Horiba IG-320, IG-331 Data sheet

■ Specifications

Optical system

IG-331

60° measurement: Incident angle 60°

Reception angle 60°

IG-320

Incident angle 60°

Reception angle 60°

20° measurement: Incident angle 20°

Reception angle 20°

Measuring area

60° measurement: 3 x 6 mm oval

12 mm x 6 mm oval

20° measurement: 3 x 4 mm oval

Light source

Detector

Measuring range

Display range

Reproducibility

Power source

Continued use time

Ambient conditions

Dimensions

LED (wavelength: 890 nm)

SPD (silicone photodiode)

0-100

0-199 (resolution: 1)

±5% F.S. ±1 digit

A3 dry-cell battery x 4

Not rechargeable

50 hours or more

10-40:

Main body: 140 (W) x 75 (H) x 34 (D) mm

5.5 (W) x 3.0 (H) x 1.3 (D) in

LED (wavelength: 880 nm)

SPD (silicone photodiode)

0-100.0

0-199.0 (resolution: 0.1)

±0.5% F.S. ±1 digit

S-006P dry battery (9VDC) for operation,

CR-2025 lithium battery (3VDC) for memory

15 hours or more

0-40:

78 (W) x 189 (H) x 58 (D) mm

3.1 (W) x 7.4 (H) x 2.3 (D) in

Optical system: 88 (W) x 30 (H) x 45 (H) mm

3.5 (W) x 1.2 (H) x 1.8 (H) in

Mass

Additional

Functions

Approx. 350g (with battery)

Automatic calibration

Automatic power cut-off

Display hold

Overrange display

Battery life display

Approx. 400g (with battery)

Automatic calibration

Automatic power cut-off

Display hold

Overrange display

Battery alarm

Built-in data memory (max. 99)

Computation of averages

Keystroke confirming tone

Note: Use the 20° measurement mode of the IG-331 when the gloss value in the 60° measurement mode exceeds 70.

Accessory

Protective cap (with standard surface for calibration)

■ Example of measurement

of ceramic tile gloss

(degree of gloss)

100

correlation coefficient

= 0.99928

75

50

25

0

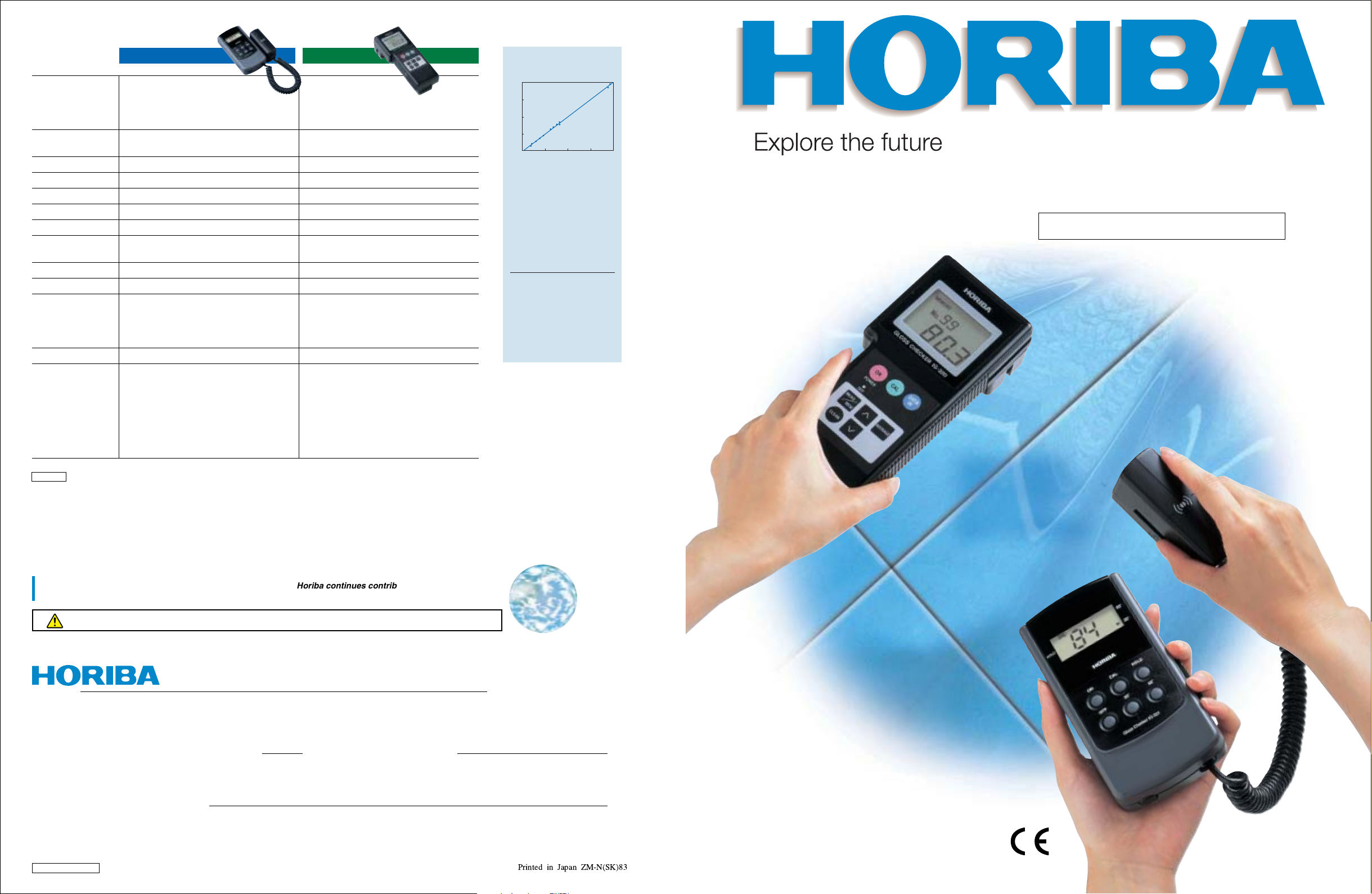

Gloss Checker IG Series

0255075100

Stationary Gloss Meter

The above graph shows the

results of measuring ceramic

tiles, widely used as the standard surface for the mediumgloss range (secondary standard surface) because of the

stability of surface conditions.

The IG Series produces extremely precise values.

●What is Glossiness?

Gloss is a quantity that expresses the degree of reflection when

light hits a surface. It is detemined by comparing the strength

of reflected light from the area being measured with that from the

standard surface.

(degree of gloss)

High-precision measurements with

an integral light source and

detector lets the user gather

and view averaged data.

IG-320

GLOSS CHECKER

IG Series

IG-320

IG-331

Digital display

brings pinpoint

Award of Certification

ISO 14001 JQA-E-90039 (Head Office/Factory)

ISO 9001 JQA-0298

Please read the operation manual before using this product to assure safe and proper handling of the product.

● The contents of this catalog are subject to change without prior notice, and without any subsequent liability to this company.

● The color of the actual products may differ from the color pictured in this catalog due to printing limitations.

● It is strictly forbidden to copy the content of this catalog in part or in full.

Horiba continues contributing to the preservation of the global

environment through analysis and measuring technology.

http://www.horiba.com e-mail: info@horiba.co.jp

●HORIBA, Ltd.

Head Office

Miyanohigashi, Kisshoin

Minami-ku, Kyoto, Japan

Phone: 81 (75) 313-8123

Fax: 81 (75) 321-5725

●HORIBA INSTRUMENTS

Pte. LTD.

10 Ubi Crescent

#05-11/12, Ubi Techpark

Singapore 408564

Phone: 65 6745-8300

Fax: 65 6745-8155

●HORIBA INSTRUMENTS

LIMITED

Kyoto Close

Summerhouse Road

Moulton Park, Northampton

NN3 6FL, U.K.

Phone: 44 (1604) 542500

Fax: 44 (1604) 542699

Bulletin:HRE-0000A

Tokyo Sales Office

1-7-8 Higashi-Kanda

Chiyoda-ku, Tokyo, Japan

Phone: 81 (3) 3861-8231

Fax: 81 (3) 3861-8259

●HORIBA INSTRUMENTS INCORPORATED

Irvine Facility

17671 Armstrong Avenue

Irvine, CA 92614, U.S.A.

Phone: 1 (949) 250-4811

Fax: 1 (949) 250-0924

●HORIBA EUROPE GmbH

Head Office

Hans-Mess-Str.6

D-61440 Oberursel/Ts.

Germany

Phone: 49 (6172) 1396-0

Fax: 49 (6172) 137385

Beijing Representative Office

Suite 1409, Tower B,

COFCO Plaza, No. 8,

Jianguomennei Avenue,

Beijing, China, 100005

Phone: 86 10-6522-7573

Fax: 86 10-6522-7582

Ann Arbor Facility

5900 Hines Drive

Ann Arbor, MI 48108

U.S.A.

Phone: 1 (734) 213-6555

Fax: 1 (734) 213-6525

Leichlingen Facility

Julius-kronenberg Strasse

D-42799 Leichlingen

Germany

Phone: 49 (2175) 8978-0

Fax: 49 (2175) 8978-50

Shanghai Representative Office

Unit F1 16F

Jiushi Fuxing Mansion,

No. 918, Huaihai Zhong Road,

Shanghai, China, 200020

Phone: 86 21-6415-3689/90

Fax: 86 21-6415-9746

●HORIBA / STEC

INCORPORATED

1080 E. Duane, Suite. A

Sunnyvale, CA 94086

U.S.A.

Phone: 1 (408) 730-4772

Fax: 1 (408) 730-8975

HORIBA FRANCE

Rue L. et A. Lumie`re

Technoparc

F-01630 St-Genis-Pouilly

France

Phone: 33 (4) 50-42-27-63

Fax: 33 (4) 50-42-07-74

Taiwan Representative Office

No.15 Alley6, Lane 485,

Sec. 1, Kuang Fu Rd.,

Hsin-Chu, Taiwan, R.O.C.

Phone: 886 (3) 5799143

Fax: 886 (3) 5799164

●HORIBA GmbH

Kaplanstrasse 5

A-3430 Tulln,

Austria

Phone: 43 (2272) 65225

Fax: 43 (2272) 65230

HORIBA SWEDEN

Hertig Carlsv¨ag 55-57

S-15138 So¨derta¨ lje

Sweden

Phone: 46 (8) 550-80701

Fax: 46 (8) 550-80567

●HORIBA KOREA L t d .

112-6 Sogong-Dong

Choong-ku, Seoul, Korea

Phone: 82 (2) 753-7911

Fax: 82 (2) 756-4972

HORIBA CZECHIA

Organizachi slozka Praha

Petrohradska 13

CZ-101 00 Praha 10, Czech Republic

Phone: 420 (2) 717-464-80

Fax: 420 (2) 717-470-64

HORIBA ITALY

Europalace

Corso Torino 43/45

10043 Orbassano,Torino,Italy

Phone: 39 (011) 9040601

Fax: 39 (011) 9000448

accuracy to

gloss evaluation.

High-efficiency and

flexibility utilizing

a separate detector

and light source offers

the ability to switch

between 60 and 20

degree measuring angles.

IG-331

CE marking compliant

Handy Digital Gloss Checkers Allow Objective,

Quantified Gloss Measurements

Designed for greater ease of operation, maintain clean surfaces and

improve quality control inspection in various industrial applications.

Guaranteeing uniform production quality and standards for gloss

mesurement. HORIBA’s IG Series Gloss Checkers display gloss

measurements as numerical data, eliminating ambiguity and ensuring

objective evaluation of a product’s quality. Compact in design and ready

when powered on, all the user needs to do is hold the portable gloss

checker against the surface being evaluated for quality control of paints,

polishes, floor maintenance and many other industrial applications.

High-Efficiency Measurements

Enables Easy Switching of

Measuring Angles (60° and 20°)

The flexible, remote connection of the probe to the display unit

ensures greater work efficiency and safety in all applications.

One-Touch Calibration

Just press the calibration key (CAL) to start

automatic, sequential zero-span calibration.

Selectable Measuring

Angle (60° or 20°)

Choose 60° for standard gloss

measurements. For high-gloss surfaces

with gloss values over 70, simply switch to

the 20° measuring angle. The selectable

angle feature makes it easy to measure

glossy surfaces.

■ Gloss Checker IG-331 Optical System

20°

20°

Power ON key

Power OFF key

High-Precision Measurements

Lets Users Gather Data or View Averages

with a Single Key Operation

The compact, lightweight design is ideal for

production line and outdoor applications.

IG-331 IG-320

Calibration key Measuring part

Hold key

Protective cap

(with standard surface for calibration)

Power ON key

Power OFF key

Mode select key

(measurement/memory)

Data delete key

Calibration key

Data input key

Up key

Average key

Down key

High-Precision Measurements

with ±0.5% Full-Scale

Reproducibility

The combination of the near infrared ray pulse

system, virtually unaffected by ambient lights or

colors, and HORIBA’s proprietary measuring

system provides a high-precision gloss checking

system compatible with JIS standards.

Gather Data or View Averages

with a Single Key Operation

Up to 99 measurements can be taken with a simple

key operation and averaged using another key. Up to

99 averages can be stored for later use. Easy data

management promises smooth inspection work.

Display of data

item No.01

Display of data

item No.99

Display of average

of all 99 data items

60°

Light

source

Sample

surface

60°

Detector

LensLens

Measured area

(6 mm x 3 mm oval) at 60° measurement

20° selection key

CE marking compliant

60° selection key

Versatile applications

●Quality control of paint and ink ●Check and diagnosis of coated surfaces ●Checking printed matter

For quality testing,

outdoor exposure testing,

hue adjustment or

luster testing.

Check external coating, cleaning or waxing

condition of vehicles, shops, aircraft, bridges,

iron/steel frames, and structures or prefabricated

structures, etc., and diagnosis

of deterioration.

Evaluation of embellishing properties

in varnishing stage (lamination,

endless processing, etc.); evaluation

of time-induced change and

uniformity of surface after

drying process; checking

paper surface condition.

of plastic molding

For checking external appearance of

molded resin

products and

evaluating weather

resistance.

Measured area

Protective cap

(with standard surface for calibration)

●Checking building and masonry finishes●Checking external appearance

Inspection of external appearance,

completed product test and site

finish test in production stage of

enamel, sash, floor materials,

stone materials, furniture, etc.

Up to 99 averages (AVERAGE No. 99) can be

■ Gloss Checker IG-320 Optical System

60°

Light

source

Sample

surface

●Floor maintenance needs

Inspection of waxed floor finishes

in hotels, office

buildings and

stores.

Lens

Measured area (6 mm x 12 mm oval)

stored by repeating two simple steps.

60°

Lens

Detector

●Other uses

For checking quality and

external appearance of film,

tape, rubber, leather, etc.

Loading...

Loading...