Page 1

Instruction Book

HNL 9136

Washing Machine

40002168.qxd 20/10/2004 19:14 Page 1

Page 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Delivery information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Do’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Don’ts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Choose a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electricity supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting to the cold water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connection of the machine to the drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Moving the machine into position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adjusting the feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Washing advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading your washing machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sorting the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

The Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Detergent dosage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dispensing instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using Inter@ct 3D for the first time. . . . . . . . . . . . . . . . . . . . 16

The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wash Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Automatic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programme Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Special Programmes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Daily Programmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Programme Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

A Typical Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Selecting the wash programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting the wash cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning and Routine Maintenance. . . . . . . . . . . . . . . . . . . . 33

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Customer Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Your Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Hoovercare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2

40002168.qxd 20/10/2004 19:32 Page 2

Page 3

Introduction

Please read and follow these instructions

carefully and operate the machine accordingly.

This booklet provides important guidelines for

safe use, installation, maintenance and some

useful advice for best results when using your

machine.

Keep all documentation in a safe place for future

reference or for any future owners.

Delivery information

Please check that the following items are

delivered with the appliance:

● Instruction manual

● Guarantee card

● Blanking plug

● Inlet hose & hooked end support

(see Unpacking and Installation Instructions)

● Base panel & x2 push clips

● Energy Label

Do’s

● All packaging materials used are

environmentally-friendly and recyclable.

Please help dispose of the packaging via

environmentally-friendly means. Your local

council will be able to give you details of

current means of disposal.

● To ensure safety when disposing of an old

washing machine disconnect the mains plug

from the socket, cut the mains power cable

and destroy this together with the plug. To

prevent children shutting themselves in the

machine break the door hinges or the door

lock.

● This machine is solely for domestic use,

i.e. to wash, rinse and spin dry household

textiles and garments.

3

Check that no

damage has

occurred to the

machine during

transit. If it has,

call for service

by GIAS.

Call

08705 400 600

PLEASE NNOTE

This mmachine

only rrequires aa

cold wwater

supply

40002168.qxd 20/10/2004 19:14 Page 3

Page 4

Don’ts

● Do not touch the appliance when hands or

feet are damp or wet.

● Do not lean on the door when loading the

machine or use the door to lift or move the

machine.

● Do not use adapters, multiple connectors

and/or extensions.

● Do not allow children to play with the

machine or its controls.

● Do not try to open the door when water is

visible in the drum, when the wash

programme is in progress or when the

DOOR LOCKED message appears on the

display.

4

Failure to

comply with

the above can

compromise the

safety of the

appliance. You

may be charged

for a service call

if a problem

with your

machine is

caused by

misuse.

If the appliance

is not running

properly or

breaks down,

switch it off,

disconnect the

plug from the

socket, turn off

the water

supply and do

not tamper

with the

appliance.

Consult GIAS

Service for

possible repair.

Call

08705 4400 6600

40002168.qxd 20/10/2004 19:14 Page 4

Page 5

Unpacking the product

Remove the machine from its packaging close to

the final location of the machine.

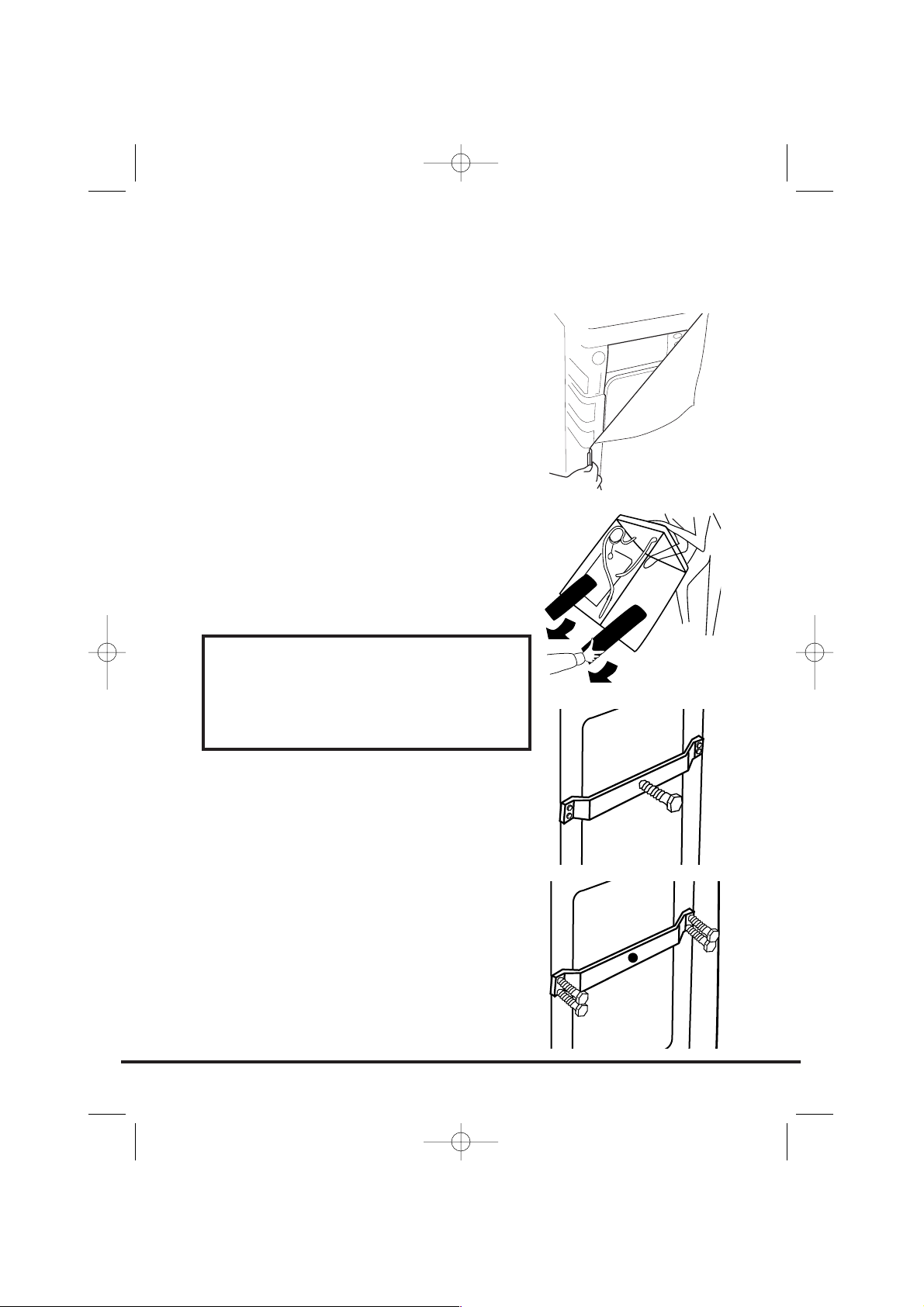

1. Cut carefully around the base of the

packaging.

2. Lay the machine on its back and remove the

base and the two polystyrene spacers on

each side of the machine. We recommend

that a second person assist in the lifting and

manoeuvring of the machine.

3. Return the machine to the upright position,

remove the remainder of the packaging and

the central screw in the transit bar.

4. Remove the four retaining screws in the

transit bar and pull out the transit bracket.

5

Dispose of the packaging safely.

Make sure it is out of the reach

of children, it is a potential

source of danger.

40002168.qxd 20/10/2004 19:14 Page 5

Page 6

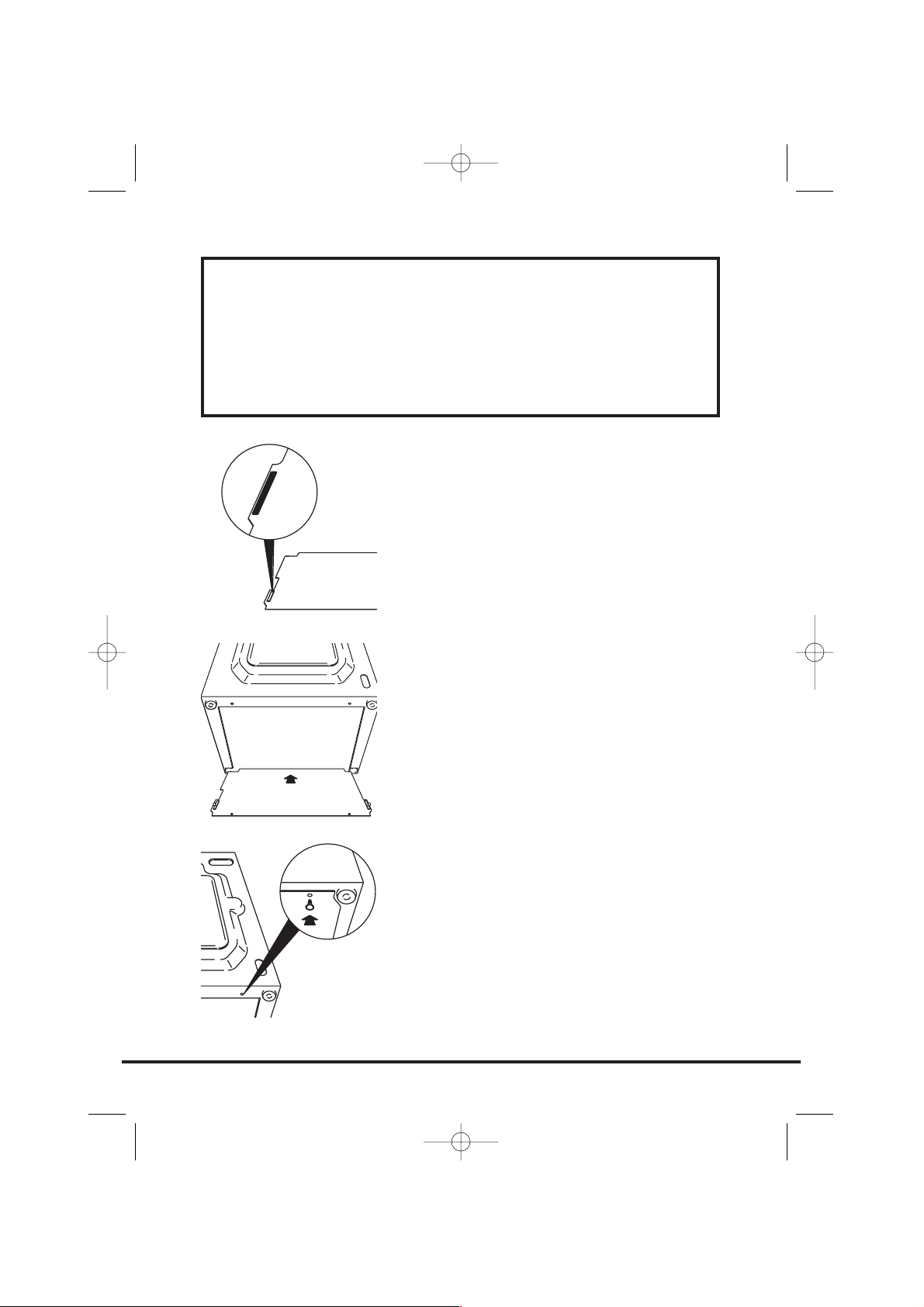

5. Take the base panel provided and fit the

two self adhesive strips by removing the

backing paper on one side and locating the

strips on each side of the base panel.

6. Tilt the machine forward and locate the

base panel under the front of the machine.

Remove the remaining backing paper from

the self-adhesive strips and offer up the

base panel to the bottom of the cabinet.

7. Take the two plastic fixing clips and fix the

base panel to the base of the machine.

Bring the machine back to the upright

position.

6

We recommend you keep the transit bracket and

screws to protect the machine for future transit.

The manufacturers will not be responsible for any

damage to the machine caused by not following the

instructions relating to releasing the transit protection.

The user is responsible for all installation costs.

40002168.qxd 20/10/2004 19:14 Page 6

Page 7

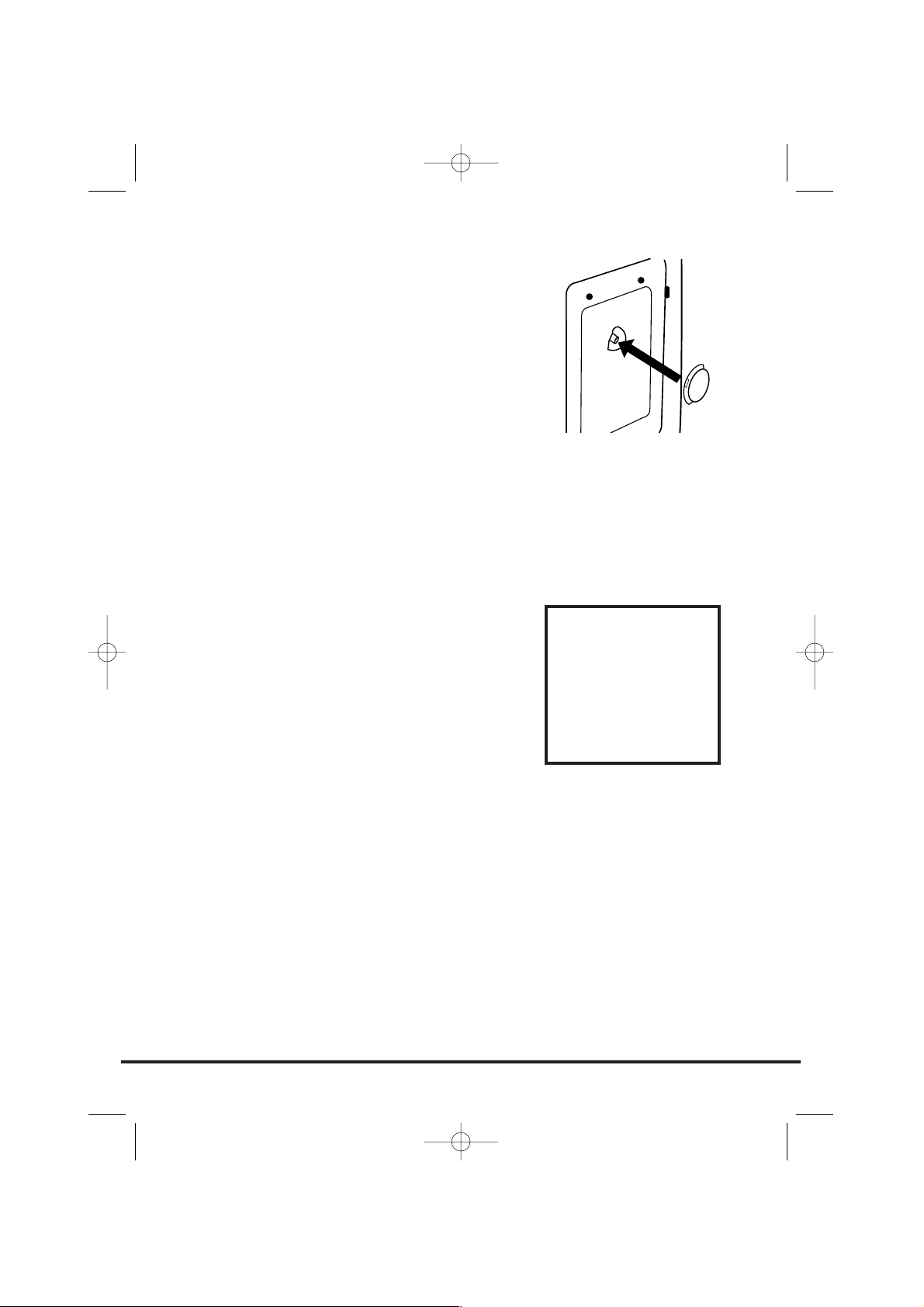

8. Cover the central hole in the rear of the

machine with the cap enclosed in the

instruction bag.

Choose a location

● After the machine has been installed, ensure

that the mains plug and water supply valves

are easily accessible.

● Make sure there is enough space for the

machine. Select a space at least 600mm wide

and 850mm high. Also leave enough space

to open the door fully so you can load and

unload it easily.

● Keep the area underneath and around the

machine free of combustible materials such

as lint, paper, rags, chemicals etc.

7

Installation

Do not plug the

machine in and

switch it on at

the mains until

the installation

is completed.

40002168.qxd 20/10/2004 19:14 Page 7

Page 8

Electricity supply

Washing machines are supplied to operate at a

voltage of 240V, 50 Hz single phase. Check that

the supply circuit is rated to at least 13A.

The plug is already equipped with a 13A fuse

which is BS 1362 ASTA approved. Any

replacement must be the same rating and

specification.

If tthe ffuse ccover iis llost, ddo nnot uuse

the pplug uuntil iit iis rreplaced.

Electricity can be extremely dangerous.

This washing machine must be earthed.

The socket outlet and the plug on the appliance

must be of the same type.

Do not use multiple adapters and/or extension

leads.

The wires in the mains lead are coloured in

accordance with the following codes:

Blue NEUTRAL

Brown LIVE

Green and Yellow EARTH

CE Appliance complies with European Directive

89/336/EEC, 73/23/EEC and subsequent

amendments.

Water supply

● The cold water pressure should be between

0.5 and 8 bar (0.05-0.8 Mpa).

● Do not connect the machine to a single

outlet instantaneous water heater.

● The water supply tap should be accessible

when the machine is installed.

● Before connecting the fill hose, check that

the water is running from the water supply

tap to be used.

8

You may be

charged for a

service call if a

problem with

your machine is

caused by

incorrect

installation.

If the mains

cord on this

appliance is

damaged, it

must be

replaced by a

special cord

which is ONLY

obtainable from

the GIAS spares

service. It must

be installed by

a competent

person.

Call GGIAS

01204 5556111

40002168.qxd 20/10/2004 19:14 Page 8

Page 9

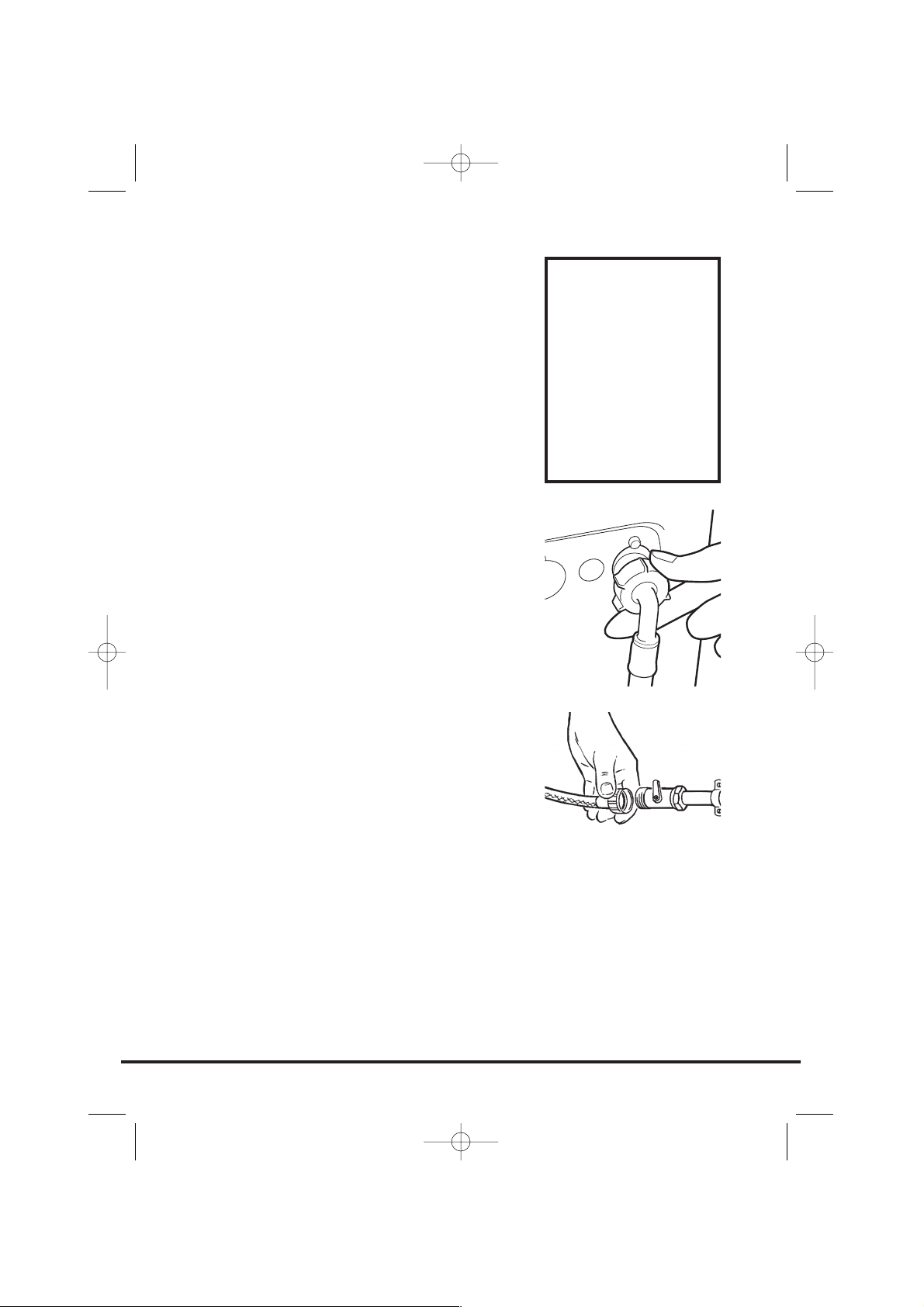

Connecting to the cold

water supply

Only one hose is required to install this machine

to a cold water supply.

Cold fill is an energy efficient system. Only the

water required to wash the laundry is heated.

There is no loss of heat in the pipeline from the

hot water tank or the boiler.

If your previous machine installation was hot and

cold fill ensure that the hot tap is firmly closed to

prevent leakage.

This machine has an inlet hose with a 19mm

(3/4") threaded ferrule fitted to the end, to

attach between the threaded connector on the

appliance and the water supply.

Only use the new hose supplied to connect the

machine and ensure that the sealing washers are

in place inside the hose connectors.

Do not re-use old hoses which are attached to

existing installations.

Do not over-tighten the connections. Hand tight

is sufficient.

Do not trap or kink the hose.

1. Connect the elbow end of the hose provided

to the threaded inlet on the back of the

machine.

Grey pipe to the white threaded inlet on

the machine.

2. Hand tighten the connector.

3. Connect the straight ends of the pipes to

the water supply; ensure that there are no

kinks.

4. Turn on the water supply and check for

leaks. If there is a leak, turn off the water

supply, disconnect the hose and check the

sealing washers are in place. Refit the hose

and turn on the water supply.

9

Thiss

Appliance

musst bbe

coonnected

too aa CCOOLD

WATER

ssupply oonly.

40002168.qxd 20/10/2004 19:14 Page 9

Page 10

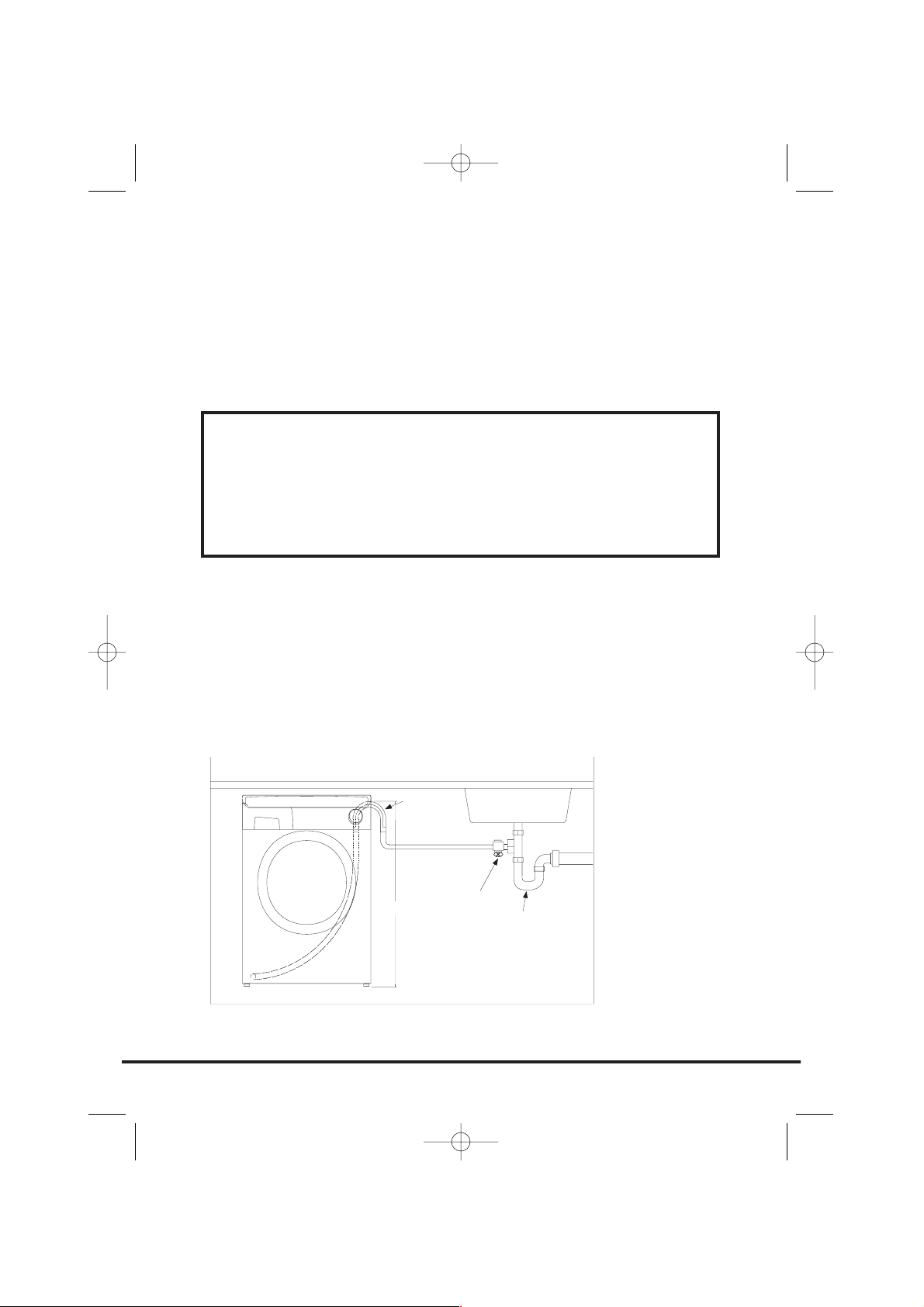

Connection of the machine to the

drain

This machine must be connected in accordance with the water supply

regulations. Water byelaws prohibit connection to a surface water drain.

Decide which plumbing option suits you best then follow the instructions

below.

Option 1

Waste pipe connection (waste trap)

Fit the hooked end support to the outlet pipe. Position at least 800mm off the

floor.

After removing the blanking plug or cutting the membrane from the waste

system securely fix the outlet pipe to the drainage system, using a hose clip.

Secure the hooked end support up to at least 800mm to avoid water being

drawn back into the machine.

10

All machines are tested with water prior to leaving the

factory so a small amount of water may remain in the

drum and drain hose.

Flooding could occur if any part of the installation is

not completed correctly.

800 mm

hose clip

hooked end support

sink

flexible

discharge hose

trap with hose

adaptor

40002168.qxd 20/10/2004 19:14 Page 10

Page 11

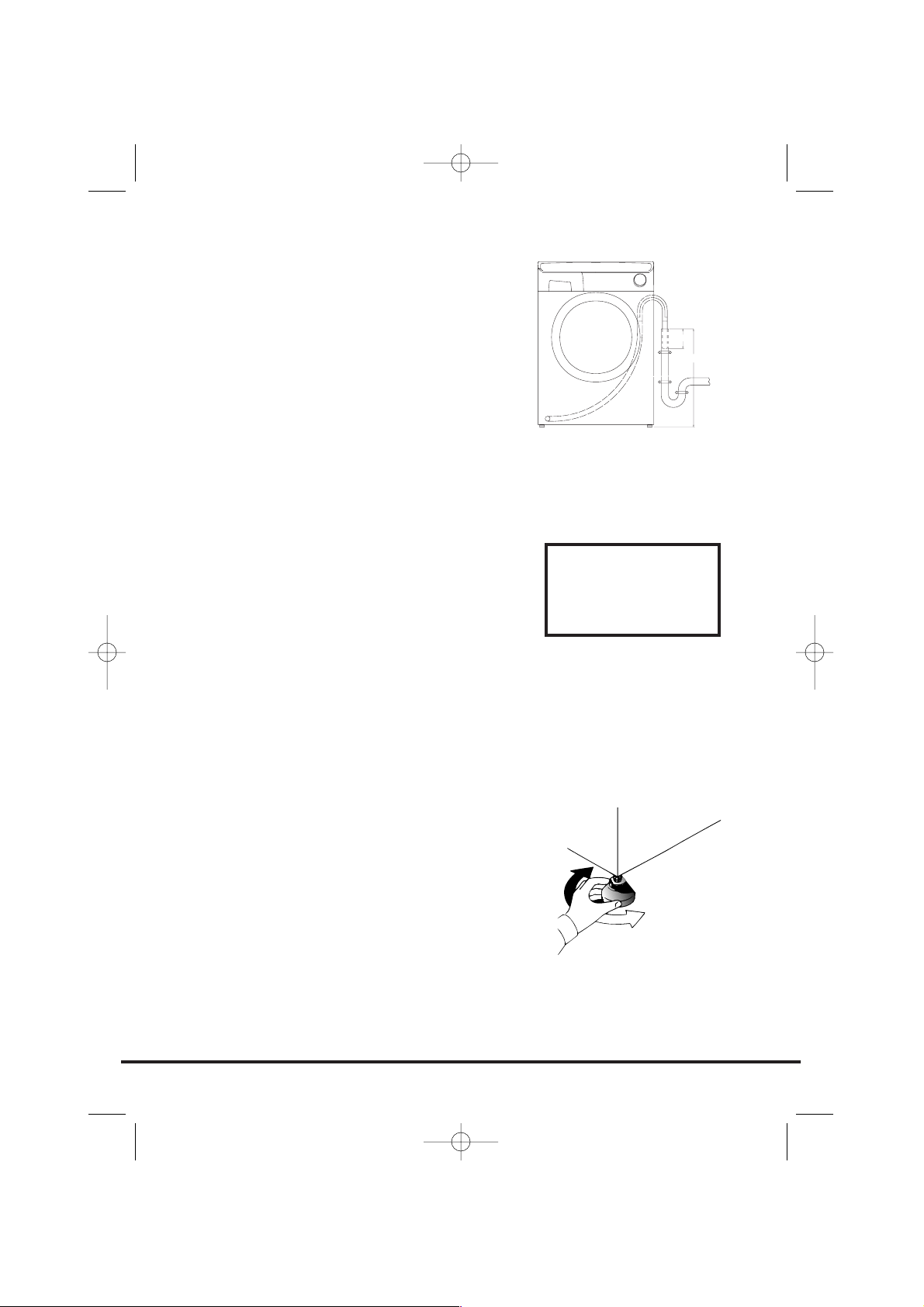

Option 2

Into a standpipe

Ensure that the standpipe is not located near

an electrical socket.

Fit the hooked end support to the outlet pipe.

Install the hose into the standpipe ensuring

that the pipe is at least 500mm from the floor.

Insert the outlet pipe approximately 100mm

into the standpipe.

Moving the machine

into position

Your machine is heavy so care must be taken

when moving it. We recommend that two people

move the machine to avoid strain and possible

injury.

● Take care not to damage flooring when

moving the machine.

● When moving the machine to its final

position take care not to kink or damage

the hose at the back of the machine.

Adjusting the feet

Once the machine is in place the feet should be

adjusted to ensure that the machine is level. If

the machine is not level it may become noisy or

move.

Adjust the feet on the front corners of the

machine until the machine is firm and level.

When the machine is firm and level, tighten the

locking nuts on the two feet.

11

Do not drag or

lift the machine

by its door.

100 mm

500 mm min

40002168.qxd 20/10/2004 19:14 Page 11

Page 12

Refer to ‘Selecting the wash programme’ for

details of how to select programmes.

1. Turn on the water supply and check for

leaks from the fill hose.

2. Switch on the electricity supply.

3. Select the spin programme and then

press the Start Pause button to start the

machine. Allow the programme to continue

for one minute and then cancel the

programme by returning the selector to the

OFF position. This will remove any water

remaining in the machine from factory

testing.

4. To check for cold water filling to the

machine:

Select the rinse programme and press

the Start Pause button to start the machine.

Allow the tumble action to continue until

the water has pumped out. Check that the

drain outlet is not leaking or overflowing.

5. Switch off the machine at the end of the

cycle by turning the programme knob to the

OFF position.

6. Select the spin programme and press

the Start Pause button to start the machine.

If the machine takes longer than one minute

to empty check the drain hose for kinks.

Installation testing is now

complete.

Now you have successfully installed the machine

we advise that you run the machine to ensure the

drum is thoroughly clean after testing and

storage. Select Cottons 90°C and run the machine

for a complete cycle using only wash detergent

and water.

12

Testing the installation

This

programme

will take

approximately

2 hours to

complete.

40002168.qxd 20/10/2004 19:14 Page 12

Page 13

The following tips are designed to assist in

getting the best results from your machine whilst

using it in the most environmentally-friendly and

economical way. It is also important to

understand the items to avoid in your laundry, to

ensure the continued safe and reliable operation

of your machine.

Loading your washing

machine

To make further reductions of energy, water and

detergent consumption, we recommend that you

put a full load into your machine. Energy savings

of up to 50% can be achieved by washing one full

load compared to two half loads.

Do not overload the machine as this will reduce

the quality of the wash and may cause damage

to the machine and your laundry.

When is prewashing really needed?

Only with particularly dirty loads! Energy savings

of 5 to 15% are made by not selecting the

prewash option for less dirty laundry. Pre-treat

awkward stains with a washable stain remover.

Which wash temperature should

you choose?

Using stain removers before machine washing

reduces the need to wash at temperatures over

60°C.

Using a 40°C wash temperature can make energy

savings of up to 50%.

Heavily soiled laundry

To ensure the best performance when washing a

particularly dirty load, we recommend that you

reduce the amount of items to be put into the

machine. Allowing more space in the drum the

items can circulate more freely and will wash

better.

13

Washing advice

40002168.qxd 20/10/2004 19:14 Page 13

Page 14

Sorting the laundry

Items to avoid

We recommend that you do not wash underwired

bras in the machine. Should the wires become

detached they could cause damage to your

clothes and the machine. If the washcare label

states that the bra is machine washable then we

advise placing it in a wash bag.

Recommendations

Always follow the wash care labelling on the

garments.

Fasten zips, tie strings and close press studs to

prevent tangling. Ensure that pockets are

emptied of loose change and other small items.

Check that there are no metal objects in the

laundry as these may damage the laundry and

the machine.

Place small items in a wash bag.

Detergent dosage

Only use detergents which are suitable for use in a washing machine. You will

obtain the best results from your wash with the minimum use of chemical

14

The Dispenser

Do not use the

machine to

wash items that

do not have a

wash label.

Do not wash

items

previously

treated with

solvents.

COMPARTMENT I

Prewash detergent

Maximum dosage 100ml of powder

COMPARTMENT II

Mainwash detergent

Maximum dosage 200ml

of powder

COMPARTMENT

Fabric Conditioner

Maximum dosage 100ml

40002168.qxd 20/10/2004 19:14 Page 14

Page 15

products, and the best care for your laundry if you take into consideration the

degree of soiling as well as the type of detergent to choose.

The amount of detergent to use depends on:

● Water hardness.

Depending on the hardness of the water and the type of detergent used,

it is possible to reduce the amount of detergent.

The softer the water supply, the less detergent is required.

● The degree of soiling.

It is possible to reduce the amount of detergent used depending on the

degree of soiling.

Use less detergent for less soiled items.

● Amount of laundry.

It is possible to reduce the amount of detergent when washing only a

small amount of laundry.

For smaller loads use less detergent.

The dosages shown on the packaging of detergents for washing delicates

often already refer to a reduced wash size. Always follow the dosage

instructions on the detergent packaging.

Dispensing instructions

The detergent drawer is split into 3 compartments:

● the first, labelled "I", is for detergent utilised

during Prewash.

● the second, labelled "II", is for detergent

utilised during the main wash.

● the third, labelled is for special additives

such as fabric softeners, fragrances, starch,

brighteners etc.

Dispensing in the drum

Liquid detergents and some tablets are dispensed

via the machine drum using the recommended

dispensing device which is placed upright on top of

the washload towards the back of the drum. Some

tablets are designed to be placed in the dispenser

drawer, check the detergent pack for details.

15

DO NOT exceed the maximum detergent dosage

Do not put any

items into the

drawer other

than detergents

that are

designed to be

dispensed from

the drawer as

they may cause

blockage or

damage.

40002168.qxd 20/10/2004 19:14 Page 15

Page 16

This machine will operate even if you do not programme the Inter@ct set-up.

However, this machine has Delay Start and Programme Set End Time functions

and for these functions to work efficiently the Inter@ct 3D must be

programmed. This is a simple operation and special care has been taken

during manufacture to ensure that the user can operate this machine simply

and effectively.

Programming the machine

Inter@ct needs to be programmed so that the correct clock setting and

personal requirements are set. When the machine is turned on and the

programme dial is moved away from the OFF position to a programme

selection, a welcome message will appear:

This message is displayed for a short time while the machine recognises which

programme has been selected. When the machine is ready, the programme

details will appear on the display and from here you may now begin

programming the machine.

Example

Please note that when using the Inter@ct menu you have 30 seconds per

operation to make your selection. Should you run out of time, the display will

16

Using Inter@ct 3D for the

first time

WELCOME!

0:00

00

00

COTTON WHITE

HEAVY SOIL

90

11

Spin Speed

x100

Programme

selected

Temperature

(°C)

40002168.qxd 20/10/2004 19:14 Page 16

Page 17

return to the start screen, and you simply have to re-enter the Inter@ct menu

and continue with the programming.

To enter the menu

Hold down the Sensitive Care and the Delay Start buttons together for 5

seconds or until the beep sounds.

The menu options can be changed by pressing the Sensitive Care button. To

confirm and enter an option press the Delay Start button.

Set New Time

This function needs to be set for two reasons, firstly to display the current

time of day on the screen and secondly for the Programme Set End Time/Delay

Start settings to work correctly.

You will notice in the display window that the hours on the clock will be

flashing. To set the hours you must press the Sensitive Care button until the

required figure is displayed. Then press the Delay Start button to enter the

chosen figure. Now the minutes on the clock will begin to flash. Again, press

the Sensitive Care button until the required minutes are displayed and press

Delay Start to input the selection. When you have set the time, the display will

ask if you wish to Set the Time Mode.

Setting the Time Mode (default setting – ABSOLUTE)

The Set Time Mode allows you choose how you wish the Programme Set End

Time and Delay Start functions to be controlled.

You will be presented with two options. The first, called Absolute Time Mode

(ABSOLUTE), allows you to set the actual time you want the programme to

begin or end, e.g. Programme to start/end at 08:00. The second, called Relative

Time Mode (RELATIVE), allows you to delay the start or end of your wash cycle

by adding hours to the current time displayed on the clock, e.g. Programme to

start/end in 4 hours 30 minutes.

You can select which option you require by pressing the Sensitive Care button

until your preferred option is displayed, and then pressing the Delay Start

button to accept the option you have chosen.

Both options are very useful, but Absolute Time Mode is easier to use since

there is no need for you to calculate how many hours to leave before you

want the machine to end or start your chosen cycle.

When you have entered your preferred Time Mode the display will then ask

17

SET NEW TIME

0:08

40002168.qxd 20/10/2004 19:14 Page 17

Page 18

for Enable Final Beeping to be set.

Enable Final Beeping (default setting – YES)

Here you have the option to have a beeping alarm to let you know the wash

cycle has finished. By pressing the Sensitive Care button you can scroll through

the YES and NO options.

To confirm your selection press the Delay Start button. The screen will then

move to the next stage and ask you if you wish to Enable Memory.

Enable Memory (default setting – NO)

This is a useful feature if you frequently wash laundry using the same

programme. Selecting Enable Memory will tell the machine to remember the

last programme/functions used and set them in the memory. This feature

works only on the Cottons, Delicates, Synthetics and Woollens programmes.

The memory does not retain settings within the Special Programmes group.

Select YES or NO by using the Sensitive Care button and confirm your selection

by pressing the Delay Start button.

Demo Mode (default setting – NO)

The display will now show a message asking if you require the demo mode to

be set. Please set this option to NO if this has not already been done. This

function is for SERVICE use only. If the demo mode option is set to YES, the

wash programme WILL NOT commence when you exit the Inter@ct 3D menu.

The Demo Mode must be set to NO for the wash cycle to commence. Select NO

using the Sensitive Care button and confirm your choice with the Delay Start

button. You will then be asked if you wish to Exit the Menu.

Exit Menu

If you are happy with the settings you have selected, you can now exit the

menu by selecting YES via the Sensitive Care button and confirm this selection

using the Delay Start button. However, if you are not happy with some of the

settings selected you must select NO and you can then start programming

again from the beginning. By pressing the Delay Start button you can enter

and bypass each option individually until you reach the option you would like

to change.

When you are completely satisfied with the menu options you have selected,

you may exit the menu. Testing of the installation may now start. If you wish

to change any of the menu settings at a later date, you can enter the menu as

previously described, run through the menu options from the beginning and

change whichever options you wish. This may be useful for changing Set New

Time when Daylight Saving starts or ends.

Once set, the menu options will remain in the memory of the machine even if

the machine is unplugged or there is a power cut.

18

40002168.qxd 20/10/2004 19:14 Page 18

Page 19

19

The Control Panel

The programme selector must be returned to the OFF

position to reset the controls between each wash cycle.

INTER@CT

Display

Stain

Buster

Spin Speed Time

Saver

Prewash Wash Temp Sensitive

Care

Start Pause

Delay Start/

Set End Time

Child Lock

Programme

Selector

40002168.qxd 20/10/2004 19:14 Page 19

Page 20

20

Turning the machine on

Turn the machine on by selecting a programme using the programme selector.

The display will then indicate the name of the programme, the spin speed and

temperature of the wash and this display will remain until you press the Start

Pause button or return the programme selector to the OFF position.

Start/Pause

Start

After selecting the programme and the required options (see the Wash

Options section of this manual), press the Start Pause button once to start the

wash cycle. The display will indicate that the door is locked and the machine

will begin to sense the wash load and ask you to wait.

After the appropriate parameters have been programmed by the machine the

display will indicate the approximate time until the end of the programme.

This calculation is based on a full load and will be adjusted to suit the size and

composition of the load as the machine progresses through the wash cycle.

COTTON WHITE

HEAVY SOIL

90

11

PLEASE WAIT

SET PARAMETERS

90

11

END: 2H 45M

WASHING

90

11

40002168.qxd 20/10/2004 19:14 Page 20

Page 21

Pause

The programme may be paused at any time during the wash cycle by holding

down the Start Pause button for about three seconds. When the machine is in

the paused mode the following display will appear:

After about two minutes the display will then change to the following, which

means that the door can now be opened:

To restart the programme, close the door and press the Start Pause button.

Cancelling and changing the programme

To cancel the programme the programme selector should be turned to the OFF

position. In this mode the display will go blank because the machine is now

OFF. When a new programme is selected the display will indicate that the

programme has been cancelled as follows:

To start another wash cycle the programme selector must be returned to OFF

once again BEFORE the next programme can be selected and started.

21

PAUSED PROGRAM

DOOR LOCKED

90

11

PAUSED PROGRAM

DOOR OPEN

90

11

CANCELLED PROG

90

11

40002168.qxd 20/10/2004 19:14 Page 21

Page 22

Spin Speed Selection (Spin Speed)

By pressing the Spin Speed option button it is possible to reduce the maximum

spin speed of your selected programme to suit your needs and to help reduce

any creasing of fabrics. The maximum spin speed will vary depending on the

specification of the machine.

The light on the option button will come on if a spin speed lower than that

stated in the programme guide has been selected.

Time Saver

This option can be used on the Cottons (Cottons, Colourfast, Non-fast) and

Synthetics programmes. By selecting the Time Saver option, the wash time can

be reduced by up to 50 minutes, depending on the selected programme,

temperature and load, without affecting the quality of the wash.

Prewash (Prewash)

This option is available on the Cottons (Cottons, Colourfast, Non-fast) and

Synthetics programmes. Prewash is set automatically on the Sports

programme. This option is particularly useful for heavily soiled loads and can

be used independently of the main wash programme. Detergent for this

programme should be added to the first compartment of the soap drawer

labelled "I" (please refer to The Dispenser section of this manual). We

recommend you use only 20% of the quantity used for the main wash

programme.

22

Wash Options

The following options should be selected BEFORE

pressing the Start Pause button. The light on each option

button will come on if the option has been selected.

Spin Speed ÷ 100 rpm; so in this example 11 = 1100 rpm

COTTON WHITE

HEAVY SOIL

90

11

40002168.qxd 20/10/2004 19:14 Page 22

Page 23

Temperature Selection (Wash Temp)

This washing machine is equipped with a variable temperature function. Each

press of the Wash Temp button reduces the temperature of the wash. Greater

energy savings can be achieved by setting the temperature between 15°C and

40°C. By setting the temperature to 15°C the wash temperature is equivalent

to the water inlet temperature, thus reducing energy consumption further.

We recommend that the temperature shown on wash care garments should

never be exceeded. The machine will not accept a temperature input that is

higher than that stated in the programme guide.

The light on the option button will come on if a temperature lower than that

stated in the programme guide has been selected.

Sensitive Care

This option is available on the Cottons programmes (Cottons, Colourfast, Nonfast) and it increases the number of rinses to five (including the final

conditioned rinse). This can help prevent skin irritation from detergent

residue, which can affect people with particularly sensitive skin. Selecting the

Sensitive Care button is also recommended when washing heavily soiled

fabrics which need a lot of detergent, or when the wash load contains

towelling fabrics that have a greater tendency to retain detergent.

Stain Buster

Selecting the Stain Buster option adds 90 minutes of gentle wash action at

35°C to the start of the selected programme. This will allow more time for

biological detergents to operate giving improved stain removal. This option is

available on cottons and synthetics wash programmes.

Delay Start

The Programme Set End Time/Delay Start options can be used if you want the

washing to be ready at a later time (but within 24 hours). The way these

buttons function will depend on which Time Mode you have selected in the

Inter@ct menu.

23

Temperature (°C)

COTTON WHITE

HEAVY SOIL

90

11

40002168.qxd 20/10/2004 19:14 Page 23

Page 24

1. Set Delay Start

Press the Delay Start button once and press the hours and minutes buttons

(Stain Buster and Child Lock) until the required time is set. The display returns

to the programme option if you do not start to set the time within 5 seconds.

Once you have set the required Delay Start, press the Start Pause button.

If the Absolute Time Mode has been selected at the menu set-up stage and

you wish to delay the start of the programme until 08.00, the display will

appear as follows:

If the Relative Time Mode has been selected at the menu set-up stage and you

wish to delay the start of the programme by 4 hours 30 minutes, the display

will appear as follows:

2. Programme Set End Time

Press the Delay Start button twice and press the hours and minutes buttons

(Stain Buster and Child Lock) until the required time is set. When you are

entering the Set End Time option, the display will automatically show the

earlier time at which the programme can end. This time may only be extended

as you require.

If the Absolute Time Mode has been selected at the menu set-up stage and

you wish to delay the end of the programme until 08.00, the display will

appear as follows:

If the Relative Time Mode has been selected at the menu set-up stage and you

wish to delay the end of the programme by 4 hours 30 minutes, the display

24

PROGRAM START

AT 08:00

DELAY START

BY 4H 30M

PROGRAM END

AT 08:00

40002168.qxd 20/10/2004 19:14 Page 24

Page 25

will appear as follows:

These options can be cancelled at any stage after they have been set by

pressing the Delay Start button for five seconds. The indicator light will go out

and the buzzer will sound.

Child Lock

This is a useful feature to prevent children playing with the option buttons

and tampering with the programme you have set. After you have set the

programme and option buttons you require, press the Start Pause button.

Press the Child Lock button in order to lock the control panel.

You may cancel this function by pressing the Child Lock button briefly until

you see the light above the button flash. While this light is flashing, press the

Spin Speed button – the display will inform you that the options are no longer

locked and further changes can now be made.

25

DELAY END

BY 4H 30M

PROGRAM LOCKED

NO CHANGES

When using the Delay Start/Set End Time functions,

detergents must only be put in the dispenser drawer.

Adding detergents etc. to the drum and then leaving

them to stand for a long period of time may damage

your laundry.

PROGRAM UNLOCK

CHANGE ALLOWED

40002168.qxd 20/10/2004 19:14 Page 25

Page 26

Automatic Features

Automatic Variable Capacity

(Half Load)

The washing machine is fitted with a self

adjusting water level system. This system enables

the machine to use the optimum amount of

water needed to wash and rinse the laundry in

relation to the particular load. This results in a

reduction of the water and electricity used

without in any way compromising the washing

and rinsing performance. The amount of water

and electricity used will always be appropriate for

the clothes load.

The washing machine automatically ensures

excellent washing results at minimum cost whilst

respecting the environment.

Out of Balance protection

This model is fitted with an electronic sensor

device that checks if the load is balanced

correctly. If the load is slightly unbalanced the

machine will re-balance it automatically to then

carry out the normal spin.

If, after several attempts, balance is not restored

a reduced spin speed will be used.

If loads are seriously unbalanced the spin stage

will be cancelled. This helps limit vibration,

reduce noise and improve the washing machine's

reliability and life.

26

40002168.qxd 20/10/2004 19:14 Page 26

Page 27

27

For handling the various types of fabric and their level of soiling in your

laundry the washing machine has different programme groups according to

type of wash, temperature, spin speeds and duration (see Programme Guide).

Cottons

The Cottons programmes are designed for maximum washing and rinsing.

With spin cycles in between, they guarantee the laundry is rinsed perfectly.

The final spin cycle ensures laundry is spun dry as much as possible up to the

maximum speed.

Synthetics and mixed fabrics

Washing and rinsing performance is optimised through drum rotation speeds

and water levels. The delicate spin action minimises creasing.

Delicates

This is a new concept in washing, with a cycle that consists of alternate periods

of activity and pauses, particularly suitable for washing very delicate fabrics.

Washing and rinsing are carried out using a high water level to provide the

best results.

Rinse, Spin and Drain

Individual programmes are available for rinsing, (including the opportunity to

add fabric conditioner), spinning, at 800rpm or less if selected via the Spin

Speed button, and draining the water from the machine.

Programme Selector

40002168.qxd 20/10/2004 19:14 Page 27

Page 28

Special Programmes

Woolmark

This is a programme dedicated to washing fabrics

labelled with the woolmark symbol . The cycle

consists of alternate periods of activity and

pauses. Washing and rinsing are carried out using

a high water level to provide the best results. The

programme has a maximum temperature of 40°C

and concludes with 3 rinses, one for fabric

conditioner, and a short spin.

Silk

This washing machine also has a gentle Silk and

Hand Wash programme. This programme allows a

complete washing cycle for garments specified as

“Hand Wash only” and laundry items made from

silk or specified “Wash as silk” on the fabric label.

The programme has a maximum temperature of

30°C and concludes with 3 rinses, one for fabric

conditioner, and no final spin.

Sports

This washing machine has a unique Sportswear

programme.

It is specially designed to wash mixed sportswear

fabrics that cannot be washed on hotter

programmes and is designed to remove the

soiling and staining created by participation in

sports activities.

This programme starts with a cold prewash that

breaks down and loosens any excess dirt and then

washes at a cool 30°C, rinses twice (one is for

fabric conditioner) and spins slowly for the best

care of your heavily soiled, delicate garments.

Detergent for the prewash part of the

programme should be added to compartment I

and detergent for the mainwash should be added

to compartment II. Follow the instructions given

in 'The Dispenser' section.

28

40002168.qxd 20/10/2004 19:14 Page 28

Page 29

29

‘A’ wash 59’

This specially designed programme maintains the

high quality wash performance identified with the

‘A’ rating whilst greatly reducing the wash time.

The programme is designed for a maximum load of

3 kg and is intended for cotton fabrics and items

colourfast to 60°C. The programme concludes with

2 rinses and a high speed spin sequence.

Daily Programmes

By maintaining exceptional washing performance,

these programmes allow you to know in advance

the necessary time for your everyday laundry. In

fact, this washing machine is equipped with two

daily rapid programmes at 40°C, that were

designed for lightly soiled fabrics and medium or

small loads.

Daily 44'

A complete washing cycle (wash, rinse and spin),

able to wash in approximately 44 minutes

suitable for:

● a maximum load of 3 kgs

● lightly soiled fabrics (cotton and mixed

fabrics)

With this programme we recommend that you

reduce the detergent loading dose (compared to

the normal one), in order to avoid detergent

waste.

Daily 29'

A complete washing cycle (wash, rinse and spin),

able to wash in approximately 29 minutes

suitable for:

● a maximum load of 2 kgs

● lightly soiled fabrics (cotton and mixed

fabrics)

With this programme we recommend that you

reduce the detergent loading dose (compared to

the normal one), in order to avoid detergent

waste.

40002168.qxd 20/10/2004 19:14 Page 29

Page 30

30

Programme Guide

Energy label data based on Colourfast programme tested in accordance with

CENELEC EN60456

CottonsSynthetics Mixed

Fabrics

Delicates

Special Programmes

Cottons

Colourfast

Non-fast

Colour Mix

Synthetics

Acrylics

Rinse

Spin

Drain

Woolmark

Silk

Sports

“A” Wash

59'

Daily

44'

Daily

29'

Maximum

Load

Size (kg)

6

6

6

6

2

2

-

-

-

1

1.5

2.5

3

3

2

Fabric Type

Cottons, linen

Cotton, colourfast

mixed fibres

Cottons, mixed fabrics,

Coloureds Non-fast

Cottons, mixed fabrics

and synthetics

Mixed fabrics

and synthetics

Synthetics, acrylics

and coloured

mixed fabrics

Mixed Fabrics

Mixed Fabrics.

Spin speed of 800 rpm

max.

Mixed Fabrics

Machine washable

wool

Silks and 'Hand Wash

only' garments

Mixed fabrics

Cotton, colourfast

mixed fibres

Lightly soiled cottons

and mixed fabrics

Lightly soiled cottons

and mixed fabrics

Maximum

Water

Temp (°C)

90

60

40

40

50

40

-

-

-

40

30

30

60

40

40

Programme

40002168.qxd 20/10/2004 19:14 Page 30

Page 31

31

This section summarises the main points when

completing a wash cycle. For detailed

explanations of features, options and details of

the machine refer to the relevant section in the

instruction manual.

Preparing the laundry

Select and sort the laundry according to the wash

care labels found on each garment. Always check

the care labels.

Loading the laundry

Open the door.

Put the laundry in the washing machine. Close

the door by pushing it until it clicks, ensuring that

no items of laundry are obstructing the lock or

door seal.

Putting detergent in machine

Open the drawer, choose the detergent and put

in the recommended amount.

Do not exceed the dosage stated below

Close the drawer again.

A Typical Wash

Maximum quantity

of powder/liquid

100ml

200ml

100ml

Wash

Prewash (option)

Main Wash

(all programmes)

Fabric Conditioner

Compartment

I

II

Liquid

detergents and

some

concentrated

powders and

tablets that are

to be placed

directly into the

drum should be

placed in the

recommended

dispensing

device.

40002168.qxd 20/10/2004 19:14 Page 31

Page 32

Refer to the Programme Guide or the programme

descriptions on the front of the machine to select

the most suitable programme.

The programme is selected by turning the

programme selector and aligning the programme

name with the indicator.

The programme will be displayed on the Inter@ct

3D screen, along with the standard spin speed and

the wash temperature for the selected programme.

Check that the tap is turned on and that the

discharge hose is positioned correctly.

Select the required wash options, including the

spin speed and wash temperature if you wish to

change these from the standard settings.

Starting the wash cycle

Press the Start Pause button. The Inter@ct 3D screen will indicate that the

machine is setting the wash parameters and then after a few seconds the wash

programme will begin. The display will then indicate the time to the end of

the cycle and the current phase of the cycle (i.e. washing, rinsing or spinning).

Do not try to open the door when the washing programme is in progress. The

screen will indicate when the door can be opened.

Do not open the dispenser drawer during the wash programme.

If you wish to pause the programme press the Start Pause button; after two

minutes you will be able to open the door. To cancel the programme please

refer to the ‘Cancelling and changing the programme’ section of this manual.

When the programme has finished

Wait approximately two minutes for the door lock to be released. When the

Inter@ct display indicates DOOR OPEN it will then be safe to open the door.

Switch off the machine by turning the programme selector to the OFF position

so that it will be ready the next time you use the machine (this action resets

the memory in the machine).

Open the door and remove the laundry.

Disconnect the plug from the mains power supply and turn off the water

supply every time you finish using it.

32

Selecting the wash programme

40002168.qxd 20/10/2004 19:14 Page 32

Page 33

33

Cleaning and Routine

Maintenance

The washing machine needs very little

maintenance, but regular attention to a few small

details will ensure the continued performance of

your washing machine.

Do not use abrasive cleaners, scouring pads,

solvent based cleaners or polishes; wiping the

outside of the machine with a damp cloth will

suffice.

Cleaning the soap dispenser

1. Clean the compartments occasionally to

remove detergents and additives.

2. To do this you just need to pull the drawer

out firmly from the machine, but without

forcing it.

3. Clean the compartments and the syphon cap

and cover under warm running water.

4. Clean the soap dispenser housing to remove

any residue of soap powder

5. Replace the drawer.

Cleaning the door glass

Regularly clean the door glass with a damp cloth.

A build up of soiling and residues from the water

may result in water leaking from the door.

Do not use abrasive cleaners as they can scratch

the surface.

40002168.qxd 20/10/2004 19:14 Page 33

Page 34

Cleaning the filter

The washing machine is fitted with a special filter

to prevent items such as coins, buttons, etc.

blocking the discharge hose. These may be

retrieved by:

1. Removing the kickplate by gently pulling it

from the bottom in an outwards and

upwards direction.

2. Use the kickplate to collect the water still in

the filter.

3. Use a screwdriver to loosen the screw

holding the filter, turn the filter

anticlockwise until it stops, remove it and

clean it. After cleaning it, reassemble

following the above instructions in reverse

order.

Replace the kickplate.

We recommend that the filter be cleaned

frequently, at least once a month.

Maintenance wash

Using small quantities of detergent and low

temperature wash programmes can cause the

gradual build up of grease, dirt and scale. Over

time these deposits can damage your laundry and

your machine. They can also cause your machine

to smell. We recommend that you carry out a

maintenance wash a couple of times per year to

keep your machine and pipe work clean and free

of these deposits. Simply run the Cottons 90°C

programme without a load and with the normal

quantity of detergent.

This wash will take approximately

2 hours to complete.

34

40002168.qxd 20/10/2004 19:14 Page 34

Page 35

35

Troubleshooting

What might be the cause of...

Defects you can remedy yourself

Before calling GIAS Service for technical advice please run through the

following checklist. A charge will be made if the machine is found to be

working or has been installed incorrectly or used incorrectly. If the problem

persists after completing the recommended checks, please call GIAS Service

(tel: 08705 400 600), they may be able to assist you over the telephone.

The machine will not start…

● Close the door. Check that there is power to the machine. Select a

programme and press Start Pause Check if the DOOR LOCKED message is

displayed.

If it is not, check the following:

1. Is the machine connected to the electrical supply?

2. Is the electrical supply OK, check another socket?

3. Has the fuse on the machine blown? If so, replace it.

● If the DOOR LOCKED message is displayed and the machine does not

start this means that the machine cannot fill with water, check the

following:

1. Check the programme dial is correctly aligned with the programme.

2. Is the water supply to the machine switched on?

3. Are the pipes kinked or restricted in any way?

Water does not drain away…

● Ensure that there is not a blockage in the drain hose or the hose is not

kinked.

● Is the drain hose installed correctly? If connected to the sink waste make

sure you have cut the membrane or removed the bung from the under

sink drainage unit.

● Check for foreign bodies in the filter. If present, clean the filter.

If you have found any of the above problems correct them and run the

machine through a spin cycle to drain the water.

Water on the floor around the washing machine…

● Is the fill hose tightened? If so, replace the rubber washers and re-tighten.

● Is the standpipe or the household drain blocked? If so, clear the blockage

yourself or call a plumber.

● Is there clothing or dirt between the door gasket and the door glass?

40002168.qxd 20/10/2004 19:14 Page 35

Page 36

Ensure that the door glass and gasket are kept clean and free of laundry

when loading the machine.

The machine does not spin…

● Water has not drained from the machine? Check the points highlighted

above.

● Have you selected an option that changes the spin profile (e.g. change of

spin speed using the Spin Speed button)? Check the feature in the

description of the controls.

● Is the load unbalanced? To reduce noise and vibration and improve the

machine’s reliability and life, the machine is fitted with an electronic

sensor that detects if the load is unbalanced. To improve the spin

performance the load can be re-distributed by hand at the end of the

cycle and then re-spun.

The machine is noisy or vibrates a lot during the cycle…

● Has the transit system been fully removed? Check that the bracket and

the polystyrene packing have been taken off the machine.

● Are there any loose items in the pockets of clothing that can rattle in the

drum and cause damage?

● Is the load unbalanced? Stop the programme, re-distribute the load and

restart.

The programme takes a long time…

● Some programmes do take a long time (over 2 hours). Low water

pressure can increase the length of the programme.

The door will not open…

● Has the programme finished?

Does the machine show 'PROGRAM ENDED DOOR OPEN'? If not the

programme is not complete, wait a further couple of minutes and the

message 'PROGRAM ENDED DOOR OPEN' will appear and you will be

able to open the door.

● If water remains in the drum refer to 'Water does not drain away…'

above.

Problem with the dispenser…

● Not all the detergent has been flushed away.

1. Check the water supply tap is fully turned on.

2. Check the inlet hose is not kinked.

● The dispenser drawer will not close properly.

1. Check the drawer is aligned properly.

2. Check the drawer is not clogged with detergent (see Cleaning and

Routine Maintenance).

36

40002168.qxd 20/10/2004 19:14 Page 36

Page 37

37

● Steam is coming from the dispenser.

The machine is designed to vent through the drawer, this is nothing to

worry about.

Remember, you may be charged for the service call if incorrect installation or

misuse causes a problem with your machine.

Note:

The use of environmentally-friendly, phosphate-free detergents (check

detergent information on pack) can have the following effects:

● Waste water from rinsing may be cloudier because of the presence of a

white powder (zeolites) held in suspension, without the rinse

performance being adversely affected.

● Presence of white powder on laundry after washing, which is not

absorbed by the fabric and does not alter the colour of the fabric.

● The presence of foam in the final rinsing water is not necessarily an

indication of poor rinsing. Carrying out more rinse cycles does not serve

any purpose in such cases.

Power Failure

If there is a power failure the wash cycle will be interrupted, and the wash

programme and functions will be suspended. When the power is restored, the

wash programme and functions will restart from the same point and complete

the programme.

During a power failure the water can be drained and the load can be removed

from the machine as follows:

1. Switch off the machine both via the programme knob and the mains

power supply. Remove the plug from the mains power supply socket.

2. Carefully move the machine so the rear of the machine is accessible.

Please follow the safety precautions which we recommend under the

Safety Notes section of this manual.

3. Unclip the drain hose from the rear panel of the machine and lower the

hose into a bowl on the floor. When the bowl is full raise the end of the

drain pipe to a height higher than the top of the appliance to stop the

flow of water. Empty and replace the bowl and continue draining the

machine until empty.

4. Once the machine is fully drained of water, clip the hose to the rear of

the machine. Open the door and remove the load.

The door can be opened approximately 2 minutes after the power failure.

Do not force open the door.

40002168.qxd 20/10/2004 19:15 Page 37

Page 38

For a period of one year from the date of

purchase the appliance is covered by a guarantee

which allows you to call Hoover Service free of

charge (except for the price of the call).

Remember to send off the guarantee certificate

for validation within 10 days of the date of

purchase.

You should retain the receipt issued by the

retailer when you purchased the machine to show

to the call out engineer, should you need to

consult one.

If your washing machine shows signs of a defect

or is not working properly, before you contact

GIAS Service we recommend you carry out the

checks detailed within the Troubleshooting

section.

If the problem with the machine persists after

completing all the recommended checks, please

dial the GIAS Service number.

You will be connected directly to GIAS. It is

important you tell the GIAS advisor your

product's model number and serial number,

which you will find on the rating label (16

characters, beginning with the number 3), found

on the front of the washing machine (door area).

By doing this, your enquiry will be responded to

more efficiently.

38

Customer Service

PPhhoonnee GGIIAASS oonn

0088770055 440000 660000

40002168.qxd 20/10/2004 19:15 Page 38

Page 39

Hoover guarantees all parts of this product for 5 years from the date of

purchase. During that time Hoover will replace or repair all defective parts

free of charge, except for parts subject to fair wear and tear such as belts. The

call out fee and labour costs are chargeable after the first 12 months. To

qualify for benefits under the guarantee, you must be able to provide proof of

date of purchase and the appliance must have been installed and used in

accordance with the instructions described in this manual. Consequential losses

and accidental damage to the machine is not covered by the guarantee.

Hoover cannot be responsible for the results of using this machine for any

purposes other than those described in this manual.

This guarantee does not effect your statutory or common law rights.

For service and repairs please call our national number:

Always use genuine Hoover spares, available direct from GIAS Service:

Hoovercare

To maintain your Hoover product in peak condition you may wish to take out

a Hoovercare policy, which for an annual payment provides a comprehensive

maintenance and repair scheme. For more information please call 08705 400

600.

The Hoovercare scheme is not available in Eire.

The manufacturer declines all responsibility in the event of any printing mistakes

in this booklet. The manufacturer also reserves the right to make appropriate

modifications to its products without changing the essential characteristics.

39

Your Guarantee

GGIIAASS SSeerrvviiccee ––TTeell:: 0088770055 440000 660000

SSuuppppoorrtt SSeerrvviiccee [[EEiirree 001188330011 666666]]

HHoooovveerr SSppaarreess SSeerrvviiccee

TTeell:: 0011220044 555566111111

40002168.qxd 20/10/2004 19:15 Page 39

Page 40

40002168

40002168.qxd 20/10/2004 19:15 Page 40

Loading...

Loading...