Hoover Nextra Instruction Manual

Instruction Book

®

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Delivery information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Do’s and Don’ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking the Product. . . . . . . . . . . . . . . . . . . . . . . . 4

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Choose a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electricity supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connecting to the cold water supply . . . . . . . . . . . . . . . . . . . . 8

Connection of the machine to the drain . . . . . . . . . . . . . . . . . 9

Moving the machine into position . . . . . . . . . . . . . . . . . . . . . 10

Adjusting the feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Testing the installation . . . . . . . . . . . . . . . . . . . . . . 11

Washing and Drying advice . . . . . . . . . . . . . . . . . 12

Loading your washing machine . . . . . . . . . . . . . . . . . . . . . . . 12

Sorting the laundry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

The Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Detergent dosage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dispensing instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wash and Dry Options . . . . . . . . . . . . . . . . . . . . . . . 18

Automatic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Programme Selector . . . . . . . . . . . . . . . . . . . . . . . . . 21

Special Programmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Daily Programmes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Programme Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

A Typical Wash and Dry Cycle . . . . . . . . . . . . . . . 24

Selecting the programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Starting the cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning and Routine Maintenance . . . . . . . . 26

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Your Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hoovercare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2

Introduction

Please read and follow these instructions carefully and operate the machine accordingly. This booklet provides important guidelines for safe use, installation, maintenance and some useful advice for best results when using your machine.

Keep all documentation in a safe place for future reference or for any future owners.

Delivery information

Please check that the following items are delivered with the appliance:

●Instruction manual

●Guarantee card

●Blanking plug

●Inlet hose & hooked end support (see Unpacking and Installation Instructions)

●Base panel & x2 push clips

●Energy Label

Do’s

●All packaging materials used are environmentally-friendly and recyclable. Please help dispose of the packaging via environmentally-friendly means. Your local council will be able to give you details of current means of disposal.

●To ensure safety when disposing of an old washing machine disconnect the mains plug from the socket, cut the mains power cable and destroy this together with the plug. To prevent children shutting themselves in the machine break the door hinges or the door lock.

●This machine is solely for domestic use, i.e. to wash, rinse and spin dry household textiles and garments.

Don’ts

●Do not touch the appliance when hands or feet are damp or wet.

●Do not lean on the door when loading the machine or use the door to lift or move the machine.

●Do not use adapters, multiple connectors and or extensions.

●Do not allow children to play with the machine or its controls.

●Do not try to open the door when water is visible in the drum or the door locked indicator is ON.

Check that no damage has occurred to the machine during transit. If it has, call for service by GIAS.

Call 08705 400 600

PLEASE NOTE

This machine only requires a cold water supply

If the appliance is not running properly or breaks down, switch it off, disconnect the plug from the socket, turn off the water supply and do not tamper with the appliance.

Consult GIAS Service for assistance.

Call 08705 400 600

Failure to comply with the above can compromise the safety of the appliance. You may be charged for a service call if a problem with your machine is caused by misuse.

3

Unpacking the product

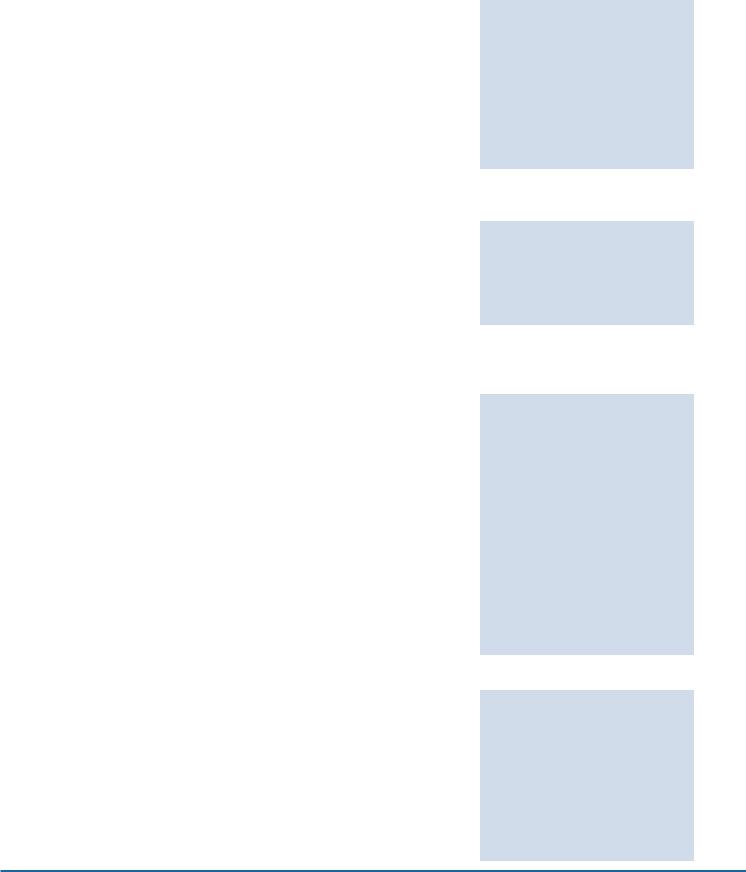

Remove the machine from its packaging close to the final location of the machine.

1.Cut carefully around the base of the packaging.

2.Lay the machine on its back and remove the base and the two polystyrene spacers on each side of the machine. We recommend that a second person assist in the lifting and manoeuvring of the machine.

Dispose of the packaging safely. Make sure it is out of the reach of children, it is a potential source of danger.

3.Return the machine to the upright position, remove the remainder of the packaging and the central screw in the transit bar.

4

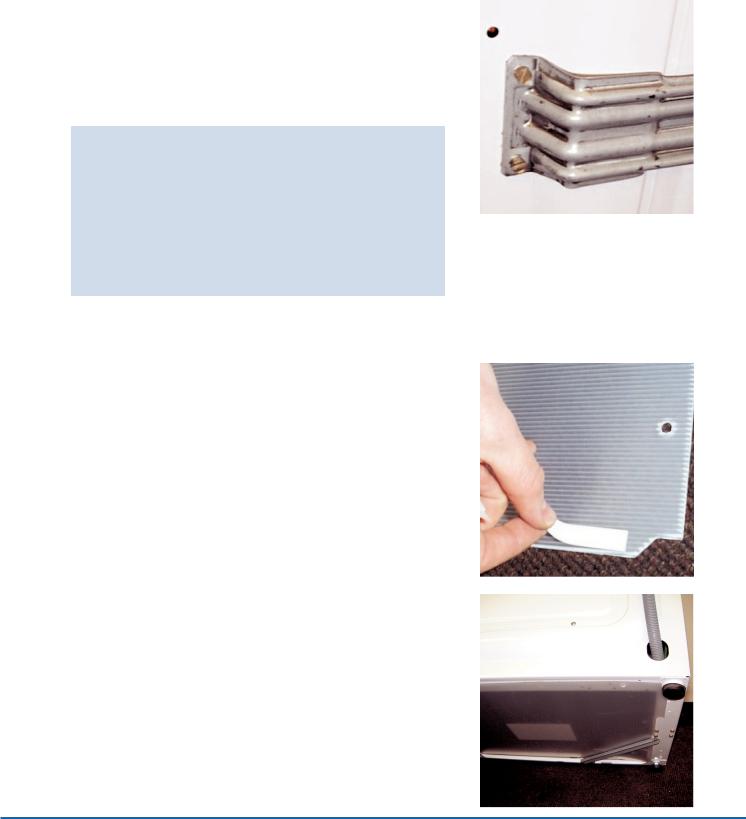

4.Remove the four retaining screws in the transit bar and pull out the transit bracket.

We recommend you keep the transit bracket and screws to protect the machine for future transit.

The manufacturers will not be responsible for any damage to the machine caused by not following the instructions relating to releasing the transit protection. The user is responsible for all installation costs.

5.Take the base panel provided and fit the two self adhesive strips by removing the backing paper on one side and locating the strips on each side of the base panel.

6.Tilt the machine forward and locate the base panel under the front of the machine. Remove the remaining backing paper from the self-adhesive strips and offer up the base panel to the bottom of the cabinet.

5

7.Take the two plastic fixing clips and fix the base panel to the base of the machine. Bring the machine back to the upright position.

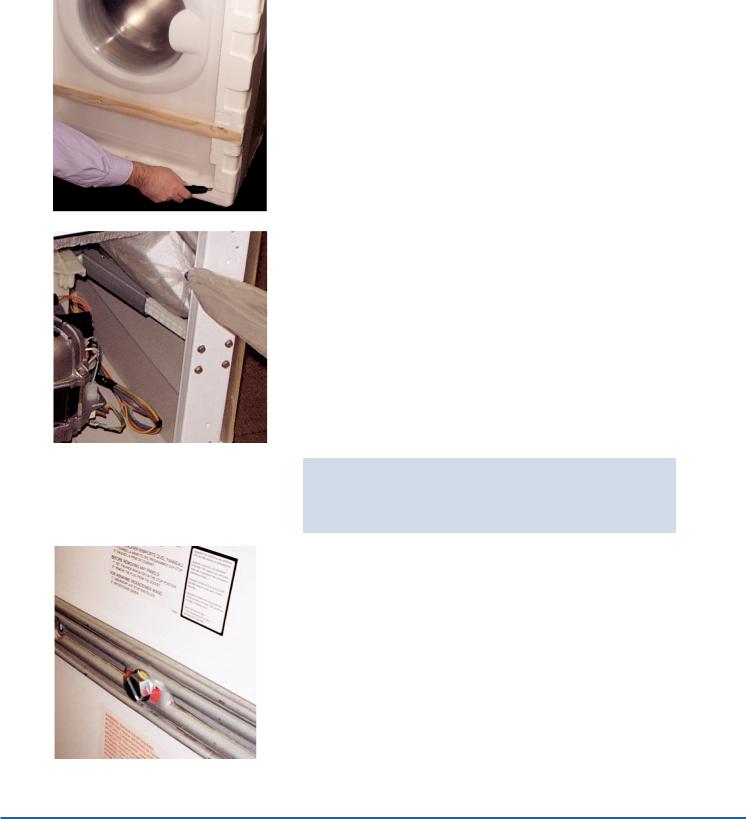

8.Cover the central hole in the rear of the machine with the cap enclosed in the instruction bag.

Installation

Do not plug the machine in and switch it on at the mains until the installation is completed.

Choose a location

●After the machine has been installed, ensure that the mains plug and water supply valves are easily accessible.

●Make sure there is enough space for the machine. Select a space at least 600mm wide and 850mm high. Also leave enough space to open the door fully so you can load and unload it easily.

●Keep the area underneath and around the machine free of combustible materials such as lint, paper, rags, chemicals etc.

6

Electricity supply

Washing machines are supplied to operate at a voltage of 230-240V, 50 Hz single phase. Check that the supply circuit is rated to at least 13A.

The plug is already equipped with a 13A fuse which is BS 1362 ASTA approved. Any replacement must be the same rating and specification. If the fuse cover is lost, do not use the plug until it is replaced.

Electricity can be extremely dangerous.

This washing machine must be earthed.

The socket outlet and the plug on the appliance must be of the same type.

Do not use multiple adapters and/or extension leads.

The wires in the mains lead are coloured in accordance with the following codes:

Blue |

NEUTRAL |

Brown |

LIVE |

Green and Yellow |

EARTH |

CE Appliance complies with European Directive 89/336/EEC, 73/23/EEC and subsequent amendments.

Water supply

●The cold water pressure should be between 0.5 and 8 bar (0.05-0.8 Mpa).

●Do not connect the machine to a single outlet instantaneous water heater.

●The water supply tap should be accessible when the machine is installed.

●Before connecting the fill hose, check that the water is running from the water supply tap to be used.

You may be charged for a service call if a problem with your machine is caused by incorrect installation.

If the mains cord on this appliance is damaged, it must be replaced by a special cord which is ONLY obtainable from the Hoover spares service. It must be installed by a competent person.

Call GIAS 01204 556111

7

This Appliance must be connected to a COLD WATER supply only.

Connecting to the cold water supply

Only one hose is required to install this machine to a cold water supply.

Cold fill is an energy efficient system. Only the water required to wash the laundry is heated. There is no loss of heat in the pipeline from the hot water tank or the boiler.

If your previous machine installation was hot and cold fill ensure that the hot tap is firmly closed to prevent leakage.

This machine has an inlet hose with a 19mm (3/4") threaded ferrule fitted to the end, to attach between the threaded connector on the appliance and the water supply.

Only use the new hose supplied to connect the machine and ensure that the sealing washers are in place inside the hose connectors.

Do not re-use old hoses which are attached to existing installations.

Do not over-tighten the connections. Hand tight is sufficient.

Do not trap or kink the hose.

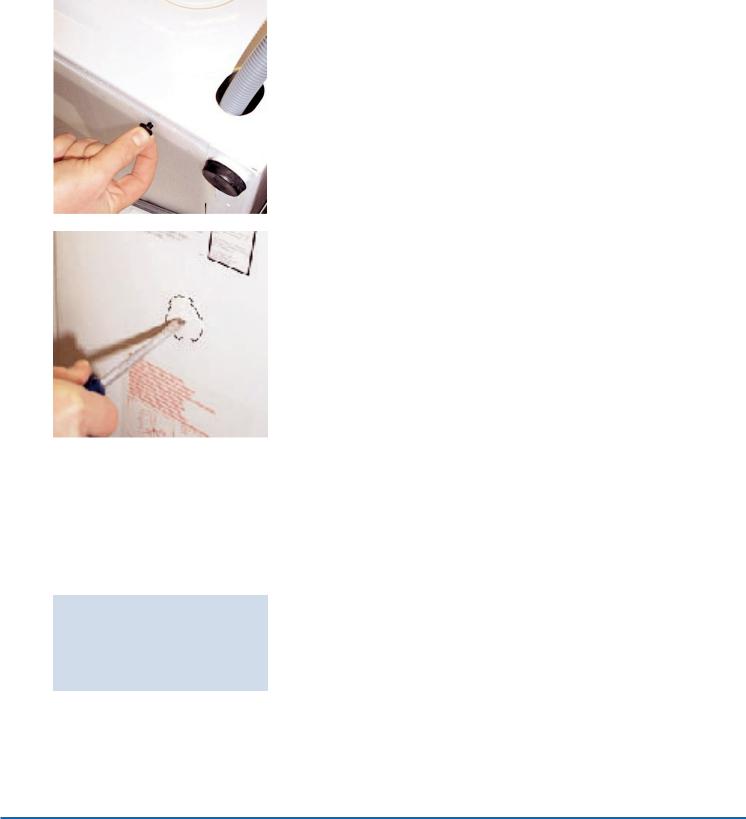

1.Connect the elbow end of the hose provided to the threaded inlet on the back of the machine.

Grey pipe to the white threaded inlet on the machine.

2.Hand tighten the connector.

3.Connect the straight ends of the pipes to the water supply; ensure that there are no kinks.

4.Turn on the water supply and check for leaks. If there is a leak, turn off the water supply, disconnect the hose and check the sealing washers are in place. Refit the hose and turn on the water supply.

8

Connection of the machine to the drain

This machine must be connected in accordance with the water supply regulations. Water byelaws prohibit connection to a surface water drain.

Decide which plumbing option suits you best then follow the instructions below.

All machines are tested with water prior to leaving the factory so a small amount of water may remain in the drum and drain hose.

Flooding could occur if any part of the installation is not completed correctly.

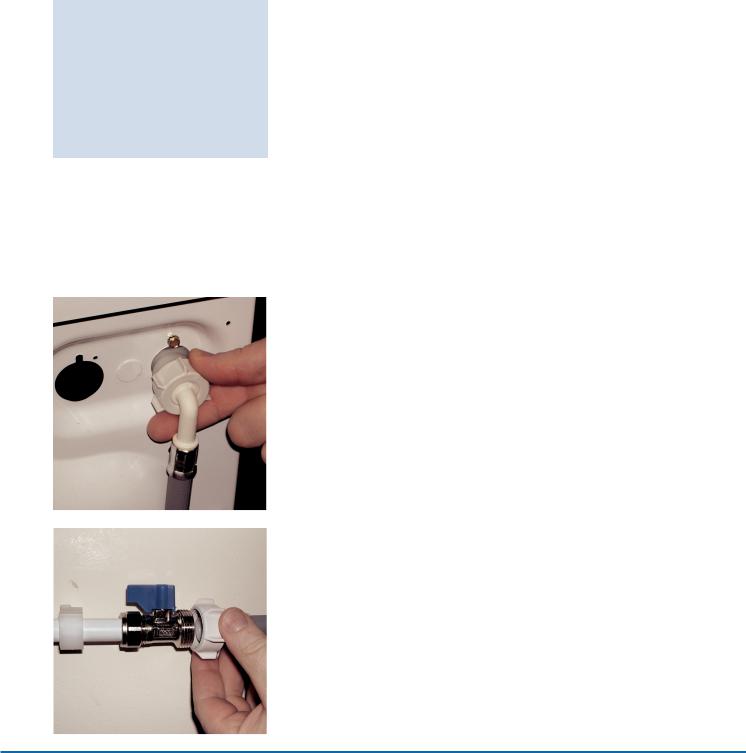

Option 1

Waste pipe connection (waste trap)

Fit the hooked end support to the outlet pipe. Position at least 800mm off the floor.

After removing the blanking plug or cutting the membrane from the waste system securely fix the outlet pipe to the drainage system, using a hose clip.

Secure the hooked end support up to at least 800mm to avoid water being drawn back into the

machine.

sink

flexible discharge hose

hose clip

800 mm

trap with hose adaptor

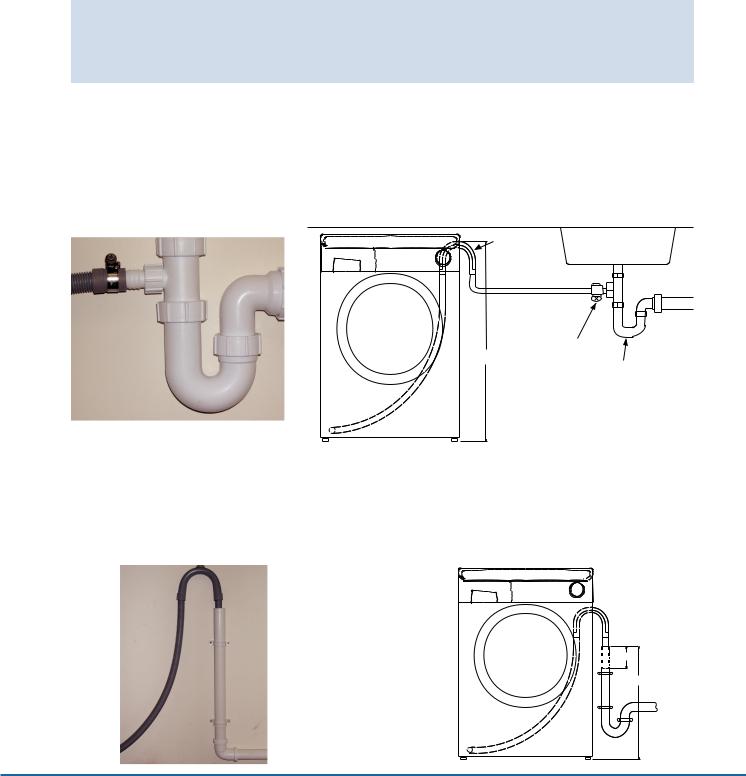

Option 2

Into a standpipe

Ensure that the standpipe (minimum diameter 38mm) is not located near an electrical socket.

Fit the hooked end support to the outlet pipe. Install the hose into the standpipe ensuring that the pipe is at least 500mm from the floor.

Insert the outlet pipe approximately 100mm into the standpipe.

100 mm

500 mm min

9

Do not drag or lift the machine by its door.

Moving the machine into position

Your machine is heavy so care must be taken when moving it. We recommend that two people move the machine to avoid strain and possible injury.

●Take care not to damage flooring when moving the machine.

●When moving the machine to its final position take care not to kink or damage the hose at the back of the machine.

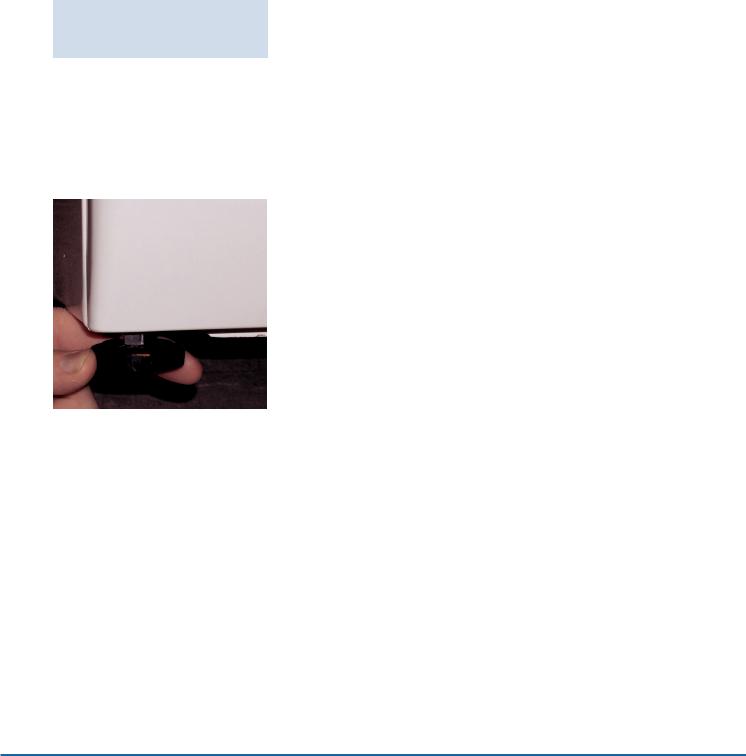

Adjusting the feet

Once the machine is in place the feet should be adjusted to ensure that the machine is level. If the machine is not level it may become noisy or move.

Adjust the feet on the front corners of the machine until the machine is firm and level.

When the machine is firm and level, tighten the locking nuts on the two feet.

10

Loading...

Loading...