Honeywell VNT5150H1000, VNT5150E1000, VNT5200H1000, VNT5200E1000, VNT5070H1000 Installation Manual

...

69-2480EF-19

ERV/HRV Ventilation Systems

Systèmes de ventilation VRÉ/VRC

PROFESSIONAL INSTALLATION GUIDE.

GUIDE D’INSTALLATION PROFESSIONNELLE.

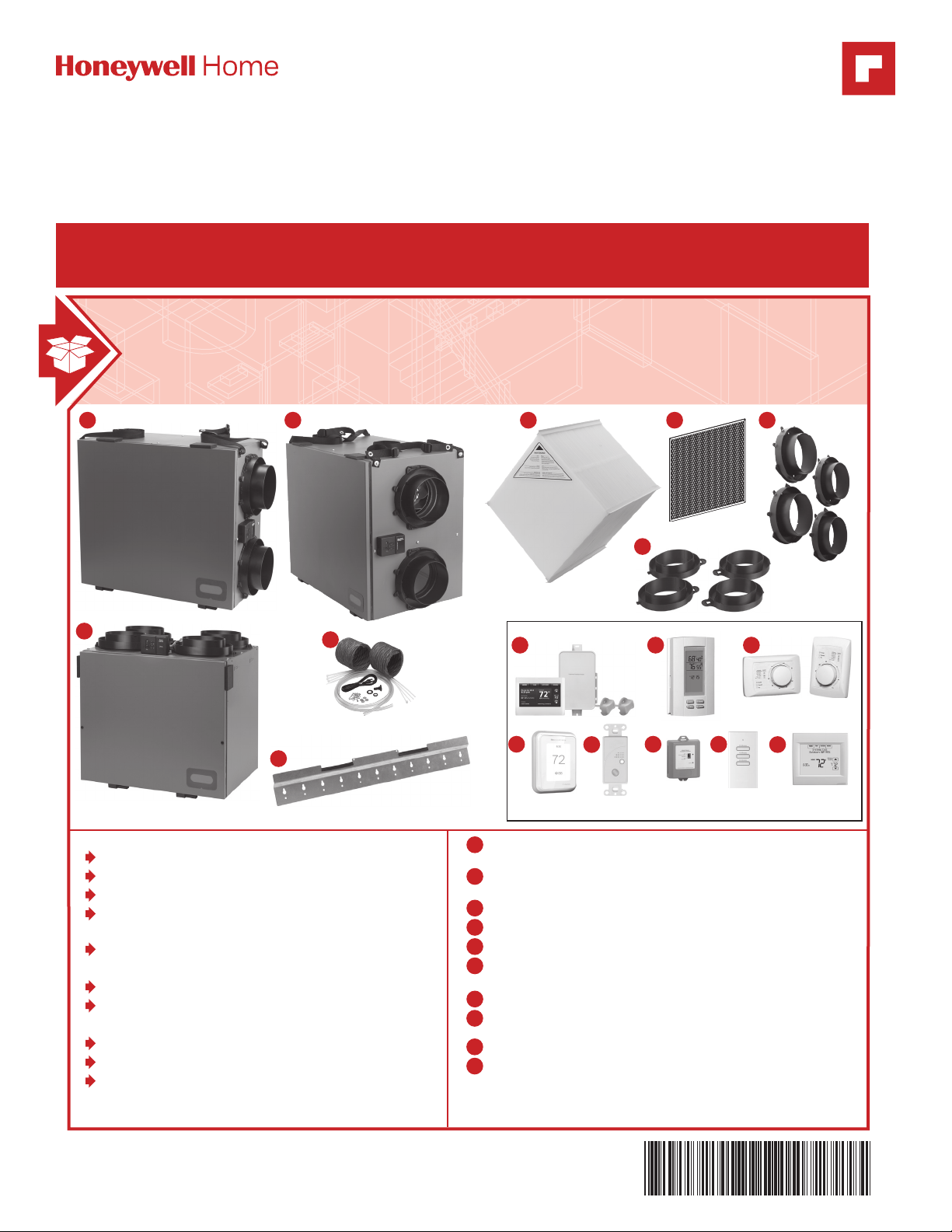

INCLUDED IN THIS BOX

A1 A2 B C

D2

A3

F

E

G1 G2

G4

G5

G6 G7

OPTIONAL CONTROLS SOLD SEPARATELY

Tools required to install ERV/HRV

Aluminum foil tape (UL181B)

Standard screwdriver

Crescent wrench

Hex driver (1/4 in.)

Accessories (not included)

6 in. Dia. insulated duct (VNT5150, VNT5200,

VNT6150 & VNT6200)

6 in. Dia. duct (VNT5150, VNT5200)

Two 6 in. Dia. weather hoods (VNT5150, VNT5200 ,

VNT6150 & VNT6200)

5 in. Dia. insulated flex duct (VNT5070)

5 in. Dia. flex duct (VNT5070)

6 in. Dia. matrix hood, 50063805009 (VNT5070)*

* 6 in. to 5 in. reducer required

ERV/HRV VNT5150H1000, VNT5150E1000 or

A1

VNT6150H1000

ERV/HRV VNT5200H1000, VNT5200E1000 or

A2

VNT6200H1000

ERV/HRV VNT5070H1000 or VNT5070E1000

A3

Heat/Energy Recovery Core (1)

B

Filter (2)

C

Round Duct Collars (4) (VNT5150 and VNT5200,

D1

VNT6150 & VNT6200)

Oval Duct Collars (VNT5070)

D2

Installation Kit (flex included with 5150 and 5200,

E

VNT6150 & VNT6200)

F

Wall Mount Bracket (VNT5070)

G

Optional Controls: 1 Prestige IAQ Kit, 2 DG115 IAQ Control,

3 - Dehumidistat H8908D, 4 - T10 Pro Smart,

5 - 20/40/60 Minute Boost Control,

6 - W8150 Ventilation Control

7 - Vent Boost Remote, 8 - VisionPRO WiFi

D1

G3

G8

Installation Checklist

Liste de vérification pour l’installation

Included in This Box

A1 ERV/HRV VNT5150H1000, VNT5150E1000 or

VNT6150H1000

A2 ERV/HRV VNT5200H1000, VNT5200E1000 or

VNT6200H1000

A3 ERV/HRV VNT5070H1000 or VNT5070E1000

B Heat/Energy Recovery Core

C Filter (2)

D1 Round Duct Collars (4) [VNT5150, VNT5200,

VNT6150, VNT6200]

D2 Oval Duct Collars (VNT5070)

E Installation Kit

F Wall Mount Bracket (VNT5070)

G Optional controls (sold seperately)

Control Options (Sold separately)

G1 - Prestige IAQ Kit

G2 - DG115 IAQ control

G3 - Dehumidistat H8908D

G4 - T10 Pro Smart

G5 - 20/40/60 Minute Boost Control

G6 - W8150 Ventilation Control

G7 - Vent Boost Remote

G8 - VisionPRO WiFi

Contenu

A1 VRE/VRC VNT5150H1000, VNT5150E1000 ou

VNT6150H1000

A2 VRE/VRC VNT5200H1000, VNT5200E1000 ou

VNT6200H1000

A3 ERV/HRV VNT5070H1000 ou VNT5070E1000

B Noyau de récupération de chaleur et d’énergie

C Filtre (2)

D1 Colliers de conduit ronds (4) (VNT5150, VNT5200, VNT6150,

VNT6200)

D2 Colliers de conduit ovales (VNT5070)

E Nécessaire d’installation (flexible inclus avec le 5150 et le 5200)

F Support de montage mural (VNT5070)

G Commandes en option (vendues séparément)

Commandes en option (vendues séparément)

G1 - Nécessaire Prestige IAQ

G2 - Régulateur numérique DG115 IAQ

G3 - Déshumidistat H8908D

G4 - T10 Pro Smart

G5 - Minuteur de ventilation à haute vitesse (20, 40 ou 60 minutes)

G6 - Régulateur de ventilation W8150

G7 - Commande à distance de surventilation

G8 - VisionPRO WiFi

Tools Required (not supplied)

• Aluminum foil tape (UL1818)

• Standard screwdriver

• Crescent wrench

• Hex driver (1/4 in.)

Accessories (not included)

• 6 in. Dia. insulated duct (VNT5150, VNT5200,

VNT6150, VNT6200)

• 6 in. Dia. duct (VNT5150, VNT5200, VNT6150,

VNT6200)

• Two 6 in. Dia. weather hoods (VNT5150,

VNT5200, VNT6150, VNT6200)

• 5 in. Dia. insulated flex duct (VNT5070)

• 5 in. Dia. flex duct (VNT5070)

• 6 in. Dia. matrix hood, 50063805009 (VNT5070)*

* 6 in. to 5 in. reducer required

Warning: Installation must be performed by a

qualified service technician and must comply

with local codes.

Remove power to the device before installing or

servicing the device.

Failure to connect the device according to these

instructions may result in damage to the device

or the controls.

Outils nécessaires (non fournis)

• Ruban d’aluminium (UL1818)

• Tournevis standard

• Clé à molette

• Tournevis à tête hexagonale (1/4 po)

Accessoires (non inclus)

• Conduit isolé de 6 po de diamètre (VNT5150, VNT5200,

VNT6150, VNT6200)

• Conduit de 6 po de diamètre (VNT5150, VNT5200, VNT6150,

VNT6200)

• Hottes anti-intempéries de 6 po (VNT5150, VNT5200,

VNT6150, VNT6200)

• Conduit flexible isolé de 5 po de dia. (VNT5070)

• Conduit flexible de 5 po de dia. (VNT5070)

• Hotte à matrice de 6 po de dia. (VNT5070)*

* Réducteur de 6 po à 5 po requis

Avertissement : L’installation doit être effectuée par un

technicien qualifié et être conforme aux règlements locaux.

Débranchez l’appareil avant de l’installer ou d’en effectuer

l’entretien.

Un branchement de l’appareil non conforme aux présentes

instructions pourrait entraîner des dommages à l’appareil

lui-même ou aux commandes.

INSTALLATION INSTRUCTIONS BEGIN ON PAGE 1

INSTRUCTIONS POUR L’INSTALLATION COMMENCENT À LA

page 44.

ERV/HRV Balanced Ventilation Systems

ABOUT THE ERV/HRV VENTILATION SYSTEM

Benefits.............................................................................................2

Determining Your Ventilation Needs .................................3

Specifications ................................................................................4

External Control Options ......................................................13

INSTALLATION

Install to Fit Your Application .............................................14

Installation Steps ......................................................................17

Automated Defrost ..................................................................24

Wiring .............................................................................................24

Terminal Description ........................................................24

Wiring with Remote Controls .......................................25

Controls Wiring ...................................................................25

Control Panel ..............................................................................28

Speed Control used as a Mode Control .................29

Speed Control used as a Balancing Control ........29

Speed Control used as a Motor Control .................29

MAINTAINENCE

Maintenance ...............................................................................33

Cleaning Steps ...........................................................................34

Troubleshooting ........................................................................35

OS and Parts List ......................................................................38

Parts Illustration: VNT5150, VNT5200,

VNT6150 & VNT6200 .......................................................39

Parts Illustration: VNT5070 .................................................40

WARRANTY

5Year Limited Warranty ....................................................... 41

Balancing Steps ........................................................................29

Balancing Reset ........................................................................31

Checkout .......................................................................................31

• Prior to installing, serious consideration must be taken to ensure this ventilation system

will operate properly if integrated to any other type of mechanical system, i.e. a forced

air system, or an air handling unit. To ensure proper operation and compatibility of

both systems, it is required that the unit’s airflows (intake and exhaust) be balanced, by

following the procedures found in this manual

• Install the unit with space to access the front panel controls and the side access panel

for maintenance and service.

• To ensure quiet operation, do not place the device directly on the structural supports of

the home.

• The product is for residential applications only. Must be installed in accordance with all

national and local regulations, building and safety codes

NEED HELP? For assistance with this product please visit http://www.resideo.com

?

or call Customer Care toll-free at 18004681502.

Read and save these instructions.

® U.S. Registered Trademark. Patents pending. Copyright © 2020 Resideo Technologies, Inc. All rights reserved.

ERV/HRV Ventilation Systems 692480EF19

1

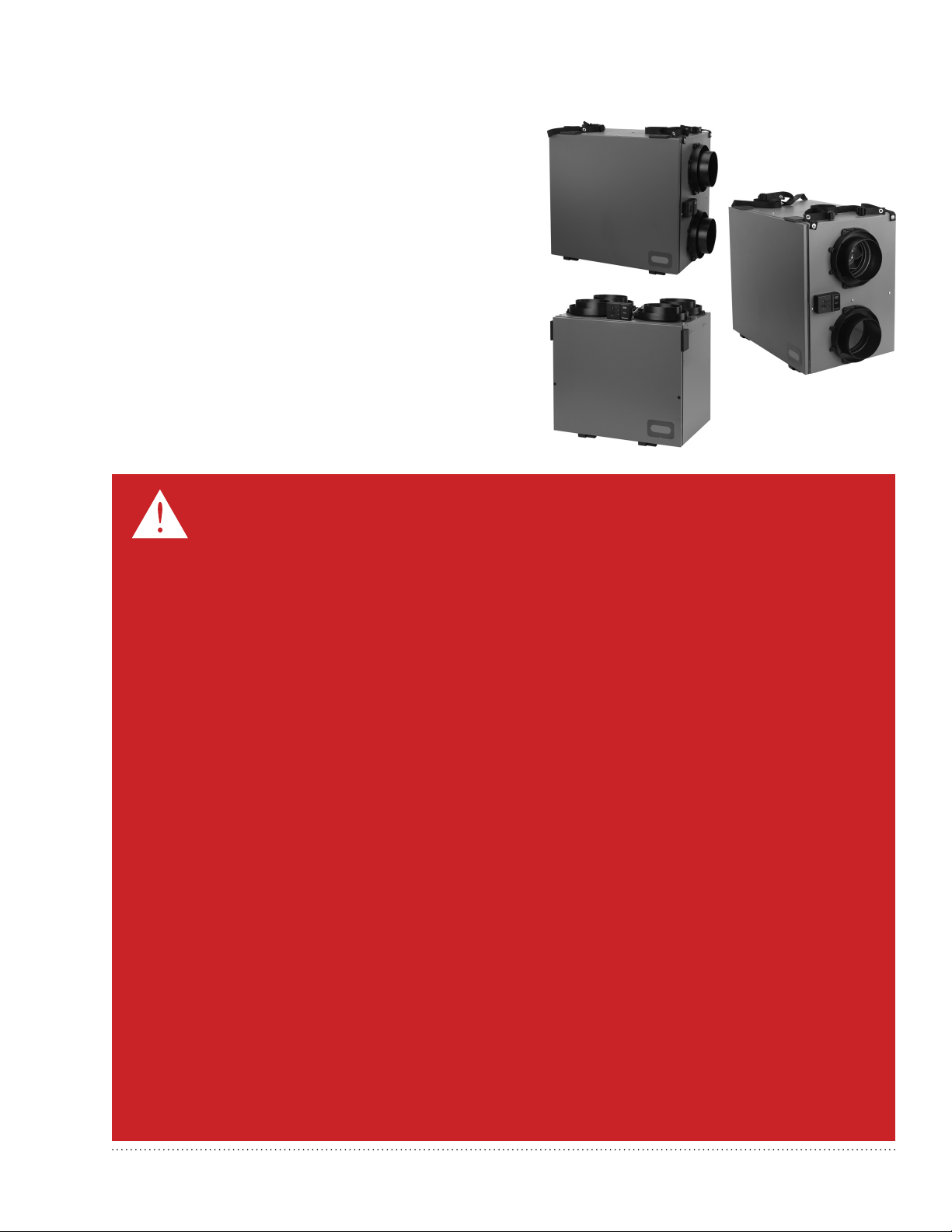

About the ERV/HRV Ventilation System

The ERV/HRV Balanced Ventilation System provides

improved indoor air quality through its high performance

and efficiency.

Benefits

• Ventilation with sensible heat recovery (ERV and HRV)

• Ventilation with latent heat recovery (ERV only)

• Simplified mounting (hanging)

• Optional hanging with included straps.

• Removable duct collars for easy ducting to the unit

• Intuitive balancing via two variable speed motors and

a speed control

• Fits in tight spaces (VNT5070)

CAUTION: Electrical shock and fire hazard. Can cause personal and equipment damage.

• Before servicing or cleaning the system, always remove the power cord from the AC

wall outlet.

• Wear protective clothing and safety glasses when installing ventilator and working

with sheet metal.

• To reduce the hazards of electric shock or fire, do not perform any service to the

system other than those stated in the operating manual instructions.

• To reduce the risk of electric shock, this ventilation system comes equipped with a

3-prong plug-in. This plug will fit in a polarized outlet only one way.

• Do not use ventilation system for outdoor application.

• Do not pull or twist power cord when disconnecting it from the ventilation system.

Grasp the plug firmly, not the cord.

• Do not modify the power plug in any way; if modified, risk of electric shock, fire, or even

damage to the unit may occur.

• Do not use the ventilation system for removal of flammable fumes, gases or connect

directly to any appliances.

• Use a 120 VAC outlet only.

• Do not use an extension cord.

• Do not obstruct or cover the air intake or air outlet of the ventilation system.

• Do not modify, repair or disassemble this system. These tasks are to be performed by

authorized serviced personnel only. Fire, electrical shock and/or bodily injury may

occur if these warnings are not followed.

• To prevent injuries, do not operate the ventilation system, while servicing or

maintaining. There are impeller wheels turning at a very high speed that must fully

stop rotating prior to accessing the inside of the unit.

• Always assess how the operation of the ventilation system may interact with vented

combustion equipment (i.e. Gas Furnace, Oil Furnace, Combustion, Appliances, etc.)

• Ensure unit is properly installed and suspended to prevent falling or dropping injuries.

2

ERV/HRV Ventilation Systems 69-2480EF—19

Determining Your Ventilation Needs

How much fresh air do you need?

Good air quality is based in part on the capacity of the home’s ventilation system. Usually, the unit’s capacity

is measured in CFM (Cubic Feet per Minute) or L/s (Liters per second) of fresh air being distributed in the

living space. Use the ASHRAE 62.2 Ventilation Standard, the Room Count Calculation Method, or the Air

Change Per Hour (ACH) Method to determine your ventilation needs.

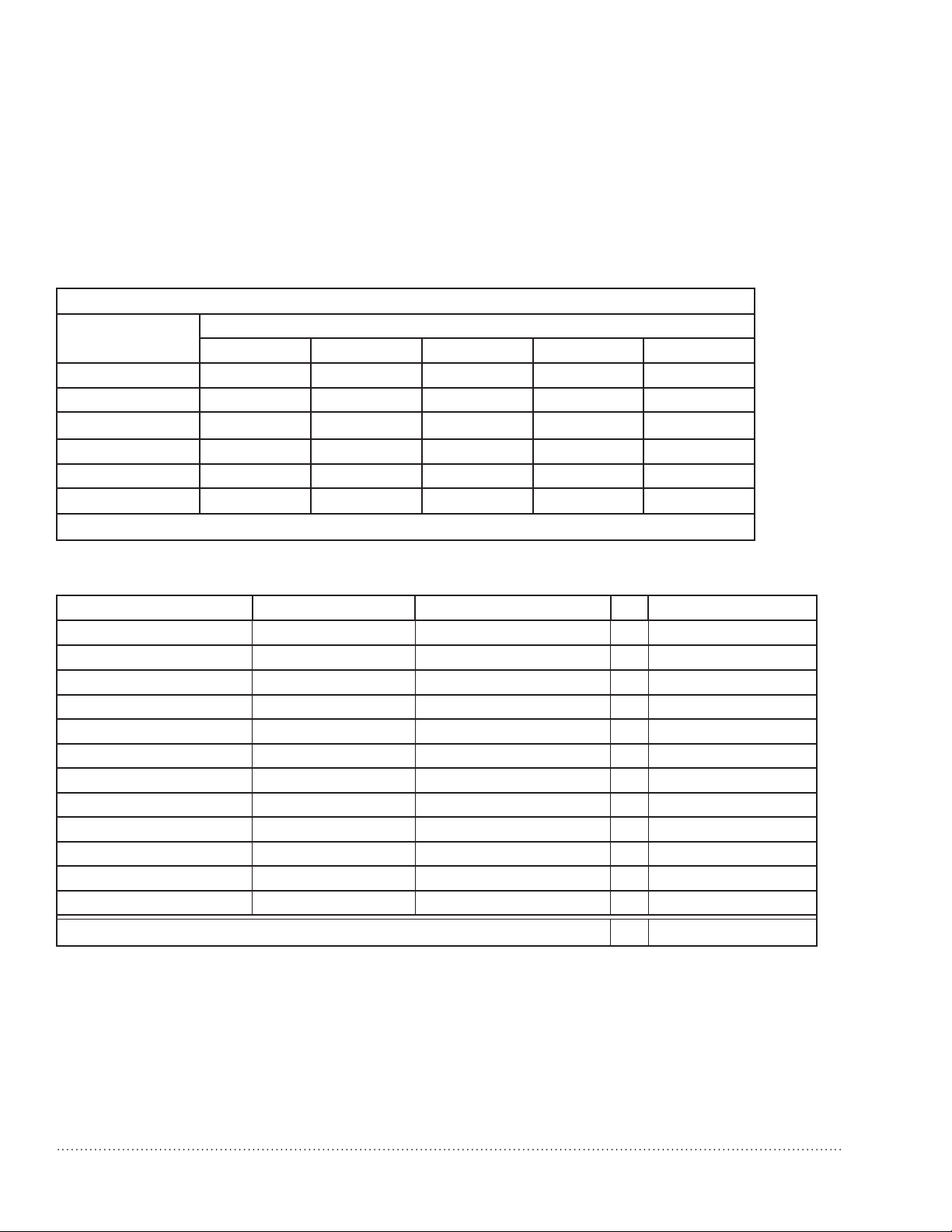

ASHRAE 62.2 Ventilation Standard

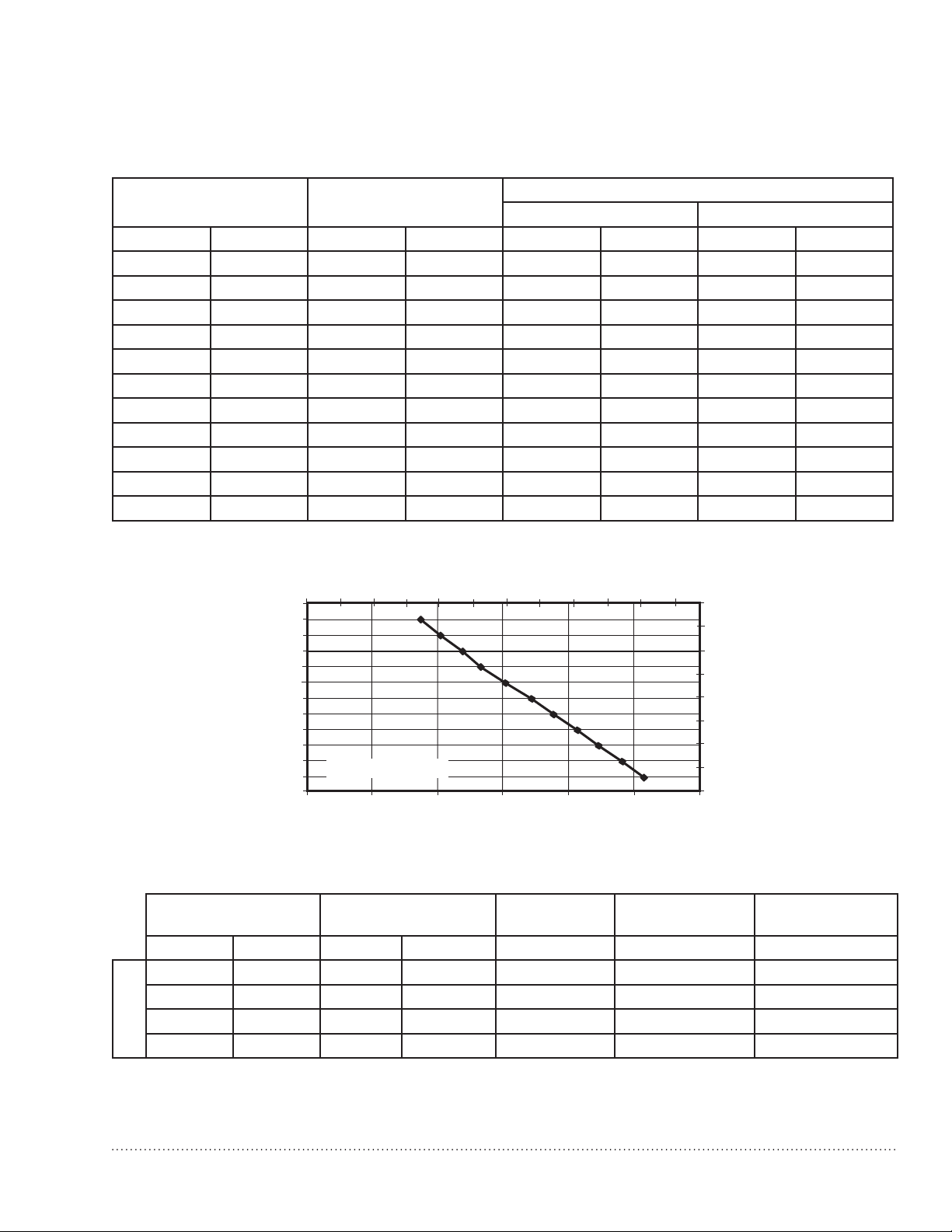

ASHRAE 62.2 CFM Sizing Chart

Floor Area (ft

< 1500 30 45 60 75 90

1501 - 3000 45 60 75 90 105

3001 - 4500 60 75 90 105 120

4501 - 6000 75 90 105 120 135

6001 - 7500 90 105 120 135 150

> 7500 105 120 135 150 165

ANSI/ASHRAE STANDARD 62.22010 - Ventilation Air Requirements; values in cfm

The above chart outlines the minimum requirements for continuous ventilation.

Number of Bedrooms / CFM

2

)

01 23 45 67 >7

Room Count Calculation Method

Living Space Number of Rooms x CFM (or L/s) = CFM Required

Master Bedroom x 20 cfm (or 10 L/s) =

Basement x 20 cfm (or 10 L/s) =

Single bedroom x 10 cfm (or 5 L/s) =

Living Room x 10 cfm (or 5 L/s) =

Dining Room x 10 cfm (or 5 L/s) =

Family Room x 10 cfm (or 5 L/s) =

Recreation Room x 10 cfm (or 5 L/s) =

Other x 10 cfm (or 5 L/s) =

Kitchen x 10 cfm (or 5 L/s) =

Bathroom x 10 cfm (or 5 L/s) =

Laundry Room x 10 cfm (or 5 L/s) =

Utility Room x 10 cfm (or 5 L/s) =

Total Ventilation Requirement =

Air Change Per Hour (ACH) Method

TOTAL cubic feet X 0.35 per hour = total cubic feet per hour

Take total and divide by 60 to get cubic feet per minute (CFM)

Example: A 25 ft. x 40 ft. (1,000 sq. ft.) house with basement

1,000 sq. ft. x 8 ft. high x 2 (1st floor + basement) = 16,000 cu. ft.

16,000 cu. ft. x 0.35 ACH = 5,600 cubic feet per hour

5,600 cu. ft. / 60 Minutes = 93 cubic feet per minute (CFM)

93 CFM is your ventilation need

ERV/HRV Ventilation Systems 69-2480EF—19 3

Specifications

FRONT CLEARANCE OF 25 INCHES

M28919A

14-1/2

M33111

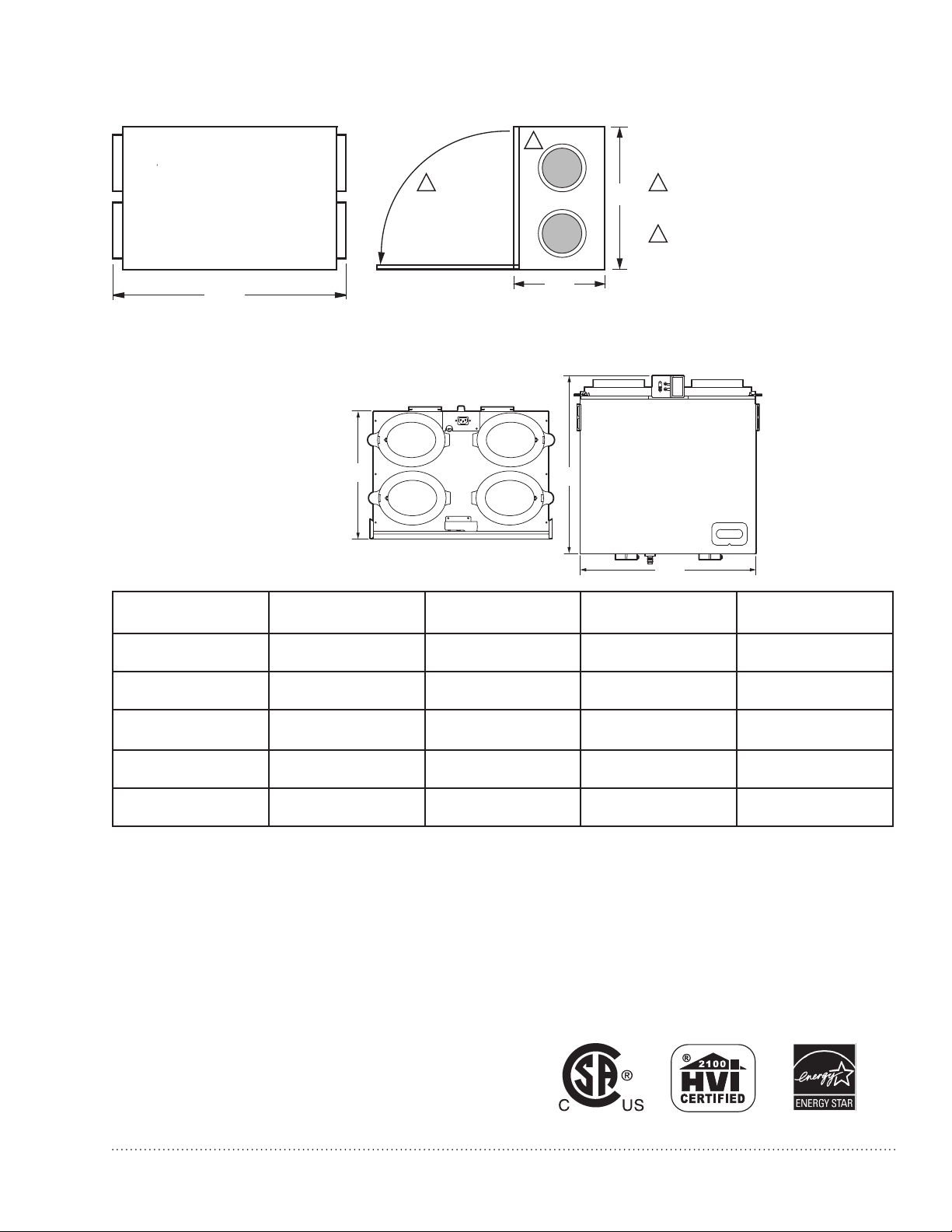

Dimensions in inches (mm) of VNT5150, VNT5200, VNT6150 and VNT6200

2

1

L

VNT5150H1000, VNT5150E1000 or VNT6150H1000: H = 22 1/2 in. (572 mm), W = 11 1/2 in. (295 mm), L = 29 1/2 in. (749 mm)

VNT5200H1000, VNT5200E1000 or VNT6200H1000: H = 22 1/2 in. (572 mm), W = 16 1/2 in. (422 mm), L = 29 1/2 in. (749 mm)

W

1

H

(635 MM) IS REQUIRED FOR

SERVICING UNIT.

ALL DUCT CONNECTIONS ARE

2

6 IN. (150 MM).

Dimensions in inches (mm) of VNT5070:

(368)

Physical Specifications:

Model Product Weight Shipping Weight Heat/Energy Core

VNT5150H1000

VNT5150E1000

VNT5200H1000

VNT5200E1000

VNT5070H1000

VNT5070E1000

VNT6150H1000 43.5 lbs. (19.7 kg) 50 lbs. (22.7 kg)

VNT6200H1000 51.5 lbs. (23.4 kg) 61.5 lbs. (27.9kg)

42 lbs. (19.0 kg) 47.5 lbs. (21.55 kg)

50 lbs. (22.68 kg) 57.5 lbs. (26.08 kg)

33 lbs. (15.0 kg) 40.5 lbs. (18.4 kg)

21

(533)

Dimensions

12”x10”x12”

305x254x305 mm

12”x15”x12”

305x381x305 mm

10”x10”x9”

254x254x228.6 mm

12”x10”x12”

305x254x305 mm

12”x15”x12”

305x381x305 mm

20 (507)

Filter Dimensions

10”x12”

254x305 mm

15”x12”

381x305 mm

9”x9.75”

228.6x247.6 mm

10”x12”

254x305 mm

15”x12”

381x305 mm

Operating Ranges:

Ambient Temperature: 34 to 140 ºF (1 to 60 ºC)

Humidity: 095% RH

• Drain tubing diameter: 1/2 in. (12.7 mm)

• Cabinet: 20 gauge galvanized steel

Electrical Ratings:

Input Voltage: 120 VAC, 60 Hz

Input Current: 1.5 A (VNT5150, VNT5200, VNT6150 &

VNT6200), 0.85 A (VNT5070)

Output Power to Terminals: 5 VDC, 1.0 A maximum

• Flexible Duct (2): VNT5150, VNT5200, VNT6150 & VNT6200: 6 in. round for inlet and outlet. Flexible vinyl,

compatible for connection to rigid or flexible ducting with sheet metal screws and/or tape. VNT5070: 5 in. oval for inlet

and outlet. Flexible vinyl, compatible for connection to flexible ducting with sheet metal screw and/or tape.

Standards and Certifications:

CSA22.2 #11310, CSA 439 Standard

UL Standard 1812

RoHS Compliant

HVI Certified

FCC Part 15, Class B

ENERGY STAR (VNT6150H1000 & VNT6200H1000)

Install the ERV/HRV Ventilation System according to national and local regulations, building, and safety codes.

4

ERV/HRV Ventilation Systems 69-2480EF—19

Specifications (continued)

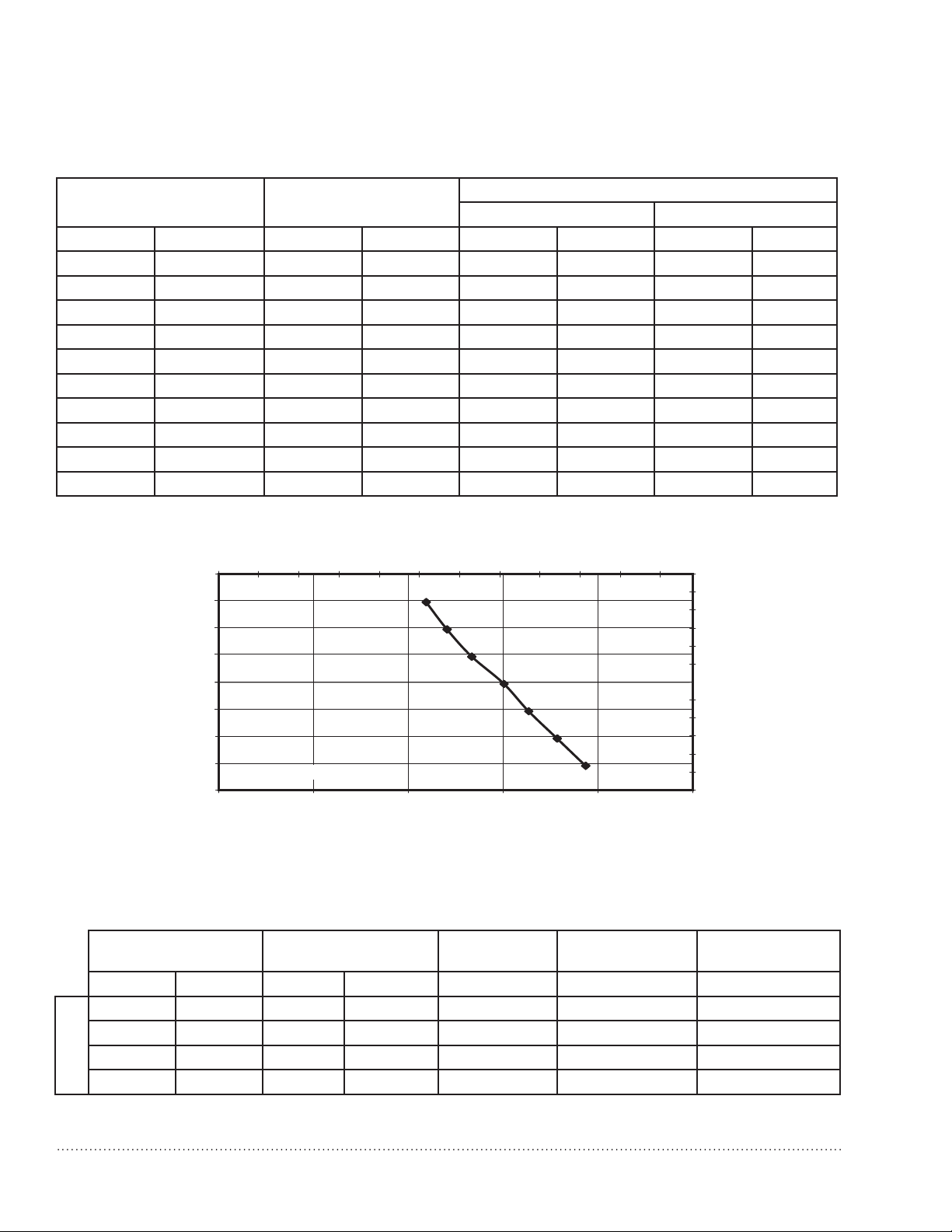

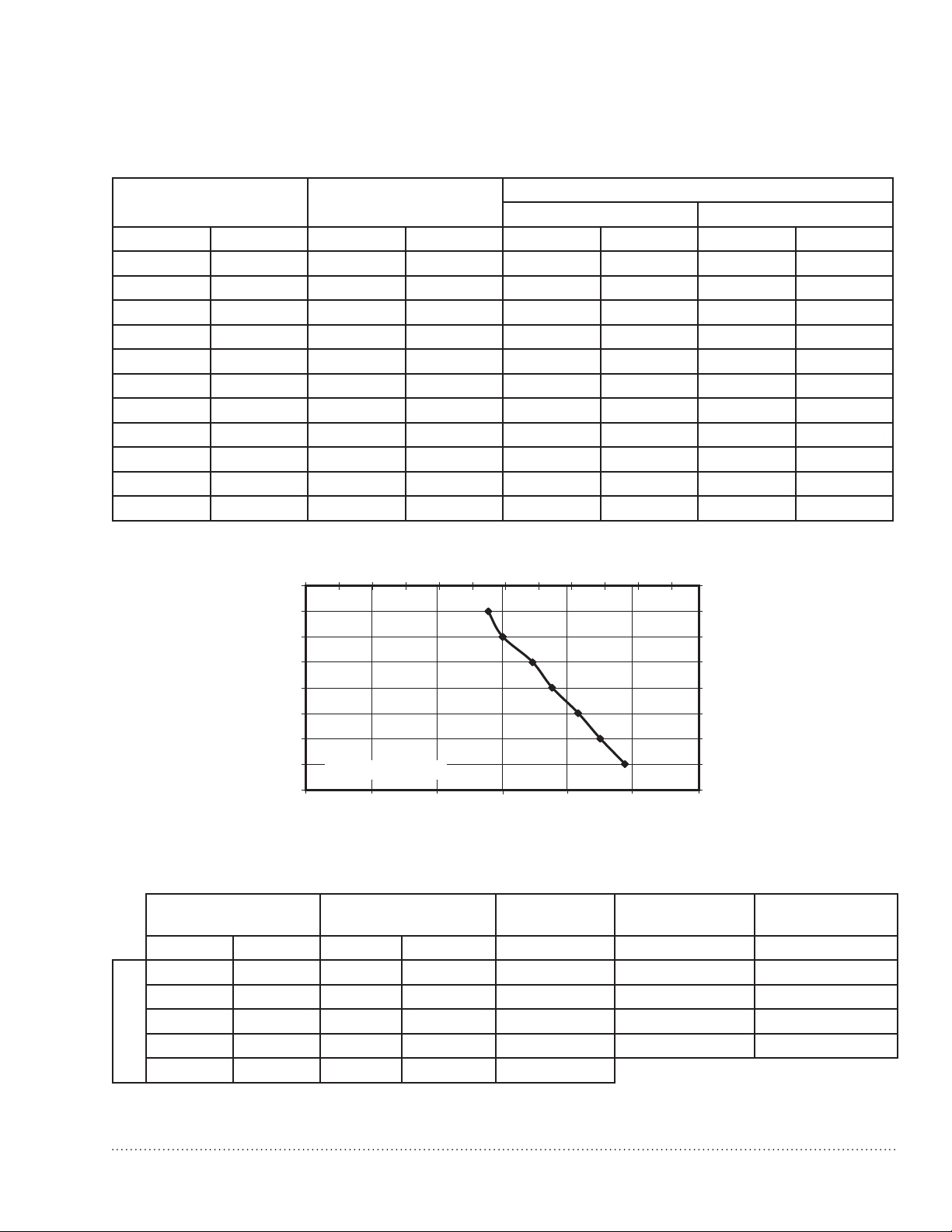

VNT5150H1000

AIR FLOW (CFM)

PRESSURE

VNT5150H1000 Ventilation Performance

External Static Pressure Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 91 193 91 194 103 217

50 0.2 84 178 85 179 95 201

75 0.3 77 163 77 163 86 183

100 0.4 71 150 71 151 80 169

125 0.5 63 133 63 134 71 152

150 0.6 57 120 57 121 66 138

175 0.7 51 109 51 109 57 121

200 0.8 46 96 46 96 50 106

225 0.9 40 85 40 86 43 91

250 1 35 75 36 75 39 82

AIR FLOW (L/S)

300

275

250

225

200

175

150

125

100

75

50

25

0

EXTERNAL

STATIC

PRESSURE

(PA)

M32358A

EXTERNAL

STATIC

(IN. W. C)

0102030405060708090100 110

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

NET SUPPLY AIR FLOW

050100 150 200 250

VNT5150H1000 Energy Performance

Supply Temperature Net Supply Air Flow

Average

Power

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 31 65 72 66 75

0 32 39 83 80 63 72

0 32 50 107 94 60 67

Heating

25 13 36 76 72 56 73

ERV/HRV Ventilation Systems 69-2480EF—19 5

Sensible

Recovery

Apparent

Sensible

Specifications (continued)

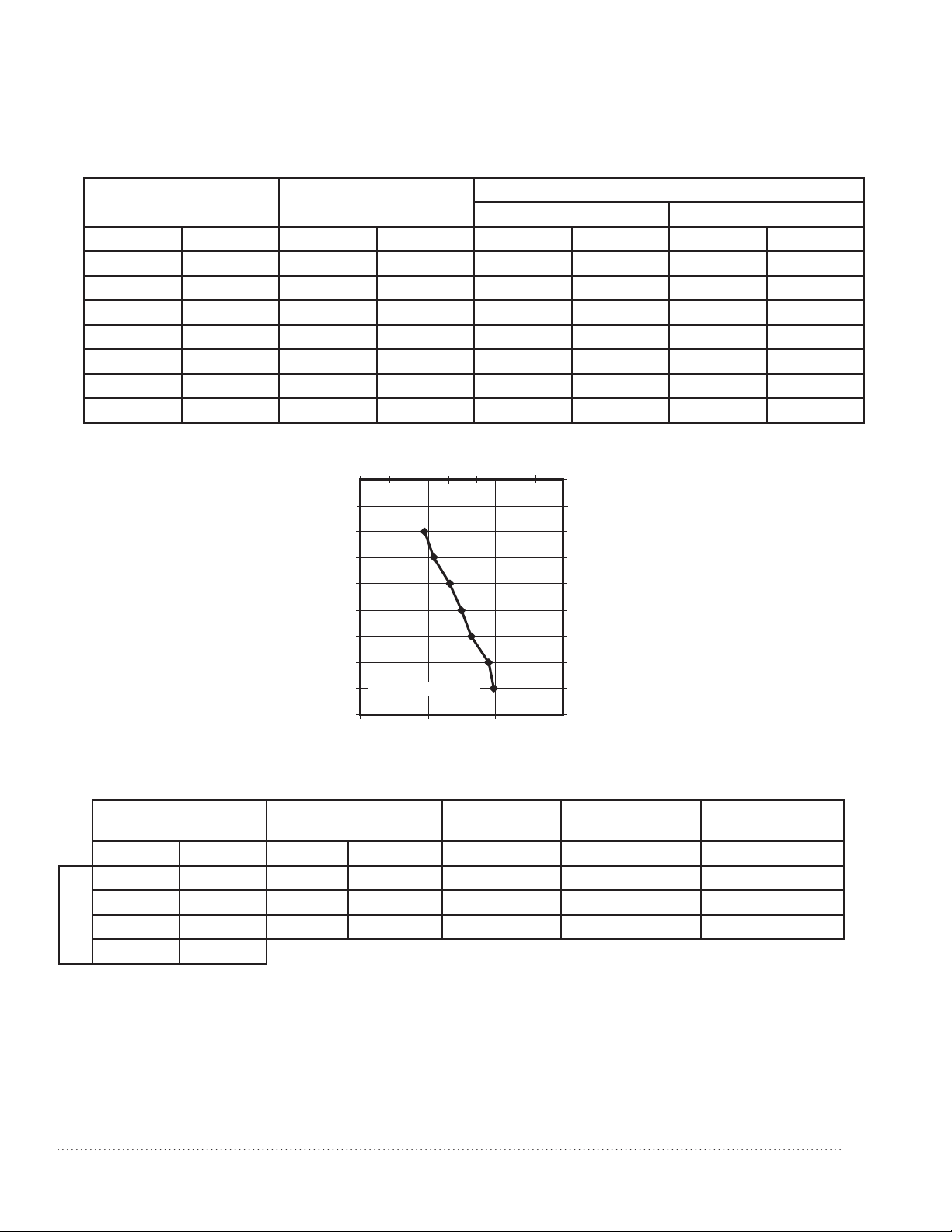

VNT5200H1000

PRESSURE

AIR FLOW (CFM)

PRESSURE

VNT5200H1000 Ventilation Performance

External Static

Pressure

Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 117 248 118 250 130 277

50 0.2 108 229 109 231 119 253

75 0.3 102 218 103 220 110 234

100 0.4 94 200 95 202 101 216

125 0.5 85 181 86 183 92 197

150 0.6 77 163 78 165 82 175

175 0.7 69 146 70 148 71 151

200 0.8 61 129 61 131 60 128

225 0.9 52 110 52 111 49 104

250 1 45 96 46 97 40 86

0102030405060708090100 110 120 130 140

0.8

0.7

0.6

AIR FLOW (L/S)

200

175

150

0.5

EXTERNAL

STATIC

0.4

(IN. W. C)

0.3

0.2

0.1

0

050 100 150 200 250 300

NET SUPPLY AIR FLOW

VNT5200H1000 Energy Performance

Supply Temperature Net Supply Air Flow

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 55 118 106 61 71

0 32 75 160 132 58 65

0 32 87 185 150 55 62

Heating

25 13 57 120 105 58 72

Average

Power

125

EXTERNAL

STATIC

100

75

50

25

0

Sensible

Recovery

Total Recovery Efficiency = 48%

(PA)

M32354

Apparent

Sensible

6

ERV/HRV Ventilation Systems 69-2480EF—19

Specifications (continued)

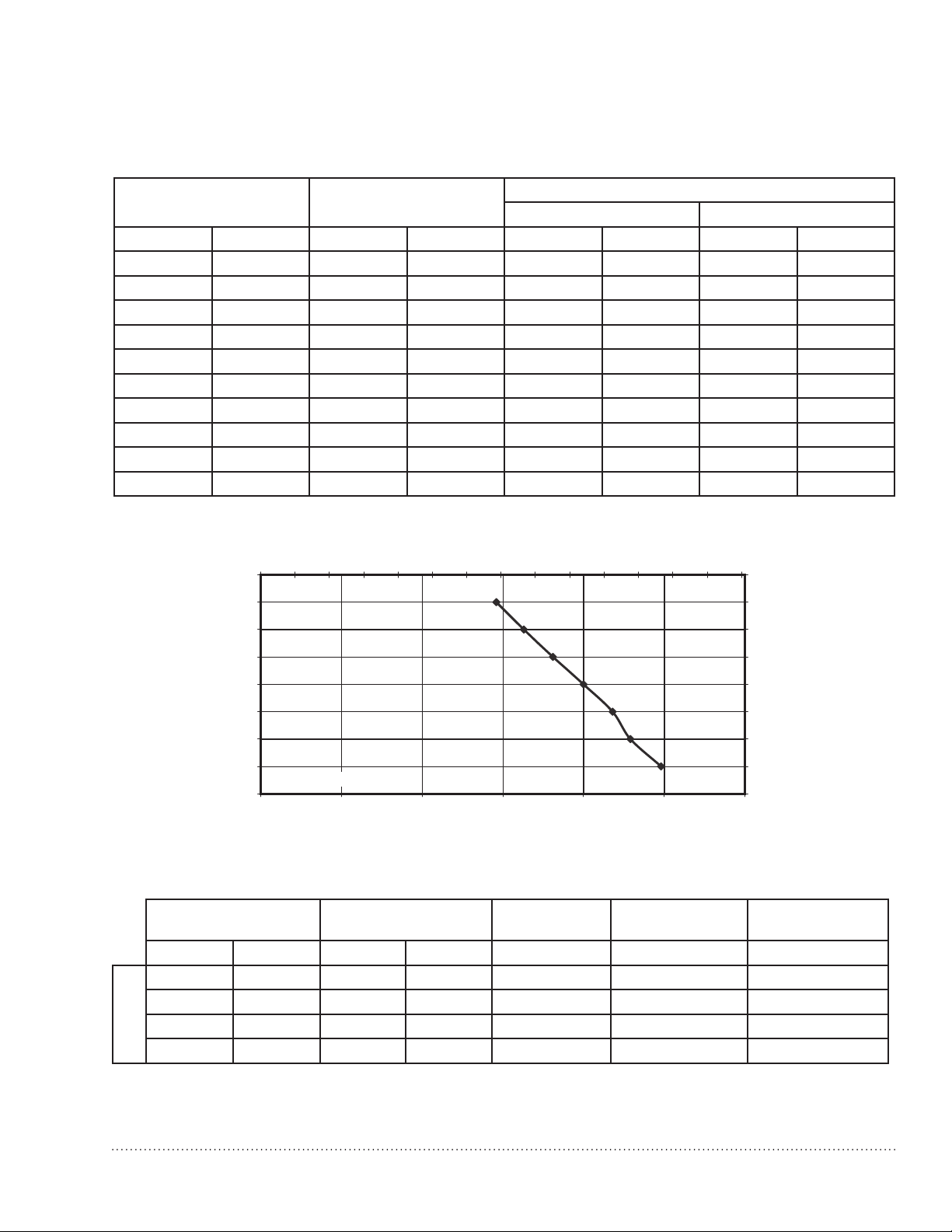

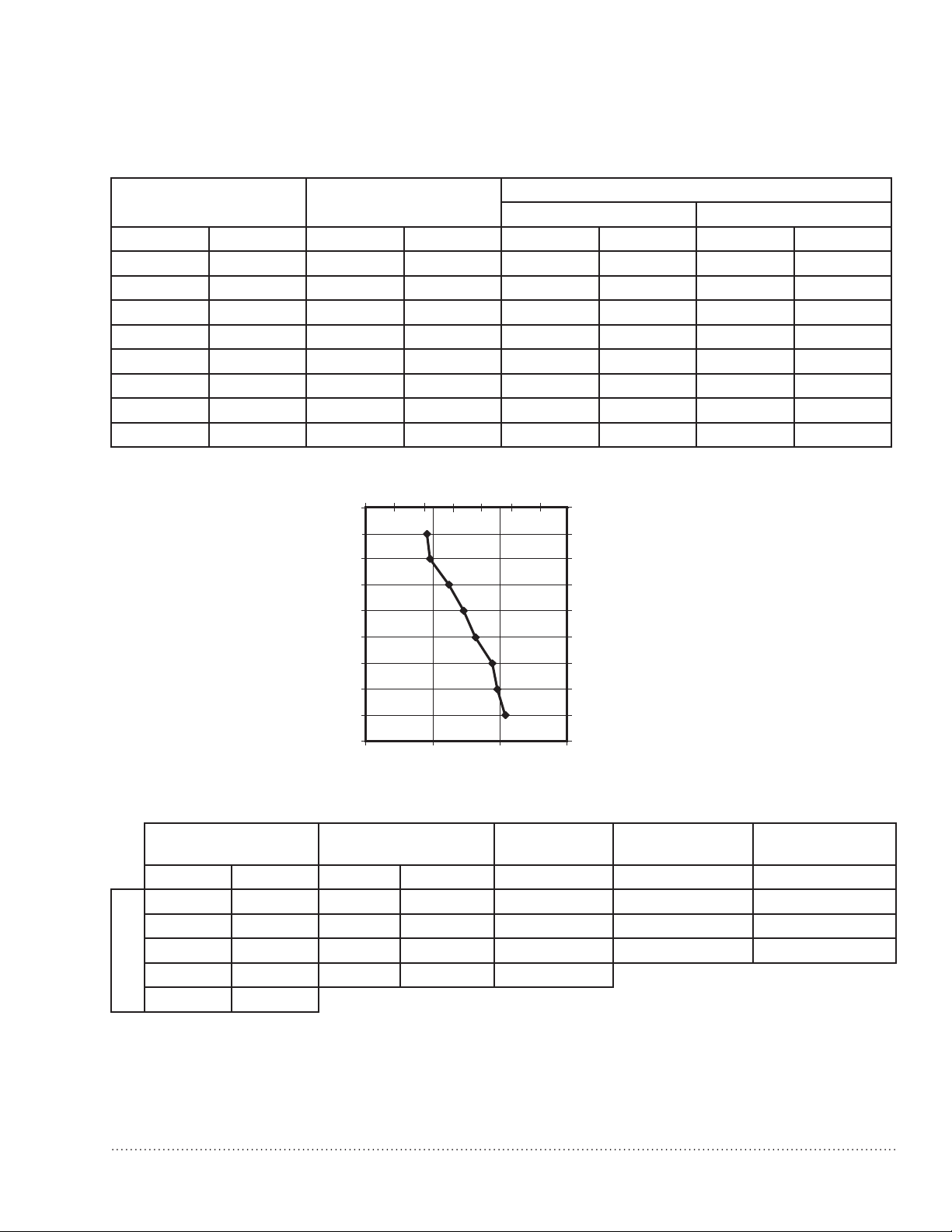

VNT5150E1000

AIR FLOW (CFM)

EXTERNAL

PRESSURE

PRESSURE

VNT5150E1000 Ventilation Performance

External Static Pressure Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 97 207 99 210 99 211

50 0.2 89 189 91 193 91 193

75 0.3 88 187 84 179 84 178

100 0.4 75 159 76 162 76 162

125 0.5 70 148 71 150 69 147

150 0.6 62 131 63 133 62 131

175 0.7 55 116 55 118 55 117

200 0.8 49 104 50 106 48 102

225 0.9 42 90 43 91 43 92

250 1.0 36 77 37 78 40 86

275 1.1 32 68 32 69 32 69

AIR FLOW (L/S)

STATIC

(IN. W. C)

0102030405060708090 100 110

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

NET SUPPLY AIR FLOW

0.0

050100 150 200 250

200

175

150

125

100

75

50

25

0

EXTERNAL

STATIC

(PA)

M32370A

VNT5150E1000 Energy Performance

Supply Temperature Net Supply Air Flow

°C °F L/s CFM Watts Efficiency % Effectiveness %

Average

Power

0 32 24 51 58 65 76

0 32 38 80 76 65 73

0 32 56 118 96 62 70

15 5 26 55 59 52 78

Heating

35 95 30 64 66

ERV/HRV Ventilation Systems 69-2480EF—19 7

Sensible

Recovery

Apparent

Sensible

Total Recovery Efficiency = 34%

Specifications (continued)

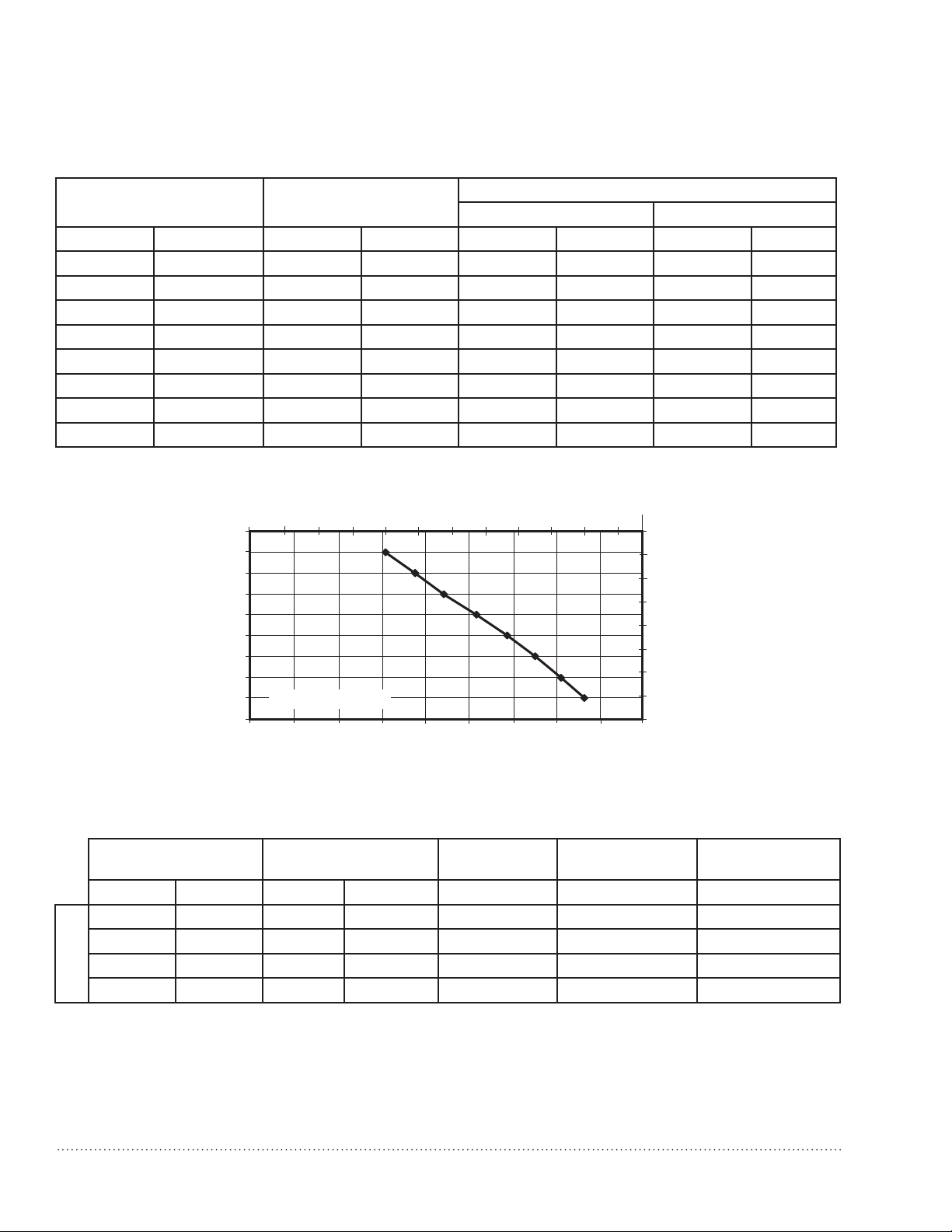

VNT5200E1000

AIR FLOW (CFM)

EXTERNAL

PRESSURE

EXTERNAL

PRESSURE

VNT5200E1000 Ventilation Performance

External Static

Pressure

Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 115 244 116 247 108 230

50 0.2 106 225 107 228 101 215

75 0.3 98 208 99 210 95 202

100 0.4 88 188 89 190 83 177

125 0.5 81 173 82 175 74 157

150 0.6 71 150 71 152 67 142

175 0.7 65 139 66 140 60 127

200 0.8 57 122 58 124 52 110

225 0.9 49 105 50 106 42 89

250 1 40 86 41 87 67 74

275 1.1 34 72 34 73 30 63

AIR FLOW (L/S)

STATIC

(IN. W. C)

0102030405060708090 100 110

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

NET SUPPLY AIR FLOW

050 100 150 200 300

250

200

175

150

125

100

75

50

25

0

STATIC

(PA)

M32369A

VNT5200E1000 Energy Performance

Supply Temperature Net Supply Air Flow

°C °F L/s CFM Watts Efficiency % Effectiveness %

Average

Power

0 32 37 78 74 71 81

0 32 50 107 80 72 79

0 32 71 150 102 69 77

15 5 36 75 65 58 82

Heating

35 95 35 75 72

8

Sensible

Recovery

Apparent

Sensible

Total Recovery Efficiency = 48%

ERV/HRV Ventilation Systems 69-2480EF—19

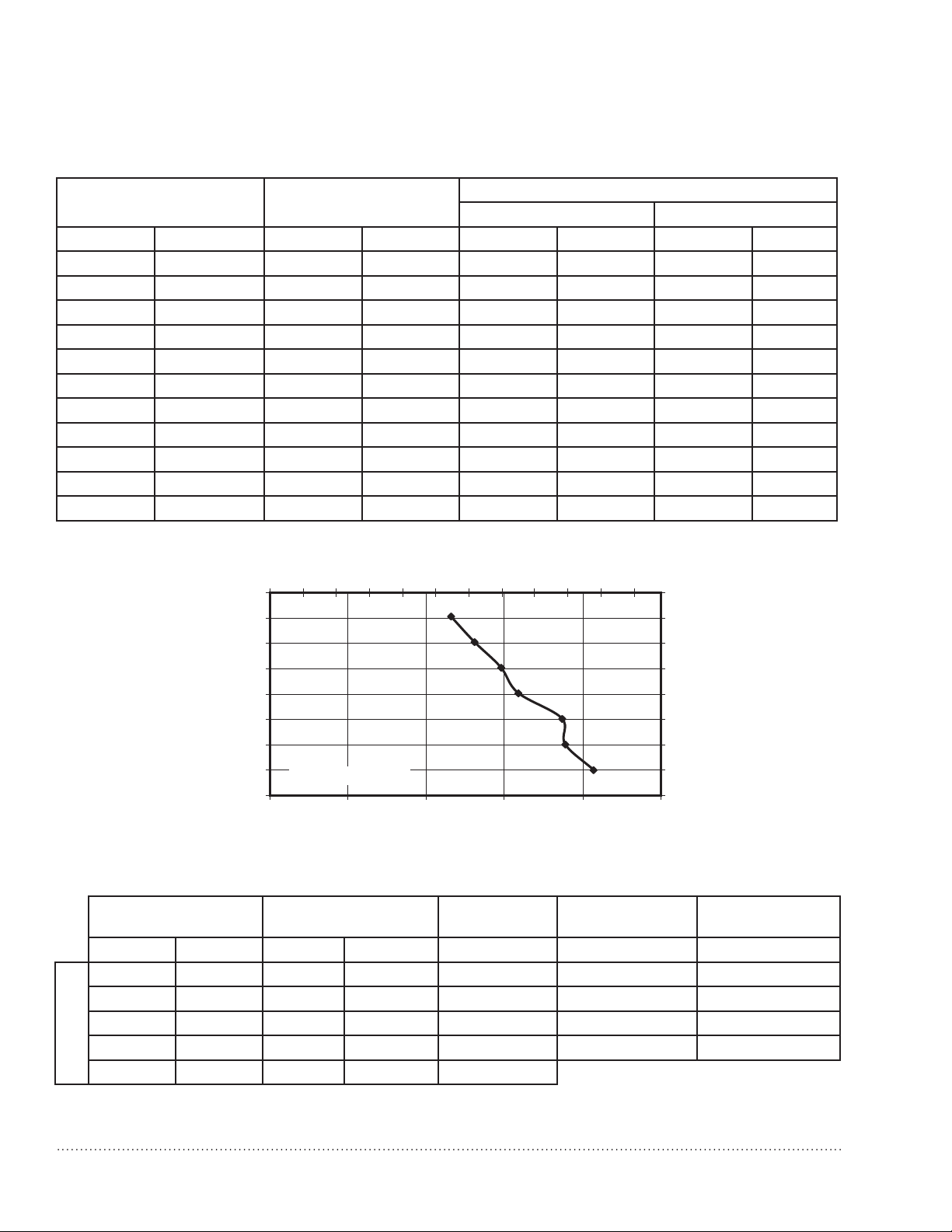

VNT5070H1000

AIR FLOW (CFM)

M33685

Specifications (continued)

VNT5070H1000 Ventilation Performance

External Static

Pressure

Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 47 99 48 100 48 102

50 0.2 44 93 45 94 43 92

75 0.3 39 83 40 84 38 80

100 0.4 35 75 35 75 36 78

125 0.5 30 65 30 66 32 68

150 0.6 27 56 27 57 25 52

175 0.7 22 46 22 47 19 41

AIR FLOW (L/S)

60

50

225

200

175

150

EXTERNAL

125

PRESSURE

100

75

50

25

0

STATIC

(PA)

EXTERNAL

STATIC

PRESSURE

(IN. W. C)

01020

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

NET SUPPLY AIR FLOW

0.1

0.0

050 100 150

40

30

VNT5070H1000 Energy Performance

Supply Temperature Net Supply Air Flow

Average

Power

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 19 40 28 64 72

0 32 30 65 40 59 66

25 13 18 37 30 55 73

Heating

ERV/HRV Ventilation Systems 69-2480EF—19 9

35 95

Sensible

Recovery

Apparent

Sensible

VNT5070E1000

AIR FLOW (CFM)

M33684

Specifications (continued)

VNT5070E1000 Ventilation Performance

External Static

Pressure

Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 49 105 49 105 46 97

50 0.2 46 97 47 99 41 86

75 0.3 44 92 44 93 41 86

100 0.4 37 80 38 81 34 73

125 0.5 34 73 35 74 29 63

150 0.6 29 62 29 63 25 52

175 0.7 23 48 23 49 18 37

200 0.8 22 46 22 47 10 20

AIR FLOW (L/S)

60

50

225

200

175

150

EXTERNAL

125

PRESSURE

100

75

50

25

0

STATIC

(PA)

EXTERNAL

STATIC

PRESSURE

(IN. W. C)

01020

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

050 100 150

40

30

10

VNT5070E1000 Energy Performance

Supply Temperature Net Supply Air Flow

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 20 41 30 65 74

0 32 30 64 36 64 71

15 5 16 35 27 54 80

Heating

35 95 19 41 30

35 95

Average

Power

Sensible

Recovery

Apparent

Sensible

Total Recovery Efficiency = 43%

ERV/HRV Ventilation Systems 69-2480EF—19

Specifications (continued)

VNT6150H1000

AIR FLOW (CFM)

PRESSURE

PRESSURE

VNT6150H1000 Ventilation Performance

External Static Pressure Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 72 153 72 153 67 142

50 0.2 67 142 68 143 61 129

75 0.3 61 130 62 130 55 116

100 0.4 55 117 55 118 47 101

125 0.5 49 103 49 103 41 87

150 0.6 42 88 42 89 34 73

175 0.7 35 75 35 75 27 59

200 0.8 28 61 28 61 22 46

AIR FLOW (L/S)

EXTERNAL

STATIC

(IN. W. C)

10

0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0206080 120 180

20

30

NET SUPPLY AIR FLOW

40

40

60

50

70 80

100 140

90

100

160

110

200

175

150

125

100

75

50

25

00

EXTERNAL

STATIC

(PA)

M34365

VNT6150H1000 Energy Performance

Supply Temperature Net Supply Air Flow

Average

Power

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 31 66 52 75 84

0 32 40 84 64 73 80

Heating

0 32 50 106 74 70 77

25 13 32 68 49 62 81

ERV/HRV Ventilation Systems 69-2480EF—19 11

Sensible

Recovery

Apparent

Sensible

Specifications (continued)

VNT6200H1000

AIR FLOW (CFM)

PRESSURE

PRESSURE

VNT6200H1000 Ventilation Performance

External Static

Pressure

Net Supply Air Flow

Supply Exhaust

Gross Air Flow

Pa in. W.C. L/s CFM L/s CFM L/s CFM

25 0.1 122 258 126 260 120 254

50 0.2 114 241 115 242 111 235

75 0.3 105 223 106 225 103 218

100 0.4 98 207 99 209 94 199

125 0.5 89 189 90 190 85 180

150 0.6 81 172 82 174 76 161

175 0.7 72 152 73 154 67 142

200 0.8 63 133 64 135 58 123

225 0.9 56 119 57 121 50 106

250 1.0 48 102 48 102 42 89

275 1.1 41 87 42 88 35 74

40

100

AIR FLOW (L/S)

60

50

70 80

150 200 300

90

100

250

110

200

175

150

125

EXTERNAL

100

75

50

25

0

STATIC

(PA)

M34366

EXTERNAL

STATIC

(IN. W. C)

0

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

050

10

20

30

NET SUPPLY AIR FLOW

12

VNT6200H1000 Energy Performance

Supply Temperature Net Supply Air Flow

°C °F L/s CFM Watts Efficiency % Effectiveness %

0 32 29 61 62 78 90

0 32 43 91 74 76 85

Heating

0 32 60 127 92 73 80

25 13 31 66 59 66 88

Average

Power

Sensible

Recovery

Apparent

Sensible

ERV/HRV Ventilation Systems 69-2480EF—19

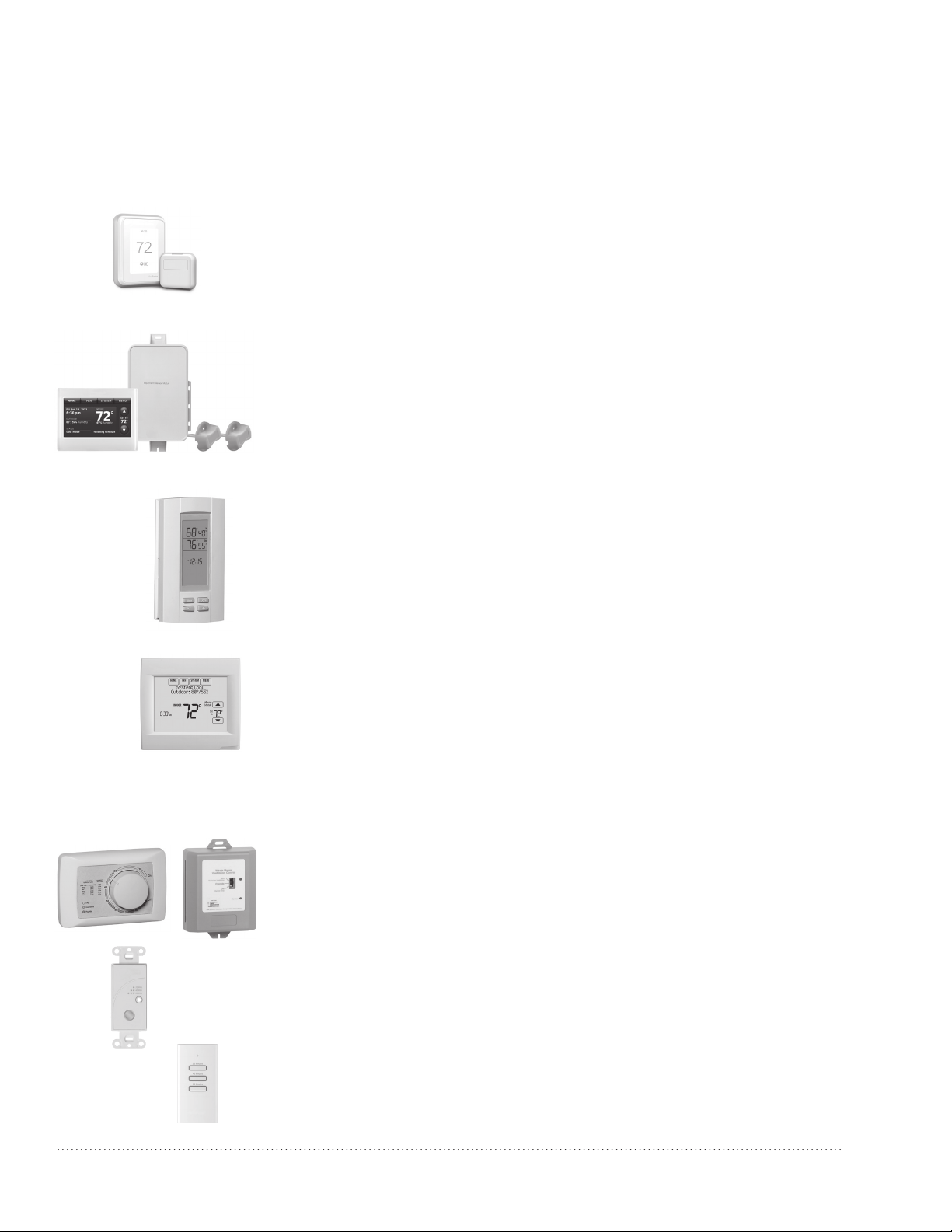

External Control Options

The ERV/HRV unit may be used with one of the following external controls:

T10 Pro Smart Thermostat

• Controls both heating/cooling and ventilation.

• Ventilation programming for time of day or Ashrae standards.

• Optional ventilation lockouts for high/low temp or humidity conditions

using Internet weather when registered to the app.

Prestige™ IAQ Kit

• Controls both heating/cooling and ventilation.

• Wireless sensor for displaying outdoor temperature and humidity.

• Advanced ventilation programming includes economizing and extreme

condition shutdown.

• Maintenance and service reminders.

• High definition color display.

• RedLINK™ Wireless technology

DG115 IAQ Digital Control

• Automatic adjustments maintain fresh air in home.

• Sensor for displaying outdoor temperature and humidity.

• Advanced ventilation programming includes economizing and extreme

condition shutdown.

• Maintenance and service reminders.

• Controls other indoor air quality equipment.

VisionPRO™ Smart or VisionPRO™ RedLINK

• WiFi™ (TH8321WF1001) or RedLINK™ Wireless technology (TH8321R1001)

• Controls both heating/cooling and ventilation.

• Display outdoor temperature and humidity.

• Ventilation programming for time of day or Ashrae standards.

• Optional ventilation lockouts for high/low temp or humidity conditions

• C7089R1013 wireless outdoor sensor for RedLINK model. Internet

weather for Smart model.

Manual Dehumidistat and Automatic Ventilation Controls

• Manual humidity control with intuitive comfort settings.

• Automatic W8150 ventilation control to ASHRAE standard, or for

continuous operation.

Boost Control Digital Timer

• Ventilation boost control for 20/40/60 minutes.

Wireless Vent Boost Remote

• 20/40/60 minute ventilation timer

• Works with RedLINK 2.0 thermostats

ERV/HRV Ventilation Systems 69-2480EF—19 13

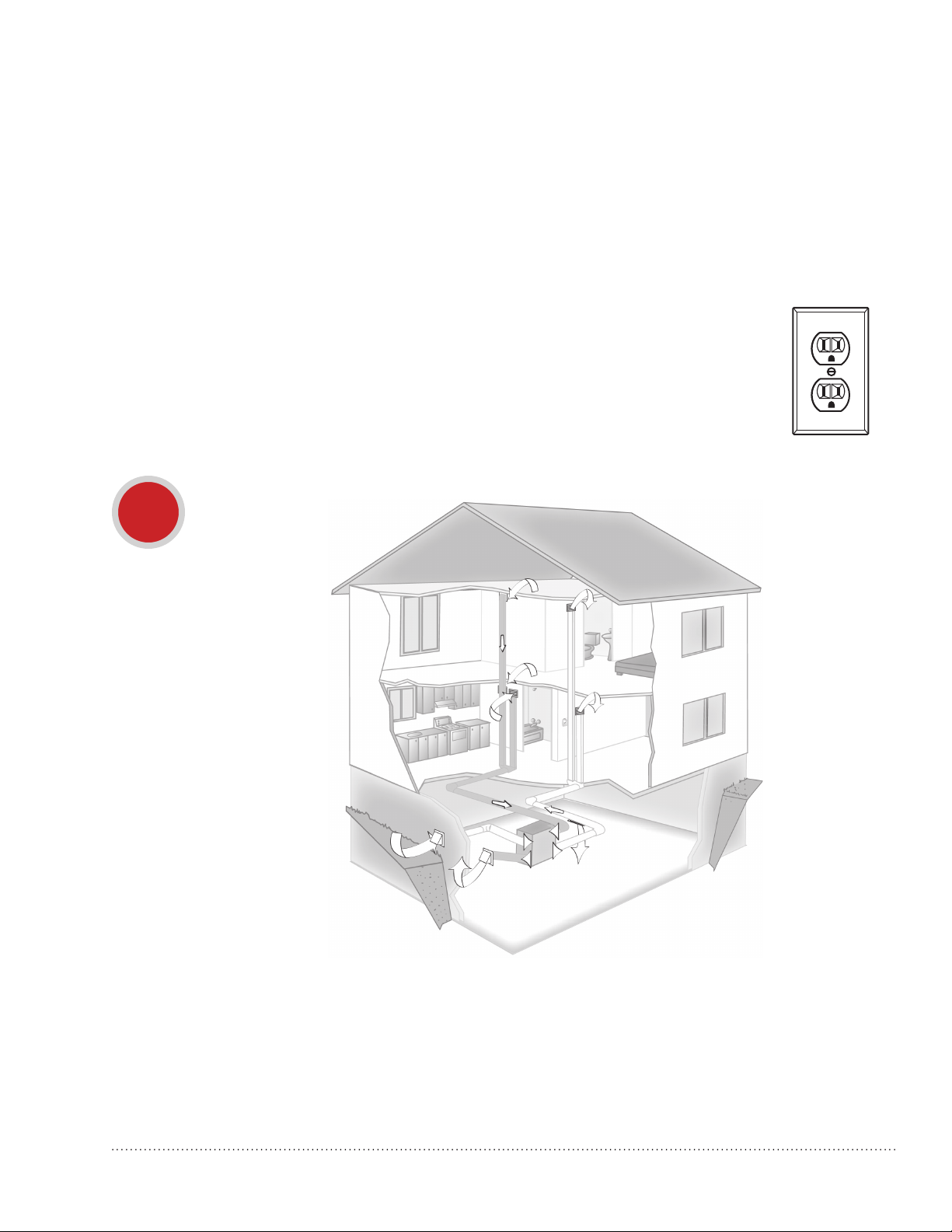

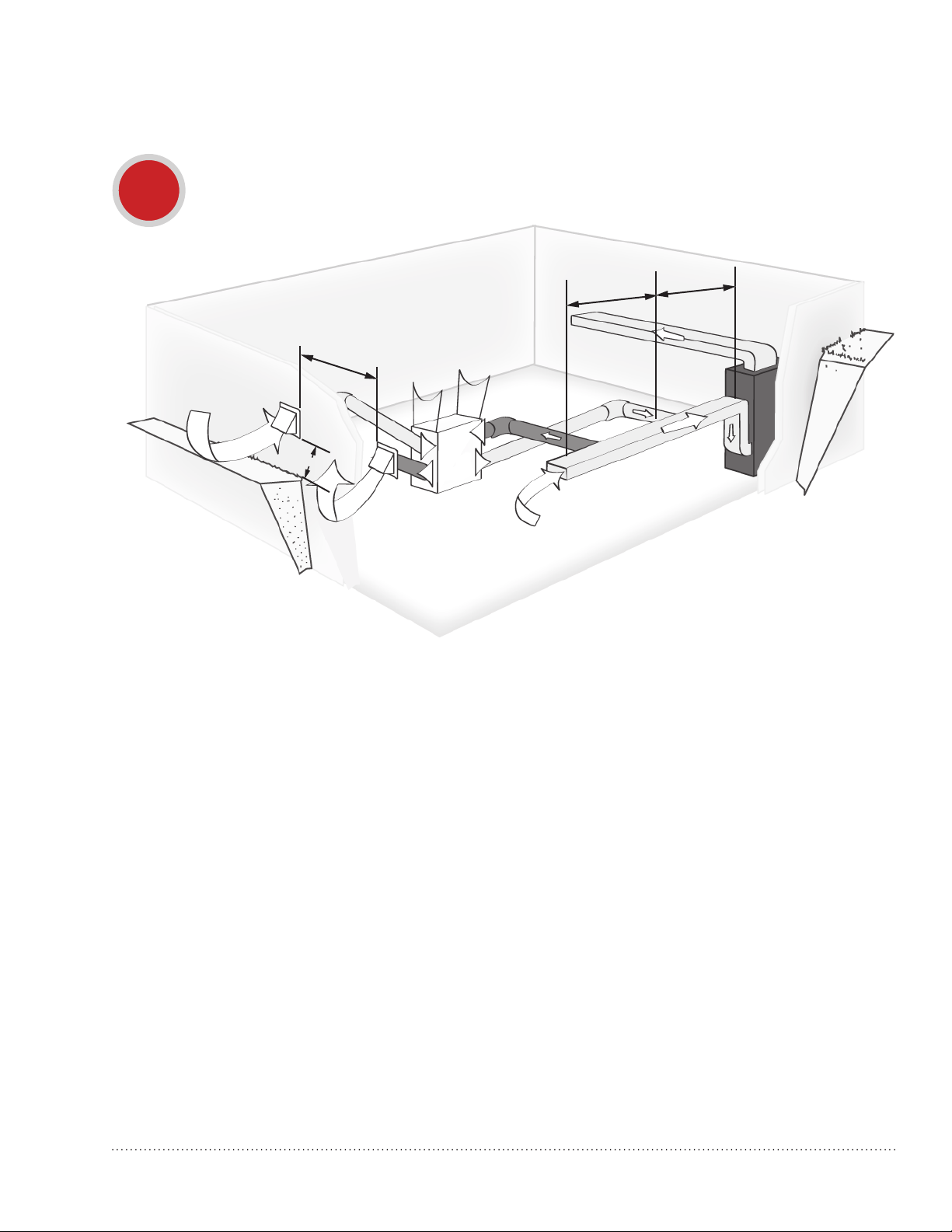

Install to Fit Your Application

M24745

M28983

NOTE: Prior to installing, serious consideration must be taken to insure this ventilation system will

operate properly if integrated with any other type of mechanical system, i.e. a forced air system,

or an air handling unit. To insure proper operation & compatibilities of both system, it is required

that the airflows of ventilation systems be balanced, by following the procedures found in this

manual.

Limitations: The product is for residential applications only. Must be installed in accordance with all

national and local regulations, building and safety codes. Flex duct is recommended for connecting to the

ERV/HRV collars to reduce vibration noise.

Electrical Requirements:

120 VAC outlet. Ground fault

interrupter (GFI) and dedicated

circuit recommended.

A

Independent System

14

This application uses a devoted duct system for the supply and the exhausting of stale air

accumulated in the home.

Honeywell Home recommends installing fresh air grilles in all bedrooms and living areas and to

exhaust the stale air from the bathroom, kitchen, and laundry room.

ERV/HRV Ventilation Systems 69-2480EF—19

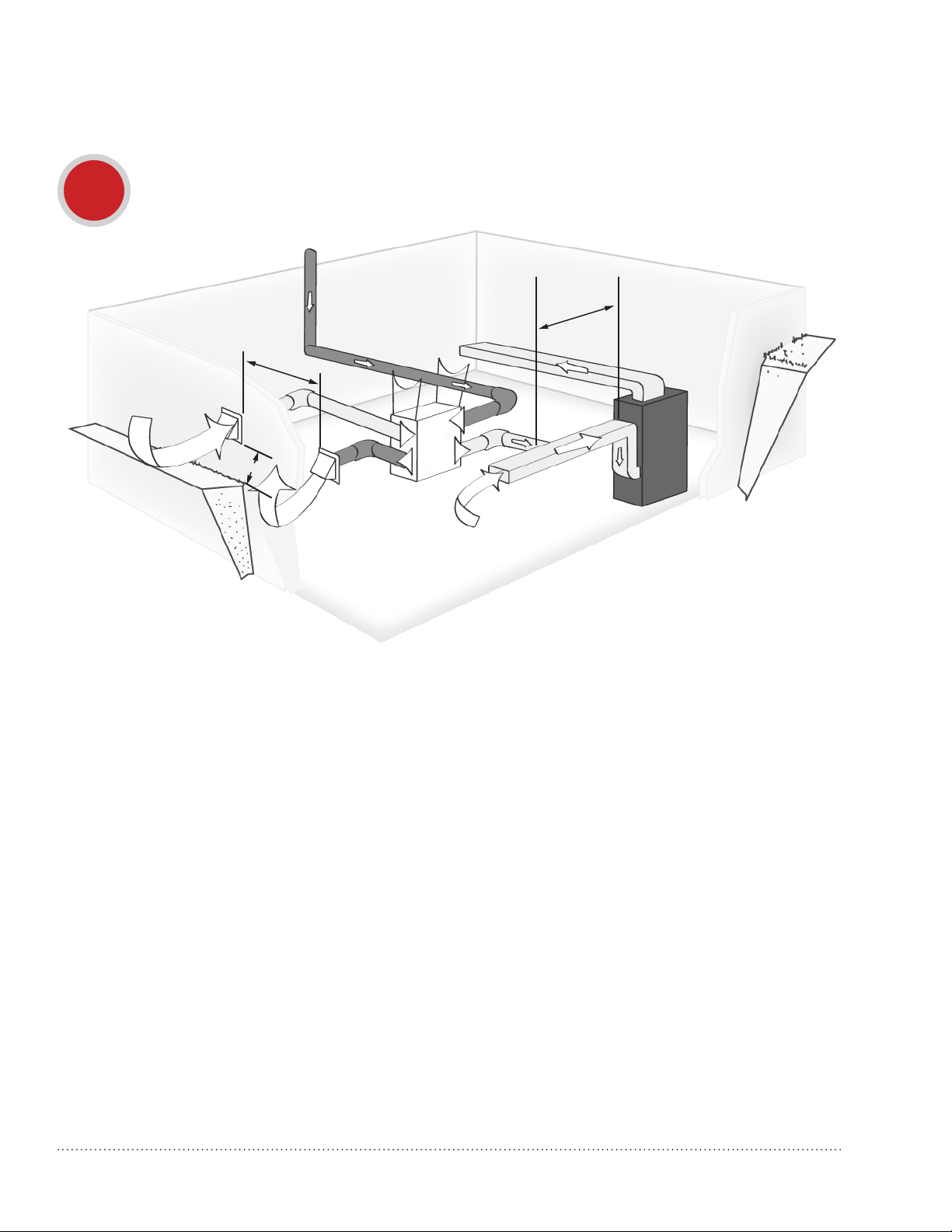

Install to Fit Your Application (continued)

B

Exhaust at the Source and Supply in the Return

STALE AIR FROM LIVING SPACE,

SUCH AS FROM BATHROOM

18 INCHES

6 FEET

OR KITCHEN

TO LIVING

HRV / ERV

SPACE

3 FEET

FORCED AIR

SYSTEM

M28984

This application uses a devoted duct system for the exhausting of stale air accumulated in the home. The

fresh air is introduced into the return air duct and is distributed through the home by the existing supply

air ductwork of the forced air system.

Make sure when using this application that your fresh air duct connection to the forced air system return

air duct is at least 3 feet from the forced air system. You should check with your local code or the forced

air system’s manufacturer.

The forced air system’s blower does not have to run when the unit is operating, but is recommended for

maximum effectiveness.

NOTE: For the minimum distance between the fresh air connection and the forced air system, check

with your local building codes and forced air system manufacturer.

NOTE: For dwellings with multiple forced air systems, Honeywell Home recommends one ERV/HRV unit

per system.

NOTE: Refer to the Wiring section (beginning on page 24) for instructions to connect the unit to

operate the forced air system with the ERV/HRV unit.

ERV/HRV Ventilation Systems 69-2480EF—19 15

Install to Fit Your Application (continued)

Exhaust and Supply in the Return

C

18 INCHES

6 FEET

HRV / ERV

TO LIVING SPACE

6 FEET

3 FEET

FORCED AIR

SYSTEM

M28985

16

When using this application make sure that there is a minimum of 6 feet between the fresh air and

exhaust air connections of the ERV/HRV unit in the return air duct. Supply air from the ERV/HRV unit

must be at least 3 feet from the forced air system. These distances can be different from one region to

another; you should check with your local code or the forced air system’s manufacturer.

NOTE: For minimum distance between return and forced air system, check with your local building

codes and forced air system manufacturer.

NOTE: Fresh air must always be down-stream from the exhaust air in the return air duct of the forced air

system.

NOTE: Furnace blower is required to operate when ventilation is required. Set the furnace blower to run

continuously, or interlock electrically (low voltage).

ERV/HRV Ventilation Systems 69-2480EF—19

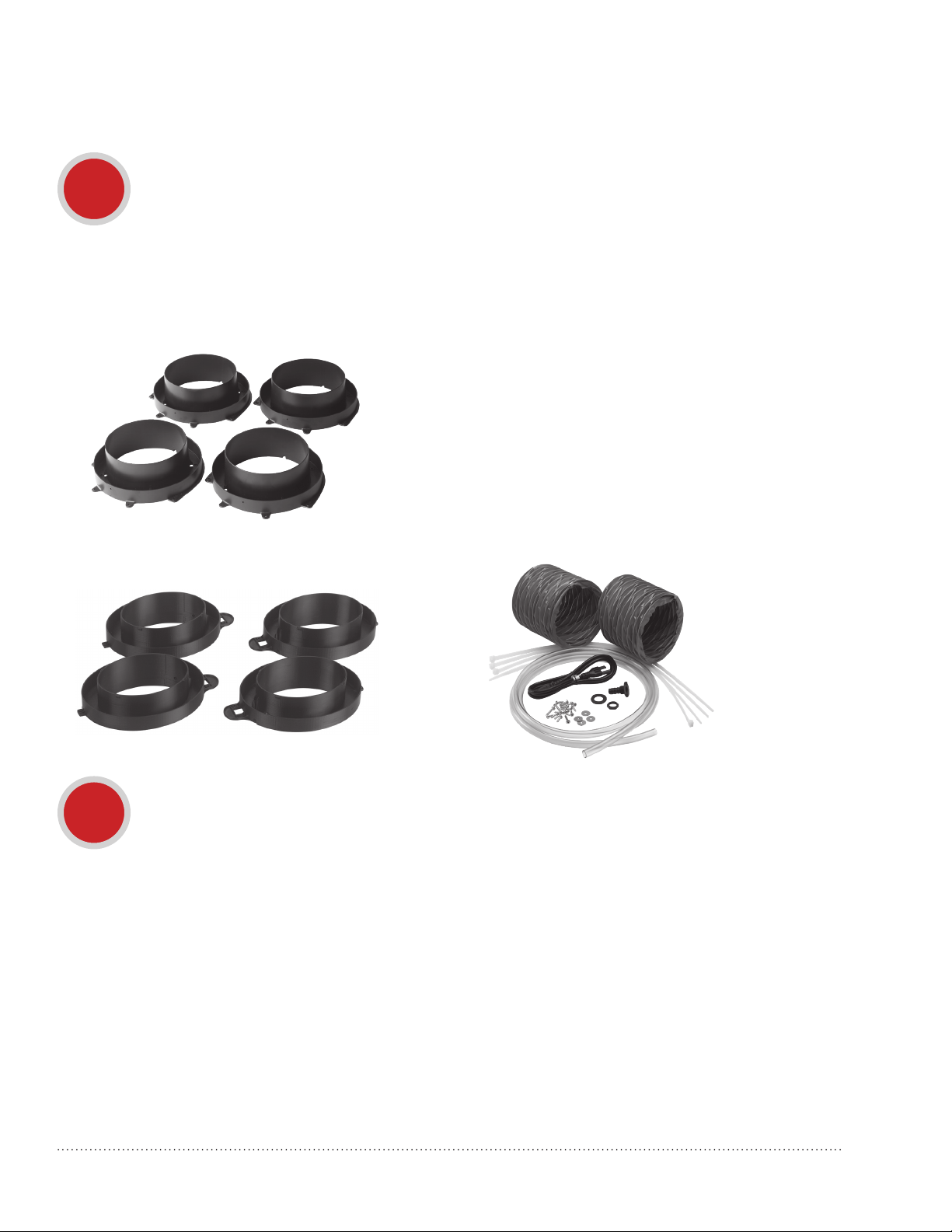

Installation Steps

1

Ensure that you have all of the following installation items:

4 Round Duct Collars (VNT5150, VNT5200,

VNT6150 & VNT6200)

Installation Kit

Installation Kit:

• 2 Flexible 6 in. Vinyl Ducts (VNT5150, VNT5200,

VNT6150, VNT6200)

• 1 Condensation Drain Line (10 in.)

• 1 Drain Adapter with Nut

• 4 Tie Wraps (30 in.)

• 16 Hex-head screws (1/4 x 5/8 in.)

• 4 Hex-head screws (1/4 x 1 in.)

• 4 Washers

• 1 Drain cap (VNT5070E1000, VNT5150E1000 and

• 1 power cord, 120 Vac (not shown)

4 Oval Duct Collars (VNT5070)

VNT5200E1000 only)

2

The ERV/HRV unit should be installed in a mechanical room or as close to an outside wall as possible.

The ERV/HRV unit must always be installed in an area where the air is conditioned to avoid freezing the

condensate line.

The contractor should install the unit in an area that allows the homeowner easy access for maintenance.

It is very important to install an electric receptacle (120 Vac) near the unit, a separate circuit breaker is

also recommended. It is best to have access to a condensate drain near the ERV/HRV unit to avoid having

to use a condensate pump.

NOTE: Installation is not recommended in unconditioned areas such as an attic or crawl space where

NOTE: Ducting in unconditioned areas must be fully sealed and insulated.

ERV/HRV Ventilation Systems 69-2480EF—19 17

Installation Area

the temperature can fall below 32 ºF (0 ºC).

Installation Steps (continued)

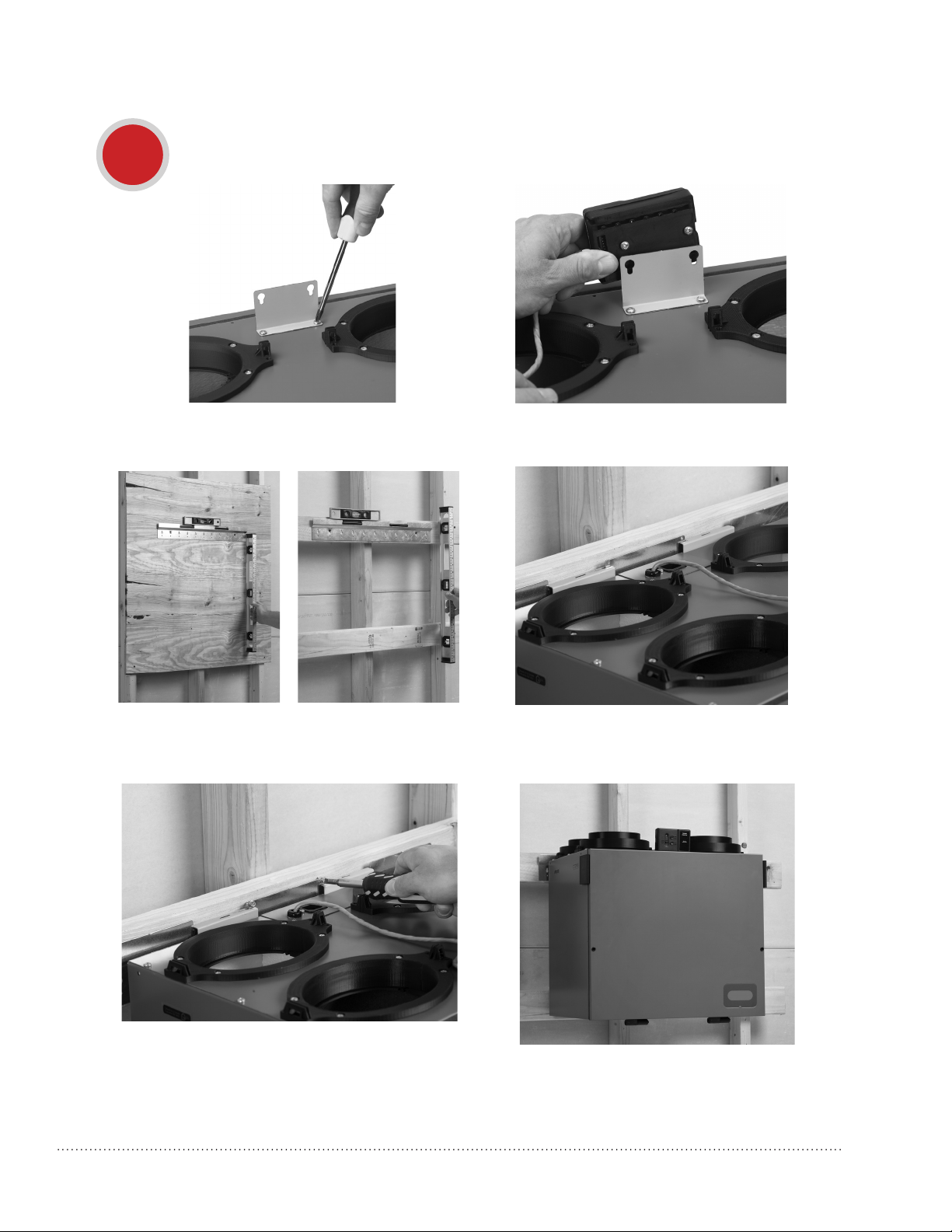

3a

Hanging the VNT5150, VNT5200, VNT6150 or VNT6200

The ERV/HRV unit enables you to save time and effort by offering a simplified hanging system.

TIP: Removing the core unit makes installation easier since the unit weighs less

without the core inside.

1. Attach straps to joist using the supplied

washers and four 1 in. hex-head hanging

screws.

3. Make final adjustments to ensure that the HRV/ERV is level.

2. Pull on middle of strap while gently lifting unit

upward to raise the unit.

NOTE: If the unit is not level, improper drainage will occur and could lead to moisture and leakage

problems.

18

ERV/HRV Ventilation Systems 69-2480EF—19

Installation Steps (continued)

3b

1. Fix the control module bracket to the top of the

VNT5070 using the supplied mounting screws.

Mounting the VNT5070

2. Slide the control module onto the bracket

using the key holes.

3. Fix the wall mount bracket to two 2x4s or to

a precut sheet of plywood using the supplied

mounting screws.

5. Secure with two sheet metal screws.

NOTE: When these mounting steps are complete, resume normal installation procedures beginning on

page 20, “Installing the flex duct to the ERV/HRV.”

4. Hang the unit on the bracket.

ERV/HRV Ventilation Systems 69-2480EF—19 19

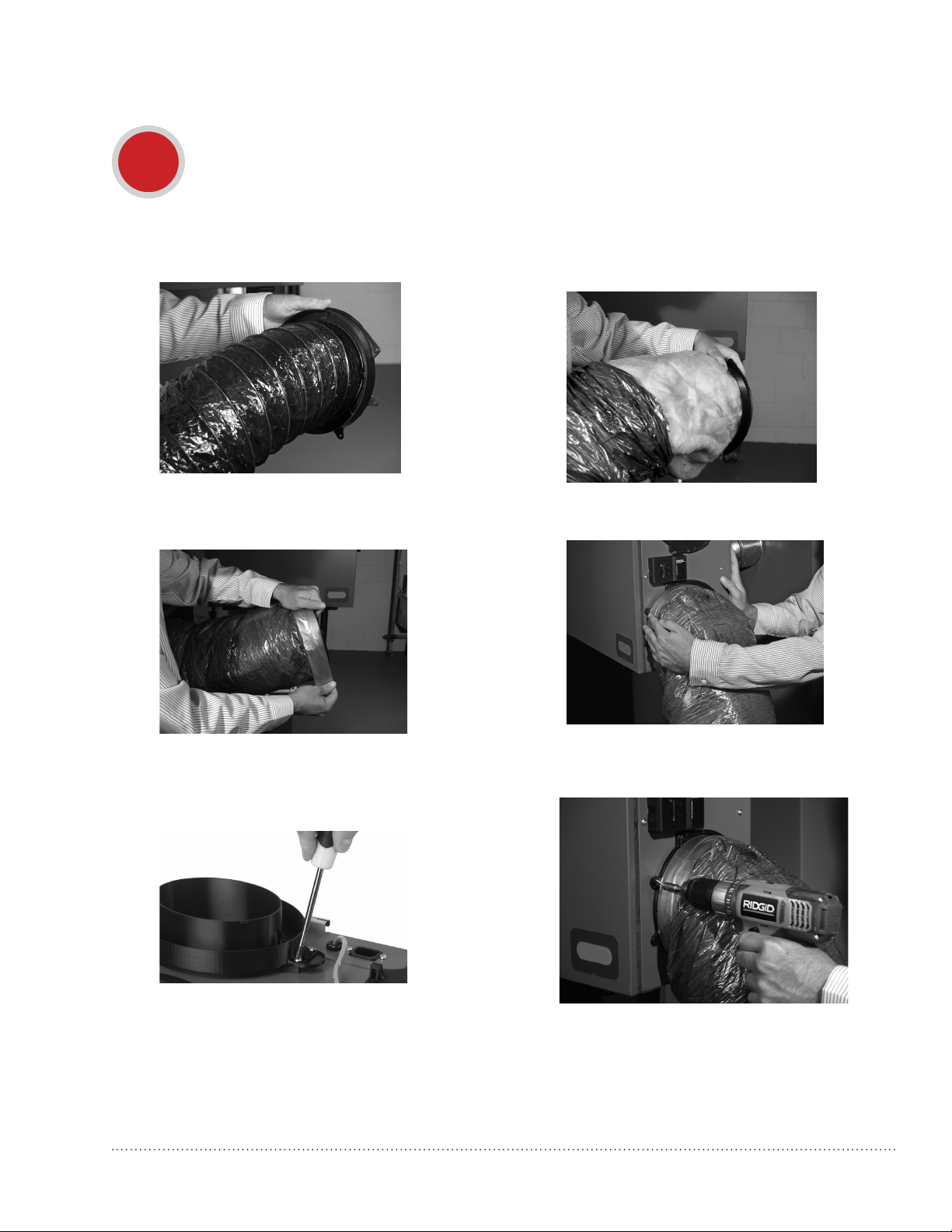

Installation Steps (continued)

4

Installing the flex duct to the ERV/HRV

TIP: Honeywell Home recommends using approximately 16 inches of flexible duct (supplied in kit

with VNT5150, VNT5200, VNT6150 and VNT6200) between the unit and the rigid duct for noise

dampening. The flex duct is mounted to the unit the same way as the insulated flex.

1. Insert the vinyl duct over the hooks on the

duct collar and seal with a supplied 30 inch

tie wrap.

2. Insert insulation inside the outer ring of the duct

collar.

20

3. Finish by taping the duct on the collar.

TIP: For the VNT5070 unit, balancing should be

done before taping the insulation onto the

collar. See balancing steps on page 29.

4b. Attach collar onto unit (VNT5070)

IMPORTANT: Always fix and secure each collar using

four of the 5/8 in. screws supplied.

This step is critical in order to prevent

condensation accumulation.

4a. Slide collar onto unit (VNT5150,

VNT5200, VNT6150 and VNT6200)

5. Secure collar with the supplied 5/8 in.

hex-head screws.

TIP: Attach the flex duct to the collar first, and then

attach the collar to the unit.

ERV/HRV Ventilation Systems 69-2480EF—19

Installation Steps (continued)

5

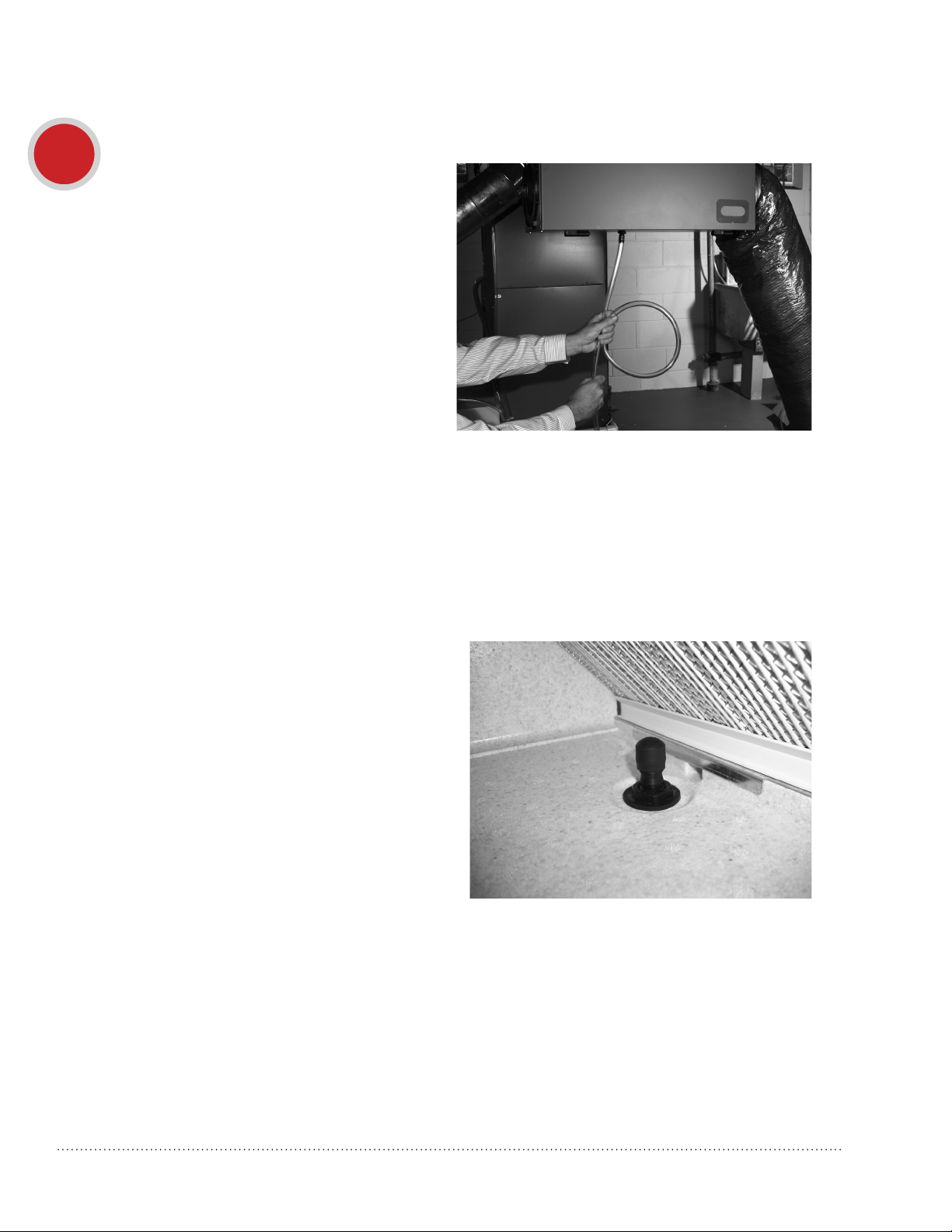

Insert the threaded drain adapter through the bottom of

the unit and hand tighten the plastic nut supplied with

the drain kit.

Use a wrench to tighten the nut another half turn to

ensure a complete seal.

Install the condensate tubing by pushing the clear

plastic tubing over the drain adapter.

Make a condensate trap by looping the clear plastic

tubing. This loop will prevent foul odors from entering

the unit.

Use a condensate pump if you don’t have access to

the floor drain.

Installing the condensation drain line

Drainless Application

NOTE: If installing an ERV unit (VNT5150E1000, VNT5200E1000, VNT5070E1000) in a region where

the outdoor temperature does not drop below freezing, the condensate drain line does not need

to be installed and the unit may be installed as a drainless application.

1. Insert the threaded drain adapter through the bottom

of the ERV with the drain connection inside of the unit

as shown in the figure.

2. Fit the rubber washer over the drain adapter and then

attach the plastic nut.

3. Hand tighten the plastic nut supplied with the drain kit.

4. Use a wrench to tighten the nut another half turn to

ensure a complete seal.

5. Attach the drain cap to the drain adapter inside the

unit.

ERV/HRV Ventilation Systems 69-2480EF—19 21

Installation Steps (continued)

M32372

6

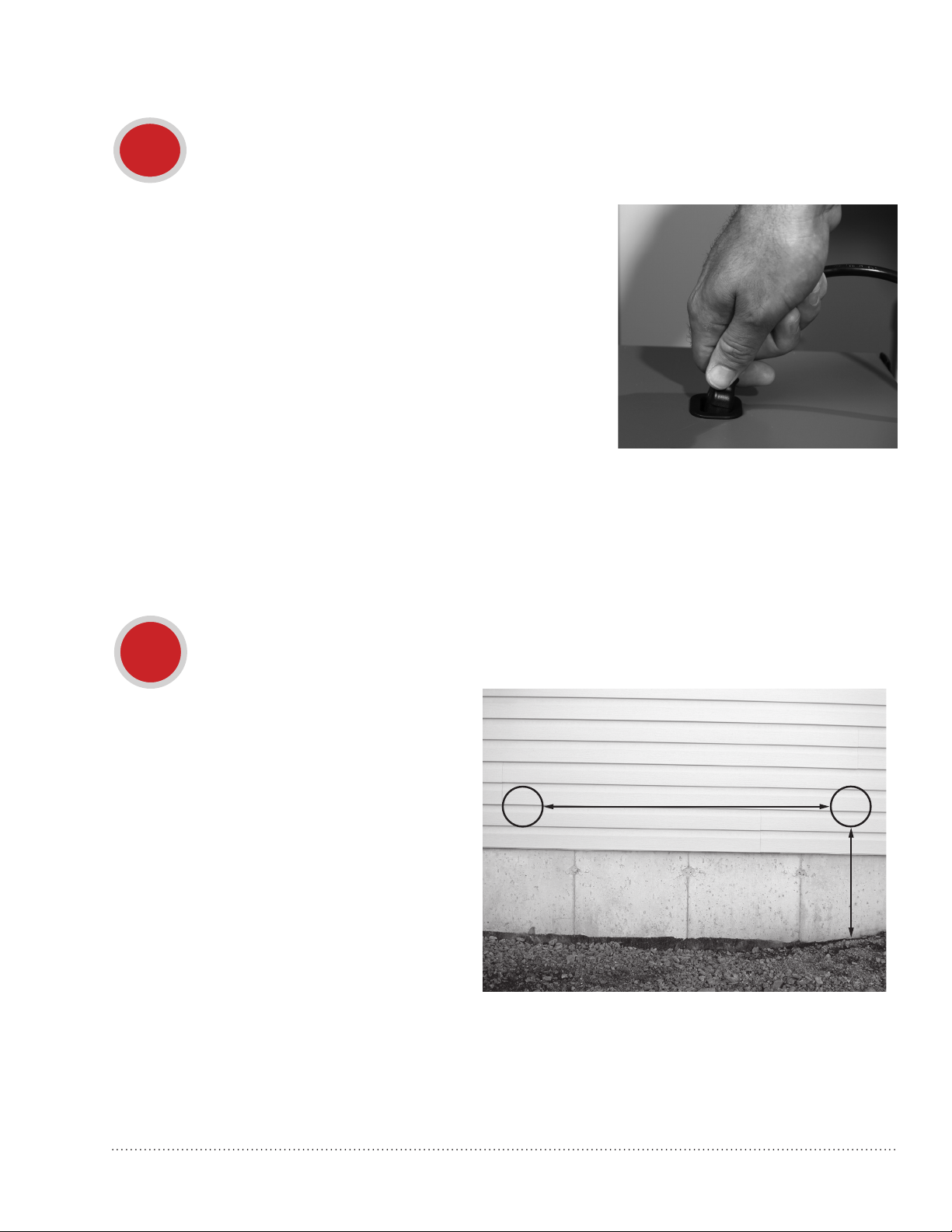

Connecting the power cord

ERV/HRV Power Cord

Insert the power cord on top of the unit. Press firmly

to make sure the power cord is secure.

IMPORTANT: Do not plug the power cord into the

wall receptacle at this time.

Electric Wall Outlet

Honeywell Home recommends that the unit has a dedicated

receptacle with 120 VAC.

Avoid connecting the unit to the wall receptacle with an

extension cord.

Honeywell Home does not recommend the use of an extension cord.

Ensure that the receptacle’s polarization is correct.

NOTE: If the LED light on the ERV/HRV control panel remains green, the motors do not energize, and the

controls do not operate; this can indicate that the polarization in the main AC outlet is inverted.

IMPORTANT: Always consult a qualified technician to ensure proper installation of main power.

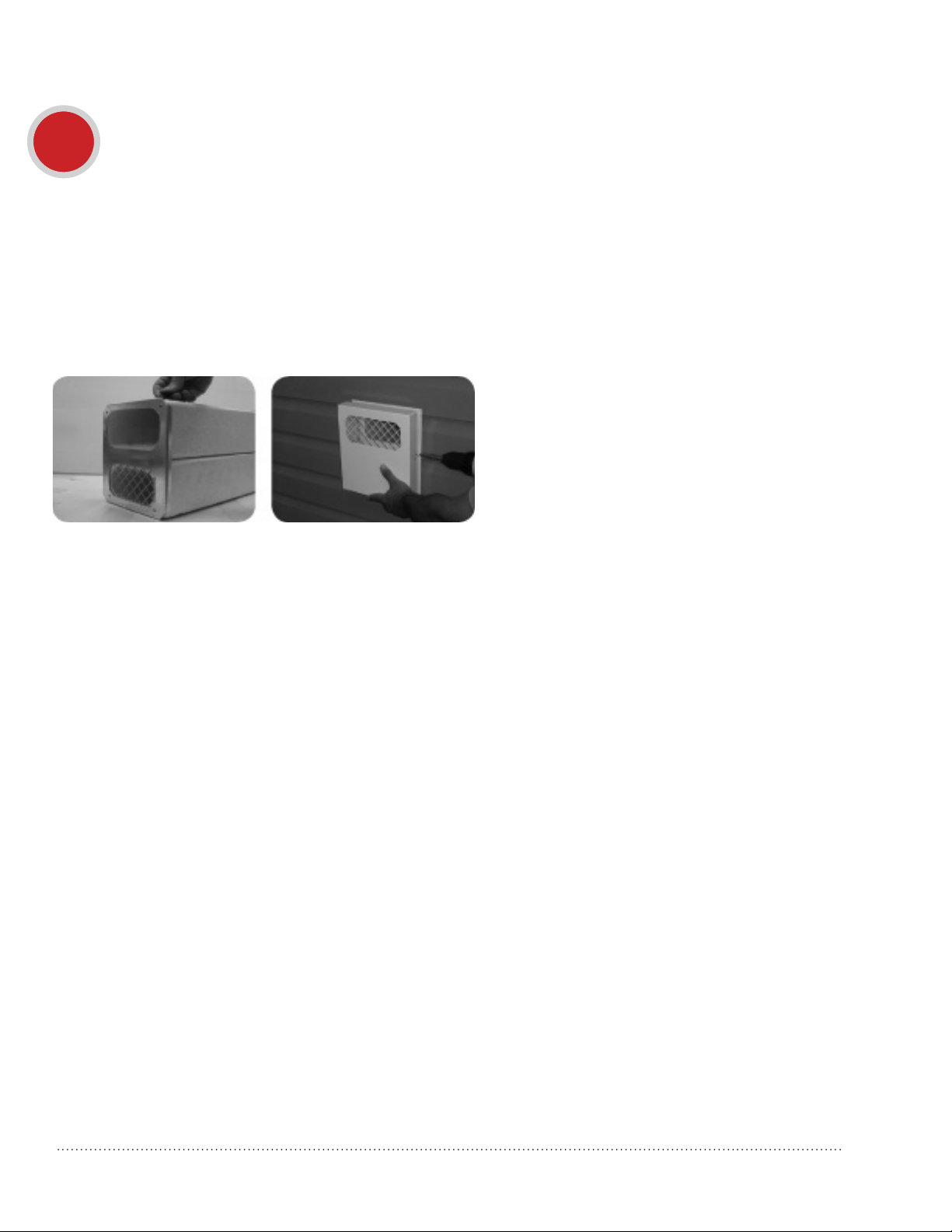

7a

Locate the outside hoods at least 18 inches

(0.46 m) above grade and at least 72 inches

(1.83 m) apart.

NOTE: Do not locate the fresh air vent

IMPORTANT: Always consult your

Installing outside hoods for the fresh air and the exhaust

hood close to known sources of

pollutants such as dryer vents.

local code for spacing

requirements in your area.

72 (1,829)

18 (457)

22

ERV/HRV Ventilation Systems 69-2480EF—19

Installation Steps (continued)

7b

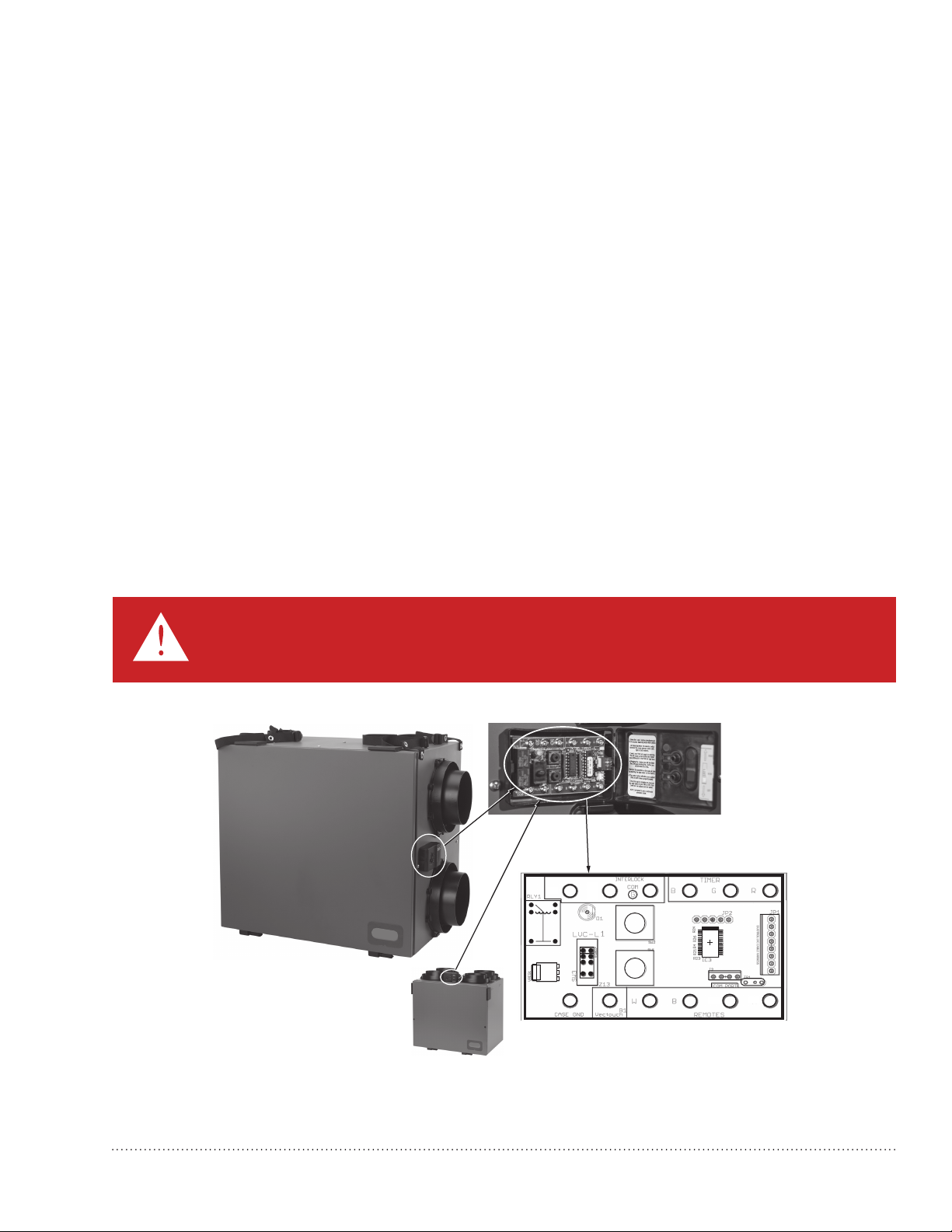

Optional Matrix hood (50063805009) installation for fresh air and

exhaust air

NOTE: Only for applications up to 115 CFM maximum speed. Higher airflow rates are limited by higher

static pressures and the potential of cross-contamination between the supply and exhaust air

streams. The Matrix hood design is suitable for smaller spaces commonly found in town homes

and condominiums which require less airflow rates.

NOTE: A 6 in. to 5 in. reducer is required if you are installing the matrix hood (50063805009) with the

VNT5070.

See Matrix hood literature for step-by-step

instructions.

ERV/HRV Ventilation Systems 69-2480EF—19 23

Automated Defrost

M33110

The ERV and HRV units are equipped with an automatic defrost feature to eliminate any ice build up on the core.

• Automatic defrost is initiated once every hour when the fresh air supply temperature drops to 23°F (5°C)

or colder.

• The defrost cycle operates by turning off the supply fan while continuing to operate the exhaust fan.

• The exhaust fan speed is adjusted proportionally based on the outdoor temperature, initially operating at

low speed.

• As the outdoor temperature continues to drop, the exhaust fan speed will increase, and will operate at

maximum speed when the outdoor temperature is 4°F (20°C) or less.

• The VNT5070 Series HRV/ERV defrost cycle runs for 5 minutes with the supply fan off followed by

35 minutes of continuous normal operation.

• The VNT5150 Series HRV/ERV defrost cycle runs for 5 minutes with the supply fan off followed by

35 minutes of continuous normal operation.

• The VNT5200 Series HRV/ERV defrost cycle runs for 4 minutes with the supply fan off followed by

40 minutes of continuous normal operation.

• VNT6150H1000 and 6200H1000 HRV cycle runs for 8 minutes with the supply fan off followed by

32 minutes of continuous normal operation.

• Defrost cycles will continue to repeat as long as the temperature is 23°F (5°C) or less.

Wiring

CAUTION: Voltage hazard.

Can cause equipment damage.

Disconnect power from the unit before beginning installation.

Terminal Description

RLY1

NC

CASE GND

NO

LVC – L1

SW3

D1

Z13

Vectouch

INTERLOCK

COM

G

W

B1

TIMER

G

B

SW2

SW1

B

REMOTES

JP2

COM PORT

G

R

JP1

R

24

The wiring terminal block is located behind the control module door on the side of the unit.

To access the terminal block, open the control panel door by swinging it open and to the right as shown above.

ERV/HRV Ventilation Systems 69-2480EF—19

Loading...

Loading...