R

Front Cover L

Small Cover

Control Box

Side Gauge L

Back Cover B

Back Cover A

Back Cover U

Back Cover L

1-8

Page 17

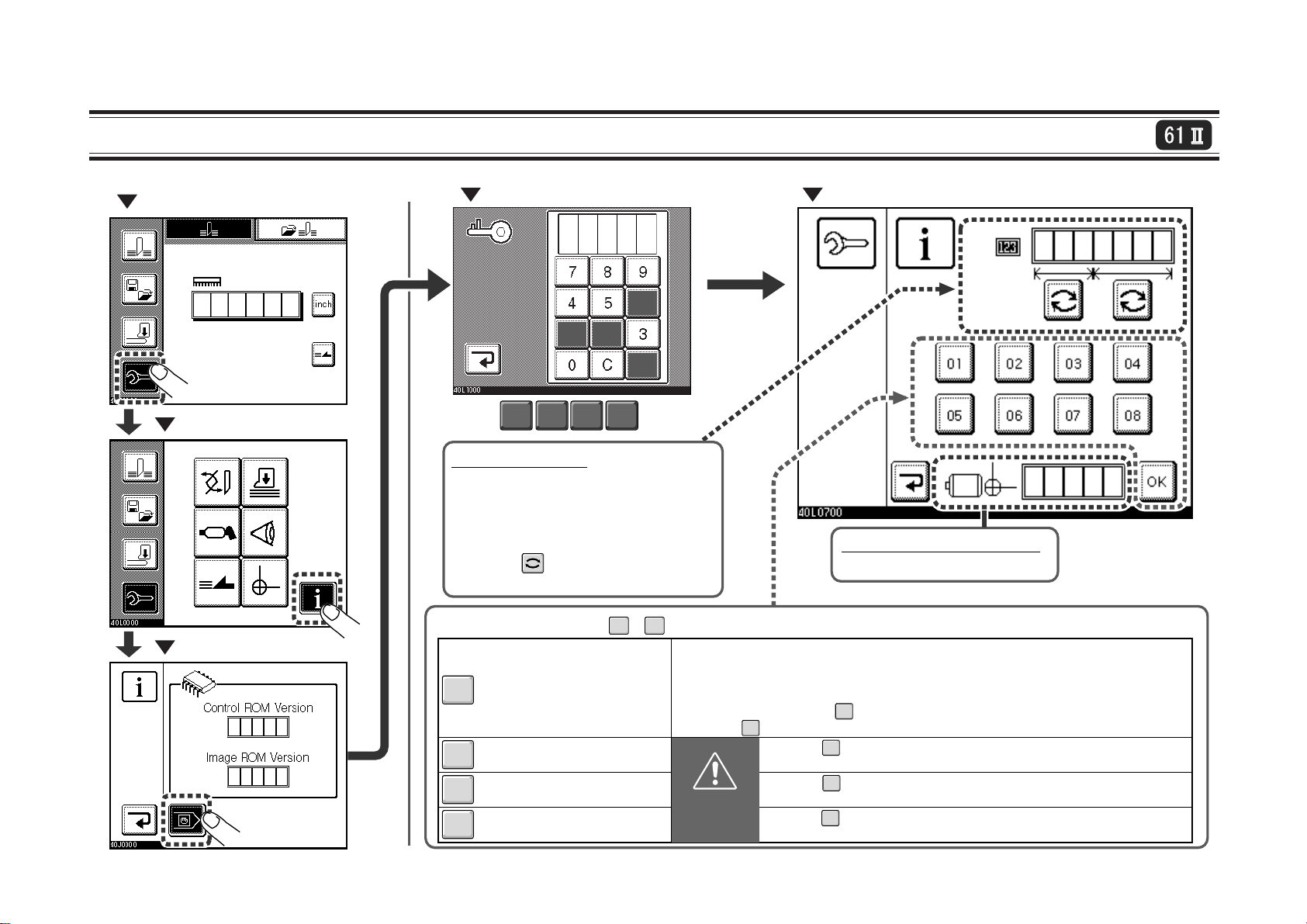

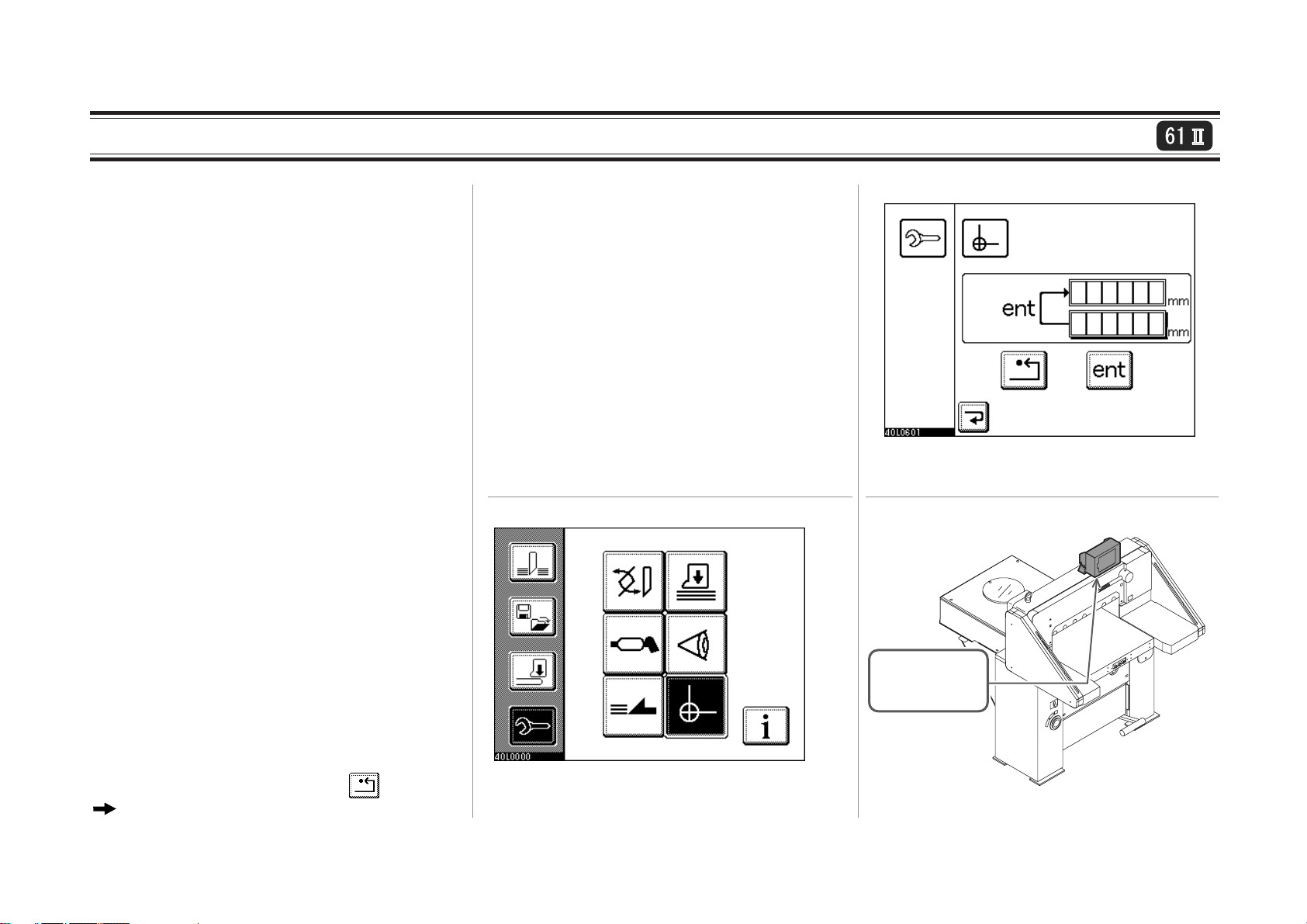

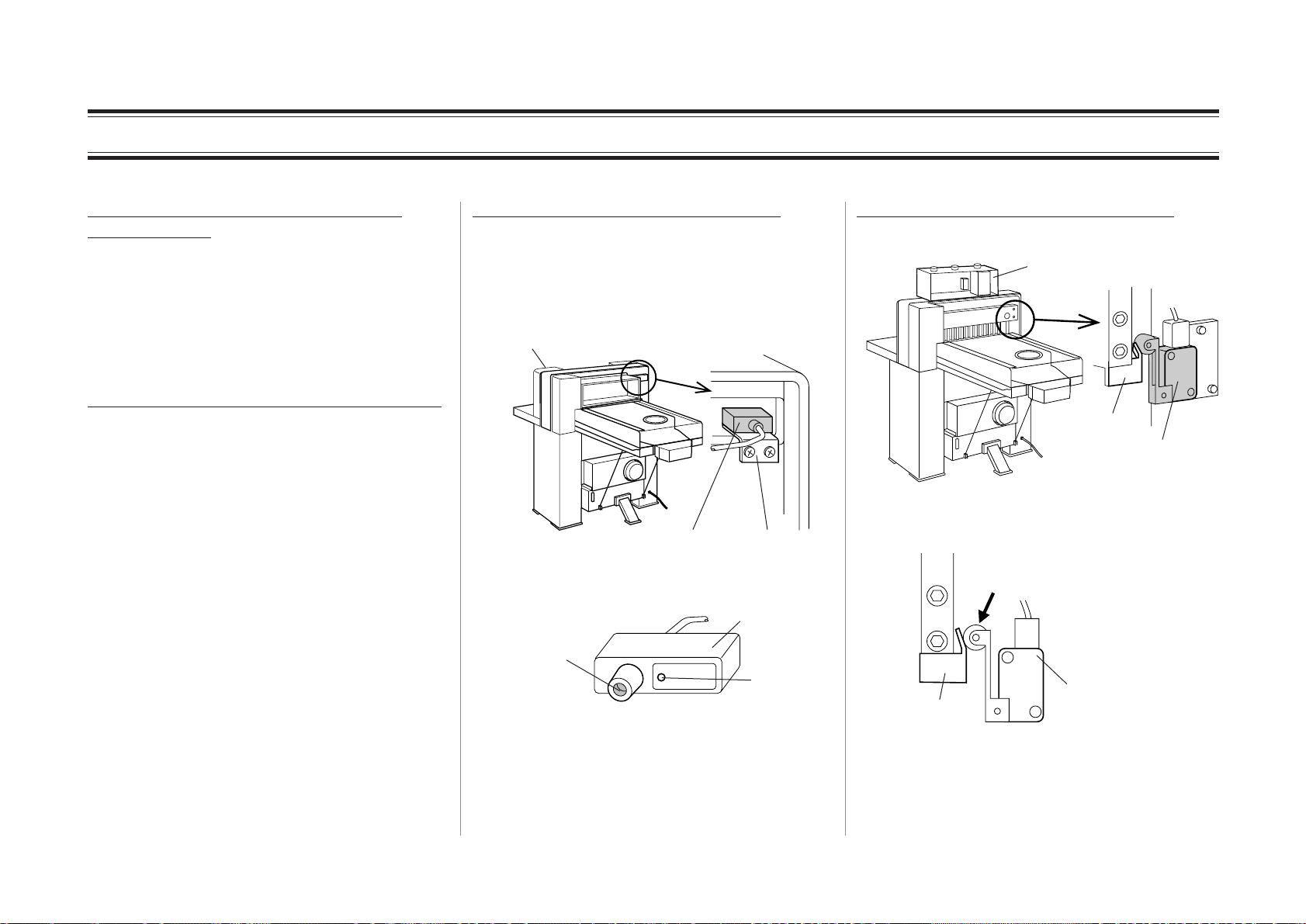

1-5 Entering Service Screen

"Normal Cutting" Screen

"Maintenance" Screen

"Information" Screen

"Numeric Keypad" Screen

612

6

2

1

ent

.

ent

05

08

- are not used.)

(

The total counts is memorized on the control P.C.B.

When replacing the control P.C.B.,

1. Write down the total counts before replacing the P.C.B.

2. Replace a new P.C.B.

3.

4. Press the button and input the total count number you wrote down.

CAUTION

Press the buttons.

6 1 2

Total Count Input

Up to five digits can be entered using the

"numeric keypad" screen at once. Input the

numbers the first three digits and the last

four digits separately

When the button is pressed, the

numeric keypad screen appears.

Special Functions

= Total Count Setting

01

= Cutting Program Clear

02

=

Resetting Home Position and

03

Push-out Length to Default

=

Total Count and Count after

04

Replacing Knife

"Service" Screen

Motor Home Position Display

Refer to 1-7 for details.

After replacement, press the button and the [OK] button to clear the total counts of a new P.C.B.

01

Press the button and the [OK] button. Saved cutting programs will be

deleted completely. Deleted cutting programs cannot be restored.

Press the button and the [OK] button. Home positioning value will be

set to 620.0, and the push-out length will be set to 50.0.

Press the button and the [OK] button. Memorized total counts and

count after replacing knife will be set to zero.

04

02

03

04

1-9

Page 18

1-6 Calibration of Home Position

1. Set the cutting length to 100.0mm.

- This is the temporary value for comparing the

set value with the actual cut length.

2. Cut some sheets.

- Do not align the sheets on the side guide. Align the

sheets only on the backgauge properly, and cut.

3. Measure the dimension of cut sheets.

- Measure the dimension of the sheets by one

decimal place. 100.6mm is given for an example here.

4. Obtain the correction value.

- Correction value is a half of the difference

between the set value and the actual cut length.

- The actual cut length is 100.6mm. Therefore,

the correction value is 0.3mm.

5. Enter a new home position. (Fig.2)

- Show the Backgauge Calibration screen.

(Fig.1, Fig2)

- Add or subtract the correction value which was

calculated in step 4 to or from the current home

position value, and enter the new home position

value. (When the actual cut length is larger than

the set value, substract the correction value.)

In the case of the example, enter the value which

is subtracted by 0.3 and press the button.

The backgauge will move to the new home

position.

6. Check.

- Follow the steps 1 through 3 and check that the

set value matches the actual cut length.

7. Rewrite the home position sheet.

- The home position sheet is attached to the

bottom of the control panel box shown in Fig.3.

Rewrite the new home position on it.

504007

1_6_1A

Fig.1 "Maintenance" Screen

504007

1_6_1B

Fig.2 "Backgauge Calibration" Screen

The home position

sheet is attached to

the bottom of the

control panel box.

504007

1_6_1C

Fig.3 Location of the Home Position Sheet

1-10

Page 19

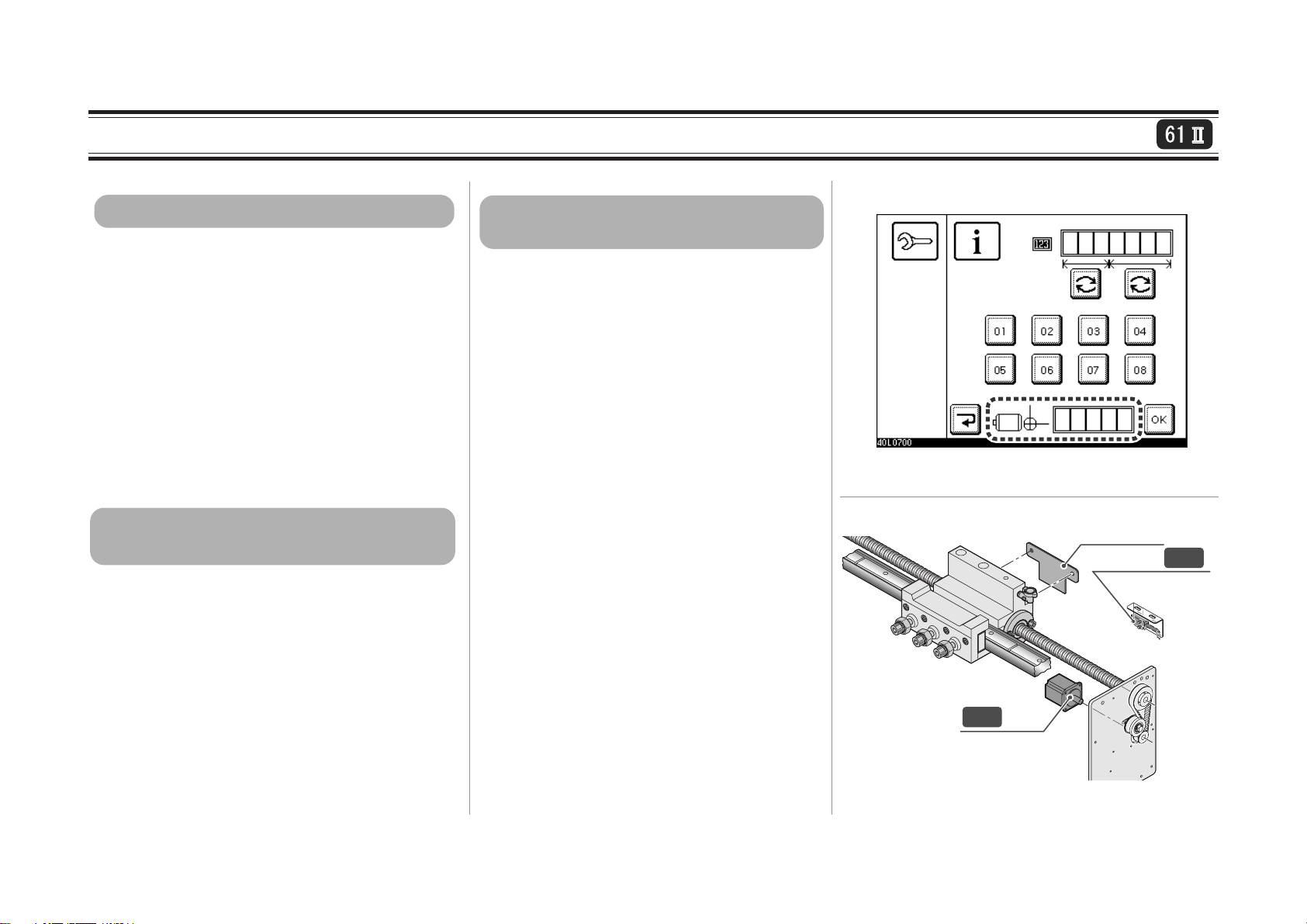

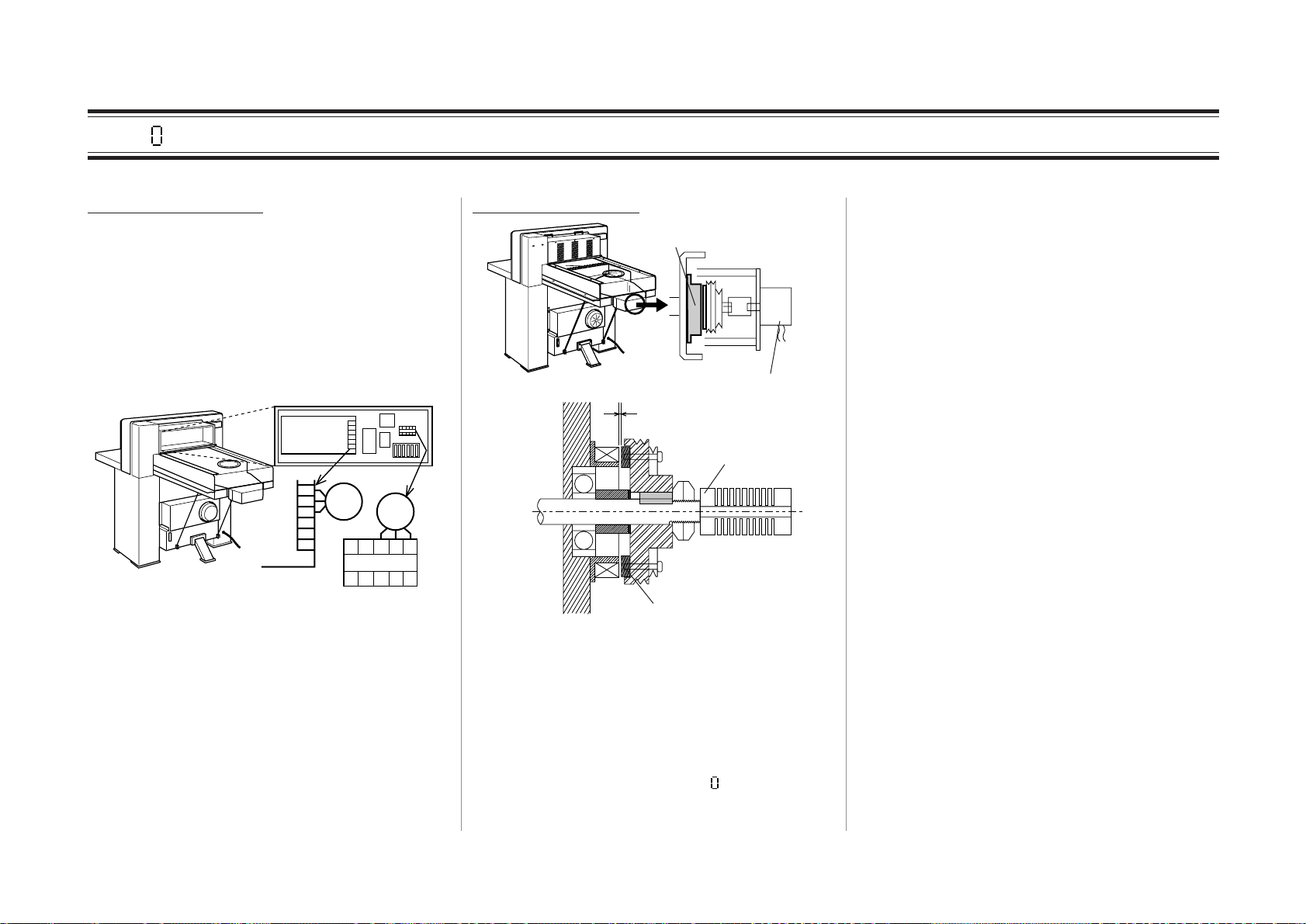

1-7 Checking Motor Home Position Distance

504007

1_7_1A

404007

1_7_1B

Home Position Sensor

Sensor Plate

B21

Servo Motor

M20

Explanation of "Home Positioning"

1. At first, the backgauge moves backward and

B21 home position sensor (Fig.2) detects the

sensor plate and turns on.

2. When B21 turns on, the servo motor M20

rotates in the reverse direction and moves the

backgauge forward, and B21 turns off.

3. The motor stops at the position where Z-phase

from the encoder is detected for the first time

in one rotation of M20. This position is the

home position.

- The encoder is housed in M20.

Explanation of "Motor Home Position

Distance"

- The motor home position distance is the

distance between the position which the B21

home position sensor turns off from on and

the position where the Z-phase from the

encoder is detected for the first time in one

rotation of M20. (steps 2 and 3 above).

- One rotation of M20 servo motor is set to 250

in APC-61II. The position of the home position sensor B21 is set so that Z-phase will be

detected at the middle of the motor rotation.

Therefore, the motor home position distance

should be around 125. (Fig.1)

Checking the Motor Home Position

Distance

- The Z-phase cannot be detected correctly

around the area that the B21 home position

sensor turned off from on, and the boundary

line of the first and second rotation of M20.

If the Z-phase appears at these areas, the

encoder may misread it, and

phase which appears next. This will set the

home position to the wrong position.

Therefore, checking the home position dis-

tance is necessary to make sure the encoder

reads Z-phase correctly in the stable area.

detects the Z-

Fig.1 "Service" Screen

Fig.2 Home Position Sensor B21

1-11

Page 20

This page is intentionally left blank.

1-12

Page 21

2. Troubleshooting

2-1 blinks on the Display (Backgauge Does Not Operate) .........2-2

2-2 Cut Size is Not Equal ...................................................................2-6

2-3 Knife Does Not Lower (Clamp Does Not Lower Either) ..........2-8

2-4 Knife Does Not Lift ....................................................................2-11

2-5 Clamp Lowers but Knife Does Not Lower...............................2-13

2-6 Clamp Does Not Lower Though Foot Pedal Is Stepped On. ..2-14

2-7 Backgauge Does Not Operate....................................................2-15

2-8 Backgauge Does Not come Forward (But goes backward) ....2-17

2-9 Backgauge Operates By Itself ...................................................2-18

2-10 Nothing Is Shown on Displays.................................................2-19

2-11 Hydraulic Pressure Does Not Operate....................................2-20

2-12 Knife Is Down before Operation........................................... -2-21

2-13 Knife Lower Limit Position Varies .........................................2-22

2-14 Backgauge Does Not Move (61II) ..........................................2-23

2-15 Error Code (61II) .....................................................................2-24

2-1

Page 22

2-1 blinks on the Display (Backgauge Does Not Operate) Part 1

Why does blink on the display ?

Backgauge is traveled by the screw shaft which is driven by motor. Encoder is installed directly at the back end of the screw shaft, and

the operation distance of backgauge is controlled by counting the number of pulse from the encoder. In case that pulse signal does not

come from encoder while the backgauge is moving, blinks on the display inform to the trouble.

Backgauge is at the front limit position.

When backgauge is at the front limit position

(in normal case about 25mm, when support

plate is fixed about 75mm), limit switch is on.

When turning the power switch on this condition, blinks on the display.

After moving the gauge a little backwards with

adjust knob, turn the power switch on again.

Adjust knob remains being pressed

Adjust Knob

Snap Ring

Spring

Bearing Unit

Micro Switch

In normal case, the adjust knob is pressed by

compression spring to the operation side.

Even if you try to move the backgauge forwards or backwards when the adjust knob

remains being pressed for some reasons, motor

does not drive and

blinks on the display

because the machine is in manual mode.

Shaft of knob is difficult to move.

When the knob does not move smoothly

forwards and backwards, check bearing unit.

Lubricate when movement is dull.

Snap ring unfastens.

When snap ring (STW-20) unfastens, fix it

again.

Compression spring is broken.

When compression spring is broken, replace it

with a new one.

2A2A5A5A5A5

A

High Speed Motor Fuse

Low Speed Motor Fuse

Fuse is blown.

When motor protection fuse is blown, screw

shaft does not operate and no pulse rises from

encoder. Replace fuse according to Ò4-22Ó and

observe it.

2-2

Page 23

2-1 blinks on the Display (Backgauge Does Not Operate) Part 2

Phase of power is lacking.

Even if one of the three-phases AC power

results in open phase, motor does not operate

and

blinks on the display.

Control Box

1

2

3

4

5

6

T

S

R

Check input voltage which comes to every

section of this terminal board between R-S, ST, and T-R.

When there is no voltage even at one point,

original power is in open phase.

There is problem in control board.

Control

Box

Varistor

1

2

3

4

5

6

SSR

LED

Cement Resistance

Cement resistance is damaged

When switching the motion of the backgauge

(forwards or backwards), short circuit exists

momentarily and this cement resistance can be

damaged. In this case, replace P.C.B.

LEDs from No.1 to No.6 do not turn on.

When LEDs from No.1 to NO.6 showing

operation of knife, clamp, and backgauge turn

on normally, input signals are OK. If there is

no problem in output motor, SSR may has a

problem. Replace P.C.B.

Backgauge belt is cut.

Low Speed Belt

High Speed Belt

Motor Blacket

High Speed Motor

When belt is cut or overturned, power is not

transmitted and screw shaft does not drive.

Therefore, no pulse rises from encoder.

Replace belt with a new one.

As for high speed belt for S/N 103001 or

above, a new wider belt is used which is hard

to overturn. To attach this wider belt to a

previous machine, gauge base and motor base

also must be replaced.

(In case of order, please notice it.)

2-3

Page 24

2-1 blinks on the Display (Backgauge Does Not Operate) Part 3

Coupling of encoder unit is broken

Screw Shaft

Coupling

Encoder

Set Screws

When coupling is broken or set screws are

loose, rotation of screw shaft is not transmitted

to encoder and no pulse rises.

When coupling is broken, replace it with a new

one.

When set screw is loose, fasten it again.

Adjust knob is heavy

Gauge Rail

Adjust Knob

Fix Nut

Adjust Nut

Screw Shaft

Adjust nut and fix nut prevent screw shaft

returning (backlash) of the backgauge. When

there is problem in screw shaft, nuts or guide,

screw shaft is hard to move and normal pulse

does not rise. Therefore,

blinks on the dis-

play.

Oil on rail and screw shaft is running out.

When oil is running out, lubricate operating

the backgauge for-and backwards to circulate

oil.

There are some foreign objects on rail and

screw shaft.

When there are some foreign objects such as

paper dust, wipe them off and lubricate

enough.

There is problem in encoder.

Encoder is very delicate. When its shaft bends

because of external shock, it does not operate

correctly, even if it is connected with coupling.

Stay

Coupling

Encoder Bracket

Encoder

Screw Shaft

Axis difference or bent of shaft

should be within 0.1mm.

When there is an axis difference as shown in

the drawing, replace not only the coupling but

also the bracket and the stay.

There is contact failure or breaking of cable

from encoder.

Check the voltage between terminal 6 and 8 on

the terminal board 1 (refer to page 7-11) while

rotating the adjust knob slowly.

If the voltage changes

while rotating the knob

signal is output

from encoder normally.

87654

2-4

Page 25

2-1 blinks on the Display (Backgauge Does Not Operate) Part 4

Motor has burned out

Backgauge is moved by 2 motors. Above all,

high speed motor repeats driving in the normal

and reverse direction according to using condition. For each motor circuit, there is 5A fuse.

However, after using for many years, motor

insulation weaken gradually and motor coil

burns out without blowing of fuse.

Control Box

6

High Speed

TAN-1

5

4

3

2

1

Low Speed

Motor

A2016

VC-1

A 19151311

Motor

14 12

To check motor coil,

For high speed motor:

Check continuity among pins 4, 5, 6 on TAN-1

on control board.

For low speed motor:

Check continuity among terminals 12, 14, 16

on electromagnetic contactor VC-1 in control

box.

Brake surface smuts.

Brake

Encoder

0.15 to 0.3mm

Coupling

Armature

There is a gap between brake and armature for

0.15 or 0.30mm. when brake surface smuts

with metal powder because of surface wear,

semi-brake condition occurs and drive system

of backgauge becomes heavier. In this case,

clutch operation becomes dull and correct

pulse does not rise. Therefore,

blinks on the

display. Remove the metal powder with compression air or wipe off paper.

2-5

Page 26

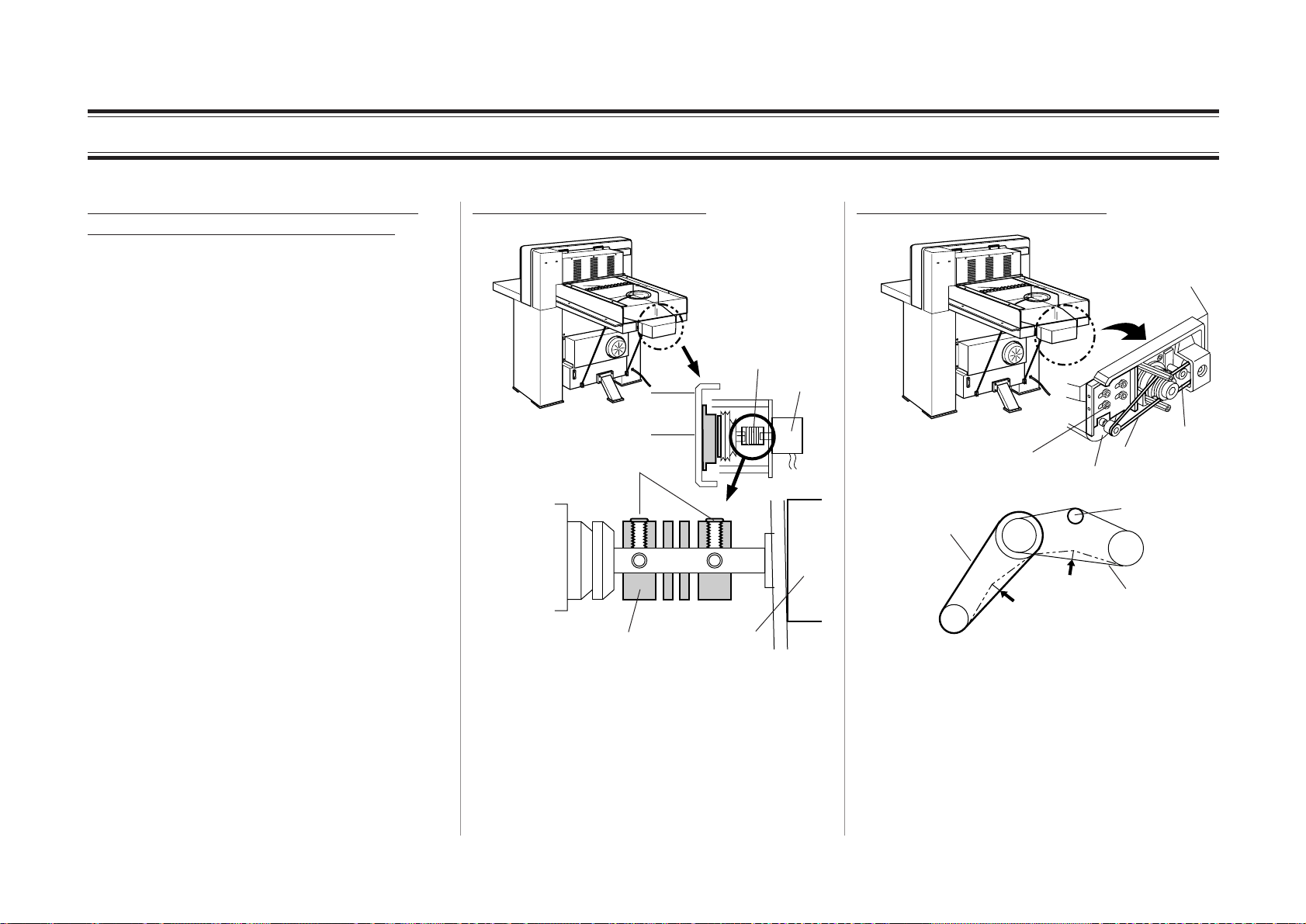

2-2 Cut Size is Not Equal Part 1

Backgauge position is determined only by

high speed for- and backward buttons.

When backgauge is operated only using the

high speed forward or backward button, the

backgauge can not stop in the correct position

because of overrun. Determine precious position using low speed forward button or forward operation with adjust knob.

Set screw of coupling is loose.

Brake

Set Screws

Coupling

Encoder

When set screw is loose, rotation of screw

shaft is not transmitted to the encoder accurately, As a result, the size indicated on the

display becomes different from the actual

cutting size.

Adjust it referring to ÒAdjustment of Cut

SizeÓ, from 3-1 to 3-3.

Encoder

Backgauge driving belt is loose.

Low Speed Belt

Motor Bracket

High Speed Belt

3 to 4mm

2 to 3mm

High Speed Belt

High Speed Motor

Motor Pulley

Low Speed Belt

The high speed belt is bent by 2 to 3mm, low

speed belt 3 to 4mm, when the part pointed

with an arrow is pressed by 1kg force.

Tension of high speed belt can be adjusted by

position of motor bracket, low speed motor by

idle pulley. Adjust able range of idle pulley

becomes larger when it is attached upside

down.

2-6

Page 27

2-2 Cut Size Is Not Equal Part 2

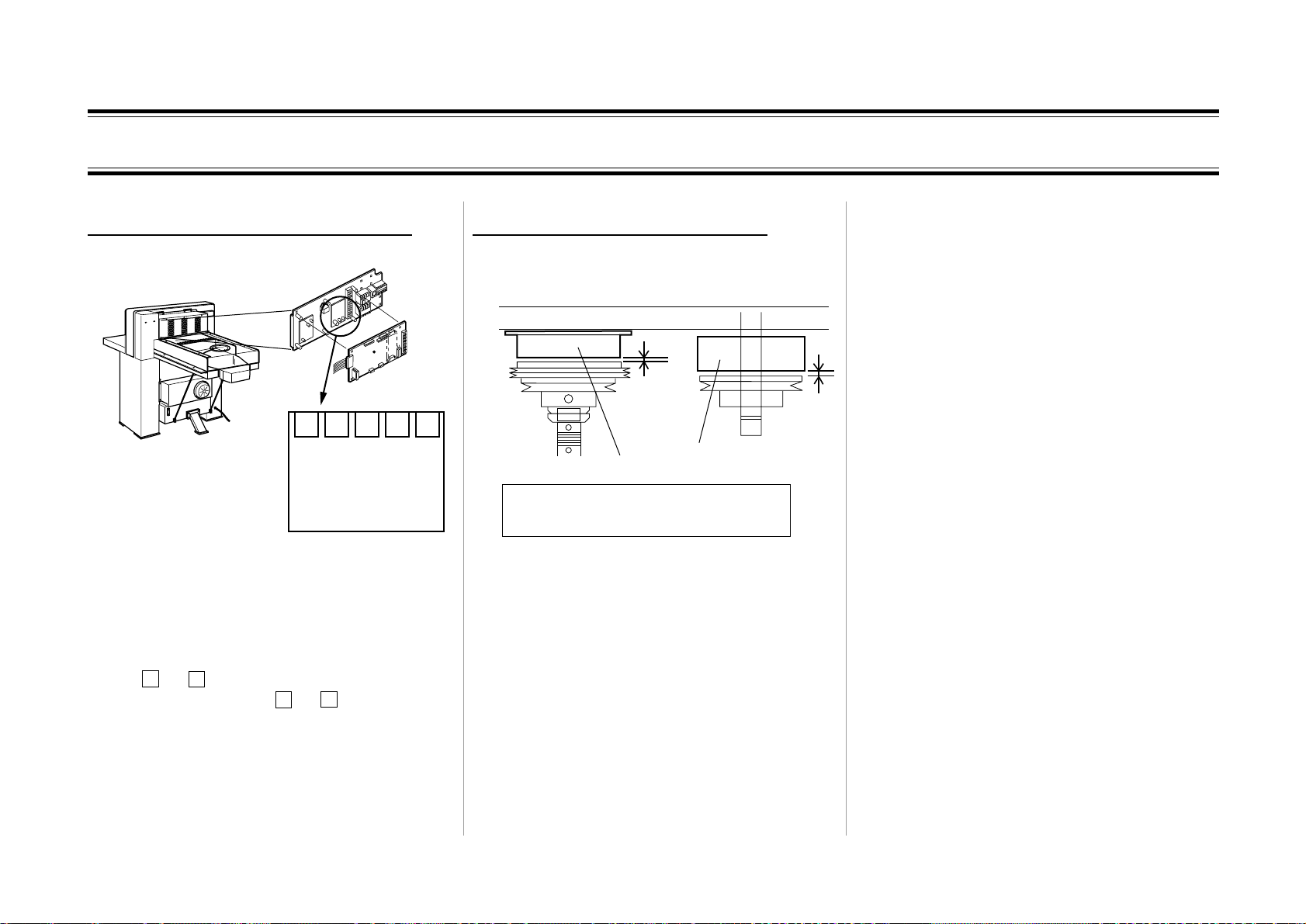

24VDC is not output from power supply.

PW-24

Power Supply PW-24

If output voltage of power supply PW-24 is

too low, the backgauge is delayed moving or

stop and the cumulative defference gets larger.

Check whether there is 24VDC output between 1 and 2 . Check whether there is

100VAC input between 4 and 5 . When there

is not 24VDC output in spite of 100VAC

input, replace power supply.

Gap of clutch or break is not correct.

Operation Side

0.15 to 0.30

0.2 to 0.3

12345

Brake

Gap of brake should be 0.15 to 0.30 mm.

Gap of clutch should be 0.2 to 0.3 mm.

Clutch

When gap of brake or clutch is not in these

ranges, the time lag results in the motion of the

screw shaft. Therefore, defference between

the indicated size on the display and the actual

cut size results.

Adjust it to correct gap.

Or when there is foreign object such as metal

powder on friction surface, remove it with

compression air or wipe off with paper.

2-7

Page 28

2-3 Knife Does Not Lower (Clamp Does Not Lower Either) Part 1

Cutting button A and B are not pressed

simultaneously.

For safety, when the timing to press cut buttons A and B differs more than 0.5 second, the

machine judges the abnormal operation and

hydraulic system does not operate. Press them

simultaneously (within 0.5 second).

There is a problem with cutting button A or B.

When each of cuttig button is pressed separately and slowly, it sounds click. When there

is no sound, there is mechanical problem or of

switch itself. Replace the cutting button

switch.

The cable from cutting button switch is connected with the machine under the front table.

Disconnect this connector and check the continuity with a tester. If there is the continuity

with cutting button pressed, it is OK. If there is

no continuity, replace cutting button switch.

When LED L2 and L4 on control board (See

Ò7-4 Control BoardÓ) lights for a moment and

go out again at the moment of pressing cutting

button, knife or clamp does not reach to the

upper limit position. See the next description.

Knife is not at the upper limit position.

The cutting operation does not start when

either knife or clamp is not at the upper limit

position. Check the sensor for upper limit

whether knife is at the upper limit position is

observed by sensor.

Front Cover

Sensor

Fixing Blacket

Remove front cover and check whether sensor

lamp is on.

Sensitive Area

Sensor

Lamp

When the lamp is on, knife is at the upper limit

position. When the lamp is not on though

knife is at the upper limit position, put a piece

of metal to sensitive of the sensor. If the lamp

turns on, sensor operates properly. Lower the

sensor bracket.

Clamp is not at the upper limit position.

Control Box

Dock

Lamp Upper Limit Position

Detecting Switch

The limit switch detecting the clamp upper

limit position should be on.

When this actuator is turned to the

right, there must be no detection

sound.

Dock

Lamp Upper Limit Position

Detecting Switch

Or check continuity between 8 and 9 of CON1

on control board with tester.

2-8

Page 29

1

2

3

4

5

6

2-3 Knife Does Not Lower (Clamp Does Not Lower Either) Part 2

APC-M61

HYDRULIC CUTTER

APC-T61

HYDRULIC CUTTER

There is an obstruction between beam

guards.

Beam Guards

When there is an obstruction on the optical line

between beam guards, the beam is blocked and

safety function operates. Therefore, knife does

not lower.

There is trouble with foot switch control

board.

If board is replaced and problem disappeared,

some of relays on the board has the contact

failure.

Ray

Obstruction

Some of switches on operation panel remains

on.

(APC-M61)

Power

(APC-T61)

Hydraulic

Repeat Setup

Current position

Current Position Display

Backgauge Travel

Put-out

Memory

Presetting

P

S

Presetting

1 2 3 4 5 6

Repeat / Setup

No More

Memory

?

Program No.

Program

Delete

P+-

S+-

Setup

Memory

Program No. Step No.

Step

Memory Delete

Opar Error

?

Step.No.

Memory

Push-out

Step Forward

Size

Memory

Push-out

Memory

Program

Forward

789

456

123

.

0

E

c

Replacing Knife

Be sure to set "knife Angle

Adjustmant" knob and "Knife

Operation Mode" select

switch to each "Replacing

Knife"Position

Cutting Operation & Knife

Vertical Adjustment

Be sure to set "knife

Operation Mode" select

switch to "cutting"

position

knife Operation

Program Extension

Replacing

knife

ON

Mode

Replacing

Knife

Cutting

For APC-M61:

Any of the step forward button, the size

memory button, and the push-out memory

button remains pressed.

For APC-T61:

After button is pressed, there is no sound and it

does not return.

When any of the switches are out of order or

remain pressed, the machine judges that it is in

the setting mode. Therefore, hydraulic system

does not operate.

2-9

There is problem in control board.

Control

Box

Varistor

SSR

LED

Cement Resistance

SSR (solid stay relay) or cement resistance is

damaged.

If its white exterior is broken or cracked because of heat, cement resistance get damaged.

And if there is continuity between the two

parts of the bottom in the following drawing,

SSR is out of order. However, no continuity

does not always mean normal.

If there is continuity,

SSR is out of order.

If this part is damaged, hydraulic pressure is

not applied. Replace the board.

If knife does not lower though hydraulic

pressure applied, check the hydraulic valve.

Page 30

2-3 Knife Does Not Lower (Clamp Does Not Lower Either) Part 3

Hydraulic valve does not operate correctly.

[Valve Section]

Hydraulic Section

[Electromagnetic Valve]

Remove the apron cover under the table and

check whether LED of electromagnetic valve

turns on, when cutting button is pressed.

LED

Spark Killer

[Top of Electromagnetic Valve]

If LED turns on, the signal comes correctly.

The internal damage of electromagnetic valve

can be considered. Replace electromagnetic

valve.

Grease on clamp rails is not enough to move

the clamp.

Clamp lifts and lowers guided by right and left

rails. However, when there is not enough

grease between clamp and rail, clamp is difficult to move because of metal friction and does

not return to the upper limit position. When the

upper limit position of clamp is not detected,

cutting operation does not start.

Rail

Clamp

Rail

[Back view of the machine]

When there is enough grease on part of

right and left rail, there is no problem. When

there is little grease, lubricate with a grease

gun. (See Ò6-4 LubricationÓ in operation

manual.)

2-10

There is problem in clamp link.

Link A

Sprocket B

Spring

Sprocket A

Clamp

Chain

Hook shaft

Chain

Check the followings.

Chain is damaged.

Sprocket A or B is detached from shaft.

Spring is detached or loose.

(For old model link A) needle bearing is detached. When an old model of the machine has

link A.

When there is problem with any of these parts,

clamp can not be lifted and return to the upper

limit position. When clamp is not the upper

limit position, the machine can not start cutting

operation.

Page 31

2-4 Knife Does Not Lift Part 1

Ajusting Knife's

Lower Dead Point

Down UP

7

When cut buttons are pressed, first clamp lowers. Second, knife lowers to cut . After that, knife stops and does not lift again. (Clamp

does not lift either.) Or when you release your hands from cut buttons, knife lifts again. However, Step does not proceed automatically.

The depth of knife is too short.

[When knife resharpened for many

times is used]

Resharpened and shortened knife should be

lowered to cutting stick by loosening 2 screws

of knife holder according to “6-2 Knife Replacement” of operation manual. However, in

this case, the tip of knife does not reach to the

cutting stick, though 2 screws are lowered to

the lowest position.

In this condition, if cutting operation starts

with all 7 screws tightened, sensor can not

detect the tip of knife. Therefore, knife tries to

continue lowering.

Replace knife to new one and operate again.

Lift the knife with the cutting depth adjust

dial in advance. Otherwise new knife can cut

into the cutting stick.

Knife does not touch cutting stick when

replacing knife.

When replacing knife, loosen 2 screws of the

knife fastened at the lower limit position in

“Knife Replace Mode”, and lower knife until

the end of knife touch cutting stick, and fix

knife again. Otherwise, knife tries to continue

lowering during normal cutting operation,

because knife is not detected by the lower limit

sensor.

Screw

knife

No Gap

Cutting Stick

After replacing knife, the position of knife

lower limit position sensor is still lower.

Cutting Depth Adjust Dial

When using knife resharpened for many times,

the position of lower limit position sensor must

be adjusted depending on shortened length of

knife. However, if the position of lower limit

position sensor does not change after replacing

knife with a new one and knife lowered, knife

cuts into cutting stick. Therefore, knife is not

detected by sensor and hydraulic system continue operating so that knife continues lowering.

After releasing your hands from cut buttons

and knife lifts, adjust the position of lower

limit position sensor upward.

2-11

Page 32

2-4 Knife Does Not Lift Part 2

Knife lower limit position sensor does not

operate correctly.

WARNING

LED

Knife Exchange

Position Sensor

LED

Lower Limit

Position Sensor

When knife lower limit position sensor is out

of order with its switch off, it does not detect

knife at the detection point and no signal rises.

Therefore, the machine determines knife does

not reach the lower limit point and operates to

continue lowering knife.

Turn off the switch of hydraulic pressure

before the following operation. Otherwise heavy accident will result.

When knife is at the upper limit position,

measure the voltage between 4 and 5 of CON1

on the control board (See “7-5 Control Board,

Connector Layout) is 5VDC. Next, in this

situation, approach a ferrous piece within

2mm. If the voltage changes into 0V, the

sensor has no problem. (LED of the sensor

turns on.)

24V

7

6RED

5WHT

4Shield

3

2

1

Sensor

Output

0V

If the voltage remains 5VDC though ferrous

piece is approached, the sensor is out of order

with its switch off.

2-12

Page 33

2-5 Clamp Lowers but Knife Does Not Lower

Clamp operates only and knife never

operates, though cut buttons are pressed.

Cutting knife ON/OFF switch is on.

View A

Knife Lower Limit

Position Sensor

Cutting Knife

ON/OFF Switch

When cutting knife ON/OFF switch is on, only

clamp operates and knife does not operate. In

normal cutting operation, turn off this switch.

When pressed cut buttons, clamp lowers

at first and knife begins to lower. But

knife lifts before it is reached to the

lower limit and clamp also lifts.

Knife lower limit position sensor does not

operate correctly.

LED

Knife Exchange

Position Sensor

LED

Lower Limit

Position Sensor

[View A]

If knife lower limit position sensor shortcircuits to ON side (close side), it determines

that knife has reached lower limit position

though it does not. Therefore, when knife

begins to lower it soon returns to the upper

limit position.

WARNING

Turn off the switch of hydraulic pressure

before the following operation. Otherwise heavy accident can result.

Check the voltage between 4 and 5 of CON1

on the control board (See “7-5 Control Board,

Connector Layout”). If it is 5VDC, sensor has

no problem. However, if it is 0VDC, sensor

short-circuits to ON (close) side.

24V

7

6RED

5WHT

4Shield

3

2

1

Sensor

Output

0V

2-13

Page 34

2-6 Clamp Does Not Lower Though Foot Pedal Is Stepped On.

RL

Joint or rod has problem.

Rod End

Rod

Rod End

Upper or lower rod end is loose and detached

from rod. Or rod is broken.

In either case, because the stepping force on

foot pedal is not transmitted to clamp, that is

why clamp does not lower.

If rod is broken, replace it and adjust to the

right position according to Ò4-10 Replacing

RodÓ.

For machines of S/N 010999 or below, the

drawing of rod is as follows.

To replace it with the present one, not only

upper and lower rod ends and rod but also

hook on parts book Fig.3-30 (M013220-00)

need to be replaced together.

Stepping Position Detecting Micro switches

are out of order (For T-58.)

Foot Pedal

Micro Switch

Cam

Check 2 micro switches detecting the position

of foot pedal. If they do not turn on or off

though foot pedal is stepped on, check whether

cams are loose. If the switches do not turn on

or off though cams are not loose, micro

switches are out of order.

2-14

Page 35

1

2

3

4

5

6

2-7 Backgauge Does Not Operate Part 1

Power is distributed to each motor.

Control Box

6

High Speed

TAN-1

5

4

3

2

1

Low Speed

Motor

A2016

VC-1

A 19151311

Motor

14 12

Check whether 200V voltage is output among

these motor terminals. When there is no voltage, check whether power switch (breaker) is

on or the following fuses are blown.

Motor coil is burnt out.

Remove the motor terminals from each terminal board and check continuity among 3

cables.

M

A

B

C

When there is no continuity in any of A, B,

and C, coil is burnt out inside the motor.

Replace motor.

Backgauge driving belt is cut.

There is problem with control board,

Control

Box

Varistor

SSR

Cement Resistance

When the cement resistance (rectangle shape

in white) is damaged, replace the whole board.

High Speed Motor Fuse

Low Speed Motor Fuse

2A2A5A5A5A5

When LED 5 (backgauge forward) and LED 6

(backgauge backward) turn on, control signal

from the board rises correctly. The damage of

A

High Speed Belt

If belt is cut, replace it.

Low Speed Belt

2-15

SSR can be considered. Replace it with the

board.

Page 36

2-7 Backgauge Does Not Operate Part 2

APC-M61

HYDRULIC CUTTER

APC-T61

HYDRULIC CUTTER

Adjust knob remains pressed.

Adjust Knob

Snap Ring

Spring

Bearing Unit

Micro Switch

Backgauge adjust knob is normally pushed to

the operation side by spring. However, when

knob remains pressed for some reason, micro

switch turns on and the machine changes into

manual mode. Therefore, backgauge does not

operate.

When the adjust knob remains pressed and

does not return, check whether there is problem with snap ring, spring, and bearing.

Any of switches on operation panel remains

on.

(APC-M61)

Power

Hydraulic

(APC-T61)

HYDRULIC CUTTER

Repeat Setup

Current position

Current Position Display

Backgauge Travel

Put-out

Memory

Presetting

P

S

Program

P+-

S+-

Setup

Memory

Program No. Step No.

Presetting

Step

1 2 3 4 5 6

Repeat / Setup

Memory Delete

No More

Opar Error

Memory

?

?

Program No.

Step.No.

Memory

Delete

Push-out

Step Forward

Size

Memory

Push-out

Memory

Program

Forward

789

456

123

.

0

E

c

Replacing Knife

Be sure to set "knife Angle

Adjustmant" knob and "Knife

Operation Mode" select

switch to each "Replacing

Knife"Position

Cutting Operation & Knife

Vertical Adjustment

Be sure to set "knife

Operation Mode" select

switch to "cutting"

position

knife Operation

Program Extension

Replacing

knife

ON

Mode

Replacing

Knife

Cutting

For APC-M61:

Any of step forward button, size memory

button, and push-out memory button remains

pressed.

For APC-T61:

After button is pressed, it can be felt that the

button returns back with a sound.

When any of the switches is out of order or

remains pressed, the machine determines

setting mode is operated. Therefore, backgauge

does not operate.

When the switch cap locks, return it to normal

condition. When the switch itself is out of

order, replace the board itself. (When replacement of switch itself only is possible, replace

separately.)

2-16

Page 37

2-8 Backgauge Does Not come Forward (But goes backward)

Limit switch remains ÒONÓ.

SW2

Limit switch 1

SW3

Limit switch 2

(When pressure support

plate is used.)

Limit switch 1 or 2 shows normally ÒClosed

(=NC)Ó. When backgauge moves forwards

and activates limit switch, it shows ÒOpenÓ

and stops backgaugeÕs forward motion. If the

actuator of limit switch is on or connector is

disconnected, the control board determines the

detection circuit is ÒOpenÓ and backgauge

can not operate forwards. (Backgauge can go

backwards.)

Check of limit switch: See Ò7-5 Control

Board, Connector LayoutÓ.

GRN

12

13WHT

14empty

15BLK

16

CON3

Control Box

When there is continuity between 16 and 15 of

CON3, there is no problem with SW2. When

there is continuity between 16 and 13, there is

no problem with SW3.

There is problem with high speed motor.

Power is supplied to the high speed motor.

Coil of high speed motor is burnt out.

High speed belt is cut.

There is problem with control board.

As for these 4 symptoms, follow the description in Ò2-7 Backgauge Does Not Operate.Ó

2-17

Page 38

2-9 Backgauge Operates By Itself

12345

PW-05

Check knife lower limit position sensor.

LED

View A

Knife Lower Limit

Position Sensor

[View A]

When ÒRepeatÓ mode is selected and lower

limit position sensor is out of order with ON

side (close side), the sensor determines

wrongly that knife reached lower limit position

soon after knife has begun to lower. Therefore, knife returns to upper limit position and

backgauge move to the position for the next

step.

WARNING

Turn off the switch of hydraulic system

before the following operation. Otherwise heavy accident will result.

24V

7

Sensor

Output

0V

When the voltage between 4 and 5 of CON1

on the control board (See Ò7-5 Control Board,

Connector LayoutÓ) is 5VDC with the knife at

upper limit position, there is no problem with

the sensor. When the voltage is 0VDC, the

sensor short-circuits to ON side. Replace the

sensor.

6RED

5WHT

4Shield

3

2

1

The voltage of power supply (PW-05)

declines.

CON7

Control Box

Power Supply (PW-05)

When the voltage between 1 and 2 becomes

lower than 5V, the operation of CPU board

becomes unstable and operate wrongly. When

under 5V, adjust the volume on this power

supply board to supply the voltage between

5.15 and 5.25V to the CPU board. The voltage

can be measured also on CON7 of the control

board. (See Ò7-5 Control Board, connector

LayoutÓ.)

When cable is pinched between power supply

and control board, cover of the cable tears and

the voltage can decline. In this case, put a

piece of paper for insulation between them.

2-18

Page 39

2-10 Nothing Is Shown on Displays

Fuse for electronic circuit is blown.

Control Box

2A2A5A5A5A5

A

Fuses for Electronic Circuit

When fuse for electronic circuit is blown,

P.C.B. does not operate and operation panel

records nothing.

Replace the fuse with a spare one in the control

box.

Distributor does not operate.

Check whether the breaker in the distributor is

on.

Check whether the fuse in the distributor is

blown.

There is problem with power switch.

Power Switch

Check the continuity of power switch.

2-19

Page 40

2-11 Hydraulic Pressure Does Not Operate

Thermal relay trips.

Thermal Relay

Control Box

14 6 4 2

Reset Button

Trip Bar

13 5 31

If there is excessive pressure on hydraulic

system, thermal relay operates and contactor

opens to shut the power off to protect the

hydraulic motor.

When thermal relay operates, trip bar is pushed

in. When green reset button is pressed, thermal

relay will be reset.

Contactor can not cut electricity because of

heat.

Thermal Relay

14 6 4 2

Contactor

13 5 31

When hydraulic pressure is not on,

There is electrification between 2 and 1 .

There is electrification between 4 and 3 .

There is electrification between 6 and 5 .

If there is electrification in any of these parts,

contactor can not cut electricity because of

heat. Replace thermal relay and contactor .

If hydraulic pressure switch is turned on in this

condition, the breaker of control box will

operate or the fuse will blow.

Any of Phases is Open.

The voltage 200V is not supplied among

contactor output terminals 1, 3, and 5.

5 3 1

When there is no voltage at any of the three

points, or when the voltage is declining to

about 100V (Open phase), the thermal relay

operates and hydraulic system does not operate.

Check the circuit between the plug of this

machine and the contactor.

Reset Button

2-20

Page 41

2-12 Knife Is Down before Operation

After finishing operation of the day before and

turning off hydraulic pressure, the oil in

hydraulic circuit return to the tank because of

slight leak of oil from valves. Therefore knife

lowers depending on the amount of leak

through the night. As a result, when turning

on the power on the next day and pressing

hydraulic pressure switch, knife lifts a little to

return to the upper limit position. If knife is

not lower than clamp before turning on hydraulic pressure switch, there is no problem

for safety and operation.

When knife is lower than clamp, a large oil

leak is occurring in hydraulic system.

Remove the cover of the machine and check

hydraulic system by the following procedure.

WARNING

Oil is leaking at hydraulic hose joint.

Touch the joint between hydraulic hose and

each hydraulic parts. If oil clings to your

finger, the connection of joint is not tight. Fix

the parts side by turning the pipe side.

Oil is leaking from hydraulic cylinder.

When oil is leaking from this part pointed by

an arrow, the problem with the cylinder packing can be considered. Replace cylinder or

disassemble the cylinder and replace rod

packing.

When replacing rod packing, replace

also dust wiper.If knife still lowers,

there is problem with interior

packing inside. Replace the whole

cylinder.

C spring to return the knife is cut.

C spring

I Bolt

Hydraulic Cylinder

When C spring is cut or loose, the force to

return the knife to upper limit position weakens and knife lowers even by a slight oil leak.

When spring is cut, replace it.

Turn power switch off before checking

hydraulic system.

2-21

Page 42

2-13 Knife Lower Limit Position Varies

[Cause 1: Oil temperature variation]

When this machine is operated for a long time,

oil temperature rises and viscosity weakens.

Therefore, the speed of hydraulic cylinder

becomes slightly faster.

When knife lowering speed becomes faster,

because lower limit position becomes lower,

lower limit position needs to be rised with the

cutting depth adjust dial. When operation

begins after long break, because oil temperature returns, uncutting occurs.

[Solution]

Because knife lower limit position changes

depending on the oil temperature variation,

adjust with cutting depth adjust dial for each

time. For S/N 103001 or above, because

hydraulic unit is renewed and oil cooler is

equipped as standerd, the temperature variation

does not occur.

The oil suited to ISO VG32 should be used.

[Cause 2: The timing of lower limit position

detection]

The signal is sent with about 10msec cycle in

this machine. Therefore, the time difference at

10m sec maximum between lower limit position detection and CPU exists.

The variation are caused by the knife moving

distance for this time.

But this variation is in allowable range.

2-22

Page 43

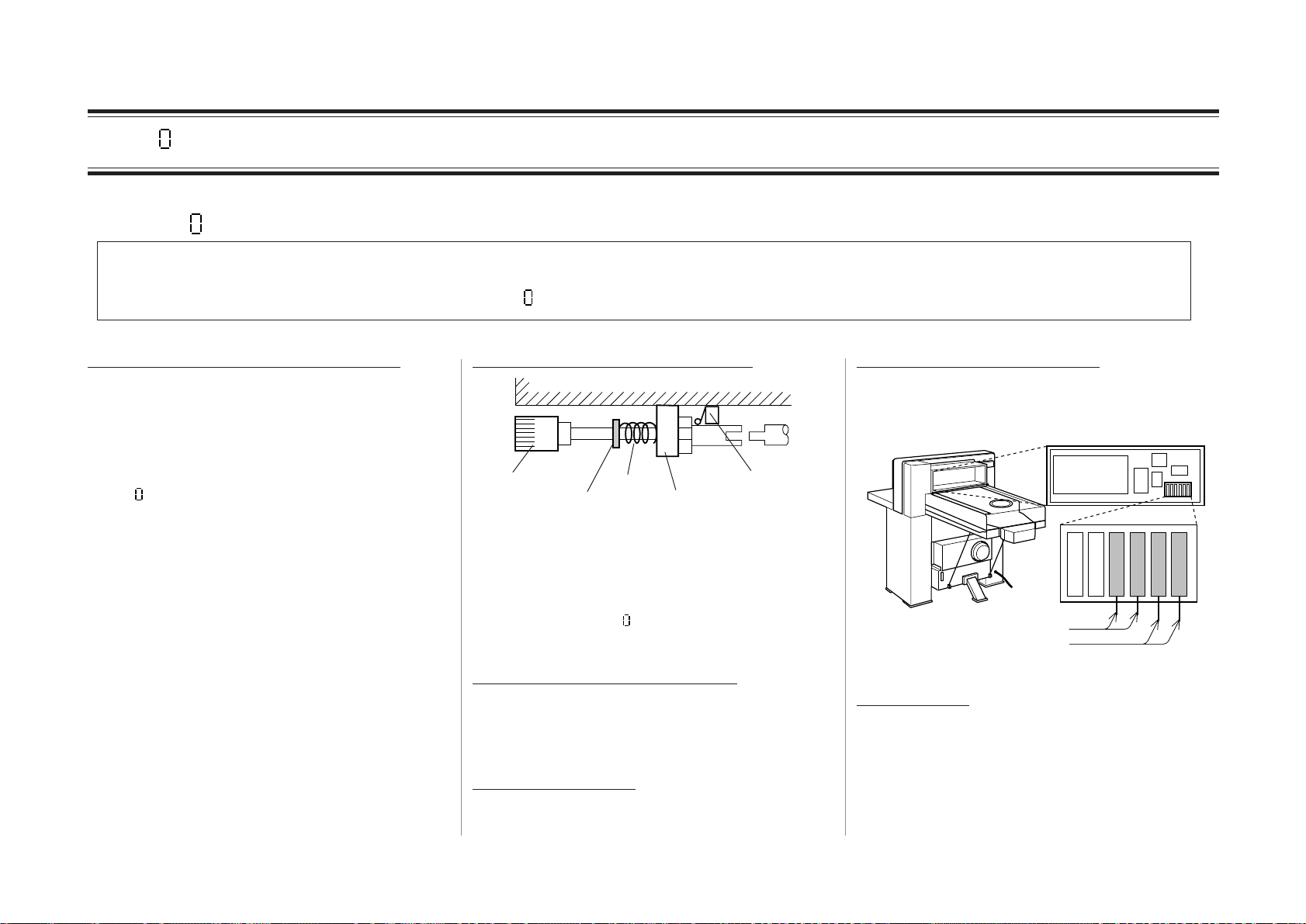

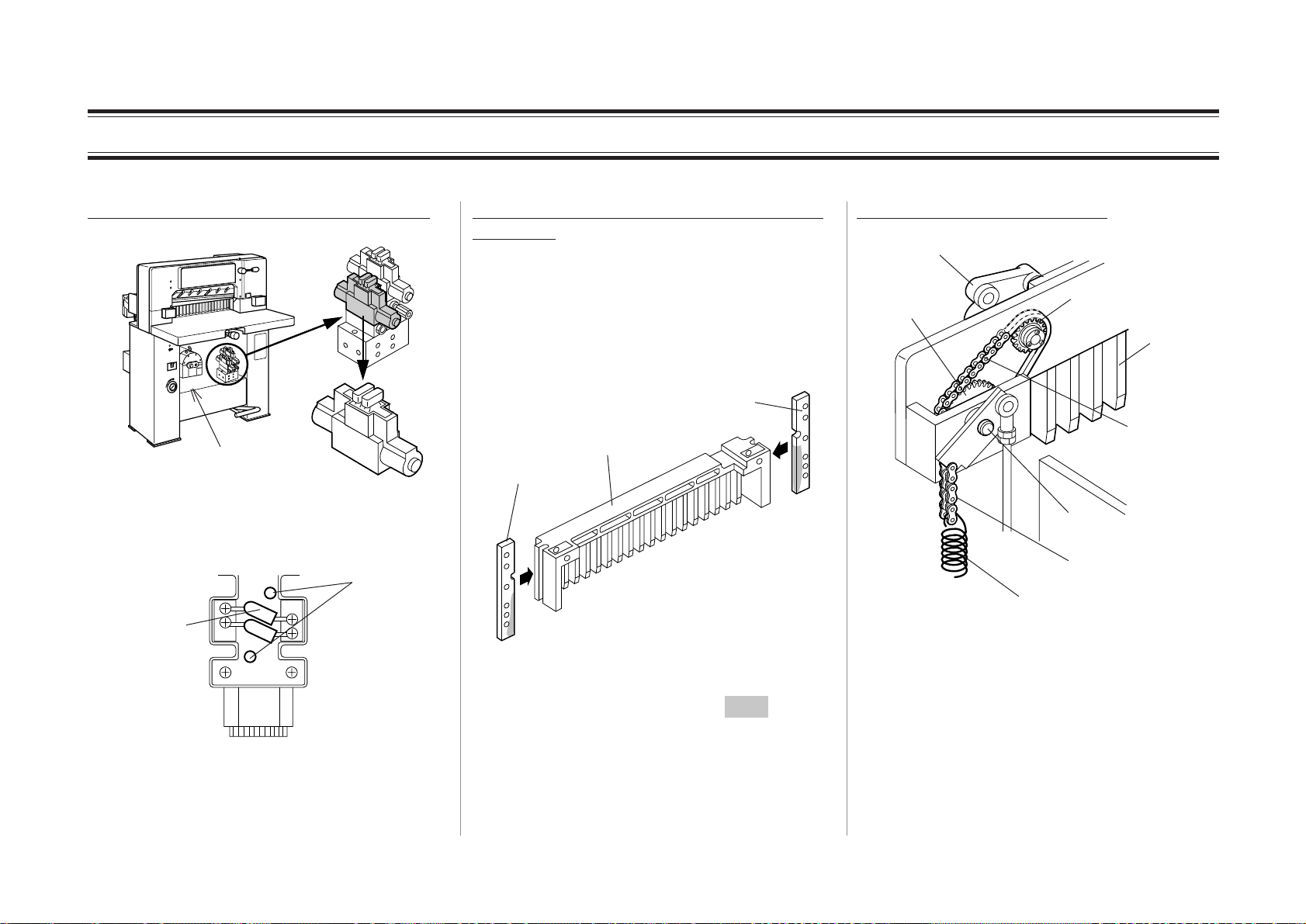

2-14 Backgauge Does Not Move

- Check that the drive mechanism of the

machine is not damaged.

Refer to 3-14 for details.

Check the items below.

1 The timing belt is not cut.

2 The idle shaft is fixed tightly.

3 The locking screw of the timing pulley is

not loose.

4 The key is attached on the spindle.

5 The locking screws of the servo motor are

not loose.

504007

2_14_1A

- Check that grease is applied.

Block

Gauge Rail

Refer to the drawing above and check the

items below.

1 Oil is applied to the spindle.

2 Grease is applied to the gauge rail.

Spindle

504007

2_14_1B

- Check that the electrical wiring is correct.

52

Q21

'

LL

2A

Q22

'

LL

2A

Q23

'

L

5A

(on the page 7-16)

M20

3

Servo Motor

54

A

55

To SD1

504007

2_14_1C

X24

WHT

BLK

T20

200V

WHT

11

BLK

22

07

0V

06

WHT

BLK

24V

2A

0V

WHT

LL

'

Q24

BLK

NN

'

5A

L

N

200V 500VA

Amplifier for

Servo Motor

A24

RED

RED

BLK

58

L

5657

RED

U

WHT

V

BLK

W

GRN

Refer to 7-14 for details

- Check at the display of A24 amplifier for

servo motor.

When the display does not show anything, go

to step 1 below. When the display shows an

alarm of A**, go to step 2 below. When the

display shows CL, go to step 3 below.

1. Refer to the electrical wiring above to check

the power circuit from transformer T20 to A24.

2. Follow the [Solution] on the displayed error

code A

3.

Remove the motor cover at the back of the

at section 2-15, No.1351.

**

machine, and turn the timing pulley by hand.

When you can turn it by hand, replace QPM-195

if the wiring and connection between A24 and

CON9 on QPM-195 are normal.

When you cannot

turn it by hand, the command from the P.C.B is

defective.

Replace control P.C.B. QPM-195.

2-23

Page 44

2-15 Error Code

】

- If an error code which is not included in the following table is displayed, it can be a communication error.

Error Code Error Details

101

801

Knif e Lower

Limit Error

Memory Error

Causes and Solut ions

【Cause】 The knife lower limit sensor B11 did not turn on, although a specific time has passed after the knife started to lower.

Check if the lower limit was set too low using the knife up and down adjusting dial. If the dial has not been op erated, check if the

lowering speed is slower than usual. If it is slower, go to following 1. If it is as usual, go to following 2.

1. Check if grease is applied to the knife holder. If it is OK, check if there is no foreign object on the sliding surface of the knife holder. If

there is no such object, the hydraulic system is defective. Check the system.

【Solution】

Cause

【

【

Information

【Solution】

】

Additional

2. Refer to section 6-6 to check the installing condition of B11. If it is OK, check B11 itself. If the LED of B11 blinks when B11 is turned

on or off (metal piece is fit completely to the detector of B11/ set apa rt from it), go to following 3. If it dose not blink, go to following 4.

3. Check if the LED5 on the control P.C.B. QPM-195 blinks when B11 is turned on or off. If LED5 blinks, although the signal reaches

normally from B11 to the P.C.B., the signal is not processed correctly. Replace QPM-195. If the LED5 does not blink, the wiring and

connection between B11 and CON5, pins 10 through 12 on QPM-195 is defective.

4. Replace B11 when the wiring and connection between B11 and CON5, pins 4 through 6 is normal. If the same error still occurs,

restore B11, and replace the control P.C.B QPM-195.

The set value of the saved data is out of range.

Data means job setting, backgauge home position and counter value.

】

If the cutting length is normal, this error can be ignored.

If this error appears repeatedly, turn off the main power for about 10 seconds and then turn it on again. If the same error still occurs,

refer to section 7-12 to replace the IC. If the same error still occurs, restore B11, and replace the control P.C.B QPM-195. After

replacing the IC or P.C.B., enter a home position again. The sheet on which home position is written is attached on the bottom of the

control panel box.

【Cause】 The program is full in the memory.

Additional

802 Memory Full

【

Information

Solution

【

99 courses and 99 processes can be saved. However, the capacity is limited. Not all can be saved.

Delete unnecessary programs. If this error appears although not many programs are memorized, replace the control P.C.B. QPM-195.

】

2-24

Page 45

2-15 Error Code

proj

g

p

Error Code Error Details

Safety Light

1051

Beam Sensor

ON Error

Photo Area

1061

Guard Sensor

ON E rro r

【

【

In form at io n 1】

【

In form at io n 2】

【

Solution

【Cause 】

【

Additional

In form at io n 1】

【

Additional

In form at io n 2】

【

Solution

【

】

Cause

Additional

Additional

】

Cause

】

】

Causes and Solutions

When B51L projector of the safety light beam sensor does not light, the B51R receiver turns on.

The APC-61II checks the B51 safety light beam sensor every time the cutting operation is done. It checks that the B51R receiver

turns on when B51L projector turns on, and when the projector turns off, the receiver turns off.

LED L41 on the control P.C.B. QPM-195 lights when the B51L projector lights. When B51L goes out, LED L41 does not light.

LED L4 2 on the control P.C.B. QPM-195 lights when B51L projector lights and the B51R receiver receives the light (th ere is no

object between the sensors).

It does not light when the receiver do es not receive the light (something is between the sensors) although the projector lights.

When the

Check the installing cond ition of B51R receiver of the sensor. Check the wiring and connection between B51R and CON13 on the

control P.C.B. If it is OK, replace the control P.C.B. QPM-195.

Although B50L projector of the sensor does not light, the B50R receiver of the sensor turns on. Or, the receiver detects as if all

beams are received although not all the beams are received.

The APC-61II checks the photo area guard sensor every time the cutting operation is done. It checks if lighting and receiving each

beam of the guard is detected correctly by sending test signals from the control P.C.B.QPM-195.

LED L2 2 on the control P.C.B. QPM-195 lights when B50L projector lights and the receiver receives all beams (there is no object

between the sensors).

It does not light wh en the receiver does not receive all beams (something is between the sensors) although the projector lights.

When LED L25 on the control P.C.B. QPM-195 lights, B50L photo area guard does not light.

When LED L25 on the control P.C.B. QPM-195

Check the wiring and connection between B50R receiver and CON13 on the contro l P.C.B.QPM-195. If it is OK, replace the control

P.C.B. QPM-195.

The knife upper limit sensor B12 did not turn on, although specific time has passed after the knife started to raise.

ector does not light, the L42 does not light.

oes out, B50L photo area guard lights and the guard function operates.

1151

Knife Upper

Limit Error

【

Solution

Refer to section 6-6 to check the installing condition of the knife upper limit sensor B12. If it is OK, check if the knife raising speed is

not slower than usual. If it is slower, go to following 1. If it is as usual, go to following 2.

1.Check if grease is applied to the knife holder. If it is OK, check if there is no foreign object on the sliding surface of the knife holder.

If there is no such object, the hydraulic system is defective. Check the system.

2.Check B12 knife upper limit sensor. If LED of B12 blinks when B12 is turned on or off (metal piece is fit completely to the detecto r

】

of B12/ set apart from it), go to following 3. If it does not blink, go to follow ing 4.

3.Check if the LED3 on the control P.C.B. QPM-195 blinks when B11 is turned on or off. If LED3 blinks, although the signal from B12

to the P.C.B. i s normal, the signal is n ot processed correctly. Replace QPM-195. If the LED3 does not b link, the wiring and

connection between B12 and CON5,

4. Replace B12 if the wiring and connection between B12 and CON5, pins 4 through 6 is normal. If the same error still occurs,

restore B12, and replace the control P.C.B QPM-195.

ins 4 through 6 on QPM-195 is defective.

2-25

Page 46

2-15 Error Code

Error Code Error Details

1351

Back gauge

Servo Error

Causes and Solutions

【Cause】 The control P.C.B. QPM-195 received an alarm signal from A24 amplifier of M20 servo motor.

Turn off the main power switch for 10 seconds and then turn it on again. If this error still appears, refer to the alarm numbers A** below

【Solution】

Additional

【

Information

Alarm A10

Alarm A12

Alarm A14

Alarm A15

Alarm A16

Alarm A17

Alarm A20

which is displayed on the screen of A24 amplifier. Regarding the mechanical troubles, refer to section 3-15 to check if enough grease

is applied to the spindle and the gauge rail. If grease is applied, remove the timing belt for the backgauge section and turn the spindle

manually to find the cause.

If a trouble occurs in servo system, the A24 sends only one signal to the control P.C.B. Check the alarm number "A**" below which is

】

displayed on the screen of the A24 amplifier to specify the cause of the trouble.

【Cause】A24 input voltage drops.

【Solution】Check the customer power source. If it is normal, check if the main power is not turned on within 5 seconds after it is

turned off. If it is OK, remove the con necto rs CN1 and CN2 o f A2 4 an d tu rn of f th e m ai n po w e r fo r m or e than 10 s e co n ds , a nd th e n turn

it on again. If this alarm appears again, replace the A24 amplifier. If the A10 does not appear, check if ground fault does not occur in

the input circuit of A24.

Cause】There is a problem with RAM/ROM in A24.

【

Solution】Disconnect the connectors CN1 and CN2 of A24 and turn off the main power for more than 10 seconds and then turn it

【

on again. If this alarm occurs again, replace the A24 amplifier.

【Cause】The CPU in A24 overdrives.

Solution】Disconnect the connectors CN1 and CN2 of A24 and turn off the main power for more than 10 seconds and then turn it

【

on again. If this alarm appears again, replace the A24 amplifier.

【Cause】There is a problem with EEPROM in A24