horiba FluoroMax-4, FluoroMax-4P Operation Manual

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

FluoroMax

FluoroMax

with USB

®

-4 &

®

-4P

Operation Manual

http://www.HORIBA.com

Rev. D

i

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

Copyright © 2011, 2012 by HORIBA Instruments Incorporated. All rights reserved. No

part of this work may be reproduced, stored, in a retrieval system, or transmitted in any

form by any means, including electronic or mechanical, photocopying and recording,

without prior written permission from HORIBA Instruments Incorporated. Requests for

permission should be requested in writing. Origin® is a registered trademark of

OriginLab Corporation. Alconox® is a registered trademark of Alconox, Inc. Ludox® is

a registered trademark of W.R. Grace and Co. Teflon® is a registered trademark of E.I.

du Pont de Nemours and Company. Windows® is a trademark of Microsoft Corporation. Uniblitz® is a registered trademark of VA, Inc.

Information in this manual is subject to change without notice, and does not represent a

commitment on the part of the vendor.

July 2012

Part Number J810005

ii

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

Table of Contents

0: Introduction ........................................................................................... 0-1

About the FluoroMax®-4 and FluoroMax®-4P .................................................................................. 0-1

Chapter overview ............................................................................................................................. 0-2

Disclaimer ......................................................................................................................................... 0-3

Safety summary ............................................................................................................................... 0-5

Risks of ultraviolet exposure ............................................................................................................ 0-7

Additional risks of xenon lamps ........................................................................................................ 0-9

CE compliance statement .............................................................................................................. 0-11

1: Requirements & Installation ........................................................................ 1-1

Safety-training requirements ............................................................................................................ 1-1

Surface requirements ....................................................................................................................... 1-2

Environmental requirements ............................................................................................................ 1-3

Electrical requirements ..................................................................................................................... 1-4

Unpacking and Installation ............................................................................................................... 1-5

Software emulation .......................................................................................................................... 1-9

2: System Description ................................................................................... 2-1

Introduction ...................................................................................................................................... 2-1

Basic theory of operation ................................................................................................................. 2-1

Optical layout.................................................................................................................................... 2-2

3: System Operation ...................................................................................... 3-1

Introduction ....................................................................................................................................... 3-1

Power switch .................................................................................................................................... 3-1

Turning on the system ...................................................................................................................... 3-2

Checking system performance ......................................................................................................... 3-3

4: Data Acquisition ....................................................................................... 4-1

Introduction to FluorEssence™ and Multigroup ............................................................................... 4-1

Experiment Menu button .................................................................................................................. 4-2

Previous Experiment Setup button .................................................................................................. 4-4

Auto Run Previous Experiment button ............................................................................................. 4-5

Make Overlay File button ................................................................................................................. 4-6

3D Scan to 3D Profile button ............................................................................................................ 4-7

Run JY Batch Experiments button ................................................................................................... 4-9

Real Time Control .......................................................................................................................... 4-11

Create/Use Calibration Curve from CWA Data .............................................................................. 4-12

2D Intensity Map ............................................................................................................................ 4-16

Launch DataStation ........................................................................................................................ 4-18

Switch menu between HJY Software Application and Origin Std. ................................................. 4-19

Multigroup ....................................................................................................................................... 4-20

Running an unknown sample ......................................................................................................... 4-23

Using corrected signals in FluorEssence™ ................................................................................... 4-28

5: Optimizing Data ....................................................................................... 5-1

Cuvette preparation .......................................................................................................................... 5-1

Sample preparation .......................................................................................................................... 5-2

Running a scan on a sample ............................................................................................................ 5-4

Measuring the G factor ..................................................................................................................... 5-5

Improving the signal-to-noise ratio ................................................................................................... 5-7

Correcting data ............................................................................................................................... 5-14

6: Maintenance ............................................................................................ 6-1

Introduction ....................................................................................................................................... 6-1

Lamp replacement ........................................................................................................................... 6-1

Electronics ...................................................................................................................................... 6-11

Updating the FluoroMax®-4 firmware ............................................................................................. 6-13

iii

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

7: Troubleshooting........................................................................................ 7-1

Chart ................................................................................................................................................. 7-1

Using diagnostic spectra .................................................................................................................. 7-4

Further assistance… ....................................................................................................................... 7-9

8: Producing Correction Factors ....................................................................... 8-1

Introduction....................................................................................................................................... 8-1

Generating emission correction factors ........................................................................................... 8-2

Calculating emission correction factors ........................................................................................... 8-3

Using correction-factor files............................................................................................................ 8-10

Excitation correction factors ........................................................................................................... 8-13

9: FluoroMax®-4P Phosphorimeter Operation ....................................................... 9-1

Introduction...................................................................................................................................... 9-1

Theory of operation .......................................................................................................................... 9-2

Applications for the phosphorimeter ................................................................................................ 9-5

Operation of the phosphorimeter .................................................................................................... 9-8

Processing phosphorimeter data ................................................................................................... 9-10

Lamp replacement ......................................................................................................................... 9-11

10: Automated Polarizers...............................................................................10-1

Introduction..................................................................................................................................... 10-1

Installation ...................................................................................................................................... 10-5

Alignment ....................................................................................................................................... 10-6

Using automated polarizers ......................................................................................................... 10-13

Maintenance ................................................................................................................................. 10-18

Troubleshooting ........................................................................................................................... 10-19

11: Technical Specifications ..........................................................................11-1

Introduction..................................................................................................................................... 11-1

Spectrofluorometer system ............................................................................................................ 11-2

Minimum host-computer requirements .......................................................................................... 11-4

Software ......................................................................................................................................... 11-4

12: Components & Accessories .......................................................................12-1

Itemized list of FluoroMax®-4 accessories ..................................................................................... 12-2

FL-1013 Liquid Nitrogen Dewar Assembly .................................................................................... 12-3

Sample cells ................................................................................................................................... 12-4

F-3026 Correction Factor Kit .......................................................................................................... 12-6

F-3023 Janis cryostat ..................................................................................................................... 12-7

F4-3000 Fiber Optic Mount and 1950 Fiber Optic Bundles ........................................................... 12-8

1939 Cut-On Filter .......................................................................................................................... 12-9

FM-2008 Cut-On Filter Holder...................................................................................................... 12-10

FL4-1011 Four-Position Thermostatted Cell Holder .................................................................... 12-11

FL4-1012 Dual-Position Thermostatted Cell Holder .................................................................... 12-13

FL4-1027 Single-Position Thermostatted Cell Holder ................................................................. 12-15

J1933 Solid Sample Holder.......................................................................................................... 12-17

F-3005/6 Autotitration Injector ...................................................................................................... 12-19

1905-OFR 150-W Xenon Lamp ................................................................................................... 12-20

F-3004 Sample Heater/Cooler Peltier Thermocouple Drive ........................................................ 12-21

MicroMax 384 Microwell Plate Reader ........................................................................................ 12-22

FM4-2000 L-Format Polarizer ...................................................................................................... 12-23

FL4-1015 Injector Port ................................................................................................................. 12-24

F-3029 Quanta-φ accessory ........................................................................................................ 12-25

FM-2002 Shutter accessory ......................................................................................................... 12-26

F-3025 Stopped-flow accessory ................................................................................................. 12-27

FM4-2015 and FM4-2016 TCSPC upgrade ................................................................................. 12-28

F4-3030 Temperature Bath .......................................................................................................... 12-29

F-3031 Transmission Accessory .................................................................................................. 12-30

J400981 Trigger Cable ................................................................................................................. 12-31

FM-2007 Windows for the FluoroMax®-4 sample compartment .................................................. 12-32

13: Glossary ............................................................................................. 13-1

iv

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

14: Bibliography .........................................................................................14-1

15: Compliance Information ...........................................................................15-1

Declaration of Conformity ............................................................................................................... 15-1

Supplementary Information ............................................................................................................ 15-1

16: Index ..................................................................................................16-1

v

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012)

vi

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Note:

Keep this and the other reference manuals near the system.

0: Introduction

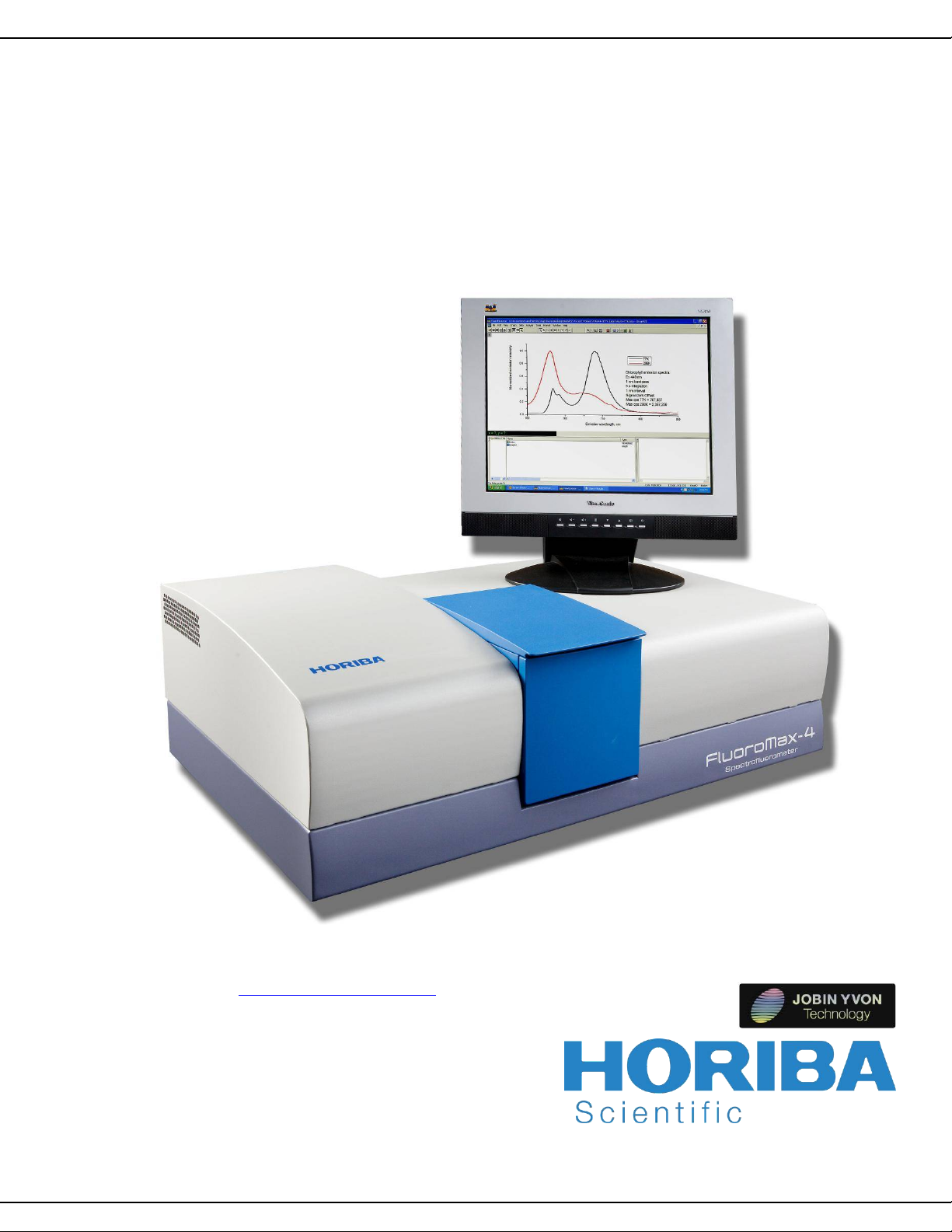

About the FluoroMax®-4 and FluoroMax®4P

Both the FluoroMax®-4 and FluoroMax®-4P are self-contained, fully automated

spectrofluorometer systems. Data output is viewed on a PC, while printouts may be obtained via an optional plotter or printer. All FluoroMax®-4 and FluoroMax®-4P functions are under the control of FluorEssence™ spectroscopy software. The main parts of

the FluoroMax®-4 and FluoroMax®-4P spectrofluorometer systems are:

State-of-the-art optical components

A personal computer

FluorEssence™ for Windows®, the driving software.

The difference between the FluoroMax®-4 and FluoroMax®-4P is that the FluoroMax®4P contains a phosphorimeter for phosphorescence measurements. This manual explains how to operate and maintain a FluoroMax®-4 and FluoroMax®-4P

spectrofluorometer. The manual also describes measurements and tests essential to obtain accurate data. For a complete discussion of the almost limitless power provided by

FluorEssence™, refer to the FluorEssence™ User’s Guide (especially regarding soft-

ware installation) and the on-line help for Origin® and FluorEssence™, which accompany the system.

0-1

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

1: Requirements & Installation

Power and environmental requirements; select the best spot

for the instrument.

2: System Description

How the FluoroMax®-4 and -4P work.

3: System Operation

Operation of the spectrofluorometer system, and calibration

instructions.

4: Data Acquisition

How to use the special FluorEssence™ buttons to acquire

and plot data; how to determine peaks in an unknown sample.

5: Optimizing Data

Hints for improving the signal-to-noise ratio, instructions

for obtaining corrected data, and other information useful

for optimizing data and ensuring reproducibility.

6: Maintenance

Routine maintenance procedures such as replacing the lamp.

7: Troubleshooting

Potential sources of problems, their most probable causes,

and possible solutions.

8: Producing Correction Factors

How to correct for variation in the system’s sensitivity

across the spectral range.

9: FluoroMax®-4P

Phosphorimeter Operation

Theory, operation, applications, and troubleshooting of the

phosphorimeter, available only on the FluoroMax®-4P system.

10: Automated Polarizers

Installation, operation, and troubleshooting of the optional

automated polarizers.

11: Technical Specifications

Instrument specifications and computer requirements.

12: Components & Accessories

Accessories available for the FluoroMax®-4, and how to use

them.

13: Glossary

Some useful technical terms related to fluorescence spectroscopy.

14: Bibliography

Other important sources of information.

15: Declaration of Conformity

16: Index

Chapter overview

0-2

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Disclaimer

By setting up or starting to use any HORIBA Instruments Incorporated product, you are

accepting the following terms:

You are responsible for understanding the information contained in this document. You

should not rely on this information as absolute or all-encompassing; there may be local

issues (in your environment) not addressed in this document that you may need to address, and there may be issues or procedures discussed that may not apply to your situation.

If you do not follow the instructions or procedures contained in this document, you are

responsible for yourself and your actions and all resulting consequences. If you rely on

the information contained in this document, you are responsible for:

Adhering to safety procedures

Following all precautions

Referring to additional safety documentation, such as Material Safety Data Sheets

(MSDS), when advised

As a condition of purchase, you agree to use safe operating procedures in the use of all

products supplied by HORIBA Instruments Incorporated, including those specified in

the MSDS provided with any chemicals and all warning and cautionary notices, and to

use all safety devices and guards when operating equipment. You agree to indemnify

and hold HORIBA Instruments Incorporated harmless from any liability or obligation

arising from your use or misuse of any such products, including, without limitation, to

persons injured directly or indirectly in connection with your use or operation of the

products. The foregoing indemnification shall in no event be deemed to have expanded

HORIBA Instruments Incorporated’s liability for the products.

HORIBA Instruments Incorporated products are not intended for any general cosmetic,

drug, food, or household application, but may be used for analytical measurements or

research in these fields. A condition of HORIBA Instruments Incorporated’s acceptance of a purchase order is that only qualified individuals, trained and familiar with

procedures suitable for the products ordered, will handle them. Training and maintenance procedures may be purchased from HORIBA Instruments Incorporated at an additional cost. HORIBA Instruments Incorporated cannot be held responsible for actions

your employer or contractor may take without proper training.

Due to HORIBA Instruments Incorporated’s efforts to continuously improve our products, all specifications, dimensions, internal workings, and operating procedures are

subject to change without notice. All specifications and measurements are approximate,

based on a standard configuration; results may vary with the application and environment. Any software manufactured by HORIBA Instruments Incorporated is also under

constant development and subject to change without notice.

Any warranties and remedies with respect to our products are limited to those provided

in writing as to a particular product. In no event shall HORIBA Instruments Incorpo-

0-3

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

rated be held liable for any special, incidental, indirect or consequential damages of any

kind, or any damages whatsoever resulting from loss of use, loss of data, or loss of

profits, arising out of or in connection with our products or the use or possession thereof. HORIBA Instruments Incorporated is also in no event liable for damages on any

theory of liability arising out of, or in connection with, the use or performance of our

hardware or software, regardless of whether you have been advised of the possibility of

damage.

0-4

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or similar that, if incorrectly performed or adhered to,

could result in personal injury or death. Do not

proceed beyond a WARNING notice until the indicated conditions are fully understood and met.

HORIBA Instruments Incorporated is not responsible for damage arising out of improper use of the

equipment.

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or similar that, if incorrectly performed or adhered to,

could result in damage to the product. Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

HORIBA Instruments Incorporated is not responsible for damage arising out of improper use of the

equipment.

Ultraviolet light! Wear protective goggles, fullface shield, skin-protection clothing, and UVblocking gloves. Do not stare into light.

Intense ultraviolet, visible, or infrared light! Wear

light-protective goggles, full-face shield, skinprotection clothing, and light-blocking gloves. Do

not stare into light.

Extreme cold! Cryogenic materials must always be

handled with care. Wear protective goggles, fullface shield, skin-protection clothing, and insulated

gloves.

Explosion hazard! Wear explosion-proof goggles,

full-face shield, skin-protection clothing, and protective gloves.

Caution:

Caution:

Caution:

Caution:

Caution:

Warning:

Safety summary

The following general safety precautions must be observed during all phases of operation of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture and intended use of instrument. HORIBA Instruments Incorporated assumes no liability for

the customer’s failure to comply with these requirements. Certain symbols are used

throughout the text for special conditions when operating the instruments:

0-5

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Risk of electric shock! This symbol warns the user

that un-insulated voltage within the unit may have

sufficient magnitude to cause electric shock.

Danger to fingers! This symbol warns the user that

the equipment is heavy, and can crush or injure the

hand if precautions are not taken.

This symbol cautions the user that excessive humidity, if present, can damage certain equipment.

Hot! This symbol warns the user that hot equipment may be present, and could create a risk of

fire or burns.

Read this manual before using or servicing the instrument.

Wear protective gloves.

Wear appropriate safety goggles to protect the

eyes.

Wear an appropriate face-shield to protect the

face.

General information is given concerning operation

of the equipment.

Note:

Caution:

Caution:

Caution:

Caution:

0-6

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Caution:

This instrument is used in conjunction with ultraviolet light. Exposure to these radiations, even reflected

or diffused, can result in serious, and sometimes irreversible, eye and skin injuries.

Overexposure to ultraviolet rays threatens human health

by causing:

Immediate painful sunburn

Skin cancer

Eye damage

Immune-system suppression

Premature aging

Risks of ultraviolet exposure

Do not aim the UV light at anyone.

Do not look directly into the light.

Always wear protective goggles, full-face shield and skin protection

clothing and gloves when using the light source.

Light is subdivided into visible light, ranging from 400 nm (violet) to 700 nm (red);

longer infrared, “above red” or > 700nm, also called heat; and shorter ultraviolet

radiation (UVR), “below violet” or < 400nm. UVR is further subdivided into UV-A

or near-UV (320–400 nm), also called black (invisible) light; UV-B or mid-UV

(290–320 nm), which is more skin penetrating; and UV-C or far-UV (< 290 nm).

Health effects of exposure to UV light are familiar to anyone who has had sunburn.

However, the UV light level around some UV equipment greatly exceeds the level

found in nature. Acute (short-term) effects include redness or ulceration of the skin.

At high levels of exposure, these burns can be serious. For chronic exposures, there

is also a cumulative risk of harm. This risk depends upon the amount of exposure

during your lifetime. The long-term risks for large cumulative exposure include

premature aging of the skin, wrinkles and, most seriously, skin cancer and cataract.

Damage to vision is likely following exposure to high-intensity UV radiation. In

adults, more than 99% of UV radiation is absorbed by the anterior structures of the

eye. UVR can contribute to the development of age-related cataract, pterygium,

photodermatitis, and cancer of the skin around the eye. It may also contribute to

age-related macular degeneration. Like the skin, the covering of the eye or the cornea, is epithelial tissue. The danger to the eye is enhanced by the fact that light can

enter from all angles around the eye and not only in the direction of vision. This is

especially true while working in a dark environment, as the pupil is wide open. The

0-7

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Caution:

UV exposures are not immediately felt. The user may not realize the hazard until it is too late and the

damage is done.

lens can also be damaged, but because the cornea acts as a filter, the chances are reduced. This should not lessen the concern over lens damage however, because cataracts are the direct result of lens damage.

Burns to the eyes are usually more painful and serious than a burn to the skin. Make

sure your eye protection is appropriate for this work. NORMAL EYEGLASSES OR

CONTACTS OFFER VERY LIMITED PROTECTION!

Training

For the use of UV sources, new users must be trained by another member of the laboratory who, in the opinion of the member of staff in charge of the department, is sufficiently competent to give instruction on the correct procedure. Newly trained users

should be overseen for some time by a competent person.

0-8

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

Warning:

Xenon lamps

are dangerous.

Please read the following precautions.

Additional risks of xenon lamps

Among the dangers associated with xenon lamps

are:

Burns caused by contact with a hot xenon lamp.

Fire ignited by hot xenon lamp.

Interaction of other nearby chemicals with intense ultraviolet, visible, or infrared

radiation.

Damage caused to apparatus placed close to the xenon lamp.

Explosion or mechanical failure of the xenon lamp.

Visible radiation

Any very bright visible light source will cause a human aversion response: we either

blink or turn our head away. Although we may see a retinal afterimage (which can last

for several minutes), the aversion response time (about 0.25 seconds) normally protects

our vision. This aversion response should be trusted and obeyed. NEVER STARE AT

ANY BRIGHT LIGHT-SOURCE FOR AN EXTENDED PERIOD. Overriding the

aversion response by forcing yourself to look at a bright light-source may result in permanent injury to the retina. This type of injury can occur during a single prolonged exposure. Excessive exposure to visible light can result in skin and eye damage.

Visible light sources that are not bright enough to cause retinal burns are not necessarily safe to view for an extended period. In fact, any sufficiently bright visible light

source viewed for an extended period will eventually cause degradation of both night

and color vision. Appropriate protective filters are needed for any light source that

causes viewing discomfort when viewed for an extended period of time. For these reasons, prolonged viewing of bright light sources should be limited by the use of appropriate filters.

The blue-light wavelengths (400–500 nm) present a unique hazard to the retina by

causing photochemical effects similar to those found in UV-radiation exposure.

Infrared radiation

Infrared (or heat) radiation is defined as having a wavelength between 780 nm and 1

mm. Specific biological effectiveness “bands” have been defined by the CIE (Commission Internationale de l’Eclairage or International Commission on Illumination) as follows:

• IR-A (near IR) (780–1400 nm)

• IR-B (mid IR) (1400–3000 nm)

• IR-C (far IR) (3000 nm–1 mm)

0-9

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

The skin and eyes absorb infrared radiation (IR) as heat. Workers normally notice excessive exposure through heat sensation and pain. Infrared radiation in the IR-A that

enters the human eye will reach (and can be focused upon) the sensitive cells of the retina. For high irradiance sources in the IR-A, the retina is the part of the eye that is at

risk. For sources in the IR-B and IR-C, both the skin and the cornea may be at risk from

“flash burns.” In addition, the heat deposited in the cornea may be conducted to the lens

of the eye. This heating of the lens is believed to be the cause of so called “glassblowers’ ” cataracts because the heat transfer may cause clouding of the lens.

Retinal IR Hazards (780 to 1400 nm): possible retinal lesions from acute high irra-

diance exposures to small dimension sources.

Lens IR Hazards (1400 to 1900 nm): possible cataract induction from chronic lower

irradiance exposures.

Corneal IR Hazards (1900 nm to 1 mm): possible flashburns from acute high irradi-

ance exposures.

Who is likely to be injured? The user and anyone exposed to the radiation or xenon

lamp shards as a result of faulty procedures. Injuries may be slight to severe.

0-10

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

CE compliance statement

The FluoroMax®-4 spectrofluorometer is tested for compliance with both the EMC Directive 89/336/EEC and the Low Voltage Directive for Safety 73/23/EEC, and bears

the international CE mark as indication of this compliance. HORIBA Instruments Incorporated guarantees the product line’s CE compliance only when original HORIBA

Instruments Incorporated supplied parts are used. Chapter 15 herein provides a table of

all CE Compliance tests and standards used to qualify this product.

0-11

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Introduction

0-12

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

1: Requirements & Installation

Safety-training requirements

Every user of the FluoroMax®-4 and FluoroMax®-4P must know general and specific

safety procedures before operating the instrument. For example, proper training includes (but is not limited to):

Understanding the risks of exposure to ultraviolet, visible, and infrared light, and

how to avoid unsafe exposures to these types of radiation

Handling xenon-lamp bulbs, and their dangers

Safe handling for all chemicals and other samples used in the instrument

Safety-training may be purchased from HORIBA Scientific. Contact your Sales Representative or the Service Department for details.

1-1

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Surface requirements

A sturdy table- or bench-top

Surface must hold 90 kg (200 lbs.).

Surface should be about 27″ × 72″ (69 cm × 183 cm) to hold spectrofluorometer, com-

puter, and accessories comfortably.

Overhead clearance should be at least 36" (91 cm).

1-2

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Caution:

For adequate cooling, do not cover, block,

or obstruct the vents on the left side and underside

of the instrument.

Caution:

Excessive humidity can damage the optics.

Environmental requirements

Temperature 59–86°F (15–30°C)

Maximum temperature fluctuation ± 2°C

Ambient relative humidity < 75%

Low dust levels

No special ventilation

1-3

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Caution:

HORIBA Scientific is not liable for damage

from line surges and voltage fluctuations. A surge

protector is strongly recommended for minor power fluctuations. For more severe voltage variations, use a generator or uninterruptible power

supply. Improper line voltages can damage the

equipment severely.

Warning:

The FluoroMax®-4 is equipped with a

three-conductor power cord that is connected to

the system frame (earth) ground. This ground

provides a return path for fault current from

equipment malfunction or external faults. For all

instruments, ground continuity is required for safe

operation. Any discontinuity in the ground line can

make the instrument unsafe for use. Do not op-

erate this system from an ungrounded source.

Note:

HORIBA Scientific recommends connecting the host computer, monitor, and printer to a single surge-protector, to make

start-up more convenient, and to conserve AC outlets. Connect

the FluoroMax®-4 to a separate line, if possible, to isolate the

xenon-lamp power supply inside the FluoroMax®-4.

Electrical requirements

The FluoroMax®-4 operates from universal AC single-phase input power over the

range of 85 to 250 V AC with a line frequency of 50 to 60 Hz. This AC input power is

applied to a two-pole fusing power entry module located on the side of the instrument.

This module incorporates two 5 × 20 mm IEC approved, 4.0 A, 250 V, Time Delay

fuses (Cooper Bussman part number GDC-4A or equivalent) to protect against line disturbances or anomalies outside the system’s normal operating range.

Have enough outlets available for:

Host computer (PC)

Monitor

Optional printer

FluoroMax®-4

Each of certain accessories, such the MicroMax, temperature bath, etc.

1-4

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Caution:

The spectrofluorometer system is a delicate

instrument. Mishandling may seriously damage its

components.

Quantity

Item

Part number

1

FluoroMax®-4

1 USB cable

J980087

1

FluoroMax®-4 Operation Manual

J810005

1

Set of Allen wrenches (Allen keys)

J53057

1

Single-cell sample-holder

J351697

1

Power cord (110 V)

(220 V)

J98015

J98020

1

FluorEssence™ software package

Note:

Many public carriers will not recognize a claim for concealed

damage if it is reported later than 15 days after delivery. In case of a

claim, inspection by an agent of the carrier is required. For this reason, the original packing material should be retained as evidence of

alleged mishandling or abuse. While HORIBA Jobin Yvon Inc. assumes no responsibility for damage occurring during transit, the company will make every effort to aid and advise.

Unpacking and installation

Introduction

The FluoroMax®-4 spectrofluorometer system is delivered in a single packing carton. If

a host computer (PC) is ordered as a part of the system, the PC is delivered in a few

clearly labeled boxes. All accessories, cables, software, and manuals ordered with the

system are included with the delivery.

Examine the shipping boxes carefully. Any evidence of damage should be noted on the

delivery receipt and signed by representatives of the receiving and carrier companies.

Once a location has been chosen, unpack and assemble the equipment as described below. To avoid excessive moving and handling, the equipment should be unpacked as

close as possible to the selected location.

FluoroMax®-4 carton contents

1-5

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

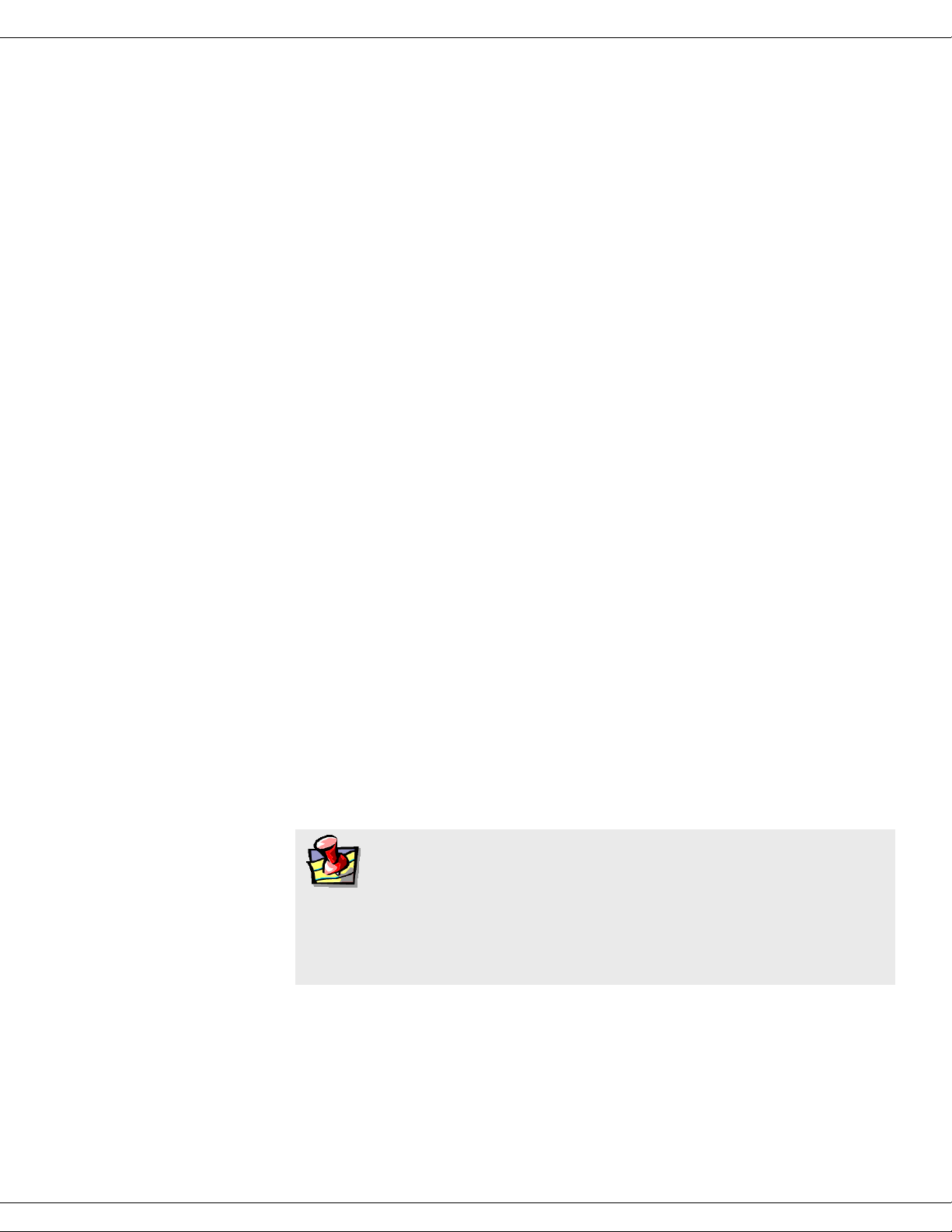

Caution:

Watch your fingers!

Directions

1 Unpack and set up the FluoroMax

a Carefully open the FluoroMax

b Remove the foam-injected top piece and any other shipping restraints in

the carton.

c With assistance, carefully lift the instrument from the carton, and rest it

on the side of the laboratory bench where the system will stay.

d Place the instrument in its permanent location.

e Level the spectrofluorometer.

Adjust the four leveling feet on the bottom of the instrument.

f Inspect for previously hidden damage.

Notify the carrier and HORIBA Scientific if any is found.

g Check the packing list to verify that all components and accessories are

present.

®

-4 shipping carton.

®

.

h Plug one end of the power cord into the proper receptacle on the right

side (while facing the unit) of the spectrofluorometer.

i Plug one end of the USB cable

into the USB receptacle.

j With an optional trigger

accessory, plug one end of the

trigger cable into the TRIGGER

connector on the FluoroMax®-4.

Allow the unconnected ends of

the cables to dangle freely; they

will be connected in later steps.

2 Set up the computer.

The information gathered by the

spectrofluorometer system is displayed

and controlled through the host PC via

FluorEssence™ software. The host PC

1-6

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Note:

Be sure to agree to the terms of the software license before using the software.

A USB dongle is supplied with FluorEssence™. This dongle

(license) must be connected to the host PC before

FluorEssence™ will operate.

may be purchased from HORIBA Scientific or another supplier.

a Set up the host PC reasonably close to the FluoroMax

limitation is the length of the USB cable. The recommended location for

the PC is just to the right of the spectrofluorometer, but other positions

are possible.

®

-4 system. The

b Follow the instructions for the host PC to set up the computer system,

including the CPU, monitor, keyboard, mouse, speakers, printers, etc.

3 Connect the FluoroMax

®

to the computer.

a Attach the free end of the USB cable to a USB receptacle on the host

computer.

b With all devices OFF, plug the power cords from the monitor, computer,

FluoroMax®, and the printer into properly grounded (earthed)

receptacles.

c Install any accessories that arrived with the system, using the

instructions that accompany the accessories.

See Chapter 12 for a detailed list of accessories.

4 Install the FluorEssence™ software.

The spectrofluorometer system is controlled by FluorEssence™ spectroscopy

software operating within the Windows® environment. If the computer and

software were purchased from HORIBA Scientific, the software installation is

complete. If the computer is not from HORIBA Scientific, perform the installation. Contact a HORIBA Scientific Sales Representative for recommended

specifications for a suitable host computer.

Before the FluorEssence™ software can be installed, however, Windows® must

be installed already and operating properly. Refer to the Windows® manual that

came with the computer for installation instructions.

The FluorEssence™ software is supplied on one CD-ROM. Follow the

FluorEssence™ User’s Guide for details on installation.

Users outside of the USA:

Users outside of the USA receive a softkey device that connects to the printer port of

the host computer for software security. The softkey should be left in place on the host

computer at all times.

1-7

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Note:

Copying, disassembly, or removal of the softkey is illegal.

1-8

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

Note:

Be sure the FluorEssence™ USB key is inserted into a

free USB port on the host computer. Without the key,

FluorEssence™ will not run properly, even in emulation mode.

Software emulation

Emulating the FluorEssence™ software means letting the computer act as though the

FluoroMax® is properly connected, even if it isn’t.

1 Disconnect the communications cable from the

host computer to the FluoroMax®.

2 Double-click the FluorEssence icon to

start FluorEssence™.

The main FluorEssence window opens:

3 Click the Experiment Menu button to open a

hardware configuration.

1-9

FluoroMax®-4 & FluoroMax®-4P with USB rev. D (30 Jul 2012) Requirements & Installation

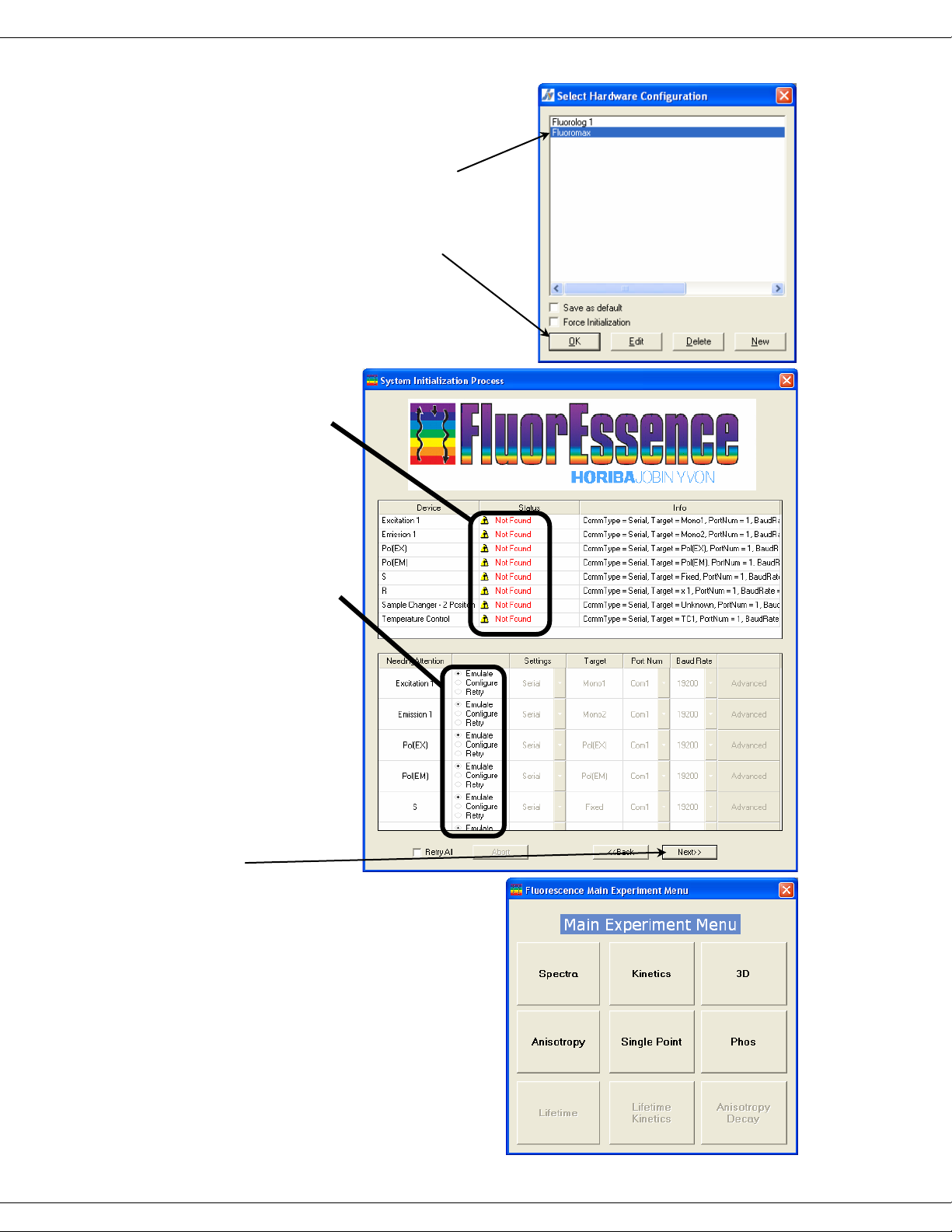

The Select Hardware Configuration window opens.

4 Choose the desired in-

strument you wish to

emulate.

5 Click the OK button.

The System Initialization Process window

opens:

Under the Status

column, warning

symbols appear for

the hardware devices, noting that they

were Not Found.

Thus

FluorEssence™

chooses the Emu-

late radio button as

the default action

for each device.

6 Click the

Next>> button.

The Fluorescence Main Experiment

Menu appears. FluorEssence™ is now

emulating the instrument.

1-10

Loading...

Loading...