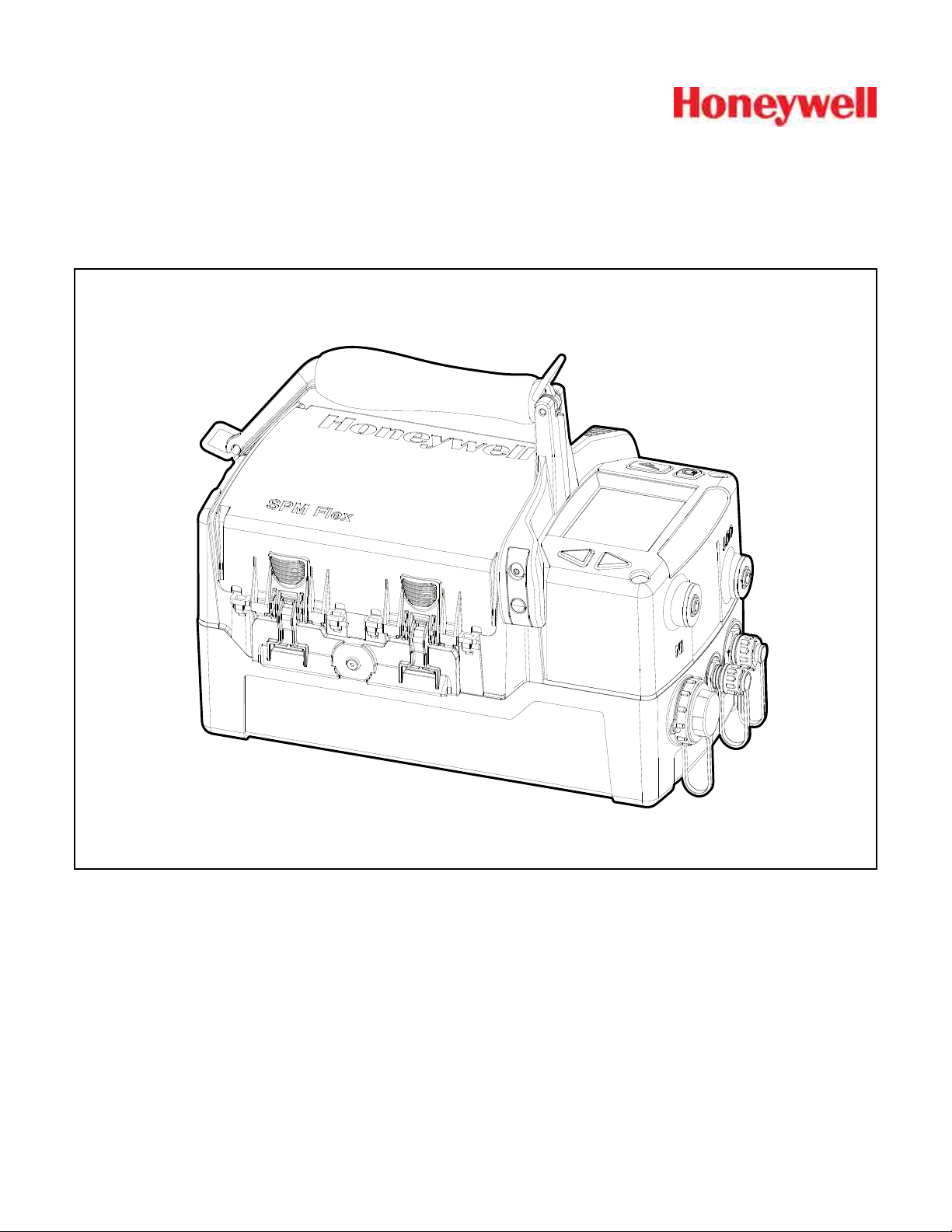

SPM Flex

Single Point Monitor Gas Detector

User’s Manual

SPM Flex Gas Detector

Introduction ����������������������������������������������������������������������������������������������������������������5

Safety Information ��������������������������������������������������������������������������������������������������6

Contact Information ������������������������������������������������������������������������������������������������ 7

Glossary ���������������������������������������������������������������������������������������������������������������������� 8

Product Overview ������������������������������������������������������������������������������������������������������� 9

Battery operation �������������������������������������������������������������������������������������������������� 10

The handle (portable model) ��������������������������������������������������������������������������������11

Opening the cover ������������������������������������������������������������������������������������������������11

Main power rocker switch ������������������������������������������������������������������������������������12

Turning the detector on and off ���������������������������������������������������������������������������� 13

Navigation �������������������������������������������������������������������������������������������������������������14

Menu Map �������������������������������������������������������������������������������������������������������������15

Wiring and tubing �����������������������������������������������������������������������������������������������������19

Typical fixed installation topologies ��������������������������������������������������������������������� 19

Wiring diagrams ���������������������������������������������������������������������������������������������������� 21

4-20 mA wiring ������������������������������������������������������������������������������������������������������ 22

Modbus register definitions ����������������������������������������������������������������������������������24

Setup ������������������������������������������������������������������������������������������������������������������������� 26

Installation drawing �����������������������������������������������������������������������������������������������26

Mounting options �������������������������������������������������������������������������������������������������� 26

Dimensions ������������������������������������������������������������������������������������������������������������27

Standard mounting bracket ����������������������������������������������������������������������������������28

Backward-compatible mounting bracket ������������������������������������������������������������29

In-line filters �����������������������������������������������������������������������������������������������������������30

Optional sampling wand ��������������������������������������������������������������������������������������� 30

Attaching the shoulder strap �������������������������������������������������������������������������������� 31

Operation ����������������������������������������������������������������������������������������������������������������� 32

Controls ����������������������������������������������������������������������������������������������������������������� 32

Setup menu ����������������������������������������������������������������������������������������������������������� 38

Troubleshooting �������������������������������������������������������������������������������������������������������� 42

Maintenance ������������������������������������������������������������������������������������������������������������� 46

Storing the detector ���������������������������������������������������������������������������������������������� 49

Recycling ���������������������������������������������������������������������������������������������������������������49

Storing Chemcassette

Labels ������������������������������������������������������������������������������������������������������������������������50

Detectable Gases ����������������������������������������������������������������������������������������������������� 51

Specifications ���������������������������������������������������������������������������������������������������������� 52

Accessories and Parts ���������������������������������������������������������������������������������������������53

Certifications ������������������������������������������������������������������������������������������������������������56

Warranties ����������������������������������������������������������������������������������������������������������������� 62

SPM Flex warranty ������������������������������������������������������������������������������������������������62

Chemcassette

®

cartridge warranty ���������������������������������������������������������������������� 62

Index �������������������������������������������������������������������������������������������������������������������������64

®

cartridges �����������������������������������������������������������������������49

3

SPM Flex Gas Detector

4

SPM Flex Gas Detector

Introduction

The SPM Flex gas detector is an extractive gas monitoring system that draws gas

®

samples locally or from a remote point to a Chemcassette

detection system� A wide range of toxic gas Chemcassette cartridges are available

that enable detection of gases used or generated in semiconductor manufacturing

and industrial environments�

The SPM Flex gas detector, available in wall mounted and portable versions,

locally displays gas concentration, alarm, fault and status information via its backlit

color LCD and LEDs� A simple to use 4-button keypad adjacent to the display

provides the ability to set-up, review, operate and make changes to the detector’s

configuration� The intuitive display and menu structure are designed to require

minimal training� The SPM Flex has a local audio alarm with user-configurable

output levels� The detector can be used both indoors and outdoors in a wide range

of weather conditions�

The detector has flexible power and communications capabilities� These include

3 on-board relays, 4-20 mA analog output and Modbus/TCP outputs for signal

and service connectivity� The gas detector is equipped with a USB port for

configuration-sharing firmware updates and data downloads� For web-enabled

devices, web pages are available via the Ethernet port�

tape-based optical gas

Standard operation conditions

The SPM Flex gas detector is designed for use in temperatures between 32ºF

and 104ºF (0ºC and 40ºC) and relative humidities between 0 and 100% (the

relative humidities are limited by tape and calibration)� The sample line will require

additional hardware to remove moisture in high relative humidity conditions where

condensing may occur (the sample must be non-condensing)� Dry conditions may

require humidification�

High-altitude applications

The SPM Flex pump is optimized for operation at altitudes between –1000 feet

(–305 meters) and 3000 ft� (945 m) above sea level� At altitudes above 3,000 ft�

(915 m), up to a maximum of 6,000 ft� (1,830 m), contact Honeywell Analytics for

calibration� (At 6,000 feet, pump capacity is reduced 18% and a flow-system

adjustment to the bypass valve is required� This must be performed by a Honeywell

Analytics certified technician� Contact Customer Service�)

5

SPM Flex Gas Detector

DANGER

!

Safety Information

Danger notices contain information that could prevent death or serious injury�

!

WARNING

Warnings contain information that could prevent injury or equipment damage�

!

CAUTION

Caution notices contain information that could prevent equipment damage�

NOTE

Notes contain helpful information�

6

Contact Information

Find out more:

www�honeywellanalytics�com

Americas

Honeywell Analytics

405 Barclay Boulevard

Lincolnshire, IL 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell�com

Europe, Middle East, and Africa

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell�com

SPM Flex Gas Detector

Asia Pacic

Honeywell Analytics Asia Pacic Co., Ltd.

#701 Kolon Science Valley (1)

43 Digital-Ro 34-Gil, Guro-Gu

Seoul, 152-729

Korea

Tel: +82 2 6909 0321

VOIP: +8 5401 0321

analytics�ap@honeywell�com

Technical Services

ha�global�service@honeywell�com

www�honeywell�com

7

SPM Flex Gas Detector

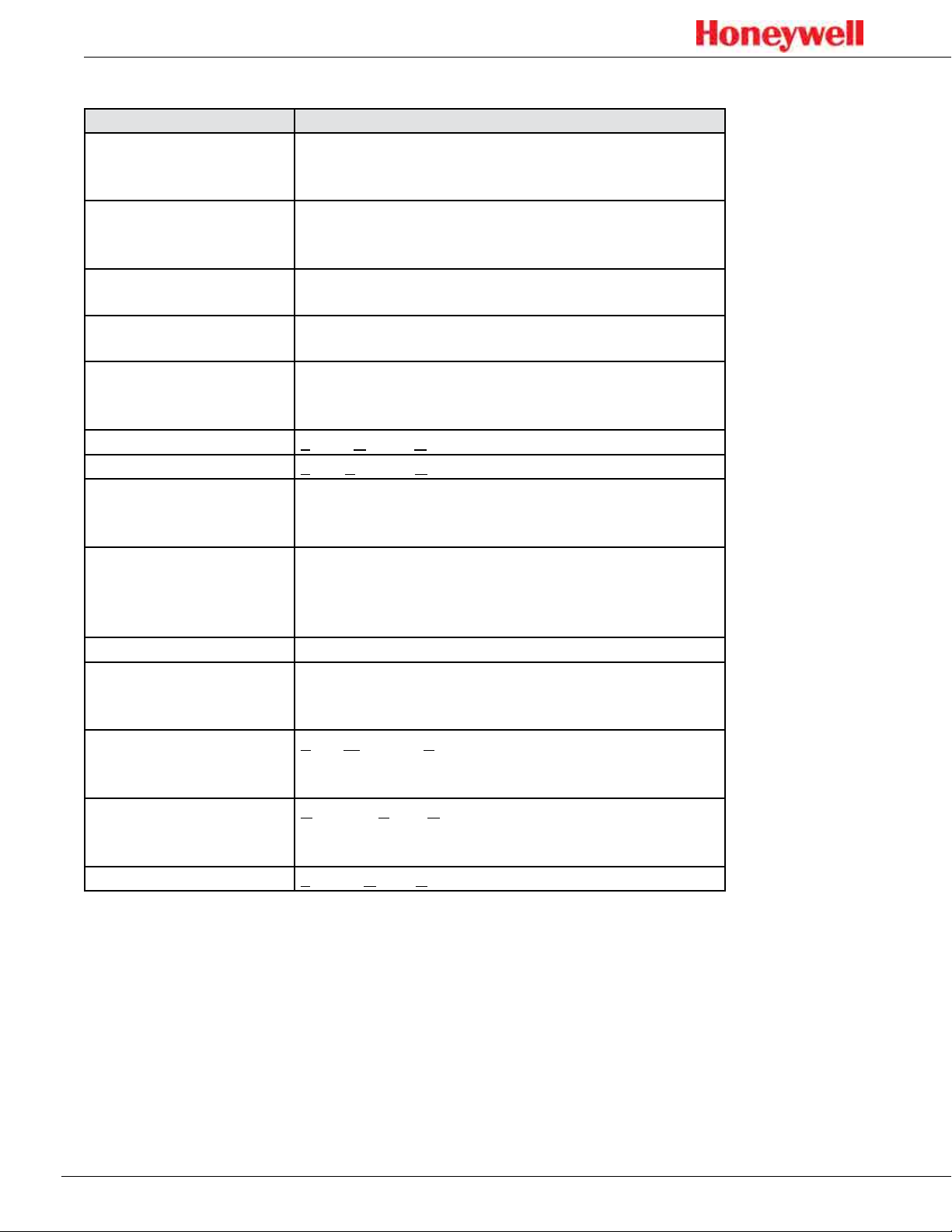

Glossary

Term Description

An analog communication method using a current

4-20 mA loop

®

Chemcassette

Ethernet

In monitor

Latching alarm or fault

LCD

LED

Modbus TCP

Non-latching alarm or

fault

Out of monitor The detector is on but idle

Relay

TWA

USB

VDC

cartridge

loop to indicate concentration readings and fault

status�

An easy-to-install case that carries Honeywell’s

Chemcassette tape� Cartridges are specific to

different gas types/families�

Commonly used network technology for wired Local

Area Networks�

The unit is actively monitoring the specified gas or

family of gases

When configured, the SPM Flex will hold the alarm or

fault status active until the user performs an alarm/

fault reset�

Liquid Crystal Display

Light Emitting Diode

Communications protocol running over Ethernet that

is commonly used for communicating with industrial

devices�

An alert in which the SPM Flex will reset

automatically when the condition is no longer

present (i�e�, the detector does not have to be reset

by the user)�

An electrical-operation output switch that can be

used to indicate the presence of alarm and fault

conditions�

Time Weighted Average, the average exposure to a

harmful gas, usually calculated over a period of eight

hours (a the typical workday)�

Universal Serial Bus is an industry standard

communications protocol and bus that is commonly

available on personal computers�

Volts of Direct Current

8

SPM Flex Gas Detector

WARNING

!

Product Overview

The SPM Flex gas detector is available in two configurations, portable and fixed�

The portable model is equipped with a handle assembly and a shoulder strap�

The fixed unit is supplied with a mounting bracket� If replacing an old SPM

detector, a retrofit bracket is available (these are shown on pages 28 and 29)�

1

All units are supplied with a power adaptor

manual, and a printed quick start guide�

Operate and service the SPM Flex gas detector only as specified in this manual

and the accompanying quick start guide� Failure to do so may impair the

protection provided by the detector and may also void the warranty�

Initial setup

Prior to use, the detector requires some minimal setup:

• Unpack the unit (save the packaging to re-use for service requests)�

• Read the quick start guide and this manual�

• Remove the paper optics card from the gate

and cable, a CD containing the user

Portable detectors

• Connect the power adaptor (in a dry, indoor location)

• Charge for at least 4 hours (the detector can be used while being charged)

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Load a chemcassette

• Configure the detector and begin to monitor (see pages 15-16 for basic

display usage)

• See detailed Operation (pages 32-41) and Optional accessories (pages 53-55)

Fixed detectors

• Install the wall-mount bracket and mount the detector to it (see pages 28-29)

• Wire in accordance with local electrical codes utilizing a trained electrician

(see pages 19-25)

• Input

• Honeywell-supplied power adaptor (indoor, dry location use only) or

• 24 VDC power supply

• Signal (as desired)

• 4-20 mA

• Relays

• Ethernet

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Load a Chemcassette cartridge

1 FSP Group Model FSP135-AAAN rated 1 5.62A / 24V (UL Listed QQGQ (E190414))

9

Loading...

Loading...