horiba TPNA-500 Instruction Manual

Automatic Total Nitrogen/Phosphorus Monitoring

System

TPNA-500

Instruction Manual

CODE:GZ0000371324D

Preface

This manual describes the operation of the Automatic Total Nitrogen/Phosphorus Monitoring

System, TPNA-500.

Be sure to read this manual before using the product to ensure proper and safe operation of

the product. Also safely store the manual so it is readily available whenever necessary.

Product specifications and appearance, as well as the contents of this manual are subject to

change without notice.

Warranty and responsibility

HORIBA Advanced Techno, Co., Ltd. warrants that the Product shall be free from defects in

material and workmanship and agrees to repair or replace free of charge, at option of HORIBA

Advanced Techno, Co., Ltd., any malfunctioned or damaged Product attributable to

responsibility of HORIBA Advanced Techno, Co., Ltd. for a period of one (1) year from the

delivery unless otherwise agreed with a written agreement. In any one of the following cases,

none of the warranties set forth herein shall be extended;

Any malfunction or damage attributable to improper operation

Any malfunction attributable to repair or modification by any person not authorized by

HORIBA Advanced Techno, Co., Ltd.

Any malfunction or damage attributable to the use in an environment not specified in this

manual

Any malfunction or damage attributable to violation of the instructions in this manual or

operations in the manner not specified in this manual

Any malfunction or damage attributable to any cause or causes beyond the reasonable

control of HORIBA Advanced Techno, Co., Ltd. such as natural disasters

Any deterioration in appearance attributable to corrosion, rust, and so on

Replacement of consumables

HORIBA Advanced Techno, Co., Ltd. SHALL NOT BE LIABLE FOR ANY DAMAGES

RESULTING FROM ANY MALFUNCTIONS OF THE PRODUCT, ANY ERASURE OF DATA,

OR ANY OTHER USES OF THE PRODUCT.

Trademarks

CompactFlash is a registered trademark or trademark of SanDisk Corporation in the

United States and other countries.

Modbus is a registered trademark of Schneider Automation Inc.

PharMed is a trademark of Saint-Gobain Performance Plastics Corporation.

Other company names and brand names are either registered trademarks or trademarks of

the respective companies. (R), (TM) symbols may be omitted in this manual.

February, 2019 © 2015 2019 HORIBA Advanced Techno, Co., Ltd.

Regulations

Note

Conformable Directive

This equipment conforms to the following directives and standards:

EMC:

RoHS:

Warning:

When the sensor cable, the transmission cable, or the contact input cable is extended to 30 m or

longer, the surge test specified in the EMC directive for CE marking is not applied.

EN61326-1

Class A, Industrial electromagnetic environment

EN50581

9. Industrial monitoring and control instruments

This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user

may be required to take adequate measures.

Installation environment

This product is designed for the following environment.

Overvoltage Category II

Pollution degree 2

Information on disposal of electrical and electronic equipment

and disposal of batteries and accumulators

The crossed out wheeled bin symbol with underbar shown on the product or accompanying

documents indicates the product requires appropriate treatment, collection and recycle for

waste electrical and electronic equipment (WEEE) under the Directive 2012/19/EU, and/or

waste batteries and accumulators under the Directive 2006/66/EC in the European Union.

The symbol might be put with one of the chemical symbols below. In this case, it satisfies the

requirements of the Directive 2006/66/EC for the object chemical.

This product should not be disposed of as unsorted household waste.

Your correct disposal of WEEE, waste batteries and accumulators will contribute to reducing

wasteful consumption of natural resources, and protecting human health and the environment

from potential negative effects caused by hazardous substance in products.

Contact your supplier for information on applicable disposal methods.

FCC rules

Any changes or modifications not expressly approved by the party responsible for compliance

shall void the user's authority to operate the equipment.

Warning

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Korea certification

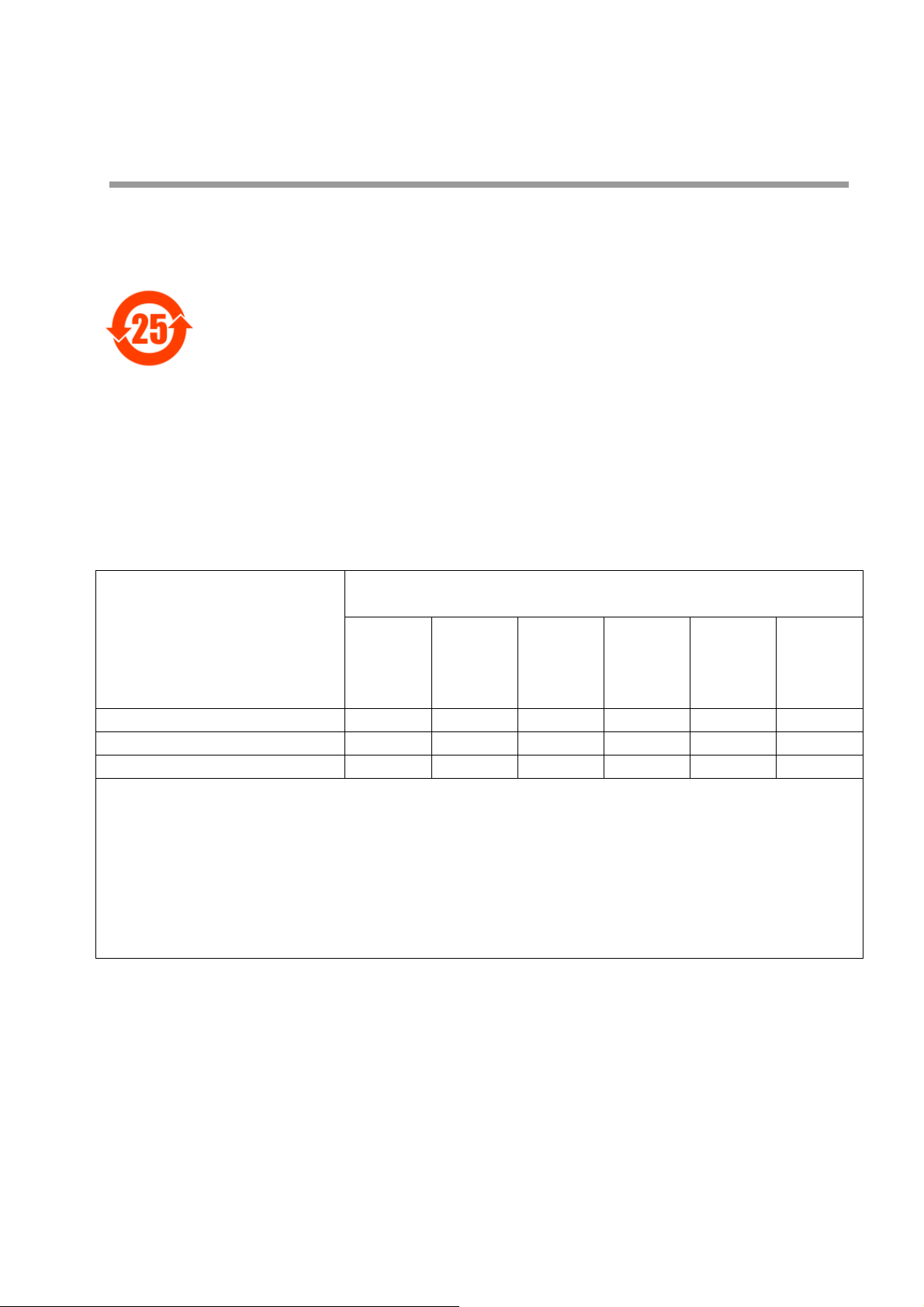

China regulation

本标记适用在中华人民共和国销售电器电子产品,标记中央的数字表示环境保护使用期限的年数。(不是表

示产品质量保证期间。) 只要遵守这个产品有关的安全和使用注意事项,从制造日开始算起在这个年限内,

不会给环境污染、人体和财产带来严重的影响。请不要随意废弃本电器电子产品。

This marking is applied to electric and electronic products sold in the People's Republic of China. The

figure at the center of the marking indicates the environmental protection use period in years. (It does not

indicate a product guarantee period.) It guarantees that the product will not cause environment pollution

nor serious influence on human body and property within the period of the indicated years which is

counted from the date of manufacture as far as the safety and usage precautions for the product are

observed. Do not throw away this product without any good reason.

本マークは、中華人民共和国で販売される電気電子製品に適用され、マークの中央の数字は環境保護使用

期限の年数を意味します(製品の品質保証期間を示すものではありません)。この製品に関する安全や使

用上の注意をお守り頂く限り、製造日から起算するこの年限内では、環境汚染や人体や財産に深刻な影響

を及ぼすことはありません。本製品をみだりに廃棄しないでください。

产品中有害物质的名称及含量

Name and amount of hazardous substance used in a product

有害物质

Hazardous substance

部件名称

Unit name

操作单元

分析单元

主机柜

本表格依据 SJ/T 11364 的规定编制。

This form is prepared in accordance with SJ/T 11364.

○: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

Denotes that the amount of the hazardous substance contained in all of the homogeneous materials used in the

component is below the limit on the acceptable amount stipulated in the GB/T 26572.

×:

表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

Denotes that the amount of the hazardous substance contained in any of the homogeneous materials used in the

component is above the limit on the acceptable amount stipulated in the GB/T 26572.

Operation unit ×

Analyzer unit × ×

Main cabinet

铅

Lead

(Pb)

○○○○○○

汞

Mercury

(Hg)

○○○○○

镉

Cadmium

(Cd)

○○○○

六价铬

Hexavalent

chromium

(Cr (VI))

多溴联苯

Polybromo-

biphenyl

(PBB)

多溴二苯醚

Polybromo-

diphenyl

ether

(PBDE)

For Your Safety

Hazard classification and warning symbols

Warning messages are described in the following manner. Read the messages and follow the

instructions carefully.

Hazard classification

This indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury. This is to be limited to the most extreme

situations.

This indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

This indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

Warning symbols

Description of what should be done, or what should be followed

Description of what should never be done, or what is prohibited

Safety precautions

WARNING

This section provides precautions for using the product safely and correctly and to prevent

injury and damage. The terms of DANGER, WARNING, and CAUTION indicate the degree of

imminency and hazardous situation. Read the precautions carefully as it contains important

safety messages.

Electric shock hazard

In order to prevent electric shock, be sure to ground the equipment. At this point, however, avoid

connecting it to hazardous locations, such as gas piping.

Electric shock hazard

Improper terminal connection can cause an electric shock and malfunction of the equipment. Be

extremely careful not to connect the terminals incorrectly.

Electric shock hazard

• Before connecting wiring to the terminal block, be sure to cut off the external power supply. Failure

to do so may cause an electric shock.

• The operation panel and the terminal block cover for the rear terminal block should only be

opened/closed by a person with full electrical knowledge.

Beware of waste liquid

The waste liquid contains acid, alkali, and heavy metals. When you handle the waste liquid, be sure to

wear protective gloves and goggles so that you will not come in direct contact with the waste liquid.

If it gets on your skin or in your eyes, rinse it off with a plenty of water immediately and contact your

doctor.

If you swallow it accidentally, contact your doctor immediately.

Chemical hazard

Some reagents are poisonous and thus it is extremely dangerous if they are touched by hand. When

replacing the reagent bottle, be sure to wear protective goggles and gloves, and be extremely careful

so that your skin will not come in direct contact with reagents. When replacing the reagent bottle, the

reagent may spill off from the bottle. If it spills off, wipe it off completely.

Chemical hazard

Dissolving the reagent generates hydrochloric vapor and heat. When mixing the cleaning solution, be

sure to wear protective goggles and gloves.

• Dissolve the reagent in a well-ventilated area such as a draft chamber.

• Always pour hydrochloric acid into pure water. Never pour pure water into hydrochloric acid.

• 35% to 37% hydrochloric acid is poisonous. Be extremely careful when handling it.

• If it comes in contact with your skin, rinse it off well with running water.

• If it gets in your eyes, rinse it off well with running water, and then immediately consult a doctor.

Fire or electric shock

• Do not bundle the power supply cord during use.

• Do not damage the power supply cord nor apply an excessive load to it, such as bending and

stretching it repeatedly, putting a heavy thing on it.

If may result in overheating, a fire, an electrical shock, or breakdown.

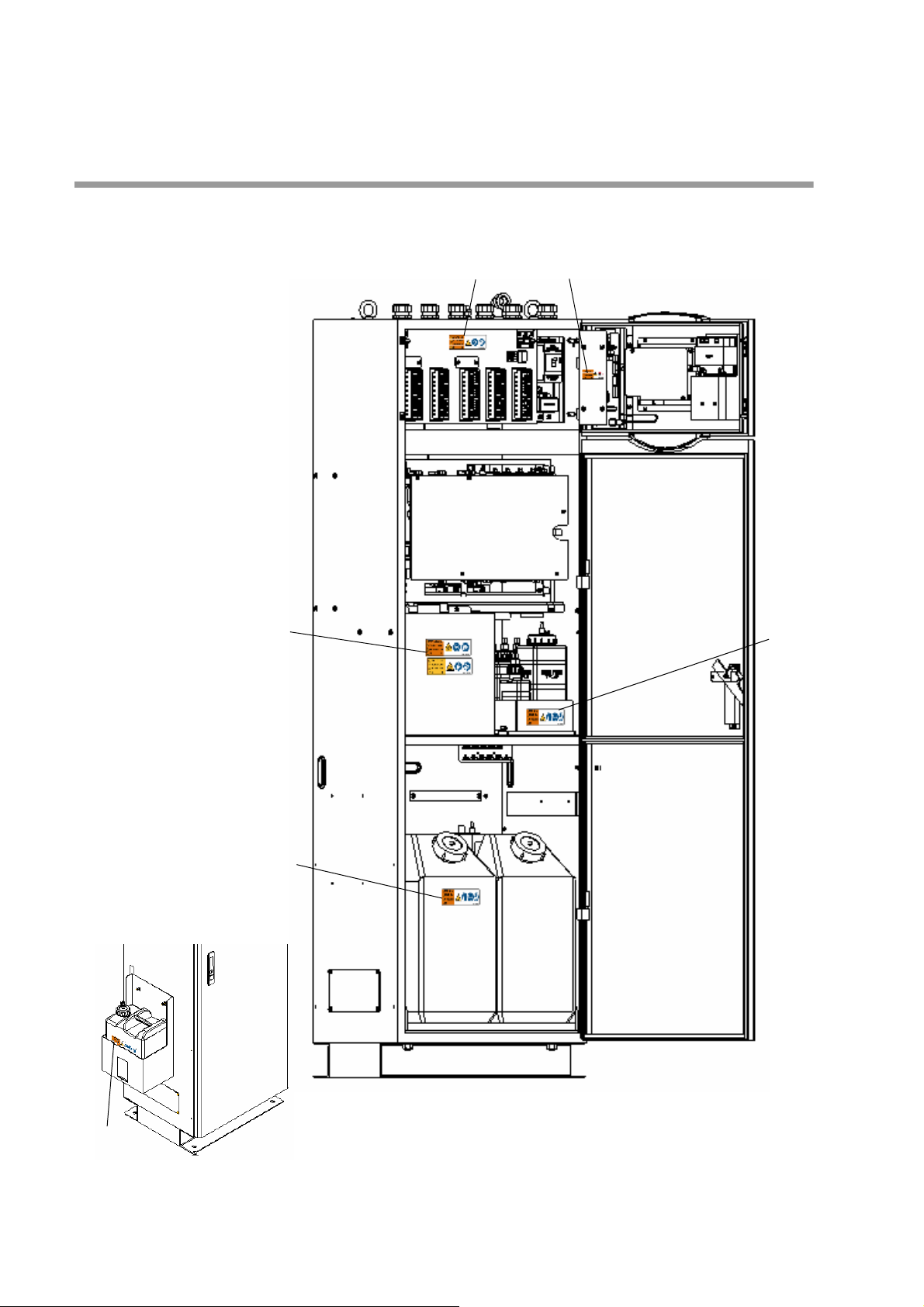

Attachment location and type of warning labels

(1)

(2)

(6)

(5)

(3)

(4)

(For automatic hydrochloric

acid cleaning specification)

Attachment location of warning labels

(1)

(2)

(4)

(3)

(5) 2 type labels

(6) For automatic hydrochloric acid cleaning specification

Type

Product Handling Information

Operational precautions

Use of the product in a manner not specified by the manufacturer may impair the protection

provided by the product. And it may also reduce product performance.

Exercise the following precautions:

Only use the product including accessories for their intended purpose.

Use the equipment in an environment that does not contain corrosive gas.

Do not apply external shock or excessive vibration to the equipment. When relocating the

equipment, contact our service or sales office.

Do not switch the power ON and OFF immediately.

Do not operate the touch panel using the tip of your finger nail or a tool with a sharp edge,

or with wet hands.

Do not use solutions such as organic solvents.

Be extremely careful when handling chemicals.

A new reagent bottle is fully charged with reagent. If you grab the side of the bottle while

the cap is open, the reagent may spill out. When opening the cap of the reagent bottle for

setting or replacing the reagent, be careful not to spill the reagent. For example, place the

bottle on a flat surface.

Perform the installation work while taking the features of the analyzer into consideration.

Also, ensure an environment in which the equipment can operate normally. Take

appropriate action so that the equipment will not be damaged even when the equipment

no longer operates correctly due to deterioration or the operational setting conditions of

the equipment, or any unexpected phenomenon.

Disposal of the product

When disposing of the product, follow the related laws and/or regulations of your country.

The waste liquid of this equipment contains acid.

The mercury lamps in this product contains 18 mg of mercury.

Manual Information

Note

Reference

Tip

Description in this manual

This interprets the necessary points for correct operation and notifies the important points for

handling the product.

This indicates the part where to refer for information.

This indicates reference information.

Contents

Before Using the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Names of each part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

How to change authority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Signal wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

External input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Analog output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contact output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Contact input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Serial input/output (RS-485/RS-232C) . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preparation for Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preparation of printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation of reagent bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Preparation of reagent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Preparing potassium peroxodisulfate aqueous solution [Reagent A] . . . . . . . . 35

Preparing sodium hydroxide aqueous solution [Reagent B] . . . . . . . . . . . . . . . 35

Preparing dilute sulfuric acid solution [Reagent C] . . . . . . . . . . . . . . . . . . . . . . 35

Preparing L-ascorbic acid aqueous solution [Reagent D] . . . . . . . . . . . . . . . . . 36

Preparing mixed reagent (ammonium molybdate + potassium antimonyl tartrate sesqui-

hydrate) [Reagent E] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Preparing hydrochloric acid solution [Reagent F] . . . . . . . . . . . . . . . . . . . . . . . 36

Preparation procedure of span solution . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Preparation for pure water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation of chemical tank (for automatic hydrochloric acid cleaning specifica-

tion). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Line cleaning solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operation method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

For initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Operation start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operation stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

When stopping the equipment for over three days . . . . . . . . . . . . . . . . . . . . . . 50

When shutting down the analyzer for more than two weeks. . . . . . . . . . . . . . . 50

Operation restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Calibration pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

List of functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Hierarchy of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

To display the [MENU] item screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[MENU] - [SETTING]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

OPERATION SET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

MEAS. LINE SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

OUTPUT SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

PAYLOAD SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

SYSTEM SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

[MENU] - [MAINTENANCE] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

REAG.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

PERIODIC CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

EXT. ANALOG OUTPUT ADJUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

STEP ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

SEPARATE ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

[MENU] - [CHECK] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

EXT. POINT INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

EXT. POINT OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

EXT. ANALOG INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

EXT. ANALOG OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

INT. ANALOG INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

To display the [DATA] item screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

[DATA] - [LOG DATA] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

MEASURE VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

HOUR REPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

[DATA] - [GRAPH] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

MEASURE VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

TREND GRAPH (MEASURE VALUE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

HOUR REPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

OPTICAL SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

TREND GRAPH (OPTICAL SIGNAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

[DATA] - [CALIBRATION HISTORY] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

[DATA] - [ALARM HISTORY] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

[DATA] - [SAVE TO USB]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

About the data to be stored . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

[DATA] - [DATA CLEAR] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

[START] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

[STOP] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

[POWER] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Modbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Software overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Function code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Exception code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Slave address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Address mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Data format example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Data definition sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

How to use data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (STATUS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (CURRENT ALARM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (MEASURE VALUE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (Hour Report History). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (Day Report History) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (EXT. ANALOG INPUT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

MEAS. (EXT. POINT INPUT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

CONTROL (EXT. ANALOG INPUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

CONTROL (EXT. POINT INPUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

CONTROL (EXT. ANALOG OUTPUT CHECK). . . . . . . . . . . . . . . . . . . . . . . . . 187

CONTROL (EXT. POINT OUTPUT CHECK). . . . . . . . . . . . . . . . . . . . . . . . . . . 187

ADJUST (EXT. ANALOG INPUT ADJUST). . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

History (Measure History) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

History (Hour Report History). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

History (Day Report History) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

History (Alarm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

History (Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

History (Optical Signal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Others (Main program information/sub program information) . . . . . . . . . . . . . . 189

Others (writing of setting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Periodic maintenance procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Waste liquid processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Replacing the reagent bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Replacement of the pure water cartridge (For the built in pure water cartridge) 201

Supplying pure water into the pure water tank (for models equipped with a pure water

tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Checking and cleaning the overflow tank (option) . . . . . . . . . . . . . . . . . . . . . . 207

Checking and cleaning the dilution tube and cell measurement tube. . . . . . . . 209

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

When measurement cannot be started. . . . . . . . . . . . . . . . . . . . . . . . . . 214

Measurement not working right. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Alarm list and operation outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Cause and corrective action for alarms . . . . . . . . . . . . . . . . . . . . . . . . . 218

Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Measurement principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Total nitrogen: Ultraviolet oxidative dissolution method . . . . . . . . . . . . . . . . . . 224

Total phosphorus: Ultraviolet oxidative dissolution - Molybdenum blue spectrophotomet-

ric method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Accessories and consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

List of reagent consumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Time chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Sequence: Preprocess, Pre-Wash, Post-Wash . . . . . . . . . . . . . . . . . . . . . . . . 234

Sequence: Zero calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Sequence: Measurement/span calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

TURB. COEFFICIENT SET (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Before Using the Product

Preface

Total nitrogen (TN) and total phosphorus (TP) have been defined as “Living Environment

Items” under Environmental Quality Standards and Effluent Standards as part of measures to

control eutrophication of enclosed bodies of water. In addition to existing COD (chemical

oxygen demand), total nitrogen and total phosphorus were incorporated into regulations

governing total pollution loads beginning with the Fifth Total Pollutant Load Control

implemented in 2004. Measurement by automatic measurement instrument is mandatory for

factories and other establishments whose waste liquid discharge volume is greater than 400

3

, per day.

m

No principles or methods of measurement are specified for automatic measurement

instrument of the total nitrogen and total phosphorus under the Total Pollutant Load Control.

Any measurement instrument complying with the standards for performance, control, and

maintenance set forth in the “Manual of measurement methods for water quality pollutant load

using nitrogen/phosphorus automatic measurement instrument (published by Japan's Ministry

of the Environment)” can be used.

The TPNA-500 uses the ultraviolet oxidative dissolution method.

Before Using the Product

Ultraviolet oxidative dissolution method

Principle of measurement for total nitrogen

Alkaline potassium peroxodisulfate solution is added to the sample solution. Irradiation by

ultraviolet light then causes oxidative dissolution of nitrogen compounds to nitrite ions (NO

Total nitrogen (TN) concentration is obtained by measuring the nitrite ion concentration using

an ultraviolet absorption photometer. The advantage of this method is the simplified

architecture of the dissolution tanks that enables dissolution to be carried out under normal

atmospheric pressure at a lower temperature (100C) than thermal decomposition methods

that require 120C.

Principle of measurement for total phosphorus

Potassium peroxodisulfate solution is added to the sample solution followed by irradiation with

ultraviolet light, causing oxidative dissolution of phosphorus compounds to phosphoric ions

3-

(PO

potassium antimonyl tartrate are then added to the sample to bring about a chromogenic

reaction forming molybdenum blue. The total phosphorus (TP) concentration is obtained by

measuring the absorbance of the molybdenum blue at the absorption wavelength of 880 nm

using an absorption photometer. The advantage of this method is the simplified architecture of

the dissolution tanks that enables dissolution to be carried out under normal atmospheric

pressure at a lower temperature (100C) than thermal decomposition methods that require

120C.

). L-ascorbic acid solution mixed with a solution of ammonium molybdate and

4

-

).

3

1

Before Using the Product

1

5

6

2

4

[Models equipped with a pure water tank]

[When open]

3

Refer to page 3.

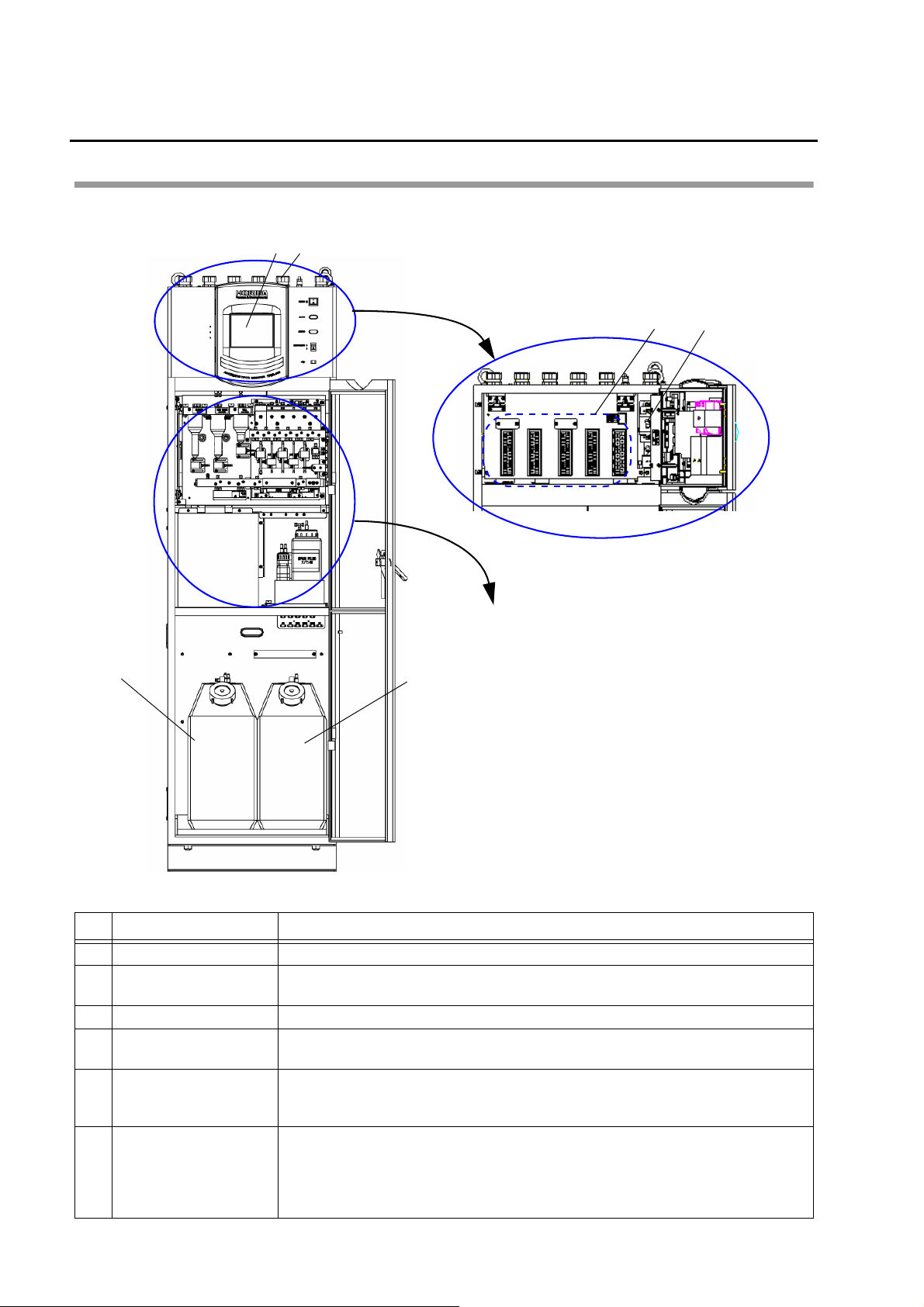

Names of each part

Analyzer

No. Name Description

1 Operation section Refer to “ Operation section” (page 5).

Electrical wiring service

2

entrance

3 Input/output terminal Power supply cable and signal lines are brought into the equipment here.

Main power switch

4

(Ground fault interrupter)

5 Waste liquid tank

6 Pure water tank

A service entrance for electrical wiring.

Turns ON/OFF the power to the equipment.

The amount of waste liquid is approximately 17 L per month. Includes alarm output

contact terminals to activate a “Full Drain Tank” alarm when the tank reaches full capacity.

Tank capacity is 20 L. Check level in the tank and dispose of waste liquid as necessary.

Storage capacity is approximately 20 L of pure water. Amount of pure water

consumed is approximately 40 L per month (depending on measurement range).

Includes alarm output contact terminals to activate a “Lack Blank” alarm when the

amount of pure water remaining is insufficient (not needed for units that use tap water

for the water supply or for units with built-in pure water unit).

2

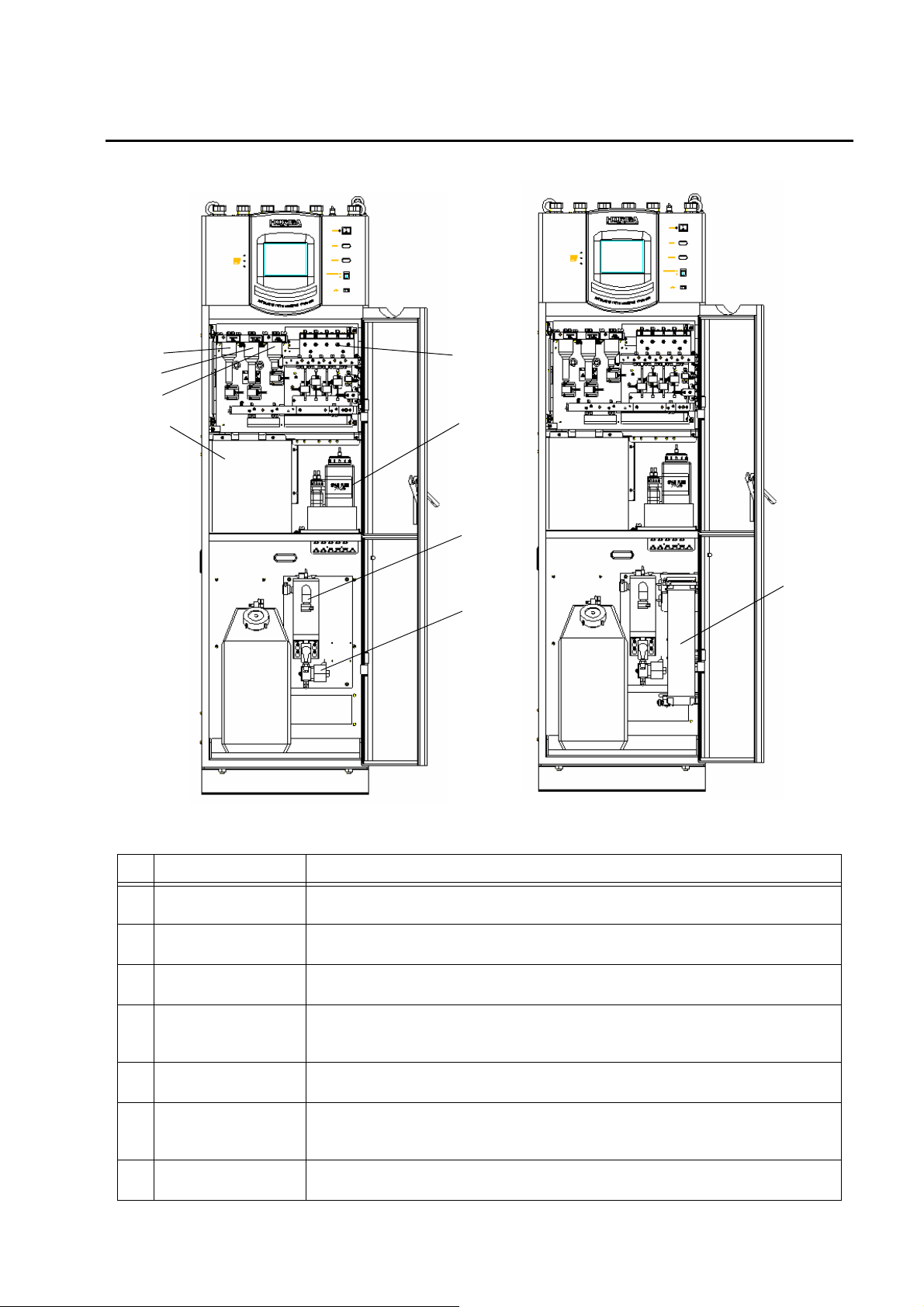

Before Using the Product

[For the built in pure water cartridge]

[Pure water supply from customer]

13

14

15

7

10

12

11

8

9

No. Name Description3

7 Dilution tube

Pure water

8

measurement tube

Cell measurement

9

tube

10 Analyzer

Reagent metering

11

section

12 Reagent bottle

13 Sub tank(Pure water)

Measures sample solution and diluted sample solution.

The sample solution is diluted with pure water according to the sample concentration.

Measures pure water.

Measures the amount of sample required for measurement and supplies the sample

to the analyzer.

Performs mixing of sample and reagent, heating, ultraviolet irradiation, agitation, and

absorbance measurement.

Measurement cells for total phosphorus and total nitrogen have been integrated.

Measures the amount of each reagent to be injected.

Stores reagent A, B, C, D, E, F and span solution. Each solution can be stored for

approximately one month. An alarm is enabled via external contact terminals when

the amount of a reagent remaining is insufficient.

It is a tank for save pure water.

When a residual quantity decreases, equipment automatically supply pure water.

3

Before Using the Product

No. Name Description3

Solenoid valve(pure

14

water supply)

15 Pure water cartridge

It is an solenoid valve for control of pure water supply.

In the case of specifications with built in pure water cartridge, it is attached.

Pure water necessary for the measurement is purified when you supplies tap water.

Can use it between six months from one year.

4

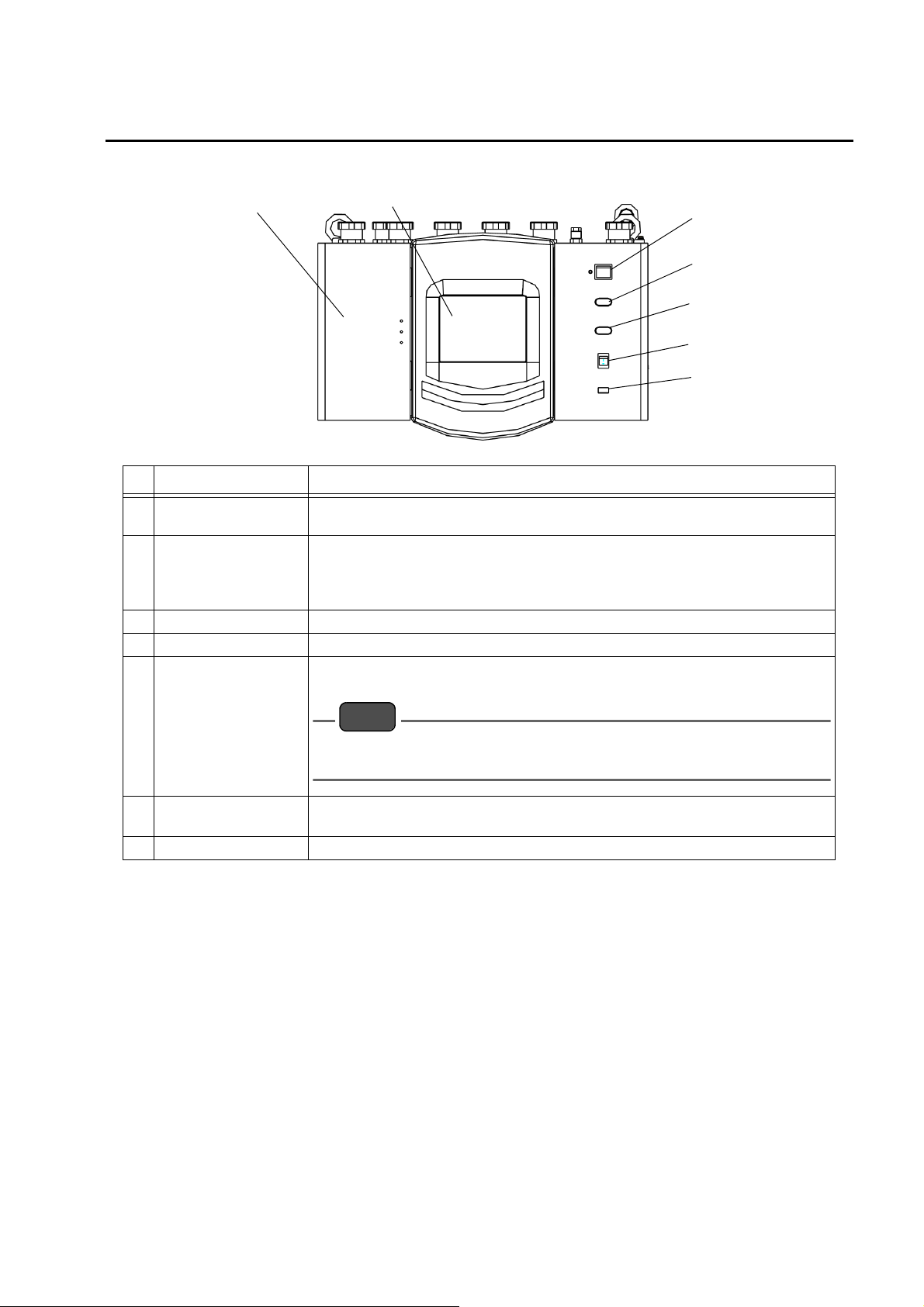

Operation section

7

2

3

6

5

4

1

Note

No. Name Description

1 Printer door

2 Touch panel

3 Power switch Turns power on and off to the operation section.

4 Alarm indicator Will light up when an alarm occurs.

The printer and its paper, and an automatic printer-paper spooling unit are housed

behind this door.

Displays measurement results, including measurement values, time, and

measurement point, condition settings, operating guidance for maintenance/

adjustment, alarm description, and function key guidance. Can be operated directly

from the screen.

Will light up when internal measurement instrument information is being stored on

an external memory device.

Before Using the Product

5 Access indicator

Do NOT turn power off while the access indicator is illuminated. This could

corrupt data contained on the CF card.

6 Maintenance switch

7 USB port Insertion slot for USB memory devices.

Use this switch when performing maintenance on the equipment. When this switch

is ON, the “Maintenance” contact is output.

5

Before Using the Product

Note

1

2

3

4

5

6

7

8

1

2

3

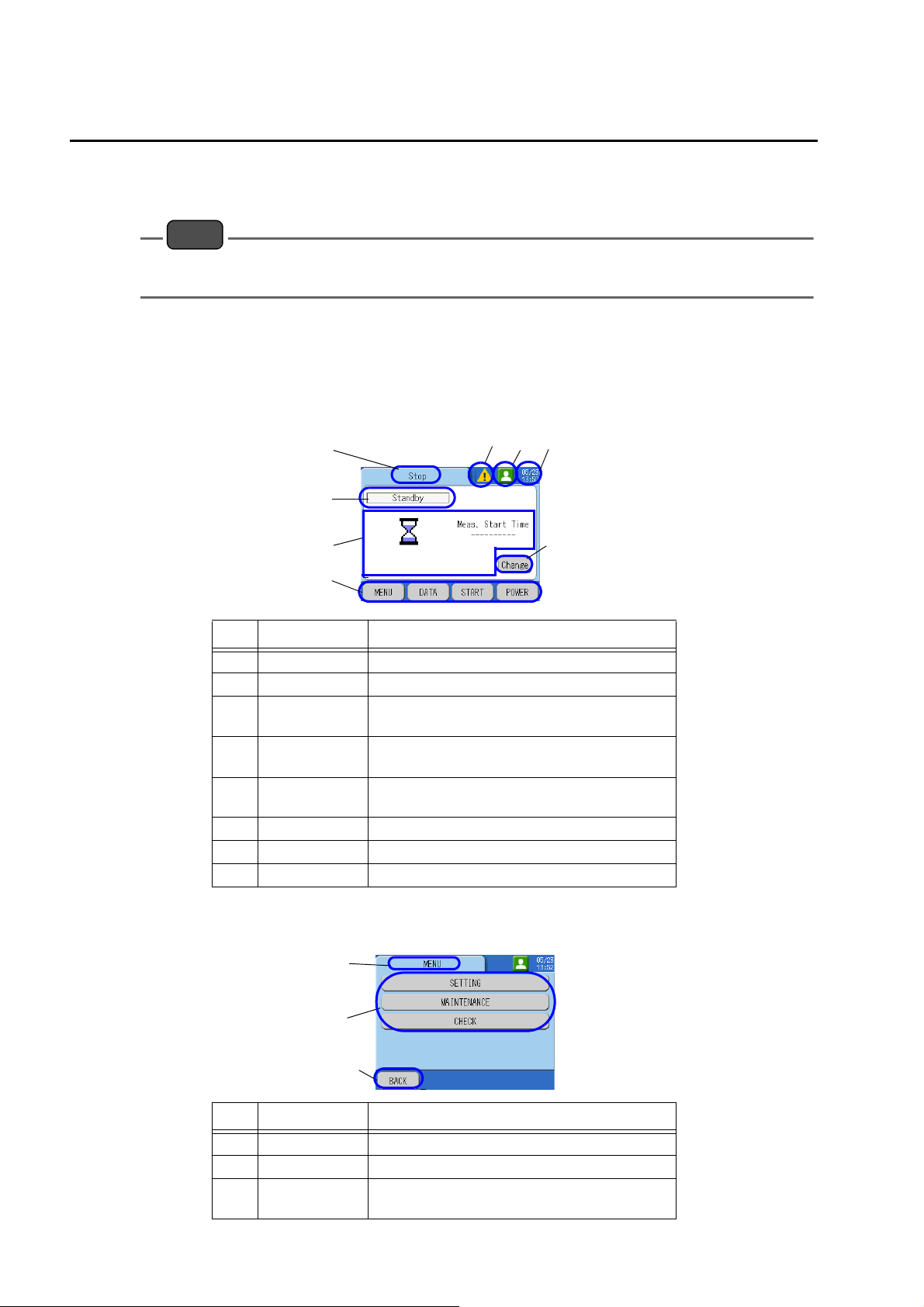

Display

A typical screen example will be used to explain the content displayed on the screen.

The display is a touch panel device. Do not operate the touch panel using the tip of your finger nail or

a tool with a sharp edge, or with wet hands.

Screen example

Display shows readings of measured parameters

This is the main screen that is initially displayed when the power is turned ON.

No. Description Details

1 Screen title Preprocess, MEAS., SETTING, LOG DATA, etc.

2 Component Displays currently active items.

Details of

3

display item

Operation

4

buttons

Equipment

5

status

6 Authority Displays the authority of the operator.

7 Clock display Displays the time.

8 Change Displays previous values.

Displays measurement values, etc.

Switches displays, etc.

Displays whether an alarm has been activated.

Screen when an operating button has been pressed

No. Description Details

1 Screen title MENU, DATA, START, STOP etc.

2 Selection items Displays available options.

Operation

3

buttons

Switches displays, etc.

6

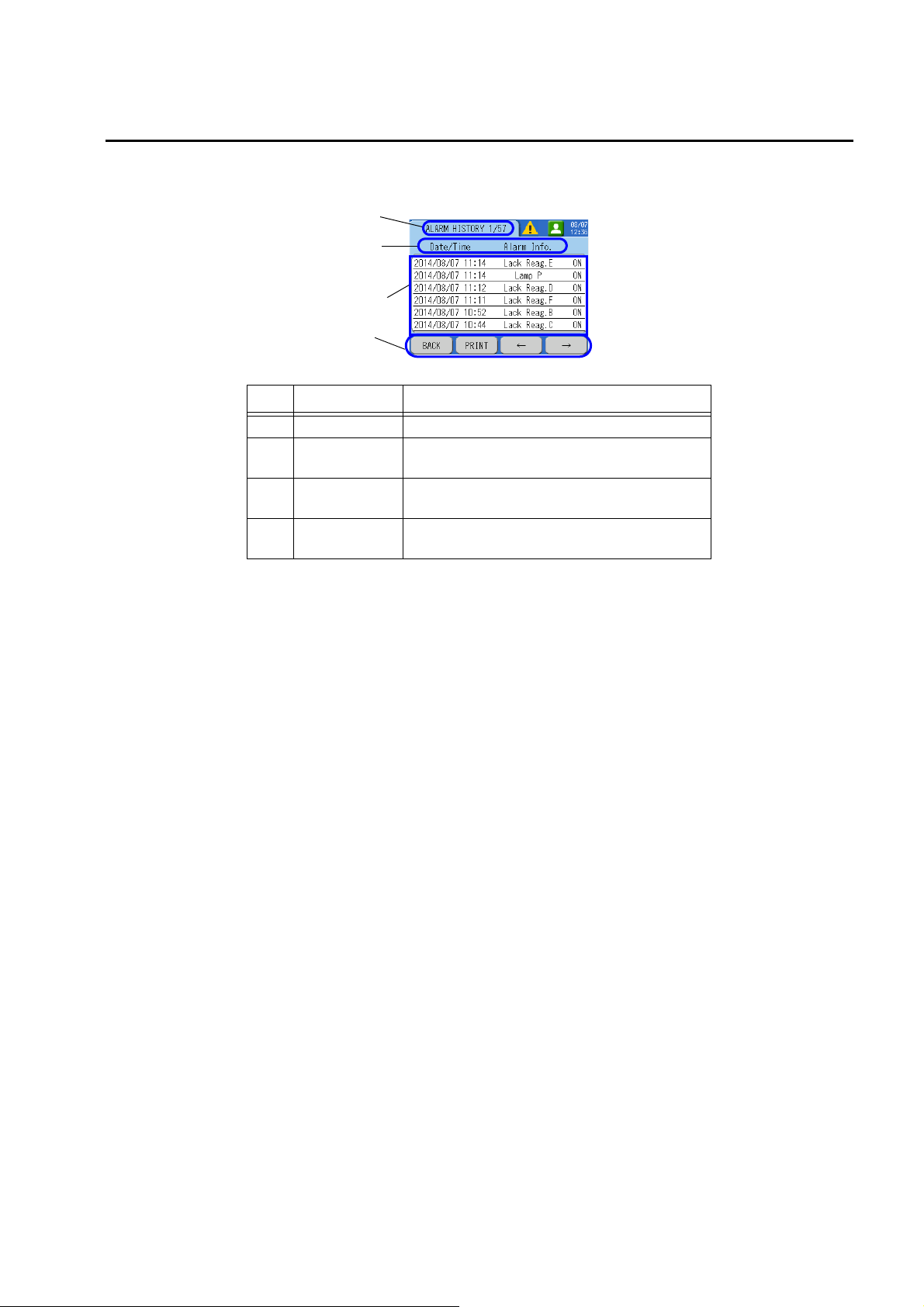

Display details of the selected item

1

2

3

4

Screen will show details of each item.

No. Description Details

1 Screen title ALARM HISTORY, etc.

Description of

2

table contents

Details of

3

display item

Operation

4

buttons

Shows the currently displayed item.

Shows details of display items.

Switches displays, etc.

Before Using the Product

7

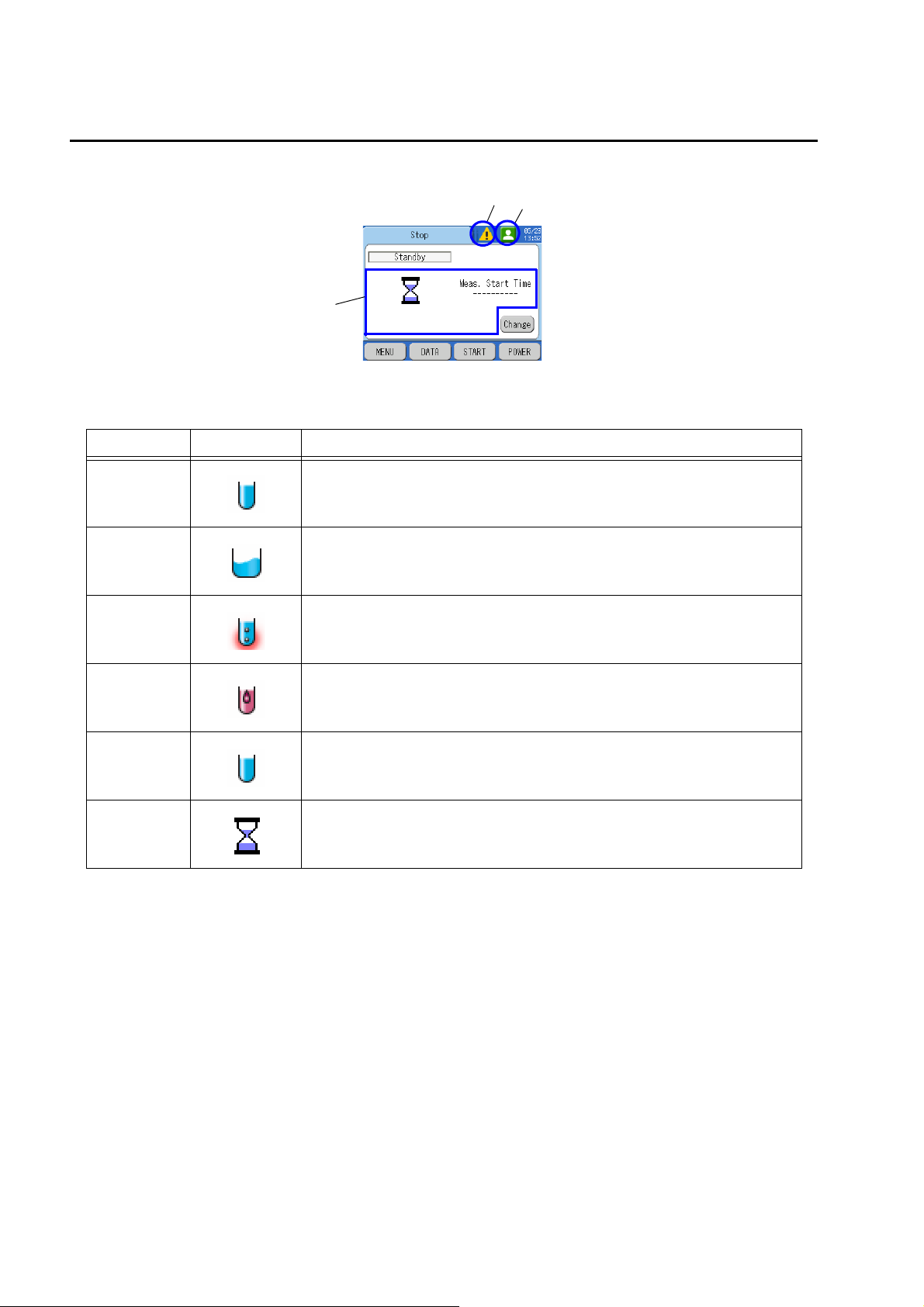

Before Using the Product

A

B

C

Description of icons

A: Description of the display item icons

Item Icon Description

Pre-processing Preparation prior to start of measurement.

Sampling

Dissolution

Measurement Reagents are added and TP and TN measurements are performed.

Cleaning The dissolution sections are cleaned.

Standby

The sample, pure water, and reagents are measured and injected into the

dissolution sections.

Solutions are exposed to ultraviolet light and heated to cause dissolution of the

compounds in the sample.

Measurements are complete and the unit remains on standby until the next

measurement is started.

8

Before Using the Product

Tip

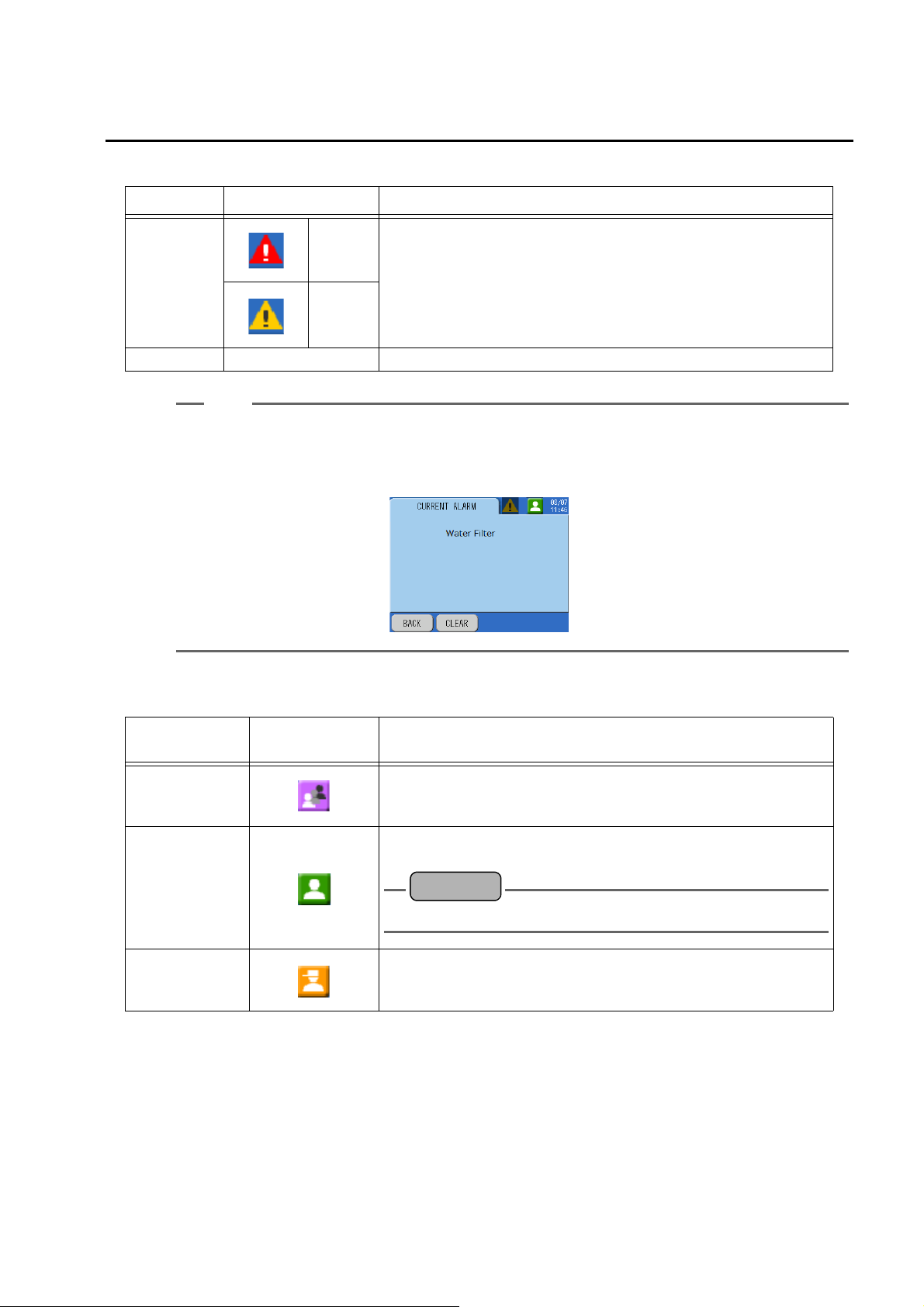

Reference

B: Description of equipment status icons

Item Icon Description

Critical

(red)

Alarm

activated

Minor

(yellow)

No alarm No display No alarm is activated.

Press the icon to display the currently activated alarms.

To cancel an alarm, take corrective action according to the nature of the alarm and press [CLEAR] on

the screen. For details on corrective actions, refer to “ Cause and corrective action for alarms” (page

218).

An alarm is activated. For details on how to check past alarm, refer to

“ [DATA] - [ALARM HISTORY]” (page 147).

C: Description of the Authority icons

Item

(Mode)

General user Normal measurements can be performed.

Power user

Administrator

Icon Description

Settings for measurement, calibration, and other items can be

performed. To log in, the user must enter a password.

“ AUTHORITY SET” (page 103)

Used while operation is under control of the manufacturer. Customer

operation is not permitted.

9

Before Using the Product

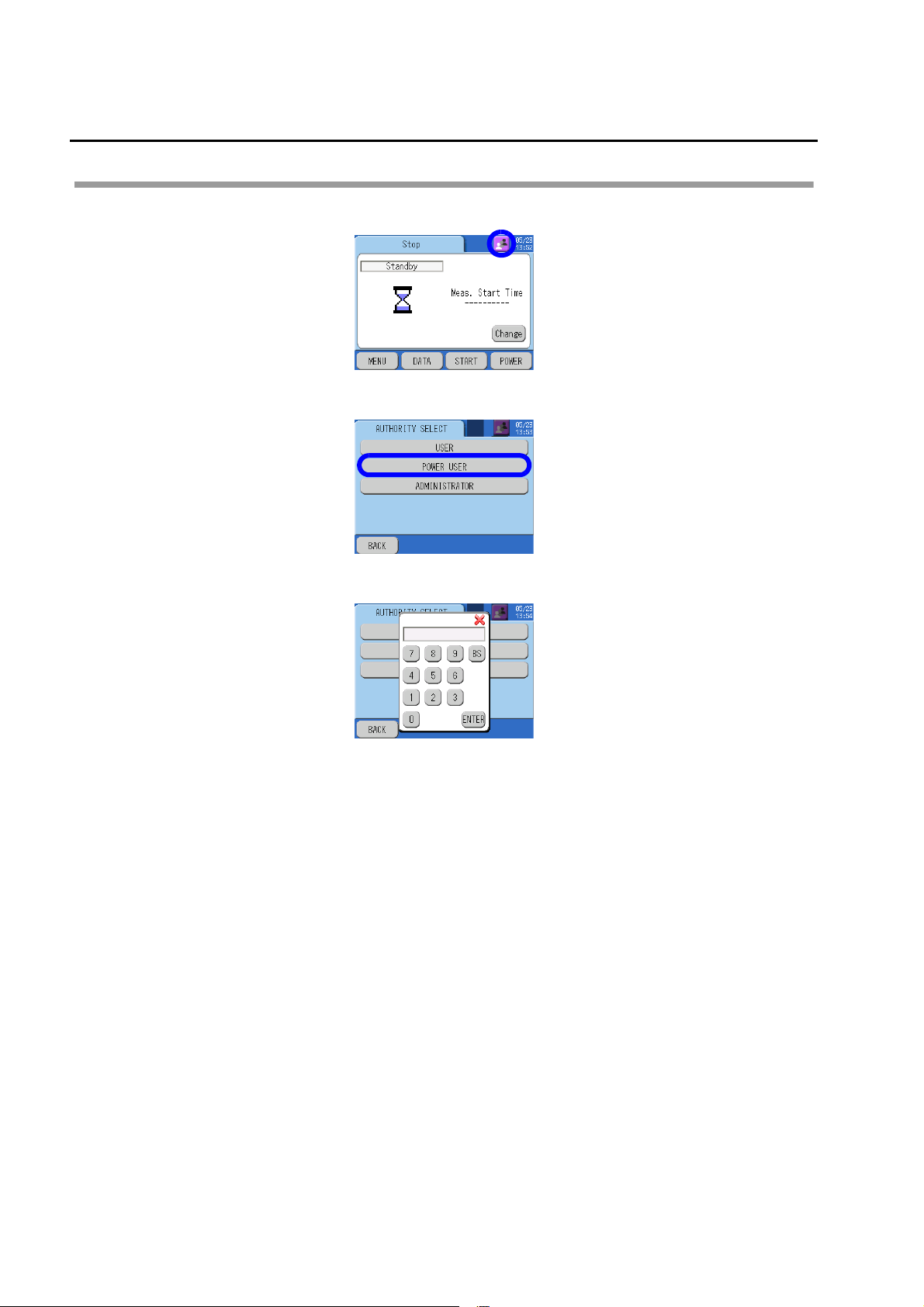

How to change authority

1. Press the icon.

2. Press the relevant authority button.

3. Enter your password and press [ENTER].

10

Connection

Contact

output

Power

Maintenance

Contact

output

Contact

output

Contact

output

Contact

input

Contact

input

Analog output

Analog input

(G)

(+)

()

(G)

(G)

(G)

(G)

(+)

()

(+)

()

(+)

()

(+)

()

(+)

(G)

(G)

(G)

(G)

()

(+)

()

(+)

()

(+)

()

()

(+)

(+)

(G)

(G)

(G)

(G)

(G)

Contact

output

Contact

output

Contact

input

Contact

input

Analog input

Analog output

(G)

(G)

(G)

(G)

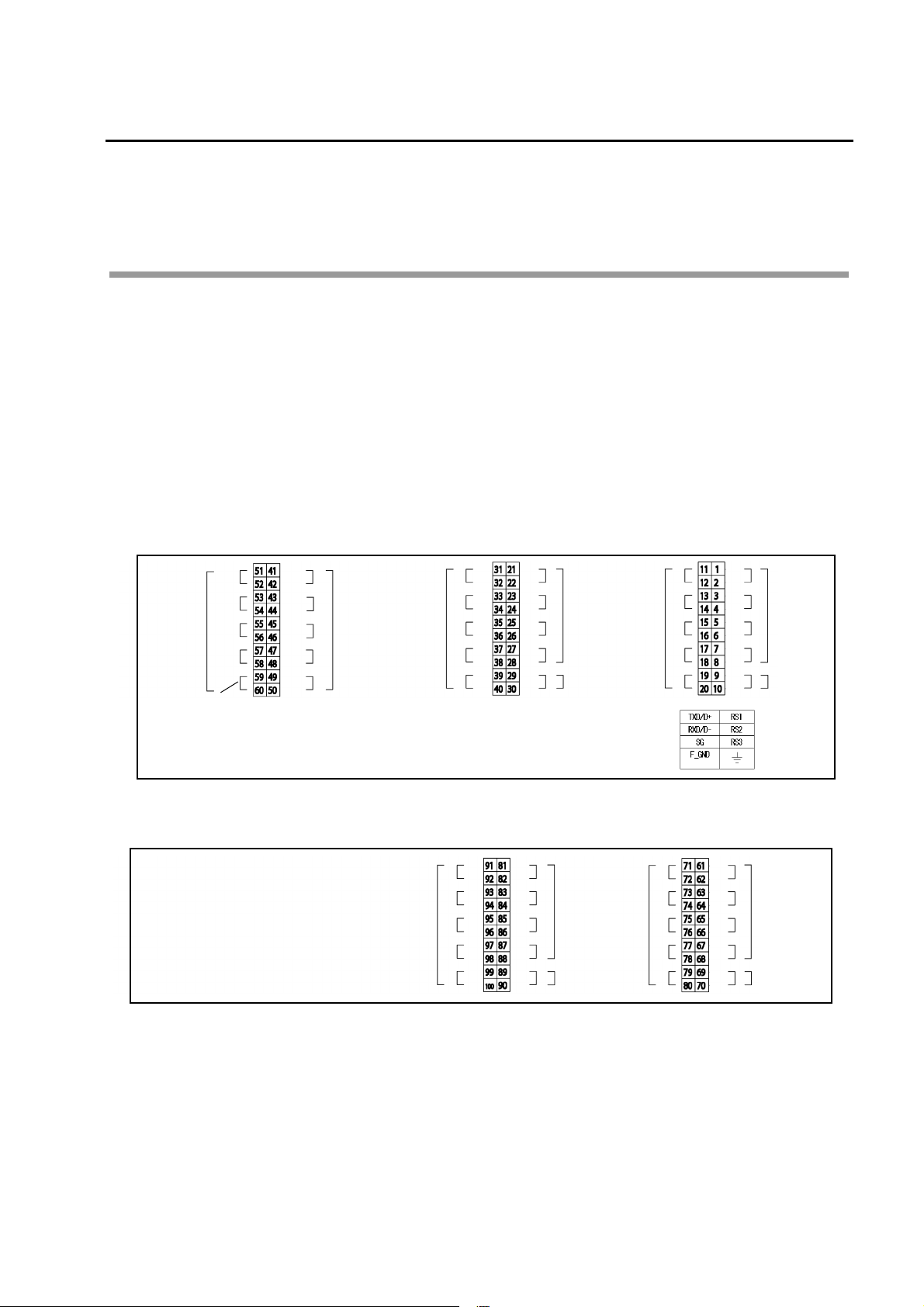

Signal wiring

External input/output

The input/output terminal connection diagram for this equipment is shown below.

The screw connection terminals inside the operation panel are used for the input/output

terminals.

Connect the signal lines according to the signal table.

Use a 2-core shielded cable for the current output signal line. Ground the shielded side to

the receiving side.

For noise protection, connect the surge absorber or noise killer in parallel with the contact

output signal lines.

Input/output terminal (standard: 1-point meter specification)

Connection

Input/output terminal (option: 3-component/2-point meter specification)

11

Connection

Note

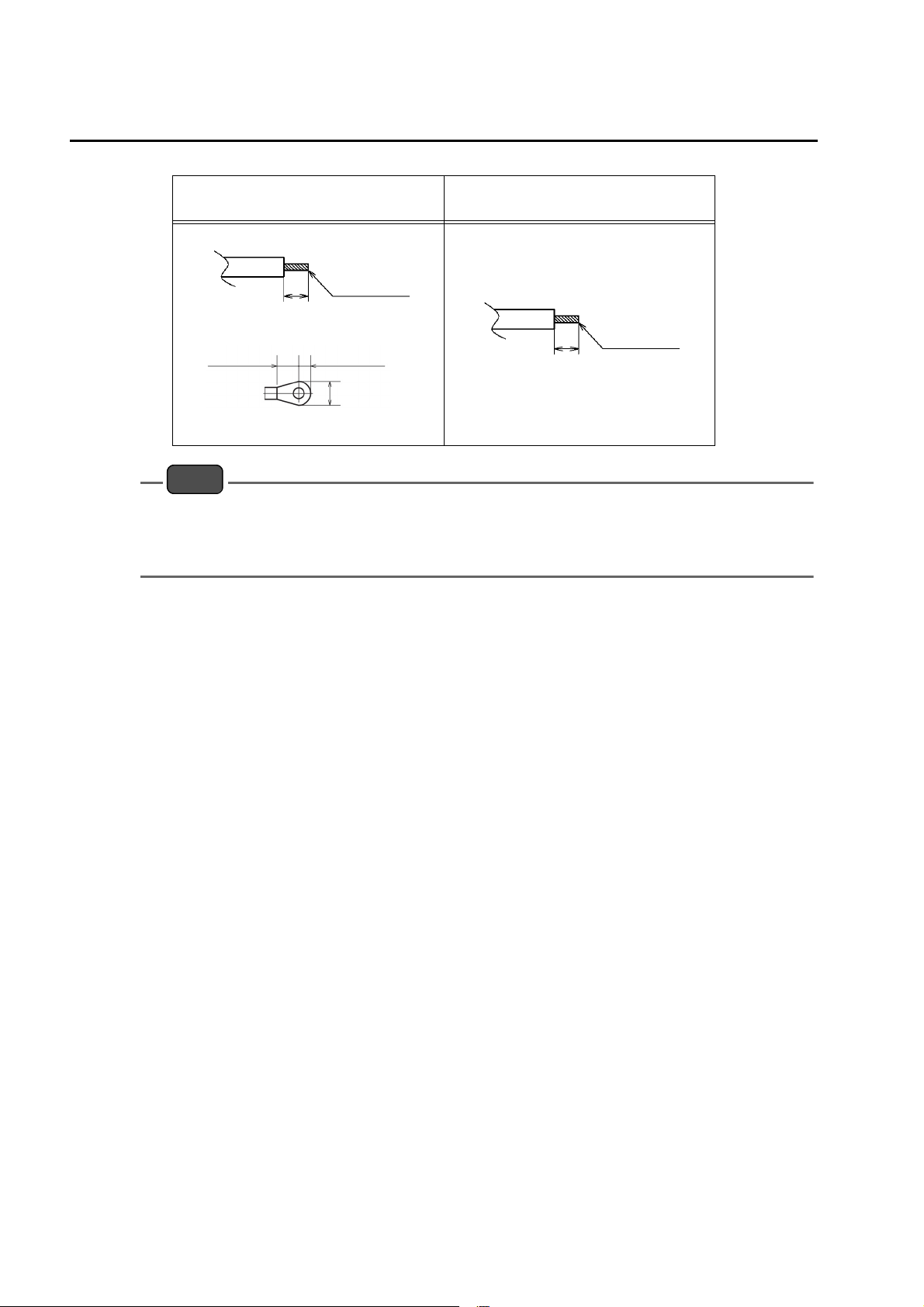

0.75 mm2 to 2.5 mm

2

(AWG18 to 14)

7 mm

Signal line terminal processing

5.2 mm (max.)

4 mm (max.)

7 mm (max.)

Applicable terminal

0.14 mm2 to 2.5 mm

2

(AWG26 to 14)

7 mm

Signal line terminal processing

Perform terminal processing for the signal lines as illustrated below.

For analog input/output and

contact input/output

Do not apply any load exceeding the maximum rating to each terminal. It could cause

For RS communication

malfunction.

Do not connect the power cable to the signal wiring section. It could cause malfunction of the

equipment.

12

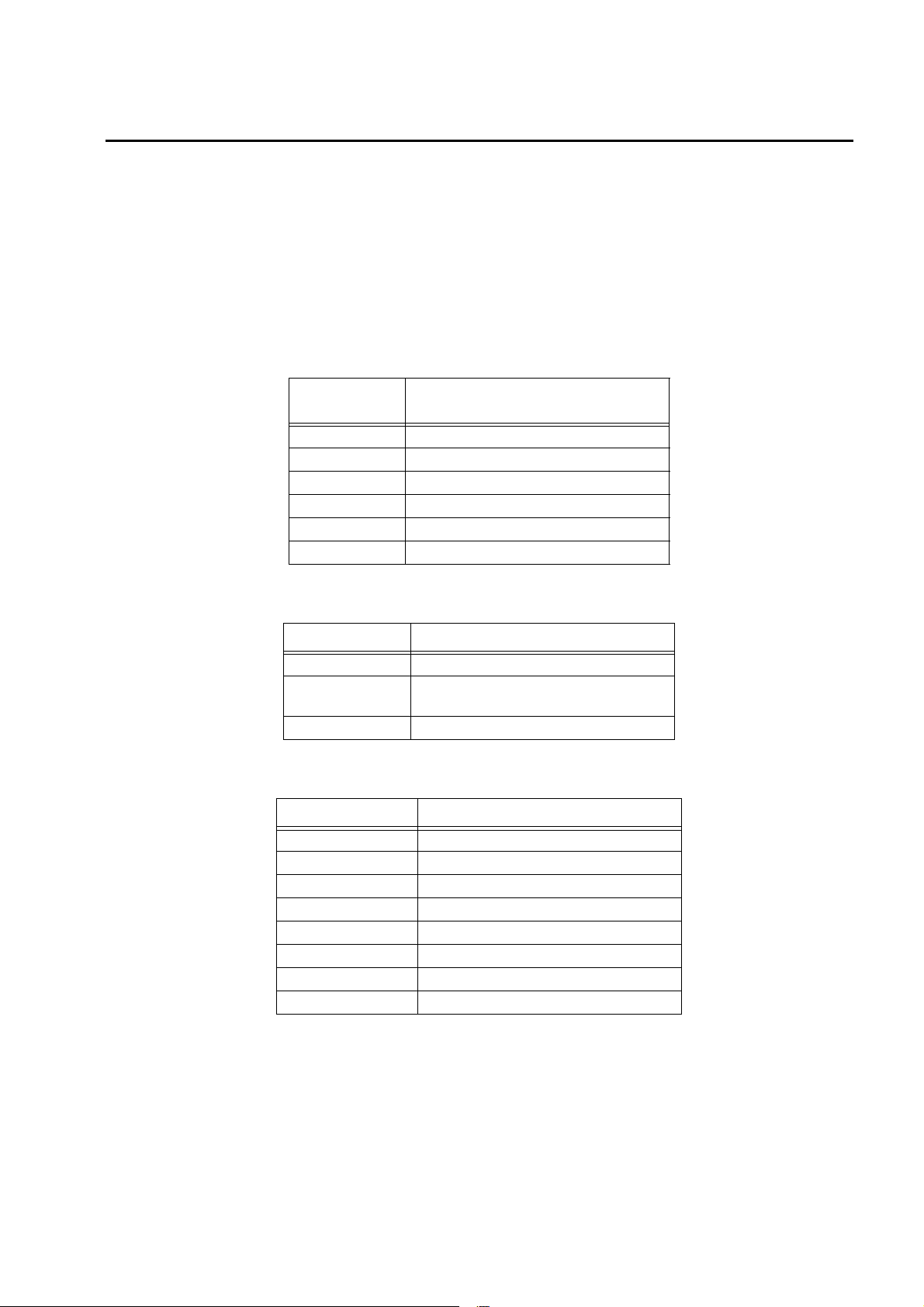

Analog output

In this equipment, the measurement values are output via the analog current/voltage output

terminals.

There are four analog output lines as standard. For output, select the desired four

components from the following five.

The values are output in accordance with the specified full-scale value.

Measurement item

Standard specification

Connection

Measurement

item

TP Conc. L1 Outputs the TP concentration for L1

TN Conc. L1 Outputs the TN concentration for L1

TP Load L1 Outputs the TP load for L1

TN Load L1 Outputs the TN load for L1

Flow L1 Outputs the L1 flow rate

No allocation -

Description

Only available for 3-component specification

Measurement item Description

COD Conc. L1 Outputs the COD concentration for L1

COD Conc-sec.L1

COD Load L1 Outputs the COD load for L1

Outputs the COD instantaneous

concentration for L1

Only available for 2-point meter specification

Measurement item Description

TP Conc. L2 Outputs the TP concentration for L2

TN Conc. L2 Outputs the TN concentration for L2

TP Load L2 Outputs the TP load for L2

TN Load L2 Outputs the TN load for L2

Flow L2 Outputs the L2 flow rate

COD Conc. L2 Not used

COD Conc-sec.L2 Not used

COD Load L2 Not used

13

Connection

Measurement item and analog output range

Example of 4 mA to 20 mA output

Measurement

item

TP Conc. L1 10 mg/L 0 mg/L 10 mg/L

Range 4 mA output 20 mA output

Example of 0 mA to 16 mA output

Measurement

item

TP Conc. L1 10 mg/L 0 mg/L 10 mg/L

Range 0 mA output 16 mA output

14

Loading...

Loading...